Carrier 30RH017 Manual

Air-to-Water Heat Pumps with Integrated Hydronic Module

Carrier is participating in the Eurovent Certification Programme. Products are as listed in the Eurovent Directory of Certified Products.

AQUASNAP

30RH 017-033

Nominal cooling capacity 16.7-29 kW

Nominal heating capacity 18.8-34 kW

This new generation of air-to-water heat pumps features the latest technological innovations, incorporating scroll compressors and operating on the ecological refrigerant HFC-407C.

The 30RH heat pumps from Carrier have an integrated hydronic module, with pump and expansion tank, limiting the installation to simple operations like connection of the power supply and the water supply and return piping.

An auto-adaptive control system ensures intelligent control of the compressor start-up sequence.

Features

nRefrigerant R-407C is a blend of R-32, R-125 and R-134a, ensures similar performances to those achieved with R-22 and offers an economical solution to environmental protection problems. It has no effect on the ozone layer and can be used as a replacement for R-22 in air conditioning applications with small and medium capacities.

nThe components of these units are specifically designed for R-407C refrigerant, and all units have been submitted to the necessary laboratory tests to ensure perfect operation.

nThe unit incorporates two axial fans with horizontal air discharge. The advanced design allows exceptionally lownoise operation.

nCompact unit dimensions facilitate installation of these units in restricted spaces.

n Prepainted steel panels.

nRemovable panels for improved service and easier access to all components.

nThe condenser coils are constructed of high-quality copper tube, expanded into pre-treated aluminium fins to offer high corrosion resistance in industrial and marine environments.

nThe refrigerant-to-water heat exchangers are plate heat exchangers, ensuring excellent heat transfer at reduced dimensions and low weight. The plates are made of welded stainless steel. This heat exchanger type requires only minimum refrigerant quantities, compared with traditional heat exchangers.

nThe scroll compressors run very quietly and vibration-free. They are known for their durability and reliability. The motor is fully cooled by suction gas and permits up to 12 starts per hour. The advanced concept of the scroll allows reverse rotation due to incorrect wiring, without impairing the operation of the compressor.

These compressors are especially designed for operation with R-407C.

nThe hydronic module is factory-installed. This eliminates the need to install the necessary components on site, making the unit more compact and easy to install.

1

Water fill system:

-Spherical check valve

-Pressure reduction valve

-Safety valve

Hydronic kit

-Flow switch

-Suction pressure gauge

-Expansion tank

-Spherical shutoff valve

-Filter

-Pressure pump

-Spherical control valve

-Discharge pressure gauge

-Automatic purge.

PRO-DIALOG Plus control

PRO-DIALOG Plus is an advanced numeric control system that combines complex intelligence with great operating simplicity. PRO-DIALOG Plus constantly monitors all machine parameters and safety devices, and precisely manages the operation of compressor and fans for optimum energy efficiency. It also controls the operation of the water pump.

A powerful control system

nThe PID control algorithm with permanent compensation for the difference between entering and leaving water temperature anticipates load variations, and ensures intelligent leaving water temperature control.

nReset of the leaving water temperature set point (according to the outdoor air temperature or the return water temperature).

nPRO-DIALOG Plus control is auto-adaptive for improved heat pump protection. Compressor cycling is automatically adapted to the characteristics of the application according to the inertia of the water loop and prevents dangerous compressor short cycling.

Clear and easy-to-use control system

nThe operator interface is clear and user-friendly: LEDs and numeric displays ensure immediate verification of the unit operating data.

nA simple push of the button positioned on the synoptic heat pump diagram gives you immediate display of the usual parameters: temperatures, pressures, set point, compressor run times etc.

n10 menus offer direct access to all machine controls, including fault history, for rapid fault diagnosis.

Extended communications capabilities

nPRO-DIALOG Plus offers a standard wired remote control with multiple functions for easy integration into any building management system: on/off control, cooling/heating mode selection, power demand limit or dual set point and a general alarm indication.

nThe optional CCN Clock Board offers enhanced control possibilities: Time scheduling of the unit with up to eight sequences, cascade operation of two units, remote control by communication bus through its RS 485 serial port, time scheduling for low-speed fan operation.

