Page 1

FANUC Robotics

R-J3iBMate Controller

(RIA R15.06 – 1999 Compliant)

Maintenance Manual

MARMIBRIA01021E REV. B

B-81535EN/02

This publication contains proprietary information of FANUC Robotics

North America, Inc. furnished for customer use only. No other uses

are authorized without the express written permission of FANUC

Robotics North America, Inc.

FANUC Robotics North America, Inc.

3900 W. Hamlin Road

Rochester Hills, Michigan 48309–3253

Page 2

The descriptions and specifications contained in this manual were in

effect at the time this manual was approved for printing. FANUC

Robotics North America, Inc, hereinafter referred to as FANUC

Robotics, reserves the right to discontinue models at any time or to

change specifications or design without notice and without incurring

obligations.

FANUC Robotics manuals present descriptions, specifications,

drawings, schematics, bills of material, parts, connections and/or

procedures for installing, disassembling, connecting, operating and

programming FANUC Robotics’ products and/or systems. Such

systems consist of robots, extended axes, robot controllers,

application software, the KAREL programming language,

INSIGHT vision equipment, and special tools.

FANUC Robotics recommends that only persons who have been

trained in one or more approved FANUC Robotics Training

Course(s) be permitted to install, operate, use, perform procedures

on, repair, and/or maintain FANUC Robotics’ products and/or

systems and their respective components. Approved training

necessitates that the courses selected be relevant to the type of

system installed and application performed at the customer site.

WARNING

This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in accordance

with the instruction manual, may cause interference to radio

communications. As temporarily permitted by regulation, it

has not been tested for compliance with the limits for Class A

computing devices pursuant to subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection

against such interference. Operation of the equipment in a

residential area is likely to cause interference, in which case

the user, at his own expense, will be required to take

whatever measure may be required to correct the

interference.

FANUC Robotics conducts courses on its systems and products on

a regularly scheduled basis at its headquarters in Rochester Hills,

Michigan. For additional information contact

FANUC Robotics North America, Inc.

Training Department

3900 W. Hamlin Road

Rochester Hills, Michigan 48309-3253

www.fanucrobotics.com

Send your comments and suggestions about this manual to:

product.documentation@fanucrobotics.com

Page 3

Conventions

Copyright 2002 by FANUC Robotics North America, Inc.

All Rights Reserved

The information illustrated or contained herein is not to be

reproduced, copied, translated into another language, or transmitted

in whole or in part in any way without the prior written consent of

FANUC Robotics North America, Inc.

AccuStat, ArcTool, DispenseTool, FANUC LASER DRILL,

KAREL, INSIGHT, INSIGHT II, PaintTool, PaintWorks,

PalletTool, SOCKETS, SOFT PARTS SpotTool,

TorchMate, and YagTool are Registered Trademarks of FANUC

Robotics.

FANUC Robotics reserves all proprietary rights, including but not

limited to trademark and trade name rights, in the following names:

AccuAir AccuCal AccuChop AccuFlow AccuPath

AccuSeal ARC Mate ARC Mate Sr. ARC Mate System 1

ARC Mate System 2 ARC Mate System 3 ARC Mate System

4 ARC Mate System 5 ARCWorks Pro AssistTool

AutoNormal AutoTCP BellTool BODYWorks Cal Mate Cell

Finder Center Finder Clean Wall CollisionGuard

DispenseTool F-100 F-200i FabTool FANUC LASER

DRILL Flexibell FlexTool HandlingTool HandlingWorks

INSIGHT INSIGHT II IntelliTrak Integrated Process Solution

Intelligent Assist Device IPC -Integrated Pump Control IPD

Integral Pneumatic Dispenser ISA Integral Servo Applicator ISD

Integral Servo Dispenser Laser Mate System 3 Laser Mate

System 4 LaserPro LaserTool LR Tool MIG Eye

MotionParts NoBots Paint Stick PaintPro PaintTool 100

PAINTWorks PAINTWorks II PAINTWorks III PalletMate

PalletMate PC PalletTool PC PayloadID RecipTool

RemovalTool Robo Chop Robo Spray S-420i S-430i

ShapeGen SoftFloat SOF PARTS SpotTool+ SR Mate

SR ShotTool SureWeld SYSTEM R-J2 Controller SYSTEM RJ3 Controller SYSTEM R-J3iB Controller TCP Mate

TurboMove TorchMate visLOC visPRO-3D visTRAC

WebServer WebTP YagTool

This manual includes information essential to the safety of

personnel, equipment, software, and data. This information is

indicated by headings and boxes in the text.

WARNING

Information appearing under WARNING concerns the

protection of personnel. It is boxed and in bold type to set it

apart from other text.

Page 4

CAUTION

Information appearing under CAUTION concerns the protection of

equipment, software, and data. It is boxed to set it apart from

other text.

NOTE Information appearing next to NOTE concerns related information

or useful hints.

Page 5

Safety

Safety-1

FANUC Robotics is not and does not represent itself as an expert in

safety systems, safety equipment, or the specific safety aspects of

your company and/or its work force. It is the responsibility of the

owner, employer, or user to take all necessary steps to guarantee

the safety of all personnel in the workplace.

The appropriate level of safety for your application and installation

can best be determined by safety system professionals. FANUC

Robotics therefore, recommends that each customer consult with

such professionals in order to provide a workplace that allows for

the safe application, use, and operation of FANUC Robotic systems.

According to the industry standard ANSI/RIA R15.06, the owner or

user is advised to consult the standards to ensure compliance with

its requests for Robotics System design, usability, operation,

maintenance, and service. Additionally, as the owner, employer, or

user of a robotic system, it is your responsibility to arrange for the

training of the operator of a robot system to recognize and respond

to known hazards associated with your robotic system and to be

aware of the recommended operating procedures for your particular

application and robot installation.

FANUC Robotics therefore, recommends that all personnel who

intend to operate, program, repair, or otherwise use the robotics

system be trained in an approved FANUC Robotics training course

and become familiar with the proper operation of the system.

Persons responsible for programming the system–including the

design, implementation, and debugging of application programs–

must be familiar with the recommended programming procedures

for your application and robot installation.

The following guidelines are provided to emphasize the importance

of safety in the workplace.

Page 6

Safety-2

y

CONSIDERING

SAFETY FOR YOUR

ROBOT

INSTALLATION

Keeping People and

Equipment Safe

Using Safet

Enhancing Devices

Safety is essential whenever robots are used. Keep in mind the

following factors with regard to safety:

• The safety of people and equipment

• Use of safety enhancing devices

• Techniques for safe teaching and manual operation of the

robot(s)

• Techniques for safe automatic operation of the robot(s)

• Regular scheduled inspection of the robot and workcell

• Proper maintenance of the robot

The safety of people is always of primary importance in any

situation. However, equipment must be kept safe, too. When

prioritizing how to apply safety to your robotic system, consider the

following:

• People

• External devices

• Robot(s)

• Tooling

• Workpiece

Always give appropriate attention to the work area that surrounds

the robot. The safety of the work area can be enhanced by the

installation of some or all of the following devices:

• Safety fences, barriers, or chains

• Light curtains

• Interlocks

• Pressure mats

• Floor markings

• Warning lights

• Mechanical stops

• EMERGENCY STOP buttons

• DEADMAN switches

Setting Up a Safe

Workcell

A safe workcell is essential to protect people and equipment.

Observe the following guidelines to ensure that the workcell is set

up safely. These suggestions are intended to supplement and not

replace existing federal, state, and local laws, regulations, and

guidelines that pertain to safety.

• Sponsor your personnel for training in approved FANUC

Robotics training course(s) related to your application. Never

permit untrained personnel to operate the robots.

Page 7

Safety-3

• Install a lockout device that uses an access code to prevent

unauthorized persons from operating the robot.

• Use anti–tie–down logic to prevent the operator from bypassing

safety measures.

• Arrange the workcell so the operator faces the workcell and can

see what is going on inside the cell.

• Clearly identify the work envelope of each robot in the system

with floor markings, signs, and special barriers. The work

envelope is the area defined by the maximum motion range of

the robot, including any tooling attached to the wrist flange that

extend this range.

• Position all controllers outside the robot work envelope.

• Never rely on software as the primary safety element.

• Mount an adequate number of EMERGENCY STOP buttons or

switches within easy reach of the operator and at critical points

inside and around the outside of the workcell.

• Install flashing lights and/or audible warning devices that

activate whenever the robot is operating, that is, whenever

power is applied to the servo drive system. Audible warning

devices shall exceed the ambient noise level at the end–use

application.

• Wherever possible, install safety fences to protect against

unauthorized entry by personnel into the work envelope.

• Install special guarding that prevents the operator from reaching

into restricted areas of the work envelope.

• Use interlocks.

• Use presence or proximity sensing devices such as light

curtains, mats, and capacitance and vision systems to enhance

safety.

• Periodically check the safety joints or safety clutches that can be

optionally installed between the robot wrist flange and tooling. If

the tooling strikes an object, these devices dislodge, remove

power from the system, and help to minimize damage to the

tooling and robot.

Page 8

Safety-4

• Make sure all external devices are properly filtered, grounded,

shielded, and suppressed to prevent hazardous motion due to

the effects of electro–magnetic interference (EMI), radio

frequency interference (RFI), and electro–static discharge

(ESD).

• Make provisions for power lockout/tagout at the controller.

• Eliminate pinch points. Pinch points are areas where personnel

could get trapped between a moving robot and other equipment.

• Provide enough room inside the workcell to permit personnel to

teach the robot and perform maintenance safely.

• Program the robot to load and unload material safely.

• If high voltage electrostatics are present, be sure to provide

appropriate interlocks, warning, and beacons.

• If materials are being applied at dangerously high pressure,

provide electrical interlocks for lockout of material flow and

pressure.

Staying Safe While

Teaching or Manually

Operating the Robot

Advise all personnel who must teach the robot or otherwise

manually operate the robot to observe the following rules:

• Never wear watches, rings, neckties, scarves, or loose clothing

that could get caught in moving machinery.

• Know whether or not you are using an intrinsically safe teach

pendant if you are working in a hazardous environment.

• Before teaching, visually inspect the robot and work envelope to

make sure that no potentially hazardous conditions exist. The

work envelope is the area defined by the maximum motion

range of the robot. These include tooling attached to the wrist

flange that extends this range.

• The area near the robot must be clean and free of oil, water, or

debris. Immediately report unsafe working conditions to the

supervisor or safety department.

• FANUC Robotics recommends that no one enter the work

envelope of a robot that is on, except for robot teaching

operations. However, if you must enter the work envelope, be

sure all safeguards are in place, check the teach pendant

DEADMAN switch for proper operation, and place the robot in

teach mode. Take the teach pendant with you, turn it on, and be

prepared to release the DEADMAN switch. Only the person

with the teach pendant should be in the work envelope.

Page 9

Safety-5

WARNING

Never bypass, strap, or otherwise deactivate a safety device,

such as a limit switch, for any operational convenience.

Deactivating a safety device is known to have resulted in

serious injury and death.

• Know the path that can be used to escape from a moving robot;

make sure the escape path is never blocked.

• Isolate the robot from all remote control signals that can cause

motion while data is being taught.

• Test any program being run for the first time in the following

manner:

WARNING

Stay outside the robot work envelope whenever a program is

being run. Failure to do so can result in injury.

Staying Safe During

Automatic Operation

- Using a low motion speed, single step the program for at

least one full cycle.

- Using a low motion speed, test run the program continuously

for at least one full cycle.

- Using the programmed speed, test run the program

continuously for at least one full cycle.

• Make sure all personnel are outside the work envelope before

running production.

Advise all personnel who operate the robot during production to

observe the following rules:

• Make sure all safety provisions are present and active.

• Know the entire workcell area. The workcell includes the robot

and its work envelope, plus the area occupied by all external

devices and other equipment with which the robot interacts.

• Understand the complete task the robot is programmed to

perform before initiating automatic operation.

• Make sure all personnel are outside the work envelope before

operating the robot.

Page 10

Safety-6

• Never enter or allow others to enter the work envelope during

automatic operation of the robot.

• Know the location and status of all switches, sensors, and

control signals that could cause the robot to move.

• Know where the EMERGENCY STOP buttons are located on

both the robot control and external control devices. Be prepared

to press these buttons in an emergency.

• Never assume that a program is complete if the robot is not

moving. The robot could be waiting for an input signal that will

permit it to continue activity.

• If the robot is running in a pattern, do not assume it will continue

to run in the same pattern.

• Never try to stop the robot, or break its motion, with your body.

The only way to stop robot motion immediately is to press an

EMERGENCY STOP button located on the controller panel,

teach pendant, or emergency stop stations around the workcell.

Staying Safe During

Inspection

When inspecting the robot, be sure to

• Turn off power at the controller.

• Lock out and tag out the power source at the controller

according to the policies of your plant.

• Turn off the compressed air source and relieve the air pressure.

• If robot motion is not needed for inspecting the electrical circuits,

press the EMERGENCY STOP button on the operator panel.

• Never wear watches, rings, neckties, scarves, or loose clothing

that could get caught in moving machinery.

• If power is needed to check the robot motion or electrical

circuits, be prepared to press the EMERGENCY STOP button,

in an emergency.

• Be aware that when you remove a servomotor or brake, the

associated robot arm will fall if it is not supported or resting on a

hard stop. Support the arm on a solid support before you

release the brake.

Staying Safe During

Maintenance

When performing maintenance on your robot system, observe the

following rules:

Page 11

Safety-7

• Never enter the work envelope while the robot or a program is in

operation.

• Before entering the work envelope, visually inspect the workcell

to make sure no potentially hazardous conditions exist.

• Never wear watches, rings, neckties, scarves, or loose clothing

that could get caught in moving machinery.

• Consider all or any overlapping work envelopes of adjoining

robots when standing in a work envelope.

• Test the teach pendant for proper operation before entering the

work envelope.

• If it is necessary for you to enter the robot work envelope while

power is turned on, you must be sure that you are in control of

the robot. Be sure to take the teach pendant with you, press the

DEADMAN switch, and turn the teach pendant on. Be prepared

to release the DEADMAN switch to turn off servo power to the

robot immediately.

• Whenever possible, perform maintenance with the power turned

off. Before you open the controller front panel or enter the work

envelope, turn off and lock out the 3–phase power source at the

controller.

• Be aware that when you remove a servomotor or brake, the

associated robot arm will fall if it is not supported or resting on a

hard stop. Support the arm on a solid support before you

release the brake.

WARNING

Lethal voltage is present in the controller WHENEVER IT IS

CONNECTED to a power source. Be extremely careful to

avoid electrical shock.

HIGH VOLTAGE IS PRESENT at the input side whenever the

controller is connected to a power source. Turning the

disconnect or circuit breaker to the OFF position removes

power from the output side of the device only.

• Release or block all stored energy. Before working on the

pneumatic system, shut off the system air supply and purge the

air lines.

Page 12

Safety-8

• Isolate the robot from all remote control signals. If maintenance

must be done when the power is on, make sure the person

inside the work envelope has sole control of the robot. The

teach pendant must be held by this person.

• Make sure personnel cannot get trapped between the moving

robot and other equipment. Know the path that can be used to

escape from a moving robot. Make sure the escape route is

never blocked.

• Use blocks, mechanical stops, and pins to prevent hazardous

movement by the robot. Make sure that such devices do not

create pinch points that could trap personnel.

WARNING

Do not try to remove any mechanical component from the

robot before thoroughly reading and understanding the

procedures in the appropriate manual. Doing so can result in

serious personal injury and component destruction.

KEEPING MACHINE

TOOLS AND

EXTERNAL

DEVICES SAFE

• Be aware that when you remove a servomotor or brake, the

associated robot arm will fall if it is not supported or resting on a

hard stop. Support the arm on a solid support before you

release the brake.

• When replacing or installing components, make sure dirt and

debris do not enter the system.

• Use only specified parts for replacement. To avoid fires and

damage to parts in the controller, never use nonspecified fuses.

• Before restarting a robot, make sure no one is inside the work

envelope; be sure that the robot and all external devices are

operating normally.

