Page 1

NRG 211-1

Installation Instructions 810 425- 00

Level Probe Type NRG 211-1

A Siebe Group Product

1

Page 2

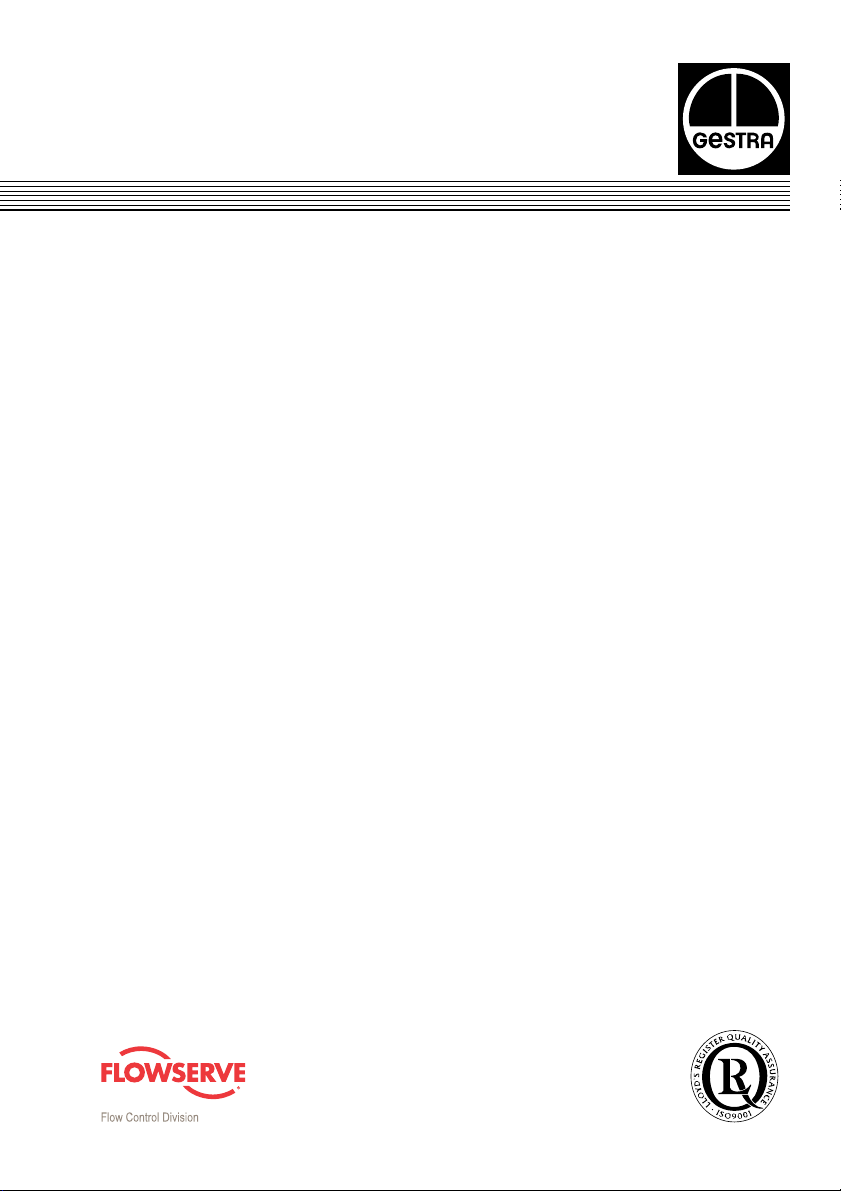

Dimensions

~118

~80

334.5

478

97

Fig. 1

∅43.5

2

Page 3

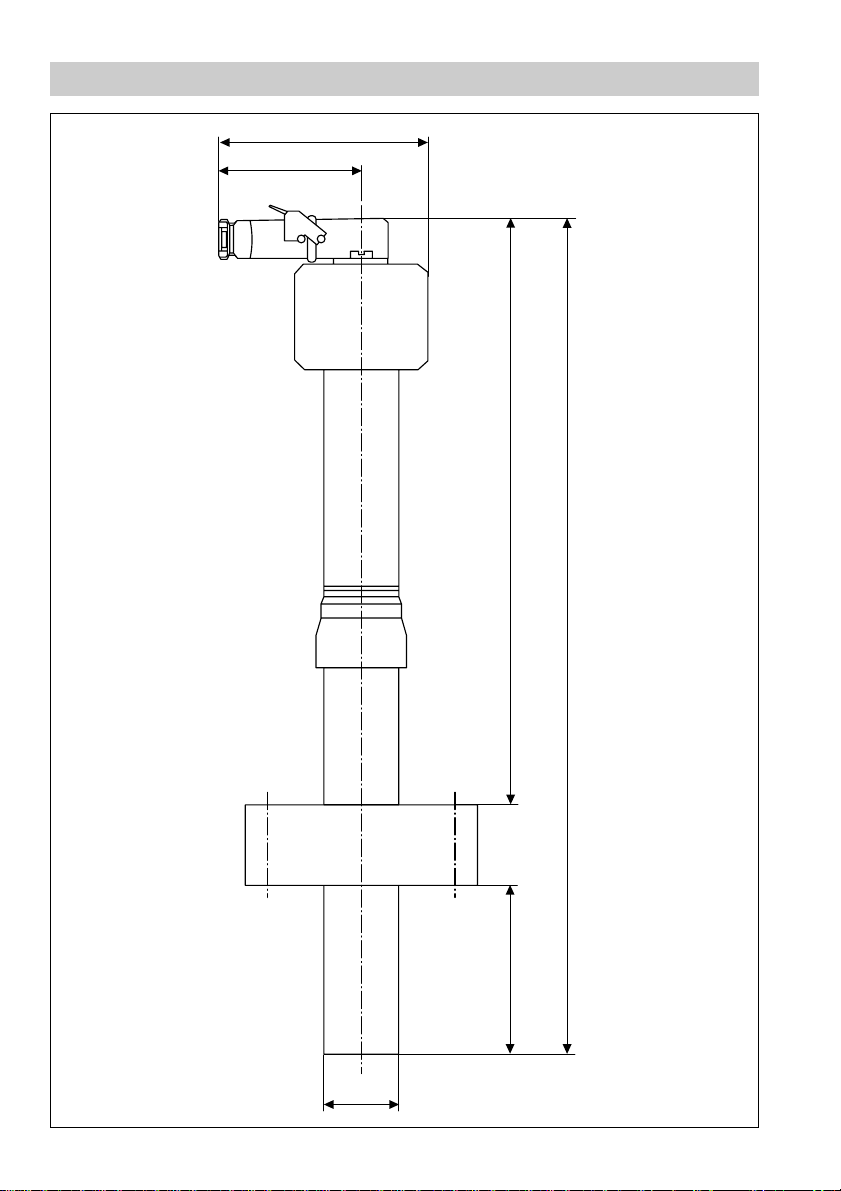

Parts Drawings

I J

HG

K

F

E

Fig. 2

L

M

N

D

C

B

A

O

3

Page 4

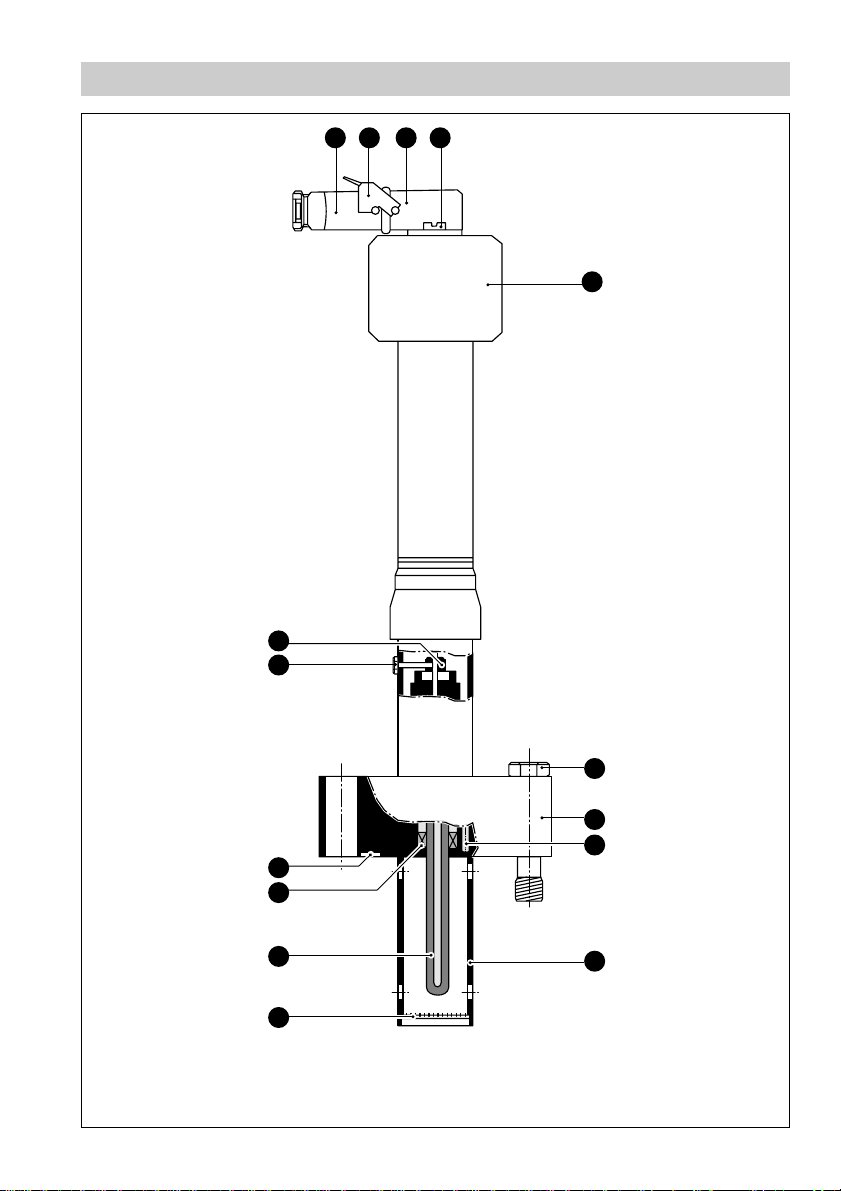

Parts Drawings

P Q G R S

40

5

Fig. 3

H

36251

4

4

Page 5

Key

A

Strainer

B

Measuring electrode

C

Stuffing box

D

Groove for gasket

E

Locking screw

F

Transit protection

G

Upper part of connector

H

Retaining clip

I

Lower part of connector

J

Fixing screw for connector

K

Terminal box with preamplifier

L

Expansion bolts

M

Flange

N

Temperature sensor

O

Protection tube

P

Cable

Q

Cable gland

R

Screw for connector insert

S

Connector insert

5

Page 6

Contents

Page

Important Notes

Safety note ...................................................................................................................... 8

Danger ............................................................................................................................ 8

Explanatory Notes

Scope of supply ..............................................................................................................9

System description .........................................................................................................9

Function .......................................................................................................................... 9

Design ............................................................................................................................. 9

Technical data – level probe .........................................................................................10

Techncial data – preamplifier........................................................................................ 10

