Page 1

FRESENIUS 2008K

HEMODIALYSIS SYSTEM

CALIBRATION

PROCEDURES

Part Number 507296 Rev. B

Page 2

FRESENIUS MEDICAL CARE

NORTH AMERICA

2637 Shadelands Drive, Walnut Creek, CA 94598

800-227-2572 or 925-295-0200

REGIONAL EQUIPMENT SPECIALIST:___________________________________

Page 3

FRESENIUS 2008K

HEMODIALYSIS SYSTEM

CALIBRATION

PROCEDURES

Part Number 507296 Rev B

Copyright 2000 - 2003 Fresenius Medical Care North America

Page 4

WARNINGS

Shock hazard. Refer servicing to qualified personnel.

Never perform maintenance when a patient is connected to the

machine. If possible, remove the machine from the treatment

area when it is being serviced. Label the machine to ensure it is

not accidentally returned to clinical use before the service work

is completed. Always fully test the machine when maintenance

is completed. Confirm dialysate conductivity and pH level

before returning the machine to clinical use.

The electrical source must be 120 volts, 60 Hz, single phase.

The outlet must be a three-conductor type with a hospital-grade

receptacle and a ground fault interrupter. Test the polarity and

ground integrity before installation and ensure it is maintained

thereafter. Failure to do so may result in electrical shock to the

operator or patient.

Calibration procedures must be performed using primary

standards or by using standards that are regularly calibrated in a

program traceable to the National Institute of Standards and

Technology (National Bureau of Standards).

Calibrate the Level Detector module for the model of venous line

being used. During calibration ensure the filter inside the drip

chamber is below the sensor heads. Also verify that the venous

clamp fully occludes the line when closed.

Failure to install, operate and maintain this equipment according

to the manufacturer’s instructions may cause injury or death to

the patient or the operator.

Page ii

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 5

CALIBRATION PROCEDURES

TABLE OF CONTENTS

1.0 INTRODUCTION..................................................................................................... 1

1.1 TEST EQUIPMENT NEEDED....................................................................................................... 2

1.2 OPERATING MODES................................................................................................................... 3

1.3 FRONT PANEL CONTROLS .......................................................................................................6

1.4 MEASURING FLUID VOLUMES..................................................................................................8

1.5 CALIBRATE IF REPLACED ........................................................................................................ 9

2.0 SERVICE MODE CALIBRATIONS ......................................................................... 10

2.1 TOUCH SCREEN CALIBRATION.............................................................................................. 10

2.2 HYDRAULIC CALIBRATION PROCEDURES........................................................................... 11

2.2.1 DEAERATION AND LOADING PRESSURE CALIBRATION............................................................ 12

2.2.2 FLOW PRESSURE CALIBRATION .................................................................................................. 14

2.2.3 BALANCE CHAMBER VOLUME CALIBRATION ............................................................................. 15

2.2.4 ACID (CONCENTRATE) PUMP VOLUME CALIBRATION .............................................................. 17

2.2.5 BICARBONATE PUMP VOLUME CALIBRATION ............................................................................ 19

2.2.6 UF PUMP VOLUME CALIBRATION................................................................................................. 21

2.3 SENSOR CALIBRATION PROCEDURES................................................................................. 24

2.3.1 ARTERIAL PRESSURE CALIBRATION........................................................................................... 25

2.3.2 VENOUS PRESSURE CALIBRATION ............................................................................................. 31

2.3.3 DIALYSATE PRESSURE CALIBRATION......................................................................................... 34

2.3.4 TEMPERATURE SENSOR CALIBRATION ...................................................................................... 36

2.3.5 POST TEMPERATURE SENSOR CALIBRATION ........................................................................... 38

2.3.6 TEMPERATURE CONTROL CALIBRATION ................................................................................... 40

2.3.6.1 TEMPERATURE CONTROL CALIBRATION (METHOD 1) ................................................... 41

2.3.6.2 TEMPERATURE CONTROL CALIBRATION (METHOD 2) ................................................... 44

2.3.6.3 TEMPERATURE CONTROL CALIBRATION (METHOD 3) ................................................... 48

2.3.6.4 TEMPERATURE CONTROL CALIBRATION (METHOD 4) ................................................... 51

2.3.7 BLOOD LEAK CALIBRATION ..........................................................................................................54

2.3.8 CONDUCTIVITY CELLS CALIBRATION.......................................................................................... 56

2.3.8.1 CONDUCTIVITY CELLS CALIBRATION (v2.16 or less)........................................................ 56

2.3.8.2 CONDUCTIVITY CELLS CALIBRATION (v2.25 or greater) ................................................... 58

2.4 MONITOR CALIBRATION PROCEDURES...............................................................................61

2.4.1 SET CLOCK...................................................................................................................................... 62

2.4.2 VOLTAGE DETECTION CALIBRATION .......................................................................................... 63

2.4.3 ARTERIAL PUMP RATE .................................................................................................................. 66

2.4.4 VENOUS PUMP RATE..................................................................................................................... 67

3.0 CALIBRATION PROCEDURES NOT PERFORMED IN SERVICE MODE ................. 68

3.1 INLET WATER PRESSURE REGULATOR CALIBRATION ..................................................... 68

3.2 LEVEL DETECTOR CALIBRATION .......................................................................................... 70

3.3 BLOOD PUMP CALIBRATION .................................................................................................. 72

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page iii

Page 6

NOTE

This document is written for Fresenius 2008K

Hemodialysis Systems using software versions

2.16 or later.

Page iv

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 7

1.0 INTRODUCTION

Calibration involves doing two things. One is making mechanical adjustments,

both to the hydraulics and to the electronics. The other part of calibration is

storing data in the electronic memory in the machine. The machine uses an

EEPROM, which stores calibration data until it is purposely erased and replaced

with new data. To store new data in the EEPROM, the machine is operated in

Service mode as described in Section 1.2. Service mode also shows important

data that is needed to make some of the mechanical adjustments.

Perform the calibration procedures only when needed following repairs, or if the

machine fails the performance tests included in the Preventive Maintenance

Procedures. Do not re-calibrate the machine routinely to verify normal operation.

Instead, use the performance tests included in the Preventive Maintenance

procedures to ensure the machine is working properly.

U

If the machine behaves erratically during calibration, perform the Preventive

Maintenance procedures. Clogged filters, leaky O-rings and similar items

routinely corrected during Preventive Maintenance are a common cause of

intermittent problems. When preparing to re-calibrate the Blood Leak Detector,

either perform a bleach rinse first or verify that it has been done recently. The

bleach rinse is required to clean the detector tube.

Warning! Once a chemical rinse is performed, the only selection the machine

will allow is a mandatory rinse. This information is stored on the functional

board. Therefore, if the functional board and EEPROM are swapped out

together when troubleshooting a calibration or machine problem, the machine

must be rinsed prior to releasing it back into service.

Page 1

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 8

1.1 TEST EQUIPMENT NEEDED

The following supplies and test equipment are required to perform the calibration

procedures.

U

Warning! All of the test equipment used must be maintained and calibrated

regularly in accordance with NIST standards. In particular, the conductivity

meter must meet the specifications given below. Failure to do so could result in

injury or death to the patient or to the operator.

• Fresenius Test Kit (Fresenius part number 150034), which contains two

gauges with fittings and hoses for measuring loading pressure and

deaeration pressure.

• Fresenius test connectors containing precision resistors that simulate the

thermistor resistance at various temperatures (Fresenius part number 190060).

• Dialysate meter to measure dialysate pressure, temperature and conductivity

at the ends of the dialysate lines. The meter must be capable of making

pressure measurements of from -250 mmHg to +400 mmHg with an

accuracy of at least ±2 mmHg up to ±200 mmHg and an accuracy of at least

1% and ±1 mmHg beyond ±200 mmHg. The temperature function of this

meter must be accurate within 0.2°C from 20°C to 45°C and must be

capable of measuring dialysate temperatures up to 85°C with an accuracy of

at least ±4.0°C. The conductivity function of this meter must be accurate to

within 0.1 mS over a range of 12 mS to 17 mS at a temperature of 25°C.

