Page 1

<

<

!

R-30iB/R-30iB MATE/R-30iB PLUS CONTROLLER

>

Basic Interference Check and

Intelligent Interference Check

OPERATOR’S MANUAL

Version 8.20 and later

MAROBBI8204121E REV F

©2013-2019 FANUC America Corporation

Page 2

Copyrights and Trademarks

This new publication contains proprietary information of FANUC America

Corporation furnished for customer use only. No other uses are authorized without

the express written permission of FANUC America Corporation.

The descriptions and specifications contained in this manual were in effect at the

time this manual was approved for printing. FANUC America Corporation,

hereinafter referred to as FANUC, reserves the right to discontinue models at any

time or to change specifications or design without notice and without incurring

obligations.

FANUC manuals present descriptions, specifications, drawings, schematics, bills of

material, parts, connections and/or procedures for installing, disassembling,

connecting, operating and programming FANUC products and/or systems. Such

systems consist of robots, extended axes, robot controllers, application software, the

KAREL® programming language, INSIGHT® vision equipment, and special tools.

FANUC recommends that only persons who have been trained in one or more

approved FANUC Training Course(s) be permitted to install, operate, use, perform

procedures on, repair, and/or maintain FANUC products and/or systems and their

respective components. Approved training necessitates that the courses selected be

relevant to the type of system installed and application performed at the customer

site.

WARNING

This equipment generates, uses, and can radiate

radiofrequency energy and if not installed and used in

accordance with the instruction manual, may cause

interference to radio communications. As temporarily

permitted by regulation, it has not been tested for

compliance with the limits for Class A computing devices

pursuant to Subpart J and Part 15 of FCC Rules, which are

designed to provide reasonable protection against such

interference. Operation of the equipment in a residential

area is likely to cause interference, in which case the user,

at his own expense, will be required to take whatever

measure may be required to correct the interference.

Page 3

FANUC conducts courses on its systems and products on a regularly scheduled

basis at the company's world headquarters in Rochester Hills, Michigan. For

additional information contact

FANUC America Corporation

Training Department

3900 W. Hamlin Road

Rochester Hills, Michigan 48309-3253

www.fanucamerica.com

For customer assistance, including Technical Support, Service, Parts & Part Repair,

and Marketing Requests, contact the Customer Resource Center, 24 hours a day, at

888-FANUC-US (888-326-8287).

Send your comments and suggestions about this manual to:

product.documentation@fanucamerica.com

Copyright © 2019 by FANUC America Corporation

All Rights Reserved

The information illustrated or contained herein is not to be

reproduced, copied, downloaded, translated into another language, published in any

physical or electronic format, including internet, or transmitted in whole or in part

in any way without the prior written consent of FANUC America Corporation.

AccuStat®, ArcTool®, iRVision®, KAREL®, PaintTool®, PalletTool®,

SOCKETS®, SpotTool®, SpotWorks®, and TorchMate® are Registered

Trademarks of FANUC.

FANUC reserves all proprietary rights, including but not

limited to trademark and trade name rights, in the following names:

AccuAir™, AccuCal™, AccuChop™, AccuFlow™, AccuPath™,

AccuSeal™, ARC Mate™, ARC Mate Sr.™, ARC Mate System 1™,

ARC Mate System 2™, ARC Mate System 3™, ARC Mate System 4™,

ARC Mate System 5™, ARCWorks Pro™, AssistTool™, AutoNormal™,

AutoTCP™, BellTool™, BODYWorks™, Cal Mate™, Cell Finder™,

Center Finder™, Clean Wall™, DualARM™, iRProgrammer™, LR Tool™,

MIG Eye™, MotionParts™, MultiARM™, NoBots™, Paint

Stick™, PaintPro™, PaintTool 100™, PAINTWorks™, PAINTWorks

II™, PAINTWorks III™, PalletMate™, PalletMate PC™,

PalletTool PC™, PayloadID™, RecipTool™, RemovalTool™,

Robo Chop™, Robo Spray™, S-420i™, S-430i™, ShapeGen™,

SoftFloat™, SOFT PARTS™, SpotTool+™, SR Mate™, SR

ShotTool™, SureWeld™, SYSTEM R-J2 Controller™, SYSTEM R-J3

Controller™, SYSTEM R-J3iB Controller™, SYSTEM R-J3iC Controller™,

SYSTEM R-30iA Controller™, SYSTEM R-30iA Mate Controller™, SYSTEM R30iB Controller™, SYSTEM R-30iB Mate Controller™, SYSTEM R-30iB Plus

Controller™, SYSTEM R-30iB Mate Plus Controller™, TCP Mate™,

TorchMate™, TripleARM™, TurboMove™, visLOC™, visPRO-3D™,

visTRAC™, WebServer™, WebTP™, and YagTool™.

©FANUC CORPORATION 2019

x No part of this manual may be reproduced in any form.

x All specifications and designs are subject to change without notice.

Page 4

Patents

One or more of the following U.S. patents might be related to the FANUC products

described in this manual.

FANUC America Corporation Patent List

4,630,567 4,639,878 4,707,647 4,708,175 4,708,580 4,942,539 4,984,745 5,238,029

5,239,739 5,272,805 5,293,107 5,293,911 5,331,264 5,367,944 5,373,221 5,421,218

5,434,489 5,644,898 5,670,202 5,696,687 5,737,218 5,823,389 5,853,027 5,887,800

5,941,679 5,959,425 5,987,726 6,059,092 6,064,168 6,070,109 6,086,294 6,122,062

6,147,323 6,204,620 6,243,621 6,253,799 6,285,920 6,313,595 6,325,302 6,345,818

6,356,807 6,360,143 6,378,190 6,385,508 6,425,177 6,477,913 6,490,369 6,518,980

6,540,104 6,541,757 6,560,513 6,569,258 6,612,449 6,703,079 6,705,361 6,726,773

6,768,078 6,845,295 6,945,483 7,149,606 7,149,606 7,211,978 7,266,422 7,399,363

FANUC CORPORATION Patent List

4,571,694 4,626,756 4,700,118 4,706,001 4,728,872 4,732,526 4,742,207 4,835,362

4,894,596 4,899,095 4,920,248 4,931,617 4,934,504 4,956,594 4,967,125 4,969,109

4,970,370 4,970,448 4,979,127 5,004,968 5,006,035 5,008,834 5,063,281 5,066,847

5,066,902 5,093,552 5,107,716 5,111,019 5,130,515 5,136,223 5,151,608 5,170,109

5,189,351 5,267,483 5,274,360 5,292,066 5,300,868 5,304,906 5,313,563 5,319,443

5,325,467 5,327,057 5,329,469 5,333,242 5,337,148 5,371,452 5,375,480 5,418,441

5,432,316 5,440,213 5,442,155 5,444,612 5,449,875 5,451,850 5,461,478 5,463,297

5,467,003 5,471,312 5,479,078 5,485,389 5,485,552 5,486,679 5,489,758

5,493,192 5,504,766 5,511,007 5,520,062 5,528,013 5,532,924 5,548,194 5,552,687

5,558,196 5,561,742 5,570,187 5,570,190 5,572,103 5,581,167 5,582,750 5,587,635

5,600,759 5,608,299 5,608,618 5,624,588 5,630,955 5,637,969 5,639,204 5,641,415

5,650,078 5,658,121 5,668,628 5,687,295 5,691,615 5,698,121 5,708,342 5,715,375

5,719,479 5,727,132 5,742,138 5,742,144 5,748,854 5,749,058 5,760,560 5,773,950

5,783,922 5,799,135 5,812,408 5,841,257 5,845,053 5,872,894 5,887,122 5,911,892

5,912,540 5,920,678 5,937,143 5,980,082 5,983,744 5,987,591 5,988,850 6,023,044

6,032,086 6,040,554 6,059,169 6,088,628 6,097,169 6,114,824 6,124,693

6,140,788 6,141,863 6,157,155 6,160,324 6,163,124 6,177,650 6,180,898 6,181,096

6,188,194 6,208,105 6,212,444 6,219,583 6,226,181 6,236,011 6,236,896 6,250,174

6,278,902 6,279,413 6,285,921 6,298,283 6,321,139 6,324,443 6,328,523 6,330,493

6,340,875 6,356,671 6,377,869 6,382,012 6,384,371 6,396,030 6,414,711 6,424,883

6,431,018 6,434,448 6,445,979 6,459,958 6,463,358 6,484,067 6,486,629 6,507,165

6,654,666 6,665,588 6,680,461 6,696,810 6,728,417 6,763,284 6,772,493 6,845,296

6,853,881 6,888,089 6,898,486 6,917,837 6,928,337 6,965,091 6,970,802 7,038,165

7,069,808 7,084,900 7,092,791 7,133,747 7,143,100 7,149,602 7,131,848

7,161,321 7,171,041 7,174,234 7,173,213 7,177,722 7,177,439 7,181,294 7,181,313

7,280,687 7,283,661 7,291,806 7,299,713 7,315,650 7,324,873 7,328,083 7,330,777

7,333,879 7,355,725 7,359,817 7,373,220 7,376,488 7,386,367 7,464,623 7,447,615

7,445,260 7,474,939 7,486,816 7,495,192 7,501,778 7,502,504 7,508,155 7,512,459

7,525,273 7,526,121

Page 5

Conventions

WARNING

Information appearing under the "WARNING" caption concerns the protection of

personnel. It is boxed and bolded to set it apart from the surrounding text.

CAUTION

Information appearing under the "CAUTION" caption concerns the protection of

equipment, software, and data. It is boxed and bolded to set it apart from the

surrounding text.

Note Information appearing next to NOTE concerns related information or useful hints.

Page 6

Page 7

Safety

FANUC America Corporation is not and does not represent itself as an expert in safety

systems, safety equipment, or the specific safety aspects of your company and/or its work

force. It is the responsibility of the owner, employer, or user to take all necessary steps to

guarantee the safety of all personnel in the workplace.

The appropriate level of safety for your application and installation can be best determined

by safety system professionals. FANUC America Corporation therefore, recommends that

each customer consult with such professionals in order to provide a workplace that allows

for the safe application, use, and operation of FANUC America Corporation systems.

According to the industry standard ANSI/RIA R15-06, the owner or user is advised to

consult the standards to ensure compliance with its requests for Robotics System design,

usability, operation, maintenance, and service. Additionally, as the owner, employer, or user

of a robotic system, it is your responsibility to arrange for the training of the operator of a

robot system to recognize and respond to known hazards associated with your robotic

system and to be aware of the recommended operating procedures for your particular

application and robot installation.

Ensure that the robot being used is appropriate for the application. Robots used in classified

(hazardous) locations must be certified for this use.

FANUC America Corporation therefore, recommends that all personnel who intend to

operate, program, repair, or otherwise use the robotics system be trained in an approved

FANUC America Corporation training course and become familiar with the proper operation

of the system. Persons responsible for programming the system–including the design,

implementation, and debugging of application programs–must be familiar with the

recommended programming procedures for your application and robot installation.

The following guidelines are provided to emphasize the importance of safety in the

workplace.

