Carrier 30MPA User Manual

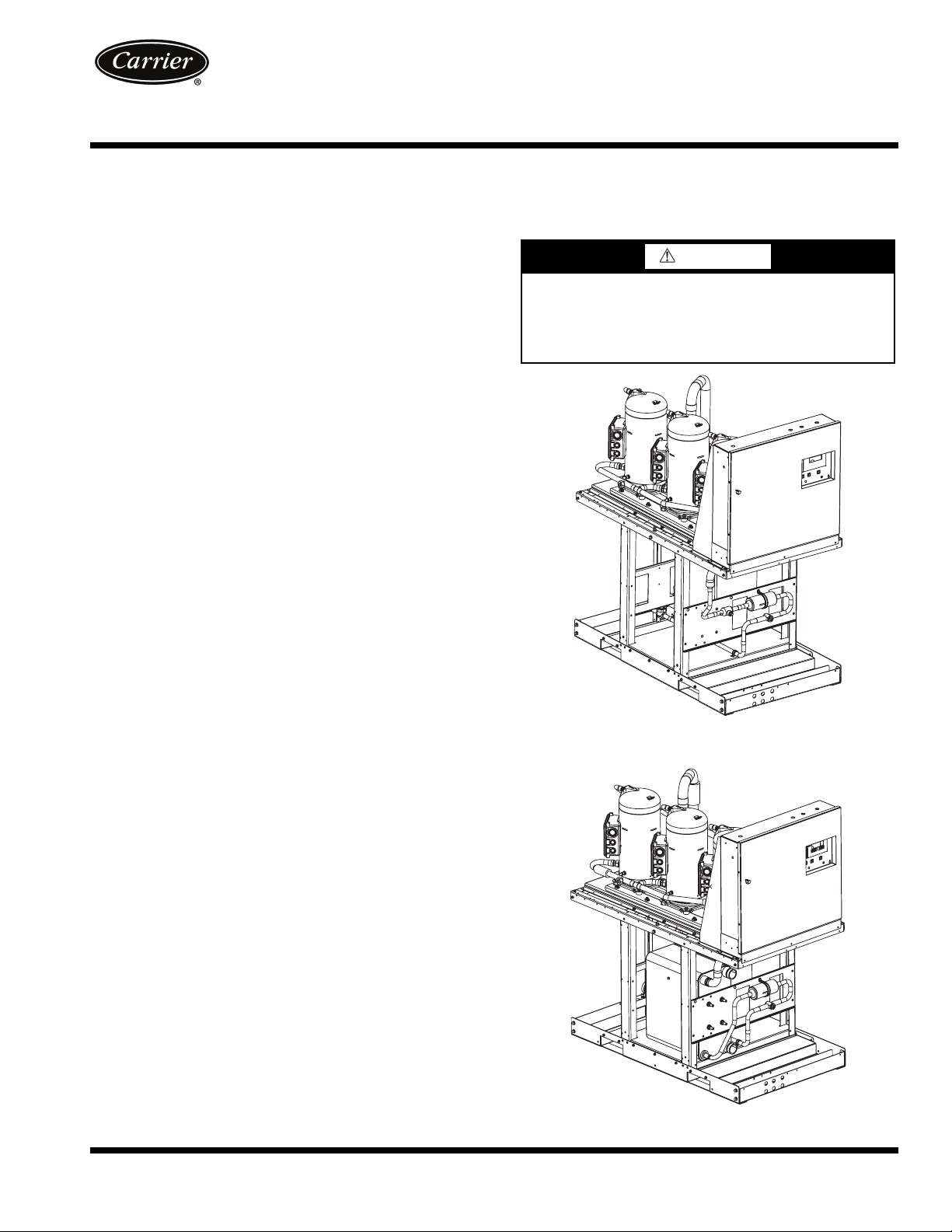

Fig. 1 — 30MPA Unit

a30-5029

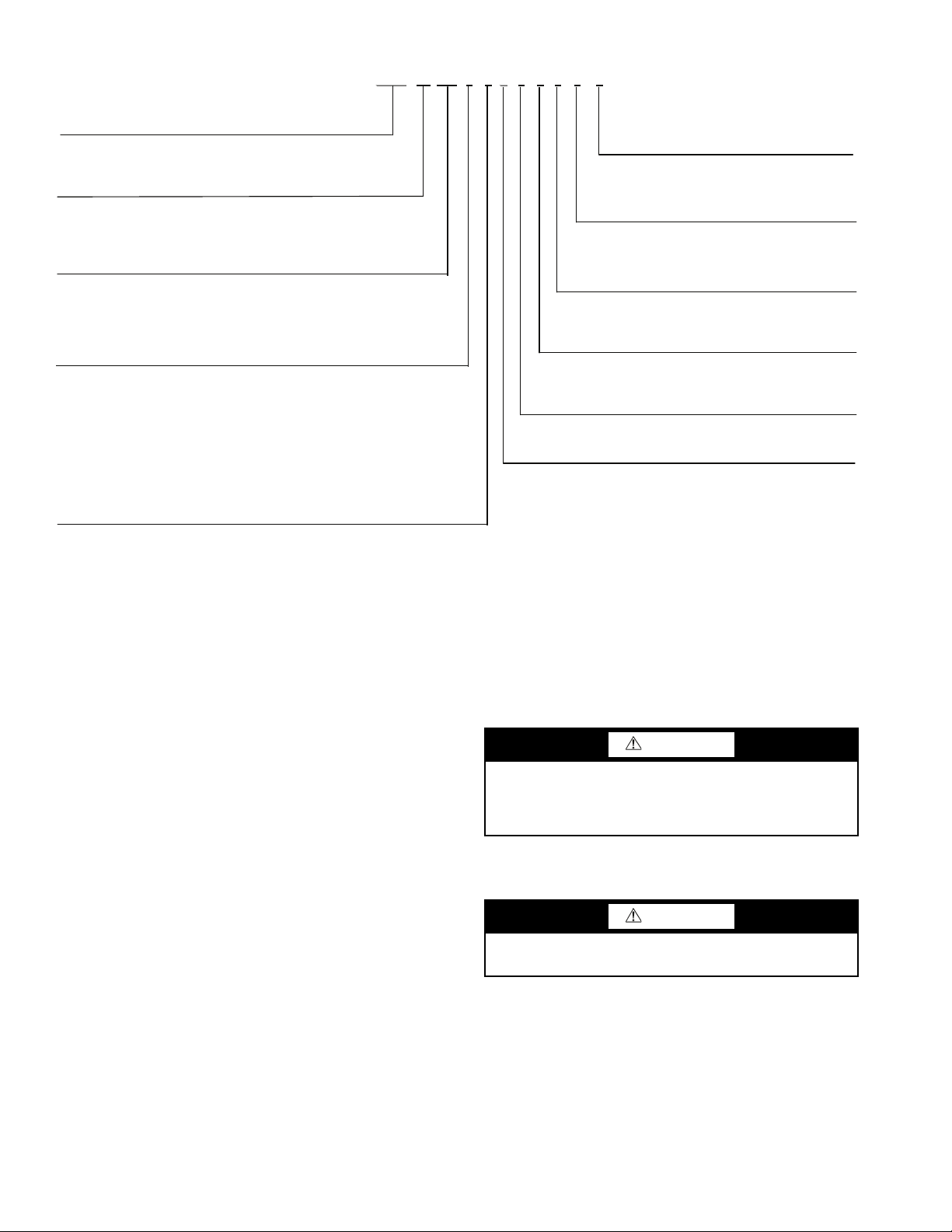

Fig. 2 — 30MPW Unit

a30-5030

30MPA,MPW015-045

with Scroll Compressors

and COMFORTLINK™ Controls

Installation Instructions

AQUASNAP

®

Liquid Chillers

CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1,2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Step 1 — Inspect Shipment . . . . . . . . . . . . . . . . . . . . 2

