Page 1

4008 HDF

Technical Manual

CareFresenius Medical

Page 2

4008 HDF

Technical Manual

Page 3

4008 HDF Technical Manual

The Technical Manual contains all information necessary for performing maintenance and repair work.

The 4008 HDF option reflects the latest state of technology and complies with the requirements of

EN 60601-1

Assembly, extension, adjustment, modification or repair may only be carried out by the manufacturer or

persons authorized by him.

Any inquiries should be addressed to:

Head office:

Fresenius Medical Care

Deutschland GmbH

Borkenberg 14

D-61440 Oberursel/Ts., Germany

Tel.: 06171-60-0

Telex: 410805 fres d

Fax: 06171-251-58

Local Service:

Manufacturer:

Fresenius Medical Care

Deutschland GmbH

Plant Schweinfurt

Hafenstraße 9

D-97424 Schweinfurt, Germany

Tel.: 09721-678-0

Fax: 09721-678-200

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 0-1Part No. 674 398 1

Page 4

0-2 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 5

How to use the Technical Manual

Search and find What? Where?

Tables Contents Pages 0-5 and at the beginning of each chapter

Purpose This manual is intended for:

– first studies (to acquire basic knowledge)

– reference purposes (for start-up, maintenance and repair)

Organization The manual is divided into 6 chapters:

0 General Notes

1 Description of machine functions

2 Technical safety checks

3 Calibration instructions

4 Circuit descriptions and circuit diagrams

5 Spare parts

Numbering system Page number 1-3 is to be interpreted as: Chapter 1, Page 3

Qualification This manual is intended for service technicians

– who are familiar with the current Operating Instructions (Operating Instruc-

tionseratining to this Technical Manual are available under part no. 674 406 1)

– who have the necessary background experience in mechanics, electrical and

medical engineering

– who have been authorized by the manufacturer to perform maintenance and

repair work

– who have access to the necessary auxiliary and measuring equipment

Restrictions The study of this manual does not represent an alternative to the training courses

offered by the manufacturer.

Manual changes Manual changes will be released as new editions, supplement sheets or product

information.

Note:

Modifications relating to circuit diagrams and component layouts (SP/BP) do not

necessarily involve a change of the footer (edition).

Refer to the index field of the respective circuit diagram or component layout for

the respective state of these diagrams. The identification on the P.C.B. permits

the user/technician to verify if the circuit diagram / component layout matches the

P.C.B. actually installed.

In general, this manual is subject to modification.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 0-3

Page 6

Representation New circuit symbols are used in the circuit diagrams. Potential data given in the

circuit diagrams and setting instructions refer to the respective earth.

For example: 24 means ground for 24 V voltage.

Component marking Example:

in circuit diagrams

This refers to a resistor with a position number 75 with a resistance of 1.5 Ohm.

The decimal point is replaced by a unit symbol (to reduce the possibility of errors).

Resistors: Capacitors:

R1: 0.1 Ωµ 1: 0.1 µF

1R5: 1.5 Ω 1µ5: 1.5 µF

1K5: 1.5 kΩ 1000µ: 1000 µF

Note: When repairing or exchanging replacement parts make sure to take the applica-

ble ESD precautions (e.g. EN 100 015-1).

During repair/troubleshooting in the hydraulic unit, protect the components from

dialysate.

Technical data: The technical data for the 4008 HDF option is to be found in Chapter 1 of the

Operating Instructions.

75

1R5

0-4 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 7

Table of contents

Section Page

1 Description of machine functions............................................................................... 1-

1.1 Description ...................................................................................................................... 1-3

1.2 Description of extended T1 test ...................................................................................... 1-8

1.3 Error messages............................................................................................................... 1-10

2 Technical safety checks............................................................................................... 2-

3 Calibration instructions ............................................................................................... 3-

3.0 General information on the calibration instructions ....................................................... 3-3

3.1 Calibrating the UF2 pump ............................................................................................... 3-5

3.2 VDE inspections.............................................................................................................. 3-7

3.3 Calibrating the 4008 HDF scale ...................................................................................... 3-8

3.4 Calibrating the substituate sensor .................................................................................. 3-13

3.5 Calibrating the HDF blood pump .................................................................................... 3-15

3.6 Repair instructions .......................................................................................................... 3-17

4 Circuit descriptions and circuit diagrams.................................................................. 4-

4.1 LP 625 display board ...................................................................................................... 4-3

4.2 LP 754 control board HDF .............................................................................................. 4-9

4.3 LP 760 HDF motor control .............................................................................................. 4-19

4.4 LP 761 HDF drive keyboard ........................................................................................... 4-27

4.5 LP 762 scale comm ........................................................................................................ 4-33

4.6 LP 763 SSE serial interface extender............................................................................. 4-39

5 Spare parts .................................................................................................................... 5-

5.0 How to use the spare parts catalog ................................................................................ 5-3

5.1 P.C.B.s............................................................................................................................ 5-4

5.2 Scales ............................................................................................................................. 5-6

5.3 Substituate lift ................................................................................................................. 5-8

5.4 UF2 pump / blood pump (HDF) / valve V 126................................................................. 5-10

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 0-5

Page 8

0-6 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 9

Table of contents

1 Description of machine functions

Section Page

1.1 Description .................................................................................................................... 1-3

1.1.1 Components.................................................................................................................... 1-3

1.1.2 Description ...................................................................................................................... 1-3

1.1.3 Component tests............................................................................................................. 1-3

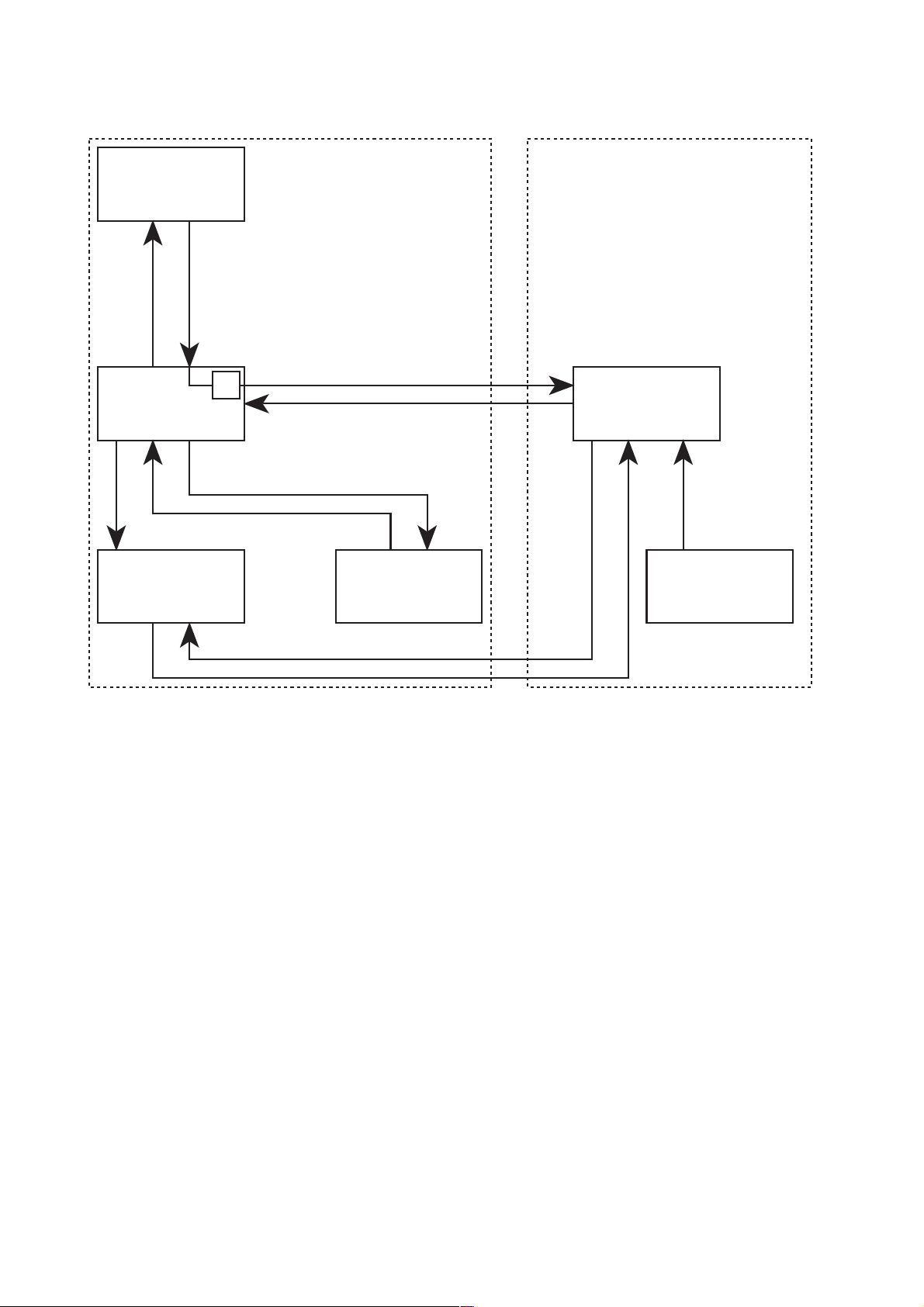

Fig.: Block diagram ......................................................................................................... 1-4

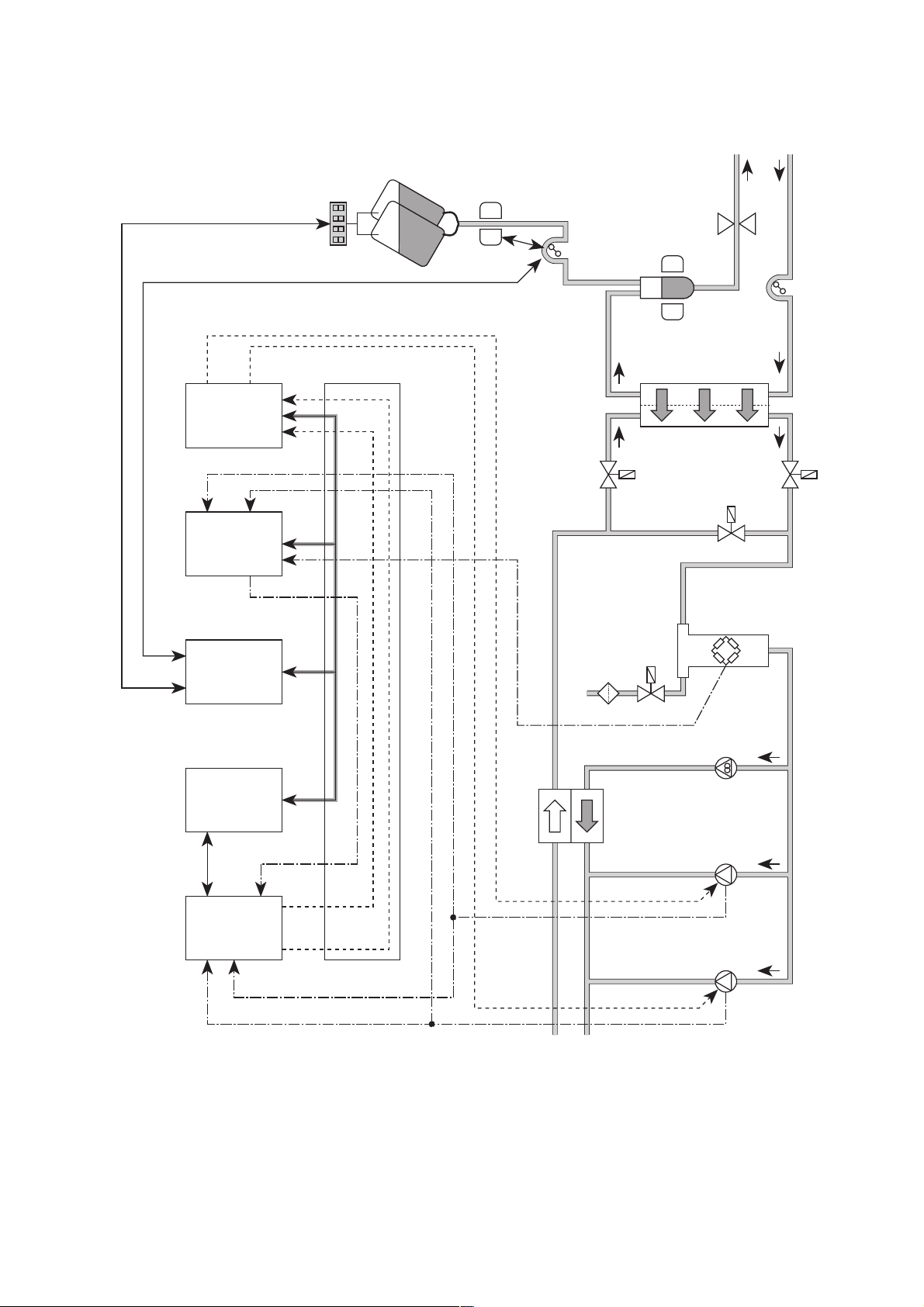

Fig.: Flow diagram .......................................................................................................... 1-5

