fanuc 150i Maintenance Manual

GE Fanuc Automation

Computer Numerical Control Products

Series 15i / 150i―Model A

Maintenance Manual

GFZ-63325EN/03 November 2000

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved.

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS RELATED TO CHECK OPERATION s–3. . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS RELATED TO REPLACEMENT s–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. WARNINGS RELATED TO PARAMETERS s–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE s–7. . . . . . . . . . . .

s–1

1

SAFETY PRECAUTIONS

B–63325EN/03

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–2

B–63325EN/03

2

SAFETY PRECAUTIONS

W ARNINGS RELA TED TO CHECK OPERATION

WARNING

1. When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2. When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3. Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

mark). Never

s–3

SAFETY PRECAUTIONS

B–63325EN/03

WARNING

5. Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

6. When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

s–4

B–63325EN/03

3

SAFETY PRECAUTIONS

W ARNINGS RELATED TO REPLACEMENT

WARNING

1. Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2. When a heavy unit is to be replaced, the task must be undertaken by two persons or more. If

the replacement is attempted by only one person, the replacement unit could slip and fall,

possibly causing injury.

3. After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4. When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury.

s–5

4

SAFETY PRECAUTIONS

B–63325EN/03

W ARNINGS RELATED TO PARAMETERS

WARNING

1. When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally, the machine may move unpredictably, possibly damaging the machine or workpiece,

and presenting a risk of injury.

2. The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

s–6

B–63325EN/03

5

1. Memory backup battery replacement

SAFETY PRECAUTIONS

W ARNINGS AND NOTES RELATED TO DAILY

MAINTENANCE

WARNING

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.10 of this manual.

s–7

SAFETY PRECAUTIONS

B–63325EN/03

WARNING

2. Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

and

s–8

B–63325EN/03

3. Fuse replacement

SAFETY PRECAUTIONS

WARNING

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–9

B–63325EN/03

PREFACE

PREFACE

Description of

this manual

1.Display and operation

This chapter covers those items, displayed on the screen, that are related

to maintenance. A list of all supported operations is also provided at the

end of this chapter.

2.Hardware

This chapter covers hardware–related items, including the hardware

configuration, connection, and NC status indicated on printed circuit

boards. A list of all units is also provided as well as an explanation of how

to replace each unit.

3.Data input/output

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, as well as the input/output

procedures for conversational data.

4.Interface between the CNC and PMC

This chapter describes the PMC specifications, the system configuration,

and the signals used by the PMC.

5.Digital servo

This chapter describes the servo tuning screen and how to adjust the

reference position return position.

6.AC spindles

These chapters describe the spindle amplifier checkpoints, as well as the

spindle tuning screen.

7.Trouble shooting

This chapter describes the procedures to be followed in the event of

certain problems occurring, for example, if the power cannot be turned on

or if manual operation cannot be performed. Countermeasures to be

applied in the event of alarms being output are also described.

APPENDIX

A BOOT SYSTEM

B ALARM LIST

p–1

PREFACE

B–63325EN/03

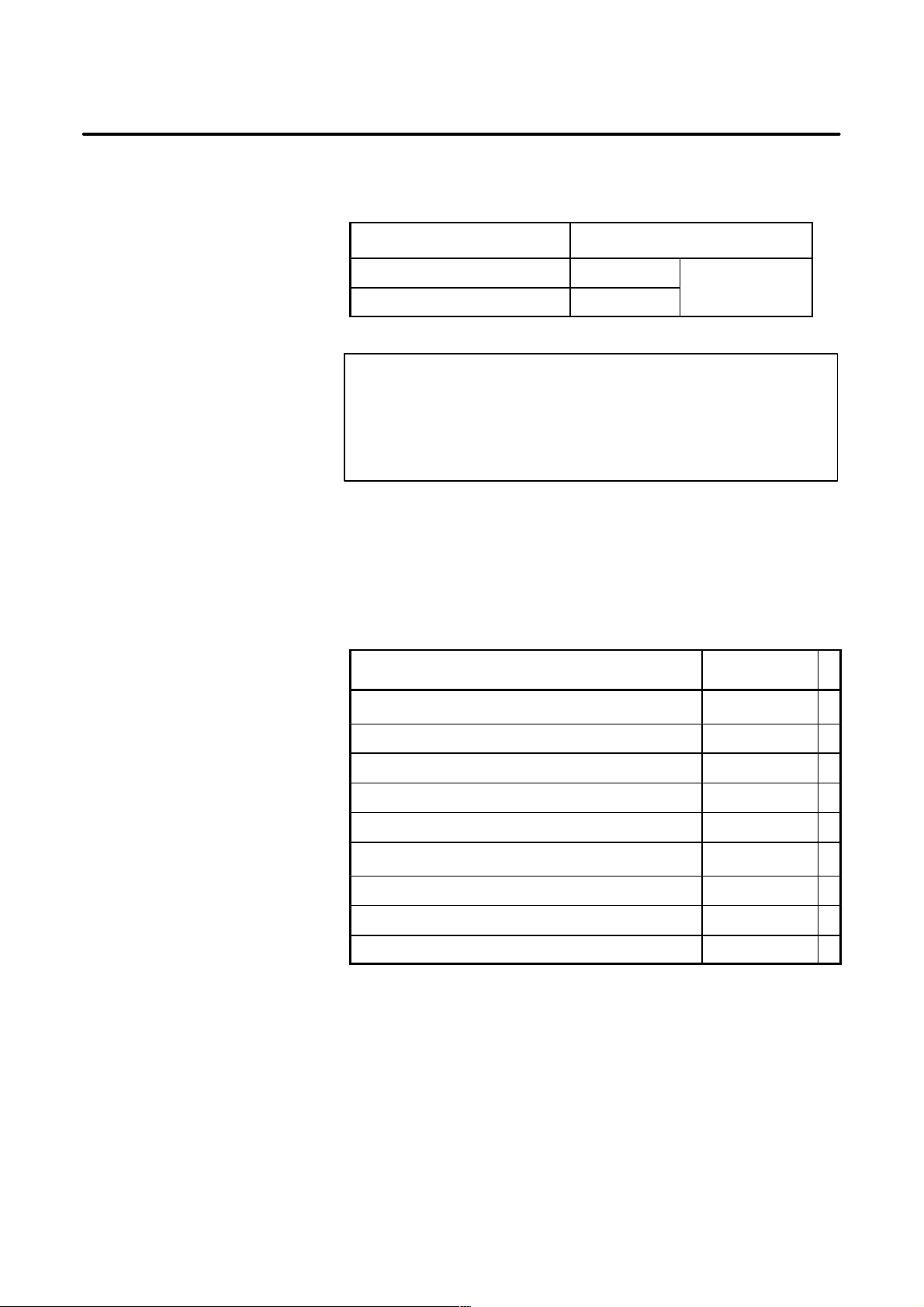

This manual can be used with the following models. The abbreviated

names may be used.

Applicable models

Related manuals

Pruduct name Abbreviation

FANUC Series 15i–MA 15i–MA

FANUC Series 150i–MA 150i–MA

M series

NOTE

Some function described in this manual may not be applied

to some products.

For details, refer to the DESCRIPTIONS manual

(B–63322EN)

The table below lists manuals related to FANUC Series

15i/150i–MODEL A.

In the table, this manual is marked with an asterisk(*).

Table 1 Related manuals

Manual name

DESCRIPTIONS B–63322EN

Specification

number

*

CONNECTION MANUAL (Hardware) B–63323EN

CONNECTION MANUAL (Function) B–63323EN–1

OPERATOR’S MANUAL (PROGRAMMING) B–63324EN

OPERATOR’S MANUAL (OPERATION) B–63324EN–1

MAINTENANCE MANUAL B–63325EN

PARAMETER MANUAL B–63330EN

DESCRIPTIONS (Supplement for Remote Buffer) B–63322EN–1

PROGRAMMING MANUAL (Macro Compiler/Macro Executor) B–63323EN–2

p–2

B–63325EN/03

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. SCREEN INDICATIONS AND OPERATIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Indication Procedure for General Screens 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 T ypes of Function Keys 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Soft Keys 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Function Selection Keys 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 Chapter Selection Keys 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.1 Position 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.2 Program 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.3 Offset/setting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.4 System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.5 Messages 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5.6 Drawing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCREEN INDICATIONS AT POWER ON 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 DIAGNOSIS FUNCTION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 CNC STATE INDICATIONS 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 WAVEFORM DIAGNOSIS FUNCTION 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 Enhancement of Waveform Diagnosis Function 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 DISPLAYING INTERNAL POSITION COMPENSATION DATA 44. . . . . . . . . . . . . . . . . . . . . . . . .