Step 2 — Position the Unit . . . . . . . . . . . . . . . . . . . . . 2

Step 3 — Place the Unit. . . . . . . . . . . . . . . . . . . . . . . . 7

Step 4 — Check Compressor Mounting. . . . . . . . 7

Step 5 — Make Piping Connections. . . . . . . . . . . . 7

• 30MPA SYSTEM CONDENSER

• 30MPW CONDENSER DESCRIPTION

• 30MPW CONDENSER

• EVAPORATOR DESCRIPTION

• EVAPORATOR PIPING

•AIR SEPARATION

Step 6 — Fill the Chilled Water Loop. . . . . . . . . . .13

• WATER SYSTEM CLEANING

• FILLING THE SYSTEM

Step 7 — Make Electrical Connections. . . . . . . . .14

•FLOW SWITCH

• CONTROL BOX, POWER SECTION

• CONTROL BOX, CONTROLS SECTION

• CONTROL BOX, FIELD CONTROL WIRING

SECTION

• UNBALANCED 3-PHASE SUPPLY VOLTAGE

.

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all disconnect locations to alert others not to restore power until work

is completed.

GENERAL

These installation instructions cover the 30MPA, MPW units

with ComfortLink controls. The 30MPA units are condenserless

units and the 30MPW units are all fluid cooled.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment (Fig. 1

and 2) can be hazardous due to system pressures, electrical

components, and equipment location (roofs, elevated structures, etc.). Model number structure is shown in Fig. 3.

Only trained, qualified installers and service technicians

should install, start up, and service this equipment.

When working on the equipment, observe precautions in the

literature and on tags, stickers, and labels attached to the

equipment.

• Follow all safety codes.

• Wear safety glasses and work gloves.

• Use care in handling, rigging, and setting bulky

equipment.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300054-01 Printed in U.S.A. Form 30MP-1SI Pg 1 910 1-10 Replaces: New

INSTALLATION

30MP

A0306 -

30MP – Aquasnap® Liquid Chiller with ComfortLink™ Controls

Condenser Option

A – Chiller without Condenser (Air-Cooled)

Design Revision Level

W – Chiller with Condenser (Water-Cooled)

- – Initial Release

Voltage Options

1 – 575-3-60

5 – 208/230-3-60

6 – 460-3-60

Unit Size – Nominal Tons (kW)

015 – 15 (54) 040 – 40 (138)

020 – 20 (71) 045 – 45 (161)

030 – 30 (108)

2 – 380-3-60

0

Sound/Mounting Options

0 – None

1 – S

ound Enclosure Panels

3 – Height Adjustment Kit

4 – Height Adjustment Kit, Sound Enclosure Panels

9 – Mobility Kit (Wheels)

B – Mobility Kit (Wheels), Sound Enclosure Panels

D – Height Adjustment Kit, Mobility Kit (Wheels)

F – Height Adjustment Kit, Mobility Kit (Wheels), Sound Enclosure Panels

0

Comfort Cooling/Medium Temp Brine Options

0 – Comfort Cooling Duty (32-60 F) (Std)

7 – Medium Temperature Brine (15-32 F)

0

Capacity Control Options

0 – Standard

1 – Hot Gas Byp

ass

0

Disconnect Options

0 – Standard (Terminal Block)

1 – Non-Fused Disconnect Switch

0

Controls/Interface Options

0 – Scrolling Marquee Display (Std)