Fig.: Flow diagram .......................................................................................................... 1-6

1.2 Description of extended T1 test / error messages in T1 test................................... 1-8

1.2.1 Test UF-Function ............................................................................................................ 1-8

1.3 Error messages during treatment and the HDF test ................................................ 1-10

1.4 Error messages, substituate pump............................................................................. 1-13

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-1

Page 10

1-2 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 11

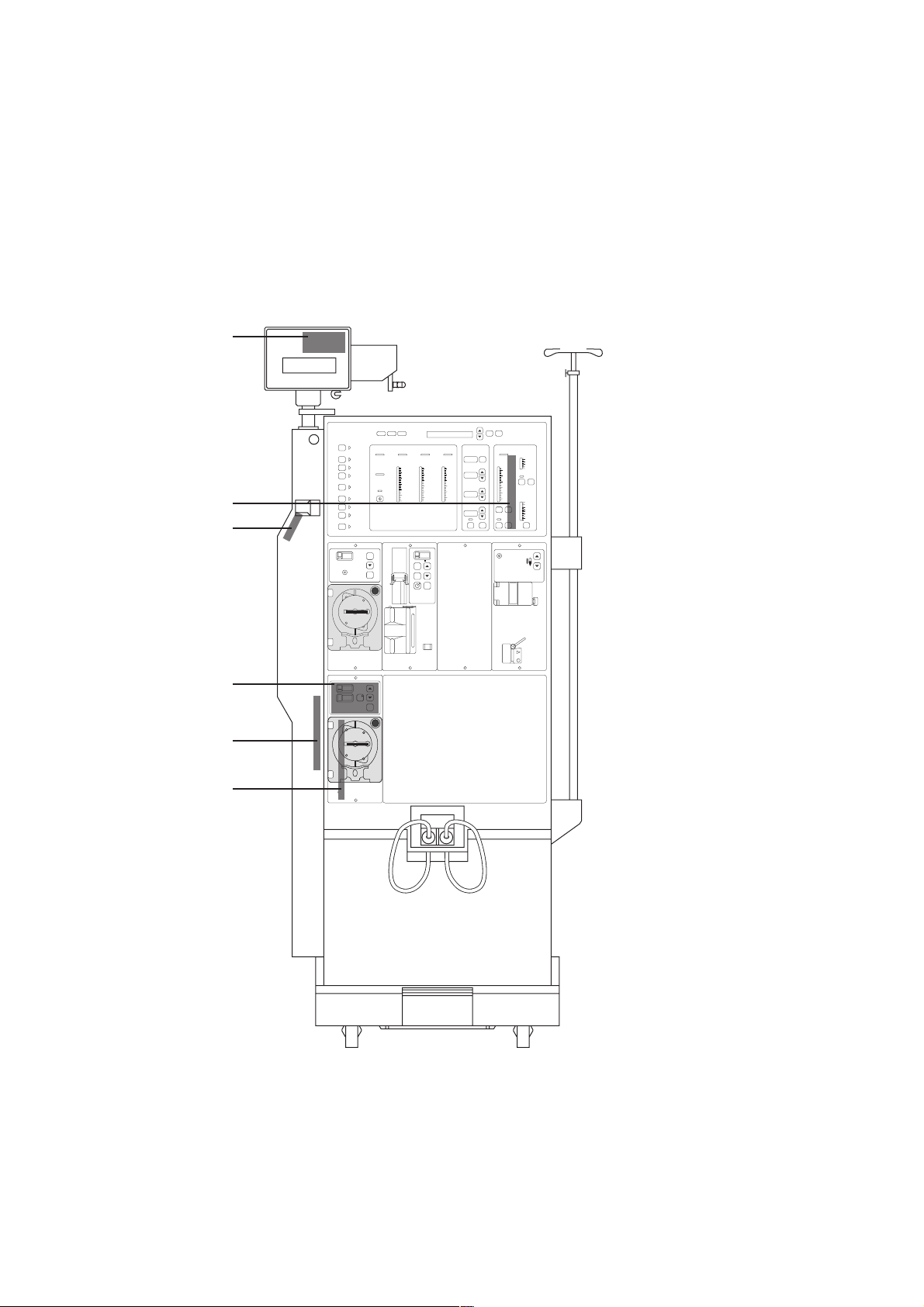

1.1 Description

1.1.1 Components

The components of the 4008 HDF option are permanently connected to the hemodialysis

machine. The 4008 HDF option comprises the following components:

– Substituate lift

– Scales (weighing range < 20 kg) with data interface and taring facility

– Substituate pump with bidirectional data interface

– UF2 pump

1.1.2 Description

The scales determine the actual weight of the substituate reserve and signals this to the

hemodialysis machine. This calculates the substituate rate depending on the set treatment time.

A substituate sensor mounted on the substituate lift recognises whether:

– Line set is fitted without substituate or

– Line set is fitted with substituate.

The substituate pump delivers the substituate solution to the venous bubble catcher. The filtrate

from the dialysis fluid circuit is removed by the UF2 pump.

1.1.3 Component tests

The scales are checked by the operator by means of a plausibility test before treatment. The

substituate sensor is tested while the 4008 HDF is filling.

The 4008 HDF test tests:

– The substituate pump

– The UF2 pump (electrically and hydraulically)

(If the 4008 HDF test is not carried out then the connections are to be tested but once).

The UF2 pump is tested cyclically during treatment.

The electric control system of the UF2 pump is checked continuously.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-3

