Faber INLT35SSV, INLT21SSV INSTALLATION INSTRUCTIONS AND OPERATION MANUAL

INCA IN-LIGHT

Installation Instructions

Use and Care Information

Instructions d'installation Utilisez et d'entretien

Instrucciones de instalación Información de uso y cuidado

INLT21SSV

INLT28SSV

INLT35SSV

CONTENTS

Section |

Page |

Important safety instructions |

3 |

Range hood dimensions |

6 |

Installation height requirements |

7 |

Parts |

8 |

Tools needed |

10 |

Venting method |

11 |

Preparing the cabinet |

12 |

Preparing to mount the range hood |

13 |

Choosing venting method |

16 |

Attach venting: option 1 - rear or top vented |

17 |

Attach venting: option 2 - non ducted recirculating |

18 |

Connecting house power |

19 |

Operating the controls |

22 |

Remote control |

23 |

Cleaning stainless steel |

24 |

Cleaning the filter cover panel |

24 |

Caring for filters |

25 |

Replacing the activated charcoal filter |

26 |

Changing and Inserting the charcoal filter |

27 |

Replacing bulbs |

27 |

Wiring diagram |

28 |

Warranty |

29 |

2

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS BEFORE YOU START

INSTALLING THIS Range Hood

WARNING: - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a)Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium setting.

b)Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes

Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c)Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d)Useproperpansize. Alwaysusecookwareappropriateforthesizeofthesurfaceelement.

WARNING: - TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

a)SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately

EVACUATE AND CALL THE FIRE DEPARTMENT.

b)NEVER PICK UP A FLAMING PAN - You may be burned.

c)DO NOT USE WATER, including wet dishcloths or towels - a violent steam explosion will result.

d)Use an extinguisher ONLY if:

1.You know you have a Class ABC extinguisher, and you already know how to operate it.

2.The fire is small and contained in the area where it started.

3.The fire department is being called.

4.You can fight the fire with your back to an exit.

* Based on "Kitchen Firesafety Tips" published by NFPA

WARNING - TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, do not use this fan with any solid-state speed control device.

WARNING-TOREDUCETHERISKOFFIRE,ELECTRICALSHOCK,ORINJURYTOPERSONS, OBSERVE THE FOLLOWING:

1.Usethisunitonlyinthemannerintendedbythemanufacturer.Ifyouhaveanyquestions, contact the manufacturer.

2.Beforeservicingorcleaningunit,switchpoweroffatservicepanelandlocktheservice disconnectingmeanstopreventpowerfrombeingswitchedonaccidentally.Whenthe service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

CAUTION: For General Ventilating Use Only. Do Not Use To Exhaust Hazardous or Explosive Materials and Vapors.

WARNING-TOREDUCETHERISKOFFIRE,ELECTRICALSHOCK,ORINJURYTOPERSONS, OBSERVE THE FOLLOWING:

1.Installation Work And Electrical Wiring Must Be Done By Qualified Person(s) In Accordance With All Applicable Codes And Standards, Including Fire-Rated Construction.

2.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer's guideline and safety standards such as those published by theNationalFireProtectionAssociation(NFPA),andtheAmericanSocietyforHeating, RefrigerationandAirConditioningEngineers(ASHRAE),andthelocalcodeauthorities.

3

3.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

4.Ducted fans must always be vented to the outdoors.

ALL WALL AND FLOOR OPENINGS WHERE THE Range Hood IS INSTALLED

MUST BE SEALED.

This Range Hood requires at least 24" of clearance between the bottom of the Range Hood and the cooking surface or countertop. This hood has been approved by UL at this distance from the cooktop.

This minimum clearance may be higher depending on local building codes. For gas cooktops and combination ranges, a minimum of 30" is recommended and may be required. Overhead cabinets on both sides of this unit must be a minimum of 18" above the cooking surface or countertop. Consult the cooktop or range installation instructions given by the manufacturer before making any cutouts.

