Faber LEVG24SS300, LEVG30SS300 INSTALLATION INSTRUCTIONS AND OPERATION MANUAL

LEVANTE G

Installation Instructions

Use and Care Information

Instructions d'installation Utilisez et d'entretien

Instrucciones de instalación Información de uso y cuidado

LEVG24SS300

LEVG30SS300

CONTENTS

Section |

Page |

Important safety instructions |

3 |

Range hood dimensions |

6 |

Installation height requirements |

7 |

Parts |

8 |

Tools needed |

9 |

Before installation remove shipping materials |

10 |

Only for Canadian market |

11 |

Choose vertical or horizontal electrical connection knockout's |

12 |

Venting method options-ducted or ductless |

14 |

Non ducted recirculation option |

15 |

Ducted - 7" round outlet |

16 |

Ducted - 3 1/4" x 10" rectangular outlet on top |

18 |

Ducted - 3 1/4" x 10" rectangular outlet rear |

19 |

Choosing the mounting method |

20 |

Mounting range hood on wall |

21 |

Mounting range hood under the cabinet |

25 |

Connecting electricity |

27 |

Operating the controls |

28 |

Caring for filters |

29 |

Replacing lighting |

31 |

Wiring diagram |

32 |

Warranty |

33 |

2

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS BEFORE YOU START

INSTALLING THIS RANGE HOOD

WARNING: - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a)Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium setting.

b)Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c)Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d)Useproperpansize. Alwaysusecookwareappropriateforthesizeofthesurfaceelement.

WARNING: - TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

a)SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately

EVACUATE AND CALL THE FIRE DEPARTMENT.

b)NEVER PICK UP A FLAMING PAN - You may be burned.

c)DO NOT USE WATER, including wet dishcloths or towels - a violent steam explosion will result.

d)Use an extinguisher ONLY if:

1.You know you have a Class ABC extinguisher, and you already know how to operate it.

2.The fire is small and contained in the area where it started.

3.The fire department is being called.

4.You can fight the fire with your back to an exit.

* Based on "Kitchen Firesafety Tips" published by NFPA

WARNING - TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, do not use this fan with any solid-state speed control device.

WARNING-TOREDUCETHERISKOFFIRE,ELECTRICALSHOCK,ORINJURYTOPERSONS, OBSERVE THE FOLLOWING:

1.Usethisunitonlyinthemannerintendedbythemanufacturer.Ifyouhaveanyquestions, contact the manufacturer.

2.Beforeservicingorcleaningunit,switchpoweroffatservice panelandlocktheservice disconnectingmeanstopreventpowerfrombeingswitchedonaccidentally.Whenthe service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

CAUTION: For General Ventilating Use Only. Do Not Use To Exhaust Hazardous or Explosive Materials and Vapors.

WARNING-TOREDUCETHERISKOFFIRE,ELECTRICALSHOCK,ORINJURYTOPERSONS, OBSERVE THE FOLLOWING:

1.Installation Work And Electrical Wiring Must Be Done By Qualified Person(s) In Accordance With All Applicable Codes And Standards, Including Fire-Rated Construction.

2.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer's guideline and safety standards such as those published by theNationalFireProtectionAssociation(NFPA),andtheAmericanSocietyforHeating, RefrigerationandAirConditioningEngineers(ASHRAE),andthelocalcodeauthorities.

3

3.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

4.Ducted fans must always be vented to the outdoors.

ALL WALL AND FLOOR OPENINGS WHERE THE RANGE HOOD IS INSTALLED

MUST BE SEALED.

This Range Hood requires at least 24" of clearance between the bottom of the Range Hood and the cooking surface or countertop. This hood has been approved by UL at this distance from the cooktop.

This minimum clearance may be higher depending on local building codes. For gas cooktops and combination ranges, a minimum of 30" is recommended and may be required. Overhead cabinets on both sides of this unit must be a minimum of 18" above the cooking surface or countertop. Consult the cooktop or range installation instructions given by the manufacturer before making any cutouts.

