Page 1

Page 2

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the

government of the country from where the product is exported.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 3

B–64160EN/01

PREFACE

PREFACE

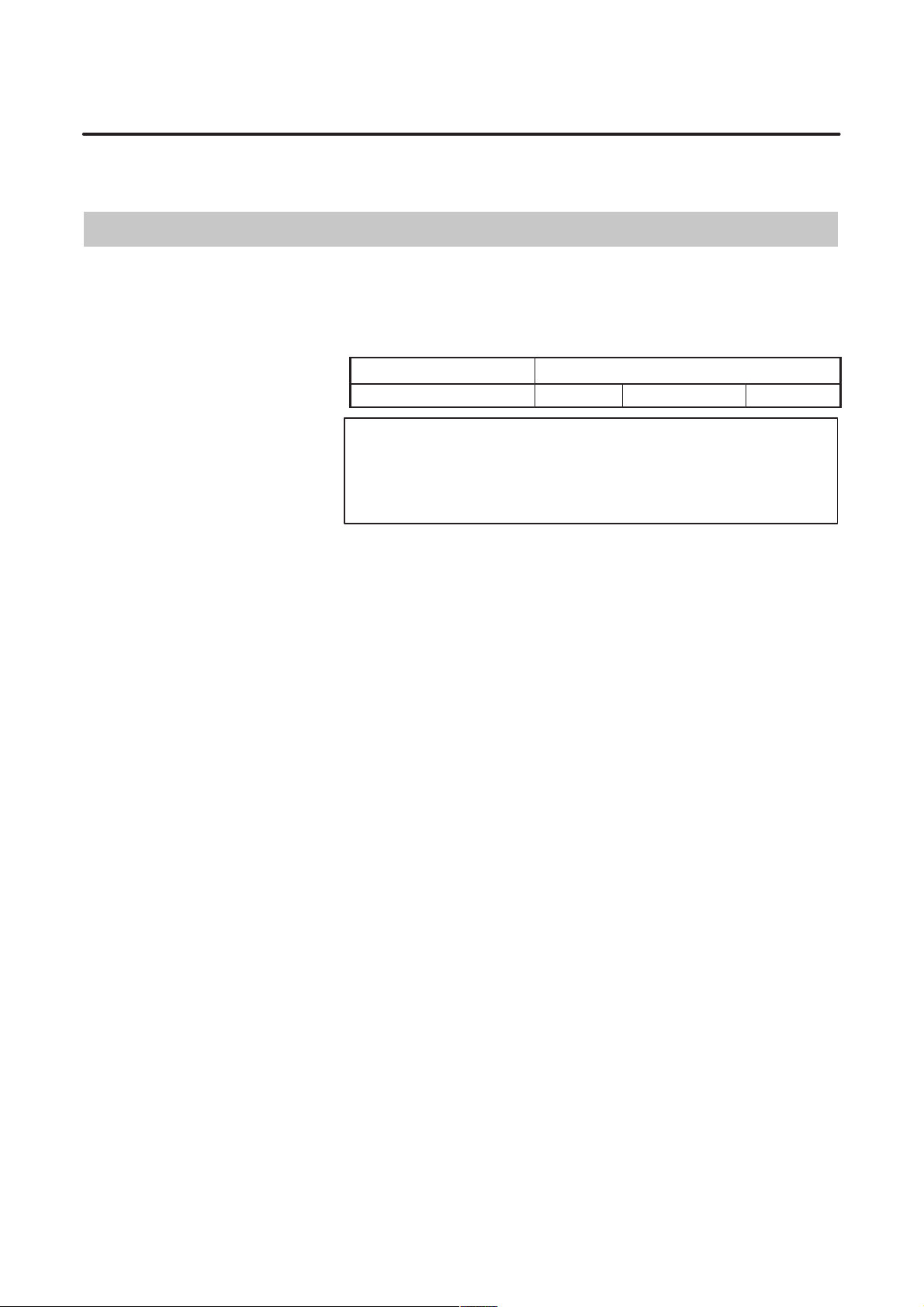

The mode covered by this manual, and their abbreviations are :

Product Name Abbreviations

FANUC Series 0i–PC 0i–PC Series 0i–C 0i

NOTE

Some functions described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS (B–64112EN).

p–1

Page 4

PREFACE

B–64160EN/01

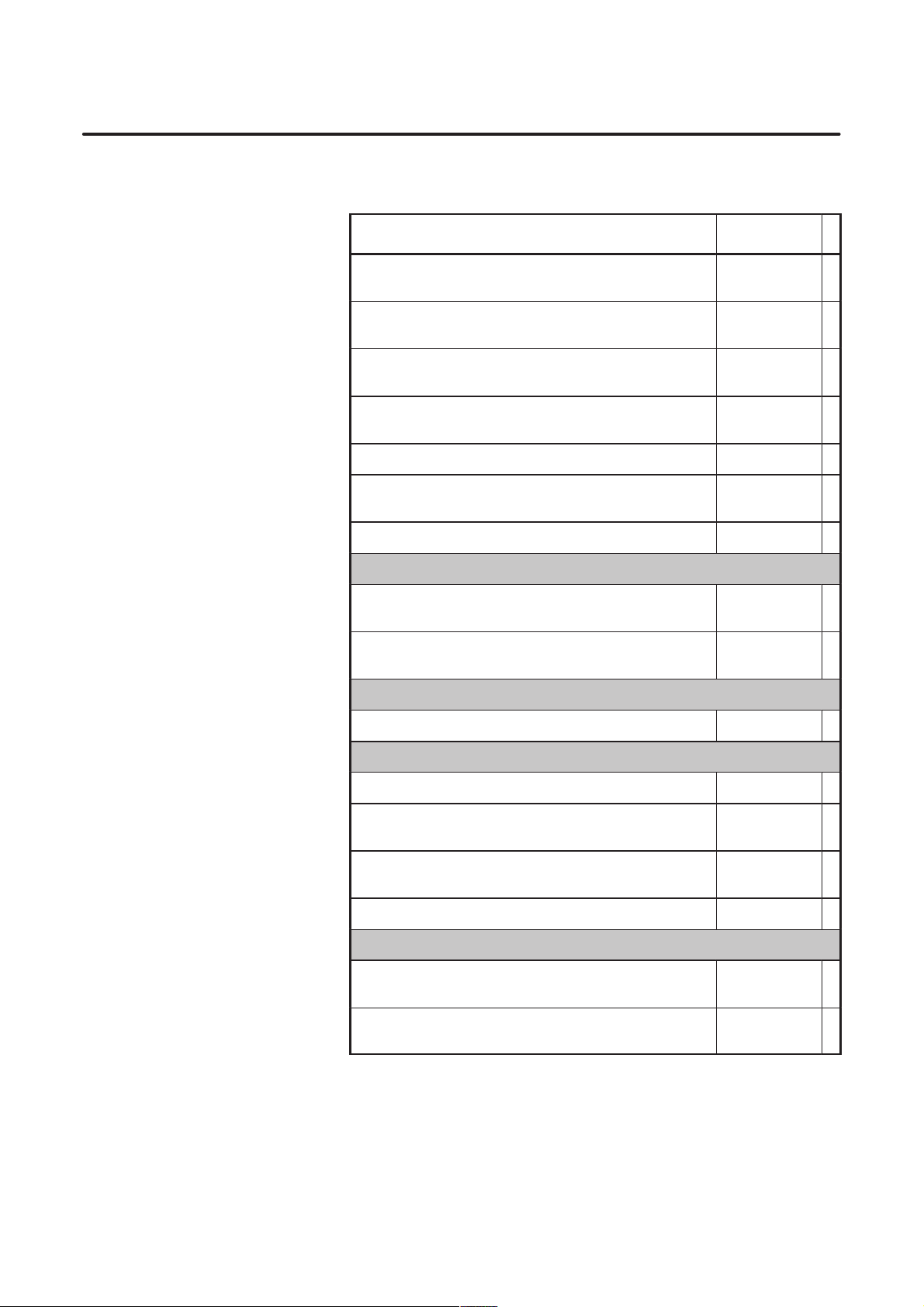

Related manuals of

Series 0i–PC

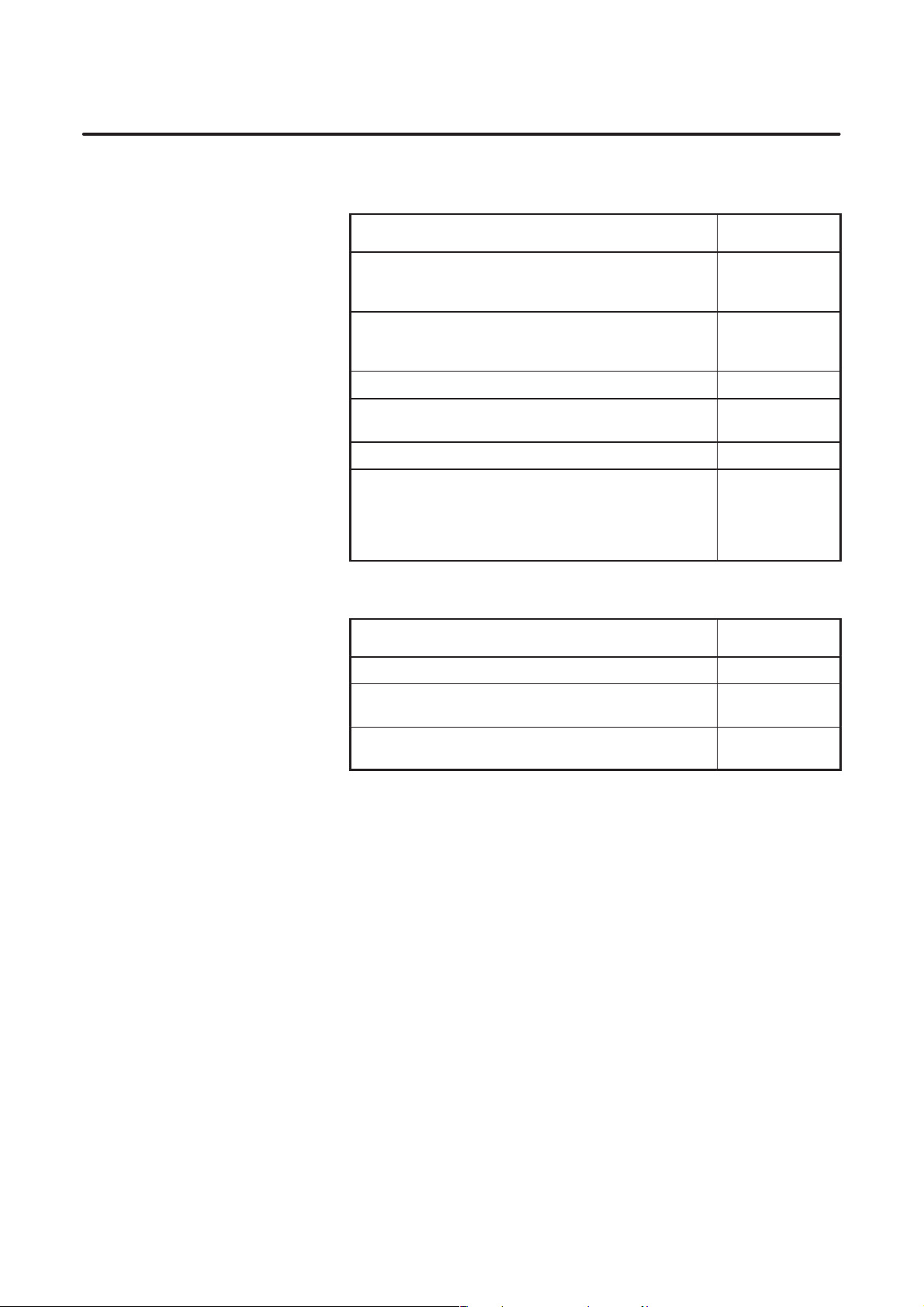

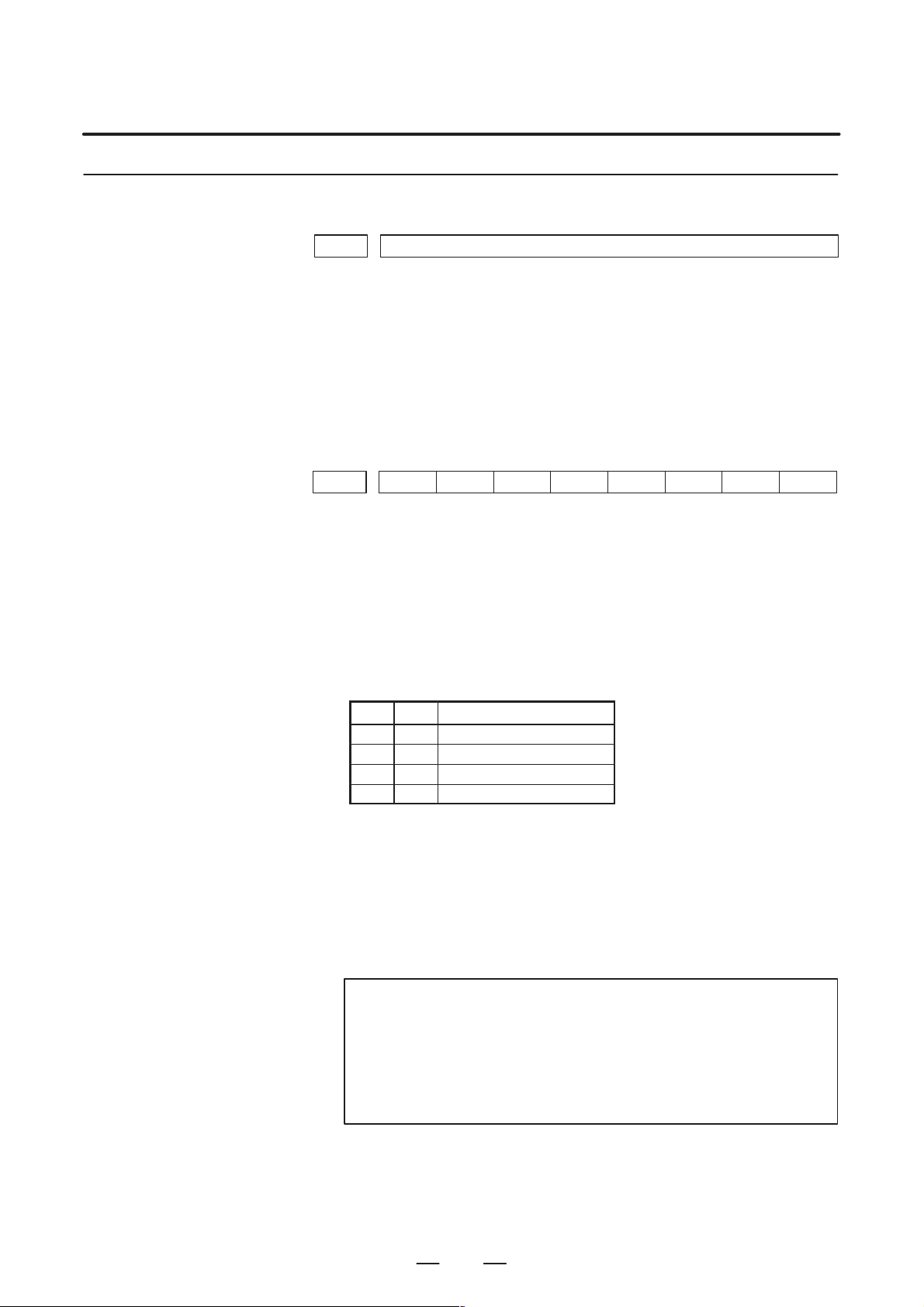

The following table lists the manuals related to Series 0i–PC.

This manual is indicated by an asterisk(*).