5 – Scrolling Marquee Display, EMM

5

Packaging Options

5 – Bag

B – Export Crate

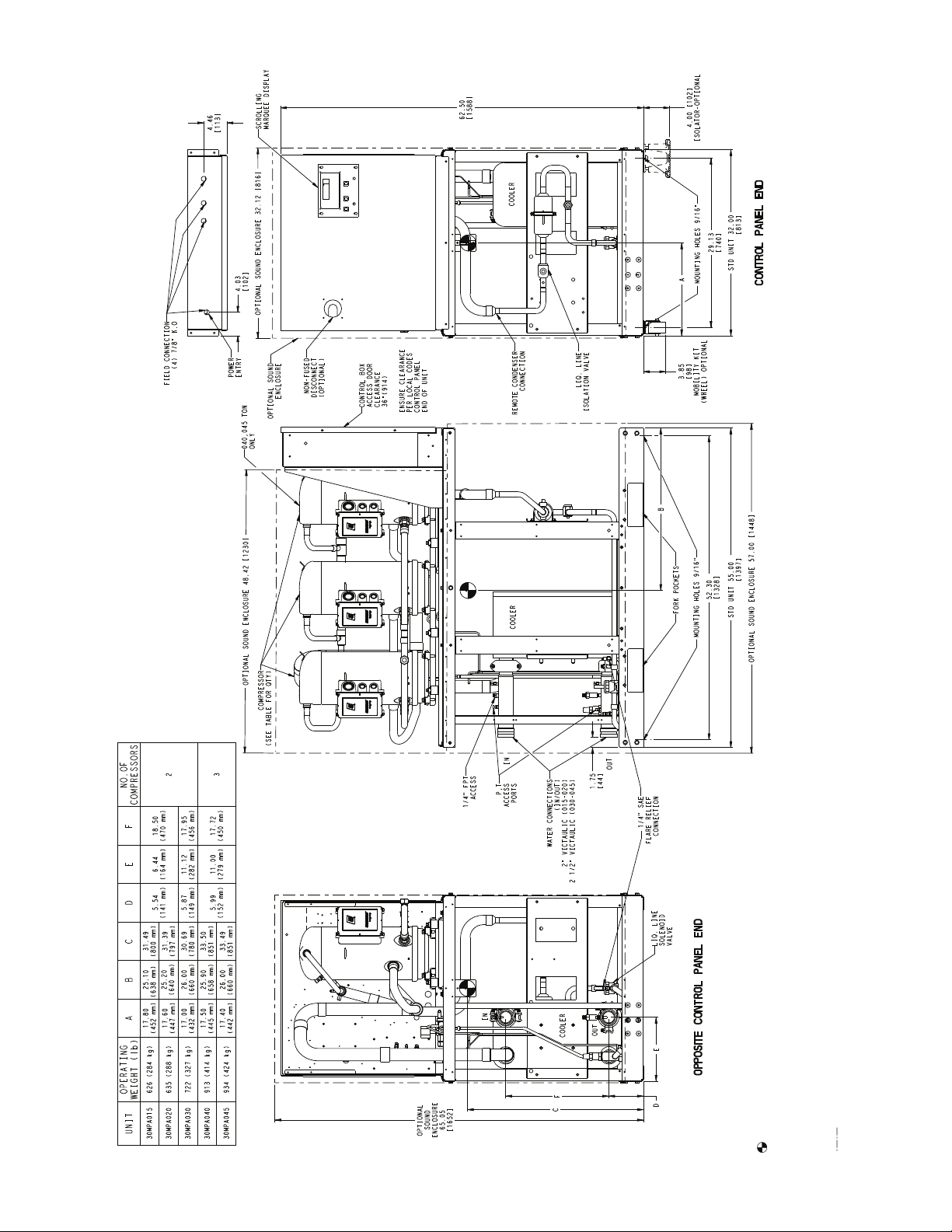

Fig. 3 — 30MP Model Number Nomenclature

LEGEND

EMM — Energy Management Module

LON — Local Operating Network

UPC — Unitary Protocol Controller

a30-5038

Location —

er because of sensitive control mechanisms and electronic

devices. Locate unit indoors. See Fig. 4 and 5 for unit dimensional details.

When considering location, consult National Electrical

Code (NEC) and local code requirements. Allow sufficient

space for wiring, piping, and service. Install unit in an area

where it will not be exposed to ambient temperatures below

50 F (10 C).

Allow 36 in. (914 mm) in front of the unit for control box

access door. Additional clearance may be required per local

codes. Prior to installation determine which direction compressor will be removed, and leave 3 to 4 ft (914 to 1219 mm)

clearance for removal.