1.7 OPERATIONS 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 WARNING SCREEN FOR OPTION CHANGE 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 WARNING SCREEN FOR SYSTEM–SOFTWARE REPLACEMENT

(SYSTEM–LABEL CHECK ERROR) 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10 MAINTENANCE INFORMATION SCREEN 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.1 Display 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.2 Procedures 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.3 Half–size Kana Input 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.10.4 Parameter 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11 PERIODIC MAINTENANCE SCREEN 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.1 Display 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.2 Procedures 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.11.3 Inputting and Outputting Set Items 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12 SYSTEM LOG SCREEN 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.1 Display 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.2 Procedures 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.12.3 Parameter 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13 SYSTEM CONFIGURATION SCREEN 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.1 Displaying the System Configuration Screen 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.2 Printed Circuit Board Configuration Screen 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.3 Software Configuration Screen 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.13.4 Module Configuration Screen 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.14 MEMORY CONTENTS INDICATIONS 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.15 TOUCH PANEL 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16 BIOS/SETUP OF THE INTELLIGENT TERMINAL 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.1 BIOS/SETUP 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.2 Functions of Keys on the Setup Screen 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Table of Contents

1.16.3 Setup Method 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.4 BIOS Messages 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.5 BIOS Menu Details 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.5.1 Main menu 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.5.2 Advance menu 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.5.3 Power savings menu 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16.5.4 Exit menu 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63325EN/03

2. 15i SERIES HARDWARE 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 HARDWARE CONFIGURATION 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 OVERVIEW OF HARDWARE 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Series 15i/150i 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 CONNECTOR LOCATIONS AND CARD CONFIGURATION

FOR EACH PRINTED CIRCUIT BOARD 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 FS15i/150i Main Board 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 FS15i/150i Additional Axis Board 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 FS15i/150i LCD Unit 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3.1 Connection for one unit 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3.2 Connection for two units (10.4”) 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 FS15i/150i Inverter PCB 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Data Server Board A1 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 Data Server Board A2 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.7 HSSB Interface Board 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.8 PMC C Board 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.9 Serial Communication Boards A1 and A2 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.10 DeviceNet Board B 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.11 DeviceNet Slave Board C 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.12 Ethernet Board 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.13 PROFIBUS–DP Board (Master) 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.14 PROFIBUS–DP Board (Slave) 144. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 LIST OF THE UNITS AND PRINTED CIRCUIT BOARDS 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Basic Unit 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Power Supply Unit 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 LCD Unit 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 Stand–alone T ype MDI Unit 146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Intelligent T erminal 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5.1 Intelligent terminal (A13B–0178–B025 to –B042) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5.2 Panel i (A08B–0082–B001 to –B023) 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5.3 Other options for intelligent terminal and panel i 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.6 Data Server Hard Disk Unit 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.7 Printed Circuit Boards of the Control Unit 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.8 Others 156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.9 Maintenance Parts 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.10 Intelligent Terminal and Panel i Maintenance Equipment 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.11 Machine Operators Panel 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 REPLACING THE PRINTED CIRCUIT BOARDS 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Replacing the Power Supply Unit, Main CPU Board, and Full–size Option Board 159. . . . . . . . . . . . . . .

2.5.1.1 Demounting the board 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1.2 Mounting a board 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Replacing the Mini Slot Option Board and Wide Mini Slot Option Board 161. . . . . . . . . . . . . . . . . . . . . .

2.5.2.1 Demounting the board 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2.2 Mounting a board 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

B–63325EN/03

2.6 MOUNTING AND DEMOUNTING CARD PCBS 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 MOUNTING AND DEMOUNTING DIMM MODULES 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 REPLACING THE BACK PANEL 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 REPLACING FUSE ON POWER UNIT 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 REPLACING THE BATTERY 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 REPLACING THE FAN MOTORS 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12 LCD UNIT FUSE REPLACEMENT 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.13 LCD BACKLIGHT REPLACEMENT 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 LIQUID CRYSTAL DISPLAY (LCD) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 INTELLIGENT TERMINAL (A13B–0178–B025 TO –B042) 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16 DISTRIBUTED I/O SETTING 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.17 REPLACING FUSE ON CONTROL UNIT 205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.18 ENVIRONMENTAL CONDITIONS OUTSIDE CABINET 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.19 POWER CONSUMPTION OF EACH UNIT 213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20 COUNTERMEASURES AGAINST NOISE 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

2.5.3 Mounting and Removing the DeviceNet Board 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3.1 Removing the board 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3.2 Mounting the board 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Demounting a Card PCB 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Mounting a Card PCB 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Demounting a DIMM Module 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Mounting a DIMM Module 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Demounting the Back Panel 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 Mounting the Back Panel 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 Replacing the Lithium Battery 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.2 When Using Alkaline Dry Cells 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.1 Parts Layout 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.2 Setting Controls 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.3 LED Display 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.4 Mounting Locations of Maintenance Parts 187. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.5 Specifications of Maintenance Parts 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.6 Replacing the Battery 190. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.7 Replacing the Fuse 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.8 Replacing the Fans 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.8.1 Replacing the fan of the main unit of intelligent terminal type 2 191. . . . . . . . . . . . . . . . . . . . . . . .

2.15.8.2 Replacing the fan of the HDD 191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.9 Replacing the LCD Backlight 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.10 Replacing the Touch Panel Protective Sheet 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.11 Troubleshooting 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.12 Notes on Using the MDI Unit 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.1 Separation of Signal Lines 215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.2 Grounding 217. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.3 Control Unit Grounding 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.4 Noise Suppressor 219. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.20.5 Cable Clamping and Shielding 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. DATA INPUT/OUTPUT 223. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 SPECIFYING PARAMETERS REQUIRED FOR INPUT/OUTPUT 224. . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Setting Parameter Screen 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Communication Setting Screen 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Table of Contents

B–63325EN/03

3.2 DATA INPUT/OUTPUT 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Output of Part Programs 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Output of System Parameters 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Output of W orkpiece Origin Offset Data 235. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Output of Pitch Error Compensation Data 236. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Output of T ool Of fset Data 237. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 Output of Custom Macro Variables 238. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Output of Volumetric Compensation Data 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.8 Output of Tool Offset Data by Tool Number 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.9 Output of Fixture Offset Data 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.10 Output of Rotary Head Dynamic T ool Compensation Data 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.11 Output of Periodic Maintenance Data 244. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.12 Output of Item Selection Menu (Machine System) Data 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.13 Output of Maintenance Information 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.14 Output of System Configuration Data 248. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.15 Output of System Log Data 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.16 Input of Part Programs 250. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.17 Output of System Parameters 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.18 Input of W orkpiece Origin Offset Data 254. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.19 Input of Pitch Error Compensation Data 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.20 Input of T ool Of fset Data 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.21 Input of Custom Macro Variables 257. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.22 Output of Volumetric Compensation Data 258. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.23 Input of Tool Offset Data by Tool Number 259. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.24 Input of Fixture Offset Data 260. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.25 Input of Rotary Head Dynamic T ool Compensation Data 261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.26 Input of Periodic Maintenance Data 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.27 Input of Item Selection Menu (Machine System) Data 263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.28 Input of Maintenance Information 265. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 FLOPPY DIRECTORY SCREEN 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 MEMORY CARD SCREEN 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERFACE BETWEEN THE NC AND PMC 277. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 INTERFACE OVERVIEW 278. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 PMC SPECIFICATION 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 PMC Specification List 279. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Addresses 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Built–in Debugging Functions 280. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.4 Internal Relay System–reserved Area 281. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.5 PMC Execution Cycle 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 PMC DISPLAYS 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Overview 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 PMC Menu Selection Procedure Based on Soft Keys 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2.1 PMC basic menu 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2.2 PMC screen transition flow and the related soft keys 286. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 PMC Input/Output Signal and Internal–relay Displays (PMCDGN) 287. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.1 T itle data display (TITLE) 287. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.2 Signal status display (STATUS) 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3.3 Alarm screen (ALARM) 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 PMC Data Setting and Display (PMCPRM) 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.1 Overview 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.2 PMC parameter entry method 290. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.3 Continuous data entry 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

B–63325EN/03

4.3.4.4 T imer screen (TIMER) 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.5 Counter screen (COUNTR) 292. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.6 Keep relay screen (KEEPRL) 293. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4.7 Data table (DATA) 295. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5 Setting Menu (SETING) 297. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.1 General–setting data display screen (GENERAL) 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.5.2 Screen for displaying setting data related to editing and debugging 299. . . . . . . . . . . . . . . . . . . . .

4.3.5.3 Online monitor parameter display/setting screen (ONLINE) 299. . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

4.4 DI/DO MONITOR FUNCTION 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 DI/DO Monitor Screen 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 Screen Manipulation 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. DIGITAL SERVO 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 SERVO PARAMETER INITIALIZATION PROCEDURE 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SETTING THE FSSB 312. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 SERVO SCREENS 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Parameter Setting 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Displaying Servo Screens 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 REFERENCE POSITION RETURN ADJUSTMENT (BASED ON DOGS) 332. . . . . . . . . . . . . . . . . .

5.4.1 Overview 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 SETTING THE REFERENCE POSITION WITHOUT DOGS 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Overview 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Operating Procedure 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Related Parameters 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. AC SPINDLES 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 SERIAL INTERFACE AC SPINDLE 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Spindle Control Overview 338. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Spindle Screens 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.1 Parameters 340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2.2 Spindle screens 341. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Automatic Setting of Standard Parameters 350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 ANALOG INTERFACE AC SPINDLE 351. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Spindle Control Overview 351. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 S Analog V oltage (D/A Converter) Adjustments 353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. TROUBLESHOOTING 355. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 BOTH MANUAL AND AUTOMATIC OPERATIONS ARE IMPOSSIBLE 356. . . . . . . . . . . . . . . . . .