CONSIDERING SAFETY FOR YOUR ROBOT INSTALLATION

Safety is essential whenever robots are used. Keep in mind the following factors with regard

to safety:

x The safety of people and equipment

x Use of safety enhancing devices

x Techniques for safe teaching and manual operation of the robot(s)

x Techniques for safe automatic operation of the robot(s)

x Regular scheduled inspection of the robot and workcell

x Proper maintenance of the robot

s-1

Page 8

Safety

Keeping People Safe

The safety of people is always of primary importance in any situation. When applying

safety measures to your robotic system, consider the following:

x External devices

x Robot(s)

x Tooling

x Workpiece

Using Safety Enhancing Devices

Always give appropriate attention to the work area that surrounds the robot. The safety of

the work area can be enhanced by the installation of some or all of the following devices:

x Safety fences, barriers, or chains

x Light curtains

x Interlocks

x Pressure mats

x Floor markings

x Warning lights

x Mechanical stops

x EMERGENCY STOP buttons

x DEADMAN switches

Setting Up a Safe Workcell

A safe workcell is essential to protect people and equipment. Observe the following

guidelines to ensure that the workcell is set up safely. These suggestions are intended to

supplement and not replace existing federal, state, and local laws, regulations, and guidelines

that pertain to safety.

x Sponsor your personnel for training in approved FANUC America Corporation training

course(s) related to your application. Never permit untrained personnel to operate the

robots.

x Install a lockout device that uses an access code to prevent unauthorized persons from

operating the robot.

x Use anti–tie–down logic to prevent the operator from bypassing safety measures.

x Arrange the workcell so the operator faces the workcell and can see what is going on

inside the cell.

x Clearly identify the work envelope of each robot in the system with floor markings,

signs, and special barriers. The work envelope is the area defined by the maximum

motion range of the robot, including any tooling attached to the wrist flange that extend

this range.

x Position all controllers outside the robot work envelope.

x Never rely on software or firmware based controllers as the primary safety element

unless they comply with applicable current robot safety standards.

x Mount an adequate number of EMERGENCY STOP buttons or switches within easy

reach of the operator and at critical points inside and around the outside of the workcell.

s-2

Page 9

Safety

x Install flashing lights and/or audible warning devices that activate whenever the robot is

operating, that is, whenever power is applied to the servo drive system. Audible

warning devices shall exceed the ambient noise level at the end–use application.

x Wherever possible, install safety fences to protect against unauthorized entry by

personnel into the work envelope.

x Install special guarding that prevents the operator from reaching into restricted areas of

the work envelope.

x Use interlocks.

x Use presence or proximity sensing devices such as light curtains, mats, and capacitance

and vision systems to enhance safety.

x Periodically check the safety joints or safety clutches that can be optionally installed

between the robot wrist flange and tooling. If the tooling strikes an object, these devices

dislodge, remove power from the system, and help to minimize damage to the tooling

and robot.

x Make sure all external devices are properly filtered, grounded, shielded, and suppressed

to prevent hazardous motion due to the effects of electro–magnetic interference (EMI),

radio frequency interference (RFI), and electro–static discharge (ESD).

x Make provisions for power lockout/tagout at the controller.

x Eliminate pinch points. Pinch points are areas where personnel could get trapped

between a moving robot and other equipment.

x Provide enough room inside the workcell to permit personnel to teach the robot and

perform maintenance safely.

x Program the robot to load and unload material safely.

x If high voltage electrostatics are present, be sure to provide appropriate interlocks,

warning, and beacons.

x If materials are being applied at dangerously high pressure, provide electrical interlocks

for lockout of material flow and pressure.

Staying Safe While Teaching or Manually Operating the Robot

Advise all personnel who must teach the robot or otherwise manually operate the robot to

observe the following rules:

x Never wear watches, rings, neckties, scarves, or loose clothing that could get caught in

moving machinery.

x Know whether or not you are using an intrinsically safe teach pendant if you are

working in a hazardous environment.

x Before teaching, visually inspect the robot and work envelope to make sure that no

potentially hazardous conditions exist. The work envelope is the area defined by the

maximum motion range of the robot. These include tooling attached to the wrist flange

that extends this range.

x The area near the robot must be clean and free of oil, water, or debris. Immediately

report unsafe working conditions to the supervisor or safety department.

x FANUC America Corporation recommends that no one enter the work envelope of a

robot that is on, except for robot teaching operations. However, if you must enter the

work envelope, be sure all safeguards are in place, check the teach pendant DEADMAN

switch for proper operation, and place the robot in teach mode. Take the teach pendant

with you, turn it on, and be prepared to release the DEADMAN switch. Only the person

with the teach pendant should be in the work envelope.

s-3

Page 10

Safety

WARNING

Never bypass, strap, or otherwise deactivate a safety device, such as a limit switch,

for any operational convenience. Deactivating a safety device is known to have

resulted in serious injury and death.

x Know the path that can be used to escape from a moving robot; make sure the escape

path is never blocked.

x Isolate the robot from all remote control signals that can cause motion while data is

being taught.

x Test any program being run for the first time in the following manner:

WARNING

Stay outside the robot work envelope whenever a program is being run. Failure to do

so can result in injury.

- Using a low motion speed, single step the program for at least one full cycle.

- Using a low motion speed, test run the program continuously for at least one full

cycle.

- Using the programmed speed, test run the program continuously for at least one

full cycle.

x Make sure all personnel are outside the work envelope before running production.

Staying Safe During Automatic Operation

Advise all personnel who operate the robot during production to observe the following rules:

x Make sure all safety provisions are present and active.

x Know the entire workcell area. The workcell includes the robot and its work envelope,

plus the area occupied by all external devices and other equipment with which the robot

interacts.

x Understand the complete task the robot is programmed to perform before initiating

automatic operation.

x Make sure all personnel are outside the work envelope before operating the robot.

x Never enter or allow others to enter the work envelope during automatic operation of the

robot.

x Know the location and status of all switches, sensors, and control signals that could

cause the robot to move.

x Know where the EMERGENCY STOP buttons are located on both the robot control and

external control devices. Be prepared to press these buttons in an emergency.

x Never assume that a program is complete if the robot is not moving. The robot could be

waiting for an input signal that will permit it to continue its activity.

x If the robot is running in a pattern, do not assume it will continue to run in the same

pattern.

s-4

Page 11

Safety

x Never try to stop the robot, or break its motion, with your body. The only way to stop

robot motion immediately is to press an EMERGENCY STOP button located on the

controller panel, teach pendant, or emergency stop stations around the workcell.

Staying Safe During Inspection

When inspecting the robot, be sure to

x Turn off power at the controller.

x Lock out and tag out the power source at the controller according to the policies of your

plant.

x Turn off the compressed air source and relieve the air pressure.

x If robot motion is not needed for inspecting the electrical circuits, press the

EMERGENCY STOP button on the operator panel.

x Never wear watches, rings, neckties, scarves, or loose clothing that could get caught in

moving machinery.

x If power is needed to check the robot motion or electrical circuits, be prepared to press

the EMERGENCY STOP button, in an emergency.

x Be aware that when you remove a servomotor or brake, the associated robot arm will fall

if it is not supported or resting on a hard stop. Support the arm on a solid support before

you release the brake.

Staying Safe During Maintenance

When performing maintenance on your robot system, observe the following rules:

x Never enter the work envelope while the robot or a program is in operation.

x Before entering the work envelope, visually inspect the workcell to make sure no

potentially hazardous conditions exist.

x Never wear watches, rings, neckties, scarves, or loose clothing that could get caught in

moving machinery.

x Consider all or any overlapping work envelopes of adjoining robots when standing in a

work envelope.

x Test the teach pendant for proper operation before entering the work envelope.

x If it is necessary for you to enter the robot work envelope while power is turned on, you

must be sure that you are in control of the robot. Be sure to take the teach pendant with

you, press the DEADMAN switch, and turn the teach pendant on. Be prepared to

release the DEADMAN switch to turn off servo power to the robot immediately.

x Whenever possible, perform maintenance with the power turned off. Before you open

the controller front panel or enter the work envelope, turn off and lock out the 3–phase

power source at the controller.

x Be aware that when you remove a servomotor or brake, the associated robot arm will fall

if it is not supported or resting on a hard stop. Support the arm on a solid support before

you release the brake.

s-5

Page 12

Safety

WARNING

Lethal voltage is present in the controller WHENEVER IT IS CONNECTED to a

power source. Be extremely careful to avoid electrical shock. HIGH VOLTAGE IS

PRESENT at the input side whenever the controller is connected to a power

source. Turning the disconnect or circuit breaker to the OFF position removes

power from the output side of the device only.

x Release or block all stored energy. Before working on the pneumatic system, shut off

the system air supply and purge the air lines.

x Isolate the robot from all remote control signals. If maintenance must be done when the

power is on, make sure the person inside the work envelope has sole control of the robot.

The teach pendant must be held by this person.

x Make sure personnel cannot get trapped between the moving robot and other equipment.

Know the path that can be used to escape from a moving robot. Make sure the escape

route is never blocked.

x Use blocks, mechanical stops, and pins to prevent hazardous movement by the robot.

Make sure that such devices do not create pinch points that could trap personnel.

WARNING

Do not try to remove any mechanical component from the robot before thoroughly

reading and understanding the procedures in the appropriate manual. Doing so can

result in serious personal injury and component destruction.

x Be aware that when you remove a servomotor or brake, the associated robot arm will fall

if it is not supported or resting on a hard stop. Support the arm on a solid support before

you release the brake.

x When replacing or installing components, make sure dirt and debris do not enter the

system.

x Use only specified parts for replacement. To avoid fires and damage to parts in the

controller, never use nonspecified fuses.

x Before restarting a robot, make sure no one is inside the work envelope; be sure that the

robot and all external devices are operating normally.

KEEPING MACHINE TOOLS AND EXTERNAL DEVICES SAFE

Certain programming and mechanical measures are useful in keeping the machine tools and

other external devices safe. Some of these measures are outlined below. Make sure you

know all associated measures for safe use of such devices.

Programming Safety Precautions

Implement the following programming safety measures to prevent damage to machine tools

and other external devices.

x Back–check limit switches in the workcell to make sure they do not fail.

x Implement ‘‘failure routines” in programs that will provide appropriate robot actions if

an external device or another robot in the workcell fails.

s-6

Page 13

Safety

x Use handshaking protocol to synchronize robot and external device operations.

x Program the robot to check the condition of all external devices during an operating

cycle.

Mechanical Safety Precautions

Implement the following mechanical safety measures to prevent damage to machine tools

and other external devices.

x Make sure the workcell is clean and free of oil, water, and debris.

x Use DCS (Dual Check Safety), software limits, limit switches, and mechanical hardstops

to prevent undesired movement of the robot into the work area of machine tools and

external devices.

s-7

Page 14

Safety

KEEPING THE ROBOT SAFE

Observe the following operating and programming guidelines to prevent damage to the

robot.

Operating Safety Precautions

The following measures are designed to prevent damage to the robot during operation.

x Use a low override speed to increase your control over the robot when jogging the robot.

x Visualize the movement the robot will make before you press the jog keys on the teach

pendant.

x Make sure the work envelope is clean and free of oil, water, or debris.

x Use circuit breakers to guard against electrical overload.

Programming Safety Precautions

The following safety measures are designed to prevent damage to the robot during

programming:

x Establish interference zones to prevent collisions when two or more robots share a work

area.

x Make sure that the program ends with the robot near or at the home position.

x Be aware of signals or other operations that could trigger operation of tooling resulting

in personal injury or equipment damage.

x In dispensing applications, be aware of all safety guidelines with respect to the

dispensing materials.