Technical data – probe ..................................................................................................10

Installation

Welding standpipe ........................................................................................................11

Note .............................................................................................................................. 11

Danger ..........................................................................................................................11

Level probe ...................................................................................................................11

Attention........................................................................................................................11

Note .............................................................................................................................. 1 2

Tools..............................................................................................................................12

Wiring

Wiring diagram ..............................................................................................................13

Key to wiring diagram ...................................................................................................14

Attention........................................................................................................................14

Commissioning

Note ..............................................................................................................................15

Check wiring .................................................................................................................15

Apply mains voltage......................................................................................................15

Check switching function .............................................................................................. 15

Check voltage ............................................................................................................... 15

Table 1 – measuring voltages....................................................................................... 16

Check resistance thermometer .................................................................................... 16

Table 2 – resistance values ..........................................................................................16

6

Page 7

Contents – continued –

Page

Maintenance

Note ..............................................................................................................................17

Replace amplifier board................................................................................................ 17

Annex

Warning.........................................................................................................................18

Fault finding list .............................................................................................................18

Spare parts ................................................................................................................... 19

Declaration of conformity ..............................................................................................20

7

Page 8

Important Notes

Safety Note

Use level probe NRG 211-1 only in combination with GESTRA level switch

NRS 2-4/ NRS 2-5 to detect and monitor water or condensate levels.

The equipment must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident

prevention – have achieved a recognised level of competence appropriate

to the installation and commissioning of this device.

Danger

When loosening the electrode live steam or hot water might escape.

This presents the danger of severe injury. It is therefore essential not to

dismantle the electrode unless the boiler pressure is verified to be zero.

