SERVICE MANUAL

Hi-Fi Component

MODEL

DN-780R

STEREO CASSETTE TAPE DECK

Some illustrations using in this service manual are slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

X0147 NC 0207

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either

side of the power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS

Type: Vertical tape loading; 4-track 2-channel stereo double cassette deck

Heads: Recording/playback head (hard permalloy) × 2

Erase head (Double-gap ferrite) × 2

Motors: Capstan (DC servo motor) × 2

Reel (DC motor) × 2

Tape Speed: 4.8 cm/sec.

Variable (PLAY): Approx. ±12%

Fast Forward, Rewind Time: Approx. 110 sec. with a C-60 cassette

Recording Bias: Approx. 105 kHz

Overall S/N Ratio

(at 3% THD level): Dolby C NR on: more than 74 dB (CCIR/ARM)

Overall Frequency Response: 20~18,000 Hz ±3 dB (at −20 dB, Metal tape)

Channel Separation: More than 40 dB (at 1 kHz)

Wow & Flutter: 0.06% WRMS, ±0.14% w.peak

Input

LINE: 50 mV (input level at maximum)

Input impedance: 240 kohm unbalanced

MIC: 0.775 mV (mic level at maximum)

Output

LINE: 775 mV (0 dB)

(with 47 kohm load, recorded level of 200 nWb/m)

PHONES: 7 mW output level at maximum

(optimum load impdance 8 ohm~1.2 kohm)

Power Supply: 33 W

Dimensions: 438 (W) × 134 (H) × 275 (D) mm

Wehght: 6.5 kg (14 lbs 5 oz)

Installation: 19-inch rack mountable (3U)

DN-780R

* For improvement purposes, specifications and functions are subject to change without advanced notice.

■ Dolby noise reduction and HX Por headroom extension manufactured under license from Dolby Laboratories

Licensing Corporation. HX pro originated by Bang & Olufsen.

■ “DOLBY”, the double-D symbol

and “HX Pro” are trademarks of Dolby Laboratories Licensing Corporation.

2

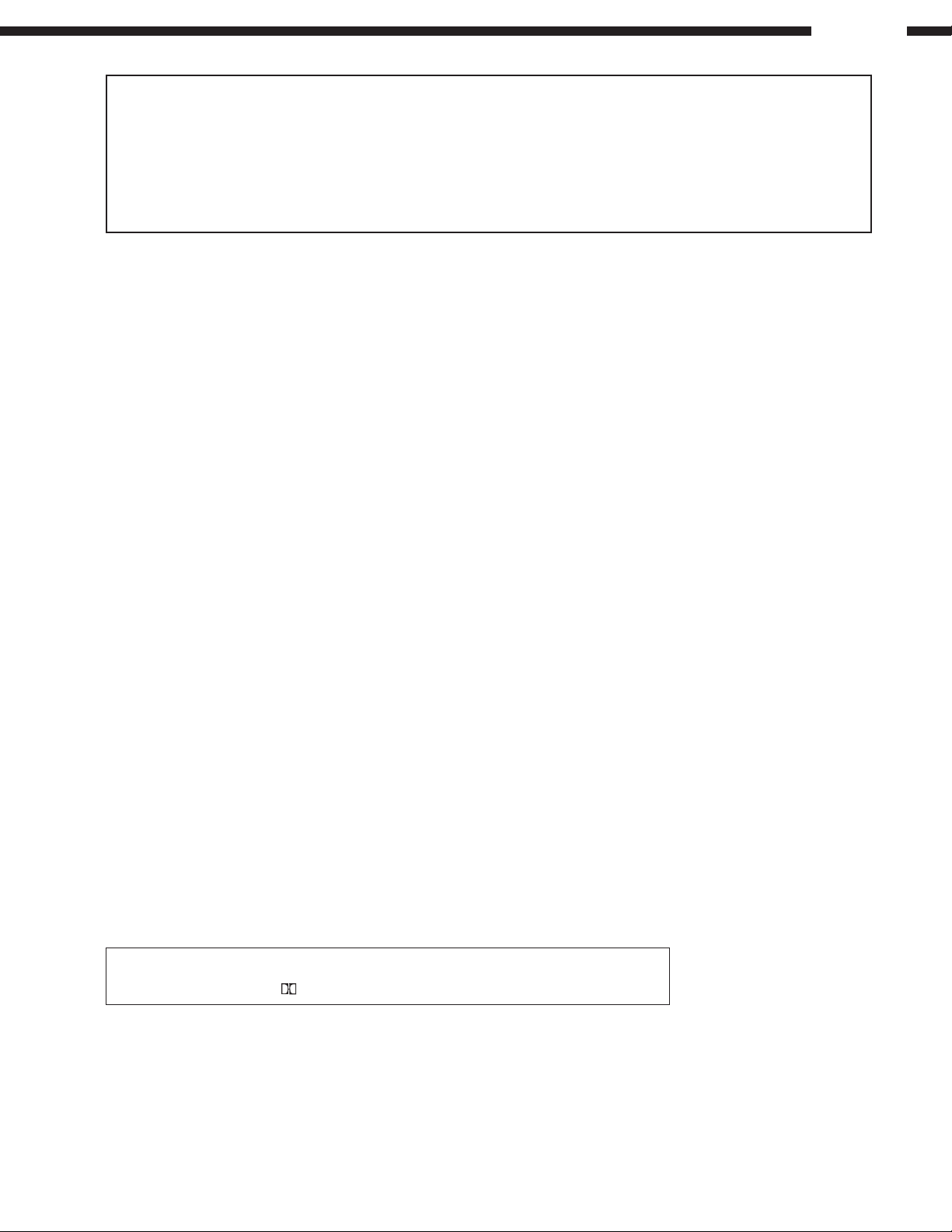

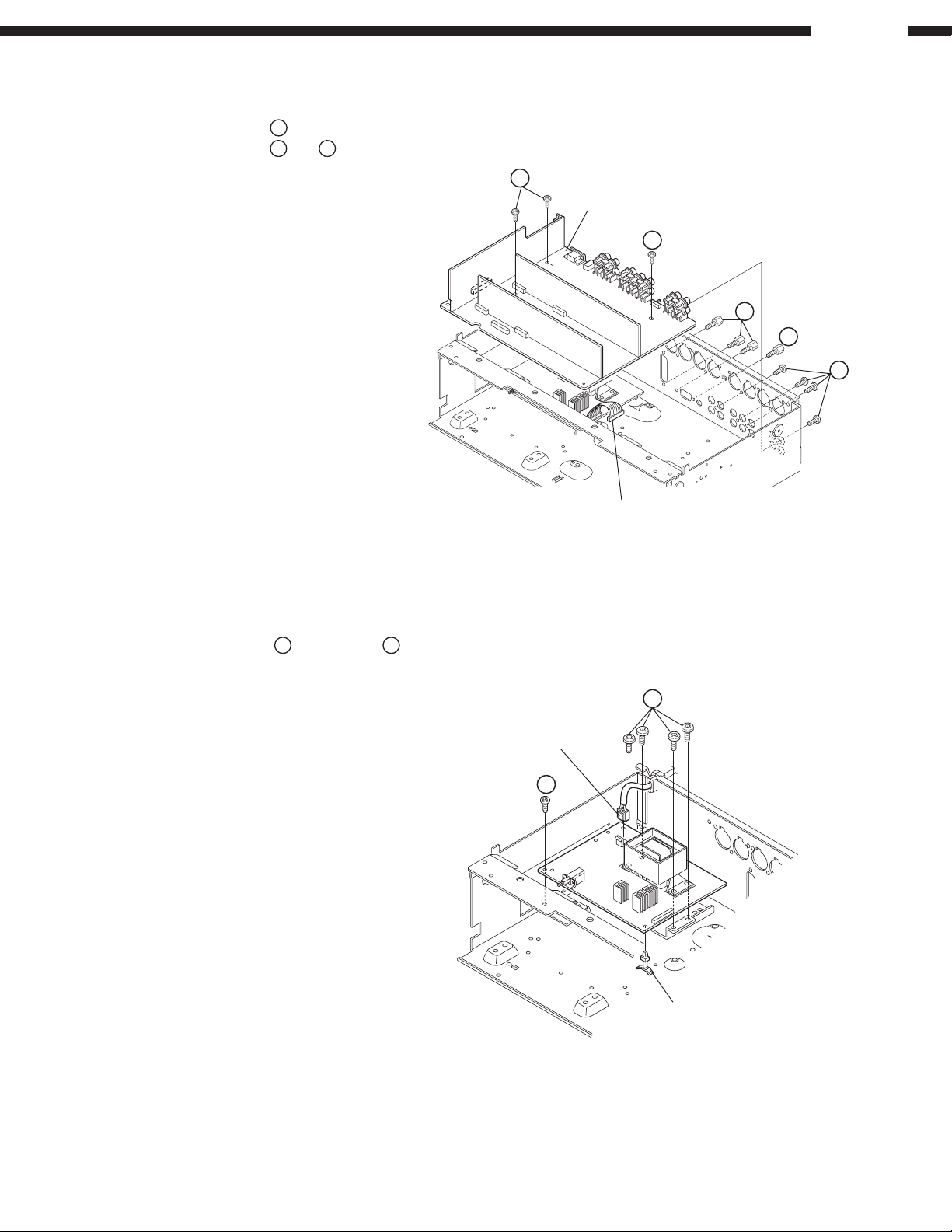

DISASSEMBLY

2

4

( Follow the procedure below in reverse order when reassembling. )

1. Top Cover

(1) From both sides, remove 4 screws 1, Bracket, and

2 screws

(2) Remove 3 screws 3 on the rear, then detach the

Top Cover to the arrow direction.

.

2

1

DN-780R

3

2

2. Front Panel

(1) Remove 2 screws 4 and 3 screws 5 from top

and bottom of the Front Panel.

(2) Disconnect the wire and 3 connectors from the

Cassette Mecha., then detach the Front Panel to

the arrow direction.

(3) Remove the screw

(4) Disconnect FFC.

(5) From the Cassette Mecha., disconnect

2 connectors.

(6) Remove 2 screws

SWB UNIT.

to free earth wire.

6

7

to detach the SWA UNIT and

SWA UNIT

Wire

1

4

Connector

5

7

Connector

6

Earth Wire

FFC

Connector

7

SWB UNIT

3

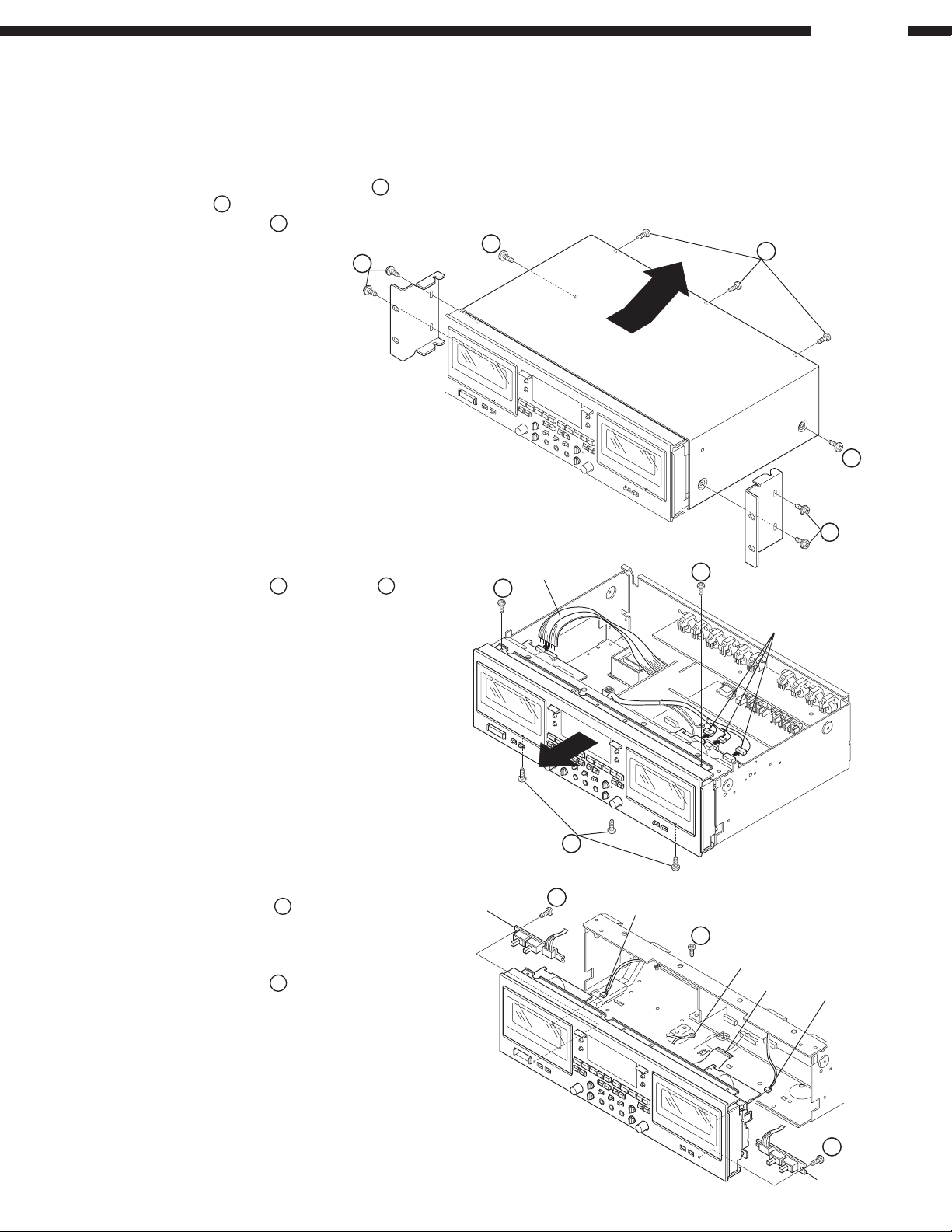

3. DISPLAY P.W.B./VOLUME P.W.B.

(1) Pull out 6 knobs on the front.

(2) Remove 9 screws 8 on the DISPLAY P.W.B.

9

(3) Remove 2 screws

on the MIC UNIT.

knob

DN-780R

DISPLAY P.W.B.

8

9

MIC UNIT

knob

4. Cassette Mecha. A & B

Remove 4 screws each on both Cassette

Mecha. A and B.

5. Cassette Door

(1) Take off the Cassette Window on the front.

(2) Remove the screw to detach

the Mini-damper.

(3) Remove the screw

Bracket.

(4) With pushing the shaft in the arrow directions,

no spring side first, detach the Cassette Door.

to detach the Door

Cassette Mecha. A

Cassette Mecha. B

Cassette Window

Mini-damper

Spring

Door Bracket

Cassette Door

Shaft

4

6. Audio P.W.B.

(1) From the Audio P.W.B., disconnect the connector.

(2) Remove 3 screws !.

"

(3) Remove 4 screws

and # each on the rear.

DN-780R

!

Audio P.W.B.

!

#

#

"

7. Power P.W.B.

(1) Disconnect the power connector.

$

(2) Remove the screw

(3) Release the P.W.B. holder.

and 4 screws %.

Connector

%

Power Connector

$

P.W.B. Holder

5

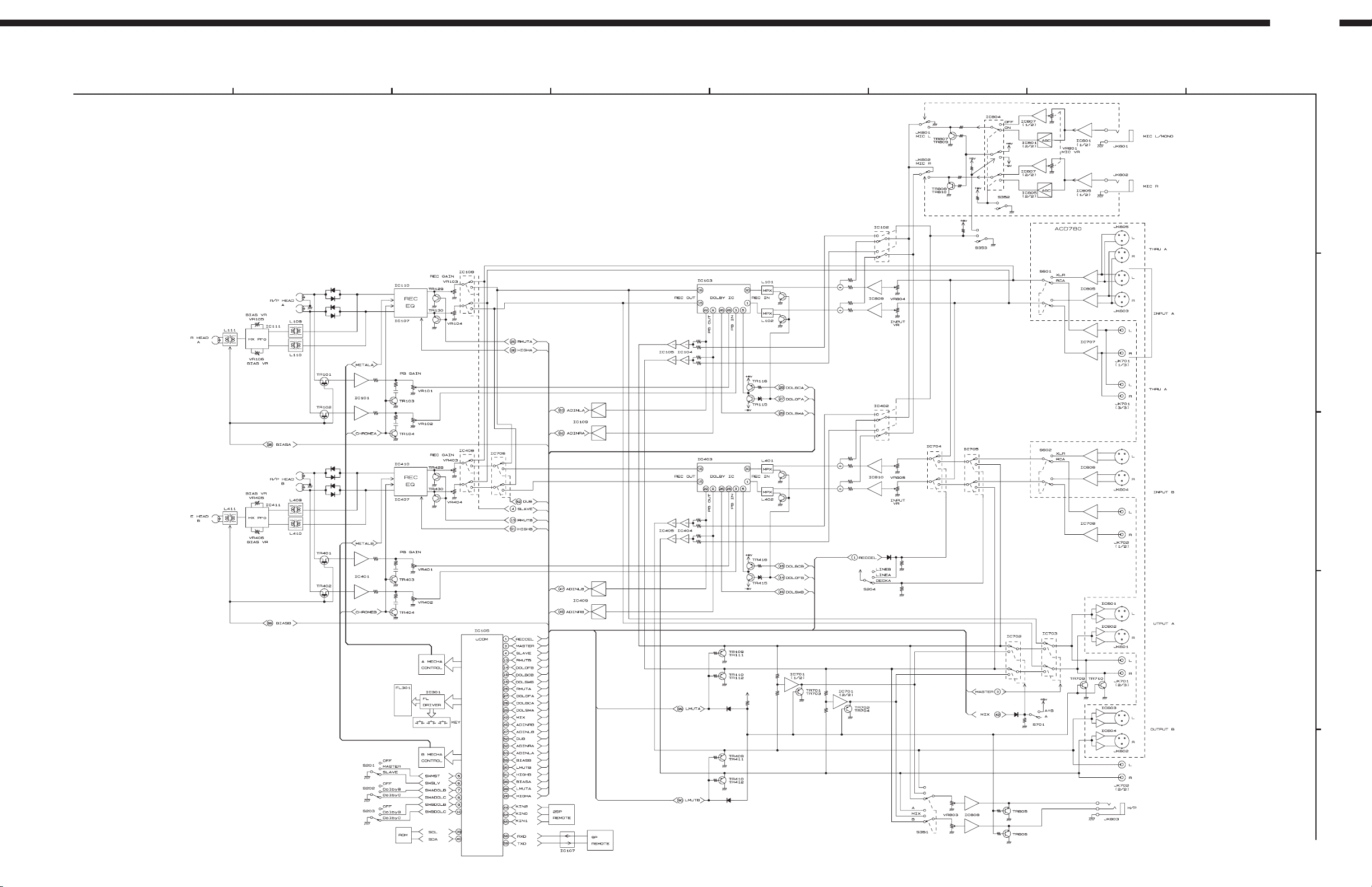

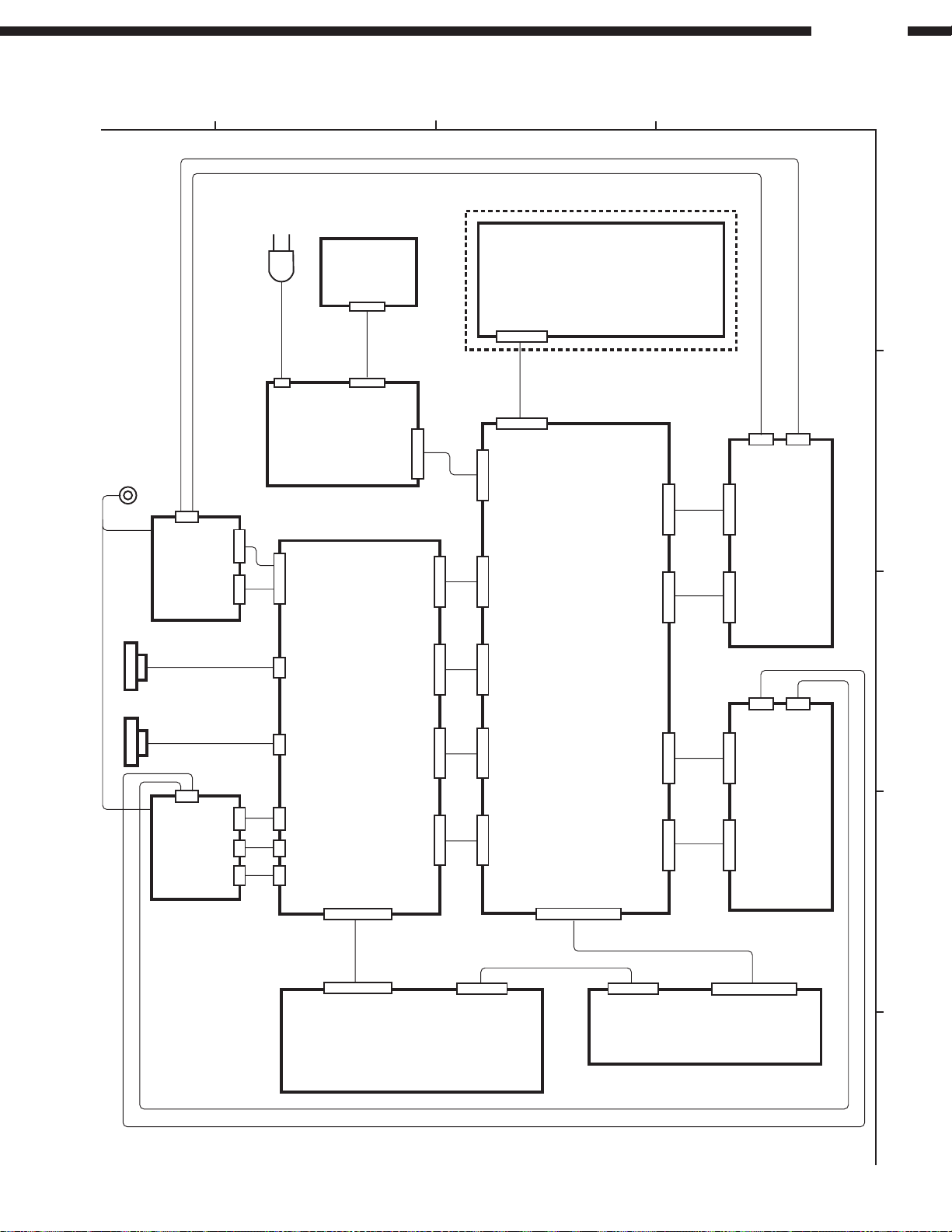

BLOCK DIAGRAM

(Option)