On all units leave 3 ft (0.9 m) of clearance behind the unit to

make water/brine connections to the evaporator, accessing the

TXV (thermostatic expansion valve), fluid thermistors, and

proof of flow switch.

On all units, leave 2 ft (610 mm) on one side for making refrigeration connections (30MPA) or fluid connections

(30MPW) to condenser. See Fig. 4 and 5.

The floor must be strong enough to support the unit operating weight (see Tables 1A and 1B and Fig. 4-6). If necessary,

add a supporting structure (steel beams or reinforced concrete

slabs) to the floor to transfer weight to nearest beams.

Do not store units in an area exposed to weath-

Additional weight of factory-installed sound enclosure op-

tion is 75 lb (34 kg).

CAUTION

Be sure interconnecting piping and electrical conduits

Step 1 — Inspect Shipment — Inspect unit for dam-

age or missing parts. If damaged, or if shipment is incomplete,

file a claim immediately with the shipping company.

are suspended freely, and are not in contact with any

adjacent walls. Be sure unit capillaries are not rubbing

against anything. Damage to unit or walls may result.

Unit is top heavy. Unit may tip if handled without care.

Damage to unit or injury may result.

CAUTION

Step 2 — Position the Unit — The unit may be

moved by means of rollers under the rails or a forklift truck.

If accessory mobility kit is to be used, install this accessory

after bringing unit into building and before moving the unit to

its final location per installation instructions provided with the

accessory. The factory-installed mobility kit option consists of

4 swivel-type wheels that are field-mounted to the legs of the

unit. See Fig. 7.

NOTE: The wheels are equipped with a thumb-screw brake.

2

52.30

1328[]

STD UNIT 55.00

1397[]

OPTIONAL SOUND ENCLOSURE 57.00 [1448]

29.13

740[]

STD UNIT 32.00

813[]

62.50

1588[]

OPTIONAL SOUND ENCLOSURE 32.12 [816]

MOBILITY KIT

(WHEEL) OPTIONAL

3.85

98[]

E

D

F

OPTIONAL SOUND ENCLOSURE 48.42 [1230]

OPTIONAL

SOUND

ENCLOSURE

65.05

[1652]

4.00 [102]

ISOLATOR-OPTIONAL

C

B

A

4.03

102[]

1.75

44[]

4.46

[113]

UNIT

OPERATING

WEIGHT (lb)

ABCDEF

NO.OF

COMPRESSORS

30MPA015 626 (284 kg)

17.80

(452 mm)

25.10

(638 mm)

31.49

(800 mm)

5.54

(141 mm)

6.44

(164 mm)

18.50

(470 mm)

230MPA020 635 (288 kg)

17.60

(447 mm)

25.20

(640 mm)

31.39

(797 mm)

30MPA030 722 (327 kg)

17.00

(432 mm)

26.00

(660 mm)

30.69

(780 mm)

5.87

(149 mm)

11.12

(282 mm)

17.95

(456 mm)

30MPA040 913 (414 kg)

17.50

(445 mm)

25.90

(658 mm)

33.50

(851 mm)

5.99

(152 mm)

11.00

(279 mm)

17.72

(450 mm)

3

30MPA045 934 (424 kg)

17.40

(442 mm)

26.00

(660 mm)

33.49

(851 mm)

COMPRESSOR

(SEE TABLE FOR QTY)

OUT

IN

OPTIONAL SOUND

ENCLOSURE

FIELD CONNECTION

(4) 7/8" K.O

NON-FUSED

DISCONNECT

(OPTIONAL)

1/4" FPT

ACCESS

P,T

ACCESS

PORTS

1/4" SAE

FLARE RELIEF

CONNECTION

POWER

ENTRY

WATER CONNECTIONS

(IN/OUT)

2" VICTAULIC (015-020)

2 1/2" VICTAULIC (030-045)

COOLER

COOLER

COOLER

CONTROL PANEL END

OPPOSITE CONTROL PANEL END

MOUNTING HOLES 9/16"

-

MOUNTING HOLES 9/16"

