Emerson IS1x0105B, IS1x0023B, IS1x0043B, IS2x0200B, IS2x0170B User Manual

...

User Guide

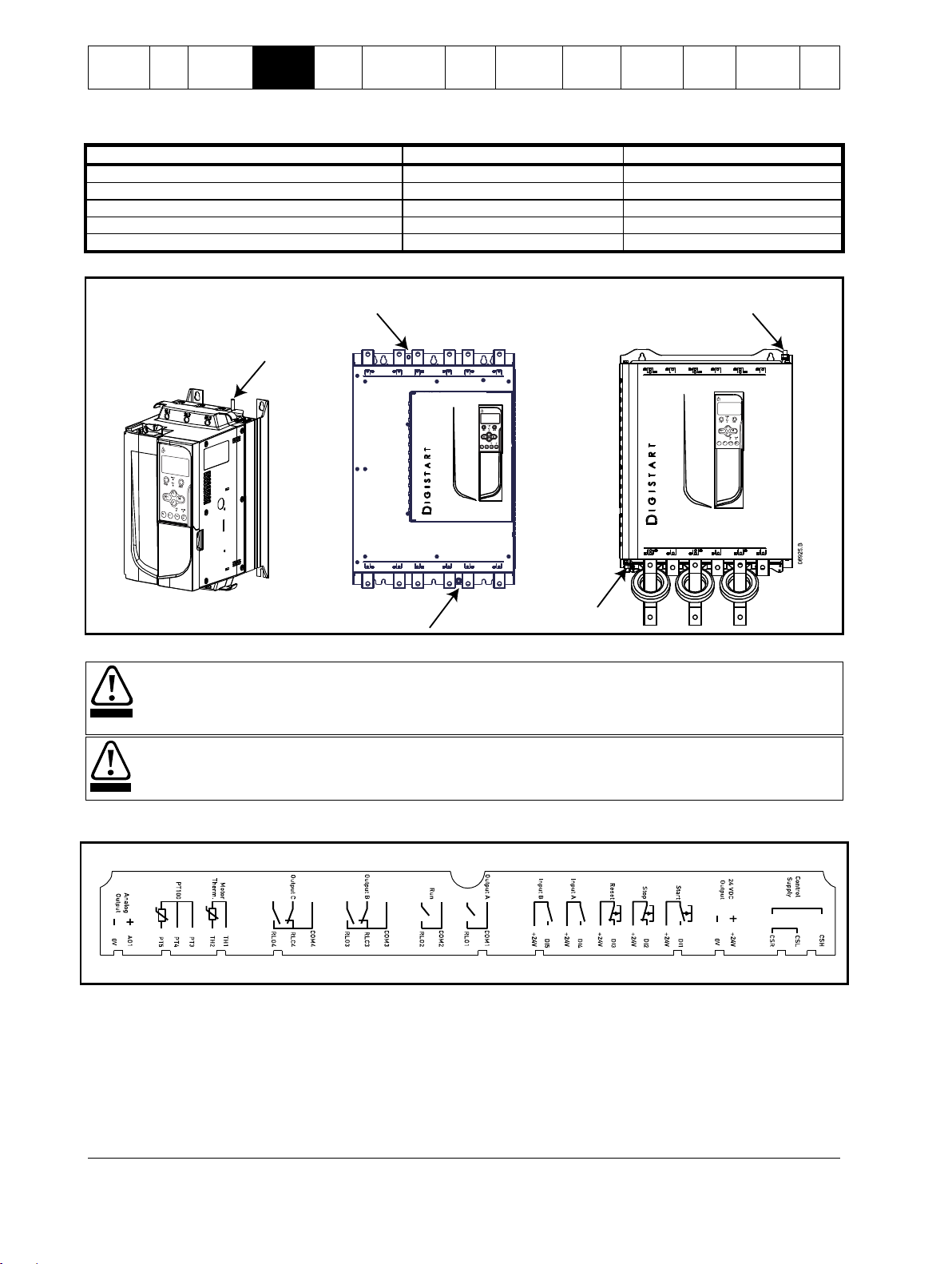

Digistart IS

Soft starters for 3 phase

induction motors

7.5 to 800kW (23A to 1600A)

200V, 400V, 575V, 690V

0477-0001-04

www.controltechniques.com

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or

adjustment of the optional parameters of the equipment or from mismatching the starter with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or

the content of the guide without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including, photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Software Version

This product is supplied with the latest version of user-interface and machine control software. If this product is to be used in a new

or existing system with other starters, there may be some differences between their software and the software in this product. These

differences may cause the product to function differently. This may also apply to starters returned from the

Service Centre.

If there is any doubt, please contact Control Techniques or your local Distributor.

Environmental Statement

Control Techniques is committed to minimising

throughout their li

International Standard ISO 14001. Further information on the EMS, our Environment Policy and other relevant information is

available on request.

When the products eventually reach the end of their useful life, they can very easily be dismantled into their major component parts

for efficient recycling. Many parts snap together and can be separated without the use of tools, while other parts are secured with

conventional screws. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller products come

in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these containers can be recycled.

Polythene, used on the protective film and bags from wrapping product, can be recycled in the same way. Control Techniques’s

packaging strategy favours easily recyclable materials of low environmental impact, and regular reviews identify opportunities for

improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH Legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier

of an article to inform the recipient if it contains more than a specified propo

European Chemicals Agency (ECHA) to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a

candidate for compulsory authorisation.

For current information on how this requirement applies in relation to specific Control Techniques products, please approach your

usual contact in the first instance. Control Techniques position statement can be veiwed at:

www.controltechniques.com/REACH

fe cycle. To this end, we operate an Environmental Management System (EMS) which is certified to the

the environmental impacts of its manufacturing operations and of its products

rtion of any substance which is considered by the

Control Techniques

For the latest manuals and software, please visit our website.

Copyright © November 2011 Control Techniques Ltd

Issue: 4

Contents

1. Safety Information ............................................................................................................................................ 5

1.1 Warnings, cautions and notes ................................................................................................................................................ 5

1.2 Electrical safety - general warning .......................................................................................................................................... 5

1.3 System design and safety of personnel .................................................................................................................................. 5

1.4 Environmental limits ............................................................................................................................................................... 5

1.5 Compliance with regulations .................................................................................................................................................. 5

1.6 Motor ..................................................................................................................................................................................... 5

1.7 Adjusting parameters ............................................................................................................................................................. 5

1.8 Electrical installation .............................................................................................................................................................. 6

2. Rating Data ........................................................................................................................................................ 7

2.1 Model code ............................................................................................................................................................................ 7

2.2 Current ratings ....................................................................................................................................................................... 7

3. Mechanical Installation ................................................................................................................................... 12

3.1 Dimensions and weights ...................................................................................................................................................... 12

3.2 Physical installation .............................................................................................................................................................. 15

3.3 Busbar adjustment procedure .............................................................................................................................................. 15

4. Electrical Installation ...................................................................................................................................... 17

4.1 Terminal layout .................................................................................................................................................................... 17

4.2 Control connections ............................................................................................................................................................. 21

4.3 Power connections ............................................................................................................................................................... 22

4.4 Fuse information .................................................................................................................................................................. 26

4.5 Bypass contactor ................................................................................................................................................................. 30

4.6 Main contactor ..................................................................................................................................................................... 30

4.7 Circuit breaker ..................................................................................................................................................................... 30

4.8 Power factor correction ........................................................................................................................................................ 30

4.9 EMC (electromagnetic compatibility) .................................................................................................................................... 31

5. Keypad and Status .......................................................................................................................................... 32

5.1 Keypad ................................................................................................................................................................................ 32

5.2 Removing and replacing the keypad .................................................................................................................................... 32

5.3 Synchronising the keypad and the starter ............................................................................................................................ 33

5.4 Displays ............................................................................................................................................................................... 33

6. Quick Start Commissioning ........................................................................................................................... 35

6.1 Control wiring ....................................................................................................................................................................... 35

6.2 Setup procedure .................................................................................................................................................................. 36

7. Operation ......................................................................................................................................................... 37

7.1 Start, stop and reset commands........................................................................................................................................... 37

7.2 Soft start methods ................................................................................................................................................................ 37

7.3 Stop methods ....................................................................................................................................................................... 39

7.4 Jog operation ....................................................................................................................................................................... 42

7.5 Inside delta operation ........................................................................................................................................................... 43

8. Programming ................................................................................................................................................... 44

8.1 Programming menu ............................................................................................................................................................. 44

8.2 Access code ........................................................................................................................................................................ 44

8.3 Adjustment lock ................................................................................................................................................................... 45

8.4 Load defaults ....................................................................................................................................................................... 45

8.5 Quick setup details ............................................................................................................................................................... 45

8.6 Standard menu .................................................................................................................................................................... 46

8.7 Advanced menu ................................................................................................................................................................... 47

8.8 Parameter descriptions ........................................................................................................................................................ 51

8.9 Maintenance tools ................................................................................................................................................................ 65

9. Diagnostics ...................................................................................................................................................... 69

9.1 Protection responses ........................................................................................................................................................... 69

9.2 Trip messages ..................................................................................................................................................................... 69

9.3 General faults ...................................................................................................................................................................... 72

10. Application Examples ..................................................................................................................................... 74

10.1 Installation with main contactor ............................................................................................................................................ 74

10.2 Installation with external bypass contactor ........................................................................................................................... 75

10.3 Emergency run operation ..................................................................................................................................................... 76

10.4 Auxiliary trip circuit ............................................................................................................................................................... 77

Digistart IS User Guide 3

Issue: 4 www.controltechniques.com

10.5 DC brake with external zero speed sensor ........................................................................................................................... 78

10.6 Soft braking.......................................................................................................................................................................... 79

10.7 Two-speed motor ................................................................................................................................................................. 80

10.8 Slip-ring motor ..................................................................................................................................................................... 81

11. Technical Data ................................................................................................................................................. 82

12. Maintenance .................................................................................................................................................... 84

12.1 Care ..................................................................................................................................................................................... 84

12.2 Measuring the motor current ................................................................................................................................................ 84

12.3 Measuring the input and output power ................................................................................................................................. 84

12.4 Exchanging products ........................................................................................................................................................... 84

13. Options ............................................................................................................................................................ 85

4 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

WARNING

A Warning contains information which is essential for avoiding a safety hazard.

CAUTION

A Caution contains information which is necessary for avoiding a risk of damage to the product or other equipment.

NOTE

A Note contains information which helps to ensure correct operation of the product.

1. Safety Information

1.1 Warnings, cautions and notes

1.2 Electrical safety - general warning

The voltages used in the starter can cause severe electrical shock and/or burns, and could be lethal. Extreme care is necessary at

all times when working with or adjacent to the starter.

Specific warnings are given at the relevant places in this guide.

1.3 System design and safety of personnel

The starter is intended as a component for professional incorporation into complete equipment or a system. If installed incorrectly,

the starter may present a safety hazard.

The starter uses high voltages and currents, carries stored electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system design to avoid hazards either in normal operation or in the

event of equipment malfunction. System design, installation, commissioning and maintenance must be carried out by personnel who

have the necessary training and experience. They must read this safety information and this guide carefully.

None of the starter functions must be used to ensure safety of personnel, i.e. they must not be used for safety-related

functions.

Careful consideration must be given to the functions of the starter which might result in a hazard, either through their intended

behaviour or through incorrect operation due to a fault. In any application where a malfunction of the starter or its control system

could lead to or allow damage, loss or injury, a risk analysis must be carried out, and where necessary, further measures taken to

reduce the risk.

The system designer is responsible for ensuring that the complete system is safe and designed correctly according to the relevant

safety standards.

1.4 Environmental limits

Instructions regarding transport, storage, installation and use of the starter must be complied with, including the specified

environmental limits. Starters must not be subjected to excessive physical force.

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring regulations, accident prevention

regulations and electromagnetic compatibility (EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses or other protection, and protective ground connections.

Within the European Union, all machinery in which this product is used must comply with the following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.6 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations. Ensure the motor shaft is not exposed.

