Page 1

Ordering number: EN5244

Monolithic Digital IC

LB1696

3-phase Brushless Motor Driver

Overview

The LB1696 is a 3-phase brushless motor driver IC that is

ideal for driving DC fan motors in air conditioners, hot-water

supply systems, and the like. The LB1696 has a regulator built

in, and can be used with a single power supply (motor power

supply only).

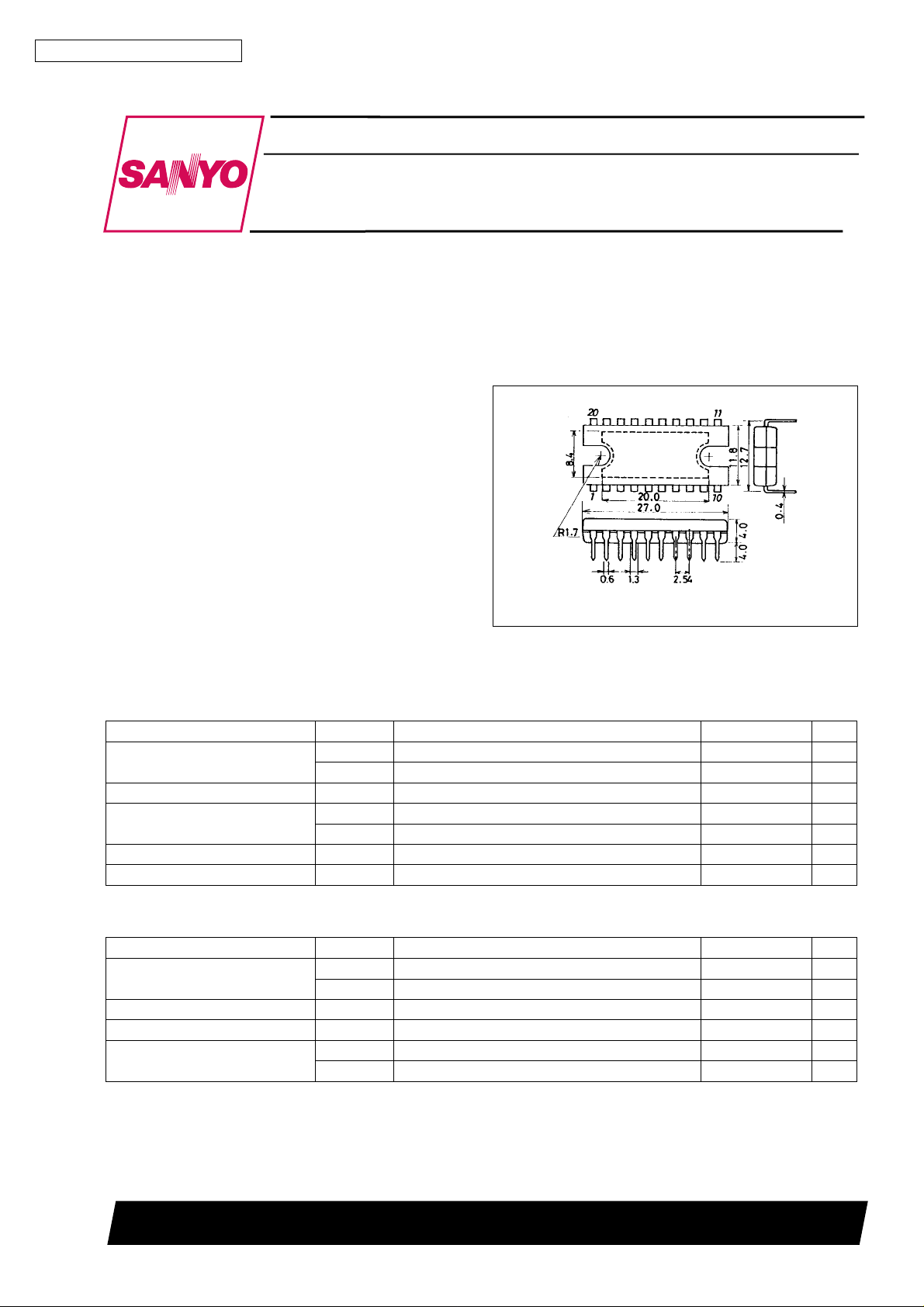

Package Dimensions

unit : mm

3037A-DIP20H

[LB1696]

Features

.

