Page 1

Routine Maintenance

5.1 Maintenance Schedule

5.2 Maintenance Chart

5.3 Maintenance Work Completed

5

39

39 Gerade

Page 2

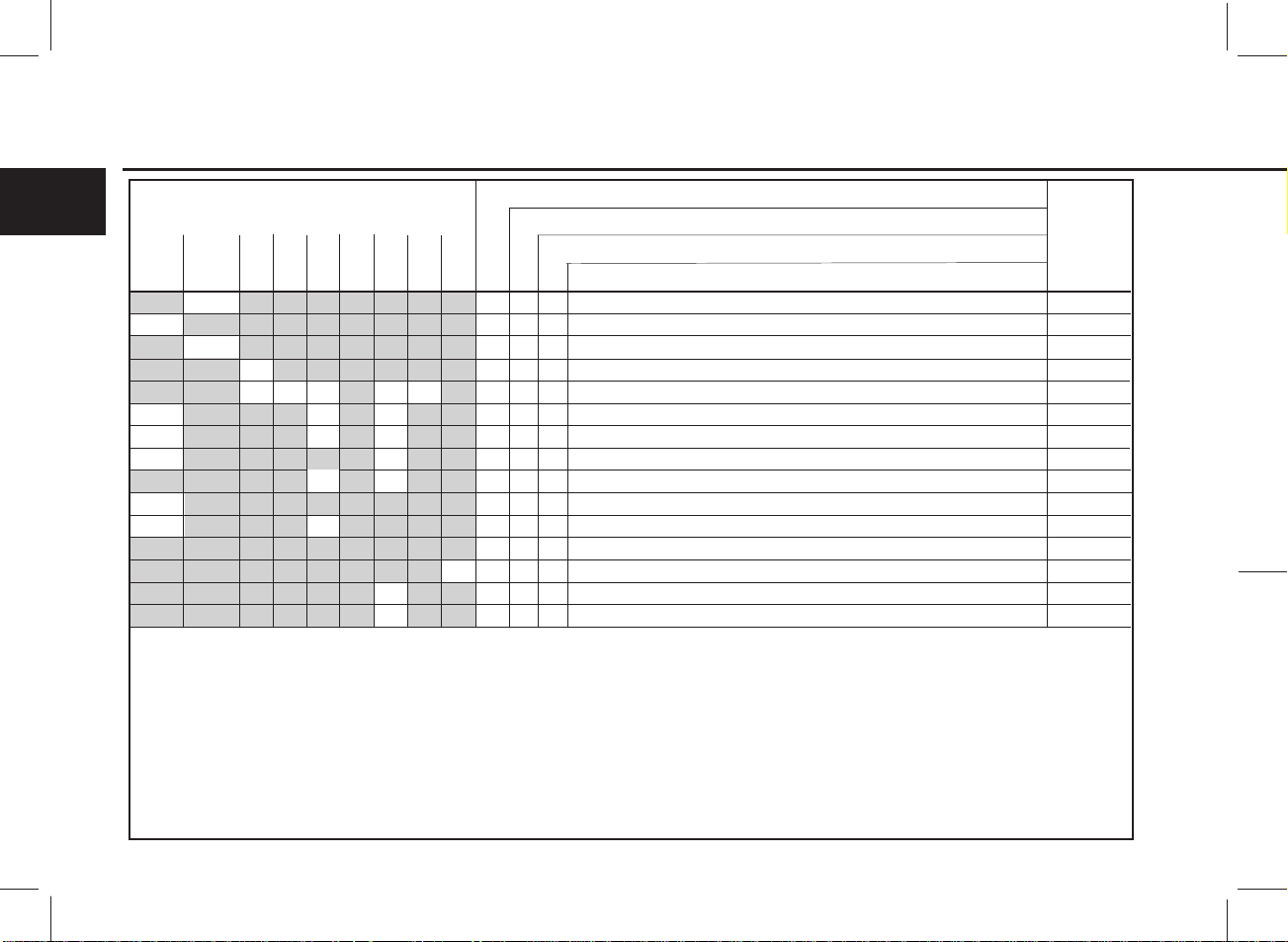

Routine Maintenance

5.1 Maintenance Schedule

5

3000

check

●

●

●

●

●

●

●

●

●

●

clean

●

change

Operation

Oil level in engine / separate container

9)

Engine leaks

Oil bath- and dry type air cleaners

3) 4) 5)

Battery and cable connectors 6.7.1

4) 6)

3)