MOBILE HOME INSTALLATION The installation of this Range Hood must conform to the Manufactured Home Construction and Safety Standards, Title 24 CFR, Part 3280 (formerly Federal Standard for Mobile Home Construction and Safety, Title 24, HUD, Part 280). See Electrical Requirements"

VENTING REQUIREMENTS

Determine which venting method is best for your application. Ductwork can extend either through the wall or the roof.

The length of the ductwork and the number of elbows should be kept to a minimum to provide efficient performance. The size of the ductwork should be uniform. Do not install two elbows together. Use duct tape to seal all joints in the ductwork system. Use caulking to seal exterior wall or floor opening around the cap.

Flexible ductwork is not recommended. Flexible ductwork creates back pressure and air turbulence that greatly reduces performance.

Make sure there is proper clearance within the wall or floor for exhaust duct before making cutouts. Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut, then a supporting frame must be constructed.

WARNING - To Reduce The Risk Of Fire, Use Only Metal Ductwork.

CAUTION - To reduce risk of fire and to properly exhaust air, be sure to duct air outside

– Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

Cold Weather installations

An additional back draft damper should be installed to minimize backward cold air flow and a nonmetallic thermal break should be installed to minimize conduction of outside temperatures as part of the vent system. The damper should be on the cold air side of the thermal break. The break should be as close as possible to where the vent system enters the heated portion of the house.

! WARNING

•Venting system MUST terminate outside the home.

•DO NOT terminate the ductwork in an attic or other enclosed space.

•DO NOT use 4" laundry-type wall caps.

•Flexible-type ductwork is not recommended.

•DO NOT obstruct the flow of combustion and ventilation air.

•Failure to follow venting requirements may result in a fire.

4

ELECTRICAL REQUIREMENTS

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp fused circuit. A time-delay fuse or circuit breaker is recommended. The fuse must be sized per local codes in accordance with the electrical rating of this unit as specified on the serial/rating plate located inside the unit near the field wiring compartment.

ELECTRICAL INSTALLATION WITH WIRING BOX

THIS UNIT MUST BE CONNECTED WITH COPPER WIRE ONLY. Wire sizes must conform to the requirements of the National Electrical Code, ANSI/NFPA 70 - latest edition, and all local codes and ordinances. Wire size and connections must conform with the rating of the appliance. Copies of the standard listed above may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fused disconnect (or circuit breaker) through flexible, armored or nonmetallic sheathed copper cable. Allow some slack in the cable so the appliance can be moved if servicing is ever necessary. A UL Listed,

1/2" conduit connector must be provided at each end of the power supply cable (at the appliance and at the junction box).

When making the electrical connection, cut a 1 1/4" hole in the wall. A hole cut through wood must be sanded until smooth. A hole through metal must have a grommet.

! WARNING

•Electrical ground is required on this Range Hood.

•If cold water pipe is interrupted by plastic, nonmetallic gaskets or other materials, DO NOT use for grounding.

•DO NOT ground to a gas pipe.

•DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit could result in electrical shock.

•Check with a qualified electrician if you are in doubt as to whether the Range

Hood is properly grounded.

•Failure to follow electrical requirements may result in a fire.

State of California Proposition 65 Warning (US only)