Certain programming and mechanical measures are useful in

keeping the machine tools and other external devices safe. Some

of these measures are outlined below. Make sure you know all

associated measures for safe use of such devices.

Programming Safety

Precautions

Implement the following programming safety measures to prevent

damage to machine tools and other external devices.

Page 13

Mechanical Safety

Precautions

Safety-9

• Back–check limit switches in the workcell to make sure they do

not fail.

• Implement ‘‘failure routines” in programs that will provide

appropriate robot actions if an external device or another robot

in the workcell fails.

• Use handshaking protocol to synchronize robot and external

device operations.

• Program the robot to check the condition of all external devices

during an operating cycle.

Implement the following mechanical safety measures to prevent

damage to machine tools and other external devices.

• Make sure the workcell is clean and free of oil, water, and

debris.

• Use software limits, limit switches, and mechanical hardstops to

prevent undesired movement of the robot into the work area of

machine tools and external devices.

KEEPING THE

ROBOT SAFE

Operating Safety

Precautions

Programming Safety

Precautions

Observe the following operating and programming guidelines to

prevent damage to the robot.

The following measures are designed to prevent damage to the

robot during operation.

• Use a low override speed to increase your control over the robot

when jogging the robot.

• Visualize the movement the robot will make before you press

the jog keys on the teach pendant.

• Make sure the work envelope is clean and free of oil, water, or

debris.

• Use circuit breakers to guard against electrical overload.

The following safety measures are designed to prevent damage to

the robot during programming:

• Establish interference zones to prevent collisions when two or

more robots share a work area.

Page 14

Safety-10

• Make sure that the program ends with the robot near or at the

home position.

• Be aware of signals or other operations that could trigger

operation of tooling resulting in personal injury or equipment

damage.

• In dispensing applications, be aware of all safety guidelines with

respect to the dispensing materials.

NOTE Any deviation from the methods and safety practices

described in this manual must conform to the approved standards of

your company. If you have questions, see your supervisor.

ADDITIONAL

SAFETY

CONSIDERATIONS

FOR PAINT ROBOT

INSTALLATIONS

Process technicians are sometimes required to enter the paint

booth, for example, during daily or routine calibration or while

teaching new paths to a robot. Maintenance personal also must

work inside the paint booth periodically.

Whenever personnel are working inside the paint booth, ventilation

equipment must be used. Instruction on the proper use of

ventilating equipment usually is provided by the paint shop

supervisor.

Although paint booth hazards have been minimized, potential

dangers still exist. Therefore, today’s highly automated paint booth

requires that process and maintenance personnel have full

awareness of the system and its capabilities. They must

understand the interaction that occurs between the vehicle moving

along the conveyor and the robot(s), hood/deck and door opening

devices, and high–voltage electrostatic tools.

Paint robots are operated in three modes:

• Teach or manual mode

• Automatic mode, including automatic and exercise operation

• Diagnostic mode

During both teach and automatic modes, the robots in the paint

booth will follow a predetermined pattern of movements. In teach

mode, the process technician teaches (programs) paint paths using

the teach pendant.

In automatic mode, robot operation is initiated at the System

Operator Console (SOC) or Manual Control Panel (MCP), if

available, and can be monitored from outside the paint booth. All

personnel must remain outside of the booth or in a designated safe

Page 15

Safety-11

area within the booth whenever automatic mode is initiated at the

SOC or MCP.

In automatic mode, the robots will execute the path movements they

were taught during teach mode, but generally at production speeds.

When process and maintenance personnel run diagnostic routines

that require them to remain in the paint booth, they must stay in a

designated safe area.

Paint System Safety

Features

Process technicians and maintenance personnel must become

totally familiar with the equipment and its capabilities. To minimize

the risk of injury when working near robots and related equipment,

personnel must comply strictly with the procedures in the manuals.

This section provides information about the safety features that are

included in the paint system and also explains the way the robot

interacts with other equipment in the system.

The paint system includes the following safety features:

• Most paint booths have red warning beacons that illuminate

when the robots are armed and ready to paint. Your booth

might have other kinds of indicators. Learn what these are.

• Some paint booths have a blue beacon that, when illuminated,

indicates that the electrostatic devices are enabled. Your booth

might have other kinds of indicators. Learn what these are.

• EMERGENCY STOP buttons are located on the robot controller

and teach pendant. Become familiar with the locations of all E–

STOP buttons.

• An intrinsically safe teach pendant is used when teaching in

hazardous paint atmospheres.

• A DEADMAN switch is located on each teach pendant. When this

switch is held in, and the teach pendant is on, power is applied to the

robot servo system. If the engaged DEADMAN switch is released

during robot operation, power is removed from the servo system, all

axis brakes are applied, and the robot comes to an EMERGENCY

STOP. Safety interlocks within the system might also E–STOP other

robots.

WARNING

An EMERGENCY STOP will occur if the DEADMAN switch is

released on a bypassed robot.

Page 16

Safety-12

• Overtravel by robot axes is prevented by software limits. All of

the major and minor axes are governed by software limits. Limit

switches and hardstops also limit travel by the major axes.

• EMERGENCY STOP limit switches and photoelectric eyes

might be part of your system. Limit switches, located on the

entrance/exit doors of each booth, will EMERGENCY STOP all

equipment in the booth if a door is opened while the system is

operating in automatic or manual mode. For some systems,

signals to these switches are inactive when the switch on the

SCC is in teach mode.

When present, photoelectric eyes are sometimes used to

monitor unauthorized intrusion through the entrance/exit

silhouette openings.

• System status is monitored by computer. Severe conditions

result in automatic system shutdown.

Staying Safe While

Operating the Paint

Robot

When you work in or near the paint booth, observe the following

rules, in addition to all rules for safe operation that apply to all robot

systems.

WARNING

Observe all safety rules and guidelines to avoid injury.

WARNING

Never bypass, strap, or otherwise deactivate a safety device,

such as a limit switch, for any operational convenience.

Deactivating a safety device is known to have resulted in

serious injury and death.

• Know the work area of the entire paint station (workcell).

• Know the work envelope of the robot and hood/deck and door

opening devices.

• Be aware of overlapping work envelopes of adjacent robots.

• Know where all red, mushroom–shaped EMERGENCY STOP

buttons are located.

Page 17

Safety-13

• Know the location and status of all switches, sensors, and/or

control signals that might cause the robot, conveyor, and

opening devices to move.

• Make sure that the work area near the robot is clean and free of

water, oil, and debris. Report unsafe conditions to your

supervisor.

• Become familiar with the complete task the robot will perform

BEFORE starting automatic mode.

• Make sure all personnel are outside the paint booth before you

turn on power to the robot servo system.

• Never enter the work envelope or paint booth before you turn off

power to the robot servo system.

• Never enter the work envelope during automatic operation

unless a safe area has been designated.

• Never wear watches, rings, neckties, scarves, or loose clothing

that could get caught in moving machinery.

Staying Safe While

Operating Paint

Application Equipment

• Remove all metallic objects, such as rings, watches, and belts,

before entering a booth when the electrostatic devices are

enabled.

• Stay out of areas where you might get trapped between a

moving robot, conveyor, or opening device and another object.

• Be aware of signals and/or operations that could result in the

triggering of guns or bells.

• Be aware of all safety precautions when dispensing of paint is

required.

• Follow the procedures described in this manual.

When you work with paint application equipment, observe the

following rules, in addition to all rules for safe operation that apply to

all robot systems.

WARNING

When working with electrostatic paint equipment, follow all

national and local codes as well as all safety guidelines

within your organization. Also reference the following

standards: NFPA 33 Standards for Spray Application Using

Flammable or Combustible Materials, and NFPA 70 National

Electrical Code.

Page 18

Safety-14

• Grounding: All electrically conductive objects in the spray area

must be grounded. This includes the spray booth, robots,

conveyors, workstations, part carriers, hooks, paint pressure

pots, as well as solvent containers. Grounding is defined as the

object or objects shall be electrically connected to ground with a

resistance of not more than 1 megohms.

• High Voltage: High voltage should only be on during actual

spray operations. Voltage should be off when the painting

process is completed. Never leave high voltage on during a cap

cleaning process.

• Avoid any accumulation of combustible vapors or coating

matter.

• Follow all manufacturer recommended cleaning procedures.

• Make sure all interlocks are operational.

• No smoking.

Staying Safe During

Maintenance

• Post all warning signs regarding the electrostatic equipment and

operation of electrostatic equipment according to NFPA 33

Standard for Spray Application Using Flammable or

Combustible Material.

• Disable all air and paint pressure to bell.

• Verify that the lines are not under pressure.

When you perform maintenance on the painter system, observe the

following rules, and all other maintenance safety rules that apply to

all robot installations. Only qualified, trained service or maintenance

personnel should perform repair work on a robot.

• Paint robots operate in a potentially explosive environment. Use

caution when working with electric tools.

• When a maintenance technician is repairing or adjusting a robot,

the work area is under the control of that technician. All

personnel not participating in the maintenance must stay out of

the area.

• For some maintenance procedures, station a second person at

the control panel within reach of the EMERGENCY STOP

button. This person must understand the robot and associated

potential hazards.

Page 19

Safety-15

• Be sure all covers and inspection plates are in good repair and

in place.

• Always return the robot to the ‘‘home’’ position before you

disarm it.

• Never use machine power to aid in removing any component

from the robot.

• During robot operations, be aware of the robot’s movements.

Excess vibration, unusual sounds, and so forth, can alert you to

potential problems.

• Whenever possible, turn off the main electrical disconnect

before you clean the robot.

• When using vinyl resin observe the following:

- Wear eye protection and protective gloves during application

and removal

- Adequate ventilation is required. Overexposure could cause

drowsiness or skin and eye irritation.

- If there is contact with the skin, wash with water.

• When using paint remover observe the following:

- Eye protection, protective rubber gloves, boots, and apron

are required during booth cleaning.

- Adequate ventilation is required. Overexposure could cause

drowsiness.

- If there is contact with the skin or eyes, rinse with water for

at least 15 minutes.

Page 20

Update Section

Single Phase Power Option

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

B–81535EN/02

Table of Contents

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 OPERATOR SAFETY 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Operator Safety 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Safety of the T each Pendant Operator 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Safety During Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SAFETY OF THE TOOLS AND PERIPHERAL DEVICES 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Precautions in Programming 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Precautions for Mechanism 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 SAFETY OF THE ROBOT MECHANISM 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Precautions in Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Precautions in Programming 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Precautions for Mechanisms 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 SAFETY OF THE END EFFECTOR 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Precautions in Programming 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 SAFETY IN MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 WARNING LABEL 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II MAINTENANCE

1. OVERVIEW 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONFIGURATION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 EXTERNAL VIEW OF THE CONTROLLER 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 COMPONENT FUNCTIONS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 PREVENTIVE MAINTENANCE 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. TROUBLESHOOTING 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 POWER CANNOT BE TURNED ON 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 T each Pendant Cannot be Turned On 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Initial Screen Remains on the T each Pendant 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 ALARM OCCURRENCE SCREEN 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 SAFETY SIGNALS 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 MASTERING 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 TROUBLESHOOTING USING THE ERROR CODE 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 TROUBLESHOOTING USING FUSES 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 TROUBLESHOOTING BASED ON LED INDICATIONS 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 POSITION DEVIATION FOUND IN RETURN TO THE REFERENCE POSITION

(POSITIONING) 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 VIBRATION OBSERVED DURING MOVEMENT 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 MANUAL OPERATION IMPOSSIBLE 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 28

Table of Contents

B–81535EN/02

4. PRINTED CIRCUIT BOARDS 1 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 ROBOT CONTROL BOARD (A16B–3200–0450) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 EMERGENCY STOP BOARD (A20B–1008–0010, –0011) 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 BACKPLANE BOARD (A20B–2003–0330) 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PROCESS I/O BOARD HE (A16B–2203–0764), HF (A16B–2203–0765) 118. . . . . . . . . . . . . . . . . . .

5. SERVO AMPLIFIERS 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 OUTLINE DRAWINGS 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Power Supply Module PSM (A06B–6115–H001) 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Servo Amplifier Module (A06B–6114–H205, A06B–6114–H302) 122. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 LED OF SERVO AMPLIFIER 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 LED of Power Supply Module 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 LED of Servo Amplifier Module 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SETTING THE POWER SUPPLY 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 BLOCK DIAGRAMS OF THE POWER SUPPLY 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 CHECKING THE POWER SUPPLY UNIT 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 CHECKING THE POWER SUPPLY MODULE 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. REPLACING A UNIT 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 REPLACING THE PRINTED–CIRCUIT BOARDS 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Replacing the Backplane Board (Unit) 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Replacing the Robot Control Board and Printed–Circuit Boards on the Backplane Unit 131. . . . . . . . . . .

7.1.3 Replacing the Emergency Stop Board 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 REPLACING CARDS AND MODULES ON THE ROBOT CONTROL BOARD 133. . . . . . . . . . . . .

7.3 REPLACING THE TRANSFORMER 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Replacing the Brake Power Transformer 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 REPLACING THE EMERGENCY STOP UNIT 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 REPLACING THE MAGNETIC CONTACTOR 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 REPLACING SERVO AMPLIFIERS 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 REPLACING THE TEACH PENDANT 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 REPLACING THE CONTROL SECTION FAN MOTOR 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 REPLACING THE FAN MOTOR OF THE SERVO AMPLIFIER CONTROL UNIT 143. . . . . . . . . .

7.10 REPLACING THE DOOR FAN UNIT AND HEAT EXCHANGER 144. . . . . . . . . . . . . . . . . . . . . . . .

7.11 REPLACING THE OPERATOR PANEL 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.12 REPLACING THE POWER SUPPLY UNIT 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13 REPLACING A FUSE 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.1 Replacing a Fuse on the Robot Control Board 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.2 Replacing a Fuse on the Emergency Stop Board 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.3 Replacing the Fuse on the Door 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.4 Replacing the Fuse on the Power Supply Module 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.5 Replacing the Fuse on the Servo Amplifier Module 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13.6 Replacing the Fuse on the Process I/O Boards 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.14 REPLACING A RELAY 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.14.1 Replacing a Relay on the Emergency Stop Board 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.15 REPLACING BATTERY 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.15.1 Battery for Memory Backup (3 VDC) 154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 29

B–81535EN/02

Table of Contents

III CONNECTION

1. GENERAL 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. BLOCK DIAGRAM 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CONNECTION DETAILS 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CONNECTION OF POWER SUPPLY CABLE 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 FANUC I/O LINK 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 CONNECTION OF I/O LINK CABLE 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 EMERGENCY STOP CIRCUIT 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Circuit Diagram of Emergency Stop 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 External Emergency Stop Input 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 External Emergency Stop Output 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 External 24 V Input 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 COONECTION OF SERVO AMPLIFIER 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 CONNECTION OF ROBOT 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 CONNECTION OF TEACH PENDANT CABLE 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 CONNECTION OF CABLE FOR RS–232–C/RS–422 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 CONNECTING A CABLE TO A PERIPHERAL DEVICE 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Peripheral Device Interfaces CRM79 and CRM81 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 When the Robot is Connected to the CNC by a Peripheral Device Cable 176. . . . . . . . . . . . . . . . . . . . . . .

3.9.3 Digital I/O Signal Specifications 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.3.1 Peripheral device interface CRM 79 and CRM 81 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.4 Peripheral Device Cable Connector 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.5 Recommended Cables 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 END EFFECTOR INTERFACE 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.1 Connecting the Mechanical Unit and End Effector 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10.2 Digital I/O Signal Specifications of End Effector Control Interface 199. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.11 TREATMENT FOR THE SHIELDED CABLE 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 PERIPHERAL DEVICE, ARC WELDING, INTERFACES 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.1 Peripheral Device Interface Types 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.2 Peripheral Device Interface Block Diagram and Specifications 202. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.3 Peripheral Device and Control Unit Connection 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.4 Connection Between the Control Unit and Welder 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.5 Digital I/O Signal Specifications of Peripheral Device Interface A 214. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.6 I/O Signal Specifications for ARC–W elding Interface 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.7 Specifications of the Cables used for Peripheral Devices A (CRM2: Honda T sushin, 50 pins) 219. . . . . .

