fanuc 15–MB Maintenance Manual

GE Fanuc Automation

Computer Numerical Control Products

Series 15 / 150 – Model B

Maintenance Manual

GFZ-62075E/04 May 1998

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1998 GE Fanuc Automation North America, Inc.

All Rights Reserved.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS RELATED TO CHECK OPERATION s–3. . . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS RELATED TO REPLACEMENT s–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. WARNINGS RELATED TO PARAMETERS s–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. WARNINGS AND NOTES RELATED TO DAIL Y MAINTENANCE s–7. . . . . . . . . . . . .

s–1

1

SAFETY PRECAUTIONS

B–62075E/04

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s–2

B–62075E/04

2

SAFETY PRECAUTIONS

WARNINGS RELATED TO CHECK OPERATION

WARNING

1.

When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2.

When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3.

Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4.

Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

mark). Never

s–3

SAFETY PRECAUTIONS

B–62075E/04

W ARNING

5.

Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

6.

When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

s–4

B–62075E/04

3

SAFETY PRECAUTIONS

WARNINGS RELATED TO REPLACEMENT

WARNING

1.

Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2.

When a heavy unit is to be replaced, the task must be undertaken by two persons. If the

replacement is attempted by only one person, the replacement unit could slip and fall, possibly

causing injury.

3.

After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4.

When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury .

s–5

4

SAFETY PRECAUTIONS

B–62075E/04

WARNINGS RELATED TO PARAMETERS

WARNING

1.

When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally , the machine may move unpredictably , possibly damaging the machine or workpiece,

and presenting a risk of injury.

2.

The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

s–6

B–62075E/04

5

SAFETY PRECAUTIONS

WARNINGS AND NOTES RELATED TO DAILY

MAINTENANCE

WARNING

1.

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory , because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CR T screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

s–7

SAFETY PRECAUTIONS

B–62075E/04

W ARNING

2.

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CR T screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

and

s–8

B–62075E/04

SAFETY PRECAUTIONS

W ARNING

3.

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–9

B–62075E/04

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. OPERATION OF MDI PANEL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 OPERATION OF MDI PANEL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Screen Transition Chart 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 DISPLAYING SYSTEM CONFIGURATIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Displaying Method 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Software Information 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Slot Information 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.4 Module Information 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 ALARM HISTORY DISPLAY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Display Method 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Alarm History Screen 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Display Format of History Data 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Restrictions 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 HELP FUNCTION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 General 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 DIAGNOSIS FUNCTION 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Displaying the Diagnosis Screen 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 Displaying the Status when it Appears that a Command is not being Executed 19. . . . . . . . . . . . .

1.6 NC STATUS DISPLAY 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 WAVEFORM DIAGNOSIS FUNCTION 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Display of Wave Diagnosis (Graph) Screen 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Setting the Waveform Diagnosis Parameters 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3 Starting or Terminating Data Sampling 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.4 Waveform Display 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.5 Editing a Displayed Waveform 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.6 Erasing a Displayed Waveform 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 OPERATING MONITOR SCREEN 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8.1 Display Method 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 INTERNAL POSITION COMPENSATION DATA DISPLAY FUNCTION 36. . . . . . . . . . . . . . . . . . .

1.9.1 Display Method 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9.2 Display Data 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 OPERATION HISTORY 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Display Method 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 Soft Key Operation 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Select DI/DO Screen 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Related Parameters 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11 OPERATION LIST 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 STRUCTURE 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 OUTLINE OF HARDWARE 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TOTAL CONNECTION 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

T ABLE OF CONTENTS

2.4 INTER–MACHINE CONNECTION 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 CRT/MDI Unit 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Reader/Puncher Interface 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Manual Pulse Generator 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 I/O Link 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Servo Interface 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 Connections by Type of Detectors 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.7 Combining Serial Spindle and Analog Spindle 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.8 Connection to α Serial Spindle Amplifier 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.9 Connection to Analog Spindle Amplifier 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.10 Remote Buffer Interface 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.11 High–speed DI Signal Interface 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.12 Environmental Requirement 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.13 Power Capacity 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.14 Action Against Noise 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 LIGHTING OF ALARM LEDS ON PCBS 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Configuration of the Power Supply Unit 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Configuration of the CPU Board (MAIN–B) 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Configuration of the Main CPU Board (MAIN–A) 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Configuration of the Upgraded Main CPU Board (MAIN–C) 104. . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Configuration of the High–speed Multiaxis Main CPU Board (MAX MAIN–A) 107. . . . . . . . . . .

2.5.6 Configuration of the Level Up Multiaxis Main CPU Board (MAX MAIN–C) 111. . . . . . . . . . . . .

2.5.7 Configuration of the PMC–NA Board 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.8 Configuration of the PMC–NA Board with or without the Conversational Function 118. . . . . . . .

2.5.9 Configuration of the PMC–NB Board with or without the Conversational Function 122. . . . . . . .

2.5.10 Configuration of the PMC–NB/NB2 Board with or without the Conversational Function 126. . . .

2.5.11 Configuration of the Axis CPU Board (ACPU) 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.12 Configuration of the Multiaxis Buffer Board 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.13 Configuration of the RISC Board 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.14 Configuration of the RISC Board 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.15 Configuration of the Sub–CPU Board (SUB–A) 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.16 Configuration of the Standard Multiaxis Sub–CPU Board (MAX SUB–B) 143. . . . . . . . . . . . . . .

2.5.17 Configuration of the Upgraded Sub–CPU Board (SUB–C) 146. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.18 Configuration of Additional Axis (ADAX) Board 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.19 Configuration of the Option 1 Board 152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.20 OSI Ethernet Board Configuration (10 Base 2) 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.21 OSI Ethernet Board Configuration (10 Base 5) 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.22 Alarm LED Display (Red) in the Event of an Error 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.23 Alarm LED (Red) Display in the Event of an Error Occurring

in the Connection Unit/Operator’s Panel Connection Unit 161. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 LIST OF THE PCBS AND UNITS 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Control Unit Rack 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Power Supply Unit 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Control Unit PCB 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Back Panel PCB 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.5 Module (For Main CPU Board) 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.6 Module (For PMC/Conversational Board) 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.7 Module (For Sub CPU Board, Additional Axis Board, or Axis CPU Board) 168. . . . . . . . . . . . . .

2.6.8 Module (For RISC Board) 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62075E/04

c–2

B–62075E/04

2.7 HOW TO REPLACE THE MODULES 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 HOW TO REPLACE THE BATTERIES 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 HOW TO REPLACE FAN MOTOR 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 FUSE REPLACEMENT IN POWER SUPPLY UNIT 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 MAINTENANCE OF HEAT PIPE TYPE HEAT EXCHANGER 182. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 ADJUSTING THE LIQUID–CRYSTAL DISPLAYS 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 REPLACING THE FUSES OF THE LIQUID–CRYSTAL DISPLAYS 187. . . . . . . . . . . . . . . . . . . . . .

2.14 REPLACING THE LCD BACKLIGHT 188. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 HOW TO REPLACE THE CRT DISPLAY 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16 HOW TO REPLACE THE MDI KEYBOARD 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.17 HOW TO REPLACE THE CARD CAGE IN THE CONTROL UNIT 191. . . . . . . . . . . . . . . . . . . . . . .

2.18 HANDLING MEMORY CARDS 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

2.6.9 Module (Option 1 Board) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.10 Module (OSI Ethernet Board) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.11 Display Unit 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.12 External Control Unit (Except I/O Unit) 173. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Removing 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Insertion 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Replace the Battery for Memory Back Up 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Replacing Batteries for Separate Absolute Pulse Coder 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.1 9.5″ LCD 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.2 10″ LCD 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.3 10″ PDP 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.4 9″ PDP 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13.1 9.5″ LCD, 10.4″ LCD (Graphic Function Built–in Type or for MMC–IV) 187. . . . . . . . . . . . . . . .

2.13.2 10″ LCD 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18.1 Overview 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18.2 Notes on Use 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18.3 Names and Functions of the Components 193. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18.4 Using Memory Cards 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18.5 Replacing the Battery 195. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. INPUT AND OUTPUT OF DATA 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SETTING THE P ARAMETERS REQUIRED FOR INPUT/OUTPUT 197. . . . . . . . . . . . . . . . . . . . . . .

3.2 DATA INPUT/OUTPUT 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Checking the Parameters Required for Data Input/Output 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Data Output 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.1 CNC parameter output 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.2 Outputting PMC parameter 208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.3 Pitch error compensation data output 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.4 Custom macro variable value output 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.5 T ool offset data output 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2.6 Part program output 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Data Input 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.1 CNC parameter input 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.2 Inputting CNC parameter 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.3 Inputting PMC data 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

T ABLE OF CONTENTS

3.2.3.4 Pitch error compensation data input 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.5 Custom macro variable value input 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.6 T ool offset data input 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3.7 Part program registration 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 15–MFB Data Input/Output 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4.1 Conversational data input/output 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4.2 Conversational data input 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4.3 Conversational data output 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62075E/04

4. INTERFACE BETWEEN NC AND PMC 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 GENERAL OF INTERFACE 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SPECIFICATION OF PMC 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Specification 226. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Address 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Built–in Debug Function 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 System Reserve Area in Internal Relay 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 Execution Period of PMC 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PMC SYSTEM CONFIGURATION 230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PMC SCREEN 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Display Method 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 PMCLAD Screen 233. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 PMCDGN Screen 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 PMCRAM Screen 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 SIGNAL AND SYMBOL CORRESPONDENCE TABLE 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. TROUBLESHOOTING 270. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 CORRECTIVE ACTION FOR FAILURES 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Investigating the Conditions under which Failure Occurred 271. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 POWER CANNOT BE TURNED ON 273. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED 276. . . . . . . .

