Page 1

KjelMaster K-375 with KjelSampler K-376/K-377

Operation Manual

11593514 en

Page 2

Page 3

Document History

Index Date Author Changes

A 25/MAY/2012 NAGG Initial version

B 16/JUL/2013 NAGG First revised version

Page 4

Page 5

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.1 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . 12

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.1 General hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.2 Instrument-related hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.3 Other hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.4 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.5.5 Built-in safety elements and measures. . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 Basic devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 Standard accessories for K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1.3 Standard accessories for K-376 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1.4 Standard accessories for K-377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.5 Optional accessories K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1.6 Optional accessories K-376/K-377 . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Technical data overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.1 Technical data KjelMaster K-375 and KjelSampler K-376/K-377. . . . . . . . . . . . 26

3.2.2 Technical data titrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 Titration solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Information on type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5 Reference substances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.1 Titrator module and dosing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.2 K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.6.3 K-376/K-377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can

be consulted at any time.

No technical modifications may be made to the device without the prior written agreement of BUCHI.

Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

If you need another language version of this manual, you can download it at

www.buchi.com.

5

K-375/376/377 Operation Manual, Version B

Page 6

Table of contents

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Device overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Opening the service door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2 Functional principle of Sampler System K-375 with K-376 or K-377. . . . . . . . . . 33

4.3 Standby function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4 System preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.1 Preheating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.2 Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.3 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.4.4 Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.5 Distillation and titration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.1 Distillation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.2 Titration Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.3 Sensor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.4 Titration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.5 Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5.6 Titration Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5.7 Determination Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.6 Different methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.7 Blank values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7.1 Blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7.2 Control blanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.8 Reference substances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.9 Result Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.10 Explanation of alkaline direct distillation . . . . . . . . . . . . . . . . . . . . . . . . 40

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.1 Connections of the K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.2.2 Connections of the K-376/K-377 . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.3 Transfer connection K-376 (K-377) – K-375 . . . . . . . . . . . . . . . . . . . . . . 46

5.3.1 Connecting the K-376 to the K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.3.2 Connecting the transfer hoses of the K-377 . . . . . . . . . . . . . . . . . . . . . . 48

5.4 Reagent/water and waste connections . . . . . . . . . . . . . . . . . . . . . . . . 49

5.5 Buret unit for titrant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6 Storage tank connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.7 Level sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.8 Connections to peripheral devices. . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.1 Connecting a printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.2 Connecting a network cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.3 Connecting a KjelSampler K-376 or K-377 . . . . . . . . . . . . . . . . . . . . . . 55

5.8.4 Connecting a balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.5 Connecting a bar code reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.8.6 External dosing unit for back titration . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.8.7 Electrode connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.9 Preparing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.9.1 Preparing the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.9.2 Preparing the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6

K-375/376/377 Operation Manual, Version B

Page 7

Table of contents

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 The operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2 The home screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2.1 The title bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.2 The bottom bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.2.3 System status icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