DN-780R

1 5678

32

4

A

B

C

D

E

6

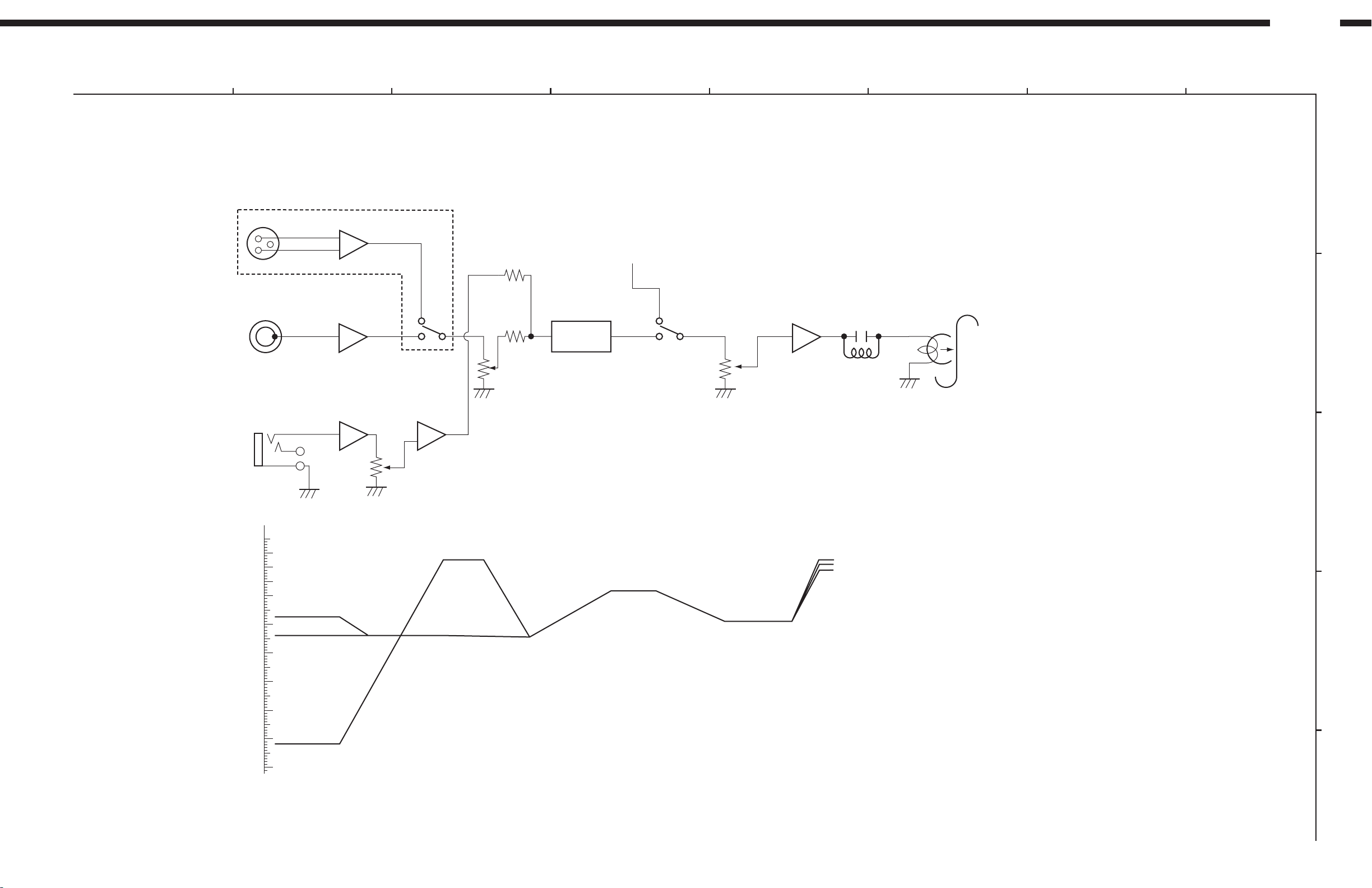

LEVEL DIAGRAMS

XLR -17.5dB

MIC -62dB

DCA -24dB

-24.5dB

-8.2dB

-19dB

+2.5dB(METAL)

+1dB (CHROME)

-1dB (NORMAL)

+2.5dB

-10dB

-50dB

-60dB

-70dB

-20dB

-40dB

-30dB

0dB

(dBV)

IC103(403)

HA12170

IC605(606)

XLR

7(1)

IC707(708) VR804(805)

VR103(403)

IC108(408) IC110(410)

RCA

1(7) 30(1) 16(15) 1(7)

IC807

7(1)

IC801(805)

7

LINE IN

MIC

ACD 780 (Option)

0dB=0.775V

* MIC MIDE = REC

MIC AGC = OFF

RECORDING SYSTEM

INPUT FREQUENCY 400Hz

DN-780R

1 5678

32

4

A

B

C

D

E

7

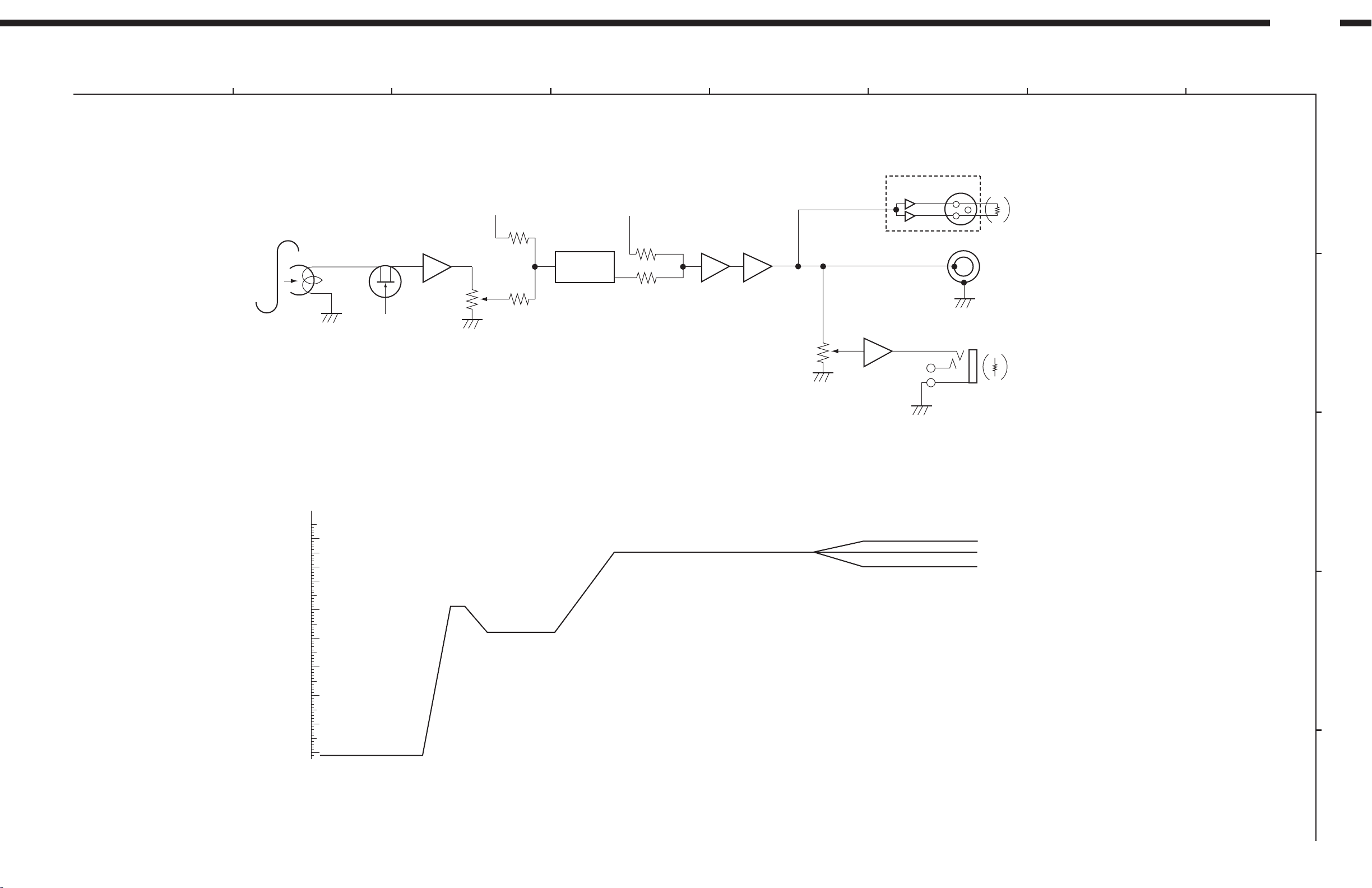

DN-780R

-71dB

-19dB

-28dB

+4dB(XLR)

0dB(RCA)

-5dB(HEAD PHONE)

-10dB

-50dB

-60dB

-70dB

-20dB

-40dB

-30dB

0dB

(dBV)

0dB=0.775V

IC103(403)

HA12170

XLR

TR101(401)

VR101(401)

IC105(405)

IC601(603)

LOAD

600 ohm

LOAD

33 ohm

IC104(404)

IC101(401)

NJM2068

3(5)

1(7)

1(7) 1(7)

28

(3)

22

(9)

LINE OUT

HEAD PHONE

RCA

ACD 780 (Option)

PLAYBACK SYSTEM

TCC-130 DOLBY B-TYPE

1 5678

32

4

A

B

C

D

E

8

ADJUSTMENT

ADJUSTING AND CHECKING THE

MECHANISM SECTION

1. Replacing Pinch Roller

Before replacing the pinch roller, clean the tape contact

surface of the pinch roller and the capstan shaft.

Most causes of poor tape transport can be traced to dirty

pinch roller and capstan shaft.

Removing the pinch roller

Remove the clips that press the pinch roller and pull the

pinch roller forward remove it.

After replacing, run a padles C-90 tape to check for tape

curls at the tape guide section of the head.

DN-780R

Capstan shaft

Pinch roller

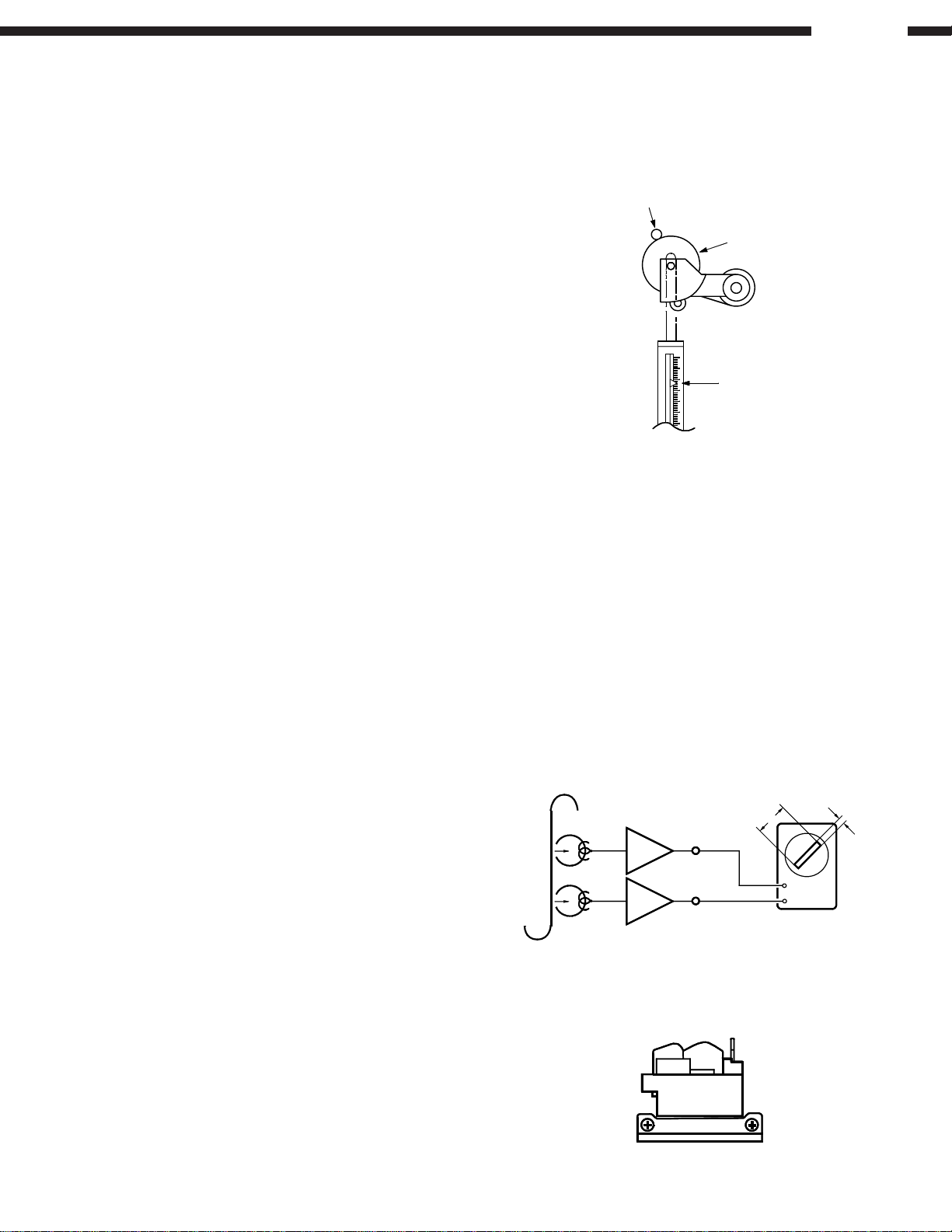

2. Checking the pressure Force of the Pinch

Roller

In the playback mode, hook a spring weight onto the

bracket at the center of the pinch roller. After separating

the pinch roller from the capstan shaft allow the pinch roller

to contact the capstan shaft again. Check to make sure

the spring weight reads between 250 ~ 350g when the

pinch roller starts to rotate.

Replace the pinch roller when it does not conform to the

standard specification values.

3. Replacing the Head Ass'y

(1) Removing the head Ass'y

1. Remove the head base mounting screws.

2. Remove the head base from the lead holder and

the wire connectors.

(2) Head Ass'y Installation

1. Assembly is the reverse of disassembly.

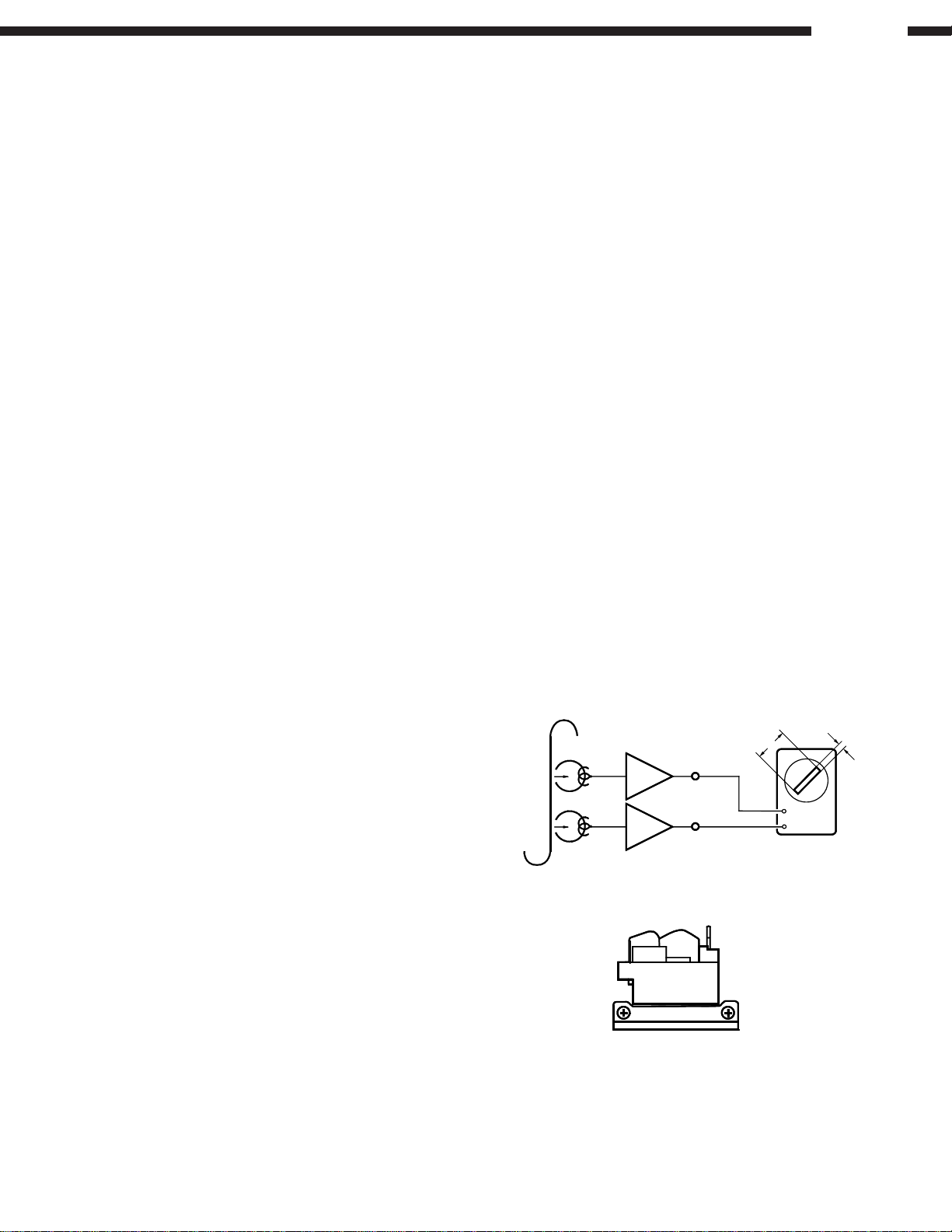

4. Adjusting the R/P HEAD

Azimuth adjustments

Set test tape A-BEX TCC-153 so that the A surface faces

forward, and adjust accordingly.

(1) Playback FWD. Turn the azimuth adjustment nut so

that the Lissajous waveform (A) is at maximum scale

and the Lissajous waveform (B) is at minimum scale.

(2) Playback REV. Turn the azimuth adjustment nut in

the same manner as (1), above.

(3) Make further adjustments to (1) and (2), above.

(4) Apply torsion locks to the adjusted nuts.

Note: Only the azimuth adjustment is necessary; no height

and tilt angle adjustments are required.

A-BEX TCC-153

PB Amp

L

R

LINE OUT

250 ~ 350g

A

B

V

H

R/P Head

FWD REV

9

DN-780R

5. Checking the Take-up Torque

Load the cassette type torque meter

FWD side .........SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure that the average torque meter reading

is within 30 ~ 70g-cm during playback. If it is not within

this range, check the voltage (approx. 4V) of the reel motor.

After the verification, replace the reel motor if there is no

problem with the voltage value.

6. Checking the FF and REW Torques

Load the cassette type torque meter (SONY TW2231).

Check to make sure the torque meter indicates within

90 ~ 180g-cm at the end of FF and REW.

7. Checking the Back Tension Torque During

Record/Playback

Load the cassette type torque meter

FWD side .........SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure the torque meter reads between

2 ~ 6g-cm during playback and that there is no unevenness.

8. Checking the FF and REW Times

Load a C-60 cassette tape (TDK AC-514); check to make

sure the tape is fast forwarded or rewound within 85 ~

115 seconds. If it is not within this range, check sections 5

and 7.

9. Checking the Operation of the Erase

Prevention, Metal and Chrome Switch

Confirm that the sensor arm properly detecting the tape

type detection holes on the cassette housing.

Caution on adjusting

(1) Before adjusting, clean the head surface, capstan and

the pinch roller with a gauze or cotton swab moistened

with alcohol.

(2) Demagnetize the R/P HEAD and the E HEAD with a

head eraser.

(3) Completely demagnetize the adjustment screwdriver.

(4) Unless instructed otherwise, set the various controls

as follows:

INPUT volume ....................... maximum

DOLBY NR button ................. OFF

TAPE SPEED-A (-B) .............Center click position

PHONES SELECT ................MIX

INPUT SELECT .................... LINE B

1. Tape Transport Check

Load the transport check cassette. In the operational mode,

illuminate the fixing guides of the R/P HEAD with a lamp

and check to make sure the tape edge does not come in

contact with the tape guide section.

The tape transport is the most important element in

determining the performance of a cassette deck.

Avoid moving the various adjustment screws, nuts, etc.,

as much as possible. Refer to the pages on "Adjusting

and Cheking the Mechanism Section" when replacing or

adjusting the R/P HEAD.