Page 12

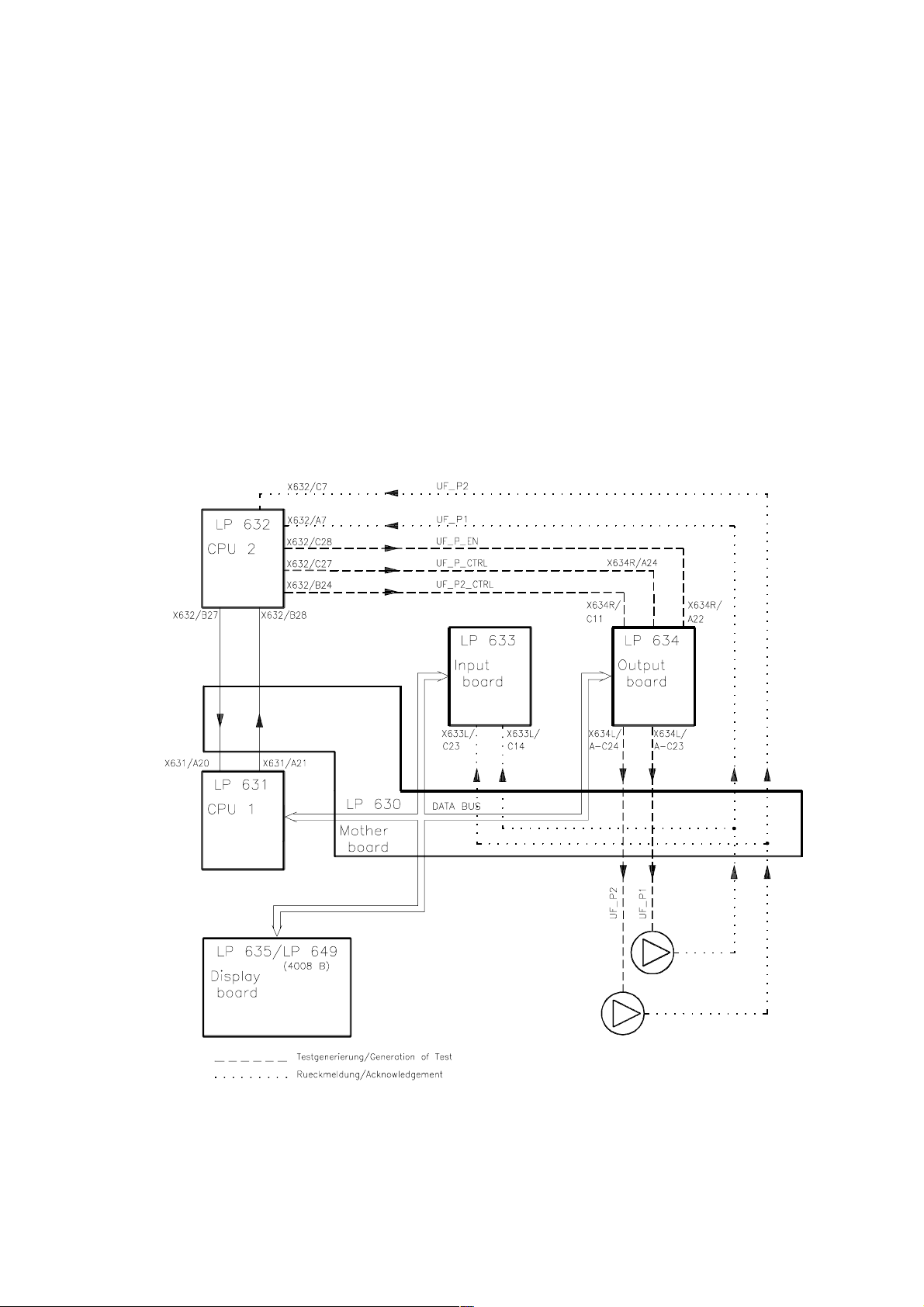

Fig.: Block diagram

Scales

Serial communication

Operating system Safety system

CPU 1

UF2 pump

W

Serial communication

Serial communication

Substituate

pump

CPU 2

TMP

1-4 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 13

UF2

pump

UF

pump

Flow

pump

Dialysate

pressure

transducer

V126

V26

V24

V24b

Dialyzer

Air detector

Venous bubble catcher

Arterial

blood pump

Venous line

clamp

Substituate

pump

Substituate

sensor

Scales

Substituate

bag

Patient

Balancing chamber

LP 632

CPU 2

LP 631

CPU 1

LP 763

SSE

Serial

interface

extender

LP 633

Input

board

LP 634

Output

board

serial

interface

X632/

B24

X632/

C27

X634 R/

C11

X634 R/

A24

serial interface

serial interface and taring line

X632/

A7

X632/

C7

X632/

A29

X634 L/

A–C24

X634 L/

A–C23

X633 L/

C14

X633 L/

C23

X633 L/

B6

Control, UF2 pump

Control, UF pump

Acknowledgement, dialysate pressure

Control, UF pump

Control, UF2 pump

Acknowledgement, UF pump

Acknowledgement, UF2 pump

Acknowledgem., dialy. pressure

XHDF 2–4

X348v/4–5

X633 R/

C28–30

Fig.: Flow diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-5

Page 14

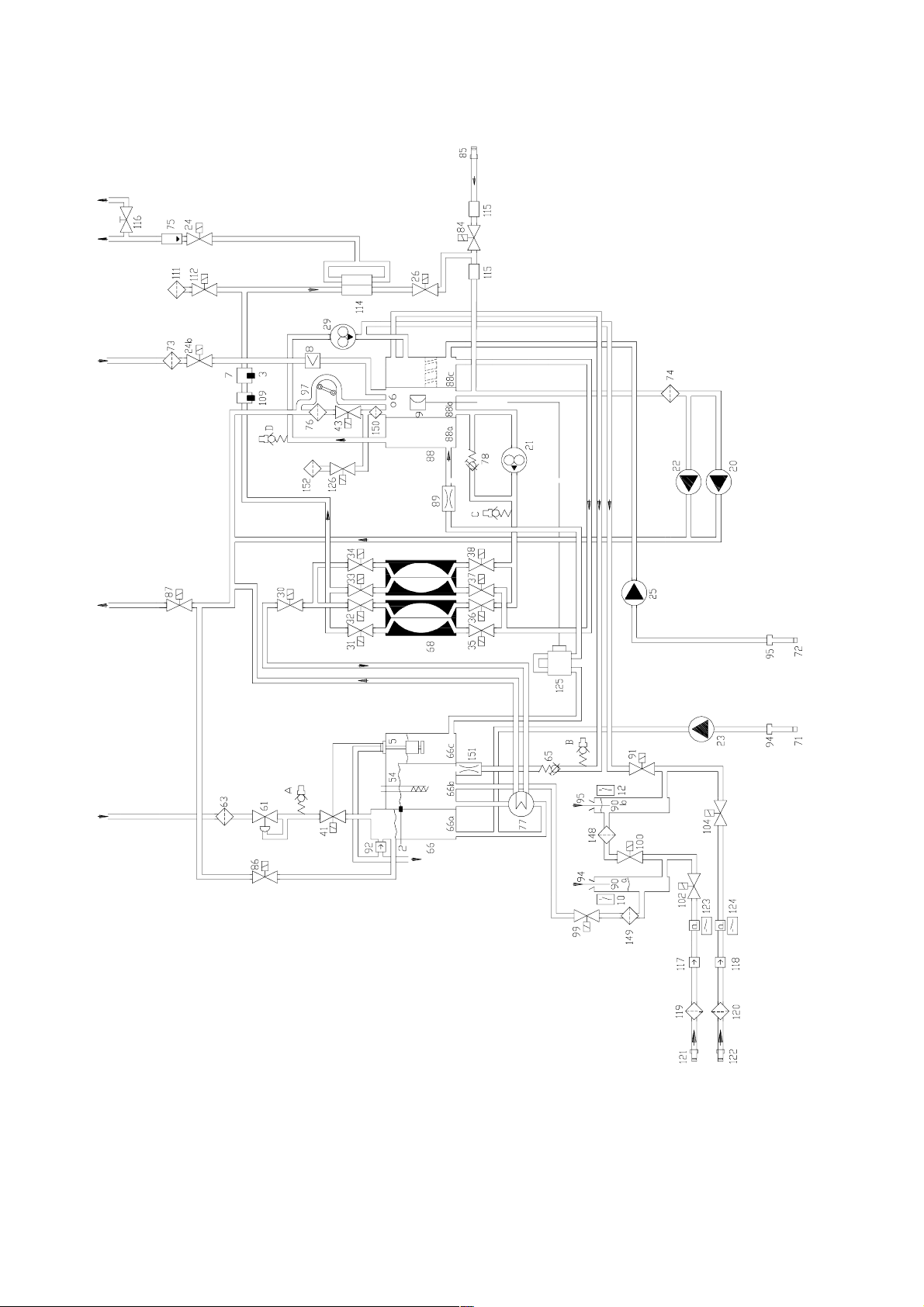

Fig.: Flow diagram

1-6 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 15

Legend

2 Temperature sensor

3 Temperature sensor

5 Float switch

6 Level sensor

7 Conductivity measuring cell

8 Blood leak detector

9 Pressure transducer

10 Reed contact for concentrate

12 Reed contact for bicarbonate

20 UF2 pump

21 Flow pump

22 UF pump

23 Concentrate pump

24 Dialyzer valve 1

24b Dialyzer valve 2

25 Bicarbonate pump

26 Bypass valve

29 Degassing pump

30 Drain valve

31 Balancing chamber valve 1

32 Balancing chamber valve 2

33 Balancing chamber valve 3

34 Balancing chamber valve 4

35 Balancing chamber valve 5

36 Balancing chamber valve 6

37 Balancing chamber valve 7

38 Balancing chamber valve 8

41 Water inlet valve

43 Fill valve

54 Heater rod

61 Pressure reducing valve

63 Filter/water inlet

65 Loading pressure valve

66 Heater block

66a Water inflow chamber

66b Heater rod chamber

66c Float chamber

68 Balancing chamber

71 Filter/concentrate

72 Filter/bicarbonate

73 Filter/external dialysate

74 Filter/UF

75 External flow indicator

76 Filter/fill valve

77 Heat exchanger

78 Relief valve

84 Disinfection valve

85 Disinfectant conncector

86 Recirculation valve

87 Discharge valve

88 Multifunction block

88a Degassing chamber

88b Secondary air separator

88c Primary air separator

89 Degassing orifice

90a Rinse chamber concentrate

90b Rinse chamber bicarbonate

91 Rinse valve

92 Vent valve

94 Concentrate suction tube

95 Bicarbonate suction tube

97 Ventilation pump

99 Rinse valve

100 Rinse valve

102 Concentrate valve in central delivery system

104 Bicarbonate valve in central delivery system

109 Temperature sensor

111 Hydrophobic filter

112 Vent valve

114 Dialysate filter

115 Disinfection valve sensor

116 Sampleing valve

117 Check valve (concentrate)

118 Check valve (bicarbonate)

119 Filter (concentrate)

120 Filter (bicarbonate)

121 Concentrate connector in central delivery system

122 Bicarbonate connector in central delivery system

123 Pressure switch for V 102

124 Pressure switch for V 104

125 Adapter plate

126 4008 HDF vent valve

148 Filter/rinse valve

149 Filter/rinse valve

150 Filter

151 Orifice

152 4008 HDF hydrophobic filter

Hydraulic measurement points

A Reduced water inlet pressure

B Balancing chamber loading pressure

C Flow pump pressure

D Degassing pump pressure

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-7

Page 16

1.2 Description of extended T1 test / error messages in the T1 test

Possible error messages displayed in the T1 test are listed in the Technical Manual for the

hemodialysis machine. If the HDF option is installed and activated the following error codes can

also appear:

1.2.1 Test UF-Function

Test description:

CPU 1 starts up the UF2 pump at a defined rate.

CPU 2 controls the hydraulic and electrical function of the UF2 pump.

CPU 2 blocks the control line of the UF2 pump and checks for standstill.

UF2 counter check.

Figure:

1-8 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 17

Error description:

Error message Description

F11 UF-Function The interval between the strokes of the UF2 pump was less than

220 ms. Correct delivery of the required volume is not safeguarded because the stroke return travel is too short.

– A pump rate which was too high was signalled by the CPU 1.

F12 UF-Function The pulse time for the UF2 pump is less than 180 ms. Correct

delivery of the required volume is not safeguarded because the

discharge time is too short.

– Monoflop on LP 634 defect (IC 42/R65/C45).

F 13 UF-Function The pulse for the UF2 pump is longer than 500 ms. A maximum

rate of 5000 ml/h is not possible.

– Monoflop on LP 634 defect (IC 42/R65/C45).

F14 UF-Function UF2 pump not active during the test (4 s).

– Acknowledgement (UF_P2, X637/B26) → X632/C7 no LOW

pulse

– Control line (UF_P2, X634L/A–C24) → X637/B26 no LOW

pulse

F15 UF-Function The UF2 pump cannot be stopped by the CPU2.

– Control line (UF_P_EN, X632/C28) → X634R/A22 no 5 V.

– Reset input to IC 42/pin 13 on LP 634 defect.

F16 UF-Function The UF pump acknowledgement from CPU1 is faulty.

– Acknowledgement (UF_P2, X637/B26) → X633/C23 no LOW

pulse

F17 UF-Function The change in pressure after a UF2 pump stroke less than

20 mmHg.

– UF2 pump mechanically defect.

– Control line (UF_P2_CRTL, X632/B24) → X634R/C11 no

HIGH pulse.

F20 UF-Function Difference in pressure between UF pump stroke and UF2 pump

stroke more than 20 %.

– Stroke rate for UF pump or UF2 pump not set correctly.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-9

Page 18

1.3 Error messages during treatment and the HDF test

Message on the

display

F321 HDF-failure

F322 HDF-failure

F323 HDF-failure

Cause

The UF pump or UF2 pump

test will not be started as long

as the level sensor (6) detects

air. The level sensor (6) will

detect air one minute after the

4008 HDF test has been selected

The UF pump or UF2 pump

has carried out more than 50

strokes and still no air has

been detected.

The substituate pump runs at a

rate of 10 ml/min. to raise the

fluid level by a defined amount

in the secondary air separator

(the fluid will just be detected).

Air will still be detected after 2

minutes.

Possible error elimination

Check level sensor (6) (defect).

Check V126 (does not open,

venous bubble catcher collapses), check V43 (whether

leaking or open).

Check UF pump or UF2 pump,

respectively (mech. defect).

Check substituate tubing

(clamped off, not connected to

the venous bubble catcher).

F324 HDF-failure

F325 HDF-failure

Since fluid has been recognized in the secondary air separator the substituate pump

starts at a rate of 10 ml/min.

until a change in weight follows

on the scales (i.e. a jump in

grammes). There was no difference in weight established

after one minute.

If the expected change in

weight (i.e. a jump in

grammes) is higher or lower

than –1 g, the respective UF

pump test will be repeated.

The UF pump test was repeated more than 5 times.

Check substituate tubing

(clamped off).

Check bag (fluctuations in air

draft)

Check scales (for drifting).

1-10 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 19

Message on the

display

Cause

Possible error elimination

F326 UF-failure

UF1 volume-Error

or

UF2 volume-Error

F327 UF-failure

The fluid level in the secondary air separator is raised

again by the substituate pump

after 100 strokes of the UF

pump or UF2 pump, respectively, until fluid is detected.

Plus run-on time at a rate of 10

ml/min. for the gramme jump.

Air will still be detected after a

specific period of time (depending on the delivery rate of

the substituate pump).

One UF pump did not pass the

test. The filling volume for the

secondary air separator is not

within the given tolerance of

100 ml; ± 5 ml. Should the test

give a reading of over 105 ml

the cause could also be air

taken in the flow from a badly

vented dialysator.

Interval between two strokes

of the UF pump less than

220 ms.

Check substituate hose

(clamped off, not connected

with the venous bubble

catcher).

Check UF pump or UF2 pump,

respectively (not calibrated,

mechanical defect).

Check CPU 1 (defect).

