Page 1

bibag® V2.0

Technician’s Manual

Part Number 490188 Rev D

Page 2

Bibag® V2.0 Technician’s Manual

© Copyright 2012 – 2014 Fresenius Medical Care, Inc.—All Rights Reserved

This document contains proprietary and confidential information of Fresenius USA, Inc. d/b/a Fresenius

Medical Care North America and its affiliates (“Fresenius Medical Care”). The contents of this document

may not be disclosed to third parties, copied, or duplicated in any form, in whole or in part, without the prior

written permission of Fresenius Medical Care.

Fresenius Medical Care, the triangle logo, 2008, and bibag are trademarks of Fresenius Medical Care

Holdings, Inc., and/or its affiliated companies. All other trademarks are the property of their respective

owners.

Any questions, contact Technical Support at 800-227-2572

Page 3

bibag V2.0 Technician’s Manual

TABLE OF CONTENTS

bibag Details ....................................................................................................................... 2

General Warnings ............................................................................................................... 3

Hydraulic Flow Diagram .................................................................................................... 4

Hydraulic Component Descriptions .................................................................................... 5

Hydraulic Operation............................................................................................................ 8

Electronic Description ...................................................................................................... 10

Electronic Block Diagram................................................................................................. 11

Calibrations ....................................................................................................................... 12

Annual Maintenance ......................................................................................................... 13

Debug Screens .................................................................................................................. 14

Troubleshooting ................................................................................................................ 27

Spare Parts ........................................................................................................................ 28

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 1

Page 4

bibag door

Door handle

bibag

Bicarbonate

outlet nozzle

Water inlet

bibag Details

The bibag connector is a hardware option that allows the usage of a dry

bicarbonate powder to generate dialysate solution for the 2008®T and the

2008K@HOME™ hemodialysis machines. The bibag is a bag filled with dry

bicarbonate powder with special inlet and outlet ports. Underneath the bibag

door, the bibag hangs on two nozzles, which allow for the entry of purified

water and the exit of bicarbonate concentrate solution. A door handle locks

the bibag door in place over the bibag.

Figure 1 – bibag connector: door closed and bibag inserted with door open

Page 2

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 5

Warning: The concentrate displayed on the screen must match the labels on the

acid container. Make certain there is enough concentrate in the containers to

complete the treatment.

Warning: The specific concentrate, sodium, and bicarbonate settings must be

prescribed by a physician.

Warning: Acid and basic bicarbonate hemodialysis concentrate must be diluted

(mixed with purified water as specified in the AAMI standards for water for

dialysis) immediately prior to application only.

Warning: Use aseptic technique.

Warning: Always verify the conductivity and approximate pH of the dialysate

solution through independent means before initiating dialysis. Verify that the pH

is normal and that the conductivity is reasonably close to the theoretical value. If it

is not, do not initiate dialysis.

Warning: Replace a leaking bibag immediately. Spills can cause damage to

carpeting and other surfaces. To contain such spills, the machine should be on a

spill-tolerant surface. Spills can cause slips and falls; clean up spills immediately.

Caution: Only the bags manufactured by Fresenius Medical Care may be used in

the bibag connector.

Note: When the bibag connector is installed, the online pressure holding test

becomes mandatory. For more information, see the Online Pressure Holding Test

section of the 2008®T Hemodialysis Machine Operator’s Manual P/N 490122 or

the 2008K@HOME™ Hemodialysis Machine Operator’s Manual P/N 490180.