NOTE: Any deviation from the methods and safety practices described in this manual must

conform to the approved standards of your company. If you have questions, see your

supervisor.

s-8

Page 15

MAROBBI8204121E REV F 1 TABLE OF CONTENTS

TABLE OF CONTENTS

1 PREFACE ..................................................................................................................................... 1

2 OUTLINE ...................................................................................................................................... 4

3 SETTINGS .................................................................................................................................... 6

3.1 NETWORK ....................................................................................................................................... 6

3.1.1 Wiring and Connection ............................................................................................................. 6

3.1.1.1 Environment ...................................................................................................................... 6

3.1.1.2 Notes ................................................................................................................................... 8

3.1.2 Settings ...................................................................................................................................... 9

3.1.2.1 Setting the host names, Internet (IP) addresses, and subnet mask ............................. 9

3.1.2.2 Setting full duplex mode (for each robot controller) ..................................................... 10

3.1.2.3 Setting full duplex mode (for the Ethernet switch) ...................................................... 10

3.1.3 Checking the Network-Related Settings .............................................................................. 10

3.1.4 Configuring RIPE automatically ........................................................................................... 11

3.1.5 Configuring RIPE with ROSIPCFG.XML ............................................................................ 13

3.2 CALIBRATION .............................................................................................................................. 14

3.2.1 Calibration Data ..................................................................................................................... 16

3.2.2 Setting Calibration Data ........................................................................................................ 17

3.2.2.1 Direct input method ........................................................................................................ 20

3.2.2.2 Three point method ......................................................................................................... 22

3.2.3 Troubleshooting ...................................................................................................................... 27

3.3 SETTING MODELS ...................................................................................................................... 27

3.3.1 Definition of Elements ............................................................................................................ 27

3.3.2 Setting Up a Hand Model....................................................................................................... 32

3.3.2.1 Hand Modeling Example ................................................................................................ 33

3.3.2.2 Add Comment To A Hand Model ................................................................................... 34

3.3.2.3 Edit Geometric Elements For A Hand Model ............................................................... 35

3.3.2.4 Setting Detail Data For A Hand Geometric Element ................................................... 37

3.3.2.5 Mapping A Hand With A Tool Number ......................................................................... 38

3.3.2.6 Clear A Hand Model ........................................................................................................ 40

3.3.3 Setting Up A Fixture Model ................................................................................................... 40

3.3.3.1 Fixture Model Example .................................................................................................. 41

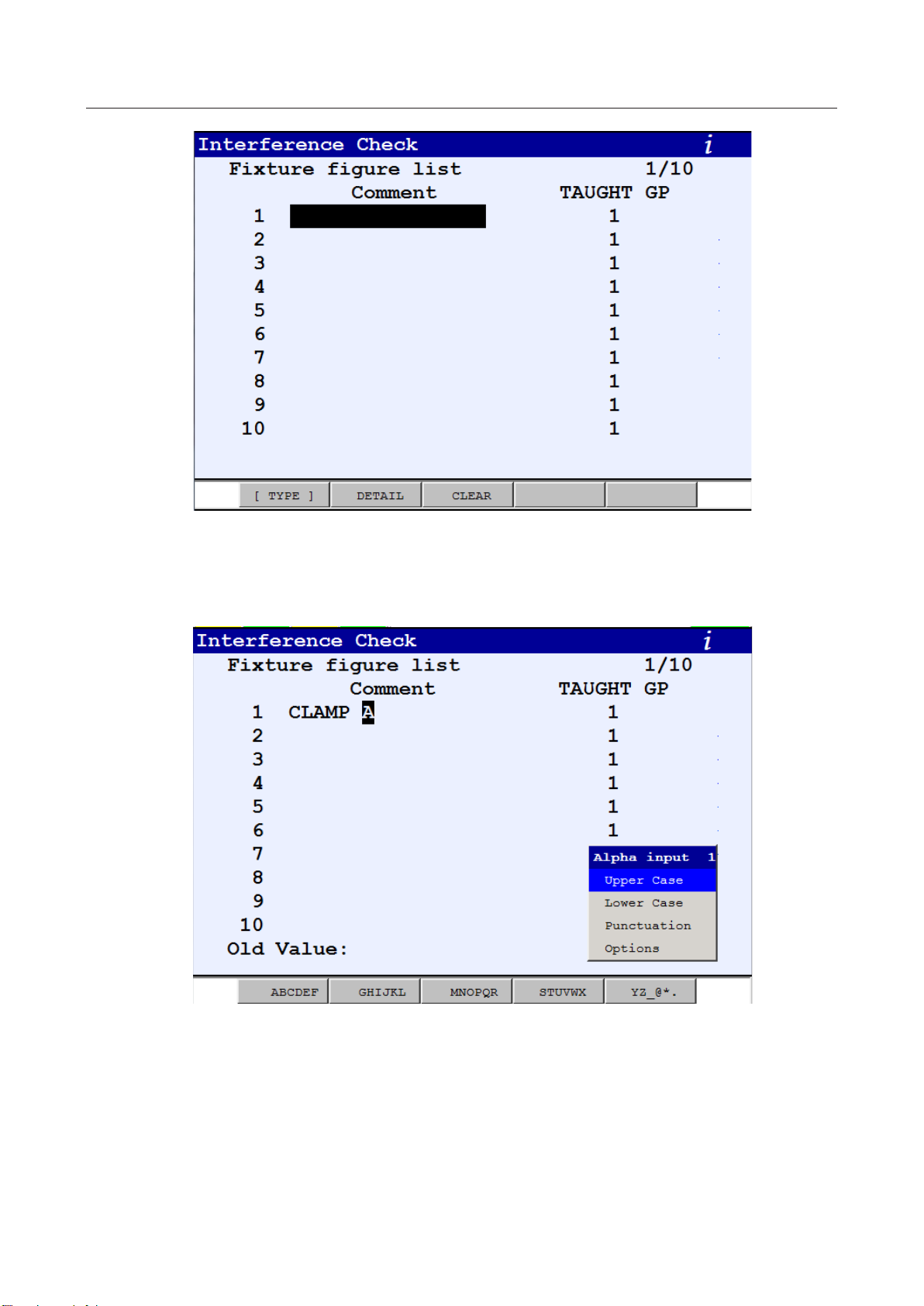

3.3.3.2 Enter A Comment ............................................................................................................ 42

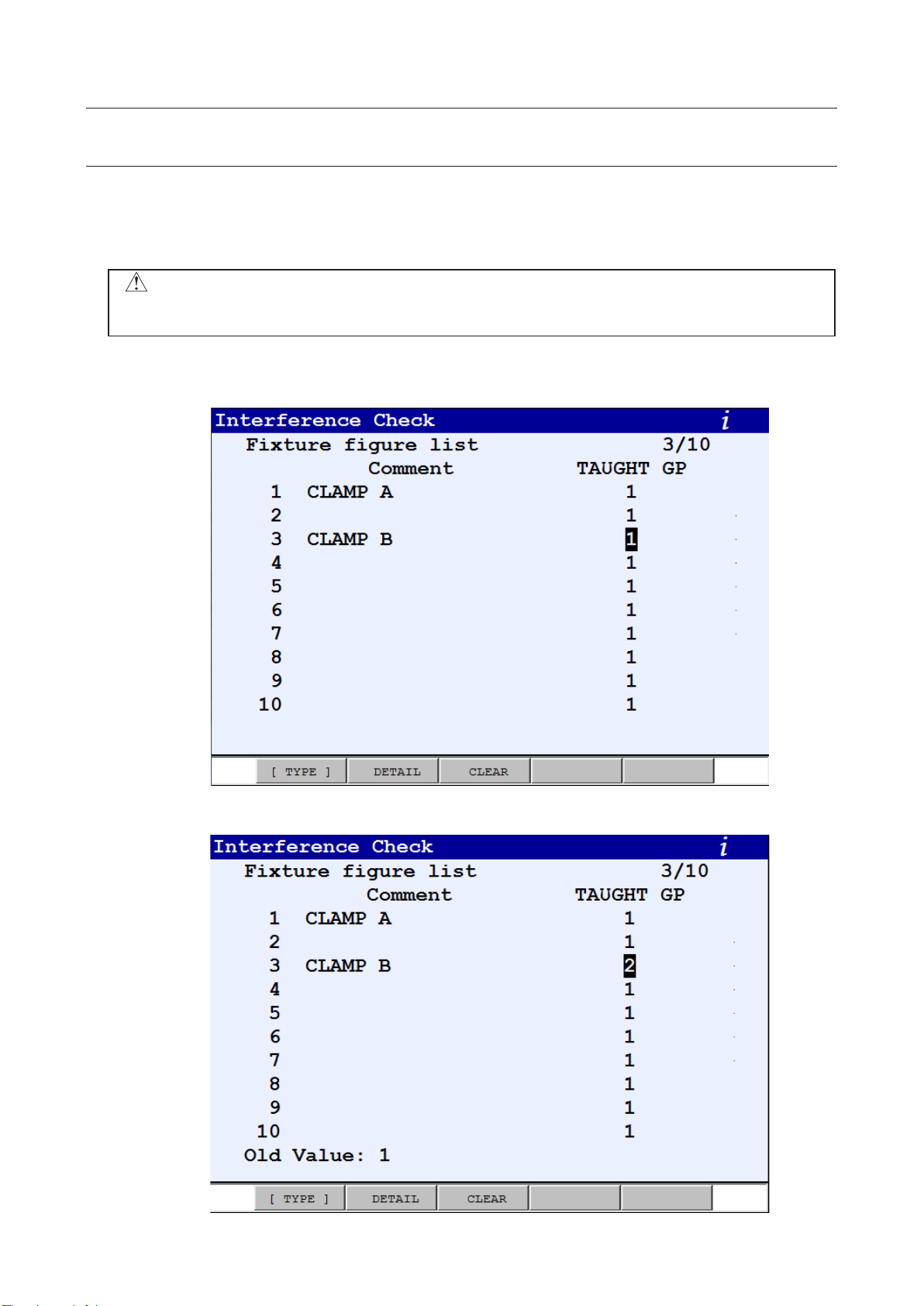

3.3.3.3 Select Reference Robot Group ........................................................................................ 44