2. Adjusting the Azimuth

(1) After completing the tape transport check, load the

test tape (A-BEX TCC-153).

(2) Playback (both FWD side and REV side) the test tape;

adjust the azimuth screw so that section A of the

Lissajous waveform is maximum and section B is

minimum.

ADJUSTING THE ELECTRICAL SECTIONS

Measuring instruments necessary for

adjustments

(1) Audio signal generator

(2) Variable resistance attenuator

(3) Electronic voltmeter

(4) Oscilloscope

(5) Frequency counter

(6) Adjustment screwdriver.

(7) Trap coil adjustment square stick

(8) Test tapes (SONY TY-224)

(A-BEX TCC-130, TCC-153, TCC-262B/162B)

(TDK AC-514)

(9) Transport Check cassette tape (A-BEX TCC-902)

A-BEX TCC-153

FWD REV

PB Amp

L

R

LINE OUT

R/P Head

A

V

H

B

10

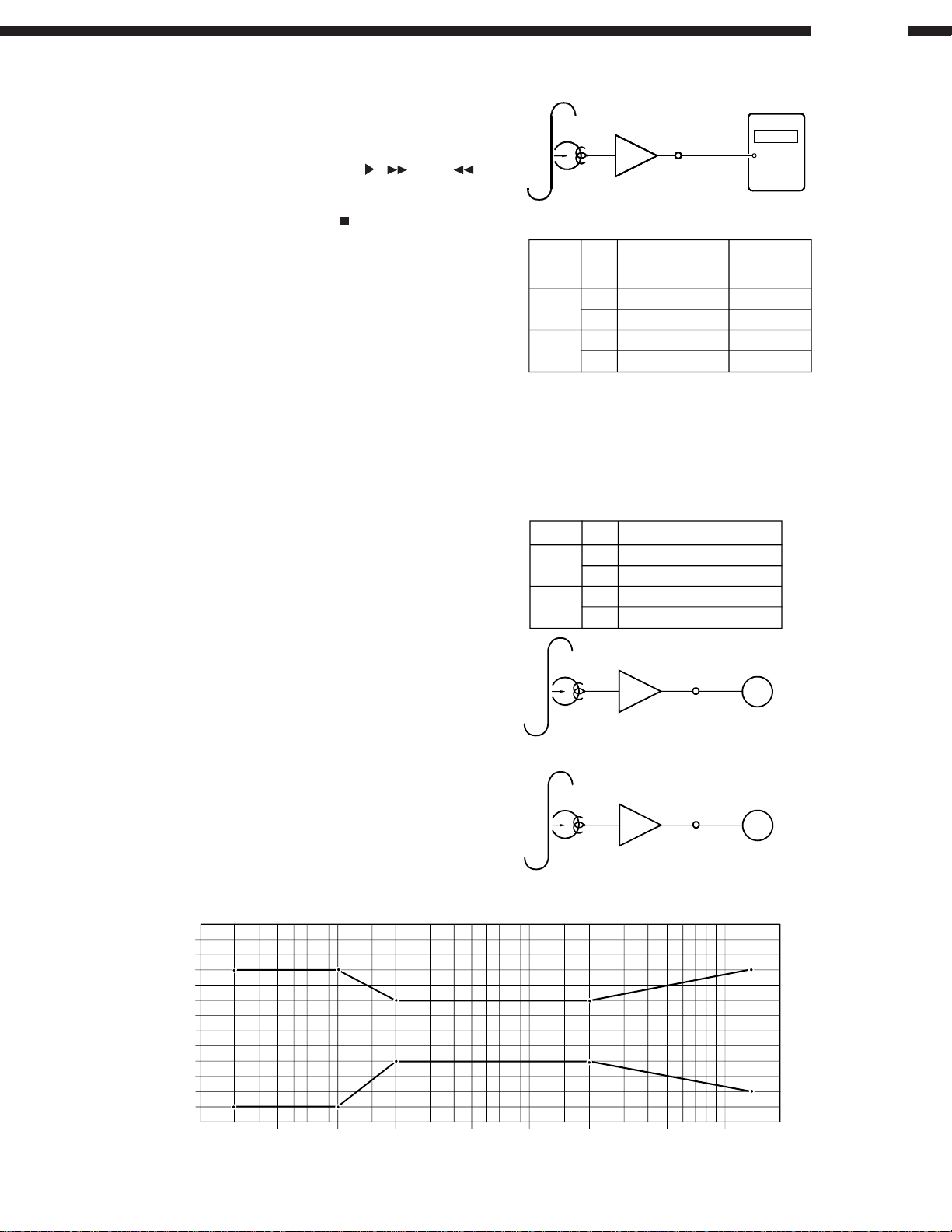

3. Checking and Adjusting the Tape Speed

(1) Connect the frequency counter to the LINE OUT

terminal and load test tape (SONY TY-224).

(2) Load cassette tapes on both cassette decks A and B.

Next, on the deck (A or B) whose speed is to be

adjusted, while holding down the

buttons of deck A together, press the POWER switch.

After the power has been on for about two seconds,

the Remote Control Indicator " " in Display will light

up and the cassette deck will begin to play in speed

adjustment mode.

(Speed adjustments can not be made, unless this

mode is first selected.)

(3) First high speed adjustments, press the DUBBING

SPEED "HIGH" Button and use VR101 for Casette

Deck A and VR102 for Cassette Deck B.

(Note that speed adjustment mode is cancelled when

the tape is ejected.)

(4) After completing high speed adjustments, press the

DUBBING SPEED "HIGH" Button again then tape

speed is slow (Normal speed). And start normal speed

adjustments, use Control Unit VR103 for Cassette

Deck A and VR104 for Cassette Deck B.

, , and

SONY TY-224

Mode

Normal

speed

High

speed

PB Amp

LINE OUT

Adjusting volume

A/B

A

B

A

B

number

VR-103

VR-104

VR-101

VR-102

DN-780R

F. Counter

F.

counter

(Hz)

3005±5

3005±5

6010±10

6010±10

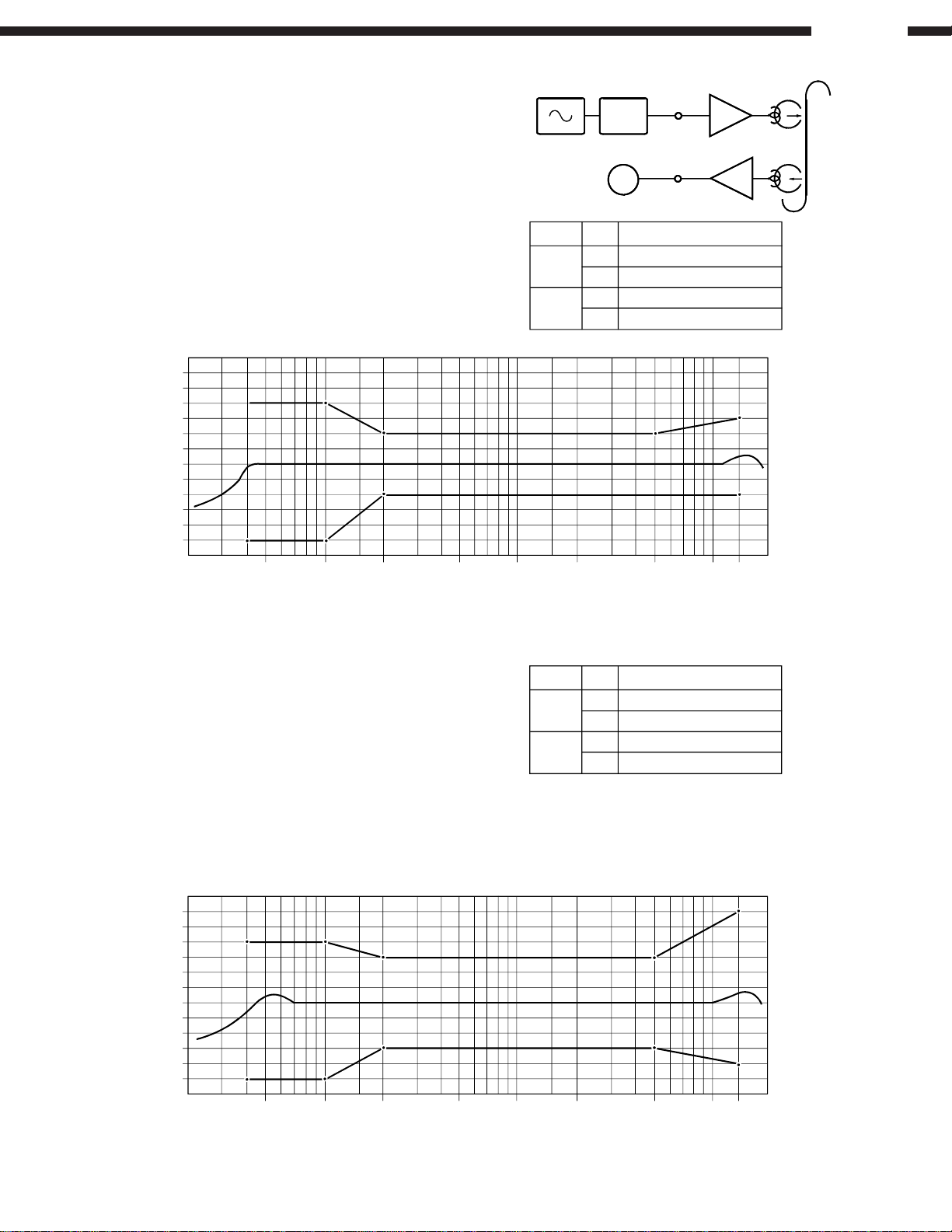

4. Playback System Adjustment

(1) Playback level

Playback a test tape for Dolby standard level (A-BEX

TCC-130). Adjust (Lch) and (Rch) so that the LINE

OUT terminal level is at 0 dB (775 mV).

(2) Verifying playback frequency characteristics

Playback the test tape (A-BEX TCC-262B/162B) and

verify that the frequency characteristics conform to

the specified standard.

Note: Before checking the playback frequency response,

first adjust the azimuth using the 8 kHz signal at the

beginning of the test tape (A-BEX TCC-262B). Also,

after checking the playback frequency, make sure

to readjust the azimuth with the test tape (A-BEX

TCC-153) and then lock the adjustment screw.

Playback frequency characteristics

(db)

+6

+

5

4

+

+3

+2

1

+

0

1

−

−2

3

−

−4

−5

6

−

20

10050

200

500

Playback Level

DECK L/R

A

B

A-BEX TCC-130

A-BEX TCC-262B/162B

1 k

Adjusting volume number

L VR-101

R

L

R

PB Amp

PB Amp

2 k

Tape: A-BEX TCC-262B/162B

VR-102

VR-401

VR-402

LINE OUT

LINE OUT

5 k

10 k 12 k

V.V

V.V

20 k (Hz)

11

DN-780R

5. Recording System Adjustment

5-1. Adjusting recording/playback comprehensive

frequency characteristics.

(1) Load a test tape TDK AC-514.

Record with a -20 dB 1 kHz input level signal into

the LINE IN terminal and playback.

(2) Make a sample recording using a 12 kHz input

signal and playback this recording. Adjust (left

channel) and (right channel) so that they conform

to the following specified characteristics.

(db)

+6

+5

+

4

+

3

2

+

+1

0

−1

−2

−3

−4

5

−

−

6

20

Record/Playback Overall Frequency Response

10050

200

500

ATT

Frequency Responce

DECK L/R

L

A

B

1 k

R

L

R

2 k

Tape

Dolby NR

Level

REC Amp

LINE IN

LINE OUT

V.V

PB Amp

Adjusting volume number

5 k

: AC-514

: Off

: −20 dB From Dolby Level

VR-105

VR-106

VR-405

VR-406

10 k 12 k

20 k (Hz)

5-2. Recording/Playback Level Adjustment

(1) Load the test tape TDK AC-514. Make a sample

recording with the 1 kHz (-20 dB) signal and play

this section back.

(2) Adjust (Lch) and (Rch) so that the output from

LINE OUT terminal is the same as the output at

recording monitoring time.

5-3. Dolby C recording and playback comprehensive

frequency characteristics verification

(1) Set the Dolby NR switch at "C" position.

(2) Use a test tape TDK AC-514 and record and

playback as in item 5-1 to verity that they satisfy

the characteristics standards.

Dolby C Record/Playback Overall Frequency Response

(db)

6

+

+5

4

+

+3

2

+

+

1

0

−1

−

2

3

−

−4

5

−

−6

20

10050

200

500

R/P Level Adjustment

DECK L/R

L VR-103

A

B

1 k

R

L

R

2 k

Tape

Dolby NR

Level

Adjusting volume number

5 k

VR-104

VR-403

VR-404

10 k 12 k

20 k (Hz)

: AC-514

: On C

: −20 dB From Dolby Level

12

DN-780R

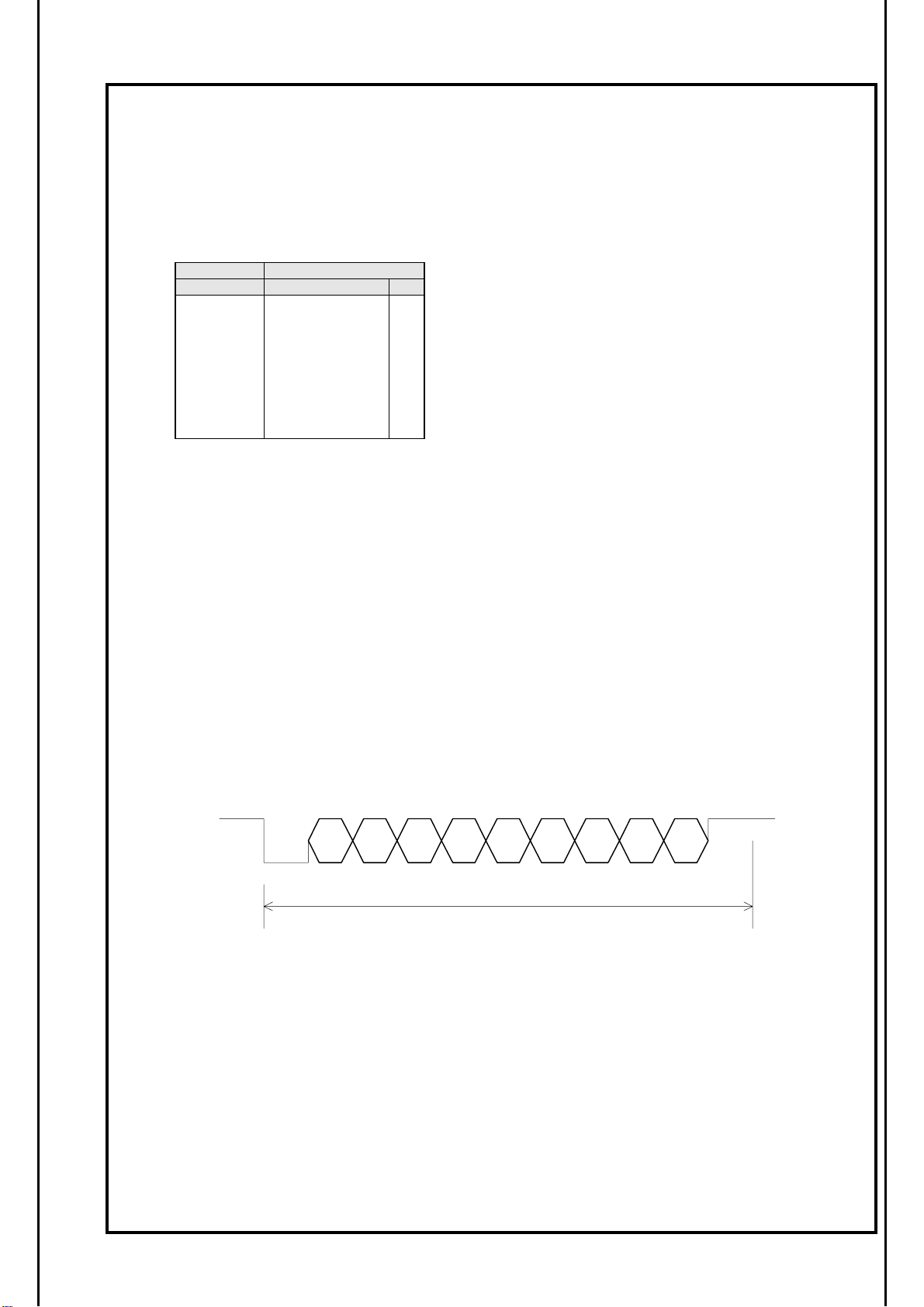

MECHANISM OPERATING TIME CHECK

The total operating time of the mechanism is registered in this unit.

Check and refer to it when replacing the mechanism, head, or motor.

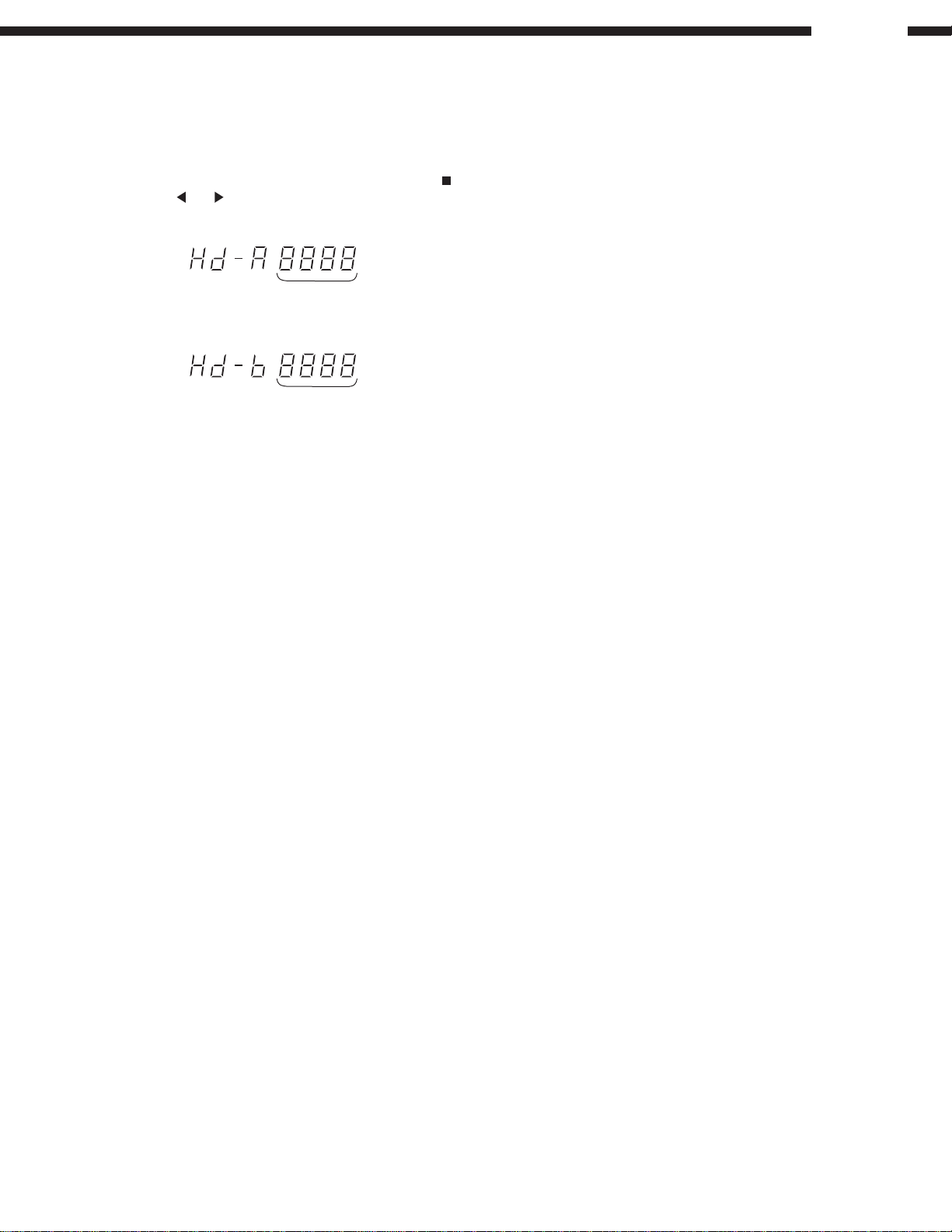

1. Displaying the Operating Time

(1) Set the power to on while pressing the “STOP ( )”, “RESET”, and “MEMO” buttons of the Deck A together.

(2) The and buttons of the Deck A are used to switch the display for the Deck A mechanism or for the Deck B mechanism.

Ex.: The operating time of the Deck A mechanism

Operating time (unit: hour)

The operating time of the Deck B mechanism

Operating time (unit: hour)

* “FuLL” is displayed when exceeding “9999”.

2. Deleting the Operating Time

When replacing the associated parts, delete the registered operating time as follows.

Press the “COUNTER MEMO” and “RESET” buttons of the Deck A together at once.

The displayed mechanism operating time of the selected Deck is set to “0000”.