5.4 JOG OPERATION CANNOT BE DONE 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 HANDLE OPERATION CANNOT BE DONE 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 AUTOMATIC OPERATION CANNOT BE DONE 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 CYCLE START LED SIGNAL HAS TURNED OFF 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 NOTHING IS DISPLAYED ON CRT 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 SR805 TO SR874 (RELATED TO READER/PUNCH INTERFACE) 298. . . . . . . . . . . . . . . . . . . . . . .

5.10 REFERENCE POSITION DEVIATES 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 PS200 (GRID SYNCHRONOUS IS F AILED) 311. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 ALARM OT32 (NEED ZRN (ABS PDR)) 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 ALARM SV101 (DATA ERROR (ABS PCDR)) 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 ALARM OT34 (BATTERY ZERO (ABS PCDR)) 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.15 ALARM SV110 (PULSE CODER ALARM1 (SERIAL)) 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.16 ALARM SV114 (ABNORMAL REV DATA) 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.17 ALARM SV115 (ABNORMAL COMMUNICATION (SERIAL PCDR)) 318. . . . . . . . . . . . . . . . . . . .

5.18 ALARM SV23 (SV OVER LOAD) 319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.19 ALARM 700 (OVERHEAT A T CONTROL SIDE) 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.20 ALARM OT117 (SPINDLE SPEED FLUCTUATION DETECTION ALARM) 322. . . . . . . . . . . . . . .

5.21 ALARM OT300 (SPINDLE SERIAL LINK CANNOT BE STARTED) 323. . . . . . . . . . . . . . . . . . . . . .

c–4

B–62075E/04

T ABLE OF CONTENTS

APPENDIX

A. MAINTENANCE PARTS 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 MAINTENANCE PARTS FOR THE FANUC Series 15–B 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. BOOT SYSTEM 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 OVERVIEW 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.1 Power–up Processing Sequence Display 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.2 Starting the Boot System 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.3 System File and User File 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1.4 Memory Cards for Use with the Boot System 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2 SCREEN CONFIGURATION AND OPERATING PROCEDURE 341. . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.1 SYSTEM DATA LOADING Screen 342. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.2 SYSTEM DATA CHECK Screen 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.3 SYSTEM DATA SAVE Screen 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.4 SRAM DATA BACKUP Screen 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.5 MEMORY CARD FORMAT Function 353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.2.6 LOAD BASIC SYSTEM 354. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 ERROR MESSAGES AND REQUIRED COUNTERMEASURES 355. . . . . . . . . . . . . . . . . . . . . . . . .

B.4 SYSTEM ALARMS AND REQUIRED COUNTERMEASURES 357. . . . . . . . . . . . . . . . . . . . . . . . . .

C. ERROR CODE TABLE 363. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 ALARM LIST (CNC) 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 ALARM LIST (PMC) 383. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 PMC ERRORS 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. WARNING MESSAGE LIST 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

B–62075E/04

PREFACE

PREFACE

Description of this

manual

This manual is organized as described below.

1. CRT/MDI display and operation

This chapter covers those items, displayed on the screen, that are

related to maintenance. A list of all supported operations is also

provided at the end of this chapter.

2. Hardware

This chapter covers hardware–related items, including the hardware

configuration, connection, and NC status indicated on printed circuit

boards. A list of all units is also provided as well as an explanation

of how to replace each unit.

3. Data input/output

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, aswell as the input/output

procedures for conversational data.

4. Interface between the NC and PMC

This chapter describes the PMC specifications, the system

configuration, and the signals used by the PMC.

5. Trouble shooting

This chapter describes the procedures to be followed in the event of

certain problems occurring, for example, if the power cannot be turned

on or if manual operation cannot be performed. Countermeasures to

be applied in the event of alarms being output are also described.

APPENDIX

The appendix consists of a list of all alarms, a list of maintenance

parts, and boot system.

This manual does not provide a parameter list. If necessary, refer to the

separate PARAMETER MANUAL (B–62560E) .

The maintenance of the servo unit, spindle motor, and amplifier is not

covered by this manual. For information related to the maintenance of

these units, refer to the relevant manuals.

This manual describes all optional functions. Refer to the manual

provided by the machine tool builder for details of any options with which

the installed machine tool is provided.

Depending on the model, some functions described in this manual may

not be available. For details, refer to the relevant descriptions.

p–1

PREFACE

15–M

15–TT

B–62075E/04

Applicable models

This manual can be used with the following models.

The abbreviated names may be used.

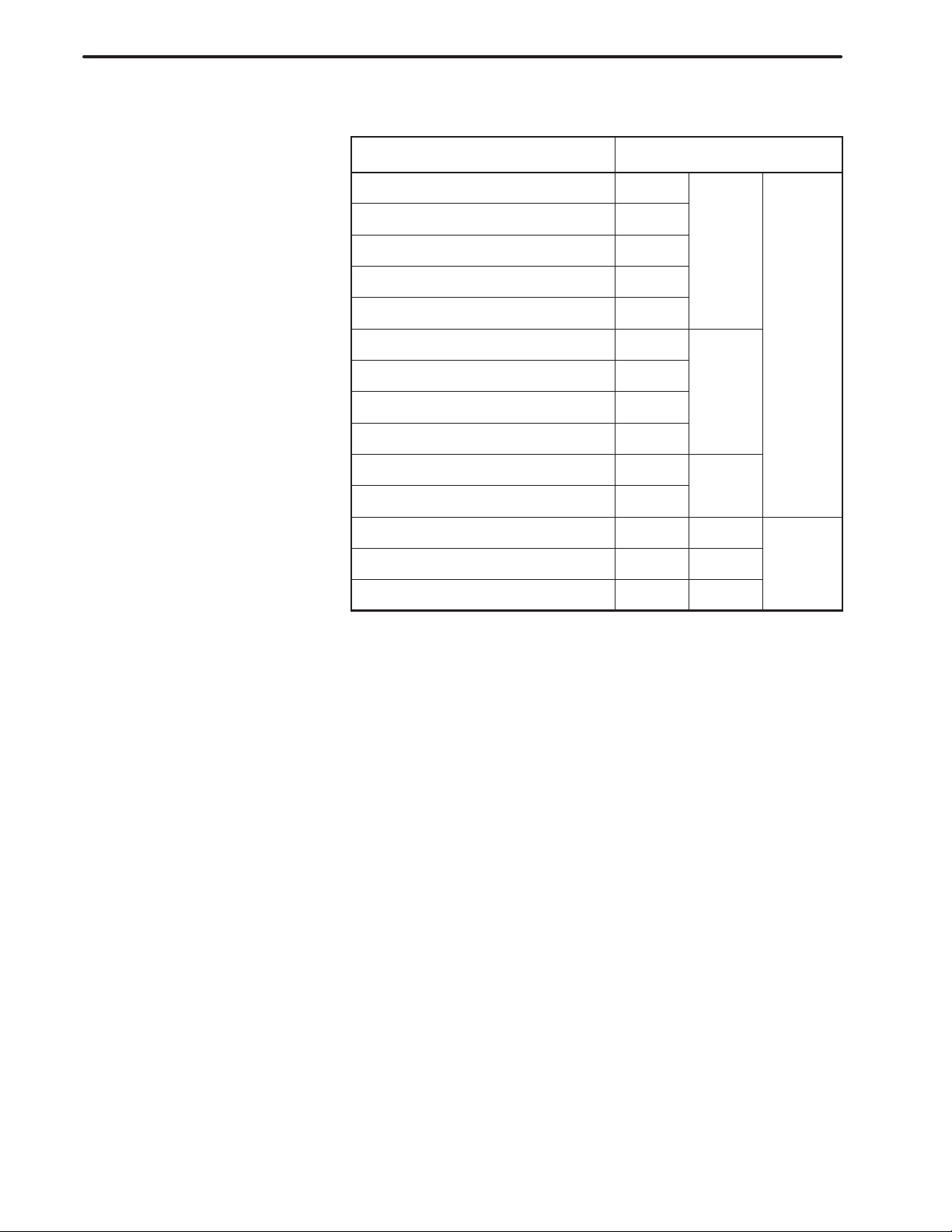

Product Name Abbreviations

FANUC Series 15–TB 15–TB

FANUC Series 15–TFB 15–TFB

FANUC Series 15TED–MODEL B–4 (*1) 15TED

FANUC Series 15TEE–MODEL B–4 (*1) 15TEE

FANUC Series 15TEF–MODEL B–4 (*1) 15TEF

FANUC Series 15–MB 15–MB

FANUC Series 15–MFB 15–MFB

FANUC Series 15MEK–MODEL B–4(*1) 15MEK

FANUC Series 15MEL–MODEL B–4 (*1) 15MEL

FANUC Series 15–TTB 15–TTB

FANUC Series 15–TTFB 15–TTFB

FANUC Series 150–TB 150–TB 150–T

15–T

–

Series 15

–

FANUC Series 150–TTB 150–TTB 150–TT

FANUC Series 150–MB 150–MB 150–M

Series 150

(*1)With 15TED, 15TEE, and 15TEF, some options are not available.

