Page 1

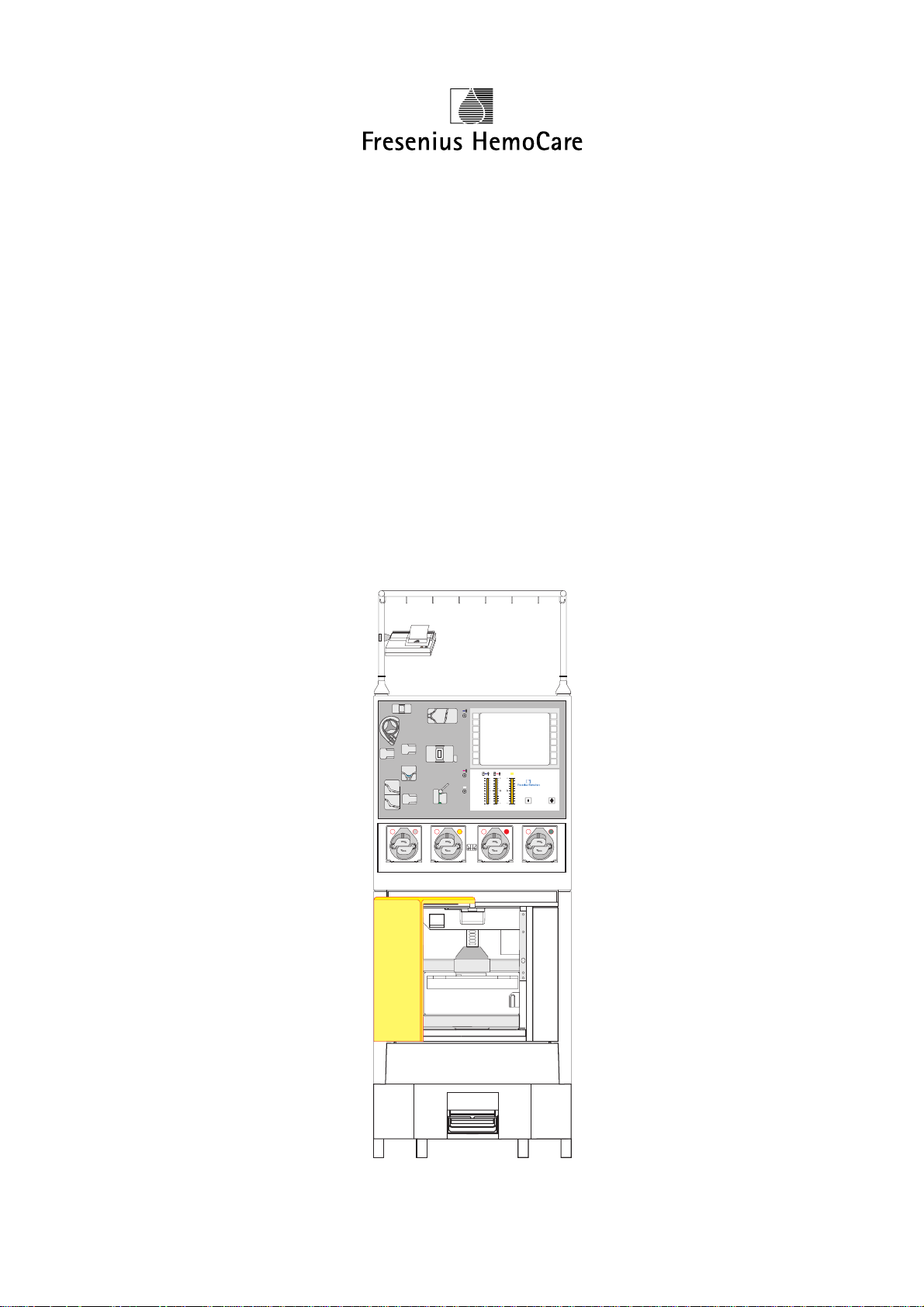

Technical Manual for COM.TEC

The Technical Manual contains all information necessary for performing maintenance and repair work.

The blood cell separator reflects the latest technology and complies with the requirements of IEC 601, Part

1.

It belongs to safety class I and should be only used in rooms reserved for medical use in accordance with

VDE 0107.

Assembly, update, readjustment, modification and repair work should be performed only by the manufac-

turer or by persons authorized by him.

Fresenius

N

O

F

F

O

PP

P3

P3

COM.TEC

Part No. 679 469 1

Fresenius HemoCare COM.TEC 1/04.01 (TM) 0-1

Page 2

Any inquiries should be addressed to:

Manufacturer:

Fresenius HemoCare Deutschland GmbH

Produktionsbereich Geräte

Hafenstrasse 9

D-97424 Schweinfurt

Tel.: ++49 9721/678-0

Fax: ++49 9721/678-200

National Service:

Fresenius Transfusions GmbH

Landsteinerstrasse 5

D-63303 Dreieich

Tel.: ++49 6103/801-0

Fax: ++49 6103/801-672

0-2 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 3

How to Use the Technical Manual

Search and Find What? Where?

Table of contents Page 0-5 and at the beginning of each chapter

Intended Use This manual is intended for:

– first studies (to acquire a basic knowledge)

– reference purposes (for start-up, maintenance and repair)

Organization The manual is divided into 6 chapters:

0 General Information

1 Config.Sys, Service.Sys, CCS Program

2 Repair / Adjustment / Maintenance

3 Circuit Descriptions and Circuit Diagrams

4 Spare Parts Catalog

5 Start-up and TSC

Page Identification Page identification 1-3 is to be interpreted as: Chapter 1, page 3.

Qualification This manual is intended to assist service technicians and assumes the following:

– that the user is familiar with the current operating instructions

– that he has the necessary background experience in mechanics, electrical

engineering and medical engineering;

– that he has been authorized by the manufacturer to perform maintenance and

repair work;

– that he has access to the necessary auxiliary and measuring equipment.

Limitations This manual is not intended to provide an alternative to instruction courses

offered by the manufacturer.

Manual changes Manual changes will be released as new editions, supplements or product

information.

Note:

Any modifications to circuit and component layout diagrams (SP/BP) do not

always affect footers (edition).

The current state of these diagrams is indicated in the index field of each

respective SP/BP.

The user/technician can use the respective marking on the printed circuit board

to verify whether the SP/BP comply with the actually existing printed circuit board

in the machine.

In general, this manual will be subject to modification.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 0-3

Page 4

Specification Unless otherwise specified, potentials indicated in circuit diagrams and calibra-

tion instructions are related to the perinent ground.

For example, 24 means ground for the 24 V voltage.

Component Example:

identification in

circuit diagrams

This refers to a resistor with position number 75 and a resistance of 1.2 ohm.

The decimal point used to indicate the value is replaced by a unit symbol (to

reduce the possibility of errors).

Resistors Capacitors:

R1: 0.1 Ωµ 1: 0.1 µF

1R2: 1.2 Ω 1µ2: 1.2 µF

1K2: 1.2 kΩ 1000µ: 1000µF

Note When repairing blood cell separators and replacing spare parts, observe the

protective ESD measures to be taken to prevent electrostatic discharge (e.g.

EN 100015-1).

75

1R2

Technical Data The technical data of the COM.TEC Blood Cell Separator are listed in the

Operating Instructions.

0-4 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 5

Table of Contents

Chapter Page

1 Config.Sys, Service.Sys, CCS Program ..................................................................... 1-

1.1 Config.sys ....................................................................................................................... 1-3

1.2 Service.sys...................................................................................................................... 1-9

1.3 PC E53............................................................................................................................ 1-11

1.4 SERVICE TOOL for COM.TEC....................................................................................... 1-13

2 Repair / Adjustment / Maintenance ............................................................................. 2-

2.1 Verification of the Interface Detection ............................................................................. 2-5

2.2 Adjustment of the Interface Detection............................................................................. 2-12

2.3 C5 Interface Sensitivity ................................................................................................... 2-22

2.4 Verification of the C5 Illuminance ................................................................................... 2-24

2.5 Inlet Pressure Monitor ..................................................................................................... 2-26

2.6 Outlet Pressure Monitor .................................................................................................. 2-31

2.7 P3 Monitor....................................................................................................................... 2-36

2.8 Operating Voltages / Battery Voltage ............................................................................. 2-41

2.9 Air Detector ..................................................................................................................... 2-42

2.10 Optical Detector in Air Detector ...................................................................................... 2-44

2.11 Hb/Hct Detector .............................................................................................................. 2-45

2.12 Spillover Detector ........................................................................................................... 2-47

2.13 Substituate-Empty Detector............................................................................................ 2-49

2.14 Gap Width of Outlet Clamp ............................................................................................. 2-51

2.15 Line Pumps ..................................................................................................................... 2-52

2.16 Clamps............................................................................................................................ 2-55

2.17 Centrifuge Door............................................................................................................... 2-57

2.18 Door Switch..................................................................................................................... 2-59

2.19 Centrifuge Motor Carbon Brushes .................................................................................. 2-61

2.20 Single Needle / Cuff Control ........................................................................................... 2-62

2.21 Removal and Installation of the Centrifuge Rotor .......................................................... 2-64

2.22 Tightening the Belts in the Rotor .................................................................................... 2-68

2.23 Brake............................................................................................................................... 2-69

2.24 Flutter Detector ............................................................................................................... 2-70

2.25 General Mechanical Checks ........................................................................................... 2-71

3 Circuit Descriptions and Circuit Diagrams ............................................................... 3-

3.1 Rear View of the COM.TEC Housing Top Part .............................................................. 3-3

3.2 Rear View of the COM.TEC Housing Bottom Part ........................................................ 3-4

3.3 COM.TEC Block Diagram ............................................................................................... 3-5

3.4 CAN Chain Block Diagram.............................................................................................. 3-7

3.5 Block Diagram of the Power Supply Separation

COM.TEC Control and Safety System ........................................................................... 3-9

3.6 Voltage Supply Block Diagram ....................................................................................... 3-11

3.7 P.C.B. LP-Z 175 Single Needle ...................................................................................... 3-13

3.8 P.C.B. LP-Z 241 Air Monitoring System.......................................................................... 3-17

3.9 P.C.B. LP 821 CAN/PC Card .......................................................................................... 3-23

3.10 P.C.B. LP 822 Keyboard Board ...................................................................................... 3-29

3.11 P.C.B. LP 823-1 Power Control Logic and Door Switch ................................................ 3-33

3.12 P.C.B. LP 826 Power Module Box .................................................................................. 3-43

3.13 P.C.B. LP 828 Dual Stroboscope.................................................................................... 3-49

3.14 P.C.B. LP 829 Flash Tube Board.................................................................................... 3-55

3.15 P.C.B. LP 830 CAN-I/O Card.......................................................................................... 3-59

3.16 P.C.B. LP 840 Alarm System.......................................................................................... 3-67

3.17 P.C.B. LP 841 Safety System ......................................................................................... 3-77

Fresenius HemoCare COM.TEC 1/04.01 (TM) 0-5

Page 6

Chapter Page

3.18 P.C.B. LP 852 Pump Control .......................................................................................... 3-83

3.19 P.C.B. LP 854 Logik Centrifuge Control Logic............................................................... 3-87

3.20 P.C.B. LP 855 Centrifuge Control................................................................................... 3-91

3.21 P.C.B. LP 857 Supply Voltage........................................................................................ 3-97

3.22 P.C.B. LP 860 Camera Logic.......................................................................................... 3-103

3.23 P.C.B. LP 861 Camera Sensor ....................................................................................... 3-107

3.24 P.C.B. LP 863 Interface Detection.................................................................................. 3-111

3.25 P.C.B. LP 864 Computer Bus Board............................................................................... 3-115

3.26 P.C.B. LP 865 Electronics Bus Board............................................................................. 3-119

3.27 P.C.B. LP 866 COM.TEC-I/O Card................................................................................. 3-123

3.28 P.C.B. LP 867 ACD Pump Unit....................................................................................... 3-133

3.29 P.C.B. LP 868 Camera Lighting...................................................................................... 3-145

3.30 P.C.B. LP 869 Clamp Control ......................................................................................... 3-149

3.31 P.C.B. LP 870 Pressure Monitor..................................................................................... 3-159

3.32 P.C.B. LP 945 Printer Adapter (Seiko) ........................................................................... 3-169