8

Page 9

Explanatory Notes

Scope of supply

NRG 211-1

1 Level probe NRG 211-1

1 Gasket with serrated faces

1 Installation Instructions

System description

The capacitance level probe NRG 211-1 serves as sensor for the level switch

NRS 2-4 (high level) / NRS 2-5 (low level) and can be used as part of a controlled

draining system in power stations or for low level detection in tanks.

Function

The electrode is designed as a rod-type capacitor, the capacitance of which is

electronically compared with a reference capacitance. The result is a levelproportional measuring voltage. The fluid temperature is measured by an integral

resistance thermometer and electronically compared with a fixed limit. When the

two values are equal in magnitude the level-proportional measuring voltage will

be limited to 4 V.

Design

NRG 211-1

Design with welding standpipe for installation in vertical pipes.

9

Page 10

Technical data – level probe

Weight

Level probe approx. 5.6 kg

Welding standpipe approx. 4.5 kg

Technical data – preamplifier

Case

Terminal box made of aluminium, painted

Wiring

Via Harting connector with 6 terminals

Cable gland PG 11

Supply voltage

12 V DC, 30 mA

Output

1–10 V DC, measuring voltage U

M

Protection

IP 54 (DIN 40050)

Admissible ambient temperature

70 ° C

Supply cable for electrode

Screened three-core cable, conductor size 0.5 mm², max. length 500 m

Technical data – probe

Connection

Probe flange PN 320 with welding standpipe for pipes DN ≤ 100; with tee piece or for

pipes DN > 100 with lateral penetration

Materials for wetted parts

Protection tube up to 500°C St 35 (1.0305)

Protection tube up to 550°C 10 CrMo 9 10 (1.7380)

Strainer X 6 CrNiMoTi 17-12-2 (1.4571)

Insulting seal of probe rod Special ceramics material

Flange joint ring X 6 CrNiTi 18-10 (1.4541)/silver

Max. admissible pH value

10 (for ceramics insulation)

Temperature sensor

Pt 1000

Pressure/Temperature ratings

Material for flange/welding standpipe 1.5415 1.7380 1.4922

Admiss. service pressure

Admiss. service temperature

[bar] 4320 2200 320 2200 4320 3230

[psig] 4642 2901 4642 2901 4642 3336

[°C] 4120 2450 120 2500 4120 3550

[°F] 4248 2842 248 2932 4248 1022

10

Page 11

Installation

Welding standpipe

Weld standpipe inclined upwards by at least 5° onto vertical pipe to ensure that the

standpipe can completely empty if the level falls. Make sure that the marking TOP is

on top. See Fig. 5 on page 21

Note

n

We recommend full-penetration butt welding (e. g. type 22 to DIN 2559)

for the connection to pipes (tee pieces) DN ≤ 100.

With larger pipes the welding standpipe can be introduced through a

lateral penetration and then be welded.

Danger

n

During the welding process and post weld heat treatment of the

standpipe the temperature of the flange seating surface must not

exceed 350 °C.

Level probe

1. Clean flange seating surfaces.

2. Insert joint ring into the groove of the welding standpipe.

3. Put the probe onto it such that the connector at the terminal box shows to the

bottom.

4. Tighten expansion bolts in diagonally opposite pairs with a torque of 170 Nm .

5. Tighten expansion bolts in diagonally opposite pairs with a torque of 130 Nm .

6. Remove the locking screw of the transit protection .

L

L

E F

I

Attention

n

Handle level probe with care. Avoid subjecting the probe to mechanical

shocks as this might cause damage to the ceramic insulating seal and

consequent leakage.

n

Do not lag the body of the electrode above the mounting flange.

n

When removing the level probe for inspection work store it in a vertical

position.

11

Page 12

Installation – continued –

Note

n

The joint ring has serrated faces and silver coated rings at both ends

which must not be removed.

Tools

n

Open-end spanner, A. F. 27 mm

n

Screwdriver for slotted screws, size 6 mm, completely insulated to VDE 0680

12

Page 13

Wiring

Use screened three-core cable, min. conductor size 0.5 mm², max. length 500 m.

1. Lift up the retaining clip and remove the upper part of the connector . Fig. 3

2. Remove screw and connector insert .

R

3. Completely unscrew the cable gland and slip it over the cable .

4. Strip off cable insulation coating and remove conductor end insulation.

5. Insert cable into the upper part of the connector and effect wiring to connector

S

insert acc. to wiring diagram. Fig. 4

P

P G

6. Fix connector insert with the aid of screw , screw in cable gland and tighten.

7. Insert the upper connector par t into the lower connector part and lock by

means of the retaining clip .