3.12.8 ARC Weld Connection Cable (CRW1: Honda Tsushin, 34 pins) 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.9 Peripheral Device Cable Connector 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12.10 Recommended Cables 221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TRANSPORTATION AND INSTALLATION 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 TRANSPORTATION 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 INSTALLATION 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 EXTERNAL CONTROLLER DIMENSIONS 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 INSTALLATION CONDITION 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 ADJUSTMENT AND CHECKS AT INSTALLATION 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 NOTE AT INSTALLATION 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 30

Table of Contents

4.7 DISABLING HAND BREAK 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

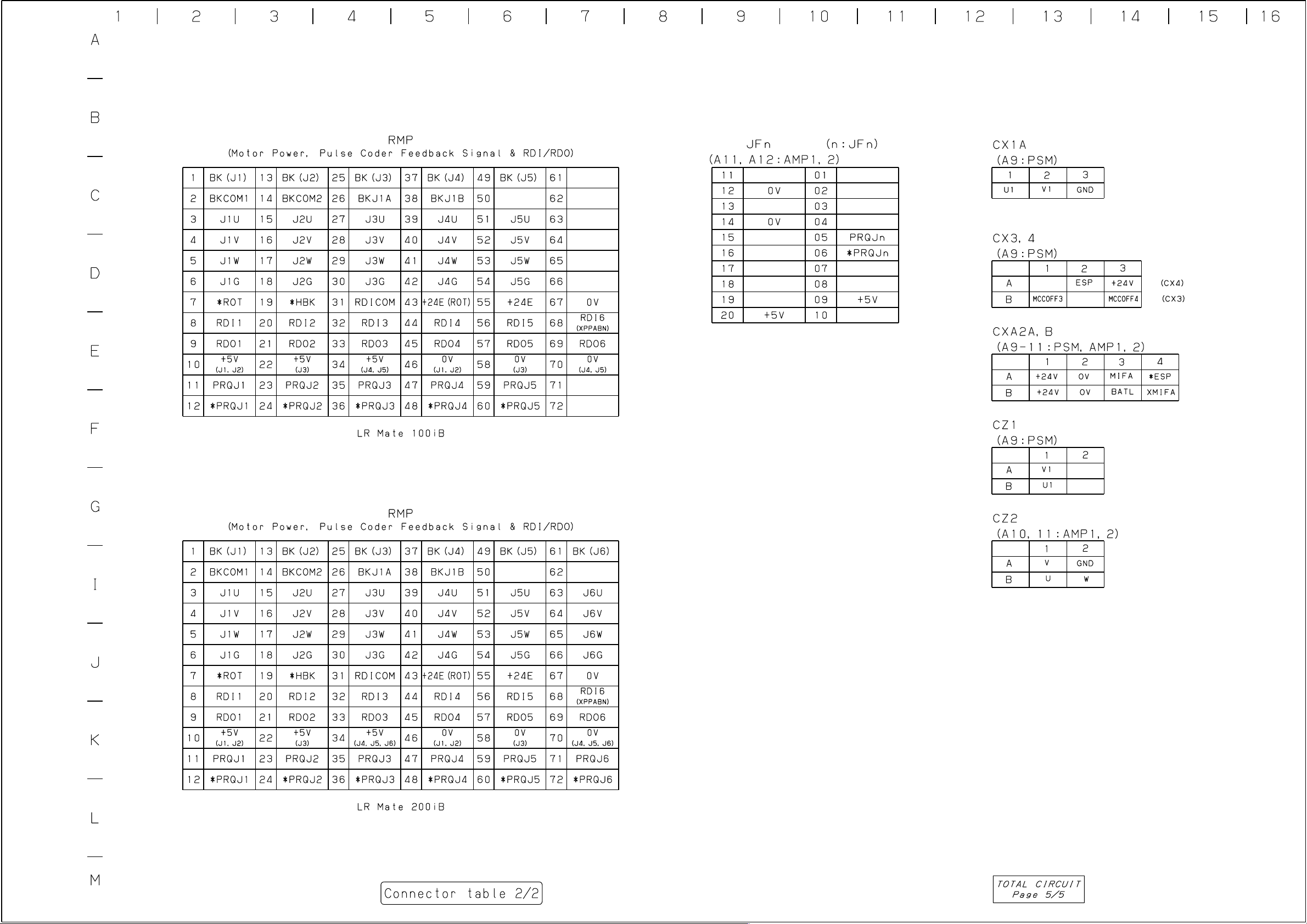

A. TOTAL CONNECTION DIAGRAM 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. PERIPHERAL INTERFACE 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 SIGNAL TYPES 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 I/O SIGNALS 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.1 Input Signals 240. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.2 Output Signals 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 SPECIFICATIONS OF DIGITAL INPUT/OUTPUT 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3.1 Overview 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3.2 Input/Output Hardware Usable in the R-J3iB Mate Controller 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3.3 Software Specifications 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. OPTICAL FIBER CABLE 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–81535EN/02

c–4

Page 31

B–81535EN/02

PREFACE

PREFACE

This manual describes the following models.

Model Abbreviation

FANUC Robot LR Mate 100iB LR Mate 100iB

FANUC Robot LR Mate 200iB LR Mate 200iB

FANUC Robot ARC Mate 50iB ARC Mate 50iB

p–1

Page 32

I SAFETY PRECAUTIONS

Page 33

Page 34

B–81535EN/02

1

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

For the safety of the operator and the system, follow all safety precautions

when operating a robot and its peripheral devices installed in a work cell.

1. SAFETY PRECAUTIONS

3

Page 35

1. SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

B–81535EN/02

1.1

OPERATOR SAFETY

Operator safety is the primary safety consideration. Because it is very

dangerous to enter the operating space of the robot during automatic

operation, adequate safety precautions must be observed.

The following lists the general safety precautions. Careful consideration

must be made to ensure operator safety.

(1) Have the robot system operators attend the training courses held by

FANUC.

FANUC provides various training courses. Contact our sales office for details.

(2) Even when the robot is stationary, it is possible that the robot is still

ready to move state and is waiting for a signal. In this state, the robot

is regarded as still in motion. To ensure operator safety, provide the

system with an alarm to indicate visually or aurally that the robot is

in motion.

(3) Install a safety fence with a gate so that no operator can enter the work

area without passing through the gate. Equip the gate with an

interlock that stops the robot when the gate is opened.

The controller is designed to receive this interlock signal. When the gate is

opened and this signal received, the controller stops the robot in an emergency .

For connection, see Fig.1.1.

(4) Provide the peripheral devices with appropriate grounding (Class 1,

Class 2, or Class 3).

(5) Try to install the peripheral devices outside the work area.

(6) Draw an outline on the floor, clearly indicating the range of the robot

motion, including the tools such as a hand.

(7) Install a mat switch or photoelectric switch on the floor with an

interlock to a visual or aural alarm that stops the robot when an

operator enters the work area.

(8) If necessary, install a safety lock so that no one except the operator

in charge can turn on the power of the robot.

The circuit breaker installed in the controller is designed to disable anyone from

turning it on when it is locked with a padlock.

4

Page 36

B–81535EN/02

SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

(9) When adjusting each peripheral device independently, be sure to turn

off the power of the robot.

Safety gate which executes with opening the door.

Fig.1.1 Safety Fence and Safety Gate

5

Page 37

1. SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

B–81535EN/02

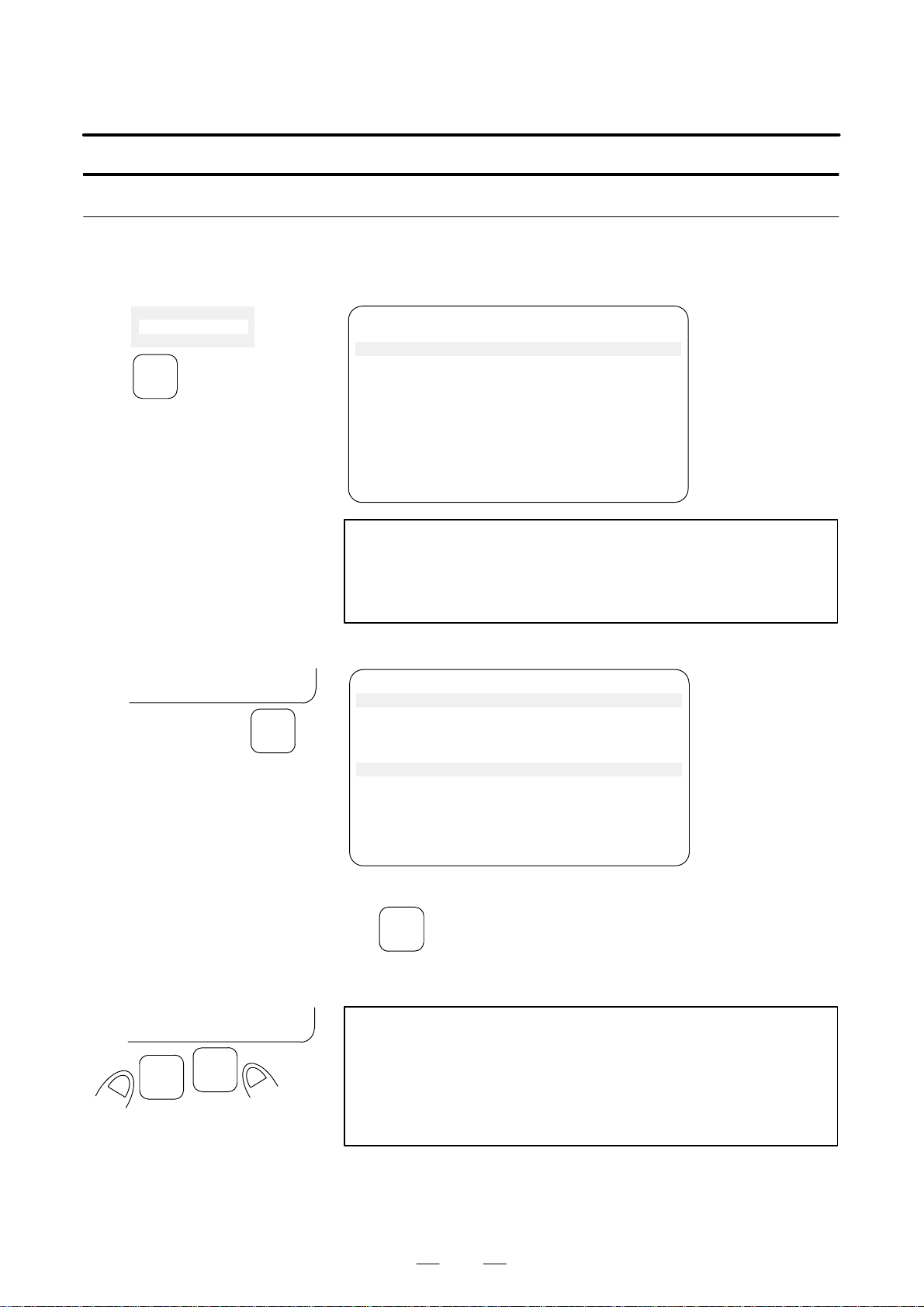

1.1.1

Operator Safety

The operator is a person who operates the robot system. In this sense, a

worker who operates the teach pendant is also an operator. However, this

section does not apply to teach pendant operators.

(1) If it is not necessary for the robot to operate, turn off the power of the

robot controller or press the EMERGENCY STOP button, and then

proceed with necessary work.

(2) Operate the robot system at a location outside the work area.

(3) Install a safety fence with a safety gate to prevent any worker other

than the operator from entering the work area unexpectedly and also

to prevent the worker from entering a dangerous area.

(4) Install an EMERGENCY STOP button within the operator’s reach.

The robot controller is designed to be connected to an external EMERGENCY

STOP button. With this connection, the controller stops the robot operation

when the external EMERGENCY STOP button is pressed. See the diagram

below for connection.

External EMERGENCY STOP button

Emergency stop board

EMGIN11

EMGIN12

EMGIN21

EMGIN22

Note) Connect between EMGIN1 and EMGIN2 and between EMGIN21 and EMGIN22.

EMGIN11, EMGIN12, EMGIN21 and EMGIN22 are on the emergency stop

board.

Fig.1.1.1 Connection Diagram for External Emergency Stop Switch

6

Page 38

B–81535EN/02

SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

1.1.2

Safety of the Teach

Pendant Operator

While teaching the robot, it is necessary for the operator to enter the work

area of the robot. It is particularly necessary to ensure the safety of the

teach pendant operator.

(1) Unless it is specifically necessary to enter the robot work area, carry

out all tasks outside the area.

(2) Before teaching the robot, check that the robot and its peripheral

devices are all in the normal operating condition.

(3) When entering the robot work area and teaching the robot, be sure to

check the location and condition of the safety devices (such as the

EMERGENCY STOP button and the deadman switch on the teach

pendant).

FANUC’s teach pendant has a switch for enabling or disabling the robot opera-

tion from the teach pendant and a deadman switch in addition to the EMERGENCY STOP button. The switches function as follows.

EMERGENCY STOP button : Pressing this button always brings the robot

to an emergency stop, irrespective of the

state of the enable/disable switch and the

mode switch of operator panel.

Deadman switch : The function of this switch depends on the

state of the enable/disable switch and the

mode switch of operator panel.

When the mode switch is in the AUTO position

– The enable/disable switch and deadman

switch are disabled.

When the mode switch is in the TI position and the enable/disable switch is

in the enable position

– Releasing the deadman switch brings the

robot to an emergency stop.

When the mode switch is in the TI position and the enable/disable switch is

in the disable position

– The robot is brought to an emergency stop

regardless of the operation of the deadman

switch.

Note)The deadman switch is provided to bring the robot to an emergency

stop when the operator releases the teach pendant in an emergency.

(4) The teach pendant operator should pay careful attention so that no

other workers enter the robot work area.

NOTE

In addition to the above, the teach pendant enable switch and the

deadman switch also have the following function.

By pressing the deadman switch while the enable switch is on, the

emergency stop factor (normally the safety gate) connected to

FENCE11 and FENCE12 of the controller is invalidated. In this

case, it is possible for an operator to enter the fence during teach

operation without making the robot in the emergency stop

condition. In other words, the system understands that the

combined operations of pressing the teach pendant enable switch

and pressing the deadman switch indicates the start of teaching.

The teach pendant o perator s hould b e w ell a ware t hat the s afety gate

is not functional under this condition and bear full res ponsibility to

ensure that no one enters the fence during teaching.

7

Page 39

1. SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

B–81535EN/02

(5) When entering the robot work area, the teach pendant operator should

enable the teach pendant whenever he or she enters the robot work

area. In particular, while the teach pendant enable switch is off, make

certain that no start command is sent to the robot from any operator

panel other than the teach pendant.

The teach pendant, operator panel, and peripheral device interface send each

robot start signal. However the validity of each signal changes as follows depending on the mode of the teach pendant enable switch and the mode switch

the remote switch on the operator panel.

Operator panel

mode switch

T1 On Independent Allowed to start Not allowed Not allowed

AUTO Off Local Not allowed Allowed to start Not allowed

AUTO Off Remote Not allowed Not allowed Allowed to start

Teach pendant

enable switch

Remote

condition

Teach

pendant

Operator panel

Peripheral

devices

(6) When a program is completed, be sure to carry out a test run according

to the procedure below.

(a) Run the program for at least one operation cycle in the single step

mode at low speed.

(b) Run the program for at least one operation cycle in the continuous

operation mode at low speed.

(c) Run the program for one operation cycle in the continuous

operation mode at the intermediate speed and check that no

abnormalities occur due to a delay in timing.

(d) Run the program for one operation cycle in the continuous

operation mode at the normal operating speed and check that the

system operates automatically without trouble.

(e) After checking the completeness of the program through the test

run above, execute it in the automatic operation mode.

(7) While operating the system in the automatic operation mode, the

teach pendant operator should leave the robot work area.

8

Page 40

B–81535EN/02

SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

1.1.3

Safety During

Maintenance

For the safety of maintenance personnel, pay utmost attention to the

following.