3-phase brushless motor driver.

.

Withstand voltage: 60 V; output current: 2.5 A.

.

Current limiter built in.

.

Low-voltage protector built in.

.

Thermal shutdown protector built in.

.

Hall amplifier with hysteresis built in.

.

FG output function.

.

Regulator built in.

SANYO : DIP20H

Specifications

Absolute Maximum Ratings atTa=25°C

Parameter Symbol Conditions Ratings Unit

V

max 10 V

Maximum supply voltage

Output current I

Allowable power dissipation

Operating temperature Topr –20 to +100

Storage temperature Tstg –55 to +150

CC

V

max 60 V

M

O

Pd max1 Independent IC 3 W

Pd max2 With arbitrarily large heat sink 20 W

2.5 A

C

°

C

°

Allowable Operating Ranges atTa=25°C

Parameter Symbol Conditions Ratings Unit

V

Supply voltage range

Regulator input voltage V

V

pin output current I

REG

Power supply voltage rise rate

*1 If the supply voltage rise rate is fast when power is applied, through current may flow to output.

CC

V

M

(REG) 7 to 56 V

M

REGO

∆V

/ ∆tVCC=V

CC

∆V

/ ∆tVM= 0 V point*1 to 0.16 V/µs

M

(OFF) point*1 to 0.04 V/µs

LVSD

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

D3095HA(II) No.5244-1/9

4.5 to 6.0 V

5to56 V

400(max) µA