WARNING

WARNING

This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

5

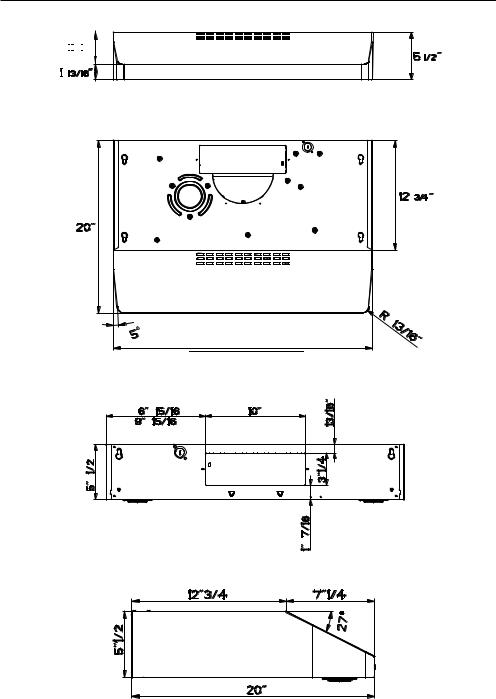

RANGE HOOD DIMENSIONS

3

24" |

30" |

23 15/16” - |

29 15/16” |

24" |

|

30" |

|

6

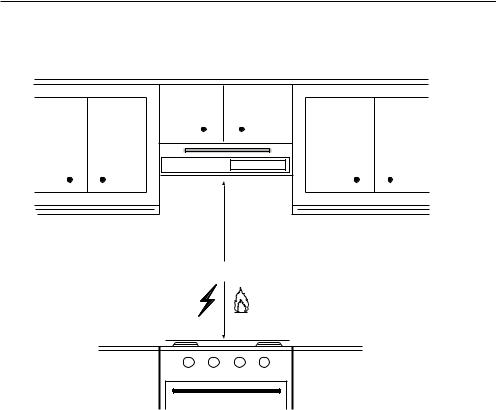

INSTALLATION HEIGHT REQUIREMENTS

MIN. 24" OVER ELECTRIC / MIN. 30" OVER GAS

Min. 24" - 30"

7

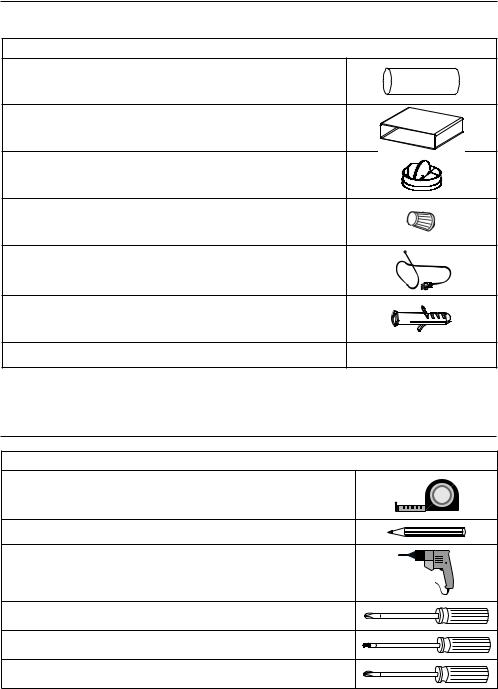

PARTS

PARTS INCLUDED

REF. PART

A Hood body – Includes Controls, Light, Filters, Blower |

1 |

|

|

|

|

B Damper (3 1/4" x 10") |

1 |

|

|

|

|

C |

7" Round Flange |

1 |

|

|

|

D |

Grid (Only for Canadian Market) |

1 |

REF |

PART |

|

E |

Pozi Screws (3/16" x 1 15/16") |

4 |

F |

Torx Screws (1/8" x 3/8") |

4 |

D  C

C

A B

Available Accessories

Activated Charcoal Filter (FILTER5)

Note: The Charcoal Filter is attached with two screws (See page 15 and Figure C).

The Charcoal Filters must be purchased with only Faber authorized dealers.

8

PARTS (cont.)

PARTS NEEDED

PART

7" Round Metal Ductwork

3 1/4" x 10" Rectangular Ductwork

7" Damper

Wire connectors.

Power Supply Cable.

-

Drywall plugs or other suitable wall fasteners based on your installation.

