Canon M3010 Service Manual

M3010 Series

Service Manual

Product Overview

Technical Overview

Periodical Services

Disassembly/Assembly

Adjustment

Trouble Shooting

Error Codes

Service Mode

Appendix

1 2 3 4 5 6 7 8

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or translated into another language, in whole or in part, without the consent of Canon Inc.

© CANON INC. 2011

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Explanation of Symbols

The following symbols are used throughout this Service Manual. |

|

|||||

Symbols |

Explanation |

|

Symbols |

Explanation |

||

|

|

|

|

|

|

|

|

Check. |

|

|

|

|

Remove the claw. |

|

Check visually. |

|

|

|

|

Insert the claw. |

|

Check the noise. |

|

|

|

|

Use the bundled part. |

|

Disconnect the connector. |

|

|

|

|

Push the part. |

|

Connect the connector. |

|

|

|

|

Plug the power cable. |

|

|

|

|

|

||

|

Remove the cable/wire |

|

|

|

|

|

|

from the cable guide or wire |

|

|

|

|

Turn on the power. |

|

saddle. |

|

|

|

|

|

Set the cable/wire to the cable guide or wire saddle.

Remove the screw.

Tighten the screw.

The following rules apply throughout this Service Manual:

1.Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams,  represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow  indicates the direction of the electric signal. The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in supplying the machine with power.

indicates the direction of the electric signal. The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in supplying the machine with power.

2.In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low". (The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be able to identify and isolate faults in the machine.

Contents

0Safety Precautions

|

CDRH Provisions-------------------------------------------------------------- |

0-2 |

|

Laser Safety--------------------------------------------------------------------- |

0-2 |

|

About Laser Beams---------------------------------------------------------------- |

0-2 |

|

Handling Laser Scanner Unit---------------------------------------------------- |

0-2 |

|

Toner Safety--------------------------------------------------------------------- |

0-3 |

|

About Toner-------------------------------------------------------------------------- |

0-3 |

|

Handling Adhered Toner---------------------------------------------------------- |

0-3 |

|

Notes on Handling Lithium Battery---------------------------------------- |

0-3 |

|

Notes on Assembly/Disassembly------------------------------------------ |

0-3 |

1 |

Product Overview |

|

|

Product Lineup----------------------------------------------------------------- |

1-2 |

|

Host Machine------------------------------------------------------------------------ |

1-2 |

|

Options-------------------------------------------------------------------------------- |

1-2 |

|

Product Features-------------------------------------------------------------- |

1-2 |

|

Product Features------------------------------------------------------------------- |

1-2 |

|

Specifications------------------------------------------------------------------- |

1-3 |

|

Product Specifications------------------------------------------------------------- |

1-3 |

|

Parts Name---------------------------------------------------------------------- |

1-4 |

|

External View------------------------------------------------------------------------ |

1-4 |

|

Front side of the machine----------------------------------------------------------------- |

1-4 |

|

Rear side of the machine------------------------------------------------------------------ |

1-4 |

|

Cross Section View---------------------------------------------------------------- |

1-5 |

|

Control Panel------------------------------------------------------------------------ |

1-5 |

2 |

Technical Overview |

|

|

Basic Configuration----------------------------------------------------------- |

2-2 |

|

Configuration function------------------------------------------------------------- |

2-2 |

|

Basic Sequence--------------------------------------------------------------------- |

2-2 |

|

Basic Sequence of Operation------------------------------------------------------------ |

2-2 |

Print Sequence------------------------------------------------------------------------------- |

2-3 |

Power-On Sequence----------------------------------------------------------------------- |

2-4 |

Controller System-------------------------------------------------------------- |

2-5 |

Main Controller---------------------------------------------------------------------- |

2-5 |

Overview--------------------------------------------------------------------------------------- |

2-5 |

Engine Controller------------------------------------------------------------------- |

2-5 |

General description------------------------------------------------------------------------- |

2-5 |

Service Works----------------------------------------------------------------------- |

2-6 |

At parts replacement----------------------------------------------------------------------- |

2-6 |

Maintenance---------------------------------------------------------------------------------- |

2-6 |

Notes on service works-------------------------------------------------------------------- |

2-6 |

Original Exposure System--------------------------------------------------- |

2-7 |

Overview------------------------------------------------------------------------------ |

2-7 |

Major Components----------------------------------------------------------------- |

2-7 |

Service Works----------------------------------------------------------------------- |

2-8 |

At parts replacement----------------------------------------------------------------------- |

2-8 |

Maintenance---------------------------------------------------------------------------------- |

2-8 |

Notes on service works-------------------------------------------------------------------- |

2-8 |

Laser Exposure System------------------------------------------------------ |

2-9 |

Overview------------------------------------------------------------------------------ |

2-9 |

Overview--------------------------------------------------------------------------------------- |

2-9 |

Controlling the Laser Activation Timing-------------------------------------- |

2-10 |

Laser ON/OFF Control-------------------------------------------------------------------- |

2-10 |

Horizontal Sync Control------------------------------------------------------------------- |

2-10 |

Laser Control----------------------------------------------------------------------- |

2-11 |

Auto Power Control (APC)--------------------------------------------------------------- |

2-11 |

Laser Scanner Motor Control--------------------------------------------------- |

2-11 |

Overview-------------------------------------------------------------------------------------- |

2-11 |

Scanner Motor Fault Detection--------------------------------------------------------- |

2-12 |

Service Works---------------------------------------------------------------------- |

2-12 |

At parts replacement---------------------------------------------------------------------- |

2-12 |

Maintenance--------------------------------------------------------------------------------- |

2-12 |

Notes on service works------------------------------------------------------------------- |

2-12 |

Image Formation System-------------------------------------------------- |

2-13 |

Overview/Configuration---------------------------------------------------------- |

2-13 |

Overview-------------------------------------------------------------------------------------- |

2-13 |

Print Process-------------------------------------------------------------------------------- |

2-13 |

Static Latent Image Formation Block-------------------------------------------------- |

2-14 |

Development Block------------------------------------------------------------------------ |

2-14 |

Transfer Block------------------------------------------------------------------------------- |

2-15 |

Fixing Block---------------------------------------------------------------------------------- |

2-15 |

Drum Cleaning Block---------------------------------------------------------------------- |

2-15 |

High-Voltage Control-------------------------------------------------------------- |

2-16 |

Overview-------------------------------------------------------------------------------------- |

2-16 |

Generating Primary Charging Bias---------------------------------------------------- |

2-16 |

Generating Developing Bias------------------------------------------------------------- |

2-16 |

Generating Transfer Bias----------------------------------------------------------------- |

2-16 |

Toner Cartridge--------------------------------------------------------------------- |

2-17 |

Toner Level Detection--------------------------------------------------------------------- |

2-17 |

Toner Cartridge Absence/Presence Detection-------------------------------------- |

2-17 |

Service Works---------------------------------------------------------------------- |

2-18 |

At parts replacement---------------------------------------------------------------------- |

2-18 |

Maintenance--------------------------------------------------------------------------------- |

2-18 |

Notes on service works------------------------------------------------------------------- |

2-18 |

Fixing System----------------------------------------------------------------- |

2-19 |

Overview/Configuration---------------------------------------------------------- |

2-19 |

Overview-------------------------------------------------------------------------------------- |

2-19 |

Main Parts of Fixing assembly---------------------------------------------------------- |

2-19 |

Various Control Mechanisms--------------------------------------------------- |

2-20 |

Fixing Temperature Control-------------------------------------------------------------- |

2-20 |

Protective Functions----------------------------------------------------------------------- |

2-20 |

Other Functions-------------------------------------------------------------------- |

2-22 |

Throughput Down Control---------------------------------------------------------------- |

2-22 |

Service Works---------------------------------------------------------------------- |

2-23 |

At parts replacement---------------------------------------------------------------------- |

2-23 |

Maintenance--------------------------------------------------------------------------------- |

2-23 |

Notes on service works------------------------------------------------------------------- |

2-23 |

Pickup Feed System-------------------------------------------------------- |

2-24 |

Overview----------------------------------------------------------------------------- |

2-24 |

Overview-------------------------------------------------------------------------------------- |

2-24 |

Detecting Jams--------------------------------------------------------------------- |

2-25 |

Jam Detection Outline--------------------------------------------------------------------- |

2-25 |

Delay Jam------------------------------------------------------------------------------------ |

2-25 |

Stationary Jam------------------------------------------------------------------------------ |

2-27 |

Other Jams----------------------------------------------------------------------------------- |

2-27 |

Service Works---------------------------------------------------------------------- |

2-28 |

At parts replacement---------------------------------------------------------------------- |

2-28 |

Maintenance--------------------------------------------------------------------------------- |

2-28 |

Notes on service works------------------------------------------------------------------- |

2-28 |

External And Controls System-------------------------------------------- |

2-29 |

Power Supply----------------------------------------------------------------------- |

2-29 |

Power Supply-------------------------------------------------------------------------------- |

2-29 |

Protective Functions----------------------------------------------------------------------- |

2-29 |

Service Works---------------------------------------------------------------------- |

2-30 |

At parts replacement---------------------------------------------------------------------- |

2-30 |

Maintenance--------------------------------------------------------------------------------- |

2-30 |

Notes on service works------------------------------------------------------------------- |

2-30 |

3 Periodical Services

Periodically Replaced Parts------------------------------------------------- |

3-2 |

Periodically Replaced Parts------------------------------------------------------ |

3-2 |

Consumables------------------------------------------------------------------- |

3-2 |

Consumables------------------------------------------------------------------------ |

3-2 |

Periodical Service------------------------------------------------------------- |

3-3 |

Scheduled Servicing--------------------------------------------------------------- |

3-3 |

Cleaning-------------------------------------------------------------------------- |

3-3 |

4Disassembly/Assembly

Outline---------------------------------------------------------------------------- |

4-2 |

List Of Parts--------------------------------------------------------------------- |

4-3 |

External View------------------------------------------------------------------------ |

4-3 |

Front Side------------------------------------------------------------------------------------- |

4-3 |

Rear Side-------------------------------------------------------------------------------------- |

4-3 |

List of Main Unit--------------------------------------------------------------------- |

4-4 |

Reader Unit----------------------------------------------------------------------------------- |

4-4 |

Printer Unit------------------------------------------------------------------------------------ |

