Page 1

2

1

3

5

4

6

7

90

8

FRESENIUS 2008K

HEMODIALYSIS SYSTEM

TROUBLESHOOTING

GUIDE

Part Number 507298 Rev. C

Page 2

FRESENIUS MEDICAL CARE

NORTH AMERICA

2637 Shadelands Drive, Walnut Creek, CA 94598

800-227-2572 or 925-295-0200

REGIONAL EQUIPMENT SPECIALIST: ___________________________________

Page 3

FRESENIUS 2008K

HEMODIALYSIS SYSTEM

TROUBLESHOOTING

GUIDE

Part Number 507298 Rev C

Copyright 2002 - 2010 Fresenius Medical Care North America

Page 4

Page 5

TABLE OF CONTENTS

USING THE TROUBLESHOOTING GUI

THE 'ORDER' OF TROUBLESHOOTING .......................................................................................................... 2

INITIAL CHECKS ................................................................................................................................................ 3

FINAL CHECKS .................................................................................................................................................. 4

EQUIPMENT NEEDED....................................................................................................................................... 4

SECTION 1 - FLOW ERRORS IN DIALYZE MODE .......................................................................................... 6

TROUBLESHOOTING MOTORS .............................................................................................. 23

SECTION 2 - NO WATER................................................................................................................................. 24

SECTION 3 - FLOW ERRORS IN CLEANING PROGRAMS........................................................................... 26

TROUBLESHOOTING VALVES ................................................................................................ 30

TROUBLESHOOTING VALVE ERRORS.................................................................................. 31

SECTION 4 - TEMPERATURE PROBLEMS.................................................................................................... 39

SECTION 5 - CONDUCTIVITY PROBLEMS.................................................................................................... 55

SECTION 6 - CONCENTRATE PUMP 'END OF STROKE' (EOS) ERRORS ................................................. 61

SECTION 7 - COND OFFSET REF OR COND OFFSET FAILURES.............................................................. 63

SECTION 8 - FILLING PROGRAM PROBLEMS.............................................................................................. 64

SECTION 9 - TMP PROBLEMS ....................................................................................................................... 69

SECTION 10 - PRESSURE HOLDING TESTS FAILING................................................................................. 72

SECTION 11 - NEGATIVE PRESSURE TESTS .............................................................................................. 77

SECTION 12 - INDUCED POSITIVE PRESSURE TESTS .............................................................................. 80

SECTION 13 - DEAERATION PROBLEMS ..................................................................................................... 81

SECTION 14 - UF PUMP PROBLEMS............................................................................................................. 83

SECTION 15 - BLOOD LEAK PROBLEMS...................................................................................................... 86

SECTION 16 - CHECKING ACTUATOR BOARD CABLE ............................................................................... 88

SECTION 17 - CHECKING SENSOR BOARD CABLE.................................................................................... 90

SECTION 18 - MANUAL BALANCING CHAMBER VALVE LEAK TESTS ...................................................... 92

SECTION 19 - TESTING FOR A LEAKING BALANCING CHAMBER DIAPHRAGM...................................... 96

DE....................................................................................................... 1

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 6

Page 7

PREFACE

This troubleshooting guide has been developed with the help of many customers and Fresenius personnel. It

is a combination of known techniques and excellent feedback from people that actually work with the

equipment.

The intent of the 2008K Troubleshooting Guide is to provide you with an aid in the diagnosis of common

problems. Since this document is only a guide and may not provide the most up-to-date solutions for every

conceivable problem, we recommend contacting our Technical Services Support line should additional

assistance be required.

WARNING: Before using this guide you must read pages 1 through 4 which outline using the

Troubleshooting Guide, Order of Troubleshooting, Initial Checks, Safety Checks and Equipment

Needed. Never troubleshoot with a patient connected to the machine. If possible, remove the

machine from the treatment area when it is being serviced. Always tag the machine to ensure it is not

accidentally returned to service before the service work is completed.

Always fully test a machine (in accordance to the Technicians Manual P/N 490049 or Operators

Manual P/N 490042) when maintenance and/or repairs have been completed. This is to include

confirmation of conductivity, pH and Temperature with a calibrated device.

Should additional technical assistance be needed, technical support is provided 24 hours a day, seven days a

week at our toll free number (800) 227-2572.

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 8

Page 9

USING THE TROUBLESHOOTING GUIDE

1. We assume that the troubleshooter is qualified and has been trained to work on Fresenius machines.

Incorrect troubleshooting can result in injury or death!

2. We assume that the troubleshooter has the necessary test equipment and knows how to use it.

3. Troubleshooting procedures are written in ‘flow chart’ style that systematically narrows in on and locates

the problem. Each procedure is critical so take the time to read each one thoroughly and then proceed

EXACTLY as directed. Trying to hurry, skipping steps, or second guessing will lead to error. Don’t assume

anything! Pay particular attention to CAUTIONS and NOTES.

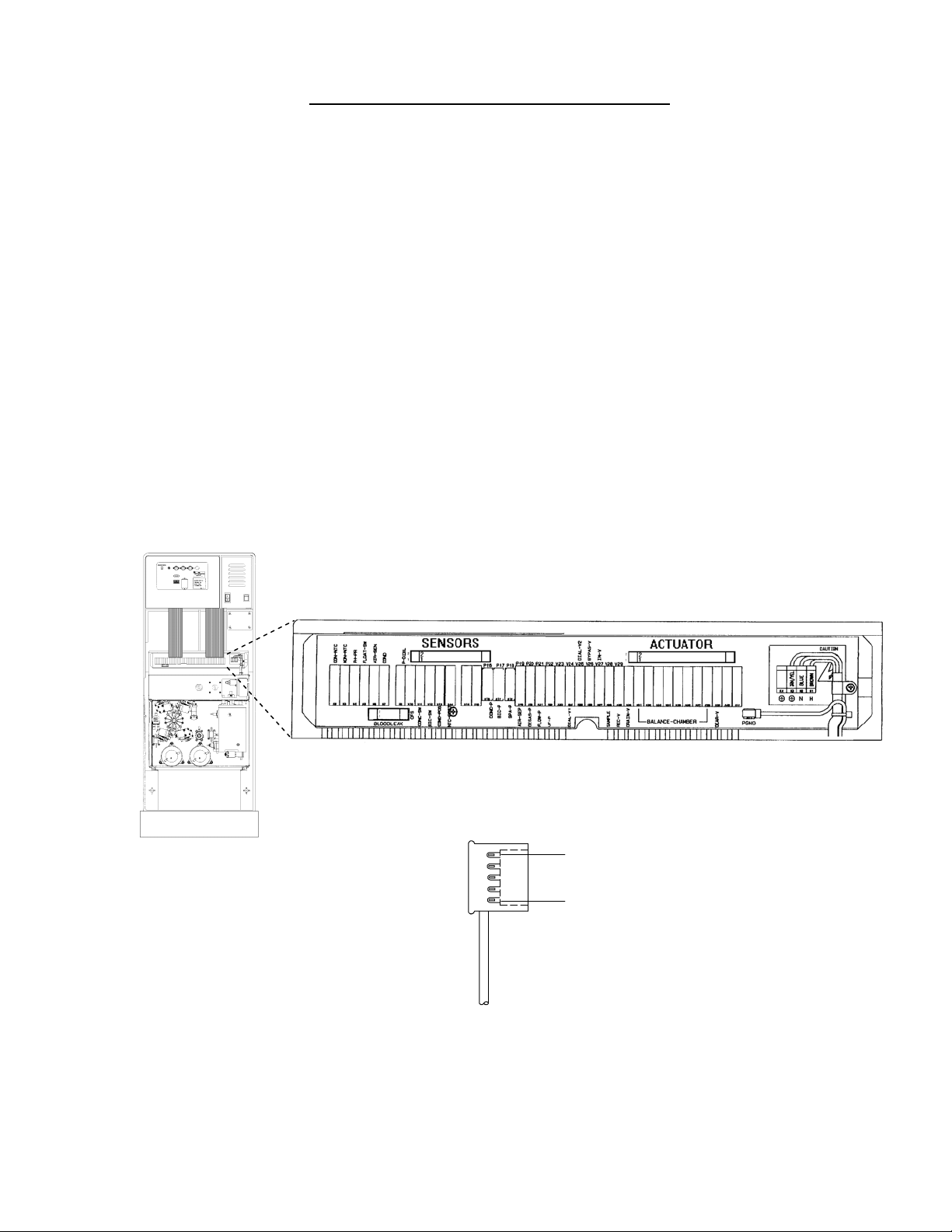

4. Most hydraulic components (valves, pumps, etc) can be checked at the DISTRIBUTION BOARD. Each

component has a numerically labeled connector ‘position’. Referring to the HYDRAULIC FLOW DIAGRAM

flow pump #21 plugs into position [P21, FLOW-P], valve 43 plugs into position [V43], etc.

NOTE: Except for the heater (CAUTION! High Voltage), sensor cable, actuator cable, acid pump, bicarbonate

pump or blood leak detector it is okay to unplug connectors with the power on.

CAUTION! Unplugging the sensor cable, actuator cable, acid pump, bicarbonate pump and the blood leak

detector with the power on may cause damage. Disconnecting the heater with the power on may cause

electrocution!