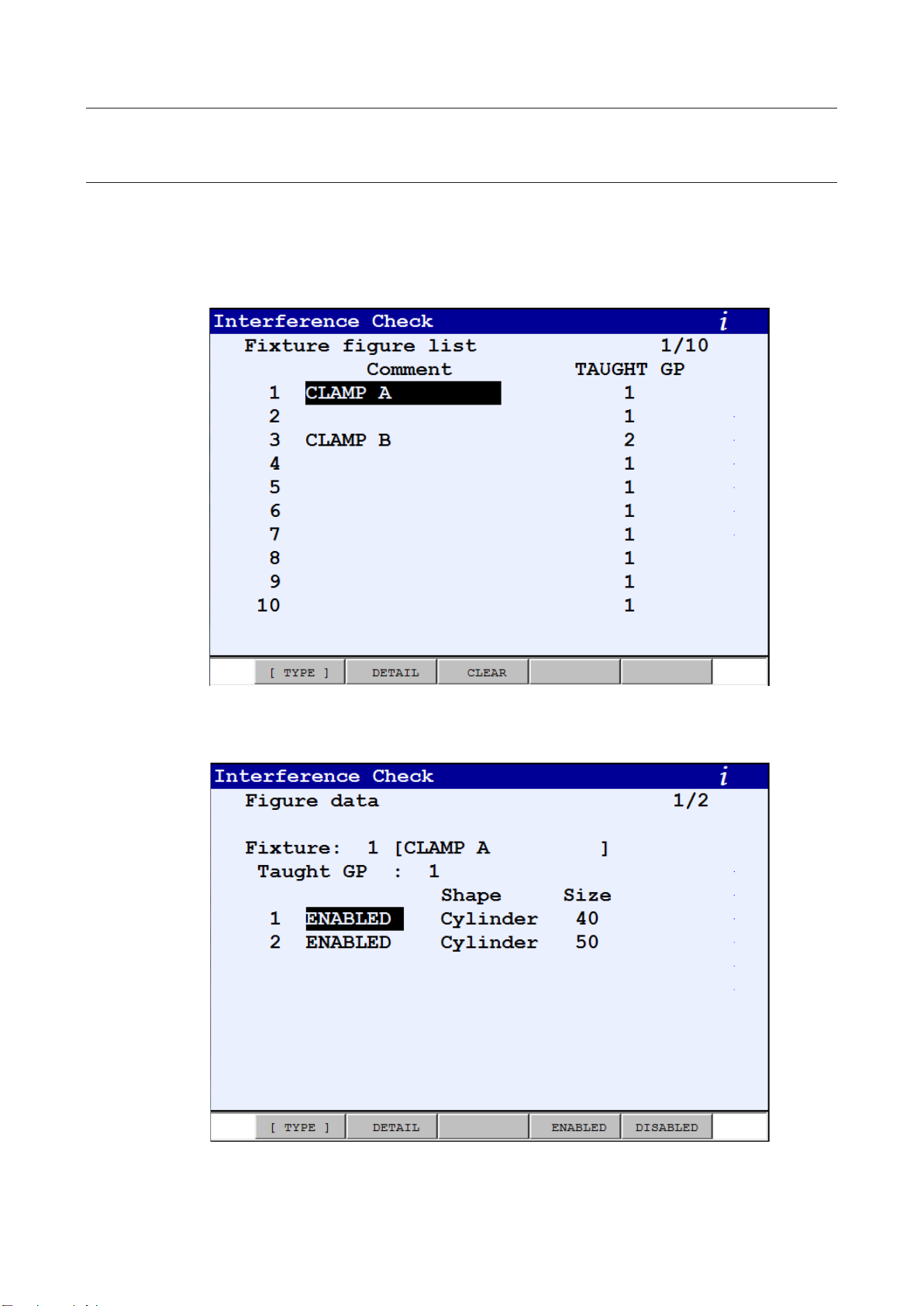

3.3.3.4 Create Geometric Model ................................................................................................. 45

3.3.3.5 Setting Fixture Elements ............................................................................................... 47

Page 16

TABLE OF CONTENTS MAROBBI8204121E REV F

3.3.3.6 Clearing a Fixture Model ................................................................................................ 49

3.3.4 Setting Up A Robot Model ...................................................................................................... 49

3.3.4.1 View Robot List ................................................................................................................ 49

3.3.4.2 View Geometric Elements of A Robot model ................................................................. 51

3.3.4.3 View/Edit Detail Geometric Element ............................................................................ 53

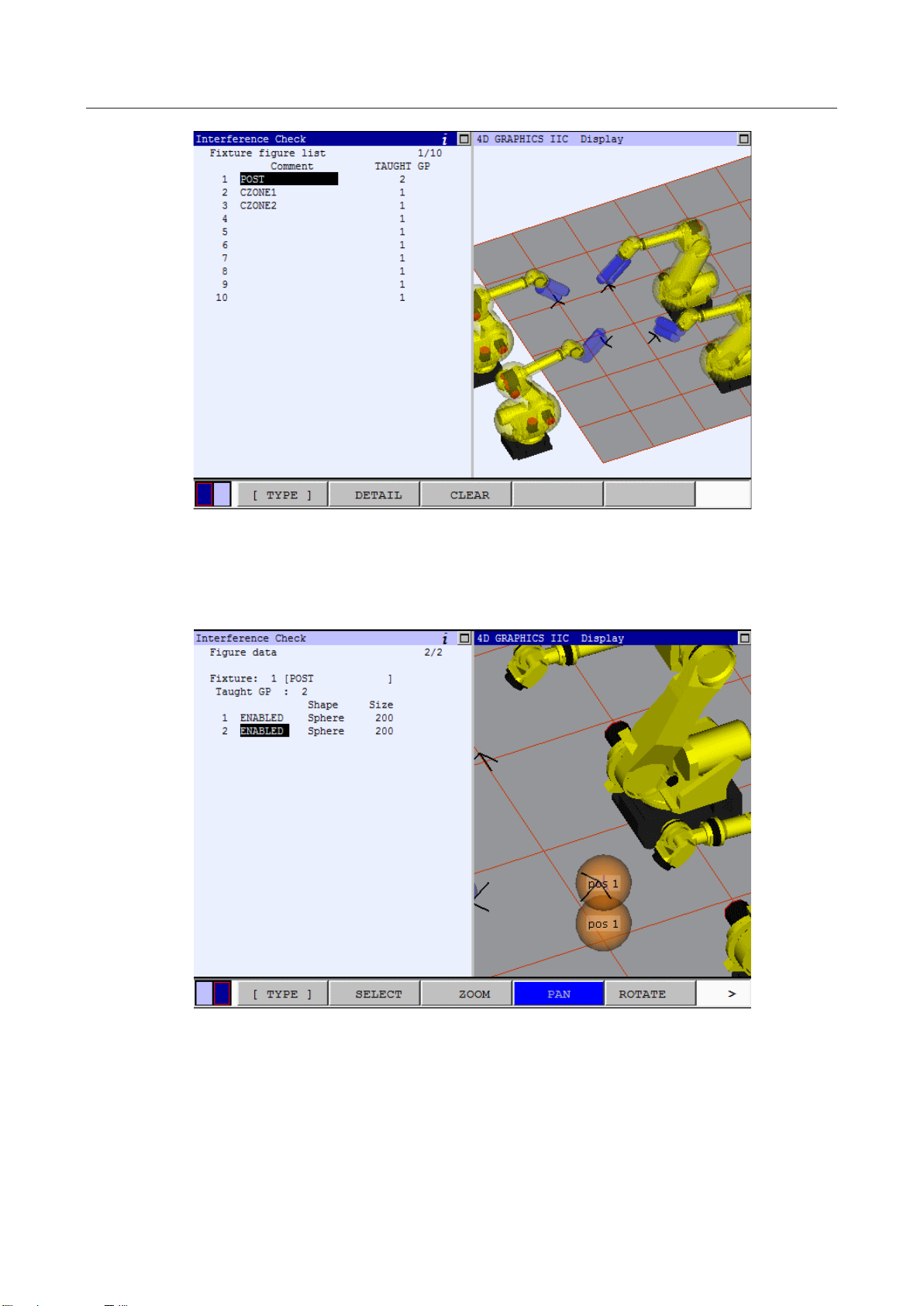

3.3.5 Using 4D Graphics In Model Setup Menus .......................................................................... 55

3.3.5.1 Using 4D Graphics In Hand Model Setup Menu .......................................................... 56

3.3.5.2 Using 4D Graphics In Fixture Model Setup Menu ....................................................... 58

3.3.5.3 Using 4D Graphics In Robot Model Setup Menu .......................................................... 62

3.3.5.4 Data Storage of The Geometric Elements ..................................................................... 64

3.3.6 Copying Models ....................................................................................................................... 65

3.3.6.1 Copy From DCS ............................................................................................................... 65

3.3.6.2 Copy from IIC .................................................................................................................. 69

3.3.6.3 Copy From/To XML ......................................................................................................... 73

3.4 SETTING INTERFERENCE CHECK COMBINATIONS ......................................................... 75

3.4.1 Setting a combination of models ............................................................................................ 75

3.4.1.1 Setting up combination for Robot + Hand ..................................................................... 79

3.4.1.2 Setting up combination for Fixture ................................................................................ 83

3.4.1.3 Setting up combination for Critical Zone ...................................................................... 86

3.4.1.4 Setting up combination for Virtual Fence ..................................................................... 89

3.4.1.5 Setting up combination for DO Only ............................................................................. 91

3.4.1.6 PLC DIN ........................................................................................................................... 93

3.4.2 Enabling combinations ........................................................................................................... 95

3.5 SETTING OTHER PARAMETERS .............................................................................................. 96

3.6 MODEL DATA STORAGE DESTINATION ................................................................................ 98

3.7 ENABLING DSP COMPUTATION ............................................................................................. 98

3.8 APPROACH WAIT COMBINATIONS ......................................................................................... 98

3.8.1 Approach Wait Combination List Screen ............................................................................. 99

3.8.1.1 Setting items .................................................................................................................. 100

3.8.2 Approach Wait Combination Detail Screen ........................................................................ 102

3.8.2.1 Settings ........................................................................................................................... 104

3.9 SETTING DEADLOCK PREVENTION .................................................................................... 105

3.9.1 Deadlock Prevention Setup Menu ....................................................................................... 107

3.9.2 Deadlock Prevention Schedule List..................................................................................... 108

3.9.3 Deadlock Prevention Schedule Detail ................................................................................. 108

3.9.4 Deadlock Prevention Limitations ........................................................................................ 112

3.10 ROBOT BYPASS FUNCTION ................................................................................................ 113

3.10.1 Robot Bypass Setup Menu ................................................................................................... 113

xvi

Page 17

MAROBBI8204121E REV F TABLE OF CONTENTS

3.10.2 Robot Bypass Runtime Check.............................................................................................. 115

3.10.3 Robot Bypass Limitations .................................................................................................... 115

3.11

3.11.1

LINE TRACKING SUPPORT ............................................................................................ 116

Line Tracking Support Limitations ............................................................................... 116

4 PROGRAM INSTRUCTIONS .................................................................................................... 117

4.1 APPROACH STOP ENABLE/DISABLE INSTRUCTION ....................................................... 117

4.1.1 Details .................................................................................................................................... 117

4.1.2 Sample Program ................................................................................................................... 118

4.1.3 Reverse Program Execution ................................................................................................. 118

4.1.4 Notes ...................................................................................................................................... 119

4.2 APPROACH WAIT ENABLE/DISABLE INSTRUCTION ....................................................... 121

4.2.1 Details .................................................................................................................................... 121

4.2.2 Sample Program ................................................................................................................... 122

4.2.3 Reverse Program Execution ................................................................................................. 123

4.2.4 Disabling Deceleration Stop Based on Approach Wait ..................................................... 124

4.2.5 Example of Use ..................................................................................................................... 124

4.2.6 Deadlock Caused by the Approach Wait Function ............................................................ 126

4.2.7 Notes ...................................................................................................................................... 126

4.3 APPROACH RATE INSTRUCTION .......................................................................................... 128

4.3.1 Details .................................................................................................................................... 128

4.3.2 Reverse Program Execution ................................................................................................. 129

4.4 COMB PAIR ENABLE INSTRUCTION .................................................................................... 129

4.5 COMB PAIR DISABLE INSTRUCTION ................................................................................... 129

4.6 MULTI ARM SYNCHRONIZATION INSTRUCTIONS ........................................................... 129

4.6.1 Setup ...................................................................................................................................... 130

4.6.2 Usage of the function ............................................................................................................ 132

4.6.2.1 WaitZone[ ] / SyncZone[ ] .............................................................................................. 132

4.6.2.2 EnterZone[ ] / ExitZone[ ] ............................................................................................. 133

4.6.3 Macros Associated with the Instructions ............................................................................ 134

4.6.4 Input parameters for the Macros ........................................................................................ 135

4.6.4.1 For WaitZone[ ] .............................................................................................................. 135

4.6.4.2 For SyncZone[ ] .............................................................................................................. 136

4.6.4.3 For EnterZone[ ] ............................................................................................................ 136

4.6.4.4 For ExitZone[ ] ............................................................................................................... 137

4.6.5 Insert/Edit the stand-alone instructions in a TPE program ............................................. 137

4.6.5.1 WaitZone[ ] or SyncZone[ ]: ........................................................................................... 138

4.6.5.2 EnterZone[ ] or ExitZone[ ] ........................................................................................... 141

4.6.6 Abort program ....................................................................................................................... 143

xvii

Page 18

TABLE OF CONTENTS MAROBBI8204121E REV F

4.6.7 Reset ...................................................................................................................................... 144