4-4 |

Electrical Components------------------------------------------------------------ |

4-5 |

Reader Unit----------------------------------------------------------------------------------- |

4-5 |

Motor------------------------------------------------------------------------------------------- |

4-5 |

Solenoid--------------------------------------------------------------------------------------- |

4-6 |

Sensor------------------------------------------------------------------------------------------ |

4-6 |

Switch------------------------------------------------------------------------------------------ |

4-7 |

Heater/Thermistor/Thermoswitch/------------------------------------------------------- |

4-7 |

PCB--------------------------------------------------------------------------------------------- |

4-8 |

List of Connectors------------------------------------------------------------- |

4-9 |

Reader Unit-------------------------------------------------------------------------- |

4-9 |

Printer Unit-------------------------------------------------------------------------- |

4-10 |

External Cover / Interior System----------------------------------------- |

4-12 |

Layout Drawing-------------------------------------------------------------------- |

4-12 |

Front Side------------------------------------------------------------------------------------ |

4-12 |

Rear Side------------------------------------------------------------------------------------- |

4-12 |

Removing the Left Cover-------------------------------------------------------- |

4-13 |

Removing the Right Cover------------------------------------------------------ |

4-14 |

Removing the Front Cover Unit------------------------------------------------ |

4-15 |

Preparation----------------------------------------------------------------------------------- |

4-15 |

Procedure------------------------------------------------------------------------------------ |

4-15 |

Removing the Upper Cover----------------------------------------------------- |

4-15 |

Preparation----------------------------------------------------------------------------------- |

4-15 |

Procedure------------------------------------------------------------------------------------ |

4-15 |

Removing the Rear Cover------------------------------------------------------- |

4-17 |

Preparation----------------------------------------------------------------------------------- |

4-17 |

Procedure------------------------------------------------------------------------------------ |

4-17 |

Original Exposure System------------------------------------------------- |

4-19 |

Layout Drawing-------------------------------------------------------------------- |

4-19 |

Removing the Copyboard Cover.---------------------------------------------- |

4-19 |

Removing the Reader Unit------------------------------------------------------ |

4-20 |

Preparation----------------------------------------------------------------------------------- |

4-20 |

Procedure------------------------------------------------------------------------------------ |

4-20 |

Removing the Copyboard Glass Unit----------------------------------------- |

4-21 |

Preparation----------------------------------------------------------------------------------- |

4-21 |

Procedure------------------------------------------------------------------------------------ |

4-21 |

Removing the Reader Motor Unit--------------------------------------------- |

4-23 |

Preparation----------------------------------------------------------------------------------- |

4-23 |

Procedure------------------------------------------------------------------------------------ |

4-23 |

Removing the CIS Unit----------------------------------------------------------- |

4-26 |

Preparation----------------------------------------------------------------------------------- |

4-26 |

Procedure------------------------------------------------------------------------------------ |

4-26 |

Controller System------------------------------------------------------------ |

4-28 |

Layout Drawing-------------------------------------------------------------------- |

4-28 |

Removing the Control Panel Unit---------------------------------------------- |

4-29 |

Removing the Drive Belt--------------------------------------------------------- |

4-29 |

Preparation----------------------------------------------------------------------------------- |

4-29 |

Procedure------------------------------------------------------------------------------------ |

4-29 |

Removing the Main Motor------------------------------------------------------- |

4-31 |

Preparation----------------------------------------------------------------------------------- |

4-31 |

Procedure------------------------------------------------------------------------------------ |

4-31 |

Removing the Main Controller PCB------------------------------------------- |

4-34 |

Preparation----------------------------------------------------------------------------------- |

4-34 |

Procedure------------------------------------------------------------------------------------ |

4-34 |

After Replacing the Main Controller PCB-------------------------------------------- |

4-34 |

Removing the Engine Controller PCB---------------------------------------- |

4-35 |

Preparation----------------------------------------------------------------------------------- |

4-35 |

Procedure------------------------------------------------------------------------------------ |

4-35 |

Removing the Paper Leading Edge Sensor-------------------------------- |

4-38 |

Preparation----------------------------------------------------------------------------------- |

4-38 |

Procedure------------------------------------------------------------------------------------ |

4-38 |

Removing the Fixing Delivery/Paper Width Sensor PCB---------------- |

4-40 |

Preparation----------------------------------------------------------------------------------- |

4-40 |

Procedure------------------------------------------------------------------------------------ |

4-40 |

Laser Exposure System---------------------------------------------------- |

4-42 |

Layout Drawing-------------------------------------------------------------------- |

4-42 |

Removing the Laser Scanner Unit-------------------------------------------- |

4-42 |

Preparation----------------------------------------------------------------------------------- |

4-42 |

Procedure------------------------------------------------------------------------------------ |

4-42 |

Image Formation System-------------------------------------------------- |

4-44 |

Layout Drawing-------------------------------------------------------------------- |

4-44 |

Removing the Transfer Roller-------------------------------------------------- |

4-44 |

Fixing System----------------------------------------------------------------- |

4-46 |

Layout Drawing-------------------------------------------------------------------- |

4-46 |

Removing the Fixing Assembly------------------------------------------------ |

4-46 |

Preparation----------------------------------------------------------------------------------- |

4-46 |

Procedure------------------------------------------------------------------------------------ |

4-46 |

Pickup Feed System-------------------------------------------------------- |

4-51 |

Layout Drawing-------------------------------------------------------------------- |

4-51 |

Removing the Pickup Unit------------------------------------------------------- |

4-51 |

Preparation----------------------------------------------------------------------------------- |

4-51 |

Procedure------------------------------------------------------------------------------------ |

4-51 |

Removing the Pickup Roller---------------------------------------------------- |

4-54 |

Removing the Pickup Solenoid------------------------------------------------ |

4-55 |

Preparation----------------------------------------------------------------------------------- |

4-55 |

Procedure------------------------------------------------------------------------------------ |

4-55 |

Removing the Separation Pad------------------------------------------------- |

4-57 |

5 |

Adjustment |

|

|

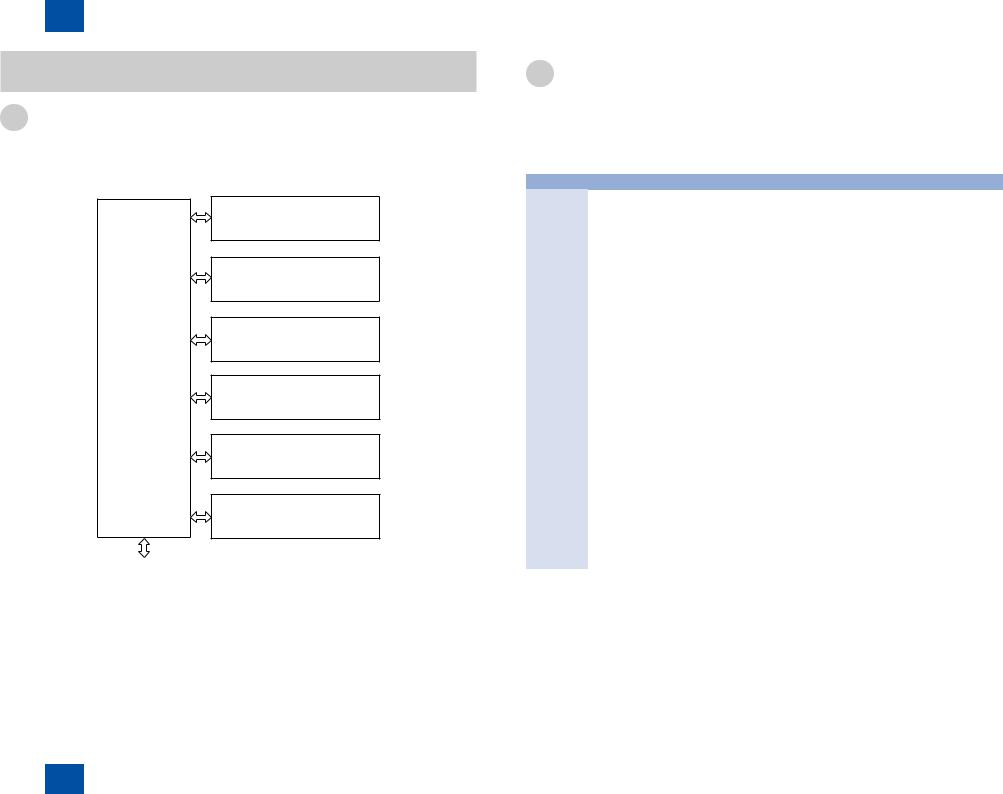

Mechanical Adjustment------------------------------------------------------- |

5-2 |

|

Confirming Nip Width-------------------------------------------------------------- |

5-2 |

6 |

Trouble Shooting |

|

|

Test Print------------------------------------------------------------------------- |

6-2 |

|

Test Print Function----------------------------------------------------------------- |

6-2 |

|

Trouble Shooting Items------------------------------------------------------- |

6-3 |

|

Image Faults------------------------------------------------------------------------- |

6-3 |

|

Smudged/Streaked------------------------------------------------------------------------- |

6-3 |

|

Version Upgrade--------------------------------------------------------------- |

6-4 |

|

Overview------------------------------------------------------------------------------ |

6-4 |

|

Preparation--------------------------------------------------------------------------- |

6-4 |

|

System Requirements---------------------------------------------------------------------- |

6-4 |

|

Preparation------------------------------------------------------------------------------------ |

6-5 |

|

Downloading System Software------------------------------------------------- |

6-5 |

7Error Codes

Overview------------------------------------------------------------------------- |

7-2 |

Error Codes--------------------------------------------------------------------- |

7-3 |

8Service Mode

Overview------------------------------------------------------------------------- |

8-2 |

Entering Service Mode------------------------------------------------------------ |

8-2 |

Exiting Service Mode-------------------------------------------------------------- |

8-2 |

Screen Operation in Service Mode-------------------------------------------- |

8-3 |

COPIER-------------------------------------------------------------------------- |

8-4 |

DISPLAY------------------------------------------------------------------------------ |

8-4 |

ADJUST------------------------------------------------------------------------------- |

8-5 |

FUNCTION--------------------------------------------------------------------------- |

8-7 |

COUNTER--------------------------------------------------------------------------- |

8-9 |

TYPE--------------------------------------------------------------------------------- |

8-10 |

TESTMODE------------------------------------------------------------------- |

8-11 |

SCAN--------------------------------------------------------------------------------- |

8-11 |

COPY--------------------------------------------------------------------------------- |

8-12 |

Appendix

Service Tools---------------------------------------------------------------------- |

