Page 1

DEMON

SERVICE MANUAL^

-I ! II II , f r'\

MODEL

DN-730R

STEREO CASSETTE TAPE DECK

— • c tja .

in

— TABLE OF CONTENTS —

SPECIFICATIONS........................................................................................................................................................3

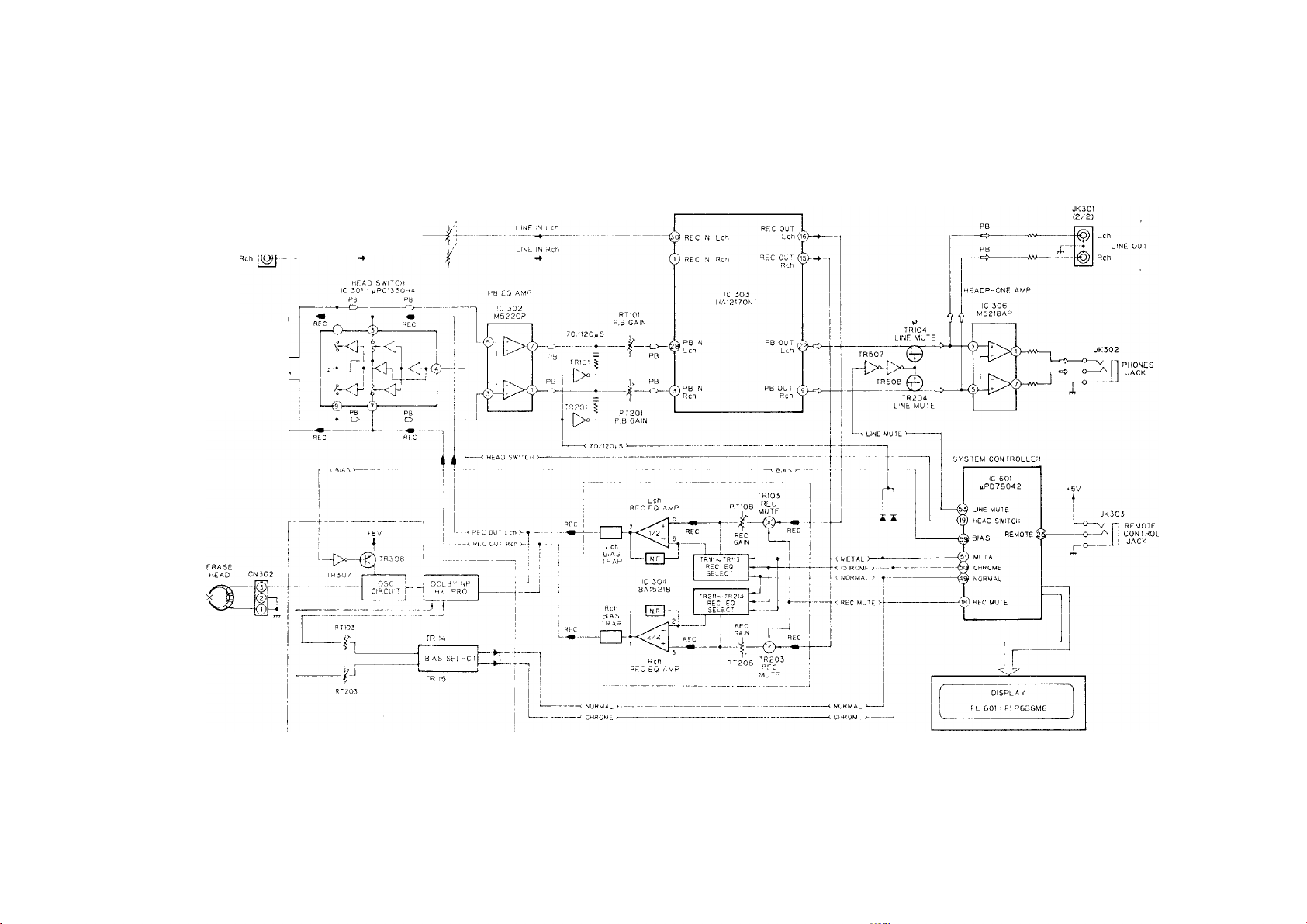

BLOCK DIAGRAM........................................................................................................................................................4

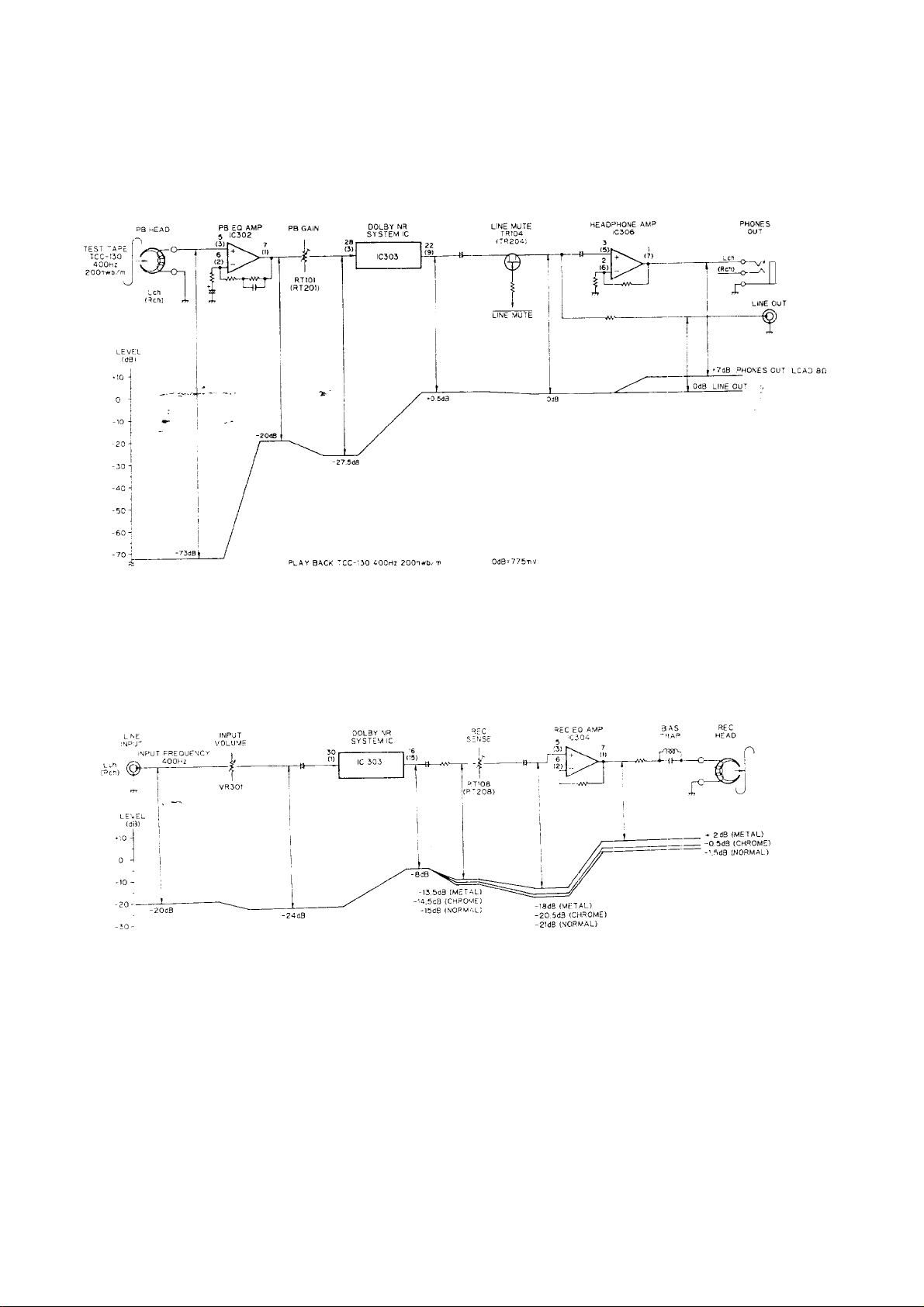

LEVEL DIAGRAM.........................................................................................................................................................5

