Carrier 30HXA, HXC076-186 User Manual

30HXA,HXC076-186 Water-Cooled and Condenserless Chillers 50/60 Hz

Installation Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-27

Step 1 Ð Inspect Shipment . . . . . . . . . . . . . . . . . . . 1

Step 2 Ð Rig and Place Unit . . . . . . . . . . . . . . . . . . 1

Step 3 Ð Piping Connections . . . . . . . . . . . . . . . . . 9

·COOLER FLUID, VENT, AND DRAIN

·BRINE UNITS

·PREPARATION FOR YEAR-ROUND OPERATION

·30HXA REFRIGERANT PIPING

·30HXC CONDENSER CONNECTIONS

·INSTALL PRESSURE RELIEF REFRIGERANT VENT PIPING

Step 4 Ð Make Electrical Connections . . . . . . . 14

·FIELD POWER CONNECTIONS

·FIELD CONTROL POWER CONNECTIONS

Step 5 Ð Install Accessories . . . . . . . . . . . . . . . . 26

·ELECTRICAL

·30HXA LOW-AMBIENT OPERATION

·MINIMUM LOAD ACCESSORY

·MISCELLANEOUS ACCESSORIES

Step 6 Ð Leak Test Unit . . . . . . . . . . . . . . . . . . . . . 26

·30HXC UNITS

·30HXA UNITS

Step 7 Ð Refrigerant Charge . . . . . . . . . . . . . . . . 26

·30HXC UNITS

·30HXA UNITS

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be hazardous due to system pressures, electrical components, and equipment location. Only trained, quali®ed installers and service mechanics should install, start up, and service this equipment.

When working on the equipment, observe precautions in the literature, and on tags, stickers, and labels attached to the equipment.

·Follow all safety codes.

·Wear safety glasses and work gloves.

·Use care in handling, rigging, and setting bulky equipment.

INTRODUCTION

These instructions cover installation of 30HX liquid chillers with electronic controls and units with factory-installed options (FIOPSs).

IMPORTANT: This equipment generates, uses, and can radiate radio frequency energy. If not installed and used in accordance with these instructions, this equipment may cause radio interference. The equipment has been tested and found to comply with the limits of a Class A computing device as de®ned by the FCC (Federal Communications Commission, U.S.A.) Regulations, Subpart J of Part 15, which are designed to provide reasonable protection against such interference when operated in a commercial environment.

INSTALLATION

Step 1 Ð Inspect Shipment Ð Inspect unit for damage upon arrival. If damage is found, ®le a claim with the shipping company right away. Do not store units in an area exposed to weather because of sensitive control mechanisms and electronic devices.

Locate unit indoors. When considering unit location, consult National Electrical Code (NEC, U.S.A.) and local code requirements. Allow sufficient space for wiring, piping, and service. Install unit in an area which will not be exposed to subfreezing weather. See Fig. 1-4 for clearance details.

Allow the following clearances for service access:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft (914 mm) Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 ft (914 mm)

Top . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 2 ft (610 mm) |

Ends . . . . . . . . . . . . . . . |

tube removal at one (either) end; |

|

3 ft (914 mm) at opposite end. |

Be sure surface beneath the unit is level and is capable of supporting the operating weight of the unit. See Fig. 5 and Tables 1A and 1B for unit operating weights. If necessary, add supporting structure (steel beams or reinforced concrete slabs) to ¯oor to transfer weight to nearest beams.

Step 2 Ð Rig and Place Unit

Rig unit from the top heat exchanger only. Rigging from the bottom heat exchanger will cause the unit to be lifted unsafely. Personal injury or damage to the unit may occur.

Do not remove unit from skid until unit is in its ®nal location. Rig from the rigging holes provided in the top heat exchanger. See Fig. 1-5 for rigging and center of gravity information. Lower the unit carefully onto the ¯oor or roller. Push or pull only on the skid, not the unit. If the unit is moved on rollers, use a minimum of 3 evenly-spaced rollers.

Copy continued on page 9.

Manufacturer reserves the right to discontinue, or change at any time, speci®cations or designs without notice and without incurring obligations.