The values of the motor parameters set in the starter affect the protection of the motor. The default values in the starter should not

be relied upon. It is essential that the correct value is entered in Pr 1A Motor Full Load Current. This affects the thermal protection of

the motor.

1.7 Adjusting parameters

Some parameters have a profound effect on the operation of the starter. They must not be altered without careful consideration of

the impact on the controlled system. Measures must be taken to prevent unwanted changes due to error or tampering.

Digistart IS User Guide 5

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

1.8 Electrical installation

1.8.1 Electrical shock risk

The voltages present in the following locations can cause severe electric shock and may be lethal:

AC supply cables and connections

Output cables and connections

Many internal parts of the starter, and external option units

The AC supply must be disconnected from the starter using an approved isolation device before any cover is removed from the

starter or before any servicing work is performed.

Models IS3x0255B to IS4x1000B, IS4x0360N to IS561600N: The busbar and heatsink are live while the unit is operating (starting,

running or stopping). If the starter is installed without a main contactor, the busbar and heatsink are live whenever mains voltage is

connected (including when the starter is ready or tripped).

1.8.2 Power-up procedure

Always apply control voltage before (or with) mains voltage.

IS1x0023B to IS1x0105B: After transportation, mechanical shock or rough handling there is a possibility that the bypass contactor

may have latched into the on state. To prevent the possibility of the motor starting immediately, on first commissioning or operation

after transportation, always ensure that the control supply is applied before the power, so that the contactor state is initialised.

1.8.3 STOP function

The STOP function does not remove dangerous voltages from the starter, the motor or any external option units.

1.8.4 Stored charge

The starter contains capacitors that remain charged to a potentially dangerous voltage after the AC supply has been disconnected.

If the starter has been energised, the AC supply must be isolated at least two minutes before work may continue.

Normally, the capacitors are discharged by an internal resistor. Under certain, unusual fault conditions, the capacitors may fail to

discharge. Do not assume that the capacitors have discharged. To protect the user and the equipment, take due care when carrying

out any work on the starter.

1.8.5 Equipment supplied by plug and socket

The control supply terminals of the starter are connected to the internal capacitors through rectifier diodes which are not intended to

give safety isolation. If the plug terminals can be touched when the plug is disconnected from the socket, a means of automatically

isolating the plug from the starter must be used (e.g. a latching relay).

1.8.6 Short circuit

Digistart IS soft starters are not short circuit proof. After severe overload or short circuit, the operation of the soft starter should be

fully tested by an authorised service agent.

1.8.7 Auto-start

Use the auto-start feature with caution. Read all the notes related to auto-start before operation.

6 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

IS

3 4 0 2 5

5 N

Bypass

B = Internal

N = Non-bypassed

Nominal current rating

Mains voltage

4 = 200 to 440 Vac (± 10%)

6 = 380 to 600 Vac (± 10%) or 380 to 690 Vac

(± 10% for grounded star supply system only)

Frame size

CAUTION

Digistart IS can only be used on 690V IT supply equipped with surge protectors. Please contact Control Techniques or

your local distributor.

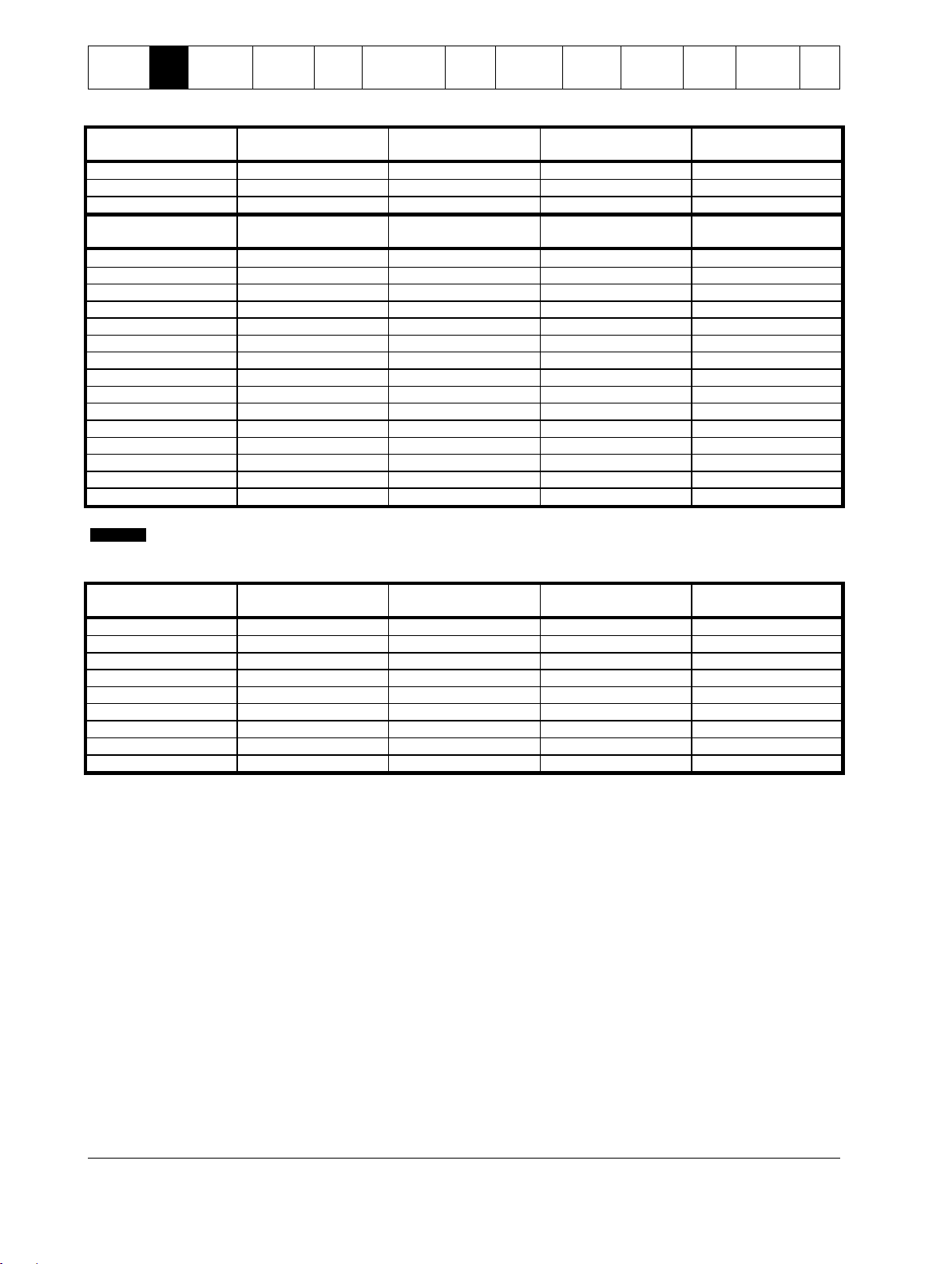

80 A : AC-53b

3.5 - 15 : 345

Off time (seconds)

Start time (seconds)

Start current (multiple of motor full load current)

Starter current rating (amperes)

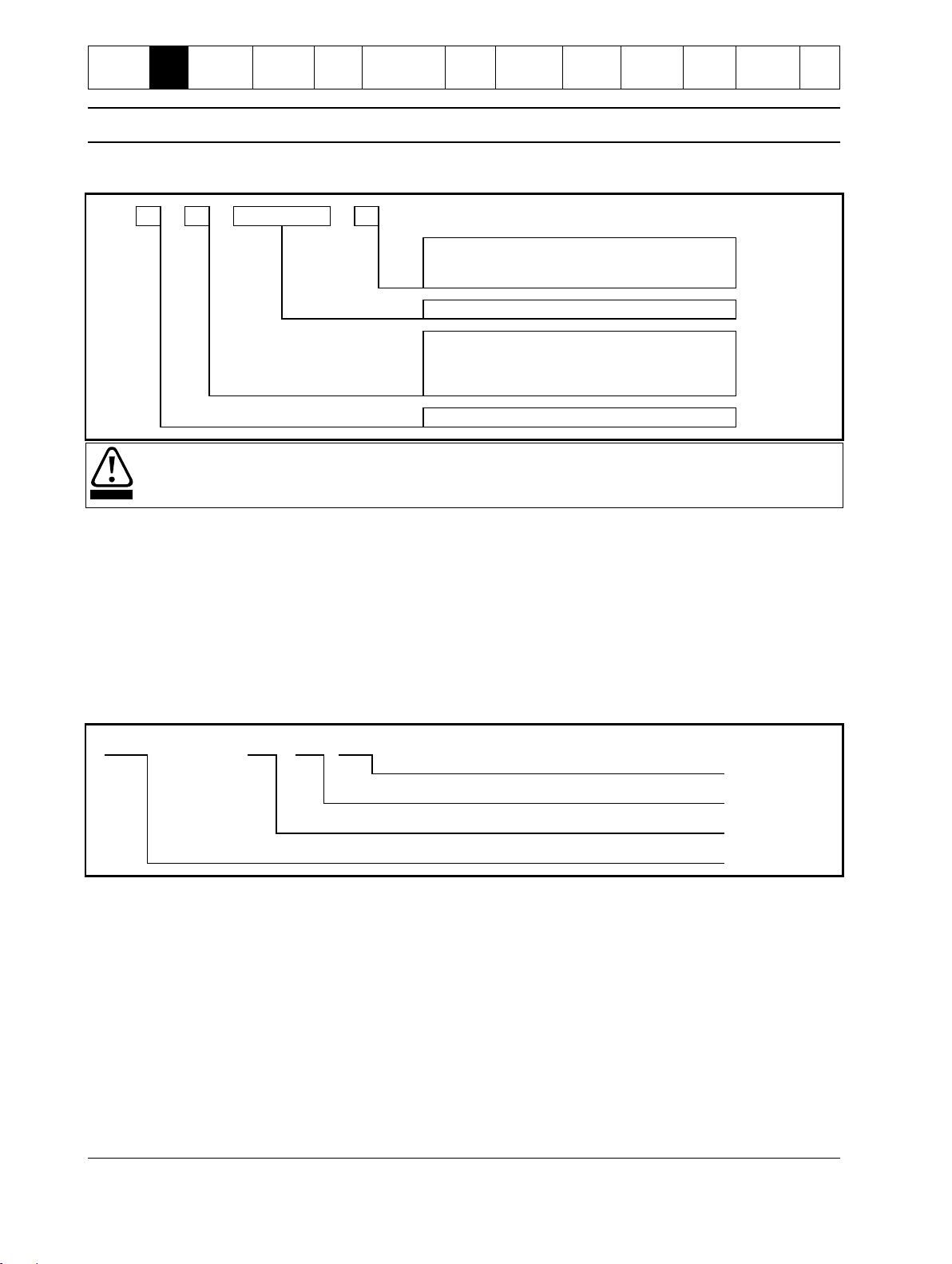

2. Rating Data

2.1 Model code

Figure 2-1 Model code explanation

2.2 Current ratings

Contact your local supplier for ratings under operating conditions not covered by these ratings charts.

2.2.1 Current ratings for bypass operation

AC53b utilisation code

The AC53b utilisation code defines the current rating and standard operating conditions for a bypassed soft starter (internally

bypassed, or installed with an external bypass contactor).

The soft starter’s current rating determines the maximum motor size it can be used with. The soft starter's rating depends on the

number of starts per hour and the length and current level of the start.

The soft starter’s current rating is only valid when used within the conditions specified in the utilisation code. The soft starter may

have a higher or lower current rating in different operating conditions.

Figure 2-2 AC53b utilisation code

Starter current rating: The full load current rating of the soft starter given the parameters detailed in the remaining sections of the

utilisation code.

Start current: The maximum available start current.

Start time: The maximum allowable start time.

Off time: The minimum allowable time between the end of one start and the beginning of the next start.