II |

Solvent/Oil List------------------------------------------------------------------- |

III |

General Circuit Diagram------------------------------------------------------ |

IV |

General Timing Chart----------------------------------------------------------- |

V |

Preparation--------------------------------------------------------------------------- |

8-2 |

Service Mode Menu---------------------------------------------------------------- |

8-2 |

Safety Precautions

■■CDRH Provisions ■■Laser Safety ■■Toner Safety

■■Notes on Handling

Lithium Battery M3010 Series ■■Notes on Assembly/

Disassembly

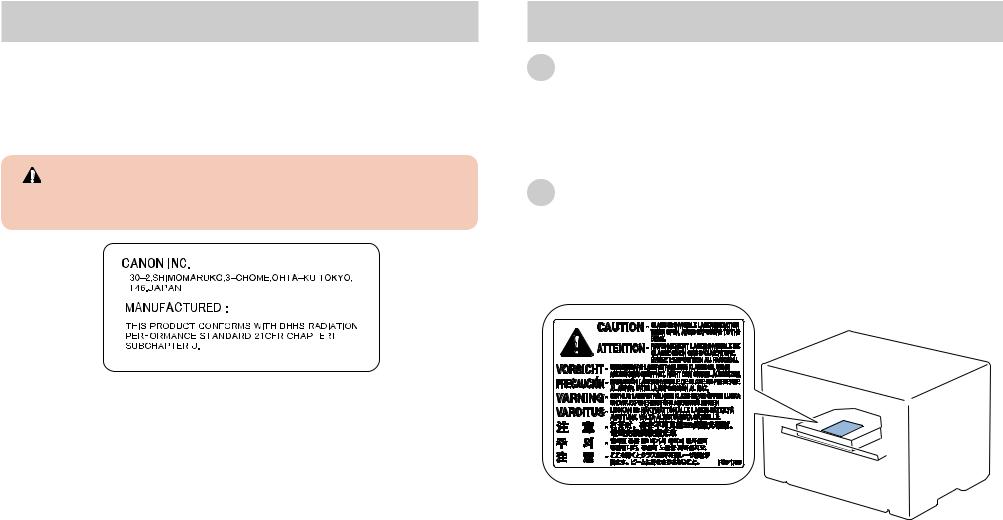

CDRH Provisions

Food and Drug CDRH (Center for Devices and Radiological Health) under FDA (Food and Drug Administration) enforced provisions of the section for laser and laser products on August 2, 1976. These provisions are applicable to all laser products manufactured or assembled after August 1, 1976 and allow only products certified their compliance with the provisions

to market in the US. Each product shall have affixed the applicable label as shown below to follow the labeling requirements prescribed in CDRH provisions.

Note that the wording included in labels is different depending on laser product classifications.

0-2

Laser Safety

About Laser Beams

Laser radiation may be hazardous to human. The laser scanner unit mounted in this device is sealed in the protective housing and the external cover to prevent laser beams from leaking to the environment. As long as the device is operated under normal conditions, users are safely guarded from laser leaks.

Handling Laser Scanner Unit

Before providing service works for the laser scanner unit and its peripherals, ensure to turn off the power of the device.

Any cover with potential dangers of laser beam reflection has affixed the caution label at the position shown in the figure below.

F-0-1

F-0-2

0-2

Toner Safety

About Toner

Toner is a non-toxic material composed of plastic, iron, small amount of pigment, etc.

Never throw toner in flames to avoid explosion.

Handling Adhered Toner

•Use dry tissue paper to wipe off toner adhered to skin or clothes and wash in water.

•Never use warm water for cleaning up toner to prevent toner particles from being able to soak into fibers permanently.

•Toner particles are reactive with vinyl polymers. Avoid contacting these materials.

Notes on Handling Lithium Battery

Replacing with wrong battery types may cause explosion.

Follow instructions to dispose used batteries properly.

0-3

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1.Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2.If not specially instructed, reverse the order of disassembly to reinstall.

3.Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4.To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to use the right screw type when assembling.

5.Unless it is specially needed, do not operate the device with some parts removed.

6.Never remove the paint-locked screws when disassembling.

0-3

1Product Overview■■Product Lineup

■■Product Features ■■Specifications ■■Parts Name

1Product Overview

|

1 |

Product Overview > Product Features > Product Features |

|

|

1-2 |

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

Product Lineup |

|

|

|

|

Product Features |

||||

|

|

|

|

|

|

|

|

|

||

|

Host Machine |

|

|

|

|

Product Features |

||||

|

|

|

|

|

|

|

|

|

|

1.Compact/high-speed printer |

|

Model name |

|

MF3010 |

|

|

|||||

|

|

|

|

|

This machine is a high-speed B&W printer with a compact body design and the print speed |

|||||

|

Configuration |

|

3in1 single-sided platen |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

of 19 ppm (LTR). |

|

|

|

|

|

|

|

|

|

|

2.Reduced standby time and low energy consumption |

|

|

|

|

|

|

|

|

|

|

This machine uses the on-demand fixing method in which power is supplied to the heater |

|

|

|

|

|

|

|

|

|

|

only at printing. |

|

Design |

|

|

|

|

|

This realized the reduction of standby time and low energy consumption during standby. |

|||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

3.Reduced operation noise and stabilized image quality |

|

|

|

|

|

|

|

|

|

|

This machine uses the belt drive method for the Main Motor's drive transmission. |

|

|

|

|

|

|

|

|

|

|

The operation noise is reduced and image quality is stabilized compared to the |

|

|

|

|

|

|

|

|

|

|

conventional gear drive method (see NOTE). |

|

|

|

|

|

|

|

|

|

|

4.Improved user operability |

|

|

|

ADF |

|

- |

|

|

|||

|

Engine |

|

2-sided |

|

- |

|

|

|

User operability is improved by concentrating the maintenance processes (jam removal |

|

|

|

1-sided |

|

Yes |

|

|

|

and cartridge replacement) in a single location at the Upper Cover. |

||

|

|

|

|

|

|

|

|

|||

|

LAN |

Port |

|

- |

|

|

|

|

||

|

|

|

FAX |

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

T-1-1 |

|

Note: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Options |

|

|

|

|

By changing the drive method from gear to belt, uneven cycle of the Photosensitive |

||||

|

|

|

|

|

Drum is reduced. This makes it possible to realize stabilized image quality. |

|||||

None

1-2

1Product Overview > Product Features > Product Features

1Product Overview > Specifications > Product Specifications

Specifications

Product Specifications

Copyboard |

Fixed Copyboard |

Machine installation method |

Desktop |

Light source |

LED (RGB) |

Image reading method |

CIS (color) |

Photosensitive medium |

OPC Drum |

Exposure method |

Laser beam (semiconductor laser) |

Charging method |

Roller charging |

Developing method |

Toner projection |

Transfer method |

Roller transfer |

Separation method |

Curvature separation |

Pickup method |

Pickup Tray: Pad separation method |

|

Multi-purpose Tray: None |

Delivery method |

Face-down |

Drum cleaning method |

Blade cleaning |

Fixing method |

On-demand method |

Toner supplying method |

Toner Cartridge replacement |

Toner level detection |

None |

Document type |

Sheet |

Maximum document size |

216 mm x 297 mm |

Magnification ratio |

100 % magnification |

|

50 to 200 % (in increments of 10 %) |

Resolution at reading |

600 dpi × 400 dpi / 600 dpi × 600 dpi * |

Print resolution |

600 dpi × 400 dpi / 600 dpi × 600 dpi * |

Warm-up time |

10 sec. or less (when replacing the Toner Cartridge with a new |

|

one: 42 sec. or less) |

First print time |

Approx. 7.7 sec. or less (LTR, default setting) |

First copy time |

Approx. 12 sec. or less (LTR, default setting) |

Print speed |

19 ppm (LTR, initial setting) |

|

12 ppm (when output adjustment mode is used) |

Copy speed |

19 ppm (LTR) |

Paper size |

Fixed size: |

|

A4, B5, A5, LGL, LTR, Statement, Executive, Officio, B-officio, |

|

M-officio, Government-Letter, Government-Legal, Foolscap, |

|

A-foolscap, Envelope COM10, Envelope C5, Envelope B5, |

|

Envelope DL |

|

Custom size: |

|

Width: 76.2 to 216 mm, Length: 127 to 356 mm |

Paper types |

Plain paper (60 to 89 g/m2), Heavy paper (90 to 163 g/m2), Rough |

|

paper (60 to 163 g/m2), Transparency, Label, Envelope |

Pickup Tray capacity |

Approx. 150 sheets (plain paper: 60 to 80 g/m2) |

Delivery Tray capacity |

Approx. 100 sheets (plain paper: 60 to 80 g/m2) |

1-3

Environment temperature range |

10 to 30 degrees Centigrade |

|

Environment humidity range |

20 to 80 % |

|

Duplex method |

None |

|

Host Interface |

Standard: USB/Hi-speed USB, Options: None |

|

Hard disk capacity |

Standard: None, Options: None |

|

Memory capacity |

Standard: 64 MB, Options: None |

|

Power supply |

AC120 to 127V +/- 10 %, ( 50,60 Hz +/- 2 Hz) |

|

|

AC220 to 240V +/- 10 %, ( 50,60 Hz +/- 2 Hz) |

|

|

|

|

Maximum power consumption |

900 |

W or less (120 V), 960 W or less (230 V) |

Power consumption |

460 |

W or less (120 V), 450 W or less (230 V) |

External dimensions (W x D xH) |

372 |

× 276 × 254 mm |

Weight |

Approx. 8.2 kg (including Toner Cartridge) |

|

T-1-2

*: Resolution switching

With this machine, 2 types of resolution can be switched by setting "Copy Type" on the printer driver.