-

IN

OUT

040,045 TON

ONLY

FORK POCKETS

SCROLLING

MARQUEE DISPLAY

REMOTE CONDENSER

CONNECTION

LIQ. LINE

ISOLATION VALVE

LIQ. LINE

SOLENOID

VALVE

CONTROL BOX

ACCESS DOOR

CLEARANCE

36"(914)

ENSURE CLEARANCE

PER LOCAL CODES

CONTROL PANEL

END OF UNIT

Fig. 4 — Dimensions — 30MPA015-045 Units

NOTES:

1. Operating weight includes weight of water and refrigerant.

2. Denotes center of gravity.

3. Dimensions are shown in inches. Dimensions in [ ] are in

millimeters.

4. Allow 36-in. (914 mm) clearance on control panel end, opposite

control panel end and above the unit. All clearances must be in

accordance with local codes.

5. Denotes accessory or factory-installed option.

a30-5032

3

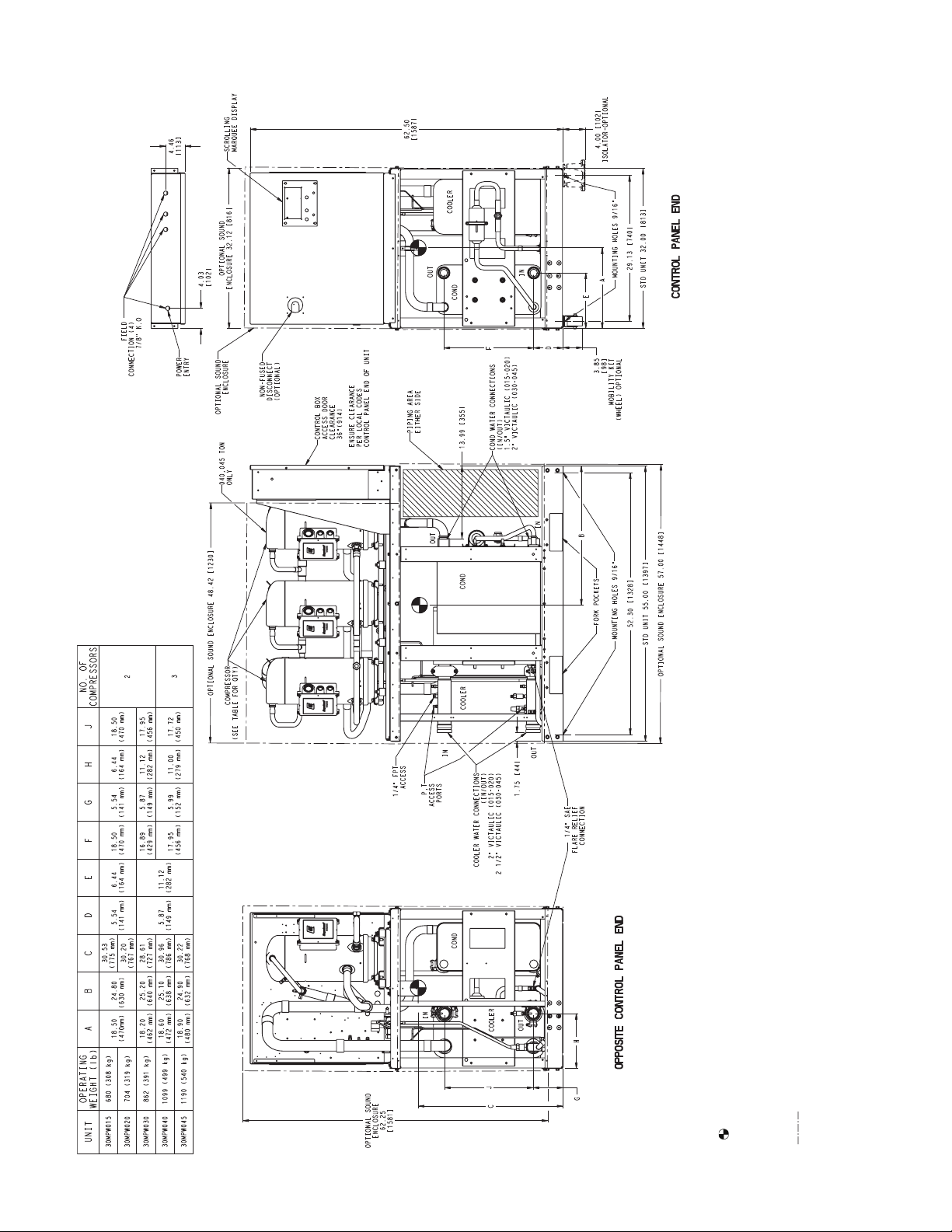

Fig. 5 — Dimensions — 30MPW015-045 Units

NOTES:

1. Operating weight includes weight of water and refrigerant.

2. Denotes center of gravity.

3. Dimensions are shown in inches. Dimensions in [ ] are in

millimeters.

4. Allow 36-in. (914 mm) clearance on control panel end, opposite

control panel end and above the unit. All clearances must be in

accordance with local codes.