MOBILE HOME INSTALLATION The installation of this Range Hood must conform to the Manufactured Home Construction and Safety Standards, Title 24 CFR, Part 3280 (formerly Federal Standard for Mobile Home Construction and Safety, Title 24, HUD, Part 280). See Electrical Requirements"

VENTING REQUIREMENTS

Determine which venting method is best for your application. Ductwork can extend either through the wall or the roof.

The length of the ductwork and the number of elbows should be kept to a minimum to provide efficient performance. The size of the ductwork should be uniform. Do not install two elbows together. Use duct tape to seal all joints in the ductwork system. Use caulking to seal exterior wall or floor opening around the cap.

Flexible ductwork is not recommended. Flexible ductwork creates back pressure and air turbulence that greatly reduces performance.

Make sure there is proper clearance within the wall or floor for exhaust duct before making cutouts. Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut, then a supporting frame must be constructed.

WARNING - To Reduce The Risk Of Fire, Use Only Metal Ductwork.

CAUTION - To reduce risk of fire and to properly exhaust air, be sure to duct air outside

– Do not vent exhaust air into spaces within walls or ceilings or into attics, crawl spaces, or garages.

Cold Weather installations

An additional back draft damper should be installed to minimize backward cold air flow and a nonmetallic thermal break should be installed to minimize conduction of outside temperatures as part of the vent system. The damper should be on the cold air side of the thermal break. The break should be as close as possible to where the vent system enters the heated portion of the house.

! WARNING

•Venting system MUST terminate outside the home.

•DO NOT terminate the ductwork in an attic or other enclosed space.

•DO NOT use 4" laundry-type wall caps.

•Flexible-type ductwork is not recommended.

•DO NOT obstruct the flow of combustion and ventilation air.

•Failure to follow venting requirements may result in a fire.

4

ELECTRICAL REQUIREMENTS

A 120 volt, 60 Hz AC-only electrical supply is required on a separate 15 amp fused circuit. A time-delay fuse or circuit breaker is recommended. The fuse must be sized per local codes in accordance with the electrical rating of this unit as specified on the serial/rating plate located inside the unit near the field wiring compartment.

ELECTRICAL INSTALLATION WITH WIRING BOX

THIS UNIT MUST BE CONNECTED WITH COPPER WIRE ONLY. Wire sizes must conform to the requirements of the National Electrical Code, ANSI/NFPA 70 - latest edition, and all local codes and ordinances. Wire size and connections must conform with the rating of the appliance. Copies of the standard listed above may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fused disconnect (or circuit breaker) through flexible, armored or nonmetallic sheathed copper cable. Allow some slack in the cable so the appliance can be moved if servicing is ever necessary. A UL Listed,

1/2" conduit connector must be provided at each end of the power supply cable (at the appliance and at the junction box).

When making the electrical connection, cut a 1 1/4" hole in the wall. A hole cut through wood must be sanded until smooth. A hole through metal must have a grommet.

! WARNING

•Electrical ground is required on this Range Hood.

•If cold water pipe is interrupted by plastic, nonmetallic gaskets or other materials, DO NOT use for grounding.

•DO NOT ground to a gas pipe.

•DO NOT have a fuse in the neutral or grounding circuit. A fuse in the neutral or grounding circuit could result in electrical shock.

•Check with a qualified electrician if you are in doubt as to whether the Range

Hood is properly grounded.

•Failure to follow electrical requirements may result in a fire.

State of California Proposition 65 Warning (US only)