Speed priority (at the time of shipment): 600 dpi × 400 dpi Resolution priority: 600 dpi × 600 dpi

1-3

1Product Overview > Specifications > Product Specifications

1 Product Overview > Parts Name > External View > Rear side of the machine |

1-4 |

|

|

|

|

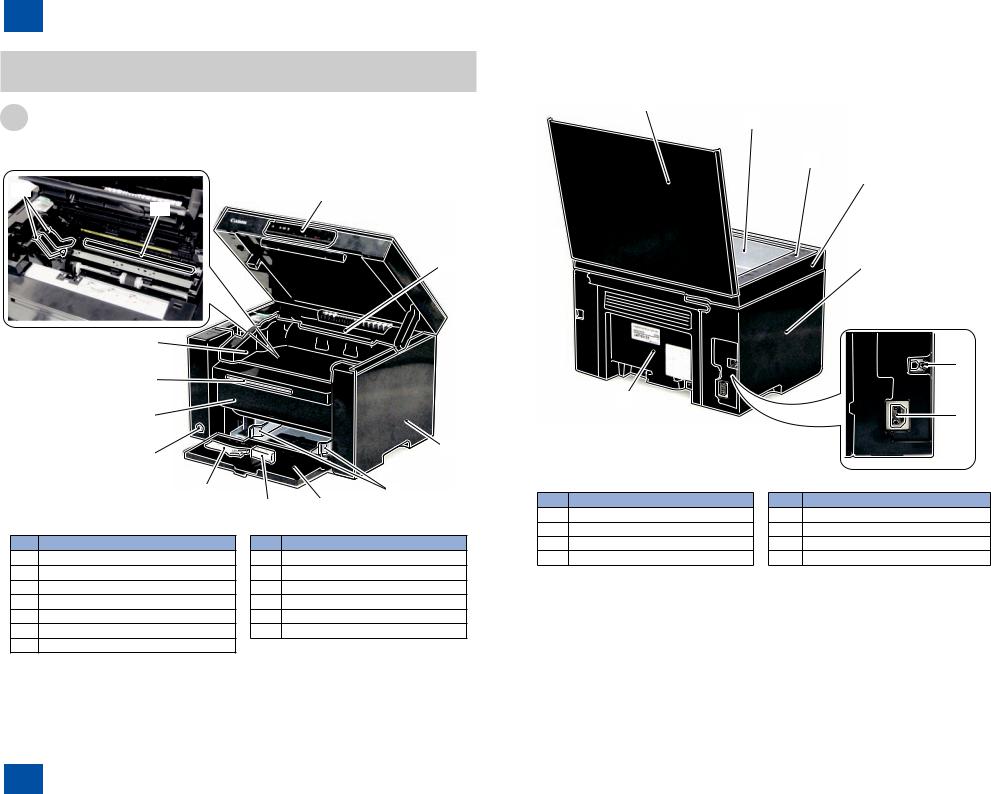

Parts Name |

|

■■Rear side of the machine |

External View |

|

[1] |

|

[2] |

|

■■Front side of the machine |

|

[3] |

|

|

|

[12] |

|

[4] |

[1] |

|

|

|

|

|

[13] |

|

|

|

[2] |

[5] |

|

[11] |

|

|

|

|

|

|

|

[10] |

|

|

|

|

|

[6] |

|

|

|

|

|

|

|

|

|

|

|

|

|

[8] |

|

|

|

[9] |

|

|

|

|

|

[7] |

|

[8] |

|

[3] |

|

|

|

|

|

|

|

|

|

|

|

|

|

[7] |

|

[4] |

|

|

|

F-1-2 |

|

|

No. |

Name |

No. |

Name |

||

|

|

[6] |

[5] |

||||

|

|

[1] |

Copyboard Cover |

[5] |

Left Cover |

||

|

|

|

F-1-1 |

||||

|

|

|

[2] |

Copyboard Glass |

[6] |

USB Device Port |

|

No. |

Name |

No. |

Name |

[3] |

Copyboard Upper Cover |

[7] Power Supply Cord Slot |

|

[1] |

Control Panel Unit |

[8] |

Power Switch |

[4] |

Copyboard Lower Cover |

[8] |

Rear Cover |

[2] |

Upper Cover |

[9] |

Front Cover Unit |

|

|

|

|

[3] |

Right Cover |

[10] |

Delivery Auxiliary Tray |

|

|

|

|

[4] Pickup Tray Paper Guides |

[11] |

Delivery Tray |

|

|

|

|

|

[5] |

Pickup Tray |

[12] |

Toner Cartridge Guide |

|

|

|

|

[6] Pickup Tray Trailing Edge Paper Guides |

[13] |

Transfer Roller |

|

|

|

|

|

[7] Small Size Paper Guides |

|

|

|

|

|

|

|

1-4

1Product Overview > Parts Name > External View > Rear side of the machine

1 |

Product Overview > Parts Name > Control Panel |

1-5 |

|

|

|

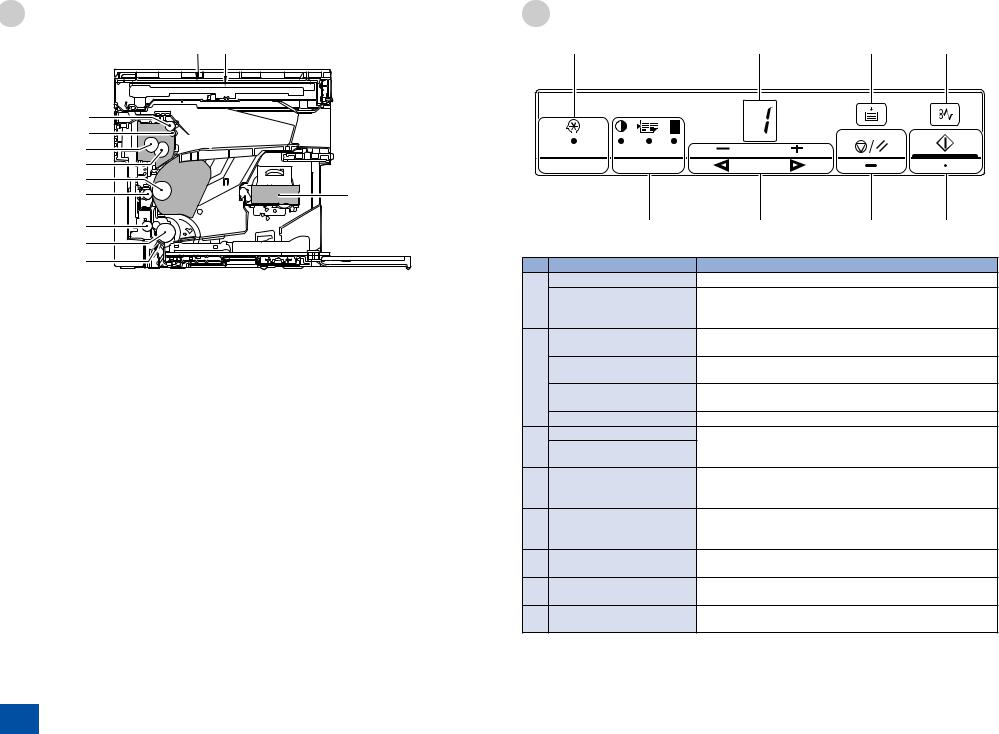

Cross Section View |

Control Panel |

|

[1] |

[2] |

[1] |

[8] |

[7] |

[6] |

[11] |

|

|

|

|

|

[10] |

|

|

|

|

|

[9] |

|

|

|

|

|

[8] |

|

|

|

|

|

[7] |

|

|

|

|

|

[6] |

|

[12] |

|

|

|

[5] |

|

|

|

|

[2] |

[3] |

[4] |

[5] |

[4] |

|

|

|

|

|

|

|

F-1-4 |

|

|

|

|

|

|

|

|

|

[3] |

|

|

|

No. |

Name |

Function |

|

|

|

|

|

|

|

||||

|

|

|

F-1-3 |

[1] |

Menu setting lamp (green) |

Blinking: Menu is being set. |

|

|

No. |

Name |

No. |

Name |

|

Menu setting key |

Menu setting mode is entered. |

|

|

[1] |

Copyboard Glass |

[7] |

Photosensitive Drum |

|

|

Pressing this key while menu is being set returns to one layer |

||

|

|

above. |

|

|

||||

[2] |

CIS Unit |

[8] |

Fixing Film Unit |

|

|

|

|

|

[2] Density setting amp (green) |

Blinking: Density is being set. |

|

|

|||||

[3] |

Separation Pad |

[9] |

Fixing Pressure Roller |

|

|

|||

|

|

Lit: When changing from the initial value |

|

|||||

[4] |

Pickup Roller |

[10] |

Fixing Assembly |

|

|

|

||

|

Page aggregation setting lamp Blinking: Reduced layout/ID Card copy is being set. |