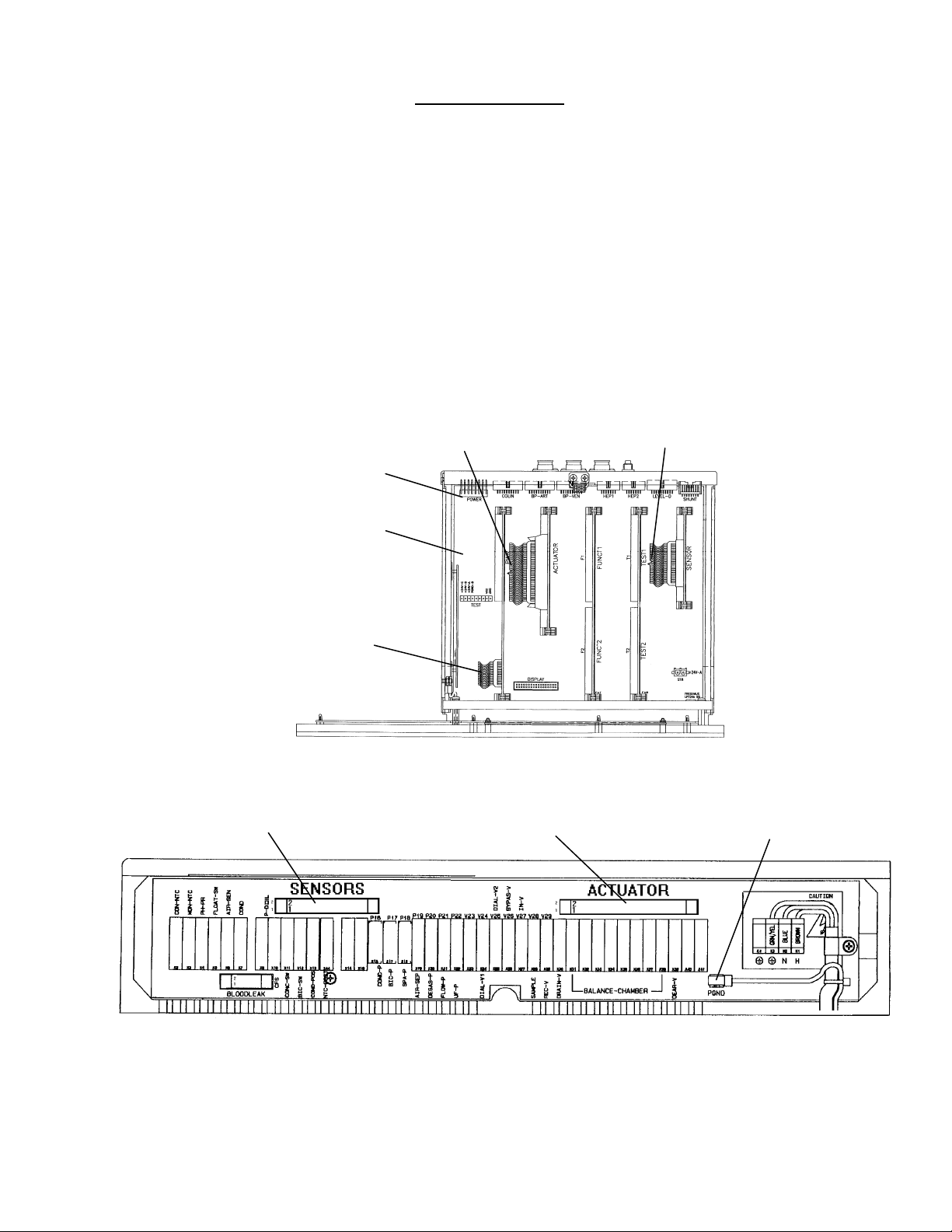

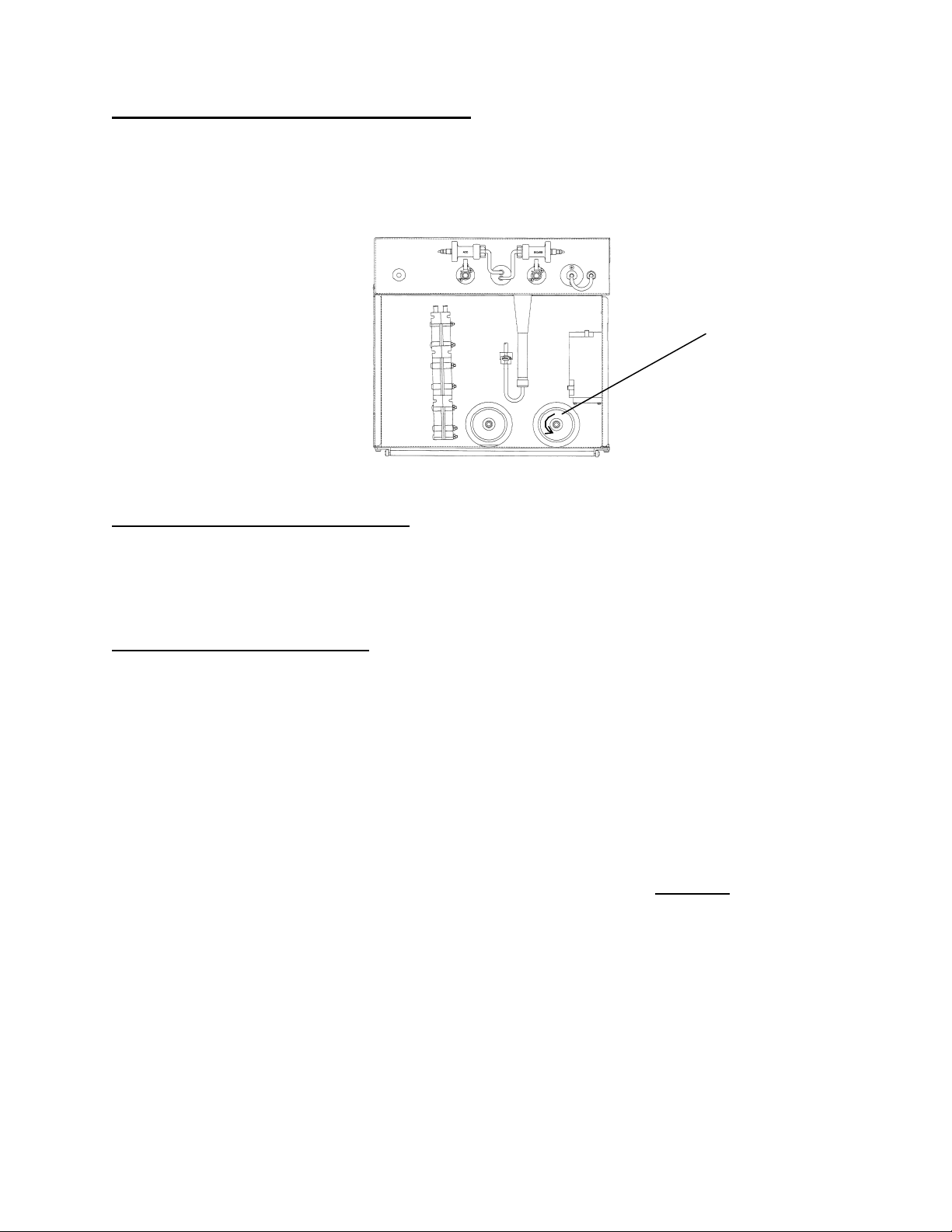

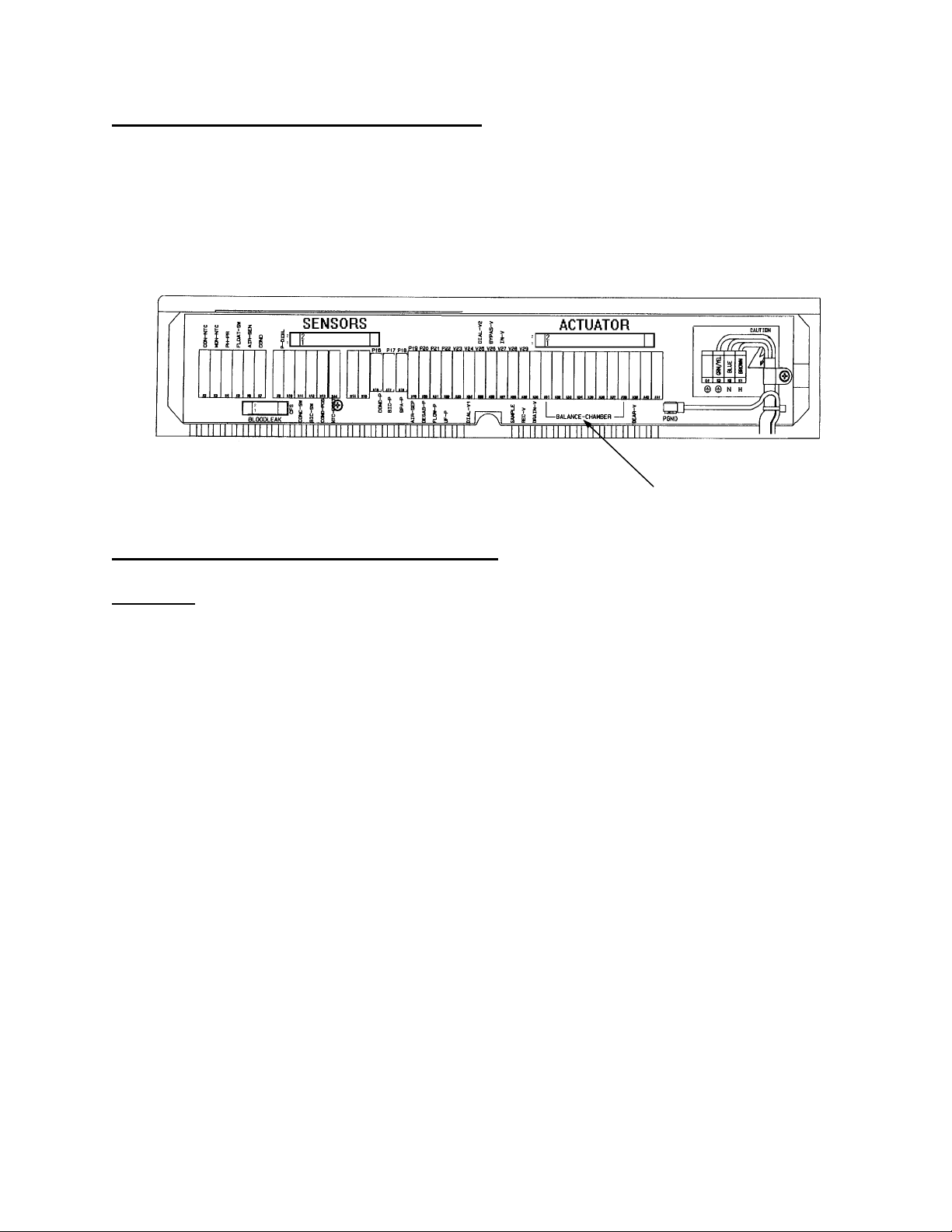

Figure 1 – Distribution Board

PIN 1

PIN 5

Figure 2 – Female Connector

5. If unsuccessful please call Technical Services at 1-800- 227- 2572.

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 1

Page 10

THE 'ORDER' OF TROUBLESHOOTING

Troubleshoot in the following order:

1. No Water

2. Flow Errors

3. Temperature

4. Conductivity

5. TMP

6. Blood Leak

7. Pressure Holding Test Failures

NOTE: Before beginning we recommend that you perform INITIAL CHECKS (page 3). This is especially

importa

1. A NO WATER alarm turns flow off. Clear NO WATER alarms before concerning yourself with other

2. Do not concern yourself with FLOW ERRORS if a NO WATER alarm is also present. Troubleshoot a NO

3. Do not concern yourself with a TEMPERATURE problem if a FLOW ERROR is also present. Flow errors

4. Do not concern yourself with CONDUCTIVITY problems if a TEMPERATURE problem is also present.

5. Do not concern yourself with a TMP problem if other hydraulic alarms (i.e. conductivity, temperature, flow)

6. Do not concern yourself with a BLOOD LEAK problem if other hydraulic alarms (i.e. conductivity,

CAUTION! Before placing the machine back into service always perform FINAL CHECKS (p

nt if someone has been working on the machine before you!

hydraulic alarms.

WATER alarm first and the FLOW ERROR will probably clear itself.

turn the heater off. Troubleshoot the FLOW ERROR first and the TEMPERATURE problem will probably

clear itself.

Conductivity is temperature compensated. Troubleshoot TEMPERATURE problems first and a

CONDUCTIVITY problem will probably clear itself.

are also present. Troubleshoot other hydraulic problems first and the TMP problem will probably clear.

temperature, flow) are also present. Troubleshoot other hydraulic problems first and the BLOOD LEAK

problem will probably clear.

age 4).

Page 2

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 11

INITIAL CHECKS

1. If the electronic card cage has been previously moved from the cabinet:

Check that all five boards are pushed down into the motherboard and locked in place.

Check that the power logic board cable is plugged in.

Check that the power cable is plugged into the power connector (see Figure 3 below).

Check that the sensor and actuator cables (see Figure 3 below) are plugged into the distribution board.

2.

Check that the PGND (power ground) wire is plugged into the distribution board (see Figure 4 below). A

3.

loose PGND cau

4. Check cables for worn insulation (bare wires) or other signs of damage (like screw holes). Replace if

damaged.

5. NEVER troubleshoot with the card cage open!

ses unpredictable symptoms.

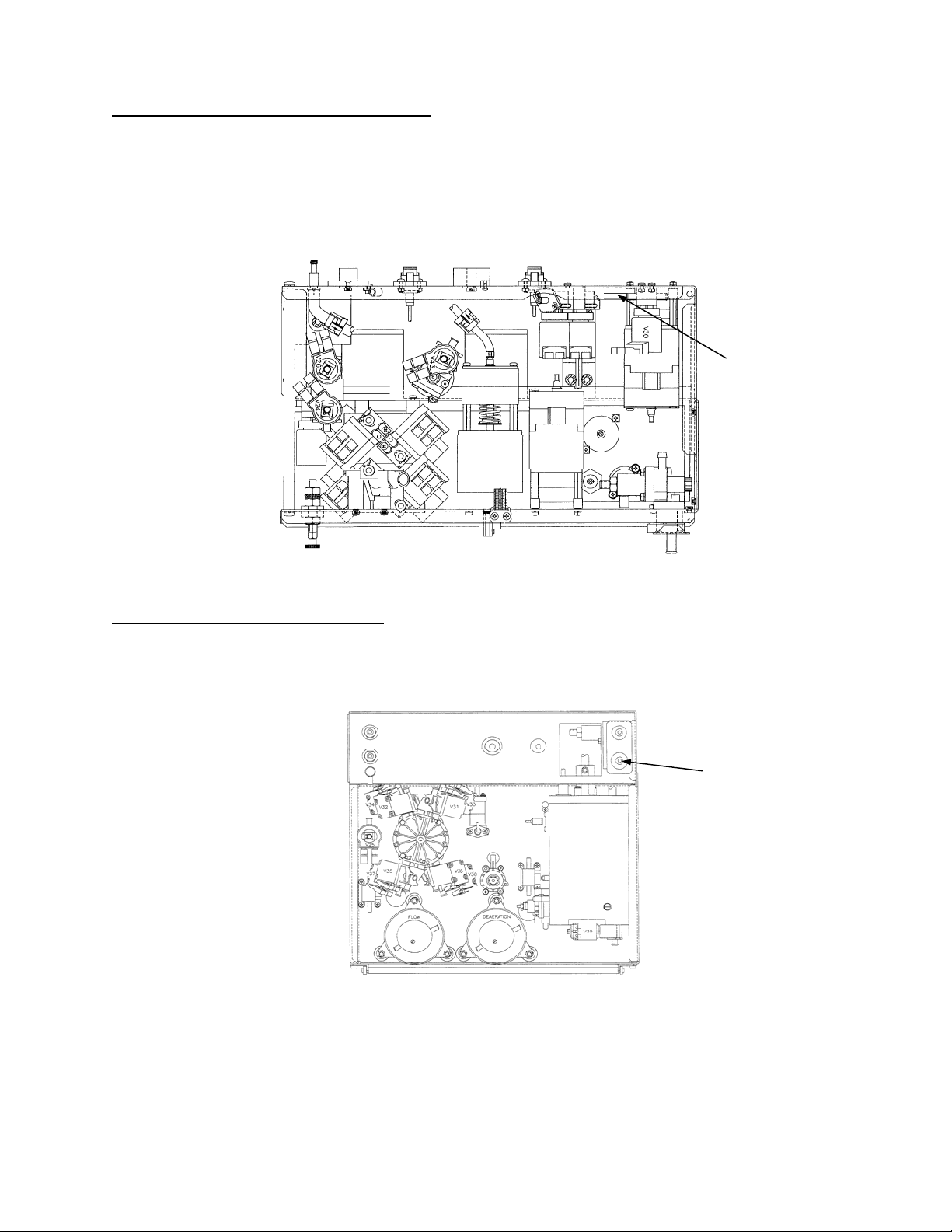

ACTUATOR CABLE SENSOR CABLE

POWER CONNECTOR

MOTHER BOARD

POWER LOGIC

CABLE

Figure 3 – Card Cage (Top View)

SENSORS CONNECTOR ACTUATOR CONNECTOR PGND WIRE

Figure 4 – Distribution Board

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 3

Page 12

FINAL CHECKS

Before placing the machine back into service:

1. Remove all troubleshooting equipment (jumpers, 'dummy' connectors, etc) from the distribution board and

make sure that all hydraulic components are plugged in properly.

2. If you were troubleshooting FILLING PROGRAMS or FLOW ERRORS make sure that the female

connectors on chamber #69 are plugged in properly (brown wire on top).

3. Turn the heater breaker switch off. Allow eight minutes and assure that the Temperature display falls to

less than 30 and that the machine goes into bypass (valve #24 closes, no flow through the external

indicator).

4. Drop the acid and bicarbonate lines into water. Allow eight minutes and assure that the Conductivity

display falls to 10.0 mS/cm and that the machine goes into bypass (no flow through the external

indicator).

5. Check that AUDIO ALARMS are working properly.

6. IMPORTANT! Perform alarm and pressure holding tests. Do NOT place the machine back into service

until all tests have pass.

EQUIPMENT NEEDED

- Fresenius gauge kit (part # 150034)

- Fresenius test (temperature) 'dummy connectors' (part # 190060)

- 60 ml syringe

- Flashlight

- Jumper wire

- Independently calibrated temperature, conductivity, and pressure meters

- Voltmeter

- Fluke TP80 meter probes. These probes have a slip-on cap that fits over the lead to 'isolate' the

measuring point and assures safe voltage measurements in ‘tight’ areas when shorting other pins or

connectors is a concern.