Book |

2 |

|

PC 903 |

Catalog No. 563-052 |

Printed in U.S.A. |

Form 30HX-1SI |

Pg 1 |

5-96 |

Replaces: New |

Tab |

5c |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

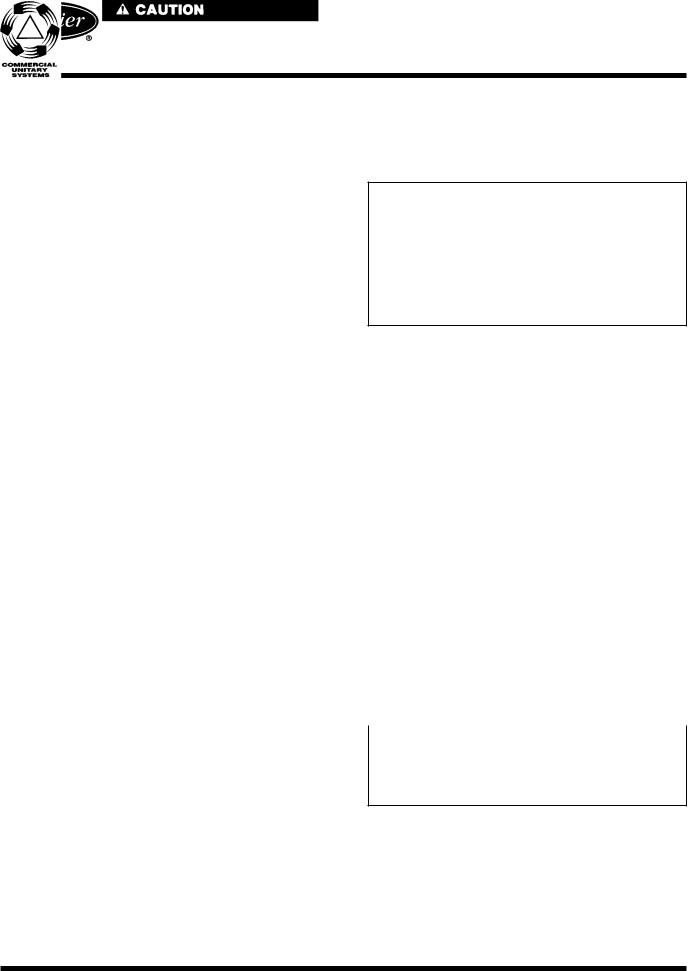

LEGEND

K.O. Ð Knockout

THK Ð Thick

TYP Ð Typical

NOTES:

1. |

Denotes center of gravity. |

2. |

Dimensions are in inches. Dimensions ( ) are in millimeters. |

3. |

Recommended service clearance around unit (front, back, and one side) is |

|

369 (914). |

DIMENSIONS Ð in. (mm)

UNIT |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

M |

N |

P |

|

30HXC |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

076 |

102.12 |

45.87 |

45.87 |

9.87 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

1.90 |

47.00 |

30.80 |

|

(2594) |

(1165) |

(1165) |

(251) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(48) |

(1194) |

(782) |

||

|

|||||||||||||||

086 |

102.12 |

45.87 |

45.87 |

9.87 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

1.90 |

47.00 |

30.80 |

|

(2594) |

(1165) |

(1165) |

(251) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(48) |

(1194) |

(782) |

||

|

|||||||||||||||

096 |

102.12 |

37.63 |

54.12 |

9.87 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

1.90 |

47.00 |

30.80 |

|

(2594) |

(956) |

(1375) |

(251) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(48) |

(1194) |

(782) |

||

|

|||||||||||||||

106 |

102.12 |

37.63 |

54.12 |

10.47 |

10.28 |

45.50 |

15.60 |

85.15 |

5.00 |

95.00 |

67.22 |

1.90 |

47.00 |

30.80 |

|

(2594) |

(956) |

(1375) |

(266) |

(261) |

(1156) |

(396) |

(2163) |

(127) |

(2413) |

(1707) |

(48) |

(1194) |

(782) |

||

|

|||||||||||||||

116 |

132.56 |

72.12 |

50.63 |

9.87 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

1.70 |

62.20 |

29.40 |

|

(3367) |

(1832) |

(1286) |

(251) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(43) |

(1580) |

(747) |

||

|

|||||||||||||||

126 |

132.56 |

72.12 |

50.63 |

9.87 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

1.70 |

62.20 |

29.40 |

|

(3367) |

(1832) |

(1286) |

(251) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(43) |

(1580) |

(747) |

||

|

|||||||||||||||

136 |

132.56 |

72.12 |

50.63 |

9.87 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

1.70 |

62.20 |

29.40 |

|

(3367) |

(1832) |

(1286) |

(251) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(43) |

(1580) |

(747) |

||

|

|||||||||||||||

146 |

132.56 |

72.12 |

50.63 |

9.87 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

1.70 |

62.20 |

29.40 |

|

(3367) |

(1832) |

(1286) |

(251) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(43) |

(1580) |

(747) |

||

|

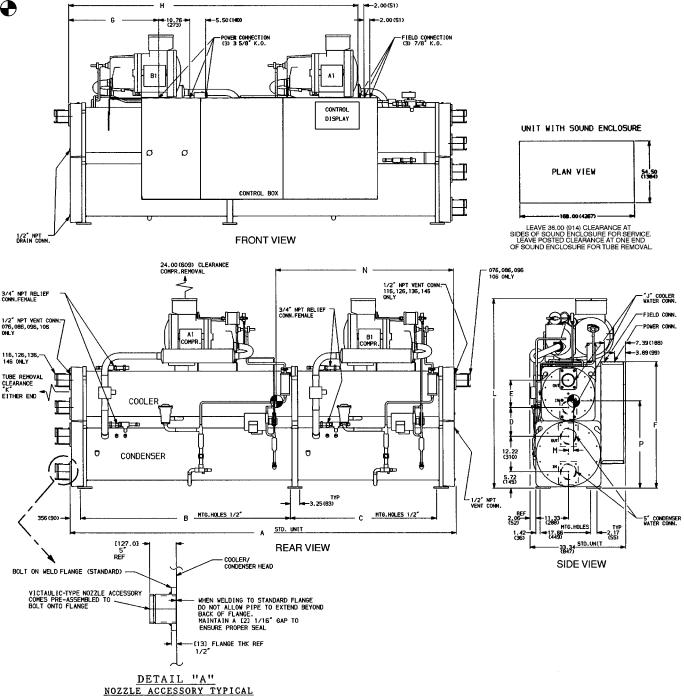

Fig. 1 Ð Base Unit Dimensions, 30HXC076-146 Units

2

DIMENSIONS Ð in. (mm)