|||||||

[5] |

Feed Roller |

[11] |

Delivery Roller |

|

||||

|

(green) |

Lit: When changing from the initial value |

|

|||||

[6] |

Transfer Roller |

[12] |

Laser Scanner Unit |

|

|

|||

|

Enlargement/reduction setting |

Blinking: Enlargement/reduction is being set. |

|

|||||

|

|

|

|

|

|

|||

|

|

|

|

|

lamp (green) |

Lit: When changing from the initial value |

|

|

|

|

|

|

|

Copy setting key |

Copy setting items are switched by each press of this key. |

||

|

|

|

|

[3] |

- (◄) key |

The menu items are switched or the setting values are |

||

|

|

|

|

|

+ (►) key |

increased/decreased in the menu setting mode. Also, the |

||

|

|

|

|

|

|

setting values of copy setting items are increased/decreased. |

||

|

|

|

|

[4] |

Stop/reset key |

The job is stopped. |

|

|

|

|

|

|

|

|

Pressing this key while menu is being set returns to one layer |

||

|

|

|

|

|

|

above. |

|

|

|

|

|

|

[5] |

Start/OK key |

Copy operation is started. |

|

|

|

|

|

|

|

|

In the menu setting mode, the menu items are selected or the |

||

|

|

|

|

|

|

setting values are determined. |

|

|

|

|

|

|

[6] |

Jam occurrence lamp (orange) Blinking: At occurrence of a jam |

|

|

|

|

|

|

|

|

|

Lit: At occurrence of a service error |

|

|

|

|

|

|

[7] Out of paper lamp (orange) |

Blinking: When paper on the Pickup Tray runs out |

|

||

|

|

|

|

|

|

Lit: At occurrence of a service error |

|

|

|

|

|

|

[8] |

Indicator (green) |

The setting values of copy setting items or the status of this |

||

|

|

|

|

|

|

product are displayed. |

|

|

|

|

|

|

|

|

|

|

T-1-3 |

1-5

1Product Overview > Parts Name > Control Panel

2Technical Overview■■Basic Configuration

■■Controller System

■■Original Exposure System

■■Laser Exposure System

■■Image Formation System

■■Fixing System

■■Pickup Feed System

■■External And Controls System

2Technical Overview

2 Technical Overview > Basic Configuration > Basic Sequence > Basic Sequence of Operation

2-2

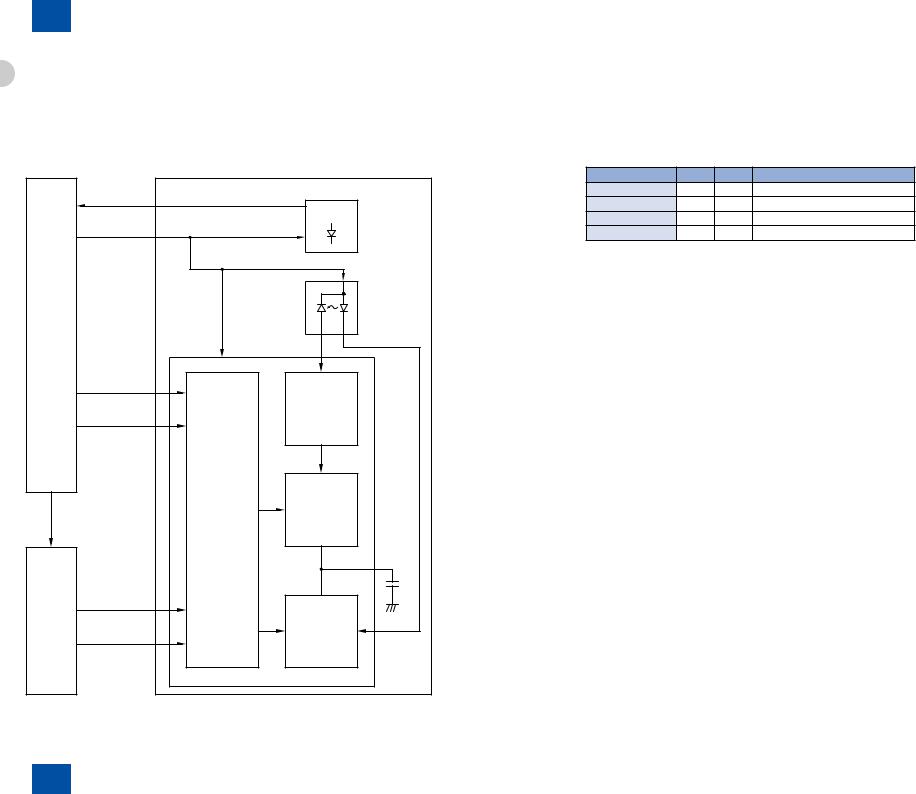

Basic Configuration

Configuration function

The machine may be broadly divided into the following 7 functional blocks: engine control system,original exposure system, laser exposure system, image formation system, pickup feed system, fixing system, and external and control system.

|

Original exposure system |

|

Laser exposure system |

|

Image formation system |

Engine control |

|

system |

Pickup feed system |

Fixing system

External and controls system

External device

F-2-1

Basic Sequence

■■Basic Sequence of Operation

The engine controller controls the operation sequence. The following table provides an outline of machine operation occurring from when the power switch is turned on to when printing ends and Main Motor (M1) stop, indicating the purposes of intervals and engine operation.

|

Interval |

Purpose |

Remarks |

WAIT |

From power-ON until initial |

To clear potential from the drum |

Detect whether the |

(Wait) |

drive for Main Motor (M1) is |

surface and to clean the transfer |

Toner cartridge is |

|

completed. |

roller. |

installed or not. |

|

|

Also to bring the heater |

|

|

|

temperature up to the targeted |

|

|

|

temperature. |

|

STBY |

From the end of the WAIT |

To keep the printer ready to |

|

(Standby) |

period or the LSTR period |

print. |

|

|

until the print command is |

|

|

|

sent from the main controller. |

|

|

|

Or, from the end of the LSTR |

|

|

|

period until power switch is |

|

|

|

turned OFF. |

|

|

INTR |

From the input of the print |

To stabilize the photosensitive |

|

(initial |

command from the main |

drum sensitivity in preparation |

|

rotation) |

controller until the Pickup |

for printing. Also to clean the |

|

|

Solenoid (SL1) is turned ON. |

transfer roller. |

|

From the end of the INTR |

To form image on the |

|

|

(print) |

period until the Paper |

photosensitive drum based on |

|

|

Leading Edge Sensor |

the VIDEO (/VDO, VDO) signals |

|

|

(PS751) detects the trailing |

input from the main controller, |

|

|

edge of paper. |

and to transfer the toner image |

|

|

|

onto paper. |

|

LSTR |

From the end of PRINT |

To deliver the last paper |

Return to the INTR |

(last |

period until the Main Motor |

completely out of the printer. |

period as soon as |

rotation) |

(M1) stops. |

|

another print command |

|

|

|

is sent from the main |

|

|

|

controller. |

|

|

|

T-2-1 |

2-2

2Technical Overview > Basic Configuration > Basic Sequence > Basic Sequence of Operation

2 Technical Overview > Basic Configuration > Basic Sequence > Print Sequence

2-3

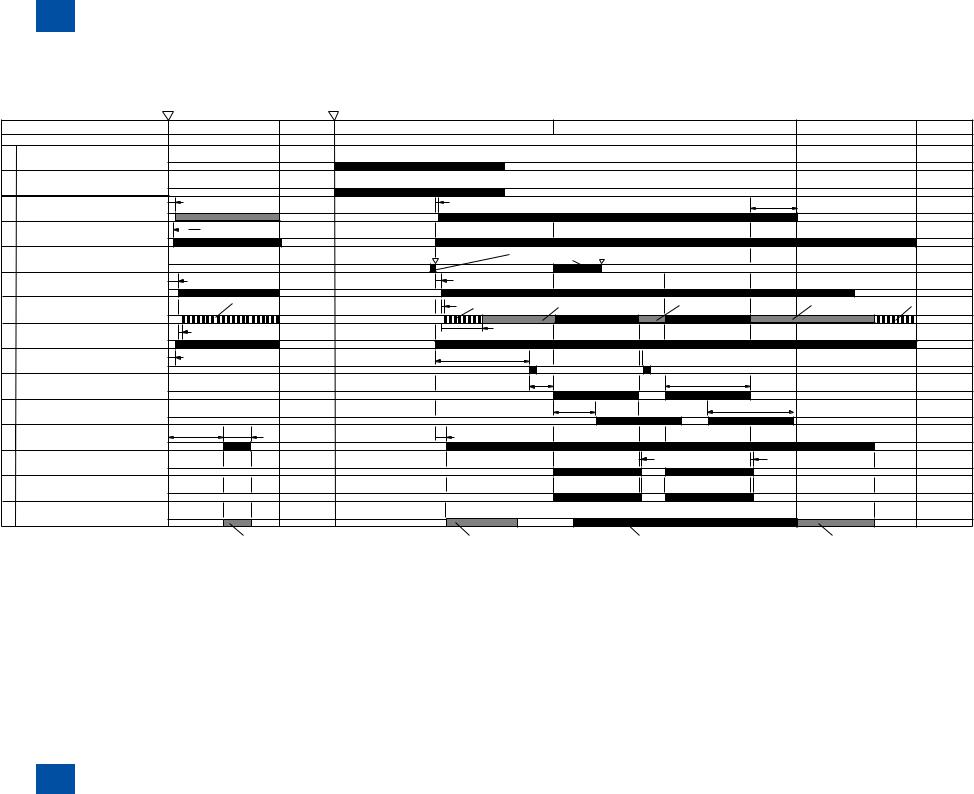

■■Print Sequence

|

Power-on |

|

Start KEY |

|

|

|

|

|

|

|

(Unit:Seconds) |

|

|

|

|

WAIT |

|

|

|

|

|

|

|

|

|

|

Sequence |

|

STBY |

INTR |

|

|

|

|

LSTR |

STBY |

||

1 |

Reader Motor (M3) |

|

|

|

|

|

|

|

|

|

|

|

2 |

CIS Unit |

|

|

|

|

|

|

|

|

|

|

|

3 |

Fixing heater |

0.9 |

Controls at 80 C |

0.1 |

|

|

Print temperature control |

|

1.3 |

|

||

|

|

|

|

|

|

|

|

|

|

|

||

4 |

Relay |

0.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

5 |

Print command |

|

|

|

Print command |

Waiting for |

|

Print command |

|

|

|

|

|

|

|

|

|

a print command |

|

|

|

|

|||

6 |

Scanner motor (M2) |

1.1 |

|

|

0.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

7 |

Laser diode |

|

BD emission/ |

0.1 |

Forcible emission |

Masking emission |

Masking emission |

Masking emission |

Forcible emission |

|||

|

Forcible emission |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||

8 |

Main motor (M1) |

0.1 |

|

|

|

|

Max.1.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

9 |

Pickup solenoid (SL1) |

0.8 |

|

|

|

2.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

10 Leading edge sensor (PS751) |

|

|

|

|

|

|

0.5 |

|

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

11 |

Fixing delivery sensor (PS701) |

|

|

|

|

|

|

0.9 |

|

2.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

12 Primary charging bias (DC) |

Max.4.1 |

1.1 |

0.5 |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|||

13 Developing bias (AC) |

|

|

|

|

|

|

|

|

0.06 |

0.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

14 Developing bias (DC) |

|

|

|

|

|

|

|

|

|

|

|

|

15 Transfer bias |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cleaning bias |

|

Cleaning bias |

|

Print bias |

Cleaning bias |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

F-2-2 |

2-3

2Technical Overview > Basic Configuration > Basic Sequence > Print Sequence

2 Technical Overview > Basic Configuration > Basic Sequence > Power-On Sequence

2-4

■■Power-On Sequence

The sequences from the power-ON to the STBY period are described below.

1)Power-ON.

2)CPU initialization.

3)Video interface communication start.

4)Residual paper check.

Detecting paper presence by each sensor signaling.