Page 2

LB1696

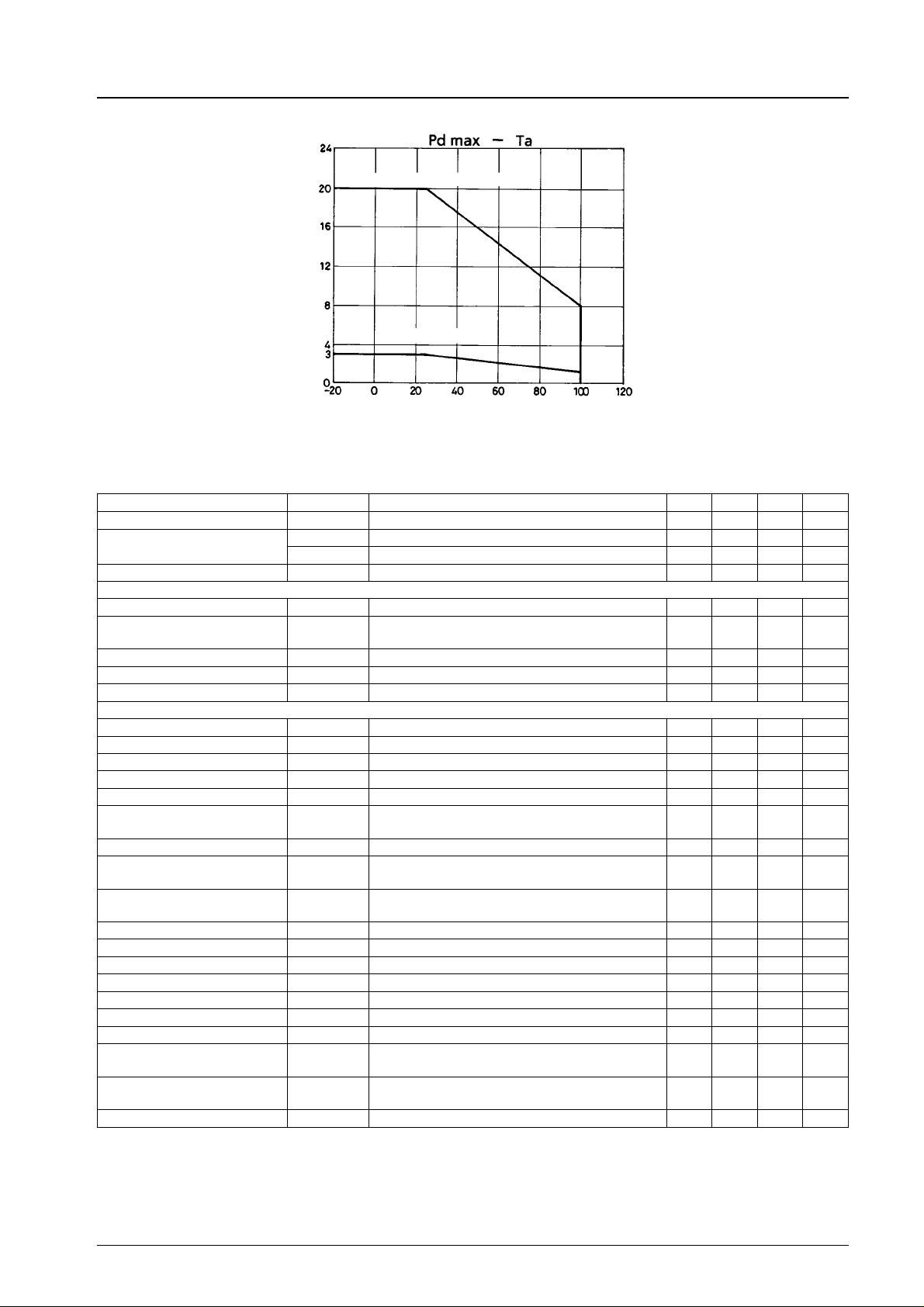

With arbitrarily large heat sink

Independent IC

Allowable power dissipation, Pd max — W

Ambient temperature, Ta —°C

Electric Characteristics atTa=25°C, VCC=5V,VM=45V

Parameter Symbol Conditions min typ max Unit

Supply current I

Output saturation voltage

Output leakage current I

CC

V

Osat1IO

V

Osat2IO

O(leak)

Hall amplifier

Input bias current I

Common-mode input voltage

range

HB

V

ICM

Hysteresis width ∆V

Input voltage L → HV

Input voltage H → LV

SLH

SHL

FG pin (rate pulse output)

Output low level voltage V

Dull-up resistance R

Forward F/R operation V

Reverse F/R operation V

Current limit operator limiter V

Thermal shutdown operation

temperature

FGL

FR1

FR2

T

FG

RF

SD

Hysteresis width ∆T

Reduced voltage protection

operation voltage

Reduced voltage protection

release voltage

Hysteresis width ∆V

C pin charge current 1 I

C pin charge current 2 I

C pin discharge current I

C pin charge start voltage V

C pin discharge start voltage V

Output current neglect time t

Output off time 1 t

Output off time 2 t

Regulator output voltage V

V

LVSD

V

LVSD(OFF)

LVSD

CL

CL

CH

CL

CH

sm

so

so

CC(REG)