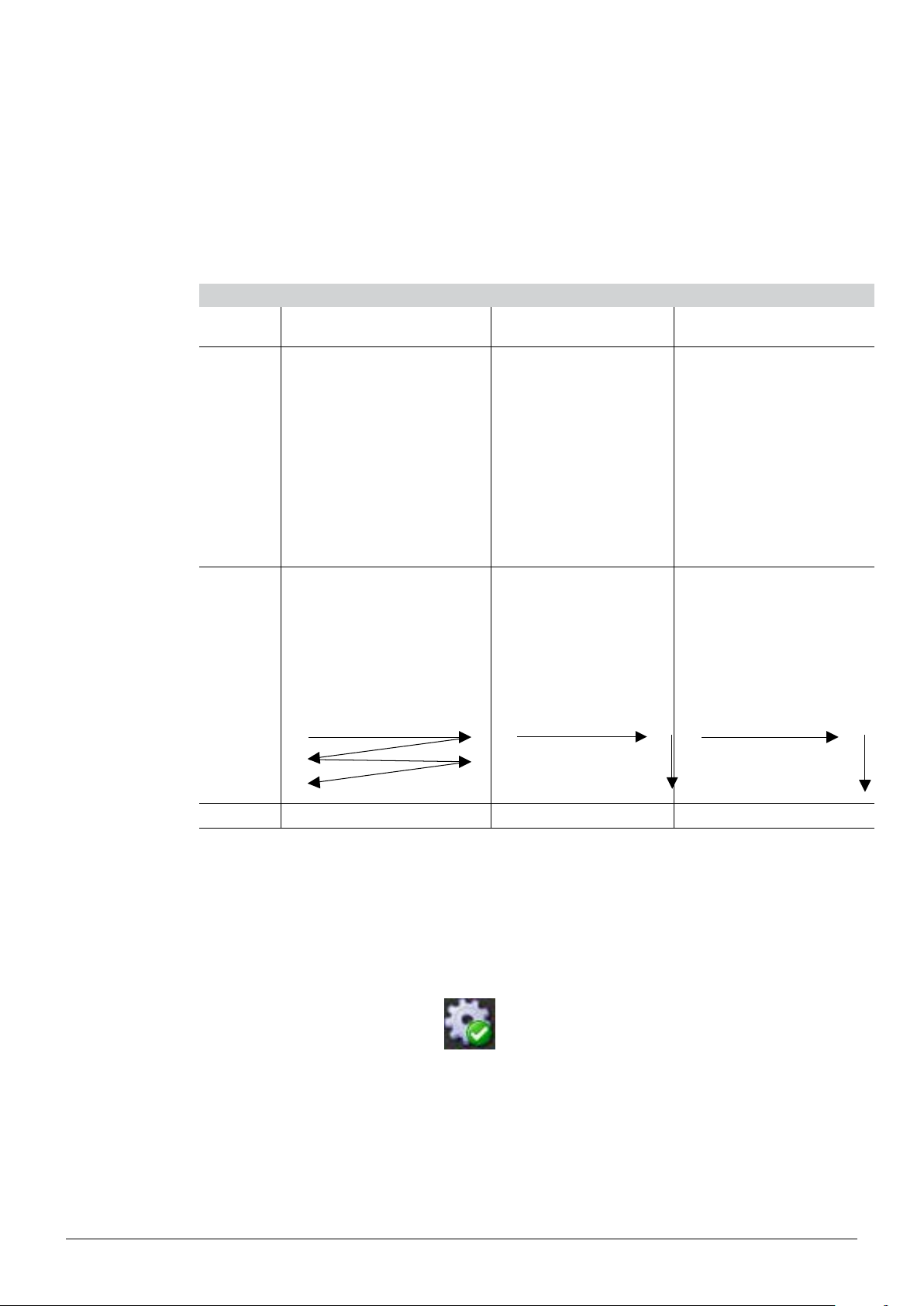

6.3 User concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.4 Editable and non-editable menu items. . . . . . . . . . . . . . . . . . . . . . . . . 63