13

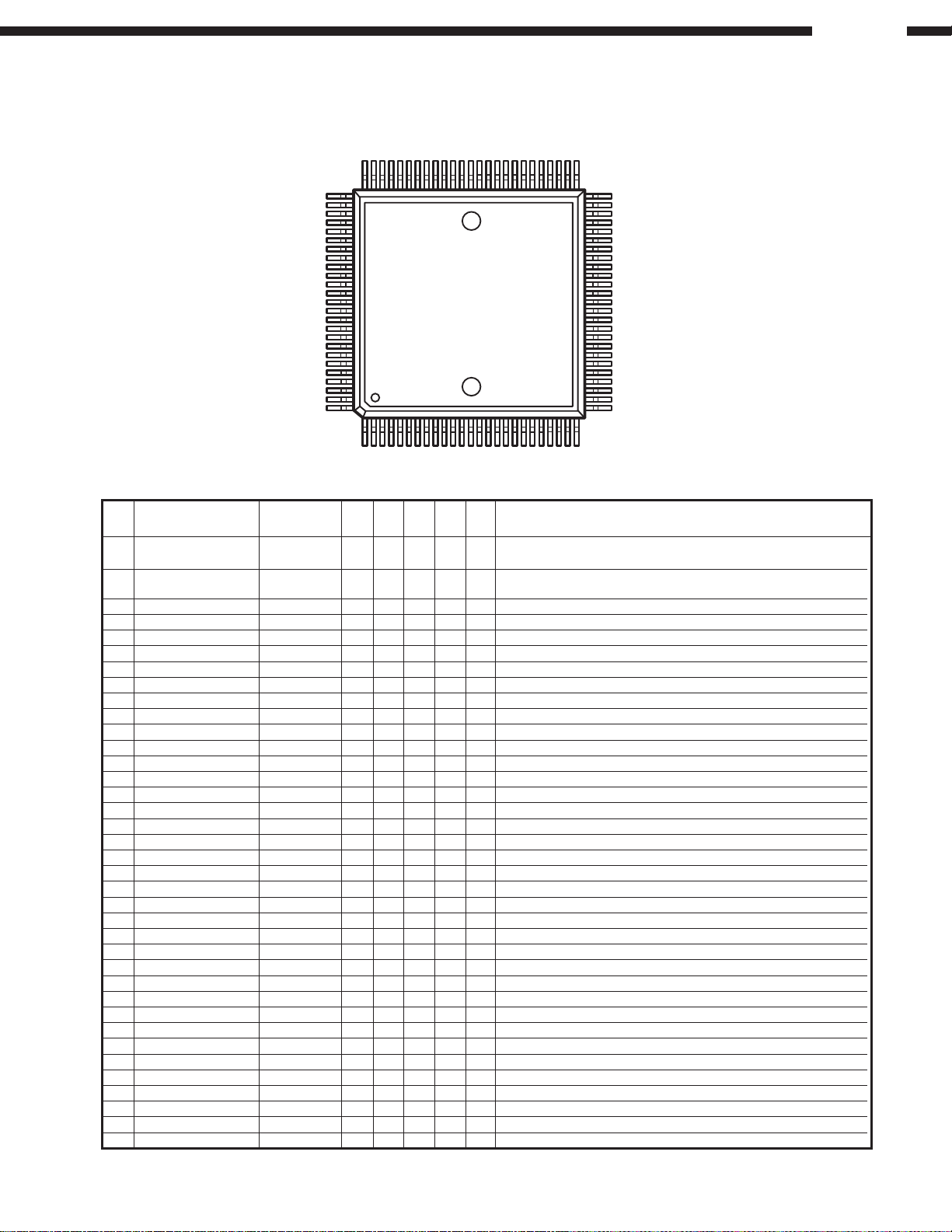

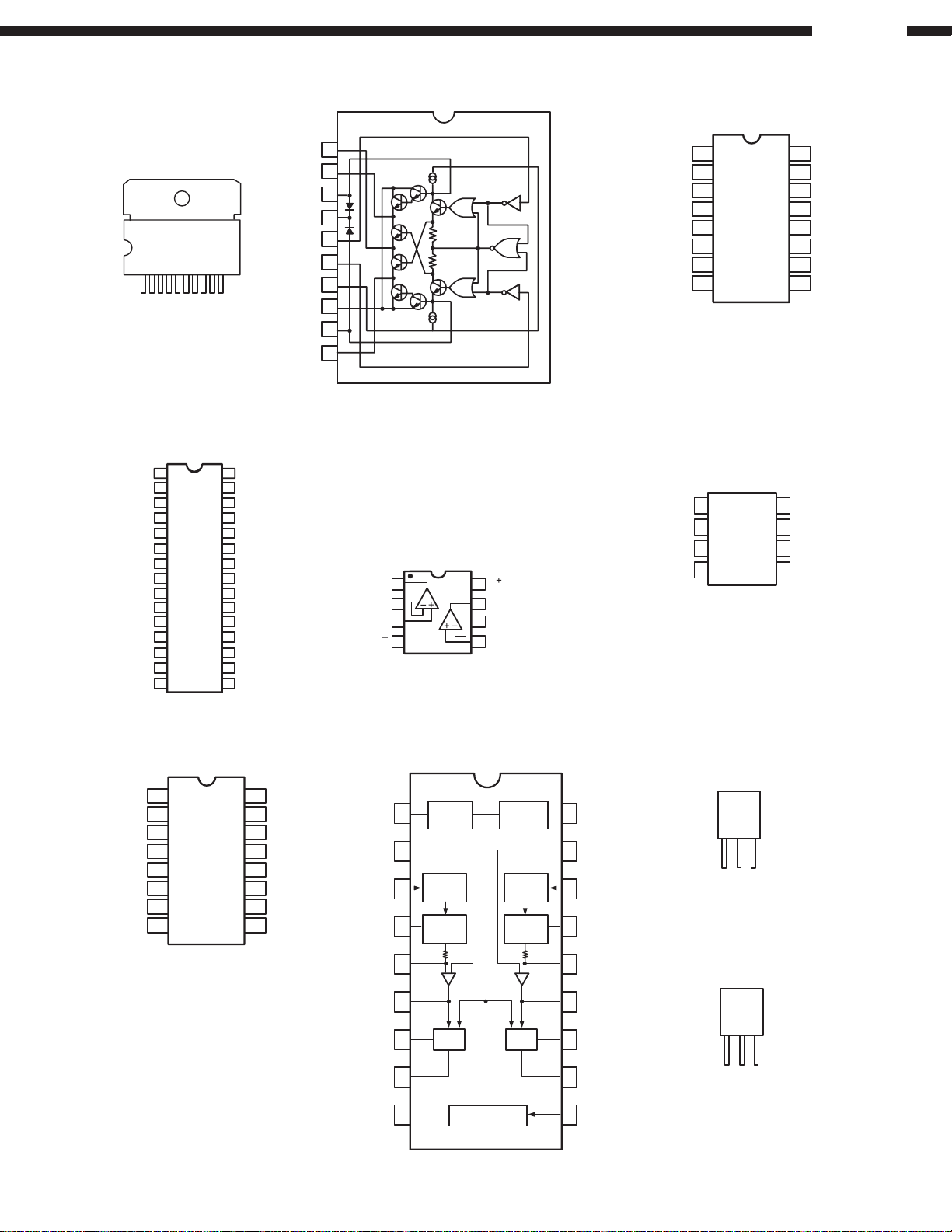

SEMICONDUCTORS

IC’s

DN-780R

MN102L62G (IC105)

µµ

µCOM

µµ

75

76

100

1

51

50

26

25

MN102L62G Terminal Function

Pin

No.

1 P60, WAIT PRECSEL O Pd L L

2 P61, _RE PIRINH O Pd L L

3 P62, _WEL PMASTER O Pd L L

4 P63, _WEH PSLAVE O Pd L L

5 P50, _CS0 PSWMST I Pu H Selection switch. L: MASTER /H: Other

6 P51, _CS1 PSWSLV I Pu H Selection switch. L: SLAVE /H: Other

7 P52, _CS2 PSWADLB I Pu H Selection switch. L: Dolby B /H: Other

8 P53, _CS3 PSWADLC I Pu H Selection switch. L: Dolby C /H: Other

9 P54, _BREQ PSWBDLB I Pu H Selection switch. L: Dolby B /H: Other

10 P55, _BRACK PSWBDLC I Pu H Selection switch. L: Dolby C /H: Other

11

12 P57, _WORD Reserved I 0V L Not used.

13 P20, A00 PRMUTB O Pu H H B mechanism REC MUTE change signal. H: MUTE ON

14 P21, A01 PDOLOFB O Pd L L B mechanism Dolby on / off change signal. H: Dolby OFF

15 P22, A02 PDOLBCB O Pu H H B mechanism Dolby B / C change signal. H: Dolby B

16 P23, A03 PDOLSWB O Pd L L B mechanism Dolby Switch change signal. H: PLAY mode

17 Vdd Vdd Power supply (+5V)

18 SYSCLK SYSCLK O OSCI ×1/2 is outputted.

19 VSS VSS GND(0V)

20 XI XI I 0V L L Not used. It connects with GND.

21 XO XO Not used. OPEN

22 VDD VDD Power supply (+5V)

23 OSCI OSCI I There is 0.16% of an error by baud rate 9600bps setup

24 OSCO OSCO O OSCI is outputted.

25 MODE MODE I H: Single tip mode

26 P24, A04 PRMUTA O Pu H H A mechanism REC MUTE change signal. H: MUTE ON

27 P25, A05 PDOLOFA O Pd L L A mechanism Dolby on / off change signal. H: Dolby OFF

28 P26, A06 PDOLBCA O Pu H H A mechanism Dolby B / C change signal. H: Dolby B

29 P27, A07 PDOLSWA O Pd L L A mechanism Dolby Switch change signal. H: PLAY mode

30 P30, A08 PRSVI1 I Pu H Preliminary input terminal 1

31 P31, A09 PRSVI2 I Pu H Preliminary input terminal 2

32 P32, A10 PRSVI3 I Pu H Preliminary input terminal 3

33 P33, A11 PRSVI4 I Pu H Preliminary input terminal 4

34 VDD VDD Power supply (+5V)

35 P34, A12 Reserved I 0V L Not used.

36 P35, A13 Reserved I 0V L Not used.

37 P36, A14 Reserved I 0V L Not used.

Pin Name

P56, ALE, _ALE, _BSTRE

Reserved I 0V L Not used.

Symbol

I/O

DET Ext Ini Res

Recording selection to B mechanism.

L: Slide switch setup / H: Deck A line in

Infrared remote control selection. L: Infrared remote control

use is possible./ H: Infrared remote control use is impossible.

MASTER function setup, turns on at the time of DUPLICATE operation.

SLAVE function setup, turns on at the time of DUPLICATE operation.

Function

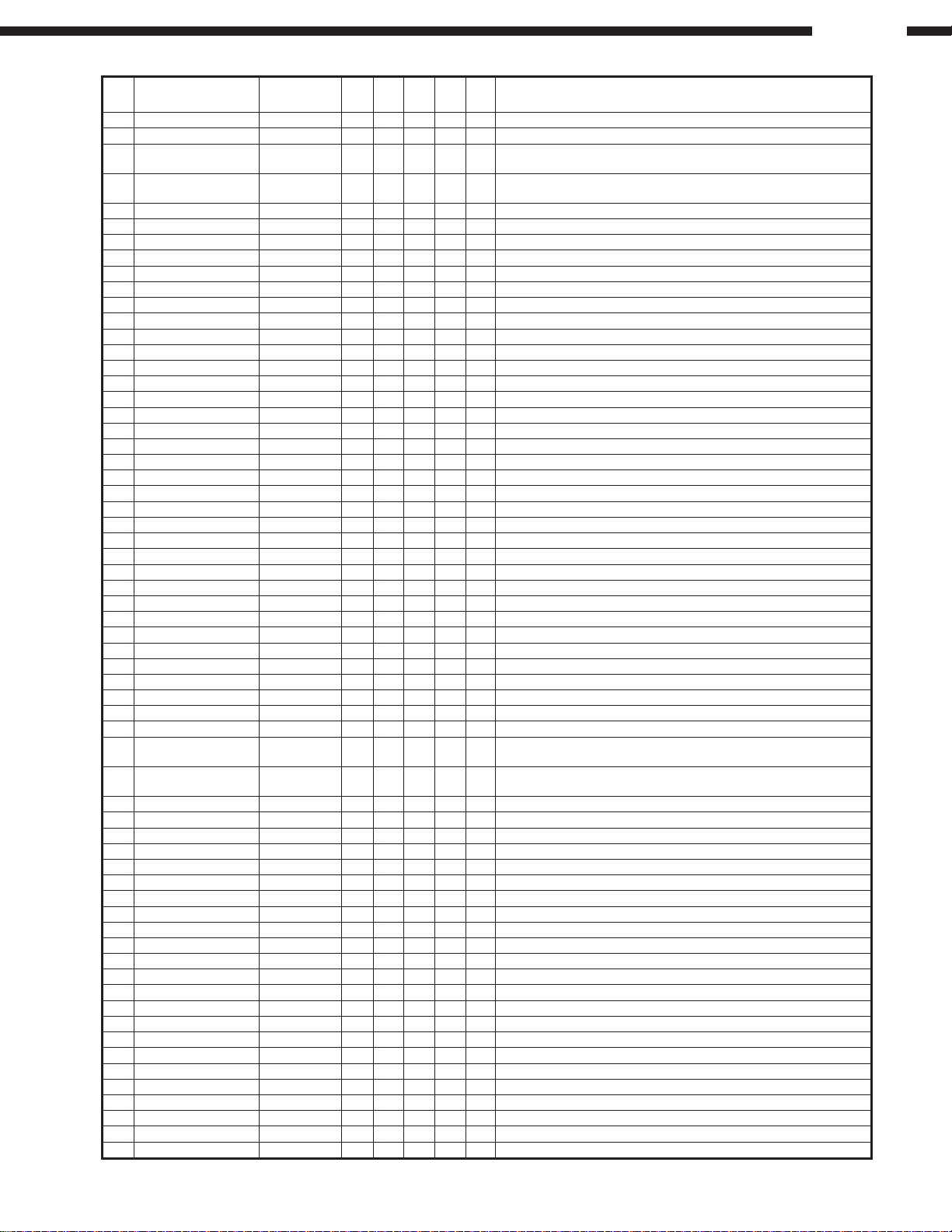

14

DN-780R

Pin

No.

38 P37, A15 Reserved I 0V L Not used.

39 P40, A16 PSCL O Pu H H EEPROM communication clock signal.

40 P41, A17 PSDA I/O Pu H In

41 P42, A18 PSELEEP I Pd L L

42 P43, A19 PMIX O Pd L L A mechanism line out. H: The mix output of A+B

43 VSS VSS GND(0V)

44 P44, AN4, A20 PKIN2 I Lv Pu H A / D conversion is used.

45 P45, AN5, A21 PREMO I Lv Pu H A / D conversion is used.

46 P46, AN6, STOP, A22 PADINRB I Lv Pd L A / D conversion is used.

47

48 P80, TM0IO PRECR I Pu H Mechanism input signal. H: REC of RVS is improper.

49 P81, TM1IO PRECF I Pu H Mechanism input signal. H: REC of FWD is improper.

50 P82, TM2IO PHALH I Pu H Mechanism switch. H: No tape.

51 P83, TM3IO PSWCOM O Pu H H Mechanism scan signal. H: A mechanism selection

52 P84, TM4IO PDUB O Pd L L Duplicate output signal. H: Duplicate

53 P85, TM5IO PRSVO4 O 0V L L Preliminary output terminal 4

54 VDD VDD Power supply (+5V)

55 P86, TM6IOA PRMTOUT O Pu H H Remote output signal.

56 P87, TM6IOB Reserved I 0V L GND(0V) and connection.

57 P90, TM6IC PQSENA I Pu H

58 P91, TM7IOA PQSENB I Pu H

59 P92, TM7IOB PRSVO1 O 0V L L Preliminary output terminal 1

60 P93, TMI7IOC PRSVO2 O 0V L L Preliminary output terminal 2

61 VSS VSS GND(0V)

62 P94, AN0 PADINRA I Lv Pd L A / D conversion is used

63 P95, AN1 PADINLA I Lv Pd L A / D conversion is used

64 P96, AN2 PKIN0 I Lv Pu H A / D conversion is used

65 P97, AN3 PKIN1 I Lv Pu H A / D conversion is used

66 VDD(VPP)VDD Power supply (+5V)

67 P70, SBT0 _PFLNCS O Pu H H Connects with NCS. L: Select

68 P71, SBI0 RxD I Pu H It is used as a serial port. (It is 9615.38bps in 20MHz.)

69 P72, SBO0 TxD O Pu H H It is used as a serial por t. (It is 9615.38bps in 20MHz.)

70 P73, SBT1 PFLCLK O Pu H H Connects with a clock.

71 P74, SBI1 PFLRD I Pu H Connects with SDO. (Key input data)

72 P75, SBO1 PFLSD O Pu H H Connects with SDI

73 TEST1 TEST1 I Pu A pull-up is carried out by 47k. (Recommendation)

74 TEST2 TEST2 I Pu A pull-up is carried out by 47k. (Recommendation)

75 _NMI _NMI I Pu H A pull-up is carried out.

76 PA0, _IRQ0 PPLSB I Ed Pu H

77 PA1, _IRQ1 PPLSA I Ed Pu H

78 PA2, _IRQ2 PPOFF I Pu H

79 PA3, _IRQ3 PEXTIN I Pu H EXT. IN input signal.

80 PA4, _IRQ4 PREMOTE I Ed Pu H RC-5/Infrared remote signal input.

81 PA5, DSEP PEXTOUT O Pu H H EXT.OUT output signal.

82 _RST _RESET I Lv L Reset signal. L: Reset

83 VDD VDD Power supply (+5V)s

84 P00, D00, AD00 PSOLHB O Pd L L B mechanism solenoid hold signal. H: Hold

85 P01, D01, AD01 PSOLKB O Pd L L B mechanism solenoid kick signal. H: kick

86 P02, D02, AD02 PRELRB O Pd L L B mechanism reel motor inversion signal. H: Inversion signal ON.

87 P03, D03, AD03 PRELFB O Pd L L B mechanism reel motor rotation signal. H: rotation signal ON.

88 P04, D04, AD04 PCAPB O Pd L L B mechanism capstan control signal. H: Capstan motor-on

89 P05, D05, AD05 PBIASB O Pd L L B mechanism bias signal. H: Bias

90 P06, D06, AD06 PLMUTB O Pd L L B mechanism line mute signal. L: Mute on

91 P07, D07, AD07 PHIGHB O Pd L H High speed signal B mechanism. L: High

92 VSS VSS GND(0V)

93 P010, D08, AD08 PSOLHA O Pd L L A mechanism solenoid hold signal. H: Hold

94 P011, D09, AD09 PSOLKA O Pd L L A mechanism solenoid kick signal. H: kick

95 P012, D10, AD10 PRELRA O Pd L L A mechanism reel motor inversion signal. H: Inversion signal ON.

96 P013, D11, AD11 PRELFA O Pd L L A mechanism reel motor rotation signal. H rotation signal ON.

97 P014, D12, AD12 PCAPA O Pd L L A mechanism capstan control signal. H: Capstan motor-on.

98 P015, D13, AD13 PBIASA O Pd L L A mechanism bias signal. H: Bias

99 P016, D14, AD14 PLMUTA O Pd L L A mechanism line mute signal. L: Mute on

100 P017, D15, AD15 PHIGHA O Pu L H High speed signal A mechanism. L: High

Pin Name

P47, AN7, WDOUT, A23

Symbol

PADINLB I Lv Pd L A / D conversion is used.

DET Ext Ini Res

I/O

Function

EEPROM communication data input¾and¾output signal.

(The input port of the time of a power supply injection is carried out.)

EEPROM selection signal. L: Old EEPROM(X24C00)

H: New EEOPRM(S24C01)

A mechanism leader tape detected signal. L: Leader tape detection.

B mechanism leader tape detected signal. L: Leader tape detection.

It counts by DOWN EDGE. It rotates one time at three counts.

(DN-770R was taken as one rotation by six pulses by both edge.)

It counts by DOWN EDGE. It rotates one time at three counts.

(DN-770R was taken as one rotation by six pulses by both edge.)

An electric-power-failure detected signal. L: Electric-power-failure detection.