7.2 MANUAL (JOG) OPERATION IS IMPOSSIBLE 360. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 HANDLE FEED (MPG) OPERATION IS IMPOSSIBLE 363. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 AUTOMATIC OPERATION IS IMPOSSIBLE 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 AUTOMATIC OPERATION START SIGNAL TURNED OFF 373. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 ALARMS SR820 TO SR854 (READER/PUNCH INTERFACE ALARMS) 375. . . . . . . . . . . . . . . . . .

7.7 ALARM PS200 (GRID SYNCHRONIZATION ERROR) 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 ALARM OT0032 (REFERENCE POSITION RETURN REQUEST) 383. . . . . . . . . . . . . . . . . . . . . . .

7.9 ALARM SV027 (INVALID DIGITAL SERVO PARAMETER) 384. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10 ALARMS RELATED TO SPINDLE CONTROL 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.1 Alarm SP0201 (Duplicate Definition of Spindle Motor Number) 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Table of Contents

7.10.2 Alarm SP0202 (Invalid Spindle Selection) 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.3 Alarm SP0220 (no Spindle Amplifier) 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.4 Alarm SP0221 (Illegal Spindle Motor Number)

Alarm SP0996 (Illegal Spindle Parameter Setting) 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.5 Alarm SP0225 (Serial Spindle CRC Error)

Alarm SP0226 (Serial Spindle Framing Error)

Alarm SP0227 (Serial Spindle Reception Error)

Alarm SP0228 (Serial Spindle Communication Error)

Alarm SP0229 (Communication Error between Serial Spindle and Spindle Amplifier) 386. . . . . . . . . . . .

7.10.6 Alarm SP0230 (Spindle Motor Number Outside Allowable Range) 386. . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.7 Alarm SP0241 (Abnormal D/A Converter) 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.8 Alarm SP0975 (Analog Spindle Control Error) 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.9 Alarm SP0976 (Serial Spindle Communication Control Error)

Alarm SP0978 (Serial Spindle Communication Control Error)

Alarm SP0979 (Serial Spindle Communication Control Error) 387. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.10 Alarm SP0980 (Serial Spindle Amplifier Error)

Alarm SP0981 (Serial Spindle Amplifier Error)

Alarm SP0982 (Serial Spindle Amplifier Error)

Alarm SP0983 (Serial Spindle Amplifier Error)

Alarm SP0984 (Serial Spindle Amplifier Error) 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.11 Alarm SP0985 (Serial Spindle Control Error) 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.12 Alarm SP0987 (Serial Spindle Control Error) 388. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–63325EN/03

7.11 SYSTEM ALARMS AND CORRECTIVE ACTIONS 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.1 System Alarm 100 (RAM PARITY ERROR) 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.2 System Alarm 103 (DRAM SUM ERROR) 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.3 System Alarms 1 14 to 127 (FSSB Disconnection Alarms) 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.4 System Alarms 129 and 130 (ABNORMAL POWER SUPPLY (SER VO:AMPn)

7.11.5 System Alarm 200 (SYSTEM ALARM (SERVO): Alarm on an Axis Control Card) 396. . . . . . . . . . . . .

7.11.6 System Alarm 300 (SYSTEM ALARM: Alarm in Another Module) 398. . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.7 System Alarms 400 to 402 (BUS ERROR INTERNAL WRITE BUS ERROR

7.11.8 System Alarm 500 (SRAM DATA ERROR (SRAM MODULE)) 400. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.9 System Alarm 501 (SRAM DA TA ERROR (BATTER Y LOW)) 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.10 System Alarm 502 (NOISE ON POWER SUPLY) 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.11.11 System Alarm 503 (ABNORMAL POWER SUPPLY (MAIN BOARD)) 404. . . . . . . . . . . . . . . . . . . . . .

7.11.12 ROM TEST ERROR 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ABNORMAL POWER SUPPLY (SER VO:PULSE MODULEn)) 395. . . . . . . . . . . . . . . . . . . . . . . . . . .

A INTERNAL WRITE BUS ERROR B) 399. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.12 IO/LINK–RELATED SYSTEM ALARM 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.13 PMC RAM PARITY ALARM 408. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.14 OTHER SYSTEM ALARMS 409. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.15 SENDING A SYSTEM ALARM FILE 410. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.16 HOW TO REPLACE THE FUSES IN EACH UNIT 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17 FAULT TRACE PROCEDURE (FOR I/O LINK) 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.1 Failure to Input and Output I/O Link Data 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.1.1 Checking whether hardware links have been established 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.1.2 Checking the I/O Link allocation 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.2 Occurrence of System Alarm PC050 NMI SLC xx:yy 414. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.2.1 If “xx#0=1” in NMI SLC xx:yy 414. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.2.2 If “xx#1=1” in NMI SLC xx:yy 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.2.3 If “xx#2=1” in NMI SLC xx:yy 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.2.4 If “xx#3=1” or “xx#4=1” in NMI SLC xx:yy 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.3 Failure to Start the NC on the Host Station 416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.17.4 In a Connector Panel I/O Unit, Data is Input to an Unexpected Address 416. . . . . . . . . . . . . . . . . . . . . . . .

7.17.5 In a Connector Panel I/O Unit, No Data is Output to an Expansion Unit 417. . . . . . . . . . . . . . . . . . . . . . .

7.17.6 If an I/O Link–related Error can not be Cleared 417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

B–63325EN/03

Table of Contents

APPENDIX

A. BOOT SYSTEM 421. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 OVERVIEW 422. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.1 Power–on Sequence Display 423. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.2 Starting the BOOT SYSTEM 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1.3 System Files and User Files 424. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2 SCREEN CONFIGURATION AND OPERATION 425. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1 SYSTEM DATA LOADING Screen 426. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1.1 MEMORY CARD CHECK & DATA LOADING screen 427. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.1.2 DATA LOADING screen 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2 SYSTEM DA TA CHECK Screen 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2.1 FROM SYSTEM screen 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2.2 MEMOR Y CARD SYSTEM screen 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2.3 ROM FILE CHECK screen 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.2.4 Deleting user files from flash memory 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.3 SYSTEM DATA SAVE Screen 435. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.4 FILE DA TA BACKUP Screen 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.5 MEMORY CARD FORMAT Screen 440. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.2.6 Load Basic System 441. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.3 ERROR MESSAGES AND CORRECTIVE ACTIONS 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. ALARM LIST 444. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 PROGRAM ERRORS/ALARMS ON PROGRAM AND OPERATION (P/S ALARM) 445. . . . . . . . .

B.2 BACKGROUND EDIT ALARM 460. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.3 SR ALARM 463. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.4 PARAMETER ENABLE SWITCH ALARM (SW ALARM) 467. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.5 SERVO ALARM (SV ALARM) 468. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.6 OVERTRAVEL ALARM (OT ALARM) 473. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.7 FILE ACCESS ALARM (IO ALARM) 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.8 POWER MUST BE TURNED OFF ALARM (PW ALARM) 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.9 SPINDLE ALARM (SP ALARM) 476. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.10 OVERHEAT ALARM (OH ALARM) 481. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. APPENDIX C FANUC PANEL I 482. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.1 SYSTEM BLOCK DIAGRAM 483. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2 CONFIGURATION OF THE PCB 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.1 Parts Layout 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.2 Adjustment 486. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3 BIOS SET–UP 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.1 What is BIOS SET–UP” 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.2 Keys Used for Operation 487. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.3 How to Begin the “BIOS SET–UP” 488. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.4 How to End the “BIOS SET–UP” 488. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.5 BIOS Diagnostic Message 489. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4 MAINTENANCE SUPPLIES 490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.1 Method of Exchanging Battery 490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.2 Method of Exchanging Fuse 491. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.3 Method of Exchanging FAN 492. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.4 Method of Exchanging LCD Backlight 494. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.5 Method of Exchanging Touch Panel Protection Sheet 499. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.5 TROUBLE SHOOTING 501. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

B–63325EN/03

1

1. SCREEN INDICATIONS AND OPERATIONS

SCREEN INDICATIONS AND OPERA TIONS

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . .

1.2 SCREEN INDICATIONS AT POWER ON 10. . . . . . . . .

1.3 DIAGNOSIS FUNCTION 11. . . . . . . . . . . . . . . . . . . . . . .

1.4 CNC STATE INDICATIONS 22. . . . . . . . . . . . . . . . . . . .

1.5 WAVEFORM DIAGNOSIS FUNCTION 24. . . . . . . . . .

1.6 DISPLAYING INTERNAL POSITION

COMPENSATION DATA 44. . . . . . . . . . . . . . . . . . . . . .

1.7 OPERATIONS 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 WARNING SCREEN FOR OPTION CHANGE 58. . . . .

1.9 WARNING SCREEN FOR SYSTEM–SOFTWARE

REPLACEMENT

(SYSTEM–LABEL CHECK ERROR) 60. . . . . . . . . . . .