UNIT |

A |

B |

C |

D |

E |

|

30HXC |

||||||

|

|

|

|

|

||

161 |

72.12 |

50.63 |

2.00 |

63.50 |

31.00 |

|

(1832) |

(1286) |

(51) |

(1588) |

(787) |

||

|

||||||

171 |

61.37 |

61.37 |

2.00 |

63.50 |

31.00 |

|

(1559) |

(1559) |

(51) |

(1588) |

(787) |

||

|

||||||

186 |

61.37 |

61.37 |

2.00 |

63.50 |

31.00 |

|

(1559) |

(1559) |

(51) |

(1588) |

(787) |

||

|

||||||

|

|

|

|

|

|

NOTES:

1.  Denotes center of gravity.

Denotes center of gravity.

2. Dimensions are in inches. Dimensions ( ) are in millimeters.

3.Recommended service clearance around unit (front, back, and one side) is 369 (914).

LEGEND

K.O. Ð Knockout

THK Ð Thick

TYP Ð Typical

Fig. 2 Ð Base Unit Dimensions, 30HXC161-186 Units

3

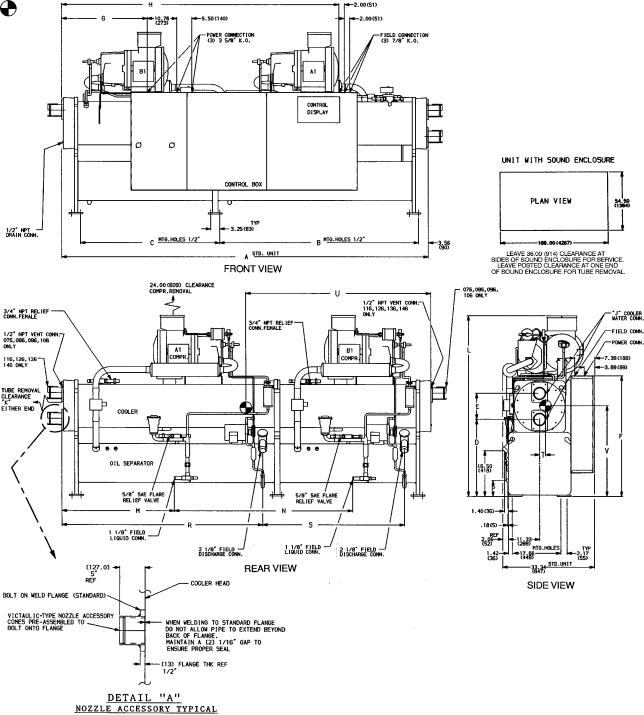

|

|

LEGEND |

K.O. Ð |

Knockout |

|

SAE |

Ð |

Society of Automotive |

THK |

Ð |

Engineers, U.S.A. |

Thick |

||

TYP |

Ð |

Typical |

NOTES:

1. |

Denotes center of gravity. |

2. |

Dimensions are in inches. Dimensions ( ) are in millimeters. |

3. |

Recommended service clearance around unit (front, back, and one side) is |

|

369 (914). |

DIMENSIONS Ð in. (mm)