F328 UF-failure

F329 UF-failure

F330 UF-failure

F331 UF-failure

F332 UF-failure

F333 UF-failure

Pulse time of a stroke of UF

pump less than 180 ml.

Pulse time of a stroke of UF

pump more than 500 ms.

Starting time for the UF pump

more than 10 seconds.

Difference between desired or

actual delivery rate of the UF

pump greater than + 10%.

UF pump stops longer than the

maximum period time.

Despite switched off ultrafiltration the change in delivery rate

of the UF pump is greater than

10 ml.

Check LP 634 (regulating

monoflop defect).

Check LP 634 (regulating

monoflop defect).

Check LP 634 (regulating end

stage defect).

Check CPU 1 / CPU 2

(communication problems).

Check LP 634 (regulating end

stage defect).

Check UF pump

(interruption, control).

Check CPU 1 / CPU 2

(communication problems)

Check CPU 1 / CPU 2

(communication problems)

F334 UF-failure

Interval between two strokes

of the UF2 pump less than

220ms.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-11

Check CPU 1 (defect).

Page 20

display

Cause

Possible error eliminationMessage on the

F335 UF-failure

F336 UF-failure

F337 UF-failure

F338 UF-failure

F339 UF-failure

F340 UF-failure

F341 UF-failure

Pulse time of a stroke of the

UF2 pump less than 180 ms.

Pulse time of a stroke of the

UF2 pump more than 500 ms.

Reaction time of the UF2

pump more than 10 seconds.

Difference in desired or actual

delivery rate of UF2 pump

greater than ± 10 %.

UF2 pump stops longer than

the maximum period time.

Despite switched off 4008HDF

change in delivery rate of the

UF2 pump greater than 10 ml.

Failure of UF pump.

Check LP 634 (regulating

monoflop defect).

Check LP 634 (regulating

monoflop defect).

Check LP 634 (regulating end

stage defect).

Check CPU 1 / CPU 2

(communication problems).

Check LP 634 (regulating end

stage defect).

Check UF pump (interruption,

control).

Check CPU 1 / CPU 2

(communication problems).

Check CPU 1 / CPU 2

(communication problems).

Check UF pump

(spring, screen)

F342 UF-failure

F343 UF-failure

F344 HDF-failure

F345 HDF-failure

F346 HDF-failure

F348 HDF-failure

F349 HDF-failure

Failure of UF2 pump.

Volume difference between UF

pump and UF2 pump.

Balance failure recognized by

CPU2 greater than ± 500 ml.

Bolus exceeded by more than

+ 20 ml, detected by CPU2.

CPU2 failed to perform the cyclic UF pump test within 5 minutes.

Weight change on the scales

during the weighing test greater than 2g.

The delivery rate correction

factor could still not be determined after 20 minutes treatment time.

Check UF2 pump

(spring, screen)

Check UF pump and UF2

pump (delivery volume)

Check monitor / scales

(communication problems).

Check monitor / scales

(communication problems).

Check V24B and V43 feedback lines.

Check sense of rotation of aspiration pump.

Check hydraulics unit for

leaks.

Check scales

Check substituate bag

Check substituate bag

(weight fluctuations)

Check HDF control system

(greater fluctuations)

1-12 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 21

1.4 Error messages, substituate pump

Code Description of failure

E.01 Line diameter outside the permitted range

E.02 Non-defined hexaswitch position

E.03 Venous pressure transducer not balanced

E.04 Failure, running time monitoring system, SN operation

E.05 SN stroke volume outside the permitted range

E.06 The SN pressure thresholds outside the value range of the AD converter

E.07 Not defined

E.08 Failure in the AD conversion

E.09 Not defined

E.10 Not defined

E.11 Not defined

E.12 Failure, speed monitoring (hall sensor)

E.13 Failure, monitoring system, current sensing resistors

E.14 Failure, monitoring system, current sensing resistors

E.15 Failure, speed monitoring system

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 1-13

Page 22

1-14 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 23

2 T echnical safety checks

General Notes

This chapter includes all necessary technical safety checks (TSC).

These inspections must be carried out every 12 months.

The technical safety inspections stipulated for the hemodialysis machine must be carried out in addition to

these technical saftey checks.

The technical safety checks are to be recorded in the equipment log.

A technical safety checks report is to be found at the page 2-3.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 2-1

Page 24

2-2 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 25

Technical safety checks report Seite 1/1

Manufacturer: ............................. Date: .............................

Machine: ............................. Technician: .............................

Operating hours: .............................

Extent of checks and time limits for technical safety checks.

TIME LIMIT: every 12 months

The following checks and inspections have to be carried out on the machine at least every 12

months by persons who are capable of carrying out such technical safety checks efficiently as

a result of their training, knowledge and experience gained in practice and are not subject to

instructions as to their checking activity.

(See also BMA Bulletin dated 02.04.1987)

TSC WA No. OKDescription Desired value/function

1 UF2 pump

TSC 1.1 ❑Delivery volume (1 ml/stroke) 60 strokes = 60 ml ± 1%

2 VDE inspections (values according to EN 60601-1)

TSC 2.1 ❑Protective ground resistance max. 0.3 Ω

TSC 2.2 ❑Summarized leakage current Must fulfill both conditions:

1. No more than 1.5 times the “summari-

zed value first measured”

(“Summarized value first measured”:

Refer to the machine card enclosed with

the machine.)

2. No more than 1 mA

The technical safety checks are to be recorded in the equipment log and the results of the

checks documented.

If the machines are not safe in function and/or operation they are to be repaired or the operator

is to be informed as to the dangers involved when using the machine in its given state.

The correct completion of the listed work and the correctness of statements made are hereby

certified.

Signature, technician: Signature, customer:

..........................., date ............................. ................................ , date .............................

.................................................................... .........................................................................

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 2-3

Page 26

2-4 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 27

Table of contents

3 Calibration instructions

Section Page

3.0 General information on the calibration instructions ................................................ 3-3

3.1 Calibrating the UF2 pump ............................................................................................ 3-5

3.2 VDE inspections............................................................................................................ 3-7

3.3 Calibrating the 4008 HDF scales ................................................................................. 3-8

3.4 Calibrating the substituate sensor.............................................................................. 3-13

3.5 Calibrating the HDF blood pump................................................................................. 3-15

3.5.1 Pressure transducer ....................................................................................................... 3-15

3.5.2 Checking SN switchover points ...................................................................................... 3-16

3.6 Repair instructions ....................................................................................................... 3-17

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-1

Page 28

3-2 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 29

3.0 General information on the calibration instructions

Measuring instruments:

The same measuring instruments as used for the hemodialysis machines are to be employed.

Required in addition is a calibration weight PT6 – 5000 g.