(1) Except when specifically necessary, turn off the power of the

controller while carrying out maintenance. Lock the power switch,

if necessary, so that no other person can turn it on.

(2) When disconnecting the pneumatic system, be sure to reduce the

supply pressure.

(3) Before the start of teaching, check that the robot and its peripheral

devices are all in the normal operating condition.

(4) If it is necessary to enter the robot work area for maintenance when

the power is turned on, the worker should indicate that the machine

is being serviced and make certain that no one starts the robot

unexpectedly.

(5) Do not operate the robot in the automatic mode while anybody is in

the robot work area.

(6) When it is necessary to maintain the robot alongside a wall or

instrument, or when multiple workers are working nearby, make

certain that their escape path is not obstructed.

(7) When a tool is mounted on the robot, or when any moving device

other than the robot is installed, such as belt conveyor, pay careful

attention to its motion.

(8) If necessary, have a worker who is familiar with the robot system

stand beside the operator panel and observe the work being

performed. If any danger arises, the worker should be ready to press

the EMERGENCY STOP button at any time.

(9) When replacing or reinstalling components, take care to prevent

foreign matter from entering the system.

(10) When handling each unit or printed circuit board in the controller

during inspection, turn off the power of the controller and also turn

off the circuit breaker to protect against electric shock.

(11)When replacing parts, be sure to use those specified by FANUC.

In particular, never use fuses or other parts of non-specified ratings.

They may cause a fire or result in damage to the components in the

controller.

9

Page 41

1. SAFETY PRECAUTIONS

1.2

SAFETY OF THE

TOOLS AND

PERIPHERAL

DEVICES

SAFETY PRECAUTIONS

B–81535EN/02

1.2.1

Precautions in

Programming

1.2.2

Precautions for

Mechanism

(1) Use a limit switch or other sensor to detect a dangerous condition and,

if necessary, design the program to stop the robot when the sensor

signal is received.

(2) Design the program to stop the robot when an abnormal condition

occurs in any other robots or peripheral devices, even though the

robot itself is normal.

(3) For a system in which the robot and its peripheral devices are in

synchronous motion, particular care must be taken in programming

so that they do not interfere with each other.

(4) Provide a suitable interface between the robot and its peripheral

devices so that the robot can detect the states of all devices in the

system and can be stopped according to the states.

(1) Keep the component cells of the robot system clean, and operate the

robot in an environment free of grease, water, and dust.

(2) Employ a limit switch or mechanical stopper to limit the robot motion

so that the robot does not come into contact with its peripheral devices

or tools.

10

Page 42

B–81535EN/02

1.3

SAFETY OF THE

ROBOT MECHANISM

SAFETY PRECAUTIONS

1. SAFETY PRECAUTIONS

1.3.1

Precautions in

Operation

1.3.2

Precautions in

Programming

1.3.3

Precautions for

Mechanisms

(1) When operating the robot in the jog mode, set it at an appropriate

speed so that the operator can manage the robot in any eventuality.

(2) Before pressing the jog key, be sure you know in advance what

motion the robot will perform in the jog mode.

(1) When the wor k a r e a s o f r o b o ts overlap, make certain that the motions

of the robots do not interfere with each other.

(2 ) Be sure to specify the predetermined work origin in a motion program

for the robot and program the motion so that it starts from the origin

and terminates at the origin.

Make it possible for the operator to easily distinguish at a glance that

the robot motion has terminated.

(1) Keep the work area of the robot clean, and operate the robot in an

environment free of grease, water, and dust.

11

Page 43

1. SAFETY PRECAUTIONS

1.4

SAFETY OF THE END

EFFECTOR

SAFETY PRECAUTIONS

B–81535EN/02

1.4.1

Precautions in

Programming

(1) To control the pneumatic, hydraulic and electric actuators, carefully

consider the necessary time delay after issuing each control command

up to actual motion and ensure safe control.

(2) Provide the end effector with a limit switch, and control the robot

system by monitoring the state of the end effector.

12

Page 44

B–81535EN/02

1.5

SAFETY IN

MAINTENANCE

SAFETY PRECAUTIONS

(1) Never enter the robot work area while the robot is operating. T urn of f

the power before entering the robot work area for inspection and

maintenance.

(2) If it is necessary to enter the robot work area with the power turned

on, first press the EMERGENCY STOP button on the operator panel.

(3) When replacing or reinstalling components, take care to prevent

foreign matter from entering the system.

When replacing the parts in the pneumatic system, be sure to reduce

the pressure in the piping to zero by turning the pressure control on

the air regulator.

(4) When handling each unit or printed circuit board in the controller

during inspection, turn off the power of the controller and turn off the

circuit breaker to protect against electric shock.

(5) When replacing parts, be sure to use those specified by FANUC.

In particular, never use fuses or other parts of non-specified ratings.

They may cause a fire or result in damage to the components in the

controller.

(6) Before restarting the robot, be sure to check that no one is in the robot

work area and that the robot and its peripheral devices are all in the

normal operating state.

1. SAFETY PRECAUTIONS

13

Page 45

1. SAFETY PRECAUTIONS

1.6

W ARNING LABEL

Description

SAFETY PRECAUTIONS

B–81535EN/02

Do not step on or climb the robot or controller as it may adversely affect

the robot or controller and you may get hurt if you lose your footing as

well.

(1) Step–on prohibitive label

Description

Description

Fig.1.6 (a) Step–on Prohibitive Label

Be cautious about a section where this label is affixed, as the section

generates heat. If you have to inevitably touch such a section when it is

hot, use a protective provision such as heat–resistant gloves.

(2) High–temperature warning label

Fig.1.6 (b) High–Temperature Warning Label

A high voltage is applied to the places where this label is attached.

Before starting maintenance, turn the power to the control unit off, then

turn the circuit breaker off to avoid electric shock hazards. Be careful with

servo amplifier and other units because high–voltage places in these units

may remain in the high–voltage state for a fixed time.

14

Page 46

B–81535EN/02

SAFETY PRECAUTIONS

(3) High–voltage warning label

Fig.1.6 (c) High–Voltage Warning Label

1. SAFETY PRECAUTIONS

Description

There may be a high voltage in a place with this label. Before working

on such a portion, turn off the power to the controller and set its circuit

breaker to the off position to avoid shock hazards.

In addition, be careful about servo amplifiers and other electric circuits

because a high voltage may remain in them for a certain period of time

after the power is turned off.

15

Page 47

Page 48

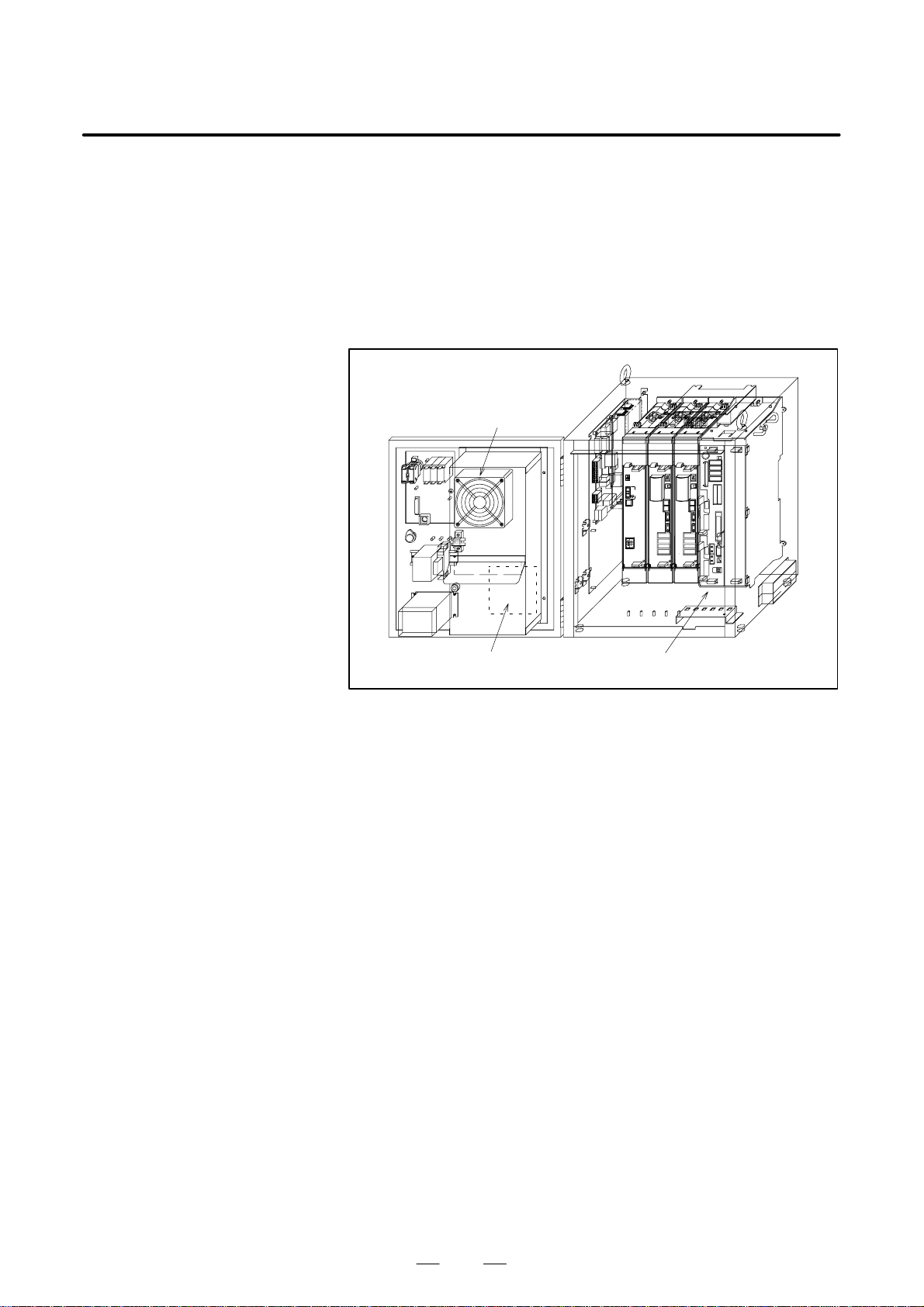

II MAINTENANCE

Page 49

Page 50

B–81535EN/02

1

1. OVERVIEWMAINTENANCE

OVERVIEW

This manual describes the maintenance and connection of the R–J3iB

Mate robot controller (called the R–J3iB Mate).

Maintenance Part : Troubleshooting, and the setting, adjustment,

and replacement of units

Connection Part : Connection of the R–J3iB Mate controller to the

robot mechanical unit and peripheral devices,

and installation of the controller

WARNING

Before you enter the robot working area, be sure to turn off

the power to the controller or press the EMERGENCY

STOP button on the operator panel or teach pendant.

Otherwise, you could injure personnel or damage

equipment.

TERM

The R–J3iB Mate robot controller uses the FANUC servo

amplifier α i series (called the servo amplifier (i).

The servo amplifier α i comprises a power supply module

(PSM) and a servo amplifier module (SVM).

In this manual, the terms “power supply module” and “servo

amplifier module” refer to the individual modules. The term

“servo amplifier” refers to the combination of the power

supply module and servo amplifier module.