Digistart IS User Guide 7

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

Model

AC53b 3.0-10:350

40 ºC <1000 metres

AC53b 3.5-15:345

40 ºC <1000 metres

AC53b 4.0-20:340

40 ºC <1000 metres

AC53b 4.5-30:330

40 ºC <1000 metres

IS1x0023B

23 A

20 A

17 A

15 A

IS1x0043B

43 A

37 A

31 A

26 A

IS1x0053B

53 A

53 A

46 A

37 A

Model

AC53b 3.0-10:590

40 ºC <1000 metres

AC53b 3.5-15:585

40 ºC <1000 metres

AC53b 4.0-20:580

40 ºC <1000 metres

AC53b 4.5-30:570

40 ºC <1000 metres

IS1x0076B

76 A

64 A

55 A

47 A

IS1x0097B

97 A

82 A

69 A

58 A

IS1x0105B

105 A

105 A

95 A

78 A

IS2x0145B

145 A

123 A

106 A

90 A

IS2x0170B

170 A

145 A

121 A

97 A

IS2x0200B

200 A

189 A

160 A

134 A

IS2x0220B

220 A

210 A

178 A

148 A

IS3x0255B

255 A

231 A

201 A

176 A

IS4x0350B

350 A

306 A

266 A

230 A

IS4x0425B

425 A

371 A

321 A

276 A

IS4x0500B

500 A

445 A

383 A

326 A

IS4x0700B

700 A

592 A

512 A

438 A

IS4x0820B

820 A

705 A

606 A

516 A

IS4x0920B

920 A

804 A

684 A

571 A

IS4x1000B

1000 A

936 A

796 A

664 A

For models IS3x0255N to IS561600N, these ratings are valid only when externally bypassed using a suitable contactor.

Model

AC53b 3.0-10:590

40 ºC <1000 metres

AC53b 3.5-15:585

40 ºC <1000 metres

AC53b 4.0-20:580

40 ºC <1000 metres

AC53b 4.5-30:570

40 ºC <1000 metres

IS3x0255N

255 A

231 A

201 A

176 A

IS4x0360N

360 A

360 A

310 A

263 A

IS4x0430N

430 A

430 A

368 A

309 A

IS4x0650N

650 A

650 A

561 A

455 A

IS4x0790N

790 A

790 A

714 A

579 A

IS4x0930N

930 A

930 A

829 A

661 A

IS561200N

1200 A

1200 A

1200 A

1071 A

IS561410N

1410 A

1410 A

1319 A

1114 A

IS561600N

1600 A

1600 A

1600 A

1353 A

NOTE

Table 2-1 Current ratings - in-line (3-wire) connection, bypassed operation

Table 2-2 Current ratings - in-line (3-wire) connection, externally bypassed

8 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

Model

AC53b 3.0-10:350

40 ºC <1000 metres

AC53b 3.5-15:345

40 ºC <1000 metres

AC53b 4.0-20:340

40 ºC <1000 metres

AC53b 4.5-30:330

40 ºC <1000 metres

IS1x0023B

34 A

30 A

26 A

22 A

IS1x0043B

64 A

59 A

51 A

44 A

IS1x0053B

79 A

79 A

69 A

55 A

Model

AC53b 3.0-10:590

40 ºC <1000 metres

AC53b 3.5-15:585

40 ºC <1000 metres

AC53b 4.0-20:580

40 ºC <1000 metres

AC53b 4.5-30:570

40 ºC <1000 metres

IS1x0076B

114 A

96 A

83 A

70 A

IS1x0097B

145 A

123 A

104 A

87 A

IS1x0105B

157 A

157 A

143 A

117 A

IS2x0145B

217 A

184 A

159 A

136 A

IS2x0170B

255 A

217 A

181 A

146 A

IS2x0200B

300 A

283 A

241 A

200 A

IS2x0220B

330 A

315 A

268 A

223 A

IS3x0255B

382 A

346 A

302 A

264 A

IS4x0350B

525 A

459 A

399 A

345 A

IS4x0425B

638 A

557 A

482 A

414 A

IS4x0500B

750 A

668 A

575 A

490 A

IS4x0700B

1050 A

889 A

768 A

658 A

IS4x0820B

1230 A

1058 A

910 A

774 A

IS4x0920B

1380 A

1206 A

1026 A

857 A

IS4x1000B

1500 A

1404 A

1194 A

997 A

For models IS3x0255N to IS561600N, these ratings are valid only when externally bypassed using a suitable contactor.

Model

AC53b 3.0-10:590

40 ºC <1000 metres

AC53b 3.5-15:585

40 ºC <1000 metres

AC53b 4.0-20:580

40 ºC <1000 metres

AC53b 4.5-30:570

40 ºC <1000 metres

IS3x0255N

382 A

346 A

302 A

264 A

IS4x0360N

540 A

540 A

465 A

395 A

IS4x0430N

645 A

645 A

552 A

464 A

IS4x0650N

975 A

975 A

842 A

683 A

IS4x0790N

1185 A

1185 A

1071 A

868 A

IS4x0930N

1395 A

1395 A

1244 A

992 A

IS561200N

1800 A

1800 A

1800 A

1606 A

IS561410N

2115 A

2115 A

1979 A

1671 A

IS561600N

2400 A

2400 A

2400 A

2030 A

NOTE

Table 2-3 Current ratings - inside delta (6-wire) connection, bypassed operation

Table 2-4 Current ratings - inside delta (6-wire) connection, externally bypassed

Digistart IS User Guide 9

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

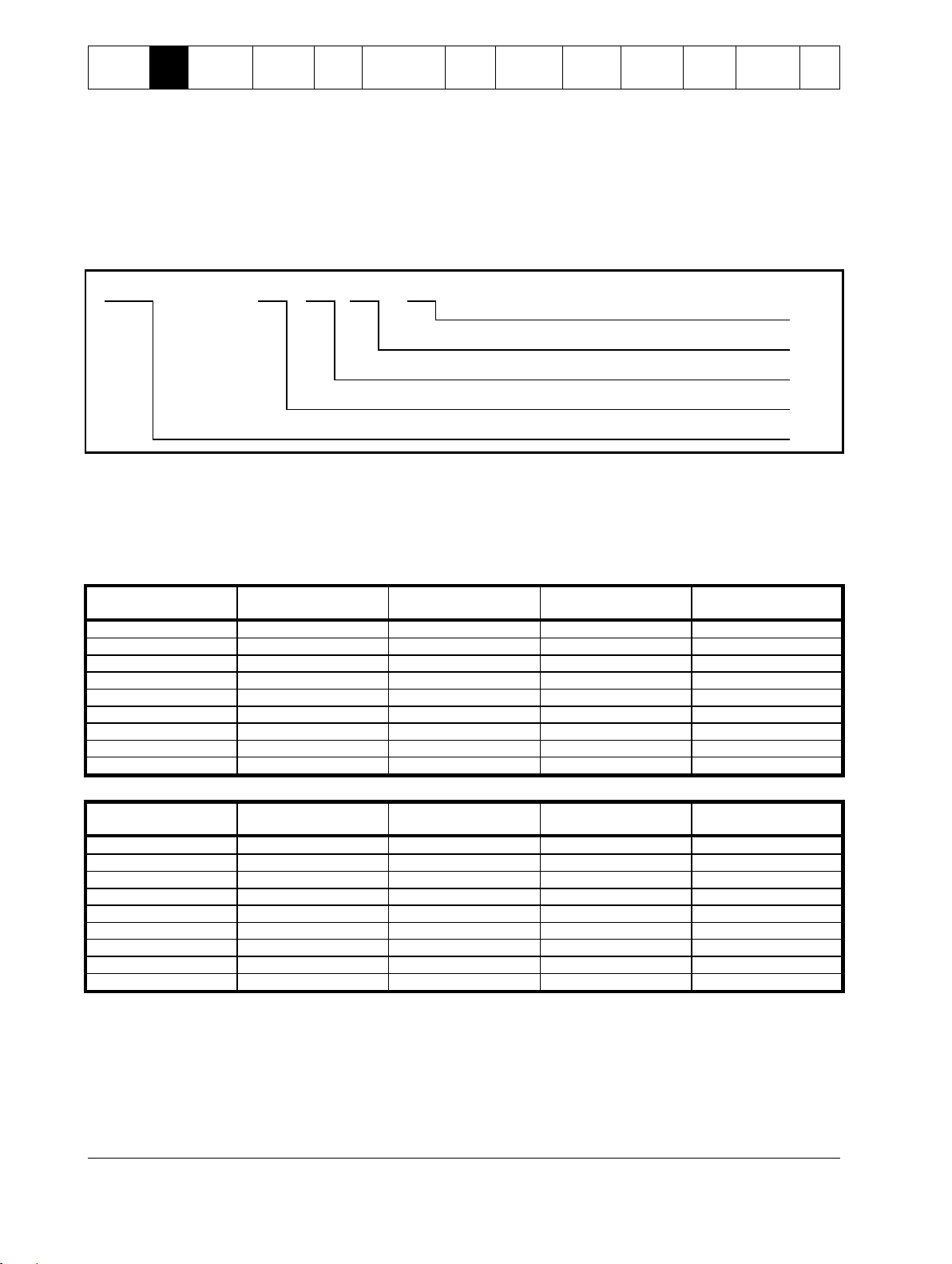

351 A

:

AC-53a

3.5 - 15 : 50 - 6

Starts per hour

On-load duty cycle (%)

Start time (seconds)

Start current (multiple of motor full load current)

Starter current rating (amperes)