Page 2

• Stopwatch with a resolution to 0.01 second and an accuracy of 0.01% or

better.

• Fresenius Buret, 25ml capacity with 0.1ml graduations (Fresenius part

number 290104).

• Graduated cylinder: 100ml capacity with a tolerance of 0.60ml at 100ml or

better.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 9

• Digital Multimeter to measure dc voltage, ac voltage and resistance with an

accuracy of at least 1% + 1 digit for dc voltage measurements 1.5% + 5

digits for ac measurements and 1% + 1 digit for resistance measurements.

• Syringe, 60 cc capacity. Tolerance is not important; the syringe is not used

for volume measurements.

For machines equipped with the blood pressure module, the following equipment

is also required to test the module as described in this manual:

• Test Device (Fresenius part number 370090). The Test Device contains two

air chambers with calibrated volumes.

• Mercury manometer or equivalent pressure meter accurate to within 1

mmHg at pressures up to 335 mmHg.

1.2 OPERATING MODES

The following calibration procedures contain instructions to place the 2008K into

Dialysis Mode and Service Mode.

To place the machine in Service Mode, turn the machine power On and wait for

the message Press CONFIRM for Service Mode to appear. Once it appears,

press the [CONFIRM] key and the message will change to Machine in Service

Mode. After the System Initializing process is complete, the machine will be in

Service Mode.

If the [CONFIRM] key is not pressed when the Press CONFIRM for Service

Mode message is on the screen, the screen will change and the message Machine

in Dialysis Mode will appear. After the System Initializing process is complete,

the machine will be in Dialysis Mode.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 3

Page 10

Upon power up in Service Mode, the following screen will appear on the front

panel display:

U

Select a calibration by touching the appropriate calibration button.

Calibration procedures that have a red button must be completed before the

machine will operate in Dialysis mode.

Select the desired calibration, then press the [CONFIRM] key to begin the

procedure.

Caution: Once a calibration procedure is begun, pressing the [CONFIRM]

key usually updates the calibration data in the EEPROM. Be careful not to

press the [CONFIRM] key unless you want to change the calibration data. To

leave a calibration procedure without changing the data in the EEPROM, press

the [Escape] key.

A safety feature in the machine helps prevent mis-calibration. If a calibration

value outside of acceptable limits is entered, the machine will reject the

calibration data and the message OPERATOR ERROR will appear on the

display screen. The data stored in the EEPROM will not be changed if this

message appears.

Page 4

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 11

)

)

DEAERATION

(DEGAS) PUMP

CONNECTOR

MON-NTC

CONNECTOR

#3

NTC-POST

CONNECTOR

#44

ADJUSTMENT

#20

UF PUMP

FLOW PUMP

BYPASS VALVE

FLOW PUMP

OUTLET

BLOOD PRESSURE

MODULE

INLET REGULATOR (61

DRAIN PORT

PRESSURE

RELIEF VALV

RELIEF VALVE (65

DEAERATION PUMP

BYPASS VALVE

DEAERATION

PUMP INLET

E (78)

Figure 1 - 2008K Rear View

Page 5

Page 5

Fresenius 2008K Calibration Procedures

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

P/N 507296 Rev B

Page 12

1.3 FRONT PANEL CONTROLS

The front panel consists of two areas, the touch screen and the control panel. The

touch screen is the area under the glass in the center of the front panel. The

control panel surrounds the touch screen and it contains the membrane keys. The

following illustrates these areas:

Touch Screen

Figure 2 - 2008K Front Panel

Control Panel

Control Panel Operation

Throughout the calibration procedures, whenever a control panel key is to be

pressed, the appropriate key name is surrounded by square brackets as in the

following example:

Press the [CONFIRM] key and the screen will change.

In this example, the [CONFIRM] key on the control panel should be pressed.

Page 6

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 13

Touch Screen Operation

The touch screen is designed to display information and is used to enter data. To

select a button during a procedure, locate the button on the screen and touch it.

Depending on the type of button, the screen will change. Data boxes are also

displayed on the touch screen. The following describes the type of buttons and

data boxes that will be encountered during the calibration process.

Data Button

A yellow data button is used during calibration to enter a

measured volume or value. When the yellow area of the data

button is touched, it will change to a darker yellow. The data

can be changed using the [

=] or [>] keys or the value can be

entered using the number keys both on the control panel.

Once the data is entered, press the [CONFIRM] key and the

data button changes back to light yellow. The [Escape] key

can be pressed when the data button is dark yellow to abort

the data entry and return it to light yellow. The entered data

does not get stored until the [CONFIRM] key is pressed.

A gray data button means the button is not active and

touching it will have no effect.

Screen Button

Blue rectangles on the touch screen are screen buttons. By

touching the blue area of the screen button the display will

either change to another screen or the selection of an option

will change. A screen button is not active if it is gray.

Data Box

This type of box shows selected data or data the machine is

measuring. During the calibration process this type of box is

used to verify a value or selection.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 7

Page 14

1.4 MEASURING FLUID VOLUMES

Several of the following procedures require measuring fluid volumes using

graduated cylinders and laboratory burets. When making these measurements do

the following:

• Make certain the container is clean and dry before collecting the fluid to be

measured. Two drops of fluid are approximately 0.1ml, which is enough to

affect the accuracy of critical measurements.

• Ensure that no items such as thermometers or tubing are allowed to come in

contact with the fluid in the graduate. Such items will change the

calibration of the graduate and affect the accuracy of measurements. Both

the total volume indicated and the amount of fluid indicated by each

increment on the graduated scale will be incorrect. For example, if a

graduate is calibrated in 1ml increments, a piece of tubing in contact with

the fluid will cause each increment to be less than 1ml, depending upon the

total volume of the tubing that penetrates into the fluid.

• Surface tension causes the fluid to curve into a meniscus (see Figure 3).

Measure the volume at the bottom of the meniscus curve as shown.

100

mL

90

BOTTOM OF

THE MENISCUS

CURVE

80

Figure 3 - Meniscus Curve

Page 8

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 15

1.5 CALIBRATE IF REPLACED

During the process of servicing a machine, components may need to be replaced.

The following table shows calibrations that must be conducted after replacing

certain components.

Replaced Component

- Deaeration Pump Head

- Deaeration Motor (or rebuild)

- Loading Pressure Relief Valve

- Flow Pump Head

- Flow Motor (or rebuild)

- Flow Pressure Relief Valve

- Balance Chamber - Balance Chamber Volume Sec. 2.2.3

- Acid Pump - Acid Pump Volume Sec. 2.2.4

- Bicarbonate Pump - Bicarbonate Pump Volume Sec. 2.2.5

- UF Pump - UF Pump Volume Sec. 2.2.6

- Dialysate Pressure Transducer - Dialysate Pressure Sec. 2.3.3

- Temperature Sensor

- Heater Bar

- Blood Leak Detector - Blood Leak Sec. 2.3.7

- Conductivity Cell - Conductivity Sec. 2.3.8

- Functional Board (New EEPROM) - All Calibrations All Sections

- Sensor Board

Then Calibrate

- Deaeration & Loading Pressure Sec. 2.2.1

- Flow Pressure Sec. 2.2.2

- Temperature Control Sec. 2.3.6

- Arterial Pressure Sec. 2.3.1

- Venous Pressure Sec. 2.3.2

- Dialysate Pressure Sec. 2.3.3

- Temperature Sec. 2.3.6

- Blood Leak Sec. 2.3.7

- Conductivity Sec. 2.3.8

- Arterial Pump Rate Sec. 2.4.3

- Venous Pump Rate Sec. 2.4.4

Refer to:

- Blood Pump Module

- Level Detector Module

Fresenius 2008K Calibration Procedures

- Arterial Pressure Sec. 2.3.1

- Arterial Pump Rate Sec. 2.4.3

- Venous Pressure Sec. 2.3.2

- Level Detector Sec. 3.2

Table 1 - Calibrate if Replaced

P/N 507296 Rev B

Page 9

Page 16

2.0 SERVICE MODE CALIBRATIONS

Place the machine in Service Mode as described in Section 1.2 to perform the

following procedures. The procedures do not have to be completed in any

particular order. Go directly to the calibration procedures needed.