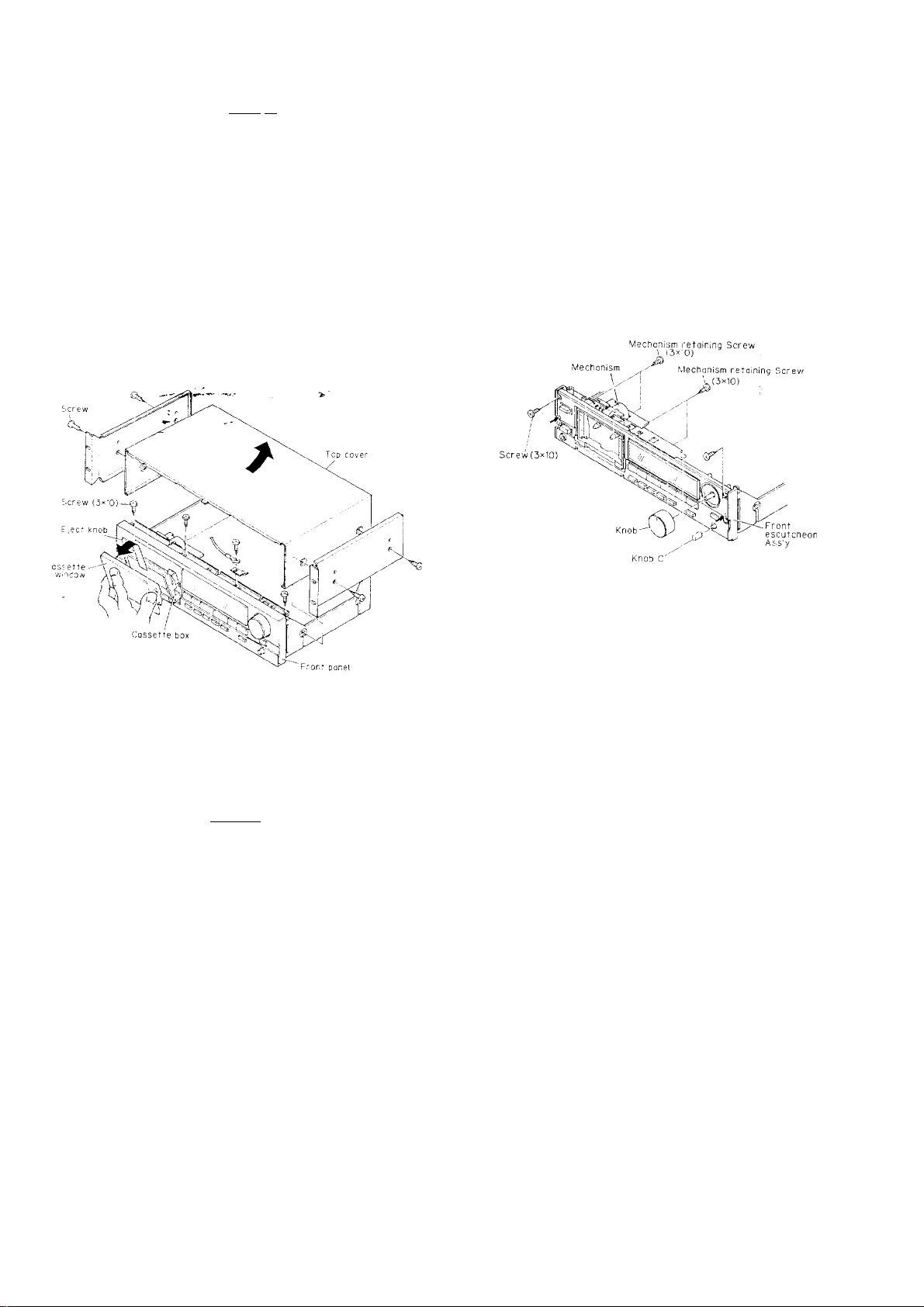

DISASSEMBLY INSTRUCTIONS............................................................................................................................6~7

ADJUSTING AND CHECKING THE MECHANISM SECTION

ADJUSTING THE ELECTRICAL SECTIONS........................................................................................................9~10

NOTE FOR PARTS LIST............................................................................................................................................10

PARTS LIST OF 3U-2584 AUDIO METER UNIT................................................................................................. 11-13

PARTS LIST OF 3U-2063 POWER SUPPLY UNIT...................................................................................................13

PARTS LIST OF EXPLODED VIEW.......................................................................................................................... 14

EXPLODED VIEW......................................................................................................................................................15

EXPLODED VIEW OF CASSETTE MECHANISM.....................................................................................................16

PARTS LIST OF CASSETTE MECHANISM EXPLODED VIEW...............................................................................17

PARTS LIST OF PACKING & ACCESSORIES.........................................................................................................17

PACKING & ACCESSORIES.....................................................................................................................................17

P.W. BOARD OF 3U-2584 AUDIO/METER UNIT......................................................................................................18

P.W. BOARD OF 3U-2063 POWER SUPPLY UNIT..................................................................................................19

SEMICONDUCTORS............................................................................................................................................20-21

BUNDLE DIAGRAM...................................................................................................................................................21

WIRING DIAGRAM.....................................................................................................................................................22

SCHEMATIC DIAGRAM.............................................................................................................................................23

....................................................................................

-

8

NIPPON COLUMBIA CO.. LTD.

Page 2

IÛN-730RI

Page 3

i'SPECIFICATICMSIS

ICDN-ySORI

Type

Heads

Motors

Tape Speed

Variable (PLAY)

Fast Forward,

Rewind Time

Flecording Bias

Overall S/N Ratio

(at 3% THD

Overall Frequency

Response

Channel Separation

Crosstalk

Wow & Flutter

Inputs

Line

Outputs

' Line

Headphone

Power supply

Power Consumption

Dimensions

Weight

Installation _

Vertical tape loading; 4-track 2-channel

stereo cassette deck

Recording/playback head (amorphous) X 1

Erase head (Double-gap ferrite) X 1

Capstan (DC servo motor) X 1

Reel (DC motor) X 1

4.8 cm/sec. (FIX)

Approx. ±12%

Approx. 110 sec. with a C-60 cassette

Approx. 105 kHz

Dolby t NR on: more than 74 dB (CCIR/ARM)

25-19,000 Hz ±3 dB (at —20 dB, Metal tape)

More than 40 dB (at 1 kHz)

More than 65 dB (at 1 kHz)

0.055% WRMS (JIS method), ±0.14% w. peak

80 mV (—20 dBm) input level at maximum

Input impedance: 50 kohm unbalanced

775 mV (0 dB) output level at maximum

(with 47 kohm load, recorded level of

200 pwb/mm)

1.2 mW output level at maximum

(optimum load impedance

8 ohm-1.2 kohm)

Voltage is shown on rating label

16 W

482 (W) X 134 (H) X 275 (D) mm

4.7 kg

19-inch rack mountable (3U)

Above specifications and design styling are subject to change for improvement.

Dolby noise reduction and HX Pro headroom extension manufactured

under licence from Dolby Laboratories Licensing Corporation. HX Pro

originated by Band & Olufsen.

"DOLBY", the double-D symbol □□ and "HX PRO" are trademarks of

Dolby Laboratories Licensing Corporation.

Best results will be obtained with use of DENOIM DX and HD Series cassette

tapes.

Page 4

REC/PB MEAD

“"-CE=i

JK301

0/2)

LINE IN LCM

- ^

-----------

I.INF: in Ren

VRiOl

ìNPJTVOL'JML'

DOLBY NR SYSTEM iC

I 00

i r”

I

□

z

O

O

7Ñ

D

>

O

30

>

Q]

□

Page 5

-LEVEL DIAGRAM

PLAYBACK SYSTEM

TCC-130 IDOLBY B-Pi^PE

400 Hz 200 nwb/m

1CDN-730RI

RECORDING SYSTEM

INPUT FREQUENCY

400 Hz

-40

-50

-60

-70 -

REC PLAY FREQUENCY : 400H7

Page 6

IDN-730RI

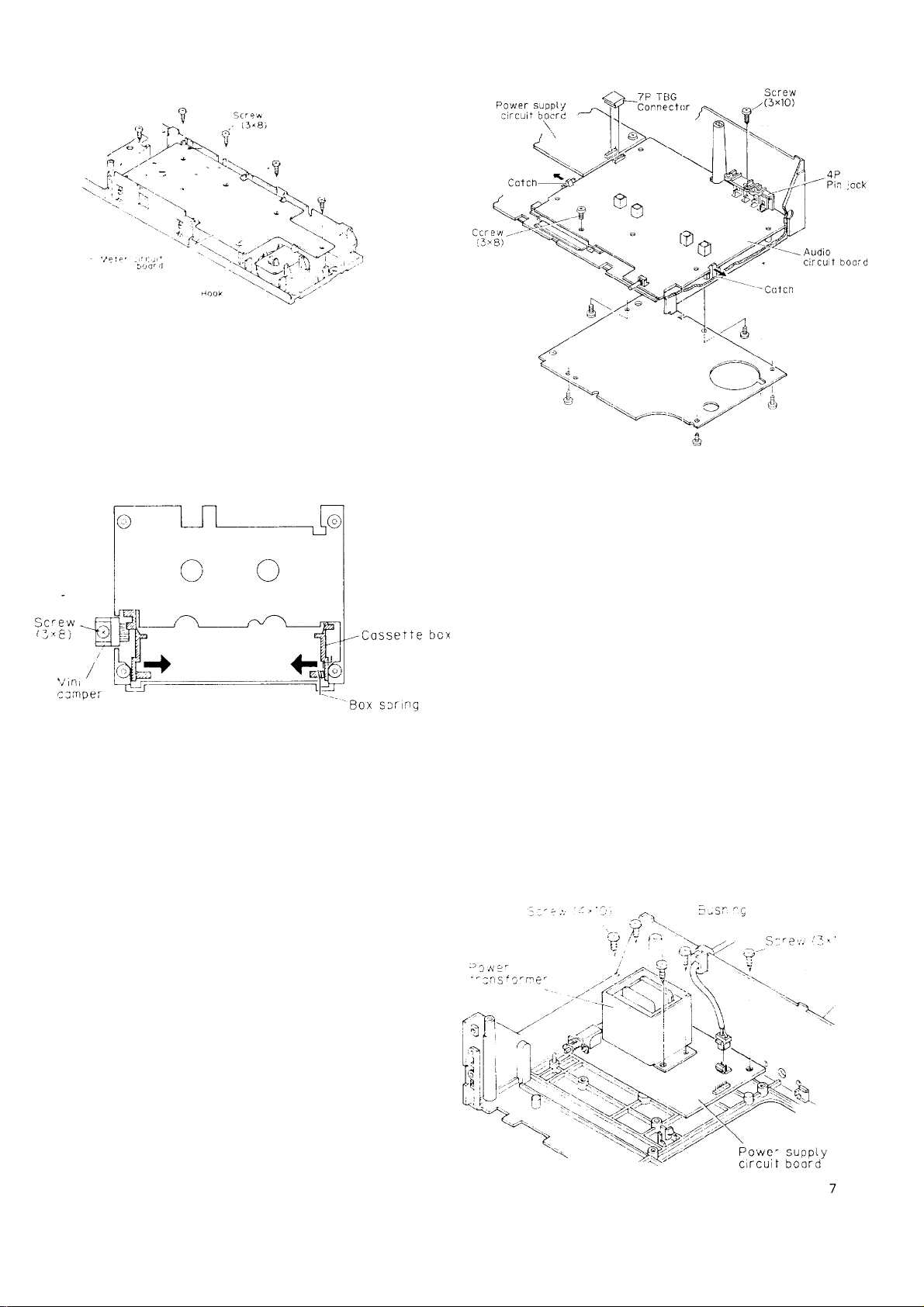

j DISASSEMBLY INSTRUCTIONS j

1. How to Remove the Front Panel

(1i Remove the four screws, (4 X 12. CBTS-P) in the side of the

top cover. Move the top cover to the rear and rise it to

remove it.