5)Initial drive for Main Motor (M1).

6)Initial drive for Fixing Heater (H1).

Controlling fixing temperature targeting for 120 deg C.

7)Initial drive of the Scanner Motor (M2).

8)High-voltage control.

Detect cartridge presence after primary charging AC bias is applied. Cleaning transfer roller.

9)Failure/Abnormality check.

Detecting fixing unit failure and door open during above periods.

2-4

2Technical Overview > Basic Configuration > Basic Sequence > Power-On Sequence

2Technical Overview > Controller System > Engine Controller > General description

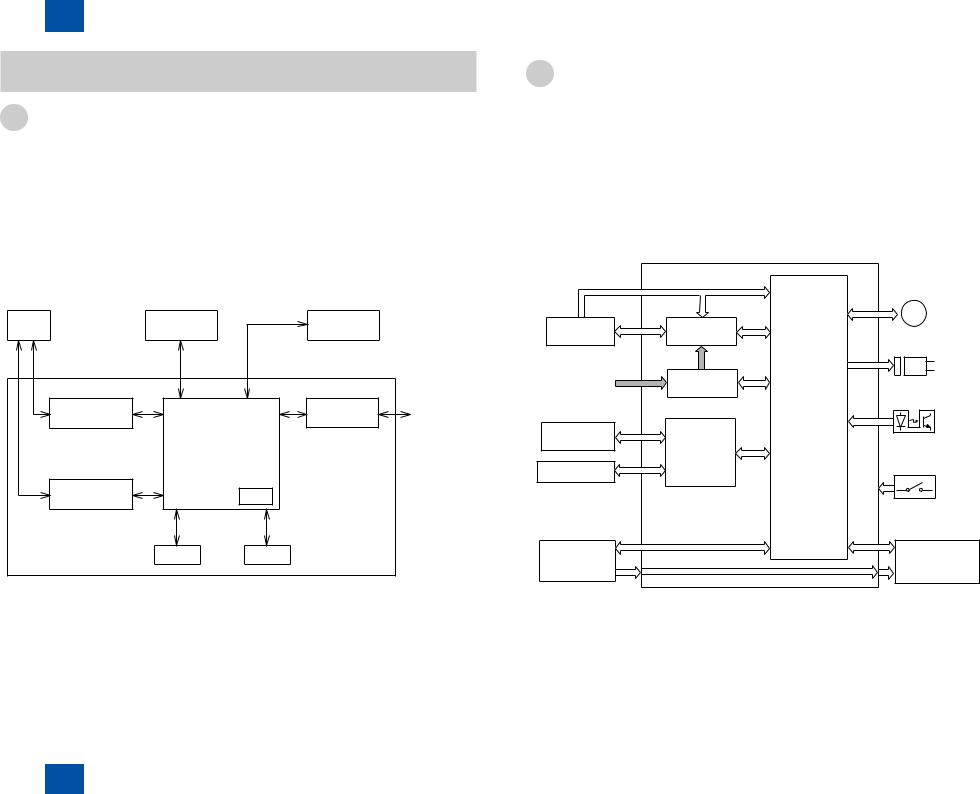

Controller System

Main Controller

■■Overview

The Main Controller receives print information from the Reader and external equipment (computer, etc.). Video data is created from the received print information, and is sent to the Engine Controller.

There are 2 types of print information from the external equipment: engine command data to exchange the status or unique information of a printer and dot data for printing.

In the case of receiving dot data, video data is created and is sent to the Engine Controller. In the case of receiving engine command data, printer status is returned to the external equipment after communicating with the Engine Controller.

READER |

ENGINE |

CONTROL PANEL |

|

|

CONTROLLER |

|

|

|

|

|

|

CONVERTER |

ASIC |

USB |

EXTERNAL |

ANALOG TO DIGITAL |

|

INTERFACE |

DEVICE |

MOTOR DRIVER |

|

CPU |

|

DC/DC CONVERTER |

|

|

|

|

DRAM |

EEPROM |

|

MAIN CONTROLLER |

|

|

|

|

|

|

F-2-3 |

2-5

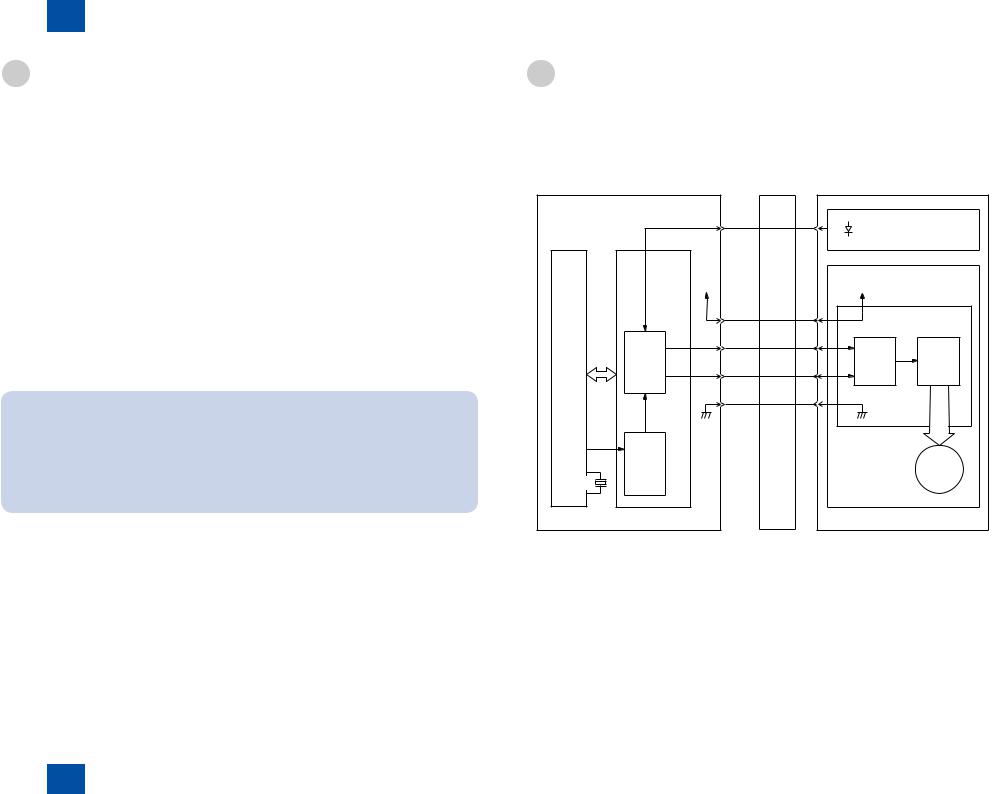

Engine Controller

■■General description

Engine controller is the circuit to control the operation sequence of the host machine and it is controlled by the CPU inside the engine controller.

When the Power Switch (SW1100) is turned ON and DC power is supplied through the low voltage power inside engine controller, CPU starts the printer operation control.

Then, CPU drives the loads such as laser diode, motors and solenoids etc. according to the image data that is input by the main controller when status becomes stand-by mode.

The following is the block diagram of this circuit.

Engine controller

Fixing |

M |

Motor |

Fixing control |

|

|

assembly |

|

|

|

|

|

|

Low-voltage |

Solenoid |

AC input |

|

|

power supply |

|

|

|

|

|

|

CPU |

|

|

|

Sensor |

Transfer roller |

High-voltage |

|

|

|

|

Toner Cartridge |

power supply |

|

|

|

|

|

|

Switch |

Main controller |

Laser scanner |

|

|

|

unit |

F-2-4

2-5

2Technical Overview > Controller System > Engine Controller > General description

2 Technical Overview > Controller System > Service Works > Notes on service works

2-6

Service Works

■■At parts replacement

No work is required for this product at parts replacement.

■■Maintenance

No periodically replaced parts, durable parts or periodical service is set for this product.

■■Notes on service works

None.

2-6

2Technical Overview > Controller System > Service Works > Notes on service works

2Technical Overview > Original Exposure System > Major Components

Original Exposure System

Overview

item |

function / method |

document exposure |

LED |

document scan |

Scan by the shift of the CIS Unit |

scanning resolution |

600 dpi x 400 dpi, 600 dpi x 600 dpi (Horizontal x Vertical) |

number of gradations |

256 gradations |

magnification |

50 % to 200 % (10 % increment) |

|

Horizontal: image processing by Main Controller PCB |

|

Vertical: change of carriage shift speed, image processing by Main |

|

Controller PCB |

lens |

CIS / Color |

CIS Unit |

number of lines: 1 line |

|

number of pixels: 5148 pixels as total pixels (5104 pixels as effective |

|

pixels) |

|

maximum document scanning width: 216 mm |

CIS Unit drive control drive control by Reader motor (M3)

