Page 1

3.1 Commissioning

3.2 Starting

3.3 Monitoring Systems

3.4 Stopping

3.5 Operating Conditions

Engine Operation

3

23 Gerade

Page 2

Engine Operation

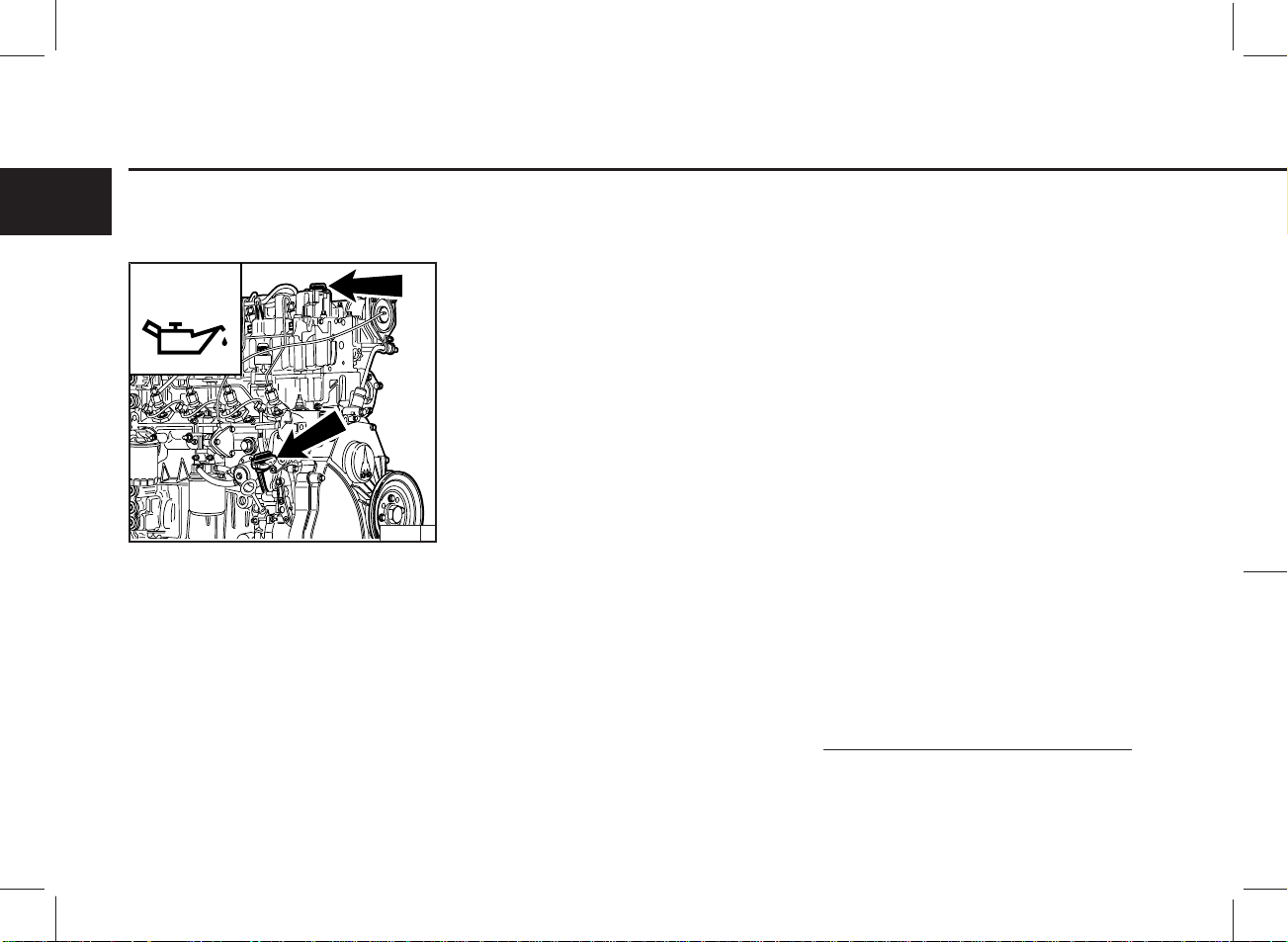

3.1.1 Adding Engine Oil

3

OIL

As a rule, engines are delivered empty of oil.

Pour lube oil into the oil filler neck (arrow).

For oil grade and viscosity, see 4.1.