If calibration is being performed after working on the hydraulics unit, especially

if the inlet water pressure regulator has been changed, we recommend that you

calibrate the inlet water pressure regulator as described in Section 3.1 first.

2.1 TOUCH SCREEN CALIBRATION

The touch screen is calibrated from the Service Mode screen.

- Press the [New Tx] key to begin the touch screen calibration.

N

Note: The touch screen needs to be calibrated only when the machine is

installed or if the touch screen is replaced.

Page 10

- Touch the asterisk on the screen. Another asterisk will appear in a different

spot on the screen. There are a total of three asterisks that will appear. Touch

each asterisk as they appear. When the calibration is complete, the screen will

prompt you to power the machine off.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 17

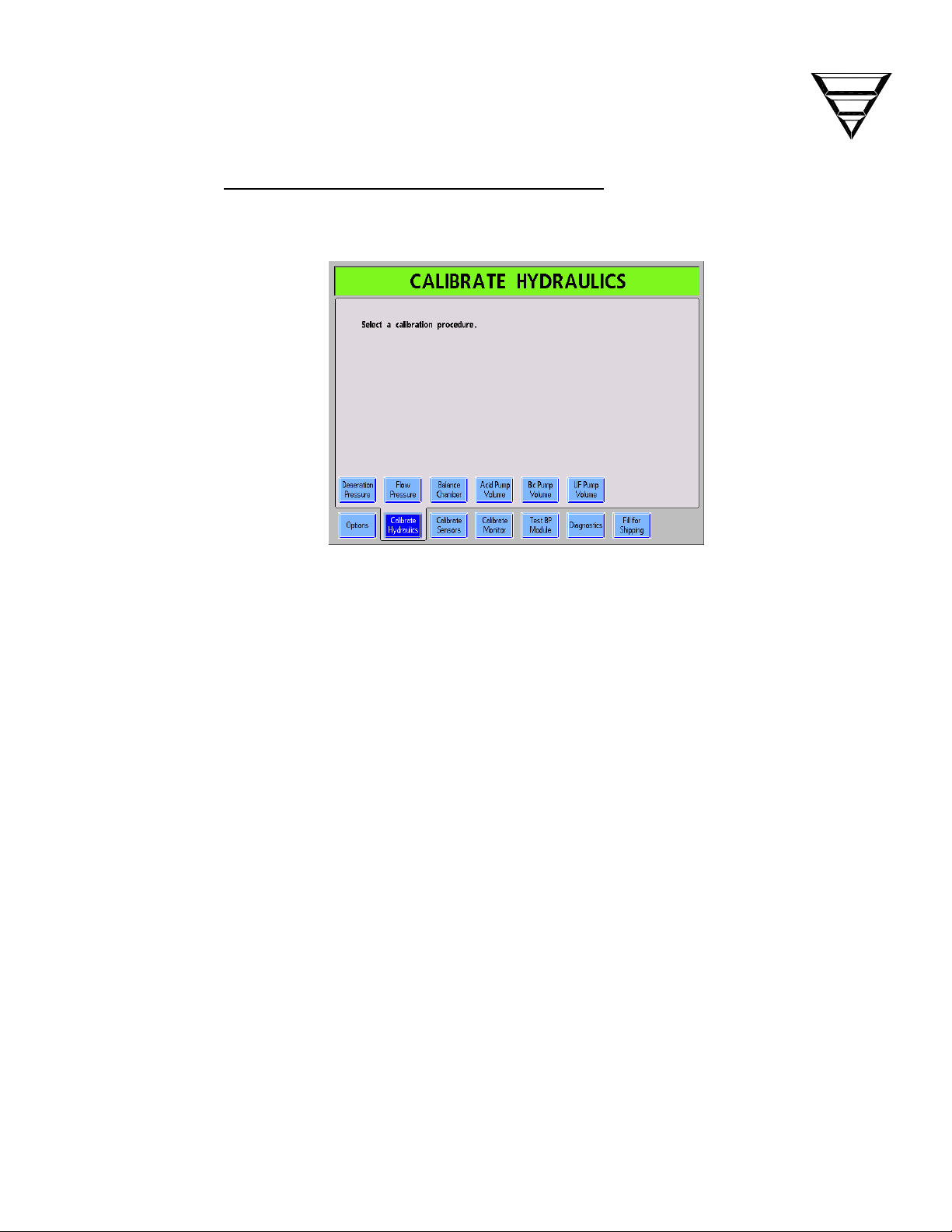

2.2 HYDRAULIC CALIBRATION PROCEDURES

From the Service Mode screen, select the Calibrate Hydraulics screen button.

The following screen will appear showing the six hydraulic calibrations:

Perform the following calibrations in the order listed below. To begin a

calibration, touch the appropriate calibration screen button.

• Deaeration Pressure

• Flow Pressure

• Balance Chamber

• Acid Pump Volume

• Bicarbonate Pump Volume

• UF Pump Volume

Page 11

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 18

2.2.1 DEAERATION AND LOADING PRESSURE CALIBRATION

From the Calibrate Hydraulics screen, select the Deaeration Pressure screen

button. The screen will change to the following:

1. Connect a gauge in line at the inlet side of the deaeration pump (See Figure 1,

pg. 5).

N

Note: The inlet side of the deaeration pump is the side with the clear

plastic line. The output side has a white reinforced jacket over the line.

2. Connect a gauge equipped with a yellow connector into the red

ACETATE/ACID port.

3. Press the [CONFIRM] key. The deaeration pump will start and the screen

will change.

4. Select the PUMP RATE data button.

Set the PUMP RATE value to 180, then press the [CONFIRM] key.

Page 12

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 19

5. Adjust the deaeration pump bypass valve (See Figure 1, pg. 5) on the

deaeration pump for a reading of -24 inHg on the gauge attached to the

deaeration pump. The gauge needle will be wiggling slightly. Set the

pressure so the maximum value is -24 inHg and verify that the needle

does not go below -25 inHg. If these values cannot be reached, set the

deaeration pump bypass valve for the closest reading possible, then

select a higher PUMP RATE value until the proper pressure is indicated

on the gauge.

6. The loading pressure gauge in the red RINSE port will be cycling between

two pressure levels. Adjust pressure relief valve #65 (See Figure 1, pg. 5) for

a reading between 18 and 20 psi when the gauge is reading its highest

pressure level. Verify that the pressure is greater than 10 psi at the lowest

level, and that it is stable within 1 psi at each level.

N

Note: If a DIASAFE

valve #65 for a reading between 23 and 25 psi when the gauge is reading

its highest pressure level.

7. Repeat steps 5 and 6 until both readings are correct without further

adjustment.

8. Press the [CONFIRM] key to save the data. The screen will change.

Remove the gauges.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Hydraulics screen.

filter system is installed, adjust pressure relief

Page 13

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 20

2.2.2 FLOW PRESSURE CALIBRATION

From the Calibrate Hydraulics screen, select the Flow Pressure screen button.

The screen will change to the following:

1. Connect a gauge in line at the output of the flow pump (See Figure 1, pg. 5).

N

N

Note: The output side of the flow pump is the side with the white

reinforced jacket over the line. The input side has clear plastic line

2. Press the [CONFIRM] key to start the flow pump.

Locate the flow bypass screw on the back of the flow pump (See Figure 1, pg. 5).

Turn the flow bypass screw all the way in (clockwise), then back it out two turns.

3. Adjust pressure relief valve #78 (See Figure 1, pg. 5) for a pressure

between 29 and 30 psi indicated on the gauge.

Note: If a DIASAFE

valve #78 for a pressure between 35 and 36 psi.

filter system is installed adjust pressure relief

Page 14

4. Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Hydraulics screen.