4 Spare Parts Catalog...................................................................................................... 4-

5 Start-Up and TSC .......................................................................................................... 5-

5.1 Instructions for Initial Start-Up ........................................................................................ 5-3

5.2 Technical Safety Checks ................................................................................................ 5-7

0-6 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 7

Table of Contents

1 Config.Sys, Service.Sys, CCS Program

Chapter Page

1.1 Config.sys...................................................................................................................... 1-3

1.1.1 Configuration Donation ................................................................................................... 1-4

1.1.2 Configuration Therapy .................................................................................................... 1-7

1.1.3 Configuration General..................................................................................................... 1-8

1.2 Service.sys .................................................................................................................... 1-9

1.2.1 Display ............................................................................................................................ 1-10

1.2.2 IF set ............................................................................................................................... 1-10

1.2.3 max. RPM ....................................................................................................................... 1-10

1.2.4 Machine No..................................................................................................................... 1-10

1.2.5 Max. temp ....................................................................................................................... 1-10

1.2.6 Expertmode..................................................................................................................... 1-10

1.2.7 DCS ................................................................................................................................ 1-10

1.3 PC E53............................................................................................................................ 1-11

1.3.1 Flash Disc ....................................................................................................................... 1-11

1.3.2 PCMCIA Card ................................................................................................................. 1-11

1.3.3 Signals ............................................................................................................................ 1-12

1.3.4 BIOS Setup ..................................................................................................................... 1-12

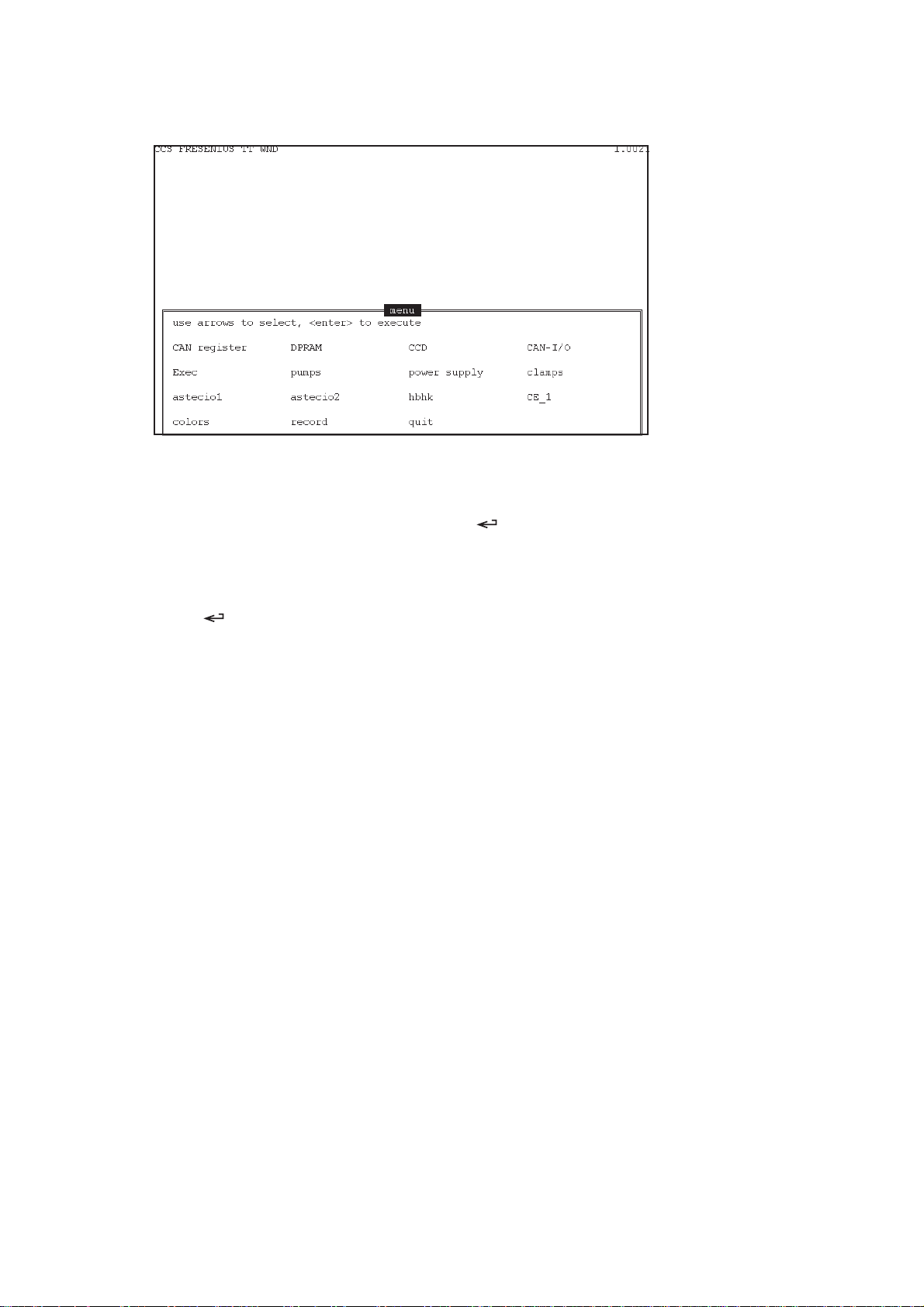

1.4 SERVICE TOOL for COM.TEC ...................................................................................... 1-13

1.4.1 How to access the SERVICE TOOL for COM.TEC ....................................................... 1-13

1.4.2 Working with the CCS Program ...................................................................................... 1-14

1.4.3 Power Supply.................................................................................................................. 1-15

1.4.4 Pumps ............................................................................................................................. 1-16

1.4.5 Clamps............................................................................................................................ 1-17

1.4.6 ASTEC IO1 ..................................................................................................................... 1-18

1.4.7 ASTEC IO2 ..................................................................................................................... 1-20

1.4.8 HBHK / spillover.............................................................................................................. 1-21

1.4.9 CCD Camera .................................................................................................................. 1-22

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-1

Page 8

1-2 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 9

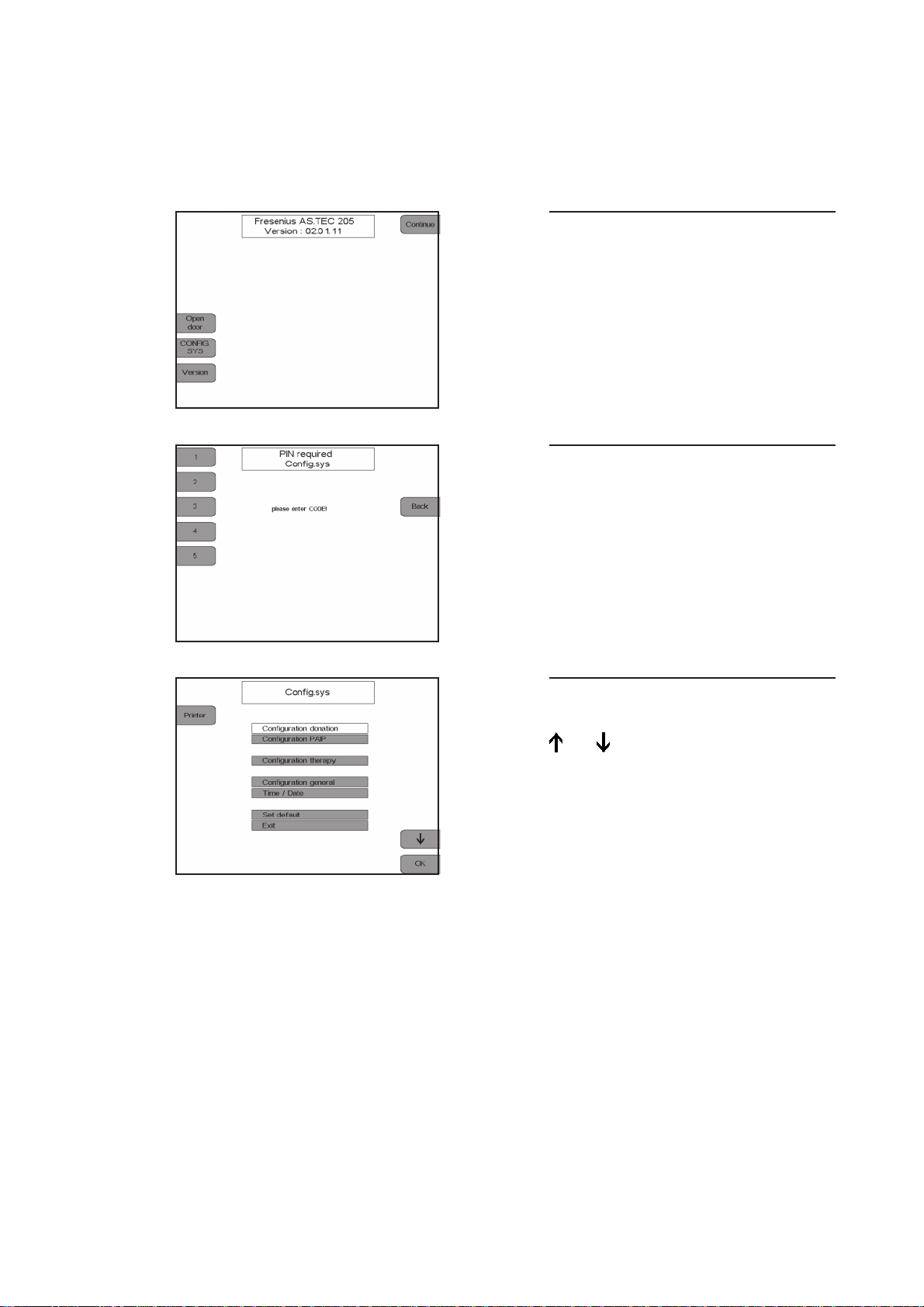

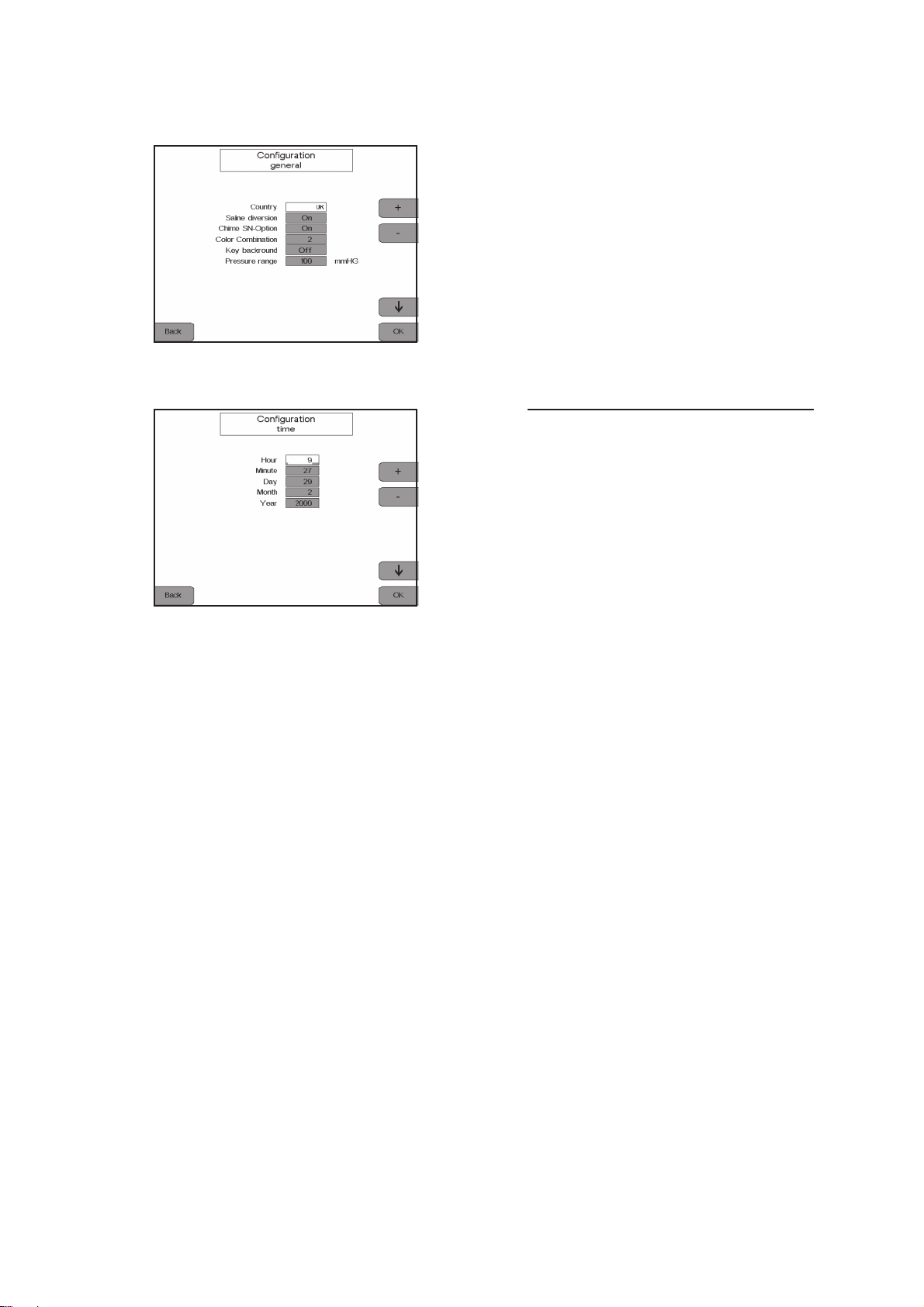

1.1 Config. Sys

The basic configuration of the COM.TEC can be changed in the Config.sys.