Manual name

FANUC Series 0i–MODEL C/0i Mate–MODEL C

DESCRIPTIONS

FANUC Series 0i–MODEL C/0i Mate–MODEL C

CONNECTION MANUAL (HARDWARE)

FANUC Series 0i–MODEL C/0i Mate–MODEL C

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–PC

CONNECTION MANUAL (FUNCTION)

FANUC Series 0i–PC OPERATOR’S MANUAL B–64154EN

FANUC Series 0i–MODEL C/0i Mate–MODEL C

MAINTENANCE MANUAL

FANUC Series 0i–PC PARAMETER MANUAL B–64160EN *

PROGRAMMING MANUAL

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

Specification

number

B–64112EN

B–64113EN

B–64113EN–1

B–64153EN

B–64115EN

B–61803E–1

FAPT MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

Network

Profibus–DP Board OPERA T OR’S MANUAL B–62924EN

FAST Ethernet Board/FAST DA TA SERVER

OPERA T OR’S MANUAL

Ethernet Board/DA T A SERVER Board

OPERA T OR’S MANUAL

DeviceNet Board OPERA T OR’S MANUAL B–63404EN

Open CNC

FANUC OPEN CNC Basic Operation Package 1

(For Windows95/NT) OPERA TOR’S MANUAL

FANUC OPEN CNC (DNC Operation Management

Package) OPERATOR’S MANUAL

B–66102E

B–63644EN

B–63354EN

B–62994EN

B–63214EN

p–2

Page 5

B–64160EN/01

PREFACE

Related manuals of

SERVO MOTOR ais/

ai series

Related manuals of

Servo Motor β series

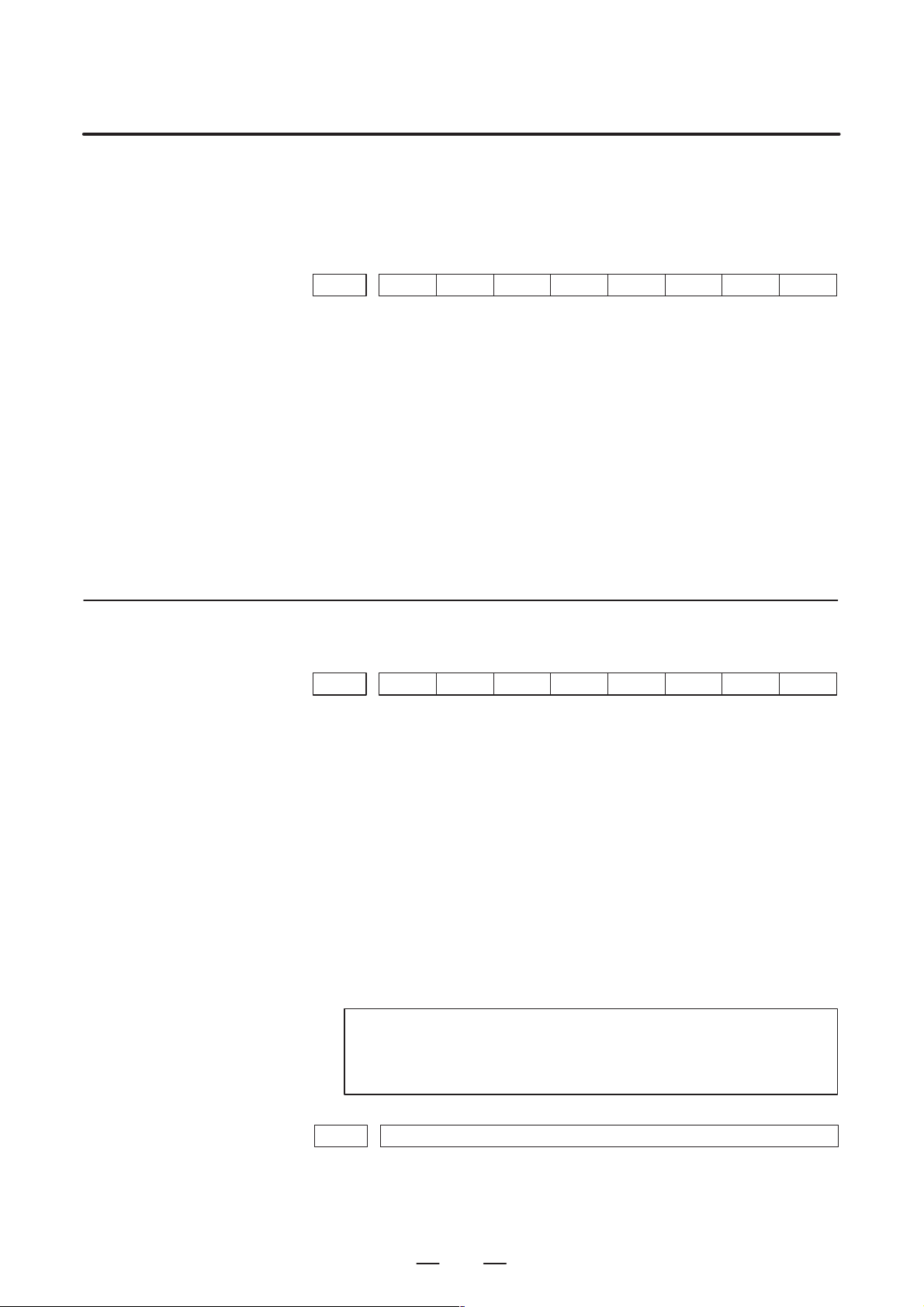

The following table lists the manuals related to SERVO MOTOR ais/

ai series.

Manual name

FANUC AC SER VO MOTOR ais series

FANUC AC SER VO MOTOR ai series

DESCRIPTIONS

FANUC AC SER VO MOTOR ais series

FANUC AC SER VO MOTOR ai series

P ARAMETER MANUAL

FANUC AC SPINDLE MOT OR ai series DESCRIPTIONS B–65272EN

FANUC AC SPINDLE MOT OR ai series

P ARAMETER MANUAL

FANUC SER VO AMPLIFIER ai series DESCRIPTIONS B–65282EN

FANUC AC SER VO MOTOR ais series

FANUC AC SER VO MOTOR ai series

FANUC AC SPINDLE MOT OR ai series

FANUC SER VO AMPLIFIER ai series

MAINTENANCE MANUAL

Specification

number

B–65262EN

B–65270EN

B–65280EN

B–65285EN

The following table lists the manuals related to Servo Motor β series.

Manual name

FANUC SER VO MOT OR β series DESCRIPTIONS B–65232EN

Specification

number

FANUC SER VO MOT OR β series

MAINTENANCE MANUAL

FANUC SER VO MOT OR β series(I/O Link Option)

DESCRIPTIONS

B–65235EN

B–65245EN

p–3

Page 6

Page 7

B–64160EN/01

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAYING PARAMETERS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SETTING PARAMETERS FROM MDI 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE

READER/PUNCHER INTERF ACE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE 5. . . . . . . .

3.2 INPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE 6. . . . . . . . . .

4. DESCRIPTION OF PARAMETERS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PARAMETERS OF SETTING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 PARAMETERS OF READER/PUNCHER INTERFACE 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Parameters Common to all Channels 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Parameters of Channel 1 (I/O CHANNEL=0) 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Parameters of Channel 1 (I/O CHANNEL=1) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Parameters of Channel 2 (I/O CHANNEL=2) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PARAMETERS OF DNC2 INTERFACE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PARAMETERS OF REMOTE DIAGNOSIS 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 PARAMETER OF MEMORY CARD INTERFACE 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 PARAMETERS OF DATA SERVER 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 PARAMETERS OF ETHERNET 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 PARAMETERS OF POWER MATE CNC MANAGER 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 PARAMETERS OF AXIS CONTROL/INCREMENT SYSTEM 28. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 PARAMETERS OF COORDINATES 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 PARAMETERS OF STROKE CHECK 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 PARAMETERS OF FEEDRATE 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 PARAMETERS OF ACCELERATION/DECELERATION CONTROL 49. . . . . . . . . . . . . . . . . . . . .

4.14 PARAMETERS OF SERVO 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 PARAMETERS OF DI/DO 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 PARAMETERS OF DISPLAY AND EDIT 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 PARAMETERS OF PROGRAMS 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.18 PARAMETERS OF PITCH ERROR COMPENSATION 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.19 PARAMETERS OF TOOL COMPENSATION 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.20 PARAMETERS OF SCALING/COORDINATE ROTATION 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 PARAMETERS OF NORMAL DIRECTION CONTROL 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.22 PARAMETERS OF CUSTOM MACROS 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 PARAMETERS OF SKIP FUNCTION 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.24 PARAMETERS OF EXTERNAL DATA INPUT/OUTPUT 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.25 PARAMETERS OF GRAPHIC DISPLAY 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.26 PARAMETERS OF DISPLAYING OPERATION TIME AND NUMBER OF PARTS 136. . . . . . . . . .

4.27 PARAMETERS OF POSITION SWITCH FUNCTIONS 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 PARAMETERS OF MANUAL HANDLE FEED AND HANDLE INTERRUPTION 144. . . . . . . . . . .

4.29 PARAMETERS OF SOFTWARE OPERATOR’S PANEL 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 8

4.30 PARAMETERS OF AXIS CONTROL BY PMC 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.31 PARAMETERS OF SIMPLE SYNCHRONOUS CONTROL 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.32 PARAMETERS OF SEQUENCE NUMBER COMPARISON AND STOP 162. . . . . . . . . . . . . . . . . . .

4.33 PARAMETERS OF FS0i BASIC FUNCTIONS 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.34 OTHER PARAMETERS 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.35 PARAMETERS OF MAINTENANCE 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.36 PARAMETERS OF OPERATION HISTORY 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.37 PARAMETERS OF THE PRESS FUNCTION 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.38 PARAMETERS FOR THE SPEED AND LOOP GAIN SWITCH 185. . . . . . . . . . . . . . . . . . . . . . . . . .

4.39 PARAMETERS FOR THE NIBBLING FUNCTION 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.40 PARAMETERS FOR THE PATTERN FUNCTION 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.41 PARAMETERS FOR THE TURRET AXIS 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.42 PARAMETERS FOR C–AXIS CONTROL 207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.43 PARAMETERS FOR THE SAFETY ZONE 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.44 ADDITIONAL PARAMETERS FOR DI/DO SIGNALS 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

Table of Contents

B–64160EN/01

A. CHARACTER CODE LIST 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 9

B–64160EN/01

1

DISPLAYING PARAMETERS

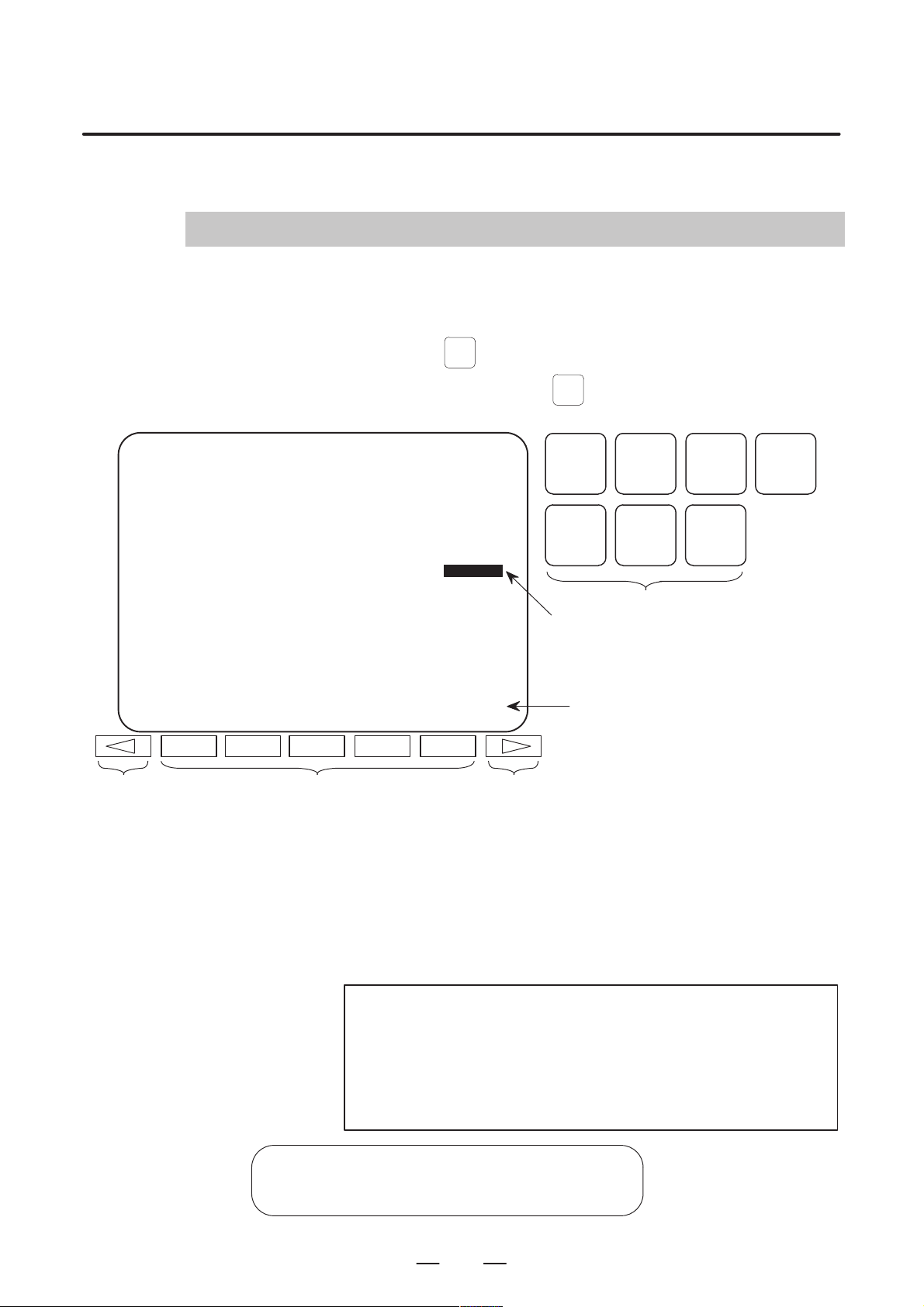

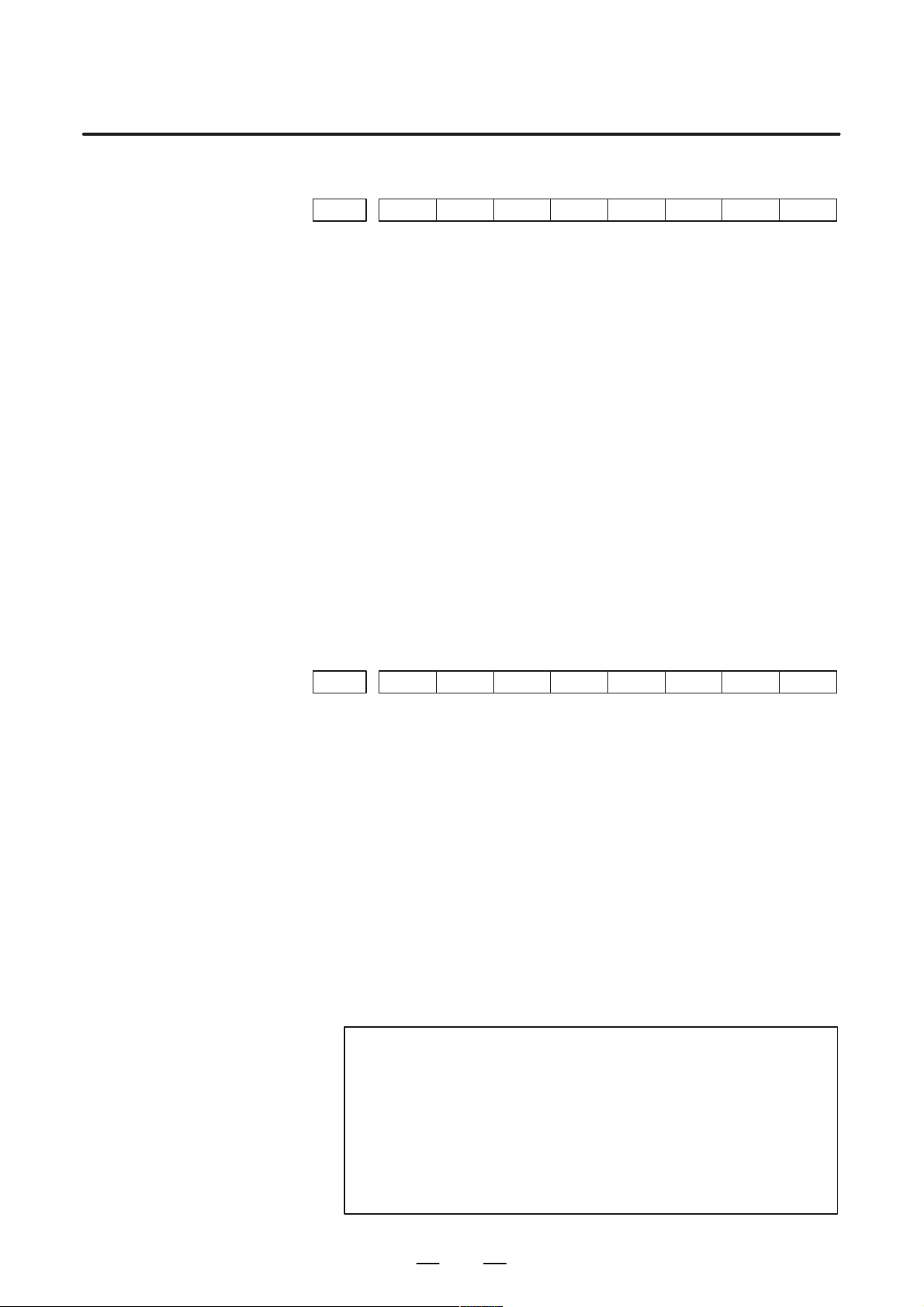

Follow the procedure below to display parameters.

(1) Press the

SYSTEM

1. DISPLAYING PARAMETERS

function key on the MDI as many times as required,

or alternatively , press the

SYSTEM

section display soft key. The parameter screen is then selected.