Remove the gauge from the flow pump output.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 21

2.2.3 BALANCE CHAMBER VOLUME CALIBRATION

The balance chamber volume is measured at the factory with a high degree of

accuracy using equipment usually not available in the field. The chamber volume

will not change in use. Record the factory-measured chamber volume for

reference should the value need to the replaced in the EEPROM. Only perform

the following procedure if the factory-measured volume has been lost, or if the

balance chamber has been repaired or replaced.

From the Calibrate Hydraulics screen, select the Balance Chamber screen

button. The screen will change to the following:

N

Note: Be prepared to remove the drain hose from the back of the machine

(See Figure 1, pg. 5) and to collect fluid from the drain port with an empty

100ml graduated cylinder.

1. Press the [Prime] key to prime the balance chamber if needed. Press the

[Prime] key again to stop this optional priming.

2. Press the [CONFIRM] key to start the calibration. The status box will

change indicating the balance chamber is being prepared.

Once the balance chamber has been prepared, the screen will change and a

progress bar will begin to fill from left to right. This bar is showing an

approximate 15-second countdown before the contents of the balance

chambers are dispensed from the drain port with two pulses of fluid.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 15

Page 22

3. While this process is going on, remove the drain hose from the back of the

machine.

4. Prepare to catch the two pulses of fluid in the empty graduated cylinder by

placing it under the drain port.

5. As soon as the progress bar is completely blue, the machine will dispense

the two pulses out the drain port.

6. Place the graduated cylinder on a level surface and read the volume of fluid

it contains.

Select the BC Volume data button.

Set the BC Volume value to the amount collected in the graduated cylinder

and then press the [CONFIRM] key.

7. Press the [CONFIRM] key again to store the data. The screen will change.

Replace the drain hose on the drain port.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Hydraulics screen.

Page 16

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 23

2.2.4 ACID (CONCENTRATE) PUMP VOLUME CALIBRATION

From the Calibrate Hydraulics screen, select the Acid Pump Volume screen

button. The screen will change to the following:

1. Fill a 25ml buret with treated water or concentrate.

2. Attach the buret to the red concentrate line with a piece of tubing.

3. Press the [Prime] key. The acid pump will begin to stroke. Allow the

pump to stroke about 20 times or more to remove the air from the line then

press the [Prime] key again to stop the pump.

4. Select the Target data button.

Set the Target value to 30 strokes, then press the [CONFIRM] key.

5. Refill the buret exactly to the full (0ml) mark.

Press the [CONFIRM] key. The acid pump will stroke and the screen will

change.

6. Wait until the Target value reaches zero.

Page 17

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 24

7. When the Target value reaches zero, the acid pump stops stroking.

Select the Volume data button.

Set the Volume value to the measured volume, then press the [CONFIRM] key.

8. Press the [CONFIRM] key again and the screen will change.

9. Refill the buret exactly to the full (0ml) mark.

U

Caution: Be sure the buret did not run out of fluid and allow air to be

pulled into the machine.

10. If needed, prime the line by pressing the [Prime] key. The acid pump will

begin to stroke. Allow the pump to stroke about 20 times or more to remove

the air from the line then press the [Prime] key again to stop the pump.

11. Select the Target data button.

Set the Target value to 30 strokes, then press the [CONFIRM] key.

12. Refill the buret exactly to the full (0ml) mark.

Press the [CONFIRM] key again. The acid pump will stroke and the

screen will change.

13. Wait until the Target value reaches zero.

14. When the Target value reaches zero, the acid pump stops stroking.

Select the Volume data button.

Page 18

Set the Volume value to the measured volume, then press the [CONFIRM] key.

15. Press the [CONFIRM] key again to save the data. The screen will change.

Press the [CONFIRM] key one more time to complete the calibration and

return to the Calibrate Hydraulics screen.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 25

2.2.5 BICARBONATE PUMP VOLUME CALIBRATION

From the Calibrate Hydraulics screen, select the Bic Pump Volume screen

button. The screen will change to the following:

1. Fill a 25ml buret with treated water or concentrate.

2. Attach the buret to the blue bicarbonate line with a piece of tubing.

3. Press the [Prime] key. The bicarbonate pump will begin to stroke.

Allow the pump to stroke about 20 times or more to remove the air from

the line then press the [Prime] key again to stop the pump.

4. Select the Target data button.

Set the Target value to 30 strokes, then press the [CONFIRM] key.

5. Refill the buret exactly to the full (0ml) mark.

Press the [CONFIRM] key. The bicarbonate pump will stroke and the

screen will change.

6. Wait until the Target value reaches zero.

Page 19

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 26

7. When the Target value reaches zero, the bicarbonate pump stops stroking.

Select the Volume data button.

Set the Volume value to the measured volume, then press the [CONFIRM] key.

8. Press the [CONFIRM] key again and the screen will change.

9. Refill the buret exactly to the full (0ml) mark.

U

Caution: Be sure the buret did not run out of fluid and allow air to be

pulled into the machine.

10. If needed, prime the line by pressing the [Prime] key. The acid pump will

begin to stroke. Allow the pump to stroke about 20 times or more to remove

the air from the line then press the [Prime] key again to stop the pump.

11. Select the Target data button.

Set the Target value to 30 strokes, then press the [CONFIRM] key.

12. Refill the buret exactly to the full (0ml) mark.

Press the [CONFIRM] key again. The bicarbonate pump will stroke and

the screen will change.

13. Wait until the Target value reaches zero.

14. When the Target value reaches zero, the bicarbonate pump stops stroking.

Select the Volume data button.

Page 20

Set the Volume value to the measured volume, then press the [CONFIRM] key.

15. Press the [CONFIRM] key again to save the data. The screen will change.

Press the [CONFIRM] key one more time to complete the calibration and

return to the Calibrate Hydraulics screen.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 27

2.2.6 UF PUMP VOLUME CALIBRATION

From the Calibrate Hydraulics screen, select the UF Pump Volume screen

button. The screen will change to the following:

1. Remove the dialysate lines from the shunt and place them in a bucket of

water.

2. Press the [CONFIRM] key to start the calibration. The screen will change.

3. Remove the tubing from the FLUID SAMPLE / ULTRA-FILTRATE

OUTPUT port and connect it to a 25ml buret. Open the buret stopcock.

4. Press the [Prime] key. The UF pump will begin to stroke.

Allow the pump to stroke about 20 times or more to remove the air from

the line then press the [Prime] key again to stop the pump.

Add or remove fluid from the buret so the meniscus is exactly on the 25ml

mark (see Figure 4).

Page 21

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 28

0ml

AFTER 24 STROKES THE

BURET SHOULD INDICATE

BETWEEN 0.90 AND 1.10 ml.

SET THE FLUID LEVEL AT

EXACTLY 25 ml TO BEGIN.

1

25

Page 22

LINE TO THE FLUID SAMPLE/ULTRAFILTRATE

OUTPUT PORT.

Figure 4 - UF Pump Volume Measurement

5. Select the Target data button.

Set the Target value to 24 strokes, then press the [CONFIRM] key.

6. Press the [CONFIRM] key again. The UF pump will stroke and the screen

will change.

7. Wait until the Target value reaches zero.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 29

8. When the Target value reaches zero, the UF pump will stop. Measure the

fluid collected in the buret. The buret scale should indicate between 0.90

and 1.10ml, indicating that between 23.90 and 24.10ml of fluid was

collected (see Figure 4). If the volume collected is not within this range,

adjust the UF pump volume as follows:

• On the rear center of the hydraulics assembly, remove the plastic cap

covering the pump adjustment screw (See Figure 1, pg. 5).

• Loosen the locking nut and turn the screw clockwise to decrease or

counter-clockwise to increase the pump volume.

N

9. Replace the plastic cap on the UF pump adjustment.

Note: Turning the adjustment screw approximately the

width of the screwdriver slot will change the amount of fluid

collected in 24 strokes by about 0.25ml. After making

adjustments, prime the pump again.