WARNING

WARNING

This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

For more information go to www.P65Warnings.ca.gov

5

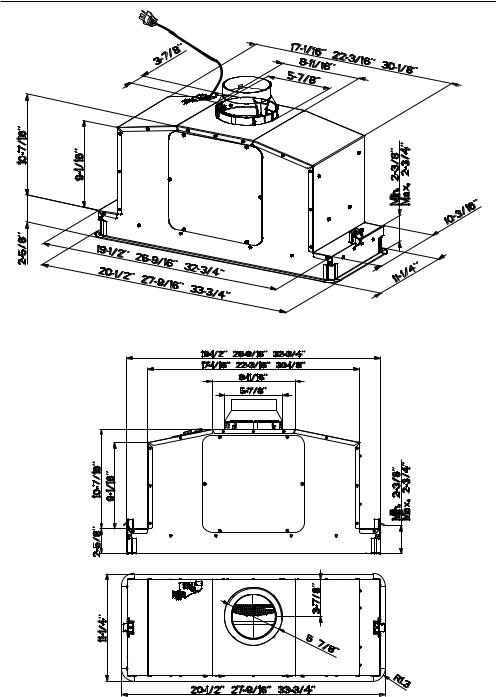

RANGE HOOD DIMENSIONS

21" |

28" |

35" |

|

||

|

|

21" |

28" |

35" |

|

||

|

|

6

INSTALLATION HEIGHT REQUIREMENTS

MIN. 24" OVER ELECTRIC / MIN. 30" OVER GAS

Min. 24" Min. 30"

7

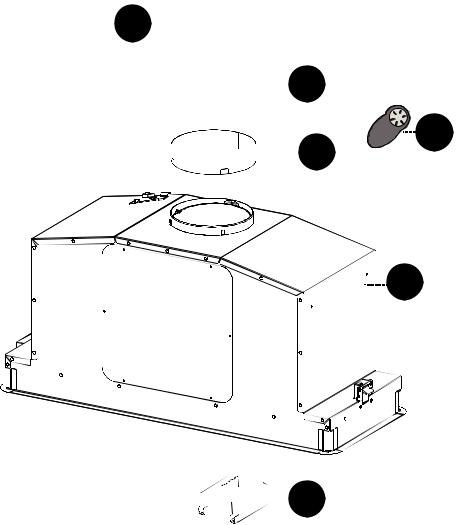

PARTS

PARTS INCLUDED

REF. |

PART |

QTY |

|

|

|

A |

Hood body |

1 |

|

|

|

B |

Bracket |

2 |

|

|

|

D |

Recirculation vent grill |

2 |

|

|

|

E |

Damper flaps |

2 |

|

|

|

F |

Metallic damper ring |

1 |

|

|

|

Z |

Remote Control |

1 |

|

|

|

REF |

PART |

|

G |

Pozi Screws (1/8" x 3/8") |

2 |

I |

Pozi Screws (1/8" x 5/8") |

4 |

L |

Screws plug |

2 |

8

D

E

E

Z

F

F

A

B

B

9

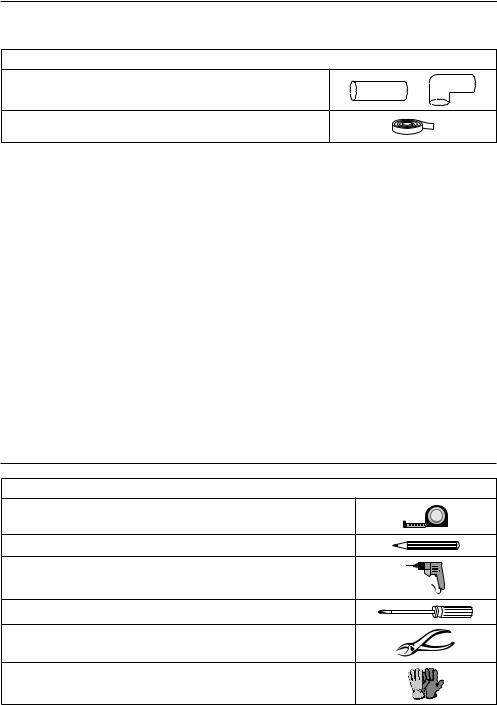

PARTS (cont.)

PARTS NEEDED

PART

6" Round Metal Ductwork

Foil tape

ACCESSORIES AVAILABLE

ACCESSORY |

SKU# |

|

|

Activated Charcoal Filter Kit |

#FILTER1 |

|

|

Activated Charcoal Filter Kit Washable Long Lasting |

#FILTER1LL |

|

|

Direct Connect Wiring Box |

#WIREBOX |

|

|

Standard Liner 24 (Use only with INLT21SSV) |

#LINE24ST |

|

|

Standard Liner 30 (Use only with INLT28SSV) |

#LINE30ST |

|

|

Standard Liner 36 (Use only with INLT28SSV) |

#LINE36ST |

|

|

Pro Liner 36 (Use only with INLT35SSV) |

#LINE36PT |

|

|

Self supporting liner (Use only with INLT28SSV) |

#LINSPT301228 |

|

|

Self supporting liner (Use only with INLT28SSV) |

#LINSPT361228 |

|

|

TOOLS NEEDED

TOOL

Tape Measure

Pencil

Electric Drill with 5/16" Drill Bit

Phillips Screwdriver

Metal sheers

Work gloves

10

VENTING METHOD

1

Option 1: REAR OR TOP VENTED

6"