document size detection none

T-2-2

2-7

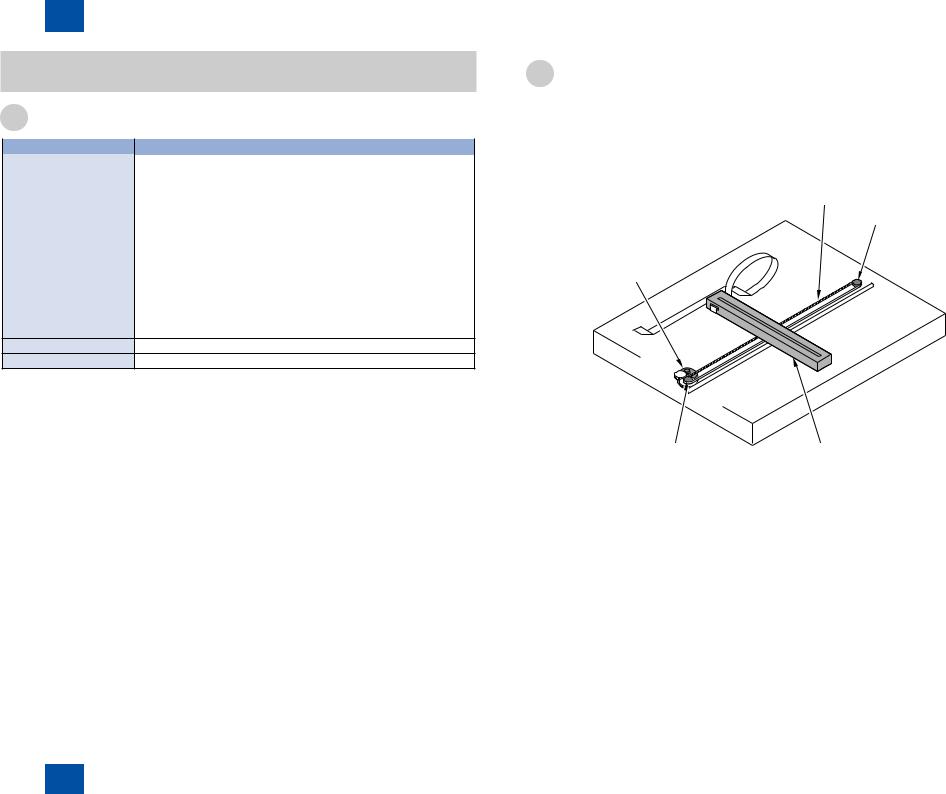

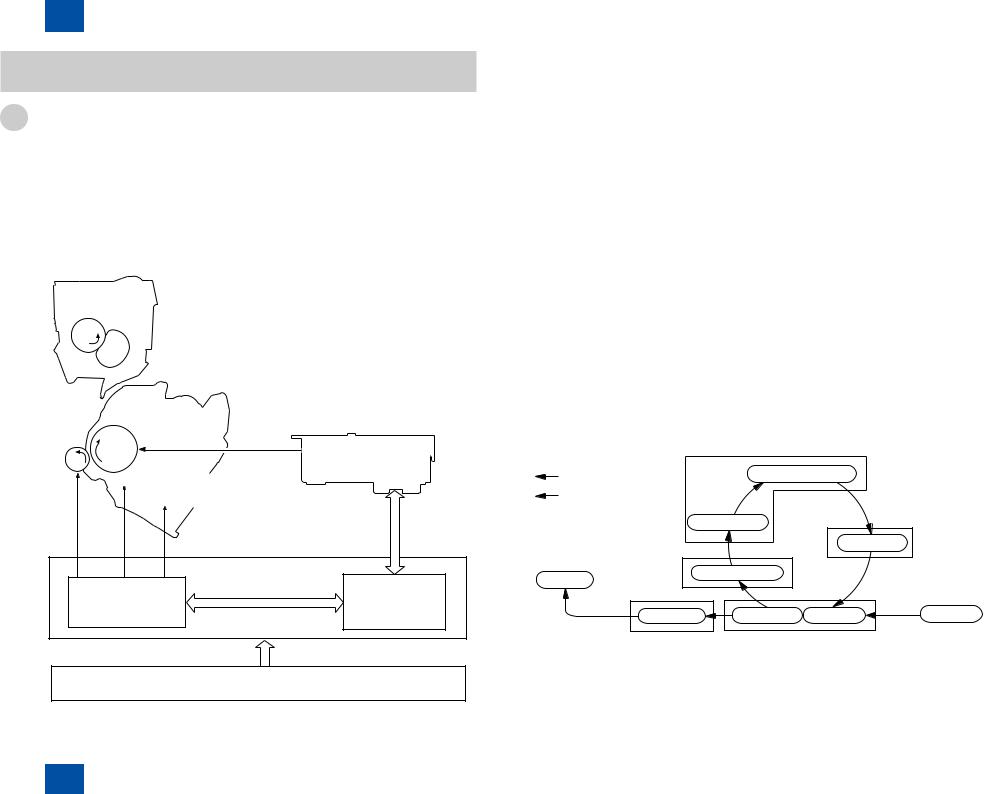

Major Components

Followings are the major components for Document Exposure System.

•The CIS Unit to scan document

•The Reader motor, the drive pulley, the drive belt, to shift the CIS Unit

In image scanning control, the CIS Unit is shifted by rotating the Reader motor based on the drive signal from the Engine Controller PCB and scan the original on the copyboard glass.

Drive Belt

Drive Pulley

Reader Motor(M3)

Drive Pulley |

CIS Unit |

F-2-5

2-7

2Technical Overview > Original Exposure System > Major Components

2 Technical Overview > Original Exposure System > Service Works > Notes on service works

2-8

Service Works

■■At parts replacement

No work is required for this product at parts replacement.

■■Maintenance

No periodically replaced parts, durable parts or periodical service is set for this product.

■■Notes on service works

None.

2-8

2Technical Overview > Original Exposure System > Service Works > Notes on service works

2Technical Overview > Laser Exposure System > Overview > Overview

Laser Exposure System

Overview

■■Overview

The laser exposure system forms static latent images on the photosensitive drum according to the VIDEO signals sent from the main controller, and is comprised of the laser driver and scanner motor, etc. These are controlled by the engine controller. The following is the outline.

Photosensitive drum

BD sensor

Laser unit |

Cylindrical lens |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Collimator |

|

Focus lens |

|||||

|

|

|

|

lens |

|

|||||

signalINPUTBD |

signalVIDEO |

CONTROLLASERsignal |

|

|

|

|

||||

|

|

MOTORSCANNER CONTROLSPEEDsignal |

Scanner Motor (M2) |

|||||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Four-faced mirror |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine Controller |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Main controller |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

F-2-6

2-9

The operational sequence of the laser scanner unit is described below.

1)When the Main controller sends print instruction command, the Engine controller rotates the Four-faced mirror, causing the Scanner Motor (M2) to rotate.

2)When the Scanner Motor (M2) starts to rotate, the Engine controller emits the laser forcibly using the Laser control signal, causing the Engine controller to start rotation control for the Scanner Motor (M2).

3)The Engine controller controls to keep a constant speed of rotation of the Scanner Motor (M2) using the Scanner motor speed control signal.

4)After the rotation speed of the Scanner motor reaches its target, the Main controller sends VIDEO signals to the Laser driver PCB.

5)The Laser driver emits laser diode according to these signals.

6)The laser beam passes through the collimator lens and the cylindrical lens and enters the Four-faced mirror rotating at a constant speed.

7)The laser beam reflected by the Four-faced mirror is focused on the Photosensitive drum via the image-forming lens at the front of the Four-faced mirror.

8)When the Four-faced mirror rotates at a constant speed, the laser beam on the Photosensitive drum is scanned on the Photosensitive drum at a constant speed.

9)When the Photosensitive drum rotates at a constant speed and the laser beam is scanned on the Photosensitive drum at a constant speed, latent images are formed on the Photosensitive drum.

2-9

2Technical Overview > Laser Exposure System > Overview > Overview

2 Technical Overview > Laser Exposure System > Controlling the Laser Activation Timing > Horizontal Sync Control

2-10

Controlling the Laser Activation Timing

■■Laser ON/OFF Control

In this control, the laser driver turns on/off the laser diode (LD) according to the laser control signal sent from the engine controller.

The following is the circuit diagram of the laser control.

The engine controller sends the laser control signals (CNT0, CNT1) for changing the operation mode of the laser to the logic circuit in the laser driver IC, as well as the video signals (VDO, /VDO) for image formation.

The laser driver IC executes laser control according to the combination of the CNT0, CNT1 signals.

The following is the combination of the laser control signal (CNT0, CNT1).

|

|

Laser driver PCB |

|

Operation mode |

CNT0 |

CNT1 |

Remarks |

|

|

/BDI |

|

Discharge |

L |

L |

The capacitor (C1) is discharged. |

||

|

|

|

|

|||||

|

|

BD Sensor |

|

Data output |

H |

H |

At normal print |

|

|

|

|

|

|||||

|

|

|

|

APC |

H |

L |

At using APC |

|

|

+3.3V |

|

|

|

||||

|

|

|

|

Forced OFF |

L |

H |

At using image mask |

|

|

|

|

|

|

|

|

|

T-2-3 |

|

|

|

|

|

■■Horizontal Sync Control |

|

|

|

|

|

PD |

|

LD |

This is the control to adjust the writing position in the image horizontal direction. |

|||

|

|

|

The following is the details of control procedure. |

|||||

|

|

|

|

|

||||

Engine |

|

|

|

|

1)The engine controller controls the laser control signal during unblanking (*) to emit the laser |

|||

Controller |

|

|

|

|

||||

|

|

|

|

|

diode (LD) forcibly. |

|

|

|

|

CNT1 |

|

|

|

2)The BD PCB exists on the scanning route of the laser beam, which is sent to the BD PCB. |

|||

|

|

|

|

|

|

|

|

|

|

CNT0 |

Comparator |

|

3)The BD PCB detects this laser beam, creates BD input signal (/BDI) and sends it to the |

||||

|

|

|

|

engine controller. |

|

|

|

|

|

|

|

|

|

4)The engine controller creates horizontal sync signals (/BD) based on /BDI signal and sends |

|||

|

|

|

|

|

the /BD signal to the main controller. |

|

|

|

|

|

Sample hold |

|

5)When /BD signal is input, the main controller outputs the video signal (VDO, /VDO) to the |

||||

/BD |

Logic PCB |

|

engine controller to adjust the writing position in image horizontal direction. |

|||||

|

circuit |

|

||||||

|

|

|

|

|

|

|

||

|

|

|

|

*: Unblanking period |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The period during which the laser diode is emitted in non-image area. |

|||

|

|

|

|

|

C1 |

|

|

|

Main |

VOD |

|

|

|

|

|

|

|

|

|

Drive |

|

|

|

|

|

|

Controller |

/VOD |

|

|

|

|

|

|

|

|

|

circuit |

|

|

|

|

|

|

|

Laser driver IC |

|

|

|

|

|

|

|

|

|

|

|

|

F-2-7 |

|

|

|

2 Technical Overview > Laser Exposure System > Controlling the Laser Activation Timing > Horizontal Sync Control |

|

|

2-10 |

|||||

|

|

|

||||||

2Technical Overview > Laser Exposure System > Laser Scanner Motor Control > Overview

Laser Control

■■Auto Power Control (APC)

This is the control to emit a constant level of laser diode.

There are two types of APC; initial APC (note 1), and line space APC (note 2). The laser driver executes the same procedure for both controls. The following is the details of the control procedure.

1)When the laser control signal enters APC mode (CNT0=H, CNT1=L), the laser driver emits LD in APC mode.

2)The emission level of LD is detected with photo diode (PD), converted from current output to voltage, and compared with the standard voltage (voltage equivalent to the target laser level).