General Warnings

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 3

Page 6

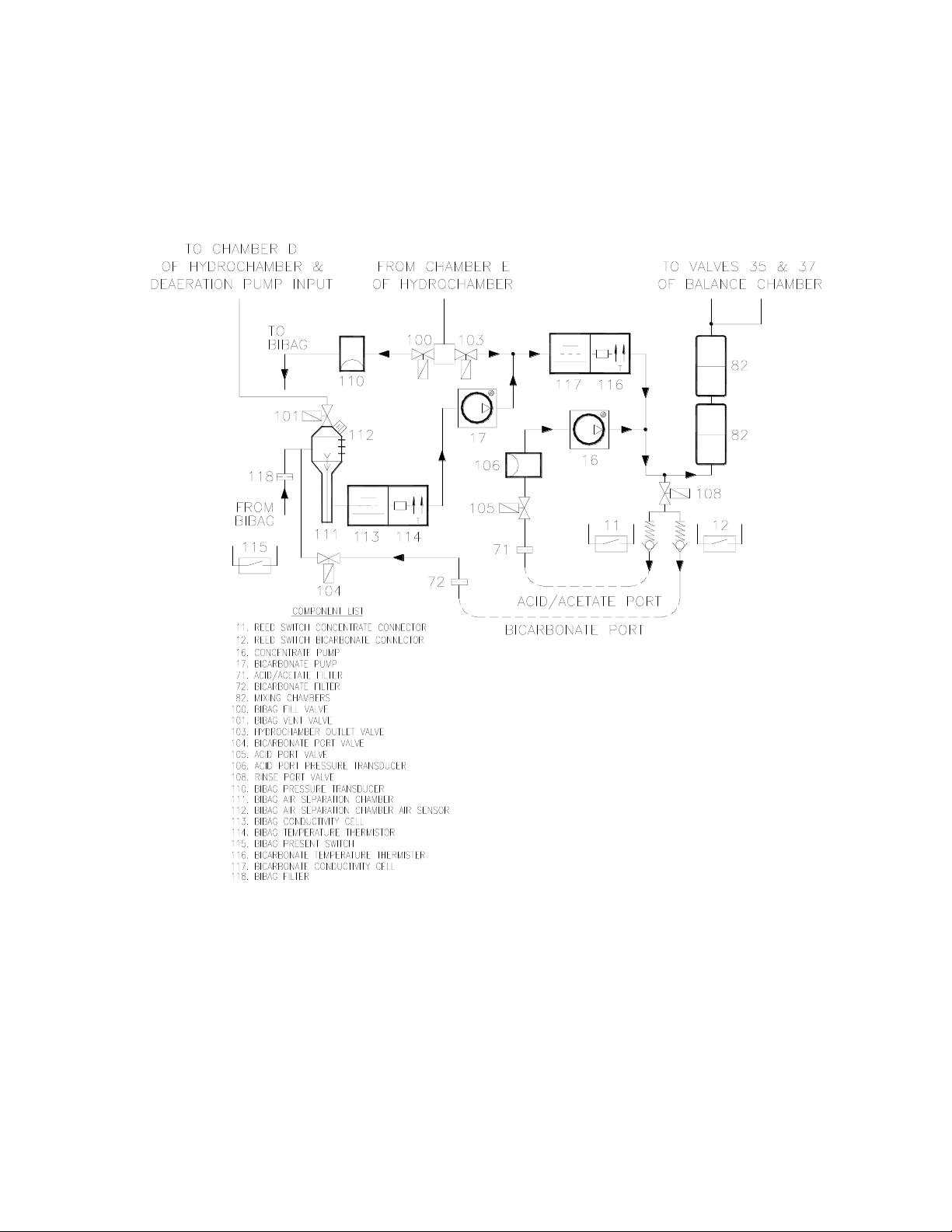

Hydraulic Flow Diagram

Page 4

Figure 2

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 7

Hydraulic Component Descriptions

100 – bibag Fill Valve

The bibag fill valve opens as needed to add water to the bibag during dialysis. When the

bibag is not used for bicarbonate during dialysis, this valve will remain closed. In rinse

and cleaning modes, this valve will alternate with valve 103.

101 – bibag Vent Valve

The bibag vent valve opens momentarily during bibag dialysis when air is detected in the

bibag air separation chamber. When the bibag is not used for bicarbonate during dialysis

(jug mode), this valve will open momentarily when air is detected in the bibag air

separation chamber.

103 – Hydrochamber Outlet Valve

The hydrochamber outlet valve opens in dialysis when valve 100 is closed. In rinse and

cleaning modes, this valve will alternate with valve 100.

104 – Bicarbonate Port Valve

Closed for bibag dialysis. Opens to empty the bibag and during bibag startup. Opens

when sodium bicarbonate concentrate is supplied. When sodium bicarbonate is supplied

by a pressurized supply, this valve will open and close based on pressure at pressure

transducer 110.

105 – Acid Port Valve

Used to regulate the pressure to the acid pump. Will open and closed based upon

pressure at pressure transducer 106.

106 – Acid Port Pressure Transducer

Senses pressure of the acid concentrate supply. Pressure detected from this sensor is used

in conjunction with valve 105 to regulate the pressure to the acid concentrate pump.