26 432 0

3.1.1.1 Initial Engine Oil Fill-Up

for B/FM1011F Series

● Fill oil into the oil sump up to the “max.” mark on

the engine dip stick (for oil top-up quantity see

9.1).

● Start the engine and allow to run at a low idling

speed for approx. 2 mins.

● Switch off the engine.

● Check the oil level, if necessary, top up oil to the

„max.“ mark.

3.1 Commissioning

3.1.1.2 Initial Engine Oil Fill-up

for B/FM 1011F Series

● Fill oil into the oil sump up to the “min.” mark on

the engine dip stick.

● In addition, top up the oil quantity of the supply

hoses and of the external oil cooler (according to

manufacturer’s details).

● Allow the engine to run warm until the thermostat

opens (at approx. 95oC).

● Allow the engine to run for approx. 2 mins.

● Switch off the engine.

● Check the oil level, and if necessary, top up oil to

the „max.“ mark.

24

If the person operating the engine does not run up

the engine until the thermostat opens, the oil level

may lie above the „max“. mark on the engine dip

stick when delivered. The level can then only be

assessed after the engine has been run up.

Page 3

3.1 Commissioning

Engine Operation

3.1.1.3 Initial Engine Oil Fill-Up for

B/FM 1011F Genset Engine

● Fill oil into the oil sump up to the “max.” mark on

the engine dip stick (for oil quantity see 9.1).

● Start up the engine and allow to run at a lower

idling speed for approx. 2 mins.

● Switch off the engine.

● Check the oil level and fill up with oil up to the

upper „max.“ mark.