UNIT |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

M |

N |

P |

R |

S |

T |

U |

V |

|

30HXA |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

076 |

102.12 |

45.87 |

45.87 |

27.81 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

13.93 |

59.48 |

5.72 |

45.81 |

46.25 |

2.40 |

46.40 |

35.00 |

|

(2594) |

(1165) |

(1165) |

(706) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(354) |

(1511) |

(145 ) |

(1164) |

(1175) |

(61) |

(1179) |

(889) |

||

|

||||||||||||||||||||

086 |

102.12 |

45.87 |

45.87 |

27.81 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

13.93 |

59.48 |

5.72 |

45.81 |

46.25 |

2.40 |

46.40 |

35.00 |

|

(2594) |

(1165) |

(1165) |

(706) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(354) |

(1511) |

(145) |

(1164) |

(1175) |

(61) |

(1179) |

(889) |

||

|

||||||||||||||||||||

096 |

102.12 |

37.63 |

54.12 |

27.81 |

9.36 |

43.50 |

15.60 |

85.15 |

4.00 |

95.00 |

65.22 |

22.15 |

42.77 |

5.72 |

54.06 |

38.00 |

2.40 |

46.40 |

35.00 |

|

(2594) |

(956) |

(1375) |

(706) |

(236) |

(1105) |

(396) |

(2163) |

(102) |

(2413) |

(1657) |

(563) |

(1086) |

(145) |

(1373) |

(965) |

(61) |

(1179) |

(889) |

||

|

||||||||||||||||||||

106 |

102.12 |

37.63 |

54.12 |

28.41 |

10.28 |

45.50 |

15.60 |

85.15 |

5.00 |

95.00 |

67.22 |

22.15 |

42.77 |

5.87 |

54.06 |

38.00 |

2.40 |

46.40 |

35.00 |

|

(2594) |

(956) |

(1375) |

(721) |

(261) |

(1156) |

(396) |

(2163) |

(127) |

(2413) |

(1707) |

(563) |

(1086) |

(149) |

(1373) |

(965) |

(61) |

(1179) |

(889) |

||

|

||||||||||||||||||||

116 |

132.56 |

72.12 |

50.63 |

27.81 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

40.16 |

64.23 |

5.72 |

72.06 |

51.01 |

2.30 |

61.00 |

34.30 |

|

(3367) |

(1832) |

(1286) |

(706) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(1020) |

(1631) |

(145) |

(1830) |

(1296) |

(58) |

(1549) |

(871) |

||

|

||||||||||||||||||||

126 |

132.56 |

72.12 |

50.63 |

27.81 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

40.16 |

64.23 |

5.72 |

72.06 |

51.01 |

2.30 |

61.00 |

34.30 |

|

(3367) |

(1832) |

(1286) |

(706) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(1020) |

(1631) |

(145) |

(1830) |

(1296) |

(58) |

(1549) |

(871) |

||

|

||||||||||||||||||||

136 |

132.56 |

72.12 |

50.63 |

27.81 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

40.16 |

64.23 |

5.72 |

72.06 |

51.01 |

2.30 |

61.00 |

34.30 |

|

(3367) |

(1832) |

(1286) |

(706) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(1020) |

(1631) |

(145) |

(1830) |

(1296) |

(58) |

(1549) |

(871) |

||

|

||||||||||||||||||||

146 |

132.56 |

72.12 |

50.63 |

27.81 |

9.36 |

43.50 |

31.11 |

100.66 |

4.00 |

126.00 |

65.22 |

40.16 |

64.23 |

5.72 |

72.06 |

51.01 |

2.30 |

61.00 |

34.30 |

|

(3367) |

(1832) |

(1286) |

(706) |

(236) |

(1105) |

(790) |

(2557) |

(102) |

(3200) |

(1657) |

(1020) |

(1631) |

(145) |

(1830) |

(1296) |

(58) |

(1549) |

(871) |

||

|

Fig. 3 Ð Base Unit Dimensions, 30HXA076-146 Units

4

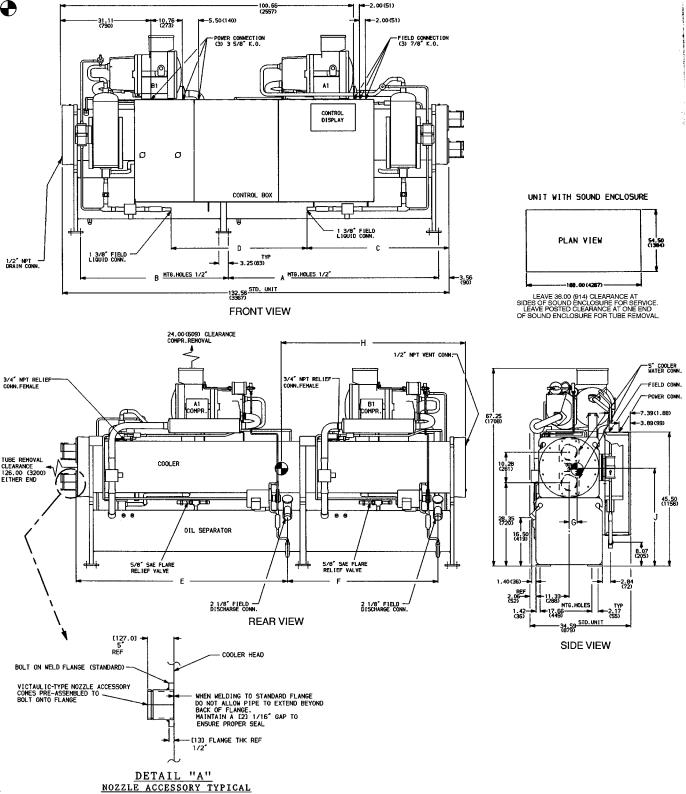

|

|

LEGEND |

K.O. Ð |

Knockout |

|

SAE |

Ð |

Society of Automotive |

THK |

Ð |

Engineers, U.S.A. |

Thick |

||

TYP |

Ð |

Typical |

NOTES:

1. |

Denotes center of gravity. |

2. |

Dimensions are in inches. Dimensions ( ) are in millimeters. |

3. |

Recommended service clearance around unit (front, back, and one side) is |

|

369 (914). |

DIMENSIONS Ð in. (mm)