Top

6"

Rear |

Option 2: RECIRCULATING

Requires purchase of Activated Charcoal Accessory kit.

11

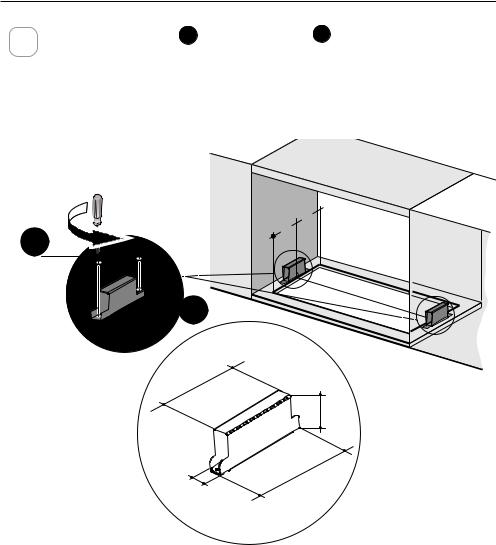

PREPARING THE CABINET

1 |

The Hood can be installed directly on the underside of the cabinet. |

|

2If you use the Self supporting liner #LINSPT301228 or #LINSPT361228, please follow the instructions included in the corresponding self supporting liner manual.

If you do not use the Self supporting liner, create a cut out in the bottom of the cabinet as shown in the illustration.

21"

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

28" |

|

|

||

|

|

|||

|

|

|

35" |

|

12

PREPARING TO MOUNT THE RANGE HOOD

3Attach the brackets B with two screws I as shown in the center of the cut out on each side. The edge of the bracket should align with the cut out edge.

If you are installing a Self supporting liner (#LINSPT301228 or #LINSPT361228), brackets need to be attached directly to the bottom lip of the metal liner.

=

=

I

4x

2x B

13

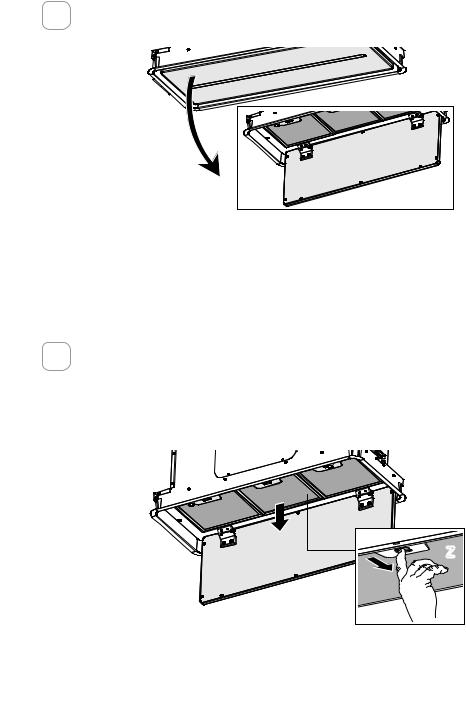

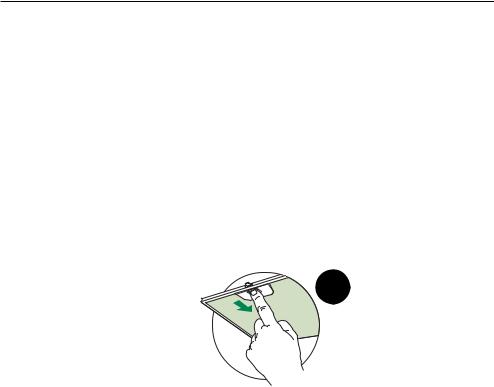

4 Open the filter panel cover away from you by pulling down from the magnetic catch.

Remove the grease filters by pushing the release tab towards the back of the hood.