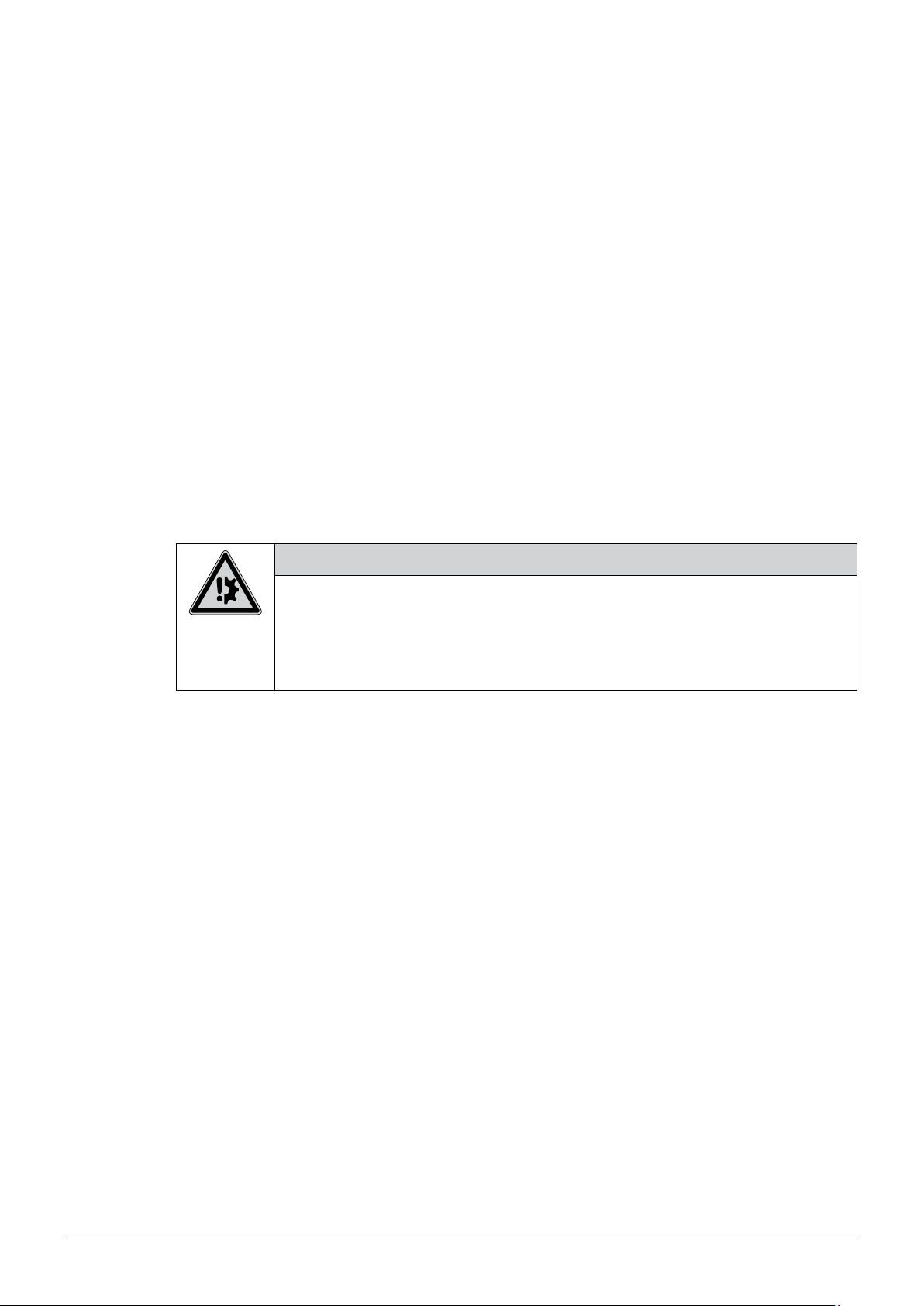

6.5 The status view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5.1 RESULT display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