UNIT |

A |

B |

C |

D |

E |

F |

G |

H |

J |

|

30HXA |

||||||||||

|

|

|

|

|

|

|

|

|

||

161 |

72.12 |

50.63 |

48.56 |

46.62 |

72.06 |

51.00 |

2.70 |

62.50 |

35.20 |

|

(1832) |

(1386) |

(1233) |

(1184) |

(1830) |

(1295) |

(69) |

(1588) |

(894) |

||

|

||||||||||

171 |

61.37 |

61.37 |

43.25 |

46.62 |

61.31 |

61.75 |

2.70 |

62.50 |

35.20 |

|

(1559) |

(1559) |

(1099) |

(1184) |

(1572) |

(1568) |

(69) |

(1588) |

(894) |

||

|

||||||||||

186 |

61.37 |

61.37 |

43.25 |

46.62 |

61.31 |

61.75 |

2.70 |

62.50 |

35.20 |

|

(1559) |

(1559) |

(1099) |

(1184) |

(1572) |

(1568) |

(69) |

(1588) |

(894) |

||

|

Fig. 4 Ð Base Unit Dimensions, 30HXA161-186 Units

5

WEIGHT DISTRIBUTION AT EACH MOUNTING PLATE, 30HXC UNITS Ð Lb (Kg)

WEIGHT DISTRIBUTION AT EACH MOUNTING PLATE, 30HXA UNITS Ð Lb (Kg)

UNIT |

|

MOUNTING PLATE NO. |

|

||||

30HXC |

1 |

2 |

3 |

4 |

5 |

6 |

|

076 |

738 |

943 |

595 |

1110 |

1418 |

896 |

|

(335) |

(428) |

(270) |

(503) |

(643) |

(406) |

||

|

|||||||

086 |

738 |

947 |

597 |

1112 |

1427 |

902 |

|

(335) |

(430) |

(271) |

(504) |

(647) |

(409) |

||

|

|||||||

096 |

686 |

968 |

693 |

1027 |

1447 |

1034 |

|

(311) |

(439) |

(314) |

(466) |

(656) |

(469) |

||

|

|||||||

106 |

730 |

1028 |

744 |

1073 |

1510 |

1092 |

|

(331) |

(466) |

(337) |

(487) |

(685) |

(495) |

||

|

|||||||

116 |

728 |

1114 |

777 |

1053 |

1615 |

1127 |

|

(330) |

(505) |

(352) |

(478) |

(733) |

(511) |

||

|

|||||||

126 |

738 |

1127 |

780 |

1061 |

1628 |

1131 |

|

(335) |

(511) |

(354) |

(481) |

(738) |

(513) |

||

|

|||||||

136 |

758 |

1176 |

811 |

1083 |

1689 |

1171 |

|

(344) |

(533) |

(368) |

(491) |

(766) |

(531) |

||

|

|||||||

146 |

763 |

1182 |

815 |

1085 |

1697 |

1172 |

|

(346) |

(536) |

(370) |

(492) |

(770) |

(532) |

||

|

|||||||

161 |

817 |

1272 |

908 |

1219 |

1890 |

1346 |

|

(371) |

(577) |

(412) |

(553) |

(857) |

(610) |

||

|

|||||||

171 |

936 |

1318 |

840 |

1379 |

1946 |

1241 |

|

(425) |

(598) |

(381) |

(626) |

(883) |

(563) |

||

|

|||||||

186 |

962 |

1361 |

860 |

1410 |

1996 |

1265 |

|

(436) |

(617) |

(390) |

(640) |

(905) |

(574) |

||

|

|||||||

NOTE: See Fig. 1-4 for center of gravity details.