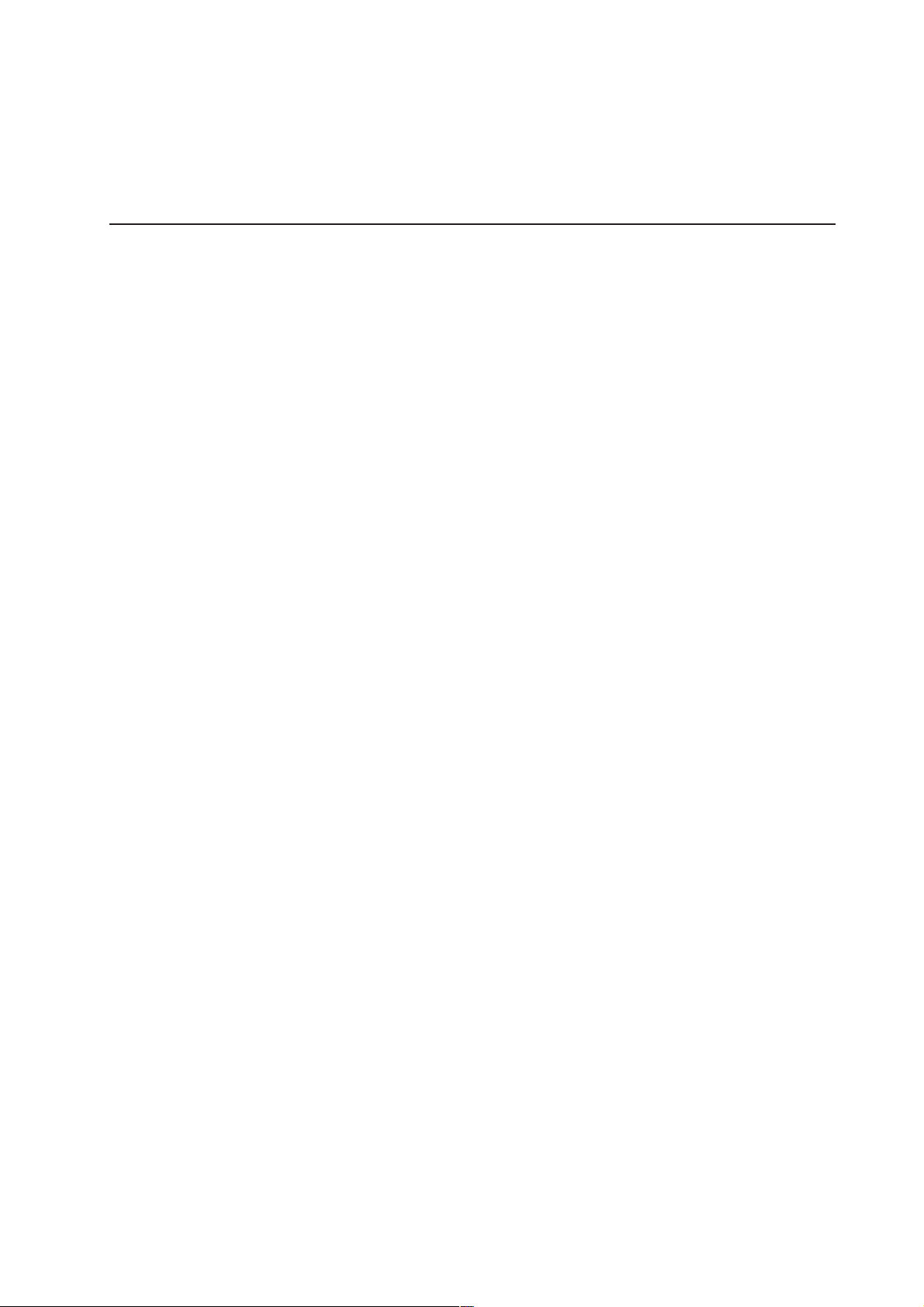

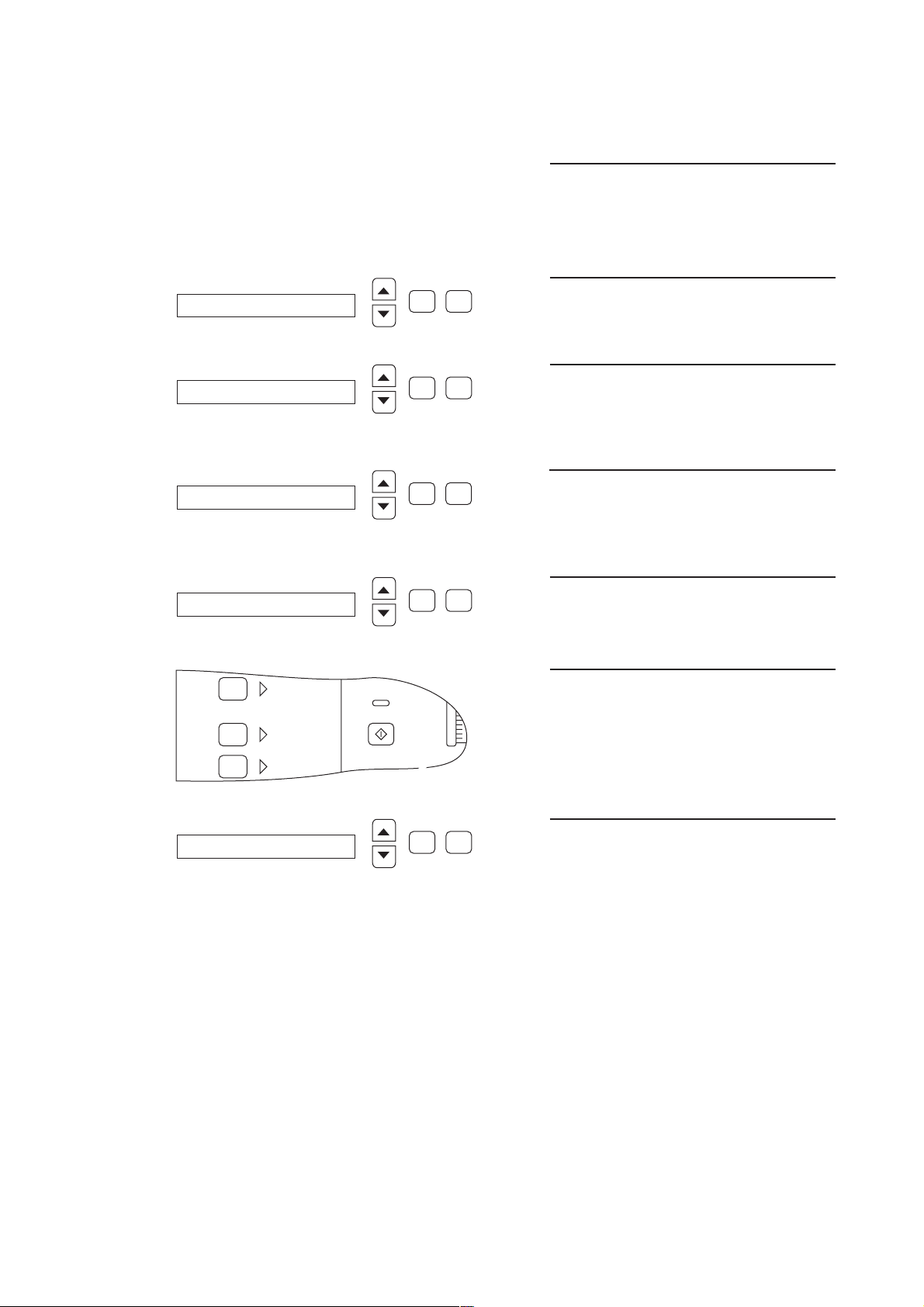

Fig.: P.C.B. overview 4008 HDF

LP 762

LP 763

LP 761

LP 625

LP 760

Fresenius Medical Care

Fresenius Medical Care

I/O

Spülen

Heißreinigen

Desinfektion

Single

Needle

Test

Vorbereiten

Dialyse Start

Alarm

Ton Aus

Rate: ml/min

(Ø: mm)

Rate: ml/min

(Ø: mm)

HDFReset

Vol : l

4008

Arterieller

Venöser

Druck

mmHgkPa mmHgkPa mmHgkPa

280

200

100

0

–100

–200

–300

Bolus

Rate

Druck

500

60

60

400

50

50

40

40

300

30

30

200

20

20

100

10

10

0

0

0

Rate: ml/h

(Bolus: ml)

( :h.min)

Start

Stop

TMP Leitfähigkeit

Luftdetektor

30

Blutleck

20

10

0

–10

–20

Überbrücken

–30

–40

Start

Stop

Start

Stop

500

400

300

200

100

0

Ultrafiltration

UF Menge

ml

Reset

UF Rate ml/h

UF Ziel ml

UF Restzeith:min

UF Variation

Prog.I/O Prog.I/O

Auswahl

Best.

Fluß

ml/min

900

700

mS/cm

(25°C)

500

300

15.5

15

14.5

SetI/O

14

13.5

Temperatur

13

°C

39

Bic.Konz.

37

35

Set

P

ven.

LP 754

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-3

Page 30

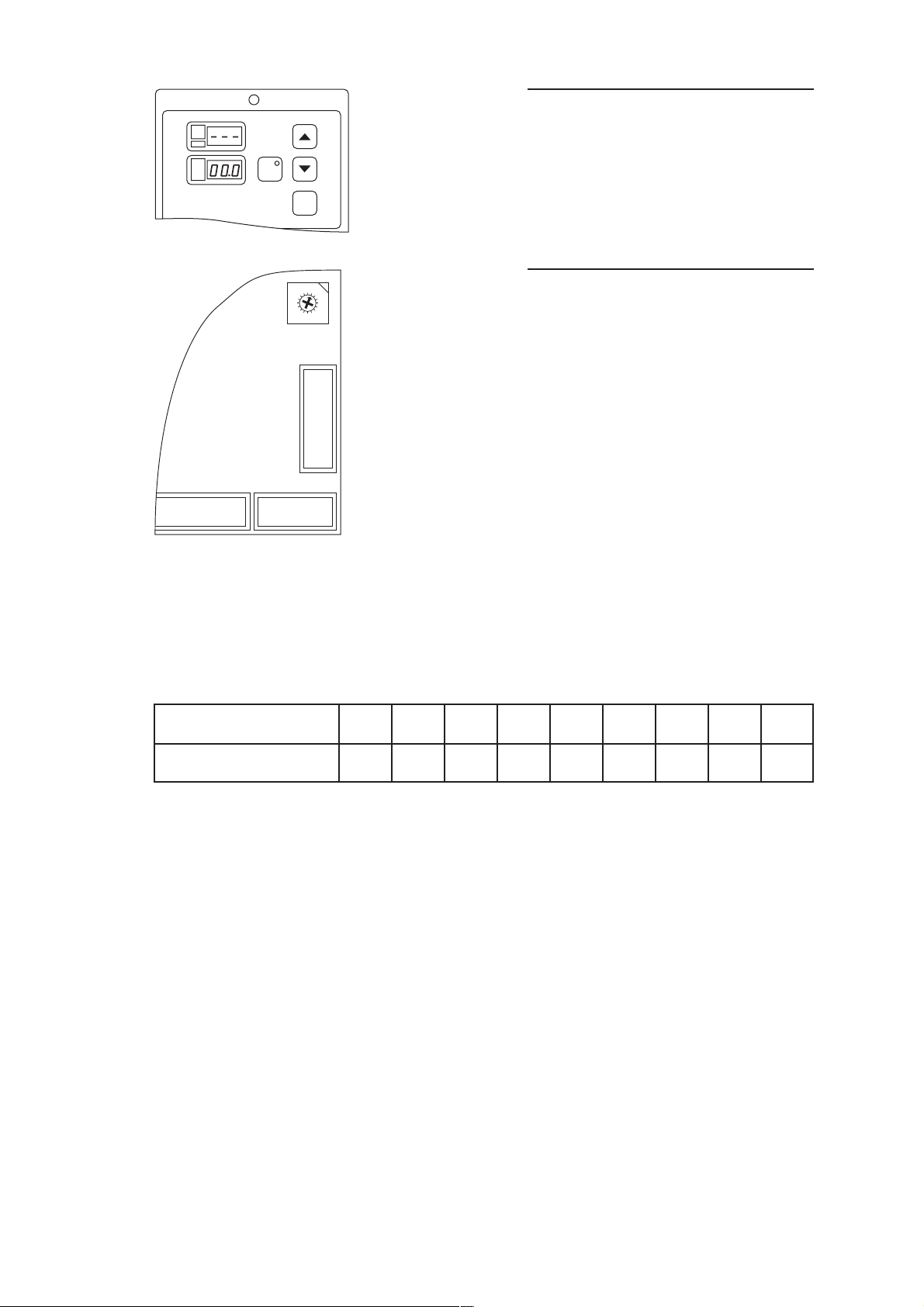

Fig.: DIP switch 4008 HDF

ON

1 2 3 4 5 6 7 8

OFF

LP 632 CPU 2

SW1

SW 1, DIP switch 8:

ON: 4008 HDF test selectable (required/not required)

OFF: 4008 HDF test carried out automatically

3-4 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 31

3.1 Calibrating the UF2 pump

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

Switch off hemodialysis machine.

Set service switch to ON (top).

Switch on hemodialysis machine.

CALIBRATION

ADJ. UF-PUMP VOLUME

UF-Pump 2

pulse-amount = 60

Confirm

Confirm

Confirm

Confirm

Select

☛

Select

☛

Select

☛

Select

☛

Press the Confirm key.

Select ADJ. UF-PUMP VOLUME by

pressing the ▲ and ▼ keys.

Press the Confirm key.

Select UF-PUMP 2 by pressing the

▲ and ▼ keys.

Press the Confirm key.

Enter the number of strokes by pressing

the ▲ and ▼ keys.

Press the Override key.

ACKNOWLEDGED

☛

Select

Confirm

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-5

Text display for approx 3 sec.

Page 32

press uf key

35

37

39

UF Variation

Prog.I/O Prog.I/O

BicConc

Set

Time Left h:min

☛

Confirm

Select

Text display

Draw off UF 2 pump line, close T-piece,

hang line in a measuring cylinder.

Press the key UF I/O.

The UF LED emits light.

The UF2 pump delivers.

uf pulses left = 59

Ultrafiltration

UF Volume ml

Reset

Volume

UF Rate ml/h

UF Goal ml

0060

Time Left h:min

UF

Prog.I/O

Confirm

Select

The remaining UF Pulses are shown in

the display.

The number of preselected pulses is

shown in the UF Goal display.

3-6 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

UF-Pump 2

Confirm

Select

Text display after completion.

Check delivered quantity.

If necessary adjust UF 2 pump and repeat process.

Delivery rate: 1 ml/stroke

(60 strokes = 60 ml)

Tolerance: ± 1 %.

Page 33

3.2 VDE inspections

(Values in accordance with EN 60601-1)

.1 Protective ground resistance:

– max. 0.3 Ω.

Measuring point

Protective

ground

resistance test

.2 Summarized leakage current

Must fulfill both conditions:

1. No more than 1.5 times the “summarized value first measured”

(“Summarized value first measured”: Refer to the machine card supplied with the machine.)

2. No more than 1 mA

The measurements must be taken in the dialysis mode of operation in the “ON phase” of the

heating control system.

The scales must be travelled out to such an extent that neither of the two end switches are

actuated (middle position).

The two leakage currents are to be measured each time with different mains connection poling.

The two leakage currents are added together and give the summarized leakage current.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-7

Page 34

3.3 Calibrating the 4008 HDF scales

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

☞

Note:

The prompts shown in the text display have to be run through correctly

by the technician since no direct return signal is given by the scales.

Switch off hemodialysis machine.

Set service switch to ON (top).

Switch on hemodialysis machine.

CALIBRATION

CALIB. HDF-SCALE

CHECKING HDF-SCALE!

calib. Switch ON?

Fresenius Medical Care

Confirm

Confirm

Confirm

Confirm

Select

Select

Select

Select

☛

☛

☛

Press the Confirm key.

Select CALIB. HDF-SCALE by pressing

the ▲ and ▼ keys.

Press the Confirm key.

Brief text display.

Display on scales is not illuminated.

Text display.

➀ Open housing of scales at the back.

➁ Set calibration switch for the scales in

ON position.

➁

☛

3-8 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Press the Override key.

Page 35

HDF-DISPL shows C?

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

Confirm

Select

Text display.