5

Z

14

6Insert the hood in the cut out until the side installation clips snap into place above the previously installed side wall brackets. Lock the hood into position by tightening the 2 screws Vf from underneath.

Insert the 2 plastic hole covers L one on each side into the screw holes.

L

L

2x

Vf

[

15

CHOOSING VENTING METHOD

7 Option 1: REAR OR TOP VENTED

6"

Top

6"

Rear

Go to Pg.17

Option 2: RECIRCULATING

Requires purchase of

Activated Charcoal

Accessory kit.

Go to Pg.18

16

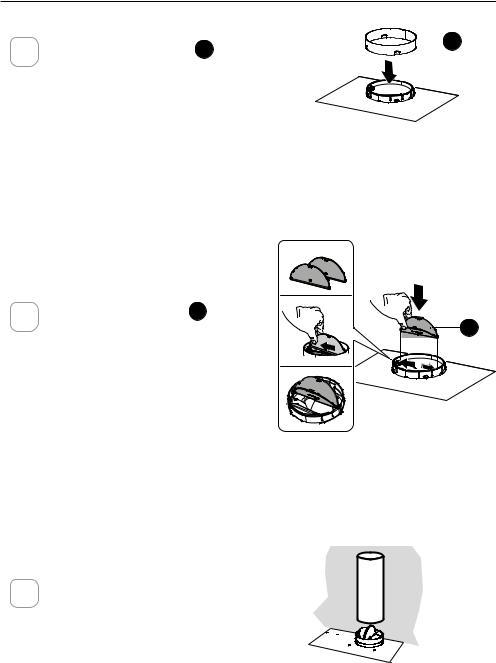

ATTACH VENTING: OPTION 1 - REAR OR TOP VENTED

D |

F |

1 Install Metal damper ring F included with |

|

the Hood. |

|

2 |

Install the Damper flaps E that are |

|

included with hood by snapping the |

||

|

||

|

tabs into place inside the top of the |

|

|

hood before connecting ductwork. |

E |

3Install Roof or Wall Cap purchased separately. Connect the 6" metal ductwork to the Roof or Wall Cap and then attach ductwork. Seal with foil tape.

17

ATTACH VENTING: OPTION 2 - NON DUCTED RECIRCULATING

1For Non-Ducted Recirculation venting route the ductwork to a location above the hood where the discharge is vented back into the room.

Use the included Recirculation Vent Grill D to cover the opening. Secure the grill with the 2 screws G provided in the Install Kit.

A straight 6" round duct that is at least 15" in length should be used to lead air from the top of the hood exhaust outlet to the exit of the cabinet above.

D |

G |

|

´

´

Required Activated Charcoal Filter Accessory - sku # - FILTER1

Long Lasting Activated Charcoal Filter Accessory - sku # FILTER1LL (purchased separately)

18

CONNECTING HOUSE POWER

ELECTRICAL INSTALLATION WITH CONNECTION CABLE

8GROUNDING INSTRUCTIONS This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. This appliance is equipped with a cord having a grounding wire with a grounding plug. The plug must be plugged into an outlet that is properly installed and grounded.

WARNING - Improper grounding can result in a risk of electric shock. Consult a qualified electrician if the grounding instructions are not completely understood, or if doubt exists as to whether the appliance is properly grounded. Do not use an extension cord. If the power supply cord is too short, have a qualified electrician install an outlet near the appliance.

Max. 33 7/16”

The power cord shall be accessible for inspection after installation.

ELECTRICAL INSTALLATION WITH OPTIONAL WIRING BOX

For permanent wiring, use only the Direct Connect Wiring Box accessory sku WIREBOX, manufactured by Faber.