Display

Press the CONFIG.SYS key.

Display

Enter the code 1 3 5 2 4

with the numeric keys.

The Config.Sys codes can be entered as

often as desired.

The Config.Sys screen displays.

Select the desired configuration with the

and keys.

Press the OK key.

The selected menu option displays.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-3

Page 10

1.1.1 Configuration Donation

Display

Select the values to be altered by press-

ing the and keys.

Alter the values by pressing the + and –

keys.

Press the OK key to save all changes.

To exit the configuration menu and to re-

turn to the previous screen, press the

Back key.

– Menu

Donor menu and donor data display can be activated and deactivated.

– PLT pre

Presetting of the donor’s mean platelet pre-value.

– HCT pre

Presetting of the donor’s mean HCT pre-value.

– Max. ACD-rate

Setting of the ACD rate per liter of whole blood volume tolerated by the donor.

– ACD:RBC

The ACD:RBC ratio influences the ACD: WB ratio based on the hematocrit. The pH value is

optimized in the storage bag.

– Coeff. DN

Operand for adapting the yield to the predicted value.

– Coeff. SN

Operand for adapting the yield to the predicted value.

– F(return)SN

Adjustment of the return flow rate to the donor.

1-4 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 11

– F(return)PLS

Adjustment of the blood pump flow during the SN return phase with active plasma collection.

– PLS-Coll.DN

Preselection of automatic plasma collection and selection of the volume to be separated (Off

= 0). Dual needle.

– PLS-Coll.SN

Preselection of automatic plasma collection and selection of the volume to be separated (Off

= 0). Single needle.

– Get sample

Selection and deselection of help texts for sample collection. Single needle.

– F(cell) return SN

Factor for the cell flow in the return phase. Single needle.

– max. PC-Vol

Determination of the maximum collection volume for the platelet concentrate.

– default PC-Vol

Selection of the standard PC volume.

– Yield

Preadjustment of the platelet yield.

– min. PLT post

Threshold for the donor’s PLT-post value which causes a warning when reached.

– F PC deaerate

Selection of the plasma pump flow during deaeration of the platelate concentrate

(Off = 0)

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-5

Page 12

● Increments and limits for donation parameter configuration

Default Increment Max. Min.

Menus On – On Off

PLTpre 265 x E9/L 1 x E9/L 400 x E9/L 100 x E9/L

HCT pre 40% 1% 60% 20%

max. ACD-rate 1.1ml/min/L 0.1 ml/min/L 2.2 ml/min/L 0.1 ml/min/L

ACD:RBC 1:3.2 0.1 1:5.0 1:2.0

Coeff. DN 49% 1% 70% 30%

Coeff. SN 59% 1% 70% 30%

F(return) SN 75 ml/min 1 ml/min 200 ml/min 50 ml/min

F(return) PLS 35 ml/min 1 ml/min 70 ml/min 35 ml/min

PLS-Coll. DN Off 10 ml 500 ml Off, 50 ml

PLS-Coll. SN Off 10 ml 500 ml Off, 50 ml

Get sample On – On Off

F(cell) return SN 0.7*F(c) coll 0.1*F(c)coll 2.0*F(c)coll 0.1*F(c)coll

max. PC-Vol 600 ml 10 ml 1500 ml 600 ml

default PC-Vol 250 ml 10 ml 600 ml 100 ml

Yield 300 x E9 10 x E9 1500 x E9 50 x E9

min. PLT post 80 E9/L 1 E9/L 150 E9/L 50 E9/L

F PC deaerate 50 ml/min 1 ml/min 120 ml/min Off, 10 ml

1-6 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 13

1.1.2 Configuration Therapy

– Menus

Selection and deselection of the TPE and RBC menus.

– HCT pre

Preadjustment of the patient’s hematocrit value for calculation of the menus.

– HCT RBC

Preadjustment of the hematocrit value, which is adjusted by the Hct controller (see controller

options) in the RBC line. During the RBC procedure, this value is computed and changed

correspondingly by the menu.

Display

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-7

Page 14

1.1.3 Configuration General

– Configuration time

Setting of year, day, hour, minute.

– Country

The country version changes language, units and clock to national conventions.

– Saline diversion

Activates and deactivates saline diversion.

– Chime SN-Option

Activates the chime if no automatic cuff is used.

– Colour combination

Setting the colour combination of the display.

– Key background

Switching the key background on and off.

– Pressure range

Selects the pressure range for the inlet pressure monitor which initiates a pre-alarm if the inlet

pressure drops.

Default: 100 mmHg

1-8 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 15

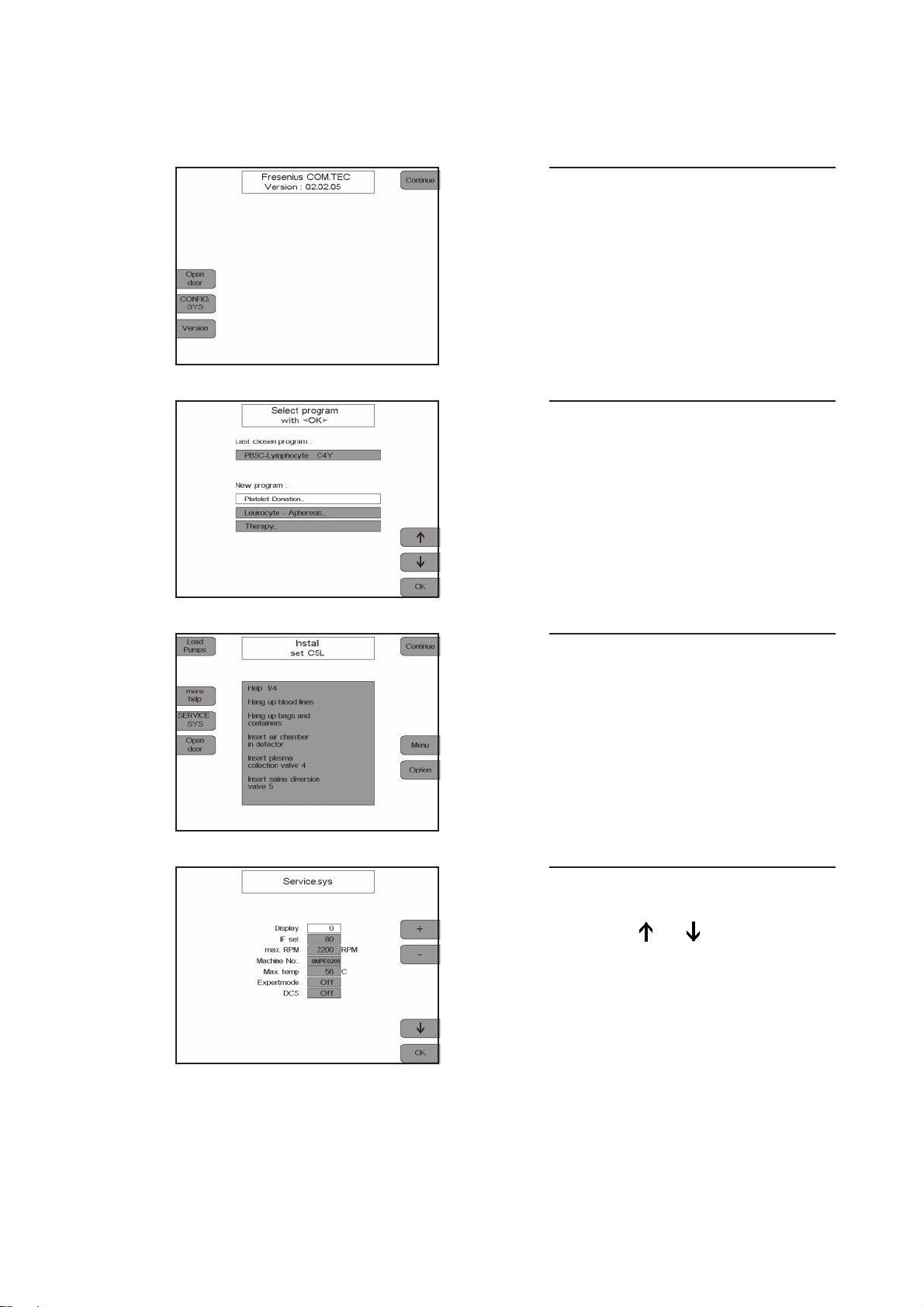

1.2 Service.sys

Display.

Press the Continue key.

Display.

Press the 2nd, the 4th and the 1st key to

the left of the display one after the other.

Press the OK key.

Display.

Press the SERVICE.SYS key.

The Service.Sys screen is displayed.