Fresenius Medical Care

50

0 100

C

g

HDF-SCALE unloaded ?

Confirm

☛

Select

The display on the scales is active.

A “C” appears at the top right.

Press the Override key.

Text display.

No weight is to be on the scales.

Press the Override key.

HDF-DISPL shows 0 ?

Fresenius Medical Care

50

0 100

C

g

Confirm

☛

Select

Text display.

Scales display.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-9

Page 36

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

☛

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

Press the Override key.

load 5 kg CAL. WEIGHT

Fresenius Medical Care

50

0 100

+

C

DISPL shows UNIT “g”?

Confirm

Confirm

Select

☛

Select

Text display.

Scales display: 5000 g

Hang calibration weight PT6 – 5000 g on

scales.

Press the Override key.

Text display.

Fresenius Medical Care

50

0 100

+

3-10 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

g

Scales display: 5000 g.

Page 37

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

☛

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

–40

0

–10

–20

–30

Single

Needle

Test

Prime

Override

Press the Override key.

calib. Switch OFF ?

Fresenius Medical Care

50

0 100

+

g

HDF-SCALE unloaded ?

Confirm

➀

Confirm

Select

☛

Select

Text display.

➀ Set calibration switch for the scales to

OFF position.

➁ Close housing.

Press the Override key.

Text display.

Remove calibration weight.

SCALE CALIBRAT. done

CALIB. HDF-SCALE

Press the Override key.

☛

Select

Confirm

Select

Confirm

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-11

Brief text display.

Text display.

Page 38

Switch off hemodialysis machine.

Set service switch to OFF (bottom).

Switch on hemodialysis machine.

Hang calibration weight PT6 – 5000 g on

scales.

Fresenius Medical Care

0 100

+

Scales display: 5000 g

50

g

Remove calibration weight.

Calibration of 4008 HDF scales

completed.

3-12 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 39

3.4 Calibrating the substituate sensor

I/O

Spülen

Heißreinigen

Desinfektion

Single

Needle

Test

Vorbereiten

Dialyse Start

Alarm

Ton Aus

Bes

Luftdetektor

Arterieller

Druck

Venöser

Druck

TMP

Blutleck

Überbrücken

Ultrafiltration

Reset

UF Menge

UF

Prog.I/O

mmHgkPa mmHgkPa mmHgkPa

ml

UF Rate ml/h

UF Ziel ml

UF Restzeith:min

4008

Rate: ml/min

(Ø: mm)

Rate: ml/h

(Bolus: ml)

Bolus

( :h.min)

–40

0

–100

–200

–300

100

200

280

0

10

20

30

–10

–20

–30

0

100

200

0

10

20

30

300

400

500

40

50

60

0

100

200

0

10

20

30

300

400

500

40

50

60

Fresenius Medical Care

XHDF

XWAAGE

X348V_SN

P1

IC14

X348V

IC17

IC2

D26

IC8

TP

I/O

Spülen

Heißreinigen

Desinfektion

Single

Needle

Test

Vorbereiten

Dialyse Start

Alarm

Ton Aus

Bes

Luftdetektor

Arterieller

Druck

Venöser

Druck

TMP

Blutleck

Überbrücken

Ultrafiltration

Reset

UF Menge

UF

Prog.I/O

mmHgkPa mmHgkPa mmHgkPa

ml

UF Rate ml/h

UF Ziel ml

UF Restzeith:min

4008

Rate: ml/min

(Ø: mm)

Rate: ml/h

(Bolus: ml)

Bolus

( :h.min)

–40

0

–100

–200

–300

100

200

280

0

10

20

30

–10

–20

–30

0

100

200

0

10

20

30

300

400

500

40

50

60

0

100

200

0

10

20

30

300

400

500

40

50

60

Fresenius Medical Care

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

Place filled substituate line in substituate sensor.

Set potentiometer P1 on the LP 754 so

that the LED D26 just illuminates.

Place empty substituate line in substituate sensor.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-13

Page 40

Adjust potentiometer P1 on LP 754 until

XHDF

XWAAGE

X348V_SN

P1

IC14

X348V

IC17

IC2

D26

IC8

TP

XHDF

XWAAGE

X348V_SN

P1

IC14

X348V

IC17

IC2

D26

IC8

TP

LED D26 just turns off.

Count the number of revolutions the

potentiometer is turned. Keep this

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

number in your mind.

Turn back the potentiometer P1 on the

LP 754 by half this number.

The LED D26 will illuminate again.

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

3-14 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 41

3.5 Calibrating the HDF blood pump

Start

Stop

Rate: ml/min

(Ø: mm)

HDFReset

Vol : l

Start

Stop

Rate: ml/min

(Ø: mm)

HDFReset

Vol : l

3.5.1 Pressure transducer

E

D

C

B

X348V_SN XHDF

0

1

F

2

3

4

5

6

A

7

9

8

Switch the hemodialysis machine off.

Set HEX switch on the LP 754 to

position “F”.

Switch the hemodialysis machine on.

XWAAGE

Display 000

Open SN pressure transducer to atmos-

phere.

Press the Start/Stop key.

☛

Display 250

Apply a pressure of 250 mmHg to the SN

pressure transducer.

Press the Start/Stop key.

☛

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-15

Page 42

Start

Stop

Rate: ml/min

(Ø: mm)

HDFReset

Vol : l

Display – – –

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

Switch off hemodialysis machine.

Set HEX switch on the LP 754 to

position 1.

Balancing out has been completed.

XWAAGE

X348V_SN

XHDF

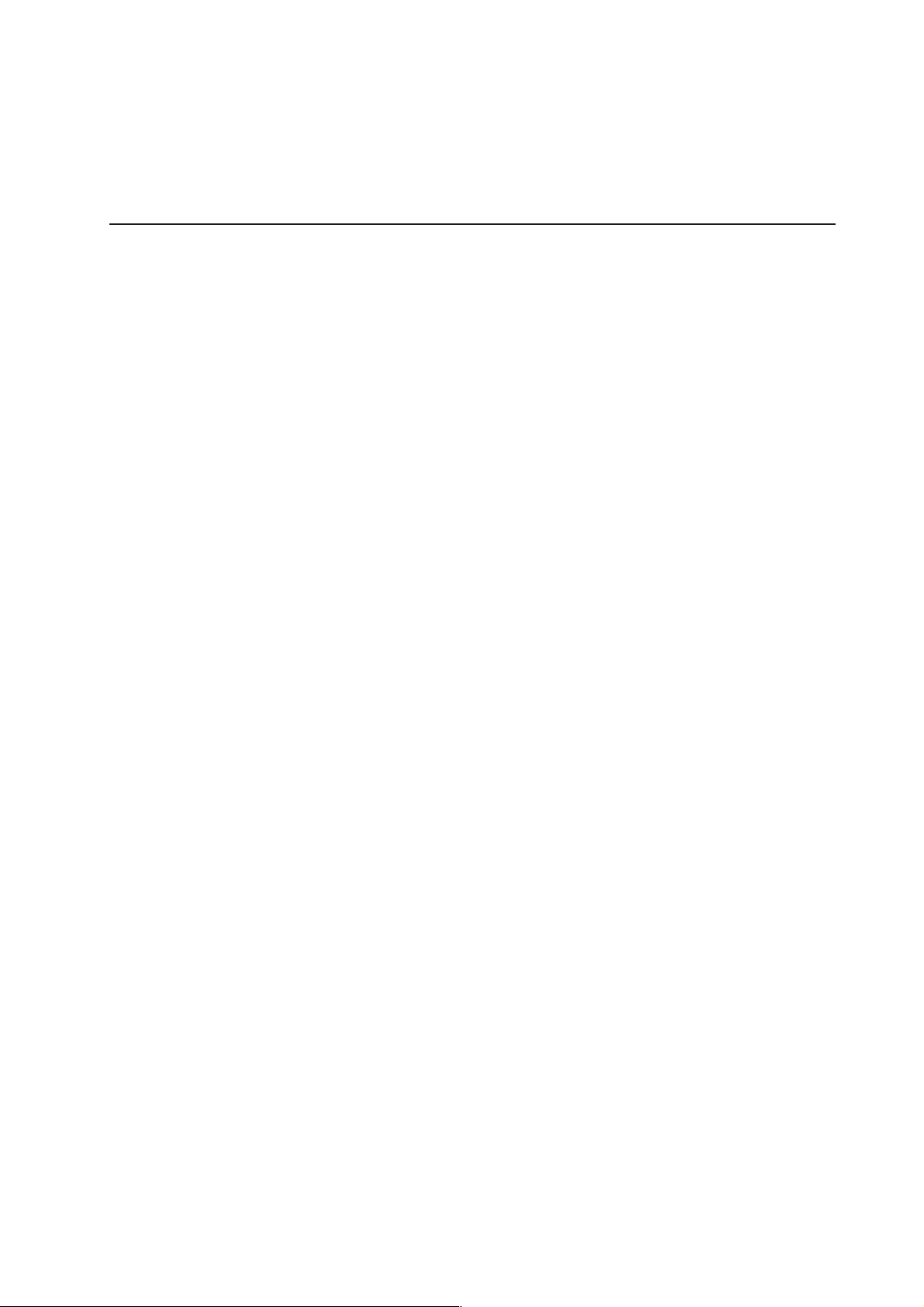

3.5.2 Checking SN switchover points

Bottom switchover point: fixed at 75 mmHg (± 6 mmHg)

Top switchover points (± 6 mmHg):

Stroke volumes (ml) 10 15 20 25 30 35 40 45 50

Top switchover point 110 130 150 172 195 219 244 270 299

3-16 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 43

3.6 Repair instructions

Important:

If the substituate lift has to be dismounted for repair the seal is to be

checked and if necessary renewed

before fitting the lift again.

Drip water protection!

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 3-17

Page 44

3-18 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 45

Table of contents

4 Circuit descriptions and circuit diagrams

Section Page

Fig.: Connection diagram 4008 HDF .............................................................................. 4-3

Fig.: Wiring diagram 4008 HDF ...................................................................................... 4-5

Fig.: Block circuit diagram, mains voltage 4008 HDF.................................................... 4-7

Fig.: Block circuit diagram, low voltage 4008 HDF ........................................................ 4-7

4.1 LP 625 display board .................................................................................................... 4-9

4.1.1 Description ...................................................................................................................... 4-9

4.1.2 Circuit and component layout diagram ........................................................................... 4-11

4.2 LP 754 control board HDF............................................................................................ 4-15

4.2.1 Description ...................................................................................................................... 4-15

4.2.2 Circuit and component layout diagram ........................................................................... 4-17

4.3 LP 760 HDF motor control............................................................................................ 4-23

4.3.1 Description ...................................................................................................................... 4-23

4.3.2 Circuit and component layout diagram ........................................................................... 4-25

4.4 LP 761 HDF drive keyboard ......................................................................................... 4-29

4.4.1 Description ...................................................................................................................... 4-29

4.4.2 Circuit and component layout diagram ........................................................................... 4-31

4.5 LP 762 scales comm..................................................................................................... 4-35

4.5.1 Description ...................................................................................................................... 4-35

4.5.2 Circuit and component layout diagram ........................................................................... 4-37

4.6 LP 763 serial interface extender .................................................................................. 4-41

4.6.1 Description ...................................................................................................................... 4-41

4.6.2 Circuit and component layout diagram ........................................................................... 4-43

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-1

Page 46

4-2 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 47

Fig.: Connection diagram 4008 HDF

LP 639

power logic

(4008 / 4008 E)

LP 744

power control 1

(4008 B)

X639B

(X744A

X744C)