UNIT |

|

MOUNTING PLATE NO. |

|

||||

30HXA |

1 |

2 |

3 |

4 |

5 |

6 |

|

076 |

555 |

793 |

418 |

926 |

1326 |

699 |

|

(252) |

(360) |

(190) |

(420) |

(601) |

(317) |

||

|

|||||||

086 |

555 |

798 |

418 |

928 |

1340 |

705 |

|

(252) |

(362) |

(190) |

(421) |

(608) |

(320) |

||

|

|||||||

096 |

509 |

808 |

493 |

848 |

1350 |

827 |

|

(231) |

(367) |

(224) |

(385) |

(612) |

(375) |

||

|

|||||||

106 |

555 |

869 |

541 |

896 |

1410 |

880 |

|

(252) |

(394) |

(245) |

(406) |

(640) |

(399) |

||

|

|||||||

116 |

530 |

895 |

540 |

855 |

1456 |

887 |

|

(240) |

(406) |

(245) |

(388) |

(660) |

(402) |

||

|

|||||||

126 |

540 |

905 |

541 |

864 |

1468 |

887 |

|

(245) |

(410) |

(245) |

(392) |

(666) |

(402) |

||

|

|||||||

136 |

548 |

926 |

555 |

8743 |

1498 |

908 |

|

(249) |

(420) |

(252) |

(396) |

(679) |

(412) |

||

|

|||||||

146 |

551 |

930 |

555 |

883 |

1506 |

908 |

|

(250) |

(422) |

(252) |

(400) |

(683) |

(412) |

||

|

|||||||

161 |

560 |

965 |

598 |

954 |

1650 |

1025 |

|

(254) |

(438) |

(271) |

(433) |

(748) |

(465) |

||

|

|||||||

171 |

627 |

968 |

534 |

1072 |

1658 |

918 |

|

(284) |

(439) |

(242) |

(486) |

(752) |

(416) |

||

|

|||||||

186 |

648 |

1004 |

552 |

1110 |

1703 |

939 |

|

(294) |

(455) |

(250) |

(504) |

(772) |

(426) |

||

|

|||||||

Fig. 5 Ð Rigging Information

6

Table 1A Ð Physical Data, English

UNIT SIZE |

076 |

086 |

096 |

106 |

116 |

126 |

136 |

|

146 |

161 |

171 |

186 |

UNIT WEIGHT (lb) |

|

|

|

|

|

|

|

|

|

|

|

|

Fluid Cooled (HXC) |

5700 |

5723 |

5855 |

6177 |

6415 |

6465 |

6688 |

|

6718 |

7452 |

7660 |

7854 |

Condenserless (HXA) |

4717 |

4744 |

4835 |

5151 |

5162 |

5205 |

5308 |

|

5333 |

5752 |

5777 |

5946 |

COMPRESSORS |

|

|

|

|

Semi-Hermetic, Twin Screw |

|

|

|

||||

Quantity |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

2 |

2 |

2 |

2 |

Nominal Capacity per |

39/39 |

46/39 |

56/39 |

66/39 |

66/46 |

66/56 |

80/56 |

|

80/66 |

80/56 |

66/80 |

80/80 |

Compressor (tons) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Economizer |

No |

No |

No |

No |

No |

No |

No |

|

No |

Yes |

Yes |

Yes |

No. Capacity Steps |

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

|

6 |

6 |

6 |

6 |

Optional (maximum) |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

8 |

8 |

8 |

8 |

Minimum Step Capacity (%) |

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

20 |

20 |

20 |

20 |

Optional |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

10 |

10 |

10 |

10 |

REFRIGERANT TYPE |

|

|

|

|

|

R-134a |

|

|

|

|

||

Charge* (lb) |

55/55 |

66/55 |

79/55 |

95/55 |

95/66 |

95/79 |

114/79 |

|

114/95 |

130/90 |

109/130 |

130/130 |

Circuit A/Circuit B |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

COOLER TYPE |

|

|

|

Shell and Tube with Enhanced Copper Tubes |

|

|

||||||

Part No. 10HX400− |

001 |

001 |

002 |

010 |

007 |

007 |

006 |

|

006 |

104 |

012 |

013 |

Net Fluid Volume (gal) |

17.0 |

17.0 |

19.0 |

22.6 |

21.4 |

21.4 |

24.0 |

|

24.0 |

28.5 |

28.5 |

33.4 |

Maximum Refrigerant Pressure |

220 |

220 |

220 |

220 |

220 |

220 |

220 |

|

220 |

220 |

220 |

220 |

(psig) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Fluid-Side Pressure |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

|

300 |

300 |

300 |

300 |

(psig) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Fluid Connections (in.) |

|

|

|

|

Steel Weld Couplings |

|

|

|

|

|||

Inlet and Outlet |

4 |

4 |

4 |

5 |

4 |

4 |

4 |

|

4 |

5 |

5 |

5 |

Drain (NPT) |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

|

1¤2 |

1¤2 |

1¤2 |

1¤2 |

30HXA OIL SEPARATOR |

|

|

|

|

|

|

|

|

|

|

|

|

Part No. 09RX400− |

007 |

007 |

008 |

008 |

009 |

009 |

009 |

|

009 |

009 |

010 |

010 |

Maximum Refrigerant Pressure |

320 |

320 |

320 |

320 |

320 |

320 |

320 |

|

320 |

320 |

320 |

320 |

(psig) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Refrigerant Connections (in.) |

|

|

|

|

|

|

|

|

|

|

|

|

Discharge |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

|

21¤8 |

21¤8 |

21¤8 |

21¤8 |

Liquid |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

|

11¤8 |

13¤8 |

13¤8 |

13¤8 |

CONDENSER (HXC) |

|

|

|

Shell and Tube with Enhanced Copper Tubes |

|

|

||||||

Part No. 09RX400− |

001 |

001 |

002 |

002 |

003 |

003 |

004 |

|

004 |

005 |

006 |

006 |

Net Fluid Volume (gal) |

16.8 |

16.8 |

18.3 |

18.3 |

23.9 |

23.9 |

27.5 |

|

27.5 |

30.6 |

37.6 |

37.6 |

Maximum Refrigerant Pressure |

220 |

220 |

220 |

220 |

220 |

220 |

220 |

|

220 |

220 |

220 |

220 |

(psig) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum Water-Side Pressure |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

|

300 |

300 |

300 |

300 |

(psig) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Connections (in.) |

|

|

|

|

Steel Weld Couplings |

|

|

|

|

|||

Inlet and Outlet |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

5 |

5 |

5 |

5 |

Drain (NPT) |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

|

1¤2 |

1¤2 |

1¤2 |

1¤2 |

*Charges listed are for 30HXC units. The 30HXA units are shipped with a holding charge only.