Model

AC53a 3-10:50-6

40 ºC <1000 metres

AC53a 3.5-15:50-6

40 ºC <1000 metres

AC53a 4-20:50-6

40 ºC <1000 metres

AC53a 4.5-30:50-6

40 ºC <1000 metres

IS3x0255N

255 A

222 A

195 A

171 A

IS4x0360N

360 A

351 A

303 A

259 A

IS4x0430N

430 A

413 A

355 A

301 A

IS4x0650N

650 A

629 A

532 A

437 A

IS4x0790N

790 A

790 A

694 A

567 A

IS4x0930N

930 A

930 A

800 A

644 A

IS561200N

1200 A

1200 A

1135 A

983 A

IS561410N

1410 A

1355 A

1187 A

1023 A

IS561600N

1600 A

1600 A

1433 A

1227 A

Model

AC53a 3-10:50-6

40 ºC <1000 metres

AC53a 3.5-15:50-6

40 ºC <1000 metres

AC53a 4-20:50-6

40 ºC <1000 metres

AC53a 4.5-30:50-6

40 ºC <1000 metres

IS3x0255N

382 A

334 A

293 A

257 A

IS4x0360N

540 A

527 A

455 A

388 A

IS4x0430N

645 A

620 A

533 A

451 A

IS4x0650N

975 A

943 A

798 A

656 A

IS4x0790N

1185 A

1185 A

1041 A

850 A

IS4x0930N

1395 A

1395 A

1200 A

966 A

IS561200N

1800 A

1800 A

1702 A

1474 A

IS561410N

2115 A

2033 A

1780 A

1535 A

IS561600N

2400 A

2400 A

2149 A

1840 A

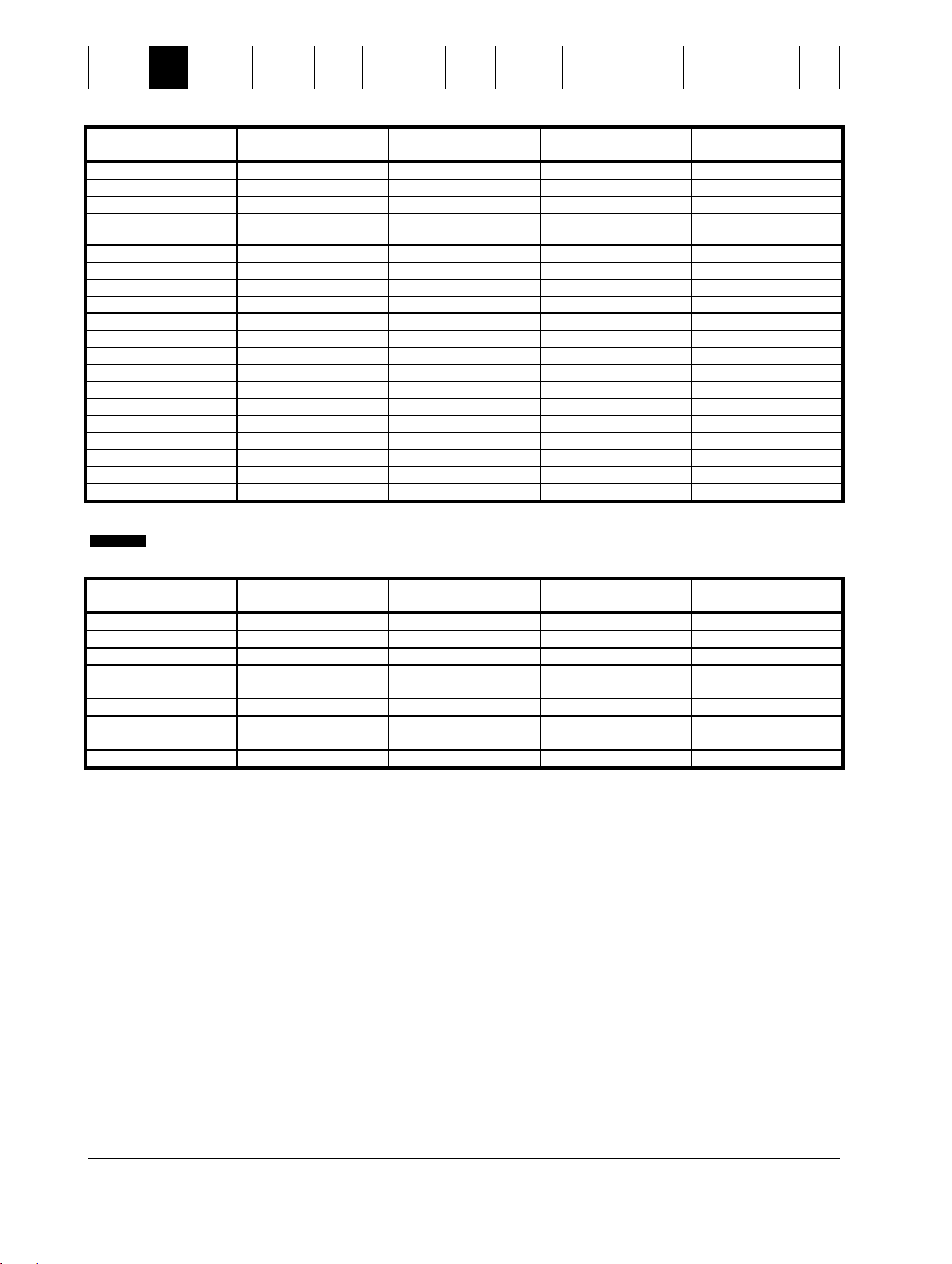

2.2.2 Current ratings for continuous operation (not bypassed)

AC53a utilisation code

The AC53a Utilisation Code defines the current rating and standard operating conditions for a non-bypassed soft starter.

The soft starter’s current rating determines the maximum motor size it can be used with. The soft starter's rating depends on the

number of starts per hour, the length and current level of the start, and the percentage of the operating cycle that the soft starter will

be running (passing current).

The soft starter’s current rating is only valid when used within the conditions specified in the utilisation code. The soft starter may

have a higher or lower current rating in different operating conditions.

Figure 2-3 AC53a utilisation code

Starter current rating: The full load current rating of the soft starter given the parameters detailed in the remaining sections of the

utilisation code.

Start current: The maximum available start current.

Start time: The maximum allowable start time.

On-load duty cycle: The maximum percentage of each operating cycle that the soft starter can operate.

Starts per hour: The maximum allowable number of starts per hour.

Table 2-5 Current ratings - in-line (3-wire) connection, non-bypassed operation

Table 2-6 Current ratings - inside delta (6-wire) connection, non-bypassed operation

10 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

In-line connection

Inside delta connection

Model

Minimum

Maximum

Minimum

Maximum

IS1x0023B

5 A

23 A

5 A

34 A

IS1x0043B

9 A

43 A

9 A

64 A

IS1x0053B

11 A

53 A

11 A

79 A

IS1x0076B

15 A

76 A

15 A

114 A

IS1x0097B

19 A

97 A

19 A

145 A

IS1x0105B

21 A

105 A

21 A

157 A

IS2x0145B

29 A

145 A

29 A

217 A

IS2x0170B

34 A

170 A

34 A

255 A

IS2x0200B

40 A

200 A

40 A

300 A

IS2x0220B

44 A

220 A

44 A

330 A

IS3x0255B

51 A

255 A

51 A

382 A

IS4x0350B

70 A

350 A

70 A

525 A

IS4x0425B

85 A

425 A

85 A

638 A

IS4x0500B

100 A

500 A

100 A

750 A

IS4x0700B

140 A

700 A

140 A

1050 A

IS4x0820B

164 A

820 A

164 A

1230 A

IS4x0920B

184 A

920 A

184 A

1380 A

IS4x1000B

200 A

1000 A

200 A

1500 A

In-line connection

Inside delta connection

Model

Minimum

Maximum

Minimum

Maximum

IS3x0255N

51 A

255 A

51 A

382 A

IS4x0360N

72 A

360 A

72 A

540 A

IS4x0430N

86 A

430 A

86 A

645 A

IS4x0650N

130 A

650 A

130 A

975 A

IS4x0790N

158 A

790 A

158 A

1185 A

IS4x0930N

186 A

930 A

186 A

1395 A

IS561200N

240 A

1200 A

240 A

1800 A

IS561410N

282 A

1410 A

282 A

2115 A

IS561600N

320 A

1600 A

320 A

2400 A

2.2.3 Minimum and maximum current settings

The Digistart IS's minimum and maximum full load current settings depend on the model:

Table 2-7 Minimum and maximum current settings, internally bypassed models

Table 2-8 Minimum and maximum current settings, externally bypassed models

Digistart IS User Guide 11

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

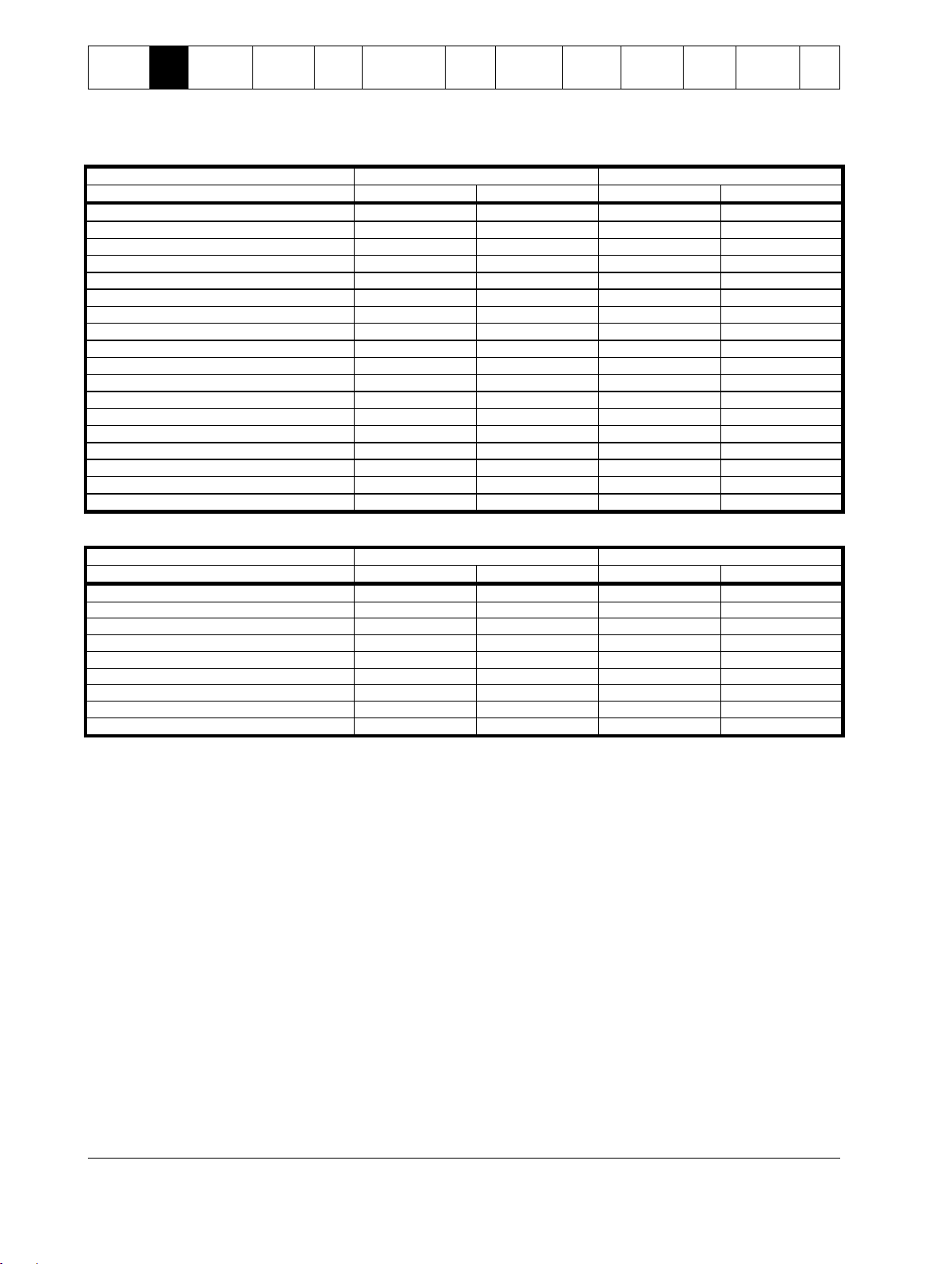

3. Mechanical Installation

WARNING

Digistart IS models IS2x0145B to IS561600N weigh in excess of 15 kg (33 lb). Use appropriate safeguards when lifting

these models.

WARNING

Models IS2x0145B to IS4x1000B and IS3x0255N to IS561600N are intended to be mounted in an enclosure which

prevents access except by trained and authorised personnel, and which prevents the ingress of contamination. The

complete range is designed for use in an environment classified as Pollution Degree 3 in accordance with IEC60664-1.

This means conductive pollution or dry, non-conductive pollution which becomes conductive due to condensation is

acceptable.

It is the installer's responsibility to ensure that any enclosure which allows access to models IS2x0145B to IS4x1000B

and IS3x0255N to IS561600N while the product is energized, provides protection against contact and ingress

requirements of IP20.

Models IS2x0145B to IS3x0255B can be installed with optional finger guards, in which case they do not need to be

mounted in an enclosure.

For further details on Digistart IS dimensions and corresponding CAD drawings please visit ww.controltechniques.com.

Model

Size

A

mm (in)

B

mm (in)

C

mm (in)

D

mm (in)

E

mm (in)

F

mm (in)

G

mm (in)

H

mm (in)

I

mm (in)

Weight

kg

(lb)

IS1x0023B

IS1x0043B

196.2

3.2

IS1x0053B

G1B

156.4

124.0

294.6

278.0

(7.72)

(7.05)

IS1x0076B

(6.16)

(4.88)

(11.60)

(10.94)

N/A

N/A

N/A

N/A

3.5 (7.22)

IS1x0097B

226.7

4.8

IS1x0105B

(8.92)

(10.58)

IS2x0145B

IS2x0170B

G2B

282

250

438

380

254

N/A

N/A

N/A

N/A

16

IS2x0200B

(11.10)

(9.84)

(17.24)

(14.96)

(10.00)

(35.27)

IS2x0220B

IS3x0255B

G3B

424

(16.54)

376

(14.8)

440

(17.32)

392

(15.43)

298

(11.73)

N/A

N/A

N/A

N/A

26

(57.2)

IS4x0350B

IS4x0425B

IS4x0500B

438

320

640

600

300

60.0

IS4x0700B

G4B

(17.24)

(12.60)

(25.20)

(23.62)

(11.81)

N/A

N/A

N/A

N/A

(132.3)

IS4x0820B

IS4x0920B

IS4x1000B

IS3x0255N

G3N

394 (15.51)

320 (12.60)

460 (18.11)

400 (15.75)

284 (11.18)

N/A

N/A

N/A

N/A

25 (55.12)

IS4x0360N

50.5

IS4x0430N

430

320

689

522

302

104.5

104.5

5.5

8.5

(111.33)

IS4x0650N

G4N

(16.93)

(12.60)

(27.12)

(20.55)

(11.89)

(4.11)

(4.11)

(0.22)

(0.33)

53.5

IS4x0790N

(117.95)

IS4x0930N

IS561200N

IS561410N

G5N

574

500

750

727

364

132.5

129 5 8.5

140

IS561600N

(22.60)

(19.69)

(29.53)

(28.62)

(14.33)

(5.22)

(5.08)

(0.20)

(0.33)

(308.65)

NOTE

3.1 Dimensions and weights

12 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

NOTE

Dimensions F, G and H are the additional space required for the output and input busbars, in addition to the overall

chassis measurement (C).