LP 754

control board

HDF

Rate: ml/min

(Ø: mm)

HDFReset

Vol : l

Start

Stop

SN

Substituate

pump

XWAAGE

X348v

XHDF

X348v

Motor

Substituate lift

Auxiliary socket

LP 762

scales

comm

X4

M

LP 761

HDF drive

keyboard

X5X4

X2X1

Switch

Substituate lift

X3

Module

Scales

Module

Scales

X1

Substituate

sensor

X2

LP 760

X2

HDF motor

control

X1

X3

XHDF

X637B

X637C

LP 763

SEE serial interface

extender

X63Z

X637B

X637C

XA1P

XA4V0

UF2 pump

LP 747 distribution board

V126

LP 630

motherboard

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-3

Page 48

4-4 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 49

Fig.: Wiring diagram 4008 HDF

LP 639

power logic

(4008 / 4008 E)

LP 744

power control 1

(4008 B)

LP 754

control board HDF

X348v XHDF

123456789

1011121314151617181920

X744A/1

X744C/3

123456789

M

N1

L1

2

3

X639B

4

N23

PE4

LP 760

control

X1

N3

LC4

PE1

PE2

X5

+12V1

UP2

STOP3

DOWN4

SE15

9

SE26

SE37

SE48

no assignment

no assignment10

X2

8

L11

L12

1

2

3

4

5

6

7

8

9

X4

HDF motor

X3

1234567

24V1

SE12

AGND (SE2)3

SE34

SE45

WRXD6

WTXD7

TARA8

no assignment9

XWAAGE

no assignment10

no assignment11

no assignment12

MOTOR_CTRL13

10

10

11

12

13

14

PWR_GND14

Substituate sensor

SUB_A1

SUB_K2

1

2

3

4

LP 761

5

6

X2

7

8

9

10

drive

keyboard

SUB_C3

X1

HDF

PWR_GND4

no assignment5

no assignment6

SN2

TXD4

RXD5

BSST1

BPST3

SNST11

ADKS7

BPR_VEN10

BPSB_VEN6

BPUS_VEN8

no assignment9

no assignment12

no assignment13

X348v XHDF

motherboard

X63Z

A1

C1

A28

A29

A31

A32

C28

C29

C31

C32

C20

C21

+5VA32

+5VC32

+24VA29

+24VC29

+12VA31

PWR_GNDA28

PWR_GNDC28

X63Z

interface extender

+12VC31

RXD_EXT_1C20

LP 763

SEE serial

TXD_EXT_1C21

DGNDA1

DGNDC1

VEN_BPR_SET14

+12V16

AGND15

LP 630

24V19

24V20

WTXD2

WRXD3

PWR_GND17

HDF_ON1

PWR_GND18

X637B X637C

UF_P226–28 26–28

X637B X637C

distribution

XA1P XA4V0

UF_P2 10

UF2 pump V 126

TARA4

BL_AL5

LP 747

board

+12V9

AGND10

HDF_LOG26

HDF_LOG17

no assignment8

V12614 14

V126 9

+12V1

X2

1

+12V

AGND2

2

END_SW

Switch substituate lift

RXD4

TARA3

X1

LP 762

scales

comm

–8

TXD5

+12V7

END_SW6

no assignment1

no assignment2

no assignment3

no assignment5

no assignment8

X3

no assignment12

no assignment13

no assignment14

X4

no assignment6

1

2

3

GND4

4

5

TXD6

6

7

GND7

8

9

GND9

10

PRINT10

11

TARA11

12

13

14

W1IW21

1

F22

2

F13

3

4

CF4

5

ON/OFF5

6

Module

scales

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-5

Page 50

4-6 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 51

Fig.: Block circuit diagram, mains voltage 4008 HDF

Main

trans-

former

T 2,5 A T 2,5 A

Mains

relay

T 2,5 A

Mains

plug

Mains

filter

Mains

switch

(on back

of machine)

511 K 1 µF T 2,5 A

Fig.: Block circuit diagram, low voltage 4008 HDF

Standby-

trans-

former

Auxiliary

socket

Motor relay

Direction of turn

switchover

M

Main

transformer

24 V

switch controller

I

≈ 15 A

max

(short circuit

cut-out)

12 V

switch controller

I

≈ 4 A

max

(current

limitation)

LP 633

input board

LP 630

motherboard

LP 634

output board

LP 754

control board

HDF

LP 761

HDF drive

keyboard

+12 V

LP 760

HDF motor control

Linear controller

+24 V +12 V

current restricted

internally to

approx. 1 A

Scales

+12 V

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-7

Page 52

4-8 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 53

4.1 LP 625 display board

4.1.1 Description

● General

The displays and the keyboard are on this P.C.B..

Plug connections to LP 625:

– X189, connection to LP 760

● Display

All necessary information is given to the user through 6 multiplex 7-segment displays and 2 LEDs

which are mounted on the socket.

● Keyboard

The keyboard comprises 3 single non-illuminated keys and 1 key with integrated LED (HDF). The

keys are soldered directly to the P.C.B..

The user receives a acknowledgement through a spring contact when the keys are pressed.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-9

Page 54

4-10 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 55

4.1.2 Circuit and component layout diagram

A

B

C

D

E

F F

E

D

C

B

AENDERUNG NAME

NAME

AUS

TAG ERSATZ

ERSATZ FORMAT

BE

GE

NO

TAG

12345678

1234

5

BLATT

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

MEDIZIN-

TECHN.

SYSTEME

SP

DISPLAY BOARD

1(1)

673872

1992

ST

LP625

30.06.

24.11. D.KOE

a

neue Zeichnung

19.02.93

Asch.

Asch.b

R86(R13)best. 12.03.93

c

SH5,IC1 neu 12.07.94

AN

AN

a

g

b

e

c

d

f

DP

AN

AN

a

g

b

e

c

d

f

DP

AN

AN

a

g

b

e

c

d

f

DP

AN

AN

a

g

b

e

c

d

f

DP

AN

AN

a

g

b

e

c

d

f

DP

AN

AN

a

g

b

e

c

d

f

DP

A8

A7

A6

A5

A4

A3

A2

A1 Y1

Y2

Y3

Y4

Y5

Y6

Y7

Y8

G2

G1

&

EN

GND

+5V

+24V

X

+24V

+24V

+5V

+5V

+5V

+5V

+5V+5V+5V+5V +5V

1

2

3

4

5

6

10

9

8

7

DP1

HDSP7801

1

2

3

4

5

6

10

9

8

7

DP2

HDSP7801

1

2

3

4

5

6

10

9

8

7

DP3

HDSP7801

1

2

3

4

5

6

10

9

8

7

DP4

HDSP7801

1

2

3

4

5

6

10

9

8

7

DP5

HDSP7801

1

2

3

4

5

6

10

9

8

7

DP6

HDSP7801

1

19

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

IC1

74HCT541

8

7

6

5

4

3

2

1

LD1

HLMP2655

12

LD2

HLMP2400

34

LD2

HLMP2400

R3

4K99

R1

4K99

R6

7K50

R5

7K50

R4

7K50

R9

7K50

R8

7K50

R7

7K50

R2

4K99

R10

4K99

R11

121R

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

RN1

8X220R

R12

150R

R13

4K99

12

SH1

RF15

12

SH2

RF15

12

SH3

RF15

21

SH4

MTG

SH5

RF15

T8

BS170

T3

BC327-40

T1

BC327-40

T6

BC327-40

T4

BC327-40

T2

BC327-40

T7

BC547B

T5

BC327-40

1

X189

10

X189

11

X189

12

X189

13

X189

14

X189

15

X189

16

X189

17

X189

18

X189

19

X189

2

X189

20

X189

21

X189

22

X189

23

X189

24

X189

25

X189

26

X189

3

X189

4

X189

5

X189

6

X189

7

X189

8

X189

9

X189

LP 625 display board

LP 625

Circuit diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-11

Page 56

4-12 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 57

LP 625

Component layout diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-13

Page 58

4-14 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 59

4.2 LP 754 control board HDF

4.2.1 Description

● General

The control, section and power pack are on the this P.C.B..

Plug connections to LP 754:

– X186, connection to position sensor

– X188, connection to stepper motor

– X189, connection to LP 748

– X190, connection to cover switch

– X192, connection to pressure transducer

– X348, connection to dialysis monitor

Hexswitches on the LP 754:

0 No function

1 Single needle blood pump / 4008 HDF / ON LINE HDF

2 – A No function

B Blood pump stop alarm (15, 30 secs.)

C No function

D Call-up operating time meter (display x 100 = number of hours)

E Test operation (only manufacturer)

F Pressure transducer calibration

● Voltage generation

The +24 V and +12 V voltage supply is made available to the blood pump by the monitor. The +5

V supply voltage is generated on the module by the switch controller IC 20 from the +24 V voltage

to minimize loss of power.

● Stepper motor control

The stepper motor is run in microstep operation to reduce noise. The resolution is 60 microsteps

per step. The RISC processor transmits a 8-bit dataword alternately on the pins 3 and 5 of the DA

converter from IC 7. Two sine form voltages are available on the output of the converter, phase

offset by 90°. They are conducted to the stepper motor controller IC 2 together with the current

direction signals. Together with the two SM drivers IC 1/IC 22 and the current sensor resistors

R58/R59 as feedback these form a closed control circuit which determine two sine-shaped

currents, phase offset by 90°, in the two coils.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-15

Page 60

● Microprocessor

The cycle frequency of the microprocessor is determined by the quartz Q2 between the processor

connections 39 and 40. Quartz oscillation is made possible by the capacitors C5 and C6.

The keyboard signals and the signals BSST, BPST are read-in through the port P4.

The IC 9 serves as intermediate memory for the addresses AO/A7.

The ALE signal on pin 50 of the microprocessor is the control line of the data address latch.

The signal from the revolution and direction of turn sensor (position sensor) in the pump bed is

read-in through port T1.

The operation data of the pump is saved in the NOVRAM IC 21 through ports 5.1 to 5.3 when the

dialysis machine is switched off or there is a voltage failure. Undervoltage detection (power down)

is through the comparitor IC 23.

With the WR line the data takeover for the display is controlled in the external data latch IC 14.

● PLL intermediate circuit

PLL component IC 4 together with the counter IC 19 causes the frequency coming from the

processor to control the stepper motor to be multiplied otherwise the processor would be too slow

to generate this frequency.

● RISC processor

The RISC processor IC 5 is supplied with a cycle signal from the processor. With each cycle an

8-bit data word is read from a look up table by the processor alternately for each phase of the

stepper motor, respectively. Included in this data word is both the current direction as well as the

current desired value.

A watchdog for the CPU is also incorporated in the RISC processor. When a cycle is missing on

pin 8/IC 5 the RISC processor triggers a reset by the CPU through pin 7.

● Display control

The data word for controlling the display is stored in IC 14. The multiplex operation of the

individual digits is made possible through the decoder IC 18.

● Speed and flow

The speed is transmitted by the processor through port P 1.1 and the flow through port P 1.2 to

the dialysis monitor.

● Pressure measurement

The differential measurement amplifier for the pressure transducer is formed by the IC 6 (1/2/3)

and IC 6 (5/6/7). The measuring signal is read-in by the processor through the AD converter input

AN 7 and calibrated for zero and steepness by the software. Afterwards the measuring signal is

modulated to pulse width through port P1.3 and transmitted through a subsequent DA converter

IC 11 (5/6/7) to the monitor.