Moreover, the following PC boards cannot be used:

D Sub–CPU board

D RISC board

D OSI ethernet board

(*2)The MMC board can be used only with the Series 150.

p–2

B–62075E/04

Series of CNC

PREFACE

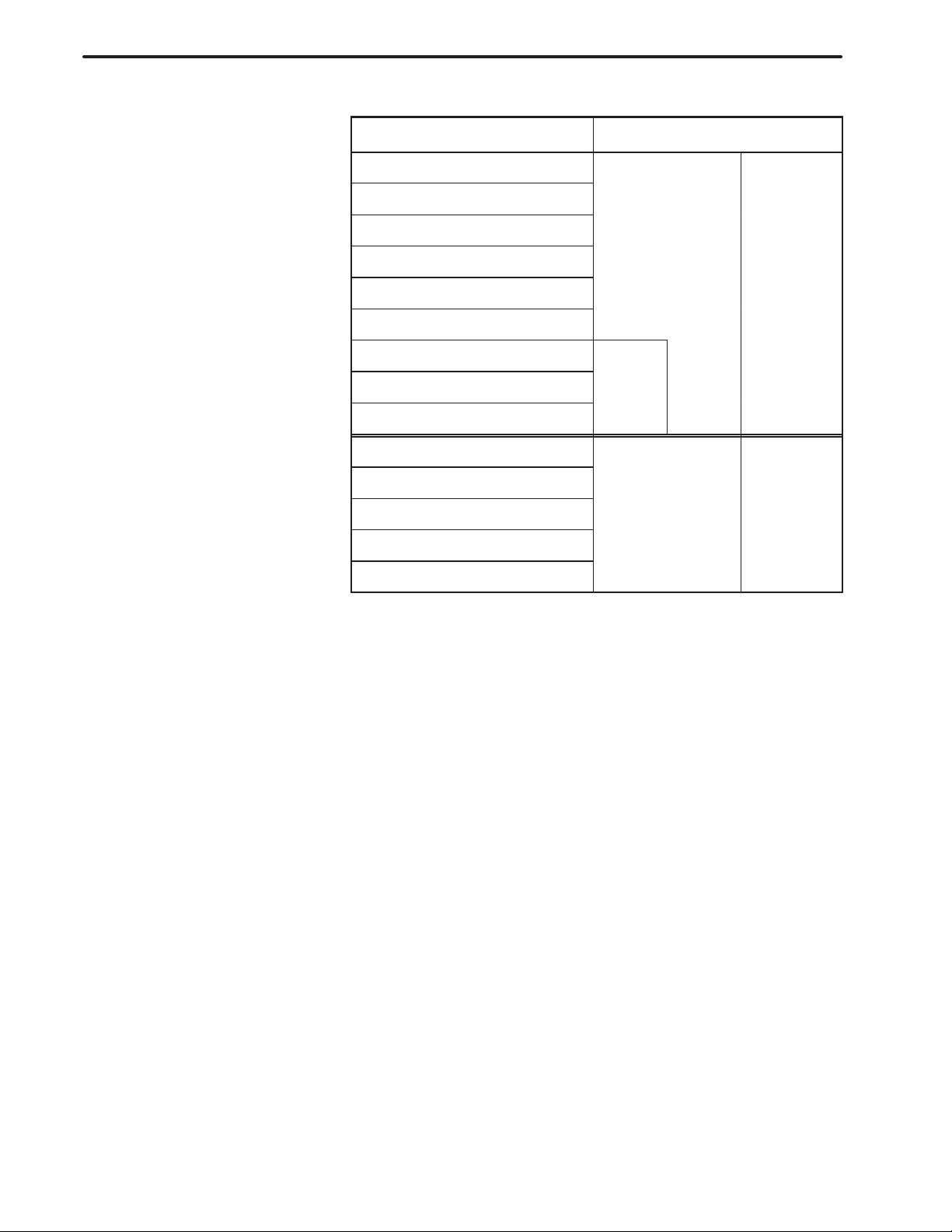

Product Name Series

FANUC Series 15–TB

FANUC Series 15–TFB

FANUC Series 15TED–MODEL B–4

FANUC Series 15TEE–MODEL B–4

FANUC Series 15TEF–MODEL B–4

FANUC Series 150–TB

FANUC Series 15–TTB

FANUC Series 15–TTFB

FANUC Series 150–TTB

FANUC Series 15–MB

FANUC Series 15–MFB

FANUC Series 15MEK–MODEL B–4

FANUC Series 15MEL–MODEL B–4

FANUC Series 150–MB

TT series

M series

T series For Lathe

For Machining

center

p–3

PREFACE

B–62075E/04

Manuals related to

Series 15/150–MODEL B

Manuals related to FANUC Series 15/150–MODEL B are as follows.

This manual is marked with an asterisk (*).

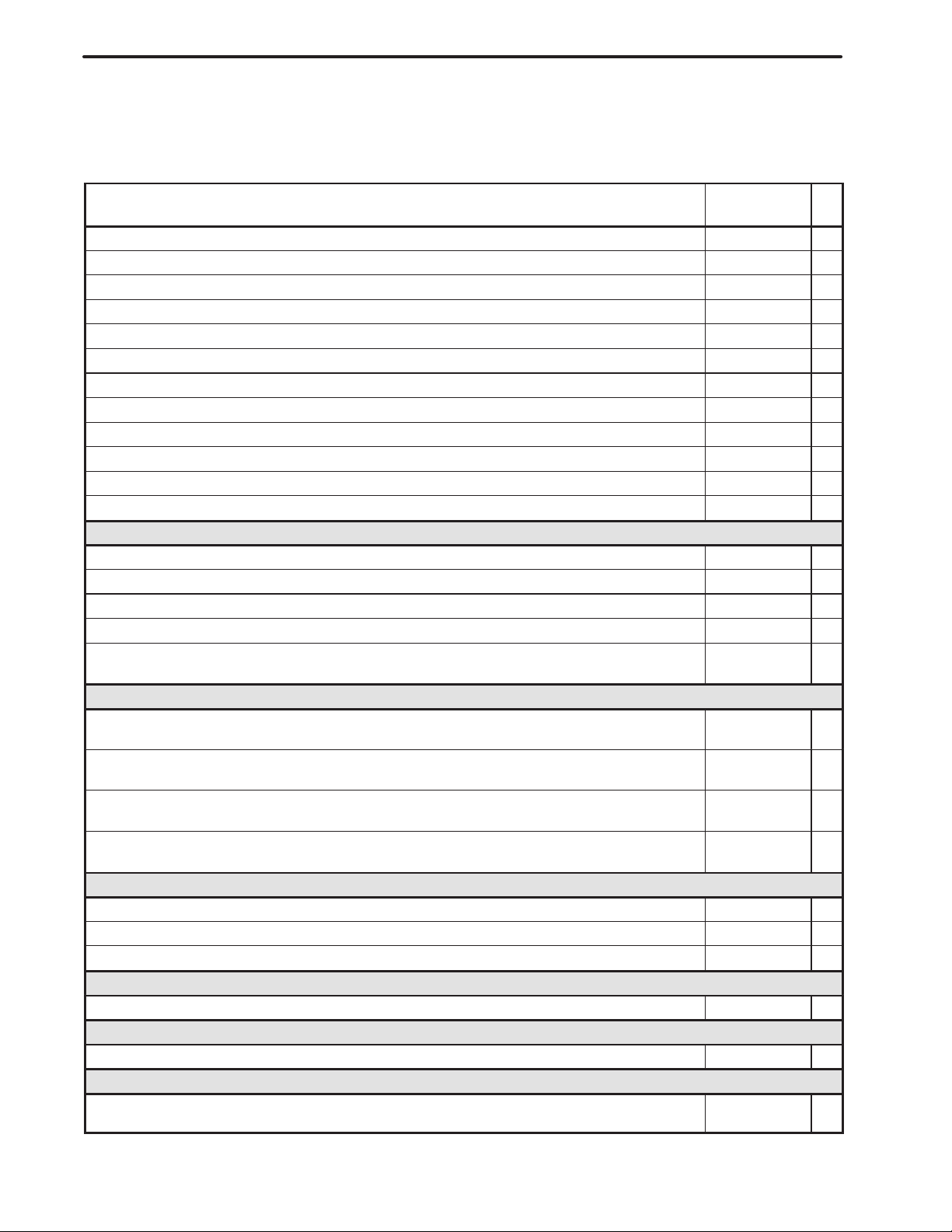

List of manuals related to Series 15/150–MODEL B

Manual Name

FANUC Series 15–TB/TFB/TTB/TTFB DESCRIPTIONS B–62072E

FANUC Series 15/150–MODEL B For Machining Center DESCRIPTIONS B–62082E

FANUC Series 15/150–MODEL B CONNECTION MANUAL B–62073E

FANUC Series 15/150–MODEL B CONNECTION MANUAL (BMI Interface) B–62073E–1

FANUC Series 15–MODEL B For Lathe OPERATOR’S MANUAL (Programming) B–62554E

FANUC Series 15–MODEL B For Lathe OPERATOR’S MANUAL (Operation) B–62554E–1

FANUC Series 15/150–MODEL B For Machining Center OPERATOR’S MANUAL (Programming) B–62564E