4.6.8 Limitations ............................................................................................................................ 144

5 INTERFERENCE STATUS MENU ............................................................................................ 146

5.1 Interference Check Status Main Menu ...................................................................................... 147

5.2 Interference Check Combination Status .................................................................................... 149

5.3 Approach Wait Status Menu ....................................................................................................... 151

6 INTERFERENCE CHECK 4D GRAPHICS ................................................................................ 155

6.1 IIC/BIC 4D Cell Display .............................................................................................................. 155

6.2 IIC/BIC 4D Display In Interference Check Menu ..................................................................... 158

6.2.1 4D Graphics in Combination Check Menu ......................................................................... 163

6.3 IIC Dead Lock Prevention 4D Display In Editor Menu ............................................................ 166

6.4 Automatic Cell Frame Update .................................................................................................... 171

7 IIC FOR ARC (R872) .........................................................................................................173

7.1

7.2

7.3

7.4

7.5

7.6

7.7

Overview ................................................................................................................................173

Loading the R872 Software Option ....................................................................................... 173

IIC for Arc Menu Items .......................................................................................................... 173

IIC Indirect Calibration .......................................................................................................... 174

TP Instruction to Disable/Enable Hand Model .................................................................... 178

Reduced Stop Distance during Slow Speed Motion.............................................................. 179

Indexer Interference Check .................................................................................................... 179

8 IIC FOR PAINTTOOL (R883).................................................................................................... 183

8.1 Overview ....................................................................................................................................... 183

8.2 R883 IIC for PaintTool Software Loading.................................................................................. 183

8.3 New IIC Menu Items for PaintTool ............................................................................................ 183

8.4 Terminology consistent with PaintTool ..................................................................................... 185

8.5 IIC Moving Fixture for Line Tracking........................................................................................ 191

8.6 Central Plane Check Schedule.................................................................................................... 194

9 TIPS .......................................................................................................................................... 196

xviii

Page 19

MAROBBI8204121E REV F 1 PREFACE

1 PREFACE

This manual describes two interference check functions, Basic Interference Check and Intelligent

Interference Check. Basic Interference Check monitors the distance from the tool or arm of a robot to a

defined object in real time to avoid interference. Intelligent Interference Check includes all the

functionality of Basic Interference Check plus adds real-time arm-to-arm interference checking within a

controller or across controllers using Ethernet communication. Intelligent Interference Check also

includes Deadlock Prevention which can analyze programs within a controller or across controllers and

automatically insert instructions to avoid interference and deadlock. Intelligent Interference Check also

includes RailZone Interference check which can be used to avoid interference between robots on a rail.

Basic Interference Check

Basic Interference Check consists of several categories of interference checking between a robot arm +

hand and virtual fixture models

1. Fixture – the robot stops and an alarm is posted when any part of the robot + hand model enters

or is about to enter a fixture model.

2. Critical Zone – when the predefined input signal is low the robot waits at the boundary of the

critical zone until the input signal becomes high

3. Virtual Fence – when any part of the robot exits the boundary of the virtual fence the robot

stops and an alarm is posted

4. DO Only – when any part of the robot + hand model enters the fixture model boundary the

output signal goes low. When the robot is outside the fixture model the output signal goes high.

5. PLC DIN – when the input signal goes low and the robot is inside the fixture model boundary

the robot waits until the input signal goes high.

Intelligent Interference Check

Intelligent Interference Check consists of three basic types of functions and includes the full

functionality of basic Interference Check:

A. Interference Check

B. Deadlock Prevention

C. RailZone Interference Check

Interference Check consists of several categories of interference checking:

1. Arm-to-Arm Interference Check – When a robot arm is moving it detects imminent collision with

another robot arm and stops motion.

2. Approach waiting function – When a robot arm is moving and detects that it is within a defined

distance to another robot the robot holds motion until the distance becomes greater then resumes

motion.

3. Fixture – the robot stops and an alarm is posted when any part of the robot + hand model enters

or is about to enter a fixture model.

1

Page 20

1 PREFACE MAROBBI8204121E REV F

4. Critical Zone – when the predefined input signal is low the robot holds and waits at the boundary

of the critical zone until the input signal becomes high

5. Virtual Fence – when any part of the robot exits the boundary of the virtual fence the robot stops

and an alarm is posted

6. DO Only – when any part of the robot + hand model enters the fixture model boundary the

output signal goes low. When the robot is outside the fixture model the output signal goes high.

7. PLC DIN – when the input signal goes low and the robot is inside the fixture model boundary the

robot holds and waits until the input signal goes high. When the signal goes high the robot

resumes motion.

When the interference check function is enabled, it always monitors the approach to each target set in

advance regardless of operation mode (such as execution of a program in progress or manual operation).

Arm-to-arm

When the approach is detected, an alarm occurs and the robot decelerates, and then stops. If there is a

possibility that the robot will cause a collision after decelerating, then stopping, however, immediate stop

is performed. Arm-to-Arm check function is only available with Intelligent Interference Check.

Arm-toArm Interference Check

Approach Wait

When the approach waiting function is enabled and the distance between robots is reaching the value set

in advance, the function automatically decelerates and stops the robots. The function waits until the

distance between the robots is increased. When the distance is increased, operation can automatically

be restarted. Approach Wait function is only available with Intelligent Interference Check.

Approach Wait

Deadlock Prevention

2

Page 21

MAROBBI8204121E REV F 1 PREFACE

The Deadlock Prevention automatically analyzes the selected programs that can reside on different

controllers and identifies portions of the programs that have potential interference and potential deadlock.

EnterZone and ExitZone instructions are inserted in the programs to avoid deadlock during program

execution. Deadlock Prevention is only available with Intelligent Interference Check.

Deadlock condition A waits on C, D waits on A, C waits on D

Deadlock Prevention function will avoid this condition

RailZone Interference Check

This function provides collision protection between the rail robots moving on the same rail. It also

provides a flexible method to setup rail barriers (software rail stopper) to control the RailZone working

range. RailZone interference check function requires no additional hardware and its operation is

independent of PLC control. The collision protection covers for the carriages, rail robot and its tooling

across the controllers. RailZone is only available for robots on a rail, including TopLoader robots.

Please see the separate user manual for RailZone Interference Check. RailZone Interference Check is

only available with Intelligent Interference Check.

RailZone Interference Check

3

Page 22

MAROBBI8204121E REV F 2 OUTLINE

2 OUTLINE

Interference Check function (Arm-to-Arm)

The Interference Check function exercises Interference Check control as follows:

1. Interference Check control is exercised over the following three types of objects: robot arm, hands,

and fixture.

2. You can set multiple hands and switch to a desired hand by associating its number with a tool

coordinate number.

3. Use points and line segments to make an approximation to the figure of each of the robot arm, hands,

and fixture. (Section 3.3, "SETTING MODELS") (Set representative points of each figure and the

distance including the figure of each of the arm, tool, and fixture.)

4. You can set a device installed on the robot arm such as a wire send-supply unit as an extension of

the robot arm figure setting.

5. You can set multiple combinations of objects over which Interference Check control is to be

exercised (robots including hands, and a robot and fixture) and can use DI to specify whether to

enable or disable the Interference Check function for each combination. (except for DO Only and

Virtual Fence)

6. If a robot is in the approach status, an alarm occurs, and the robot decelerates, then stops. If there is

a possibility that the robot will cause a collision after decelerating, then stopping, however,

immediate stop is performed.

7. You can use the status screen to check the recent Interference Check status (status in which the

indicated points overlap one another). If multiple points are in the approach status, up to 10

approach points can be displayed.

8. To teach the positional relationships among multiple robots, a calibration function is available.

Perform calibration for each pair of robots. Make the TCPs of two robots touch at three different

points and teach each position to determine the positional relationship between the robots. You can

also enter numeric values directly. For more than two robots, determine a reference robot and

perform calibration for another robot based on the reference robot.

9. If the operation speed of a robot is fast, this function detects the approach earlier than usual to avoid

collisions.

10. When a model is in the approach status, pressing the RESET key, and then releasing it while

holding the SHIFT key down disables the Interference Check function. The function remains

disabled until the SHIFT key is released or program execution operation is performed. Use this

operation if models cannot be released from the approach status because the distance between the

models is decreased by jog feed in any direction. If no model is in the approach status and SHIFT +

RESET operation is performed, this function is not performed (the Interference Check function is

not disabled).

11. You can load hand model data set on one controller onto another controller using a memory card or

another medium.

12. You can use program instructions to temporarily disable this function and enable it again.

Approach waiting function (Arm-to-Arm or Arm-to-Fixture)

The approach waiting function exercises approach-waiting control as follows:

1. Under approach waiting control, when the distance to the specified monitoring target reaches the

specified distance (approach waiting distance), the robot automatically decelerates, and then stops.

The robot waits until the distance to the monitoring target is increased (this status is called the

approach waiting status).

2. You can specify the following three types of objects: another robot arm, hand, and fixture as

monitoring targets of approach waiting control.

3. You can set multiple monitoring targets of approach waiting control.

4

Page 23

2 OUTLINE MAROBBI8204121E REV F

4. Set the approach waiting distance for each of another robot arm, hand, and fixture specified as

monitoring targets of approach waiting control. Set the distance to each monitoring target based on

the figure of the robot arm, hand, or fixture set for Interference Check control as the approach

waiting distance.

5. Use program instructions to specify the operating range in which approach waiting control is to be

applied.

6. If a robot enters the approach status in the operating range in which approach waiting control is

applied, the robot automatically decelerates, then stops. When the distance to the monitoring target

is increased after that, operation can automatically be restarted.

7. Within the operating range in which approach-waiting control is applied, you can use the status

screen to check the current distance and shortest approach distance to each monitoring target.

8. If the operation speed of a robot is fast, this function detects the approach earlier than usual to avoid

collisions.

Restrictions

z Automatic stop/restart by the approach waiting function does not function during the following

operations:

Use of the continuous rotation function

z Even if Constant Path function is enabled, when the approach is detected near the CNT motion

corner and the robot is decelerated, the path during the deceleration will become nearer to the

corner taught point.

5

Page 24

MAROBBI8204121E REV F 3 SETTINGS

Mount the switch

Switch

Fix the cable at two places.

so that

3 SETTINGS

Interference check settings can roughly be divided into the following six types:

1. Network settings

2. Calibration settings

3. Model settings

4. Combination settings

5. Other data settings

6. Approach wait settings

This chapter explains each type of setting and how to change each setting.

3.1 NETWORK

3.1.1 Wiring and Connection

3.1.1.1 Environment

z For Ethernet cables, use twisted pair cables for 10BASE-T that are protected against noise.

For details, refer to APPENDIX D, "CABLE CONNECTION," in the R-30iB/R-30iB Mate

CONTROLLER Ethernet Function OPERATOR’S MANUAL.

z An Ethernet hub (switch) is required for constructing a network. Use a switching hub, because high

communication speed is important for interference check. To protect the robot link network against

noise generated from the main line, use of a switching hub with no shield (metal) on the modular

connectors is recommended.

z Use standard Ethernet cables. Two controllers can be connected directly to each other using a

standard Ethernet cable (a crossover cable can also be used, but is unnecessary). Three or more

controllers can be connected using an Ethernet switch.

z Run the Ethernet cables so that each cable can make good contact with the hub without damaging

the cables. For example, install the Ethernet cables and hub as follows:

At least 50 mm At least 30 mm

Connect the connectors to the switch

the connections are perpendicular.

6

Page 25

3 SETTINGS MAROBBI8204121E REV F

The customer must provide the cables and switch. Purchasing spares is

recommended.