(2) Press the eject knob, open the cassette box and remove the

cassette window as shown in the figure. .

Note: Handle the cassette window with care because it

can be scratched easily.

(3' Remove the three screws (3x10 CBTS-P) on top of the

front panel, the two hooks on the top, the three hooks on

the bottom and pull the unit forward to detach it.

(3) Disconnect all lead connectors.

C Mechanism ( W151 (7P) — CN151 '

I Head wire — CN301

1

Head wire — CN302

Meter circuit

board

Remove Volume Knob and Volume Knob (C).

(4)

Remove the four retaining screws (2 6 x 6 CBTS(Si)-Z) (3

(5)

X 10 CBTS(P)-B) holding the Mecha Bracket.

Remove the Hooks at the left and right of the f 'ont face of

(6)

the Front Esc. Ass'y, and the two hooks on the bottom.

Front Ass'y can be removed towards the front.

I W131 (3P) - CN131

1

23PFFC-CB121 .

Audio

circuit

board

2 hooks on the top of the front panet

m,...i. i. .... a

T

3 hooks on the bottom of the front panel

_ _____________0_

2. How to Remove the Front Escutcheon Ass'y

(1) Remove the top cover and front panel. (Refer to Step 1 )

(2) Remove the three retaining screws 3x10 CBTS-(P)-B

holding the Front Escutcheon at the front.

T

Hooks at left and right of Front Esc. Ass'y

3. How to Remove the Mec hanisms

Remove the four Mechanism retaining screws 3x10 CBTS(P)-B

and lake out C Mechanism.

4. How to Remove the Meter Circuit Board

(1) Remove the top cover and the front panel. (Refer to section

1.)

(2) Remove the front esc. ass'y, (Refer to section 2.)

(3) If you remove the five binding screws (3x8 CBTS -P tight)

of the meter circuit board, and loosening the five hooks, the

meter circuit board can be taken off.

Note; When replacing the tact switch, check to make sure

that It is not floating above the circuit board. If it is

floating, the switch will oe in the on condition when

the set is assembled

o

X

Page 7

Meter Circuit Board

5. How to Remove the Cassette Door

(1 ) Remove the MINIthA'I'JIPER'retaining screw J x 8 CBTS(P)-

B and take out thé MINI DAMPER,

(2) Hold the legs of the CASSETTE BOX folded inwards and

pull up to remove the CASSETTE BOX and BOX SPRING.

tDN-730RI

Front surface of Front Ass'y

6. How to Remove the Audio Circuit Board

(1) Remove the top cover and the front panel. (Refer to section

. 1.)

Remove the front esc. ass'y. (Refer to section 2.)

(21

Remove the connectors from the audio circuit boaid and

(3)

power supply circuit board.

Side of the Side of the

Power supply CN901 — (7P) — CN901 audio circuit

circuit board TBG board

' CONNECTOR

Note: • Almost all of the service repairs to the audio cir

cuit board can be performed by removing the

bottom cover on the rear side of the chassis

Only when it IS unavoidable should you refer to

the removal method mentioned above.

• When reassembling, follow the procedures in

the reverse order. However, if each of the various

parts are not assembled properly in their respec

tive position, the sel cannot be assembled in

somie cases. Therefore, check the work of each

step carefully when assembling.

How to Remove the Power Supply Circuit Board

Remove the top cover and the front panel. (Refer to section

1 )

Remove the bushing that is fixing the power supply cord

from the chassis.

When the five screws (4x19 CBTS-P tight) (3x10

(3)

CBTS-P tight) that are holding the power transformer and

chicuit board are removed, the power supply circuit board

can be removed by raising it.

Cress.s

Remove the screw (3 x 10 CBTS-P tight) (3 xBCBTS-S

(4)

tight) that is holding down the 4P pin jack and circuit board.

By removing the two catches (left and right) of the chassis

holding down the circuit board in the directions of the

arrows shown below, the audio circuit board can be pulled

forward.

Page 8

IE)N-730ni

ADJUSTING AND CHECKING THE

MECHANISM SECTION

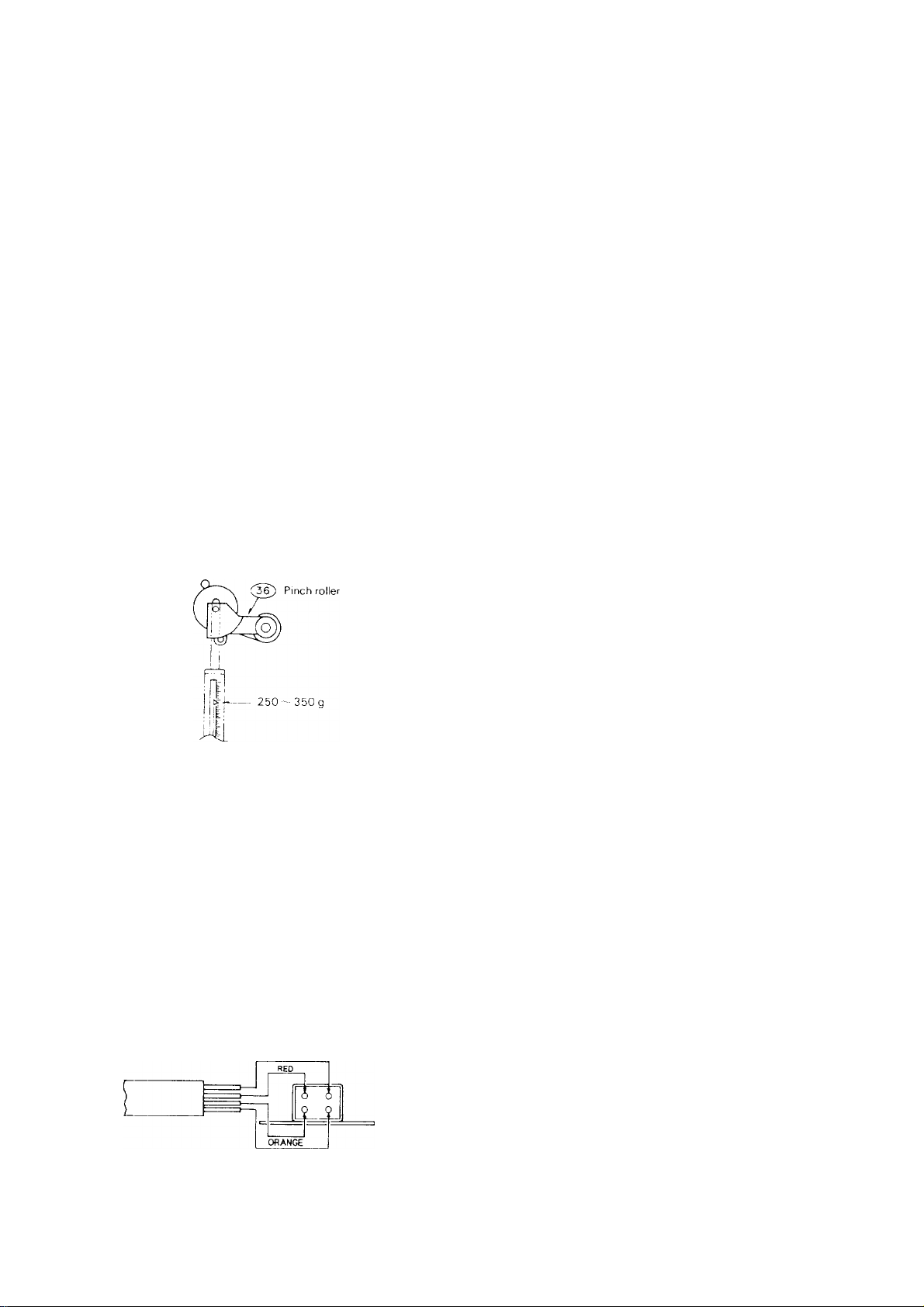

1. Replacing-the Pinch Roller (36)

Before replacing the pjnch roller, clean the tape contact surface

of the pinch roller and the capstan shaft.