19

Page 51

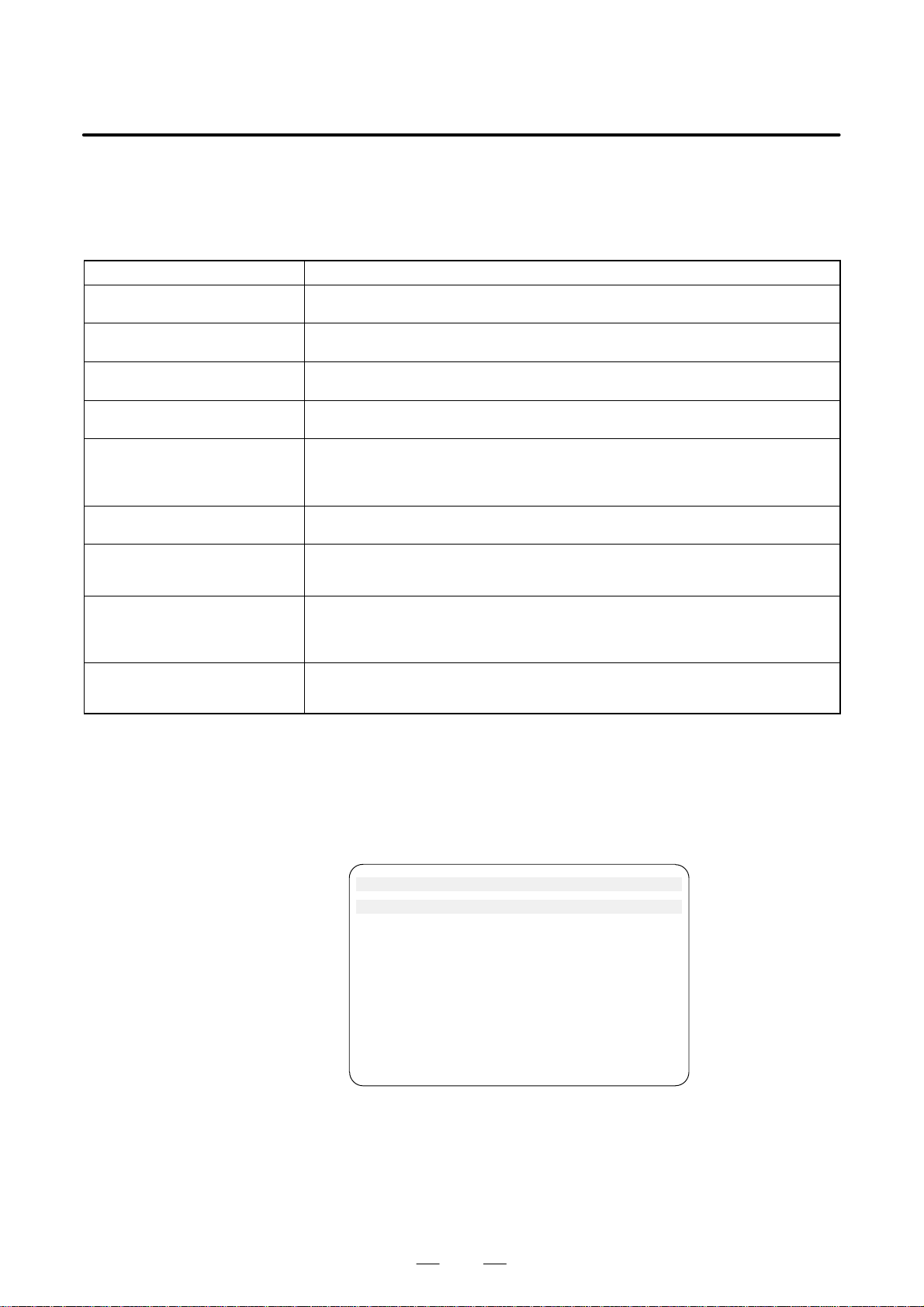

2. CONFIGURATION

CONFIGURATION

2

MAINTENANCE

B–81535EN/02

20

Page 52

B–81535EN/02

2. CONFIGURATIONMAINTENANCE

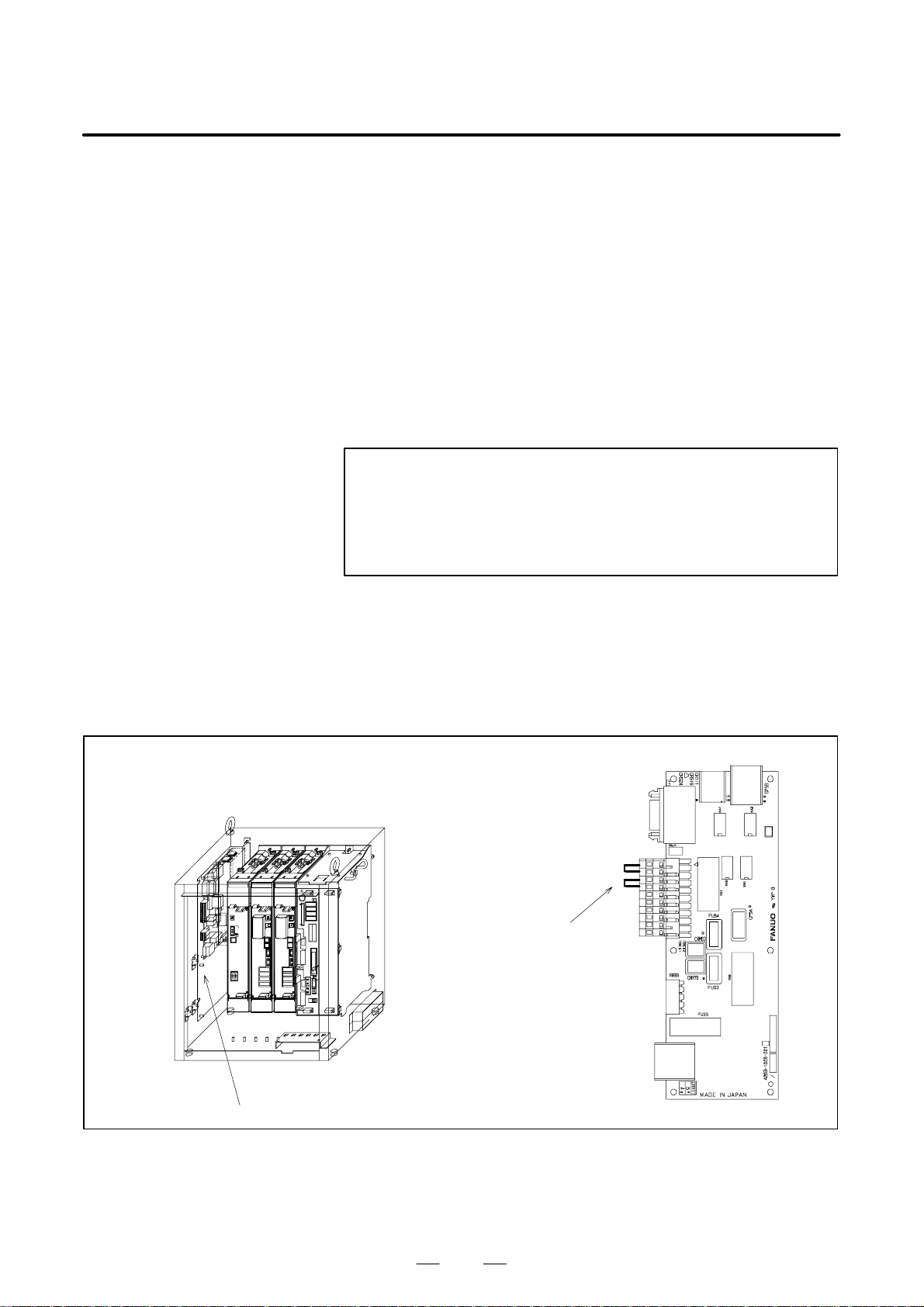

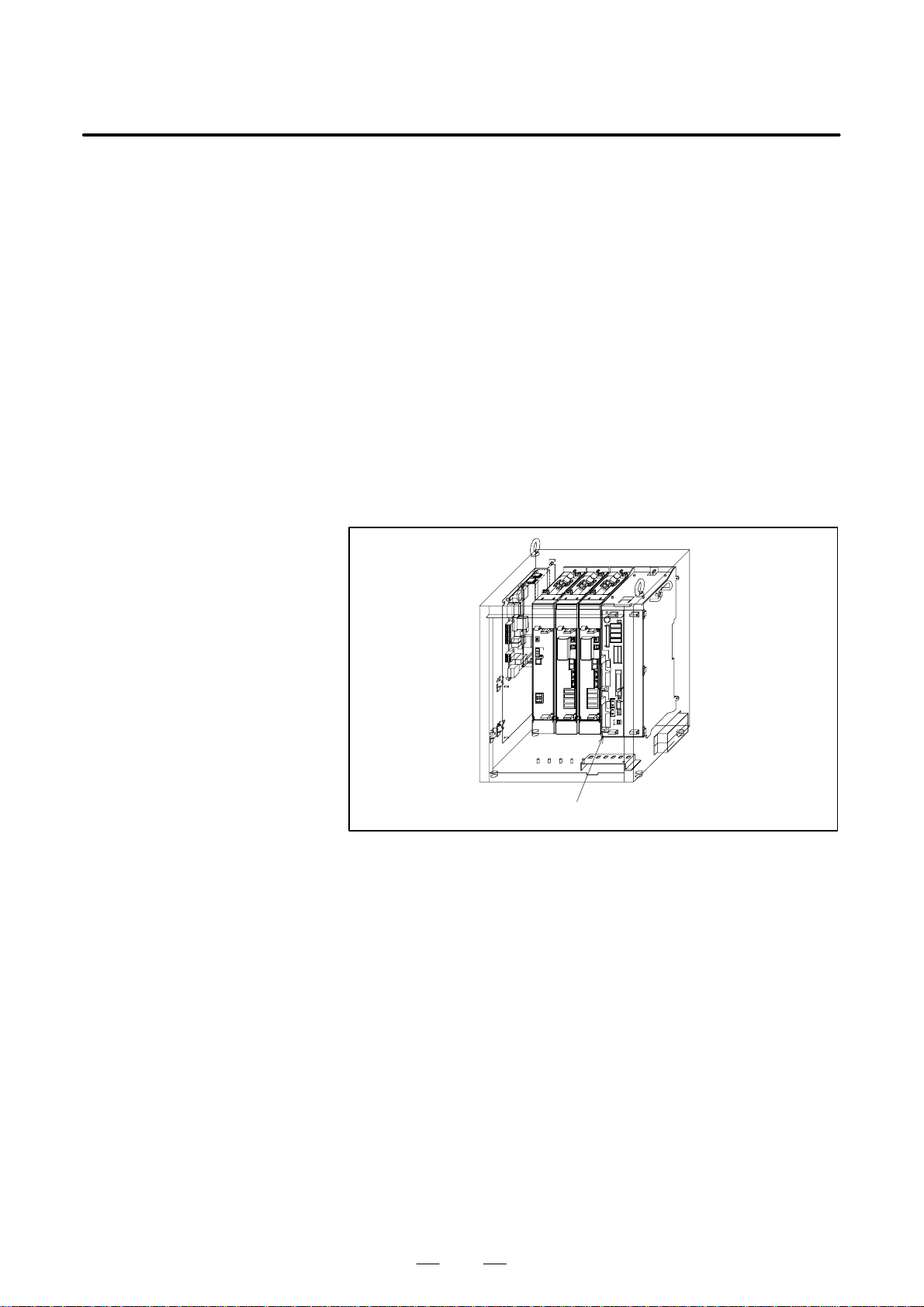

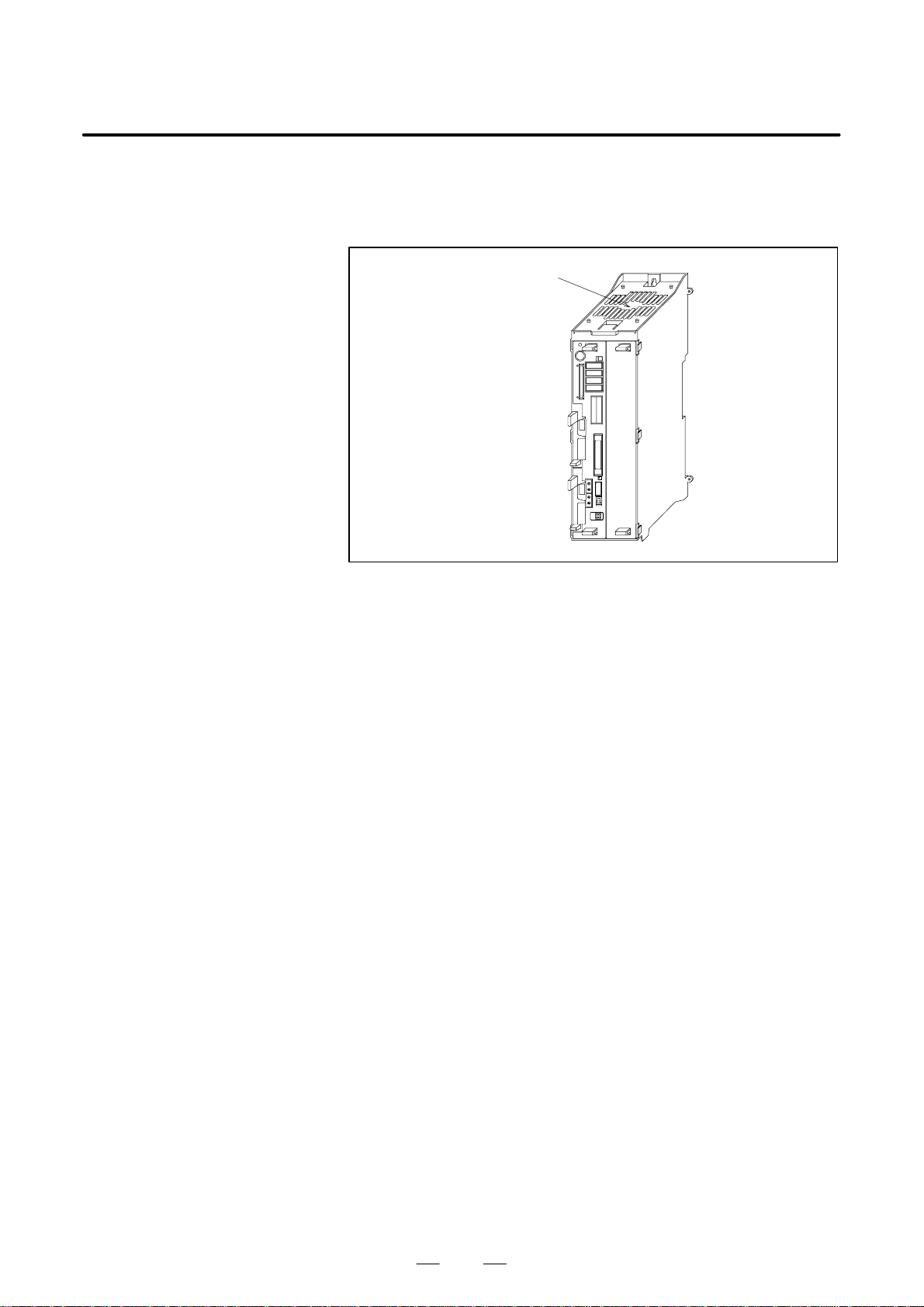

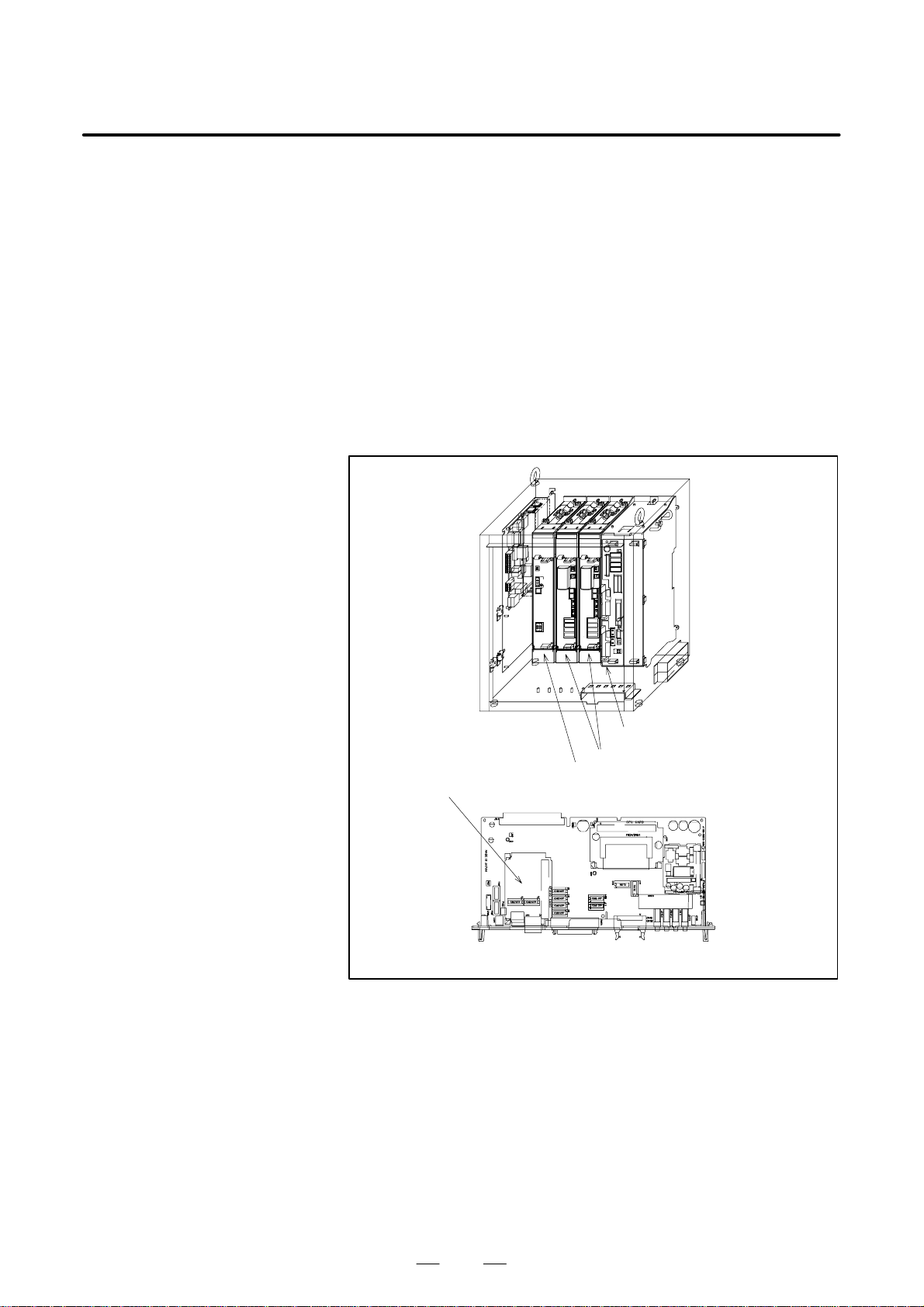

2.1

EXTERNAL VIEW OF

THE CONTROLLER

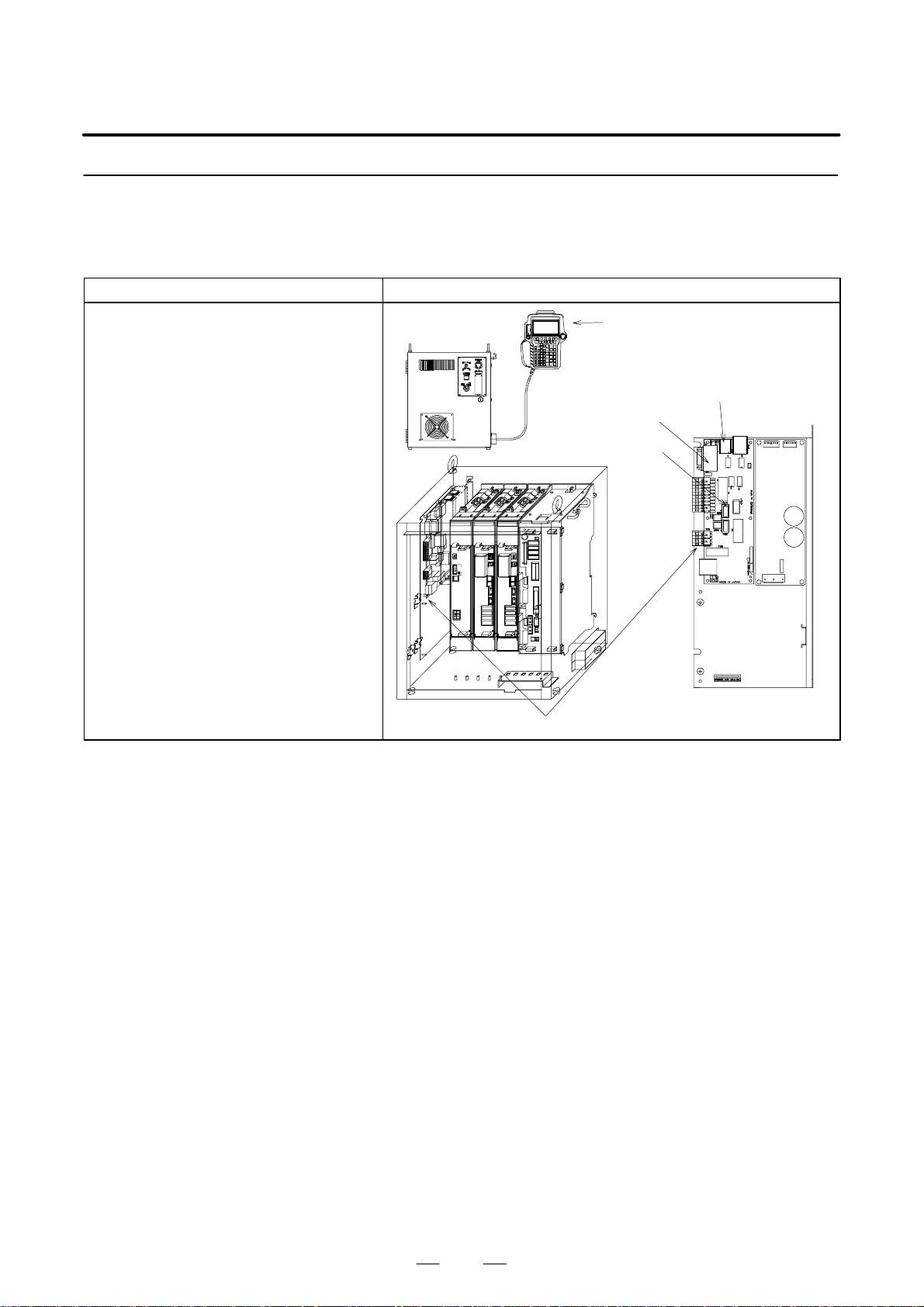

The appearance and components might slightly differ depending on the

controlled robot, application, and options used.