4) 6)

Cooling system (depending on engine use

●

Engine oil (depending on engine use)

●

Oil filter cartridge (depending on oil change interval)

●

Fuel filter cartridge 6.2.1

Valve clearance (adjust if necessary) 6.6.1

Engine mounts (retighten if necessary) 9.2

V-belts (retension if necessary) 6.5

●

Toothed belts

8) 10)

Injection valves

Fuel pump / strainer

Fuel leakage line (change defective lines)

5)

11)

Section

6.1.2/3.1.4

6.4

6.3.1

6.1.1

6.1.3

6.2.2

6.2.3

once

Operating Hours (OP) every 1)

every

after

10 OH

2)

or daily

50-150

●

●

●

●

● ● ● ● ●

●●

●●

● ●

●

●●

125

250

750

500

7)

7)

2)

●

●

●

●

●

●

1000

6)

6)

2000

●

The specified engine maintenance times are maximum values. Depending on the operating environment, shorter maintenance intervals may be required. Please

observe the operating instructions of the equipment manufacturer.

1) recommended maximum

2) once when commissioning new and reconditioned engines

3) clean if needed

4)Oil quality API-CF-4, CG-4, CH-4 or ACEA-E1-3/96 and E4-98

5) change if required

6) for oil change intervals, naturally aspirated engines, see

Section 6.1.1

7) for oil change intervals, turbocharged engines, see Section 6.1.1

8) without toothed belt ventilation renew after 3000 running hours, after 5 years at the

latest if running hours are not reached: in both cases together with idler pulley

with toothed belt ventilation renew after 4500 running hours, after 5 years at the latest

if running hours are not reached: in both cases together with idler pulley

9) during run-in period, check 2 x daily

10) retensioning of toothed belts is not permitted

11) Change at the latest after 2 years .