108 – Rinse Port Valve

This valve is electrically in parallel with valve 104. It opens and closes at the same time

as valve 104.

110 - bibag Pressure Transducer

The bibag pressure transducer is used to measure the pressure inside the bibag. Also used to

measure the pressure of the sodium bicarbonate concentrate source when bibag is not used.

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 5

Page 8

Hydraulic Component Descriptions (cont.)

111 – bibag Air Separation Chamber

The bibag air separation chamber separates air from the sodium bicarbonate concentrate

upon leaving the bibag. It also is used to separate air from the sodium bicarbonate

concentrate supplied by external sources (pre-mixed concentrates).

112 – bibag Air Separation Chamber Air Sensor

The bibag air separation chamber air sensor detects air in the air separation chamber.

113 – bibag Conductivity Cell

The bibag conductivity cell is used to measure the conductivity of the sodium bicarbonate

concentrate leaving the bibag and the conductivity of the pre-mixed concentrates.

114 – bibag Temperature Thermistor

The bibag temperature thermistor is used to measure the temperature of the bicarbonate

concentrate leaving the bibag and the pre-mixed concentrate.

115 – bibag Present Switch

The bibag present switch is built into the bibag connector. The switch is positioned so

that when a bibag is attached to the bibag connector the switch is pressed indicating the

presence of a bibag bag.

116 – Bicarbonate Temperature Thermister

Used with conductivity cell 117 to measure conductivity.

117 – Bicarbonate Conductivity Cell

Measures conductivity of the bicarbonate concentrate from the bibag after it is mixed

with R.O. water.

118 – bibag Filter

Removes any particles that may enter through the bibag.

Page 6

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 9

bibag Connector

3

2 4 5

bibag

1

Door

The bibag connector holds the bag with dry bicarbonate during dialysis. The bibag

connector incorporates a three position door (see Figure 3). The door may be placed in

the position open, operating, or bypass. In the open position (1) and (4), a bibag may be

installed or removed from the connector. The operating position (5) is used when a bibag

is installed for dialysis. The bypass position (3) is the completely closed position (not

possible if a bag is hanging from the connector). The door must be in the closed position

(3) for rinse, cleaning, and jug dialysis mode. Position (2) should not be used.

Figure 3

Page 7

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 10

Hydraulic Operation

Dialysis with bibag

Heated water from chamber E of the hydrochamber flows to the junction of valves 100 and

103. Valve 100 opens and the bibag will start filling when the dialysate temperature at

temperature sensor 3 reaches 30 degrees C. Valve 100 will close when the pressure

reaches 150mmHg as monitored by the pressure transducer 110. After this initial fill,

valves 104 and 108 open, valve 103 closes, the balancing chamber valves open and any

excess gas generated in the bag is flushed through the hydraulics down the drain. The flow

pump runs and the machine is kept in bypass during this initial flush. Afterwards,

additional water will be added to the bag to maintain pressure in the bag of about 90mmHg.

The conductivity cell (113) and temperature sensor (114) measure the conductivity and

temperature of the sodium bicarbonate concentrate as it leaves the bag. The temperature

compensated conductivity determines the concentration of the sodium bicarbonate

concentrate and the delivery rate of the bicarbonate pump (17).

If air is sensed by the probes (112) in the air separation chamber, valve 101 is

momentarily opened to vent the air.

If the bibag pressure does not change while the bicarbonate pump is pumping, an airlock

condition is detected. To remove the airlocked condition in the bicarbonate pump, valve

100 opens to pressurize the bag to 150mmHg. Next, the flow is stopped, the balance

chamber valves are opened up, the flow pump runs, and the machine is kept in bypass.

Conductivity cell 117 checks the amount of sodium bicarbonate added to the dialysate

and an error will be displayed if the solution is not within ±5% of expected.

Dialysis with Sodium Bicarbonate Concentrates

Jug bicarbonate dialysis is also supported with the bibag hydraulics. To run in this mode,

the bibag connector door must be completely closed and the bicarbonate connector pulled

out. Valves 104 and 108 will open and close based on pressure transducer 110 to allow

bicarbonate concentrate to reach the bicarbonate pump. Conductivity and temperature of

the solution is monitored.

Rinse & Mandatory Rinse

Mandatory rinse is run after a chemical disinfect. Both rinse and mandatory rinse are the

same valve sequence for the valves in the bibag hydraulics. Valves 104 and 108 alternate

opening every 3 seconds. Valves 100 and 103 alternate opening every 3 seconds. Valve

101 is also opened periodically when conductivity is low. Valve 105 is open.