Wall Cap/Roof Cap Needs to be purchased separately

TOOLS NEEDED

TOOL

Tape Measure

Pencil

Electric Drill with 5/16" Drill Bit

Phillips Screwdriver

Torx Screwdriver

Pozi Screwdriver

9

BEFORE INSTALLATION REMOVE SHIPPING MATERIALS

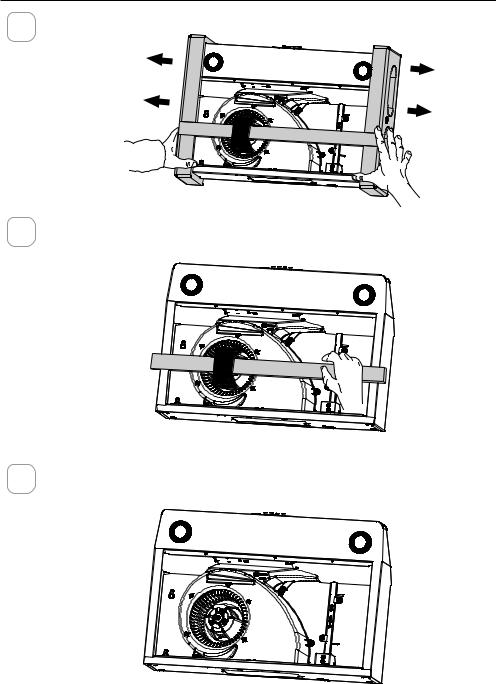

1 Remove the side packaging.

Caution: Do not pick up hood using the wood bar

2 Remove the foam packaging and wood bar.

3 |

Ready for Installation. |

|

10

ONLY FOR CANADIAN MARKET

For ducted installations only:

1Remove the filters one at a time by pushing towards the back of the hood and pulling down at the same time.

2Remove the screws as pictured.

Remove two of the screws from the motor assembly housing as pictured.

3Install the screws as pictured.

Install Grid D with the two screws removed from step 2. Screw the protection grid into the location shown in the picture below. (The correct location has a rectangular cut out to accommodate the grid.)

Take care to screw the grid completely flush to avoid unwanted noise.

D

D

Phillips Screwdriver

11

CHOOSE VERTICAL OR HORIZONTAL ELECTRICAL CONNECTION KNOCKOUT'S

13/16"

13/16"

13/16"

7"1/2

Preparing the hood for electrical knockouts

1Remove the filters one at a time by pushing them

towards the back of the hood and pulling down at the same time.

2 Remove the wiring box cover by unscrewing the 2 screws.

Phillips Screwdriver

12

3

4

Rear Hole (Horizontal)

Choose the rear hole for the electric connection and break with a screwdriver or other tool.

During the installation thread Power Supply Cable through this hole.

Top Hole (Vertical)

Choose the top hole for the electric connection and break with a screwdriver or other tool.

During the installation thread Power Supply Cable through this hole.

13

VENTING METHOD OPTIONS-DUCTED OR DUCTLESS

NON DUCTED - RECIRCULATION |

DUCTED WITH 7" ROUND OUTLET: |

OPTION |

– Vertical |

|

– Horizontal |

|

Top |

|

7" |

Requires |

|

purchase |

Rear |

of |

|

Activated |

|

Charcoal |

|

Accessory |

|

Go to page 15 |

Go to page 16 |

DUCTED WITH 3 1/4" X 10" RECTANGULAR OUTLET

–Vertical

–Horizontal

Top |

10"

Rear

<![if ! IE]><![endif]>"1/4 3

10"

<![endif]>"1/4 3

Go to page 18

14

NON DUCTED RECIRCULATION OPTION

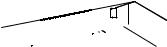

a

Remove the indicated blower cover (do not discard the screw).

b3

Required Activated Charcoal Filter Accessory - (FILTER5) purchased separately.

Non Ducted installations only:

1.Remove the two screws located on the motor housing in the location indicated.

2.Place the charcoal filter with the tabs against the blower housing in the location indicated on figure c . The front side of the FILTER5 will have the keyhole mounting on the top surface of the filter. A layer of charcoal will be visible through the grills.

3.Use the two screws removed earlier to attach

the FILTER5 in place.