3)The laser driver controls the laser current to achieve the voltage of LD target level.

4)When the laser control signal enters LD forced OFF mode, the LD is forcibly turned off. The laser driver saves the adjusted laser intensity to the capacitor (C1).

NOTE:

1.Initial APC

APC that is executed during initial rotation. APC adjusts laser intensity and detects faults in the laser.

2.Line space APC

APC that is executed during printing. Laser intensity for one line is adjusted before writing one line.

2-11

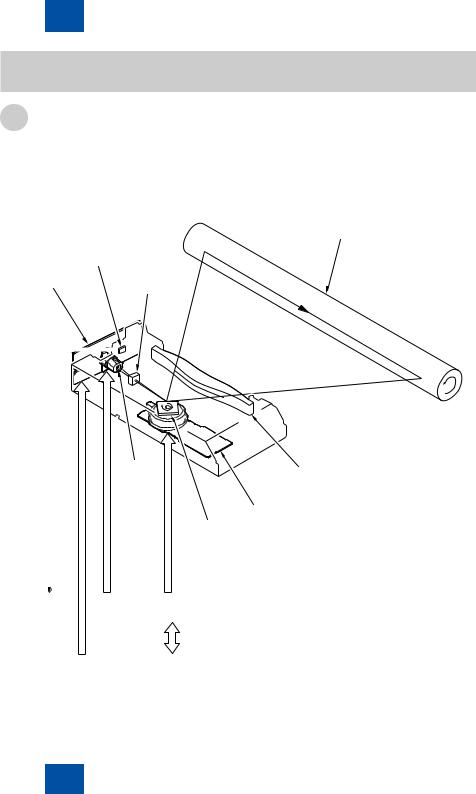

Laser Scanner Motor Control

■■Overview

This is the control to rotate the Scanner Motor (M2) at a constant speed to emit the laser beam on the correct position on the photosensitive drum.

The following is the control circuit of the Scanner Motor (M2).

|

Engine controller |

Motor driver PCB |

Laser scanner unit |

|

|

|

/BDI |

BD PCB |

|

|

|

|

||

CPU |

ASIC |

|

|

|

|

|

+24VA |

|

Scanner motor |

|

|

+24VA |

|

|

|

|

|

|

Scanner motor |

|

|

ACC |

|

driver IC |

|

|

|

Drive |

|

|

Frequency |

|

Integration |

|

|

comparator |

DEC |

circuit |

circuit |

|

|

|

|

|

|

Reference |

|

|

|

|

clock |

|

|

|

|

Oscillator |

|

|

M |

X501 |

|

|

||

|

|

|

||

|

|

|

|

F-2-8 |

The engine controller creates standard clock based on oscillation frequency of the oscillator (X501); the cycles of the standard clock is compared with that of BD input signal (/BDI) with a frequency comparator and the rotations of the Scanner Motor (M2) is monitored.

The engine controller sends the scanner motor acceleration signal (ACC) and scanner motor deceleration signal (DEC) to the scanner motor driver according to the detected rotation speed to control the rotation speed.

2-11

2Technical Overview > Laser Exposure System > Laser Scanner Motor Control > Overview

2Technical Overview > Laser Exposure System > Service Works > Notes on service works

■■Scanner Motor Fault Detection

This is the detection of faults in the laser scanner unit.

When the laser scanner unit falls into either of the following status, the engine controller judges it as a fault in the laser scanner unit system and notices the status of fault to the main controller.

The operations of the host machine are stopped.

1.Fault in BD input

At startup of the scanner, /BDI signal cannot be detected within 0.1 sec from the completion of forced acceleration of the Scanner Motor (M2).

2.Fault in startup

During activating the Scanner Motor (M2) at startup of the scanner, the motor rotation exceeds the specified range (98.3 to 102.1%).

3.Fault in control

After startup of the scanner completes correctly, /BDI signal exceeds the specified value of cycle 10 consecutive times.

2-12

Service Works

■■At parts replacement

No work is required for this product at parts replacement.

■■Maintenance

No periodically replaced parts, durable parts or periodical service is set for this product.

■■Notes on service works

None.

2-12

2Technical Overview > Laser Exposure System > Service Works > Notes on service works

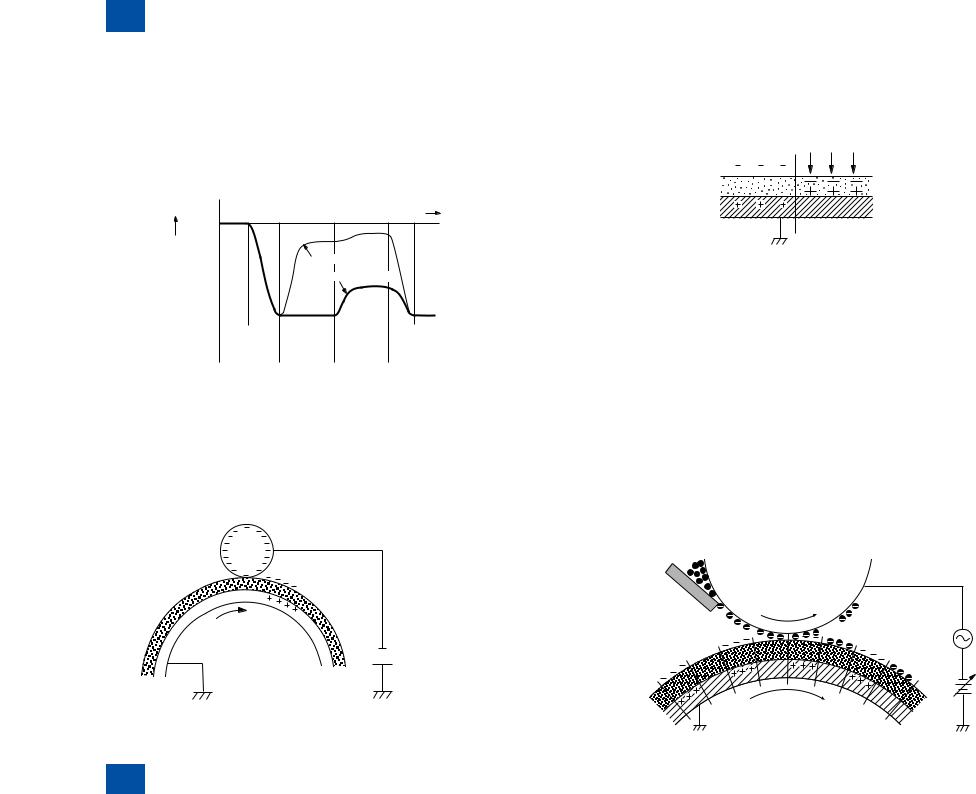

2Technical Overview > Image Formation System > Overview/Configuration > Print Process

Image Formation System

Overview/Configuration

■■Overview

The image formation system is the core of this equipment; it forms toner images on papers. The image formation system is comprised of the following components.

The engine controller controls the laser scanner unit and high-voltage power supply circuit and forms images based on the video signals on papers.

The following are the details of print process for this equipment and the functions of image formation.

Fixing assembly

Pressure roller

Fixing Film

Fixing Film

Cartridge

Photosensitive drum

Transfer roller |

Laser beam |

Laser/scanner unit |

|

To primary charging roller

To developing cylinder

TR |

PRI |

DEV |

Engine controller |

|

High-voltage |

CPU |

|

|

power supply |

||

|

|

||

VIDEO signal

Main controller

F-2-9

2-13

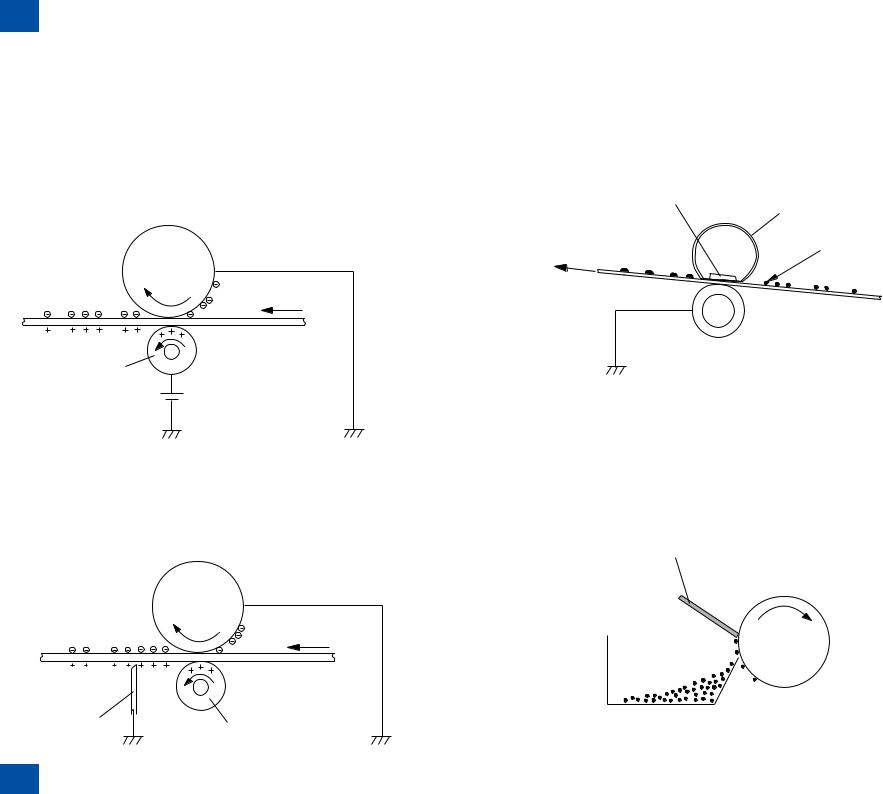

■■Print Process

This explains the basic process of the operations that a printer executes for image formation. The print process of this equipment is divided largely into 5 blocks, 7 steps.

Toner images are formed on papers by executing the steps of each block in order. The following are the blocks of print process and the steps.

1.Static latent image formation block Step 1: Primary charging

Step 2: Laser beam exposure

2.Development block Step 3: Development

3.Transfer block Step 4: Transfer Step 5: Separation

4.Fixing block Step 6: Fixing

5.Drum cleaning block Step 7: Drum cleaning

|

Electrostatic latent image formation block |

|

||

Paper path |

|

|