CAUTION:

formation between controllers.

If the interference check information is shared on a building network, it can be

disruptive to other network traffic, or interference check performance might be

For this reason,

FANUC recommends to isolate interference check traffic on a local network.

Two Ethernet ports are available, so each controller can be connected to both a

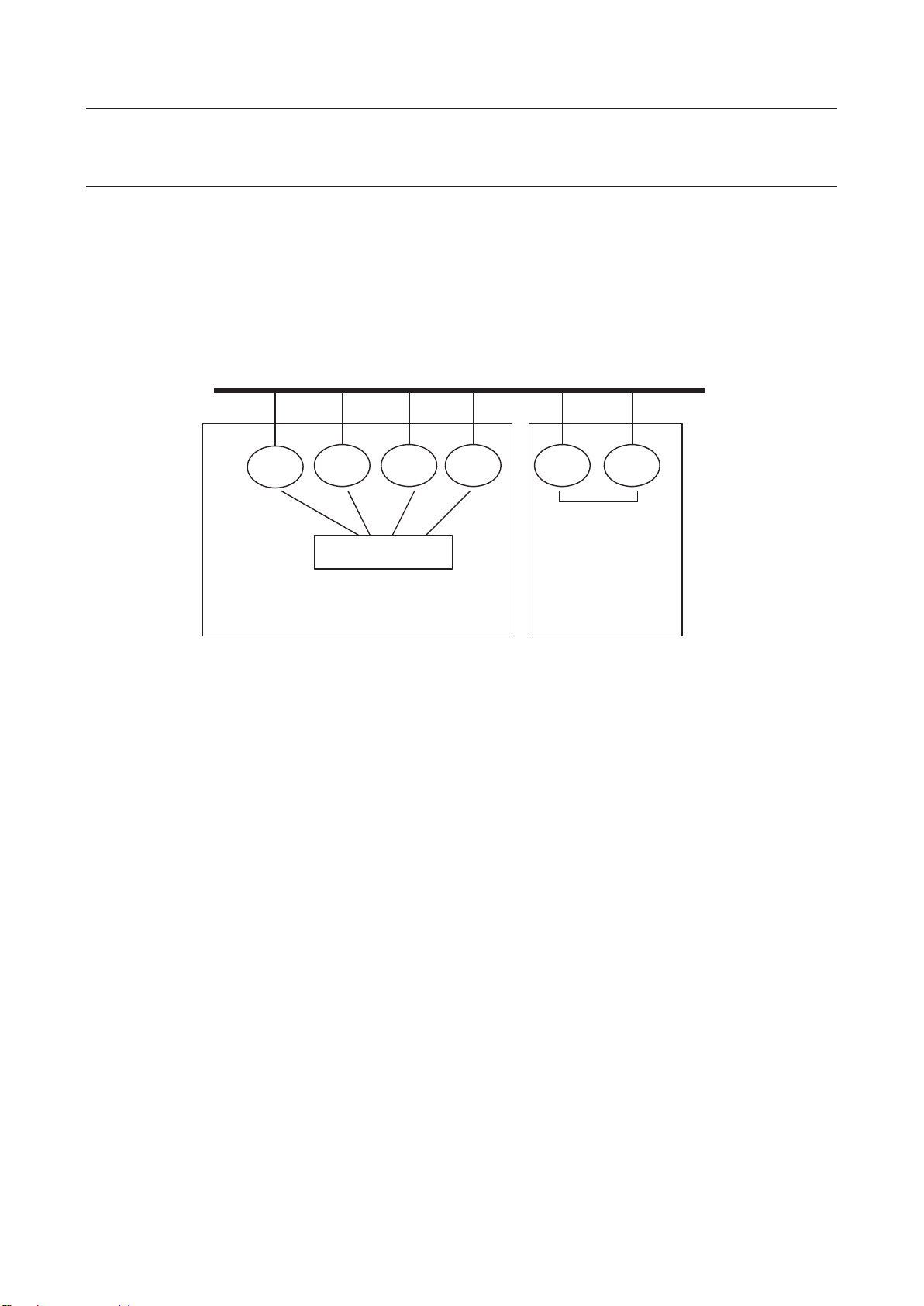

area network for general plant use and a local network for interference check

RC

Ethernet Switch

RC: Robot controller

RC

RC

RC

RC

RC

z Install the switch according to the specifications of the switch manufacturer. For example, the

switch must be installed in a dustproof location that is free from vibrations.

z Full protection against noise is required for good communication performance.

For details, refer to APPENDIX D, "CABLE CONNECTION," in the R-30iA/R-30iA Mate

CONTROLLER Ethernet Function OPERATOR’S MANUAL.

Interference check transmits a significant amount of in

impeded by other network traffic, which could allow a collision.

widecommunication.

z Configure the Ethernet network as follows: In the configuration shown in the figure below, the

controllers connect to the building network on Port #1, and form a RIPE ring using Port #2, so that

the building network and interference check RIPE ring can be isolated from each other.

Building network

Port #1

Port #2

RIPE ring with 2

controllers can be

RIPE ring with more than 2 controllers

requires an Ethernet switch

directly connected

7

Page 26

MAROBBI8204121E REV F 3 SETTINGS

RC

Ethernet Switch

RC: Robot controller

RC

RC

RC

RC

RC

3.1.1.2 Notes

Basic notes on using the robot link approach deterrence function are listed below. Your system must

satisfy the following minimum requirements at the minimum. The customer is responsible for additional

measures if required by safety standards.

z The RIPE ring must be isolated from the main Ethernet line to prevent interaction with the building

network and unintended interaction between different RIPE rings.

Building network

Port #1

Port #2

RIPE ring with 2

controllers can be

RIPE ring with more than 2 controllers

requires an Ethernet switch

directly connected

z The Ethernet cables must be routed so that they will not be accidentally damaged

z The Ethernet cables must be routed so they will not be affected by EMF noise. Avoid routing the

ethernet cables near sources of EMF noise.

z The power cable to the switching hub must be routed to avoid accidental damage or disconnection.

z Consider the Ethernet cable routing and location where the switching hub is to be installed so that

the connector of each cable can make reliable contact with the hub. If the contact is poor,

cross-controller communication could be affected and incorrect interference detection could result.

z When an Ethernet cable is connected between the Ethernet switch and the controller and both

switch and controller are powered on, the green LED on the printed circuit board at the back of the

socket glows to indicate a successful connection. If the LED does not glow, the main board may be

faulty. Contact the FANUC Service Center.

z The Ethernet switch has LEDs to indicated the communication status. Install the switch in a location

where the status LEDs can be easily observed, to help investigate communication problems if

necessary.

z On the TCP/IP setting screen, the correct IP addresses and host names must be set correctly.

Otherwise, the wrong robot might be used for interference checking. To avoid confusion, distinct

host names and IP addresses are used for each robot on the robot link network.

z RIPE communication must be configured. Otherwise, interference checking cannot be performed.

See the chapter titled "SETTINGS" in this manual for instructions to configure RIPE configuration.

z The settings on the Interference Check calibration menu must be correct and precise calibration

must be performed. Otherwise, false interference my be detected or a robot may collide because the

calibration does not match the cell configuration.

8

Page 27

3 SETTINGS MAROBBI8204121E REV F

Ether net

Switch

G1

G2

RC21

Controlle r 1

G1

RC24

Controlle r 4

G1

RC22

Controlle r 2

G1

G2

RC23

G3

Controlle r 3

CAUTION:

character string contains a space (blank) (leading spaces are difficult to check

in particular), communication cannot be performed properly. In this case, delete

the entire line, and then reenter a character string.

3.1.2 Settings

The interference check function uses Ethernet to share robot positions across controllers. Settings for

using Ethernet must be made first.

This section explains how to make the settings using the following system configuration as an example:

Controller 1 is a two-group system. Its host name is RC21.

Controller 2 is a one-group system. Its host name is RC22.

Controller 3 is a three-group system. Its host name is RC23.

Controller 4 is a one-group system. Its host name is RC24.

3.1.2.1 Setting the host names, Internet (IP) addresses, and subnet

mask

Display the Host Com setup menu, then the TCP/IP menu.

On the TCP/IP setup menu, configure the following items:

z Node name of the local controller

z Subnet mask

z Port #2 IP address. If Port #1 will be used for RIPE communication, configure Port #1 IP address

instead. If the RIPE ring uses a dedicated Ethernet switch, the IP address can be a standard value

(for example, starting with 192.168.0.2) .

z Make the above settings on all robot controllers on the RIPE ring. The settings for "Node name" and

"IP address" must be unique for each controller on the RIPE ring.

Characters must be entered to set the items on this screen. If an entered

9

Page 28

MAROBBI8204121E REV F 3 SETTINGS

Example settings are shown below:

3.1.2.2 Setting full duplex mode (for each robot controller)

Set each robot controller to the full duplex mode. Set system variable

$ENETMODE[].$FULL_DUPLEX to TRUE.

3.1.2.3 Setting full duplex mode (for the Ethernet switch)

If the ethernet switch has a DIP switch for switching between full duplex and half duplex, set the switch

to the full duplex mode. Some Ethernet switches automatically select between full duplex and half

duplex.

3.1.3 Checking the Network-Related Settings

After setting the above items, check the following items to confirm that the settings are correct:

1. Check whether an Ethernet cable is connected between the Ethernet switch and each robot

controller. (or directly between controllers if there are only two)

2. ˢ if no cable is connected, connect a cable.

3. When the power to the hub and robot controllers are on, check whether the green LEDs on the

printed circuit board at the back of the Ethernet cable socket on the main board in each robot

controller glow.

4. ˢ if the LED does not glow, reinsert the cable, and turn the power to the hub and controller off,

then on again. If the LED still does not glow, the main board may be faulty. Contact the FANUC

Service Center.