Page 8

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 11

Hydraulic Operation (cont.)

Chemical Disinfection/Rinse

The same bibag valve sequence as in rinse.

Chemical Disinfection/Dwell

The same bibag valve sequence as in rinse

Acid Clean

The bibag valve sequence is the same as chemical rinse. Both concentrate and

bicarbonate connectors are plugged into acid.

Heat disinfect

The bibag valve sequence is the same as rinse.

Flow off

Valves 100 and 101 closed. Valve 103 open

bibag Empty

The bibag empty procedure removes the liquid solution from the bag to make disposal of

the used bag easier and cleaner. To empty the bag, valves 100, 103 and 105 are closed

while the balancing chamber and valves 104 and 108 are opened up. The flow pump runs

to suck solution from the bag and send it out the drain. During the emptying process, the

hydraulics are kept in bypass. When the empty is complete, the operator is notified,

normal balance chamber switching resumes, but the hydraulics remain in bypass until a

new bag is installed and correct conductivity of the dialysate returns.

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 9

Page 12

Electronic Description

bibag Interface Board

The bibag interface board ‘piggybacks’ onto the actuator - test board and communicates

with it. The bibag hydraulic assembly and the bibag distribution box 2 connect

electrically to the bibag interface board with ribbon cables.

The bibag interface board contains all of the electronics required to activate the 5

additional valves, read conductivity from the bibag and bicarbonate conductivity cells,

read temperature from the bibag and bicarbonate temperature thermistor, read the status

of the bibag air sensor, and read the status of the bibag door’s internal switches. A

microcontroller on the board controls all of these processes and communicates serially

with the actuator - test board. The presence of the communications between the bibag

interface board and the actuator - test board indicates to the system the presence of the

bibag hydraulic components.

The bibag pressure transducer is automatically calibrated when the door is open, and the

value is saved into memory on the bibag interface board.

bibag Hydraulic Assembly – Distribution Board

The bibag hydraulic assembly - distribution board is a passive board that connects to the

bibag interface board through a 26 pin cable. All of the individual bibag components on

the bibag hydraulic assembly connect electrically to this distribution board.

bibag Distribution Box 2 – Distribution Board

The bibag distribution box 2 - distribution board is a passive board that connects to the

bibag interface board through a 20 pin cable. All of the individual bibag components on

the distribution box 2 connect electrically to this distribution board.

Page 10

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 13

Electronic Block Diagram

bibag Connector

P/N 190598

bibag

Holder

Door

Switch

bibag

Present

Switch

(111)

bibag Conductivity

Cell

(113)

bibag Temp

Sensor

(114)

bibag Pressure

Transducer

(110)

Air Sensing

Probes

(112)

Hydrochamber

Outlet Valve

(103)

bibag Vent Valve

(101)

bibag Fill Valve

(100)

bibag Hydraulics

Distribution Board

bibag

Interface

Board (V2.0)

P/N 190861-01

Actuator-Test

Board

bibag Hydraulic Assembly

P/N 190591

bibag Distribution Box 2

Assembly P/N 190869

Acid Port

Valve (105)

Rinse Port

Valve (108)

Acid Port

Pressure Transducer

(106)

Bicarbonate

Temperature

Thermister (116)

Bicarbonate

Conductivity

Cell (117)

bibag Distribution Box 2

Distribution Board

bibag Connector

Distribution Board

Bicarbonate Port

Valve (104)

Figure 4

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 11

Page 14

Mesa 90XL

Dialysate Meter

With Conductivity/Temperature Module

Mesa Serial Cable

(P/N 368402-10)

Null Modem

(P/N 190323)

Calibrations

Pressure Transducers

Power the machine on and enter Service Mode.

From the Calibrate Sensors screen, select the Pressure Transducers screen button.

On the Pressure Transducers screen, select the Regulator Pressure screen button.

1. Pull the Acid and Bicarbonate connectors and insert them halfway back into their

ports.

2. Press the [Confirm] key to set the 0 (zero) pressure calibration. The screen will

change.

When prompted, press the [Confirm] key to save the calibration. The screen will

change.

Press the [Confirm] key again to finish the calibration process.