15

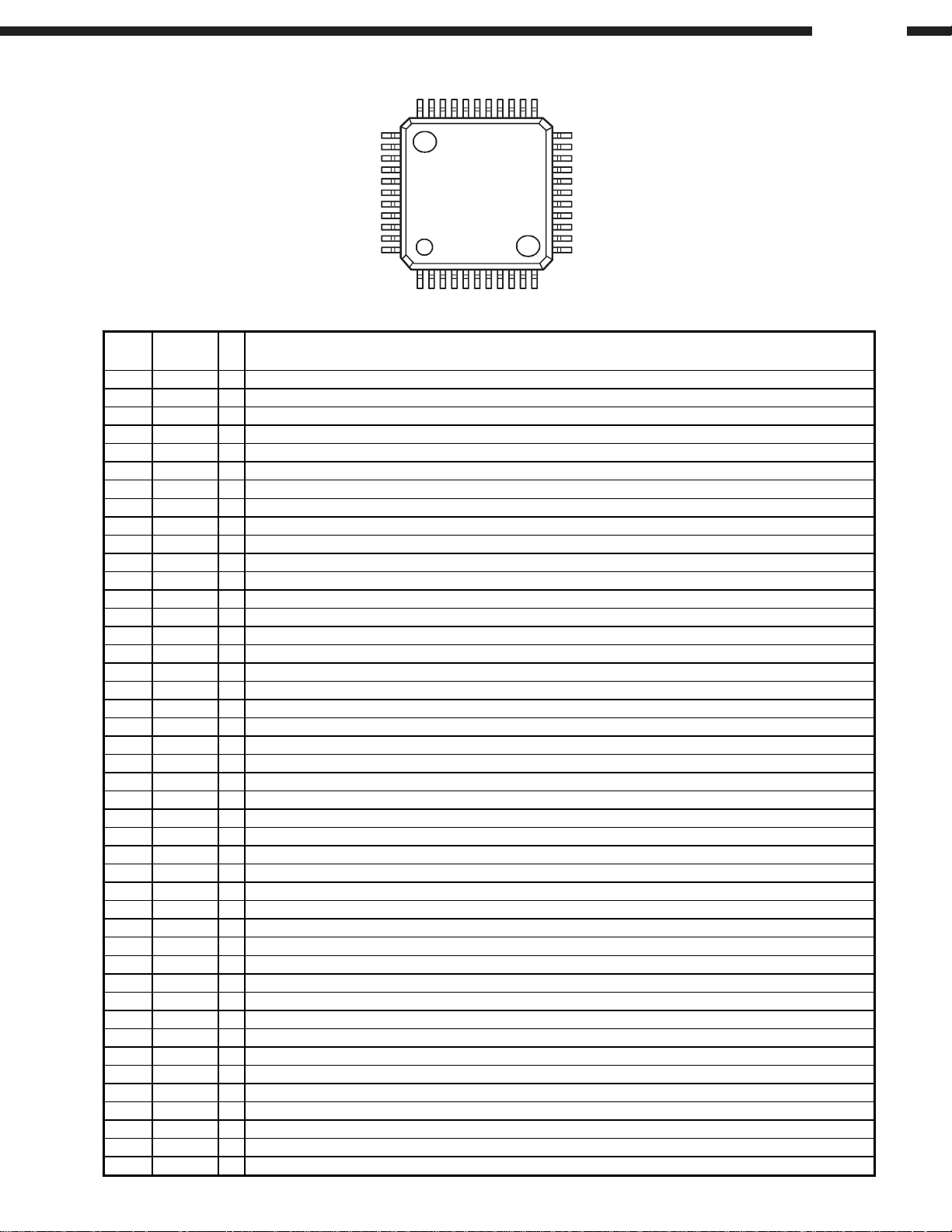

MN12510F (IC301)

y

FL DRIVER

DN-780R

33

34

23

22

44

1

MN12510F Terminal Function

Pin

No.

1 P21 O Segment output15 (hi-voltage proof output).

2 P20 O LED drive output (hi-voltage proof output).

3 P03 O No connection.

4 P02 O No connection.

5 P01 O Digit output10 (hi-voltage proof output).

6 P00 O Digit output9 (hi-voltage proof output).

7 DGT7 O Digit output8 (hi-voltage proof output).

8 DGT6 O Digit output7 (hi-voltage proof output).

9 DGT5 O Digit output6 (hi-voltage proof output).

10 DGT4 O Digit output5 (hi-voltage proof output).

11 NC

12 DGT3 O Digit output4 (hi-voltage proof output).

13 DGT2 O Digit output3 (hi-voltage proof output).

14 DGT1 O Digit output2 (hi-voltage proof output).

15 DGT0 O Digit output1 (hi-voltage proof output).

16 Vpp I ELP driver power supply, VPP: VDD -35V.

17 NC

18 V

19 OSC1 I Clock oscillation input terminal.

20 OSC2 O Clock oscillation output terminal.

21 Vss I Power supply terminal, Vss: 0V.

22 NCS I Chip select input, “L”: Serial input enable, “H”: Disable.

23 SCK I Clock input for serial transference.

24 SDI O Serial data input terminal.

25 SDO O Serial data output terminal.

26 P30 I Key scan input terminal.

27 P31 I Key scan input terminal.

28 P32 I Key scan input terminal.

29 P33 O LED drive output terminal.

30 P34 O LED drive output terminal.

31 SEG0 O Segment output1 (hi-voltage proof output).

32 SEG1 O Segment output2 (hi-voltage proof output).

33 SEG2 O Segment output3 (hi-voltage proof output).

34 SEG3 O Segment output4 (hi-voltage proof output).

35 SEG4 O Segment output5 (hi-voltage proof output).

36 SEG5 O Segment output6 (hi-voltage proof output).

37 SEG6 O Segment output7 (hi-voltage proof output).

38 SEG7 O Segment output8 (hi-voltage proof output).

39 P10 O Segment output9 (hi-voltage proof output).

40 P11 O Segment output10 (hi-voltage proof output).

41 P12 O Segment output11 (hi-voltage proof output).

42 P13 O Segment output12 (hi-voltage proof output).

43 P23 O Segment output13 (hi-voltage proof output).

44 P22 O Segment output14 (hi-voltage proof output).

mbol I/O Function

S

No connection.

No connection.

DD

I Power supply terminal, VDD: +5V r0.5V.

12

11

16

DN-780R

BA6109U1 (IC101, 102)

FRONT VIEW

1 10

HA12170NT (IC103, 403)

REC IN

Vcc

PB IN

REF

C/B/OFF

IA OUT

NR IN

VREF

PB OUT

SS1

SS2

CCR

HLS DET

LLS DET

REC OUT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

REC IN

GND

PB IN

BIAS

M/R/P

IA OUT

NR IN

VREF

PB OUT

SS1

SS2

CCR

HLS DET

LLS DET

REC OUT

GND

V OUT 1

VZ 1

VR

F IN

R IN

VCC 1

VCC 2

VZ2

V OUT 2

1

2

3

4

5

6

7

8

9

10

BA10393F (IC103, 104)

BA15218F (IC104, 105, 107,

109, 110, 404, 405,

407, 409, 410, 701,

707~709, 807~810)

M5220FP (IC101, 401, 801, 805)

V

2

8

B OUTPUT

7

6

B –INPUT

B +INPUT

5

A OUTPUT

A –INPUT

A+INPUT

V

1

1

2

3

4

TC4053BF (IC102, 106, 108,

402, 406, 408, 702~706, 804)

IY

OY

Z-COM

OZ

INH

V

V

1

2

3

IZ

4

5

6

7

EE

8

SS

16

15

14

13

12

11

10

9

DD

V

Y-COM

X-COM

IX

OX

A

B

C

X24C00S (IC106)

EEPROM

NC

NC

NC

Vss

1

2

3

4

8

7

6

5

Vcc

NC

CLK

DATA

MAX202CSE (IC107)

C1+

1

2

V+

3

C1-

C2+

4

C2-

5

V-

6

R2IN

7

8

T2OUT

16

15

14

13

12

11

10

9

Vcc

GND

T1OUT

R1IN

R1OUT

T1IN

T2IN

R2OUT

m

PC1297CA (IC111, 411)

VST

VR1

VIN (R) 1

PH1

CIN1

COUT1

VOUT11

VOUT12

GND

STABI-

1

LIZER

2

ABSO

3

DET

PEAK

4

DET

5

6

7

VCA

8

9

PRE DRIVER

PRO-

TECTER

ABSO

DET

PEAK

DET

VCA

18

17

16

15

14

13

12

11

10

Vcc

VR2

CIN (R) 2

PH2

CIN2

COUT2

VOUT21

VOUT22

VIN (0)

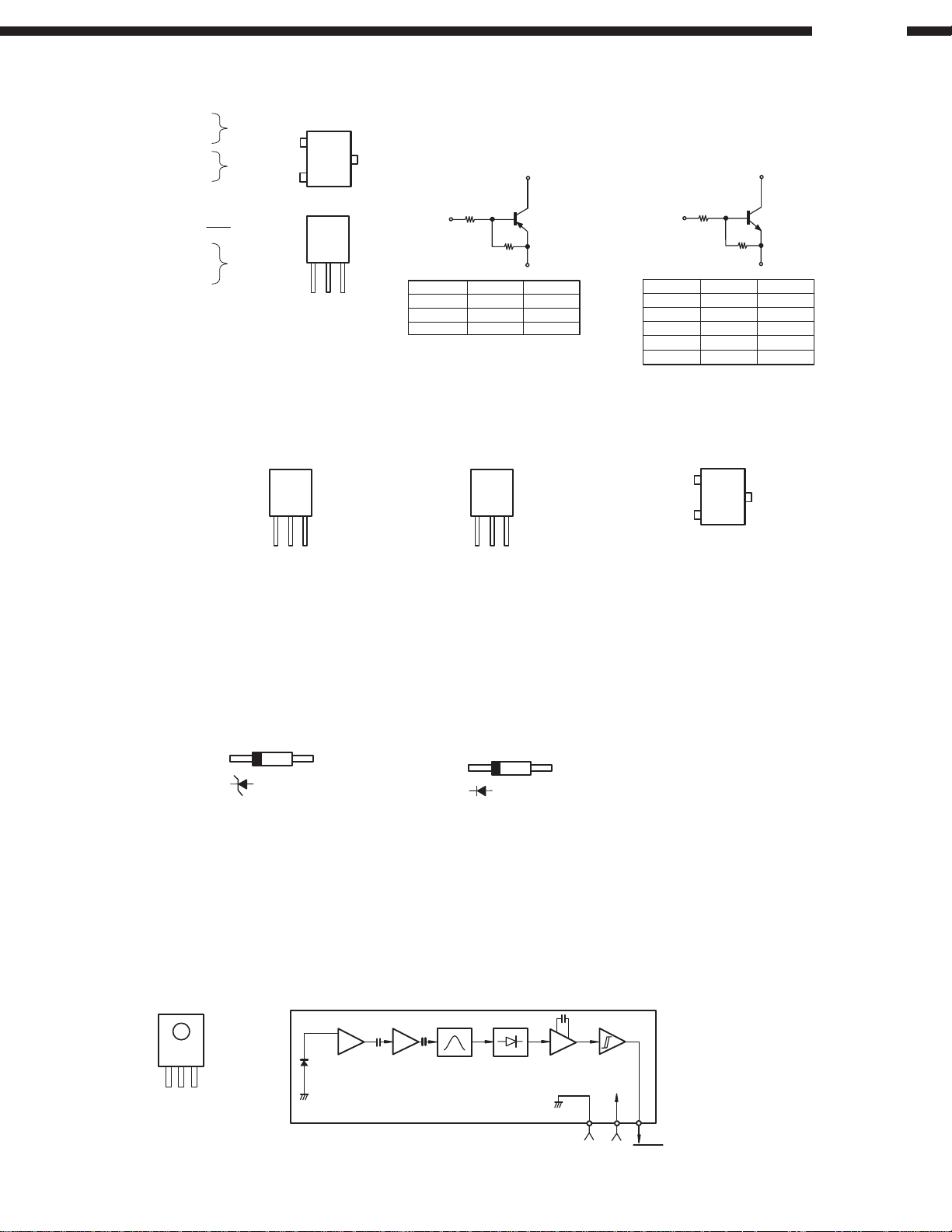

NJM7805FA(S) (IC903)

NJM7808FA(S) (IC901)

FRONT

VIEW

Input

GND

Output

NJM7908FA (IC902)

FRONT

VIEW

Input

GND

Output

17

TRANSISTORS

l

DTA114EK

DTA144EK

DTC114EK

DTC144EK

PNP

NPN

DN-780R

B

TOP

C

VIEW

E

DTA Series

C

DTC Series

C

DTA144ES

DTC114ES

DTC124XS

DTC143ES

2SA933

2SB562(C)

2SC5395(E/F)

2SD2144

2SD468(C)

PNP

NPN

FRONT

VIEW

C

E

FRONT

VIEW

E

B

R1

B

R2

E

C

B

DTA114EK

DTA144EK

DTA144ES

R1

10kohm /

47kohm /

47kohm /W47kohm /

W

W

R2

10kohm /

47kohm /

W

W

W

DTC114EK

DTC114ES

DTC124XS

DTC143ES

DTC144EK

2SK373(Y)

R1

B

R2

R1

10kohm /

W

10kohm /W10kohm /

22kohm /W 47kohm /W

4.7kohm /W4.7kohm /

47kohm /W47kohm /

2SC2412K(S)

E

R2

10kohm /

W

W

W

W

KTC2875B

B

FRONT

VIEW

G

S

D

TOP

C

VIEW

E

DIODES/LED

l

HZS4C

HZS5C

HZS12B

HZS6C

HZS22C

HZS7B

MTZJ9.1A

OTHERS

l

GP1U271X (Remote Control Sensor)

(IC551)

TOP VIEW

CC

OUT

V

GND

V

Head

Amp

Limiter

Amp

1SS355

1SR35-400A

Detector &

BPF Integrator

Comparator

Hysteresis

Comparator

GND

VCCV

OUT

18

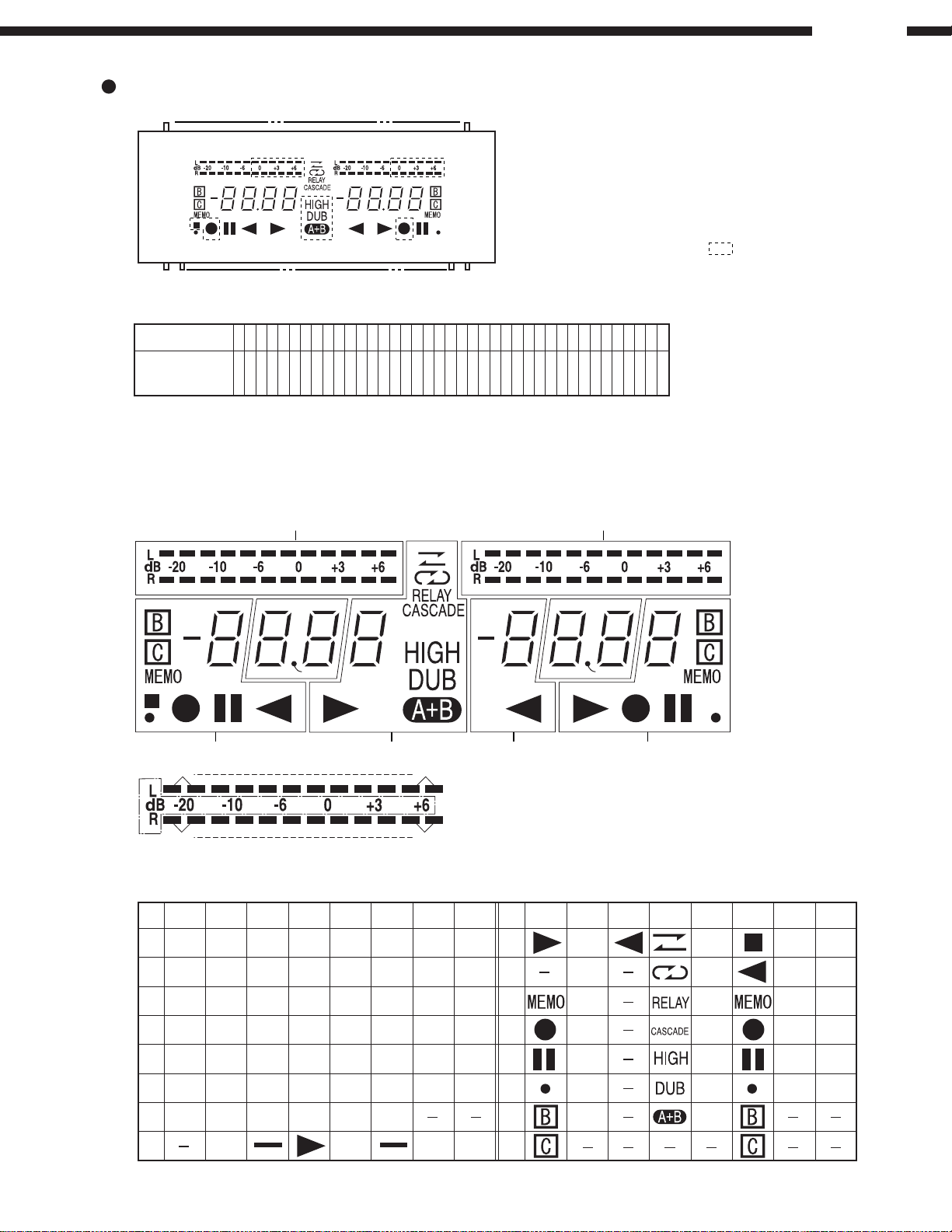

FL DISPLAY BJ881GHK (FL301)

PIN CONNECTION

3

3

3

3

3

3

3

3

3

3

2

2

2

2

PIN NO.

CONNECTION

1) F1,F2 ---------- Filament

NOTE

2) NP ------------- No pin

3) NX ------------- No extend pin

4) DL ------------ Datum line

5) 1G~8G ------- Grid

9

8

F

F

2

2

(NC pin should be electorically open on the PC board)

7

6

5

4

3

2

1

0

P

P

P

P

P

N

N

1

P

P

6

P

1

1

1

1

1

5

4

3

2

1

2

9

8

7

6

5

P

P

P

P

P

9

8

7

6

5

DN-780R

COLOR ILLUMINATION

Reddish Orange ----- Above pattern part

Green ------------------ Other

139

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

P

N

N

N

N

N

N

N

P

P

P

P

1

4

P

P

P

P

P

P

P

4

2

3

2

1

G

G

3

4

5

6

7

G

G

G

G

G

5

4

3

2

1

8

N

N

F

F

G

P

P

1

1

GRID ASSIGNMENT

1a 1a1a2a 1a 1a1a2a

3G

B1

B7

2G 1G

4G

Dp2 Dp1

ANODE CONNECTION

7G 6G 5G 4G 3G 2G 1G 8G

8G

P1

1a 1a 1a 1a 1a 1a B1 B1

7G

f

e

5G 6G 8G

B6

[2G,1G]