Forward 16 23 mA

= 1 A, VO(sink) + VO(source) 2.1 3.0 V

= 2 A, VO(sink) + VO(source) 3.0 4.2 V

IN

IFG= 5 mA 0.4 V

Design target 150 165

Design target 25

SD

1 R1=68kΩ, R2 = open 15 21 27 µA

2 R1=68kΩ,R2=10kΩ 111 158 205 µA

R1=68kΩ 168 225 282 µA

R1=68kΩ 0.3 0.4 0.5 V

R1=68kΩ 1.5 2.0 2.5 V

R1=68kΩ, C = 6800 pF 42 51 60 µs

R1=68kΩ, R2 = open,

1

C = 6800 pF

R1=68kΩ,R2=10kΩ,

2

C = 6800 pF

100 µA

14µA

1.5 3.2 V

27 32 36 mV

816 23mV

–23 –16 –8 mV

7.5 10 12.5 kΩ

0 0.8 V

4.2 5.0 V

0.42 0.5 0.6 V

3.5 3.8 4.1 V

4.3 4.5 V

0.4 0.5 0.6 V

462 545 628 µs

51 74 97 µs

4.5 5.2 5.9 V

C

°

C

°

No.5244-2/9

Page 3

Truth Table

Input F/R control Output FG output

IN1 IN2 IN3 F/R Source → Sink FG1 FG2

1HLH

2HLL

3HHL

4LHL

5LHH

6LLH

LB1696

L OUT2 → OUT1

H OUT1 → OUT2

L OUT3 → OUT1

H OUT1 → OUT3

L OUT3 → OUT2

H OUT2 → OUT3

L OUT1 → OUT2

H OUT2 → OUT1

L OUT1 → OUT3

H OUT3 → OUT1

L OUT2 → OUT3

H OUT3 → OUT2

LL

LH

LL

HH

HL

HH

F/R

Forward L 0.0 to 0.8 V

Reverse H 4.2 to 5.0 V

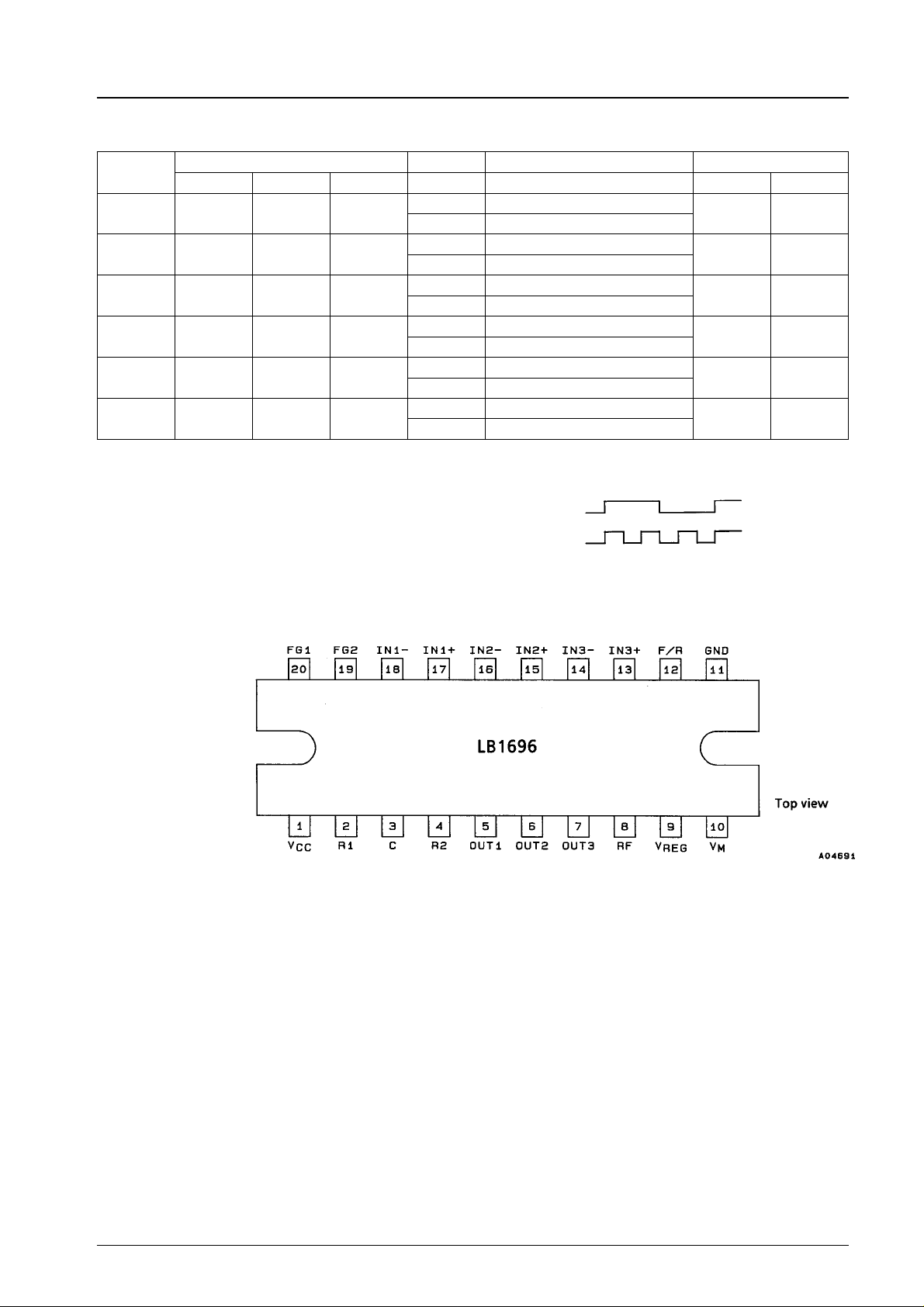

Pin Assignment

FG output

FG1

FG2

No.5244-3/9

Page 4

LB1696

Block Diagram and Peripheral Circuit Diagram

No.5244-4/9

Page 5

LB1696

Pin Functions

Pin No. Pin Name Pin Voltage Equivalent Circuit Pin Function

1V

CC

2R1

Supplies power to all circuits except output

block.