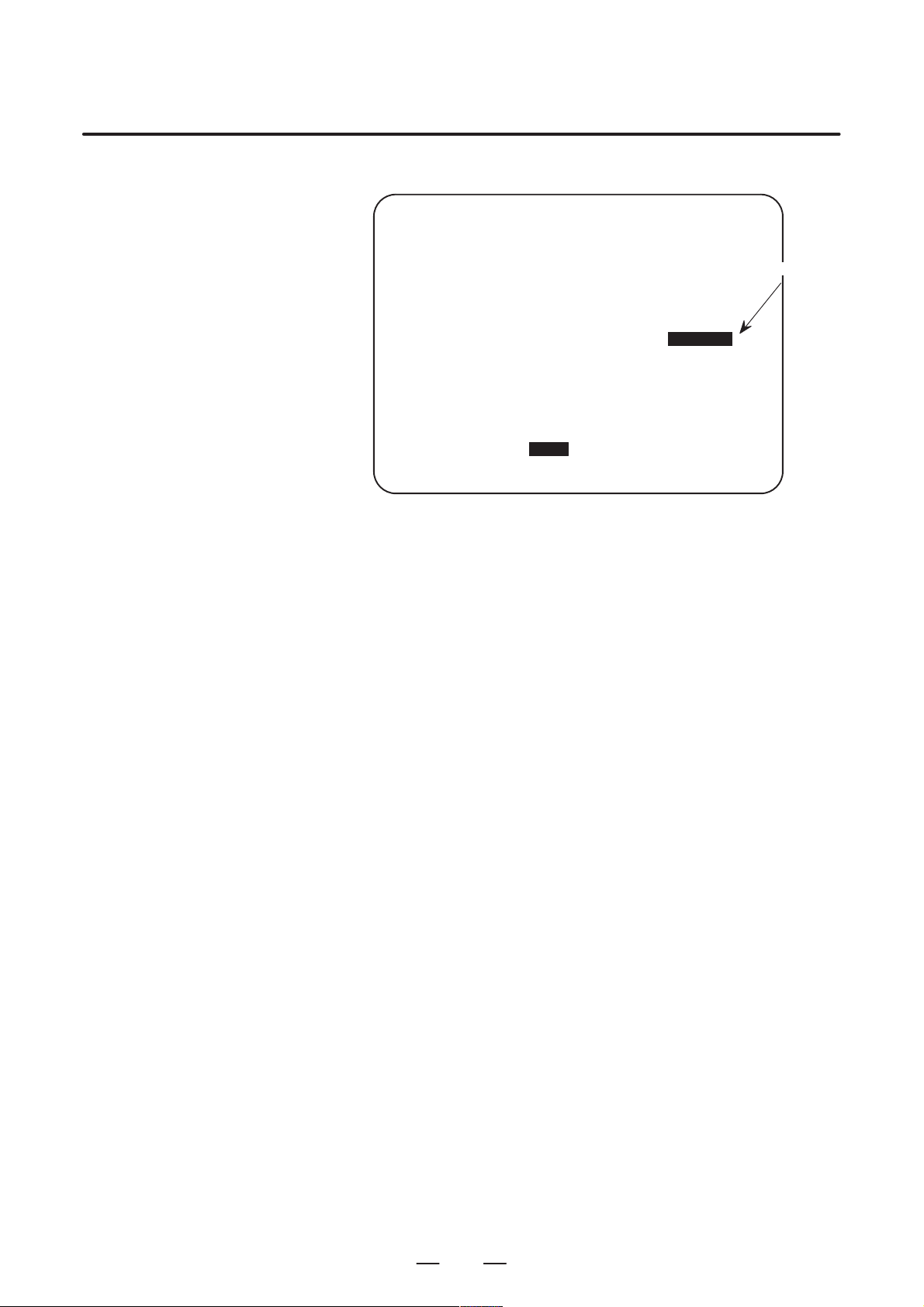

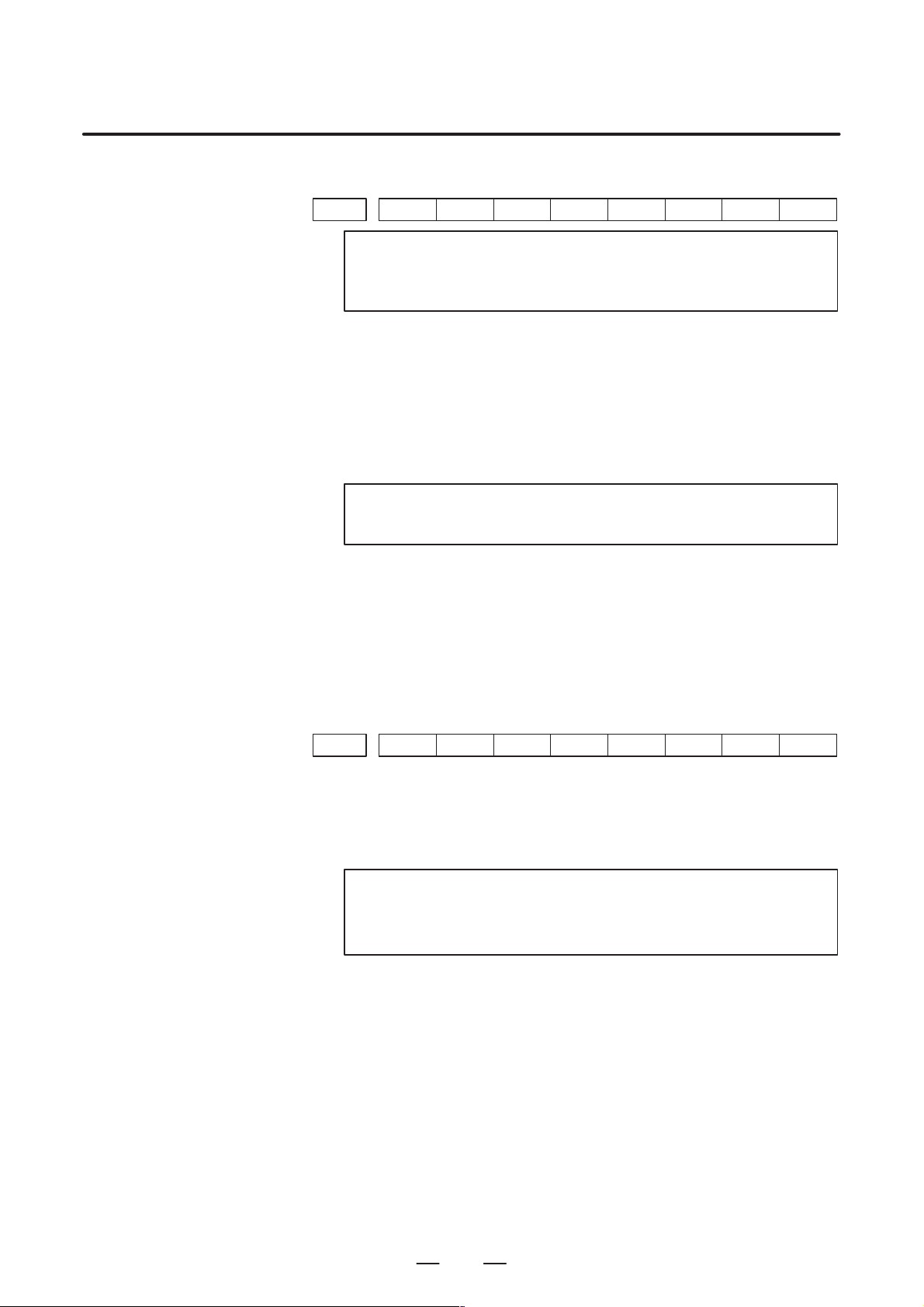

PARAMETER (FEEDRATE) O0001 N12345

1401 RDR JZR RF0 LRP RPD

0 0 0 0 0 0 0 0

1402 DLF HFC

0 0 0 0 0 0 0 0

1410 DRY RUN FEEDRATE 10000

1411 INIT.CUTTING F 0

1420 RAPID FEEDRATE X 15000

Y 15000

Z 15000

>

MEM STRT MTN FIN *** 10:02:35

[PARAM] [DGNOS] [ PMC ] [SYSTEM] [(OPRT)]

Return menu key Soft key Continuous menu key

POS PROG

SYSTEM MESSAGE GRAPH

Cursor

(2) The parameter screen consists of multiple pages. Use step (a) or (b)

to display the page that contains the parameter you want to display.

(a) Use the page select key or the cursor move keys to display the de-

sired page.

(b) Enter the data number of the parameter you want to display from

the keyboard, then press the [NO.SRH] soft key. The parameter

page containing the specified data number appears with the cursor positioned at the data number. (The data is displayed in reverse video.)

function key once, then the PARAM

OFFSET

SETTING

Function key

Soft key display

(section select)

CUSTOM

NOTE

If key entry is started with the section select soft keys

displayed, they are replaced automatically by operation

select soft keys including [NO.SRH]. Pressing the [(OPRT)]

soft key can also cause the operation select keys to be

displayed.

>

MEM STRT MTN FIN *** 10:02:34

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT ]

1

Data entered from

←

the keyboard

Soft key display

←

(section select)

Page 10

2. SETTING PARAMETERS FROM MDI

SETTING P ARAMETERS FROM MDI

2

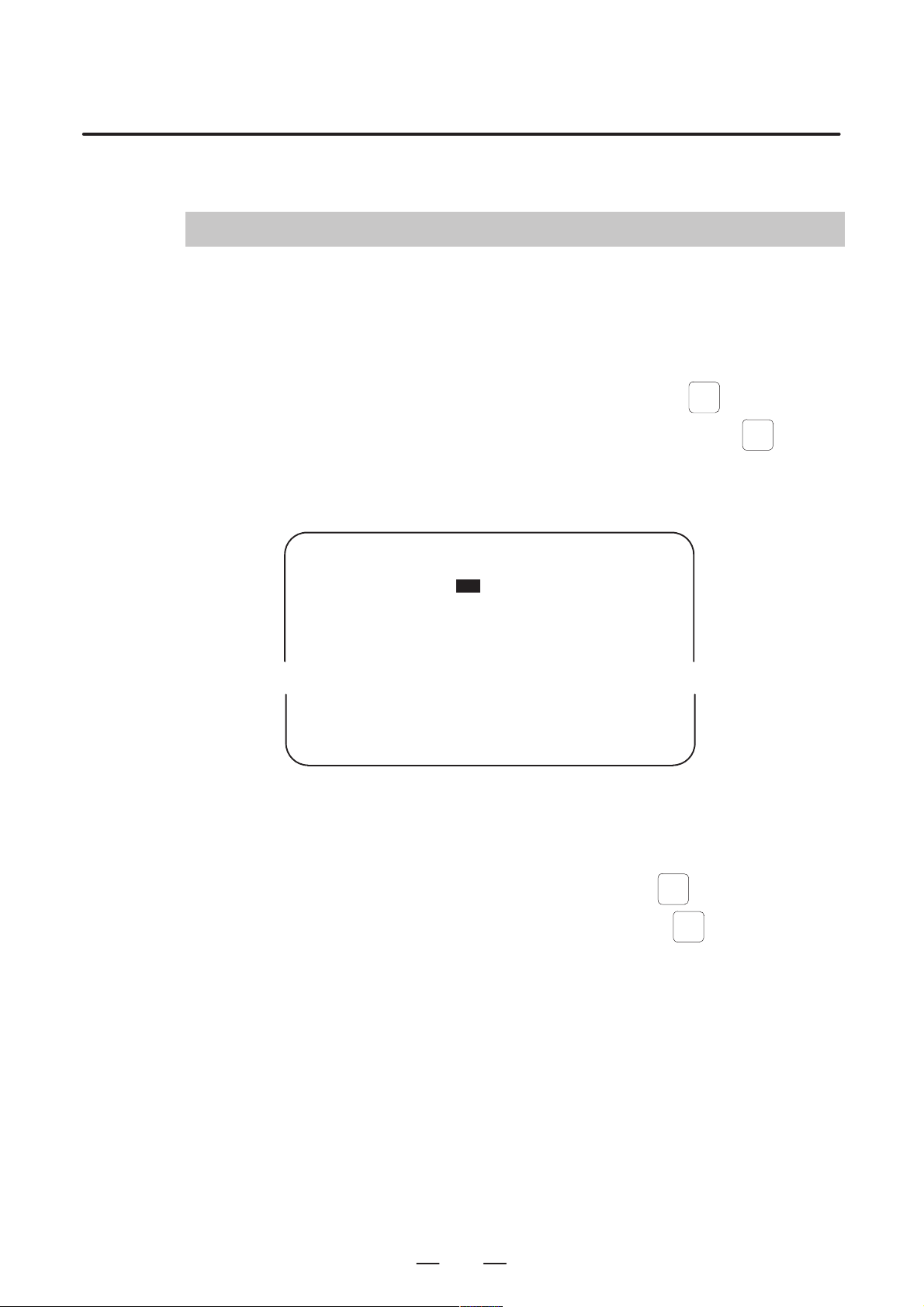

Follow the procedure below to set parameters.

(1) Place the NC in the MDI mode or the emergency stop state.

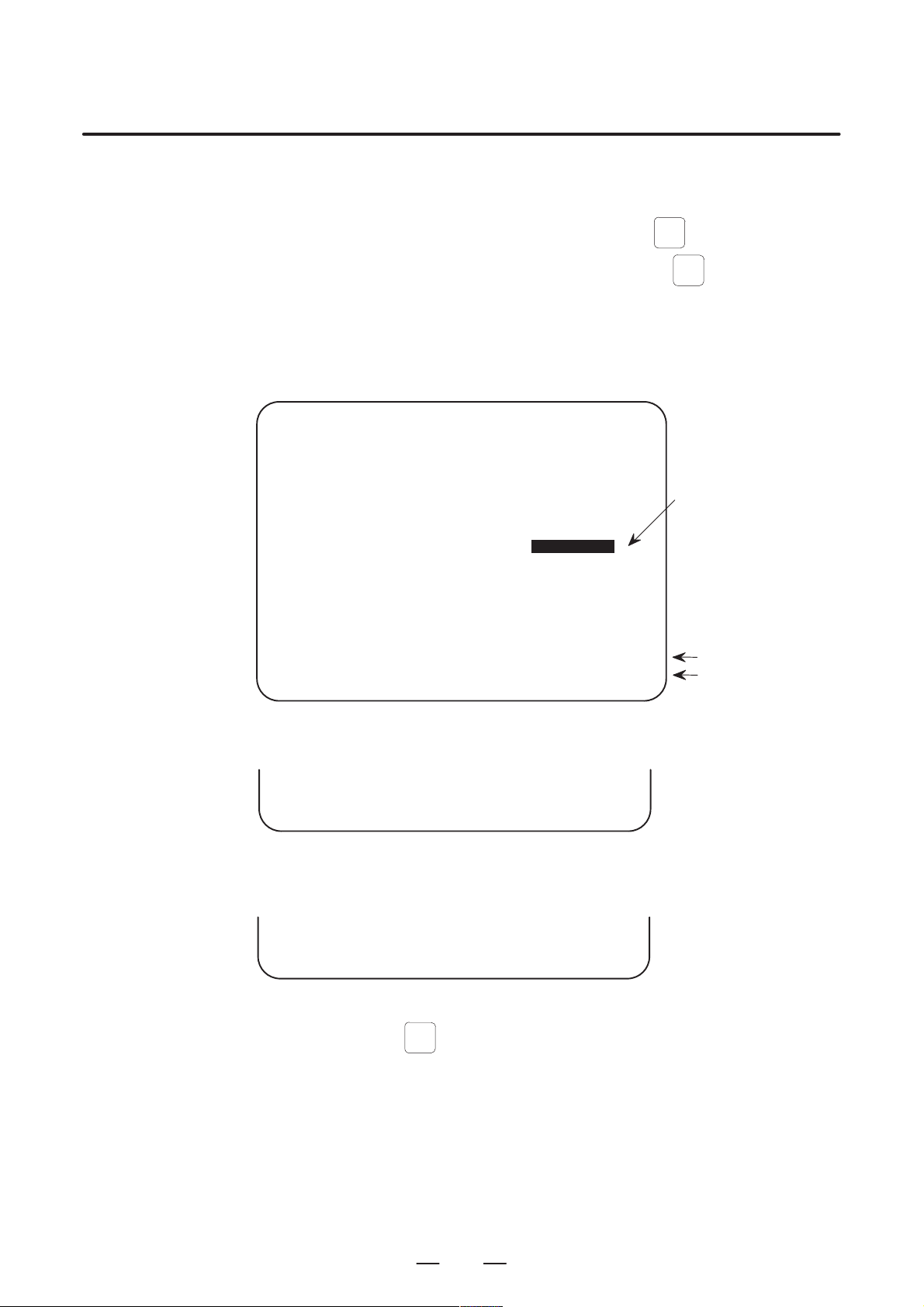

(2) Follow the substeps below to enable writing of parameters.

1. To display the setting screen, press the

B–64160EN/01

OFFSET

function key as

SETTING

many times as required, or alternatively press the

key once, then the [SETTING] section select soft key. The first

page of the setting screen appears.

2. Position the cursor on “P ARAMETER WRITE” using the cursor

move keys.