7

Table 1B Ð Physical Data, SI

UNIT SIZE |

076 |

086 |

096 |

106 |

116 |

126 |

136 |

146 |

161 |

171 |

186 |

|

UNIT WEIGHT (Kg) |

|

|

|

|

|

|

|

|

|

|

|

|

Fluid Cooled (HXC) |

2586 |

2596 |

2656 |

2802 |

2910 |

2933 |

3034 |

3047 |

3380 |

3476 |

3563 |

|

Condenserless (HXA) |

2140 |

2152 |

2193 |

2336 |

2341 |

2361 |

2408 |

2419 |

2609 |

2620 |

2697 |

|

COMPRESSORS |

|

|

|

|

Semi-Hermetic, Twin Screw |

|

|

|

|

|||

Quantity |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

Nominal Capacity per |

137/137 |

162/137 |

197/137 |

232/137 |

232/137 |

232/197 |

281/197 |

281/232 |

281/197 |

232/281 |

281/281 |

|

Compressor (kW) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Economizer |

No |

No |

No |

No |

No |

No |

No |

No |

Yes |

Yes |

Yes |

|

No. Capacity Steps |

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

6 |

|

Optional (maximum) |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

8 |

|

Minimum Step Capacity (%) |

|

|

|

|

|

|

|

|

|

|

|

|

Standard |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

Optional |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

10 |

|

REFRIGERANT TYPE |

|

|

|

|

|

R-134a |

|

|

|

|

|

|

Charge* (Kg) |

24.9/ |

29.9/ |

35.8/ |

43.1/ |

43.1/ |

43.1/ |

51.7/ |

51.7/ |

59.0/ |

49.4/ |

59.0/ |

|

Circuit A/Circuit B |

||||||||||||

24.9 |

24.9 |

24.9 |

24.9 |

29.9 |

35.8 |

35.8 |

43.1 |

40.8 |

59.0 |

59.0 |

||

|

||||||||||||

COOLER TYPE |

|

|

|

Shell and Tube with Enhanced Copper Tubes |

|

|

|

|||||

Part No. 10HX400− |

001 |

001 |

002 |

010 |

007 |

007 |

006 |

006 |

104 |

012 |

013 |

|

Net Fluid Volume (L) |

64.3 |

64.3 |

71.9 |

85.5 |

81.0 |

81.0 |

90.8 |

90.8 |

107.9 |

107.9 |

126.4 |

|

Maximum Refrigerant |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

|

Pressure (kPa) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Maximum Fluid-Side |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

|

Pressure (kPa) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Fluid Connections (in.) |

|

|

|

|

Steel |

Weld Couplings |

|

|

|

|

||

Inlet and Outlet |

4 |

4 |

4 |

5 |

4 |

4 |

4 |

4 |

5 |

5 |

5 |

|

Drain (NPT) |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

|

30HXA OIL SEPARATOR |

|

|

|

|

|

|

|

|

|

|

|

|

Part No. 09RX400− |

007 |

007 |

008 |

008 |

009 |

009 |

009 |

009 |

009 |

010 |

010 |

|

Maximum Refrigerant |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

2205 |

|

Pressure (kPa) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Refrigerant Connections (in.) |

|

|

|

|

|

|

|

|

|

|

|

|

Discharge |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

21¤8 |

|

Liquid |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

11¤8 |

13¤8 |

13¤8 |

13¤8 |

|

CONDENSER (HXC) |

|

|

|

Shell and Tube with Enhanced Copper Tubes |

|

|

|

|||||

Part No. 09RX400− |

001 |

001 |

002 |

002 |

003 |

003 |

004 |

004 |

105 |

006 |

006 |

|

Net Fluid Volume (L) |

63.6 |

63.6 |

69.3 |

69.3 |

90.5 |

90.5 |

104.1 |

104.1 |

115.8 |

142.3 |

142.3 |

|

Maximum Refrigerant |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

1517 |

|

Pressure (kPa) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Maximum Water-Side |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

2068 |

|

Pressure (kPa) |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

||

Water Connections (in.) |

|

|

|

|

Steel |

Weld Couplings |

|

|

|

|

||

Inlet and Outlet |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

5 |

|

Drain (NPT) |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

1¤2 |

|

*Charges listed are for 30HXC units. The 30HXA units are shipped with a holding charge only.

8

IMPORTANT: Some of the unit skids are larger than standard door openings. Be sure that the path to the unit's ®nal destination is wide enough to accommodate unit shipping skid. Remove the skid if necessary. If skid is removed and rollers are used, attach rollers to unit tube sheets while moving unit.