Options/accessories

|

Option |

Accessory |

Unit without neutral |

x |

|

|

|

|

220-3-50 power supply |

x |

|

|

|

|

Unit without hydronic kit |

x |

|

|

|

|

Water fill system |

x |

x |

|

|

|

Coil protection grille |

x |

x |

|

|

|

2

Physical data

30RH |

|

017 |

021 |

026 |

033 |

Net cooling capacity* |

kW |

16.70 |

21.60 |

24.60 |

29.00 |

|

|

|

|

|

|

Net heating capacity** |

kW |

18.80 |

24.80 |

27.80 |

34.00 |

|

|

|

|

|

|

Operating weight |

kg |

|

|

|

|

Without hydronic module |

|

245 |

275 |

305 |

340 |

With hydronic module |

|

265 |

305 |

335 |

370 |

|

|

|

|

|

|

Refrigerant charge R-407C |

kg |

7.15 |

7.83 |

9.30 |

10.50 |

Compressor |

|

One scroll compressor |

|

|

|

|

|

|

|

|

|

Control type |

|

Pro-Dialog Plus |

|

|

|

|

|

|

|

|

|

Water heat exchanger |

|

One plate heat exchanger |

|

|

|

Net water volume |

l |

1.50 |

1.88 |

2.16 |

2.82 |

Water connections (MPT gas) |

in |

1 |

1 |

1-1/4 |

1-1/4 |

Maximum water pressure (option without hydronic module) |

kPa |

1000 |

1000 |

1000 |

1000 |

|

|

|

|||

Hydronic module |

|

Pump, screen filter, expansion tank, pressure gauge, purge valve, flow switch and flow |

|||

|

|

control |

|

|

|

Pump |

|

One single-speed |

|

|

|

Available pressure*** |

kPa |

142 |

125 |

155 |

142 |

Water inlet connections |

in |

1-1/4 |

1-1/4 |

1-1/4 |

1-1/4 |

Water outlet connections |

in |

1 |

1 |

1-1/4 |

1-1/4 |

Expansion tank water volume |

l |

8 |

8 |

8 |

8 |

|

|

|

|

|

|

Water fill system (option) |

|

|

|

|

|

Inlet/outlet diameter |

in |

1/2 |

1/2 |

1/2 |

1/2 |

|

|

|

|

||

Air heat exchanger |

|

One, copper tubes and pre-treated aluminium fins |

|

||

Tube diameter |

in |

3/8 |

3/8 |

3/8 |

3/8 |

No. of rows |

|

3 |

2 |

3 |

4 |

Tubes/row |

|

52 |

60 |

60 |

60 |

Fin spacing |

mm |

1.81 |

1.81 |

1.81 |

1.81 |

|

|

|

|

|

|

Fan |

|

Two propeller fans |

|

|

|

Diameter |

mm |

500 |

610 |

610 |

610 |

No. of blades |

|

5 |

5 |

5 |

5 |

Air flow |

l/s |

2222 |

3611 |

3111 |

3333 |

Fan speed |

r/s |

14.50 |

14.33 |

13.58 |

13.33 |

*Based on an outdoor entering air temperature of 35°C dry bulb, and a water heat exchanger entering/leaving water temperature of 12°C/7°C.

**Based on an outdoor entering air temperature of 7°C dry bulb/6°C wet bulb, and a water heat exchanger entering/leaving water temperature of 40°C/45°C.