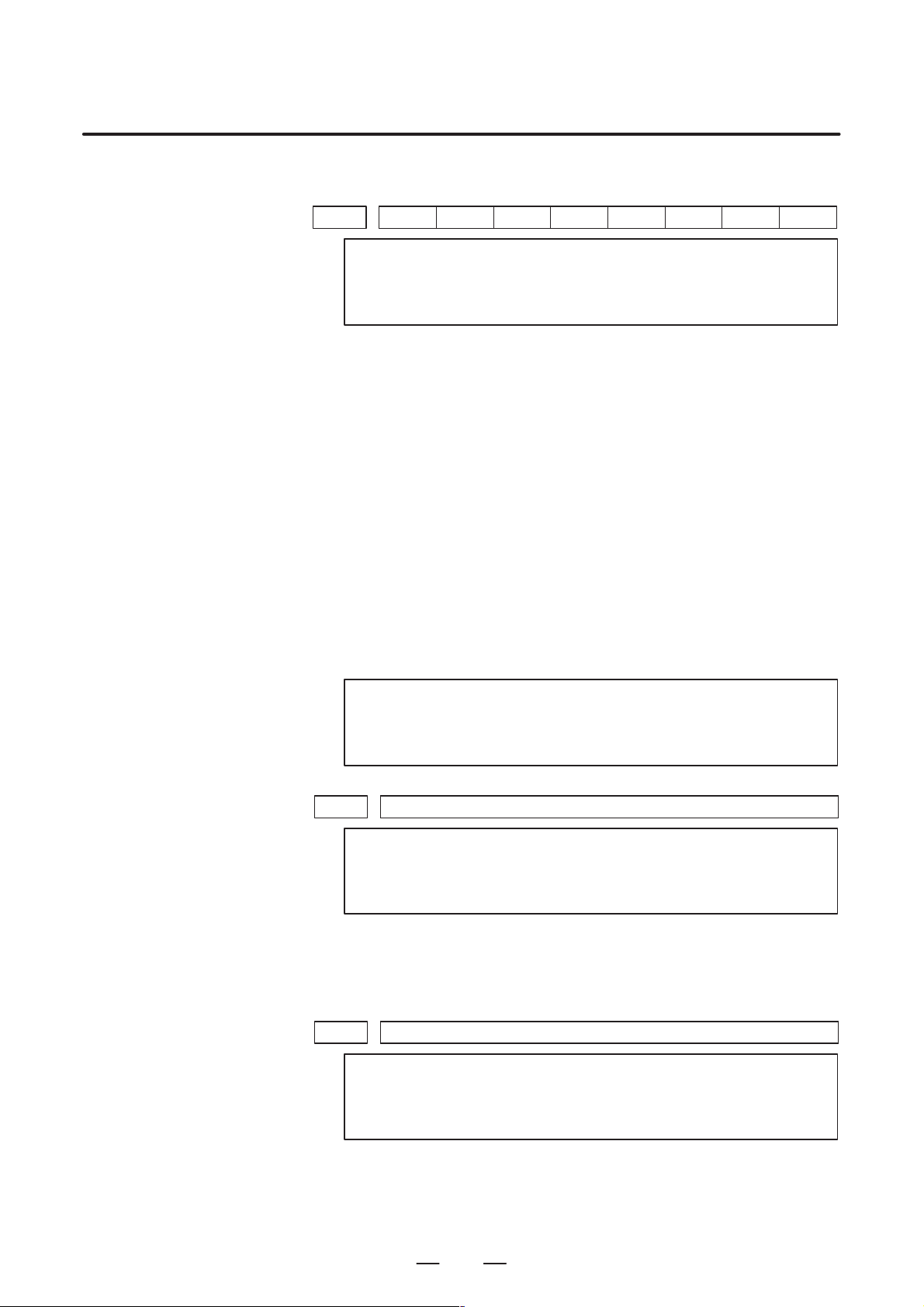

SETTING (HANDY) O0001 N00010

PARAMETER WRITE = (0:DISABLE 1:ENABLE)

TV CHECK = 0 (0:OFF 1:ON)

PUNCH CODE = 0 (0:EIA 1:ISO)

INPUT UNIT = 0 (0:MM 1:INCH)

I/O CHANNEL = 0 (0–3:CHANNEL NO.)

0

3. Press the [(OPRT)] soft key to display operation select soft keys.

>

MDI STOP *** *** *** 10:03:02

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

4. To set “PARAMETER WRITE=” to 1, press the ON:1 soft key,

or alternatively enter 1 and press the INPUT soft key . From now

on, the parameters can be set. At the same time an alarm condition (P/S100 PARAMETER WRITE ENABLE) occurs in the

CNC.

OFFSET

function

SETTING

← Soft key display

(section select)

SYSTEM

(3 ) To display the parameter screen, press the

times as required, or alternatively press the

function key as many

SYSTEM

function key once,

then the PARAM section select soft key.

(See “1. Displaying Parameters.”)

(4) Display the page containing the parameter you want to set, and position

the cursor on the parameter. (See “1. Displaying Parameters.”)

(5 ) Enter data, then press the [INPUT] soft key. The parameter indicated

by the cursor is set to the entered data.

2

Page 11

B–64160EN/01

2. SETTING PARAMETERS FROM MDI

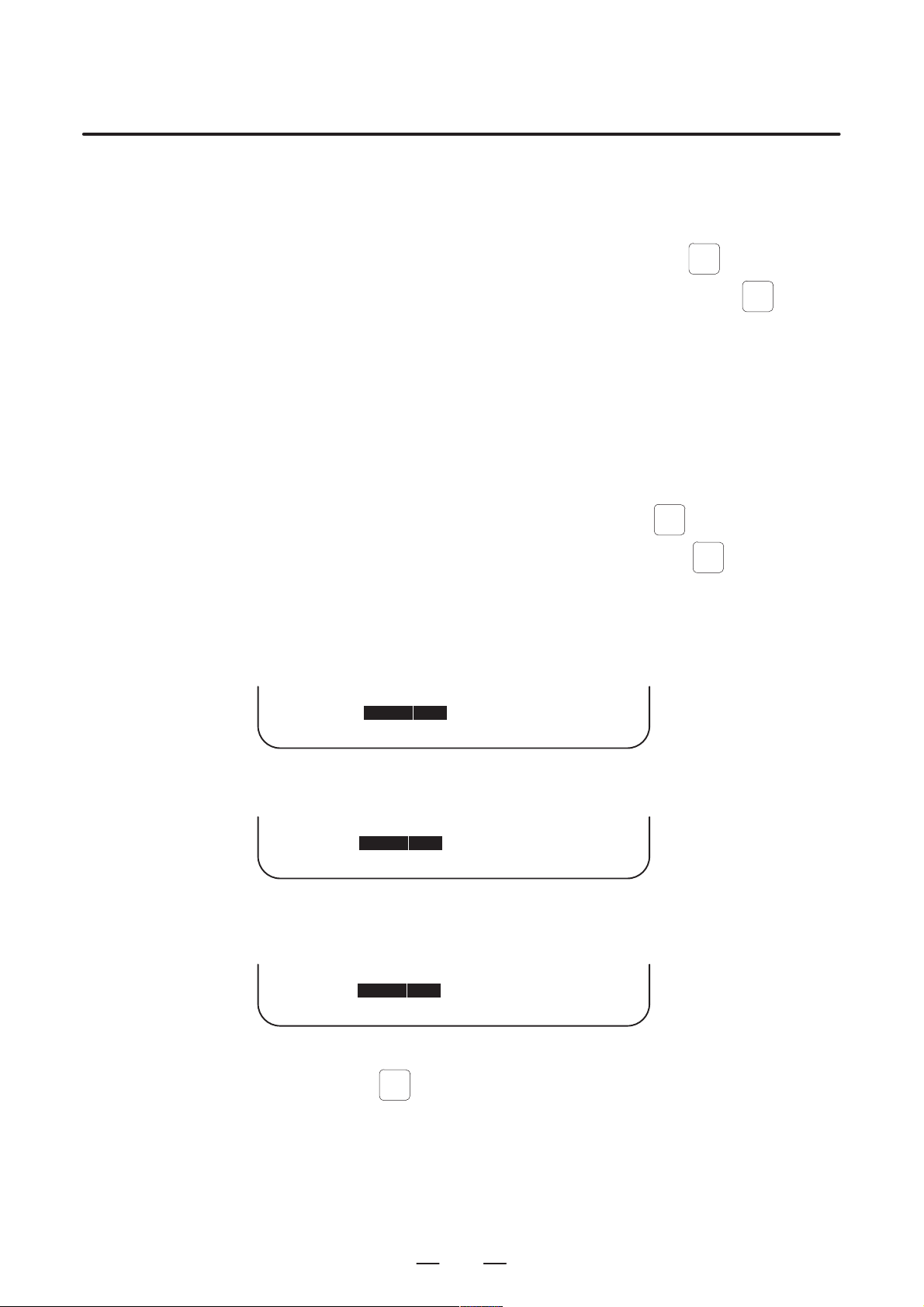

[Example] 12000 [INPUT]

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

00000000

1402 JRV

00000000

1410 DRY RUN FEEDRATE

1412 0

1420 RAPID FEEDRATEX 15000

Y 15000

Z 15000

>

MDI STOP *** *** ALM 10:03:10

[NO.SRH] [ ON:1 ] [ OFF:0 ] [+INPUT] [INPUT]

12000

Cursor

Data can be entered continuously for parameters, starting at the selected

parameter, by separating each data item with a semicolon (;).

[Example] Entering 10;20;30;40 and pressing the INPUT key assigns values 10, 20,

30, and 40 to parameters in order starting at the parameter indicatedby the

cursor.

(6) Repeat steps (4) and (5) as required.

(7) If parameter setting is complete, set “PARAMETER WRITE=” to 0

on the setting screen to disable further parameter setting.

(8) Reset the NC to release the alarm condition (P/S100).

If an alarm condition (P/S000 PLEASE TURN OFF POWER) occurs

in the NC, turn it off before continuing operation.

3

Page 12

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

INPUTTING AND OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERF ACE

3

This section explains the parameter input/output procedures for

input/output devices connected to the reader/puncher interface.

The following description assumes the input/output devices are ready for

input/output. It also assumes parameters peculiar to the input/output

devices, such as the baud rate and the number of stop bits, have been set

in advance. (See Section 4.2)

B–64160EN/01

4

Page 13

B–64160EN/01

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

3.1

OUTPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE

PARAMETER (FEEDRATE) O0001 N00010

1401 RDR JZR RPD

1402 JRV

1410 DRY RUN FEEDRATE

1412 0

1420 RAPID FEEDRATEX 15000

(1) Select the EDIT mode or set to Emergency stop.

SYSTEM

(2 ) To select the parameter screen, press the

times as required, or alternatively press the

function key as many

SYSTEM

function key once,

then the [PARAM] section select soft key.

(3 ) Press the [(OPRT)] soft key to display operation select soft keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select keys including

[PUNCH].

00000000

00000000

12000

Y 15000

Z 15000

Cursor

>

MDI STOP *** *** ALM 10:03:10

[NO.SRH] [ON:1] [OFF:0] [+INPUT] [INPUT]

(4) Pressing the [PUNCH] soft key changes the soft key display as

shown below:

>

EDIT STOP *** *** *** 10:35:03

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(5) Press the [EXEC] soft key to start parameter output. When

parameters are being output, “OUTPUT” blinks in the state display

field on the lower part of the screen.

>

EDIT STOP *** *** *** 10:35:04 OUTPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

(6 ) When parameter output terminates, “OUTPUT” stops blinking. Press

RESET

the

key to interrupt parameter output.

State display

Soft key display

(operation select)

← OUTPUT blinking

5

Page 14

3. INPUTTING AND OUTPUTTING PARAMETERS THROUGH

THE READER/PUNCHER INTERFACE

B–64160EN/01

3.2

INPUTTING PARAMETERS THROUGH THE READER/PUNCHER INTERFACE

(1) Place the NC in the emergency stop state.

(2) Enable parameter writing.

OFFSET

1. To display the setting screen, press the

many times as required, or alternatively press the

function key as

SETTING

OFFSET

SETTING

function

key once, then the [SETING] section select soft key. The first

page of the setting screen appears.

2. Position the cursor on “P ARAMETER WRITE” using the cursor

move keys.

3. Press the [(OPRT)] soft key to display operation select soft keys.

4. To set “PARAMETER WRITE=” to 1, press the ON:1 soft key,

or alternatively enter 1, then press the [INPUT] soft key. From

now on, parameters can be set. At the same time an alarm condition (P/S100 PARAMETER WRITE ENABLE) occurs in the

NC.

(3 ) To select the parameter screen, press the

times as required, or alternatively press the

SYSTEM

function key as many

SYSTEM

key once, then

[PARAM] soft key.

(4) Press the [(OPRT)] soft key to display operation select keys, then

press the forward menu key located at the right–hand side of the soft

keys to display another set of operation select soft keys including

[READ].

>

EDIT STOP ALM 10:37:30

[ ] [ READ ] [PUNCH] [ ] [ ]

–EMG– ALM

(5) Pressing the [READ] soft key changes the soft key display as shown

below:

>

EDIT STOP ALM 10:37:30

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMG– ALM

(6) Press the [EXEC] soft key to start inputting parameters from the

input/output device. When parameters are being input, “INPUT”

blinks in the state display field on the lower part of the screen.

>

EDIT STOP ALM 10:37:30 INPUT

[ ] [ ] [ ] [CANCEL] [ EXEC ]

–EMG– ALM

(7 ) When parameter input terminates, “INPUT” stops blinking. Press the

RESET

key to interrupt parameter input.

(8) When parameter read terminates, “INPUT” stops blinking, and an

alarm condition (P/S000) occurs in the NC. Turn it off before

continuing operation.

← State display

← Soft key display

← INPUT blinking

6

Page 15

B–64160EN/01

0 or 1

–128 to 127

In some parameters, signs are

–128 to 127

In some parameters, signs are

–32768 to 32767

In some parameters, signs are

–32768 to 32767

In some parameters, signs are

–99999999 to 99999999

4

DESCRIPTION OF PARAMETERS

Parameters are classified by data type as follows:

Table 4 Data Types and Valid Data Ranges of Parameters

Data type Valid data range Remarks

Bit

Bit axis

Byte

Byte axis

Word

Word axis

2–word

2–word axis

0 to 255

0 to 65535

4. DESCRIPTION OF PARAMETERS

ignored.

ignored.

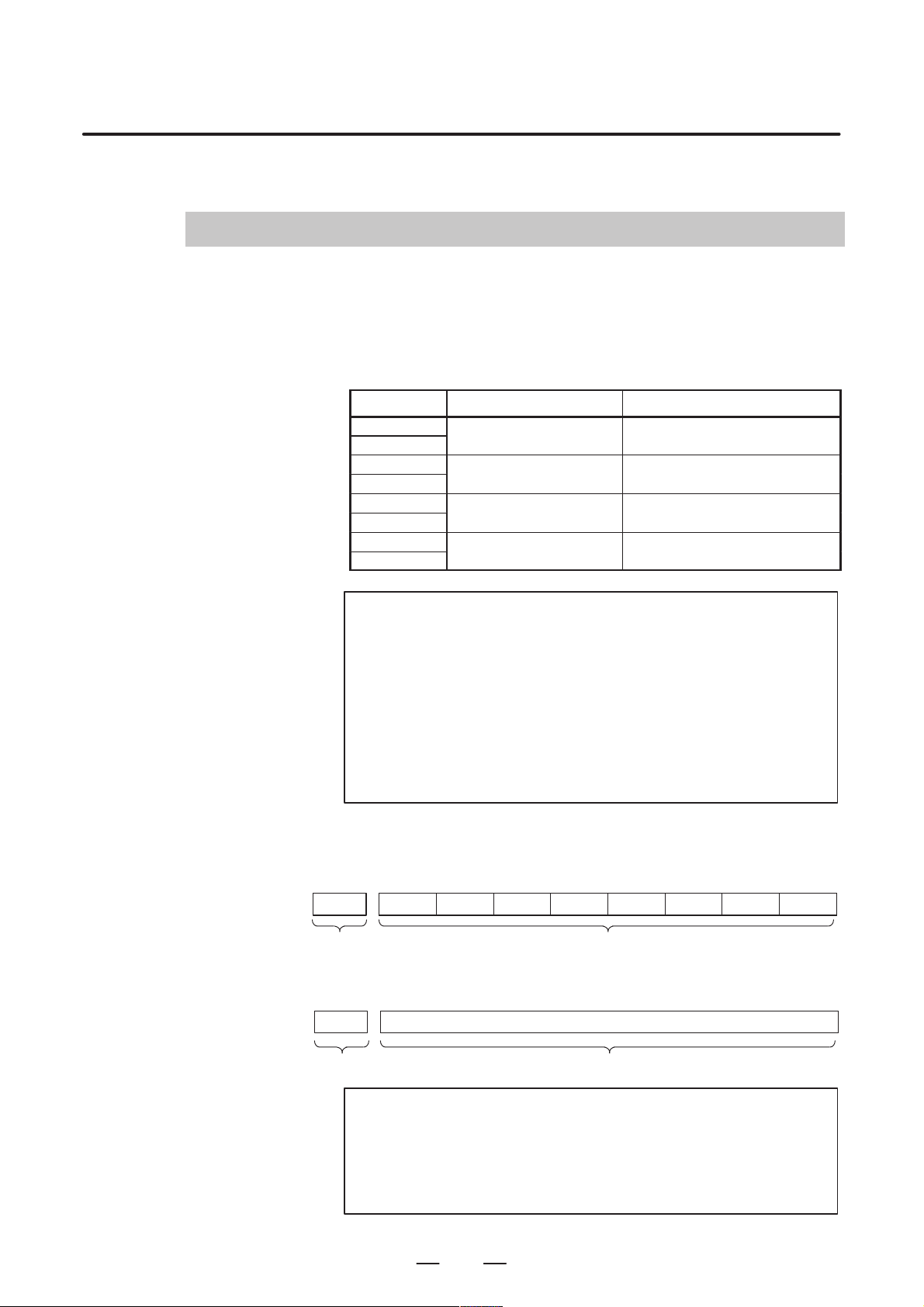

[Example]

0000

Data No.

1023 Servo axis number of a specific axis

Data No.

NOTE

1 For the bit type and bit axis type parameters, a single data

number is assigned to 8 bits. Each bit has a different

meaning.

2 The axis type allows data to be set separately for each

control axis.

3 The valid data range for each data type indicates a general

range. The range varies according to the parameters. For

the valid data range of a specific parameter, see the

explanation of the parameter.

(1) Notation of bit type and bit axis type parameters

#7

#6 #5

SEQ

#4 #3 #2

Data #0 to #7 are bit positions.

INI

#1

ISO

(2) Notation of parameters other than bit type and bit axis type

Data.

#0

TVC

NOTE

The bits left blank in 4. DESCRIPTION OF PARAMETERS

and parameter numbers that appear on the display but are

not found in the parameter list are reserved for future

expansion. They must always be 0.

7

Page 16

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

4.1

P ARAMETERS OF SETTING

[Data type] Bit

#7

0000

#6 #5

SEQ

#4 #3 #2

The following parameter can be set at “Setting screen”.

TVC TV check

0 : Not performed

1 : Performed

ISO Code used for data output

0 : EIA code

1 : ISO code

INI Unit of input

0 : In mm

1 : In inches

SEQ Automatic insertion of sequence numbers

0: Not performed

1: Performed

When a program is prepared by using MDI keys in the part program

storage and edit mode, a sequence number can automatically be assigned

to each block in set increments. Set the increment to parameter 3216.

INI

#1

ISO

#0

TVC

SJZ0002

The following parameters can be set at “Setting screen”.

[Data type] Bit

RDG Remote diagnosis is

0: Not performed.