Direct Connect Wiring Box Accessory sku # WIREBOX (purchased separately)

19

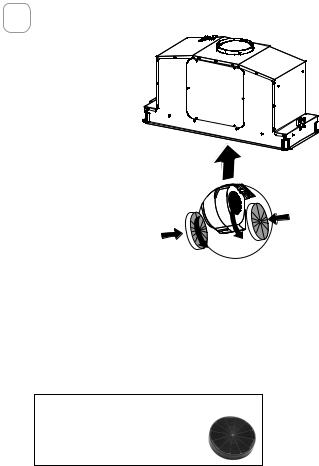

9 FOR NON-DUCTED RECIRCULATION OPTION

1

2

Attach each charcoal filter to the black grid on each side of the blower. Press the charcoal filter tightly to the black grid on the blower side and rotate the filter clockwise (towards the front of the insert hood) until it locks into place. Turn counterclockwise (towards the back of the insert hood)

to remove (for more details see paragraph Changing and Inserting the Charcoal Filter)

.

Required Activated Charcoal Filter Accessory - sku # - FILTER1

Long Lasting Activated Charcoal Filter Accessory - sku # FILTER1LL (purchased separately)

20

10 Reinstall the grease filters removed previously.

=

11 |

Close the filter panel cover by pushing it back into place until the magnetic |

|

latch has secured the panel. |

||

|

21

OPERATING THE CONTROLS

FOR BEST RESULTS

Start the Range Hood several minutes before cooking to develop proper airflow. Allow the Range Hood to operate for several minutes after cooking is complete to clear all smoke and odors from the kitchen.

Button Function

Fan Off Button:Turn the blower Off. The fan can be operated by pressing any of the fan setting buttons.

Hold down this button for 2 seconds to activate delayed off function which will keep the fan On for 15 minutes and automatically shut Off.

Fan Settings Buttons: Low Speed.

Fan Settings Buttons: Medium Speed.

Fan Settings Buttons: High Speed.

Hold down the button for 2 seconds to activate the INTENSIVE SPEED, which is timed to run for 10 minutes. At the end of this time it will automatically return to the speed set before.Suitable to deal with maximum levels of cooking fumes.

Light Button: On/Off switch for the Led lights. Press the LIGHT button to turn the light on, and again to turn off.

NOTE: If your product has had a CFM adjustment, refer to the CFM adjustment manual for the information. Some motor speeds or functions may be reduced.

22

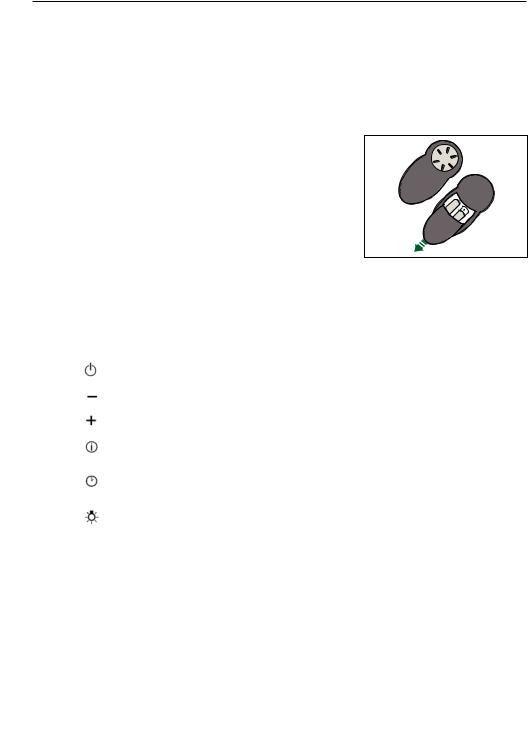

REMOTE CONTROL

Installing the Battery

•The appliance can be controlled using a remote control powered by a 1.5 V carbon-zinc alkaline batteries of the standard LR03-AAA type (not included).

•Used batteries must be disposed of in the proper manner.

Caution:

•Do not place the remote control near heat sources.

•Do not discard the batteries with normal waste, they must be put into the specific containers.