Figure 3-1 Unit dimensions (bypassed models)

D3-1x-0023-B, D3-1x-0043-B, D3-1x-0053-B

D3-1x-0076-B, D3-1x-0097-B, D3-1x-105-B

D3-1x-0145-B, D3-1x-0170-B, D3-1x-0200-B, D3-1x-0220-B

D3-1x-0255-B

D3-1x-0350-B, D3-1x-0425-B, D3-1x-0500-B, D3-1x-0700-B

D3-1x-0820-B, D3-1x-0920-B, D3-1x-1000-B

A

B

CED

08337.D

A

B

C

E

D

A

B

C

E

D

Digistart IS User Guide 13

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

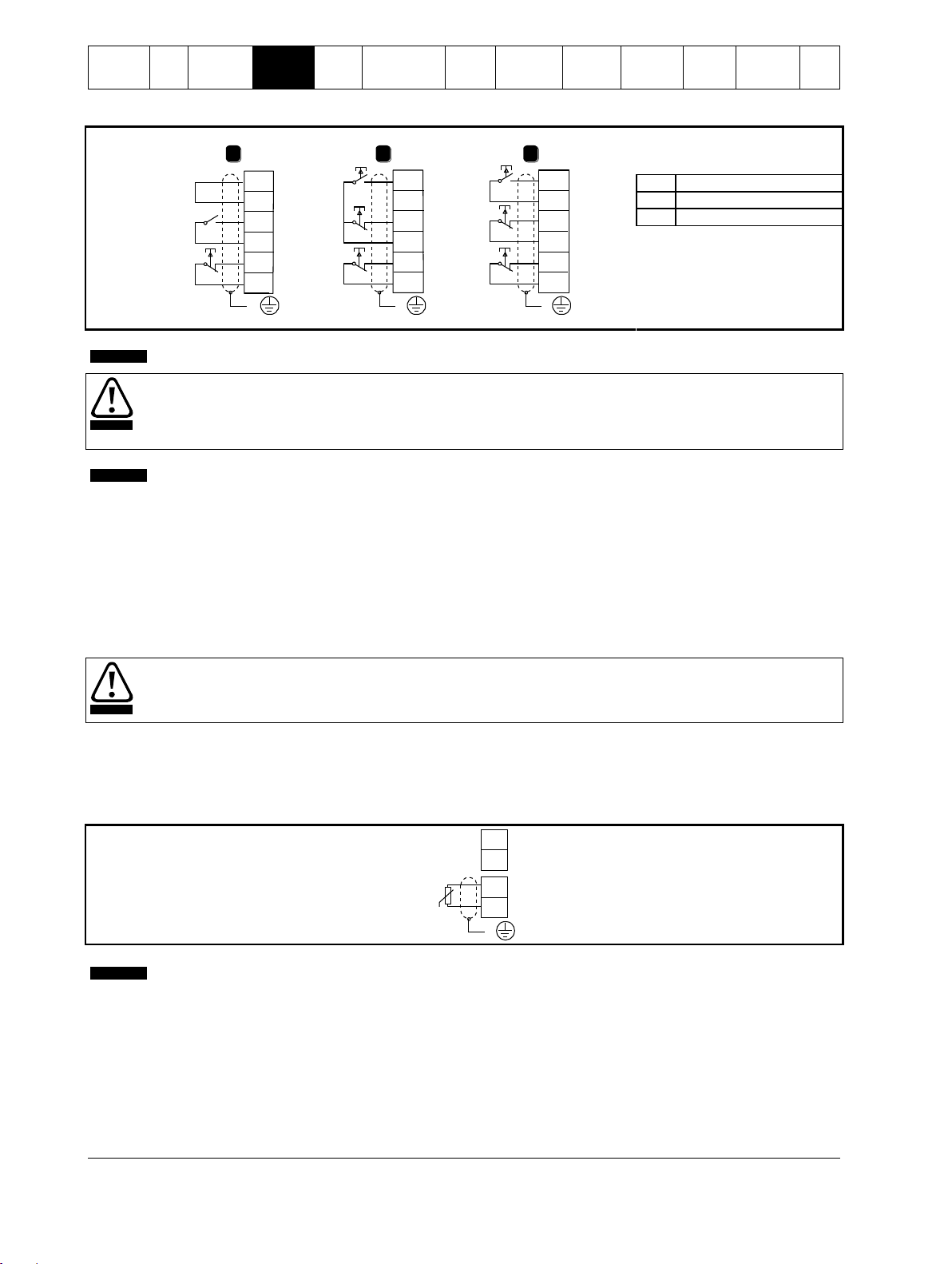

Figure 3-2 Unit dimensions (non-bypassed models)

D3-1x-0255-N

D3-1x-0360-N, D3-1x-0430-N, D3-1x-0650-N, D3-1x-0790-N

D3-1x-0930-N, D3-16-1200-N, D3-16-1410-N, D3-16-1600-N

A

13511.A

A

B

B

E

E

CCD

D

F

I

G

H

14 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

3.2 Physical installation

1

3 4

2

08338.A

1

IS1x0023B to IS2x0220B: Allow 100 mm (3.94 in) between soft starters.

IS3x0255B to IS4x1000B: Allow 200 mm (7.88 in) between soft starters.

IS3x0255N: Allow 100 mm (3.94 in) between soft starters.

IS4x0360N to IS561600N: Allow 200 mm (7.88 in) between soft starters.

2

IS1x0023B to IS2x0220B: Allow 50 mm (1.97 in) between the soft starter and solid surfaces.

IS3x0255B to IS4x1000B: Allow 200 mm (7.88 in) between the soft starter and solid surfaces.

IS3x0255N: Allow 100 mm (3.94 in) between the soft starter and solid surfaces.

IS4x0360N to IS561600N: Allow 200 mm (7.88 in) between the soft starter and solid surfaces.

3

Soft starters may be mounted side by side with no clearance (that is, if mounted without communications modules).

4

The soft starter may be mounted on its side. Derate the soft starter's rated current by 15%.

WARNING

It is the user's responsibility to follow these instructions correctly. Control Techniques cannot be held responsible for

any damage to the starter or associated equipment from incorrect practice.

Input/Output

Output

Input

08350 .A

Input/Output

Input

Output

Figure 3-3 Mounting clearances

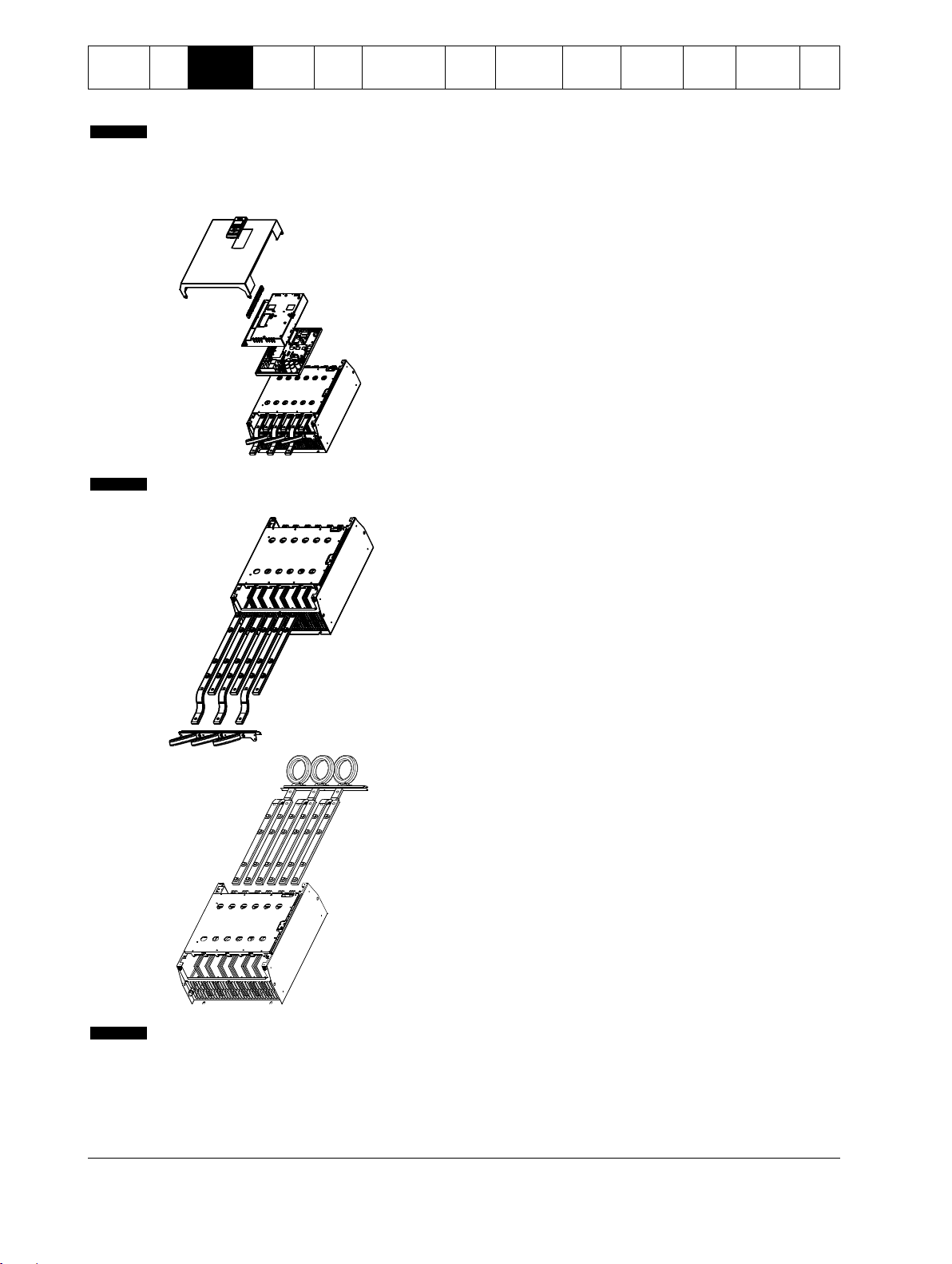

3.3 Busbar adjustment procedure

The busbars on non-bypassed models IS4x0360N to IS561600N can be adjusted for top or bottom input and output as required.

Figure 3-4 Busbar configuration options

Digistart IS User Guide 15

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

NOTE

Many electronic components are sensitive to static electricity. Voltages so low that they cannot be felt, seen or heard,

can reduce the life, affect performance, or completely destroy sensitive electronic components. When performing

service, proper ESD equipment should be used to prevent possible damage from occurring.

08604.A

1. Remove all wiring and links from the soft starter before

dismantling the unit.

2. Remove the unit cover (4 screws).

3. Remove the keypad faceplate, then gently remove the

keypad (2 screws).

4. Remove the control terminal plugs.

5. Gently fold the main plastic away from the starter (12

screws).

6. Unplug the keypad loom from CON 1 (see note).

7. Label each SCR firing loom with the number of the

corresponding terminal on the backplane PCB, then unplug

the looms.

8. Unplug the thermistor, fan and current transformer wires

from the model board.