1: Performed.

To use an RS–232C serial port for performing remote diagnosis, connect

and setup the modem, cable, and the like, then set 1 in this parameter.

SJZ Manual reference position si performed as follows:

0 : When no reference position has been set, reference position return is

performed using deceleration dogs. When a reference position is

already set, reference position return is performed using rapid traverse

and deceleration dogs are ignored.

1 : Reference position return is performed using deceleration dogs at all

times.

Note

SJZ is enabled when bit 3 (HJZ) of parameter No.1005 is

set to 1. When a reference position is set without a dog,

(i.e. when bit 1 (DLZ) of parameter No.1002 is set to 1 or

bit 1 (DLZx) of parameter No.1005 is set to 1) reference

position return after reference position setting is

performed using rapid traverse at all times, regardless of

the setting of SJZ.

#7

#6 #5 #4 #3 #2 #1 #0

RDG

8

Page 17

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

0012

The following parameters can be set at “Setting screen”.

[Data type] Bit axis

MIRx Mirror image for each axis

0 : Mirror image is off.

1 : Mirror image is on.

0020

This parameter can be set at “Setting screen”.

[Data type] Byte

[Valid data range] 0 to 35

I/O CHANNEL: Selection of the input/output device to be used

The CNC provides the following interfaces for data transfer to and from

the host computer and external input/output devices:

D Input/output device interface (RS–232C serial port 1, 2)

D DNC2 interface

Data can be transferred to and from a personal computer connected via the

FOCAS1/Ethernet or FOCAS1/HSSB.

In addition, data can be transferred to and from the Power Mate via the

FANUC I/O Link.

This parameter selects the interface used to transfer data to and from an

input/output device.

#7

I/O CHANNEL: Selection of an input/output device or selection of input device in

the foreground

#6 #5 #4 #3 #2 #1 #0

MIRx

Setting Description

0, 1 RS–232C serial port 1

2 RS–232C serial port 2

4 Memory card interface

5 Data server interface

6 The DNC operation is performed or M198 is specified by FOCAS1/

Ethernet.

10 DNC2 interface

15 M198 is specified by FOCAS1/HSSB. (Bit 1 (NWD) of parameter

20

21

22

34

35

No. 8706) must also be specified.)

Group 0

|

Group 1

Group 2

|

Group 14

Group 15

Data is transferred between the CNC and a Power

Mate in group n (n: 0 to 15) via the FANUC I/O Link.

Supplemental remark 1

If the DNC operation is performed with FOCAS1/HSSB, the setting

of parameter No. 20 does not matter. The DMMC signal <G042.7>

is used.

Supplemental remark 2

If bit 0 (IO4) of parameter No. 110 is set to control the I/O channels

separately , the I/O channels can be divided into four types: input and

output in the foreground and input and output in the background. If

so, parameter No. 20 becomes a parameter for selecting the input

device in the foreground.

9

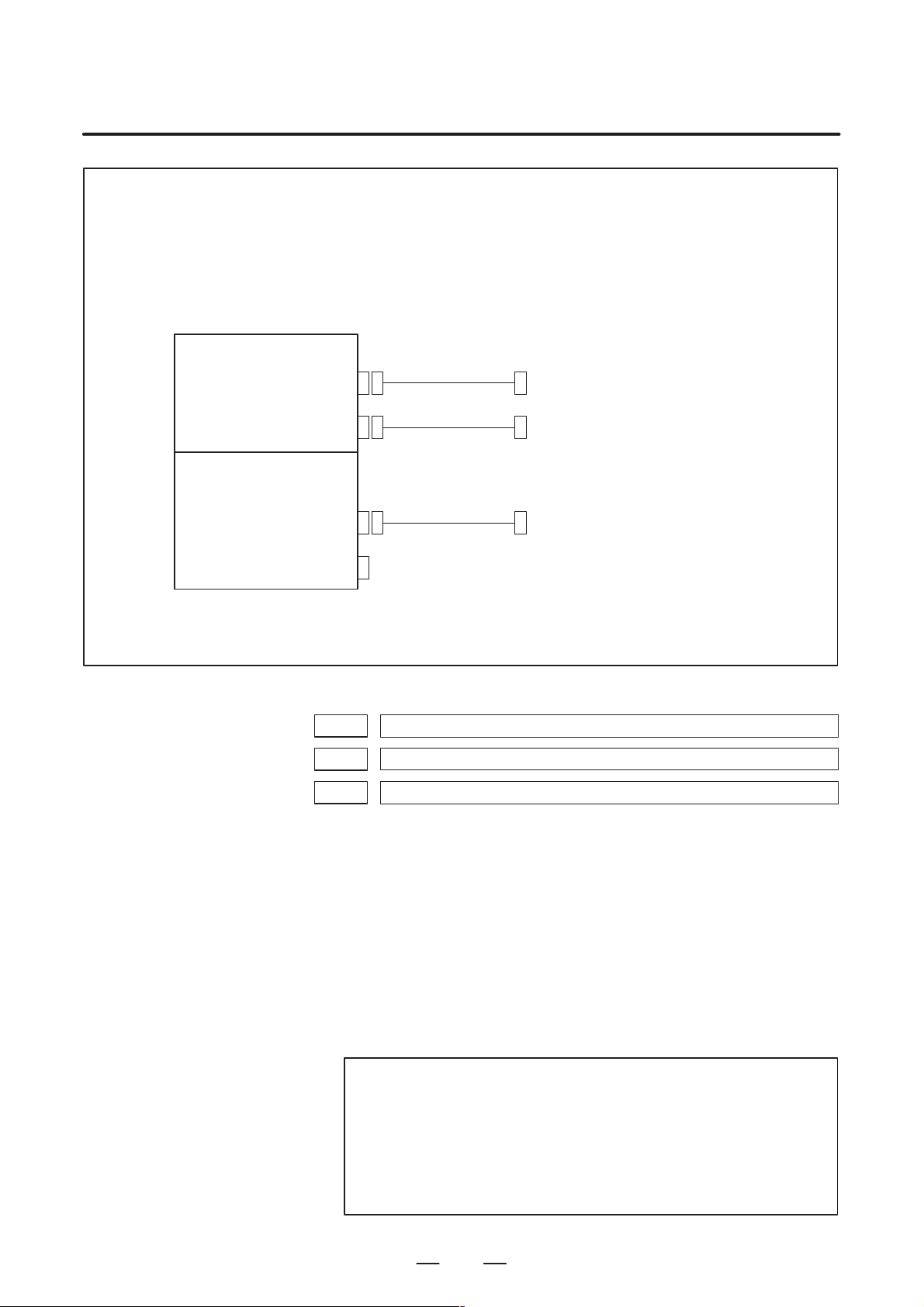

Page 18

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

NOTE

1 An input/output device can also be selected using the setting screen. Usually, the setting screen

is used.

2 The specifications (such as the baud rate and the number of stop bits) of the input/output

devices to be connected must be set in the corresponding parameters for each interface

beforehand. (See Section 4.2.) I/O CHANNEL = 0 and I/O CHANNEL = 1 represent input/output

devices connected to RS–232C serial port 1. Separate parameters for the baud rate, stop bits,

and other specifications are provided for each channel.

Mother board

RS–232–C serial port 1

R232–1(JD36A)

RS–232–C serial port 2

R232–2(JD36B)

Serial communication board

DNC2 board

I/O CHANNEL=0, 1

(Channel 1)

I/O CHANNEL=2

(Channel 2)

RS-232-C I/O device

RS-232-C I/O device

R232-3(JD28A)

R422-1(JD6A)

I/O CHANNEL=3

(Channel 3)

RS-232-C I/O device

(when a remote buffer or DNC2 board is used)

3 The input/output unit interface may be referred to as the reader/punch interface.

RS–232C serial port 1 and RS–232C serial port 2 are also referred to as channel 1 and channel

2, respectively.

0021 Setting of the output device in the foreground

0022 Setting of the input device in the background

0023 Setting of the output device in the background

These parameters can be set at “Setting screen”.

[Data type] Byte

[Valid data range] 0 to 2, 5, 10

These parameters are valid only when bit 0 (IO4) of parameter No. 110 is

set to control the I/O channels separately.

The parameters set individual input/output devices if the I/O channels are

divided into these four types: input and output in the foreground and input

and output in the background. The input device in the foreground is set in

parameter No. 20. For the details of the settings, see the table provided

with the description of parameter No. 20.

NOTE

If different input/output devices are simultaneously used in

the foreground and background, just a value from 0 to 2 can

be specified for the background device.

If an attempt is made to use a busy input/output device, an

alarm (P/S233 or BP/S233) will be raised. Note that the

settings 0 and 1 indicate the same input/output device.

10

Page 19

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

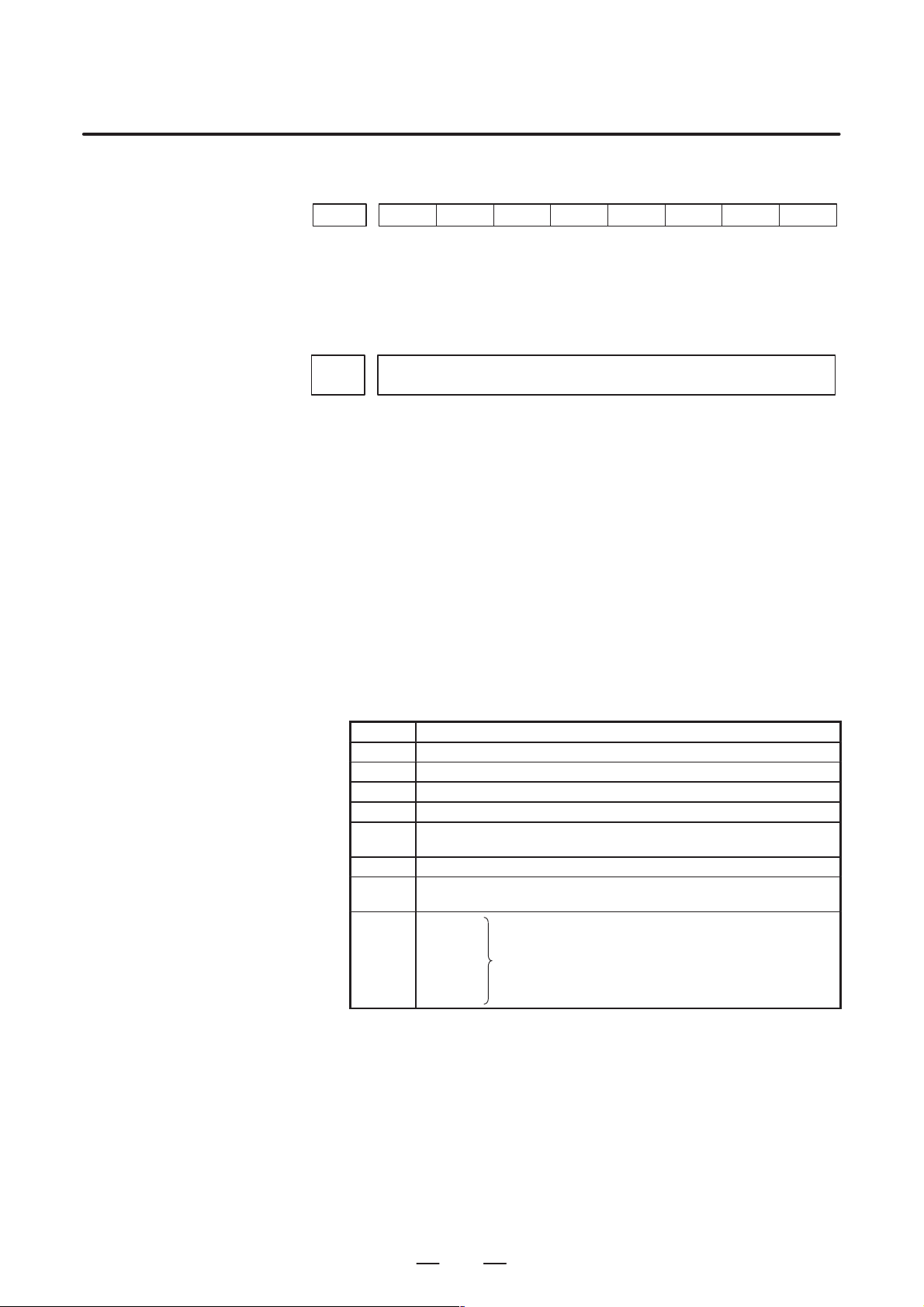

4.2

PARAMETERS OF READER/PUNCHER INTERFACE

0020

Specify a channel for an input/output device.

I/ O CHANNEL

=0 : Channel1

=1 : Channel1

=2 : Channel2

I/O CHANNEL

This CNC has two channels CRS–232–C serial port1 and RS–232–C

serial port2 of input/output device interfaces. The input/output device to

be used is specified by setting the channel connected to that device in

setting parameter I/O CHANNEL.

The specified data, such as a baud rate and the number of stop bits, of an

input/output device connected to a specific channel must be set in

parameters for that channel in advance.

For channel 1, two combinations of parameters to specify the input/output

device data are provided.