• Tighten the locking nut before proceeding.

• Press the [Escape] key and repeat the UF Pump Volume calibration

until the fluid fills the buret to between 0.90 and 1.10 on the scale

after 24 strokes of the UF pump.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Hydraulics screen.

Page 23

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 30

2.3 SENSOR CALIBRATION PROCEDURES

From the Service Mode screen, select the Calibrate Sensors screen button.

The following screen will appear showing the eight sensor calibrations:

Perform the following calibrations in the order listed below. To begin a

calibration, touch the appropriate calibration screen button.

• Arterial Pressure

• Venous Pressure

• Dialysate Pressure

• Temperature Sensor

• Post Temperature Sensor

• Temperature Control

• Blood Leak Detector

• Conductivity Cells

Page 24

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 31

2.3.1 ARTERIAL PRESSURE CALIBRATION

The K arterial blood pump does not use potentiometers to calibrate the arterial

pressure. Instead, it stores a value in the blood pump. In order to calibrate the arterial

pressure, the pump must be put into its own service mode. This is done by moving the

Service Jumper located on the blood pump LP955 board. Refer to Figure 5 for

location and positioning of the Service Jumper.

N

Note: The DIP switches and Service Jumper on the blood pump must be set

prior to turning the machine ON.

R

O

T

I

N

O

M

LP955

E

C

I

V

F

F

O

/

N

O

R

E

S

E

C

L

D

A

A

I

F

N

R

R

G

E

E

S

T

N

I

D

E

N

C

G

I

A

V

R

E

S

F

F

O

/

N

O

F

N

F

O

O

Dip

switch Description

ON for future use

1

OFF for use on the 2008K

ON for Pre-Pump Arterial Pressure

2

OFF for Post-Pump Arterial Pressure

3 Not Used

ON for blood pump stop alarm after 30 sec

4

OFF for blood pump stop alarm after 15 sec

5 Not Used

6 Not Used

7 Not Used

ON for tubing diameter selection 2 to 10mm

(0.2mm increments)

8

OFF for tubing diameter selection 2.6, 4.8,

6.4 and 8.0mm only

ON/OFF

SERVICE

In Service Mode Not In Service Mode

ON/OFF

SERVICE

Figure 5 - K Blood Pump DIP switches & Service Jumper

Page 25

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 32

The following procedure calibrates the pressure sensor on the K arterial blood

pump.

- With the machine turned OFF, position the blood pump Service Jumper into

the In Service Mode position.

- Locate DIP switch 2 on the blood pump LP955 board and configure it as

follows:

• For prepump, DIP switch 2 must be in the ON position

• For postpump, DIP switch 2 must be in the OFF position

- With the 2008K machine in Service mode, turn the power ON.

- When the power up sequence is complete, the blood pump display will be

alternating between these two displays:

N

Note: If the above display has a number 2 instead of a number 1, press the

[>] down key on the blood pump control panel to change it to 1.

Page 26

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 33

From the Calibrate Sensors screen, select the Arterial Pressure screen button.

The screen will change to the following:

N

N

Note: Depending on the HARDWARE OPTION set for the ART PUMP

option, the above display may read POSTPUMP instead of PREPUMP.

The bargraph scale will also be different (500 to –80mmHg).

1. Open arterial transducer port P

(atmospheric pressure).

Note: Use the Arterial Level Adjust [

panel to abort the calibration process without changing the stored DAC

value on the blood pump.

Press the [Start/Stop] key on the blood pump and its display will change to

the following:

on the blood pump module to air

ART.

=] key on the blood pump control

Page 27

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 34

Press the [Start/Stop] key again and the small zero will start to flash.

2. Use the [

=] and [>] keys on the blood pump to adjust the Arterial

Pressure data box on the 2008K display to indicate 0 mmHg.

Press the [CONFIRM] key and the 2008K display will change.

Press the [Start/Stop] key on the blood pump and its display will change

back to the following alternating display:

Press the [Start/Stop] key again and the display will change to the

following:

Press the [

=] key on the blood pump to change it to the following:

Page 28

Press the [Start/Stop] key and the small zero will start to flash.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 35

3. Attach a syringe and a calibrated pressure gauge to the P

port using a

ART.

T- fitting.

4. Push the syringe plunger in to show a pressure of 200mmHg on the

external pressure gauge.

5. While holding this pressure, do the following:

• Use the [=] and [>] keys on the blood pump to adjust the Arterial

Pressure data box on the 2008K display to indicate 200mmHg.

• Press the [CONFIRM] key and the 2008K display will change.

• Press the [Start/Stop] key on the blood pump and its display will

change back to the alternating display:

• Verify that the Arterial Pressure and Pressure at Actuator Board

meter boxes are within 10 mmHg of each other.

N

Note: After pressing the [CONFIRM] key, a delay of approximately

8 seconds may occur before the Pressure at Actuator Board data box

changes to be within 10 mmHg of the Arterial Pressure data box on the

display screen.

6. Pressurize the P

port by either pushing or pulling on the syringe.

ART.

7. Verify that the Arterial Pressure and Pressure at Actuator Board meter

boxes can reach at least 290mmHg (510mmHg for postpump) and that they are

within 10mmHg of each other.

Verify that the Arterial Pressure and Pressure at Actuator Board meter

boxes can reach at least -310mmHg (-90mmHg for postpump) and that they are

within 10mmHg of each other.

8. Press the [CONFIRM] key to save the data. The screen will change.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 29

Page 36

Caution: The following step must be performed on the blood pump or the

U

calibration data you just collected and tested will be lost when the machine

is turned off.

Press the [=] and [>] keys on the blood pump at the same time to save the

DAC values to the blood pump memory. While pressing both keys, the

blood pump display will show dashes as shown below:

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Power the machine OFF and move the blood pump Service Jumper into the

Not in Service Mode position (see Figure 5).

Page 30

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 37

2.3.2 VENOUS PRESSURE CALIBRATION

From the Calibrate Sensors screen, select the Venous Pressure screen button.

The screen will change to the following:

1. Open the venous transducer port P

on the level detector module to air

VEN.

(atmospheric pressure).

2. Adjust the ZERO SET potentiometer (see Figure 6) so that the Venous

Pressure data box indicates zero mmHg.

Press the [CONFIRM] key and the screen will change.

3. Attach a syringe and a calibrated pressure gauge to the P

port using a

VEN.

T- fitting.

Page 31

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 38

(

)

ZERO SET

(P3)

ZERO SET

(POT 146)

400 MMHG SET

POT 40

400 MMHG

SET

400 MMHG

SET

ZERO SET

(POT 39)

Page 32

POTENTIOMETER LOCATIONS

DEPEND UPON THE VERSION

OF THE BOARD AS SHOWN

Figure 6 - Venous Pressure Display Adjustments

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 39

4. Push the syringe plunger in to show a pressure of 400mmHg on the

external pressure gauge.

5. While holding this pressure, do the following:

• Adjust the 400 MMHG SET potentiometer (see Figure 6) so the

Venous Pressure data box indicates 400 mmHg.

• Press the [CONFIRM] key and the screen will change.

• Verify that the Venous Pressure and Pressure at Actuator Board

meter boxes are within 10 mmHg of each other.

N

Note: After pressing the [CONFIRM] key, a delay of approximately

8 seconds may occur before the Pressure at Actuator Board data box

changes to be within 10 mmHg of the Venous Pressure data box on the

display screen.

6. Pressurize the P

7. Verify that the Venous Pressure and Pressure at Actuator Board meter

boxes can reach at least 510mmHg and that they are within 10mmHg of each

other.

Verify that the Venous Pressure and Pressure at Actuator Board meter

boxes can reach at least –90mmHg and that they are within 10mmHg of each

other.

8. Press the [CONFIRM] key to save the calibration. The screen will change.

Press the [CONFIRM] key again to complete the calibration and return to

the Calibrate Sensors screen.

port by either pushing or pulling on the syringe.

VEN.