1.10 MAINTENANCE INFORMATION SCREEN 61. . . . . .

1.11 PERIODIC MAINTENANCE SCREEN 70. . . . . . . . . . .

1.12 SYSTEM LOG SCREEN 80. . . . . . . . . . . . . . . . . . . . . . .

1.13 SYSTEM CONFIGURATION SCREEN 87. . . . . . . . . .

1.14 MEMORY CONTENTS INDICATIONS 92. . . . . . . . . .

1.15 TOUCH PANEL 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.16 BIOS/SETUP OF THE INTELLIGENT

TERMINAL 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1. SCREEN INDICATIONS AND OPERATIONS

1.1

FUNCTION KEYS

AND SOFT KEYS

B–63325EN/03

1.1.1

Indication Procedure

for General Screens

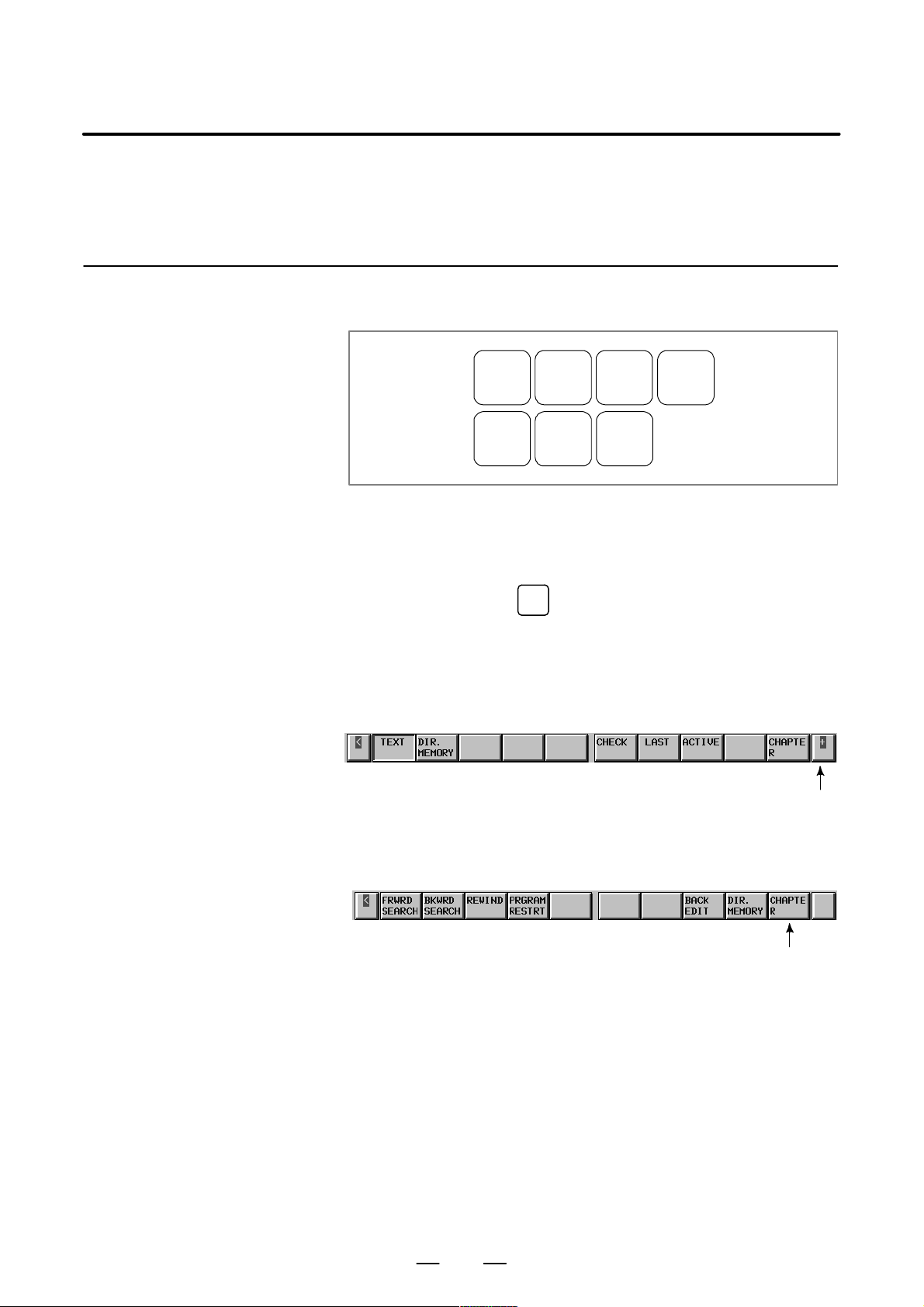

(1) Press a function key on the MDI panel to show the soft keys for

chapter selection related to the function.

POS PROG

SYSTEM

MESSAGE

OFFSET

SETTING

GRAPH

CUSTOM

(2) Press one of the indicated soft keys for chapter selection to display the

corresponding screen.

(3) Press an operation menu key to perform an operation on the displayed

chapter screen.

PROG

When you press the

key, for example, the following soft keys

for chapter selection are shown.

When the screen is first displayed, the first chapter is selected. (In this

example, “TEXT” is selected.)

To show an operation selection menu on this screen, press an

operation menu key at the rightmost position.

Operation menu key

(4) To return to the indications of the chapter–menu keys for chapter

selection while the operation selection menu is being displayed, press

the CHAPTER key.

CHAPTER key

The foregoing indication procedure is for general screens.

An actual indication procedure depends on each screen.

For specific operations, see each operation description.

2

B–63325EN/03

1. SCREEN INDICATIONS AND OPERATIONS

1.1.2

Types of Function Keys

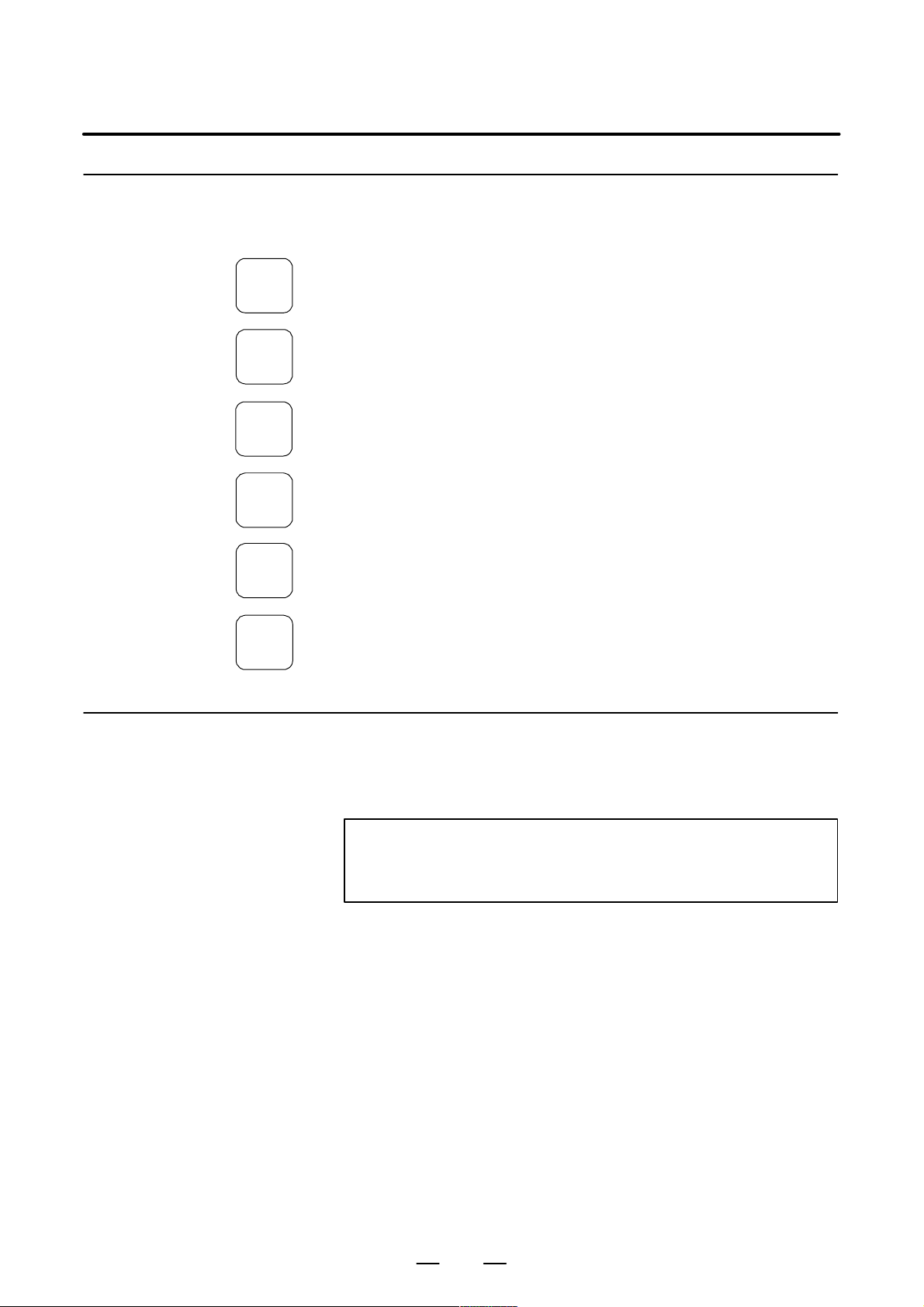

POS

PROG

OFFSET

SETTING

SYSTEM

MESSAGE

GRAPH

Use a function key to select the corresponding function.