10

Page 29

3 SETTINGS MAROBBI8204121E REV F

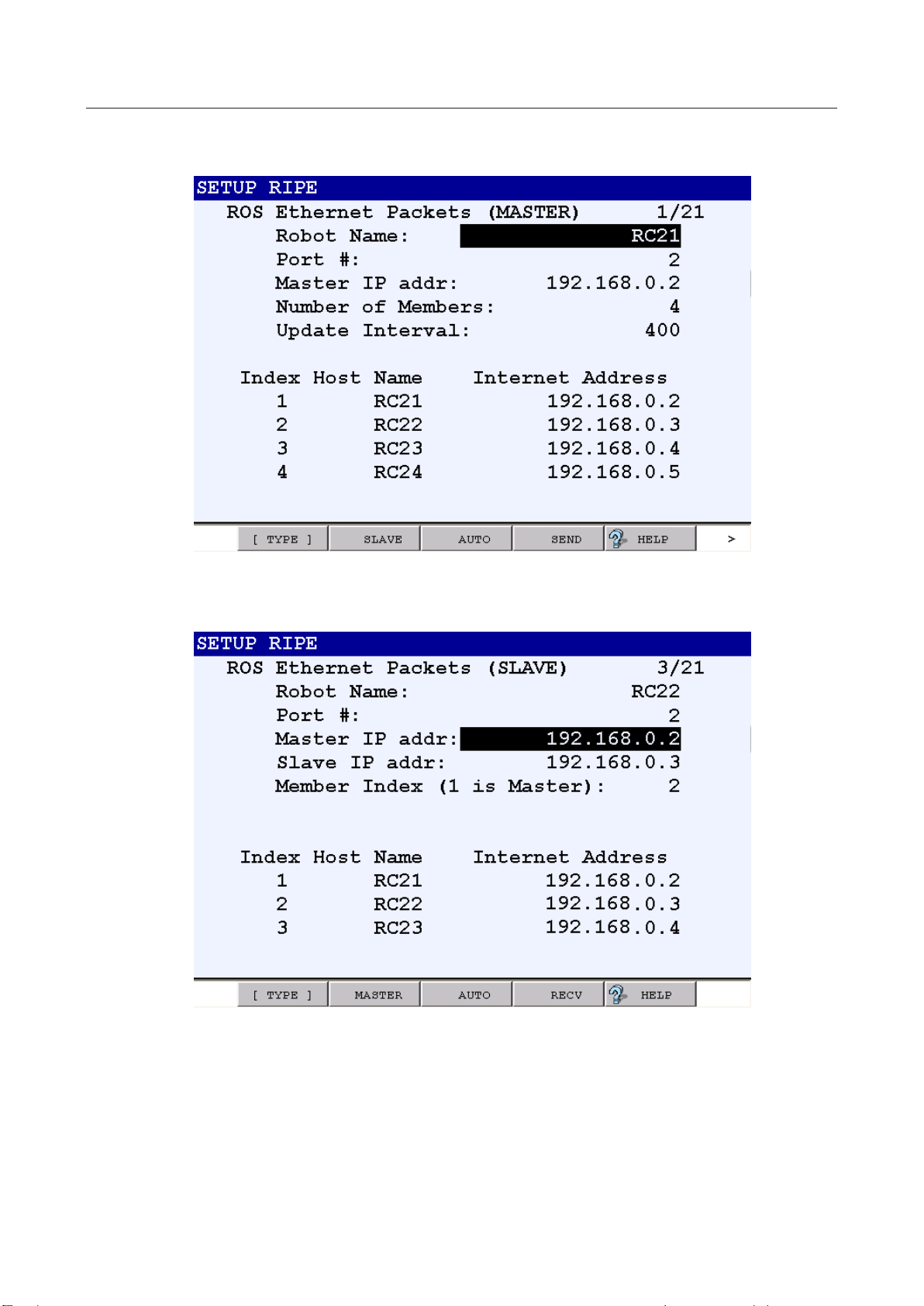

3.1.4 Configuring RIPE automatically

Interference Check uses RIPE (ROS Internet Packets over Ethernet) to share positions between one

controller and another. Before intelligent interference check can be used, RIPE must be configured.

RIPE uses a “Master” controller which serves to coordinate the RIPE network ring, and one or more

“Slave” controllers which share the RIPE ring.

RIPE can be configured automatically using the below procedure. RIPE configuration should be done

after the host name, Port #2 IP address, and Port #2 subnet mask are configured in the Host

Comm->TCP/IP menu.

For details of RIPE setup and operations, refer to: ROS INTERFACE PACKETS OVER ETHERNET

(RIPE) chapter in the Internet Options Setup and Operations Manual

Procedure

1. Press MENUS

2. Select SETUP

3. Select Host Comm. The master Host Comm menu will be displayed.

11

Page 30

MAROBBI8204121E REV F 3 SETTINGS

4. Move the cursor to RIPE and press F3 [DETAIL] to enter the RIPE setup menu.

5. Enter a name for your robot. RC21, for example.

6. On the slave controllers, press F2 SLAVE. The following screen is displayed:

7. Set up the RIPE ring on the slave controllers

a. Select a unique “Member Index” for all slave robots 2 to n where n is the number of

controllers in the ring

b. Press F3 AUTO on all of the SLAVE controllers to configure them to WAIT for the config

file from the master

c. When “Repower after receiving data?” is displayed, select YES

12

Page 31

3 SETTINGS MAROBBI8204121E REV F

[ROSIPCFG.XML]

8. Set up the RIPE ring on the master controller. Press F2 MASTER if necessary to return to the

MASTER setup menu

a. Verify that the port number is correct. If possible, use a port that is not already in use for a

factory communications link. Typically, port #2 is available. Refer to the “Setting up a Port”

section in the Software Installation Manual for more information.

b. Set up the number of members in the ring

c. Set the Update Interval. 400ms is acceptable.

d. Press F3 AUTO on the MASTER controller to generate the ROSIPCFG.XML file and send it to

all of the waiting slaves.

e. When “Put all SLAVES in AUTO mode” is displayed, enter CONTINUE

f. When “Cycle power for setting to take effect?” is displayed, select YES to automatically cycle

power and install RIPE configuration on all controllers in RIPE ring.

3.1.5 Configuring RIPE with ROSIPCFG.XML

An alternative to automatic RIPE configuration is to directly edit ROSIPCFG.XML.

Create and install ROSIPCFG.XML according to the procedure below. ROSIPCFG.XML should be

updated whenever host name or IP address changes in the host communication menu, or a member is

added or removed from the RIPE ring.

Procedure

1. Create the following XML file (called ROSIPCFG.XML) using a text editor.

2. Make a note of the host name and IP address of all controllers connected to robot link.

3. Edit <MEMBER> tag (line 7 and 8) in ROSIPCFG.XML according to the following example.

(Example) <MEMBER name="Host name" ipadd="IP address"/>

13

Page 32

MAROBBI8204121E REV F 3 SETTINGS

<?xml version="1.0" ?>

<!--

The order implies the "index" in the ring

-->

<ROSIPCFG>

<ROBOTRING count="4" timeslot="400">

<MEMBER name="RC21" ipadd="192.168.0.2">

</MEMBER>

<MEMBER name="RC22" ipadd="192.168.0.3">

</MEMBER>

<MEMBER name="RC23" ipadd="192.168.0.4">

</MEMBER>

<MEMBER name="RC24" ipadd="192.168.0.5">

</MEMBER>

</ROBOTRING>

</ROSIPCFG>

[SETXML.CM]

frcopy mc:rosipcfg.xml frs:rosipcfg.xml

x Change count="4" (line 6) to match the number of robots, and add or remove

<MEMBER ...> lines if necessary.

4. Create the following command file (called SETXML.CM) using a text editor.

5. Copy ROSIPCFG.XML and SETXML.CM into memory card.

6. On each controller in the RIPE ring, load the ROSIPCFG.XML file using these steps:

x Display all files in the memory card using DIR *.* in the file menu.

x Select “SETXML.CM” and press ENTER key.

x Question “Execute SETXML.CM?” will appear, answer F4 (YES).

x After “OK” is appears on lower right corner of the menu, cycle power.

3.2 CALIBRATION

Calibration is to teach a robot the position of the calibration robot coordinate system viewed from the

reference robot coordinate system. More precisely, calibration is to set the position and posture of the

world coordinate system of a certain calibration robot viewed from the world coordinate system of the

reference robot.

Calibration must be performed as many times as the number of robots because all robots are required to

know their position in the reference robot coordinate system.

14

Page 33

3 SETTINGS MAROBBI8204121E REV F

CAUTION:

It is highly recommended that you use the same software version among all Ethernet

connected controllers using BIC/IIC.

If multiple controllers are used and connected through ethernet then all controllers on the robot ring must

be powered on during the calibration. RIPE and the associated rosipcfg.xml files must be set up before

calibration is started. Please refer to section 3.1 for the network setup. If only a single controller is used

then RIPE setup is not required.

This section explains calibration data, then calibration. The following outlines calibration:

z Set a calibration TCP on each robot.

z Make the TCPs of the reference robot and a robot to be calibrated touch and teach the position on

each robot.

The TCPs must touch at three different points for each pair of the reference robot and another robot.

The three points must be widely separated and form a triangle. They must not be close to a straight

line. The points are recorded separately for each robot, so there are two method of teaching the

reference points and the calibration points:

o The points can be where the robot TCPs are touching each other

o The points can be where the robot TCPs are touching the same points in space, such as a mark

or target on a fixture. It is essential that the order of the points be the same for each robot.

Example of robots touching the same points on a fixture

Example of robots touching TCPs

15

Page 34

MAROBBI8204121E REV F 3 SETTINGS

Z

Z

axis

X

axis

X

axis

R1

R2

Y

axis

Y

axis

Reference robot

R1

R2

3.2.1 Calibration Data

To use the interference check function, the positional relationships among installed robots must be set.

Calibration must be performed as many times as the number of robots because all robots are required to

know their position in the reference coordinate system.

As specific setting data, set the position (X, Y, Z) of the origin and posture (W, P, R) of the calibration

coordinate system viewed from the world coordinate system of the reference robot.

Directly enter the values of the position and posture of the calibration coordinate system to set data.

Sample calibration data

Assume that two robots are installed as shown in the figure. The zero points of these robots are deviated

from each other by 3000 mm horizontally (X-axis direction). There is no deviation vertically (Z-axis

direction) or perpendicularly (Y-axis direction). The following shows calibration data when R1 is set as

the reference robot in this status:

Data to be set for R2 when R1 is set as the reference robot

(X, Y, Z, W, P, R) = (3000, 0, 0, 0, 0, 180)

Data set automatically for R1 when R1 is set as the reference robot

(X, Y, Z, W, P, R) = (0, 0, 0, 0, 0, 0)

-axis

1

-

2

-

1

-

1

-

2

Data to be set for R2 when R1 is set as the reference robot

(X, Y, Z, W, P, R) = (0, -1500, 0, 0, 0, 0)

Data set automatically for R1 when R1 is set as the reference robot

(X, Y, Z, W, P, R) = (0, 0, 0, 0, 0, 0)

X1 Axis

Y1 Axis

Y2 Axis

Calibration robot

X2 Axis

-

2

Reference robot

Calibration robot

16

Page 35

3 SETTINGS MAROBBI8204121E REV F

3.2.2 Setting Calibration Data

Set the position and posture between two robots.

To set calibration data, directly enter the numeric values indicating the position and posture of the world

coordinate system of a calibration robot viewed from a reference robot.

Calibration data is automatically set to (0,0,0,0,0,0) for the reference robot.