Page 33

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 40

2.3.3 DIALYSATE PRESSURE CALIBRATION

From the Calibrate Sensors screen, select the Dialysate Pressure screen

button. The screen will change to the following:

1. Hang a four-way connector on the I.V. pole at the normal dialyzer height.

Remove the dialyzer lines from the shunt and attach them to the connector.

N

N

Note: The four-way connector is included in the Fresenius Test Kit part

number 150034.

Connect a 30cc syringe to one of the four-way connector outlets and clamp

the tubing.

Connect an external pressure gauge to the remaining four-way connector

outlet and clamp the tubing.

2. Dialysate should be flowing, as indicated by the flow indicator in the

dialysate lines.

Note: If there is no dialysate flow through the flow indicator, make sure

the yellow [Dialysate Flow on/off] light is off and the shunt door is closed.

Page 34

Wait until no air is visible passing through the flow indicator, then press

the [CONFIRM] key. The screen will change.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 41

3. Press the [Dialysate Flow on/off] key to stop dialysate flow.

Unclamp the lines leading to the 30cc syringe and the pressure gauge.

4. Use the syringe to create a pressure reading of 0mmHg on the external

pressure gauge.

5. While holding this pressure, press the [CONFIRM] key. The screen will

change.

6. Use the syringe to create pressure reading of -250mmHg on the external

pressure gauge.

7. While holding this pressure, press the [CONFIRM] key to save the data.

The screen will change.

8. Press the [Dialysate Flow on/off] key to start dialysate flow.

9. Open the shunt and remove the lines from the external pressure gauge.

Replace them on the shunt and close the door.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Page 35

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 42

2.3.4 TEMPERATURE SENSOR CALIBRATION

Perform the temperature sensor calibration as follows using the test connector set

referenced in Section 1.1. The display screen calls for connecting specific

resistances to the X3 (MON-NTC) connector position on the distribution panel

(See Figure 1, pg. 5) for each test. The test connectors contain resistors which are

the closest 1% tolerance resistor available to these values. In the following

procedure, each test connector is identified by the number marked on its cover.

From the Calibrate Sensors screen, select the Temp Sensor screen button.

The screen will change to the following:

Page 36

1. Remove the distribution board cover from the back of the machine.

Unplug the X3 (MON-NTC) connector from the distribution board.

Connect test connector 34 (6.808KΩ) into X3 (MON-NTC) connection on

the distribution board.

Press the [CONFIRM] key to save the data. The screen will change.

2. Remove the previous test connector and connect test connector 40

(5.117KΩ) into X3 (MON-NTC) connection on the distribution board.

Press the [CONFIRM] key to save the data. The screen will change.

3. Remove the previous test connector and connect test connector 80

(1.255KΩ) into X3 (MON-NTC) connection on the distribution board.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 43

Press the [CONFIRM] key to save the data. The screen will change.

4. Remove the previous test connector and connect test connector 90

(0.915KΩ) into X3 (MON-NTC) connection on the distribution board.

Press the [CONFIRM] key to save the data.

5. The screen will confirm the calibration has been saved:

6. Insert each of the test connectors into X3 (MON-NTC) to confirm the

saved calibration data. Each connector must be within 0.1°C of the

Pre-Temperature data box.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Remove the test connector and replace the X3 (MON-NTC) connector on

the distribution board.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 37

Page 44

2.3.5 POST TEMPERATURE SENSOR CALIBRATION

Perform the post temperature sensor calibration as follows using the test

connector set referenced in Section 1.1. The display screen calls for connecting

specific resistances to the X44 (NTC-POST) connector position on the

distribution panel (See Figure 1, pg. 5) for each test. The test connectors contain

resistors which are the closest 1% tolerance resistor available to these values. In

the following procedure, each test connector is identified by the number marked

on its cover.

From the Calibrate Sensors screen, select the Post Temp Sensor screen

button. The screen will change to the following:

Page 38

1. Remove the distribution board cover from the back of the machine.

Unplug the X44 (NTC-POST) connector from the distribution board.

Connect test connector 34 (6.808KΩ) into X44 (NTC-POST) connection

on the distribution board.

Wait for the Post-Temperature Reference data box to stabilize.

Press the [CONFIRM] key to save the data. The screen will change.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 45

2. Remove the previous test connector and connect test connector 40

(5.117KΩ) into X44 (NTC-POST) connection on the distribution board.

Wait for the Post-Temperature Reference data box to stabilize.

Press the [CONFIRM] key to save the data.

3. The screen will confirm the calibration has been saved:

4. Insert each of the test connectors into X44 (NTC-POST) to confirm

the saved calibration data. Each connector must be within 0.1°C of the

Post-Temperature data box.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Remove the test connector and replace the X44 (NTC-POST) connector

on the distribution board.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 39

Page 46

2.3.6 TEMPERATURE CONTROL CALIBRATION

The Temperature Control Calibration is dependent upon Function Software

version and enabled options. Perform the appropriate calibration according to the

list below:

Function Software V2.16 or less:

Perform section 2.3.6.1 if all the following apply:

- CRRT option is not installed and Slow Flow option is disabled.

Perform section 2.3.6.2 if all the following apply:

- CRRT option is installed or Slow Flow option is enabled

Function Software V2.25 or greater:

Perform section 2.3.6.1 if all the following apply:

- OLC option not installed OR

OLC option is installed but Temp Comp

option is disabled.

- CRRT option is not installed and Slow Flow option is disabled.

Perform section 2.3.6.2 if all the following apply:

- OLC option not installed OR

OLC option is installed but Temp Comp

option is disabled.

- CRRT option is installed or Slow Flow option is enabled.

Perform section 2.3.6.3 if all the following apply:

- OLC option is installed and Temp Comp option is enabled.

Page 40

- CRRT option is not installed and Slow Flow option is disabled.

Perform section 2.3.6.4 if all the following apply:

- OLC option is installed and Temp Comp option is enabled.

- CRRT option is installed or Slow Flow option is enabled.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 47

2.3.6.1 TEMPERATURE CONTROL CALIBRATION (METHOD 1)

Perform this section only if the machine is equipped with the following:

- Functional Software v2.16 or less, the machine is not equipped with the

CRRT option and the slow flow option is disabled.

- Functional Software v2.25 or greater, the machine does not have the OLC

option installed OR OLC option is installed but the Temp Comp option is

disabled, the machine is not equipped with the CRRT option and the slow

flow option is disabled.

Replace any panels that have been removed so that the machine is closed up as it

would be in normal operation. It is important for this calibration that ventilation

around the hydraulics unit be the same as it is when the machine is used for

dialysis.

From the Calibrate Sensors screen, select the Temp Control screen button.

The screen will change to the following:

Page 41

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 48

1. Verify in the Selected Concentrate box that the type of concentrate used

is selected.

If not correct, press the Change Type button.

N

N

Note: If the Change Type button is pressed, the Enter Conc screen will

be displayed. Change the selected concentrate and then select Calibrate

Sensors screen button and then Temp Control screen button to return to

step 1 above.

2. Press the [CONFIRM] key to start the calibration. The screen will change.

3. Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

4. Remove the dialysate lines from the shunt and connect them to an external

temperature meter. Close the shunt door.

5. Press the [CONFIRM] key and the screen will change.

6. Select the TEMP DAC data button.

Adjust the TEMP DAC value, then press the [CONFIRM] key.

Note: Changing the DAC value by 2 or 3 units will produce a temperature

change of about 0.1°C. Wait for the temperature to change and stabilize

before changing it again to avoid overshooting the proper setting.

Page 42

N

Note: The TEMP DAC value does not take effect until the [CONFIRM]

key is pressed and the TEMP DAC data button is light yellow.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 49

The temperature of the dialysate shown on the external meter will change

after a delay. Find a TEMP DAC value that produces a temperature on the

external meter of 37°C.

Wait five minutes after the last adjustment of the TEMP DAC value, then

verify that the temperature on the external meter has remained at 37°C. If

not, change the TEMP DAC value, and wait five minutes again.