FANUC Series 15/150–MODEL B For Machining Center OPERATOR’S MANUAL (Operation) B–62564E–1

FANUC Series 15/150–MODEL B PARAMETER MANUAL B–62560E

FANUC Series 15/150–MODEL B MAINTENANCE MANUAL B–62075E *

FANUC Series 15–MODEL B DESCRIPTIONS (Supplement for Remote Buffer) B–62072E–1

FANUC Series 15–MODEL B PROGRAMMING MANUAL (Macro Compiler / Macro Executer) B–62073E–2

PMC

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (Ladder Language) B–61013E

FANUC PMC–MODEL NB/NB2 PROGRAMMING MANUAL (Ladder Language) B–61863E

FANUC PMC–MODEL N/NA PROGRAMMING MANUAL (C Language) B–61013E–2

FANUC PMC–MODEL NB PROGRAMMING MANUAL (C Language) B–61863E–1

FANUC PMC–MODEL N/NA

PROGRAMMING MANUAL (C Language – Tool Management Library)

Conversational Automatic Programming Function

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) PROGRAMMING MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR MACHINING CENTER

(Series 15–MF/MFB) OPERATOR’S MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION FOR LATHE

(Series 15–TF/TTF/TFB/TTFB) OPERATOR’S MANUAL

CONVERSATIONAL AUTOMATIC PROGRAMMING FUNCTION II FOR LATHE

(Series 15–TFB/TTFB) OPERATOR’S MANUAL

Tracing / Digitizing

FANUC Series 15–MB DESCRIPTIONS (Supplement for Tracing / Digitizing) B–62472E

FANUC Series 15–MB CONNECTION MANUAL (Supplement for Tracing / Digitizing) B–62473E

FANUC Series 15–MB OPERATOR’S MANUAL (Supplement for Tracing / Digitizing) B–62474E

Gas, Laser Plasma Cutting Machine

FANUC Series 15–MB DESCRIPTIONS (FOR GAS, LASER PLASMA CUTTING MACHINE) B–62082EN–1

Multi–T eaching Function

FANUC Series 15–MB CONNECTION MANUAL (Multi–Teaching Function) B–62083E–1

Multiple–axis and Multiple–path Control Function

FANUC Series 15–TTB OPERATOR’S MANUAL

(Supplement Explanations for Multiple–axis and Multiple–path Control Function)

Specification

Number

B–61013E–4

B–61263E

B–61264E

B–61234E

B–61804E–2

B–62074E–1

p–4

B–62075E/04

1

1. OPERATION OF MDI PANEL

OPERATION OF MDI PANEL

This chapter describes how to display and operate each screen, and so

forth.

1.1 OPERATION OF MDI PANEL 2. . . . . . . . . . . . . . . . . . . . . .

1.2 DISPLAYING SYSTEM CONFIGURATIONS 9. . . . . . . . .

1.3 ALARM HISTORY DISPLAY 13. . . . . . . . . . . . . . . . . . . . .

1.4 HELP FUNCTION 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 DIAGNOSIS FUNCTION 19. . . . . . . . . . . . . . . . . . . . . . . . .

1.6 NC STATUS DISPLAY 28. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 WAVEFORM DIAGNOSIS FUNCTION 30. . . . . . . . . . . . .

1.8 OPERATING MONITOR SCREEN 35. . . . . . . . . . . . . . . . .

1.9 INTERNAL POSITION COMPENSATION DATA

DISPLAY FUNCTION 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 OPERATION HISTORY 41. . . . . . . . . . . . . . . . . . . . . . . . . .