Page 4

Figure 5 - Fluke TP80 Meter Probes (with slip on cap)

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 13

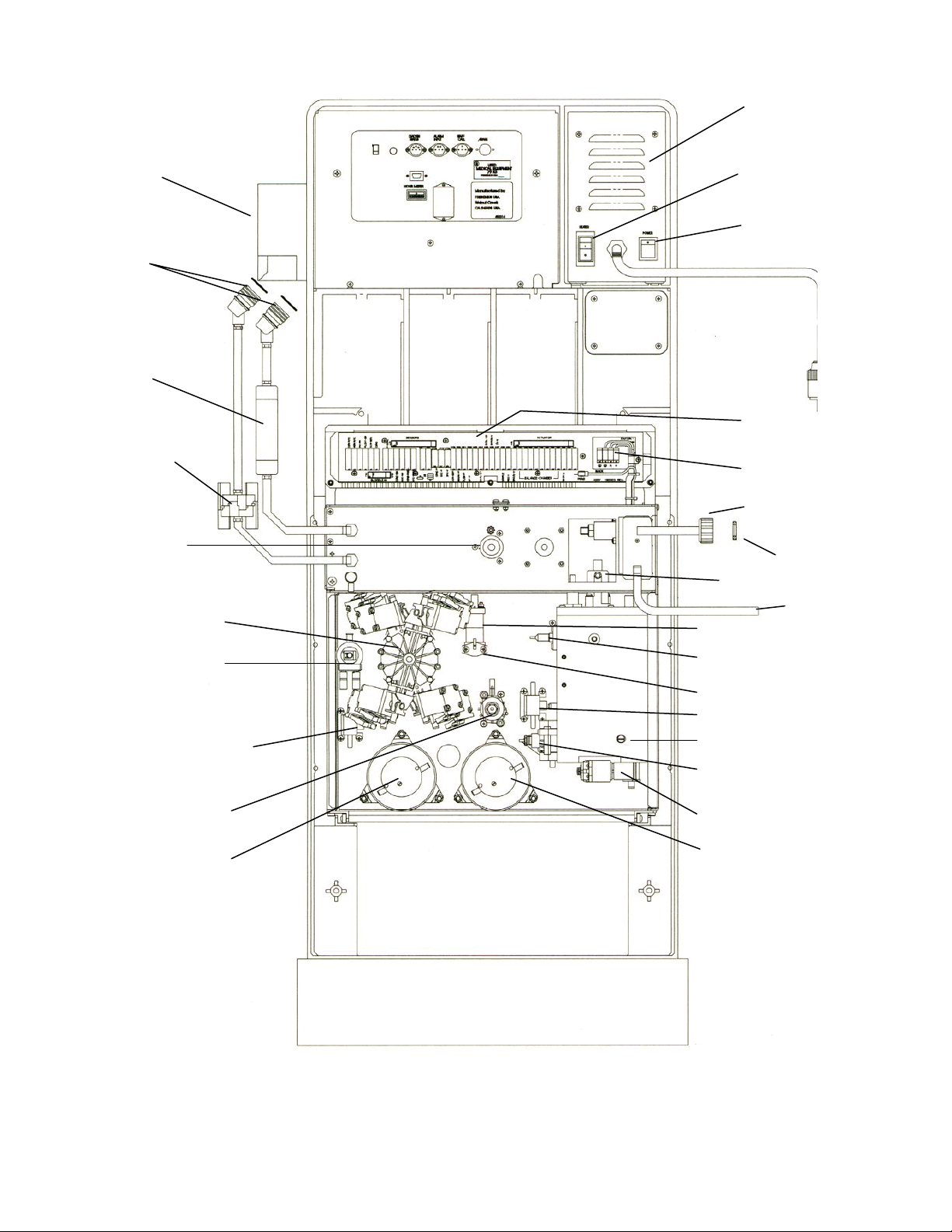

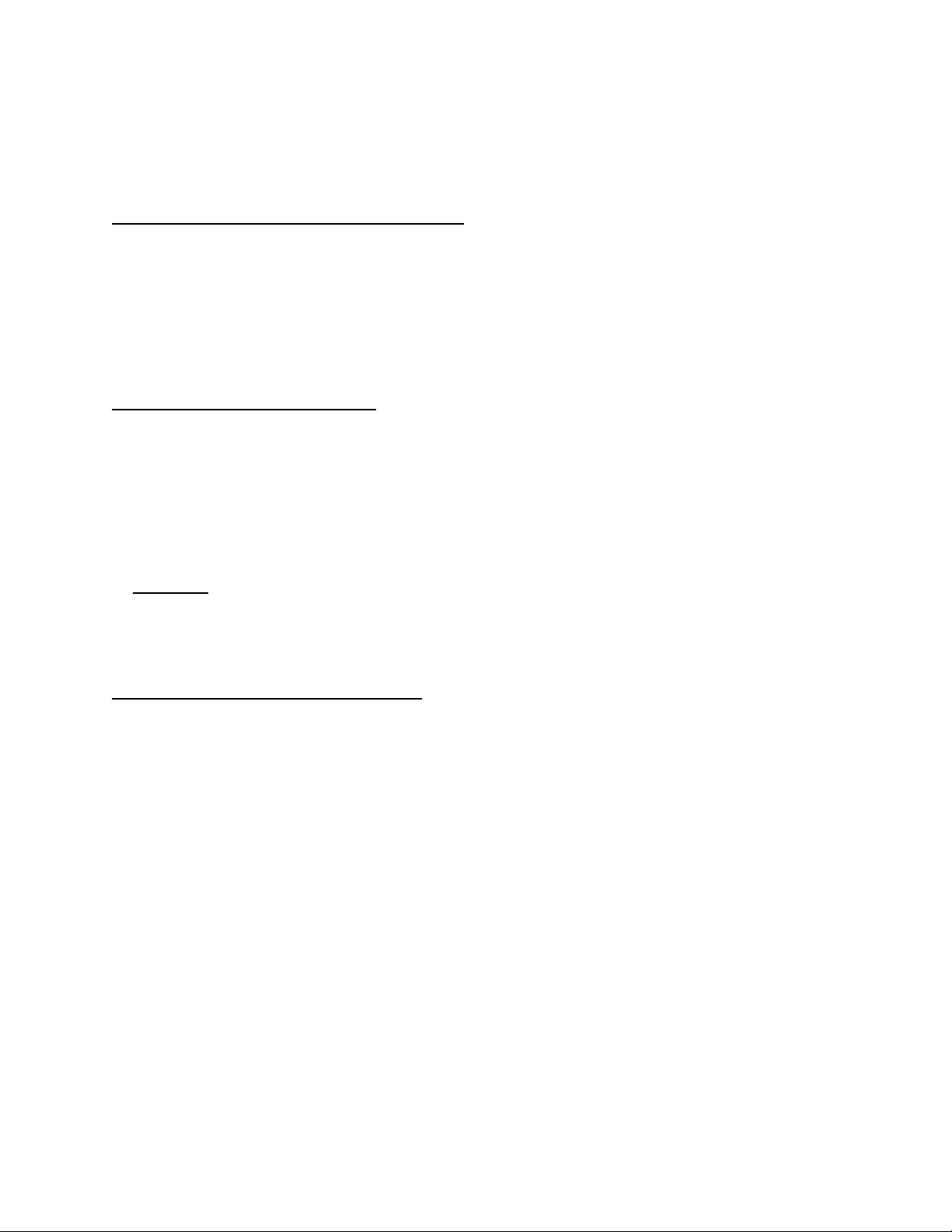

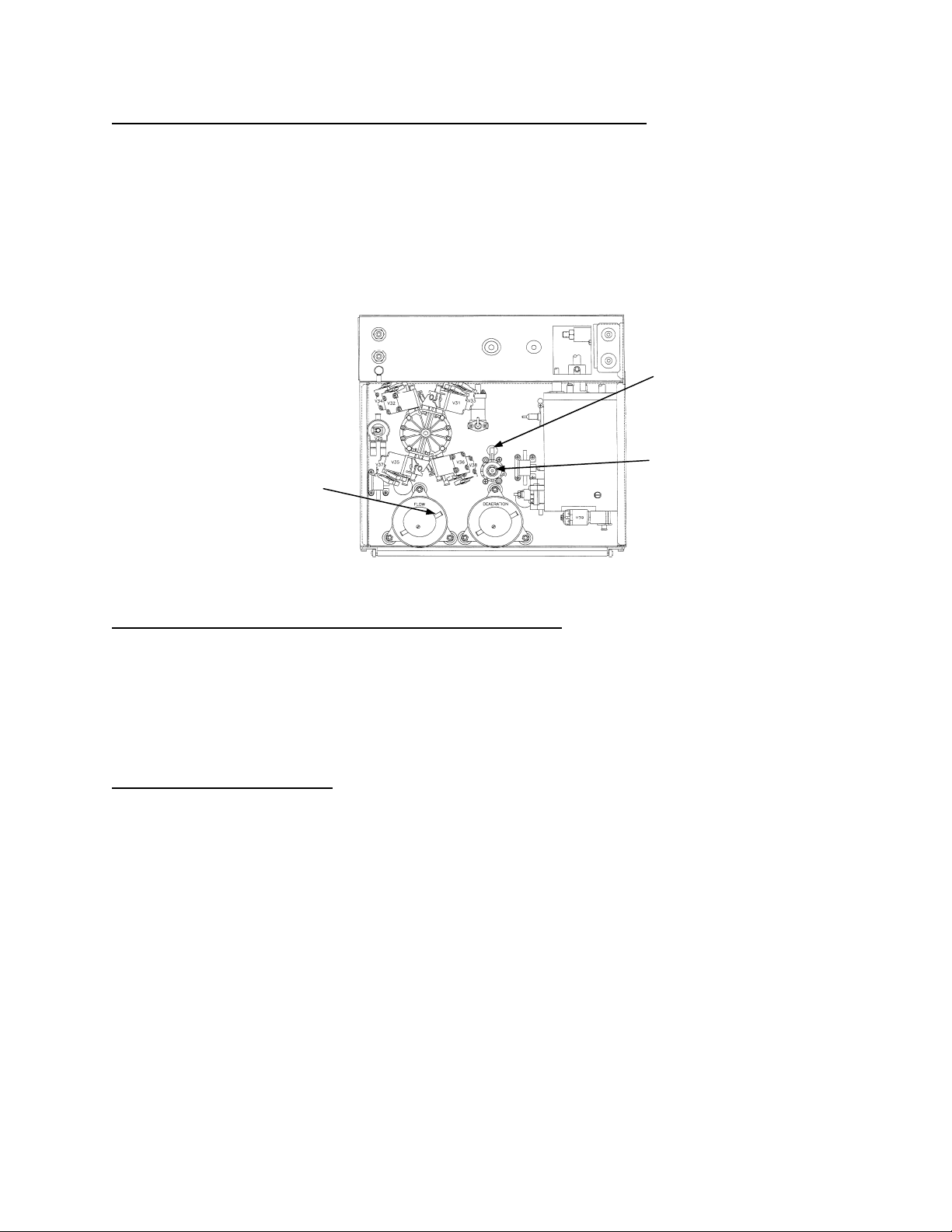

POWER SUPPLY

SHUNT DOOR

DIALYZER QUICK

CONNECTORS

EXTERNAL FLOW

INDICATOR #75

DIALYSATE LINE

FILTER #73

UF PUMP #22

BALANCING

CHAMBER #68

HEATER BREAKER

SWITCH

ON/OFF SWITCH

DISTRIBUTION BOARD

(INSIDE COVER)

HEATER

CONNECTOR

INPUT WATER

FILTER

FILTER

VENT LINE

DRAIN LINE

CONDUCTIVITY CELL #7

VALVE #25

Note: On Later version,

Valve 25 may be on the

front side of hydraulics

DIALYSATE PRESSURE

TRANSDUCER #9

REGULATOR #78

FLOW PUMP #21

NTC #2

NTC #3

CFS TRANSDUCER #10

ORIFICE #48

LOADING PRESSURE

REGULATOR #65

VALVE 39

DEAERATION PUMP #20

Figure 6 – Machine Rear View

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 5

Page 14

SECTION 1 - FLOW ERRORS IN DIALYZE MODE

F- 1.0.0 CHECK LOADING PRESSURE

a) Assure that the vent tubing (back of machine) is not 'pinched' (see Figure 6, page 5).

b)

Assure that dialysate flow is on (flow on/off LED off).

1

TIGHTLY insert a 2loading pressure gauge into the red ACETATE/ACID port. Proceed accordingly:

c)

0 to 10 psi. See F- 15.0.0, LOW LOADING PRESSURE (pa

ge 19).

10 to 17 psi. Calibrate loading pressure per CALIBRATION PROCEDURES. If

unsuccessful, the loading pressure regulator #65 (see Figure 6, page 5)

may be bad.

18 to 25 psi. See F- 2.0.0

Greater than 25 psi Calibrate loading pressure per CALIBRATION PROCEDURES. If

unsuccessful the loading pressure regulator #65 (see Figure 6, page 5)

may be bad.

1

If the gauge is not in the port correctly you will always read low pressure!

2

If the gauge does not read 0 psi at atmosphere compensate for this when reading it.

F- 2.0.0 CHECK DEBUG ERRORS (NO WATER AND FLOW ERROR)

a) Lift the shunt door to force bypass (bypass LED on). This should be done even if the machine is already in

bypass!

NOTE Unless instructed do NOT

try to reset alarms while troubleshooting flow errors.

b) Call debug screen 0. Intermittent problems are easily missed with a ‘quick look’ so watch for two minutes

or

until you see either a NO WATER alarm or a flow error (FLOW ERROR = “1”). Proceed accordingly:

NO WATER alarm (intermittent or constant). See SECTION 2 - NO WATER (p

age 24).

FLOW ERROR = “0” (constant). See F- 2.0.1

Page 6

FLOW ERROR = “1” (intermittent or constant). See F- 3.0.0

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 15

Section 1 – Flow Errors in Dialyze Mode

F- 2.0.1 FLOW ERROR NOT INDICATED (FLOW ERROR = “0”)

a) Leaving the shunt door open push the blue HOME screen button to return to the Home screen. Allow

Temperature and Conductivity to come out of alarm state.

NOTE: If the Temperature or Conductivity windows (in the main screen) are RED an alarm is present.

When alarms clear the windows turn yellow.

NOTE: Conductivity alarm limits can be adjusted: 1) Push the Conductivity data button to go to the

Dialysate screen. Select either Alarm Position or Alarm Width by pushing the appropriate blue

screen button 2) Adjust the limits using the UP or DOWN arrow keys. 3) Push the CONFIRM key.

4) Push the blue HOME screen button to return to the Home screen.

NOTE: If Temperature and Conductivity alarms do not clear and you are sure that FLOW ERROR = “0”

constant do NOT continue troubleshooting flow errors!

b) Close the shunt door. Assure that the machine is ‘out of bypass’ (bypass LED turns off). Is there flow

through the external flow indicator (is the bob rising)?

Yes See F- 2.0.2

See F- 14.0.0, TROUBLESHOOTING FLOW ERRORS ‘OUT OF B

No

F- 2.0.2 CHECK FLOW ERROR ‘OUT OF BYPASS’

YPASS’ (page 18).

Call debug screen 0. Intermittent problems are easily missed with a ‘quick look’ so watch FLOW ERROR for

five minutes

or until you see FLOW ERROR = “1”. Proceed accordingly:

FLOW ERROR = “0” (constant). Stop here! A flow error is not present.

FLOW ERROR = “1” (intermittent or constant). See F- 14.0.0, TROUBLESHOOTING FLOW

ERRORS ‘OUT OF BYPASS’ (page 18).

F- 3.0.0 CHECK FOR FILLING PROGRAM

Call debug screen 1. FILACT = "1"?

Yes Proceed to SECTION 8 - FILLING PROGRAM PROBLEMS (pag

e 64)

No See F- 4.0.0

F- 4.0.0 CHECK FOR A VALVE ERROR (VERR)

NOTE: Valve errors are caused by electrical current problems in a ‘valve circuit’. If present, VERR (debug

screen 1) increases (to a maximum of 255). If not present VERR remains 0.

Call debug screen 1. VERR is in the lower right corner. Is VERR = “0”?

Yes See F- 4.0.1

No

NOTE that you are in DIALYSIS program and proceed to TROUBLESHOOTING VALVE

ERRO

RS (page 31)

F- 4.0.1 CHECK FLOW ERROR “IN BYPASS”

Open the shunt door to cause bypass. Go to debug screen 0 and watch Flow Error for one minute. Does

Flow Error remain “0” constantly or does it still = “1” (either constant or intermittent)?