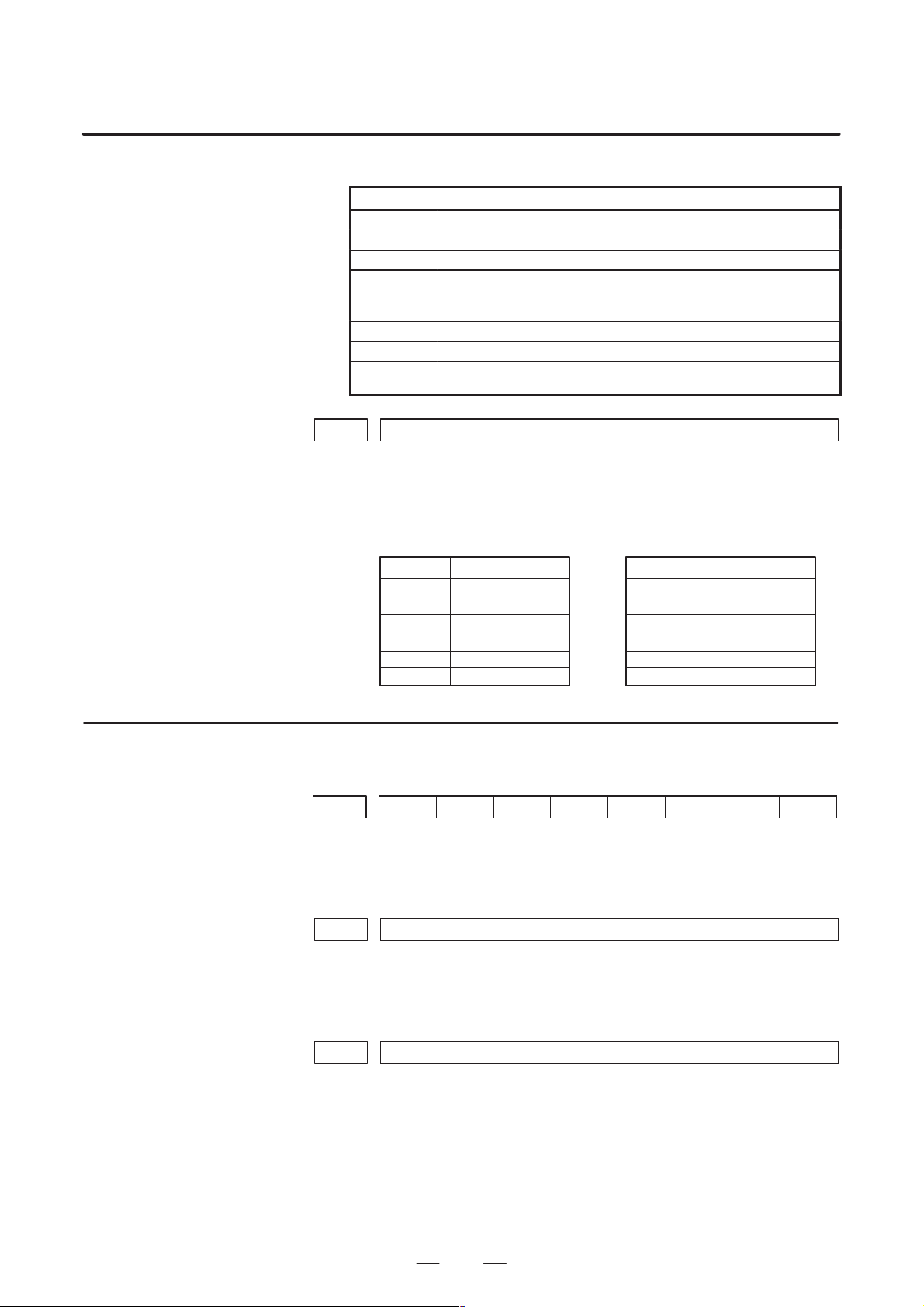

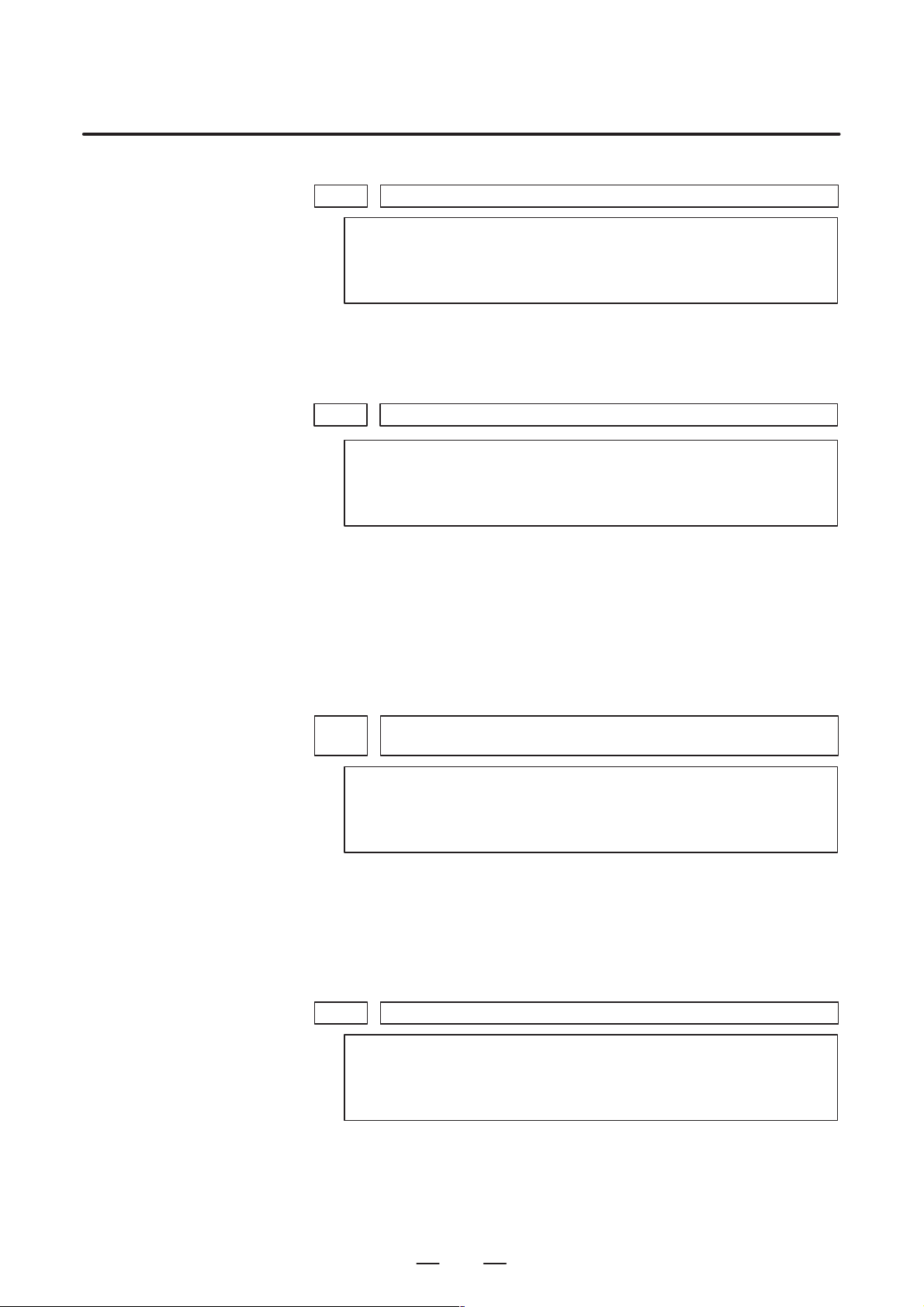

The following shows the interrelation between the input/output device

interface parameters for the channels.

Input/output channel number (parameter No.0020)

↓

Stop bit and other data

Number specified for the input/

output device

Baud rate

Stop bit and other data

Number specified for the input/

output device

Baud rate

I/O CHANNEL=0

(channel 1)

I/O CHANNEL=1

(channel 1)

0101

0102

0103

0111

0112

0113

0121

I/O CHANNEL=2

(channel 2)

Fig.4.2 I/O Device Interface Settings

0122

0123

Stop bit and other data

Number specified for the input/

output device

Baud rate

11

Page 20

4. DESCRIPTION OF PARAMETERS

4.2.1

Parameters Common to all Channels

[Data type] Byte

0024 Port for communication with the PMC ladder development tool (FAPT LADDER–II/III)

B–64160EN/01

This parameter can be set at “Setting screen”.

This parameter sets the port to be used for communication with the PMC

ladder development tool (FAPT LADDER–II/III).

0 : HSSB (COP7)

1 : RS–232C serial port 1 (JD36A)

2 : RS–232C serial port 2 (JD36B)

#7

ENS0100

#6

IOP

#5

ND3

#4 #3

NCR#2CRF

#1

CTV

[Data type] Bit

CTV: Character counting for TV check in the comment section of a program.

0 : Performed

1 : Not performed

CRF EOB (end of block) to be output in the ISO code:

0: Depends on the setting of bit 3 (NCR) of parameter No. 100.

1: is “CR”“LF”.

Note) The EOB output patterns are as shown below:

NCR CRF EOB output format

0 0 “LF” “CR” “CR”

0 1 “CR” “LF”

1 0 “LF”

1 1 “CR” “LF”

NCR Output of the end of block (EOB) in ISO code

0 : LF, CR, CR are output.

1 : Only LF is output.

ND3 In DNC operation, a program is:

0 : Read block by block. (A DC3 code is output for each block.)

1 : Read continuously until the buffer becomes full. (A DC3 code is

output when the buffer becomes full.)

#0

NOTE

In general, reading is performed more efficiently when ND3

set to 1. This specification reduces the number of buffering

interruptions caused by reading of a series of blocks

specifying short movements. This in turn reduces the

effective cycle time.

IOP Specifies how to stop program input/output operations.

0 : An NC reset can stop program input/output operations.

1 : Only the [STOP] soft key can stop program input/output operations.

(An reset cannot stop program input/output operations.)

12

Page 21

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

ENS Action taken when a NULL code is found during read of EIA code

0 : An alarm is generated.

1 : The NULL code is ignored.

4.2.2

Parameters of Channel 1 (I/O CHANNEL=0)

0110

[Data type] Bit

IO4 Separate control of I/O channel numbers is:

0: Not performed.

1: Performed.

If the I/O channels are not separately controlled, set the input/output

device in parameter No. 20.

If the I/O channels are separately controlled, set the input device and

output device in the foreground and the input device and output device in

the background in parameters No. 20 to No. 23 respectively.

Separate control of I/O channels makes it possible to perform background

editing, program input/output, and the like during the DNC operation.

[Data type] Bit type

#7

#7

NFD0101

#6 #5 #4 #3 #2 #1 #0

IO4

#6 #5 #4 #3

ASI

#2 #1

HAD

#0

SB2

SB2 The number of stop bits

0 : 1

1 : 2

HAD An alarm raised for the internal handy file is:

0: Not displayed in detail on the NC screen. (PS alarm 86 is displayed.)

1: Displayed in detail on the NC screen.

ASI Code used at data input

0 : EIA or ISO code (automatically distinguished)

1 : ASCII code

NFD Feed before and after the data at data output

0 : Output

1 : Not output

NOTE

When input/output devices other than the FANUC PPR

are used, set NFD to 1.

0102 Number specified for the input/ou tpu t device (when the I/O CHANNEL is set to 0)

[Data type] Byte

Set the number specified for the input/output device used when the I/O

CHANNEL is set to 0, with one of the set values listed in Table 4.2 (a).

13

Page 22

4. DESCRIPTION OF PARAMETERS

0103 Baud rate (when the I/O CHANNEL is set to 0)

[Data type] Byte

B–64160EN/01

Table 4.2.2 (a) Set value and Input/Output Device

Set value Input/output device

0 RS–232–C (Used control codes DC1 to DC4)

1 FANUC CASSETTE ADAPTOR 1 (FANUC CASSETTE B1/ B2)

2 FANUC CASSETTE ADAPTOR 3 (FANUC CASSETTE F1)

3 FANUC PROGRAM FILE Mate, FANUC FA Card Adaptor

4 RS–232–C (Not used control codes DC1 to DC4)

5 Portable tape reader

6 FANUC PPR

FANUC FLOPPY CASSETTE ADAPT OR, FANUC Handy File

FANUC SYSTEM P-MODEL H

FANUC SYSTEM P-MODEL G, FANUC SYSTEM P-MODEL H

Set baud rate of the input/output device used when the I/O CHANNEL is

set to 0, with a set value in Table 4.2 (b).

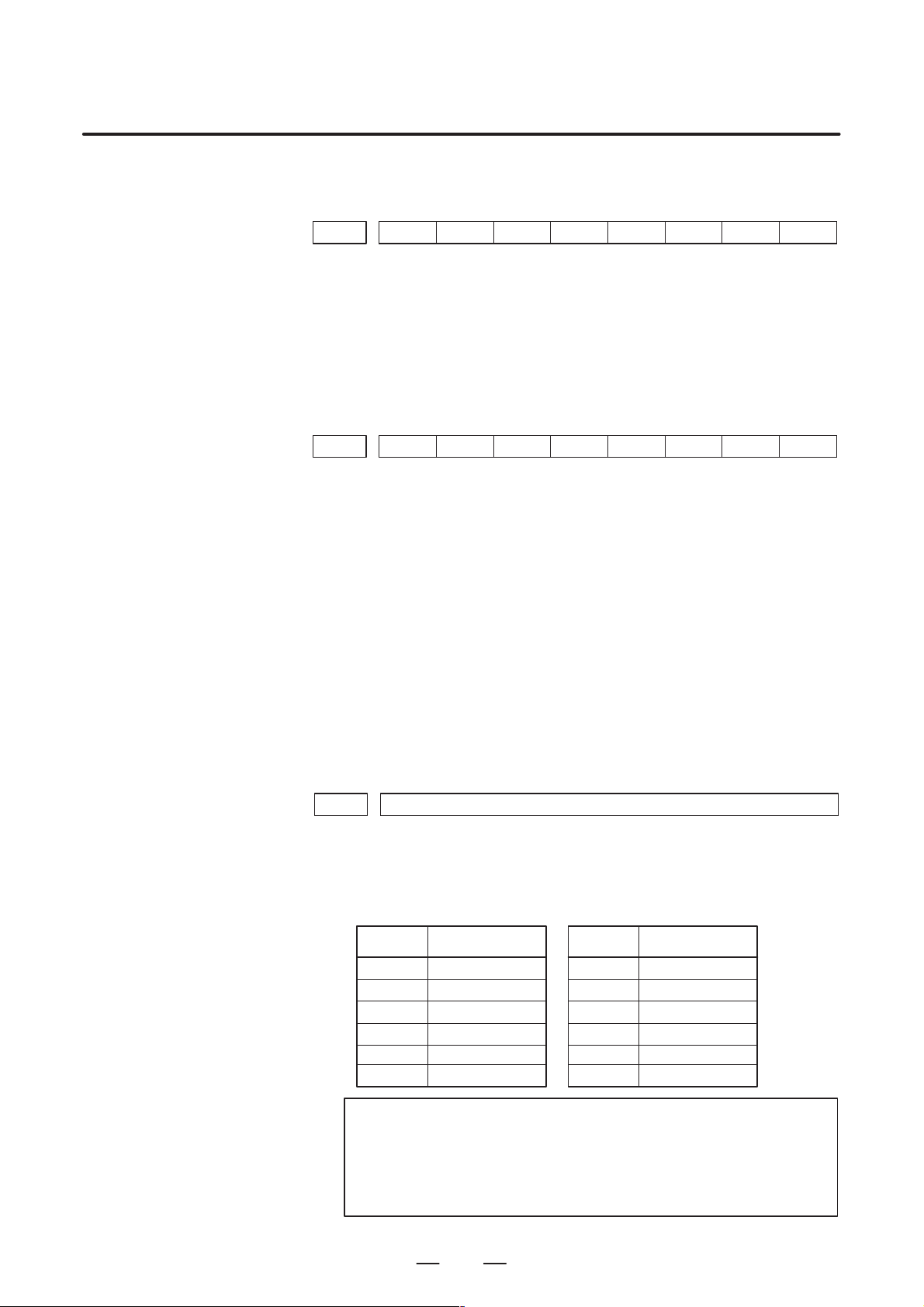

Table 4.2.2 (b)

Set value Baud rate (bps)

1

2

3

4

5

6

50

100

110

150

200

300

Set value Baud rate (bps)

7

8

9

10

11

12

600

1200

2400

4800

9600

19200

4.2.3

Parameters of Channel 1 (I/O CHANNEL=1)

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 1. The meanings

of the bits are the same as for parameter 0101.

0112 Number specified for the input/output device (when I/O CHANNEL is set to 1)

[Data type] Byte

Set the number specified for the input/output device used when the I/O

CHANNEL is set to 1, with one of the set values listed in Table 4.2 (a).

0113 Baud rate (when I/O CHNNEL is set to 1)

[Data type] Byte

Set the baud rate of the input/output device used when I/O CHANNEL is

set to 1, with a value in Table 4.2 (b).

#7

NFD0111

#6 #5 #4 #3

ASI

#2 #1 #0

SB2

14

Page 23

B–64160EN/01

4.2.4

Parameters of Channel 2 (I/O CHANNEL=2)

[Data type] Bit

These parameters are used when I/O CHANNEL is set to 2. The meanings

of the bits are the same as for parameter 0101.

0122 Number specified for the input/output device (when I/O CHANNEL is set to 2)

[Data type] Byte

Set the number specified for the input/output device used when I/O

CHANNEL is set to 2, with a value in Table 4.2 (a).

0123 Baud rate (when the I/O CHANNEL is set to 2)

[Data type] Byte

Set the baud rate of the input/output device used when I/O CHANNEL is

set to 2, with a value in Table 4.2 (b).

4. DESCRIPTION OF PARAMETERS

#7

NFD0121

#6 #5 #4 #3

ASI

#2 #1 #0

SB2

#7

0134

#6 #5 #4

NCD

#3 #2

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

PRY Parity bit

0: Not used

1: Used

SYN Reset/alarm in protocol B

0: Not reported to the host

1: Reported to the host with SYN and NAK codes

NCD CD (signal quality detection) of the RS–232C interface

0: Checked

1: Not checked

SYN

#1

PRY

#0

15

Page 24

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

#7

RMS0135

#6 #5 #4 #3 #2

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit

ASC Communication code except NC data

0: ISO code

1: ASCII code

ETX End code for protocol A or extended protocol A

0: CR code in ASCII/ISO

1: ETX code in ASCII/ISO

NOTE

Use of ASCII/ISO is specified by ASC.

PRA Communication protocol

0: Protocol B

1: Protocol A

RMS State of remote/tape operation when protocol A is used

0: Always 0 is returned.

1: Contents of the change request of the remote/tape operation in the

SET command from the host is returned.

PRA

#1

ETX

#0

ASC

#7

MDN0138

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit

MDN The DNC operation function by a memory card is:

0: Disabled.

1: Enabled. (A PCMCIA card attachment is required.)

NOTE

Use a PCMCIA card attachment suited to the CNC to secure

the memory card in the CNC.

16

Page 25

B–64160EN/01

4.3

P ARAMETERS OF DNC2 INTERF ACE

[Data type] Bit

4. DESCRIPTION OF PARAMETERS

#7

0140

#6 #5 #4 #3

ECD#2NCE

#1 #0

BCC

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

BCC The BCC value (block check characters) for the DNC2 interface is:

0: Checked.

1: Not checked.

Even if the BCC value is not checked, the BCC value itself must be

specified.

NCE The ER (RS–232C) and TR (RS422) signals are:

0: Checked.

1: Not checked.

This parameter is provided only for the DNC2 interface.

ECD Error code of negative acknowledgment

0: A four–digit hexadecimal error code is added to a negative

acknowledgment.

1: No error code is added to a negative acknowledgment.

This parameter is provided only for the DNC2 interface.

NOTE

To use FANUC DNC2 communications library for the host

computer, set this parameter to 1.

0143 Time limit specified for the timer monitoring a response (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] S

[Valid data range] 1 to 60 (The standard setting is 3.)

0144 Time limit specified for the timer monitoring the EOT signal (DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] S

[Valid data range] 1 to 60 (The standard setting is 5.)

17

Page 26

4. DESCRIPTION OF PARAMETERS

0145 Time required for switching RECV and SEND (DNC2 interface)

[Data type] Byte

[Unit of data] S

[Valid data range] 1 to 60 (The standard setting is 1.)

0146 Number of times the system retries holding communication (DNC2 interface)

[Data type] Byte

B–64160EN/01

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Unit of data] S

[Valid data range] 1 to 10 (The standard setting is 3.)

Set the maximum number of times the system retries holding

communication with the remote device if the remote device uses an

invalid protocol in the data–link layer or the remote device does not

respond to the request.

0147

Number of times the system sends the message in response to the NAK signal

(DNC2 interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Unit of data] Number of times

[Valid data range] 1 to 10 (The standard setting is 2.)

Set the maximum number of times the system retries sending the message

in response to the NAK signal.

0148 Number of characters in overrun (DNC2) interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Valid data range] 10 to 225 (The standard setting is 10.)

Set the number of characters the system can receive after transmission is

stopped (CS off).

18

Page 27

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

0149

Number of characters in the data section of the communication packet (DNC2

interface)

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Word

[Valid range] 80 to 256 (The standard setting is 256.)

The standard setting is 256. If the specified value is out of range, a value of

80 or 256 is used.

This parameter determines the maximum length of the packet used in

transmission over the DNC2 interface. Including the two characters at the

start of the packet, the four characters used for a command, and the three

characters at the end, the maximum number of characters in the packet is

nine plus the number specified in parameter No.0149.