B12

7G 6G 5G 4G 3G 2G 1G

P9

2a 2a B7 B7

b

g

c

d

1b 1b 1b 1b 1b 1b B2 B2

P2

1f 1f 1f 1f 1f 1f B3 B3

P3

1g 1g 1g 1g 1g 1g B4 B4

P4

1c 1c 1c 1c 1c 1c B5 B5

P5

1e 1e 1e 1e 1e 1e

P6

1d 1d 1d 1d 1d 1d

P7

P8

Dp1 Dp2 S1 S1

B6 B6

P10

P11

P12

P13

P14

P15

P16

2b 2b B8 B8

2f 2f B9 B9

2g 2g B10 B10

2c 2c B11 B11

2e 2e

2d 2d

B12 B12

19

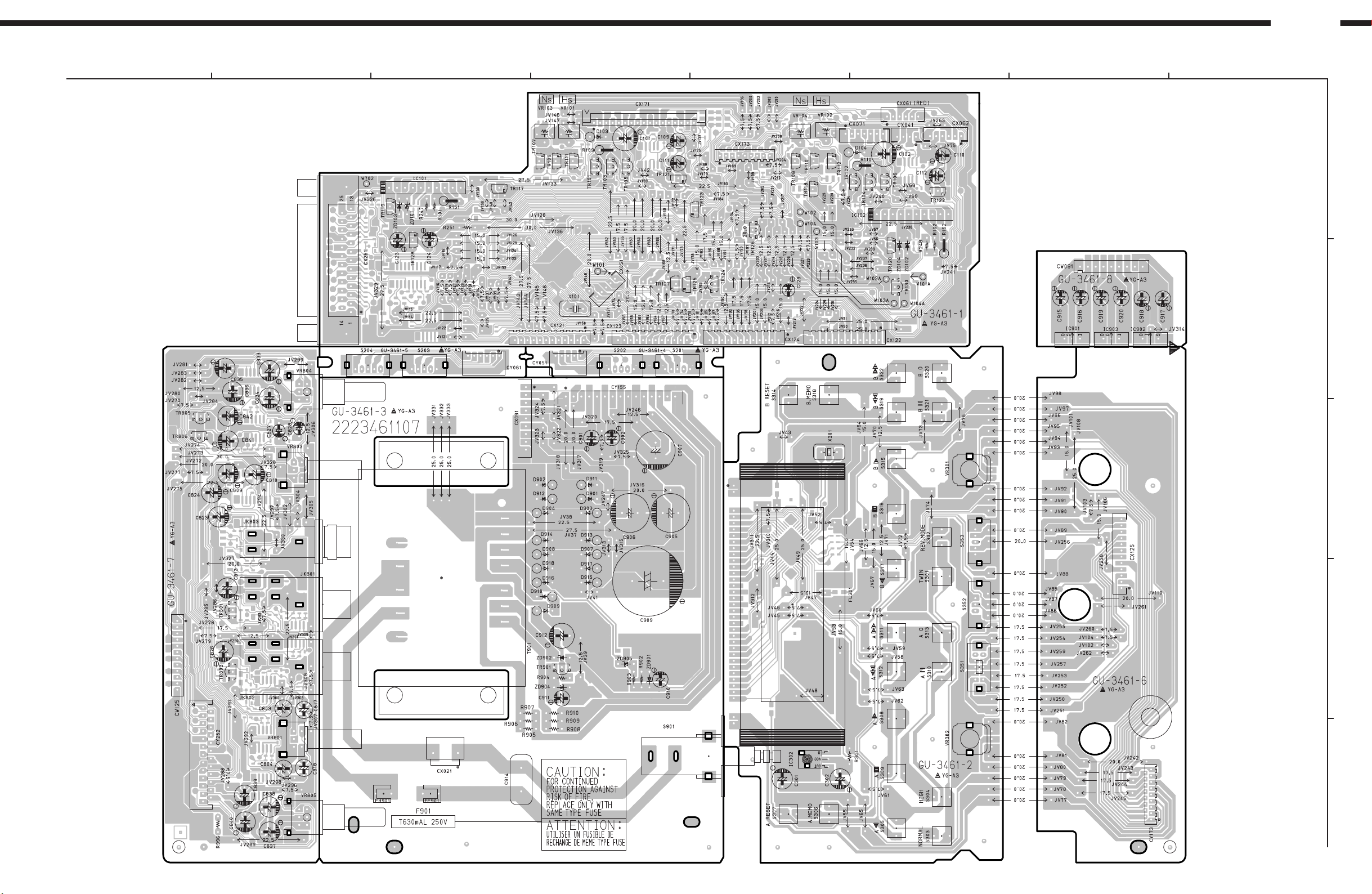

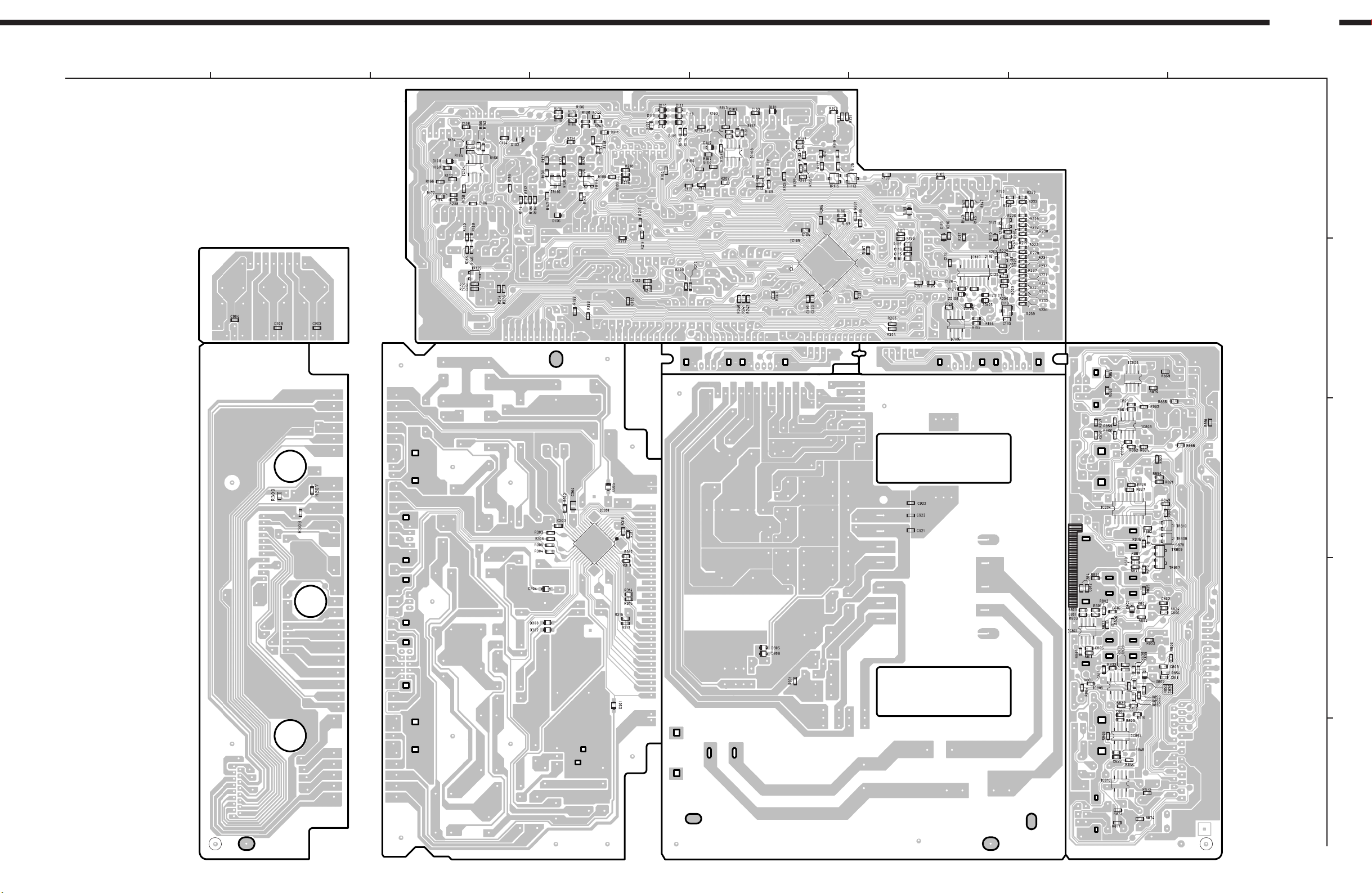

PRINTED WIRING BOARD

DN-780R

1

CONTROL POWER UNIT Ass'y

2

1

3

10

4

1

1

5

17

2

1

5

1 6

1 14

16

17

1

7

1

6

10

76

1 9

8

A

B

112

12 112 112

1

16

5

1

1

1

15

9

C

12

1

1

D

12

1

224

12

17

E

25

2 16

1

COMPONENT SIDE

20

DN-780R

1

CONTROL POWER UNIT Ass'y

2

3

14

8

5

4

5

5

14

8

75

76

100

1

25

51

50

26

16

9

8

1

8

5

4

1

76

8

A

B

1

4

5 8

1

4

5 8

C

16

9

11

12

22

23

1

44

33

34

8

5

4

1

8

1

D

8

5

4

1

8

5

4

1

1

4

8

5

E

FOIL SIDE

21

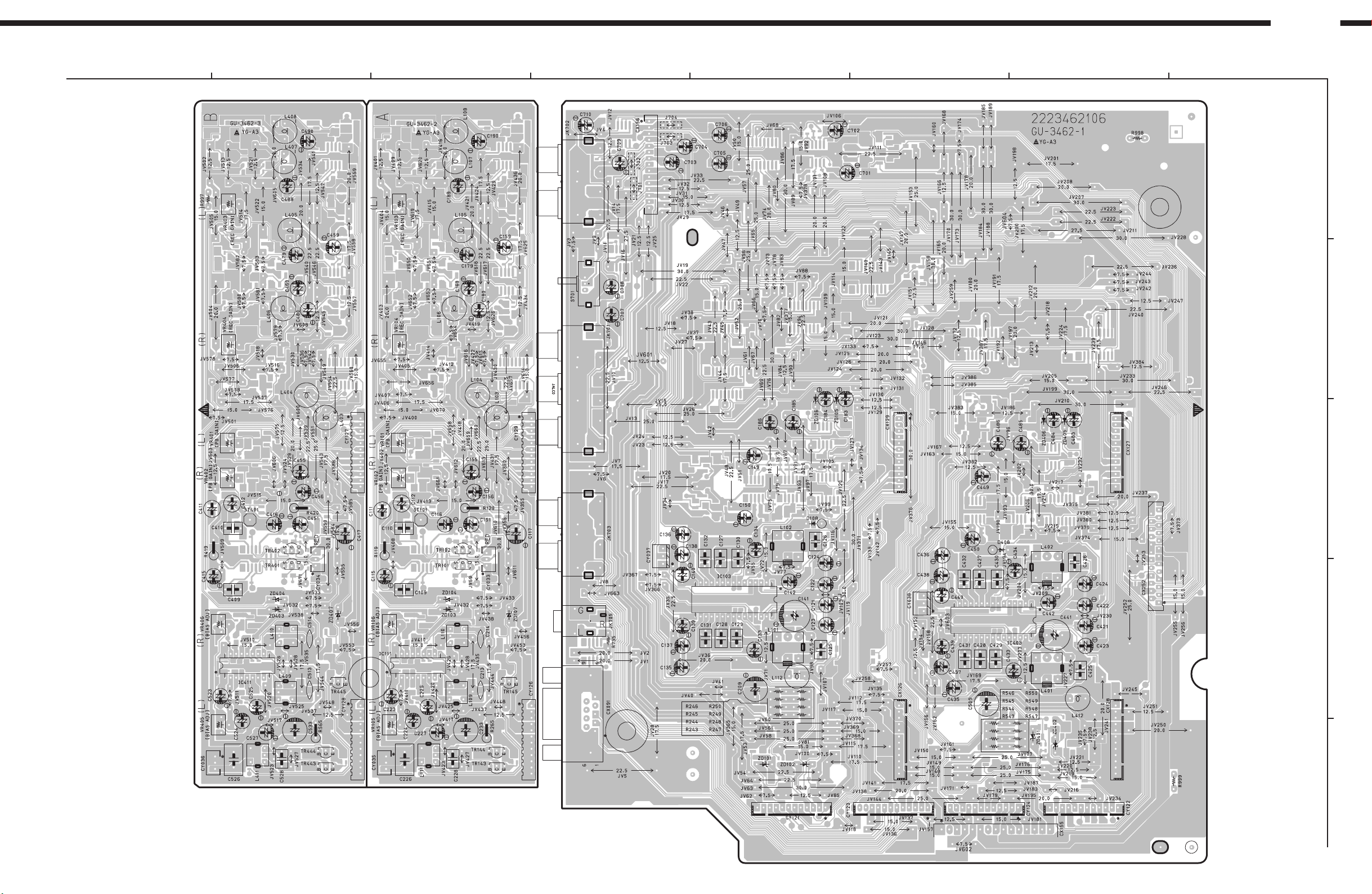

DN-780R

1

AUDIO UNIT Ass'y

2

3

4

115

5

76

8

A

B

1

12112

1 3

18

1

10

9

18

1

10

9

1 3

112

13

15

16

112

1

30

112

13

1

15

16

1

30

112

C

25

2 24

1

D

112

13

13

12

12

12

1

12

1

1 15

1

12

1

E

COMPONENT SIDE

22

DN-780R

1

AUDIO UNIT Ass'y

2

8

9

3

8

1

8

1

9

16

1

16

4

8

5

4

8

1

9

16

1

9

16

8

1

9

16

8

1

9

16

5

5

8

5

1

4

5

8

1

4

8

1

4

5

8

1

4

8

1

76

5

8

1

4

5

4

8

A

B

16

9

8

1

16

9

8

1

5

8

5

8

1

4

16

9

1

4

5

8

8

1

1

4

5

8

1

4

16

9

4

4

1

8

5

8

1

1

8

5

4

1

8

5

5

8

1

4

4

1

8

5

C

D

FOIL SIDE

E

23

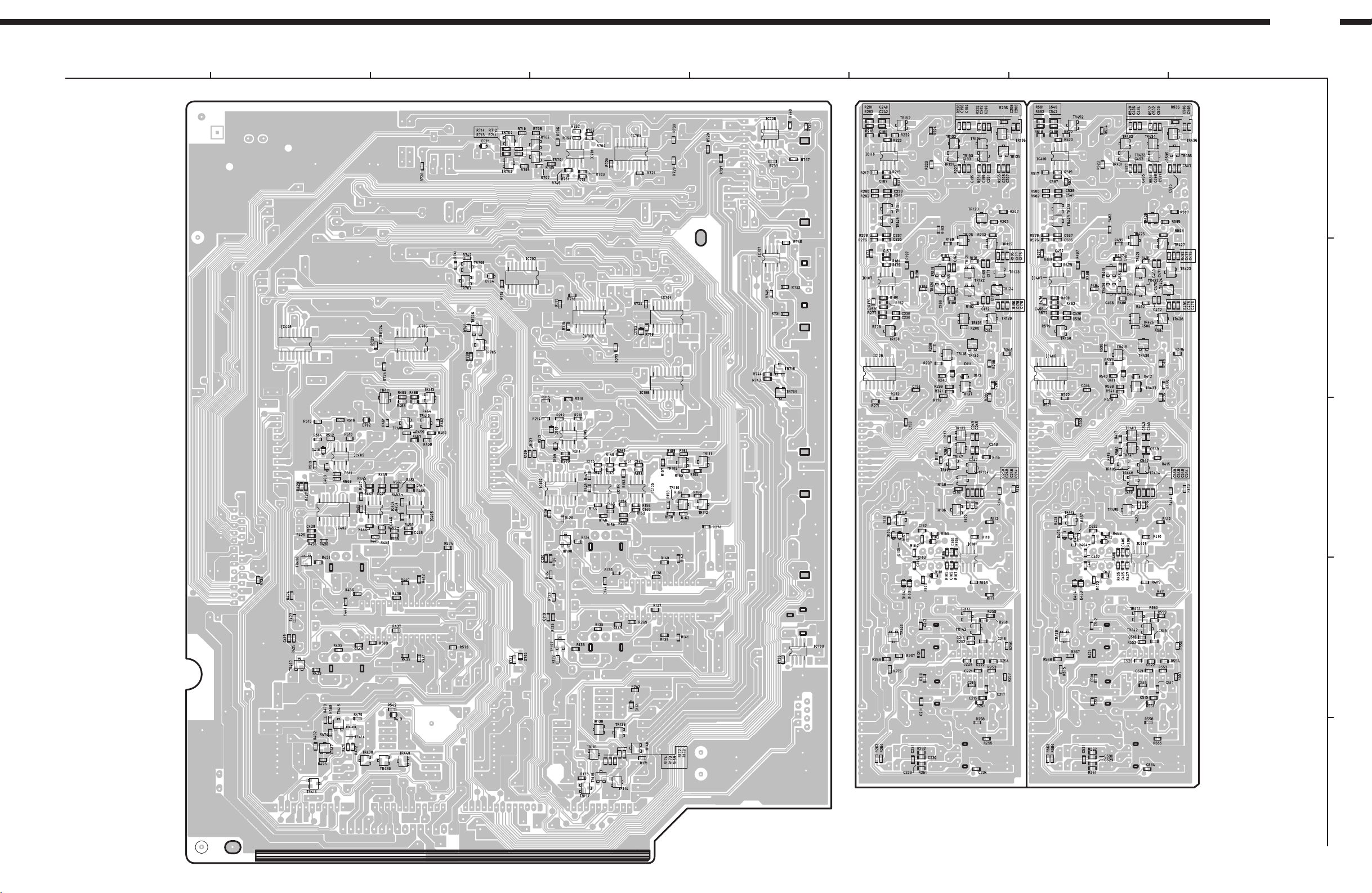

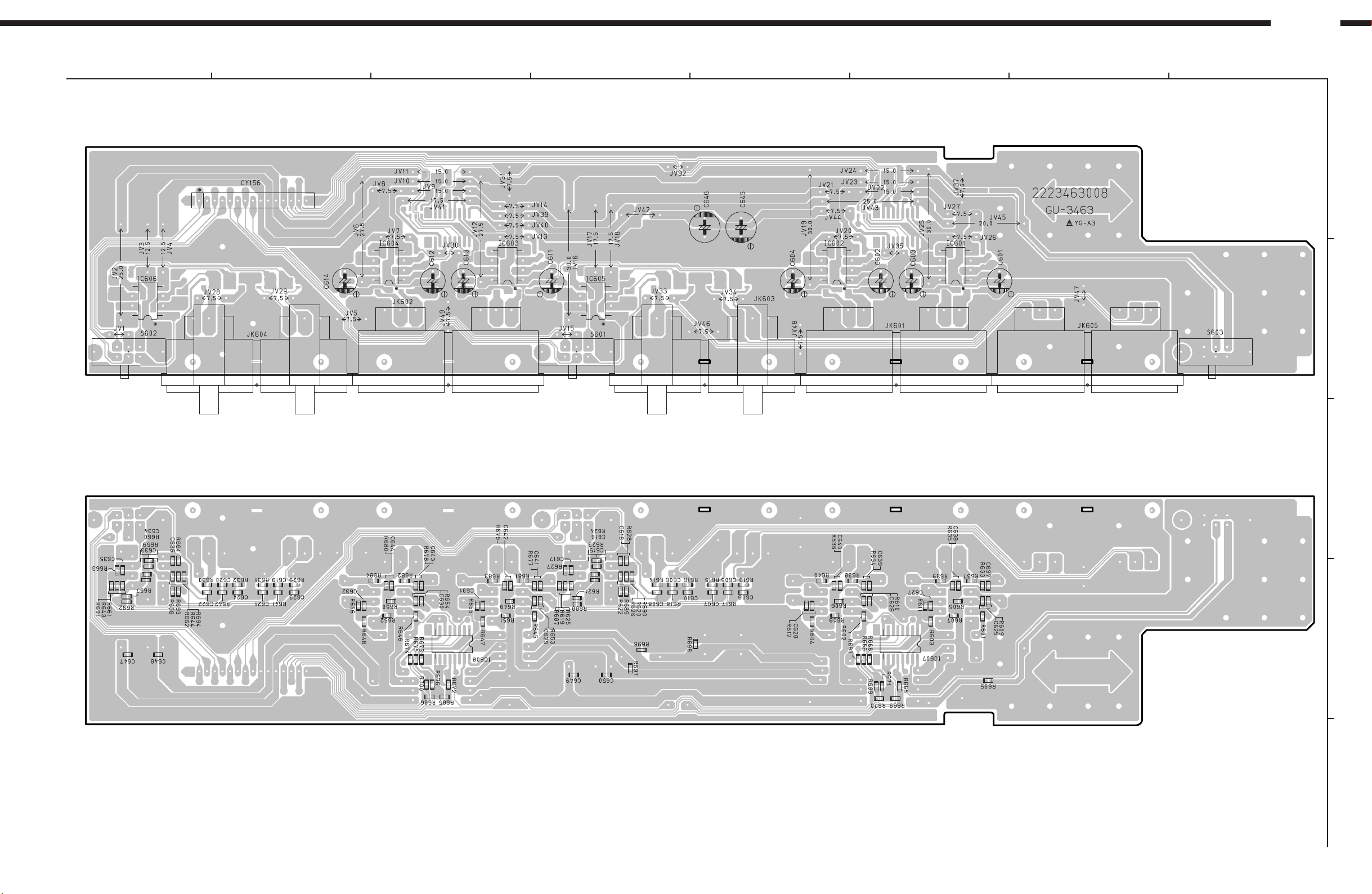

DN-780R

1

GU-3463 XLR UNIT Ass'y (ACD-780:Option)

1 15

5

8

4

1

2

3

4

5

76

8

A

5

8

4

1

5

8

4

1

5

8

4

1

5

8

4

1

5

8

4

1

B

1 8

916

COMPONENT SIDE

C

1 8

D

916

FOIL SIDE

24

E

NOTE FOR PARTS LIST

l Part indicated with the mark "" are not always in stock and possibly to take a long period of time for supplying, or in

some case supplying of part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark " " is not illustrated in the exploded view.

l Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

have critical characteristics.

DN-780R

ll

l Resistors

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

t

RD : Carbon 2B : 1/8W F : ±1% P : Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

t

3H : 5W

Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

t

t

ll

l Capacitors

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

t

CE : Aluminum foil 0J : 6.3V F : ±1% HS : High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR: Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL part

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

t

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

t

Capacity (electrolyte only)

2 2 2 ⇒ 2200µF

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

2-digit effective number.