Bicarbonate Conductivity Cell

Required Tools:

Required Supplies:

Liquid bicarbonate

Machine must be connected to an R.O. water source for this calibration.

Power the machine on and enter Service Mode.

From the Calibrate Sensors screen, select the Cond Cells screen button.

On the Cond Cells screen, select Bicarb Cell screen button.

1. Using the Null Modem, connect the Mesa Serial Cable between the 90XL

Dialysate Meter and the RS232 port on the rear of the card cage.

2. Connect the Dialysate Lines to the 90XL Conductivity/Temperature Module.

3. Select Conductivity on the 90XL.

4. Connect the acid connector to a container of R.O. water and the bicarbonate

connector to a container of sodium bicarbonate concentrate.

5. Press the [Confirm] key to start the calibration.

The screen will change and the screen will display Calibration In Progress…

During the calibration process, the 90XL will communicate with the machine

through the RS232 port.

When the calibration process is complete, the screen will display Bicarb Cond

Cell calibration is complete.

Page 12

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 15

Annual Maintenance

From bibag

connector

To bibag air

separator

Note the direction of the flow

arrow on the filter housing

Annual bibag maintenance consists of the following:

Perform bibag Inlet Filter Replacement.

Perform bibag Connector Maintenance.

Perform the bibag Pressure Transducers calibration. (see page 12)

bibag Inlet Filter Replacement

Annually replace the filter (P/N M30225) in tubing assembly labeled 1 connected

between the bibag connector and the bibag air separator.

Figure 5 – bibag Inlet Filter (M30225)

bibag Connector Maintenance

Annually replace the two (2) o-rings (P/N 640919) on the bibag connector door.

Figure 6– bibag Connector Door O-Rings (640919)

Page 13

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 16

Debug Screens

Debug Screen 0 – HYDRAULIC FLOW - bibag portion

D

The bibag connector is in the correct state for dialysis (i.e., it is in the Operating state).

O

The bibag connector is open (i.e., it is in the Open No bibag, Closed No bibag, or Open

with bibag present).

C

The bibag connector is closed (i.e., it is in the Bypass state).

Page 14

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 17

Debug Screens (cont.)

Debug Screen 0 – HYDRAULIC FLOW - bibag portion (cont.)

100

This displays the status of the bibag fill valve. The valve opens as needed to add water to

the bibag during dialysis. When the bibag is not used for bicarbonate during dialysis, this

valve will remain closed. In rinse and cleaning modes, this valve will alternate with

valve 103. The indicator turns blue when the valve is open.

101

This displays the status of the bibag vent valve. The valve opens during bibag dialysis

when air is detected in the bibag air separation chamber. When the bibag is not used for

bicarbonate during dialysis (jug mode), this valve will open when air is detected in the

bibag air separation chamber. The indicator turns blue when the valve is open.

103

This displays the status of the hydrochamber outlet valve. The valve opens in dialysis

when valve 100 is closed. In rinse and cleaning modes, this valve will alternate with

valve 100. The indicator turns blue when the valve is open.

104

This displays the status of the bicarbonate port valve. Closed for bibag dialysis. Opens

to empty the bibag and during bibag startup. Opens when sodium bicarbonate

concentrate is supplied. When sodium bicarbonate is supplied by a pressurized supply,

this valve will open and close based on pressure at pressure transducer 110.

105

This displays the status of the acid port valve. Used to regulate the pressure to the acid

pump. Will open and closed based upon pressure at pressure transducer 106

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 15

Page 18

Debug Screens (cont.)

Debug Screen 14 – bibag

Note: Debug Screen 15 on 2008K@HOME™

Open None

No bag on bibag connector, bibag door fully open.

1 =Yes / 0 = No

Operating

Bag on bibag connector, bibag door in bibag dialysis position.

1 =Yes / 0 = No

Bypass

No bag on bibag connector, bibag door fully closed.

1 =Yes / 0 = No

Cls None

No bag on bibag connector, bibag door partially closed.

1 =Yes / 0 = No

Page 16

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 19

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

Opn Bag

Bag on connector, bibag door fully open.

1 =Yes / 0 = No

Bag On

Bag on bibag connector.

1 =Yes / 0 = No

D bd Ver

bibag interface board (daughter board) software version.

Init State

System is in the bibag Initial state.

1 =Yes / 0 = No

Tx State

System is in the bibag Treatment state.

1 =Yes / 0 = No

End State

System is in the bibag End state.