•Tighten the battery cover screw tight.

|

|

|

|

|

Motor |

Brief pressure: Motor On/Off. |

|

|

|

|

|

|

|

|

|

|

- |

Decreases the working speed each time it is pressed. |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

Increases the working speed each time it is pressed. |

||||

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Intensive |

Increases the working speed each time it is pressed. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Briefpressure:Activates/DeactivatestheDelayfunction:automatic |

|

|

|

|

|

|

|

|

|

|

|

|

Delay |

switch-off with a 30’ delay. The display shows the operating speed |

|

|

|

|

|

|

and the dot at the bottom right flashes once a second. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Light |

Brief pressure: Lights On / Off. |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23

CLEANING STAINLESS STEEL

Cleaning Exterior surfaces:

Please note, abrasives and scouring agents can scratch range hood finishes and should not be used to clean finished surfaces.

Stainless Steel finish cleaning instructions:

Clean exterior surfaces with a commercially available stainless steel cleaner.

CLEANING THE FILTER COVER PANEL

1.Open the Panel by pulling it down.

2.Clean the outside with a damp cloth and neutral detergent.

3.Clean the inside using a damp cloth and neutral detergent.

4.Do not use wet cloths or sponges, or jets of water; do not use abrasive substances.

24

CARING FOR FILTERS

CLEANING METAL GREASE FILTERS

The metal grease filters can be cleaned in hot detergent solution or washed in the dishwasher. They should be cleaned every 2 months use, or more frequently if use is particularly heavy.

1.Open the Panel by pulling it down.

2.Remove the filter, pushing the lever towards the back of the unit and at the same time pulling downward.

3.Wash the filter without bending it, leave it to dry thoroughly before replacing (if the surface of the filter changes color over time, this will have absolutely no effect on its efficiency).

4.Replace, taking care to ensure that the handle faces forward.

5.Cleaning in dishwasher may dull the finish of the metal grease filter.

6.Close the Panel.

7.Completely dry the filters before installing back into the hood. No water should be trapped in the filter before reinstalling.

Z

25

REPLACING THE ACTIVATED CHARCOAL FILTER

The Activated Charcoal Filters (FILTER1) are not washable and cannot be regenerated,andmustbereplacedapproximatelyevery4monthsofoperation, or more frequently with heavy usage.

1.Open the Panel by pulling it down.

2.Remove the Filter, pushing it towards the back of the unit and at the same time pulling downward.

3.Remove the saturated Activated Charcoal Filters, as indicated (A).

4.Fit the new Filters, as indicated (B).

5.Replace, taking care to ensure that the handle faces forwards.

6.Close the Panel.

CAUTION: When used in recirculation mode, to Reduce the Risk of Fire and Shock use only conversion kit Model FILTER 1 or FILTER1LL.

A

NOTE: For FILTER1LL, |

|

Long lasting filters, |

|

they can be washed |

|

and reused. |

|

See instructions |

|

included with those |

|

filters. |

B |

|

W

26

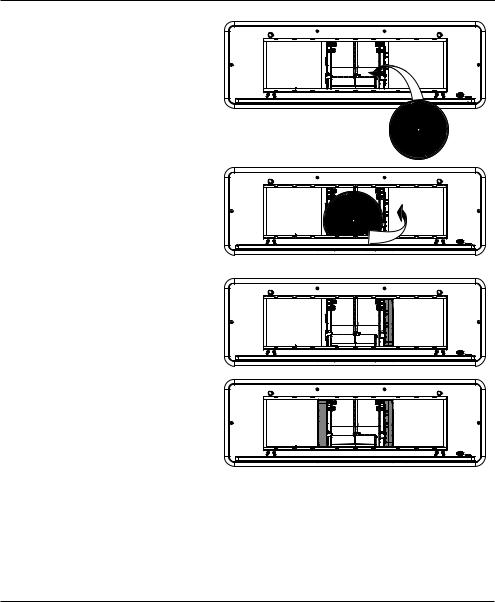

CHANGING AND INSERTING THE CHARCOAL FILTER

1) Angle the top of the filter up and into the area below the motor and then insert the lower portion of the filter.

2)Turn the filter to the right around the motor and slide the filter between the motor and side wall.

3)Positionthefilterontheside of the blower and turn to lock in place.

4)Repeat on the left side.

REPLACING BULBS

LED lights must be replaced by Faber factory authorized service.

27

Loading...

Loading...