1.11 OPERATION LIST 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1. OPERATION OF MDI PANEL

1.1

OPERATION OF MDI

PANEL

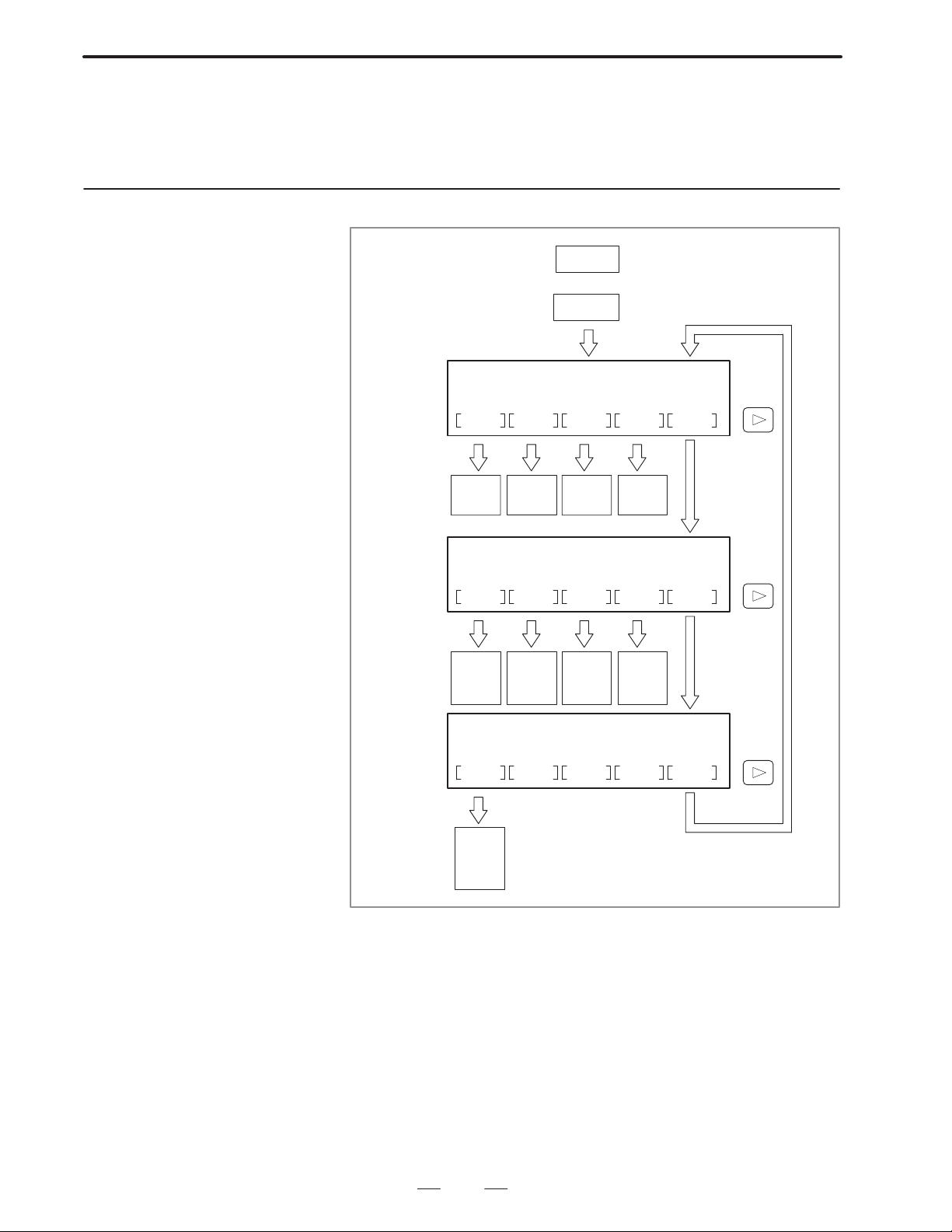

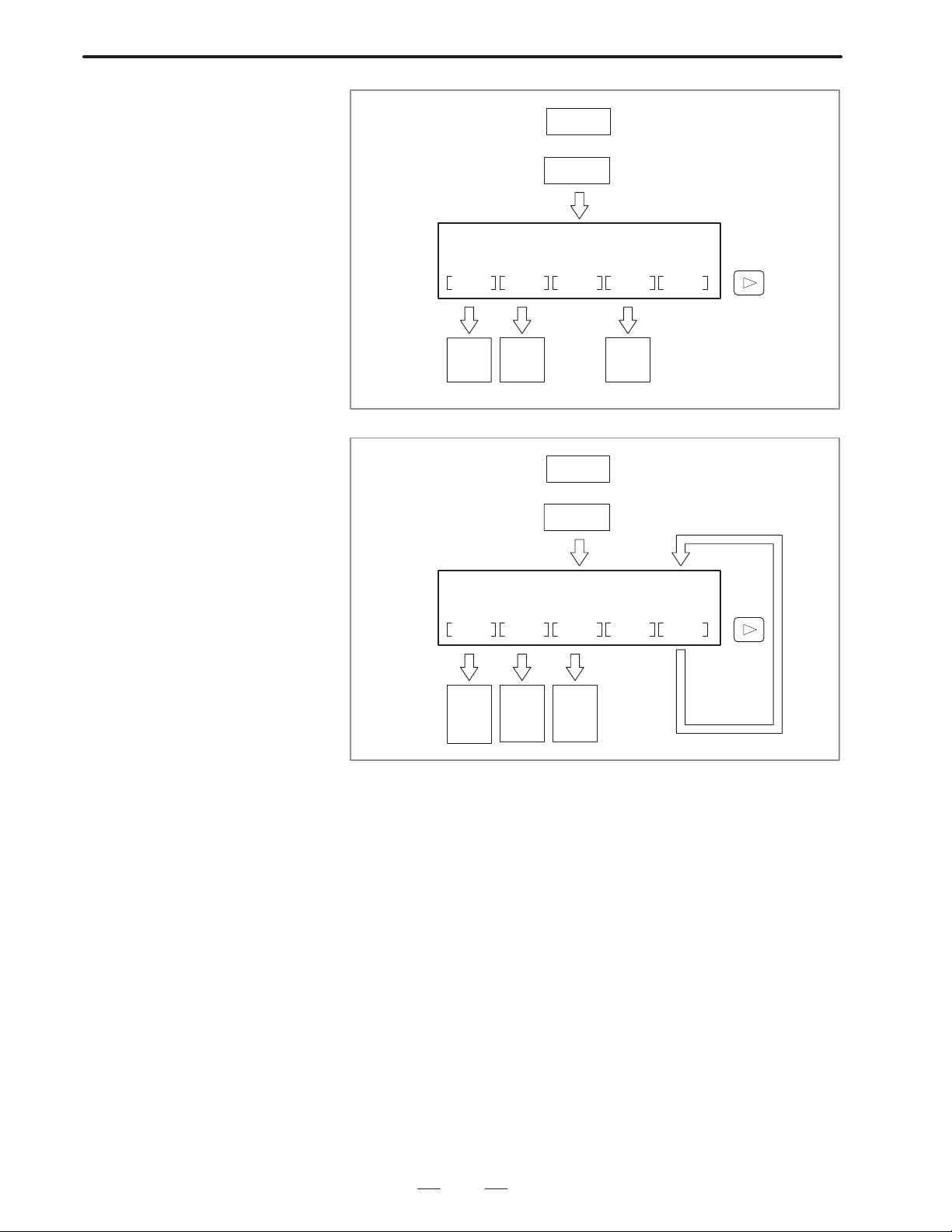

1.1.1

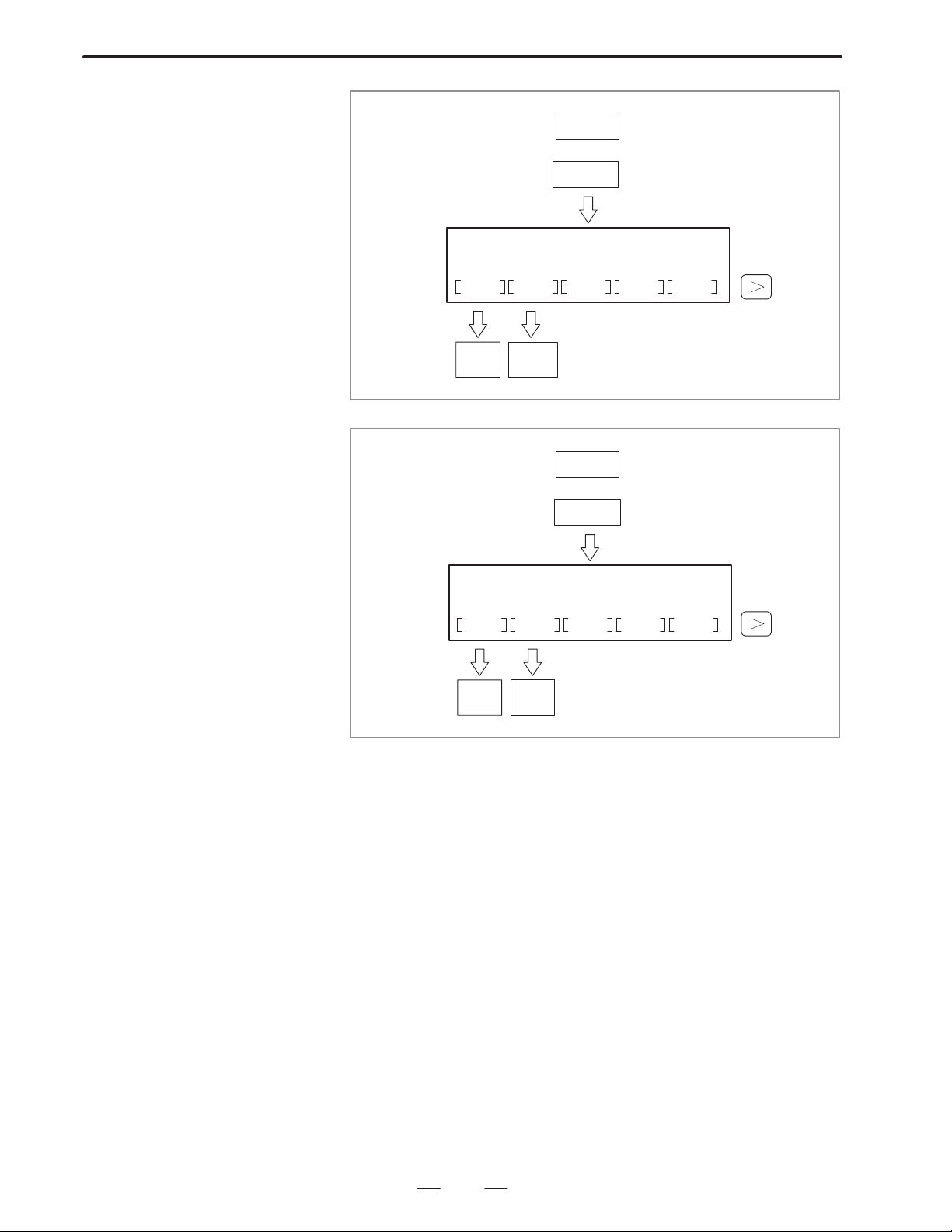

Screen Transition Chart

Screens included in

POSITION

POSITION

ACTUAL POSITION (ALL POSITION)

OVERALL RELATIVE ABSOLUT MACHINE CHAPTER

B–62075E/04

ACTUAL

POSITION

(ALL)

ACTUAL

POSITON

(RELATINVE)

ACTUAL

POSITION

(ABSOLUTE)

ACTUAL

POSITON

(MACHINE)

ACTUAL POSITION (ALL POSITION)

MANUAL

SHIFT

ACTUAL

POSITON

(MANUAL

INTERRUPTION VALUE)

RESTART P.RSTRT TL_HEAD CHAPTER

ACTUAL

POSITION

(BLOCK

RESTART)

ACTUAL

POSITION

(PROGRAM RESTART)

ACTURAL

POSITION

(TOOL

NOSE)

ACTUAL POSITION (ALL POSITION)

HDL_PLS CHAPTER

ACTUAL

POSITION

(MANUAL

INTERRUPTION PULSE

VALUE)