The following function keys are provided for the MDI panel.

Press this key to show an actual position screen.

Press this key to show a program screen.

Press this key to show an offset/setting screen.

Press this key to show a system screen.

Press this key to show a message screen.

Press this key to show a graphic screen.

1.1.3

Soft Keys

A screen can be selected with the corresponding soft key instead of the

corresponding function key.

Soft keys are also used to perform actual operations.

A function menu and a list of chapter selection menus are shown below .

NOTE

All soft keys described below are not necessarily shown.

Some soft keys are not shown according to a set option.

3

1. SCREEN INDICATIONS AND OPERATIONS

B–63325EN/03

1.1.4

Function Selection

Keys

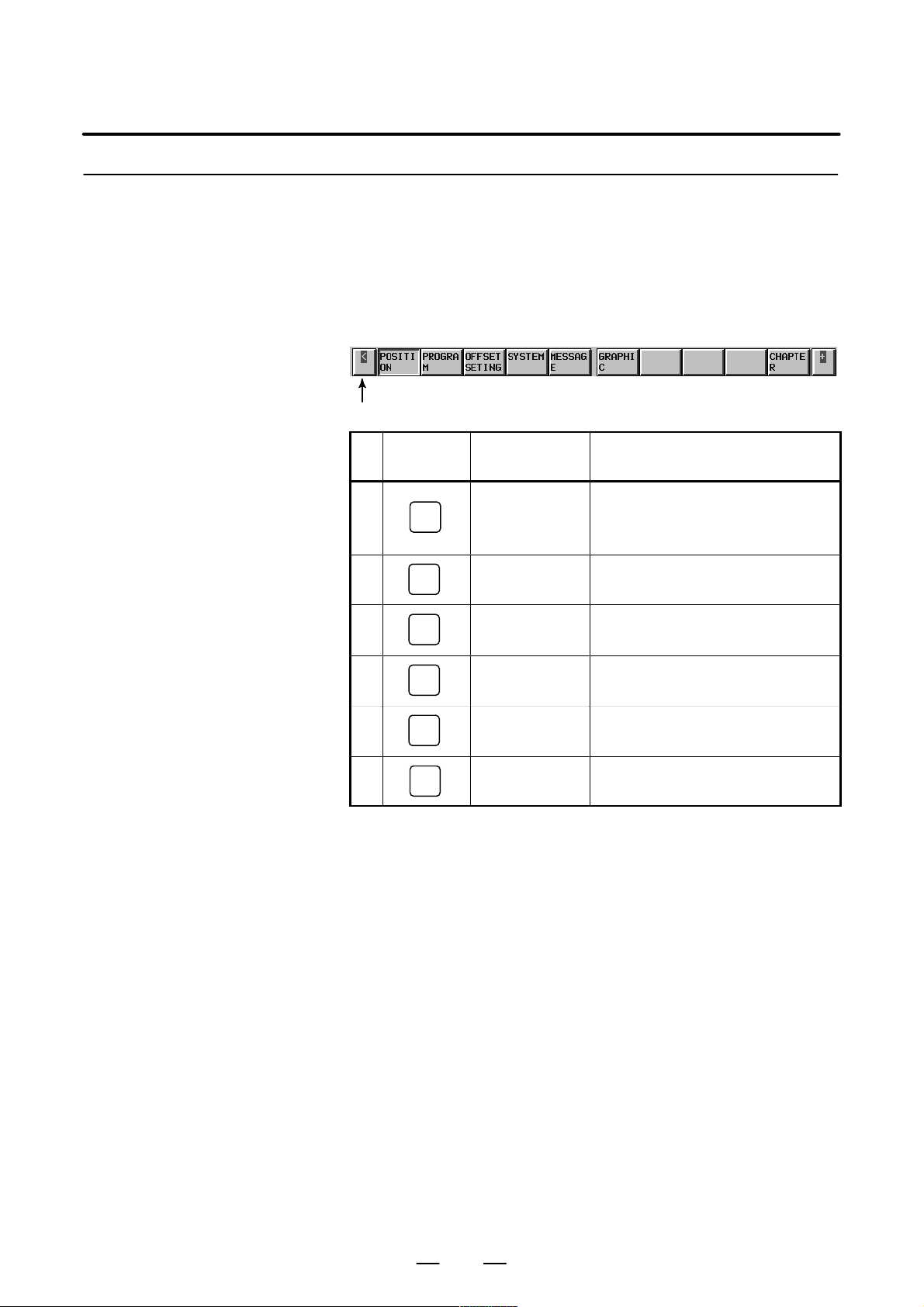

To select a function with the corresponding soft key, press the function

menu key first to set soft keys to a function selection key state, and then

press the desired function selection key.

Function selection is allowed in any mode.

Use a chapter selection key to specify detailed function selection.

The following function selection keys are provided.

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Function selection key

No.

(1)

(2)

(3)

Function key

(MDI panel)

POS

PROG

OFFSET

SETTING

Function selection

key (soft key)

POSITION Selects a current–position information

screen, including absolute coordinates, machine coordinates, relative coordinates, and

a remaining movement distance.

PROGRAM Selects a part program screen or a program

check screen.

OFFSETSETING Selects a tool offset screen or a workpiece

origin offset screen.

Description

(4)

(5)

(6)

SYSTEM

MESSAGE

GRAPH

SYSTEM Selects a parameter screen, a diagnosis

screen, or a PMC screen.

MESSAGE Selects a screen for alarm messages and

operator messages.

GRAPHIC Selects a graphic screen.

4

B–63325EN/03

1. SCREEN INDICATIONS AND OPERATIONS

1.1.5

Chapter Selection Keys

1.1.5.1

Position

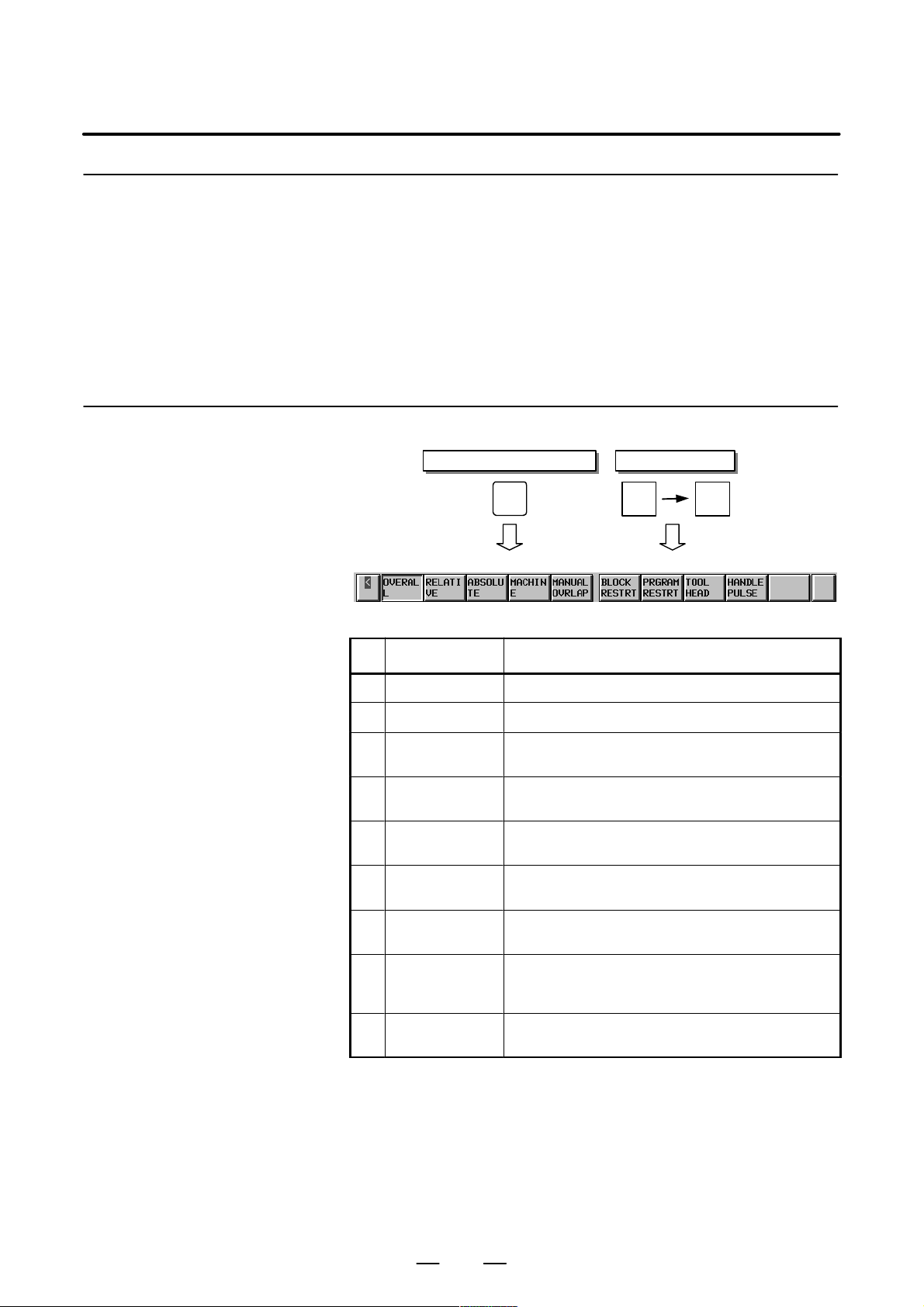

Use function selection keys to select items (functions).