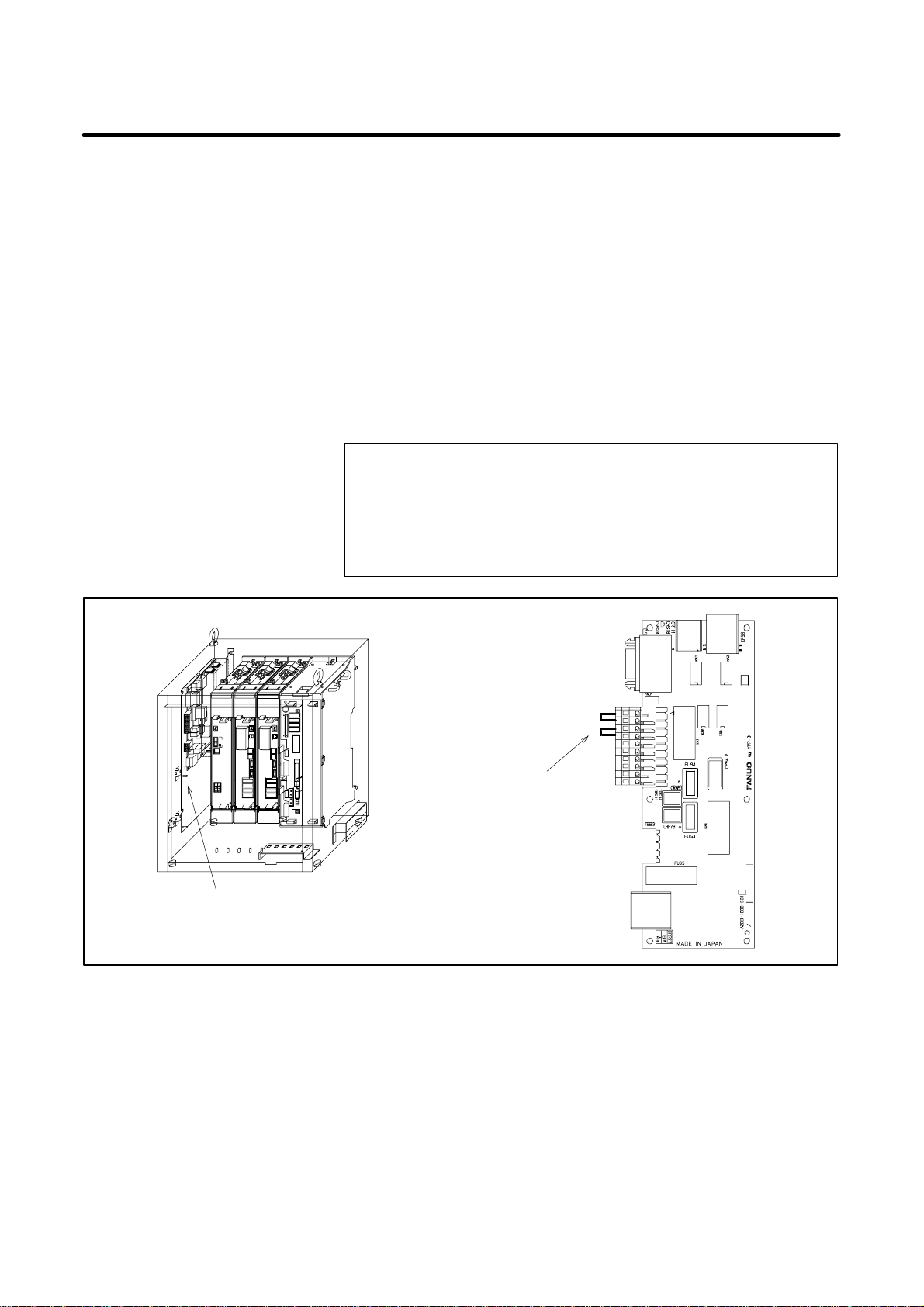

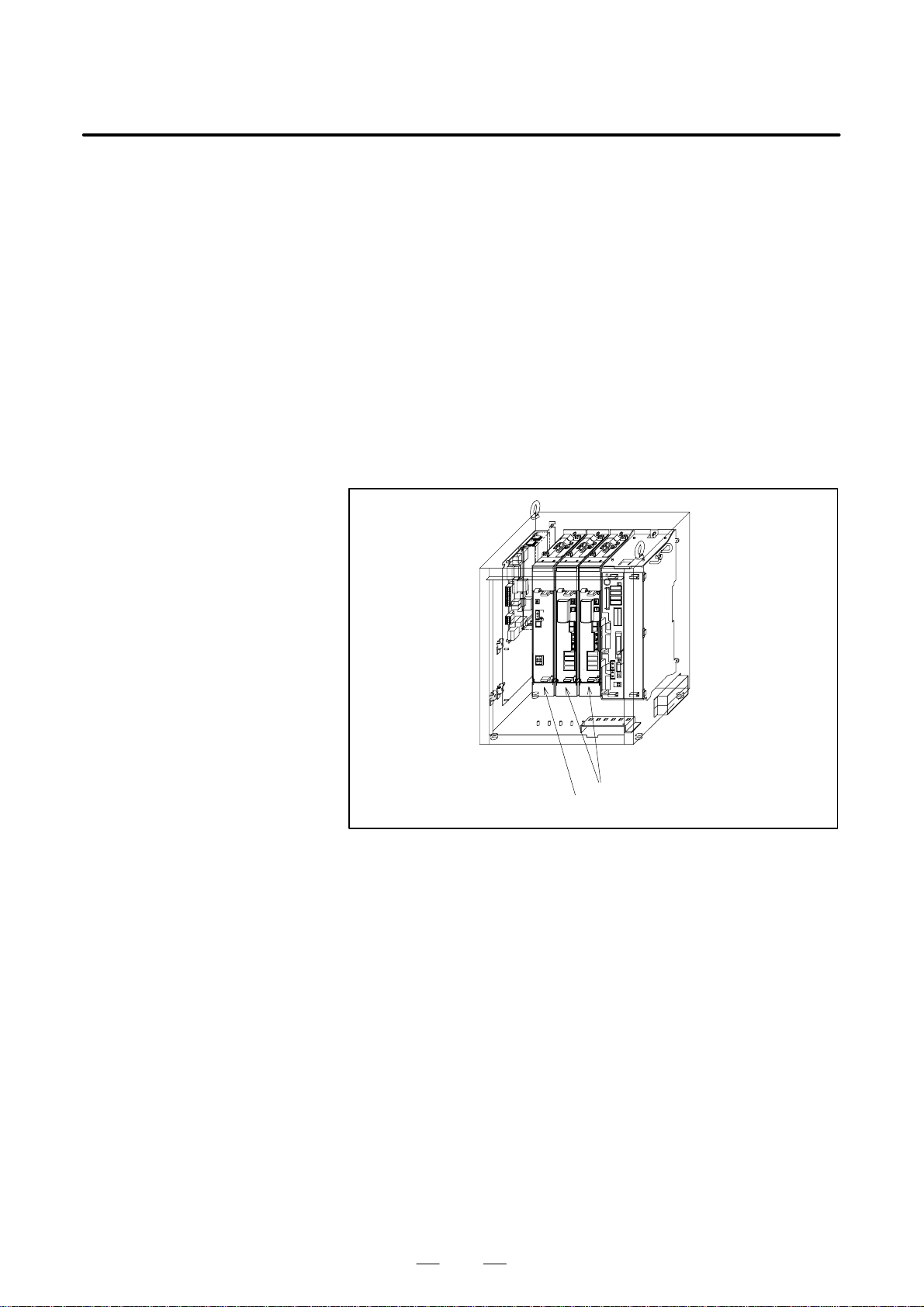

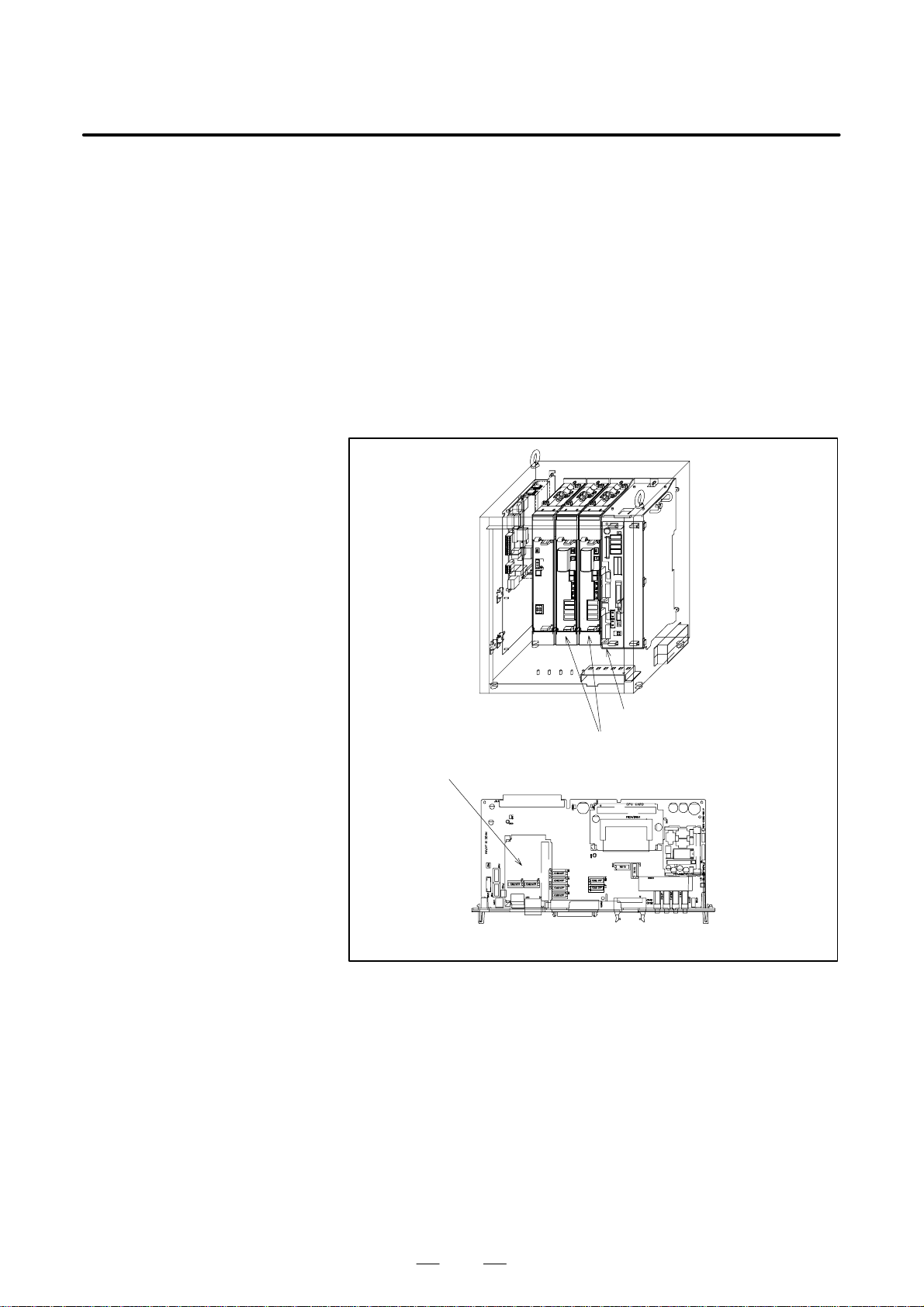

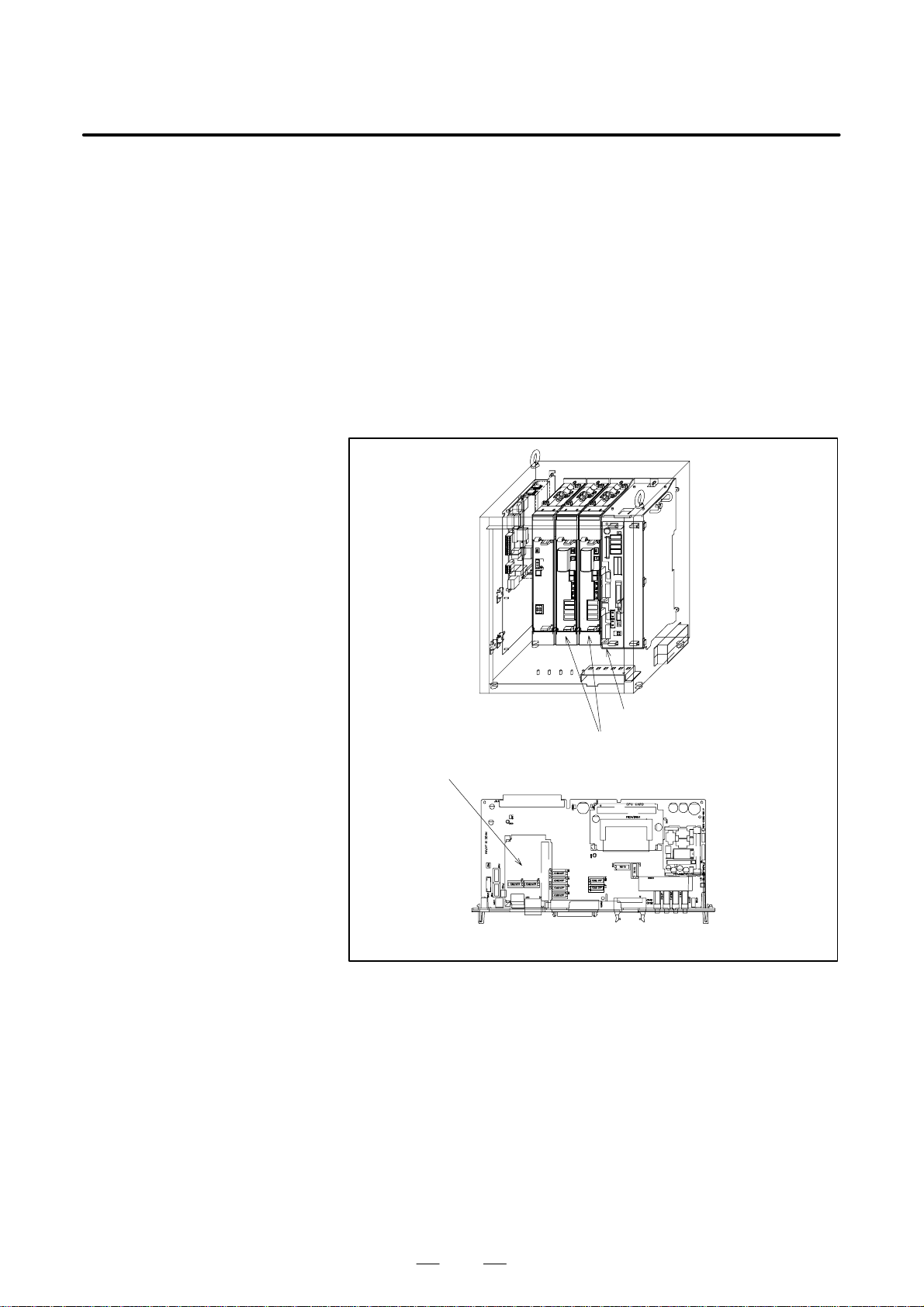

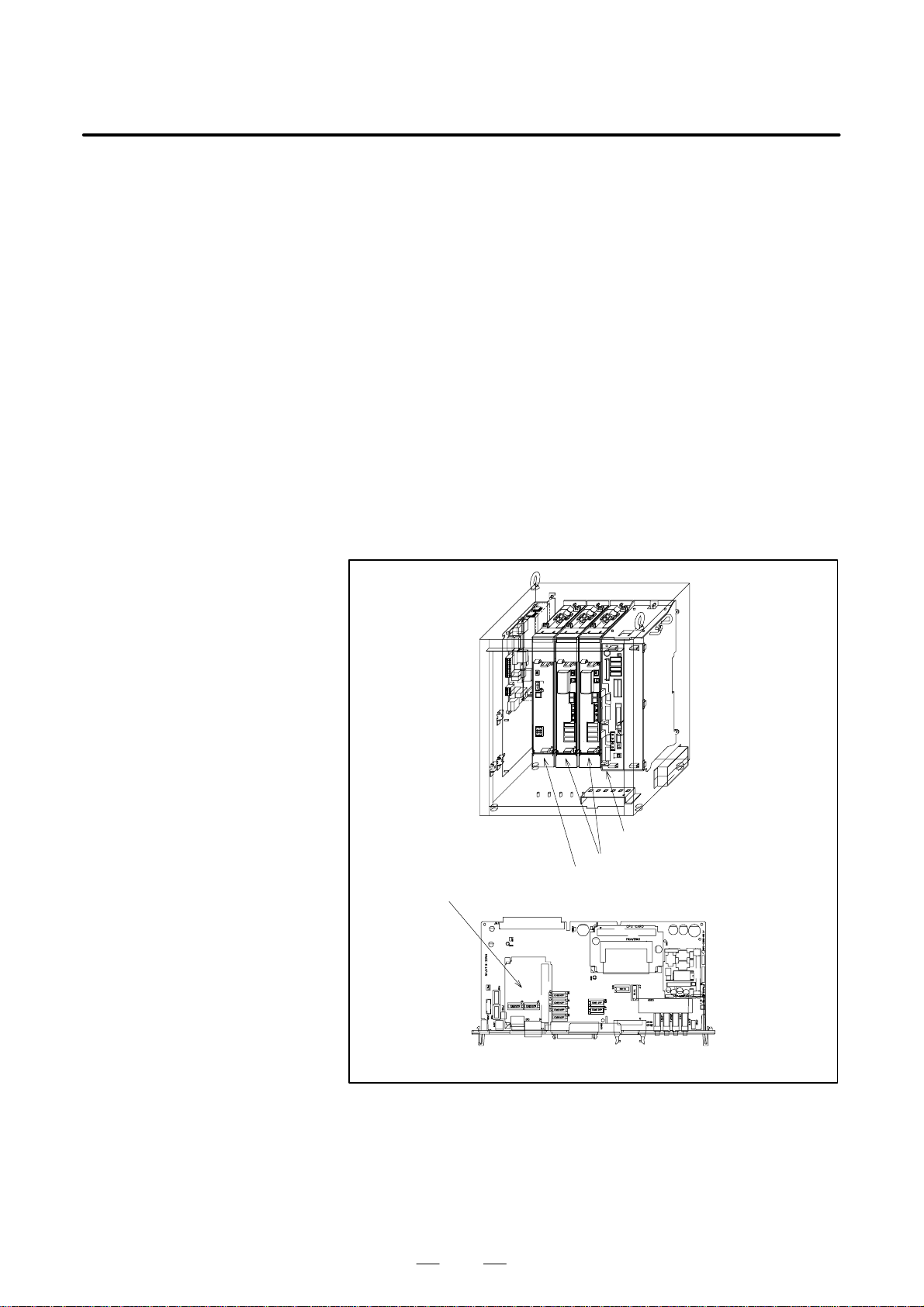