2

B–62075E/04

1. OPERATION OF MDI PANEL

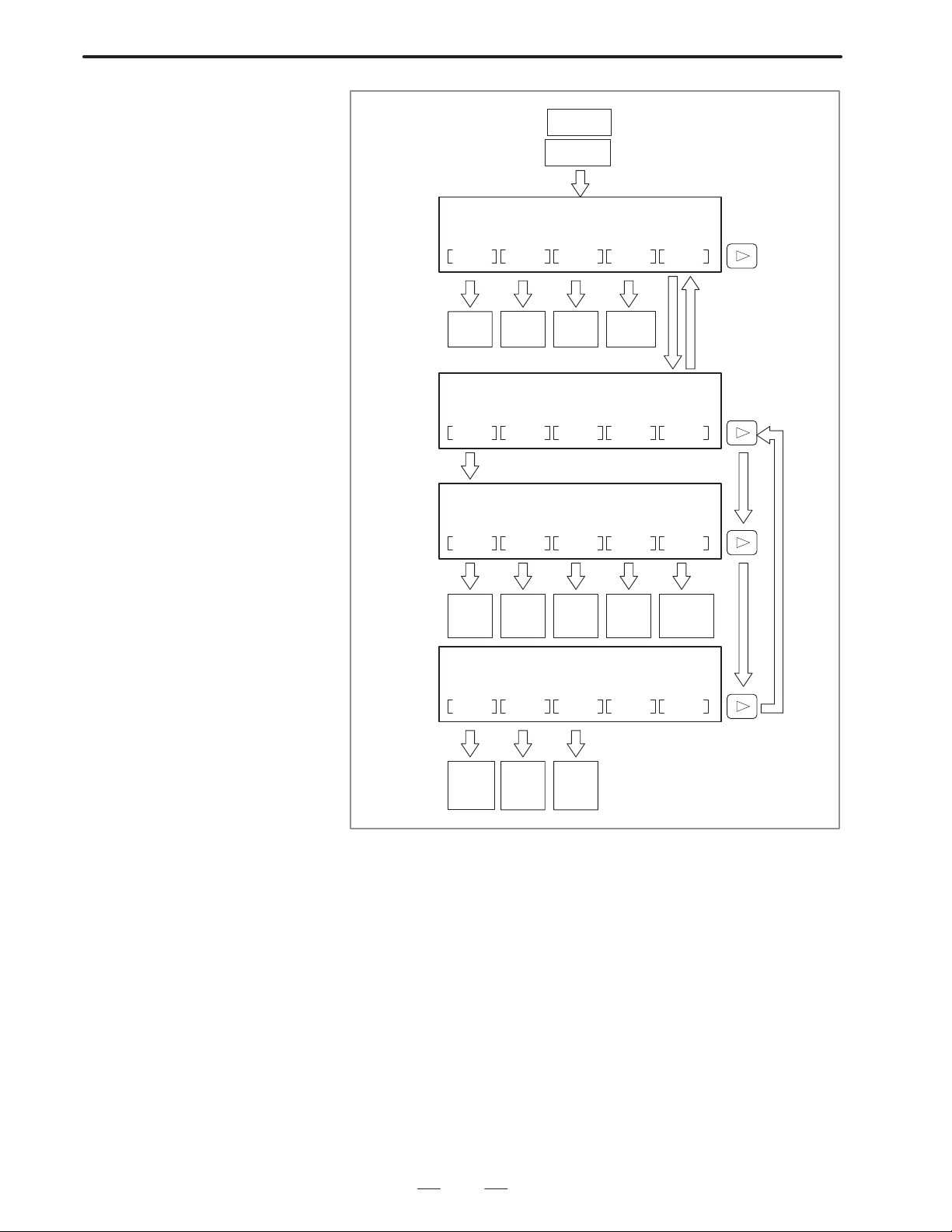

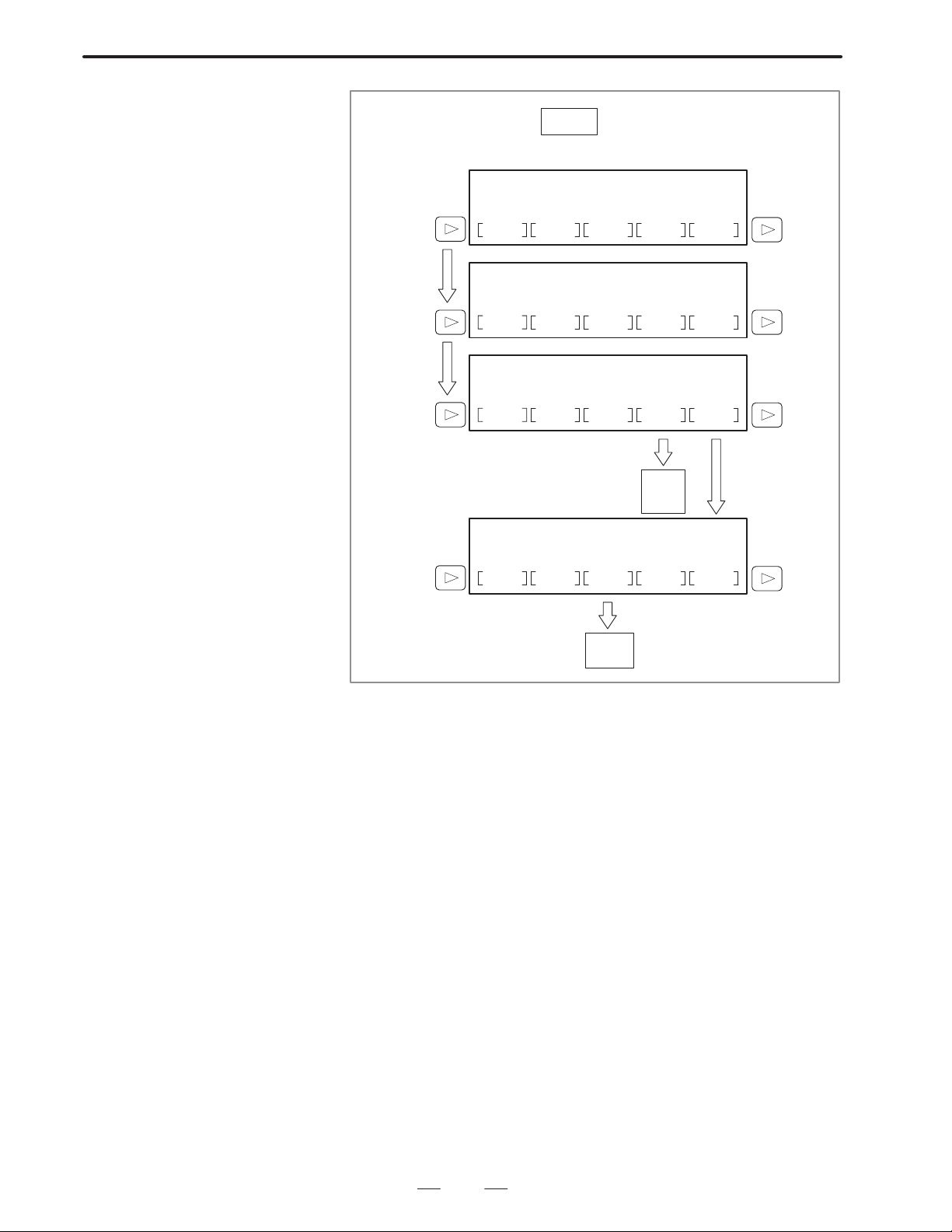

Screens included in

PROGRAM

PROGRAM

PROGRAM SCREEN

TEXT DIR_MEM DIR_FLP CHPTER

CONTENTS

OF PROGRAM

PROGRAM DIRECTRY

SCREEN

FILE

DIRECTRY

Screens included in

OFFSET

OFFSET

OFFSET SCREEN

TOOL WRK.ZER TLC_OFS CHAPTER

TOOL

OFFSET

VALUE

SCREEN

WORK

ORIGIN

OFFSET

VALUE

SCREEN

TOOL

LENTH

MEASUEMENT

CSREEN

3

1. OPERATION OF MDI PANEL

B–62075E/04

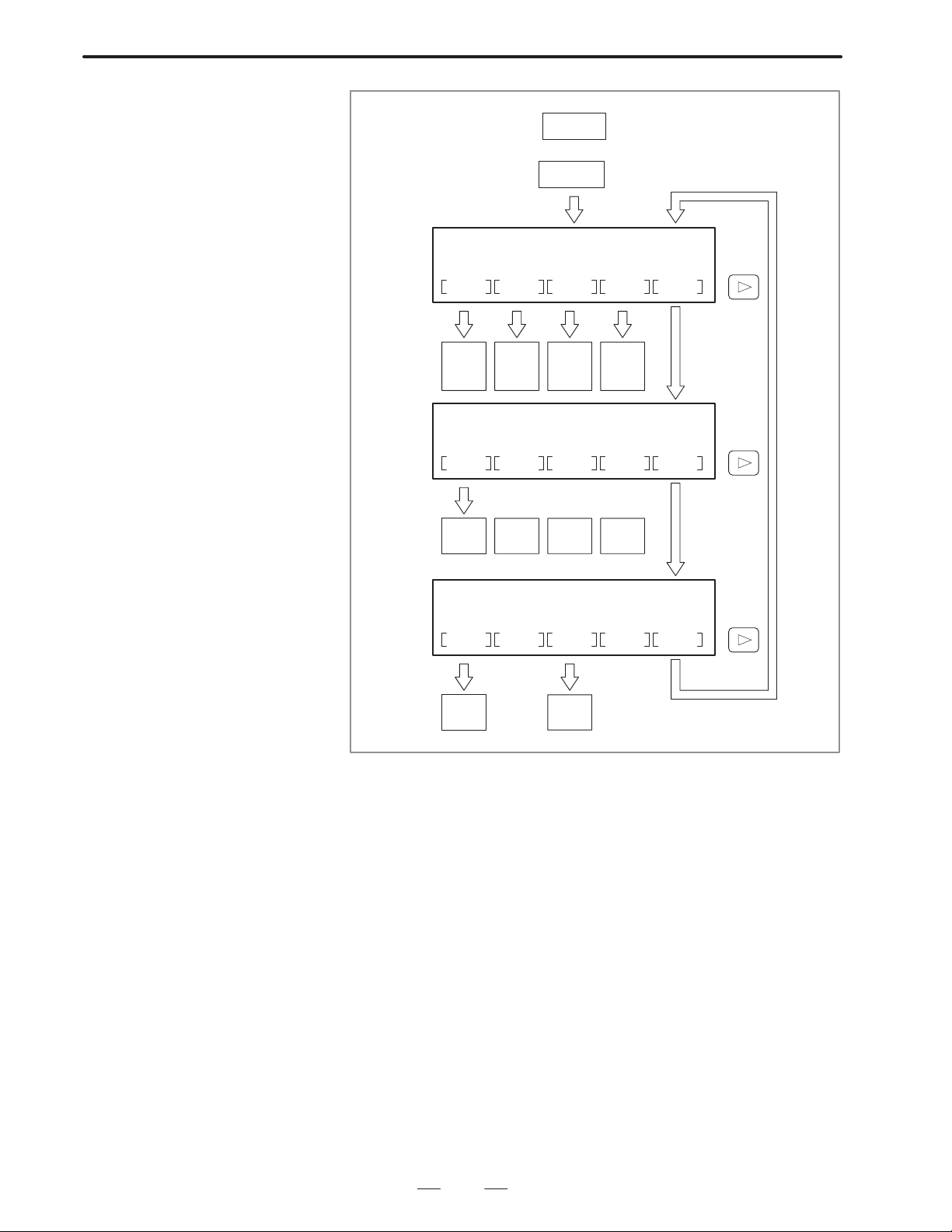

Screens included in

PRG_CHK

PRG_CHK

COMMAND SCREEN

CHECK LAST ACTIVE

PROGRAM

CHECK

SCREEN

PROGRAM

(LAST

BLOCK)