Sets the C pin charge/discharge current. In

current limiter operation when the motor is

locked, the charge current set by this pin

becomes charge current I

1 for the C pin.

CL

3C Sets the output off time and output current

neglect time during current limiter operation.

4R2 Sets the C pin charging current.

In current limiter operation when the motor is

rotating, the sum of the current set by this pin

and the current I

becomes charge current I

the C pin.

5

OUT1

6

OUT2

7

OUT3

Output pin 1

Output pin 2

Output pin 3

1 set by the R1 pin

CL

CL

2 for

8RF Output current detection pin. By inserting

resistor R

output current is detected as voltage. The

between this pin and GND, the

f

output current is limited to a current value set

10 V

M

9V

REG

by V

Power supply pin providing output

Regulator pin.

When using a singlepowersupply(V

(5.2 V) is supplied by adding an external

(current limit operation).

RF/Rf

), V

M

transistor.

The recommended transistor is the

2SD1724T. If a regulator is not used, this pin

should either be open or grounded.

11 GND GND for other than output.

The minimum potential of output transistor is

the RF pin voltage.

12 F/R 0.0 V min

V

max

CC

Forward/reverse control pin.

CC

17, 18,

15, 16,

13, 14

1920FG2

+

IN1

, IN1

IN2+, IN2

IN3+, IN3

FG1

–

–

–

1.5 V min

V

– 1.8 V

CC

max

Hall device input pin

Logic ‘‘H’’ represents IN

Rate pulse output pin 2.

Pull-up resistor built in.

Rate pulse output pin 1.

Pull-up resistor built in.

+

> IN–.

No.5244-5/9

Page 6

LB1696

1. Hall input circuit

The Hall input circuit is a differential amplifier with hysteresis (32 mV typ). The operating DC level must be within the common

mode input voltage range (1.5 V to V

to 160 mVp-p) is recommended to be independent of noise, etc. If the handling capability needs to be considered in noise

evaluation, etc., connect a capacitor (about 0.01 µF) between the Hall inputs IN

2. Protectors

2-1. Reduced voltage protector

drops below the prescribed voltage (V

If V

CC

malfunction which may occur when V

2-2. Thermal shutdown protector

If the junction temperature exceeds the prescribed temperature (T

protector prevents the IC from being damaged by heat. Thermal design must be such that no operation is performed in other

modes than abnormality.

3. FG output circuit

IN1, IN2, and IN3 Hall input signals are composited and wave shaped to be output. FG1 has the same frequency as for Hall input,

while FG2 3-fold as many.

4. Forward/reverse controller

– 1.8 V). An input level that is at least three times greater than the hysteresis (from 120

CC

+

and IN–.

), the output transistor on the sink side turns off. This protector prevents

LVSD

is reduced.

CC

), the output transistor on the sink side turns off. This

SD

No forward/reverse (F/R) switching is assumed to be performed during motor running period. If F/R switching is performed

during motor running period, through current flows to output and ASO needs to be considered. It is recommended that F/R

switching be performed when the V

5. V

If the supply voltage (V

and VMpower supplies

CC

CC,VM

considered. The supply voltage rise rate must be such that ∆V

desirable order of applying power is V

then V

have a possibility that V

off after motor stop. If, after VMis turned off, VCCis turned off during motor’s inertial running, some types of motors

CC

voltage rises, exceeding the withstand voltage. Because the LB1696 has a regulator built in, it can be

M

used with a single power supply (V

transistor (NPN) and resistor to the V

power supply is off (in motor stop mode).