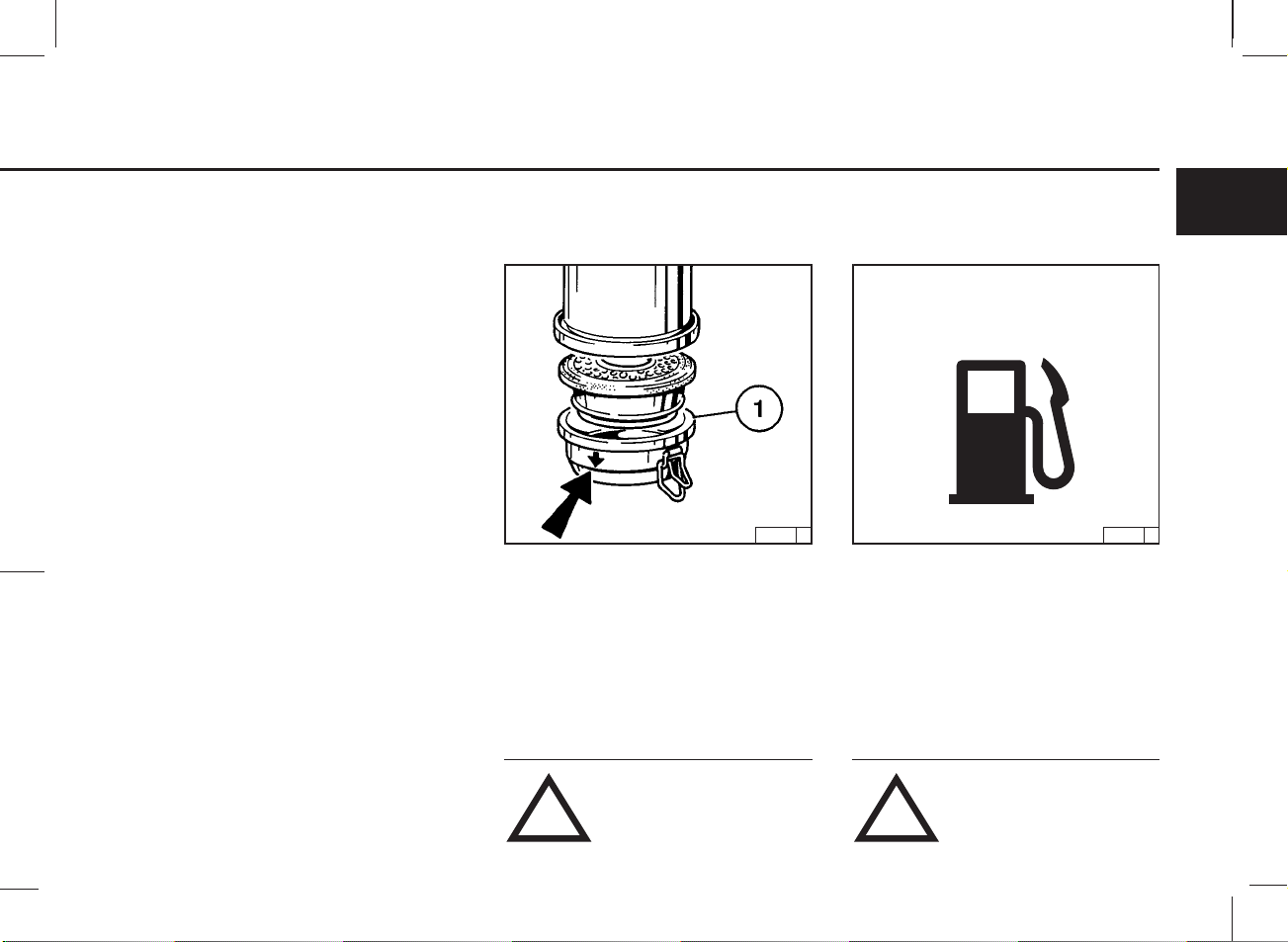

3.1.2 Filling Oil Bath Air Filter with

Engine Oil

24 980 2 26 398 0

Fill oil cup 1 of the oil bath air cleaner with oil up to

the arrow.

For oil grade and viscosity, see 4.1.

3.1.3 Adding Fuel

FUEL

Use only commercial-grade diesel fuel. For fuel

grade, see 4.2. Use summer or winter-grade fuel,

depending on the ambient temperature.

3

Do not fill the precleaner dust collector (if fitted) with oil.

! !

Never fill the tank while the engine

is running. Keep the filler cap area

clean and do not spill fuel.

25 Gerade

Page 4

Engine Operation

3.1 Commissioning

3.1.4 Other Preparations

3

● Check battery and cable connections, see 6.7.1

● Transport hooks

Remove if fitted (see 6.7.3)

● Trial run

After the engine has been prepared, let it run

for about 10 minutes without load.

During and after trial run

– Check the engine for leaks

After the engine has been turned off

– Check the oil level,

– Retension V-belts, see 6.5

● Breaking in

During the break-in phase – about 200 operating hours – check the oil level twice a day. After

the engine is broken in, checking once a day

will be sufficient.

see 6.1.2

If necessary, top up oil,

see 3.1.1

3.1.5 Additional Maintenance Work

When commissioning new and reconditioned engines, the following additional maintenance work

must be carried out:

After 50-150 OH

● Change lube oil,

see 6.1.2

● Change oil filter cartridge,

see 6.1.3

● Change fuel filter cartridge,

see 6.2.1

● Check V-belts and retension as necessary,

see 6.5.

● Check the engine for leaks

● Check the engine mount and adjust as neces-

sary, see 9.2

After 500 OH

● Check the valve clearance and adjust as neces-

sary, see 6.6.1.

26

Page 5

3

27 Gerade

Page 6

Engine Operation

3.2.1 Electric Starting

3

Before starting, make sure that nobody is standing in the immediate

vicinity of the engine or driven machine.

!

After repair work:

replaced and that all tools have been removed from

the engine.

When starting with glow plugs, do not use any other

starter substance (e.g. injection with start pilot).

Caution: If the speed regulator has been removed, the engine must not be tested under any

circumstances:

Disconnect the battery.

Check that all guards have been

3.2 Starting

Starting without Cold-Start Aid

2

1

26 423 0 25 746 2

Do not actuate the starter for more than 20 seconds. If the engine does not catch, wait a minute

then try again.

If the engine does not catch after two attempts,

refer to the Diagnosis Chart (see 7.1).

28

● Where possible, disengage the clutch to sepa-

rate the engine from any driven parts.

● Move speed control lever 1 into idle position.

● Move cut-out handle 2 into operating position.

● Insert key.

– Position 0 = no operating voltage

● Turn key clockwise

– Position 1 = operating voltage

– Pilot lights come on

● Push the key in and turn it further clockwise

against spring pressure

– Position 2 = no function

– Position 3 = start

● Release key as soon as engine fires

– Pilot lights go out

Page 7

3.2 Starting

Engine Operation

with Cold-Start Aid

– Glow Plug

25 746 2 25 746 2 25 963 0

● Insert key.

– Position 0 = no operating voltage

● Turn key clockwise

– Position 1 = operating voltage

– Pilot lights come on

● Push key in and turn further clockwise against

spring pressure

– Position 2 = Preheat, hold for approx.

1 minute.