“0” constant See F- 2.0.2

Still = “1”

Close the shunt door and see F- 5.0.0

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 7

Page 16

Section 1 – Flow Errors in Dialyze Mode

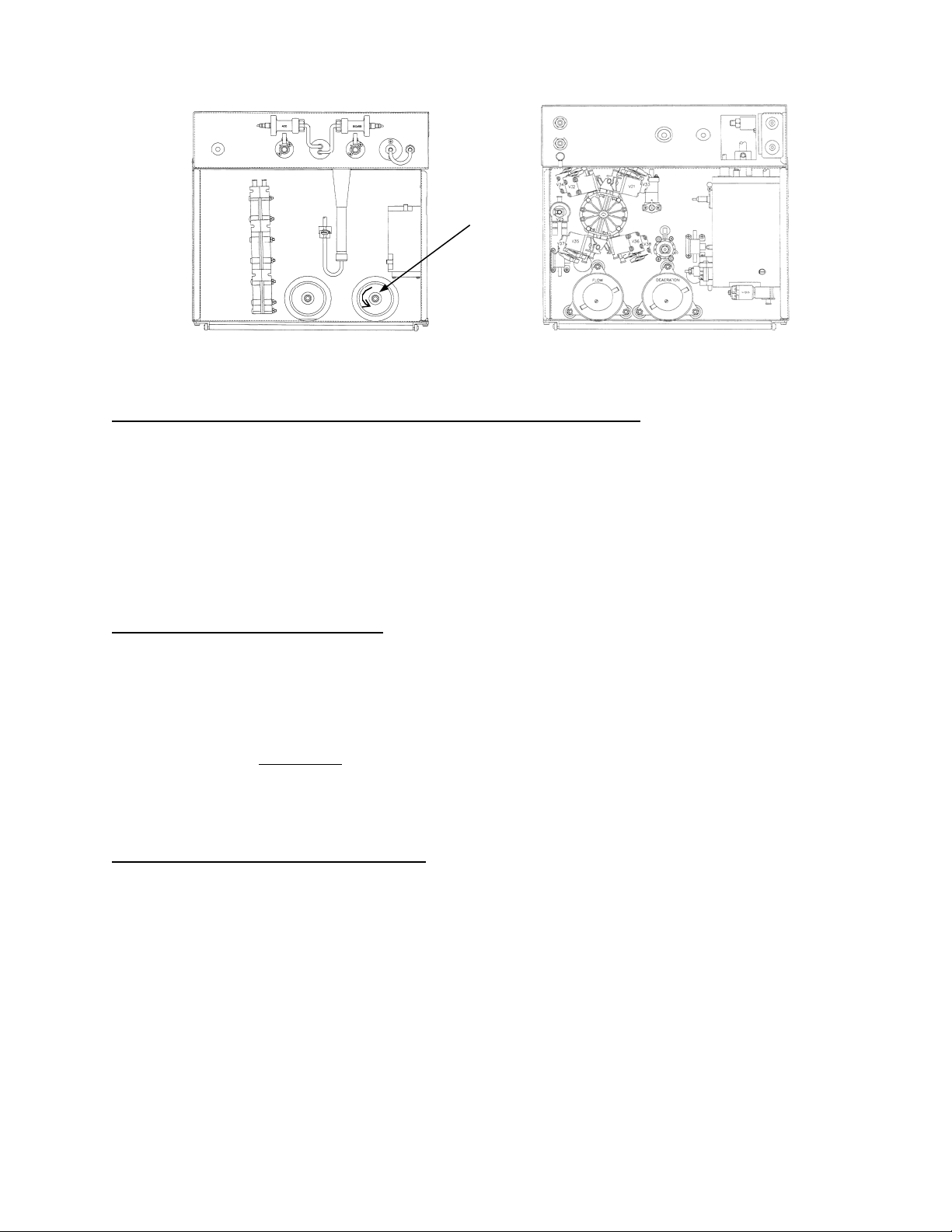

F- 5.0.0 CHECK FOR A RUNNING FLOW MOTOR

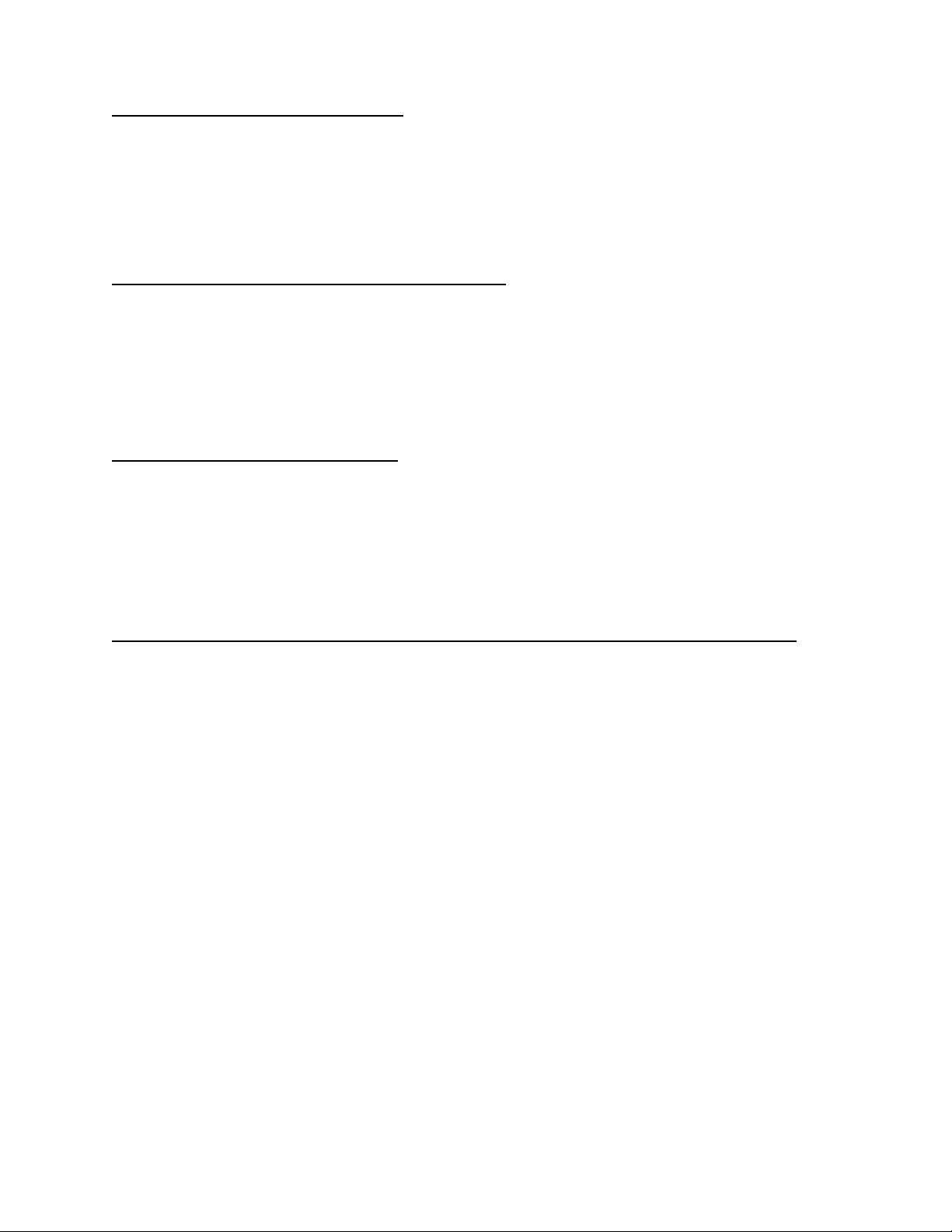

The flow pump’s motor shaft can be viewed from the front of the hydraulics (see Figure 7). Is the shaft

rotating count

er-clockwise (viewed from the FRONT!)?

Yes See F- 6.0.0

See TROUBLESHOOTING MOTORS (p

No

age 23) to check the FLOW MOTOR.

FLOW

MOTOR SHAFT

Figure 7 – Hydraulics (Front View)

F- 6.0.0 CHECK FLOW PUMP CONTROL

Turn dialysate flow off (flow on/off LED on) and check the flow pump's motor shaft again. Still rotating?

Yes Replace the actuator board (shorted driver).

No See F- 7.0.0

F- 7.0.0 DETERMINE DRAIN FLOW

Normal Fresenius flow 'pulses' in 30 ml (approximately) increments when the balancing chamber valves cycle

and ‘stops completely’ in between. Determine flow ‘type’ as defined below:

Normal: 30 ml - Stops completely - 30 ml - Stops completely – etc

Abnormal: Continuous flow (never stops, i.e. cannot distinguish 30 ml increments)

OR

30 ml – continuous – 30 ml – stops completely - etc

None: No drain output

a) IMPORTANT: Turn dialysate flow on (flow on/off LED off).

b) Go to end of the drain tubing. Hold the tubing so that the opening is pointed UPWARD!

(at about 45

degrees). CAUTION!! If the opening is held DOWNWARD this test is invalid.

c) Watch drain flow for 30 seconds. Proceed accordingly:

Normal: See F- 8.0.0 (page 12)

Abnorm

al or None: See F- 7.0.1

Page 8

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 17

Section 1 – Flow Errors in Dialyze Mode

F- 7.0.1 CHECK (DRAIN) VALVE #30 INPUT

a) Turn dialysate flow off (flow on/off LED on) and remove (drain) valve 30’s INPUT tubing (see Figure 8).

Point the tubing’s o

utput AWAY from the hydraulics! Have a bucket ready to catch any output.

b) Turn dialysate flow on (flow on/off LED off). Proceed accordingly:

Normal: See F- 7.0.2

Abnorm

al or None: See F- 7.0.3

VALVE 30

INPUT

TUBING

Figure 8 – Hydraulics (Top View)

F- 7.0.2 CHECK VALVE #30 OUTPUT

a) Turn flow off (flow on/off LED on) and reconnect the tubing to valve 30.

b) Remove the tubing from bottom (drain) port at the rear of the machine (see Figure 9). Have a bucket ready

to c

atch any output.

Figure 9 - Hydraulics (Rear View)

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

DRAIN PORT

Page 9

Page 18

Section 1 – Flow Errors in Dialyze Mode

c) Turn flow on (flow on/off LED off). Proceed accordingly:

Normal: The drain tubing or the drain itself is restricted. Locate and repair.

Abnormal or None: A problem is indicated with the actuator board or VALVE 30. NOTE this

and proceed to TROUBLESHOOTING VALVES (page 30).

F- 7.0.3 CHECK FILLING PROGRAM FUNCTION

a) Unplug the air sensor connector from distribution board position x6, AIR-SEN.

b) Wait 30 seconds and call debug screen 1. Does FILACT = “1”?

Yes A) Plug the connector back into the distribution board (position x6, AIR_SEN), allow

30 seconds, and assure that FILACT = “0”; B) See F– 7.0.4

No

Using a flashlight, check inside the distribution board for ‘white’ corrosion (indicative of

spillage). If no corrosion, two possibilities: 1) Bad sensor board; 2) Bad function board.

F- 7.0.4 CHECK ‘IN BYPASS’ FLOW

For this procedure a bucket 1/2 filled with water is needed.

a) Plug the acid and bicarbonate concentrate connectors into their ports. The screen returns to the SELECT

PROGRAM screen.

b) Reconnect the tubing to valve 30.

c) Place the machine into RINSE.

d) Open the shunt door (COVER OPEN message) and remove both quick connectors. Drop the RED quick

connector into the bucket. Hold the BLUE quick connector over the bucket such that the opening is held

UPWARD!

(at about 45 degrees). CAUTION!! If the opening is held DOWNWARD this test is invalid.

e) IMPORTANT leave the shunt door open!

f) Watch flow here for 30 seconds and NOTE flow ‘type’ (Normal, Abnormal, None) for later use. Proceed to

step F- 7.0.5

®

F- 7.0.5 DETERMINING DIASAFE

The DIASAFE

®

filter looks like a dialyzer that is mounted in the bottom compartment under the hydraulics.

FILTER

Also, there is a ‘test valve’ on the rear panel.

a) Unplug the acid connector from its port to INTERRUPT rinse then plug it back in.

b) Place the quick connectors back into the shunt and close the door.

®

c) Does this machine have a DIASAFE

filter?

Yes See F- 7.0.6

No

See F- 7.0.8

Page 10

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 19

Section 1 – Flow Errors in Dialyze Mode

®

F- 7.0.6 CHECK THE DIASAFE

a) If the DIASAFE

®

filter and its quick connector o-rings have not been replaced in the last 90 days do so now

and see F- 7.0.7. If it has been repla

FILTER

ced see part b.

b) Assure that the ‘test valve’ is set in DIALYZE position. If not, set it there, and see F– 7.0.7. If already in

DIALYZE position see p

c) Check for tubing restrictions at the DIASAFE

art c

®

filter. Clear all restrictions and see F- 7.0.7. If not restricted

see step F- 7.0.8

F- 7.0.7 TROUBLESHOOTING THE DIASAFE

®

FILTER

a) Return to the SELECT PROGRAM screen by reconnecting the acid and bicarbonate concentrate

connectors to their ports on the front of the machine.

b) Place the machine into RINSE for three minutes.

c) Remove the acid and bicarbonate concentrate connectors from their ports and plug them back into

concentrate.

®

d) If the DIASAFE

F- 7.0.8 DETERMINE FLOW PROBLEM

As noted, in step F- 7.0.4 a

filter was the problem the flow error will clear. Return to step F- 2.0.0.

bove, was flow through the BLUE quick connector:

Normal: A problem is indicated with the actuator board or VALVE 26. NOTE this and proceed

to TROUBLESHOOTING VALVES (page 30).

Abnorm

None: Possibly two balancing chamber valves stuck closed! Try replacing the actuator

al: See F- 7.0.9

board.

F- 7.0.9 CHECK BALANCING CHAMBER VALVES AND BALANCING

CHAMBER DIAPHRAGM

Perform SECTION 18 - MANUAL BALANCING CHAMBER VALVE LEAK TESTS (page 92) on the balancing

cham

ber valves (V31 through V38). Did the leak test indicate a leaking valve?

Yes See F- 7.1.1

Possible leaking balancing chamber diaphragm. Perform SECTION 19 - TESTING FOR A

No

LEAKING BALANCI

NG CHAMBER DIAPHRAGM (page 96).

Fresenius 2008K Troubleshooting Guide

Page 11

P/N 507298 Rev. C

Page 20

Section 1 – Flow Errors in Dialyze Mode

F- 7.1.1 CHECK FOR A SHORTED VALVE DRIVER

a) Unplug the indicated leaking valve from the distribution board (see Figure 10 below). Using a flashlight,

che

ck inside the distribution board, for ‘white corrosion’ (indicative of spillage).

b) If no corrosion: measure volts dc, inside the distribution board, BETWEEN male pins 1 and 5 (top and

bottom). Place the red lead at pin 5 (bottom). Greater than one volt?

Yes Replace the actuator board (shorted driver).

No Replace the indicated leaking balancing chamber valve.

BALANCING CHAMBER

VALVE POSITIONS

Figure 10 – Distribution Board

F- 8.0.0 CHECK CFS TRANSDUCER SIGNAL (ACFS)

Call debug screen 0. Intermittent problems are easily missed with a ‘quick look’ so watch ACFS (in volts) for

two minutes

or until you have determined the symptom. Proceed accordingly:

ACFS remaining between 3.0 and 7.0. See F- 9.0.0 (page 13)

ACFS remaining between 7.0 and 12. See F- 10.0.0 (page 14*)

ACFS remaining between 0 and 3.0. See F- 11.0.0 (page 14)

ACFS cycling from about 4 (4.0 to 5.5) to about 2 (0 to 3.0). See F- 13.0.0 (p

ACFS intermittently going to between 7 and 12. See F- 10.0.0 (pa

ge 14)

age 17).