7. When the temperature remains at 37°C, press the [CONFIRM] key. The

screen will change.

8. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the

external temperature meter at 37°C and then press the [CONFIRM] key.

9. Press the [CONFIRM] key again to save the data. The screen will change.

Open the shunt to stop the dialysate flow, remove the lines from the

external meter and replace them on the shunt.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 43

Page 50

2.3.6.2 TEMPERATURE CONTROL CALIBRATION (METHOD 2)

Perform this section only if the machine is equipped with the following:

- Functional Software v2.16 or less, the machine is equipped with the CRRT

option OR the slow flow option is enabled.

- Functional Software v2.25 or greater, the machine does not have the OLC

option installed OR OLC option is installed but the Temp Comp option is

disabled, the machine is equipped with the CRRT option OR the slow flow

option is enabled.

If the CRRT option is installed or if the slow flow option is enabled, the Temp

Control calibration is done in two parts. The DAC and temperature monitor

calibration is performed at 500ml/min flow rate and then it is calibrated at a

100ml/min flow rate.

Replace any panels that have been removed so that the machine is closed up as it

would be in normal operation. It is important for this calibration that ventilation

around the hydraulics unit be the same as it is when the machine is used for

dialysis.

From the Calibrate Sensors screen, select the Temp Control screen button.

The screen will change to the following:

Page 44

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 51

1. Verify in the Selected Concentrate box that the type of concentrate used

is selected.

If not correct, press the Change Type button.

N

Note: If the Change Type button is pressed, the Enter Conc screen will

be displayed. Change the selected concentrate and then select Calibrate

Sensors screen button and then Temp Control screen button to return to

step 1 above.

2. Press the [CONFIRM] key to start the calibration. The screen will change.

3. Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

4. Remove the dialysate lines from the shunt and connect them to an external

temperature meter. Close the shunt door.

5. Press the [CONFIRM] key and the screen will change.

6. The Temp Control calibration begins with the flow at 500ml/min.

Select the TEMP DAC data button.

Adjust the TEMP DAC value, then press the [CONFIRM] key.

N

N

Note: Changing the DAC value by 2 or 3 units will produce a temperature

change of about 0.1°C. Wait for the temperature to change and stabilize

before changing it again to avoid overshooting the proper setting.

Note: The TEMP DAC value does not take effect until the [CONFIRM]

key is pressed and the TEMP DAC data button is light yellow.

Page 45

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 52

The temperature of the dialysate shown on the external meter will change

after a delay. Find a TEMP DAC value that produces a temperature on the

external meter of 37°C.

Wait five minutes after the last adjustment of the TEMP DAC value, then

verify that the temperature on the external meter has remained at 37°C. If

not, change the TEMP DAC value, and wait five minutes again.

7. When the temperature remains at 37°C, press the [CONFIRM] key. The

screen will change.

8. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the external

temperature meter at 37°C and then press the [CONFIRM] key.

9. Press the [CONFIRM] key again and the screen will change.

10. The Temp Control calibration now changes the flow to 100ml/min.

Press the [CONFIRM] key and then select the TEMP DAC data button.

Adjust the TEMP DAC value, then press the [CONFIRM] key.

N

N

Note: The TEMP DAC value does not take effect until the [CONFIRM]

key is pressed and the TEMP DAC data button is light yellow.

The temperature of the dialysate shown on the external meter will change

after a delay. Find a TEMP DAC value that produces a temperature on the

external meter of 37°C. Be patient, the 100ml/min flow rate calibration

takes time.

Note: Depending on the incoming water temperature, the DAC value

during the 100ml/min flow calibration may have to be set to the maximum

(255). If the temperature is less than 37°C, the DAC value is at 255, and

enough time has passed, go ahead and save the DAC value of 255. This

circumstance will be compensated for in dialysis or CRRT modes.

Page 46

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 53

Wait five minutes after the last adjustment of the TEMP DAC value, then

verify that the temperature on the external meter has remained at 37°C. If

not, change the TEMP DAC value, and wait five minutes again.

11. When the temperature remains at 37°C, press the [CONFIRM] key. The

screen will change.

12. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the

external temperature meter at 37°C and then press the [CONFIRM] key.

13. Press the [CONFIRM] key again to save the data. The screen will change.

Open the shunt to stop the dialysate flow, remove the lines from the

external meter and replace them on the shunt.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 47

Page 54

2.3.6.3 TEMPERATURE CONTROL CALIBRATION (METHOD 3)

Perform this section only if the machine is equipped with the following:

- Functional Software v2.25 or greater, the machine has the OLC option

installed AND the Temp Comp option is enabled, the machine is not

equipped with the CRRT option and the slow flow option is disabled.

N

Note: The Temp Comp option is only present in Functional Software v2.25 or

greater and uses post temperature sensor NTC44. Do not attempt to calibrate a

non-OLC machine with the Temp Comp option enabled since NTC44 is not

present and an Operator Error will occur.

Replace any panels that have been removed so that the machine is closed up as it

would be in normal operation. It is important for this calibration that ventilation

around the hydraulics unit be the same as it is when the machine is used for

dialysis.

From the Calibrate Sensors screen, select the Temp Control screen button.

The screen will change to the following:

Page 48

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 55

1. Verify in the Selected Concentrate box that the type of concentrated

used is selected.

If not correct, press the Change Type button.

N

Note: If the Change Type button is pressed, the Enter Conc screen will

be displayed. Change the selected concentrate and then select Calibrate

Sensors screen button and then Temp Control screen button to return to

step 1 above.

Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

2. Press the [CONFIRM] key to start the calibration. The screen will change.

3. Remove the dialysate lines from the shunt and connect them to an external

temperature meter. Close the shunt door.

4. Press the [CONFIRM] key and the screen will change.

5. The screen will display Please wait, getting stable temperature.

The machine will run at a 500ml/min flow rate to bring up conductivity and

temperature. When the temperature becomes stable, the Stability counter

will start to count up. As soon as it is greater than 70 a 2-minute Timer

starts to count down. During this time the Stability counter will continue

to increase to 100 and stay at 100 for the remaining 2-minutes. Once the

2-minutes Timer reaches zero, the screen will change.

N

Note: If the Stability counter drops below 70 during the 2-minute Timer,

the 2-minutes will be reset and will wait for the Stability counter to be

greater than 70 again.

Page 49

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 56

6. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the

external temperature and then press the [CONFIRM] key and the screen

will change.

7. Press the [CONFIRM] key again and the screen will display Please wait,

getting stable temperature.

The machine now runs in bypass at a 500ml/min flow rate for 2-minutes.

Once the 2-minute Timer has reached zero, a 6-minute Timer is set. The

machine continues to run in bypass and at a 500ml/min flow rate and

depending on the stability, the 6-minute Timer may start to count down. It

is normal for the Stability counter to decrease during this time. If the

Stability counter becomes less than 70, the Timer will be reset to 6minutes and will wait for the Stability counter to be greater than 70 again.

Once the 6-minute Timer reaches zero, the screen will change.

8. Press the [CONFIRM] key to save the data. The screen will change.

Open the shunt to stop the dialysate flow, remove the lines from the

external meter and replace them on the shunt.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Page 50

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 57

2.3.6.4 TEMPERATURE CONTROL CALIBRATION (METHOD 4)

Perform this section only if the machine is equipped with the following:

- Functional Software v2.25 or greater, the machine has the OLC option

installed AND the Temp Comp option is enabled, the machine is equipped

with the CRRT option OR the slow flow option is enabled.

N

Note: The Temp Comp option is only present in Functional Software v2.25 or

greater and uses post temperature sensor NTC44. Do not attempt to calibrate a

non-OLC machine with the Temp Comp option enabled since NTC44 is not

present and an Operator Error will occur.

If the CRRT option is installed or if the slow flow option is enabled, the Temp

Control calibration is done in two parts. The DAC and temperature monitor

calibration is performed at 500ml/min flow rate and then it is calibrated at a

100ml/min flow rate.