2-digit effective number.

t

requency

25

DN-780R

PARTS LIST OF P.W.B. UNIT ASS'Y

GU-3461 CONTROL POWER UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Ref. No. Part No. Part Name Remarks

SEMICONDUCTORS GROUP

IC101,102 262 0326 007 BA6109

IC103,104 263 0673 902 BA10393F-E2

IC105 262 3145 007 MN102L62GBC

IC106 262 1711 909 X24C00S

IC107 262 2090 904 MAX202CSE

IC301 262 2459 008 MN12510F

IC302 499 0303 004 GP1UM271XK

IC801 263 0700 901 M5220FP(TP)

IC804 262 0707 901 TC4053BF (TAPE)

IC805 263 0700 901 M5220FP(TP)

IC807-810 263 0615 902 BA15218F-DXE2

IC901 263 0810 008 NJM7808FA(S)

IC902 263 0503 001 NJM7908FA

IC903 263 0809 006 NJM7805FA(S)

TR101-106 274 0036 905 2SD468(C)TF

TR107-112 271 0308 906 2SA933ASTPS

TR113-116 269 0054 901 DTC144EKT96

TR117-120 269 0015 908 DTC124XS (22K-47K) T

TR121,122 269 0099 908 DTC143TS(4.7K) T

TR123 269 0018 905 DTC143ES(4.7K-4.7K)T

TR124 274 0036 905 2SD468(C)TF

TR125 269 0093 904 DTA144ES (47K-47K) T

TR126 274 0036 905 2SD468(C)TF

TR127 269 0093 904 DTA144ES (47K-47K) T

TR128 269 0020 906 DTC114ES(10K-10K)T

TR129 269 0055 900 DTA144EKT96

TR130 275 0042 905 2SK373(Y)TPE2

TR801 275 0042 905 2SK373(Y)TPE2

TR803 275 0042 905 2SK373(Y)TPE2

TR805,806 274 0160 907 2SD2144STPU

TR807-810 273 0460 905 2SA933ASTPS

TR901 272 0025 907 2SB562(C)TF

D101,102 276 0717 903 1SS355 TE-17

D103,104 276 0704 903 1SR35-400A(T93X)

D105-116 276 0717 903 1SS355 TE-17

D117-119 276 0529 900 MA157A-TX

D301-305 276 0717 903 1SS355 TE-17

D801,802 276 0717 903 1SS355 TE-17

ZD101,102 276 0465 912 HZS7B-2TD

ZD103,104 276 0457 904 HZS4C-1TD

ZD105-108 276 0692 905 RD24SB-T1

ZD901 276 0460 904 HZS5C-1TD

ZD902 276 0463 901 HZS6C-1TD

ZD904 276 0480 900 HZS22-1TD

RESISTORS GROUP

R103,104 247 2007 943 RM73B--102JT

R105,106 247 2012 925 RM73B--104JT

R107,108 247 2010 972 RM73B--243JT

R109,110 244 2043 966 RS14B3A150JNBST(S)

R111,112 247 2007 943 RM73B--102JT

R113,114 247 2012 925 RM73B--104JT

R115,116 247 2007 943 RM73B--102JT

R117,118 247 2018 903 RM73B--0R0KT

R119-122 247 2011 971 RM73B--623JT

R123,124 247 2010 998 RM73B--303JT

R125-128 247 2012 996 RM73B--204JT

R129,130 247 2012 925 RM73B--104JT

R131,132 247 2010 972 RM73B--243JT

R133,134 247 2006 986 RM73B--561JT

R135-138 247 2008 955 RM73B--302JT

R139-142 247 2009 909 RM73B--472JT (1608)

R143-146 247 2012 925 RM73B--104JT

R147-150 247 2007 943 RM73B--102JT

R151,152 241 2313 901 RD14B2E101GFRST

R153,154 247 2011 900 RM73B--333JT

R155,156 247 2011 955 RM73B--513JT

R157,158 247 2013 908 RM73B--224JT

R159,160 247 2011 913 RM73B--363JT

R161,162 247 2014 923 RM73B--684JT

R163,164 247 2013 908 RM73B--224JT

R165,166 247 2009 983 RM73B--103JT

R167,168 247 2012 925 RM73B--104JT

R169,170 247 2017 904 RM73B--106KT

R171,172 247 2009 983 RM73B--103JT

R173-178 247 2010 956 RM73B--203JT

R179,180 247 2008 926 RM73B--222JT

R181-183 247 2012 996 RM73B--204JT

R185-187 247 2018 903 RM73B--0R0KT

R190 247 2007 943 RM73B--102JT

R192,193 247 2014 965 RM73B--105JT

R194,195 247 2009 983 RM73B--103JT

R196,197 247 2011 942 RM73B--473JT

R198-201 247 2004 920 RM73B--470JT

D901-904 276 0704 903 1SR35-400A(T93X)

D905,906 276 0717 903 1SS355 TE-17

D907-918 276 0704 903 1SR35-400A(T93X)

R202,203 247 2007 943 RM73B--102JT

R204,205 247 2014 965 RM73B--105JT

R206 247 2010 969 RM73B--223JT

R207,208 247 2009 983 RM73B--103JT

26

DN-780R

Ref. No. Part No. Part Name Remarks Ref. No. Part No. Part Name Remarks

R209 247 2011 942 RM73B--473JT

R210 247 2009 983 RM73B--103JT

R211 247 2017 904 RM73B--106KT

R212,213 247 2011 942 RM73B--473JT

R214 247 2009 983 RM73B--103JT

R215 247 2009 954 RM73B--752JT

R216 247 2009 983 RM73B--103JT

R217,218 247 2012 925 RM73B--104JT

R219-221 247 2005 945 RM73B--151JT

R222-224 247 2005 961 RM73B--181JT

R225-227 247 2006 915 RM73B--271JT

R228-230 247 2006 944 RM73B--391JT

R231-233 247 2007 901 RM73B--681JT

R234-236 247 2007 972 RM73B--132JT

R237-239 247 2008 984 RM73B--392JT

R240-245 247 2012 925 RM73B--104JT

R246 247 2009 909 RM73B--472JT (1608)

R249,250 247 2009 909 RM73B--472JT (1608)

R252,253 247 2015 948 RM73B--225KT

R255 247 2012 925 RM73B--104JT

R854 247 2015 948 RM73B--225KT

R855 247 2011 942 RM73B--473JT

R856 247 2007 943 RM73B--102JT

R857,858 247 2011 942 RM73B--473JT

R859,860 247 2009 967 RM73B--822JT

R861,862 247 2009 996 RM73B--113JT

R863,864 247 2005 903 RM73B--101JT

R865,866 247 2009 983 RM73B--103JT

R867,868 247 2011 942 RM73B--473JT

R869,870 247 2010 956 RM73B--203JT

R871,872 247 2011 942 RM73B--473JT

R873,874 247 2010 956 RM73B--203JT

R875,876 247 2005 974 RM73B--201JT

R877,878 247 2009 983 RM73B--103JT

R879,880 247 2005 974 RM73B--201JT

R881,882 247 2009 983 RM73B--103JT

R883,884 247 2018 903 RM73B--0R0KT

R891 247 2018 903 RM73B--0R0KT

R901 247 2012 925 RM73B--104JT

R302 247 2018 903 RM73B--0R0KT

R303-306 247 2006 960 RM73B--471JT

R307-317 247 2012 925 RM73B--104JT

R801 247 2011 942 RM73B--473JT

R802,803 247 2004 920 RM73B--470JT

R804 247 2010 956 RM73B--203JT

R805 247 2008 939 RM73B--242JT

R806 247 2010 956 RM73B--203JT

R807 247 2008 926 RM73B--222JT

R809 247 2009 983 RM73B--103JT

R811 247 2013 908 RM73B--224JT

R816 247 2009 909 RM73B--472JT (1608)

R820 247 2012 970 RM73B--164JT

R821,822 247 2011 942 RM73B--473JT

R823 247 2009 983 RM73B--103JT

R824 247 2015 948 RM73B--225KT

R825 247 2011 942 RM73B--473JT

R826 247 2007 943 RM73B--102JT

R827,828 247 2011 942 RM73B--473JT

R829 247 2006 960 RM73B--471JT

R830,831 247 2004 920 RM73B--470JT

R833 247 2008 939 RM73B--242JT

R835 247 2008 926 RM73B--222JT

R837 247 2009 983 RM73B--103JT

R839 247 2013 908 RM73B--224JT

R844 247 2009 909 RM73B--472JT (1608)

R846 247 2018 903 RM73B--0R0KT

R848 247 2012 970 RM73B--164JT

R849-852 247 2011 942 RM73B--473JT

R853 247 2009 983 RM73B--103JT

VR101,102 211 6146 911 RH063LC14R(103)

VR103,104 211 6146 924 RH063LCJ4R(223)

VR301,302 211 5644 003 V09P15FB103T

VR801 211 5645 002 V092Q20FA103

VR803 211 5645 002 V092Q20FA103

VR804,805 211 5646 001 V092Q20FA103 (METAL)

CAPACITORS GROUP

C101,102 254 4541 955 CE04W1E221MT SMG/RE3

C103,104 257 0516 909 CK73B1E223KT

C105,106 257 0501 901 CK73B1H103KT (1608)

C107,108 257 0509 929 CK73B1H102KT

C109,110 254 4524 943 CE04W1H010MT SMG/RE3

C111,112 254 4522 903 CE04W1V4R7MT SMG/RE3

C113-117 257 0509 929 CK73B1H102KT

C118 257 0512 903 CK73F1E104ZT

C119,120 257 0503 967 CC73CH1H150JT

C121 257 0512 903 CK73F1E104ZT

C122 257 0516 954 CK73B1E104KT

C123 254 4524 985 CE04W1H100MT SMG/RE3

C124 254 4524 956 CE04W1H2R2MT SMG/RE3

C125-128 257 0512 903 CK73F1E104ZT

C129 254 4299 906 CE04W1C100MT(SRE)

C130 257 0512 903 CK73F1E104ZT

C131-133 257 0511 904 CK73F1H103ZT

C134 257 0516 941 CK73B1E473KT

C301,302 254 4300 963 CE04W0J101MT(SRE)

C303 257 0512 903 CK73F1E104ZT

27

DN-780R

Ref. No. Part No. Part Name Remarks Ref. No. Part No. Part Name Remarks Q'ty

C801 257 0504 982 CC73CH1H470JT

C802 257 0506 951 CC73CH1H101JT

C803,804 254 3068 905 CE04D1H010MBPT(SRA)

C805 257 0504 982 CC73CH1H470JT

C806 257 0506 951 CC73CH1H101JT

C807 257 0504 982 CC73CH1H470JT

C808 257 0506 951 CC73CH1H101JT

C809,810 254 4302 958 CE04W1A470MT(SRE)

C811 257 0506 951 CC73CH1H101JT

C812 247 2018 903 RM73B—0R0KT

C813 254 4302 974 CE04W1A101MT(SRE)

C814 247 2018 903 RM73B—0R0KT

C815 257 0504 982 CC73CH1H470JT

C816 257 0512 903 CK73F1E104ZT

C817,818 254 3068 905 CE04D1H010MBPT(SRA)

C819 257 0504 982 CC73CH1H470JT

C820 257 0512 903 CK73F1E104ZT

C822 257 0504 982 CC73CH1H470JT

C823,824 254 4302 958 CE04W1A470MT(SRE)

C826 254 4302 974 CE04W1A101MT(SRE)

C827,828 254 4304 927 CE04W1V4R7MT(SRE)

C829,830 257 0506 951 CC73CH1H101JT

C833-842 254 4302 974 CE04W1A101MT(SRE)

C901,902 254 4536 928 CE04W1A101MT SMG/RE3

C903,904 257 0512 903 CK73F1E104ZT

C905 254 4403 721 CE04W1E222MC (SMG)

C905 257 0512 903 CK73F1E104ZT

C906 254 4403 721 CE04W1E222MC (SMG)

C907 254 4534 726 CE04W0J472MC SMG/RE3

C909 254 4403 747 CE04W1E103MC (SMG)

C910 254 4524 956 CE04W1H2R2MT SMG/RE3

C911 254 4522 945 CE04W1V470MT SMG/RE3

C912 254 4525 926 CE04W1H101MT SMG/RE3

C914 253 8022 707 CK45F2EAC103MC

C915-920 254 4541 900 CE04W1E100MT SMG/RE3

C921 257 0512 903 CK73F1E104ZT

OTHER PARTS GROUP

CW91 204 2946 007 9P EH-SCN CON.CORD 1

CW125 204 6264 015 12P KR-DA CON CORD 1

CX21 205 0581 001 2P VH CONNECTOR BASE 1

CX41 205 0343 045 4P CONN.BASE(KR-PH) 1

CX51 205 0343 058 5P CONN.BASE(KR-PH) 1

CX61 205 0321 067 6P CONNE.BASE (RED) 1

CX62 205 0343 061 6P CONN.BASE(KR-PH) 1

CX71 205 0343 074 7P CONN.BASE(KR-PH) 1

CX91 205 0233 090 9P EH CONNECTOR BASE 1

CX121-124 205 0885 079 12P CON.SOCKET TUC-P 4

CX125 205 0375 026 12P CONN.BASE(KR-PH) 1

CX171 205 0801 008 17P TRAP CON BASE 1

CX173 205 1100 038 17P FFC BASE(P=1) 1

CX251 205 1244 004 25P DSUB KIT 1

CY51 205 0355 059 5P KR CON BASE(L) 1

CY61 205 0355 062 6P KR CON BASE(L) 1

CY155 205 0275 058 15P EH.CONN.BASE 1

CY173 205 1100 038 17P FFC BASE(P=1) 1

CY252 205 0702 097 25P FFC CON.BASE(L) 1

FF901 202 0040 909 FUSE CLIP (TAPE) 1

FH901 202 0040 909 FUSE CLIP (TAPE) 1

FL301 393 8065 004 FL TUBE(BJ881GNK) 1

JK801,802 204 8401 012 MIC JACK 2

JK803 204 8264 068 H/P JACK 1

S201-204 212 0417 005 SLIDE SWITCH(1-3) 4

S301-322 212 5604 907 TACT SWITCH-TA(ALPS) 22

S351 212 0485 008 SLIDE SWITCH(2-3) 1

S352 212 1167 008 SLIDE SWITCH 1

S353 212 0417 005 SLIDE SWITCH(1-3) 1

S901 212 1030 009 POWER SWITCH (TV-5) 1

W101 203 0515 039 1P SIN CON.CORD 1

W102-104 203 0605 033 1P SIN CON CORD 3

X101 399 0352 904 CSA20.0MXZ040-TF01 1

X301 399 0661 909 CSTS4.00MG06 1

461 0984 075 FL SPACER 2

28

GU-3462 AUDIO UNIT ASS'Y

Ref. No. Part No. Part Name Remarks

SEMICONDUCTORS GROUP

IC101 263 0896 909 NJM2068MD-TE1

IC102 262 0707 901 TC4053BF (TAPE)

IC103 263 0720 004 HA12170NT

IC104,105 263 0615 902 BA15218F-DXE2

IC106 262 0707 901 TC4053BF (TAPE)

IC107 263 0615 902 BA15218F-DXE2

IC108 262 0707 901 TC4053BF (TAPE)

IC109,110 263 0615 902 BA15218F-DXE2

IC111 263 0354 001 UPC1297CA

IC401 263 0896 909 NJM2068MD-TE1

IC402 262 0707 901 TC4053BF (TAPE)

IC403 263 0720 004 HA12170NT

IC404,405 263 0615 902 BA15218F-DXE2

IC406 262 0707 901 TC4053BF (TAPE)

IC407 263 0615 902 BA15218F-DXE2

IC408 262 0707 901 TC4053BF (TAPE)

IC409,410 263 0615 902 BA15218F-DXE2

IC411 263 0354 001 UPC1297CA

IC701 263 0615 902 BA15218F-DXE2

IC702-706 262 0707 901 TC4053BF (TAPE)

IC707-709 263 0615 902 BA15218F-DXE2

TR101,102 275 0042 905 2SK373(Y)TPE2

TR103-106 273 0426 907 2SC2412KLNT146

TR107,108 269 0082 902 DTC114EKT96

TR109-112 273 0460 905 KTC2875B-RTK

TR113 269 0083 901 DTA114EKT96

TR114,115 269 0082 902 DTC114EKT96

TR116 269 0083 901 DTA114EKT96

TR117,118 269 0082 902 DTC114EKT96

TR119-128 269 0088 906 DTC114TKT96

TR129,130 273 0460 905 KTC2875B-RTK

TR131-136 269 0088 906 DTC114TKT96

TR137,138 269 0082 902 DTC114EKT96

TR139 269 0083 901 DTA114EKT96

TR140-142 269 0082 902 DTC114EKT96

TR143,144 273 0456 906 2SC5395-T12-E/F

TR145 272 0025 907 2SB562(C)TF

TR146 269 0054 901 DTC144EKT96

TR147,148 273 0426 907 2SC2412KLNT146

TR149-152 269 0088 906 DTC114TKT96

TR401,402 275 0042 905 2SK373(Y)TPE2

TR403-406 273 0426 907 2SC2412KLNT146

TR407,408 269 0082 902 DTC114EKT96

TR409-412 273 0460 905 KTC2875B-RTK

TR413 269 0083 901 DTA114EKT96

TR414,415 269 0082 902 DTC114EKT96

TR416 269 0083 901 DTA114EKT96

DN-780R

Ref. No. Part No. Part Name Remarks

TR417,418 269 0082 902 DTC114EKT96

TR419-428 269 0088 906 DTC114TKT96

TR429,430 273 0460 905 KTC2875B-RTK

TR431-436 269 0088 906 DTC114TKT96

TR437,438 269 0082 902 DTC114EKT96

TR439 269 0083 901 DTA114EKT96

TR440-442 269 0082 902 DTC114EKT96

TR443,444 273 0456 906 2SC5395-T12-E/F

TR445 272 0025 907 2SB562(C)TF

TR446 269 0054 901 DTC144EKT96

TR447,448 273 0426 907 2SC2412KLNT146

TR449-452 269 0088 906 DTC114TKT96

TR701-704 273 0460 905 KTC2875B-RTK

TR705-708 269 0082 902 DTC114EKT96

TR709,710 273 0460 905 KTC2875B-RTK

D101-106 276 0717 903 1SS355 TE-17

D108 276 0704 903 1SR35-400A(T93X)

D109,110 276 0717 903 1SS355 TE-17

D111,112 276 0773 905 RB501V-40

D113 276 0717 903 1SS355 TE-17

D401-406 276 0717 903 1SS355 TE-17

D408 276 0704 903 1SR35-400A(T93X)

D409,410 276 0717 903 1SS355 TE-17

D411,412 276 0773 905 RB501V-40

D413 276 0717 903 1SS355 TE-17

D701-705 276 0717 903 1SS355 TE-17

ZD101-104 276 0644 937 MTZJ9.1A T77

ZD105,106 276 0460 904 HZS5C-1TD

ZD107 276 0474 916 HZS12B-2TD

ZD401-404 276 0644 937 MTZJ9.1A T77

ZD405,406 276 0460 904 HZS5C-1TD

ZD407 276 0474 916 HZS12B-2TD

RESISTORS GROUP

R103,104 247 2015 948 RM73B--225KT

R105,106 247 2011 942 RM73B--473JT

R107,108 247 2005 945 RM73B--151JT

R109,110 247 2010 985 RM73B--273JT

R111,112 247 2013 966 RM73B--394JT

R113,114 247 2008 968 RM73B--332JT

R115,116 247 2008 984 RM73B--392JT

R117,118 247 2009 983 RM73B--103JT

R119,120 244 2052 960 RS14B3A221JNBST(S)

R121 247 2018 903 RM73B--0R0KT

R122 247 2009 909 RM73B--472JT (1608)

29

DN-780R

Ref. No. Part No. Part Name Remarks

R123,124 247 2012 925 RM73B--104JT

R127,128 247 2012 925 RM73B--104JT

R129,130 247 2009 912 RM73B--512JT

R131 247 2007 943 RM73B--102JT

R132 247 2010 969 RM73B--223JT

R133,134 247 2014 965 RM73B--105JT

R135,136 247 2008 968 RM73B--332JT

R137,138 247 2009 941 RM73B--682JT

R139,140 247 2010 969 RM73B--223JT

R141,142 247 2006 986 RM73B--561JT

R143,144 247 2010 956 RM73B--203JT

R145,146 247 2009 983 RM73B--103JT

R147,148 247 2009 912 RM73B--512JT

R149-152 247 2009 983 RM73B--103JT

R153,154 247 2009 912 RM73B--512JT

R155,156 247 2009 983 RM73B--103JT

R157,158 247 2012 925 RM73B--104JT

R159-162 247 2005 945 RM73B--151JT

R163-167 247 2009 983 RM73B--103JT

R168 247 2012 925 RM73B--104JT

R169,170 247 2010 969 RM73B--223JT

R171-173 247 2012 925 RM73B--104JT

R174 247 2006 902 RM73B--331JT (1608)

R175 247 2012 925 RM73B--104JT

R176 247 2008 926 RM73B--222JT

R177,178 247 2007 943 RM73B--102JT

R179,180 247 2010 998 RM73B--303JT

R181,182 247 2011 939 RM73B--433JT

R183,184 247 2008 955 RM73B--302JT

R187,188 247 2007 901 RM73B--681JT

R191,192 247 2006 960 RM73B--471JT

R195,196 247 2006 960 RM73B--471JT

R197,198 247 2010 969 RM73B--223JT

R199,200 247 2009 967 RM73B--822JT

R203,204 247 2010 956 RM73B--203JT

R205,206 247 2007 943 RM73B--102JT

R207,208 247 2008 955 RM73B--302JT

R209,210 247 2011 997 RM73B--753JT

R211,212 247 2011 926 RM73B--393JT

R213,214 247 2005 903 RM73B--101JT

R215,216 247 2006 960 RM73B--471JT

R217,218 247 2007 943 RM73B--102JT

R219,220 247 2012 983 RM73B--184JT

R221,222 247 2010 998 RM73B--303JT

R223,224 247 2008 955 RM73B--302JT

R227,228 247 2006 928 RM73B--301JT

R231,232 247 2005 945 RM73B--151JT

R235,236 247 2006 944 RM73B--391JT

R237-241 247 2008 913 RM73B--202JT

R242 247 2005 903 RM73B--101JT

R251,252 247 2012 967 RM73B--154JT

Ref. No. Part No. Part Name Remarks

R253,254 247 2010 927 RM73B--153JT

R255,256 247 2018 903 RM73B--0R0KT

R257 247 2008 955 RM73B--302JT

R258 247 2011 900 RM73B--333JT

R259 247 2008 942 RM73B--272JT

R260 247 2009 967 RM73B--822JT

R261,262 247 2012 941 RM73B--124JT

R263,264 247 2001 981 RM73B--4R7KT

R265 241 2315 925 RD14B2E220GFRST

R267 247 2009 912 RM73B--512JT

R268 247 2009 983 RM73B--103JT

R269 247 2010 943 RM73B--183JT

R271,272 247 2009 983 RM73B--103JT

R273,274 247 2012 925 RM73B--104JT

R275 247 2018 903 RM73B--0R0KT

R276,277 247 2008 955 RM73B--302JT

R278,279 247 2007 956 RM73B--112JT

R280,281 247 2008 997 RM73B--432JT

R282,283 247 2008 913 RM73B--202JT

R284 247 2009 983 RM73B--103JT

R285 247 2018 903 RM73B--0R0KT

R403,404 247 2015 948 RM73B--225KT

R405,406 247 2011 942 RM73B--473JT

R407,408 247 2005 945 RM73B--151JT

R409,410 247 2010 985 RM73B--273JT

R411,412 247 2013 966 RM73B--394JT

R413,414 247 2008 968 RM73B--332JT

R415,416 247 2008 984 RM73B--392JT

R417,418 247 2009 983 RM73B--103JT

R419,420 244 2052 960 RS14B3A221JNBST(S)

R421 247 2018 903 RM73B--0R0KT

R422 247 2009 909 RM73B--472JT (1608)

R423,424 247 2012 925 RM73B--104JT

R427,428 247 2012 925 RM73B--104JT

R429,430 247 2009 912 RM73B--512JT

R431 247 2007 943 RM73B--102JT

R432 247 2010 969 RM73B--223JT

R433,434 247 2014 965 RM73B--105JT

R435,436 247 2008 968 RM73B--332JT

R437,438 247 2009 941 RM73B--682JT

R439,440 247 2010 969 RM73B--223JT

R441,442 247 2006 986 RM73B--561JT

R443,444 247 2010 956 RM73B--203JT

R445,446 247 2009 983 RM73B--103JT

R447,448 247 2009 912 RM73B--512JT

R449-452 247 2009 983 RM73B--103JT

R453,454 247 2009 912 RM73B--512JT

R455,456 247 2009 983 RM73B--103JT

R457,458 247 2012 925 RM73B--104JT

R459-462 247 2005 945 RM73B--151JT

R463-467 247 2009 983 RM73B--103JT

30

DN-780R

Ref. No. Part No. Part Name Remarks

R468 247 2012 925 RM73B--104JT

R469,470 247 2010 969 RM73B--223JT

R471-473 247 2012 925 RM73B--104JT

R474 247 2006 902 RM73B--331JT (1608)