Most causes of poor tape transport can be traced to dirty pinch

roller and capstan shaft. Remove the clips that press the pinch roller and pull the pinch

roller forward to remove it.

After replacing, run a padless C-90 tape to check for tape curls

at the tape guide section of the head.

2. Checking the Pressure Force of the Pinch

Roller (36).

In the playback mgdej^hpok a spring weight opto the bracket at

the center o* the pinch roller. After separating the pinch roller

from the capstan siTaft, allow the pinch roller to contact the caps

tan shaft again. Check to make sure the spring weight reads be

tween 250 ~ 350 g when the pinch roller starts to rotate

Replace the pinch roller (36) when it does not conform to the

standard specification values.

Capstan shaft

\

4. Replacing the ERASE HEAD (15)

(1) Unscrew the erase head holding screws (53).

(2) By unsoldering the HEAD W RES can be taken off the

mechanism unit.

(3) When the replacement is completed, secure the screws

with the screw lock.

white;

5. Checking the Take-up Torque

Load the cassette type torque meter (SONY TW21;1 1).

Check to make sure that the average torque meter reading is

within 30-70 g-crn during playback. If it is not within this range,

check the voltage (approx. 4V) of tha reel motor. If the voltage is

low, the torque will be weak: if it is high, the torque will be strong.

6. Checking the FF and REW Torques

Load the cassette type torque meter (SONY TW2231). Check to

make sure the torque meter indicates within 90—180 g-cm at

the end of FF and REW.

7. Checking the Back Tension Torque During

Record/Playback

Load the cassette type torque meter (SONY TW21 11) : check

to make sure the torque meter reads between 2 —6 g-cm during

playback and that there is no unevenness.

If it is not within this range, replace the reel ass'y (5) or Washer.

3. Replacing the Record/Playback Head (14)

(1) How to remove the R/P HEAD.

1) Remove securing screw (1) and azimuth adjusting

screw (1) from the record/playback head.

2) Remove the soldered head wire and disassemble the

mechanical unit to remove the record/playback head.

(2) How to assemble the R/P HEAD.

Reverse the above 1 procedures for removing the R/P

HEAD.

' Solder the HEAD WIRE according to the diagram,

mechanism (recording/play back head)

8. Checking the FF and REW Times

Load a C-60 cassette tape (DEMON GR-2/60): check to make

sure the tape is fast forwarded or rewound within 110 sec

onds. If it is not within this range, check sections 5 and 6.

9. Checking the Existence of a Cassette Housing and the Operation of the Erase Prevention, Metal and Chrome Switch

Confirm that the sensor arm properly detecting the tape t/pe de

tection holes on the cassette housina.

Page 9

DN-730RI

ADJUSTING AND CHECKING THE ELECTRICAL SECTION

e

Caution on adjusting

Before adjusting, clean the head surface, capstan and the

(1)

pinch roller with a gauze or a cotton swab moistened with

alcohol.

(2)

Demagnetize the R/P HEAD and the E. HEAD with a head

eraser

(3)

Completely demagnetize the adjustment screwdriver.

(4)

Unless instructed otherwise, set the various controls as fol

lows.

O INPUT volume

............................................................

maximum

O DOLBY NR switch................................................................OFF

O TAPE SPEED volume........................................Center position

1. Tape Transport Check

Load the transport check cassette. In the operational mode, illu

minate the fixing guides of the R/P HEAD with a lamp and check

to make sure the tape edge does not come in contact with the

tape guide section.

The tape transport is the most important element in determining

the performance of a cassette deck.

Avoid moving the various adjustment screws, nuts, etc., as much

as possible Refer to the pages on "Adjusting and Checking the

Mechanism Section" when replacing or adjusting the R/P HEAD.

3. Checking and Adjusting the Tape Speed

(1) Connect the frequency counter to the LINE OUT terminal

and load test tape (SONY TY-224).

(2) Playback a test tape. At about halfway through the tape,

where the tape transport is stable, adjust the adjustment

points (RT305) on the P.W. BOARD (222 2778 ♦**) so that

the frequency counter will have a reading within the

range of 3,000 Hz ±6 Hz. Fig. 3-1

F. Counter

PB Amp

LINE OUT

SONY TY-224

3000 I

3000 Hz

Í 6Hz

4. Adjusting the Playback and Recording

Section

Procedure Item

1 PLAYBACK

GAIN

2 P.B.

Frequency

REC/P.B.

3

Frequency

4

REC GAIN

REC/P.B.

5

Frequency

Usage tape —

input condition

A-BEX

TCC-130

A-BEX

TCC-162B,262B

GR-2/60

1 kHz, -40 dB

10 kHz, -40 dB

GR-2/60

1 kHz, -30 dB

GR-2/60

Dolby NR C

Response Mode

Fig. 4-1

Fig. 4-1

Fig. 4-2 REC. PLAY

Fig. 4-2 REC. PLAY

Fig. 4-3 REC. PLAY

PLAYBACK

PLAYBACK

1

PLAYBACK

1

PLAYBACK

i

PLAYBACK

Playback Fraquancy Raaponaa

Adjustment

iocation

RT-101 (L)

RT-201 (R)

RT-103 (L)

RT-203 (R)

RT-108 (L)

RT-208 (R)

Adjustment procedure

Adjust the LINEOUT output to 775 mV

(OdBs).

Make sure the playback characteristics

conform to Figure 4-2.

Record 1 kHz and 10 kHz alternately.

Adjust each volume so the 10 kHz

playback output is 0.5 dB in relation to

the 1 kHz playback output.

Adjust each volume to the playback output

is the same as when the recording monitor

is output.

Make sure that the DOLBY NR C recording

and playback characteristics conform to

Figure 4-3.

2.

Adjusting the Azimuth

After completing the tape transport check, load the test

(1)

tape (A-BEX TCC-153). Fig. 2-1

(2)

Playback the test tape; adjust the azimuth screw so that

section A of the resurge wave form is maximum and section

B is minimum. Fig. 2-2

OSCILLOSCOPE

RESURGE VYAVE

Y

O'

y

30'

Y

OK NG

O

90'

135'

180'

L-CM fl-CH

Fig. 3-1

Racord/Playback Ovarall Fraquancy Rasponsa

Tape HD-7E'60

Dolby NR Off

Level — 20 dB from Dolby Level

Dolby C Racord/Playback Ovarall Fraquancy Rasponsa

Fig. 4-1

Fig. 4-2

Fig. 4-3

Fig. 2-2

Page 10

I LJI\]- /LáUH I

EQUIPMENT FOR ADJUSTING AND CHECKING

MEASURING TAPE

II

TYPE NAME BRAND

TW-2111A/2121A SONY

TY-2231

GR-2/60 DENON

TCC-153 A-BEX

TY-224

TCC-130 A-BEX

TCC-162/262B A-BEX

TCC-902 A-BEX

2) MEASURING INSTRUMENT

Tension gauge

Audio signal generator

Variable resistance attenuator

Electronic voltmeter

Oscilloscope

Frequency counter

Adjustment screwdriver

Trap coil adjustment square stick

. TYPE NAME, BRAND AND USES

USES

Checking the Take-up Torque and

Back Tension.

SONY

Checking the FF and REW Torque

Checking the FF and REW Times.

Adjusting the Azimuth.

SONY

Checking and Adjusting the Tape

Speed.

Adjusting the Playback Level

Checking the Playback Frequency

Response

Transport checking cassette tape

NOTE FOR PARTS LIST

• Part indicated with the mark '' ® ” are not always in stock and possibly to take a long period of time for supplying, or in some

case supplying of part may be refused.

•When ordering of part, clearly indicate “1” and ‘T (i) to avoid mis-supplying.

• Ordering part without stating its part number can not be supplied.

• Part indicated with the mark is not illustrated inthe exploded view.

• Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol A WBSS have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

• Resistors

Ex.: RN

RD Carbon

Composition

RC

RS : Metal oxide film 2H . 1/2W

RW Winding

RN

. Metal film 3D 2W M

RK

Metal mixture

» Units; ohm

R 2

* Capacity (electrolyte only)

2 2 2

I ^

• Units: pF.

2 R 2 —

TL±

e Units: |iF.

14K

Type Shape Power Resist- Allowable Others

------------------

-----------------

2E 182 FR

and per

formance

2B 1/8W F

2E : 1/4W

3A . 1W K

3F

3H

1800 ohm “ 1.8 kohm

Indicates number of zeros after effective number

2-dlgit effective number.

-1,2 ohm

-1 -digit effective number.

-2-digit effective number, decimal point indicated by R.

2200pF

Indicates number of zeros after effective number,

- 2-digit effective number,

-2.2nF

-1 -digit effective number,

-2-digit effective number, decimal point indicated by R.

ance error

G

J ±5% NB . Non-burning type

3W

5W

1 formance | , 1

\

: ±1% P : Pulse-resistant type

±2%

NL : Low noise type

±10% FR Fuse-resistor

F

±20%

. Lead wire forming

• Capacitors

Ex.: ÇE 04W 1H ^ M ^

Type Shape Dielectric Capacity Allowable Others

1 and per- strength error

i I 1

CE . Aluminum (Oil

electrolytic

CA : Aluminum solid

electrolytic

CS : Tantalm electrolitic

Film

CO

CK

. Ceramic IV

CC . Ceramic 1H 50V

CP

Oil 2A 100V

CM ; Mica

CF

Meiaiized

CH

. Meiaiized

OJ

1A

1C : 16V J ±5% HR : Ripple-resistant type

IE 25V K

2B 125V P

2C 160 V

2D 200V

2E 250V D

2H

2J

* Capacity (except electrolyte)

2 2 2

-------------- 2200tiMF - 0.0022pF

I ^— (More than 2) — Indicates number of zeros after effective number.