5. Denotes accessory or factory-installed option.

a30-5033

910

4

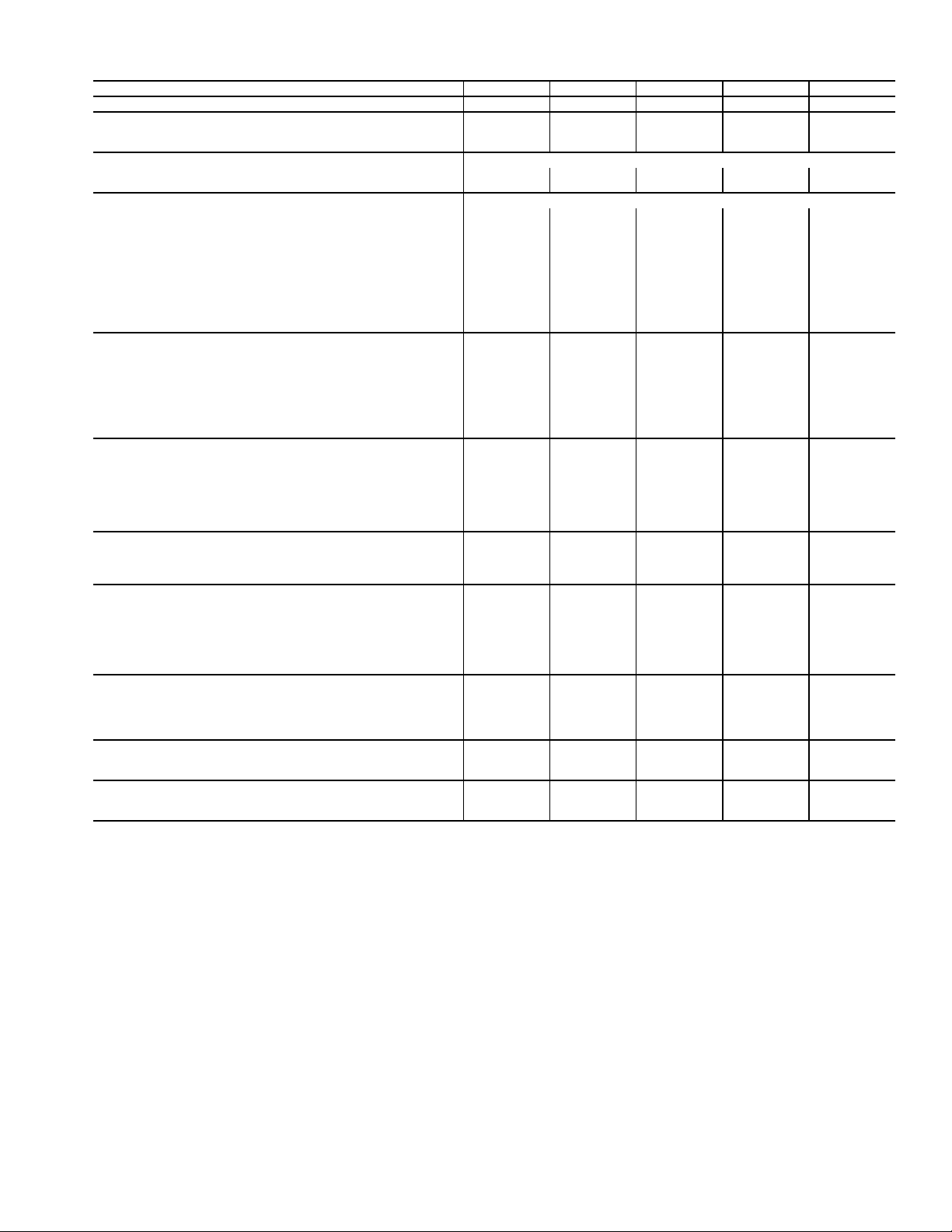

Table 1A — 30MPA Air-Cooled and 30MPW Liquid-Cooled Units — English

UNIT 30MPA,MPW 015 020 030 040 045

NOMINAL TONS 15 20 30 40 45

OPERATING WT (lb)

MPA 626 635 722 913 934

MPW 680 704 862 1099 1190

REFRIGERANT (lb) R-410A

MPA —————

MPW 11.6 15.2 23.1 29.4 34.4

COMPRESSOR Scroll, Hermetic

Quantity 22233

Speed (rpm) 3500 3500 3500 3500 3500

Compressor Nominal Tons 7.510151315

Oil Charge (pt) 10.6 13.8 13.8 20.6 20.6

Capacity Control — Standard

No. of Steps 22233

Minimum Step Capacity (%) 50 50 50 33 33

Capacity Control — Optional Hot Gas Bypass

No. of Steps 33344

Minimum Step Capacity (%) 18 25 34 21 22

EVAPORATOR

Weight (lb, empty) 27.5 40.3 91.8 122.3 128.3

Net Fluid Volume (gal.) 0.8 1.2 2.4 3.2 3.4

Maximum Refrigerant Pressure (psig) 650 650 650 650 650

Maximum Fluid-Side Pressure (psig) 300 300 300 300 300

Water Connections (in.)

Inlet and Outlet (Victualic) 222

Drain (NPT)

CONDENSER (30MPW Only)

Weight (lb, empty) 34.9 43.6 104.6 136.7 188.3

Net Fluid Volume (gal.) 1.2 1.6 2.9 4.1 5.9