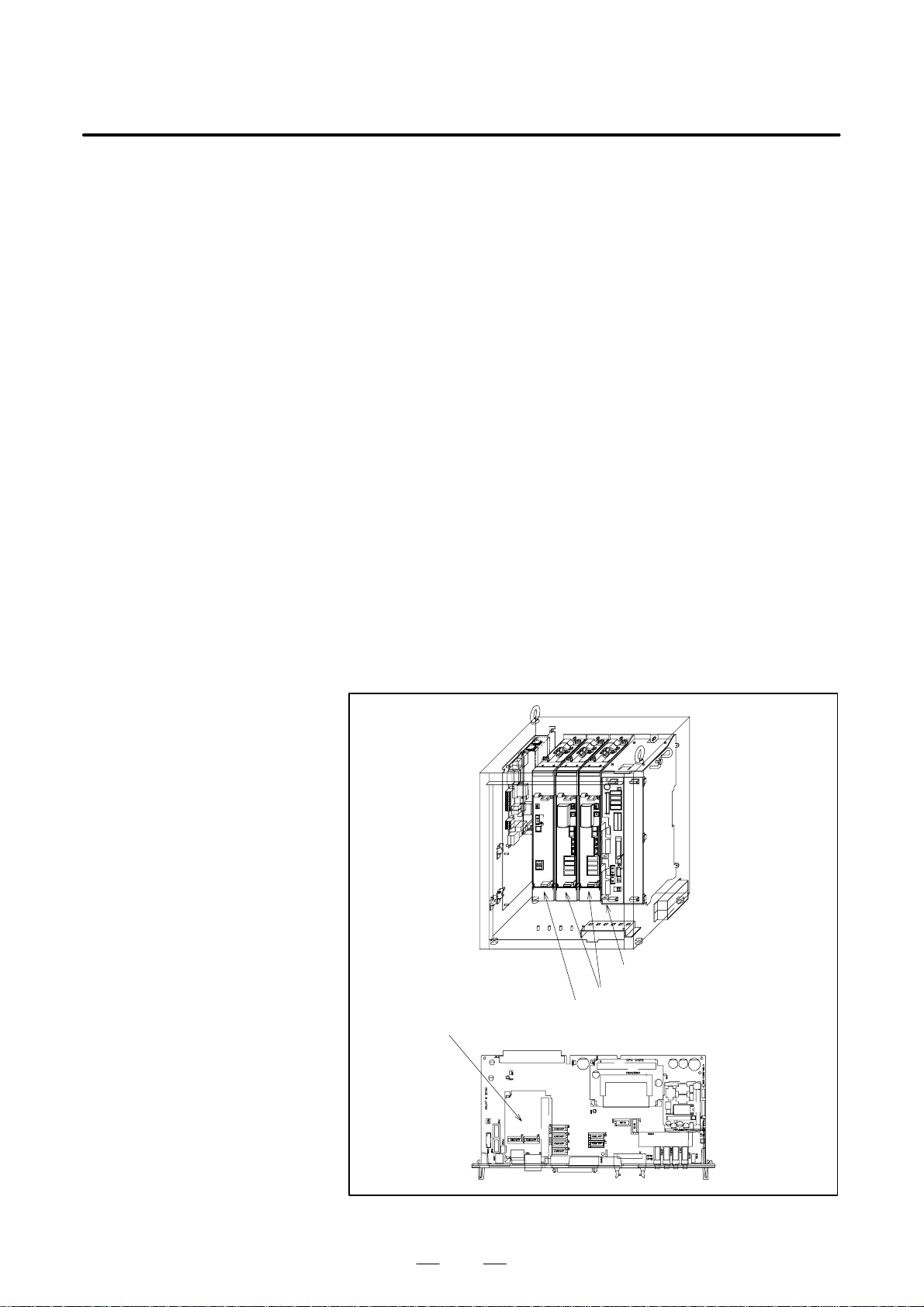

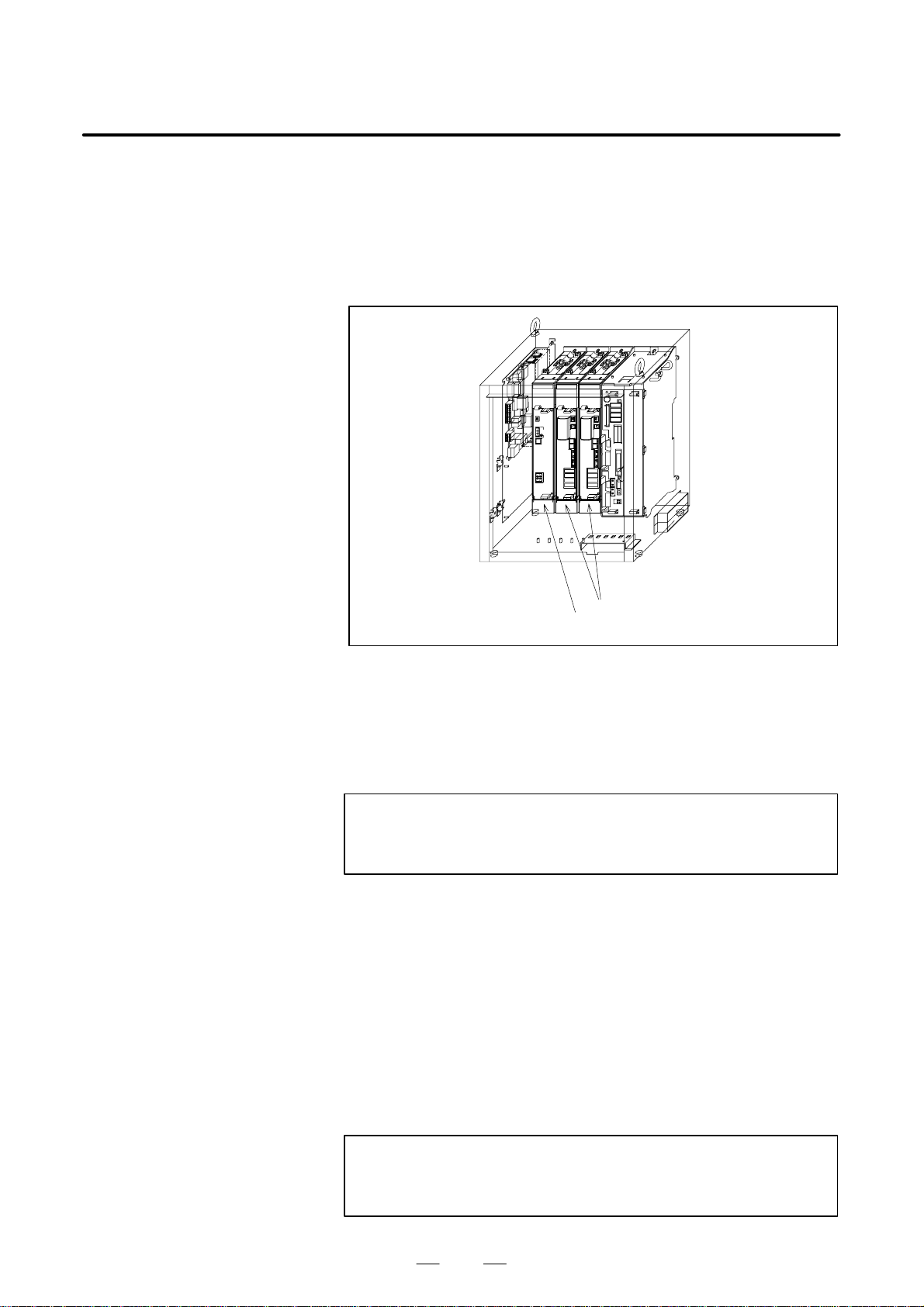

Fig.2.1 (a) shows the view of R–J3iB Mate.

Fig.2.1 (b) shows the R–J3iB Mate consists of the R–J3iB Mate controller.