Areas where unit mounting points will be located must be level to within 1¤16 in. per ft (1 mm per m) along the long axis of the unit. Once unit is in place and level, bolt unit to the ¯oor. Use isolation pads under the unit to aid in vibration isolation as required.

Step 3 Ð |

Piping Connections Ð See Fig. 6 and |

7 for typical |

piping applications. |

COOLER FLUID, VENT, AND DRAIN Ð The inlet (return) ¯uid connection is always the lower of the 2 cooler connections. See Fig. 6 for locations. A screen strainer with a minimum of 20 mesh should be installed ahead of the cooler inlet to prevent debris from damaging internal tubes of the cooler. Outlet (supply) ¯uid connection is the upper connection of the 2 cooler connections.

The cooler has weld ¯anges to connect the ®eld-supplied piping. Plan the piping arrangement in accordance with good piping practices and so that the piping does not cross in front of the cooler head. Use ¯exible connections on cooler piping to reduce vibration transmission. Offset the piping to permit removal of the cooler head for maintenance. Install pipe hangers where needed. Make sure no weight or stress is placed on the water nozzle.

To install cooler piping:

1.Remove bolts on weld ¯anges, and remove ¯anges from cooler ¯uid heads.

Remove the weld ¯anges before welding piping to the ¯anges. Refer to Fig. 1-4 for weld ¯ange locations. Failure to remove the ¯anges may damage the sensors and insulation.

2.To keep debris from entering the heat exchanger during shipping and storage, the gaskets between the weld flanges and the ¯uid heads do not have holes cut into them. The gaskets have perforations where the holes are to be cut. Carefully cut a hole along the designated perforations.

IMPORTANT: Be sure to remove ¯anges and cut holes in the gaskets between the ¯anges and the fluid heads as indicated.

3.Apply a thin coat of oil to both sides of each gasket to help ensure a good seal, and reattach each gasket to each ¯uid head.

4.Weld the ®eld-supplied piping to the weld ¯anges.

5.Bolt the weld ¯anges back onto their respective ¯uid heads.

IMPORTANT: When bolting the weld ¯anges to the ¯uid heads, be sure to locate the ¯ange such that the hole in each ¯ange lines up completely with the hole in each ¯uid head. If installed incorrectly, part of the hole in the ¯uid head will be blocked off. This will result in impaired ¯uid ¯ow in high pressure drop applications.

Tighten all cooler head bolts to 250 ft-lb (339 N-m) before ®lling system with water (or brine).

6.Install ®eld-supplied differential ¯ow switches in the cooler piping for protection against loss of ¯ow. The differential ¯ow switches must be installed on top of the pipe in a horizontal run and should be at least 5 pipe diameters from any bend. Install the low-pressure differential ¯ow switch into the outlet line piping, and install the high-pressure differential ¯ow switch into the inlet line piping as shown in Fig. 8.

7.Provide openings in ¯uid piping for pressure gages and thermometers (if used). These openings should be 5 to 10 pipe diameters from the unit water nozzles. For thorough mixing and temperature stabilization, wells in the leaving ¯uid pipe should extend at least 2 in. (50 mm) into the pipe.

Accessory Victaulic-type connections are available. Follow the connection directions provided with the accessory.

Although cooler has an air vent, it is recommended that a ®eld-supplied air vent be installed in the system to facilitate servicing. Field-supplied shut-off and balancing valves should also be installed to facilitate servicing and ¯ow balancing. Locate valves in return and supply ¯uid lines as close to the chiller as possible. Locate air vent at highest point of the cooler ¯uid system. See Fig. 6.

Provide drain connections at all low points to permit complete drainage of the system.

BRINE UNITS Ð Special factory modi®cations to the units are required to allow them to operate at ¯uid temperatures less than 34 F (1.1 C). Be sure that the ¯uid has sufficient inhibited ethylene glycol or other suitable corrosionresistant antifreeze solution to prevent cooler freeze up.

PREPARATION FOR YEAR-ROUND OPERATION Ð In areas where the piping or unit is exposed to 32 F (0 °C) or lower ambient temperatures, freeze-up protection is recommended using inhibited ethylene glycol or other suitable corrosion-resistant antifreeze solution and electric heater tapes. Heater tapes should have a rating for area ambient temperatures and be covered with a suitable thickness of closed-cell insulation. Route power for the heater tapes from a separatelyfused disconnect. Mount the disconnect within sight from the unit per local or NEC codes. Identify disconnect as heater tape power source with warning that power must not be turned off except when servicing unit.

Fill the ¯uid loop with water (or brine) and a corrosionresistant inhibitor suitable for the water of the area. Consult the local water authority for characteristics of area water and a recommended inhibitor for the cooler ¯uid loop. It is recommended that once the cooler water lines have been installed and leak checked that the cooler heads be insulated with a suitable thickness of closed-cell insulation. This will minimize the amount of condensation that will form on the cooler heads.

IMPORTANT: Before starting the unit, be sure all of the air has been purged from the system.

A drain connection is located at the bottom of the cooler head. See Fig. 3 and 4 for connection location. Install shutoff valves to the drain line before ®lling the system with fluid.

9

Loading...

Loading...