Select the desired program item by

pressing the and keys.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-9

Page 16

1.2.1 Display

Selection of the program phase window

1.2.2 IF set

Adjustment of the interface sensitivity

1.2.3 max. RPM

Maximum centrifuge speed set to 2200 rpm

1.2.4 Machine No.

Possibility to enter the machine no. shown on the type label

1.2.5 Max. temp

Indication of the maximum temperature that prevailed inside the centrifuge

1.2.6 Expertmode

Possibility to create RAM programs

1.2.7 DCS

Activation/deactivation of the optional radio communication interface

1-10 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 17

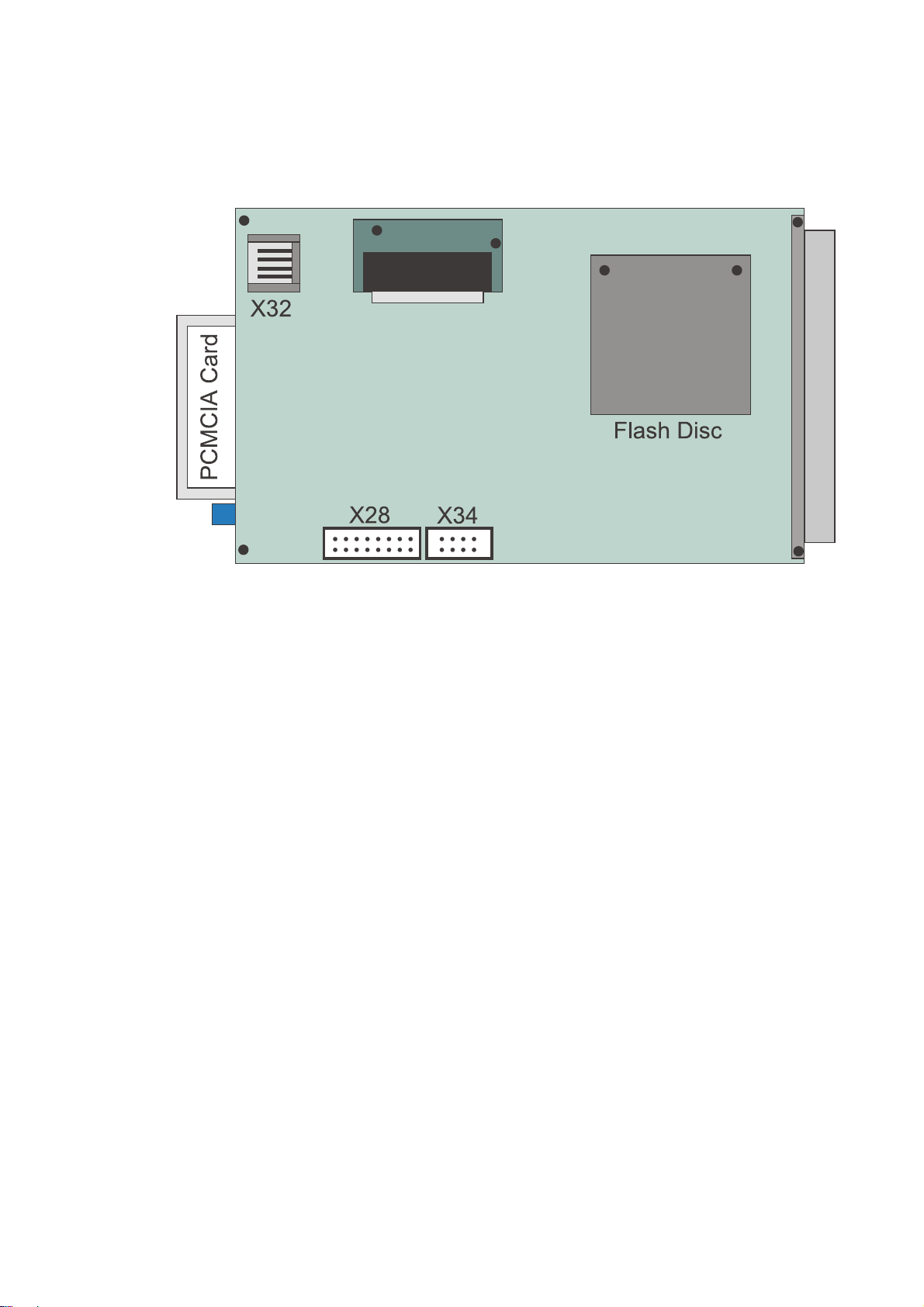

1.3 PC E53

Fig.: PC E53

1.3.1 Flash Disc

The Flash Disc is incorporated as system drive C:\ and contains the DOS system, the program

control and display software.

1.3.2 PCMCIA Card

The PCMCIA Card is incorporated in the system as drive C:\. In this case, the Flash Disc

automatically becomes drive D:\.

The PCMCIA Card contains the current program control and display software (in case of a

software update) and the diagnosis/service program.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-11

Page 18

1.3.3 Signals

LCD/X33

PIN Signal

1VS

2HS

3 VCKL

4nc

5nc

6 _Blank

7nc

8 VID

9nc

– nc

1.3.4 BIOS Setup

The BIOS setup is accessed by pressing the Ctrl + Alt + F6 keys, when turning power on to the

COM.TEC.

X32

PIN Signal

1 GND

2 DATA

3 VCC

4 CLK

E 5 3 S E T U P P R O G R A M

DISK DRIVE 0 TYP 0: NOT INSTALLED

DISK DRIVE 1 TYP 0: NOT INSTALLED

PCMCIA - ATA / IDE BOOT DRIVE SELECT

BOOT FROM 1: ATA-CARD ATA-BIOS EXT : YES

SHOW BOOT MESSAGES: NO KEYBOARD TEST: NO

SELECT DISPLAY TYPE: AUTO

POST WAIT TIME IN SECONDS: 00

BOOT FROM: HARD DISC

CTL ALT DEL RESET: ACTIVATE HW

COM3 / COM4 IRQ: 4 / 3

ALL INPUTS ARE CORRECT? (1)

KEYS: <↑> CHANGE VALUE, <RET> NEXT ITEM

1-12 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 19

1.4 SERVICE TOOL for COM.TEC

1.4.1 How to access the SERVICE TOOL for COM.TEC

– Turn the COM.TEC power off.

– Insert the PCMCIA card in the PC.

– Connect the external keyboard to X32 / PC.

– Turn the COM.TEC power on.

– Press the key.

– The Service Tool for COM.TEC screen displays.

– The following options are available:

Menu key Menu key Menu key

Service Tool S

Update U Software Update to A Select BIOS Version

BIOS E53 00.01.06 A

BIOS E53 00.01.07 B

System Config C Install DCS Driver I

Deinstall DCS Driver D

Exit Update E

EXIT UPDATE E

– The desired option is selected by pressing the associated key.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-13

Page 20

1.4.2 Working with the CCS program

– Use the cursor to select the desired menu.

– Display the menu selected by pressing the key.

– Press the Esc key to exit the respective menu.

– To exit the CCS program, select quit using the cursor and confirm this selection by pressing

the key.

– Within the CCS program, menu-specific help is available, which can be displayed by pressing

the F1 key.

1-14 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 21

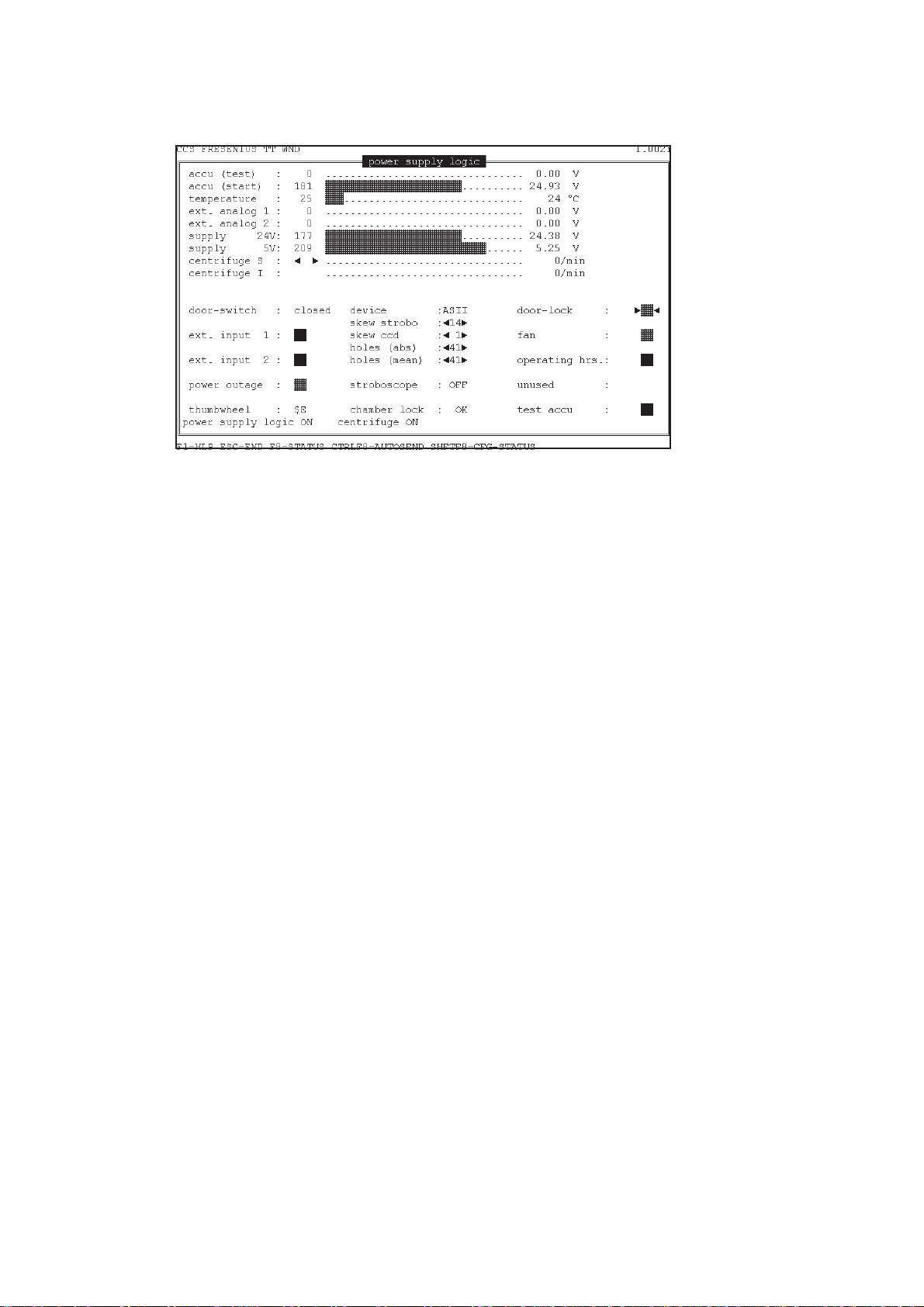

1.4.3 Power Supply

accu (test): battery voltage during the battery test

accu (start): battery voltage

temperature: temperature of power supply unit

supply 24 V: current value of the 24-V supply voltage

supply 5 V: current value of the 5-V supply voltage

centrifuge S: target centrifuge speed; see help menu for adjustment

centrifuge I: actual centrifuge speed

door-switch: door switch display: close - alarm - open

device: must be set to AS II

door-lock: door opener

fan: activation/deactivation of the fan

operating hrs.: activation/deactivation of the time meter

test accu: activation of the battery test

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-15

Page 22

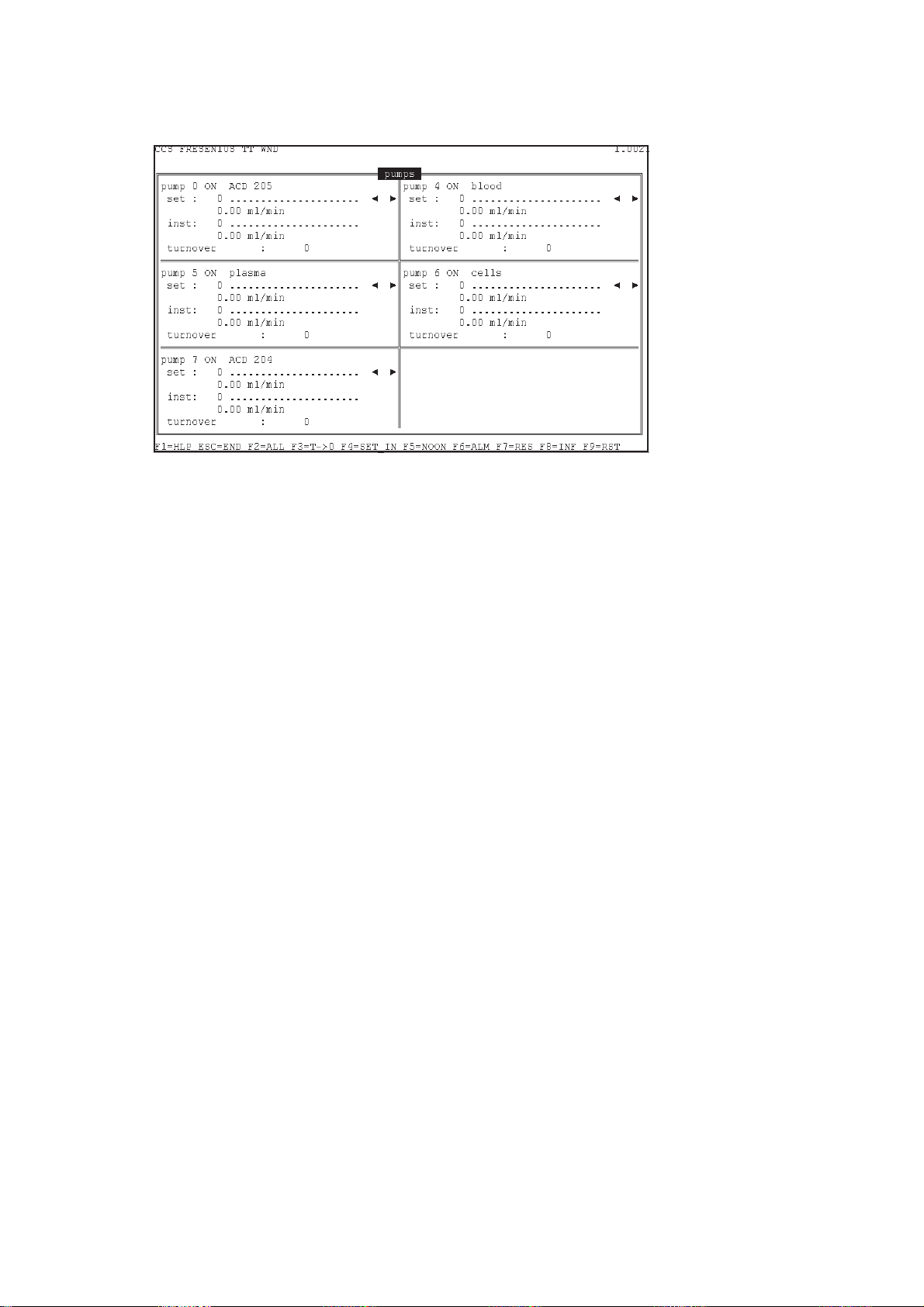

1.4.4 Pumps

Pins 9 and 10 of relay RL 300 / P.C.B. LP 823-1 must be bridged to activate the pumps.