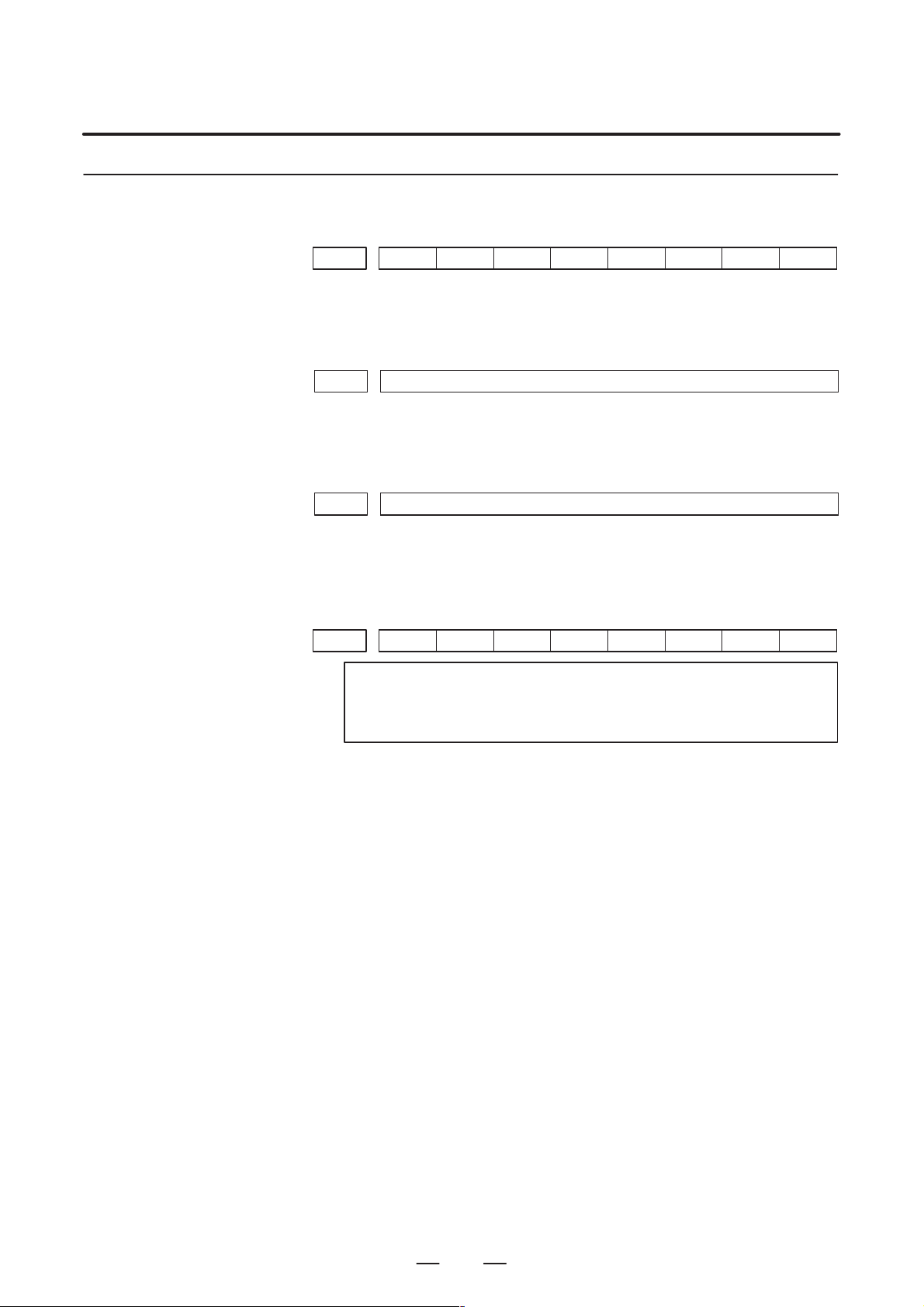

Length of the packet

DLE STX

2 bytes 4 bytes 80 to 256 bytes 3 bytes

Command Data section DEL ETX BCC

19

Page 28

4. DESCRIPTION OF PARAMETERS

4.4

B–64160EN/01

PARAMETERS OF REMOTE DIAGNOSIS

[Data type] Bit

[Data type] Bit

#7

0002

#6 #5 #4 #3 #2 #1 #0

RDG Remote diagnosis is:

0: Not performed.

1: Performed.

If an RS–232C serial port is used to carry out remote diagnosis, connect

and set up the modem, cable, and the like, then set 1 in this parameter.

#7

0201

#6 #5 #4 #3 #2

SB2 The number of stop bits is

0: 1.

1: 2.

To carry out remote diagnosis, set 0.

ASC The code to be used for data output is:

0: ISO code.

1: ASCII code.

NCR

#1

ASC

RDG

#0

SB2

To carry out remote diagnosis, set 1.

NCR EOB (end of block) is output as:

0: ”LF””CR””CR”.

1: Just as ”LF”.

To carry out remote diagnosis, set 1.

0203 Baud rate (for remote diagnosis)

[Data type] Byte

Set the baud rate of data input/output by remote diagnosis, with reference

to the tables given below.

When using an RS–232C serial port

Setting Baud rate (bps)

1

2

3

4

5

6

100

110

150

200

300

50

Setting Baud rate (bps)

7

8

9

10

11

12

600

1200

2400

4800

9600

19200

NOTE

The tables above indicate the baud rates of communication

between the CNC and modem. The actual communication

baud rate may be lowered, depending on the modem and

communication line.

20

Page 29

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

0204 Remote diagnosis channel

[Data type] Byte

[Valid data range] 0, 1, 2

The interface to be used for remote diagnosis is:

0, 1: RS–232C serial port 1 (channel 1).

2 : RS–232C serial port 2 (channel 2).

0211 Password 1 for remote diagnosis

0212 Password 2 for remote diagnosis

0213 Password 3 for remote diagnosis

[Data type] 2–word

[Valid data range] 1 to 99999999

Specify a password for using the remote diagnosis function.

The remote diagnosis function has the following password settings. Data

can be protected by preventing a third party from accessing any system

parameter or machining program without permission.

Password 1:

Set a password for the whole service of the remote diagnosis function.

(The whole remote diagnosis service is available only when this password

is input on the host side (PC, for instance).)

Password 2:

Set a password of a part program. (The input/output, verification, and the

like of a program are possible only when this password is input on the host

side (PC, for instance).)

Password 3:

Set a password of a parameter. (The input/output or the like of a parameter

is possible only when this password is input on the host side (PC, for

instance).)

NOTE

Once any value other than 0 is specified as a password, the

password can be changed only when the same value is

specified in the corresponding keyword (parameters No. 221

to No. 223). If any value other than 0 is specified as a

password, the password setting is not displayed on the

parameter screen (blank display is provided). Take great

care when setting the password.

21

Page 30

4. DESCRIPTION OF PARAMETERS

0221 Keyword 1 for remote diagnosis

0222 Keyword 2 for remote diagnosis

0223 Keyword 3 for remote diagnosis

[Data type] 2–word

[Valid range] 1 to 99999999

B–64160EN/01

Set a keyword corresponding to a password of the remote diagnosis

function.

Keyword 1: Keyword for password 1 (parameter No. 211)

Keyword 2: Keyword for password 2 (parameter No. 212)

Keyword 3: Keyword for password 3 (parameter No. 213)

If any value other than 0 is specified as a password (parameters No. 211

to No. 213), the password can be changed only when the same value is

specified as the corresponding keyword.

NOTE

The keyword value is reset to 0 at power–up.

On the parameter screen, the keyword setting is not

displayed (blank display is provided).

22

Page 31

B–64160EN/01

4.5

4. DESCRIPTION OF PARAMETERS

PARAMETER OF MEMORY CARD INTERFACE

#7

0300

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit

PCM If the CNC screen display function is enabled, when a memory card

interface is provided on the NC side (HSSB connection),

0 : The memory card interface on the NC side is used.

1 : The memory card interface on the PC side is used.

If this parameter is set to 0 while the HSSB board is used for connection,

the I/O channel specified in parameter No. 0020 is used.

If this parameter is set to 1, data input/output from and to the PC is

performed irrespective of the setting of parameter No. 20. This parameter

is valid only while the CNC screen display function is active.

PCM

23

Page 32

4. DESCRIPTION OF PARAMETERS

4.6

B–64160EN/01

P ARAMETERS OF DATA SERVER

[Data type] Bit

[Data type] Word

[Set value] ASCII code (decimal)

[Data type] Word

[Set value] ASCII code (decimal)

#7

0900

#6 #5 #4 #3 #2 #1

ONS

#0

DSV

DSV The data server function is

0: Enabled

1: Disabled

ONS When the O number of the data server file name and the O number in an

NC program do not match:

0: The O number of the file name takes priority.

1: The O number in the NC program takes priority.

0911 Altemate MDI character

0912 Character not provided in MDI keys

When specifying a character which is not provided as a MDI keys for

HOST DIRECTORY of DATA SERVER SETTING–1, use these

parameters to assign an alternative key to that character.

[Example]

If ODSERVERONCPROG is specified for HOST DIRECTORY, you

cannot enter “\” with the MDI keys. To use “@” as an alternative

character , set 64 (ASCII code for @) in parameter No.0911 and 92 (ASCII

code for \) in parameter No.0912.

When

“DSERVER@NCPROG”

is specified for HOST DIRECTORY, the data server converts it to

“ODSERVERONCPROG”.

NOTE

When both parameters No.0911 and 0912 are set to 0, the

data server assumes the following setting:

No.0911 = 32 (blank)

No.0912 = 92 (\)

24

Page 33

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

0921 OS selected for host computer 1 of data server

0922 OS selected for host computer 2 of data server

0923 OS selected for host computer 3 of data server

[Data type] Word

[Valid data range] 0

to 1

1 : UNIX or VMS is selected.

0 : Windows95/98/NT is selected.

0924 Latency setting for FOCAS1/Ethernet

[Data type] Word

[Unit of data] ms

[Valid data range] 0 to 255

Set service latency of FOCAS1/Ethernet while FOCAS1/Ethernet is used

together with the data server function.

If a value between 0 and 2 is set, 2 ms is assumed.

25

Page 34

4. DESCRIPTION OF PARAMETERS

4.7

P ARAMETERS OF ETHERNET

[Data type] Byte

[Valid data range] 32 to 95

0931 Special character code corresponding to soft key [CHAR–1]

0932 Special character code corresponding to soft key [CHAR–2]

0933 Special character code corresponding to soft key [CHAR–3]

0934 Special character code corresponding to soft key [CHAR–4]

0935 Special character code corresponding to soft key [CHAR–5]

B–64160EN/01

These parameters are provided to allow a special character that is not

provided on the MDI panel but needed in a user name, password, or login

DIR to be input by pressing a soft key on the Ethernet parameter screen.

If a value other than 0 is input as a parameter, the special character

assigned to the corresponding input soft key [CHAR–1] to [CHAR–5] is

displayed.

The special character codes correspond to the ASCII codes.

Sample special character codes

Special

character

Blank 32 ) 41 < 60

! 33 * 42 > 62

” 34 + 43 ? 63

# 35 , 44 @ 64

$ 36 – 45 [ 91

% 37 . 46 ^ 92

& 38 / 47 ¥ 93

’ 39 : 58 ] 94

( 40 ; 59 _ 95

Code

Special

character

Code

Special

character

Code

26

Page 35

B–64160EN/01

4.8

P ARAMETERS OF POWER MATE CNC MANAGER

[Data type] Bit

4. DESCRIPTION OF PARAMETERS

#7

0960

#6 #5 #4 #3

PMN#2MD2

#1

MD1

#0

SLV

SLV When the power mate CNC manager is selected, the screen displays:

0 : One slave.

1 : Up to four slaves with the screen divided into four.

MD1,MD2

These parameters set a slave parameter input/output destination.

MD2 MD1 Input/output destination

0 0 Part program storage

0 1 Memory card

In either case, slave parameters are output in program format.

PMN The power mate CNC manager function is:

0 : Enabled.

1 : Disabled. (Communication with slaves is not performed.)

27

Page 36

4. DESCRIPTION OF PARAMETERS

4.9

P ARAMETERS OF AXIS CONTROL/ INCREMENT SYSTEM

1001

[Data type] Bit

INM Least command increment on the linear axis

#7

#6 #5 #4 #3 #2 #1 #0

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

0 : In mm (metric system machine)

1 : In inches (inch system machine)

B–64160EN/01

INM

#7

IDG1002

#6 #5 #4

XIK

#3

AZR

#2

SFD

DLZ

[Data type] Bit

JAX Number of axes controlled simultaneously in manual continuous feed,

manual rapid traverse and manual reference position return

0 : 1 axis

1 : 3 axes

DLZ Function setting the reference position without dog

0 : Disabled

1 : Enabled (enabled for all axes)

NOTE

1 This function can be specified for each axis by DLZx, bit 1 of

parameter No.1005.

2 For a system including an axis of Cs contour control or

spindle positioning, avoid using this parameter. Use bit 1

(DLZx) of parameter No. 1005 instead to set just a required

axis.

SFD The function for shifting the reference position is

0: Not used.

1: Used.

#1

#0

JAX

AZR When no reference position is set, the G28 command causes:

0: Reference position return using deceleration dogs (as during manual

reference position return) to be exected.

1: P/S alarm No.090 to be issued.

NOTE

When reference position return without dogs is specified,

(when bit 1 (DLZ) of parameter No.1002 is set to 1 or bit 1

(DLZx) of parameter No.1005 is set to 1) the G28 command

specified before a reference position is set causes P/S

alarm No.090 to be issued, regardless of the setting of AZR.

28

Page 37

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

XIK When LRP, bit 1 of parameter No.1401, is set to 0, namely, when

positioning is performed using non–linear type positioning, if an

interlock is applied to the machine along one of axes in positioning,

0: The machine stops moving along the axis for which the interlock is

applied and continues to move along the other axes.

1: The machine stops moving along all the axes.

IDG When the reference position is set without dogs, automatic setting of the

IDGx parameter (bit 0 of parameter No.1012) to prevent the reference

position from being set again is:

0 : Not performed.

1 : Performed.

1004

[Data type] Bit

ISA The least input increment and least command increment are set.

IPR Whether the least input increment for each axis is set to a value 10 times as

large as the least command increment is specified, in increment systems

of IS–B at setting mm.

0: The least input increment is not set to a value 10 times as larg as the

1: The least input increment is set to a value 10 times as large as the least

If IPR is set to 1, the least input increment is set as follows:

#7

IPR

#6 #5 #4 #3 #2 #1 #0

ISA

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

ISA Least input increment and least command increment Symbol

0 0.001 mm, 0.001 deg, or 0.0001 inch IS–B

1 0.01 mm, 0.01 deg, or 0.001 inch IS–A

least command increment.

command increment.

Input increment Least input increment

IS–B 0.01 mm, 0.01 deg, or 0.0001 inch

NOTE

For IS–A, the least input increment cannot be set to a value

10 times as large as the least command increment.

The least input increment is not multiplied by 10 also when

the calculator–type decimal point input (bit 0 (DPI) of

parameter No. 3401) is used.

29

Page 38

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

#7

1005

#6 #5

EDMx#4EDPx#3HJZx

#2 #1

DLZx#0ZRNx

[Data type] Bit axis

ZRNx When a command specifying the movement except for G28 is issued in

automatic operation (memory, MDI, or DNC operation) and when a

return to the reference position has not been performed since the power

was turned on

0 : An alarm is generated (P/S alarm 224).

1 : An alarm is not generated.

NOTE

The state in which the reference position has not been

established refers to that state in which reference position

return has not been performed after power–on when an

absolute position detector is not being used, or that state in

which the association of the machine position with the position

detected with the absolute position detector has not been

completed (see the descriptio n of bit 4 (APZx) of parameter

No. 1815) when an absolute position detector is being used.

DLZx Function for setting the reference position without dogs

0 : Disabled

1 : Enabled

NOTE

When DLZ of parameter No.1002 is 0, DLZx is enabled.

When DLZ of parameter No.1002 is 1, DLZx is disabled, and

the function for setting the reference position without dogs

is enabled for all axes.

HJZx When a reference position is already set:

0 : Manual reference position return is performed with deceleration sogs.

1 : Manual reference position return is performed using rapid traverse

without deceleration dogs, or manual reference position return is

performed with deceleration dogs, depending on the setting of bit 7

(SJZ) of parameter No.0002.

NOTE

When reference position return without dogs is specified,

(see bit 1 (DLZ) of parameter No.1002) reference position

return after a reference position is set is performed using

rapid traverse, regardless of the setting of HJZ.

EDPx External deceleration signal in the positive direction for each axis

0 : Valid only for rapid traverse

1 : Valid for rapid traverse and cutting feed

EDMx External deceleration signal in the negative direction for each axis

0 : Valid only for rapid traverse

1 : Valid for rapid traverse and cutting feed

30

Page 39

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

#7

1006

#6 #5

ZMIx

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit axis

ROTx, ROSx Setting linear or rotation axis.

ROSx ROTx Meaning

0 0 Linear axis

0 1 Rotation axis (A type)

1 0 Setting is invalid (unused)

1 1 Rotation axis (B type)

(1) Inch/metric conversion is done.

(2) All coordinate values are linear axis type.

(Is not rounded in 0 to 360_)

(3) Stored pitch error compensation is linear axis type

(Refer to parameter No.3624)

(1) Inch/metric conversion is not done.

(2) Machine coordinate values are rounded in 0 to 360_.

Absolute coordinate values are rounded or not rounded

by parameter No.1008#0(ROAx) and #2(RRLx).

(3) Stored pitch error compensation is the rotation type.

(Refer to parameter No.3624)

(4) Automatic reference position return (G28, G30) is done

in the reference position return direction and the move

amount does not exceed one rotation.

(1) Inch/metric conversion, absolute coordinate values and

relative coordinate values are not done.

(2) Machine coordinate values, absolute coordinate values

and relative coordinate values are linear axis type. (Is

not rounded in 0 to 360_).

(3) Stored pitch error compensation is linear axis type (Re-

fer to parameter No.3624)

(4) Cannot be used with the rotation axis roll over function

and the index table indexing function (M series)

#4 #3 #2 #1

ROSx#0ROTx

ZMIx The direction of reference position return.