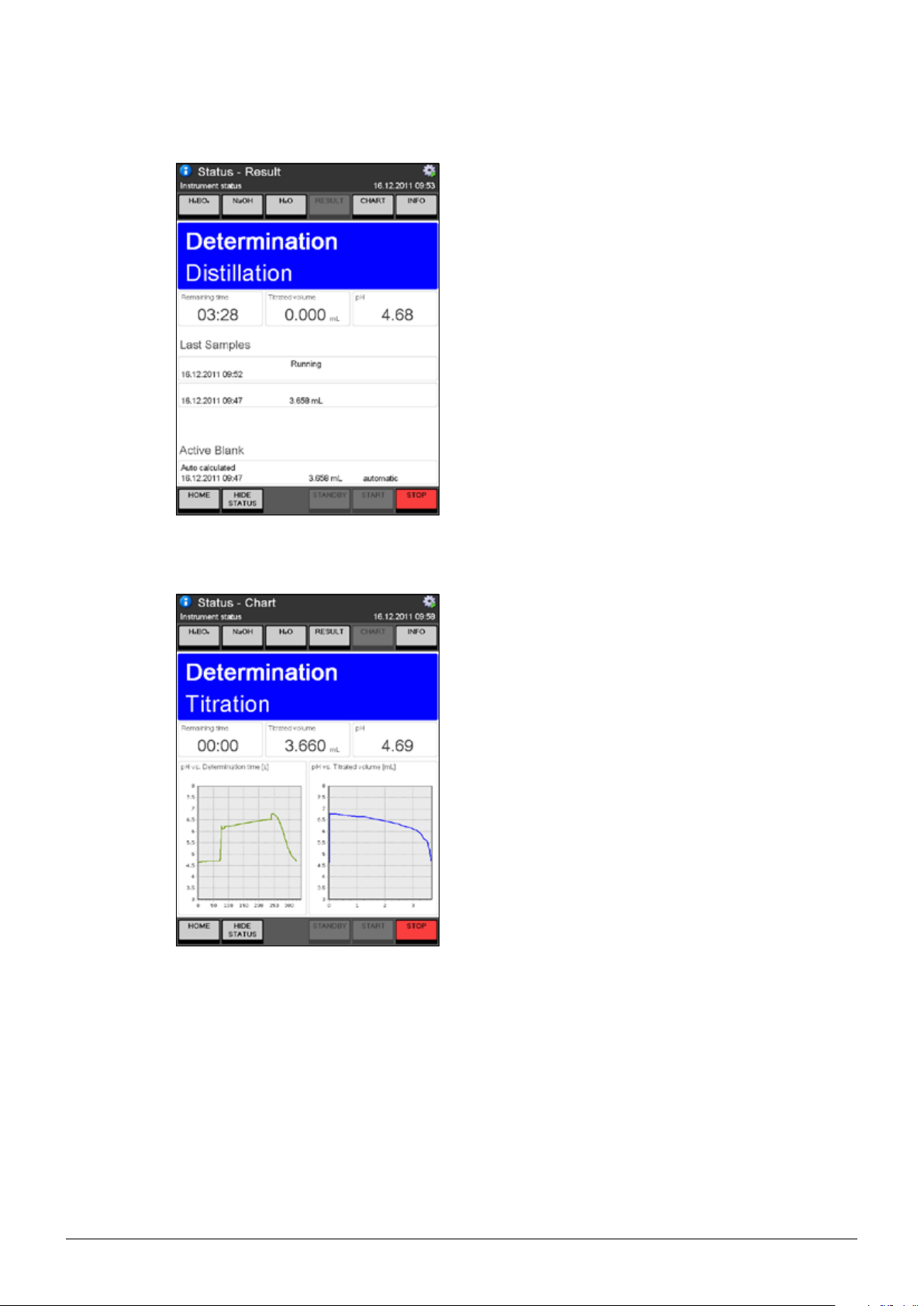

6.5.2 CHART display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

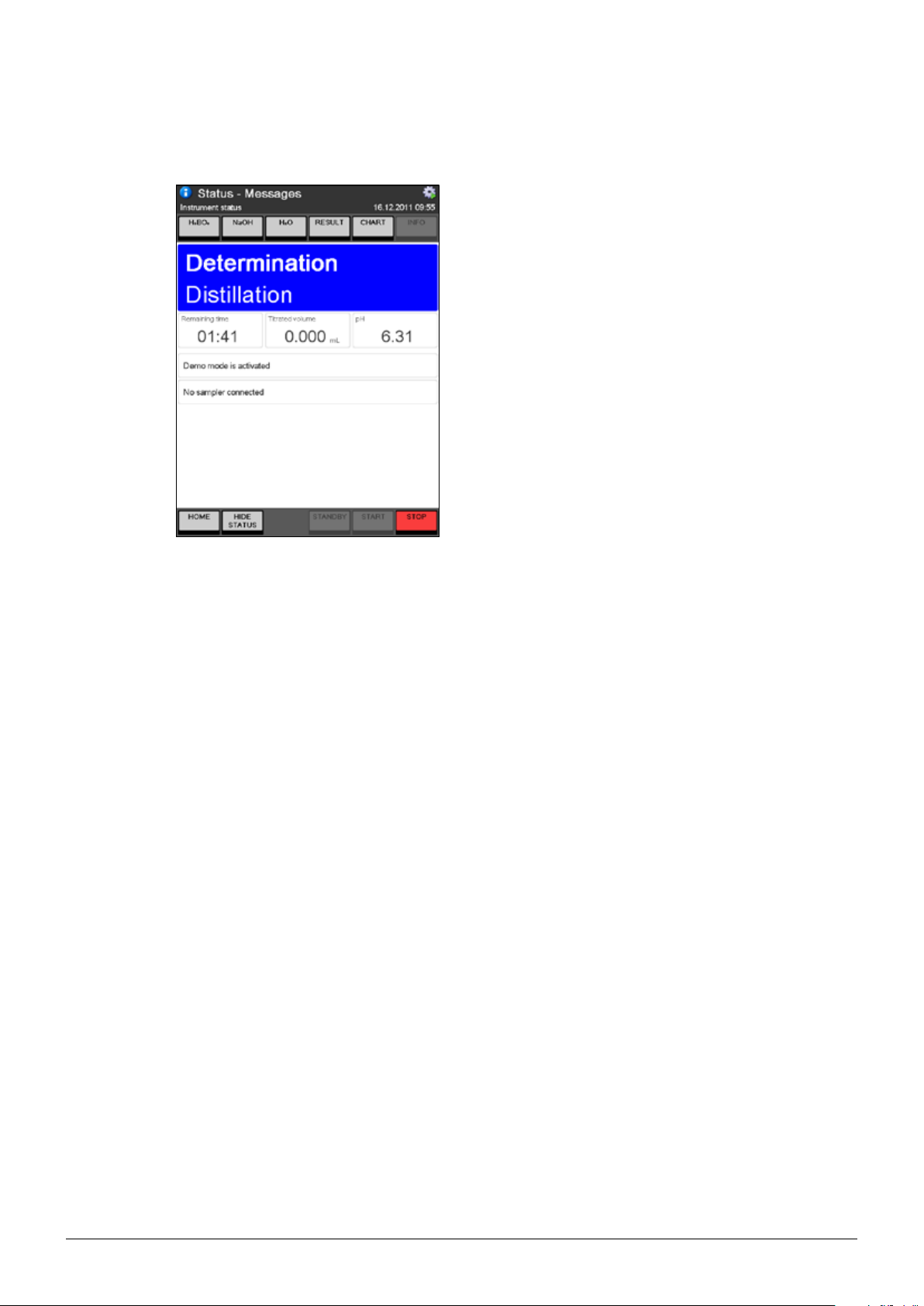

6.5.3 INFO display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.6 Determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