– Preheat lamp comes on

– Position 3 = Start

● Release key as soon as engine fires

– Pilot lights go out

with Cold-Start Aid

– Ether Starting System

● Insert key

– Position 0 = no operating voltage

● Turn key clockwise

– Position 1 = operating voltage

– Pilot lights come on

● Push key in and turn further clockwise against

spring pressure

– Position 2 = no function

– Position 3 = start

● Release key as soon as engine fires

– Pilot lights go out

● Starting fluid is injected automatically in switch

position A, as long as the starter is operated.

● To assist acceleration at lower temperatures

and to avoid white fumes, briefly hold the

arctic switch in switch position H.

The switch must not be moved to

position H when the engine is

switched off and the ignition is

!

switched on.

3

29 Gerade

Page 8

Engine Operation

3.3.1 Engine Oil Pressure

3

Oil Pressure Pilot Light

Oil Pressure Indicator

25 752 1 25 754 025 753 0

3.3 Monitoring Systems

Oil Pressure Gauge

● The oil pressure pilot light comes on with oper-

ating voltage on and engine off.

● The oil pressure pilot light should go out when

the engine is running.

30

● The pointer must remain in the green sector over

the entire range.

● The pointer must indicate the minimum oil

pressure (see 9.1).

Page 9

3.3 Monitoring Systems Engine Operation

3.3.2 Coolant Temperature

Engine Temperature Gauge

24 985 0

● The engine temperature gauge pointer should

remain in the green sector most of the time. It

should rarely enter the yellow-green sector. If the

pointer enters the orange sector, the engine is

overheating. Turn off and establish the cause

from the Diagnosis Chart (see 7.1).

3

31 Gerade

Page 10

Engine Operation

3.4 Stopping

3.4.1 Mechanical Shutdown

3

2

1

● Move speed control lever 1 to low idle.

● Operate shutdown lever 2 until the engine comes

to a stop. The charge pilot light and the oil

pressure pilot light will come on when the engine

stops.

● Turn key counterclockwise (to position 0) and

remove. The pilot lights will go out.

26 424 0

3.4.2 Electrical Shutdown

(Ignition Key)

25 746 2

● Turn key counterclockwise (to position 0) and

remove. The pilot lights will go out.

32

If possible, do not suddenly switch off the engine

when under full load.

Page 11

Engine Operation3.5 Operating Conditions

3.5.1 Winter Operation

● Lube Oil Viscosity

– Select the oil viscosity (SAE grade) accord-

ing to the ambient temperature when the

engine is started, see 4.1.2.

– Increase oil change frequency when oper-

ating below -10 °C, see 6.1.1.

● Diesel Fuel

– Use winter-grade diesel fuel for operation

below 0 °C, see 4.2.2.

● Additional Maintenance Work

– Drain the sludge from the fuel tank once a

week. (Unscrew the sludge drain plug)

– If necessary, allow the oil in the oil bath air

cleaner and the engine oil to settle at the

ambient temperature.

– Below -20 °C, after removing the starter if

necessary, smear the ring gear on the fly

wheel via the pinion bore from time to time

with cold-resistant grease.

(e.g. Bosch grease FT 1 V 31).

● Cold-Start Aid

– At temperatures near or below freezing

point, use glow plugs if necessary, see

3.2.1.

This not only lowers the starting limit temperature, but provides easier starting at

temperatures normally not requiring a starting aid.

3

● Battery

– Efficient cold starting requires a healthy

battery, see 6.7.1.

– The starting limit temperatures can be low-

ered by 4-5 °C by heating the battery up to

about +20 °C . (To do so, remove the battery

and store in a warm place).

26 248 0

33 Gerade

Page 12

Engine Operation

3.5.2 High Ambient Temperatures,

3

High Altitude

● As the altitude and ambient temperature rise, the

density of air tends to decrease, which affects

the maximum power output of the engine, the

exhaust gas quality and, in extreme cases, the

starting behavior. Under transient conditions,

the engine can be used at altitudes up to 1000 m

and temperatures up to 30 °C. If the engine is to

operate under more severe conditions (at higher

altitudes or temperatures), it will be necessary to

reduce the injected fuel quantity and thus, engine power.

● If you have any doubts about engine operation

under these or similar conditions, ask your engine or equipment supplier whether the engine

has been derated in the interests of reliability,

service life and exhaust gas quality (smoke).

Otherwise contact DEUTZ SERVICE.

3.5 Operating Conditions

C F

0 32

25 901 1

34

Loading...

Loading...