PROGRAM

(CURRENT

BLOCK)

OPE.MNTR

OPERATING

MONITOR

SCREEN

CHAPTER

COMMAND SCREEN

POS_DAT CHAPTER

INTERNAL POSITION COMPENSATION DATA DISPLAY

CUT_CMP TLC_OFS

CAN_CYL ROTATON 3DM_CNV

CUTTER

COMPENSATION

SCREEN

TOOL

LENGTH

COMPENSATION

SCREEN

CANNED

CYCLE

SCREEN

COORDINATE SYSTEM ROTATION

SCREEN

3–DIMENSIONAL COORDINATE SYSTEM

ROTATION

SCREEN

INTERNAL POSITION COMPENSATION DATA DISPLAY

PRG_MRR SCALING 3DM_OFS

PROGRAM

MIRROR

SCREEN

SCALLING

SCREEN

3–DIMENSIONAL

TOOL

OFFSET

SCREEN

CHPTER

4

B–62075E/04

1. OPERATION OF MDI PANEL

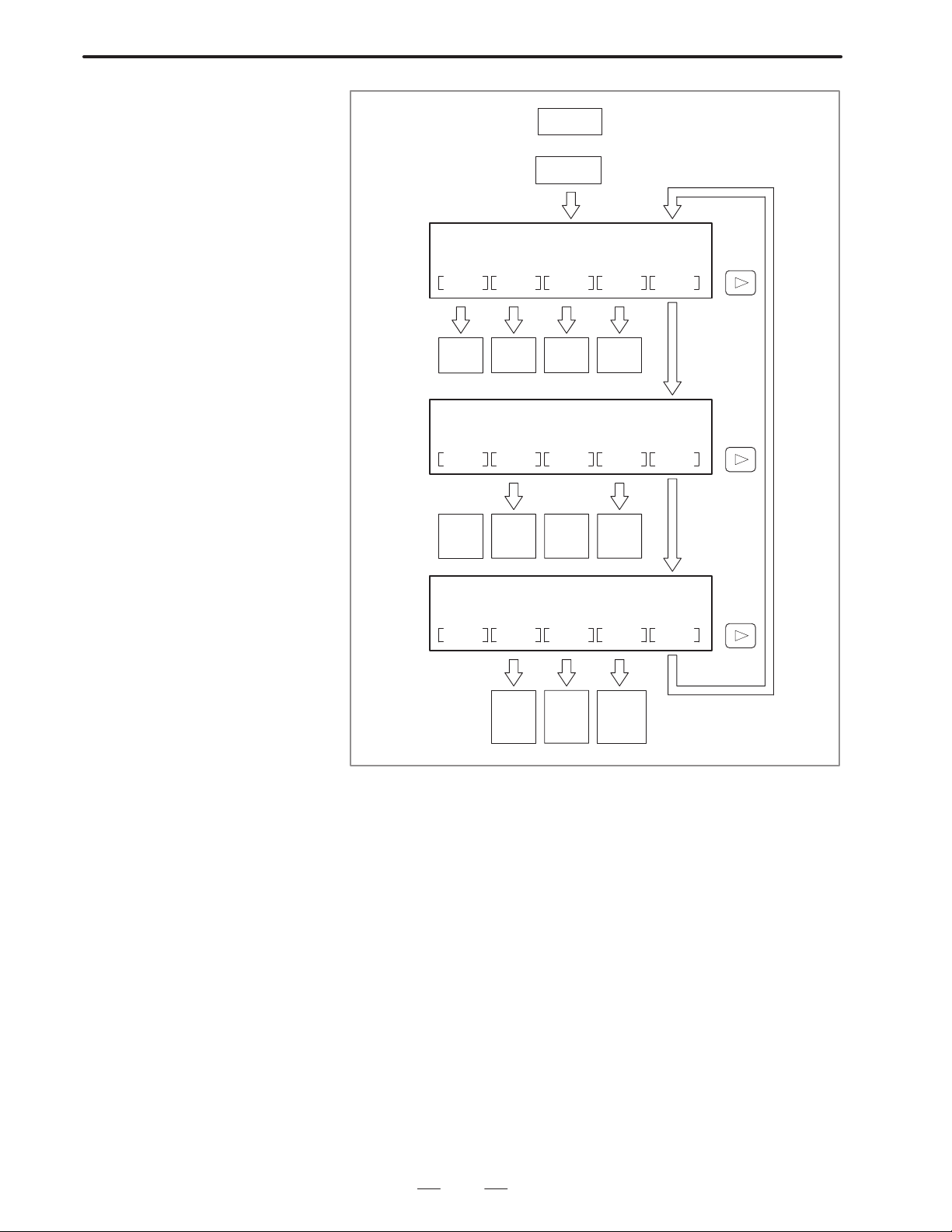

Screens indluded in

SETTING

SETTING

SETTING SCREEN

HANDY GENERAL OP .PANEL MACRO CHAPTER

SETTING

(INPUT/

OUTPU)

SETTING

(GENERAL)

SETTING

(OPERATOR’S

PANEL)

SETTING

(MACRO

VARIABLE)

SETTING SCREEN

TL.LIFE CHAPTER

TOOL LIFE

MANAGEMENT

SETTING SCREEN

TIMER RS232C CHAPTER

SETTING

(TIMER)