set: target speed in digits; see help menu for adjustment

inst: actual speed in digits

turnover: number of rotor revolutions

cover closed: pump cover display: close - alarm

1-16 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 23

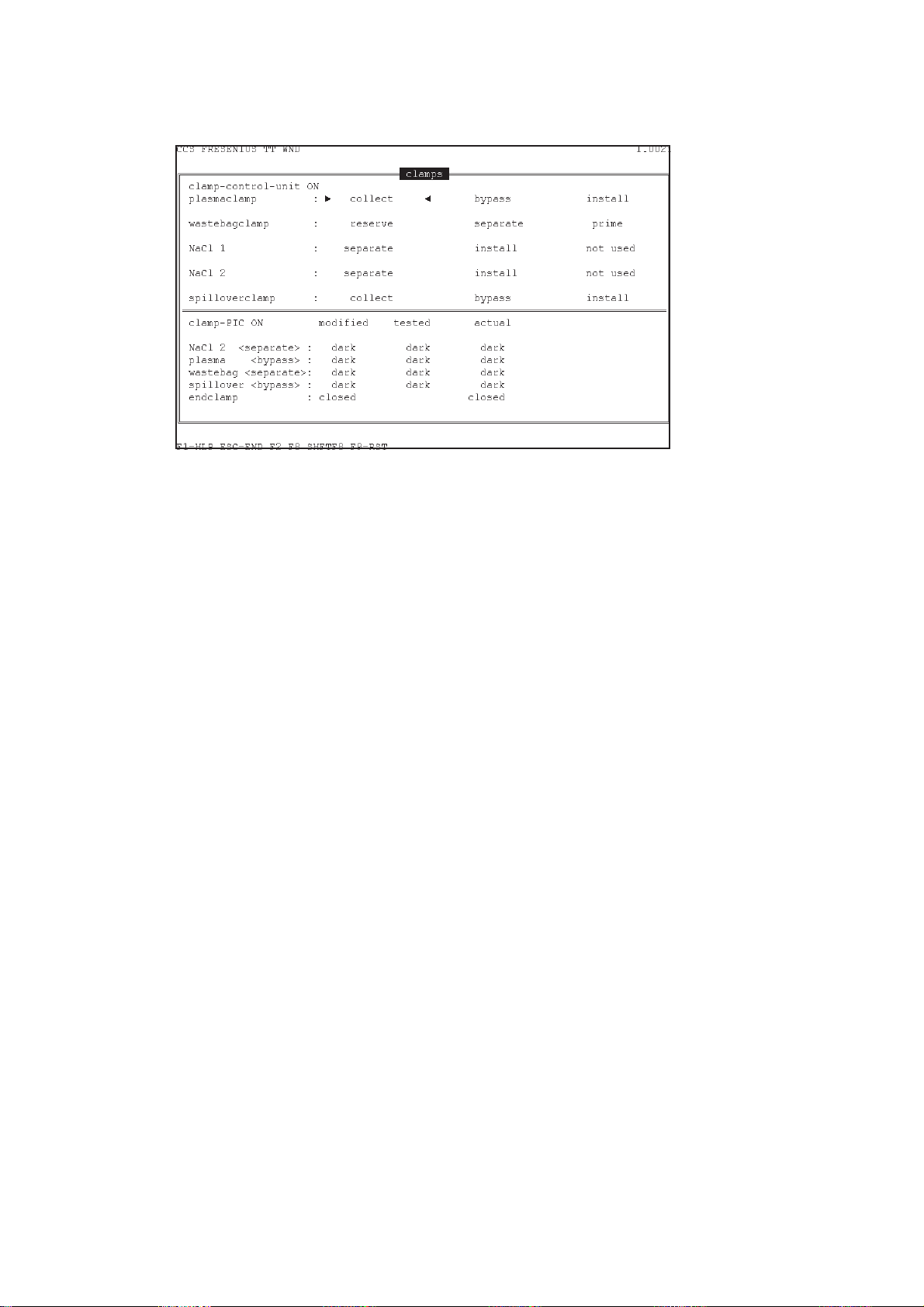

1.4.5 Clamps

clamp-control-unit: clamp-control-unit display: on - off

plasmaclamp: position of the plasma collection clamp

wastebagclamp: position of the saline diversion clamp

NaCl 1: position of the saline clamp in the inlet line

NaCl 2: position of the saline clamp in the return line

spilloverclamp: position of the collection / return clamp

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-17

Page 24

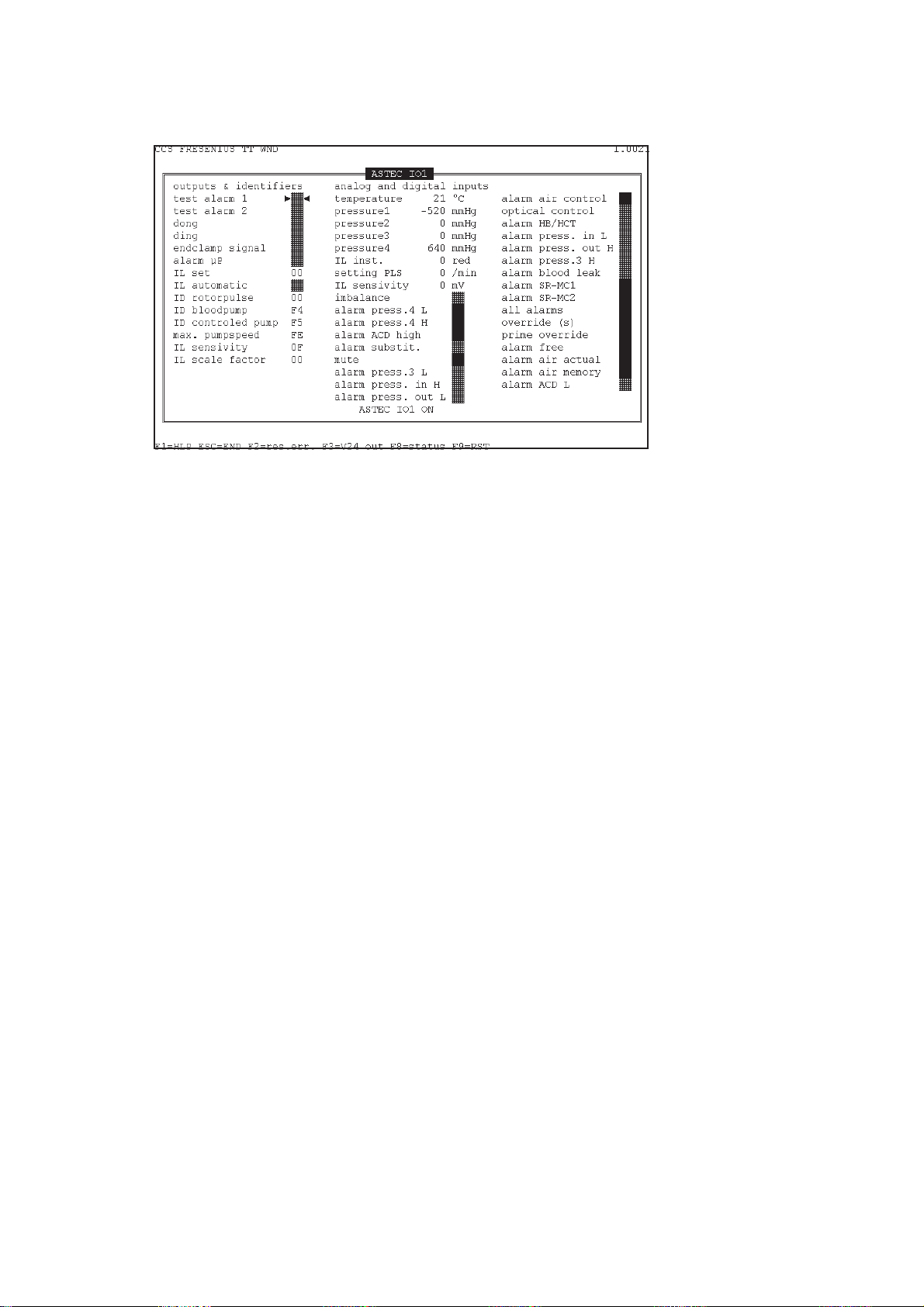

1.4.6 ASTEC IO1

Digital outputs and identifier:

test alarm 1: initiates the alarm test

test alarm 2: cancels stored alarms

dong: deep signal tone

ding: high signal tone

endclamp signal: opens the return clamp of the air detector if no alarm is pending and if

alarm µP: alarm-free if the output is set

IL set: target value of the interface position

IL automatic: interface controller

ID rotorpulse: CAN identifier; do not change

ID bloodpump: CAN identifier; do not change

ID controlled pump: CAN identifier; do not change

max pumpspeed: max. speed of the pump; do not change

IL sensitivity: sensitivity of the interface

IL scale factor: activation of the interface control by the PLS pump

alarm µP is set

Analog inputs:

temperature: temperature inside the centrifuge

pressure 1: P3 pressure value

pressure 2: inlet pressure value

pressure 3: return pressure value

pressure 4: reserve pressure channel value

IL inst.: number of red holes of the interface detection

setting PLS: target value of the PLS pump

IL sensitivity: value of the control voltage

1-18 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 25

Digital inputs:

imbalance: imbalance alarm

alarm press. 4 L: alarm pressure 4 too low

alarm press 4 H: alarm pressure 4 too high

alarm ACD high: alarm ACD ratio too high

alarm substit.: alarm no replacement fluid

mute: mute alarm tone generator

alarm press. 3 L: alarm pressure P3 too low

alarm press in H: alarm inlet pressure too high

alarm press. out L: alarm return pressure too low

air control: alarm air detector

optical control: optical detector of the return clamp of the air detector

alarm HB/HK: alarm hemolysis

alarm press. in L: alarm inlet pressure too low

alarm press. out H: alarm return pressure too high

alarm press. 3 H: alarm pressure P3 too high

alarm blood leak: alarm blood leak

alarm SR-MC 1: alarm safety system, channel 1

alarm SR-MC 2: alarm safety system, channel 2

all alarms: all alarms are active (scanned during the alarm test)

override(s): brief overriding of alarms (to fill the drip chamber)

prime override: overriding of alarms during priming

alarm alarm free: no alarm is pending

alarm air actual: current air detector alarm

alarm air memory: stored air detector alarm

alarm ACD L: alarm - ACD ratio too low

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-19

Page 26

1.4.7 ASTEC IO2

cuff pump: activates the single-needle pump

cuff valve: activates the single-needle valve (the end clamp must also be activated)

endclamp signal: end clamp signal for single-needle control

pressure: indicates whether the pressure has been achieved

cuff present: single-needle assembly P.C.B. LP-Z 175 present

1-20 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 27

1.4.8 HBHK / spillover

ACD drops: number of ACD drops

EEPROM: indicates position of switch S1 / LP 867

substituade: status of substituate-empty detector

HBHK: Hb/Hk detector

spillover: spillover detector

dimming: dimness of detector in digits

coloring: coloring of detector in digits

alarm: Alarm Hb/Hk or Spillover

is adj.: lights after adjustment of the reference value

adj.: lights during adjustment of the reference value

is calib.: lights after calibration

calib: lights during calibration

Fresenius HemoCare COM.TEC 1/04.01 (TM) 1-21

Page 28

1.4.9 CCD camera

loop control: –

chamberlight: chamber light on - off

mirrorlight: mirror light on - off

initsearch: initialisation phase on - off

automatic: automatic position test on - locked

holeskew: hole skew, camera trigger

startpixel: start pixel, interface window

resetcounter: number of camera resets

edgepixelval.: –

ADC ref. low: reference voltage low

ADC ref. high: reference voltage high

lighttime ml.: mirror light exposure time

lighttime cl.: chamber light exposure time

errorbyte: internal display error counter

set. line: target interface value

interfaceline: actual interface value

pmp max.: –

set. pmp: –

1-22 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 29

Table of Contents

2 Repair / Adjustment / Maintenance

Chapter Page

2.1 Verification of the Interface Detection ........................................................................ 2-5

2.1.1 Verification of the Optical Sensor ................................................................................... 2-6