Procedure

1. Press the MENUS key to display the screen menu and select "SETUP".

2. Press the [TYPE] (F1) key and select "Interference".

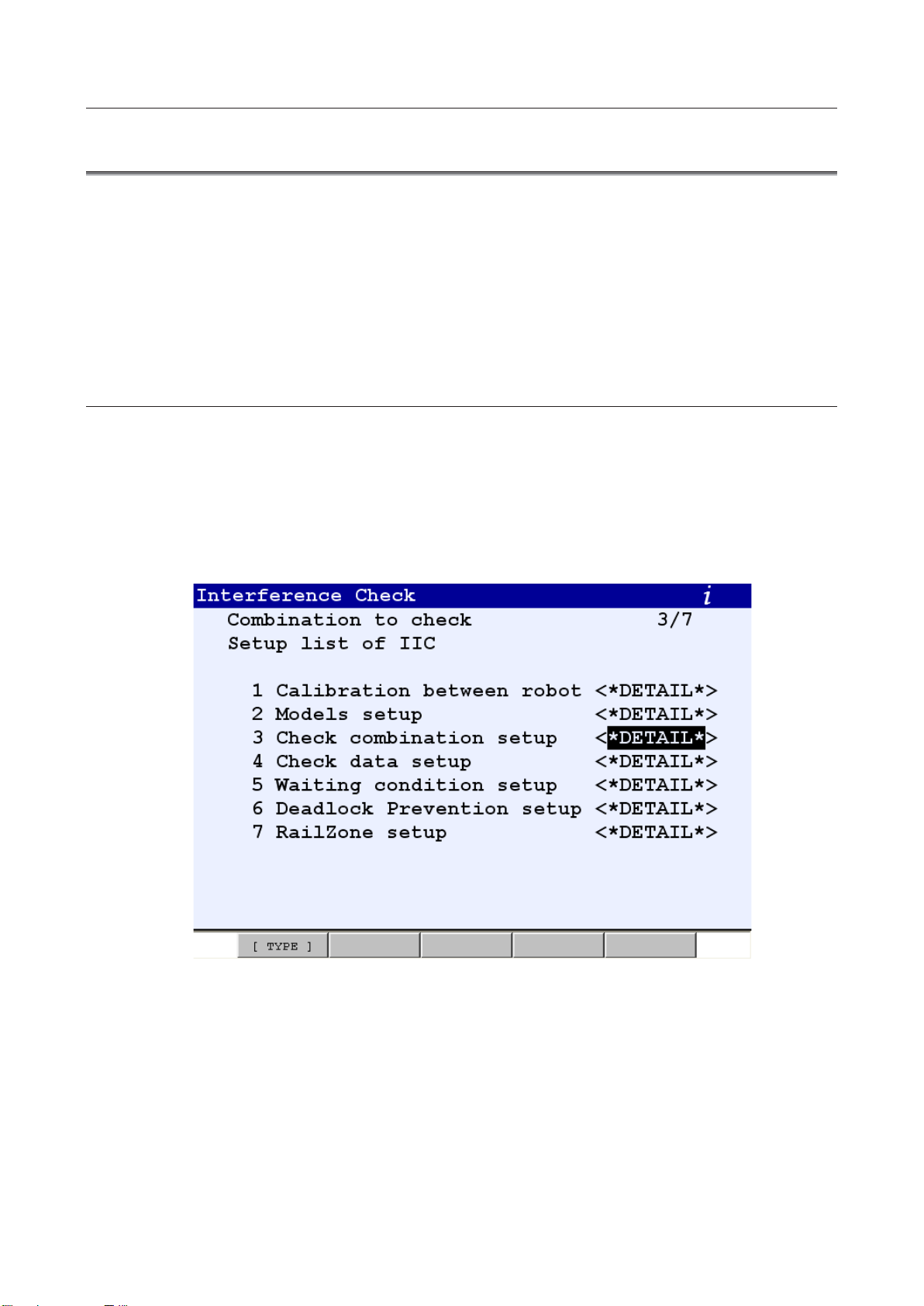

Menu for Intelligent Interference Check

Menu for Basic Interference Check

17

Page 36

MAROBBI8204121E REV F 3 SETTINGS

3. Position the cursor on "1 Calibration between robot <*DETAIL*>" and press the Enter key.

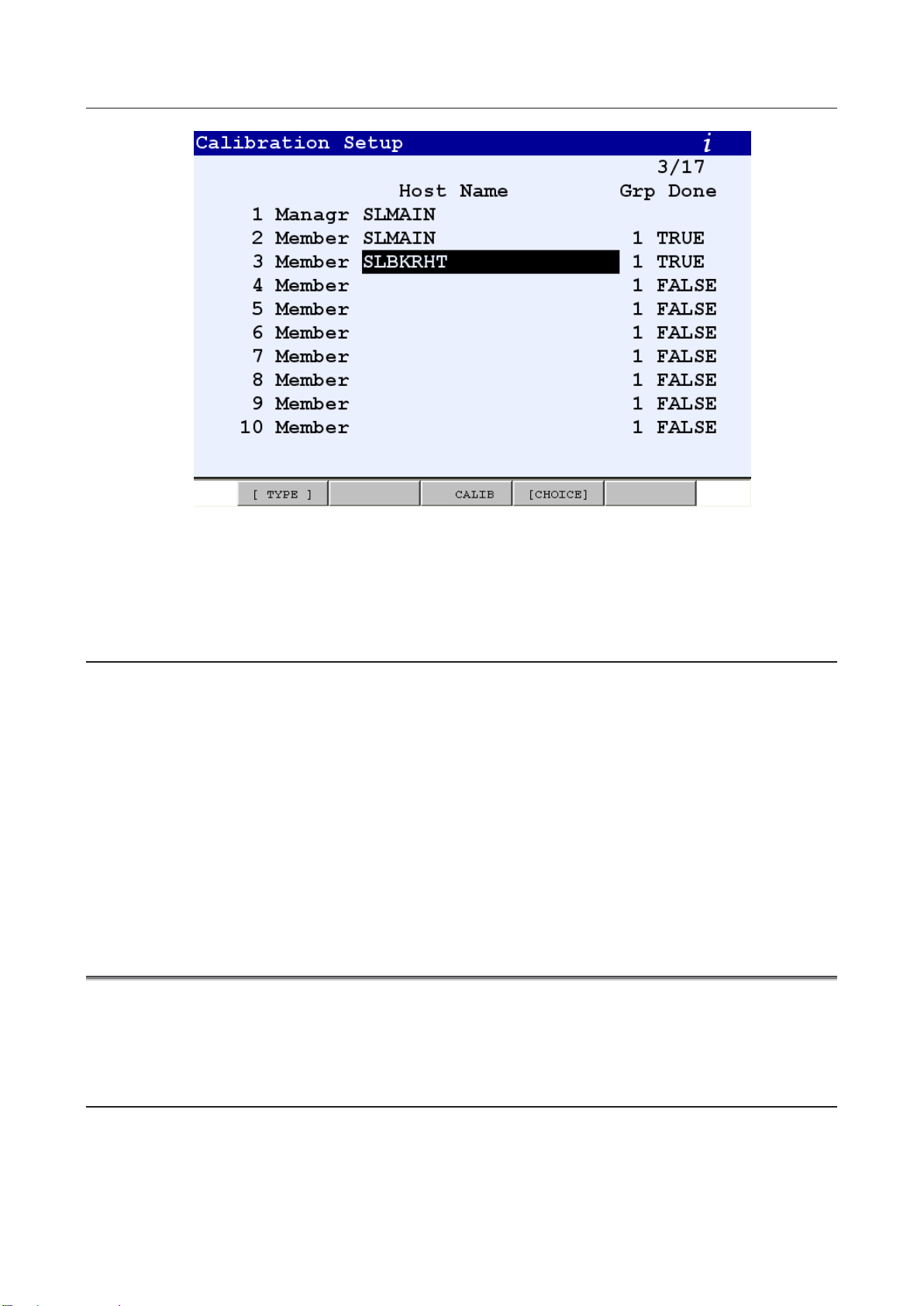

4. Position the cursor on the name of the robot for which calibration data is to be entered and for the

Manager Robot. (In this example, the cursor is positioned on Manager Host Name.

5. Press the [CHOICE] key. The screen changes as shown below:

18

Page 37

3 SETTINGS MAROBBI8204121E REV F

For the Manager Host Name the first name on the list should be chosen. Also use this host name for

the first Member robot. The robots are members of the ring of robots that can be calibrated for

Interference Check. The first Member robot is the reference robot for all robot calibration. The

Calibration data for all other robots will be that robot position in the reference robot world frame. In

this example the reference robot is Group 1 in the controller with host name SLMAIN.

Repeat selecting the host names for all robot groups that will be calibrated. Note that the first

Member host name, on line 2, must be the same as the Manager host name. When the first

member robot host name is entered the DONE field becomes TRUE because this robot is the

reference robot and does not need calibration data.

6. Cursor to the Group for the first Member robot and enter the group number for the reference robot.

In the example below Group 1 of the controller SLMAIN is the reference robot.

19

Page 38

MAROBBI8204121E REV F 3 SETTINGS

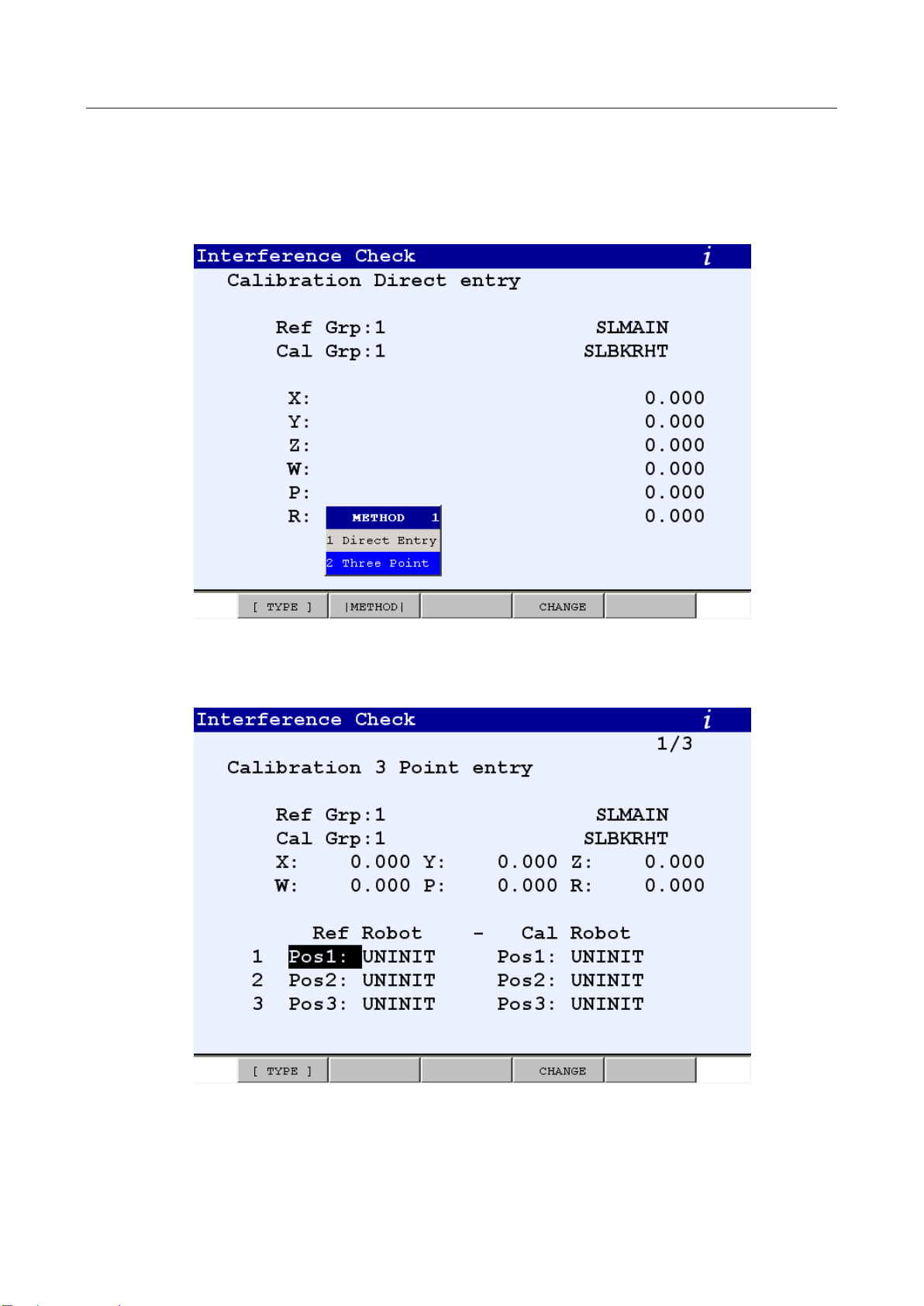

3.2.2.1 Direct input method

1. Set the group numbers associated with the other Members. Select the group number for the robot you

want to calibrate and press F3 (CALIB).

2. The following screen similar to the following will appear. Press F4 (CHANGE) to bring the screen

for direct entry of calibration parameters.

20

Page 39

3 SETTINGS MAROBBI8204121E REV F

3. After Press F4 (CHANGE) to allow direct entry of the calibration parameters. The screen changes to

one similar to that shown below:

4. Cursor to the value associated with each element, x, y, z, w, p, r and enter the appropriate value.