Each item is further divided into subitems (chapters). Use a chapter

selection key to select the corresponding subitem (chapter).

To select a chapter, press the CHAPTER key to set the soft keys to a

chapter selection key state, and then press the desired chapter selection

key.

Alternatively, press a hardware function key repeatedly to change a

chapter selection.

The list of chapters included in each function is shown below.

Function key on the MDI panel

POS

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

POSI-

TION

Soft keys

CHAP-

TER

No. Chapter menu Description

(1) OVERALL Selects an overall position indication screen.

(2) RELATIVE Selects a relative position indication screen.

(3) ABSOLUTE Selects a position indication screen in a workpiece coordi-

(4) MACHINE Selects a position indication screen in a machine coordinate

(5) MANUALOVRLAP Selects an operation screen for performing an operation with

(6) BLOCK RESTRT Selects an operation screen for restarting the operation from

(7) PROGRAM-

RESTRT

(8) TOOL HEAD Indicates the absolute coordinates and the actual speed of

(9) HANDLEPULSE Indicates a handle–pulse interruption amount in three–di-

nate system.

system.

manual handle interruption.

the suspended block.

Selects an operation screen for restarting the suspended

program operation.

the tool head in tool direction handle feed, tool normal direction handle feed, and rotational handle feed around tool tip.

mensional handle feed.

5

1. SCREEN INDICATIONS AND OPERATIONS

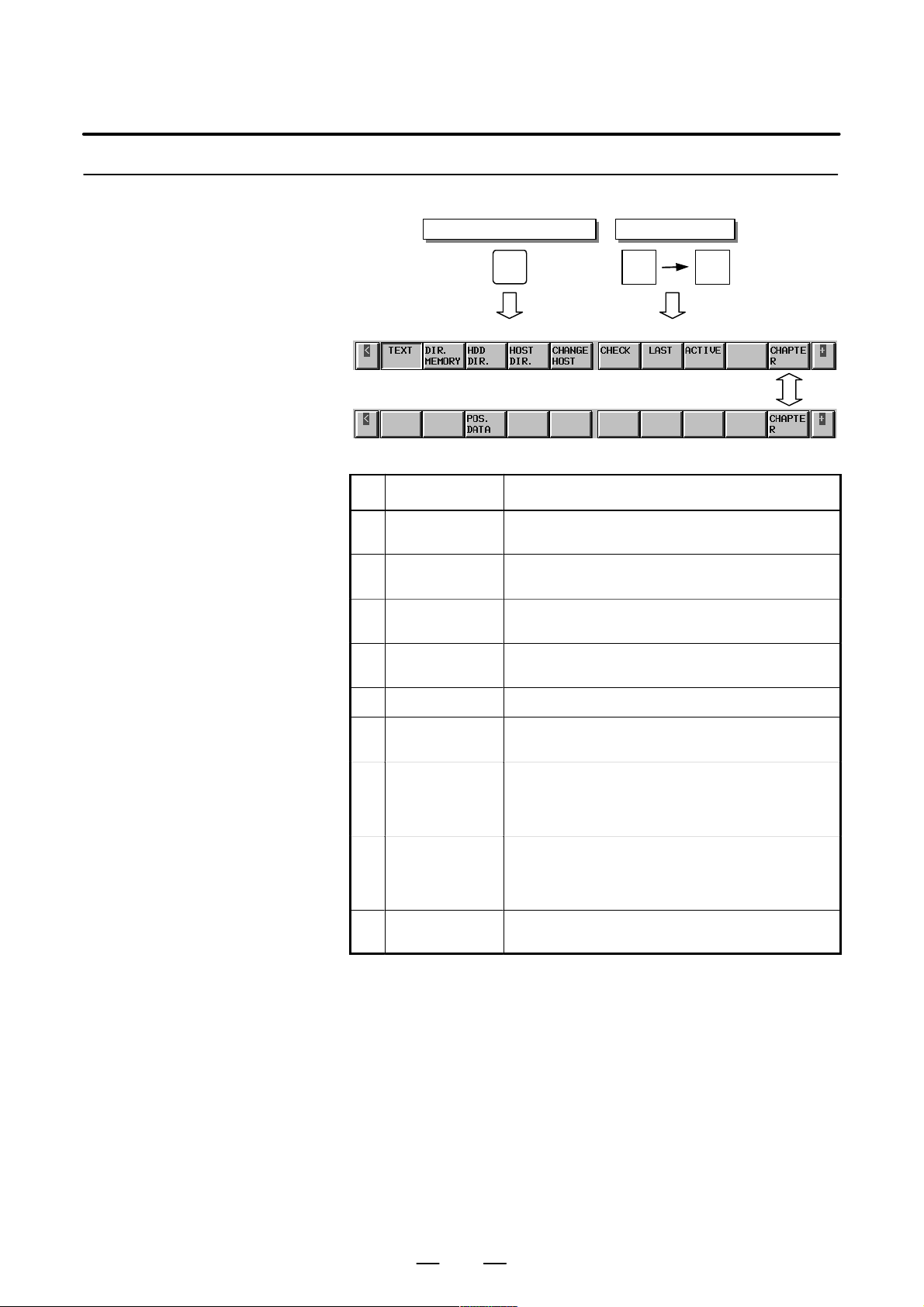

1.1.5.2

Program

Function key on the MDI panel

B–63325EN/03

Soft keys

PROG

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

(11) (12) (13) (14) (15) (16) (17) (18) (19)

PRO-

GRAM

CHAP-

TER

No. Chapter menu Description

(1) TEXT Selects a screen for indicating the contents of the currently

(2) DIR. MEMORY Selects a screen for indicating the list of currently registered

(3) HDD DIR. Selects a screen for indicating the list of files stored in the

(4) HOST DIR. Selects a screen for indicating the list of files stored in the

(5) CHANGE HOST Selects a screen for changing connected host computer.

selected part program.

part programs.

hard disk on the data server.

host computer.

(6) CHECK Selects a screen for indicating a program, a position, and

(7) LAST Selects a screen for indicating a specified value in the last

(8) ACTIVE Selects a screen for indicating a specified value in the block

(13) POS. DAT A Selects a screen for indicating information related to position

modal information at the same time.

block currently being executed, and modal values such as

G codes and F codes specified until then, among specified

values.

currently being executed, and modal values such as G

codes and F codes specified until then, among specified

values.

compensation.