0 : Positive direction

1 : Negative direction

NOTE

The direction of the initial backlash, which occurs when

power is switched on, is opposite to the direction of a

reference position return.

31

Page 40

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

#7

1008

#6 #5 #4 #3 #2

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Bit axis

ROAx The roll–over function of a rotation axis is

0 : Invalid

1 : Valid

NOTE

ROAx specifies the function only for a rotation axis (for which

ROTx, #0 of parameter No.1006, is set to 1)

RABx In the absolute commands, the axis rotates in the direction

0 : In which the distance to the target is shorter.

1 : Specified by the sign of command value.

NOTE

RABx is valid only when ROAx is 1.

RRLx#1RABx#0ROAx

RRLx Relative coordinates are

0 : Not rounded by the amount of the shift per one rotation

1 : Rounded by the amount of the shift per one rotation

NOTE

1 RRLx is valid only when ROAx is 1.

2 Assign the amount of the shift per one rotation in parameter

No.1260.

1010 Number of CNC–controlled axes

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] Byte

[Valid data range] 1, 2, 3, ..., the number of controlled axes

Set the maximum number of axes that can be controlled by the CNC.

[Example]

Suppose that the first axis is the X axis, and the second and subsequent axes

are the Y, Z, and A axes in that order, and that they are controlled as follows:

X, Y, and Z axes: Controlled by the CNC

A axis: Controlled by the PMC

Then set this parameter to 3 (total 3: X, Y, and Z)

With this setting, the fourth axis (A axis) is controlled only by the PMC,

and therefore cannot be controlled directly by the CNC.

32

Page 41

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

#7

1012

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit axis

IDGx The function for setting the reference position again, without dogs, is:

0 : Not inhibited.

1 : Inhibited.

NOTE

1 IDGx is enabled when the IDG parameter (bit 7 of parameter

No.1002) is 1.

2 When the function for setting the reference position, without

dogs, is used, and the reference position is lost for some

reason, an alarm requesting reference position return

(No.300) is generated when the power is next turned on. If

the operator performs reference position return, as a result

of mistakenly identifying the alarm as that requesting the

operator to perform a normal reference position return, an

invalid reference position may be set. To prevent such an

operator error, the IDGx parameter is provided to prevent the

reference position from being set again without dogs.

(1) If the IDG parameter (bit 7 of parameter No.1002) is set

to 1, the IDGx parameter (bit 0 of parameter No.1012)

is automatically set to 1 when the reference position is

set using the function for setting the reference position

without dogs. This prevents the reference position from

being set again without dogs.

(2) Once the reference position is prevented from being set

for an axis again, without dogs, any attempt to set the

reference position for the axis without dogs results in the

output of an alarm (No.090).

(3) When the reference position must be set again without

dogs, set IDGx to 0 before setting the reference position.

IDGx

33

Page 42

4. DESCRIPTION OF PARAMETERS

1020 Program axis name for each axis

[Data type] Byte axis

B–64160EN/01

Set the program axis name for each controlled axis, using one of the values

listed in the following table:

Axis

name

Setting

X 88 U 85 A 65 T 84

Y 89 V 86 B 66

Z 90 W 87 C 67

Axis

name

Setting

Axis

name

Setting

Axis

name

Setting

NOTE

1 The same axis name cannot be assigned to more than one

axis.

2 When the addresses A, B, U, V, and W are used as the axis

name, refer to the parameters ABM and UVW (No. 16200 #6

and #7).

3 When the secondary auxiliary function is provided, the

address used by the secondary auxiliary function cannot be

used as an axis name.

1022 Setting of each axis in the basic coordinate system

NOTE

When this parameter is set, power must be turned off before

operation is continued.

[Data type] Byte axis

To determine the following planes used for circular interpolation, cutter

compensation C (for the M series), tool nose radius compensation (for the

T series), etc., each control axis is set to one of the basic three axes X, Y,

and Z, or an axis parallel to the X, Y, or Z axis.

G17: Plane Xp–Yp

G18: Plane Zp–Xp

G19: Plane Yp–Zp

Only one axis can be set for each of the three basic axes X, Y, and Z, but

two or more parallel axes can be set.

Set value Meaning

0 Neither the basic three axes nor a parallel axis

1 X axis of the basic three axes

2 Y axis of the basic three axes

3 Z axis of the basic three axes

5 Axis parallel to the X axis

6 Axis parallel to the Y axis

7 Axis parallel to the Z axis

34

Page 43

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

1023 Number of the servo axis for each axis

NOTE

When this parameter is set, power must be turned off before

operation is continued.

[Data type] Byte axis

[Valid data range] 1, 2, 3, ..., number of control axes /–1, –2

Set the servo axis for each control axis.

Usually set to same number as the control axis number.

The control axis number is the order number that is used for setting the

axis–type parameters or axis–type machine signals

Refer to FSSB section of CONNECTION MANUAL (Function)

B–64113EN–1.

35

Page 44

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

4.10

P ARAMETERS OF COORDINATES

[Data type] Bit

[Data type] Bit

#7

1201

#6 #5

AWK

#4 #3 #2

ZCL

#1 #0

ZCL Local coordinate system when the manual reference position return is

performed

0 : The local coordinate system is not canceled.

1 : The local coordinate system is canceled.

AWK When the workpiece zero point offset value is changed

0 : The absolute position display changed when the next bufforing block

is performed.

1 : The absolute position display is changed immediately.

Changed value is valid ofter baffering the next block.

#7

1202

#6 #5 #4

G52

#3

RLC

#2 #1 #0

RLC Local coordinate system is

0 : Not cancelled by reset

1 : Cancelled by reset

G52 In local coordinate system setting (G52), a cutter compensation vector is:

0 : Not considered.

1 : Considered.

NOTE

Select a local coordinate system setting operation when

cutter compensation is applied, and when two or more

blocks specifying no movement exist prior to the

specification of G52, or when G52 is specified after cutter

compensation mode is canceled without eliminating the

offset vector.

#7

1203

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit

EMC The extended external machine zero point shift function is:

0: Disabled.

1: Enabled.

NOTE

1 To use the extended external machine zero point shift

function, the external machine zero point shift function or the

external data input function is required.

2 When the extended machine zero point shift function is

enabled, the conventional external machine zero point shift

function is disabled.

EMC

36

Page 45

B–64160EN/01

1220 External workpiece zero point of fset value

[Data type] 2–word axis

[Unit of data]

Input increment IS–A IS–B Unit

Linear axis (input in mm) 0.01 0.001

Linear axis (input in inches) 0.001 0.0001 inch

Rotation axis 0.01 0.001 deg

[Valid data range] –99999999 to 99999999

This is one of the parameters that give the position of the origin of

workpiece coordinate system (G54 to G59). It gives an offset of the

workpiece origin common to all workpiece coordinate systems. In

general, the offset varies depending on the workpiece coordinate systems.

The value can be set from the PMC using the external data input function.

1221 Workpiece zero point offset value in workpiece coordinate system 1 (G54)

1222 W orkpiece zero point offset value in workpiece coordinate system 2(G55)

1223 W orkpiece zero point offset value in workpiece coordinate system 3(G56)

4. DESCRIPTION OF PARAMETERS

mm

1224 Workpiece zero point offset value in workpiece coordinate system 4 (G57)

1225 Workpiece zero point offset value in workpiece coordinate system 5 (G58)

1226 Workpiece zero point offset value in workpiece coordinate system 6 (G59)

[Data type] 2–word axis

[Unit of data]

Input increment IS–A IS–B Unit

Linear axis (input in mm) 0.01 0.001 mm

Linear axis (input in inches) 0.001 0.0001 inch

Rotation axis 0.01 0.001 deg

[Valid data range] –99999999 to 99999999

The workpiece zero point of fset values in workpiece coordinate systems 1

to 6 (G54 to G59) are set.

Workpiece coordinate system 1 (G54)

Workpiece zero point offset

Workpiece coordinate system 2 (G55)

Origin of machine coordinate system

37

Page 46

4. DESCRIPTION OF PARAMETERS

B–64160EN/01

NOTE

The workpiece origin offset can also be set using the

workpiece coordinate system screen.

1240

NOTE

When this parameter is set, power must be turned off before

operation is continued.

1241

1242

1243

[Data type] 2–word axis

[Unit of data]

Increment system IS–A IS–B Unit

Millimeter machine 0.01 0.001

Inch machine 0.001 0.0001

Rotation axis 0.01 0.001

Coordinate value of the reference position on each axis in the machine

coordinate system

Coordinate value of the second reference position on each axis in the machine

coordinate system

Coordinate value of the third reference position on each axis in the machine coordinate system

Coordinate value of the fourth reference position on each axis in the machine

coordinate system

mm

inch

deg

[Valid data range] –99999999 to 99999999

Set the coordinate values of the first to fourth reference positions in the

machine coordinate system.

1260 Amount of a shift per one rotation of a rotation axis

NOTE

When this parameter is set, the power must be turned off

before operation is continued.

[Data type] 2–word axis

[Unit of data]

Increment system Unit of data Standard value

IS–A 0.01 deg 36000

IS–B 0.001 deg 360000

[Valid data range] 1000 to 9999999

Set the amount of a shift per one rotaion of a rotaion axis.

38

Page 47

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

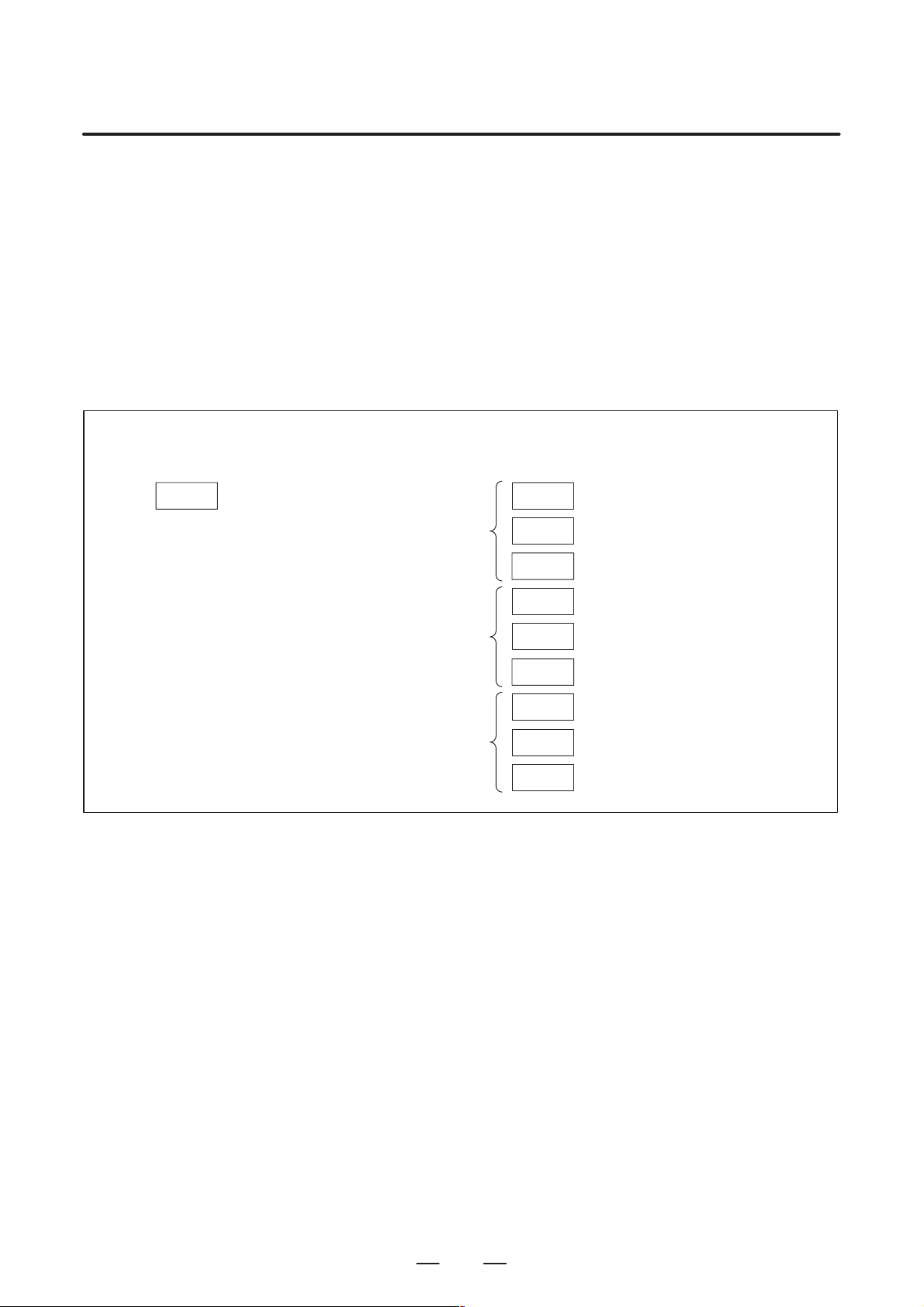

1280

First address of the signal group used by the external machine zero point shift

extension

[Data type] Word

[Valid data range] 0 to 65535

Set the first address of the signal group used by the external machine zero

point shift extension. If 100 is specified, R0100 to R0115 can be used.

R0100

R0101

R0102

R0103

:

:

Shift amount of external machine zero point shift extension for

the first axis (LOW)

Shift amount of external machine zero point shift extension for

the first axis (HIGH)

Shift amount of external machine zero point shift extension for

the second axis (LOW)

Shift amount of external machine zero point shift extension for

the second axis (HIGH)

::

:

:

:

R0114

R0115

Shift amount of external machine zero point shift extension for

the eighth axis (LOW)

Shift amount of external machine zero point shift extension for

the eighth axis (HIGH)

:

NOTE

1 This parameter is valid when bit 0 (EMC) of parameter No.

1203 is set to 1.

2 If the specified number is not present, the external machine

zero point shift extension is disabled.

3 A shift amount of the external machine zero point shift

extension can be written from the C executer or macro

executer.

39

Page 48

4. DESCRIPTION OF PARAMETERS

4.11

P ARAMETERS OF STROKE CHECK

[Data type] Bit

1300

OUT The area inside or outside of the stored stroke check 2 is set as an

LMS The EXLM signal for switching stored stroke check

B–64160EN/01

#7

BFA LZR LMS OUT

#6 #5 #4 #3 #2 #1 #0

inhibition area (setting by the parameters No.1322 and No.1323).

0: Inside

1: Outside

0: Disabled

1: Enabled

NOTE

Stored stroke check 1 supports two pairs of parameters for

setting the prohibited area. The stored stroke limit switching

signal is used to enable either of the prohibited areas set with

these parameter pairs.

(1) Prohibited area I: Parameters No.1320 and No.1321

(2) Prohibited area II: Parameters No.1326 and No.1327

LZR Checking of stored stroke check 1 during the time from power–on to the

manual position reference return

0: The stroke check 1 is checked.

1: The stroke check 1 is not checked

NOTE

When an absolute position detector is used and a reference

position is already set upon power–up, stored stroke limit

check 1 is started immediately after power–up, regardless of

the setting.

BFA When a command that exceeds a stored stroke check is issued

0: An alarm is generated after the stroke check is exceeded.

1: An alarm is generated before the stroke check is exceeded.

NOTE

The tool stops at a point up to F/7500 mm short of or ahead

of the boundary.

(F: Feedrate when the tool reaches the boundary (mm/min))

#7

1301

#6 #5 #4

OF1

#3 #2 #1 #0

DLM

[Data type] Bit

DLM The stored stroke limit switching signal for each axial direction is:

0: Enabled.

1: Disabled.

OF1 If the tool is moved into the range allowed on the axis after an alarm is

raised by stored stroke check 1,

0: The alarm is not canceled before a reset is made.

1: The OT alarm is immediately canceled.

40

Page 49

B–64160EN/01

4. DESCRIPTION OF PARAMETERS

CAUTION

In the cases below, the automatic release function is

disabled. To release an alarm, a reset operation is required.

1 When a setting is made to issue an alarm before a stored

stroke limit is exceeded (bit 7 (BFA) of parameter No.

1300)

2 When an another overtravel alarm (such as stored stroke

check 2 and stored stroke check 3) is already issued

#7

1310

#6 #5 #4 #3 #2 #1 #0

[Data type] Bit axis

OT2x Whether stored stroke check 2 is checked for each axis is set.

0: Stored stroke check 2 is not checked.

1: Stored stroke check 2 is checked.

1320 Coordinate value I of stored stroke check 1 in the positive direction on each axis

1321 Coordinate value I of stored stroke check 1 in the negative direction on each axis

[Data type] 2–word axis

[Unit of data]

Increment system IS–A IS–B Unit

Millimeter machine 0.01 0.001 mm

Inch machine 0.001 0.0001 inch

Rotation axis 0.01 0.001 deg

[Valid data range] –99999999 to 99999999

The coordinate values of stored stroke check 1 in the positive and negative

directions are setfor each axis in the machine coordinate system. The

outside area of the two checks set in the parameters is inhibited.

OT2x

(Xm,Ym,Zm)

41

(Xp,Yp,Zp)

Set the machine coordinates of the

boundaries in the positive direction

(Xp, Yp, and Zp) using parameter No.

1320, and those of the boundaries in

the negative direction (Xm, Ym, and

Zm) using parameter No. 1321. The

prohibited area thus becomes the

hatched area in the figure on the left.

Page 50

4. DESCRIPTION OF PARAMETERS

1322 Coordinate value of stored stroke check 2 in the positive direction on each axis

1323 Coordinate value of stored stroke check 2 in the negative direction on each axis

B–64160EN/01

NOTE

1 For axes with diameter specification, a diameter value must

be set.

2 When the parameters are set as follows, the stroke becomes

infinite:

parameter 1320 < parameter 1321

For movement along the axis for which infinite stroke is set,