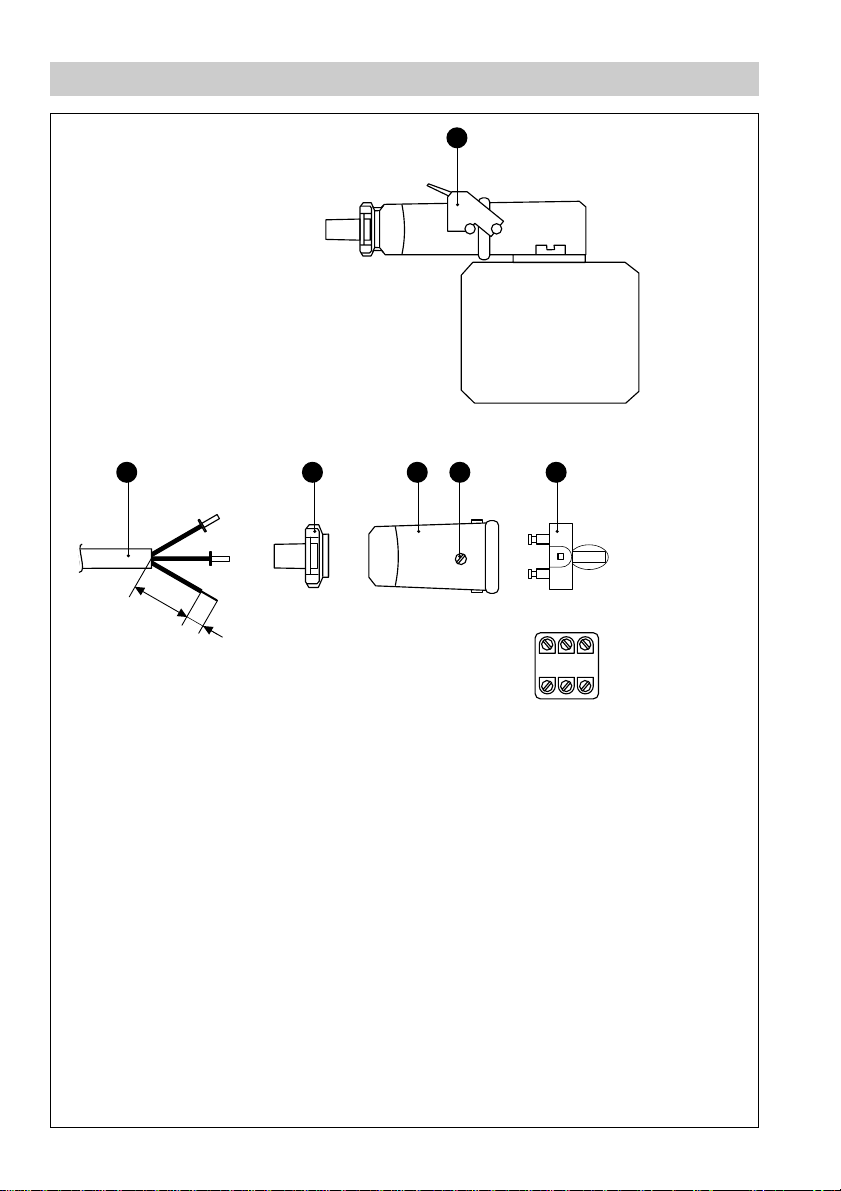

Wiring diagram

H G

S

Q P

S R Q

G I

H

1

2

Fig. 4

NRG 211

C

M

NRV 2-30

4

321

U

M

6

3

4

5

6

ϑ

6

5

Ω

Pt 1000

13

Page 14

Key to wiring diagram

1

Supply voltage 12 V DC

2

Measuring voltage 1– 10 V DC

3

Pins

4

For resistance measurement: strip off conductor

5

For resistance measurement: Pt 1000

6

Fixing screws for amplifier board

Attention

n

Screen must not make any other electrical contact.

n

Connect the screen to the level switch only.

n

When switching off inductive loads, voltage spikes are produced

that may impair the operation of control and measuring systems.

Inductive loads should be provided with commercial arc suppressor

RC combinations, e. g. 0.1 µF/100 Ω.