Page 12

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 21

Section 1 – Flow Errors in Dialyze Mode

F- 9.0.0 ACFS BETWEEN 3.0 AND 7.0 - CHE

CK FLOW PUMP PRESSURE

The CFS signal is not switching the balancing chambers properly.

a) Turn dialysate flow off and tee a psi gauge between the flow pump's output nozzle and the WHITE tubing

(see Figure 11 below, for gauge location).

Turn the dialysate flow on (flow on/off LED off) and set to 500 ml/min. Does pressure peak to 14 psi or

b)

greater?

Yes See F- 9.0.2

See F- 9.0.1

No

CLAMP HERE

REGULATOR #78

FLOW PUMP

OUTPUT

Figure 11 - Hydraulics (Rear View)

F- 9.0.1 CHECK FLOW RELIEF PRESSURE REGULATOR #78

With a metal hemostat TIGHTLY clamp regulator #78 at the location specified in the Figure 11 above. Does

flow pump p

F- 9.0.2 CHECK CFS CIRCUIT

a) Unplug the CFS transducer from distribution board position CFS. Using a flashlight, check inside the

distribution board, for ‘white’ corrosion (indicative of spillage).

b) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken male

pins.

c) If all pins are okay: is ACFS between 7.0 and 10?

ressure peak to 14 psi or greater now?

Yes Calibrate FLOW RELIEF PRESSURE per CALIBRATION PROCEDURES. If unsuccessful

regulator #78 may be malfunctioning.

No Three possibilities: 1) Bad actuator board; 2) Bad flow pump head; 3) Bad flow pump motor

Yes See F- 9.0.3

See F- 12.0.0 (page 16)

No

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 13

Page 22

Section 1 – Flow Errors in Dialyze Mode

F- 9.0.3 CHECK SENSOR BOARD CABLE

a) Plug the CFS transducer back into the distribution board.

If ACFS remains between 7 and 10 make sure that you have plugged in properly.

If ACFS starts cycling from about 4 (4.0 to 5.5) to about 2 (0 to 3.0) and if the flow error is still

present return to F- 2.0.0

b)

Have you tried calibrating FLOW RELIEF PRESSURE during this troubleshooting session?

Yes Three possibilities: 1) Bad CFS transducer (see Figure 6, page 5); 2) Bad flow pump head;

3) Bad flow m

otor (try new brushes)

No Try calibration FLOW RELIEF PRESSURE per CALIBRATION PROCEDURES and return to

F- 2.0.0. If F

F- 10.0.0 ACFS BETWEEN 7.0 AND 10 – CHECK CFS CIRCUIT

LOW RELIEF PRESSURE was the problem, the flow error will clear.

The CFS transducer is acting ‘open’.

a) Unplug the CFS transducer from distribution board position CFS. Using a flashlight, check inside the

distribution board connector for ‘white’ corrosion (indicative of spillage).

b) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

c) If all pins are okay: plug the 34degree temperature ‘dummy connector’ into distribution board position CFS

(this simulates a good transducer). From debug screen 0, does ACFS go to 0?

Yes See F- 10.0.1

Possible: 1)

No

1

The sensor board cable can be checked for continuity. Note that you are checking CFS TRANSDUCER

connections and proceed to SECTION 17 - CHECKING SENSOR BOARD CABLE (pag

F- 10.0.1 CHECK CFS TRANSDUCER

1

Bad sensor board cable; 2) Bad sensor board; 3) Bad actuator board

e 90).

Plug the CFS transducer back into the distribution board. Does ACFS start cycling from about 4 (4.0 to 5.5)

to about 2 (0 to 3.0)?

Yes The CFS transducer seems to be working okay. Return to F- 2.0.0 but if you return he

re

replace the CFS transducer (see Figure 6, page 5)

Bad CFS transducer (see Figure 6, page 5).

No

F- 11.0.0 ACFS BETWEEN 0 AND 3.0 – CHECK FLOW PUMP ‘DEAD HEAD’

The CFS transducer is acting ‘shorted’.

Turn dialysate flow off (flow on/off LED on). Is ACFS between 4.0 and 7.0?

Yes The CFS transducer is good! Return to F- 2.0.0.

No

See F- 11.0.1

Page 14

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 23

Section 1 – Flow Errors in Dialyze Mode

F- 11.0.1 CHECK CFS CIRCUIT

a) Unplug the CFS transducer from distribution board position CFS. Using a flashlight, check inside the

distribution board for ‘white’ corrosion (indicative of spillage).

b) If corrosion not present: Inside the distribution board there should be five male pins. Check for bent or

broken male pins.

c) If all five pins are okay: is ACFS between 7.0 and 10?

Yes See F- 11.0.3

See F- 12.0.0

No

F- 11.0.3 CHECK FOR A LEAKING BALANCING CHAMBER VALVE

a) Plug the CFS transducer back into the distribution board. If ACFS remains between 7 and 12 make sure

that you have plugged the transducer in properly.

b) Turn dialysate flow on (flow on/off LED off).

c) Push the blue HOME screen button to return to the main dialysis screen. Does the digital TMP reading

have positive (+) sign (example +220 mmHg)?

Yes See F- 11.0.4

Replace the CFS transducer (see Figure 6, page 5).

No

NOTE: TMP readin

gs with no sign (example 220 mmHg) indicates that venous pressure is greater than

dialysate pressure. If TMP readings have a positive sign (example +220 mmHg) dialysate pressure is greater

than venous pressure.

F- 11.0.4 CHECK FOR (+) POSITIVE TMP

a) Push and release the RESET key. The message "RESET TO ADJUST TMP" appears.

b) Immediately push and HOLD the RESET key. After the "ADJUSTING TMP" message is gone does TMP

return to a positive (+) value or remain relatively stable?

Returns positive (+) See F- 11.0.5

ns stable Replace the CFS transducer (see Figure 6, page 5).

Remai

F- 11.0.5 CHECKING BALANCING CHAMBER VALVES

Perform SECTION 18 - MANUAL BALANCING CHAMBER VALVE LEAK TESTS (page 92) on the balancing

cham

ber valves (V31 through V38). Did the leak test indicate a leaking valve?

Yes See F- 11.0.6.

Replace the CFS transducer (see Figure 6, page 5).

No

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 15

Page 24

Section 1 – Flow Errors in Dialyze Mode

F- 11.0.6 CHECK FOR A SHORTED VALVE DRIVER

Remain in DIAGNOSTICS for this procedure.

a) Unplug the NOTED leaking balancing chamber valve from the distribution board. Using a flashlight, check

inside the distribution board for ‘white’ corrosion (indicative of spillage).

b) Measure volts dc, inside the distribution board, BETWEEN male pins 1 (top) and 5 (bottom). Place the

meter’s red lead at pin 5. Greater than one volt?

Yes Replace the actuator board (shorted driver).

No Replace the NOTED leaking balancing chamber valve

F- 12.0.0 CHECK SENSOR BOARD CABLE

a) Turn the power off, slide the electronic card cage out, and unplug the sensor board’s ribbon cable (see

Figure 3, page 3).

b)

Check, inside the sensor board connector, for bent or broken male pins.

c) If pins are okay: leaving the cable unplugged, turn the power on.

d) Return to debug screen 0. Ignore all alarms! Is ACFS between 7.0 and 10?

Yes A) Unplug the sensor board ribbon cable from the distribution board SENSORS connector

(see Figure 12 below); B) Using a flashlight, che

ck inside the distribution board’s SENSORS

connector for ‘white’ corrosion (indicative of spillage) and for bent or broken male pins; C) If

no corrosion and all pins are okay: replace the sensor board ribbon cable.

No Possible: 1) Bad sensor board; 2) Bad actuator board.

Page 16

Figure 12 – Distribution Board

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

BALANCING CHAMBER

VALVE POSITIONS

Page 25

Section 1 – Flow Errors in Dialyze Mode

Figure 13 - Hydraulics (Rear View)

F- 13.0.0 ACFS CYCLING - CHECK BALANCING CHAMBER VALVES (STUCK CLOSED)

a) Assure that all balancing chamber valves are plugged into the distribution board at their proper position (see

Figure 12, page 16 and Figure 13 above).

b)

IMPORTANT: Set dialysate flow rate to 500 ml/min.

NOTE: Flow errors caused by a balancing chamber valve not opening are predictably cyclic.

c) Call debug screen 0 and watch ACFS for one minute

where it remains for 3 seconds to about 2 volts (0 to 2.8 volts) where it remains for ten seconds?

Yes A balancing chamber valve is not opening. See F- 13.0.1

No

F- 13.0.1 CHECK THE ACTUATOR BOARD

Return to step F- 2.0.0

Have you already tried replacing the actuator board during this troubleshooting session?

Yes See F- 13.0.2

No

Try replacing the actuator board and return to F- 2.0.0.

the flow error will clear.

. Is ACFS cycling from about 4 volts (4.0 to 5.5 volts)

If the actuator board is the problem

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 17

Page 26

Section 1 – Flow Errors in Dialyze Mode

F- 13.0.2 TROUBLESHOOTING A ‘MECHANICALLY’ CLOSED BALANCING CHAMBER VALVE

a) Using a metal hemostat tightly clamp balancing chamber valve #35 as close to the valve as you can. From

the rear valve #35 is in the lower, left side (see Figure 13, page 17).

b)

Wait 30 seconds. From debug screen 0 does ACFS remain between 0 and 2.8 and FLOW ERROR = “1”

constant?

Yes Valve #33 or #34 or #37 or #38 is not opening.

No Flow Error remains intermittent: Valve #31 or #32 or #35 or #36 is not opening.

F- 14.0.0 TROUBLESHOOTING FLOW ERRORS 'OUT OF BYPASS'

A restriction is indicated in the 'out of bypass' circuit, which includes the *DIASAFE

®

filter (if present), external

dialysate filter #73, valve #24 and valve #25.

®

*The DIASAFE

filter looks like a dialyzer that is mounted in the bottom compartment under the hydraulics.

Also, there is a ‘test valve’ on the rear panel

Normal Fresenius flow pulses in 30 ml (±1ml) increments when the balancing chamber valves cycle and

‘stops completely’ in between. During the following procedure determine flow ‘type’ as defined below:

Normal: 30 ml - Stops completely - 30 ml - Stops completely – etc

Abnormal: Continuous flow (never stops, i.e. cannot distinguish 30 ml increments)

None: No output

®

F- 14.0.1 CHECK V24 AND THE DIASAFE

FILTER (IF PRESENT)

a) Plug the acid and bicarbonate concentrate connectors into their ports. The machine returns to the SELECT

PROGRAM screen.

b) Place the machine into RINSE. Have a bucket ready to catch any output.

c) With a bucket ready to catch any output, open the shunt door (COVER OPEN message) and remove the

RED quick connector.

d) IMPORTANT Leave the door open! There should be flow through the shunt door port. Proceed accordingly:

®

Normal: See F- 14.0.2 (valve #24 and the DIASAFE

filter (if present) are okay)

Abnormal or None: See F- 14.0.3

F- 14.0.2 CHECK EXTERNAL DIALYSATE FILTER #73

a) Unplug the acid connector from its port to INTERRUPT rinse then plug it back in.

b) Place the quick connectors back into the shunt and close the door.

c) Check the external dialysate filter #73 (see Figure 6, page 5) for restrictions.

If filter #73 is okay: a problem is indicated with the actuator board or VALVE 25. NOTE this and proceed to

d)

TROUBLESHOOTING VALVES (page 30).

Page 18

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 27

Section 1 – Flow Errors in Dialyze Mode

®

F- 14.0.3 CHECK V24 AND THE DIASAFE

FILTER

a) Unplug the acid connector from its port to INTERRUPT rinse then plug it back in.

b) Place the quick connectors back into the shunt and close the door.

®

c) Does this machine have the DIASAFE

filter?

Yes See F- 14.0.4

No

A problem is indicated with the actuator board, actuator cable, or VALVE 24. NOTE this and

proceed to TROUBLESHOOTING VALVES (page 30).

F- 14.0.4 CHECK DIASAFE

a) If the DIASAFE

®

filter and its quick connector o-rings have not been replaced in the last 90 days do so now

and see F- 14.0.5. If

®

FILTER

it has been replaced, proceed to part b.

b) Assure that the ‘test valve’ is set in DIALYZE position. If not set it there and see F- 14.0.5. If already set i

DIALYZE position proceed to part c.

®

c) Check for tubing restrictions at the DIASAFE

filter. Clear all restrictions and see F- 14.0.5. If not restricted

proceed to part d.

d) A problem is indicated with the actuator board or VALVE 24. NOTE this and proceed to

TROUBLESHOOTING VALVES (page 30).

®

F- 14.0.5 TROUBLESHOOTING THE DIASAFE

FILTER

a) Return to the SELECT PROGRAM screen by reconnecting the acid and bicarbonate concentrate

connectors to their ports on the front of the machine.

b) Place the machine into RINSE for three minutes.

c) Remove the acid and bicarbonate concentrate connectors from their ports and plug them back into

concentrate.

®

d) If the DIASAFE

F- 15.0.0 LOADING PRESSURE LOW (0 to 10 psi) /CHECK DEAERATION PUMP

filter was the problem the flow error will clear. Return to step F- 2.0.0.

The deaeration pump's motor shaft can be viewed from the front of the hydraulics (see Figure 14, page 20).

Is

the shaft rotating counter-clockwise (from the FRONT!)?

n

Yes See F- 15.0.1

See TROUBLESHOOTING MOTORS (p

No

age 23) to check the DEAERATION MOTOR.

Fresenius 2008K Troubleshooting Guide

Page 19

P/N 507298 Rev. C

Page 28

Section 1 – Flow Errors in Dialyze Mode

FLOW

MOTOR SHAFT

HYDRAULICS (FRONT VIEW) HYDRAULICS (REAR VIEW)

Figure 14

F- 15.0.1 LOADING PRESSURE LOW - DEAERATION MOTOR RUNNING

NOTE: This procedure checks for water in the hydro block.

a) Turn flow off (flow on/off LED on). Call debug screen 0 and wait until DEAP = 255 (indicates deaeration

motor is off).

b) Remove the CLEAR (input) tubing from the deaeration pump's nozzle (see Figure 14 above). Hold it below

the pump. Is there continu

ous (never stops) flow from this tubing?

Yes See F- 15.0.2

See F- 15.0.5

No

F- 15.0.2 CHECK INCOMING WATER

a) Allow flow to continue from the tubing (use a bucket to catch it).

b) Call debug screen 0. When the float’s bob drops, incoming water valve #41 is energized open. This is

indicated when the circle (next to the valve) turns solid blue. Normally (if the incoming water circuit is okay)

valve #41 will open for about one second per cycle.

c) Intermittent water problems are missed with a ‘quick look’. Watch specifically (and carefully) for a NO

WATER alarm for two minutes

Yes Reconnect the tubing to the deaeration pump and see SECTION 2 - NO WATER (pa

. Is a NO WATER alarm ever present?

ge 24).