see

40

Page 3

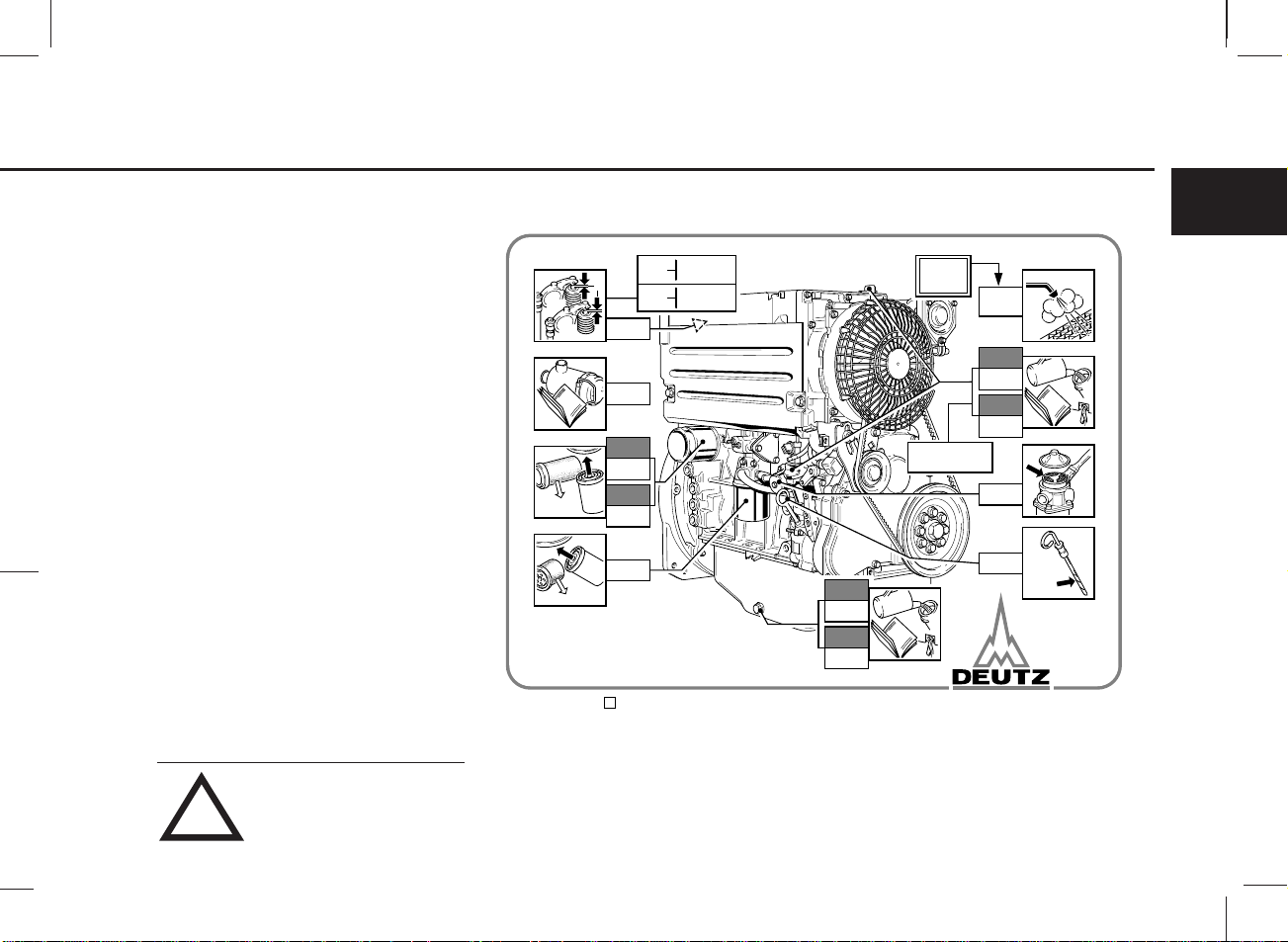

5.2 Maintenance Chart

Routine Maintenance

5

The maintenance chart shown here is supplied as a selfadhesive label with each engine. It should be affixed

where it can be seen clearly on the engine or driven

equipment.

Check that this is the case.

If necessary, ask your engine or equipment supplier for

a fresh supply of labels.

Routine work should be carried out according to the

schedule in 5.1.

Stop the engine before carrying out

any maintenance work.

!

0,3 mm

in.

ex.

0.012 in.

0,5 mm

0.020 in.

a

ex.

in.

1000

AIR

FUEL

OIL

10

BFL

500

FL

1000

1000

B/FL 1011F

0297 7279

1

BFL

500

FL

1000

Std.

API CD

ACEA E1-96

OIL

h

1252000

BFL

OIL

500

FL

1000

1000

10

OIL

max.

41

41 Gerade

Page 4

5

Routine Maintenance

The maintenance chart shown here is supplied as a selfadhesive label with each engine. It should be affixed

where it can be seen clearly on the engine or driven

equipment.

Check that this is the case.

If necessary, ask your engine or equipment supplier for

a fresh supply of labels.

Routine work should be carried out according to the

schedule in 5.1.

0,3 mm

in.

ex.

0.012 in.

0,5 mm

0.020 in.

a

ex.

in.

1000

AIR

OIL

FUEL

10

BFM

500

FM

1000

1000

B/FM 1011/F

5.2 Maintenance Chart

h

BFM

500

FM

1000

Std.

API CD

ACEA E1-96

OIL

1252000

BFM

500

FM

1000

1000

10

OIL

max.

OIL

42

Stop the engine before carrying out

any maintenance work.

!

0297 7281

2

Page 5

5.3 Completed Maintenance Jobs Routine Maintenance

Hours

50-150

Date

*

Signaure / Stamp Hours Date Signaure / Stamp

125

375

625

875

1125

1375

1625

1875

2115

2375

2625

* Commissioning new and overhauled engines

The maintenance jobs duly completed can be recorded in the above table.

-

250

500

750

1000

1250

1500

1750

2000

2250

2500

2750

5

1

2

3

4

5

6

7

8

9

49_en

10

Page 6

Routine Maintenance 5.3 Completed Maintenance Jobs

1

5

Hours.

2875

2

3125

3375

3

3625

4

3875

4125

5

4375

6

4625

4875

7

5125

8

5375

5625

9

The maintenance jobs duly completed can be recorded in the above table.

Date

Signaure / Stamp Hours

3000

3250

3500

3750

4000

4250

4500

4750

5000

5250

5500

5750

Date

Signaure / Stamp

10

50_en

Page 7

5.3 Completed Maintenance Jobs Routine Maintenance

Hours

Date

Signaure / Stamp Hours Date Signaure / Stamp

5875

6125

6375

6625

6875

7125

7375

7625

7825

8125

8375

8625

The maintenance jobs duly completed can be recorded in the above table.

6000

6250

6500

6750

7000

7250

7500

7750

8000

8250

8500

8750

5

1

2

3

4

5

6

7

8

9

51_en

10

Page 8

5

Seite 46Gasmotor 1015

Loading...

Loading...