NOTE: For Non ducted installations the Canadian Grid should NOT be used.

d

b1 Cut the cover where indicated in picture b1.

b2 DiscardRecycle / upper pieces of blower cover.

Reinstall the modified blower cover with the same screw.

c

Reinstall the existing Grease Filters afterinstallingtheActivatedCharcoal Filter before operating hood.

Go to page 20

15

DUCTED - 7" ROUND OUTLET

Top

Rear |

Required; 7" Round Damper purchase separately.

7"

Caution: If an elbow is required, do it

as far away from the hood's exhaust opening as possible.

1Cut where indicated.

Remove both the rectangular and semicircle areas with metal shears.

16

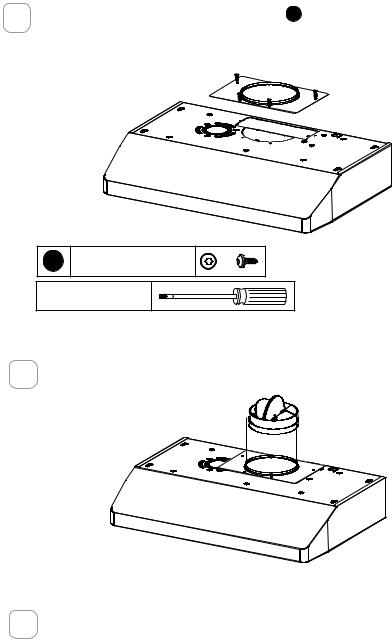

2Install the Flange with Flange transition screws F .

NOTE: The Flange must be mounted with the lip facing upward.

Only use the screws provided for the flange

F Torx Screws (1/8" x 3/8")

Torx Screwdriver

3 Install 7" Round Damper purchased separately. Secure damper with foil duct tape.

4Connect the 7" Round Metal Ductwork to the Roof or Wall Cap purchased separately and then attach ductwork.

Go to page 20

17

DUCTED - 3 1/4" X 10" RECTANGULAR OUTLET ON TOP

Top |

Rear |

3 1/4" x 10"

Caution: If an elbow is required, do it as far away from the hood's exhaust opening as possible.

1Choose the rectangular upper air outlet or rectangular rear air outlet and cut where indicated.(See page 19 for Rear Outlet)

Top

2 Install the included rectangular air outlet with two screws F .

3Connect the metal ductwork to the Roof or Wall Cap purchased separately and then attach ductwork.

F Torx Screws (1/8" x 3/8")

Torx Screwdriver

18

DUCTED - 3 1/4" X 10" RECTANGULAR OUTLET REAR

3 1/4" x 10"

Rear

Rear

Caution: If an elbow is required, do it as far away from the hood's exhaust opening as possible.

1 Use the rear air outlet and cut where indicated.

Rear

2 Install the included rectangular air outlet with two screws F .

3Connect the metal ductwork to the Roof or Wall Cap purchased separately and then attach ductwork.

F Torx Screws (1/8" x 3/8")

Torx Screwdriver

Go to page 20

19

CHOOSING THE MOUNTING METHOD

Installation for Mounting on the Wall

Page

21

Installation for Mounting to the cabinet

Page

25

20

MOUNTING RANGE HOOD ON WALL

1DRAW POSITIONING LINES

Draw a vertical line H from the supporting back wall to the ceiling or upper limit, at the center of the area in which the hood will be installed.

Draw a horizontal line I from where the bottom edge of hood will be located, to a minimum of 24" above an electric cooking surface and 30" above a gas cooking surface.

|

I |

= |

= |

H |

|

Min. 24" Min.30"

MIN. 24" OVER ELECTRIC/MIN. 30" OVER GAS

21

MOUNTING RANGE HOOD ON WALL

2 |

Mark the wall for the upper anchors. |

|

|

Mark the wall where indicated 4 15/16" above the horizontal I |

line at J distance on |

||

|

the left and right of the vertical line H .

| <![if ! IE]> <![endif]>415/16” |

<![if ! IE]> <![endif]>415/16” |

|

I |

|

H |

J |

24" = 21 3/8" |

|

30" = 27 3/8" |

3Mark the wall for lower anchors.