^

------------------------------

e Units: pF

2 2 1

---------------

l—(0 or 1)

T

-----------------------------

• Units. PF.

a When the dielectric strength is indicated in AC. “AC" is included after the

dielectric strength value.

220PF

----------------

F

:6 3V

10V

35V

; 500V

630V

±1%

HS : High stability type

G . ±2% BP

: ±10% DL : For charge and discharge

M

±20% HF : For assuring high

Z : +80%

-20%

+ 100% W UL-CSA type

-0%

+025pF

C

±0.5pF

-

: Others

• Non-polar type

frequency

U : UL part

C : CSA part

F

. Lead wire foming

2-digit effective number.

Indicates number of zeros after effective number.

2-digit effective number

10

Page 11

□N-730R

PARTS LIST OF GU-2778 AUDIO/METER UNIT

■< Ref. No.

1 Part No.

SEMICONDUCTORS GROUP

IC301

iC3o;:

j

IC303

1C304

1C306

IC307

■ IC501 '

'lC601

i 1СЭ02

1 1СЭ03

IC309

IC602

1СЭ01

IC9C4

IC910, 911

TRI 01

TR102

TR103

TR104

TRIOS, 109

TR111~113

TR114, 115

TR201

TR202

TR203

TR204

TR208, 209

TR211-213

TR'307

TR.308

TR309, 310

TR370

TR371

TR507

TR508

TR515

TR552, 553

~P554~556

TF 557

TR558

TR559

TR560, 561

TR601

TH904

' DI55

D255

D315, 316

D320

D503

D517, 518

D553

D554

D601,602

D901~904

СЭ10, 911

C915, 916

ZD304, 305

ZD410

2D531

2D551

ZD552

¿:D907

I ZD912

ZD913

i

_

262 0590 001

1 262 08&ÌÌ106

263 0720 Ó04 _

263 C565 007

¡ 263 0711 000

1 263 0354 001

263 0565 007

! 262 0447 009

1 222 2045 001

1

262 1711 909

1 263 0810 008

I 263 0503 001

263 0793 002

263 3432 907

268 0072 003 ICJ’rotector ICP-NIO

269 0074‘*907’'|Trarrsistcir DTA114TS(10K) ^ Built in Resistor

269 0102 905 Transistor DTC124EKT146 Built in Resistor

273 024S900 | Transistor 2SC2603E/F T [

275 0048 912 ! Transistor 2SK381 (B)/(C)-T j

269 0038 906

____

269 0088 906

269 0102 905 I Transistor DTC124EKT146- | Built in Resistor

269 0074 907 ] Transistor DTAl 14TS(1 OK) j Built in Resistor

269 0102 905 Transistor DTCl 24EKT146 Built in Resistor

273 0245 900 i Trans stor 2SC2603E/F T |

275 0048 912 i Transistor 2SK381 (B)/(C)-T |

269 0088 906 ! Transistor DTCl 14TKT96 ; Built in Resistor

269 0088 906 I Transistor DTCl 14TKT96 | Built in Resistor

265 0040 902 j Transistor DTC144ES(47K-47K) 1 Built m Resistor

272 0025 907 j Transistor 2SB562iC)TF

273 0245 900 , Transistor 2SC2603E/F T

I 269 0018 905

! 269 0022 904

269 0062 906 ' Transistor DTC124E5(22K-22K) Built in Resistor

269 0016 907 i Transistor DTA144WS(47K-22K) Built in Resistor

269 0018 905 I TransistO' DTC143ES[4.7K-4.7K) Built in Resistor

269 0091 906 ^ Transistor DTC143TKT96 ' Built in Resistor

274 Q03B 905 ; Transistor 2SD468[C)TF j

269 0015 908 Transistor DTC124XS(22K-47K) | Built in Resistor

269 0082 902 I Transistor DTCl 14EKT96 ! Built in Resistor

269 0054 901 Transistor DTC144EKT96 , Built in Resistor

271 C183 92-7 ■ Transistor 2SA933(R/S)T93 i

269 C122 901 ‘ Transistor DTC144WKT146 | Built in Resistor

272 0025 907 '

276 0432 903 ¡

276 0432 903

276 0432 903

276 0432 903

, 2>

_ ’6 0432 903 i Diode 1 SS270A TE |

■ 2

276 0553 905 i Diode 1 SR35-200A{T93X) '

276 0432 903 : Diode 1SS270A TE j

276 0432 903 | Diode 1SS270A TE |

276 0553 905 I Diode 1 SR35-200A(T93X) |

2 76 0553 905 ' Diode 1SR35-200A(T93X) i

Transistor DTC114TKT96 | Built in Resistor

^6 0553 905 i Diode 1 SR35-200A(T93X) |

Part Name

TCUPC1330HA

1C UPG4570C 1C HA12170NT

1C BA15218

1C M5218AP

1C UPC1297CA

1C BAI 5218

1C BA6109U1

^ Computer UPD78043GF-

100-3B9

IC X24C00S

1C NJM7808FA(S)

IC NJM7908FA

IC NJM7806FA(S)

IC NJM78L05AT

Transistor DTC114TKT96 ! Built in Resistor

I

Transistor DTC143ES(4.7K'4.7K) Built in Resistor

Transistor DTA143ES(4.7K-4.7K) Built in Resistor

Transistor 2SB562(C)TF .

Diode 1SS270A TE

Diode 1SS270ATE |

Dioce 1SS270ATE

Diode 1SS270ATE |

Diode 1SR35-200A{T93X}

Zener Diode HZS9B-1TD

Zener Diode HZS9B-1TD

Zener Diode HZS9B-1TD

Zener Diode HZS4C-1TD

Zener Diode HZS7B-1TD |

Zener Diode HZS6C-1TD

Zener Diode HZS27-1TD

Zener Diode HZS11C-1TD

i

i

j

Remarks

Ref. No.

RESISTORS GROUP

(not included Carbon Film ±

VR101

i

VR103

VR108

VR201

VR203

VR208

VR301

VR304

VP305

R101, 102

R103

R104

R105

R108

R41

R112

R118

R120

RI32

R135

R140

R141

R142

R143

R144

R145

R150

R151

AR152

R156

R160

L

R161

FÌ162

R163

R164

R175

R177

R173

RISO

RISI

RI 89

R199

R201, 202

R203

R204

R205

R208

R212

R218

R220

R229

R232

R235

R240

R241

R242

R243

R244

R245

R250

R251

Part No.

211 6093 967

211 6093 970

211 6093 954

211 6093 967

211 6093 970

211 6093 954

211 0707 000

211 0835 008

211 6093 912

247 0010 987

247 0005 947

247 0010 974

247 0014 912

247 0014 967

247 0008 960

247 0009 ÍM3

247 0009 985

247 0010 929

247 0006 962

247 0007 '945

247 0011 986

247 001 1 944

247 0012 927

247 0010 929

247 ООП 902

247 0005 905

247 0012 969

247 0010 929

‘241 2315 912

247 0005 905

247 0010 961

247 0012 927

247 0010 961

247 0006 988

247 0006 975

247 0014 967

247 0007 974

247 0009 914

247 0009 901

247 0008 902

247 0017 906

247 0010 974

247 0010 987

247 0005 947

247 0010 974

247 0C14 912

247 0014 967

247 0009 943

247 0009 985

247 0010 929

247 0009 956

247 0006 962

247 0007 945

247 0011 986

247 ООП 944

247 0012 927

247 001 о 929

247 0011 902

247 0005 905

247 0012 969

i 247 001 о 929

Part Nam6:

-5% 1/4 W type)

Adjust 47K ohm

Adjust 100K ohm

Adjust 22K ohm

Adjust 47K ohm

Adjust 100K ohm

Adjust 22K cihrn

Valiable 100K ohm (INPUT)

Valiable 5K ohm

Adiust 4.7K ohm

Ch p 27K ohm

Ch.p 150 ohm

Chip 24K ohm

Chip 620K ohm

Chip IM ohm

Chip 3.3K ohm

Chip 6.3K ohm

ChiplOKohrr

Chip 15K ohrr

Chip 470 ohm

Chip IK ohm

Chip 68K ohiTi

Chip 47K Ohm

Chip 100K ohm

Chip 15K ohm

Chip 33K ohm

Chip 100 ohni

Chip 150K ohm

Cnip 15K ohm

Carbon Him 10 ohm 1/4W

¡Fusible) ; . uuh

Chip 100 ohn

Chip 22K ohm

Chip 100K ohm

Chip 22K ohm

Chip 560 ohm

Chip 510 ohrn

Chip ’ M chn

Cihip 1,3K ot m

Chip 5.1 К ohm

Chip 4.7K ohm

Chip 1,8K ohm

j Chip lOM ohm

j Chip 24K ohm

Chip 27K ohm

Chip 150 ohm

Chip 24K oh m

Chip 620K C'hrr

Chip IM ohm

i Chip 6.SK ohmi

i Chip lOK ohm

Chip 15K ohm

Chip 7.5K ohm

i Chip 470 ohm

Chip IK ohm

Chip 68K oim

Chip 47K onm

Chip 100K ohn

Chip 15K ohm

Chip 33K ohm

Chip 100 onm

Chip 150K ohm

Chip 15K chrr

Remarks

V06PB473T

V06PB104T

V06PB223T

V06PB473T

V06PB104T

V06PB223T

V09V25FA104. i

V16V25Í-B502MG

1

V06PB472T

I

RM73B-273JT

I RM73B-U51JT I

RM73B--243JT '

I RM73B-624.T !