6

B–63325EN/03

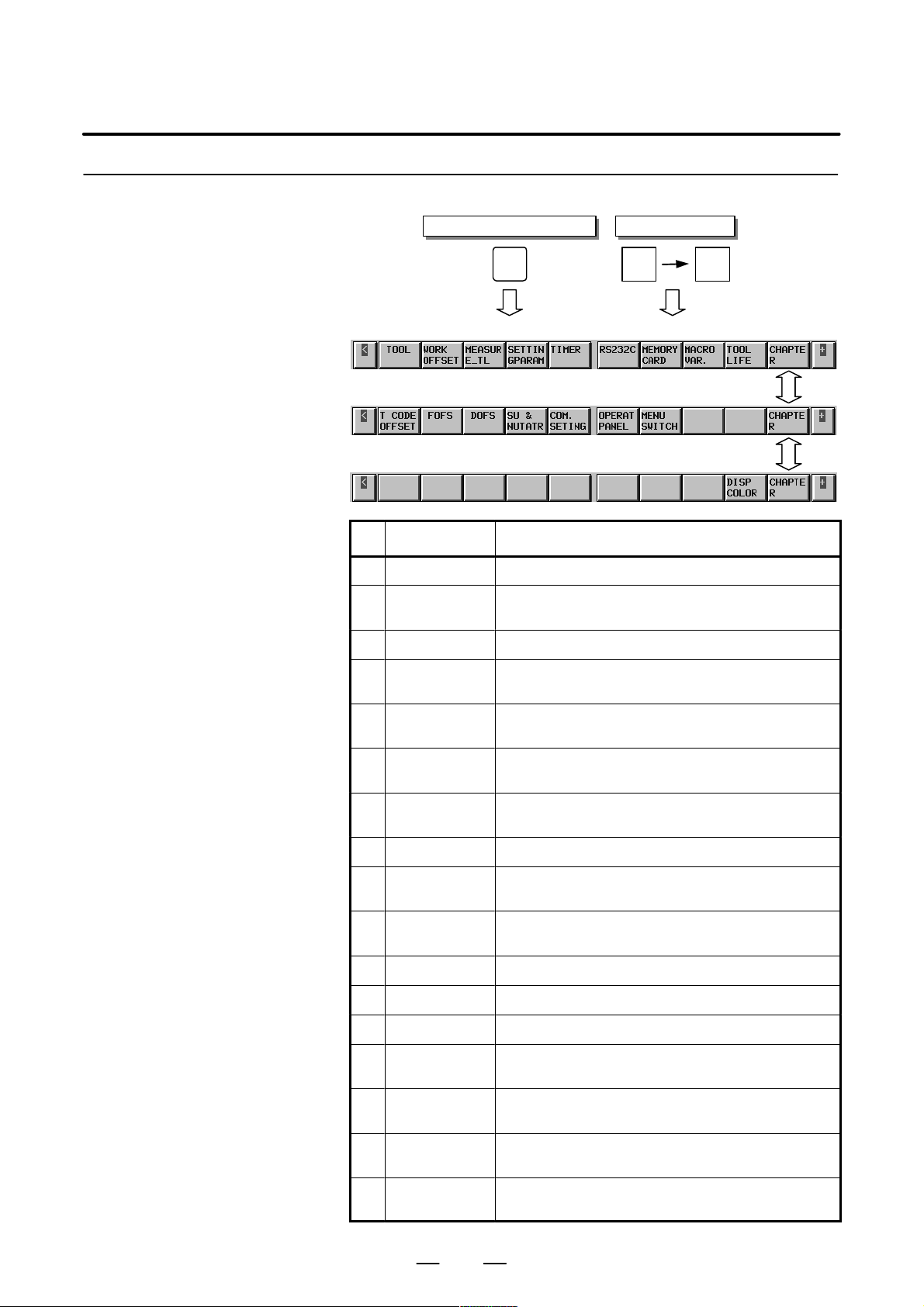

1.1.5.3

Offset/setting

1. SCREEN INDICATIONS AND OPERATIONS

Function key on the MDI panel

Soft keys

OFFSET

SET-

TING

OFFSET

SETTING

CHAP-

TER

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

(11) (12) (13) (14) (15) (16) (17) (18) (19)

(21) (22) (23) (24) (25) (26) (27) (28) (29)

No. Chapter menu Description

(1) TOOL Selects a screen for setting a tool offset value.

(2) WORK OFFSET Selects a screen for setting an offset in the workpiece coordi-

(3) MEASURE_TL Selects a screen for measuring a tool length.

(4) SETTINGPARA-

METER

nate system.

Selects a screen for specifying setting parameters.

(5) TIMER Selects a screen for indicating information related to the num-

ber of machined parts and the operation time period.

(6) RS232C Selects a screen for operating a unit connected to the

RS–232C interface.

(7) MEMORYCARD Selects a screen for performing an operation related to a

memory card.

(8) MACRO VAR. Selects a screen for setting a macro variable.

(9) TOOL LIFE Selects a screen for performing a setting related to tool life

management.

(11) T CODEOFFSET Selects a screen for setting a tool number , a pot number , and

a tool offset value in tool offset by the tool number .

(12) FOFS Selects a fixture offset screen.

(13) DOFS Selects a dynamic tool offset screen.

(14) SU & NUTATR Selects an SU & NUTATR of fset screen.

(15) COM. SETING Selects a screen for performing a setting related to RS 232C

and RS 422.

(16) OPERATPANEL Selects a screen for operating a part of the operation switches

on the machine operator’s panel as soft switches.

(17) MENU SWITCH Selects a screen for setting a part of input switch signals input

by a signal from the machine, in CNC operations.

(29) ETHERNET Selects a screen for performing a setting related to an Ether-

net board.

7

1. SCREEN INDICATIONS AND OPERATIONS

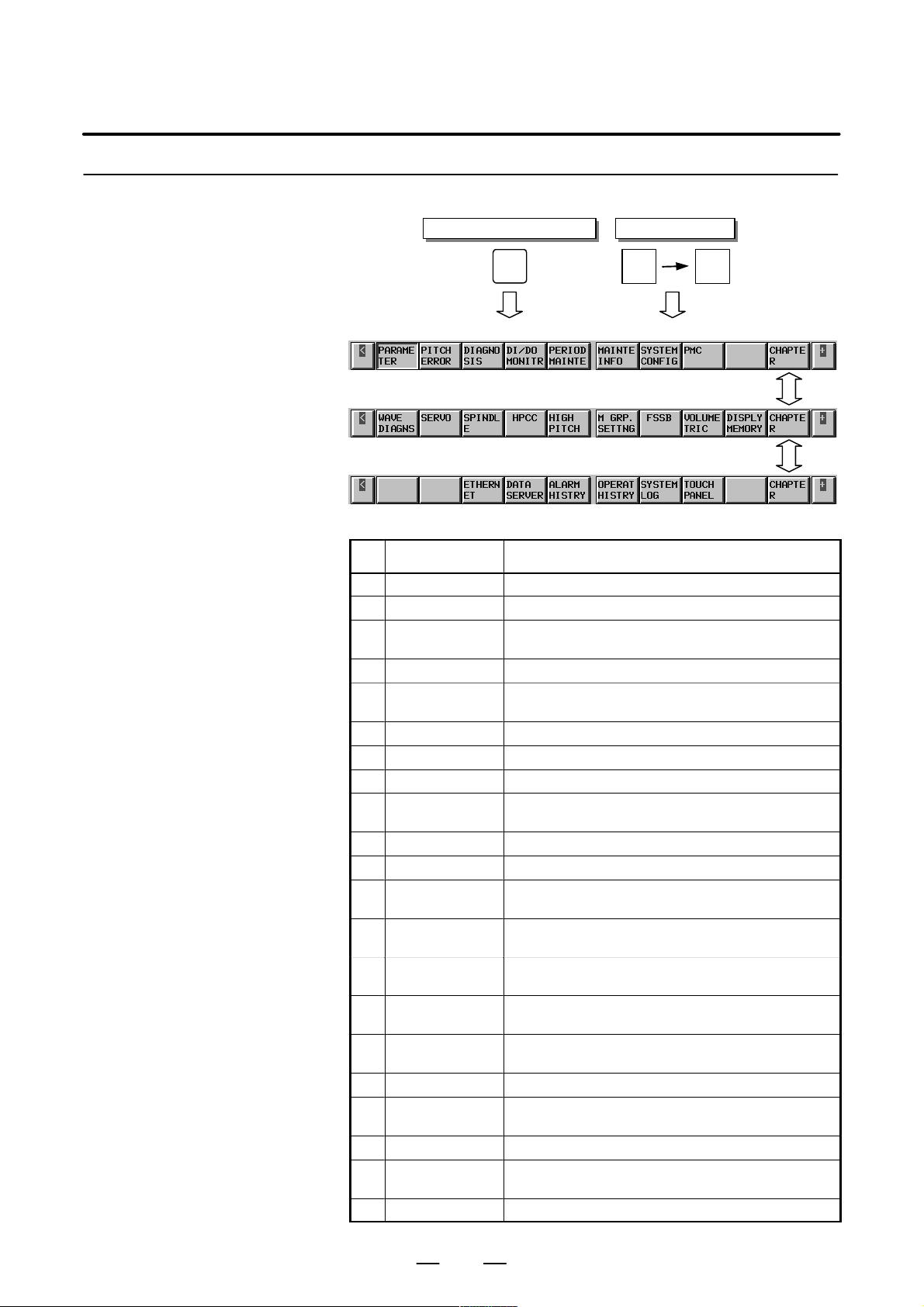

1.1.5.4

System

Function key on the MDI panel

B–63325EN/03

Soft keys

SYSTEM

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

(11) (12) (13) (14) (15) (16) (17) (18) (19)

(21) (22) (23) (24) (25) (26) (27) (28) (29)

SYSTEM

CHAP-

TER

No. Chapter menu Description

(1) PARAMETER Selects a screen for setting a parameter .

(2) PITCH ERROR Selects a screen for setting pitch error compensation.

(3) DIAGNOSIS Selects a screen for showing information indicating a CNC

(4) DI/DO MONITOR Selects a screen for showing status information of signal.

(5) PERIODMAINTE Selects a screen for setting a maintenance item to be peri-

(6) MAINTEINFO Selects a screen for setting information in maintenance.

(7) SYSTEMCONFIG Selects a screen for showing the current system state.

(8) PMC Selects a screen related to PMC.

(11) WA VE DIAGNS Selects a screen for showing data, such as a servo position

(12) SERVO Selects a screen for performing servo setting.

(13) SPINDLE Selects a screen for performing spindle setting.

(14) HPCC Selects a screen for performing a setting related to high–

(17) FSSB Selects a screen for performing a setting related to a high–

(18) VOLUMETRIC Selects a screen for setting three–dimensional error com-

(19) DISPLYMEMORY Selects a screen for showing the contents of the current

(23) ETHERNET Selects a screen for maintenance and setting of the Ether-

(24) DATA SERVER Selects the screen for Data server maintenance and setting.

(25) ALARM HISTRY Selects a screen for showing the contents of a previously

(26) OPERAT HISTORY Selects a screen for showing operation history.

(27) SYSTEMLOG Selects a screen for showing the contents of a previously

(28) TOUCH PANEL Selects a screen for setting a touch panel.

state.

odically controlled.

error , torque, and a machine signal, in a graph.

precision contour control.

speed serial bus (FSSB: Fanuc serial servo bus).

pensation.

CNC memory.

net board.

generated alarm.

generated system alarm.