14

Page 15

Commissioning

Note

The level probe NRG 211-1 can only be operated and checked in combination with the level switch NRS 2-4 (high level) or NRS 2-5 (low level).

Check wiring

1. Check whether the 19" slide-in unit has been properly installed in the magazine.

2. Check whether the mains supply corresponds to the wiring carried out on the level

probe.

Apply mains voltage

1. Switch on the mains supply and check whether the mains voltage is applied

across the level switch. See installation instructions NRS 2-4 or NRS 2-5.

Check switching function

1. With level switch NRS 2-4

Check the switching function “high level”. To assist with this objective raise the water

level in the tank above the preset high level. The LED high level located at the level

switch NRS 2-4 must light up and the corresponding function in the secondary

circuit must be operated.

With level switch NRS 2-5

Check the switching function “low level”. To assist with this objective lower the water

level in the tank below the preset low level. The LED low level located at the level

switch NRS 2-5 must light up and the corresponding function in the secondary

circuit must be operated.

2. Raise (NRS 2-5) or lower (NRS 2-4) the water level in the tank. The level electrode

NRG 211-1 must switch back to normal operation.

Check voltage

1. Check the supply and measuring voltage of the level electrode. The voltages can

be measured at the electrode or level switch. Fig. 4

Supply voltage: 12 V DC

Measuring voltage: see table 1 – measuring voltages on page 16

In order to check the measuring voltage for probe exposed refer to “Check

Resistance Thermometer”

15

Page 16

Table 1 Measuring voltages

Measuring voltage U

Decoding NRS 2-4 Decoding NRS 2-5

M

≤ 0 V – 1 V Malfunction in probe Malfunction in probe

supply line (short circuit supply line (short circuit

or interruption) or interruption)

= 1 V – 4 V Probe exposed / fluid Probe submerged

temperature ≥ 395°C

= 4 V – 7 V Probe submerged, Probe exposed,

HIGH level LOW level

≥ 9 V Malfunction in probe Malfunction in probe

(defective insulating seal, (defective insulating seal,

leaky stuffing box) leaky stuffing box)

Check resistance thermometer

1. Check the built-in resistance thermometer Pt 1000 and the measuring voltage

for

ELECTRODE EXPOSED. Lift the retaining clip and remove the upper part of

the connector . Fig. 3

2. Remove screw and connector insert .

3. Completely unscrew cable gland and slip it over the cable .

G

R

Q

H

S

P

4. Pull out the sensor supply cable for the thermometer and connect the ohmmeter.

Fig. 4

5. The setpoint to be measured depends on the plant temperature, see table 2

RESISTANCE VALUES.

6. Check measuring voltage: it must be within 1 – 4 V DC (electrode exposed)

7. Reconnect the sensor supply cable.

8. Fix connector insert with screw , screw in cable gland and tighten.

9. Put upper part of the connector into lower part of the connector and lock by

means of retaining clip .

S R

G

H

Q

I

Table 2 Resistance values

°C0 102030405060708090100Ω/°C

100 1000.0 1039.0 1077.9 1116.7 1155.4 1194.0 1232.4 1270.7 1308.9 1347.0 1385.0 3.85

100 1385.0 1422.8 1460.6 1498.2 1535.7 1573.2 1610.1 1647.6 1684.7 1721.6 1758.4 3.73

200 1758.4 1795.1 1831.7 1868.2 1904.6 1940.8 1977.0 2013.0 2048.8 2084.6 2120.3 3.61

300 2120.3 2155.8 2191.3 2226.6 2261.8 2296.9 2331.9 2366.7 2401.5 2436.1 2470.6 3.50

400 2470.6 2505.0 2539.3 2573.4 2607.5 2641.4 2675.2 2708.9 2742.5 2776.0 2809.3 3.38

500 2809.3 2842.6 2875.7 2908.7 2941.6 2974.3 3007.0 3039.5 3072.0 3104.3 3136.5 3.27

600 3136.5 3168.6 3200.5 3232.4 3264.1 3295.7 3327.2 3358.6 3389.9 3421.0 3452.1 3.15

700 3452.1 3483.0 3513.8 3544.5 3575.1 3605.5 3635.9 3666.1 3696.2 3726.2 3756.1 3.04

800 3756.1 3815.5 3815.5 3845.0 3874.5 3903.8 –––––2.95

Mean values of 100 °C ranges

16

1

Page 17

Maintenance

Note

n

Store probe only in vertical position.