***Based on water flow at nominal cooling conditions

Electrical data

30RH |

|

017 |

021 |

026 |

033 |

Power supply |

V-ph-Hz |

400-3-50 |

|

|

|

|

|

|

|

|

|

Voltage range |

V |

360-440 |

|

|

|

|

|

|

|

|

|

Nominal power input* |

kW |

6.28 |

8.95 |

9.05 |

11.75 |

|

|

|

|

|

|

Effective power input** |

kW |

6.38 |

8.10 |

9.25 |

12.00 |

|

|

|

|

|

|

Nominal current drawn* |

A |

10.75 |

15.50 |

18.80 |

24.55 |

|

|

|

|

|

|

Effective current drawn** |

A |

10.95 |

15.75 |

19.10 |

24.95 |

|

|

|

|

|

|

Maximum power input*** |

kW |

7.87 |

10.80 |

12.23 |

14.95 |

|

|

|

|

|

|

Maximum current drawn*** |

A |

13.50 |

20.00 |

22.50 |

28.00 |

|

|

|

|

|

|

Starting current |

A |

87 |

132 |

134 |

139 |

|

|

|

|

|

|

Pump power input |

kW |

0.65 |

0.68 |

0.89 |

0.93 |

*Based on an outdoor entering air temperature of 35°C dry bulb, and a water heat exchanger entering/leaving water temperature of 12°C/7°C.

**Eurovent standard

***Based on an outdoor entering air temperature of 46°C and a water heat exchanger leaving water temperature of 10°C.

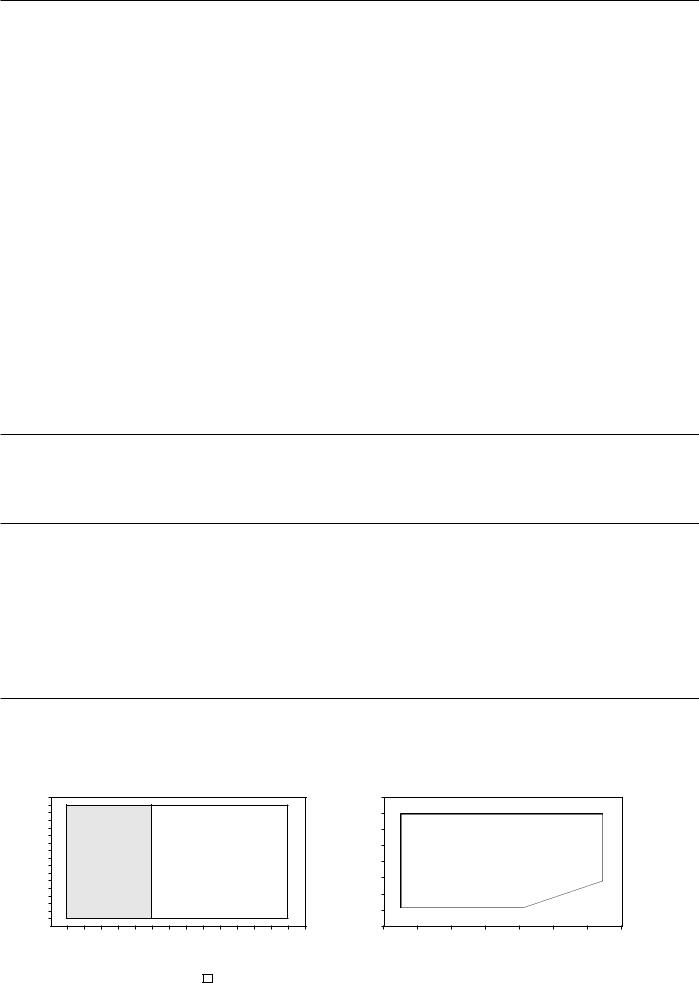

Outdoor air temperature ºC

Operating range – 30RH units

Cooling

50

46

42

38

34

30

26

22

18

14

10

6

2 -2 -6 -10 -14

-1 |

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

Heating |

|

|

|

|

|

|

|

ºC |

25 |

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

temperature |

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

air |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Outdoor |

-5 |

|

|

|

|

|

|

|

-10 |

|

|

|

|

|

|

|

|

-15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

Leaving water temperature ºC |

Leaving water temperature ºC |

|

Operating range with anti-freeze solution and with special |

3 |

|

||

|

configuration of the Pro-Dialog control system |

|

Loading...

Loading...