Teach pendant

R–J3iB Mate controller

Operator

panel

Fan unit

Fig.2.1 (a) External View of the R–J3iB Mate Controller

Teach pendant cable

21

Page 53

2. CONFIGURATION

MAINTENANCE

B–81535EN/02

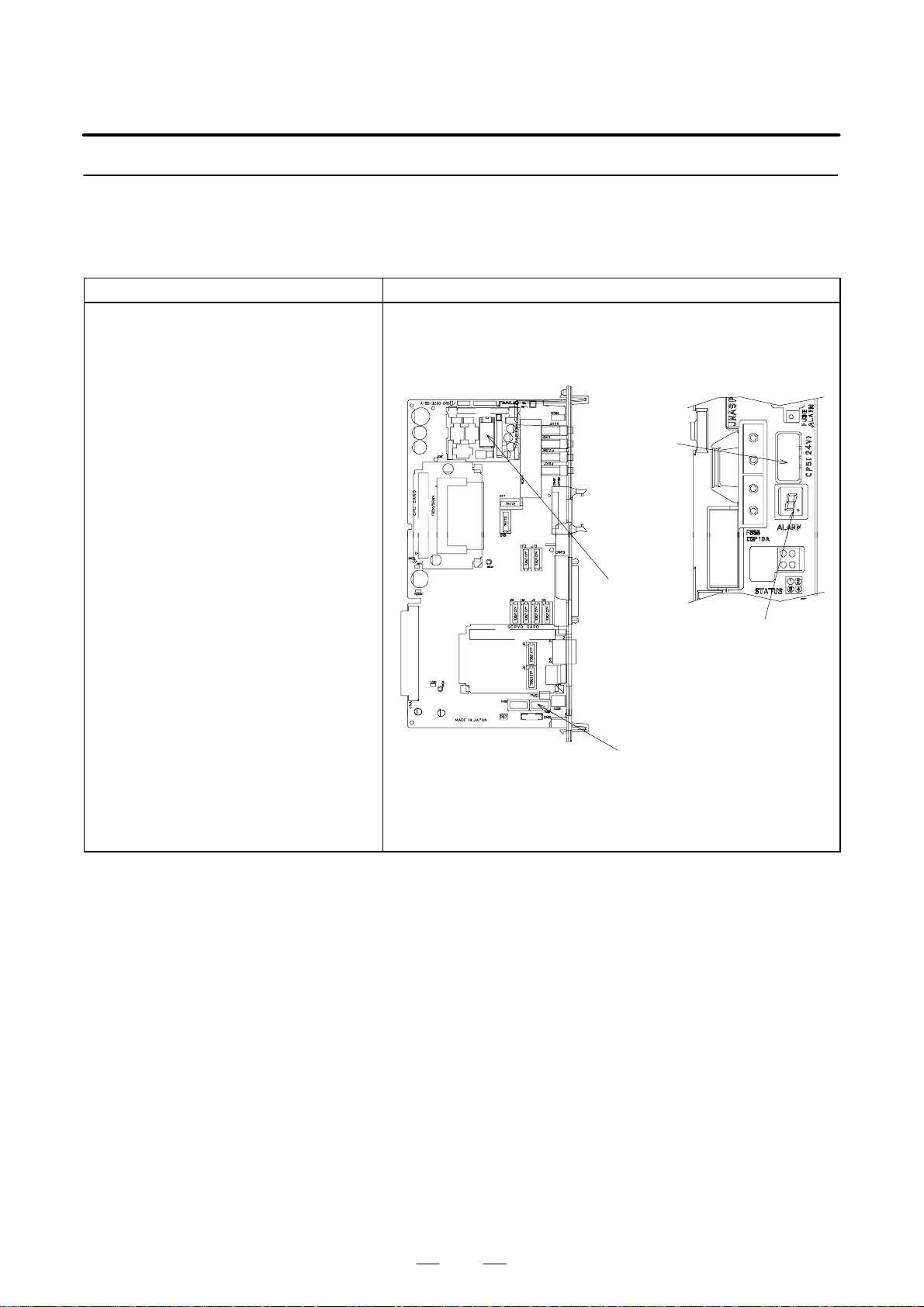

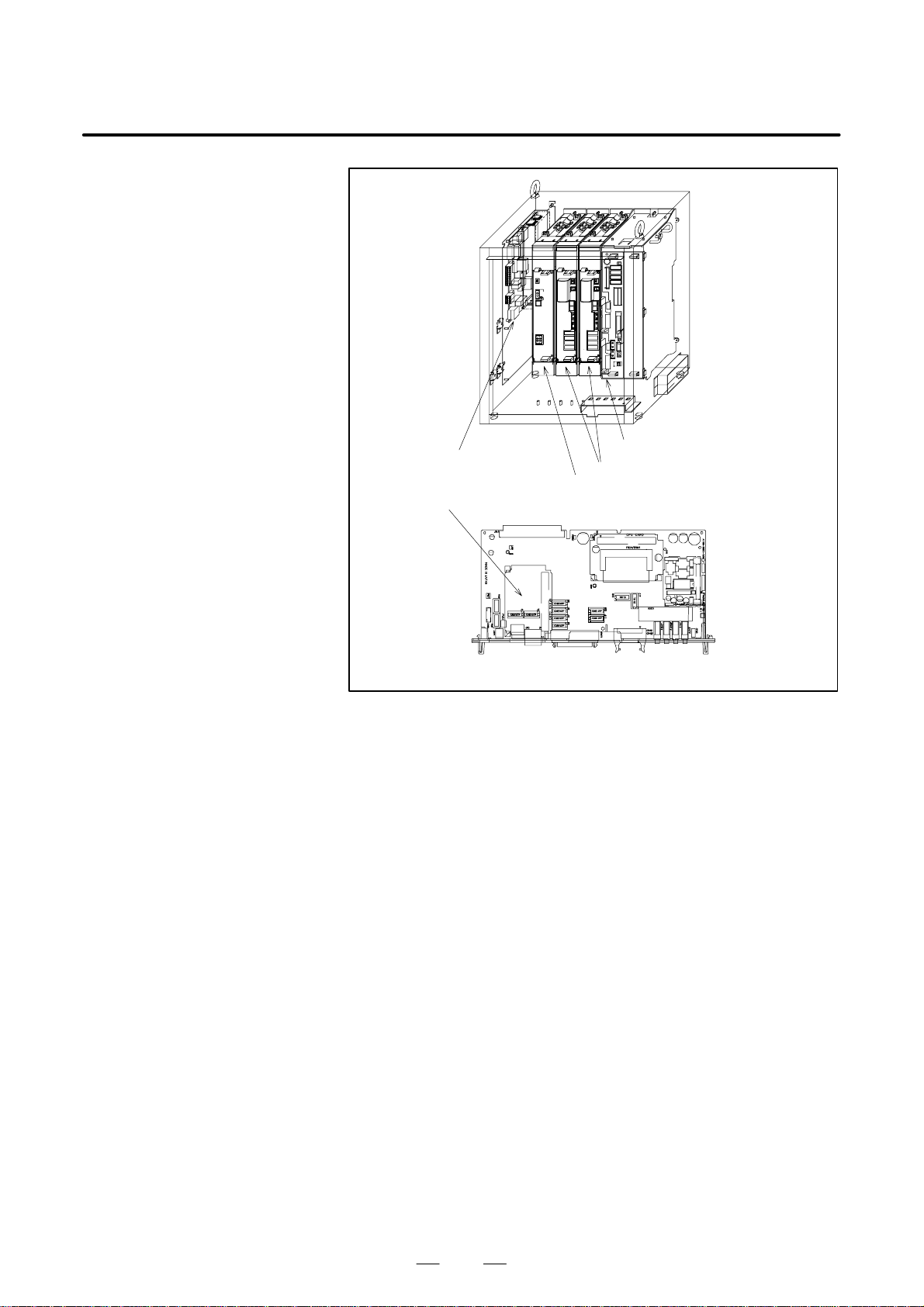

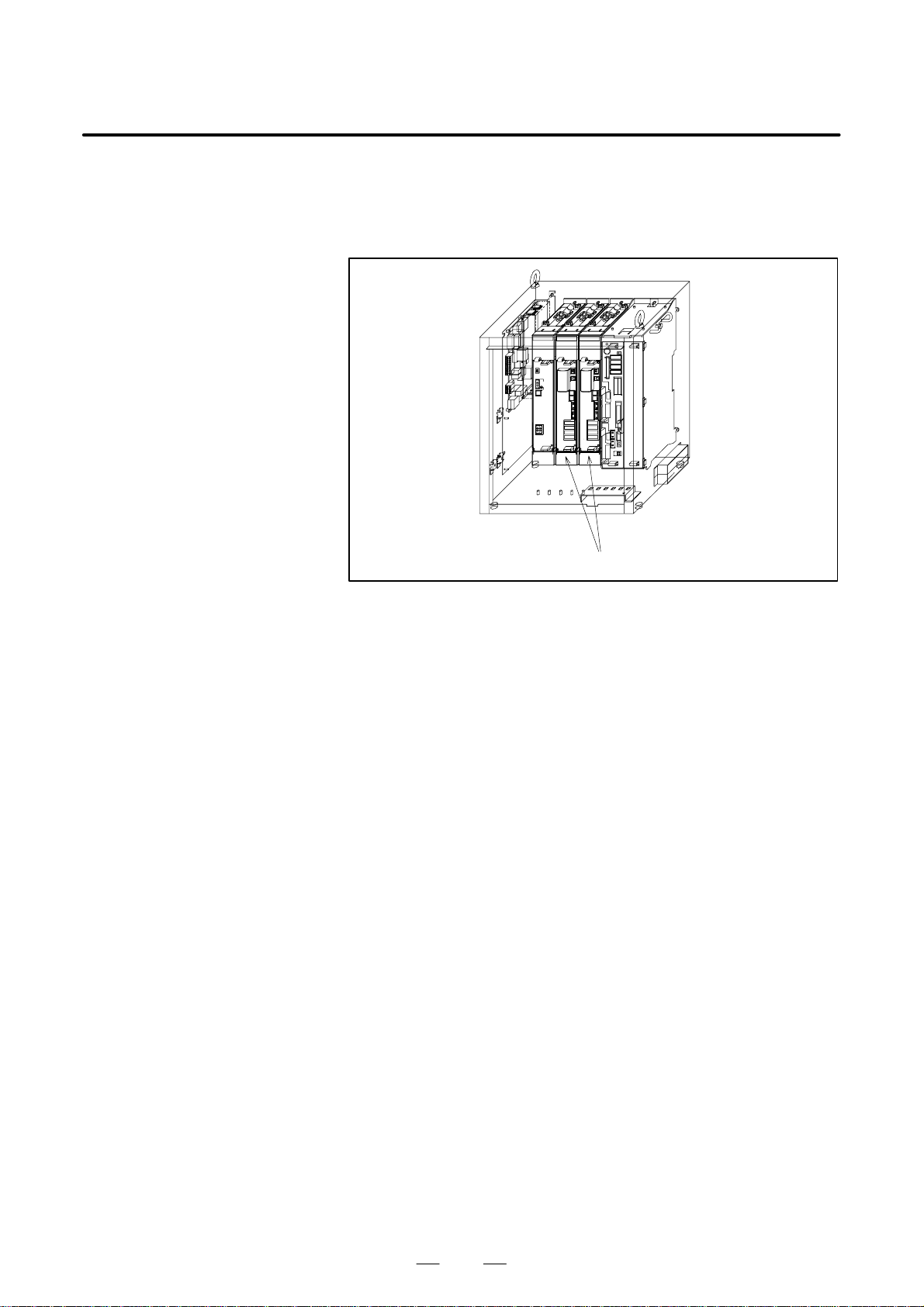

Circuit protector

Emergency stop

button

Mode

switch

Emergency stop unit

Emergency stop board

Heat exchange

Fuse

MCC

Power supply unit

Power supply transformer

for brake

Servo amplifier module2 (AMP2)

Servo amplifier module1 (AMP1)

Power supply module (PSM)

Enable/disable switch Emergency stop

Option slot (Process I/O board)

Robot control board

Teach pendan t

button

Back plane board

Robot

LR Mate 100iB

LR Mate 200iB

LR Mate 200iB

ARC Mate 50iB

ARC Mate 50iB

Fig.2.1 (b) R–J3iB Mate interior (Front)

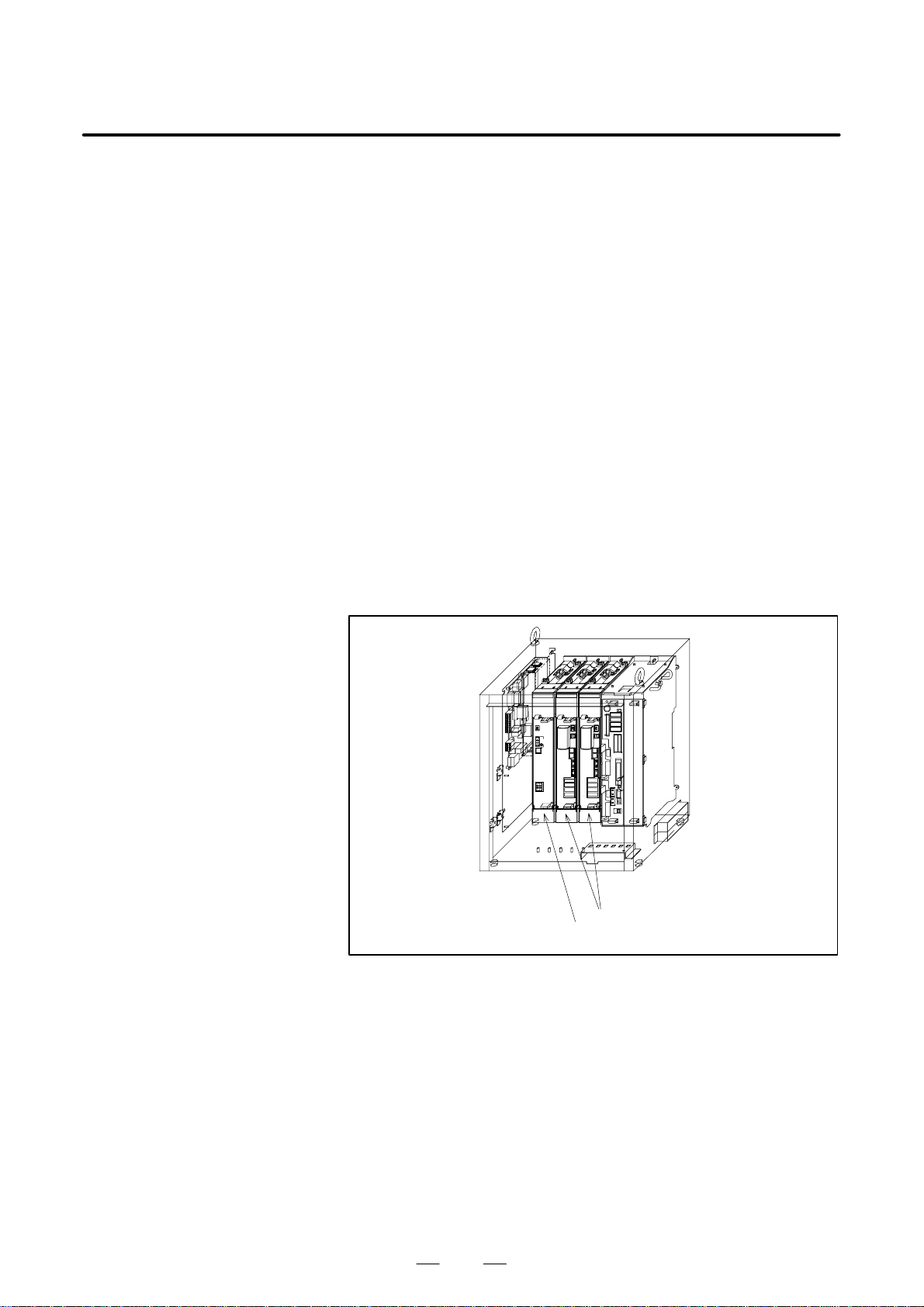

Table 2.1 Servo amplifier specifications

Power supply module Servo amplifier module1 Servo amplifier module2

A06B–6115–H001

(αPSMR–1i)

A06B–6114–H205

(αSVM–20/20i)

A06B–6114–H302

(αSVM–10/10/10i)

L M L M N

J1 J2 J3 J4 J5

A06B–6115–H001

(αPSMR–1i)

A06B–6114–H302

(αSVM–10/10/10i)

A06B–6114–H302

(αSVM–10/10/10i)

L M N L M N

J1 J2 J3 J4 J5 J6

22

Page 54

B–81535EN/02

2. CONFIGURATIONMAINTENANCE

2.2

COMPONENT

FUNCTIONS

– Robot control printed circuit board

This board is equipped with a microprocessor and its peripheral

circuitry , memory, and operator panel control circuit. A servo control

circuit is also included.

– Emergency stop unit, emergency stop printed circuit board

This unit controls the emergency stop system, magnetic contactor

(MCC) of the servo amplifier, and brake. The unit contains the power

supply unit for converting the AC power to the DC power.

– Backplane board

Various control boards are mounted on the backplane board.

– Teach pendant

This unit is used to carry out all operations including robot

programming. The liquid crystal display (LCD) of this unit displays

the status of the control unit, data, and the like.

– Servo amplifier

The servo amplifier amplifies the power of the servo amplifier and

controls the pulse coder.

– MCC

The MCC controls the main power of the servo amplifier.

– Operator panel

The operator panel has a port for the serial interface to an external

device. The panel also has an EMERGENCY STOP button.

– Fan unit, heat exchanger

These components are used to cool the inside of the control unit.

– Circuit protector

This component turns on or off the power.

The input power is connected to the circuit protector in order to

protect the equipment from a large current that could result from a

problem in the electric system of the control unit or an abnormal input

power.

23

Page 55

2. CONFIGURATION

MAINTENANCE

B–81535EN/02

2.3

PREVENTIVE

MAINTENANCE

Daily maintenance and periodic maintenance/inspection ensure reliable

robot performance for extended periods of time.

(1) Daily maintenance

Before operating the system each day, clean each part of the system

and check the system parts for any damage or cracks. Also check the

following:

(a) Before service operation

Check the cable connected to the teach pendant for excessive

twisting. Check the controller and peripheral devices for

abnormalities.

(b) After service operation

At the end of service operation, return the robot to the specified

position, then turn off the controller. Clean each part, and check

for any damage or cracks. If the ventilation port of the controller

is dusty, clean it.

(c) Check after one month

Check that the fan is rotating normally. If the fan has dirt and dust

built up, clean the fan according to step (d) described below for

inspection to be performed every 6 months.

(d) Periodic inspection performed every six months

Remove the top cover, louver, and back panel (if possible), then

remove any dirt and dust from the inside of the transformer

compartment. Wipe off dirt and dust from the fan and

transformer.

(2) Maintenance tools

The following maintenance tools are recommended:

(a) Measuring instruments

AC/DC voltmeter (A digital voltmeter is sometimes required.)

Oscilloscope with a frequency range of 5 MHz or higher, two

channels

(b) Tools

Phillips screwdrivers : Large, medium, and small

Standard screwdrivers: Large, medium, and small

Nut driver set (Metric)

Pliers