9. Remove the plastic tray from the starter (four screws).

NOTE

Remove the main plastic slowly to avoid damaging the keypad wiring loom which runs between the main plastic and the

backplane PCB.

08605.A

10. Unscrew and remove the magnetic bypass plates (models

IS4x0430N to IS561600N only).

11. Remove the current transformer assembly (three screws).

12. Identify which busbars are to be moved. Remove the bolts

holding these busbars in place then slide the busbars out

through the bottom of the starter (four bolts per busbar).

08606.A

13. Slide the busbars in through the top of the starter. For input

busbars, the short curved end should be outside the starter.

For output busbars, the unthreaded hole should be outside

the starter.

14. Replace the dome washers with the flat face towards the

busbar, then tighten the bolts holding the busbars in place to

20 Nm.

15. Place the current transformer assembly over the input

busbars and screw the assembly to the body of the starter

(see note).

16. Run all wiring to the side of the starter and secure with cable

ties.

NOTE

If moving the input busbars, the current transformers (CTs) must also be reconfigured.

1. Label the CTs L1, L2 and L3 (L1 is leftmost when looking from the front of the starter). Remove the cable ties and

unscrew the CTs from the bracket.

2. Move the CT bracket to the top of the starter. Position the CTs for the correct phases, then screw the CTs to the

bracket. For models IS4x0360N to IS4x0930N, the CTs must be placed on an angle (the left hand legs of each CT

will be on the top row of holes and the right hand legs will be on the bottom tabs).

All units are manufactured with input and output busbars at the bottom of the unit as standard. The input and/or output busbars can

be moved to the top of the unit if required.

16 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

WARNING

Always apply control voltage before (or with) mains voltage.

WARNING

Always follow the specified tightening torque for all power and ground terminal connections.

NOTE

Some units use aluminium bus bars. When connecting power terminations, we recommend cleaning the surface contact

area thoroughly (using an emery or stainless steel brush) and using an appropriate jointing compound to prevent

corrosion.

NOTE

For personnel safety, the power terminals on models up to IS1x0105B are protected by snap-off tabs. When using large

cables, it may be necessary to break off these tabs.

Models which are internally bypassed do not require an external bypass contactor.

4. Electrical Installation

For specifications and detailed technical data, see Technical Data on page 82.

4.1 Terminal layout

4.1.1 Power terminations

Use only copper stranded or solid conductors, rated for 75 ºC.

Digistart IS User Guide 17

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

IS1x0023B to IS1x0105B

IS2x0145B

Power (L1/T1, L2/T2, L3/T3)

8.5 Nm (6.3 ft-lb)

11290.A

11291.A

14 (0.55)

mm (in)

5-60 (10-1/0)

mm2 (AWG)

Torx

T20 x 150

Torque =

4 Nm

2.9 Ft-lb

Flat

7mm x 150

Torque =

4 Nm

2.9 Ft-lb

IS2x0170B to IS2x0220B

IS3x0255B

8.5 Nm (6.3 ft-lb)

38 Nm (28.5 ft-lb)

5 mm

28 mm

11 mm

131 81.A

IS4x0350B to IS4x1000B

IS3x0255N

38 Nm (28.5 ft-lb)

17 Nm (12.5 ft-lb)

6 mm

32 mm

11 mm

098 66.A

6 mm

32 mm

10.5 mm

08353. A

IS4x0360N to IS4x0930N

IS561200N to IS561600N

38 Nm (28.5 ft-lb)

58 Nm (42.7 ft-lb)

13 mm32 mm

10.5 mm

08354. A

NOTE

Internally bypassed models IS4x0350B to IS4x1000B have input and output busbars at both the top and bottom of the

unit. The IS3x0255B is different, with input only busbars at the top of the unit. It can be mounted 'Top in, Bottom out' or

'Bottom in, Bottom out'. These busbars do not need to be adjusted.

Figure 4-1 Cable sizes, busbar dimensions and maximum torque settings

4.1.2 Ground terminals

Ground terminals are located at the back of the soft starter.

IS1x0023B to IS1x0105B have one terminal on the input side (top).

IS2x0145B to IS4x1000B and IS3x0255N to IS561600N have two terminals, one on the input side (top) and one on the

output side (bottom).

The ground terminal may also be used for a ground shield connection if necessary.

18 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

Tighten the cables as follows:

Models

Terminal size

Torque

IS1x0023B to IS1x0105B

M6

3 Nm

IS2x0145B to IS3x0255B

M8

5 Nm

IS3x0255N

M8

5 Nm

IS4x0350B to IS4x1000B

M10

8.5 Nm

IS4x0360N to IS561600N

M10

8.5 Nm

IS1x0023B to IS1x0105B

IS3x0255B to IS4x1000B

IS2x0145B to IS2x0220B and IS3x0255N to

IS561600N

CAUTION

Always connect control voltage to the correct terminals:

110 to 210 Vac: CSL-CSR or

220 to 440 Vac: CSH-CSR

WARNING

The installer must ensure that the external control circuits are insulated from human contact by at least one layer of

insulation (supplementary insulation) rated for use at the AC supply voltage.

08339.A

220~440VAC

110~210VAC

Table 4-1 Ground terminal maximum torque settings

Figure 4-2 Ground terminal locations

4.1.3 Control terminals

Control terminations use 2.5mm2 plug-in terminal blocks. Unplug each block, complete the wiring, then reinsert the block.

Figure 4-3 Control terminal layout

4.1.4 Start/Stop control logic

The Digistart IS has three fixed inputs for remote control. These inputs should be controlled by contacts rated for low voltage, low

current operation (gold flash or similar).

The maximum cable run is determined by the type of cable used, provided the maximum resistance of this cable does not exceed

100 Ohms. The cables must be twisted in pairs and shielded. The shield must be grounded at one end only, that is, at the soft

starter end. To avoid any EMC disturbance from the motor power cables, the thermistor cable must be separated from the motor

power cables by a minimum parallel distance of 300 mm.

Digistart IS User Guide 19

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

1 2 3

+24V

DI2

+24V

DI1

+24V

DI3

E E E

+24V

DI2

+24V

DI1

+24V

DI3

+24V

DI2

+24V

DI1

+24V

DI3

08340.A

Start/stop

Reset

Start

Stop

Reset

Start

Stop

Reset

1 Two-wire control

2

Three-wire control

3

Four-wire control

NOTE

For comprehensive information on control connection, see Control connections on page 21.

CAUTION

Do not apply voltage to the control input terminals. These are active 24 Vdc inputs and must be controlled with potential

free contacts.

Cables to the control inputs must be segregated from mains voltage and motor cabling.

NOTE

You can set the Reset input to either NO or NC (default). See Pr 3N Remote Reset Logic.

CAUTION

Some electronic contactor coils are not suitable for direct switching with PCB mount relays. Consult the contactor

manufacturer/supplier to confirm suitability.

No motor thermistors

Motor thermistors

TH2

TH1

TH2

TH1

08528.A

E

Thermistor input

NOTE

If no motor thermistors are connected to the Digistart IS thermistor input terminals TH1, TH2 must be open. If TH1, TH2

are shorted, the Digistart IS will trip.

The thermistor circuit should be run in screened cable and must be electrically isolated from ground and all other power

and control circuits.

Figure 4-4 Control wiring options

4.1.5 Relay outputs

The Digistart IS provides four relay outputs, one fixed and three programmable.

The Run output closes when the soft start is complete (when the starting current falls below 120% of the programmed motor full load

current) and remains closed until the beginning of a stop (either soft stop or coast to stop).

Operation of the programmable outputs is determined by the settings of Pr 4A to 4I.

If assigned to Main Contactor, the output activates as soon as the soft starter receives a start command and remains

active while the soft starter is controlling the motor (until the motor starts a coast to stop, or until the end of a soft stop).

If assigned to a trip function, the output activates when a trip occurs.

If assigned to a flag, the output activates when the specified flag is active (Pr 7A to 7C).

Three additional outputs are available on the input/output expansion card.

4.1.6 Motor thermistors

Motor thermistors can be connected directly to the Digistart IS. The soft starter will trip when the resistance of the thermistor circuit

exceeds approximately 3.6 kor falls below 20 .

Figure 4-5 Motor thermistor connection

4.1.7 Programmable inputs

The default setting of programmable input A is 'Emergency Stop' (Pr 3A). If emergency stop is not required, change the setting

of Pr 3A or connect a link across DI4, +24V.

If programmable input A is set to 'Emergency Stop', an open circuit across DI4, +24V will initiate an emergency stop. The soft starter

will allow the motor to coast to stop, ignoring the soft stop mode set in Pr 2H.

20 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

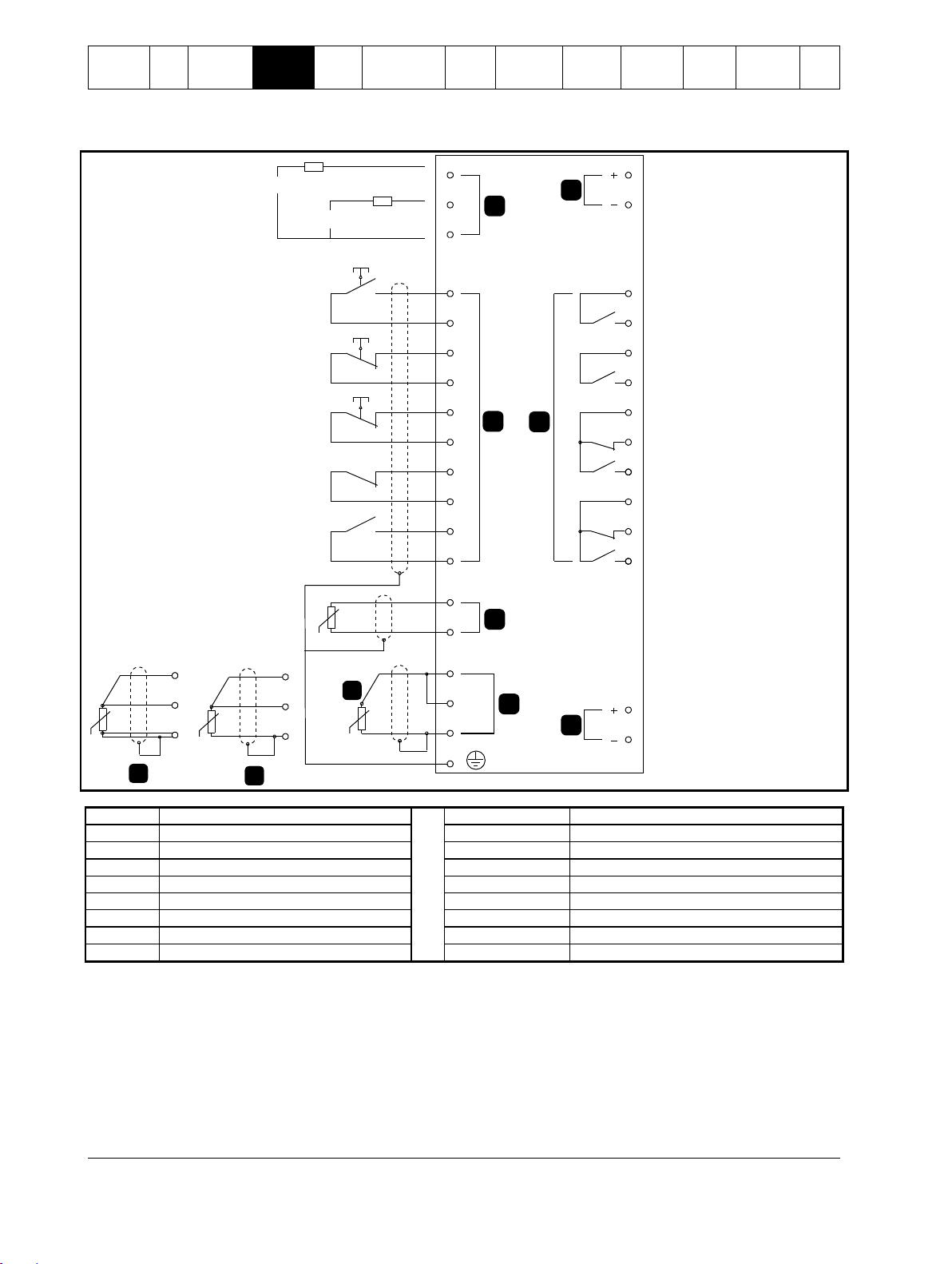

4.2 Control connections

08347.A

5

4

3

2

1

RLC3

COM3

COM1

RLO1

+24V

0V

RLO2

COM2

RLO3

AO1

0V

COM4

RLC4

RLO4

TH2

TH1

DI2

+24V

DI3

+24V

DI4

+24V

+24V

+24V

DI5

PT4

PT5

PT3

CSR

CSL

CSH

DI1

+10%

-15%

+10%

-15%

A

PT4

PT5

PT3

C

PT4

PT5

PT3

BB

E

7

6

220-440 VAC

110-210 VAC

1

Control voltage

DI1, +24V

Start 2 Remote control inputs

DI2, +24V

Stop

3

Motor thermistor input

DI3, +24V

Reset

4A

RTD/PT100 input - 2-wire

DI4, +24V

Programmable input A

4B

RTD/PT100 input - 3-wire

DI5, +24V

Programmable input B

4C

RTD/PT100 input - 4-wire

COM1, RLO1

Relay output A

5

24 Vdc output

COM2, RLO2

Run relay output

6

Relay outputs

COM3, RLC3, RLO3

Relay output B

7

Analog output

COM4, RLC4, RLO4

Relay output C

Figure 4-6 Digistart IS electrical schematic

The Digistart IS can be commanded to emergency stop the motor, ignoring the soft stop mode set in Pr 2H.