No See F- 15.0.3

F- 15.0.3 RECHECK LOADING PRESSURE

a) Reconnect the tubing and turn flow on (flow on/off LED off).

b) Wait 30 seconds. Does loading pressure return to normal (18 to 25 psi)?

Yes Problem maybe solved. If low loading pressure symptoms repeat: 1) Possible bad deaeration

pump head; 2) Possible bad deaeration motor (try brushes); 3) Possible bad (intermittent)

float switch; 4) Possible stripped orifice fitting or bad orifice o-rings.

No See F- 15.0.4

Page 20

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 29

Section 1 – Flow Errors in Dialyze Mode

F- 15.0.4 CHECK DEAERATION PUMP AND LOADING PRESSURE REGULATOR

While watching the loading pressure gauge, tightly clamp the white tubing between the loading pressure

regulator #65 and the hydroblock (see Figure 15 below). Does loading pressure increase to greater than

20 psi

?

Yes The loading pressure regulator #65 (see Figure 15 below) is bad.

Two possibilities: 1) Deaeration pump head; 2) Deaeration motor brushes (see brush

No

replacement process in the PREVENTATIVE MAINTENANCE manual).

F- 15.0.5 CHECK THE ORIFICE AND FLOAT

a) Reconnect the tubing and turn the water OFF.

b) Clamp the hydro block vent tube (see Figure 15 below). Unscrew and pull the o

block (see Figure 15 below). If the small opening, at the end of the shaft, is plugged thi

rifice (#48) from the hydro

s is the problem!

FLOAT (FULLY DOWN ON SHAFT)

HEATER

VENT TUBE

ORIFICE (#48)

LOADING PRESSURE

REGULATOR #65

Figure 15 – Hydroblock

SOLID TUBING

(CLAMP HERE,

Step F- 15.0.4)

c) Re-install the orifice (don’t over tighten!) and UNCLAMP the vent tube.

d) Remove the float (see Figure 15 above). CAU

TION! Don't pull on the wiring harness!

e) Holding the float FULLY UP turn the water ON.

f) CAUTION Avoid overflow during this step! Looking into the hydro block’s float cavity move the float bob

FULLY DOWN. Is the water level rising?

Yes a) Turn the water off and reinstall the float; b) Turn the water on and see F- 15.0.7

See F- 15.0.6

No

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 21

Page 30

Section 1 – Flow Errors in Dialyze Mode

F- 15.0.6 CHECK THE FLOAT CIRCUIT

a) Turn the water off.

b) Unplug the float from distribution board position FLOAT-SW. Using a flashlight, check inside the distribution

board for ‘white’ corrosion (indicative of spillage).

c) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

d) If all pins are okay: place a jumper wire, inside the distribution board, BETWEEN male pins 1 and 3 (top

and middle). This simulates a ‘closed’ float switch. IMPORTANT! Make VERY sure of a good jumper

connection!

e) Call debug screen 0. Is the circle next to valve #41 solid blue (indicating valve #41 is energized)?

Yes The float is bad. Replace it and see F 15.0.7

No

Two possibilities: 1) *Bad sensor board cable; 2) Bad actuator board.

*The sensor cable can be checked for continuity. Note that you are checking the FLOAT connection and see

SECTION 17 - CHECKING SENSOR BOARD CABLE (page 90).

F- 15.0.7 CLEARING AN AIR LOCK

There should be flow through the hydro block unless an air lock is present.

a) Assure that the water in ON.

b) Connect a 60 ml syringe (with plunger) to the deaeration pumps clear INLET tubing and draw on the

plunger. You may have to pull several syringes full of air before you achieve continuous flow. If unable to

achieve continuous flow (after five or six tries) the orifice fitting may be 'stripped'.

c) Reconnect the tubing to the deaeration pump nozzle and turn flow on.

d) Allow loading pressure to return to normal (18 to 25 psi).

NOTE: Recurring air locks may be indicative a 'stripped' orifice fitting, bad orifice o-rings or bad (intermittent)

float switch.

Page 22

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 31

Section 1 – Flow Errors in Dialyze Mode

TROUBLESHOOTING MOTORS

IMPORTANT! Proceed ONLY with the NOTED motor.

NOTE: If the motor shaft is turning but clockwise (when viewed from the motor end!) someone has misaligned

the housing and motor cap. This can be corrected by turning the motor cap 180 degrees from its present

location (see DEAERATION MOTOR BRUSHES in the PREVENTATIVE MAINTENANCE manual).

a) Assure that the NOTED motor is plugged into the correct distribution board position (see Table 1 below).

Wiggle the female distribution board connector and check if the motor starts rotating. If so there may be a

b)

bad connection inside the female connector.

c) Tap the motor with a screwdriver and check if the motor starts rotating. If so the brushes need replacing.

d) Assure that dialysate flow is on and set at the rate as directed in Table 1 below.

Unplug the motor from its distribution board position. Using a flashlight check inside the distribution board

e)

for ‘white’ corrosion (indicative of spillage).

f) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

g) If all pins are okay: set your meter to DC voltage and clip the leads, inside the distribution board, BETWEEN

pins 1 and 5 (top and bottom). IMPORTANT! Make certain of good meter connections. Place the red

male

meter lead at pin 1 (top pin). Follow the directions given in Table 1.

Table 1 – Motor Troubleshooting

DISTRIBUTION

PUMP

BOARD

POSITION

DEAERATION P20, DEGAS-P 500

FLOW P21, FLOW-P 800

1

The actuator cable can be checked for continuity. Note that you are checking DEAERATION MOTOR

connections and see SECTION 16 - CHECKING ACTUATOR BOARD

2

The actuator cable can be checked for continuity. Note that you are checking FLOW MOTOR connections

and see SECTION 16 - CHECKING ACTUATOR BOARD

FLOW

RATE

(ml/min)

VOLTAGE

RANGE

BAD

16 vdc or greater Replace the pump head

Two Possibilities:

1

Less than 16 vdc

Actuator cable

1.

2. Actuator board

12 vdc or greater Replace the pump head

Two Possibilities:

Less than 12 vdc

2

1.

Actuator cable

2. Actuator board

CABLE (page 88).

CABLE (page 88).

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 23

Page 32

SECTION 2 - NO WATER

NW- 1.0.0 CHECK INCOMING WATER SYSTEM

a) Assure that the water is ON!

b) Assure that the vent tubing (back of machine) is not 'pinched' (see Figure 6, page 5).

c)

Turn the water off and check the input water filter (if present) for restrictions (see Figure 6, page 5).

Before hooking the incoming water line back up assure that there is adequate incoming water flow

d)

(1 liter/min or greater).

e) Tee a pressure gauge at the output side of pressure regulator #61 (see Figure 16 below for location).

Turn the water on. Is gauge reading 18 psi or greater?

f)

Yes Leave the gauge in place and see NW- 2.0.0

Calibrate INLET WATER PRESSURE per CALIBRATION PROCEDURES. If unsuccessful a

No

bad pressure regulator #61 is indicated.

VALVE #41

PLACE GAUGE HERE

REGULATOR #61

Figure 16 – Hydraulics (Top View)

Page 24

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 33

Section 2 – No Water

NW- 2.0.0 CHECK FLOAT SIGNAL

a) Turn the water off.

b) Unplug the float connector from distribution board position x5, FLOAT-SW. Using a flashlight, check inside

the distribution board for ‘white’ corrosion (indicative of spillage).

c) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

d) If all pins are okay: place a jumper wire, inside the distribution board, BETWEEN male pins 1 and 3 (top

and middle). This simulates a ‘closed’ float switch. IMPORTANT! Make VERY sure of a good jumper

connection!

e) Call debug screen 0. Is the circle next to valve #41 solid blue (indicating valve #41 is energized)?

Yes Leave the jumper in place and see NW- 2.0.1

No

Two possibilities: 1) *Bad sensor board cable; 2) Bad actuator board.

*The sensor cable can be checked for continuity. Note that you are checking the FLOAT connection and

proceed to SECTION 17 - CHECKING SENSOR BOARD CABLE (pag

NW- 2.0.1 CHECK VALVE #41

e 90).

Does the gauge at regulator #61 indicate low pressure (about 0 psi)?

Yes Bad float

No See NW- 3.0.0 (valve #41 i

s not opening)

NW- 3.0.0 CHECK FOR VALVE ERROR (VERR) AT VALVE #41

NOTE: Valve errors are caused by electrical current problems in a ‘valve circuit’. If present, VERR (debug

screen 1) increases (to a maximum of 255). If not present VERR remains 0. VERR is in the lower right

corner of screen 1.

a) IMPORTANT. Turn the power off and then back on.

b) Place the machine into DIALYSIS program and QUICKLY enter debug screen 1. Is VERR increasing?

Yes A) Plug the float back into the distribution board (position x5, FLOAT-SW); B) Turn the water

on; C) NOTE that you are in DIALYSIS program and there is a valve error at VALVE #41.

Proceed to TROUBLESHOOTING VALVE ERRORS (page 31).

Leave the jumper in place! A problem is indicated with the actuator board or VALVE #41.

No

NOTE this and see TROUBLESHOOTING VALVES (pag

e 30).

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 25

Page 34

SECTION 3 - FLOW ERRORS IN CLEANING PROGRAMS

CLEAN- 1.0.0 CHECK FOR ERRORS IN DIALYSIS PROGRAM

This procedure determines if the flow error is occurring SPECIFICALLY in cleaning programs.

a) Pull the concentrate connectors out of their ports and plug into concentrate.

b) Place the machine in DIALYSIS PROGRAM.

NOTE: If the machine is locked in MANDATORY RINSE (i.e. after chemical disinfection, only RINSE is

allowed) swap in another function board. To avoid calibration reference errors go into Service Mode and

select YES for T and C (Test and Calibration) Mode on the Hardware Options screen. Remember to press

the CONFIRM key to activate the change. When troubleshooting is complete, go back into Service Mode and

select NO for T and C Mode then turn the power off and put the original function board back in.

c) Call debug screen 0. Intermittent problems are easily missed with a ‘quick look’ so watch carefully for two

minutes or until you see either a NO WATER alarm or a flow error (FLOW ERROR = “1”). Proceed

accordingly:

NO WATER alarm (intermittent or constant). Proceed to SECTION 2 - NO WATER (p

FLOW ERROR = “0” (constant). See CLEAN- 1.0.2

FLOW ERROR = “1” (intermittent or constant). Proceed to SECTION 1 - FLOW ERRORS IN

DIALYZE MODE (pa

CLEAN- 1.0.2 CHECK FOR FLOW ERRORS ‘OUT OF BYPASS’

Allow temperature and conductivity to become normal (about eight minutes) so that the machine comes out of

bypass (the bypass LED turns off). Carefully watch FLOW ERROR. Proceed accordingly:

FLOW ERROR = “0” (constant). See CLEAN- 1.0.3.

FLOW ERROR = “1” (intermittent or constant). Proceed to SECTION 1 - FLOW ERRORS IN

DIALYZE MODE (pa

CLEAN- 1.0.3 CHECK FOR VALVE ERRORS (VERR)

a) Valve errors are caused by electrical current problems in a ‘valve circuit’. If present, VERR (debug

screen 1) increases (to a maximum of 255). If not present VERR remains 0.

b) During these procedures you will place the machine into a RINSE program and watch for a valve error

(VERR). In RINSE debug is called by pushing the DOWN ARROW key ONLY. You need to enter debug

and then call screen 1 (push the UP ARROW key) as quickly

corner.

c) At times you will also be asked to call and watch screen 0’s valve #43 and #29. Become familiar with where

these valves are located in the FLOW DIAGRAM! When a valve is energized the circle, next to the valve,

turns solid blue.

d) Proceed to CLEAN- 1.0.4

ge 6)

ge 6)

as you can. VERR is in the lower right hand

age 24).

Page 26

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 35

Section 3 – Flow Errors in Cleaning Programs

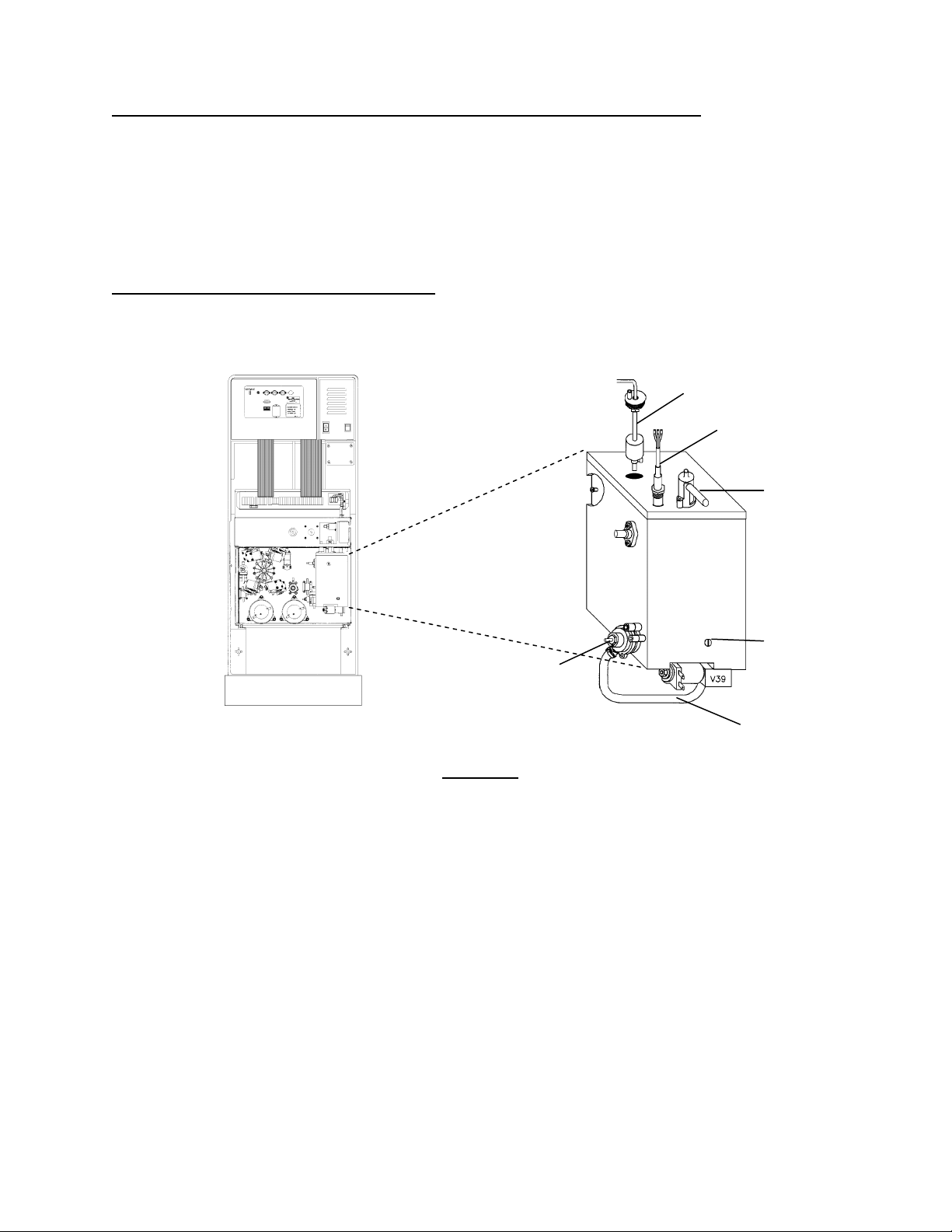

CLEAN- 1.0.4 CHECK FOR A VALVE ERROR AT VALVE #39

a) IMPORTANT. Turn the power off and then back on.

b) Place the concentrate connectors back into their ports and place the machine into RINSE program

c) QUICKLY enter debug and call screen 1. Is VERR increasing?