I RM73B--105.T ;

RM73B--332JT '

I RM73B-6S2JT i

RM73B-103JT

RM73B-153JT

RM73B-.471.it

RM73B-102.JT '

RM73B-683.JT

RM73B-473JT

RM73B-104JT

RM73B-153JT

RM73B-333JT

RM73B-101JT

RM73B-154JT

RM73B-153JT

RD14B2E100GFnST

-101JT

RM73B

-223JT

RM73B-

104JT

RM733-

■223JT

RM73B-

-561JT

RM73B-

-51IJT

RM73B

105JT

RM73B-

-132JT

RM73B

■-512JT

RM73B-

-472JT

RM73B-

-182JT

RM73B-

-106KT

RM73B-

-243JT

RM73B-

-273JT

RM73B-

-1E4JT

RM73B-

-243JT

RM73B-

-624JT

RM73B

-105JT

! RM73B-

-682JT

RM7 3B

--103JT

RM73B

-153JT

RM73B

--752JT

j

RM73B-

-471JT

RM73B-

-102JT

; RM73B-

■633JT

j

RM73B-

--473JT

1 RM73B-

-104JT

j RM73B

-153JT

RM73B

-333JT

RM73B-

-101JT

i RM73B-

-154JT

RM73B

-153JT

RM73B-

j

j

j

i

11

Page 12

IDN-‘730R I

Ref. No.

r-7 - -■'

fáSR25:

: R253

i R256

Í

R257

1 R260

I

R261

' R262

R263

' R280

R289

R299

, R301

■ R321

R330

R331

, R332

' R334

R336, 337

R360, 361

R36¿*363 .

R364

R365

R370. 371

R401,402

, R403

R404

R405

R406

: R501-506

■ R507

: - R508

R510, 511

R513, 514

^ R516

R518

R520, 521

R540

R556

R557

R558

R559

R560

R561

R562

1

а \ н5б з у

R564. 565

- R571

R573 : 247 0009 956 1 Chip 7.5K ohm

R574 : 247 0009 985 | Chip 10K ohm

R577-580 ^ 247 0012 927 ' Chip 100K ohm

R581 ; 247 0012 927 Chip 100K ohm

R602 247 0010 916 ChipISKchm

R603, 604 247 0007 945 i Chip IK ohm

R605. 606 247 0012 927 ' Chip 100K ohm

R610. 611 I 247 0007 945 | Chip 1К ohm

R612 i 247 0007 945 | Chip IK ohm

R613 247 0009 985 | Chip 10K ohm

R650 247 0005 947 : Chip 150 ohm

R652 247 0005 963 | Chip 180 ohm

R654 .247 0006 917

R660 , 247 0005 947

R662 247 0005 963

R664 247 0006 917

R666 247 0006 956

R670 247 0005 947

R672 247 0005 963

R674 247 0006 917

R676 j 247 0006 959

■ Part No.

241-2315 912

247 0009 aS5

247 0005 905

241 ТЮ14 907

'247 001СГ 961

247 0012 927

247 0010 961

247 0006 988

247 0008 944

247 0017 906

247 0010 974

247 0010 961

247 0010 945

247 0009 985

247 0009 901

241 0007 987

, 247 0007 961

j 247 0008 así

: 247 0012 943 1

1 241 2815 925'!

247 0009 901

247 0009 985

247 0001 983 ;

247 0012 943

1 247 0012 Э27

24.7 0005 989

, 247 0004 922

' 247 0012 927

247 001 2 927

247 0011 944

247 0015 940

( 247 0011 944

1 247 0012 927

247 0018 905

1 247 0009 985

; 247 0009 985

' 247 0009 985

247 0010 961

247 0009 985

247 0010 961

247 0009 985

247 0007 945

244 2055 970

247 0007 987

1 241 2з!?912

247 0009 985

247 0018 905

Chip 10K ohm

Chip 100 ohm

Chip 1M ohm

Chip 22K ohm

Chip TOOK ohm

Chip 22K ohm

Chip 560 ohm

Chip 2.7K ohm

Chip 10M ohm

Chip 24K ohm

Chip 22K ohm

Chip 18K ohm

Chip 10K ohm

Chip 4.7K ohm

Chip 1.5K ohm

Chip 1,2K ohm

Chip-3Kohm >

Chip 120K ohm

Carimn Film 22 ohm 1/4W (Fusible)

Chip 120K ohm

Cnip 100K ohm

Chip 220 ohm

Chip 47 ohm

Chip 100K ohm

Chip 100K ohm

Chip 47K ohm

Chip 2.2M ohm

Chip 47K ohm

Chip 100K ohm

Chip 0 ohm

Chip 10K ohm

Chip 10K ohm

Chip 10K ohm

Chip 22 ohm

Chip 10K ohm

Chip 22K ohm

Part Name

Chip 300 ohm

Chip 150 ohm

Chip 180 ohm

Chip 300 ohm

Chip 430 ohm

Chip 150 ohm

Chip 180 ohm

Chip 300 ohm

Chip 430 ohm

Remarks !

RD14B2E100GFRSt|

RM73B-103JT

RM73B-101JT

RM73B-105JT

RM73B-223JT

RM73B-104JT

RM73B-223JT

RM73B-561JT

RM73B-272JT

RM73B-106KT

RM73B-243JT

RM73B-223JT I

RM73B-183JT i

RM73B-103JT I

RM73B-472JT I

RM73B-152JT

RM73B-122JT

RM73B-302JT

RM73B-124JT j

RD14B2E220GFRST |

RM73B- 472JT

RV173B--103JT

RM73B--4R7KT

RM73B-124JT

RM73B-104JT

RM73B--221JT

RM73B-470JT

RM73B-104JT

RM733-104JT

RM73B-473JT

RM73B-225JT

RM738-473JT

RM73B-104JT

j RM73B-0R0KT

RM73B-103JT

RM733-103JT

RM73B-103JT

RM73B-223JT

! RM73B-103JT

RM73B--223JT

RM73B--103JT

RM73B-102JT

RSi4B3A560JST(s:i

RM73B-152JT

I RD14B2E100GFRST

RM75B-103JT

RM73B-OROKT

RM73B-752JT

RM73B-103JT

RM73B--104JT

RM73B-104JT

RM73B'-133JT

RM73B--102JT

RM73B-104JT

! RM73B-102JT

RM73B-102JT

RM73B-103JT

RM73B-151JT

RM73B-181JT

RM73B-301JT

RM73B-151JT

RM73B-181JT

RM73B'-301JT

RIV173B-431JT

RM73B-151JT

RM73B-181JT

RM73B-301JT

RM73B-431JT

Ref. No.

Part No.

_L

CAPACITORS GROUP

C101

Cl 03

Cl 09

Cl 27

C142

C150

C151

C152

Cl 53

C154

Cl 55

C201

C203

C209

C227

C242

C250

C251

C252

C253

C254

C255

C350 ■

C352

C353

C354

C355

C356

C402

C403

C501-504

C506

C507

С50Э, 510

C512, 513

C515, 516

C517

C551, 552

C553

C554

C555

C601-603

C6Ü4

C902, 903

C906, 907

C908

C910

СЭ11

C913

C918

R126

R169

R226

R269

257 0008 996

257 0009 979

257 0009 937

257 0005 902

257 0005 944 i

257 0008 996

257 0010 900

257 0004 961

253 1131 909

257 0011 967

257 0010 942

257 0008 996

257 0009 979

257 0009 937

; 257 0005 902

¡ 257 0005 944

I

257 0008 996

257 0010 900

257 0004 961

j 253 1131 909

i 257 0011 967

; 257 0010 942'

I 257 0013 907

I 257 0002 921

I

257 C009 940

257 0009 940

257 0010 900

! 257 0009 995

I 257 0002 92"

j 257 0014 935

■ 257 0008 983

257 0008 983

257 0008 983

257 0010 900

I 257 0008 983

! 257 0008 983

257 0013 910

. 257 0010 900

^ 257 0011 941

257 0010 900

254 4403 71 3

i 257 0008 983

257 1013 977

i 254 4403 713

257 0013 910

254 4403 721

254 4250 796

257 0Ü13 910

25^1 4414 707

257 0013 910

257 0008 983

257 0008 967

257 0008 983

257 0008 967

OTHER PARTS

LlOl

LI 03

LI 04

L105

L201

L203

L204

L205

L301

232 0109 003

235 0020 945

235 0020 916

239 0010 009

232 0109 003

235 0020 945

235 0020 916

239 0010 009

231 0078 005

Part Name

Chip (Cerarnici 0.0012 |iF/50 V

Chip (Ceramic) 0.0056 ¡iF/SOV

Chip (Ceramic) 0.0027 u.F/50 V

Chip (Ceram c) 150 pF/50 V

Chip (Ceram, c) 220 pF/50 V

Chip (Ceramic) 0.0012 pF/50 V

Chip (Ceramic) 0,01 pF/50 V

Chip (Ceram c) 100 pF/50 V (

Ceramic 390 pF/500 V i

Chip (Ceramic] 0,033 pF/25 V |

Chip (Ceramic) 0.022 pF/50 V 1

Chip (Ceramic) 0.0012 u.F/50 V j

Chip (Ceramic) 0.0G56 pF/50 V i

Chip (Cera Tiic) 0.0C27 pF/50 V i

Chip tCeramic) 1 50 pF/50 V

Chip iCeramic) 220 pF/50 V-^

Chip [Ceramic 0.0012 uF/50 У -|

Chip (Ceramic) 0,01 u.F/50 V !