Maximum Refrigerant Pressure (psig) 650 650 650 650 650

Maximum Fluid-Side Pressure (psig) 300 300 300 300 300

Water Connections (in.)

Inlet and Outlet (Victualic) 222

1

/

2

1

/

2

CHASSIS DIMENSIONS (in.)

Length 55 55 55 55 55

Width 32 32 32 32 32

Height 63 63 63 63 63

MINIMUM SYSTEM FLUID VOLUME (gal. per Ton)

Normal Air Conditioning

Standard 66644

Optional Hot Gas Bypass 44433

Low Outdoor Ambient Cooling Operation (30MPA Units)

Standard 10 10 10 88

Optional Hot Gas Bypass 77766

CAPACITY STEPS

Step 1 100% 100% 100% 100% 100%

Step 2 50% 50% 50% 67% 67%

Step 3 18%* 25%* 34%* 33% 33%

Step 4 — — — 21%* 22%*

MINIMUM FLOW RATES (gpm)

Evaporator 22 28 43 55 64

Condenser 22 28 43 55 64

MAXIMUM FLOW RATES (gpm)

Evaporator 74 97 148 188 220

Condenser 74 97 148 188 220

* With optional hot gas bypass. NOTES:

1. Operating weight includes refrigerant operating charge and

weight of fluid in the heat exchangers.

2. 30MPW units are shipped with full operating charge.

1

/

2

1

/

2

1

/

2

2 1/

1

2 1/

2

/

2

2

21/

21/

2

1

/

2

2

5

Loading...

Loading...