2.1.2 Verification of the 8 Hole Pulses ..................................................................................... 2-7

2.1.3 Verification of the Interface Sensitivity of the 8 Hole Pulses ......................................... 2-9

2.1.4 Verification of the C5 Interface Detection ....................................................................... 2-10

2.2 Adjustment of the Interface Detection ........................................................................ 2-12

2.2.1 Adjustment of the Optical Sensor ................................................................................... 2-13

2.2.2 Basic Adjustment of the Camera and the Lighting Unit ................................................. 2-14

2.2.3 Precision Adjustment of the Camera and the Lighting Unit ........................................... 2-15

2.2.4 Adjustment of the 8 Hole Pulses (Basic Adjustment C5 Detection) .............................. 2-17

2.2.5 Adjustment of the Interface Sensitivity of the 8 Hole Pulses ......................................... 2-18

2.2.6 Adjustment of the C5 Interface Detection ....................................................................... 2-19

2.3 C5 Interface Sensitivity ................................................................................................ 2-22

2.3.1 Verification of the C5 Interface Sensitivity ...................................................................... 2-22

2.3.2 Adjustment of the C5 Interface Sensitivity ...................................................................... 2-23

2.4 Verification of the C5 Illuminance ............................................................................... 2-24

2.5 Inlet Pressure Monitor .................................................................................................. 2-26

2.5.1 Verification of the Gain ................................................................................................... 2-26

2.5.2 Verification of the Alarm Limits ....................................................................................... 2-26

2.5.3 Adjustment of the Gain ................................................................................................... 2-27

2.5.4 Adjustment of the Alarm Limits ....................................................................................... 2-29

2.6 Outlet Pressure Monitor ............................................................................................... 2-31

2.6.1 Verification of the Gain ................................................................................................... 2-31

2.6.2 Verification of the Alarm Limits ....................................................................................... 2-31

2.6.3 Adjustment of the Gain ................................................................................................... 2-32

2.6.4 Adjustment of the Alarm Limits ....................................................................................... 2-34

2.7 P3 Monitor ..................................................................................................................... 2-36

2.7.1 Verification of the Gain ................................................................................................... 2-36

2.7.2 Verification of the Alarm Limits ....................................................................................... 2-36

2.7.3 Adjustment of the Gain ................................................................................................... 2-37

2.7.4 Adjustment of the Alarm Limits ....................................................................................... 2-39

2.8 Operating Voltages / Battery Voltage ......................................................................... 2-41

2.8.1 Verification ...................................................................................................................... 2-41

2.9 Air Detector ................................................................................................................... 2-42

2.9.1 Verification ...................................................................................................................... 2-42

2.9.2 Adjustment ...................................................................................................................... 2-43

2.10 Optical Detector in Air Detector .................................................................................. 2-44

2.10.1 Verification ...................................................................................................................... 2-44

2.10.2 Calibration of the Optical Detector.................................................................................. 2-44

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-1

Page 30

Chapter Page

2.11 Hb/Hct Detector............................................................................................................. 2-45

2.11.1 Verification ...................................................................................................................... 2-45

2.11.2 Adjustment...................................................................................................................... 2-46

2.12 Spillover Detector ......................................................................................................... 2-47

2.12.1 Verification ...................................................................................................................... 2-47

2.12.2 Adjustment...................................................................................................................... 2-48

2.13 Substituate-Empty Detector ........................................................................................ 2-49

2.18.1 Verification ...................................................................................................................... 2-49

2.13.2 Adjustment...................................................................................................................... 2-50

2.14 Gap Width of Outlet Clamp .......................................................................................... 2-51

2.14.1 Verification of Gap Width ................................................................................................ 2-51

2.14.2 Verification of Line Occlusion ......................................................................................... 2-51

2.14.3 Adjustment...................................................................................................................... 2-51

2.15 Line Pumps.................................................................................................................... 2-52

2.15.1 Verification ...................................................................................................................... 2-52

2.15.2 Verification of the 5 Line Pumps..................................................................................... 2-53

2.15.3 Cleaning of the Pump Rotors and the Pump Beds........................................................ 2-53

2.15.4 Adjustment of the Pump Rotors Nr. 4, 5, 6, 7................................................................. 2-54

2.15.5 Final Check..................................................................................................................... 2-54

2.16 Clamps ........................................................................................................................... 2-55

2.16.1 Verification of the Occlusion Pressure of the Clamps ................................................... 2-56

2.17 Centrifuge Door............................................................................................................. 2-57

2.17.1 Removing the Door......................................................................................................... 2-57

2.17.2 Removing the Door Frame (Chassis) and the Pivot Bearing......................................... 2-57

2.17.3 Adjustment...................................................................................................................... 2-58

2.18 Door Switch ................................................................................................................... 2-59

2.18.1 Verification ...................................................................................................................... 2-59

2.18.2 Removal / Installation ..................................................................................................... 2-60

2.18.3 Adjustment...................................................................................................................... 2-60

2.19 Centrifuge Motor Carbon Brushes.............................................................................. 2-61

2.19.1 Verification ...................................................................................................................... 2-61

2.20 Single Needle / Cuff Control ........................................................................................ 2-62

2.20.1 Verifications .................................................................................................................... 2-62

2.20.2 Adjustment...................................................................................................................... 2-63

2.21 Removal and Installation of the Centrifuge Rotor .................................................... 2-64

2.21.1 Removal of the Centrifuge Rotor .................................................................................... 2-65

2.21.2 Installation of the Centrifuge Rotor ................................................................................. 2-66

2.22 Tightening the Belts in the Rotor ................................................................................ 2-68

2.21.1 Verification ...................................................................................................................... 2-68

2.22.2 Adjustment...................................................................................................................... 2-68

2.23 Brake .............................................................................................................................. 2-69

2.23.1 Removal / Installation ..................................................................................................... 2-69

2.23.2 Adjustment...................................................................................................................... 2-69

2-2 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 31

Chapter Page

2.24 Flutter Detector ............................................................................................................. 2-70

2.24.1 Verification ...................................................................................................................... 2-70

2.25 General Mechanical Checks ........................................................................................ 2-71

2.25.1 Housing........................................................................................................................... 2-71

2.25.2 Rubber Pads ................................................................................................................... 2-71

2.25.3 Mounting Screws ............................................................................................................ 2-71

2.25.4 Optical Sensors............................................................................................................... 2-71

2.25.5 Fan.................................................................................................................................. 2-71

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-3

Page 32

2-4 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 33

2.1 Verification of the Interface Detection

Measuring equipment: 2-channel storage oscilloscope,

CCD test adapter – camera (part no. 678 617 1),

BNC test cable (part no. 678 482 1),

Reference chamber (part no. M60 383 1),

Test cable (part no. 679 763 1)

Mode of operation: CCS program

Caution

Clean the optical axis prior to the verification of the interface detection.

– Access the CCS program.

– Select the power supply menu.

– The following screen displays:

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-5

Page 34

2.1.1 Verification of the Optical Sensor

Fig.: P.C.B. LP 823-1

– Stop the centrifuge (pos. 1), open the door (door lock).

– Connect the oscilloscope to P400 /LP 823-1 and GND / LP 823-1.

– Set the centrifuge speed to 1000 rpm.

P400

Gnd

Oscilloscope setting:

P400 / LP 823-1: 1 V/Div.

Time base: 0.5 ms/Div

– Check the optical sensor signal at 300 rpm and 2000 rpm.

Optical sensor signal:

Amplitude: >4.7 V

Pulse duty factor: 50 % ± 10 %

– Signal not flickering

– If the optical sensor signal deviates from the target values the interface detection must be

completely adjusted. (➜ Chapter 2.2).

2-6 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 35

2.1.2 Verification of the 8 Hole Pulses

MP1

MP0

– Install the reference chamber with segment 1.

– Connect the test cable to connector X3 / LP 863.

– Connect the oscilloscope to the test adapter X3.2 / LP 863 (ground) and to X3.1 / LP 863 (hole

pulses).

– Connect the oscilloscope to MP 0 / LP 866 (ground) and to MP 1 / LP 866 (current of the

transmitting diode).

– Close the centrifuge door and set the centrifuge speed to 1000 rpm in the power supply

menu.

– Activate automatic sending of the target values (AUTOSEND) by pressing the Ctrl and the F8

key. Press the key.

– Exit the power supply menu and select the CAN-I/O menu.

– Activate the trigger unit output 2 / no. 0.

Note

☞

The current of the transmitting diode depends on the temperature. Before the

verification the centrifuge must therefore have been in operation for at least 10

minutes, with the trigger unit output 2 / no. 0 activated, and the current of the

transmitting diode must be 300 mA.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-7

Page 36

Oscilloscope setting:

X3.1 / LP 863 2 V / Div

(hole pulses):

MP 1 / LP 866 0.1 V / Div

(current of the

transmitting diode):

Time base: 0.5 ms / Div

Triggering: current of the

transmitting diode,

ascending edge

– The 8 hole pulses must appear within the signal of the current of the transmitting diode (see

figure).

– Reduce the centrifuge speed to 300 rpm and then increase the speed to 2200 rpm. While

altering the speed, the 8 hole pulses must always be within the signal of the current of the

transmitting diode (see figure).

– If the 8 hole pulses are not within the signal of the current of the transmitting diode or if they

leave this signal when the speed is altered, the interface detection must be completely

adjusted (➜ Chapter 2.2).

2-8 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 37

2.1.3 Verification of the Interface Sensitivity of the 8 Hole Pulses

– Stop the centrifuge (pos. 1), open the door (door lock ).

– Insert the reference chamber with the C4 hole area covered with adhesive foil (segment 2).

– Connect the oscilloscope to the test adapter X3.2 / LP 863 (ground) and to X3.4 / LP 863

(digital hole pulses).

– Connect the oscilloscope to MP 0 / LP 866 (ground) and MP 1 / LP 866 (current of the

transmitting diode).

– Close the door, set the centrifuge speed to 1000 rpm.

Oscilloscope setting:

MP 1 / LP 866 0.1 V / Div

(current of the

transmitting diode):

X3.4 / LP 863 2 V / Div

(digital

hole pulses):

Time base: 0.5 ms / Div

Triggering: current of the

transmitting diode,

ascending edge

Note

☞

– All of the 8 hole pulses (digital) must just be visible and may not flicker (see figure).

– If the 8 hole pulses (digital) are not visible or flicker, the interface detection must be completely

adjusted (➜ Chapter 2.2).

The current of the transmitting diode depends on the temperature. Before the

verification the centrifuge must therefore have been in operation for at least 10

minutes, with the trigger unit output 2 / no. 0 activated. The current of the

transmitting diode must be 300 mA.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-9

Page 38

2.1.4 Verification of the C5 Interface Detection

– Stop the centrifuge (pos. 1), open the door (door lock).

– Insert the reference chamber segment 5.

– Connect the CCD test adapter to the plug connector that exits the camera housing.

– Connect the oscilloscope with the two BNC test cables to the CCD test adapter.

– Close the door, set the centrifuge speed to 2200 rpm.

– Exit the power supply menu and select the CCD menu.

– Press the F9 and the key to reset the camera and wait until the initialization phase of the

camera is completed (initsearch: OFF) and segment 5 of the reference chamber has been

detected (C5 detected: ON).

– Use the F3 key to set chamberlight: ON (lighting).

– Use the F6 key to set automatic: locked.

Caution

If the camera does not receive a new CAN command within one minute

(holeskew, lighttime cl, startpixel), it automatically exits the locked mode and

the display changes from automatic: locked to automatic: ON.

– Use the and keys to select holeskew and use the and key to set the value to 8

(reference signal).