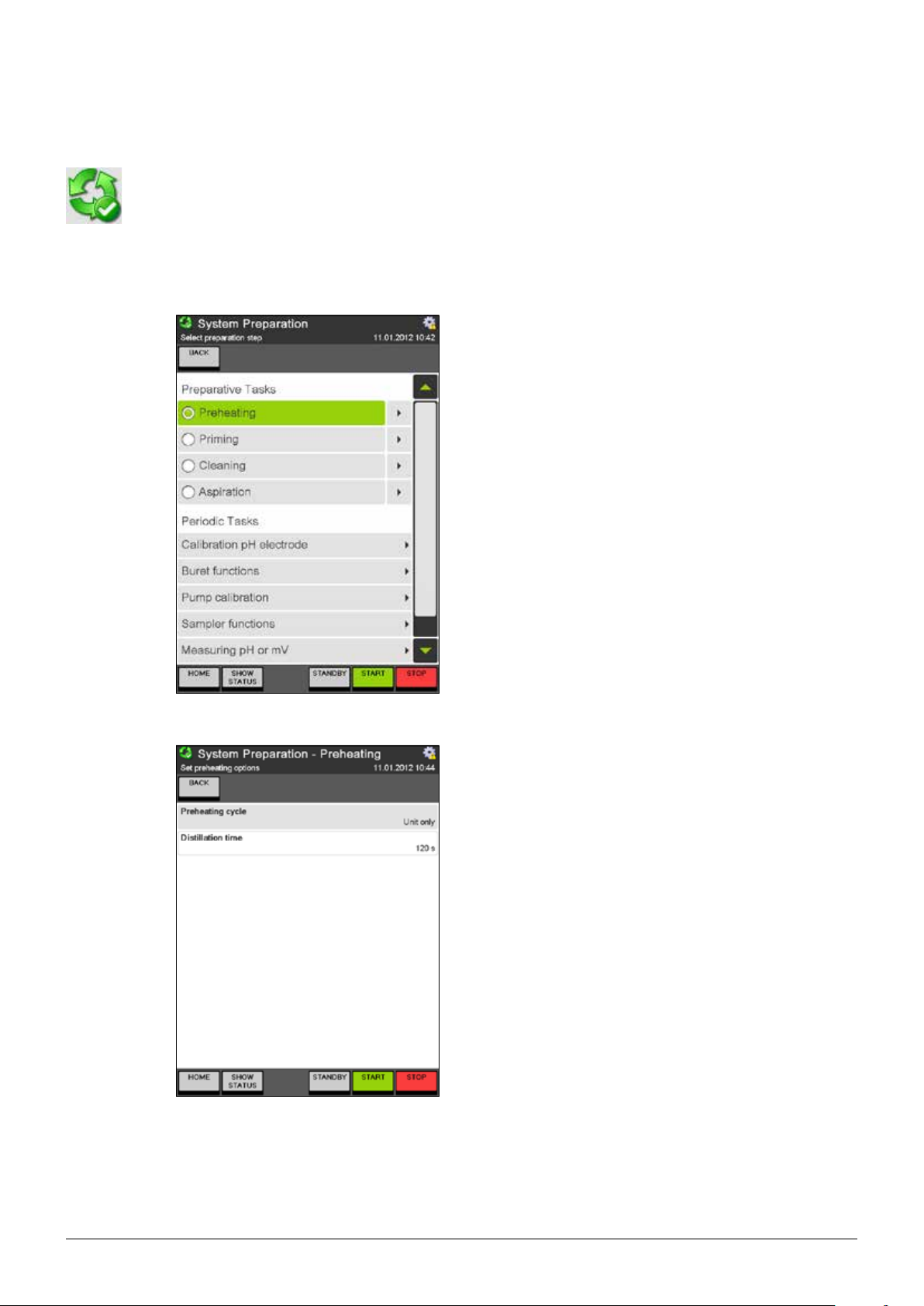

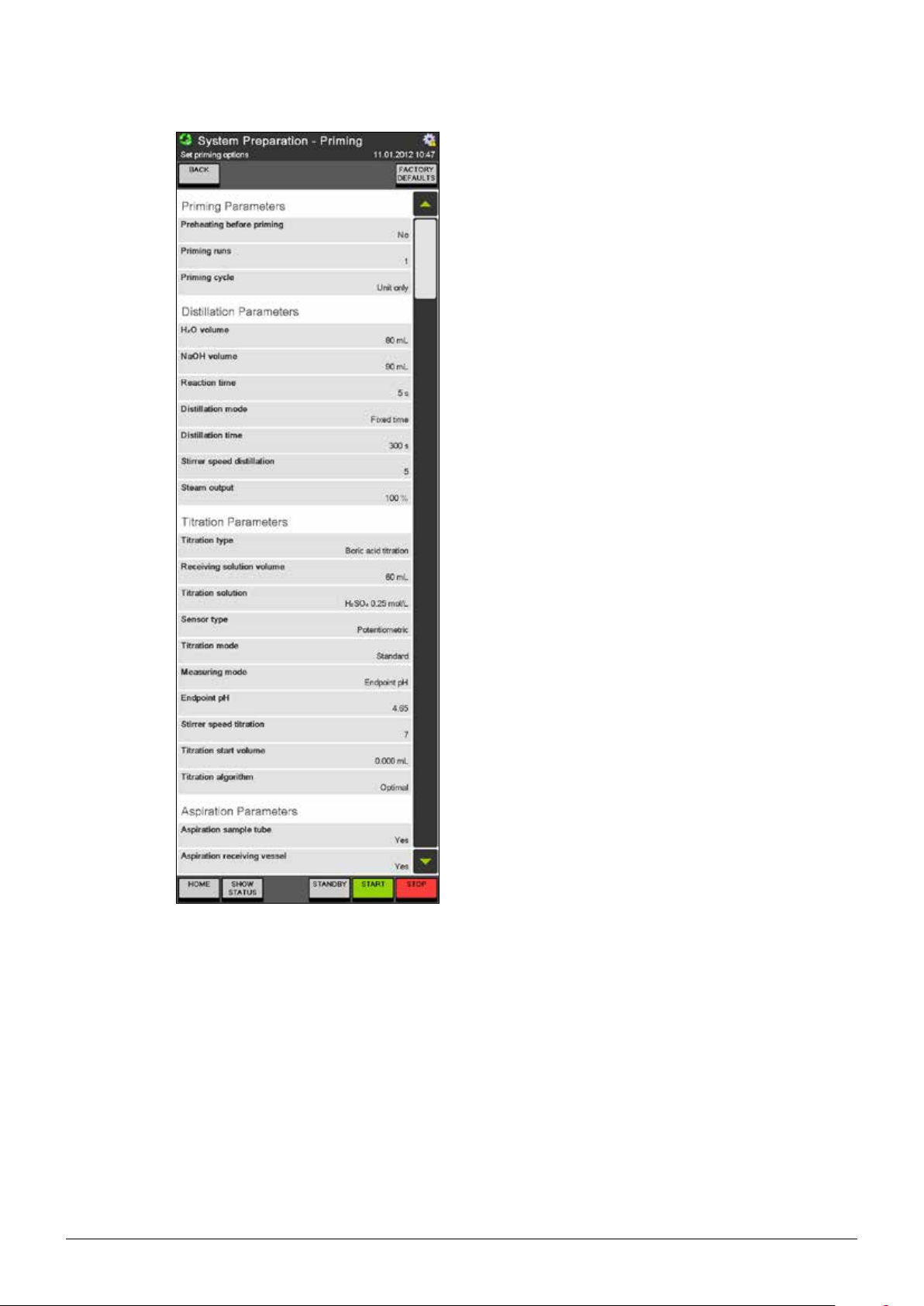

6.6.1 System Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.6.2 Single Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