Mark 1” below the Step 2. Upper Anchors. Take care to keep level.

|

|

I |

| <![if ! IE]> <![endif]>1” |

|

<![if ! IE]> <![endif]>1” |

|

H |

|

|

24” - - > A= 21 |

8” |

J |

24" = 21 3/8" |

|

30" = 27 3/8" |

||

22

MOUNTING RANGE HOOD ON WALL

4Drill a 3/16th hole directly into the wall at the center points marked in step 3.

If fastener locations do not align with the studs, insert the purchased wall plugs in the holes.

; |

´ |

5 In upper holes use two of the supplied screws E to secure the hood body to the wall.

E Pozi Screws (3/16" x 1 15/16")

Pozi Screwdriver

23

MOUNTING RANGE HOOD ON WALL

6 Using two remaining screws E anchor the hood in lower holes as indicated.

E Pozi Screws (3/16" x 1 15/16")

Pozi Screwdriver

CAUTION! For installations that have a recessed bottom, 1”X 2” x 12” (approximate length) wood strips will need to be purchased and fitted to provide a level mounting area. The 12C Wall Mount Screws may work as fasteners, if not then 4 flat head wood screws would need to be purchased and used for this type of installation.

24

MOUNTING RANGE HOOD UNDER THE CABINET

1Locate the hole on the Range Hood for the power cord (See Section " CHOOSE VERTICAL OR HORIZONTAL ELECTRICAL CONNECTION KNOCKOUT'S ") and pass the cord through the appropriate hole.

<![endif]>20"  7" 11/16 2"

7" 11/16 2"

|

Top View |

1" 5/16 |

1" 5/16 |

|

7" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>13/16 |

<![if ! IE]> <![endif]>10" 1/2 |

<![if ! IE]> <![endif]>12" |

|

|

|

<![if ! IE]> <![endif]>2" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24"-30"-36" |

|

BackView |

23 15/16" - 29 15/16" |

|

|

|

13/16" |

|

|

13/16" |

1/2 |

|

7" |

|

|

|

2Lift the hood to the cabinet and pass the power cord through the appropriate holes on the Range Hood and through the cabinet to the power source.

25

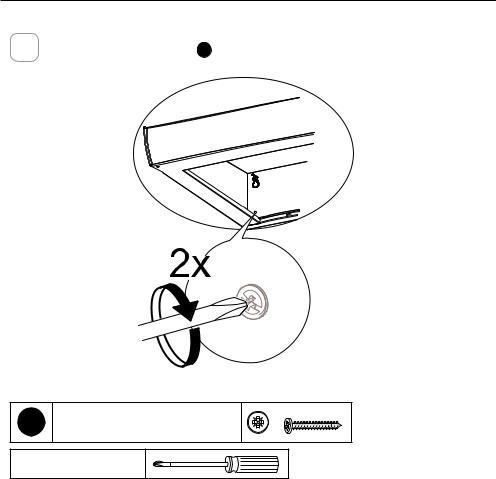

MOUNTING RANGE HOOD UNDER THE CABINET

3Mark the holes for attaching the hood to the cabinet. Verify the measurement with the diagram on the previous page.

4 Attach the Hood body with 4 screws E from the bottom available with the hood.

E Pozi Screws (3/16" x 1 15/16")

Pozi Screwdriver

26

CONNECTING ELECTRICITY

1Connecting the House Power.

Caution! Do not turn on the house power until the installation is complete.

• Feed the Power Supply Cable through the electrical knock out.