M

) rise rate is fast when power is applied, through current flows to output and ASO needs to be

/∆t = 0.04 V/µs or less and ∆VM/∆t = 0.16 V/µs or less. The

on first and then VMon. The desirable of turning off power supply is VMoff first and

CC

power supply only). In this case, VCC(5.2 V typ.) can be supplied by connecting an external

M

pin. If the regulator is not used, the V

REG

CC

pin must be left open or connected to GND.

REG

6. Power supply stabilization capacitor

Great fluctuations in the V

to be connected to the V

line may cause the reduced-voltage protector, etc. to malfunction. A capacitor (of several µF) needs

CC

line (between VCCand GND) for stabilization. Since a large switching current flows in the line, wiring

CC

inductance componenet etc. fluctuates. Because there are also fluctuations in the GND line, a capacitor needs to be connected to

the V

line (between VMand GND) for stabilization, thus preventing malfunction and keeping withstand voltage from being

M

exceeded. Especially when the routing of wiring (V

, or GND) is long, be sure to connect capacitors with adequate capacity

M,VCC

for power line stabilization.

No.5244-6/9

Page 7

LB1696

7. Current limiter

The current limiter turns off the sink side output transistor when the output current-set current value (limiter value) is reached. The

output current is limited by the limit value. The RF pin is used to detect the output current. The output current is detected as

voltage by connecting resistor R

operates so that the output current is limited to the 0.5/R

7-1. Output off time

The current limiter is so designed that current limit function turns on to turn off the sink side output transistor and then turn

on the transistor again after off period of a fixed time (output off time) has elapsed. Since the LB1696 uses this output

switching method for the current limiter, the ASO problems when current limitation goes into operated mode as compared

with the output unsaturated current limited one. In addition, by separating current limiter operation into two modes, one when

the motor is locked and one when the motor is rotating (during start-up), it was possible to implement a current limiter circuit

with excellent motor start-up characteristics. The explanation of current limiter operation below is divided into two parts: one

for the mode used when the motor is locked and one for the mode used when the motor is rotating. The output off time

depends on the charge time of capacitor C connected to the C pin. When the current limiter turns on, C begins charging and

the output is kept off until C is charged up to 2 V (typ). When C has been charged up to 2 V, the sink side output turns on

again. The C charging current is a constant-regulated current, which depends on resistor R1 connected to the R1 pin and

resistor R2 connected to the R2 pin. In the LB1696, the charge current can be switched for when the motor is locked and for

when the motor is rotating in order to support motors for a large number of applications. As a result, it is possible to set the

output off time so that it is different for when the motor is locked and for when the motor is rotating. By setting the output

off time so that it is shorter when the motor is rotating (at start-up) as opposed to when the motor is locked, it is possible to

reduce the decrease in torque at start-up caused by the output off time. The charge currents and output off times for when the

motor is locked and for when the motor is rotating are as follows:

between RF pin and GND. When the RF pin voltage reaches 0.5 V (typ), the current limiter

f

-set limiter value.

f

(1) Charge current I

(2) Charge current I

and output off time t

CL1

I

6 1.4/R1

CL1

t

6 C/I

off1

CL1

× 2.0

when the motor is locked

off1

6 1.42 × R1 × C

(R1 must be set between 14 kΩ and 100 kΩ.)

and output off time t

CL2

I

6 I

CL2

off2

6 C/I

CL1

CL2

t

+ (1.4/R2)

× 2.0

when the motor is rotating

off2

6 1.42 × R × C{R=R1×R2/(R1 + R2)}

(R2 must be set between 7 kΩ and 100 kΩ.)

No.5244-7/9

Page 8

LB1696

7-2. Output current neglect time

While the current limiter turns on and the sink side output is off, the regeneration current flows through the external diode

used for absorbing the regeneration current above the output that was turned off. After the output off time elapses and the

sink side output is turned on again, reverse current flows momentarily through the external diode (for the diode’s reverse

recovery time), causing a current that reaches the limiter value to flow momentarily through the output. Because this current

will cause current limiter to turn on again, turning off the output, the average current decreases, causing the torque to be

decreased at motor start-up, etc. Therefore, in order to prevent this current from being detected, the current limiter is designed