Replace amplifier board

1. Unscrew fixing screw and remove terminal box cover. Fig. 2

J

2. Withdraw all terminals from pins.

3. Unscrew fixing screw and remove board. Fig. 4

4. Insert new board and screw in fixing screws .

6

6

5. Connect terminals to pins.

6. Re-install terminal box cover, screw in fixing screw and tighten.

J

17

Page 18

Annex

Warning

The terminal strip of the NRS 2-4/NRS 2-5 is live during operation. This

presents the danger of electric shock.

Cut off power supply before inserting or removing the 19" slide-in unit and

before undertaking any installation or maintenance work.

Fault finding list

Green LED OPERATION at level switch NRS 2-4 / NRS 2-5 is not illuminated

Fault: The supply voltage has failed.

Remedy: Measure the voltage across A/C28 and A/C30 of the NRS 2-4 / NRS 2-5.

Check power supply and wiring.

No function when level falls or rises – LED

HIGH LEVEL on level switch NRS 2-4 or LOW LEVEL on level switch NRS 2-5

MALFUNCTION IN PROBE and

are illuminated

Fault: The locking screw has not been removed from the level probe NRG 211-1.

Remedy: Remove locking screw.

Fault: Defective level probe (defective insulating seal, untight stuffing box)

Remedy: Measure voltage across C18/A18 of NRS 2-4 / NRS 2-5. Measure voltage

across terminals 2 and 3 of the NRG 211-1. If voltage ≥ 9 V check probe

supply cable and wiring.

No function when level falls or rises – LED

MALFUNCTION IN CABLE on level switch

NRS 2-4 / NRS 2-5 is illuminated

Fault: Malfunction in probe supply cable (short circuit, interr uption).

Remedy: Measure voltage across C18/A18 of NRS 2-4 / NRS 2-5. Measure voltage

across terminals 2 and 3 of level probe NRG 211-1. If voltage ≤ 1 V check

probe supply cable and wiring.

Level switch NRS 2-4: No function when level falls or rises or when high level

is exceeded – only the green LED

OPERATION of the level switch NRS 2-4 is

illuminated

Fault: Level probe does not enter the liquid.

Remedy: Measure voltage across C18/A18 of NRS 2-4. Check installation of

NRG 211-1 and measure voltage across terminals 2 and 3. If necessary

change position of installation of the level probe.

Fault: Defective level switch.

Remedy: Measure voltage across C16/A18 (supply voltage for level probe) on

NRS 2-4. Replace level switch if no voltage can be measured.

Fault: Defective preamplifier.

Remedy: Measure voltage across C18/A18 of NRS 2-4. Measure supply voltage

across terminals 1 and 3 of NRG 211-1 and measuring voltage across

terminals 2 and 3. If supply voltage = 12 V and no measuring voltage can

be measured, replace preamplifier.

18

Page 19

Annex – continued –

Fault: Defective temperature sensor.

Remedy: Check the measuring voltage across terminals 2 and 3 of NRG 211-1.

If the supply voltage 1 – 4 V check temperature sensor. If temperature

sensor is defective replace level probe.

Level switch NRS 2-5: No function when level falls or rises or when level is

below min. level – only the green LED

illuminated

Fault: Level probe does not enter the liquid.

Remedy: Measure voltage across C18/A18 of NRS 2-5. Check installation of

NRG 211-1 and measure voltage across terminals 2 and 3. If necessary

change position of installation of the level probe.

Fault: Defective level switch.

Remedy: Measure voltage across C16/A18 (supply voltage for level probe) on

NRS 2-5. Replace level switch if no voltage can be measured.

Fault: Defective preamplifier.

Remedy: Measure voltage across C18/A18 of NRS 2-5. Measure supply voltage

across terminals 1 and 3 of NRG 211-1 and measuring voltage across

terminals 2 and 3. If supply voltage = 12 V and no measuring voltage

can be measured, replace preamplifier.

Fault: Defective temperature sensor.

Remedy: Check the measuring voltage across terminals 2 and 3 of NRG 211-1.

If supply voltage = 1 – 4 V check temperature sensor. If temperature

sensor is defective replace level probe.

The temperature measured by means of the resistance thermometer does not

correspond to the actual installation temperature

Fault: Defective Pt 1000.