Replace any panels that have been removed so that the machine is closed up as it

would be in normal operation. It is important for this calibration that ventilation

around the hydraulics unit be the same as it is when the machine is used for dialysis.

From the Calibrate Sensors screen, select the Temp Control screen button.

The screen will change to the following:

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 51

Page 58

1. Verify in the Selected Concentrate box that the type of concentrate used

is selected.

If not correct, press the Change Type button.

N

Note: If the Change Type button is pressed, the Enter Conc screen will

be displayed. Change the selected concentrate and then select Calibrate

Sensors screen button and then Temp Control screen button to return to

step 1 above.

Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

2. Press the [CONFIRM] key to start the calibration. The screen will change.

3. Remove the dialysate lines from the shunt and connect them to an external

temperature meter. Close the shunt door.

4. Press the [CONFIRM] key and the screen will change.

5. The screen will display Please wait, getting stable temperature.

The machine will run at a 500ml/min flow rate to bring up conductivity and

temperature. When the temperature becomes stable, the Stability counter

will start to count up. As soon as it is greater than 70 a 2-minute Timer

starts to count down. During this time the Stability counter will continue

to increase to 100 and stay at 100 for the remaining 2-minutes. Once the

2-minutes counter reaches zero, the screen will change.

Page 52

N

Note: If the Stability counter drops below 70 during the 2-minute Timer,

the 2 minutes will be reset and will wait for the Stability counter to be

greater than 70 again.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 59

6. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the

external temperature and then press the [CONFIRM] key and the screen

will change.

7. Press the [CONFIRM] key again and the screen will display Please wait,

getting stable temperature.

The machine now runs in bypass at a 500ml/min flow rate for 2-minutes.

Once the 2-minute Timer has reached zero, a 6-minute Timer is set. The

machine continues to run in bypass and at a 500ml/min flow rate and

depending on the stability, the 6-minute Timer may start to count down. It

is normal for the Stability counter to decrease during this time. If the

Stability counter becomes less than 70, the Timer will be reset to 6-minutes

and will wait for the Stability counter to be greater than 70 again.

Once the 6-minute counter reaches zero, a 10-minute Timer is set. The

machine comes out of bypass and changes to a 100ml/min flow rate. When

the temperature becomes stable, the Stability counter will start to count up.

As soon as it is greater than 70 the 10-minute Timer starts to count down.

During this time the Stability counter will continue to increase to 100 and

stay at 100 for the remaining 10-minutes. Once the 10-minutes Timer

reaches zero, the screen will change.

N

Note: If the Stability counter drops below 70 during the 10-minute Timer

starts, the 10-minutes will be reset and will wait for the Stability counter to

be greater than 70 again.

8. Select the Monitor Reference data button.

Adjust the value shown for Monitor Reference until it matches the external

temperature and then press the [CONFIRM] key and the screen will change.

9. Press the [CONFIRM] key again to save the data. The screen will change.

Open the shunt to stop the dialysate flow, remove the lines from the

external meter and replace them on the shunt.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

Page 53

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 60

2.3.7 BLOOD LEAK CALIBRATION

The glass tube in the blood leak detector must be clean before the blood leak

detector calibration can be completed successfully. The glass tube in the detector

is cleaned by performing a bleach rinse, which washes the tube out along with the

rest of the hydraulics.

There are two calibrations performed on the Blood Leak Detector. One calibrates

the detector itself and the other calibrates the dimness circuits. Perform the

procedures as described below.

From the Calibrate Sensors screen, select the Blood Leak Detector screen

button. The screen will change to the following:

Page 54

N

Note: The blood leak and blood dimness calibration is performed

automatically. Once started, the calibration will proceed on its own until

the calibration complete screen is displayed.

1. Verify that the machine has received a bleach rinse recently, or perform a

bleach rinse as described in the Operator’s Manual before calibrating the

blood leak detector.

2. Press the [CONFIRM] key. The screen will change and the blood leak

calibration will start.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 61

3. The first calibration that is performed is the automatic blood leak

calibration. When its finished, the screen will change.

4. The second calibration that is performed is the automatic blood dimness

calibration. When its finished, the following calibration complete screen

will be displayed:

5. Press the [CONFIRM] key to save the data. The screen will change.

Press the [CONFIRM] key again to complete the calibration and return to

the Calibrate Sensors screen.

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 55

Page 62

2.3.8 CONDUCTIVITY CELLS CALIBRATION

If the machine is equipped with Functional Software v2.16 or less then perform

Section 2.3.8.1. If the machine is equipped with Functional Software v2.25 or

greater then perform Section 2.3.8.2.

2.3.8.1 CONDUCTIVITY CELLS CALIBRATION (v2.16 or less)

Machines equipped with Online Clearance (OLC) have two conductivity cells.

The first conductivity cell is PRE dialyzer and the second conductivity cell is

POST dialyzer.

N

Note: If the Clearance option is set to NO in Hardware Options, the post

conductivity cell will not be calibrated.

From the Calibrate Sensors screen, select the Cond Cells screen button. The

screen will change to the following:

Page 56

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 63

1. Identify the concentrate you will be using to calibrate the conductivity cells.

Select the concentrate by pressing the Conc button. The screen will

change showing a list of concentrates. Use the [

through the list to locate your concentrate.

=] or [>] keys to scroll

N

N

Note: In order to select your concentrate from the list, it must have been

previously entered in the Enter Conc screen. This screen can be found by

pressing the OPTIONS screen button.

Press the [CONFIRM] key to select your concentrate and the screen will

return to the CALIBRATE CONDUCTIVITY CELL(S) screen.

2. Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

3. Remove the dialysate lines from the shunt and connect them to an external

conductivity meter. Close the shunt door.

Note: If using the Automata Neo-1 meter, attach the ground strap per the

manufacturer’s instructions.

Press the [CONFIRM] key to start the calibration. The screen will change.

4. Wait until the conductivity value is stable. When conductivity is stable, the

screen will change.

5. Once the conductivity is stable and the screen has changed, select the

Conductivity data button.

Adjust the value shown for Conductivity until it matches the reading on the

external conductivity meter and then press the [CONFIRM] key.

6. Press the [CONFIRM] key again and the screen will change.

7. The machine is now adjusting to its first reference point of conductivity for

the post conductivity cell. When the reference conductivity is stable, the

screen will change.

Page 57

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 64

8. The machine is now adjusting to a second reference point of conductivity

for the post conductivity cell. When the conductivity is stable again, the

screen will change.

Press the [CONFIRM] key to save the data. The screen will change.

Disconnect the conductivity meter and replace the dialysate lines in the shunt.

Press the [CONFIRM] key to complete the calibration and return to the

Calibrate Sensors screen.

2.3.8.2 CONDUCTIVITY CELLS CALIBRATION (v2.25 or greater)

Machines equipped with Online Clearance (OLC) have two conductivity cells.

The first conductivity cell is PRE dialyzer and the second conductivity cell is

POST dialyzer.

N

Note: If the Clearance option is set to NO in Hardware Options, the post

conductivity cell will not be calibrated.

From the Calibrate Sensors screen, select the Cond Cells screen button. The

screen will change to the following:

Page 58

Fresenius 2008K Calibration Procedures

P/N 507296 Rev B

Page 65

1. Identify the concentrate you will be using to calibrate the conductivity cells.

Select the concentrate by pressing the Conc button. The screen will

change showing a list of concentrates. Use the [

through the list to locate your concentrate.

=] or [>] keys to scroll

N

N

Note: In order to select your concentrate from the list, it must have been

previously entered in the Enter Conc screen. This screen can be found by

pressing the OPTIONS screen button.

Press the [CONFIRM] key to select your concentrate and the screen will

return to the CALIBRATE CONDUCTIVITY CELL(S) screen.

2. Connect the red and blue concentrate connectors to concentrate solutions as

in normal dialysis operation.

3. Remove the dialysate lines from the shunt and connect them to an external

conductivity meter. Close the shunt door.

Note: If using the Automata Neo-1 meter, attach the ground strap per the

manufacturer’s instructions.