1 =Yes / 0 = No

Vent

System is running the bibag vent process.

1 =Yes / 0 = No

DeAirLock

System is running the bibag deairlock (air lock removal) process.

1 =Yes / 0 = No

Tm Bypass

System is running the bibag timed bypass process.

1 =Yes / 0 = No

Post Flush

System is running the bibag post empty flush process.

1 =Yes / 0 = No

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 17

Page 20

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

Fill

System is running the bibag fill process (Initial state).

1 =Yes / 0 = No

Bic Pump

System requests the bicarbonate pump to be on for a bibag process.

1 =Yes / 0 = No

Bypass Ctl

System requests bypass of the dialyzer for a bibag process.

1 =Yes / 0 = No

V43 Ctl

System is suppressing the “Valve 43 Failure” error for a bibag process.

1 =Yes / 0 = No

TMP Ctl

System requests TMP control, which isolates the dialyzer and freezes dialysate pressure

for a bibag process.

1 =Yes / 0 = No

Vent En

System indicates that it is enabled to do the bibag vent process.

1 =Yes / 0 = No

Air

Air is detected by the bibag air separation chamber air sensor.

1 =Yes / 0 = No

Empty

System is running the bibag empty process.

1 =Yes / 0 = No

Emptied

System indicates that the bag is emptied.

1 =Yes / 0 = No

Page 18

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 21

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

No Comm

Indicates a bibag No Communication error.

1 =Yes / 0 = No

12V Err

Indicates a bibag +12 V error.

1 =Yes / 0 = No

5V Err

Indicates a bibag +5 V error.

1 =Yes / 0 = No

-5V Err

Indicates a bibag -5 V error.

1 =Yes / 0 = No

I2C Err

Indicates a bibag I2C error.

1 =Yes / 0 = No

Door Err

Indicates a bibag Door error.

1 =Yes / 0 = No

Cond Cal

Indicates a bibag Conductivity Calibration error.

1 =Yes / 0 = No

Temp Cal

Indicates a bibag Temperature Calibration error.

1 =Yes / 0 = No

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 19

Page 22

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

Pres Cal

Indicates a bibag Pressure Calibration error.

1 =Yes / 0 = No

Empty Long

Indicates a bibag Emptying Too Long error.

1 =Yes / 0 = No

Vent Long

Indicates a bibag Venting Too Long error.

1 =Yes / 0 = No

Bag Leak

Indicates a bibag Bag Leak error.

1 =Yes / 0 = No

Pres Snr

Indicates a bibag Pressure Sensor error.

1 =Yes / 0 = No

Pres Hi

Indicates a bibag Pressure Too High error.

1 =Yes / 0 = No

Pres Low

Indicates a bibag Pressure Too Low error.

1 =Yes / 0 = No

Val Comm

Indicates a bibag Valve Communication error.

1 =Yes / 0 = No

Val1 Err

Indicates a bibag Valve 1 error.

1 =Yes / 0 = No

Page 20

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 23

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

Val2 Err

Indicates a bibag Valve 2 error.

1 =Yes / 0 = No

Cond High

Indicates a bibag Conductivity High error.

1 =Yes / 0 = No

Cond Low

Indicates a bibag Conductivity Low error.

1 =Yes / 0 = No

Cond Senr

Indicates a bibag Conductivity Sensor error. This bit is only set in the Rinse program.

1 =Yes / 0 = No

Temp Senr

Indicates a bibag Temperature Sensor error. This bit is only set in the Rinse program.

1 =Yes / 0 = No

Bic Lock

Indicates a bibag Bicarbonate Pump Air Locked error.

1 =Yes / 0 = No

Temperature

Displays the temperature in °C of the sodium bicarbonate concentrate from either the

bibag or a jug.

Conductivity

Displays the conductivity in mS/cm of the sodium bicarbonate concentrate from either

the bibag or a jug. This value is temperature compensated.

Pressure

Displays the bibag pressure in mmHg.

Concentration

Displays the bibag concentration in g/L during bibag dialysis.

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 21

Page 24

Debug Screens (cont.)

Debug Screen 14 (15) – bibag (cont.)

JCon Low

Indicates a bicarbonate (jug) conductivity low error.

1 =Yes / 0 = No

JCon Hi

Indicates a bicarbonate (jug) conductivity high error.