8

B–63325EN/03

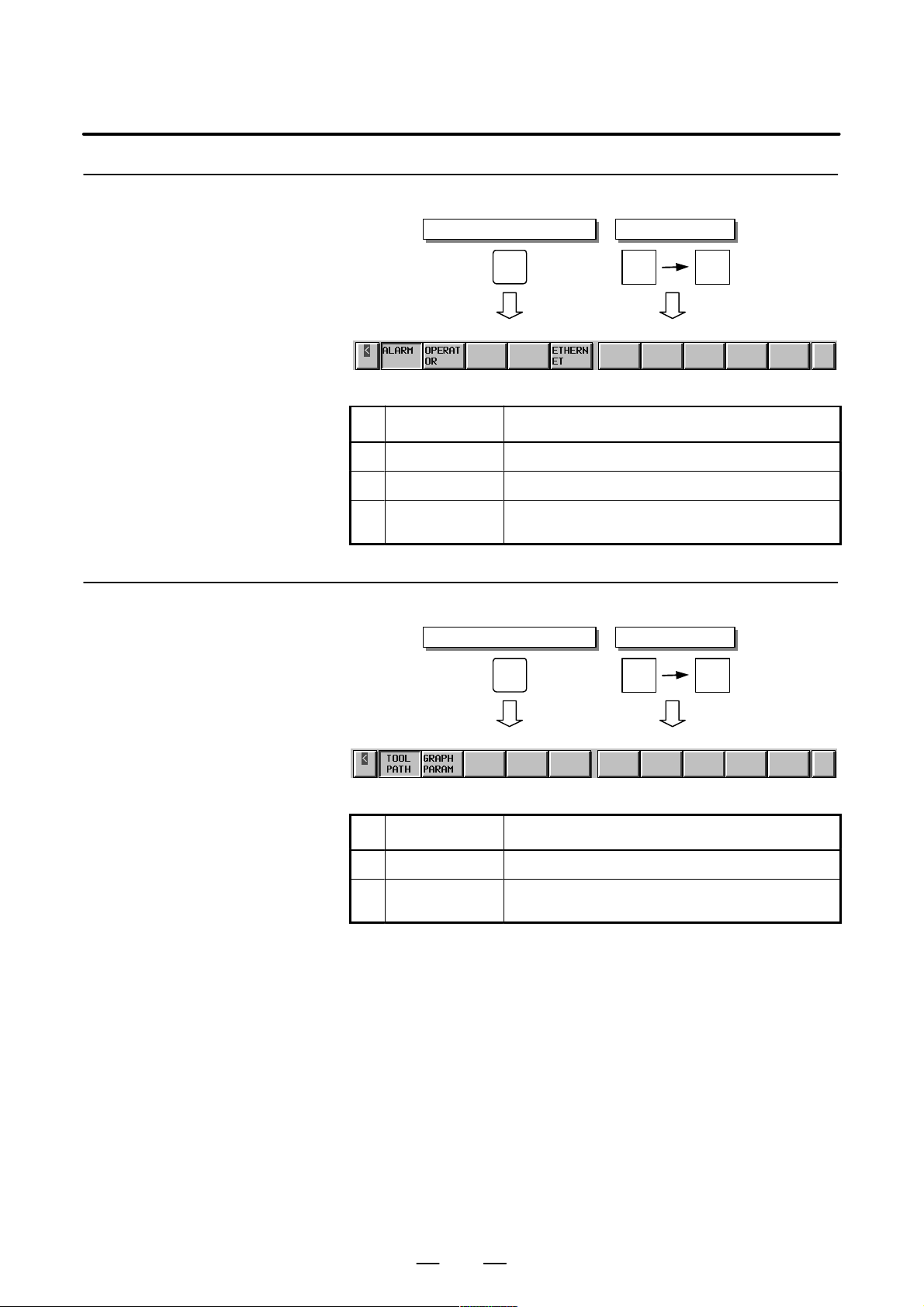

1.1.5.5

Messages

1. SCREEN INDICATIONS AND OPERATIONS

Function key on the MDI panel

Soft keys

1.1.5.6

Drawing

MES-

SAGE

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

MES-

SAGE

CHAP-

TER

No. Chapter menu Description

(1) ALARM Selects an alarm message screen.

(2) OPERATOR Selects an operator message screen.

(5) ETHERNET Selects a screen for showing logging information on Ether-

Function key on the MDI panel

net board.

GRAPH

GRAP-

HIC

Soft keys

CHAP-

TER

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

No. Chapter menu Description

(1) TOOL PATH Selects a screen for graphic indication of a tool path.

(2) GRAPH PARAM Selects a screen for performing a setting of tool–path draw-

ing.

9

1. SCREEN INDICATIONS AND OPERATIONS

B–63325EN/03

1.2

SCREEN

INDICATIONS A T

POWER ON

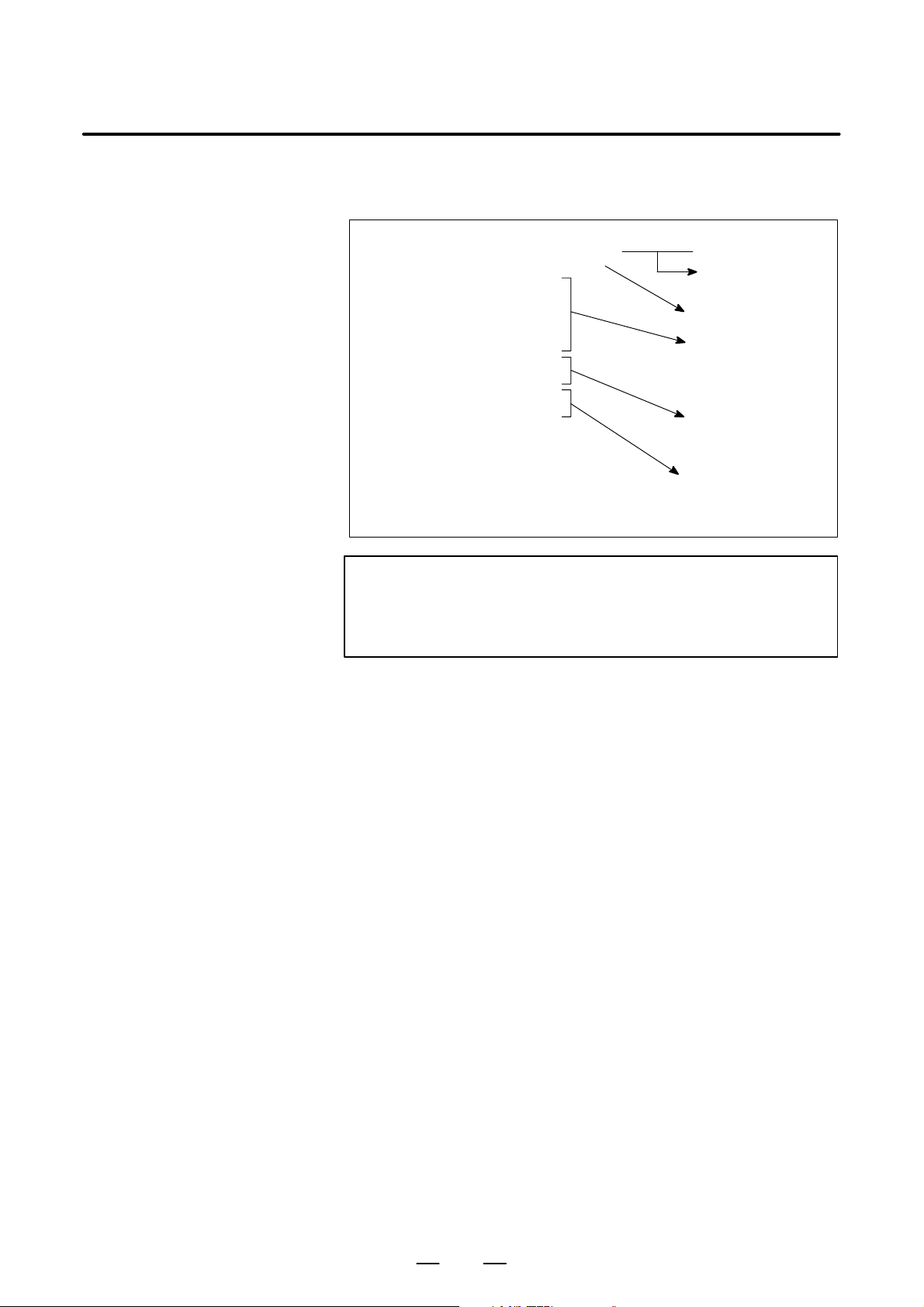

The test results of hardware (RAM and ROM), and the check results of

control software and file data are indicated on the screen at power on.

FANUC SERIES 15I F010A

COPYRIGHT(C) FANUC LTD 1997–1999

RAM TEST : END

ROM TEST : END

PMC ROM TEST : END

SERVO RAM TEST : END

SERVO ROM TEST : END

LOAD SYSTEM LABEL : END

CHECK SYSTEM LABEL : END

LOAD FILES : END

LOAD MESSAGE DATA : END

CAUTION

If a hardware error is detected in the RAM and ROM tests

for the CNC, PMC, and digital servo system, power–on

processing is stopped.

Series and edition of

CNC control software

Copyright indication

Test results of RAM and

ROM mounted on CNC,

PMC, and digital servo

system

Verification result of

compatibility of CNC

control software