Remedy: Replace level probe.

Spare parts

OPERATION of the level switch NRS 2-5 is

Designation Reference no.

Amplifier board NRV 2-30 391 241

19

Page 20

Annex – continued –

Declaration of conformity

We hereby declare that the equipment NRG 211-1 conforms to the following

European guidelines:

n

LV guideline 73/23/EWG version 93/68/EWG

n

EMC guideline 89/336/EWG version 93/68/EWG

which are based on the following harmonised standards:

n

LV standard EN 60947-5-1: 1991

n

EMC standard EN 50 081-2, EN 50 082-2

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 28th April 1997

GESTRA GmbH

Dr. Anno Krautwald

Dr. Christian P olitt

20

Page 21

Examples of Installation

DN ≤ 100/4"

8

≈12

7

8

Fig. 5

∅ 63.5

8

≈24

∅ 63.5

DN ≥ 100/4"

Key

A

By customer

B

Welding standpipe (GESTRA)

21

Page 22

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

España

España

GESTRA ESPAÑOLA S.A.

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

Luis Cabrera, 86-88

E-28002 Madrid

E-28002 Madrid

Tel. 003491/5152032

T el. (+34) 915152032

Fa x0 0349 1/413674 7; 515203 6

Fax (+34) 914136747; (+34) 915152036

E-mail: gestra@gestra.es

Polska

Polska

GESTRA POLONIA Spolka zo.o.

GESTRA POLONIA Spolka z. o.o.

Ul. Schuberta 104, P.O. Box 71

Ul. Schuberta 1 04, P.O.B. 727

PL-80-172 Gdansk

PL-80-958 Gdansk 50

Tel. 00 4858/3061002 oder 30610 10

T el. (58) 3061002

Fax 00 4858 /3061003 oder 30633 00

Fax (58) 3061003

E-mail: gestra@gestra.pl

France Portugal

France Portugal

GESTRA S.A.R.L.

10 Avenue du Centaure, BP 8263 CERGY

Flowserve Flow Control S.A.S.

F-95801 CERGY PONTOISE Cedex

10 Avenue du Centaure, BP 8263

Tél. (00 33) 01.34.43.26.60

F-95801 CERGY PONTOISE CEDEX

Fax (0033) 01.34.43.26.87

Tél. 0 0331/3443 2660

Fax 00331/34432687

Great Britain

E-mail: gnation@flowserve.com

GESTRA (U.K.) LTD.

9-11 Bancroft Court

Italia

Hitchin, Hertfordshire, SG5 1PH

T el. (01462) 4316 81

Italgestra S.r.l.

Fax (014 62) 4203 96

Via Carducci 125

l-20099 Sesto San Giovanni (MI)

Italia

Tel. 00 3902/2410 12.1

Fax 00 3902/2410 12.460

ITALGESTRA S.r.l.

E-mail: info@italgestra.it

Via Carducci 125

l-20099 S.S. Giovanni (MI)

T el. (02) 26297 -0

Fax (02) 26297460

GESTRA PORTUGUESA VAL VULAS LDA.

Av . Dr . Antunes Guimarães, 1159

GESTRA PORTUGUESA VALVULAS LDA.

P-4100 Porto

Av. Dr. Antunes Guimarães, 1159

T el. (2) 6107551

Porto 4100-082

Fax (2) 610 7575

Tel. 0035122/6 198770

Fax 0035122/ 6107575

USA

E-mail: gestra@gestra.pt

GESTRA Division

10 Y ork Avenue

West Caldwell, NJ 07006

T el. (973) 403-1556

Fax (973) 4 03-1557

®

®

GESTRA GmbH

Postfach 10 54 6 0

GESTRA GmbH

D-28054 Bremen

Münchener Str. 77

Hemmstraße 130

D-28215 Bremen

D-28215 Bremen

Tel. +49 (0) 421 35 03-0

Tel. +49 (0) 421 35 03-0

Fax+49 (0) 421 35 03-393

Fax +49 (0) 421 35 03-393

E-mail

gestra.gmbh@gestra.de

Internet www.gestra.de

Internet www.gestra.de

E-mail

gestra.gmbh@gestra.de

A Unit of Flowserve Corporation

A Siebe Group Company

810425-00/499c · ©1997 GESTRA GmbH · Bremen · Printed in Germany

22

Loading...

Loading...