When the circuit across DI4, +24V is opened, the soft starter allows the motor to coast to stop.

To use the emergency stop function, set Pr 3A to 'Emergency Stop' (this is the default setting).

If emergency stop is not required, change the setting of Pr 3A or connect a link across DI4, +24V.

For keypad control, the soft starter requires:

control supply connections (terminals CSH, CSL, CSR depending on the control voltage)

programmable input A (DI4, +24V) must be closed or Pr 3A Input A Function must be changed from Emergency Stop

Digistart IS User Guide 21

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

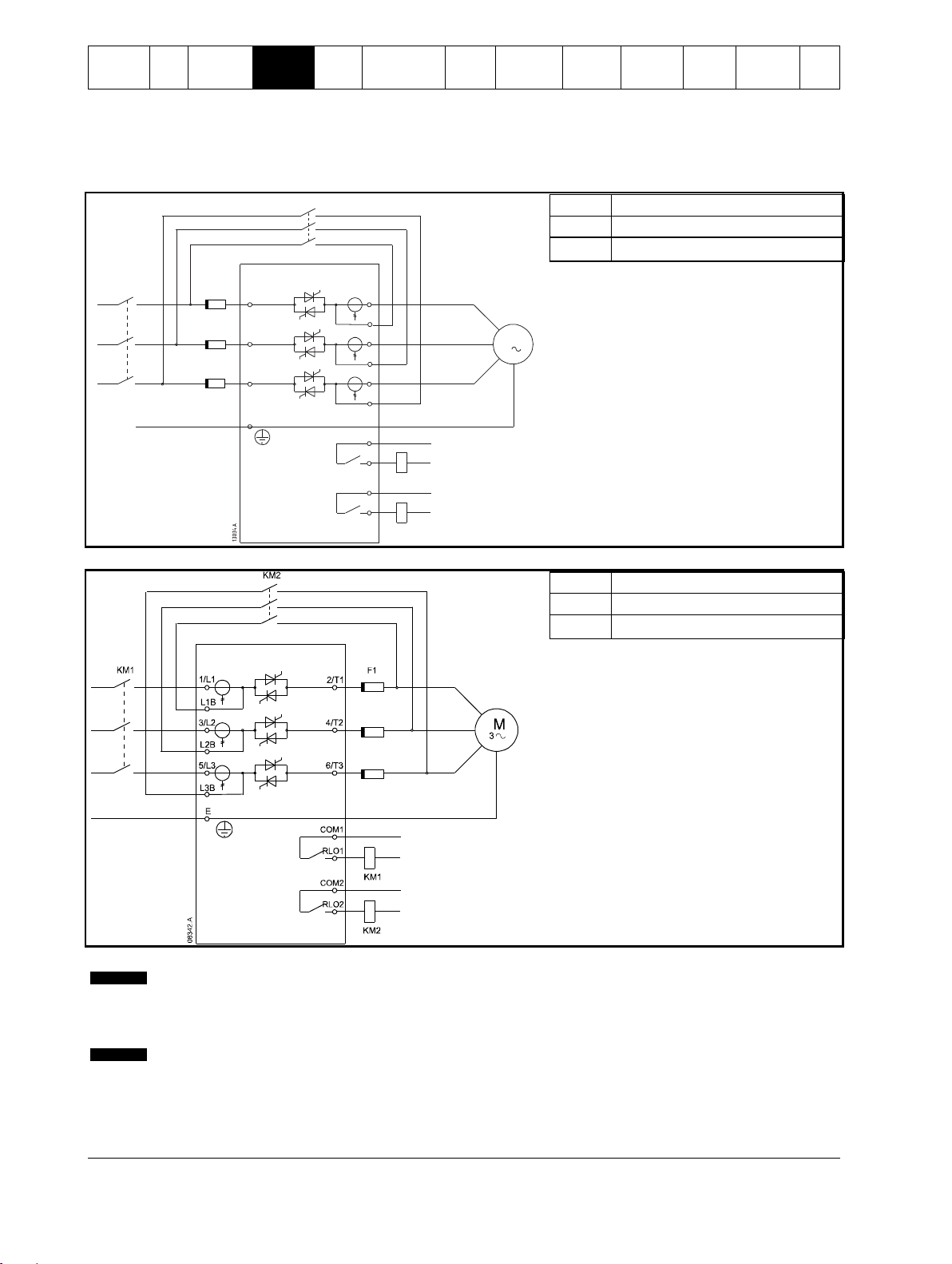

NOTE

For personnel safety, the power terminals on models up to IS1x0105B are protected by snap-off tabs. When using large

cables, it may be necessary to break off these tabs.

Models which are internally bypassed do not require an external bypass contactor.

6/T3

2/T1

5/L3

3/L2

1/L1

COM1

RLO1

4/T2

E

KM1

KM1 F1

M

3

08341.A

KM1

Main contactor (optional)

F1

Semiconductor fuses (optional)

NOTE

Main contactor is the default setting for Pr 4A Relay A Action (COM1, RLO1).

4.3 Power connections

4.3.1 Motor connection

Digistart IS soft starters can be connected to the motor in-line or inside delta (also called three-wire and six-wire connection). When

connecting in inside delta, enter the motor full load current (FLC) for Pr 1A. The Digistart IS will automatically detect whether the

motor is connected in-line or inside delta and will calculate the correct inside delta current level.

Internally bypassed models:

IS1x0023B, IS1x0043B, IS1x0053B, IS1x0076B, IS1x0097B, IS1x0105B, IS2x0145B, IS2x0170B, IS2x0200B, IS2x0220B,

IS3x0255B, IS4x0350B, IS4x0425B, IS4x0500B, IS4x0700B, IS4x0820B, IS4x0920B, IS4x1000B

Non-bypassed models:

IS3x0255N, IS4x0360N, IS4x0430N, IS4x0650N, IS4x0790N, IS4x0930N, IS561200N, IS561410N, IS561600N

4.3.2 In-line installation

In-line installation, internally bypassed

Figure 4-7 Power connections - in-line installation, internally bypassed

22 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

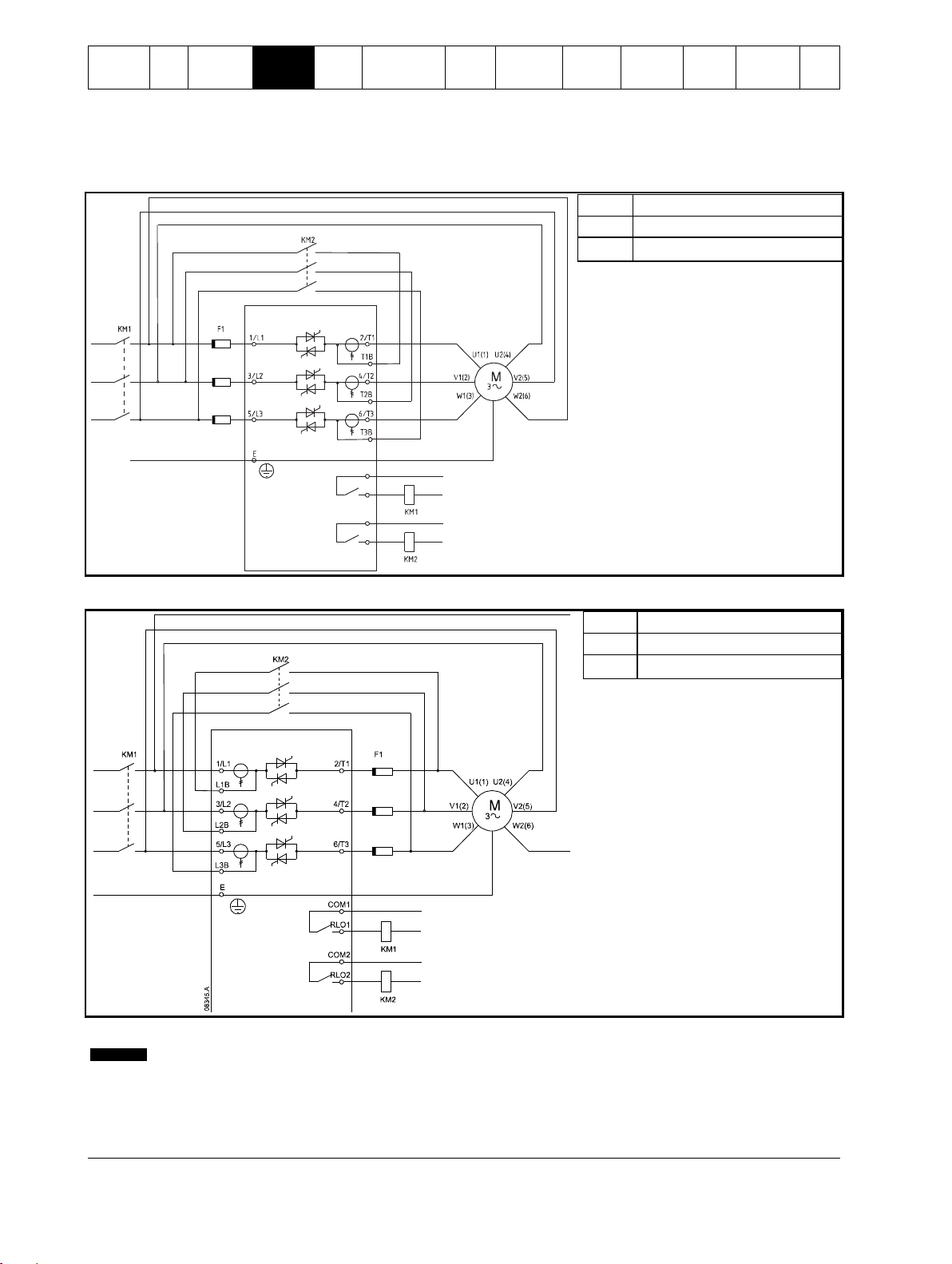

M

3

F1

6/ T3

2/ T1

5/L3

3/L2

1/ L1

COM1

RLO1

4/ T2

E

KM1

KM1

T1B

T2B

T3B

KM2

RLO2

COM2

KM2

KM1

Main contactor (optional)

KM2

Bypass contactor (external)

F1

Semiconductor fuses (optional)

KM1

Main contactor (optional)

KM2

Bypass contactor (external)

F1

Semiconductor fuses (optional)

NOTE

The bypass terminals on IS3x0255N are T1B, T2B, T3B. The bypass terminals on IS4x0360N to IS561600N are L1B,

L2B, L3B.