– The C5 reference signal must appear within the gate pulse (see figure).

Oscilloscope setting:

Video signal: 0.5 V / Div

Gate pulse: 2 V / Div

Time base: 5 ms / Div

Triggering: gate pulse, ascending

edge

– If the C5 reference signal is not within the gate pulse, the interface detection must be

completely adjusted (➜ Chapter 2.2).

2-10 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 39

– Use the and keys to select holeskew and use the and keay to set the value to 11

(C5 interface signal).

– The C5 interface signal must appear within the gate pulse (see figure).

Oscilloscope setting:

Video signal: 0.5 V / Div

Gate pulse: 2 V / Div

Time base: 5 ms / Div

Triggering: gate pulse, ascending

edge

– If the C5 interface signal is not within the gate pulse, the interface detection must be

completely adjusted (➜ Chapter 2.2).

– If the C5 interface signal is flickering, the interface detection need not be adjusted.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-11

Page 40

2.2 Adjustment of the Interface Detection

Measuring equipment: 2-channel storage oscilloscope,

CCD test adapter – camera (part no. 678 617 1),

BNC test cable (part no. 678 482 1),

Reference chamber (part no. M60 383 1),

Test cable (part no. 679 763 1)

Mode of operation: CCS program

Caution

Before adjusting the interface detection:

– Check the belt tension and adjust, if necessary.

– Clean the optical axis.

– Access the CCS program.

– Select the power supply menu.

– The following screen displays:

2-12 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 41

2.2.1 Adjustment of the Optical Sensor

Fig.: P.C.B. LP 823-1

– Stop the centrifuge (pos. 1), open the door (door lock ).

– Unscrew the 2 Allen screws that secure the optical sensor bracket.

– Connect the oscilloscope to P 400 / LP 823-1 and to GND / LP 823-1.

– Set the centrifuge speed to 1000 rpm.

P400

Gnd

Oscilloscope setting:

P400 / LP 823-1: 1 V/Div.

Time base: 0.5 ms/Div

– Radially adjust the optical sensor bracket until the pulse duty factor is 50 % ± 10 % (see

figure).

Caution

Do not adjust the optical sensor bracket unless the centrifuge is completely

stopped (0 rpm).

– Tighten the fixing screw of the optical sensor bracket.

– Check the optical sensor signal at 300 rpm and 2000 rpm:

Amplitude: > 4.7 V

Pulse-duty factor: 50 % ± 10 %

Signal not flickering

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-13

Page 42

2.2.2 Basic Adjustement of the Camera and the Lighting Unit

– Stop the centrifuge (pos. 1), open the door (door lock).

– Loosen the four size 3 Allen screws of the camera and the size 2.5 Allen screw of the support

bracket to permit positioning of the camera.

– Position the camera with 3 mm distance to the front stop and parallel to the telescopic rail of

the power supply unit.

– Lightly loosen the size 4 Allen screw of the lighting unit to permit positioning of the lighting unit.

– Position the lighting unit centrally to the drilled hole and perpendicular to the front panel.

2-14 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 43

2.2.3 Precision Adjustment of the Camera and the Lighting Unit

MP5

MP1

P2

MP3

MP4

MP0

– Insert the reference chamber with segment 1.

– Place the interface window into the optical axis. The missing hole on the perforated disc

should now be located within the optical sensor.

Adjustment:

Loosen the size 2.5 Allen screw of the perforated disc carrier and position the missing hole to

be within the optical sensor while maintaining the position of the reference chamber. Re-

tighten the size 2.5 Allen screw when the adjustment is completed.

– Connect the test cable to connector X3 / LP 863 (ground).

– Connect the oscilloscope to the test adapter X3.2 / LP 863 (ground) and to X3.1 / LP 863 (hole

pulses).

– Connect the oscilloscope to MP 0 / LP 866 (ground) and to MP 1 / LP 866 (current of the

transmitting diode).

– Close the centrifuge door and set the centrifuge speed to 1000 rpm in the power supply

menu.

– Activate automatic sending of target values ( AUTOSEND) by pressing the Ctrl and the F8

keys. Press the key.

– Exit the power supply menu and select the CAN-I/O menu.

– Activate the trigger unit output 2 / no. 0.

– Use P2 / LP 866 to set the current of the transmitting diode to 300 mA (equals a 300 mV

amplitude on the oscilloscope).

Note

☞

The current of the transmitting diode depends on the temperature. Before the

verification the centrifuge must therefore have been in operation for at least 10

minutes, with the trigger unit output 2 / no. 0 activated, and the current of the

transmitting diode must be 300 mA.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-15

Page 44

Oscilloscope setting:

X3.1 / LP 863 2 V / Div

(hole pulses):

MP 1 / LP 866 0.1 V / Div

(current of the

transmitting diode):

Time base: 0.5 ms / Div

Triggering: Current of the

transmitting diode,

ascending edge

– Move the camera and the lighting unit to set the optimum amplitude height. The difference

between the maximum and the minimum amplitude may not exceed 50 %. Use P1 / LP 863 to

adjust the amplitude height so that clipping of one amplitude occurs.

– On completion of the adjustment the camera should be positioned parallel to the telescopic rail

of the power supply unit and the lighting unit should be parallel to the front panel.

– Stop the centrifuge (pos. 1), open the door (door lock).

– Tighten the four size 3 Allen screws of the camera.

– Tighten the size 4 Allen screw of the lighting unit.

– Verify the adjustment and repeat, if necessary.

2-16 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 45

2.2.4 Adjustment of the 8 Hole Pulses (Basic Adjustment C5 Detection)

Oscilloscope setting:

X3.1 / LP 863 2 V / Div

(hole pulses):

MP 1 / LP 866 0.1 V / Div

(current of the

transmitting diode):

Time base: 0.5 ms / Div

Triggering: current of the

– The descending edge of the 1st hole pulse should appear 1 – 1.4 ms after the ascending edge

of the current of the transmitting diode (see figure).

– Ascertain whether the 8 hole pulses are to the left or the right of the desired position.

transmitting diode,

ascending edge

– Exit the CAN I/O menu and select the power supply menu.

– Stop the centrifuge (pos. 1), open the door (door lock ).

– Loosen the size 2.5 Allen screw of the perforated disc carrier.

– Rotate the perforated disc while holding the rotor shaft.

If the 8 holes are to the right of the desired position, the perforated disc must be turned anti-

clockwise (rotor viewed from below).

If the 8 holes are to the left of the desired position, the perforated disc must be turned slightly

clockwise (rotor viewed from below).

– Tighten the size 2.5 Allen screw of the perforated disc carrier.

– Verify the adjustment and repeat, if necessary.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-17

Page 46

2.2.5 Adjustment of the Interface Sensitivity of the 8 Hole Pulses

– Stop the centrifuge (pos. 1), open the door (door lock).

– Insert the reference chamber with the C4 hole area (segment 2) covered with foil.

– Connect the oscilloscope to the test adapter X3.2 / LP 863 (ground) and to X3.4 / LP 863

(digital hole pulses).

– Connect the oscilloscope to MP 0 / LP 866 (ground) and to MP 1 / LP 866 (current of the

transmitting diode).

– Close the door, set the centrifuge speed to 1000 rpm.

Oscilloscope setting:

MP 1 / LP 866 0.1 V / Div

(current of the

transmitting diode):

X3.4 / LP 863 2 V / Div

(digital

hole pulses):

Time base: 0.5 ms / Div

Triggering: current of the

transmitting diode,

ascending edge

Note

☞

– Use P1 / LP 863 to adjust the 8 hole pulses (digital) so that they are all just visible and do not

flicker (see figure).

The current of the transmitting diode depends on the temperature. Before the

verification the centrifuge must therefore have been in operation for at least 10

minutes, with the trigger unit output 2 / no. 0 activated. The current of the

transmitting diode must be 300 mA.

2-18 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 47

2.2.6 Adjustment of the C5 Interface Detection

– Stop the centrifuge (pos. 1), open the door (door lock ).

– Insert the reference chamber, segment 5.

– Connect the CCD test adapter to the plug connection that exits the camera housing.

– Connect the oscilloscope with the two BNC test cables to the CCD test adapter.

– Close the door, set the centrifuge speed to 2200 rpm.

– Exit the power supply menu and select the CCD menu.

– Reset the camera with the F9 key and the key and wait until the intialisation phase of the

camera is completed (initsearch: OFF) and segment 5 of the reference chamber has been

detected (C5 detected: ON).

– Use the F3 key to set chamberlight: ON (lighting).

– Use the F6 key to set automatic: locked.

Caution

If the camera does not receive a new CAN command (holeskew, lighttime cl,

startpixel) within one minute, it automatically exits the locked mode and the

display changes from automatic: locked to automatic: ON.

– Use the and keys to select holeskew and set the value to 8 (reference signal) by pressing

the and keys.

– The C5 reference signal must now be within the gate pulse (see figure).

Oscilloscope setting:

Video signal: 0.5 V / Div

Gate pulse: 2 V / Div

Time base: 5 ms / Div

Triggering: gate pulse,

ascending edge

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-19

Page 48

– Use the and keys to select holeskew and use the and keys to set the value to 11

(C5 interface signal).

Oscilloscope setting:

Video signal: 0.5 V / Div

Gate pulse: 2 V / Div

Time base: 5 ms / Div

Triggering: gate pulse,

ascending edge

– If no C5 interface signal appears, use the and keys to select lighttime cl (exposure time)

and use the key to increment the value to 15 while observing the oscilloscope for the C5

interface signal to appear.

– Exit the CCD menu and select the power supply menu.

– Stop the centrifuge (pos. 1), open the door (door lock).

– Loosen the size 2.5 Allen screw of the perforated disc carrier.

– Rotate the perforated disc in the following direction while holding the rotor shaft.

– C5 interface signal visible when increasing the exposure time:

Turn the perforated disc slightly anticlockwise (rotor viewed from below).

– C5 interface signal not visible when increasing the exposure time:

Turn the perforated disc slightly clockwise (rotor viewed from below).

– Tighten the size 2.5 Allen screw of the perforated disc carrier.

– Close the door, set the centrifuge speed to 2200 rpm.

– Exit the power supply menu and select the CCD menu.

Caution

If the camera does not receive a new CAN command within one minute

(holeskew, lighttime cl, startpixel), it automatically exits the locked mode and

the display changes from automatic: locked to automatic: ON.

– Use the and keys to select holeskew and use the and keys to set the value to 11.

2-20 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 49

– Use the and keys to select lighttime cl (exposure time) and then use the and keys

to set the value to 0.

– The C5 interface signal should now appear within the gate pulse.

If the C5 interface signal fails to appear within the gate pulse, the adjustment must be

repeated.

– Exit the CCD menu and select the power supply menu.

– Stop the centrifuge (pos. 1), open the door (door lock ).

– Tighten the size 2.5 Allen screw of the fixing bracket of the camera.

– Set the centrifuge speed to 2200 rpm.

– Exit the power supply menu and select CCD menu.

– Use the F6 key to set automatic: locked.

Caution

If the camera does not receive a new CAN command within one minute

(holeskew, lighttime cl, startpixel), it automatically exits the locked mode and

the display changes from automatic: locked to automatic: ON.

– Use the and keys to select holeskew and use the and key to set the value to 11.

– Use the and keys to select lighttime cl (exposure time) and then use the and keys

to set the value to 0.

– The C5 interface signal should now appear within the gate pulse.

Oscilloscope setting:

Video signal: 0.5 V / Div

Gate pulse: 2 V / Div

Time base: 5 ms / Div

Triggering: gate pulse,

ascending edge

– On completion of the adjustment the 8 hole pulses in the gate pulse must be verified using the

C4 reference chamber, segment 1. At 1000 rpm and 2200 rpm the 8 hole pulses must appear

within the gate pulse.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-21

Page 50

2.3 C5 Interface Sensitivity

Measuring equipment: Reference chamber (part no. M60 383 1)

Mode of operation: PLT-5d program

2.3.1 Verification of the Interface Sensitivity

– Turn the COM.TEC power on.

– Enter the Service.sys code (Chapter 1.2).

– Access the PLT-5d program.

– Insert the reference chamber with segment 6.

– Access the Service.sys (Chapter 1.2).

Use the and keys to select Expert

Mode.

Use the + and – keys to set Expert

Mode to On.