4-16 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 61

4.2.2 Circuit and component layout diagram

LP 754 control board HDF

LP 754

Circuit diagram 1/2

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-17

Page 62

4-18 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 63

LP 754

Circuit diagram 2/2

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-19

Page 64

4-20 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 65

LP 754

Component layout diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-21

Page 66

4-22 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 67

4.3 LP 760 HDF motor control

4.3.1 Description

● General

The LP 760 serves to control the lift drive.

Lift operation presupposes that the scales are swung away. This is recognized by a limit switch.

The scales can be moved upwards or downwards by pressing the ▲ or ▼ keys. The drive is

switched off automatically, likewise by limit switches, when reaching the uppermost or bottommost position. When the scales are being travelled upwards or downwards they can be stopped

at any time with the Stop key.

The motor for the lift drive is safeguarded against overloading by means of an integrated

thermoswitch. If this protection facility responds the lift will come to a standstill. The lift can be

used again after the motor has cooled down.

● Circuit structure

Supply voltage

The control circuit is supplied with +12 V. This voltage is generated from the +24 V voltage of the

hemodialysis machine by the linear controller T1 in conjunction with the capacitors C4, C5 and

C6.

Motor control

Two types of circuit are implemented to control the motor:

a) continuous operation (R21 with components, R22 without components

b) inching operation for downwards movement (R21 without components, R22 with

components).

To Point a):

One D flip-flop is available for each direction of movement (IC 3). The flip-flops are set by a high

level on X2/2 (key ▲) or X2/4 (key ▼). The flip-flop for the respective other direction of movement

is reset at the same time by pressing the appropriate key. The two flip-flops are reset through high

level on X2/3 (Stop key). This also takes place should the head of the scales be swung over the

machine (high level on X1/6).

To Point b):

There is only one flip-flop available for the upwards movement (IC 3/pin 1/2). The flip-flop for the

downward movement is set through IC 5. The control logic for the downward operation is not

influenced by this (see Point a). However, the drive is only active as long as the key ▼ is pressed.

The IC 5 works as an 8 to 1 multiplexer. The address (0 to 7) of the input to be interconnected is

provided through the pins 11 to 13. Only the address 3 leads to a low level on output IC 5/14 and,

as a result, to the motor starting. R 20 serves as a pull-up resistor. A defined output level is

obtained with the IC 5/14 in high ohmic state, caused by pressing the Stop key (high level on IC

5/15).

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-23

Page 68

● Other circuit sections

The motor feed lines are circuited through the relay RL 1 and RL 2. The position of RL 1

determines the travel direction of the lift. The motor is switched on and off through RL 2. Both

relays are controlled by the transistors T 2 (RL 1) and T 3 (RL 2). T 2 is controlled directly from the

non-inverted output IC 3/1. The output signals of both flip-flops, IC 3/2 and IC 3/12 (inverted) are

used to control T 3 and are linked with each other through IC 1/1 and IC 1/2. In the case of low

level on one of the two flip-flop outputs IC 3/2 or IC 3/13 (i.e. the respective flip-flop has been set)

the IC 1/pin 3 links up high level and T 3 switches RL 2.

● Motor current recognition

The motor current is monitored while the lift is operating. The internal thermal-protective switch

responds in the case of the motor becoming overheated. Both flip-flops (IC 3) are reset by motor

current recognition so that the motor does not start up again automatically after the drive has

cooled down. The voltage drop is evaluated through the high load resistor R 18 for motor current

recognition. The generated alternate voltage caused by the current flow through R 18 is

connected to the capacitor C 14 and C 13 through the diodes D 4 and D 5. The resulting direct

voltage through R 13 is approx. double so high as the peak value of a half wave of the alternate

voltage on R 18 less the on state voltages of D 4 and D 5. The direct voltage controls the

optocoupler IC 4 through R 14. R 13 serves to completely discharge C 13 and C 14 when the

motor is switched off.

IC 4 ensures protective isolation of the control circuit from the mains voltage conducting

components of the current recognition system.

The output of the optocoupler is circuited with the pull-up resistor R 19 against 12 V. High level on

the collector of IC 4 resets both flip-flops through IC 1/pin 12 and 13 and IC 1/8. This would lead

to continuous blocking of the control circuit unless further measures were taken. This is why the

output of IC 4 is connected up parallel to a further transistor T 4. In switched off state the capacitor

C 12 is charged through high level on IC 1/4 through D 3 and R 10. This makes the transistor T 4

conductive. After setting one of the flip-flops (IC 3) the IC 1/4 goes to low. C 12 discharges itself

through R 11, R 12 and the B-E path from T 4. T 4 blocks after approx. 500 ms. The output

transistor must be linked by IC 4 before this time has elapsed otherwise both flip-flops will be reset

again.

4-24 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 69

4.3.2 Circuit and component layout diagram

A

B

C

D

E

F

G

12345678910

B

C

D

E

F

G

H

12345

H

BLATT

NAMTAGAUS

BE

GE

NO

AENDERUNG

TAG NAME

ERSATZ ERSATZ FORMAT

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

MEDIZIN-

TECHN.

SYSTEME

A3

1994

1(1)

SP

673 720 LP760

21.09. OTT

C1-C3 STUETZKONDENSATOREN

HDF-MOTOR-STEUERUNG

HDF-MOTOR-CONTROL

(1)

(2)

(3)

T100mA

*

*

R22 NICHT BESTUECKT / NOT FITTED

M

a

X1.1war +24V

>1_

>1_

I

AD

O

1D

S

R

C1

1D

S

R

C1

X7

X6

X5

X4

X3

X2

X1

X0

C

B

A

Z

INH

EN

+24V

AGNDAGND AGND

+12V

AGND

UP

STOP

AGND

DOWN

AGND

+12V

AGND

AGND

+12V

AGND

END_SW

AGND

AGND

SE1

SE2

SE3

SE4

+12V

+12V

SE1

SE2

SE3

SE4

+24V

RXD

+24V

AGND

AGND

+24V

AGND AGND

+24V

L1

L1

N2

PE

PE

N

LC

TXD

TARA

MOTOR_CTRL

AGND

AGND

TARA

RXD

TXD

+12V

+12V

AGND

+12V +12V

AGND

+12V

+12V

AGND AGND

AGNDAGND

PE

+12V

AGND

R5

73K2

2

3

4

5

1

IC2

4072

9

10

11

12

13

IC2

4072

1

2

3

T1

7812

C5

100N

C4

10U

C6

1U0

6

5

3

4

1

2

IC3

4013

8

9

11

10

13

12

IC3

4013

R2

10K0

R3

10K0

R4

10K0

2

X2

3

X2

4

X2

C7

10U

C8

1N0

C10

1N0

R1

10K0

6

X1

5

X2

6

X2

7

X2

8

X2

1

X2

2

X3

3

X3

4

X3

5

X3

1

X3

6

X3

4

5

31

2

RL1

VSB24

D1

1N4448

R7

0R0

R6

0R0

C9

100N

C11

100N

R8

10K0

R9

10K0

D2

1N4448

ab

RL2

VSB24

12

RL2

VSB24

1

X4

2

X4

3

X4

1

X5

2

X5

3

X5

4

X5

7

X3

8

X3

13

X3

14

X3

2

X1

3

X1

4

X1

5

X1

7

X1

1

X1

C1

100N

C2

100N

C3

100N

D6

ZPD15

D7

ZPD15

3

T5

Q6025

&9

8

10

IC1

4011

&5

6

4

IC1

4011

&1

2

3

IC1

4011

&12

13

11

IC1

4011

R19

20K5

T4

BC337-40

1

2

4

3

IC4

SFH617G-3

D3

1N4448

R10

20K5

R11

20K5

R12

40K2

R14

499R

R13

10K0

R16

10R0

R15

10R0

D5

1N4007

D4

1N4007

R17

1K00

R18

2R4

4

X4

F1

C12

10U

C14

47U

C13

47U

T2

BSS91

T3

BSS91

15

10

14

11

12

13

1

2

3

4

5

6

7

9

IC5

4512

R20

10K0

R21

0R0

R22

0R0

LP 760 HDF motor control

LP 760

Circuit diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-25

Page 70

4-26 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 71

LP 760

Component layout diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-27

Page 72

4-28 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 73

4.4 LP 761 HDF drive keyboard

4.4.1 Description

● General

The keys for controlling the substituate lift are found on this P.C.B..

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-29

Page 74

4-30 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 75

4.4.2 Circuit and component layout diagram

LP 761 HDF drive keyboard

1234

LP 761

Circuit diagram

F

F

+12V

E

+12V

X2

1

E

S1

X2

X2

X2

X2

2

3

4

5

UP

STOP

D

DOWN

SE1

RF15

12

UP

S2

RF15

12

STOP

S3

RF15

12

DOWN

D

X1

2

SUB_K

20

19

18

17

16

15

14

13

12

11

10

X2

X2

X2

6

7

8

SE2

C

SE3

SE4

B

9

8

7

6

5

4

3

2

1

a

0

X1 geandert

AENDERUNGAUS

TAG

NAM

1994

BE

GE

NO

TAG

04.08.

05.08.

X1

4

X1

1

X1

3

X1

5

X1

6

NAME

OTT

ASCH

MEDIZINTECHN.

SYSTEME

PWR_GND

SUB_A

SUB_C

HDF-ANTRIEB-TASTATUR

HDF-MOTOR-KEYBOARD

LP761 673 766

ERSATZERSATZ FORMAT

BLATT

1(1)

SP

C

B

A4

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-31

Page 76

4-32 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 77

LP 761

Component layout diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-33

Page 78

4-34 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 79

4.5 LP 762 scales comm

4.5.1 Description

The LP 762 serves as interface between the dialysis machine and the scales.

The serial transmission from the dialysis machine arrives on the plug X1 pin 4 (RXD) and is

converted at the interface IC 1 (max. 232) to 5 V level. IC 2 makes a serial parallel conversion and

passes the signal on to the scales. The scales are switched on or off, respectively, by the

transistor T1.

The serial carry forward (weight) comes from the scales to the plug X3 pin 6 (TXD) and is

converted by IC 1 from 5 V to RS 232 level. The signal arrives at the dialysis machine through

plug X1 pin 5 (TXD).

SP1 (ML78L05) converts the 12 V into 5 V which serves as the supply voltage for LP 762.

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-35

Page 80

4-36 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 81

4.5.2 Circuit and component layout diagram

LP 762 scales comm

LP 762

Circuit diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-37

Page 82

4-38 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 83

LP 762

Component layout diagram

Fresenius Medical Care 4008 HDF 3/11.97 (TM) 4-39

Page 84

4-40 Fresenius Medical Care 4008 HDF 3/11.97 (TM)

Page 85

4.6 LP 763 SSE serial interface extender

4.6.1 Description

● General

The LP 763 is necessary for serial communication of the monitor with the scales and the HDF

pump module.

● Circuit structure

The circuit of the LP 763 comprises two circuit units independent of each other.

Serial interfaces

Heart of the LP 763 P.C.B. is an 8-fold UART (universal asynchronous receiver/transmitter), i.e.

an interface IC (IC 1) with eight independent serial channels. Also to be found on the P.C.B. are

two TTL/RS232 level converters (IC 2 and IC 3) and an interrupt logic IC (IC 4), as well as diverse

resistors, capacitors and an oscillation quartz Q1 for generating the working cycle for IC 1.

COMMCO connection

The slot 63Z used by the LP 763 P.C.B. is also provided for the installation of P.C.B. LP 752. The

LP 752 takes over the connection of the 4008 monitor signals to the COMMCO P.C.B. LP 729. In

order to be able to also continue the linking to COMMCO/FINESSE in 4008 HDF machines the

circuit section of the LP 752 P.C.B. is taken over in the LP 763 P.C.B..

● Function