R475 247 2012 925 RM73B--104JT

R476 247 2008 926 RM73B--222JT

R477,478 247 2007 943 RM73B--102JT

R479,480 247 2010 998 RM73B--303JT

R481,482 247 2011 939 RM73B--433JT

R483,484 247 2008 955 RM73B--302JT

R487,488 247 2007 901 RM73B--681JT

R491,492 247 2006 960 RM73B--471JT

R495,496 247 2006 960 RM73B--471JT

R497,498 247 2010 969 RM73B--223JT

R499,500 247 2009 967 RM73B--822JT

R503,504 247 2010 956 RM73B--203JT

R505,506 247 2007 943 RM73B--102JT

R507,508 247 2008 955 RM73B--302JT

R509,510 247 2011 997 RM73B--753JT

R511,512 247 2011 926 RM73B--393JT

R513,514 247 2005 903 RM73B--101JT

R515,516 247 2006 960 RM73B--471JT

R517,518 247 2007 943 RM73B--102JT

R519,520 247 2012 983 RM73B--184JT

R521,522 247 2010 998 RM73B--303JT

R523,524 247 2008 955 RM73B--302JT

R527,528 247 2006 928 RM73B--301JT

R531,532 247 2005 945 RM73B--151JT

R535,536 247 2006 944 RM73B--391JT

R537-541 247 2008 913 RM73B--202JT

R542 247 2005 903 RM73B--101JT

R551,552 247 2012 967 RM73B--154JT

R553,554 247 2010 927 RM73B--153JT

R555,556 247 2018 903 RM73B--0R0KT

R557 247 2008 955 RM73B--302JT

R558 247 2011 900 RM73B--333JT

R559 247 2008 942 RM73B--272JT

R560 247 2009 967 RM73B--822JT

R561,562 247 2012 941 RM73B--124JT

R563,564 247 2001 981 RM73B--4R7KT

R565 241 2315 925 RD14B2E220GFRST

R567 247 2009 912 RM73B--512JT

R568 247 2009 983 RM73B--103JT

R569 247 2010 943 RM73B--183JT

R571,572 247 2009 983 RM73B--103JT

R573,574 247 2012 925 RM73B--104JT

R575 247 2018 903 RM73B--0R0KT

R576,577 247 2008 955 RM73B--302JT

R578,579 247 2007 956 RM73B--112JT

R580,581 247 2008 997 RM73B--432JT

R582,583 247 2008 913 RM73B--202JT

Ref. No. Part No. Part Name Remarks

R584 247 2009 983 RM73B--103JT

R585 247 2018 903 RM73B--0R0KT

R701-704 247 2013 982 RM73B--474JT

R705,706 247 2012 925 RM73B--104JT

R707-710 247 2005 945 RM73B--151JT

R711-714 247 2009 983 RM73B--103JT

R715,716 247 2010 972 RM73B--243JT

R717,718 247 2015 948 RM73B--225KT

R719 247 2010 972 RM73B--243JT

R720 247 2010 998 RM73B--303JT

R721,722 247 2015 948 RM73B--225KT

R723,724 247 2011 942 RM73B--473JT

R725 247 2010 972 RM73B--243JT

R726 247 2009 983 RM73B--103JT

R727-730 247 2011 942 RM73B--473JT

R731-734 247 2013 911 RM73B--244JT

R736 247 2012 925 RM73B--104JT

R737-744 247 2009 983 RM73B--103JT

R745-748 247 2010 985 RM73B--273JT

R749-752 247 2013 982 RM73B--474JT

VR101,102 211 6146 937 RH063LCS4R(473)

VR103,104 211 6146 924 RH063LCJ4R(223)

VR105,106 211 6146 937 RH063LCS4R(473)

VR401,402 211 6146 937 RH063LCS4R(473)

VR403,404 211 6146 924 RH063LCJ4R(223)

VR405,406 211 6146 937 RH063LCS4R(473)

CAPACITORS GROUP

C101,102 257 0509 929 CK73B1H102KT

C105,106 257 0508 933 CC73CH1H561JT

C109,110 255 1264 995 CQ93M1H562JT(B)

C111,112 254 3056 917 CE04D1H010MBPT (SME)

C115,116 254 4538 900 CE04W1C100MT SMG/RE3

C117 254 4302 974 CE04W1A101MT(SRE)

C118 257 0512 903 CK73F1E104ZT

C121-124 254 4524 943 CE04W1H010MT SMG/RE3

C125,126 255 1264 953 CQ93M1H272JT(B)

C127-132 255 1264 940 CQ93M1H222JT(B)

C133,134 254 4522 903 CE04W1V4R7MT SMG/RE3

C135-138 254 4524 901 CE04W1H0R1MT SMG/RE3

C139,140 254 4538 942 CE04W1C101MT SMG/RE3

C141 254 4539 705 CE04W1C102MC SMG/RE3

C142 254 4538 900 CE04W1C100MT SMG/RE3

C143,144 257 0511 904 CK73F1H103ZT

C145-148 257 0504 982 CC73CH1H470JT

C149,150 254 4522 903 CE04W1V4R7MT SMG/RE3

C152 257 0509 929 CK73B1H102KT

C153,154 257 0506 993 CC73CH1H151JT

C155,156 254 4538 942 CE04W1C101MT SMG/RE3

31

DN-780R

Ref. No. Part No. Part Name Remarks Ref. No. Part No. Part Name Remarks

C157,158 257 0510 905 CK73B1H272KT

C159,160 254 4536 915 CE04W1A470MT SMG/RE3

C163,164 257 0509 990 CK73B1H222KT

C165,166 257 0510 918 CK73B1H332KT

C169,170 257 0509 990 CK73B1H222KT

C171,172 257 0510 918 CK73B1H332KT

C177,178 257 0510 905 CK73B1H272KT

C179,180 254 4522 903 CE04W1V4R7MT SMG/RE3

C183,184 254 4524 930 CE04W1HR47MT SMG/RE3

C185,186 254 4538 900 CE04W1C100MT SMG/RE3

C187,188 257 0517 937 CK73B1C823KT

C189,190 254 4536 915 CE04W1A470MT SMG/RE3

C193,194 257 0510 950 CK73B1H682KT

C195,196 257 0510 963 CK73B1H822KT

C199,200 257 0510 950 CK73B1H682KT

C201,202 257 0510 963 CK73B1H822KT

C205,206 257 0509 945 CK73B1H122KT

C207,208 257 0510 963 CK73B1H822KT

C209 254 4541 955 CE04W1E221MT SMG/RE3

C210 257 0516 941 CK73B1E473KT

C211,212 257 0506 951 CC73CH1H101JT

C213,214 253 1131 909 CK45B2H391KT

C215,216 257 0509 945 CK73B1H122KT

C217,218 257 0501 901 CK73B1H103KT (1608)

C219,220 257 0516 925 CK73B1E333KT

C221,222 257 0516 909 CK73B1E223KT

C223 254 4538 942 CE04W1C101MT SMG/RE3

C224 254 4541 913 CE04W1E220MT SMG/RE3

C226 255 4120 900 CQ93P2A682JT

C228 255 1265 907 CQ93M1H682JT(B)

C229,230 257 0510 918 CK73B1H332KT

C231 257 0511 904 CK73F1H103ZT

C233 254 4541 955 CE04W1E221MT SMG/RE3

C234 257 0503 925 CC73CH1H100DT

C235,236 257 0516 909 CK73B1E223KT

C237,238 257 0516 912 CK73B1E273KT(1608)

C239,240 257 0501 927 CK73B1H153KT

C241,242 257 0516 925 CK73B1E333KT

C243,244 257 0510 934 CK73B1H472KT

C245,246 257 0510 905 CK73B1H272KT

C247,248 257 0510 934 CK73B1H472KT

C249,250 257 0510 905 CK73B1H272KT

C401,402 257 0509 929 CK73B1H102KT

C405,406 257 0508 933 CC73CH1H561JT

C409,410 255 1264 995 CQ93M1H562JT(B)

C411,412 254 3056 917 CE04D1H010MBPT (SME)

C415,416 254 4538 900 CE04W1C100MT SMG/RE3

C417 254 4302 974 CE04W1A101MT(SRE)

C418 257 0512 903 CK73F1E104ZT

C421-424 254 4524 943 CE04W1H010MT SMG/RE3

C425,426 255 1264 953 CQ93M1H272JT(B)

C427-432 255 1264 940 CQ93M1H222JT(B)

C433,434 254 4522 903 CE04W1V4R7MT SMG/RE3

C435-438 254 4524 901 CE04W1H0R1MT SMG/RE3

C439,440 254 4538 942 CE04W1C101MT SMG/RE3

C441 254 4539 705 CE04W1C102MC SMG/RE3

C442 254 4538 900 CE04W1C100MT SMG/RE3

C443,444 257 0511 904 CK73F1H103ZT

C445-448 257 0504 982 CC73CH1H470JT

C449,450 254 4522 903 CE04W1V4R7MT SMG/RE3

C452 257 0509 929 CK73B1H102KT

C453,454 257 0506 993 CC73CH1H151JT

C455,456 254 4538 942 CE04W1C101MT SMG/RE3

C457,458 257 0510 963 CK73B1H822KT

C459,460 254 4536 915 CE04W1A470MT SMG/RE3

C463,464 257 0509 990 CK73B1H222KT

C465,466 257 0510 918 CK73B1H332KT

C469,470 257 0509 990 CK73B1H222KT

C471,472 257 0510 918 CK73B1H332KT

C477,478 257 0510 905 CK73B1H272KT

C479,480 254 4522 903 CE04W1V4R7MT SMG/RE3

C483,484 254 4524 930 CE04W1HR47MT SMG/RE3

C485,486 254 4538 900 CE04W1C100MT SMG/RE3

C487,488 257 0517 937 CK73B1C823KT

C489,490 254 4536 915 CE04W1A470MT SMG/RE3

C493,494 257 0510 950 CK73B1H682KT

C495,496 257 0510 963 CK73B1H822KT

C499,500 257 0510 950 CK73B1H682KT

C501,502 257 0510 963 CK73B1H822KT

C505,506 257 0509 945 CK73B1H122KT

C507,508 257 0510 963 CK73B1H822KT

C509 254 4541 955 CE04W1E221MT SMG/RE3

C510 257 0516 941 CK73B1E473KT

C511,512 257 0506 951 CC73CH1H101JT

C513,514 253 1131 909 CK45B2H391KT

C515,516 257 0509 945 CK73B1H122KT

C517,518 257 0501 901 CK73B1H103KT (1608)

C519,520 257 0516 925 CK73B1E333KT

C521,522 257 0516 909 CK73B1E223KT

C523 254 4538 942 CE04W1C101MT SMG/RE3

C524 254 4541 913 CE04W1E220MT SMG/RE3

C526 255 4120 900 CQ93P2A682JT

C528 255 1265 907 CQ93M1H682JT(B)

C529,530 257 0510 918 CK73B1H332KT

C531 257 0511 904 CK73F1H103ZT

C533 254 4541 955 CE04W1E221MT SMG/RE3

C534 257 0503 925 CC73CH1H100DT

C535,536 257 0516 909 CK73B1E223KT

C537,538 257 0516 912 CK73B1E273KT(1608)

C539,540 257 0501 927 CK73B1H153KT

C541,542 257 0516 925 CK73B1E333KT

32

Ref. No. Part No. Part Name Remarks

C543,544 257 0510 934 CK73B1H472KT

C545,546 257 0510 905 CK73B1H272KT

C547,548 257 0510 934 CK73B1H472KT

C549,550 257 0510 905 CK73B1H272KT

DN-780R

GU-3463 XLR UNIT ASS'Y (ACD-780:Option)

Ref. No. Part No. Part Name Remarks

SEMICONDUCTORS GROUP

IC601-606 263 0565 007 BA15218

IC607,608 262 0707 901 TC4053BF (TAPE)

C701,702 254 4522 903 CE04W1V4R7MT SMG/RE3

C703-706 254 4538 900 CE04W1C100MT SMG/RE3

C707-710 254 4524 943 CE04W1H010MT SMG/RE3

OTHER PARTS GROUP Q’ty

CX91 205 1243 005 9P DSUB KIT 1

CX126-129 205 0884 070 12P CON.BASE TUC-P 4

CX155 205 0275 058 15P EH.CONN.BASE 1

CX156 205 0375 055 15P CONN.BASE(KR-PH) 1

CX252 205 0736 089 25P FFC CON.BASE 1

CY33,34 205 0321 038 3P CONNE.BASE(RED) 2

CY35,36 205 0343 032 3P CONN.BASE(KR-PH) 2

CY37,38 205 0190 036 3P NH CONNECTOR BASE 2

CY121-124 205 0884 070 12P CON.BASE TUC-P 4

CY126-129 205 0885 079 12P CON.SOCKET TUC-P 4

JK701 204 8543 006 6P PIN JACK 1

JK702 204 8540 009 4P PIN JACK 1

JK703 204 8540 025 4P PIN JACK 1

JK705 204 8416 007 MINI JACK 1

L101,102 232 0109 003 MPX FILTER 2

L103,104 235 0020 945 INDUCTOR 153JT 2

L105-108 235 0020 916 INDUCTOR 822JT 4

L109,110 239 0010 009 HX STEP UP COIL 2

L111 231 0078 005 OSC COIL 1

L112 235 0020 945 INDUCTOR 153JT 1

L401,402 232 0109 003 MPX FILTER 2

L403,404 235 0020 945 INDUCTOR 153JT 2

L405-408 235 0020 916 INDUCTOR 822JT 4

L409,410 239 0010 009 HX STEP UP COIL 2

L411 231 0078 005 OSC COIL 1

L412 235 0020 945 INDUCTOR 153JT 1

S701 212 1154 008 SLIDE SWITCH 1

253 1180 921 CK45B1H102KT(DD-3) 1

RESISTORS GROUP

R601,602 247 2018 903 RM73B--0R0KT

R603,604 247 2010 956 RM73B--203JT

R605,606 247 2012 996 RM73B--204JT

R607,608 247 2012 967 RM73B--154JT

R609,610 247 2015 948 RM73B--225KT

R611,612 247 2013 911 RM73B--244JT

R613-616 247 2005 958 RM73B--161JT

R617,618 247 2012 996 RM73B--204JT

R619-622 247 2013 924 RM73B--274JT

R623,624 247 2011 997 RM73B--753JT

R625,626 247 2011 942 RM73B--473JT

R627,628 247 2011 997 RM73B--753JT

R629-632 247 2005 958 RM73B--161JT

R633-636 247 2010 956 RM73B--203JT

R637-640 247 2004 920 RM73B--470JT

R641,642 247 2012 996 RM73B--204JT

R643,644 247 2013 924 RM73B--274JT

R645,646 247 2018 903 RM73B--0R0KT

R647,648 247 2010 956 RM73B--203JT

R649,650 247 2012 996 RM73B--204JT

R651,652 247 2012 967 RM73B--154JT

R653,654 247 2015 948 RM73B--225KT

R655,656 247 2013 911 RM73B--244JT

R657,658 247 2013 924 RM73B--274JT

R659,660 247 2011 997 RM73B--753JT

R661,662 247 2011 942 RM73B--473JT

R663,664 247 2011 997 RM73B--753JT

R665 247 2013 911 RM73B--244JT

R666 247 2012 996 RM73B--204JT

R667 247 2013 911 RM73B--244JT

R668-670 247 2012 941 RM73B--124JT

R671 247 2012 909 RM73B--823JT

R672 247 2013 911 RM73B--244JT

R673 247 2012 941 RM73B--124JT

R674 247 2013 911 RM73B--244JT

R675 247 2012 996 RM73B--204JT

R676 247 2012 909 RM73B--823JT

R677-680 247 2010 956 RM73B--203JT

R681-684 247 2004 920 RM73B--470JT

R685,686 247 2012 941 RM73B--124JT

R687-694 247 2013 924 RM73B--274JT

R695-698 247 2008 913 RM73B--202JT

R699,700 247 2011 939 RM73B--433JT

33

Ref. No. Part No. Part Name Remarks

CAPACITORS GROUP

C601-604 254 4522 958 CE04W1V101MT SMG/RE3

C605,606 257 0506 951 CC73CH1H101JT

C607-610 257 0509 929 CK73B1H102KT

C611-614 254 4522 958 CE04W1V101MT SMG/RE3

C615-618 257 0504 940 CC73CH1H330JT

C619,620 257 0506 951 CC73CH1H101JT

C621-624 257 0509 929 CK73B1H102KT

C625,626 257 0502 926 CC73CH1H010CT

C627,628 257 0503 925 CC73CH1H100DT

C629,630 257 0502 926 CC73CH1H010CT

C631,632 257 0503 925 CC73CH1H100DT

C633-636 257 0504 940 CC73CH1H330JT

C637-644 257 0509 929 CK73B1H102KT

C645,646 254 4538 968 CE04W1C331MT SMG/RE3

DN-780R

OTHER PARTS GROUP Q’ty

JK601,602 205 1046 008 3P CANNON (OUT) 2

JK603,604 205 1047 007 3P CANNON (IN) 2

JK605 205 1046 008 3P CANNON (OUT) 1

S601-603 212 1147 002 SLIDE SW 3

34

EXPLODED VIEW OF CABINET

DN-780R

1

103

68

2

111

67

66

108

42

3

105

105

108

38

37

4

105

111

52

68

103

69

5

19

17

101

9

11

44

45

76

101

8

WARNING:

Parts marked with this symbol have critical

112

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

101

10

110

101

A

B

101

101

15

102

63

57

20

104

62

26

34

61

60

27

29

33

25

106

22

43

35

26

24

108

28

106

109

41

24

27

59

23

28

106

106

33

33

31

109

36

106

106

106

41

39

54

40

106

108

48

53

50

49

47

46

108

16

13

101

12

7

8

105

5

4

C

D

34

62

105

64 30

57

3

101

51

105

105

6

E

35

PARTS LIST OF EXPLODED VIEW

Ref. No. Part No. Part Name Remarks

1 GU-3461 CONTROL POWER UNIT 1

CONTROL UNIT

DISPLAY UNIT

POWER UNIT

SWA UNIT

SWB UNIT

MIC UNIT

2 GU-3462 AUDIO UNIT

3 411 1360 305 CHASSIS 1

4 449 0050 064 CARD SPACER 2

5 415 9016 006 P.W.B. HOLDER 1

6 461 0911 006 FOOT SHEET 2

7 412 4971 008 TRANS BRACKET 1

8 412 4975 004 P.W.B. BRACKET 1

9 105 1410 101 BACK PANEL 1

10 412 4987 005 BLIND PLATE 1

11 412 4812 015 SPRING PLATE 1

12 412 2814 086 CARD SPACER (L=14.8) 1

13 233 5815 023 POWER TRANS(E3) E3 Model 1

233 6015 026 POWER TRANS (E2) E2 Model 1

14 206 1087 002 FUSE (ET0.63A) F901,E3 Model 1

206 1031 045 FUSE (0.25)A F901,E2 Model 1

15 204 6744 001 15P PH CON.CORD 1

16 412 4969 104 FRONT BRIDGE 1

17 206 2160 009 AC CORD VH N/I E3 E3 Model 1

206 2089 106 AC CORD W/CON.E2 E2 Model 1

18 342 0027 000 FERRITE CORE E2 Model 1

19 445 0056 008 CORD BUSH 1

20 144 2805 202 FRONT PANEL 1

21 103 1758 100 INNER PANEL ASS’Y 1

22 143 1154 003 METER WINDOW 1

23 113 1943 006 FUNCTION KNOB 1

24 113 1944 005 TACT KNOB 2

25 113 1556 011 EJECT KNOB 2

26 103 1372 612 CASSETTE DOOR 2

27 463 0655 009 CASSETTE SPRING 4

28 421 9007 007 MINI DAMPER 2

29 463 0727 005 BOX SPRING (L) 1

30 463 0728 004 BOX SPRING (R) 1

31 415 0335 003 P.W.B. SUPPORT 2

32 461 0984 088 SPACER 2

33 122 0239 003 BLIND SHEET(SW) 7

34 122 0240 005 BLIND SHEET(VR) 1

35 203 8469 019 5P KR-KR CON.CORD 1

36 204 0327 013 6P KR-KR CON.CORD 1

37 412 3597 302 EJECT LEVER (A) 1

38 412 3599 009 LEVER STAY (A) 1

39 412 3598 301 EJECT LEVER (B) 1

40 412 3628 006 LEVER STAY (B) 1

41 463 8238 004 SPRING 2

42 338 0161 006 C.MECHA (A) 1

43 203 8353 057 5P SHIELD WIRE ASS 1

44 002 9022 027 10C R.WIRE ASS(#26) 1

45 002 9032 020 7C R.WIRE ASS(AWG26) 1

Note: The symbols in the column “Remarks” indicate the following destinations.

E2: Europe model

E3: U.S.A. & Canada model

Q'ty

Ref. No. Part No. Part Name Remarks

46 338 0191 005 C.MECHA(B) 1

47 203 8353 060 5P SHIELD WIRE ASS 1

48 204 2426 064 7P KR-KR CON.CORD 1

49 204 0307 088 6P KR-KR CON.CORD 1