so that the output current is not detected for a fixed period of time after the sink side output is turned on again. This length

of time is the output current neglect time. The output current neglect time is determined by the discharge time of the

capacitor C connected to the C pin. When current limiter turns on and C charges to 2 V, C begins discharging, and the output

current neglect time is the time it takes for C to discharge to the point where the voltage at C is 0.4 V (typ). The C discharge

current is a constant current, and is set at about 11 times the I

output current neglect time is about 1/11 of the output off time when the motor is locked. Because the C discharge current is

the same whether the motor is locked or is rotating, the output current neglect time is also the same whether the motor is

locked or is rotating. The C discharge current I

and the output current neglect time tsmare determined according to the

CH

following equations:

I

6 1.4/R1 × 11

CH

t

6 C/ICH× 1.6

sm

6 0.10 × R1 × C

Because there is a slope to the time at which the sink side output is turned on again, the reverse current is not very large,

even if a rectifier diode (a diode in which the reverse recovery time is not short) is used as the external diode for absorbing

the regeneration current in the current limiter.

of charge current when the motor is locked. As a result, the

CL1

7-3. Output off time setting

It is necessary to set the output off time to a suitable level for the type of motor being used. (The output off time is set by

the external resistors connected to the R1 and R2 pins, and by the external capacitor connected to the C pin.) In the LB1696,

the output off time when the motor is rotating can be set so that it is shorter than when the motor is locked. Set the optimal

output off time for when the motor is locked, and then set the output off time for when the motor is rotating. Fig. 1 shows

the current limiter operation waveform.

(1) When the output off time is set short

The output current neglect time is set by a circuit within the IC to about 1/11 of the output off time when the motor is

locked. Therefore, if the output off time is set to a very short length of time, the output current neglect time may not be

adequate. If the output current neglect time is inadequate, the current limiter will turn on in response to reverse current

from the external diode used to absorb the regeneration current. (Refer to Section 7-2.) Furthermore, if the output off time

is short, the diode reverse current becomes large and ASO must be considered.

(2) When the output off time is set long

If the output off time when the motor is rotating (at motor start-up) is set to a very long length of time, the average

current decreases, causing the torque at motor start-up to drop. Depending on the type of motor, it may be impossible to

shift from the current limiter operation state to the normal rotation state. In current limiter operation when the motor is

locked, it is necessary to set the output time to a comparatively long length of time. Therefore, first set the output off

time t

shorter than t

for when the motor is locked, and then set the output off time t

off1

off1

.

for when the motor is rotating so that t

off2

off2

is

No.5244-8/9

Page 9

LB1696

C pin voltage

RF pin voltage

Fig. 1 Current Limiter Operation Waveform (When Motor Is Locked)

8. Calculation of the IC’s internal power dissipation

Pd=(V

× ICC)+(VM×IM) – (power dissipated by the motor coil)

CC

9. Measuring the increase in the IC’s temperature

Because the temperature of the IC chip cannot be measured directly, the temperature is normally measured using one of the

following methods.

9-1. Measurement using a thermocouple

In order to measure the temperature by using a thermocouple, mount the thermocouple on the fin. Although this method of

measurement is simple, the measurement error is great, if the rate of heat generation has not stabilized.

9-2. Measurement using the characteristics of a diode within the IC

It is recommended that the parasitic diode between FG1 and GND be used to measure the temperature of the IC. Set FG1

high (the ‘‘off’’ state), measure the parasitic diode voltage V

characteristics of the voltage V

(Sanyo’s data: I

No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace equipment,

nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of which may directly or

indirectly cause injury, death or property loss.

Anyone purchasing any products described or contained herein for an above-mentioned use shall:

1 Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors

and all their officers and employees, jointly and severally, against any and all claims and litigation and all damages, cost and

expenses associated with such use:

2 Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on SANYO

ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees jointly or severally.

Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for volume

production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied regarding its use

or any infringements of intellectual property rights or other rights of third parties.

= –1 mA, VFtemperature characteristics: approximately –2 mV/°C)

F

.

F

, and calculate the temperature based on the temperature

F

This catalog provides information as of December, 1995. Specifications and information herein are subject to change without notice.

No.5244-9/9

Loading...

Loading...