Yes NOTE that you are in RINSE program and there is a valve error at VALVE #39. Proceed to

TROUBLESHOOTING VALVE ERRORS (page 31)

See CLEAN- 1.0.5

No

CLEAN- 1.0.5 CHECK FOR VALVE ERROR AT VALVE #43

QUICKLY return to screen 0 and watch V43. When it energizes call screen 1. Is VERR increasing?

Yes NOTE that you are in RINSE program and there is a valve error at VALVE #43. Proceed to

TROUBLESHOOTING VALVE ERRORS (page 31)

No

See CLEAN- 1.0.6

CLEAN- 1.0.6 CHECK FOR VALVE ERROR AT VALVE #29

QUICKLY return to screen 0 and watch V29. When it energizes call screen 1. Is VERR increasing?

Yes NOTE that you are in RINSE program and there is a valve error at VALVE #29. Proceed to

TROUBLESHOOTING VALVE ERRORS (page 31)

No

See CLEAN- 2.0.0

CLEAN- 2.0.0 CHECK VALVE #39

a) Interrupt the RINSE program by pulling the ACID connector from its port.

b) Connect a gauge in line at the INPUT side of the deaeration pump (see Figure 17, page 28).

c)

Place the ACID connector back into its port and place the machine into RINSE. Is gauge pressure less

than –14 inHg?

Yes See CLEAN- 2.0.1

A problem is indicated with the actuator board or VALVE #39. NOTE this and see

No

TROUBLESHOOTING VALVES (page 30).

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 27

Page 36

Section 3 – Flow Errors in Cleaning Programs

DEAERATION

PUMP INLET

Figure 17 – Hydraulics (Rear View)

CLEAN- 2.0.1 CHECK VALVE #29

a) Interrupt the RINSE program by pulling the ACID connector from its port.

b) Clamp the clear tubing at the input nozzle of valve 29, as close to the valve as possible (see Figure 18

belo

w), and remove the tubing from the valve.

c) Fill a syringe with water with tubing attached the same size as the input nozzle of valve 29. Attach the

tubing to the input nozzle of valve 29.

d) Place the ACID connector back into its port and place the machine into RINSE.

e) Call debug screen 0, when V29 is energized (circle solid blue) try to push water through the valve. Are you

able to push water through the valve?

Yes See CLEAN- 2.0.2

A problem is indicated with the actuator board or VALVE #29. NOTE this and see

No

TROUBLESHOOTING VALVES (page 30).

VALVE 43 OUTPUT NOZZLE VALVE 29 INPUT NOZZLE

Figure 18 – Hydraulics (Top View)

Page 28

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 37

Section 3 – Flow Errors in Cleaning Programs

CLEAN- 2.0.2 CHECK VALVE #43

a) Connect the tubing back to valve #29 and REMOVE the clamp.

b) Clamp and remove the output tubing from valve #43 (see Figure 18, on previous page).

c)

From debug screen 0, when V43 is energized (circle solid blue) is there good ‘pulsing’ flow from the nozzle?

Yes See CLEAN- 2.0.3

A problem is indicated with the actuator board or VALVE #43. NOTE this and see

No

TROUBLESHOOTING VALVES (page 30).

CLEAN- 2.0.3 CHECK ACTUATOR BOARD SIGNAL

a) Place the machine into DIALYSIS PROGRAM and unplug valve #30 from its distribution board position

(V30, DRAIN-V). Using a flashlight check inside the distribution board for ‘white’ corrosion (indicative of

spillage).

b) If no corrosion: set your voltage meter to DC volts. Clip the leads BETWEEN male

pins 1 and 5 (top and

bottom) inside the distribution board. Place the red lead on pin 5 (bottom). Less than 2 volts?

Yes Replace valve #30.

No Replace the actuator board.

CLEAN- 3.0.0 CHECK FLOW ERROR

Place the machine into whatever cleaning program the flow error was occurring. If the flow error is still

present. Possibilities:

Bad deaeration motor brushes (especially if they have not been replaced in the last 8000 hours).

Bad deaeration pump head.

Bad (intermittent) dialysate pressure transducer #9.

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 29

Page 38

Section 3 – Flow Errors in Cleaning Programs

TROUBLESHOOTING VALVES

The troubleshooting procedure that brought you here asked you to NOTE which valve is the problem.

Proceed ONLY with the NOTED valve!

a) Unplug the NOTED valve from its distribution board position as instructed in Table 2 below. Using a

flashlig

b) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

c) If all pins are okay: set your voltage meter to DC volts. Clip the leads, inside the distribution board,

BETWEEN male

d) Some valves are checked from RINSE program, others in DIALYSIS program as instructed in the table

below. Place the machine into the indicated program.

e) Call debug screen 0. The valve is ‘energized’ when the circle (next to the valve) is solid blue. In RINSE

program some valves are ‘energized’ only at certain times. Take the voltage measurement ONLY when

the valve is energized.

Table 2 – Troubleshooting Valves

ht check inside the distribution board for ‘white’ corrosion (indicative of spillage).

pins 1 and 5 (top and bottom). Clip the red lead on pin 5 (bottom).

VALVE

DISTRIBUTION

POSITION

PROGRAM

MODE

GOOD

(22 to 26 Volts DC)

24 V24, DIAL-V1 RINSE Valve #24 bad or restricted

26 V26, BYPASS-V RINSE Valve #26 bad or restricted

29 V29, REC-V RINSE

43 V43 RINSE

Valve #29 bad or restricted

Valve #43 bad or restricted

25 V25, DIAL-V2 RINSE Valve #25 bad or restricted

39 V39, DEAR-V RINSE Valve #39 bad or restricted

41 V27 DIALYSIS Valve #41 bad or restricted

30 V30, DRAIN-V DIALYSIS

Valve #30 bad or restricted

BAD

(0 to 22 Volts DC)

Two possibilities:

1

1)

Bad actuator cable

2) Bad actuator board

Two possibilities:

1

Bad actuator cable

1)

2) Bad actuator board

Two possibilities:

1

Bad actuator cable

1)

2) Bad actuator board

Two possibilities:

1

1)

Bad actuator cable

2) Bad actuator board

Two possibilities:

1

1)

Bad actuator cable

2) Bad actuator board

Two possibilities:

1

1)

Bad actuator cable

2) Bad actuator board

Two possibilities:

1

1)

Bad actuator cable

2) Bad actuator board

Two possibilities:

1

Bad actuator cable

1)

2) Bad actuator board

1

The actuator cable can be checked for continuity. Note that you are checking DEAERATION PUMP

connections and see SECTION 16 - CHECKING ACTUATOR BOARD

CABLE (page 88).

Page 30

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 39

Section 3 – Flow Errors in Cleaning Programs

TROUBLESHOOTING VALVE ERRORS

Valve errors indicate a resistance problem in a ‘valve circuit’ and are generated when the actuator board tries

to ‘energize’ that valve’s solenoid. The easiest (and best) place to check is at the actuator board.

a) IMPORTANT! Turn the power off and slide electronic card cage forward.

b) Clip a ground lead onto PGND-B at the motherboard’s TEST connector (see Figure 19 below). If the

–12 volt conv

–12 volts converter correctly before placing the machine back into service.

erter board is plugged in here remove it for now. IMPORTANT! Make sure to reinstall the

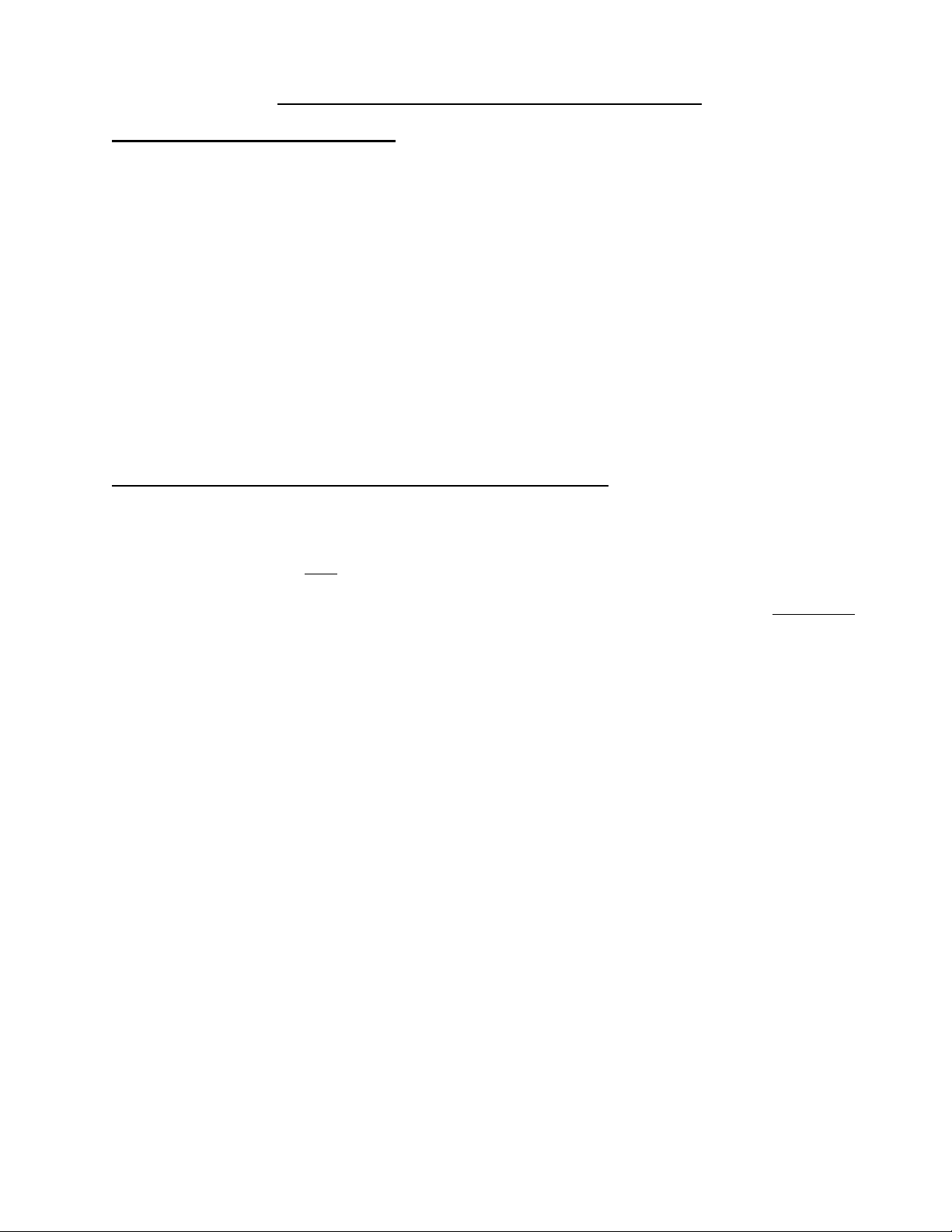

P2 CONNECTOR

PIN 2 (TOP)

TEST CONNECTOR

(FOR GROUND)

ACTUATOR BOARD

(SOLDER SIDE)

PIN 1 (BOTTOM)

REAR OF MACHINE

Figure 19 – Electronic Card Cage

c) At the top of the actuator board (second board from the left) there is a 50-pin connector called 'P2' (see

Figure 19 above). The actuator ribbon-cable terminates here. Assure the

d) The actuator cable runs into the distribution board and terminates at the ACTUATOR connector. Assure

the cable is plugged in properly at the distribution board.

e) Check the actuator ribbon-cable for damage along its entire length. Replace if damaged.

f) From the solder (back) side of the actuator board’s ‘P2’ connector note that there are two rows of pins. All

‘odd’ numbered pins (1, 3, 5, etc) are in the bottom row. The ‘even’ numbered pins (2, 4, 6, etc) are in the

top row. Each ‘valve circuit’ will be checked by measuring resistance from these pins. It will be easier to

use a meter ‘probe’ instead of a clip-on lead!

g) The troubleshooting procedure that brought you here asked you to note which machine program the valve

error is occurring. Is the VALVE ERROR occurring in RINSE or DIALYSIS program?

DIALYSIS See VE- 1.0.0

cable is plugged in properly.

RINSE

VE- 1.0.0 VALVE ERRORS OCCURING IN DIALYSIS

See VE- 2.0.0

CAUTION! If VERR reaches 255 (its maximum) the valve error cannot be determined. If VERR reaches 255

turn the power off, back on, return to DIALYSIS program and continue from where you left off.

a) Turn the power on and place the machine into DIALYSIS program.

b) Call debug screen 1. If VERR is not increasing do NOT continue!

c) Allow 20 seconds and call screen 0. Is a NO WATER ALARM indicated?

Yes See VE- 1.0.1

See VE- 1.0.2

No

Fresenius 2008K Troubleshooting Guide

Page 31

P/N 507298 Rev. C

Page 40

Section 3 – Flow Errors in Cleaning Programs

VE- 1.0.1 VALVE ERROR AT VALVE #41

A NO WATER alarm is indicated.

a) IMPORTANT! Turn the power off.

b) Set your meter to resistance (Ω) and measure from the solder (back) side pin, of the actuator board ‘P2’

connector, as directed in Table 3 below. IMPOR

TANT! A reading like 2.42 MΩ is 2.42 million Ohms.

Table 3 – Troubleshooting Valve Error at Valve #41

VALVE PIN

41 32

VE- 1.0.2 VE- 1.0.1 CHECK FOR A VALVE ERROR AT VALVE #25

a) Call debug screen 1.

b) Open the shunt door (to closes valve #25). Does VERR stop increasing (and not = 255)?

Yes See VE- 1.0.3

No

See VE- 1.0.4

P2 PIN

LOCATION

Top row, 10 pins

from front

GOOD = BETWEEN

40 Ω AND 100 Ω

Replace the

actuator board

BAD = LESS THAN 40 Ω OR

GREATER THAN 100 Ω

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

VE- 1.0.3 VALVE ERROR AT VALVE #25

VERR stopped increasing when you opened the shunt door.

a) IMPORTANT! Turn the power off.

b) Set your meter to resistance (Ω) and measure from the solder (back) side pin, of the actuator board ‘P2’

connector, as directed in the table below. IMPORTANT! A reading like 2.42 MΩ is 2.42 million ohms!

Table 4 - Troubleshooting Valve Error at Valve #25

VALVE PIN

25 30

VE- 1.0.4 VE- 1.0.2 CHECK FOR A VALVE ERROR AT A BALANCING CHAMBER VALVE

Turn dialysate flow off (flow on/off LED on). This closes all eight balancing chamber valves. Does VERR stop

increasing (and not = 255)?