1 =Yes / 0 = No

JConLowLmt

Displays the bicarbonate (jug) conductivity lower limit in mS/cm.

JConHiLmt

Displays the bicarbonate (jug) conductivity higher limit in mS/cm.

Page 22

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 25

Debug Screens (cont.)

Debug Screen 15 – Bic Mon & Act. Reg

Note: Debug Screen 16 on 2008K@HOME™

Bic Low

This bit is normally set to 0, and is set to 1 when the bicarbonate conductivity (Bic Mon

Cond) has been less than “Bic Lo Th” for 40 balance chamber switches.

Bic Hi

This bit is normally set to 0, and is set to 1 when the bicarbonate conductivity (Bic Mon

Cond) has been greater than “Bic Hi Th” for 40 balance chamber switches.

Bic Cell Cond

The raw uncompensated bicarbonate conductivity being seen at the Bicarbonate

Conductivity Cell 117.

Bic Mon temp

The temperature being seen at the Bicarbonate Temperature Thermistor 116.

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 23

Page 26

Debug Screens (cont.)

Debug Screen 15 (16) – Bic Mon & Act. Reg (cont.)

RO Cond

The RO water conductivity value measured at the end of rinse used to compensate “Bic

Cell Cond”.

TCB

Theoretical Conductivity of Bicarbonate based on the machines Base Na+ and

Bicarbonate settings.

Bic Lo Th

The lower threshold for compensated bicarbonate conductivity (Bic Mon Cond), 5%

below TCB.

Bic Mon Cond

The compensated bicarbonate conductivity based on Bic Cell Cond, Bic Mon temp, Bic

Slope, Bic Offset, and RO Cond.

Bic Hi Th

The upper threshold for compensated bicarbonate conductivity (Bic Mon Cond), 5%

above TCB.

Bic Slope

The slope value of the bicarbonate conductivity calculated from the bicarbonate

conductivity cell calibration.

Bic Offset

The offset value of the bicarbonate conductivity calculated from the bicarbonate

conductivity cell calibration.

Acid Press

The compensated pressure seen at the Acid Port Pressure Transducer 106.

Bic Press

The compensated pressure seen by the bibag Pressure Transducer 110 (bibag machine) or

the bicarbonate Pressure Transducer 107 (non-bibag machine).

Inlet W temp – (Not used)

Page 24

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 27

Debug Screens (cont.)

Debug Screen 15 (16) – Bic Mon & Act. Reg (cont.)

PHT Err

Indicates a bibag Pressure Holding Test failure.

1 =Yes / 0 = No

AcidPr Cal Er

Indicates an Acid Pressure Calibration Error.

1 =Yes / 0 = No

InletT Cal Er – (Not Used)

BicT Cal Er

Indicates a Bicarb Temperature Calibration Error.

1 =Yes / 0 = No

V105 Er

Indicates a Valve 105 Error.

1 =Yes / 0 = No

V104 Er

Indicates a Valve 104 or Valve 108 Error.

1 =Yes / 0 = No

Reg O/S Rx

Indicates the bibag interface board has received the Regulator Pressure service mode

calibration data.

1 = Data Received / 0 = Data not Received.

V105 Er O

Indicates Valve 105 is Stuck Open.

1 =Yes / 0 = No

V105 Er C

Indicates Valve 105 is Stuck Closed.

1 =Yes / 0 = No

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 25

Page 28

Debug Screens (cont.)

Debug Screen 15 (16) – Bic Mon & Act. Reg (cont.)

V104 Er O

Indicates Valve 104 or Valve 108 is Stuck Open.

1 =Yes / 0 = No

V104 Er C

Indicates Valve 104 or Valve 108 is Stuck Closed.

1 =Yes / 0 = No

Acid PresOff

The compensation value for Acid Port Pressure Transducer 106 based on the Regulator

Pressure service mode calibration.

Bic PresOff

The compensation value for bibag Pressure Transducer 110 (bibag machine) based on the

Regulator Pressure service mode calibration.

Page 26

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 29

Troubleshooting

Error messages

All status messages are displayed on the control panel screen. These messages

are generated due to conditions and events that occur in the machine during

operation. These messages will reset when the condition causing the message is

corrected. In some cases, the operator must reset them.

A list of bibag -related messages can be found in the

2008®T Hemodialysis Machine bibag

Operator’s Manual P/N 508213.

2008K@HOME™ Hemodialysis Machine bibag

Operator’s Manual P/N 508340.