Chip (Ceramic) 100 pF/50 V i

Ceramic ЗЭС pF/500V '

Chip (Cerarnici 0.033 uF/25 V (

Chip (Cerarnici 0.022 uF/50 У !

Chip (Ceramic) 0.047 uF/50 У

Chip (Ceran'ic) 10 pF/50 V

Chip (Ceramic) 0,0033 pF/'50 У i

Chip (Ceramic) 0.0033 uF/50 V ;

Chip (Cerarr ic) 0.01 uF/50 V i

Chip (Ceramic} 0.0082 |iF/50 V

Chip (Ce'ariic) 10 pF/50 V j

Chip (Ce'arriic) C.l jiF/50 V '

Chip (Ceramic) 0.001 uF/50 У

Chip {Ceramic) 0.001 uF/50 V

Chip (Ceramic) 0.001 pF/50 V

Chip (Ceramic) 0.01 uF/50 V

Chip (Cera.mi:) 0.001 uF/50 V

I Chip (Ceramic) 0.001 uF/50 V

j Cnip (Ceriimic i 0,058 uF/50V

: Chip iCeramic') 0.01 uF/50 У

1 Chip iCeram.iC) C.022 uF/25 V

j Chip iCera.micl 0 01 uF.'OO V

i Electrolvtic 1000 pF/25 V

Chip ■Ceramic) O.ODl pF/50 У

Chip (Ceramic) 0.C68 uF/50 V

Electrol\tic 1000 pF/25 V

Chip ;Cer smic) 0.068 uF/50 V

' Electralytic 2200 uF/25 V

I Electrolytic 4700 uF/6.3 V

; Chip (Ceramy) 0.C58 i.iF/50 V

Electrolytic 470 uE/50 V

■ Chip (Ceram:) 0.068 uF/50 V

j Chip (Cetamie) 0,001 uF/50 У

I Chip iCerarnic) 380 pF/50 V

I

Chip (Ceramm) 0 001 pF/50 V

I Chip iCeramic) 680 pF/50 V

МРХ Filter

Inductor 163JT

Inductor 8:¿2JT

HX Step up coi

MPX Filter

Inducto' 153JT

Inducto' 822JT

HX Step u|) coil

OSC Coil j

Remarks

CC73SL-H122JT

CK73B1H562KT

CK73B1H272KT

CC73SL1H151JT

CC73SL1H221JT

CK73B1H122KT

CK73B1H103KT i

CC73SL1H101JT I

CK45B2H391KT |

CK73B1E333KT

CK73B1H223KT

CC73SLIH122JT

СК73В1Ч562КТ

CK73B1 H272KT

CC73SL1H151JT

CC73SL1H151JT

CK73B1H122KT

CK73B1H103KT

CC73SL1H101JT

CK45B2H391KT

CK73B1E333KT

CK73B1H223KT

CK73B1H473ZT

CC73SL1H100DT

CK73B1H332KT

CK73B1H332KT

CK73B1H103KT

! CK73B1H822KT

I

CC73SL1H100DT

CK73F1E104ZT

CK73B1H102KT

CC73B1H102KT

CK73B1H102KT

; CK73B1H103KT

CK73B1H102KT

CK73B1H102KT

c:<73B’ H683ZT

C<73B'H103KT

C<73B'E223KT

C<73B‘ H103KT

ci;04vv'ii02Mc;sMG

CK73B1H102KT

CK73B1H683KT

C::04 VV1 E10 2:> .1C S: \1G

CK73BIH683ZT

CE04 W1E 222M CS MG

CE04 WOJ4 72 MC iSMCl

CK73BIH683ZT

CE04 W1H 471M CSM G

CK73B1H683ZT

CK73B1H102KT

CK73B1H681KT

CK73B1H102KT

; CK73B1H681KT

I

12

Page 13

Re1. No.

XT501

FL601

SW610, 612,

614,

620, 622,

624,

628, 630,

632. 634,

636, 638,

JK301 204 8261 003

JK302 : 204 8264 026 Head phone Jack

JK303 204 8416 007 Mini Jack

CN121 ; 205 0880 003 23P FFC Connector Base

CN122 i 205 0343 061 6P Connector Base (KR-PH)

CN131

CN141 ■ 205 0343 049 4P Connector Base (KR-PH)

CN191 205 0711 075 7P TBG Connector Base

CN301

CN302 i 205 0:i43 032 3P Connector Base (KR-PH)

W122 ! 204 0265TI78 6P KR-DA Connector Cord

W131

W141

W151 204 2326 009

WÌ51 1 203 6236 066 4P KR'DA Connector Cord

W252

WARNING:

• Pans marked with .T;, and/or shading have special characteristics important

to safety.

Be sure to use the specified parts for replacement.

Part No.

399 0107 007

393 8002 009

212 5604 910

616,

626,

205 0343 032 3P Connector Base (KR-PH)

, 205 03143-05^.

j 203 4753 046

! 203 6374 025 4P KR'DA Connector Cord

' 203 8216 042 5P KR-DA Connector Cord

Part Name

Ceramic Oscillator

£L Tube

Tact Switch

4P Pin Jack

Connector Base (KR-PH)^,

3P KR-DA Connector Cord

7P KR-DA Connector Cord

CTS4.19MGW

F1P6BGM6

LINE IN, OUT

HEAD PHONE

CD SYNCRO.

Remarks

iDN-yaOR

PARTS LIST OF 3U-2603 POWER SUPPLY UNIT

Ref. No.

SW901

CN191

CN901

ii' C901

4^' ' .

h F901

.'îi

WARNING:

• Parts marked

to safety.

Part No. Part Narne

212 0286 003

205 0711 075

205 0581 001

253 8014 702

445 0056 008

206 2089 009

206 2123 009

206 2110 004

206 7088 000

■

233 5985 005

233 5758 009

233 5760 000

206 1031 045

202 0022 0C3

212 4698 008-

with

Power Switch

7P TBG Connector Base

2P VH Connector Base

Ceramic Capacitorff.Ci‘uF/400VAC

Cord Bush ' ; ' ' iXt} i

AC Cord With Connector-M;

AC Coni Wilh Connector’.^AC Cord With Connector'^'j

AC Cord Wi»h Connector, **

Power Transforncr r }■

Power Trans .

P.jwer Tr.i'is'oinor ‘

Fuso 10 25'A

I Fuse Holder . - " 3^-^

j Voltage Selecioi (D)

and/or shading have special characteristics important

For AC Core

CK45f2GAC103MC

USA Canada^’r";

Multi-Voltage '

I Multi-Voltage Only

I Multi-Voltage Only

|MiHl^Voltage Only

Remarks

13

Page 14

l[DN--y30RI

PARTS LIST OF EXPLODED VIEW

Ref. No.

• 1

•; 2

•) 3

4

Í. 5

.Í,

A .

A 6 ,

A 1 "

A

A-

A -

A 8

• 9

• n

12

. 13

, 13-1

, 13*2

* 13-3

• 13-4

. 14

15

16

18

19

21

22

- 23

25 431 0310 046

26

27 113 1436 393

28 113 1480 255

29 113 1438 045

30

31

• 32

* 33

• 34

35 103 1511 318 CASSETTE BOX

36

37 463 Ò659 018 BOX SPRING [R)

38 103 1660 007

39

• 40 414 0595 015

• 41 203 2279 014 2C TERMINAL WIRE 3T

• 45 102 0434 419

• 46 473 8047 001 SPECIAL SCREW

• 47 412 3676 207 EJECT LEVER

• 48

• 49 463 8238 004 SPRING

• 50

• 51

• 53

* 54 412 3942 009 VOLUME BRACKET

101 473 7508 017 3 X 10 CBTS(P)-B

102

103

104

105 473 7500 044 3X8 CBTS(P)-B

106 473 7002 018 3X8 C8TS(S)-Z

107

108

■ Part No.

411 1000 652 CHASSIS

411 1000 681

411.1000 665 CHASSIS

412 2523 115

105 0787*107

338 0168 009 CASSETTE MECHANISM

■'233'^'5«)5'

233 5758 009

233 5760 000

CHASSIS

EARTH BRACKET

BOTTOM COVER

^ER'TRANSFORMER ’' Europe, U.K, .

POWER TRANSFORMER -

POWER TRANSFORMER

212 0286 003 POWER SWITCH . , •

206 2089 106 i AC CORD WITH CONNECTOR J

206 2128 009 AC CORD WITH CONNECTOR

206 2110 004

AC CORO WITH CONNECTOR. ’ ■

206 2088 000 AC CORD WITH CONNECTOR ' '

445 0056 008

412 2008 012 BUSHING PLATE

414 0637 009 SHIELD LABEL

104 020a2-U^ FOOT ASS’Y 1.

GU-2778

—

— METER P.W.B.

— H/P JACK P.W.B.