SETTING

RS–232–C

5

1. OPERATION OF MDI PANEL

B–62075E/04

Screens included in

SERVICE

SERVICE

SERVICE SCREEN

PARAM PITCH DIAGNOS DSP.MEM CHAPTER

PARAMETER

SCRREN

PITCH

ERROR

SCREEN

DIAGNOSIS

SCREEN

MEMORY

DISPLAY

SERVICE SCREEN

SYSTEM WAV– CHAPTER

SYSTEM

STRUCTURE

SCREEN

WAVEFORM

DIAGNOSIS

SCREEN

SERVICE SCREEN

SERVO SPINDLE HPCC CHAPTER

SERVO

SETTING

AND ADJUSTING

SCREEN

SPINDLE

SETTING

AND ADJUSTING

SCREEN

HIGH–

SPEED AND

HIGH–PRECISION MACHINING

6

B–62075E/04

1. OPERATION OF MDI PANEL

Screens included in

MESSAGE SCREEN

ALARM

OPERATOR

ALARM

SCREEN

OPERATOR

MESSAGE

SCREEN

Screens included in

MESSAGE

MESSAGE

CHAPTER

GRAPHIC

GRAPHIC

GRAPHIC SCREEN

GRAPH P ARAM CHAPTER

GRAPHIC

DISPLAY

GRAPHIC

PARAMETER

7

1. OPERATION OF MDI PANEL

B–62075E/04

Screens included in

POSITION PROGRAM OFFSET PRG_CHK

SETTING SERVICE MESSAGE GRAPHIC

HISTORY

CHAPTER

CHAPTER

HISTORY CHAPTER

OPERATION HISTORY

SCREEN

ALM_HIS CHAPTER

ALARM

HISTORY

SCREEN

8

B–62075E/04

1. OPERATION OF MDI PANEL

1.2

DISPLAYING SYSTEM CONFIGURA TIONS

1.2.1

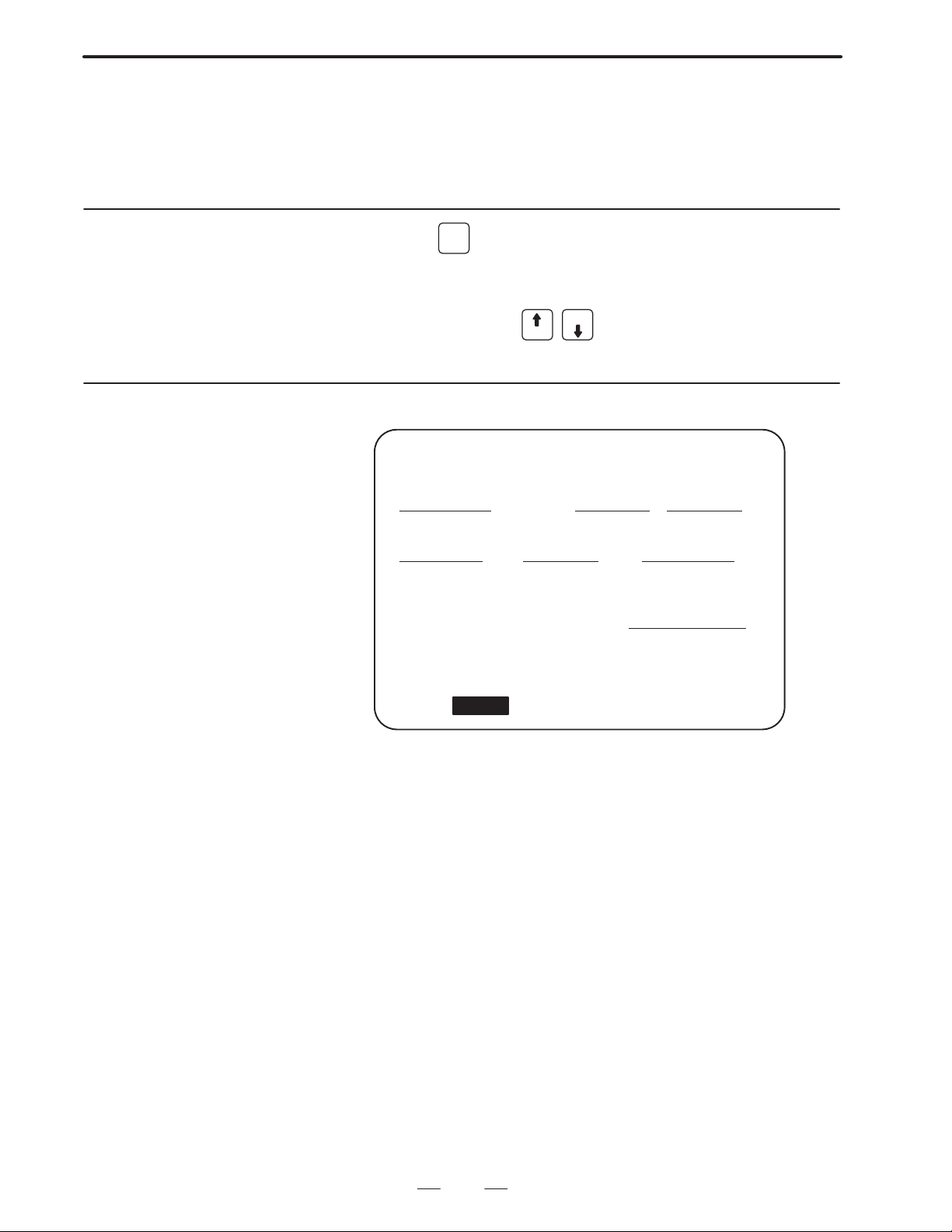

Displaying Method

1.2.2

Software Information

The software and hardware configuration of the CNC unit can be

displayed on the CRT display. This feature allows you to easily obtain

hardware or software information necessary, for example, when

maintaining the CNC.

(1)Press the

SERVICE

key or [SER VICE] soft key to display screens such as

parameter screens.

(2)Press the [SYSTEM] soft key.

(3)Press the page keys (

SYSTEM CONFIG (SOFTWARE) O1234 N12345

CNC SYSTEM ID : SERIES / EDITION

F15M9A (1)

ASSEMBLY EDITION DRAM SIZE

BASIC (4)

OPTION A1 0001

OPTION A2 0001

OPTION A3 0001 MACHINE NAME

OPTION A4 –––– ABCDEFGHIJ (7)

BASIC (SUB) 0001

OPTION S1 ––––

: AAB1 (2) 0001 (3)

PAGE

PAGE

0001 (5) 8MBYTE (6)

) to switch the screen.

MEM *** STOP **** *** *** 01 : 23 : 45 LSK

SYSTEM CHAPTER+

(1)CNC system ID

(2)CNC control software series

(3)CNC control software general edition

(4)Assemblies providing CNC control software

(5)Edition of each assembly

(A dash indicates that the assembly is not used.)

(6)DRAM size of CNC

(7)Machine name

(displayed only when set in parameter No.2390 to 2399)

9

1. OPERATION OF MDI PANEL

SYSTEM CONFIG (SOFTWARE) O1234 N12345

SOFTWARE KIND : SERIES / EDITION

HELP MESSAGE (1)

SYSTEM BOOT : 6014 / 0005

DIGITAL SERVO : 9060 / 0005

SERIAL SPDL #1 : 9A20 / 0008

SERIAL SPDL #2 : 9A20 / 0008

PMC – NA : 4046 / 0005

GRAPHIC : 6001 / 0003

RMT BUF / DNC1 : 609A / 0004

MEM *** STOP **** *** *** 01 : 23 : 45 LSK

SYSTEM CHAPTER+

: AH00 (2) / 0001 (3)

(1)Software type

(2)Software series

(3)Software edition

B–62075E/04

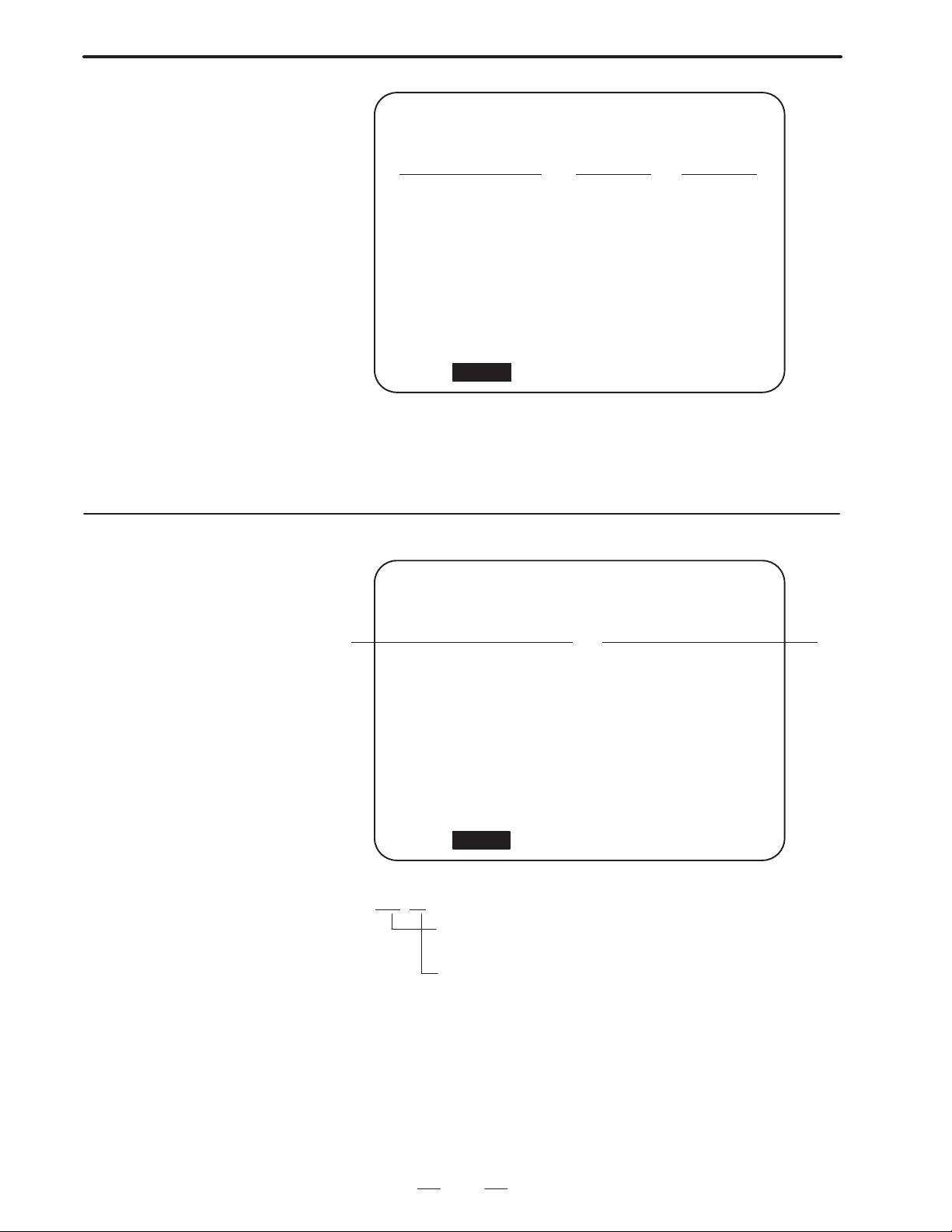

1.2.3

Slot Information

SYSTEM CONFIG (SLOT) O1234 N12345

SLOT KIND ID SER./VER.

(1) 00:0 CNC CPU BOARD (2)

02:1 PMC CPU BOARD 2077:3D 4046/0005

03:3 CNC SUB CPU BOARD F163:3A AAB1/0001

04:4 GRAPHIC 0145:40 600I/0003

84:6 REMOTE BUFFER 013F:3C 609A/0004

MEM *** STOP **** *** *** 01 : 23 : 45 LSK

SYSTEM CHAPTER+

(3)1262:37 AAB1/0001 (4)

(1)Slot number

XX

: X

Physical slot number of FBUS00 to 0F

(primary slots on the front)

Logical slot number (slot number, logically assigned by

CNC control software immediately

after power–on)

(2)Type of printed–circuit board

10

Loading...

Loading...