Press the OK key.

– Start the PLT-5d separation program.

– Read the actual interface value IF

displayed.

act

– Stop the separation program.

– Determine the difference between the actual interface value displayed IF

value IF

printed on the chamber. The value determined for IF

chamber

difference

+5 and –5.

IF

act

– IF

chamber

= IF

(tolerance: ±5).

difference

and the interface

act

must range between

2-22 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 51

2.3.2 Adjustment of the Interface Sensitivity

– Access the Service.sys (Chapter 1.2).

– Start the PLT-5d separation program.

Use the and keys to select IF set.

Use the + and – keys to change IF set

by the value determined for IF

IF set ± IF

difference

= IF set

new

difference

:

Press the OK key.

– On completion of the adjustment the actual interface value displayed, IF

the value IF

printed on the chamber.

chamber

, must correspond to

act

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-23

Page 52

2.4 Verification of the C5 Illuminance

Measuring equipment: Reference chamber (part no. M60 383 1)

Mode of operation: CCS program

– Access the CCS program.

– Select the power supply menu.

– The following screen displays:

– Stop the centrifuge (pos. 1), open the door (door lock).

– Insert the reference chamber with segment 6.

– Set the centrifuge speed to 2000 rpm.

– Activate automatic sending of the target values (AUTOSEND) by pressing the Ctrl and the F8

key. Press the key.

– Exit the power supply menu and select the CCD menu.

– Reset the camera with the F9 key and the key and wait until the intialisation phase of the

camera is completed (initsearch: OFF) and segment 5 of the reference chamber has been

detected (C5 detected: ON).

– Use the F3 key to set chamberlight: ON (lighting).

2-24 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 53

– Use the F6 key to set automatic: locked.

Caution

If the camera does not receive a new CAN command (holeskew, lighttime cl,

startpixel) within one minute, it automatically exits the locked mode and the

display changes from automatic: locked to automatic: ON.

– Use the and keys to select holeskew and set the value to 11 (reference signal) by

pressing the and keys.

– Use the and keys to select lighttime cl (exposure time) and then use the and keys

to set the value to 8.

– Press the F7 key to access the CCD camera display module.

– Use the F8 (right) key and the shift F8 (left) key to move the red column to determine the

illuminance.

– Shift the column until the right edge intersects the center of the descending edge of the signal,

note down the pixels (pixel1).

Typical pixel value: 40 – 65

– Shift the column until the right edge intersects the center of the ascending edge of the signal,

note down the pixels (pixel2).

Typical pixel value: 60 – 85

– Determine the difference between pixel2 and pixel

The value determined for the illuminance

1.

should range between 18 and 45 pixels.

Illuminance = pixel2 – pixel1 (typcal values: 18 – 45 pixels).

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-25

Page 54

2.5 Inlet Pressure Monitor

Measuring equipment: Pressure gauge in mmHg

Measurement point: Pressure port – inlet pressure

Measuring signal: Pressure display, LED D201, LED D202

Mode of operation: CCS program

– Access the CCS program.

– Select the astecio1 menu.

– The following screen displays:

2.5.1 Verification of the Gain

– Zero:

With the pressure port open, verify that the inlet pressure display pressure2 indicates

0 mmHg.

– Gain:

Apply a pressure of 240 mmHg to the inlet pressure port; verify that the pressure2 display

indicates 240 mmHg.

If one of the values displayed deviates from the target value, adjust the pressure.

2.5.2 Verification of the Alarm Limits

– Lower alarm limit: –310 mmHg ±10mmHg

– Upper alarm limit: +310 mmHg ±10mmHg

2-26 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 55

2.5.3 Adjustment of the Gain

Fig.: P.C.B LP 870

● Reset of the Pressure Monitor

Note

☞

After a reset of the inlet pressure monitor, zero, gain and alarm limits of the inlet

pressure monitor must be readjusted.

D202 D201S200S1

– Set the mode switch S200 to position C.

– Press the S1 button twice.

All values of the inlet pressure monitor that were stored will be erased.

● Calibration of the Zero

– Set the mode switch S200 to position D, the LED D201/P.C.B. LP 870 lights.

– With the inlet pressure port open (0 mmHg/0 Pa), press the S1 button.

After successful calibration, the LED D201/P.C.B. LP 870 will stop lighting and the LED D202/

P.C.B. LP 870 will start lighting.

– Press the S1 button again, the LED D202/P.C.B. LP 870 stops lighting.

Note

☞

If the LED D201/P.C.B. LP 870 is flashing after the S1 button has been pressed

for the first time, this may be due to one of the following errors:

1. The pressure being applied to the inlet pressure port exceeds +16.6 mmHg

or is lower than –20.8 mmHg.

2. The IC 201/P.C.B. LP 870 or its external wiring is defective.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-27

Page 56

● Calibration of the Gain

– Set the mode switch S200 to position E, the LED D202/P.C.B. LP 870 lights.

– Apply +500 mmHg (66661 Pa) to the inlet pressure port and press the S1 button.

After successful calibration, the LED D202/P.C.B. LP 870 will stop lighting and the LED D201/

P.C.B. LP 870 will start lighting.

– Press the S1 button again, the LED D201/P.C.B. LP 870 stops lighting.

Note

☞

– Set the mode switch S200 to position 0.

● Final Check

– Check the pressure transducer for tightness at 500 mmHg.

If the LED D202/P.C.B. LP 870 is flashing after the S1 button has been pressed

for the first time, the pressure being applied to the inlet pressure port is lower

than +16.6 mmHg (2213 Pa).

☞

Note

Verify after completion of the adjustment and readjust, if necessary.

2-28 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 57

2.5.4 Adjustment of the Alarm Limits

Fig.: P.C.B. LP 870

● Reset of the Pressure Monitor

Note

☞

After a reset of the inlet pressure monitor, zero, gain and alarm limits of the inlet

pressure monitor must be readjusted.

D202 D201S200S1

– Set the mode switch S200 to position C.

– Press the S1 button twice.

All values of the inlet pressure monitor that were stored will be erased.

● Adjustment

– Set the mode switch S200 to position F, the LEDs D201/P.C.B. 870 and D202/P.C.B. 870

light.

– Apply +310 mmHg (upper alarm limit) to the inlet pressure port and press the S1 button.

– After successful calibration, the LED D202/P.C.B. LP 870 stops lighting and the LED

D201/P.C.B. LP 870 will start lighting.

Note

☞

If the LEDs D201/P.C.B. 870 and D202/P.C.B. 870 are flashing after the S1

button has been pressed for the first time, the pressure being applied to the inlet

pressure port is lower than +16.6 mmHg (2213 Pa).

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-29

Page 58

– Apply –310 mmHg (lower alarm limit) to the inlet pressure port and press the S1 button.

– After successful calibration, the LED D201/P.C.B. LP 870 stops lighting.

Note

☞

– Set the mode switch S200 to position 0.

● Final Check

– Start the test alarm 1 test. The actual value on the bargraph display must be one LED above

the upper limit and one LED below the lower limit.

– Start the test alarm 2 test. All alarms are reset.

If the LEDs D201/P.C.B. LP 870 and D202/P.C.B. LP 870 are flashing after the

S1 button has been pressed for the first time, the pressure being applied to the

inlet pressure port exceeds –20 mmHg (2666 Pa). A recalibration of the upper

and lower alarm limits must be performed.

2-30 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 59

2.6 Outlet Pressure Monitor

Measuring equipment: Pressure gauge in mmHg

Measurement point: Pressure port – outlet pressure

Measuring signal: Pressure display, LED D301, LED D302

Mode of operation: CCS program

– Access the CCS program.

– Select the astecio1 menu.

– The following screen displays:

2.6.1 Verification of the Gain

– Zero:

With the pressure port open, verify that the outlet pressure display pressuer3 indicates

0 mmHg.

– Gain:

Apply 240 mmHg to the outlet pressure port and verify that the pressure3 display indicates

240 mmHg.

If one of the values displayed deviates from the target value, adjust the pressure.

2.6.2 Verification of the Alarm Limits

– Lower alarm limit: –110 mmHg ± 10 mmHg

– Upper alarm limit: +310 mmHg ± 10 mmHg

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-31

Page 60

2.6.3 Adjustment of the Gain

Fig.: P.C.B. LP 870

● Reset of the Outlet Pressure Monitor

Note

☞

After a reset of the outlet pressure monitor, zero, gain and alarm limits of the

outlet pressure monitor must be readjusted.

D302 D301S300S1

– Set the mode switch S300 to position C.

– Press the S1 button twice.

All values of the outlet pressure monitor that were stored will be erased.

● Calibration of the Zero

– Set the mode switch S300 to position D, the LED D301/P.C.B. LP 870 lights.

– With the outlet pressure port open (0 mmHg/0 Pa), press the S1 button.

After successful calibration, the LED D301/P.C.B. LP 870 will stop lighting and the LED

D302/P.C.B. LP 870 will start lighting.

– Press the S1 button again, the LED D302/P.C.B. LP 870 stops lighting.

Note

☞

If the LED D301/P.C.B. LP 870 is flashing after the S1 button has been pressed

for the first time, this may be due to one of the following errors:

1. The pressure being applied to the outlet pressure port exceeds +16.6 mmHg

or is lower than –20.8 mmHg.

2. The IC 301/P.C.B. LP 870 or the external wiring of IC 301/P.C.B. LP 870 is

defective.

2-32 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 61

● Calibration of the Gain

– Set the mode switch S300 to position E, the LED D302/P.C.B. LP 870 lights.

– Apply +500 mmHg (66661 Pa) to the outlet pressure port and press the S1 button.

After successful calibration, the LED D302/P.C.B. LP 870 will stop lighting and the LED

D301/P.C.B. LP 870 will start lighting.

– Press the S1 button again, the LED D301/P.C.B. LP 870 stops lighting.

Note

☞

– Set the mode switch S300 to position 0.

● Final Check

– Check the pressure transducer for tightness at 500 mmHg.

If the LED D302/P.C.B. LP 870 is flashing after the S1 button has been pressed

for the first time, the pressure being applied to the outlet pressure port is lower

than +16.6 mmHg (2213 Pa).

☞

Note

Verify after completion of the adjustment and readjust, if necessary.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-33

Page 62

2.6.4 Adjustment of the Alarm Limits

Fig.: P.C.B. LP 870

● Reset of the Outlet Pressure Monitor

Note

☞

After a reset of the outlet pressure monitor, zero, gain and alarm limits of the

outlet pressure monitor must be readjusted.

D302 D301S300S1

– Set the mode switch S300 to position C.

– Press the S1 button twice.

All values of the outlet pressure monitor that were stored will be erased.

● Adjustment

– Set the mode switch S300 to position F, the LEDs D301/P.C.B. 870 and D302/P.C.B. 870

light.

– Apply +310 mmHg (upper alarm limit) to the outlet pressure port and press the S1 button.

– After successful calibration, the LED D302/P.C.B. LP 870 will stop lighting and the LED

D301/P.C.B. LP 870 will start lighting.

Note

☞

If the LEDs D301/P.C.B. LP 870 and D302/P.C.B. LP 870 are flashing after the

S1 button has been pressed for the first time, the pressure applied to the outlet

pressure port is lower than +16.6 mmHg (2213 Pa).

2-34 Fresenius HemoCare COM.TEC 1/04.01 (TM)

Page 63

– Apply –110 mmHg (lower alarm limit) to the outlet pressure port and press the S1 button.

– After successful calibration, the LED D301/P.C.B. LP 870 will stop lighting.

Note

☞

– Set the mode switch S300 to position 0.

● Final Check

– Start the test alarm 1 test. The actual value on the bargraph display must be one LED above

the upper limit and one LED below the lower limit.

– Start the test alarm 2 test. All alarms are reset.

If the LEDs D301/P.C.B. LP 870 and D302/P.C.B. LP 870 are flashing after the

S1 button has been pressed for the first time, the pressure applied to the outlet

pressure port exceeds –20 mmHg (2666 Pa). The upper and lower alarm limits

must be readjusted.

Fresenius HemoCare COM.TEC 1/04.01 (TM) 2-35

Page 64

2.7 P3-Monitor

Measuring equipment: Pressure gauge in mmHg

Measurement point: Pressure port – P3-pressure

Measuring signal: Pressure display, LED D101, LED D102