3U-2603

205 0712 074

204 8261 003 4P PIN JACK

211 0707 000

412 3951 003

211 0835 008

204 8264 026 HEAD PHONE JACK

393 8002 009 EL TUBE (FIP6BGM6)

113 1481 364 PUSH KNOB (B)

112 0515 173 VOLUME KNOB

112 0727 042 VOLUME KNOB (C)

103 1650 101

143 0765 215 METER WINDOW

144 2309 216

463 0655 009 CASSETTE SPRING

421 9007 007 MINI DAMPER

412 3628 006

412 3677 015

445 8028 009 CORD HOLDER

513 2150 001 WARNING SHEET

477 0262 006 SPECIAL SCREW

473 7502 013 4 X 10 CBTS(P)-Z

473 7509 058 4X12 CBTS(P)-B

473 7007 039

471 3102 013 2 X 5 CBS-Z

CORD BUSH , , •

AUDIO/METER P.W.B UNIT

AUDIO P.W.B.

VARI PITCH P.W.B,

POWER TRANS P.W.B. UNIT

7P TBG-S CONNECTOR

VARIABLE RESISTOR 100K

REFLECTOR

VARIABLE RESISTOR 5K

POWER SWITCH LEVER

ASS'Y

FUNCTION KEY

PUSH KNOB (A)

EJECT KNOB

FRONT ESCUTCHEON ASSY iTK)

FRONT PANEL

CASSEHE WINDOW lA) ASS'Y

EARTH PLATE

TOP COVER

LEVER STAY (B|

MOUNT BRACKET

4 X 20 CBTS(S)-B

Part Name

Remarks

Europe, U.K.

U.S.A., Canada

Multi-Voltage

U.S.A., Canaria ,

Multi-Voltage

(SW001) ' ' ■

Europe

U.K.

U.S.A., Canada '

Multi-Voltage 7. »•

(jK3oi:

V0920V25FA104

V1620V35FA502 (MG)

(FL601)

WARNING:

• Parts marked with

to safety.

Be sure to use the specified parts for replacement.

• Part indicated with the mark are not always in stock and possibly to take a

long period of time for supplying, or in some case supplying of part may be

refused.

and/or shading have special characteristics Important

14

Page 15

EXPLODED VIEW

IDN-730RI

ao4).._

WARNING:

Parts marked with this symbol A EM have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

D

15

Page 16

IUN-‘/3aRI

EXPLODED VIEW OF CASSETTE MECHANISM

16

Page 17

I DN-73DRI

PARTS LIST OF CASSETTE MECHANISM EXPLODED

VIEW

Ref. No.

2

3

4

5

6

7

8

10

11

12

13

14

15

16

») 17

18

19

20

21

24

25

26

27

28

29

30

31

32

33

34

36

38

39

40

41

42

43

44

51

52

53

54

Part No.

9DF 5170 49

9DF 5642 85

9DF 6121 51

9DF 6230 37

9DF G156 11A

9DF Jill 17

9DU J12V 11

9DF C52E 47

9DF K26N 14

9DF D45T 17

9DF U192 11

9DF U18K 12

9DF K21U 11

9DF 5252 56

9DF 5673 52

9DAW13G 00

9DU E16E 11

9DF C39S 33

9DF C52H 12

9DF D45G 21

9DF D45B 16

9DF D44T 14

9DF D44Y 12

9DF D44V 12

9DF F17W31

9DF J111 30

9DF Jill 14

9DF K28M 12

9DF K28R 11

9DF R22H 11

9DF R20L 22

9DF G114 14

9DF G15S 11A

9DU G13U 15

9DU G20B 11

9DF 7652 63

9DF L39H 12A

9DF L39K 12

9DW H63P 05

9DW H55L 05A

9DF G137 18

9DF F17C 12

Part Name

IDLER

REEL MOTOR

CHASSIS BASE

REEL BASE

SCREW 2.6 X 6.4 ZN

WASHER 1.7 X 0.25T

POLY WASHER 2.1 X 0.25T

HEAD BASE

HB SPRING

HEAD SPACER

ERASE HEAD

R/P HEAD

SPRING

MAIN MOTOR

CONTROL P.W.B. Ass'y

REEL SENSOR (GP2S04B)

PUSH SWITCH

EJECT PROTECT ARM

CASSETTE SPRING

PLAY ARM

CAM GEAR (3R)

REC. SENSOR LEVER

PACK SENSOR LEVER

METAL SENSOR LEVER

MAIN BELT

POLY WASHER 2.6 X 0.25T

POLY WASHER 2.6 X 0.5T

EJECT PROTECT SPRING

SLIDE SPRING

FLYWHEEL Ass'y

PINCH ROLLER Ass'y (R)

SCREW 2.6 X 5 ZN

SCREW WITH STEP (7.7)

E RING

WAVE SCREW 3 X 8 ZN

SOLENOID

IRON CORE

PLUNGER

ERASE HEAD CORD

R/P HEAD CORD

2 X 9F LOCK SCREW

HOLDER CUSHION

Remarks

PARTS LIST OF PACKING & ACCESSORIES

Ref. No. Part No. Part Name Remarks Q'ty

1 505 8092 007 LAMINATE ENVELOPE FOR SET 1

3

4 501 1698 037

5 505 0038 030 POLY COVER

6

7 399 0250 006

8

9 203 4880 003

10 515 0692 004 DEL WARRANTY COM U.S.A. Only 1

11 502 0852 000

m ^

WARNING:

• Parts marked with ^ and/or shading have special characteristics important

to safety.

Be sure to use the specified parts for replacement.

503 1079 005 CUSHION 2

501 1853 005

511 2682 007 INST. MANUAL (5) 1

203 2360 004 2P PIN CORD 2

CARTON CASE 1

CARTON CASE U.K. 1

REMOTE UNIT (RC^I) 1

3P MINI PLUG CORD 1

PAD ASS'Y

U.K. Only

PACKING & ACCESSORIES

1

1

17

Page 18

lUN- 73GHI

ì P.W. BOARD OF GU-2778 AUDIO/METER UNIT

D

18

Page 19

P.W. BOARD OF 3U-2603 POWER SUPPLY UNIT

IDN-730RI

Remarks

1. The following table shows the power circuit parts used for the 3U-2603 board by area.

2. Parts used are marked O, parts not used —.

Ref.No.

Areas

Europe (E2)

U.K. (EK)

Multi-Voltage (E1)

U.S.A. & Canada (E3)

Power T rans

part No.

2335985005

2335760000

2335758009

Voltage

Selector

- -

— -

O

-

FUSE

F901

O

-

JV901

o

o

--

o

JV904 JV905 JV908

JV903

- -

o

-

o

O

-

-

o

-

-

- -

-

-

O

19

Page 20

IDN-TSORI

SEMICONDUCTORS

• 1C

M15218AP

|.iPC4570C

TL4558

3 GND

2 INPUT

1 OUTPUT

• NJM7908

3 INPUT

2 GND

1 OUTPUT

• NJM7808

• NJM7806

20

/LtPC1330HA

Page 21

^ 2

Q P,

<

g

H

fO ro _

с

<<O

M O

<

O

X

O

Z

о

< с

< N Н

Г О -, —

СЛ СЛ

J3 СЛ

w M

X X X X I

rsi N fSI N1 NJ

СЛ СЛ (Л СЛ СЛ

<D 0> 0> 05

Ш 9 ro n О

NJ CO

X X X X

N1 N1 N rsl

СЛ СЛ (/) СЛ

CO Ю -»

ro Ш ^

PO M ^

• •

о о

H -I

n о

11

m <

о

5’

Q.

(D

(Л

со PO —‘

О ГО

О ш

— v>

Q)

3

3

w

rô

O

-Ч

t/l

t

О Q

Н Н

> >

1

• • • •

о о о о

н н н н

о о о о

^ ^ PO PO

''Р

• •

О о

-I н

о о

со -с>.

7^ X

5

1

■:5

гЛ

со 4^ .1^

m m >< m

(Л (/> (Л (Л

O

—<

O

'^O

СЛ СЛ

O ro

^ en

05 05

00 M

ri

00

c

g

>

O

J3

>

L .J

□

Z

I

\l

Cjü

□

I

I

Page 22

IDN-yaORI

WIRING DIAGRAM

LINE IN

LINE OUT

GU-2778-1

AUDIO P.W.B

JK301

GU-2778-3

HEADPHONE P.W.B

JK302

PHONES

JACK

O c c i S

R a: u o (0 5

9 £ _/ o: □ o ^

Q i O O < “ ^

>zO's\iuQ:a:_

K>o(L<<x>>a:

Q®(5X^>SX6X5®®®(»^^ —

_J Lii

< 2 _l

2 O <

or q: h

O Z u

z o 2

GU-2778-2

CONTROL P.W.B

o o

N. lU

CD QL

(/}

^ LU

O (~

cg o

S 2 2

O < lU

N CD q:

CN122

r

_____________

W122

z o X ^ o r?

LU LU

-J -I

o o

(0 (0

3U-2603

POWER SUPPLY P.W.B

1

0

22

Page 23

SCHEMATIC DIAGRAM

IDN-yaORI

Note: • Resistance shall bp 1/4 W unless othen/vise specified and

the unit is ohm.

• The unit of capacitor is pF, P is pF unless otherwise speci

fied.

• This circuit diagram shows the basic circuit It is subject to

change for the purpose of improvement.

Parts marked with this symbol A M have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

23

Page 24

□N-730RI

Page 25

DENON

Loading...

Loading...