Yes See VE- 1.0.5

No

See VE- 1.0.6

P2 PIN

LOCATION

Top row, 11 pins

from front

GOOD = BETWEEN

40 Ω AND 100 Ω

Replace the

actuator board

BAD = LESS THAN 40 Ω OR

GREATER THAN 100 Ω

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Page 32

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 41

Section 3 – Flow Errors in Cleaning Programs

VE- 1.0.5 VALVE ERROR AT BA

LANCING CHAMBER VALVES

VERR stopped increasing when you turned dialysate flow off.

a) IMPORTANT! Turn the power off.

b) Set your meter to resistance (Ω) and measure from the solder (back) side pins, of the actuator board ‘P2’

connector, as directed in the table below. IMPORTANT! A reading like 2.42 MΩ is 2.42 million ohms!

Table 5 - Troubleshooting Valve Error at Balancing Chamber Valves

VALVE PIN

31 36

32 37

33 38

34 39

P2 PIN

LOCATION

Top row, 8 pins

from front

Bottom row, 7

pins from front

Top row, 7 pins

from front

Bottom row, 6

pins from front

GOOD = BETWEEN

40 Ω AND 100 Ω

Check also valve #32

Check also valve #33

Check also valve #34

Check also valve #35

BAD = LESS THAN 40 Ω OR

GREATER THAN 100 Ω

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

35 40

36 41

37 42

38 43

Top row, 6 pins

from front

Bottom row, 5

pins from front

Top row, 5 pins

from front

Bottom row, 4

pins from front

Check also valve #36

Check also valve #37

Check also valve #38

Replace the actuator

board

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 33

Page 42

Section 3 – Flow Errors in Cleaning Programs

VE- 1.0.6 VALVE ERROR AT VALVE #30 OR VALVE #26

VERR continued to increase with the shunt door open and with dialysate flow off.

a) IMPORTANT! Turn the power off.

b) Set your meter to resistance (Ω) and measure from the solder (back) side pins, of the actuator board ‘P2’

connector, as directed in the table below. IMPORTANT! A reading like 2.42 MΩ is 2.42 million ohms!

Table 6 - Troubleshooting Valve Error at Valve #30 or Valve #26

VALVE PIN

30 35

26 31

VE- 2.0.0 VALVE ERRORS OCCURRING IN RINSE

The troubleshooting procedures in SECTION 3 - FLOW ERRORS IN CLEANING PROGRAMS asked you to

note where valve error is occurring. Proceed ONLY with that valve.

a) IMPORTANT! Turn the power off.

b) Set your meter to resistance (Ω) and measure from the solder (back) side pin, of the actuator board ‘P2’

connector, as directed in the table below. IMPORTANT! A reading like 2.42 MΩ is 2.42 million ohms!

P2 PIN

LOCATION

Bottom row, 8

pins from front

Bottom row, 10

pins from front

GOOD = BETWEEN

40 Ω AND 100 Ω

Check also valve #26

Replace the actuator

board

BAD = LESS THAN 40 Ω OR

GREATER THAN 100 Ω

Greater than 100 Ω, See VE- 3.0.0

Less than 4

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

0 Ω, See VE- 4.0.0

Table 7 - Troubleshooting Valve Errors Occurring in Rinse

VALVE PIN

39 44

29 34

43 46

P2 PIN

LOCATION

Top row, 4 pins

from front

Top row, 9 pins

from front

Top row, 3 pins

from front

GOOD = BETWEEN

40 Ω AND 100 Ω

Replace the actuator

board

Replace the actuator

board

Replace the actuator

board

BAD = LESS THAN 40 Ω OR

GREATER THAN 100 Ω

Greater than 100 Ω, See VE- 3.0.0

Less than 4

Greater than 100 Ω, See VE- 3.0.0

Less than 4

Greater than 100 Ω, See VE- 3.0.0

Less than 4

0 Ω, See VE- 4.0.0

0 Ω, See VE- 4.0.0

0 Ω, See VE- 4.0.0

Page 34

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 43

Section 3 – Flow Errors in Cleaning Programs

VE- 3.0.0 CHECK FOR AN 'OPEN' (GREATER THAN 100 Ω )

VALVE CIRCUIT

a) Verify that the NOTED valve is plugged into the correct location on the distribution board (for example,

valve 36 plugs into position V36). Note that valve 41 plugs into the position labeled 27IN-V.

b) Unplug the NOTED valve from its distribution board position. Using a flashlight, check inside the

distribution board, for ‘white’ corrosion (indicative of spillage).

c) If no corrosion: inside the distribution board there should be five male pins. Check for bent or broken

male pins.

d) If all pins are okay: open the female connector’s, plastic, cover and check for good solder connections.

e) Leaving the connector unplugged measure resistance, inside the female

connector, between pins 1 and 5

(where the wires are soldered). Note that valve 26 is wired to pins 2 and 5. Is the resistance between 40

and 100 Ω?

Yes See VE- 3.0.1

See VE- 3.0.2

No

VE- 3.0.1 CHECK ACTUATOR BOARD CABLE

a) Unplug the 50-conductor actuator cable from both ends (the cable terminates at actuator board and at the

distribution board’s ACTUATOR connector).

b) Using a flashlight, check the male side of both connectors for ‘white’ corrosion (indicative of spillage).

c) If no corrosion: check for bent or broken male pins.

d) If all pins are okay: replace the actuator cable.

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 35

Page 44

Section 3 – Flow Errors in Cleaning Programs

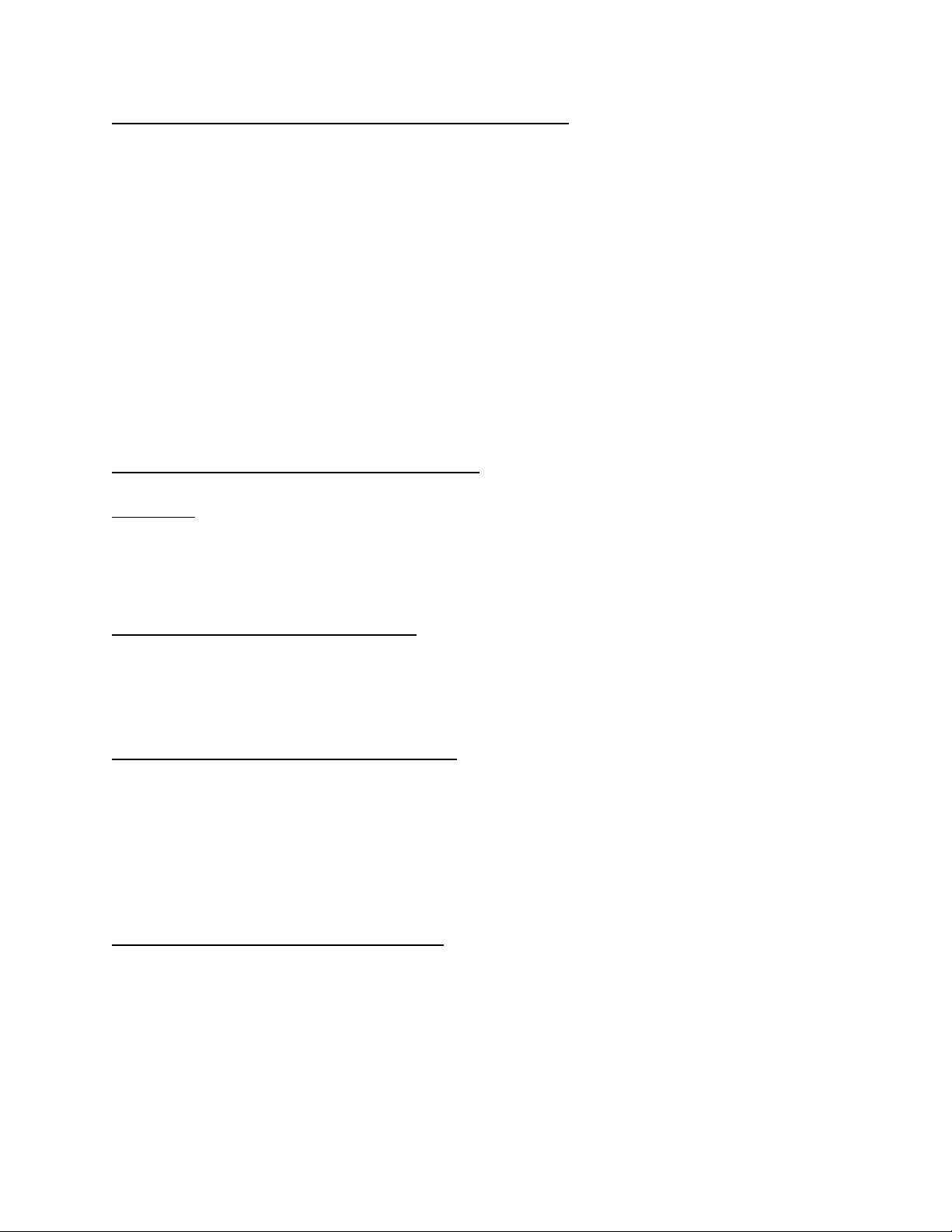

VE- 3.0.2 CHECK VALVE SOLENOID

Each valve has a two-wire harness that runs from the distribution board and terminates at its solenoid where it

plugs onto two male terminals (see Figure 20 and Figure 21 below to locate the valve). Unplug the two-wire

harn

ess and measure between the male

solenoid terminals. Between 40 and 100 Ω?

Yes The two-wire harness is bad.

No Replace the valve.

VALVE 34

(BEHIND VALVE 32)

VALVE 32

VALVE 37

(BEHIND VALVE 35)

VALVE 35

VALVE 33

(BEHIND VALVE 31)

VALVE 31

VALVE 38

(BEHIND VALVE 36)

VALVE 36

VALVE 39

Figure 20 – Hydraulics (Rear View)

VALVE 26

VALVE 24

VALVE 43 VALVE 29 VALVE 41

VALVE 30

Figure 21 – Hydraulics (Top View)

Page 36

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 45

Section 3 – Flow Errors in Cleaning Programs

VE- 4.0.0 CHECK FOR A ‘SHORTED’ (LESS THAN 40 Ω )VA

LVE CIRCUIT

IMPORTANT! A previous reading like 2.42 MΩ is 2.42 million ohms! A reading like 2.42 KΩ is 2.42 thousand

ohms. Make CERTAIN that you are reading the meter correctly before continuing with these procedures!

a) Assure that the NOTED valve is plugged into the distribution board at the correct location (for example,

valve 36 plugs into position V36).

b) Unplug the NOTED valve from its distribution board position. Using a flashlight check, inside the

distribution board, for ‘white’ corrosion (indicative of spillage).

c) If no corrosion: do NOT plug the valve into the distribution board yet. Measure resistance again at the

NOTED valve's actuator board ‘P2’ connector pin (as instructed in the table). Greater than 2 MΩ (possibly

O.L., depends on meter)?

Yes Replace the valve (shorted solenoid). See Figure 20 and Figure 21 (on previous page), to

locate the val

ve.

No See VE- 4.0.1

VE- 4.0.1 CHECK ACTUATOR BOARD FOR A ‘SHORT’

Unplug the 50-conductor actuator ribbon-cable from the actuator board and measure resistance again at the

NOTED valve's actuator board ‘P2’ connector pin (as instructed in the table). Greater than 2 MΩ (possibly

O.L., depends on meter)?

Yes Using a flashlight check, inside the actuator board male connector, for bent or broken pins. If

okay: replace the actuator board (shorted valve driver).

No See VE- 4.0.2

VE- 4.0.2 CHECK ACTUATOR BOARD CABLE CONNECTIONS

a) Using a flashlight check, inside the actuator board male connector, for bent or broken pins. If okay, plug

the actuator cable back into the actuator board.

b) Unplug the 50-conductor actuator ribbon-cable from the distribution board’s ACTUATORS connector.

Using a flashlight check, inside the distribution board’s ACTUATOR connector, for ‘white’ corrosion

(indicative of spillage).

c) If no corrosion: check, inside the distribution board’s ACTUATOR connector, for bent or broken male pins.

d) If all pins are okay: measure resistance again at the NOTED valve's actuator board ‘P2’ connector pin (as

instructed in the table). Greater than 2 MΩ (possibly O.L., depends on meter)?

Yes See VE- 4.0.3

Replace the actuator ribbon-cable.

No

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 37

Page 46

Section 3 – Flow Errors in Cleaning Programs

VE- 4.0.3 CHECK ACTUATOR CONNECTOR PINS/ VALVE HARNESS

a) Check the 2-pin wiring harness that runs from the NOTED valve's distribution board connector to the valve,

for exposed wire.

b) Plug the actuator cable back the distribution board’s ACTUATORS connector.

c) Plug the valve back into the distribution board. IMPORTANT! Be SURE to plug the valve into the correct

position!

d) Measure resistance again at the NOTED valve's actuator board ‘P2’ connector pin (as instructed in the

table). Between 40 and 100Ω?

Yes There may have been a bad connection at the distribution board.

No VE- 4.0.4

VE- 4.0.4 CHECK VALVE SOLENOID

a) Locate the noted valve (use Figure 20 and Figure 21 on page 36).

b)

Unplug the two-wire distribution board harness directly from the solenoid.

c) Measure resistance BETWEEN the solenoid terminals. ). Between 40 and 100Ω?

Yes Possible: 1) Bad actuator cable; 2) Bad two-wire valve harness; 3)Bad actuator board; 4) Bad

distribution board

No Replace the valve.

Page 38

Fresenius 2008K Troubleshooting Guide

P/N 507298 Rev. C

Page 47

SECTION 4 - TEMPERATURE PROBLEMS

Read the following list of symptoms and proceed with the one that best describes the problem:

1. Machine is in DIALYSIS program and:

o

Temperature remains less than 30

Temperature increases to about 40

2. You are attempting HEATER CONTROL CALIBRATION and:

Temperature stabilizes but will not calibrate to 37

see T- 1.0.0.

Temperature increases to about 40

and see T- 4.0.0.

Machine is HEAT DISINFECT program and:

3.

Temperature remains less than 30

Temperature fails to reach 80

Temperature increases to about 90

C. See T- 1.0.0.

o

C falls and rises again. See T- 4.0.0.

o

C. Return to DIALYSIS program and

o

C falls and rises again. Return to DIALYSIS program

o

C. Return to DIALYSIS program and see T- 1.0.0.

o

C but is greater than 30ºC. See T- 3.0.0.

o

C falls and then rises again. See T- 4.0.0.

T- 1.0.0 CHECK HEATER BREAKER AND NO WATER AND FLOW ERROR

a) Make sure the heater breaker switch (rear panel) is on. If not this is the problem!

b) Call debug screen 0. Intermittent problems are easily missed with a ‘quick look’ so watch for two minutes

until you see either a NO WATER alarm or a flow error (FLOW ERROR = “1”). Proceed accordingly:

NO WATER alarm (intermittent or constant). See SECTION 2 - NO WATER (p

age 24).

FLOW ERROR = “0” (constant). See T- 1.0.1