The fuses can be installed on the input side if required.

NOTE

Main contactor is the default setting for Pr 4A Relay A Action (COM1, RLO1). Output relay COM2, RLO2 is dedicated to

Run output operation and is ideal for managing an external bypass contactor.

In-line installation, externally bypassed

Non-bypassed models have dedicated bypass terminals, which allow the Digistart IS to continue providing protection and monitoring

functions even when bypassed via an external bypass contactor. The bypass contactor must be connected to the bypass terminals

and controlled by the soft starter's run output (terminals COM2, RLO2).

Figure 4-8 Power connections - in-line installation, externally bypassed (IS3x0255N)

Figure 4-9 Power connections - in-line installation, externally bypassed (IS4x0360N to IS561600N)

Digistart IS User Guide 23

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

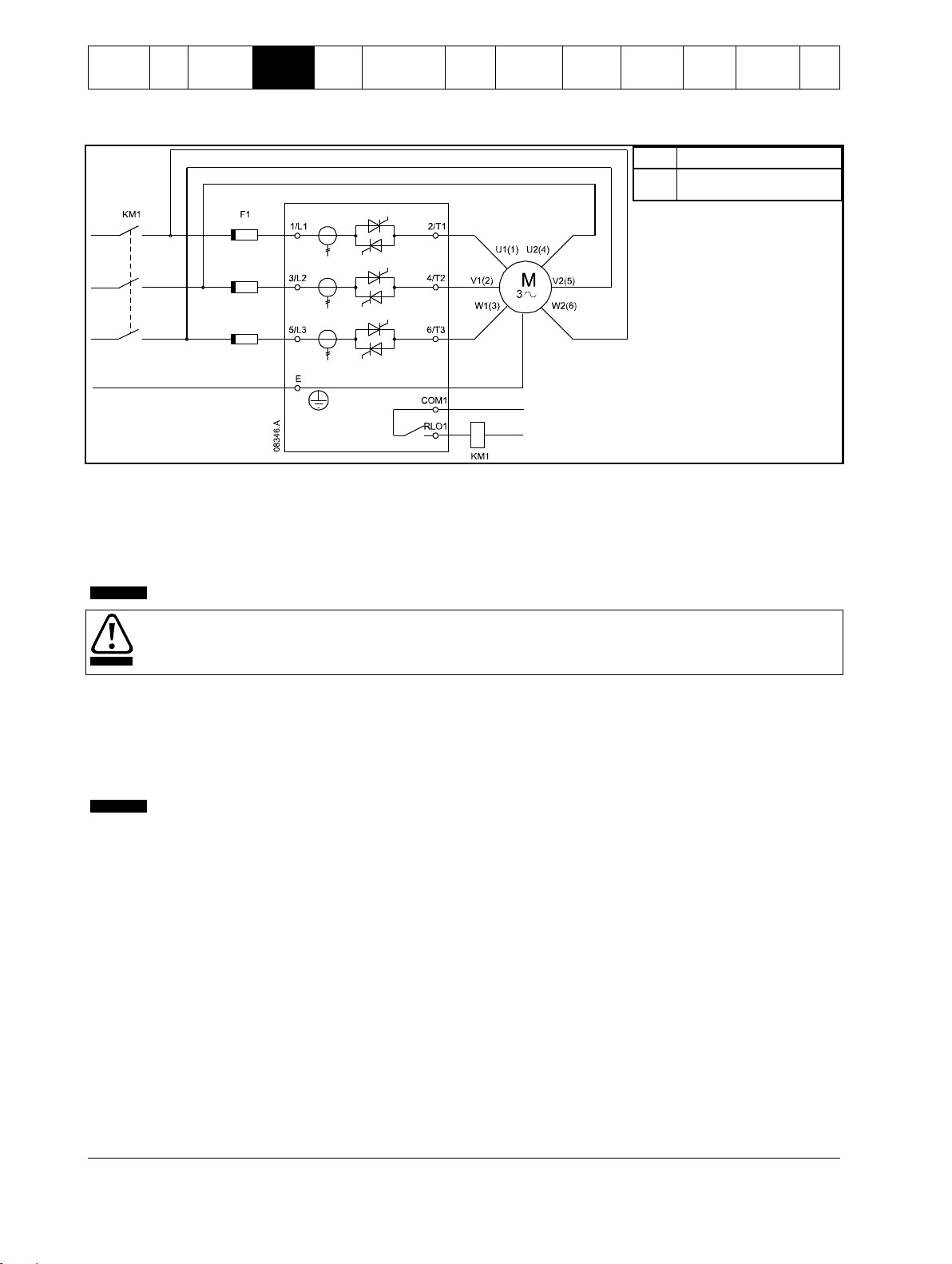

KM1

Main contactor (optional)

F1

Semiconductor fuses (optional)

CAUTION

When connecting the Digistart IS in inside delta configuration, always install a main contactor or shunt trip circuit

breaker.

NOTE

When connecting in inside delta, enter the motor full load current (FLC) for Pr 1A. The Digistart IS will automatically

detect whether the motor is connected in-line or inside delta and will calculate the correct inside delta current level.

08344.A

M

3

6/T3

2/T1

COM1

RLO1

4/T2

KM1

U1(1) U2(4)

V1(2)

V2(5)

W1(3) W2(6)

5/L3

3/L2

1/L1

E

KM1 F1

KM1

Main contactor

F1

Semiconductor fuses

(optional)

In-line installation, non-bypassed

Figure 4-10 Power connections - in-line installation, non-bypassed

4.3.3 Inside delta installation

Inside delta installation, internally bypassed

Figure 4-11 Power connections - inside delta installation, internally bypassed

24 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

13037.A

COM1

COM2

RLO2

RLO1

KM1

Main contactor

KM2

Bypass contactor (external)

F1

Semiconductor fuses (optional)

KM1

Main contactor

KM2

Bypass contactor (external)

F1

Semiconductor fuses (optional)

NOTE

The bypass terminals on IS3x0255N are T1B, T2B, T3B. The bypass terminals on IS4x0360N to IS561600N are L1B,

L2B, L3B.

The fuses can be installed on the input side if required.

Inside delta installation, externally bypassed

Non-bypassed models have dedicated bypass terminals, which allow the Digistart IS to continue providing protection and monitoring

functions even when bypassed via an external bypass contactor. The bypass contactor must be connected to the bypass terminals

and controlled by the soft starter's run output (terminals COM2, RLO2).

Figure 4-12 Power connections - inside delta installation, externally bypassed (IS3x0255N)

Figure 4-13 Power connections - inside delta installation, externally bypassed (IS4x0360N to IS561600N)

Digistart IS User Guide 25

Issue: 4 www.controltechniques.com

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

KM1

Main contactor

F1

Semiconductor fuses

(optional)

NOTE

Fuses are not delivered with Digistart IS soft starters.

CAUTION

Adaptive Control controls the motor's speed profile, within the programmed time limit. This may result in a higher level

of current than traditional control methods.

NOTE

Fuse selection is based on a 400% FLC start for 20 seconds in conjunction with standard published starts per hour,

duty cycle, 40°C ambient temperature and up to 1000 m altitude. For installations operating outside these conditions,

consult your local supplier.

These fuse tables contain recommendations only. Always consult your local supplier to confirm the selection for your

particular application.

Inside delta installation, non-bypassed

Figure 4-14 Power connections - inside delta installation, non-bypassed

4.4 Fuse information

4.4.1 Power supply fuses

Semiconductor fuses can be used for Type 2 coordination (according to IEC 60947-4-2 standard) and to reduce the risk of damage

to SCRs from transient overload currents.

HRC fuses (such as Ferraz AJT fuses) can be used for Type 1 coordination according to IEC 60947-4-2 standard.

For applications using Adaptive Control to soft stop the motor with stop times greater than 30 seconds, motor branch protection

should be selected as follows:

standard HRC line fuses: minimum 150% motor full load current

motor rated line fuses: minimum rating 100/150% motor full load current

motor control circuit breaker minimum long time setting: 150% motor full load current,

motor control circuit breaker minimum short time setting: 400% motor full load current for 30 seconds

26 Digistart IS User Guide

www.controltechniques.com Issue: 4

Safety

Information

Rating

Data

Mechanical

Installation

Electrical

Installation

Keypad

and

Status

Quick Start

Commissioning

Operation

Programming

Diagnostics

Application

Examples

Technical

Data

Maintenance

Options

Table 4-2 Bussman fuses - square body (170M)

Model

SCR I2t (A2s)

Supply Voltage

(< 440 Vac)

Supply Voltage

(< 575 Vac)

Supply Voltage

(< 690 Vac)

IS1x0023B

1150

170M1314

170M1314

170M1314

IS1x0043B

8000

170M1316

170M1316

170M1316

IS1x0053B

15000

170M1318

170M1318

170M1318

IS1x0076B

15000

170M1319

170M1319

170M1318

IS1x0097B

51200

170M1321

170M1321

170M1319

IS1x0105B

125000

170M1321

170M1321

170M1321

IS2x0145B

125000

170M1321

170M1321

170M1321

IS2x0170B

320000

170M2621

170M2621

170M2621

IS2x0200B

320000

170M2621

170M2621

170M2621

IS2x0220B

320000

170M2621

170M2621

170M2621

IS3x0255B

320000

170M2621

170M2621

170M2621

IS4x0350B

202000

170M5011

170M5011

––

IS4x0425B

320000

170M6011

––

––

IS4x0500B

320000

170M6008*

––

––

IS4x0700B

781000

170M5015

170M5015

––

IS4x0820B

1200000

170M5017

170M6015

––

IS4x0920B

2530000

170M6017

170M6017

––

IS4x1000B

2530000

170M6018

170M6013*

––

IS3x0255N

320000

170M2621

170M2621

170M2621

IS4x0360N

320000

170M6010

170M6010

170M6010

IS4x0430N

320000

170M6011

170M6011

––

IS4x0650N

1200000

170M6015

170M6015

170M6014

IS4x0790N

2530000

170M6017

170M6017

170M6016

IS4x0930N

4500000

170M6019

170M6019

170M6019

IS561200N

4500000

170M6021

––

––

IS561410N

6480000

––

––

––

IS561600N

12500000

170M6019*

––

––

Model

SCR I2t (A2s)

Supply Voltage

(< 440 Vac)

Supply Voltage

(< 575 Vac)

Supply Voltage

(< 690 Vac)

IS1x0023B

1150

63FE

63FE

63FE

IS1x0043B

8000

120FEE

120FEE

120FEE

IS1x0053B

15000

200FEE

200FEE

200FEE

IS1x0076B

15000

200FEE

200FEE

200FEE

IS1x0097B

51200

200FEE

200FEE

200FEE

IS1x0105B

125000

280FM

280FM

280FM

IS2x0145B

125000

280FM

280FM

280FM

IS2x0170B

320000

450FMM

450FMM

450FMM

IS2x0200B

320000

450FMM

450FMM

450FMM

IS2x0220B

320000

450FMM

450FMM

450FMM

IS3x0255B

320000

450FMM

450FMM

450FMM

IS4x0350B

202000

315FM*

––

––

IS4x0425B

320000

400FMM*

––

––

IS4x0500B

320000

450FMM*

––

––

IS4x0700B

781000

630FMM*

––

––

IS4x0820B

1200000

––

––

––

IS4x0920B

2530000

––

––

––

IS4x1000B

2530000

––

––

––

IS3x0255N

320000

450FMM

450FMM

450FMM

IS4x0360N

320000

––

––

––

IS4x0430N

320000

––

––

––

IS4x0650N

1200000

630FMM*

630FMM*

––

IS4x0790N

2530000

––

––

––

IS4x0930N

4500000

––

––

––

IS561200N

4500000

––

––

––

* Two parallel connected fuses required per phase.

Table 4-3 Bussman fuses - British style (BS88)

Digistart IS User Guide 27

Issue: 4 www.controltechniques.com

Loading...

Loading...