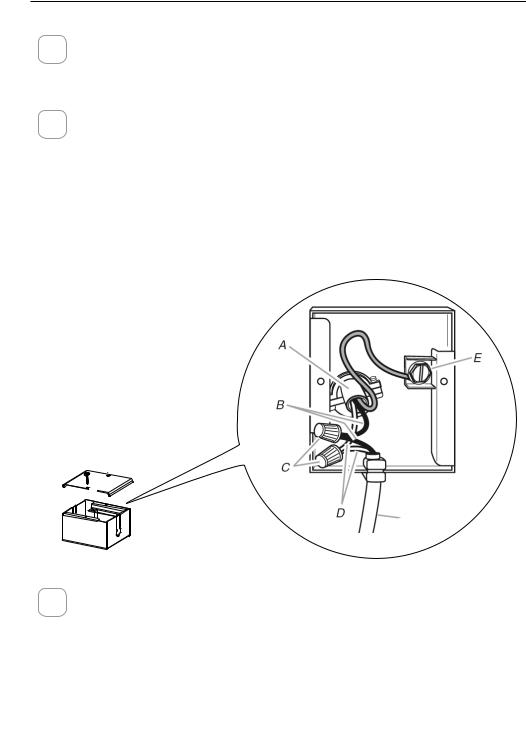

2Wiring Box Connections.

•Attach the White lead of the Power Supply (A) to the White lead of the Range Hood (D) with a twist-on type connector.

•Attach the Black lead of the Power Supply to the Black lead of the Range Hood (B) with a twist-on type wire connector (C).

•Connect the Green (E) (Green and Yellow) ground wire under the grounding screw.

Hood wiring

3 Replace the field wiring compartment cover and the grease filters

27

OPERATING THE CONTROLS

FOR BEST RESULTS

Start the Range Hood several minutes before cooking to develop proper airflow. Allow the

Range Hood to operate for several minutes after cooking is complete to clear all smoke and odors from the kitchen.

Button Function

LED indicator light (L) - indicates current speed with color

Green - speed 1

Orange - speed 2

Red - speed 3

Flashing Red - intensive speed

Light On/Off Button

On/Off switch for the Lights.

Press the button to turn the light ON and press again to turn it OFF.

Blower On/Off Button On/Off button for the blower.

Press the button to turn the blower ON to speed one (indicated by green LED) and press again to turn the hood off.

Blower Speed 2

Press this button to turn the hood onto speed #2. (indicated by orange LED).

Blower Speed 3 / Intensive

Press this button to turn the hood onto speed #3. (indicated by solid red LED)

Hold down the speed 3 button for 2 seconds to activate the intensive speed. The intensive speed setting is indicated by a blinking red light.

This operates the hood for 10 minutes on the highest speed and then returns to the previous speed.

28

CARING FOR FILTERS

CLEANING METAL GREASE FILTERS

The metal grease filtaers can be cleaned in hot detergent solution or washed in the dishwasher.

They should be cleaned every 2 months use, or more frequently if use is particularly heavy.

Remove the filter, pushing the lever to-

1 wards the back of the unit while pulling downward.

2Wash the filter without bending it. Leave it to dry thoroughly before reinstalling. If the surface of the filter changes color over time, efficiency will not be affected.

3 To reinstall the filter, push the filter up into position while pulling the latch forward, then release the latch to lock into place

NOTES:

•Cleaning in a dishwasher may dull the finish of the metal grease filters.

•Ensure that the filters are completely dry before installing them back into the Range Hood.

CLEANING EXTERIOR SURFACES

Please note, abrasives and scouring agents can scratch range hood finishes and should not be used to clean finished surfaces.

Stainless Steel finish cleaning instructions:

Clean exterior surfaces with a commercially available stainless steel cleaner.

29

REPLACING ACTIVATED CHARCOAL FILTER

The Activated Charcoal Filters are not washable and cannot be regenerated, and must be replaced approximately every 4 months of operation, or more frequently with heavy usage.

1 Remove the grease filters.

2 |

Remove the old carbon |

filter by removing the two |

screws and then install the new filter using the same two screw holes.

3 Reinstall the grease filters.

30

Loading...

Loading...