The list includes:

The bibag related Message

Meaning of the Message

Action Required

A full list of machine messages may be found in the

2008®T Hemodialysis Machine Operator’s Manual P/N 490122

2008K@HOME™ Hemodialysis Machine Operator’s Manual P/N 490180

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 27

Page 30

2 3 5

4

1

Spare Parts

Item # Description Part Number

1. bibag connector complete 190598

2. bibag connector o-ring 640919

3. bibag connector circuit board 190547

4. Rubber tubing label “1” M42437

5. Rubber tubing label “2” M42438

Page 28

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 31

10

11 7 8 4 5 3 1 6 9

2

Spare Parts (cont.)

Item # Description Part Number

bibag Hydraulic assembly 190591

Includes all shown components including items 1 through 12.

1. bibag Fill Valve (V100) 642951

2. bibag Vent Valve (V101) 674349

3. Hydrochamber Outlet Valve (V103) 642951

4. bibag Pressure Transducer (110) 190140

5. bibag Air Separation Chamber (111) 190673

with V101 and Air Sensor Probes; item 6 not included

6. bibag Air Separation Chamber Air Sensor Probe Cable 668033

7. bibag Conductivity Cell (113) M39797

8. bibag Temperature Thermistor (114) 676502

9. bibag Distribution board (inside box) 190526

10. Cable - bibag distribution board to bibag connector 190525

11. Cable - bibag distribution board to bibag interface board 190670

12. Assembly, bibag distribution 190669

Includes items 9 and 11

Page 29

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 32

2 1 3 4 8

7 6 5

Spare Parts (cont.)

Item # Description Part Number

Distribution Box 2 assembly 190869

Includes all shown components including items 1 through 10.

1. Acid Port Valve (V105) 643418

2. Bicarbonate Port Valve (V104) 643418

3. Acid Port Pressure Transducer (106) 190140

4. bibag Conductivity Cell (117) M39797

5. bibag Temperature Thermistor (116) 676502

6. Cable - bibag Distribution Box 2 to bibag interface board 190865

7. Retaining Pin 330801-03

8. Distribution Box 2 only 290684

9. Distribution Box 2 cover 290685

Item not shown – cover inside item 8 and is used to retain item 10.

10. Distribution Box 2 circuit board 190860

Item not shown – board inside item 8

Page 30

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 33

1 2 3

Spare Parts (cont.)

Item # Description Part Number

Valve 108 Assembly 190959

Includes all shown components including items 1 through 3.

1. Valve 108 643418

2. Bracket, Valve Single Mount 290767

3. bibag Valve 108 Cable Assembly 190958

Page 31

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 34

1

2

3

4

7* 5 7*

6

Spare Parts (cont.)

Item # Description Part Number

1. Tubing 21.5” Assembly labeled 1 190877

2. Tubing 19” labeled 2 190602

3. Rubber tubing label “1” M42437

4. Rubber tubing label “2” M42438

5. Tee Connector, 3/16 674648

6. Reducer Fitting M38033

7. bibag Inlet Filter* M30225

*Note: When replacing item 7 (bibag Inlet Filter), reference the arrow on the housing for proper directional flow.

Correct flow is from the bibag connector to the bibag air separator.

Page 32

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 35

Spare Parts (cont.)

bibag hydraulics

ribbon cable plugs

in here.

bibag distribution

box 2 plugs in here.

Item # Description Part Number

1. bibag Interface Board with software 190861-01

The following items are not illustrated

2 bibag V2.0 Technician’s Manual 490188

3 2008T bibag Operator’s Instructions 508213

4 2008T bibag Installation Kit 190872

5 2008T bibag V2.0 Upgrade Kit 190873

6 2008K@HOME bibag Operator’s Instructions 508340

7 2008K@HOME bibag Installation Kit 190883

8 2008K@HOME bibag V2.0 Upgrade Kit 190884

Page 33

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 36

NOTES:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Page 34

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 37

NOTES:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Page 35

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 38

NOTES:

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

________________________________________________________________________

Page 36

bibag V2.0 Technician’s Manual

P/N 490188 Rev. D

Page 39

NOTES

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

Page 40

Fresenius Medical Care North America

Manufactured by:

Fresenius USA, Inc.

4040 Nelson Avenue

Concord, CA 94520

800 227-2572

http://www.fmcna.com

Loading...

Loading...