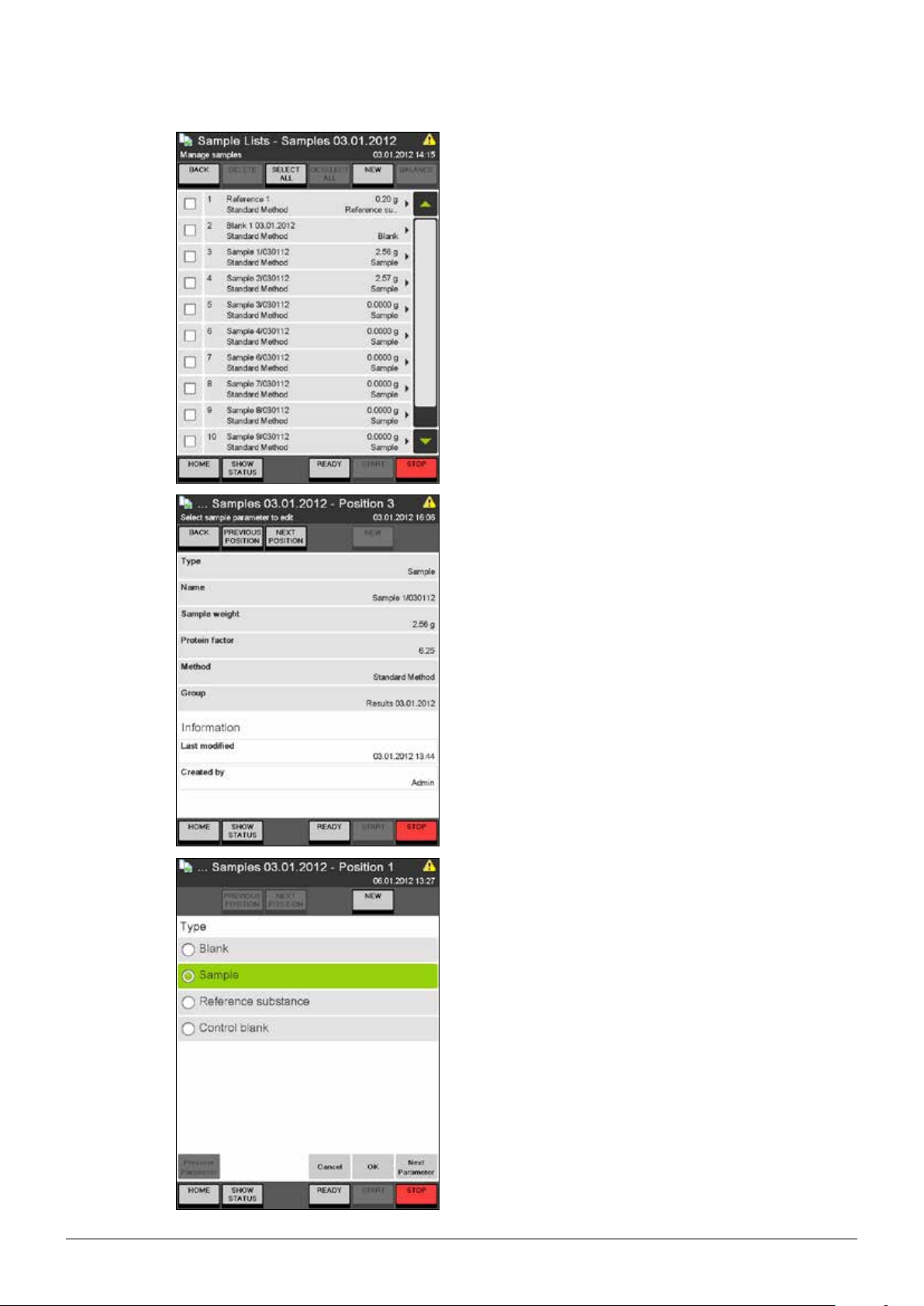

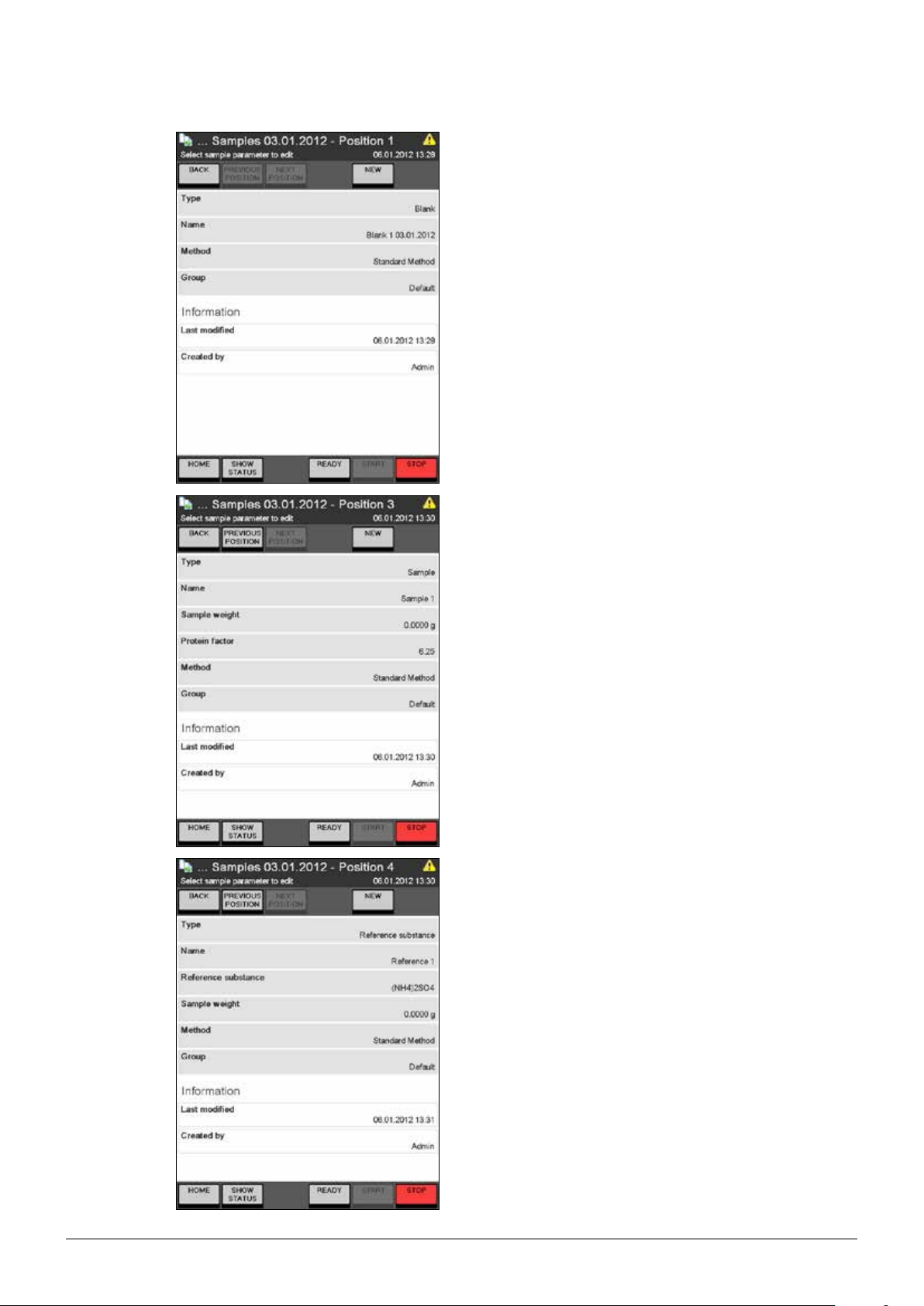

6.6.3 Sample Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

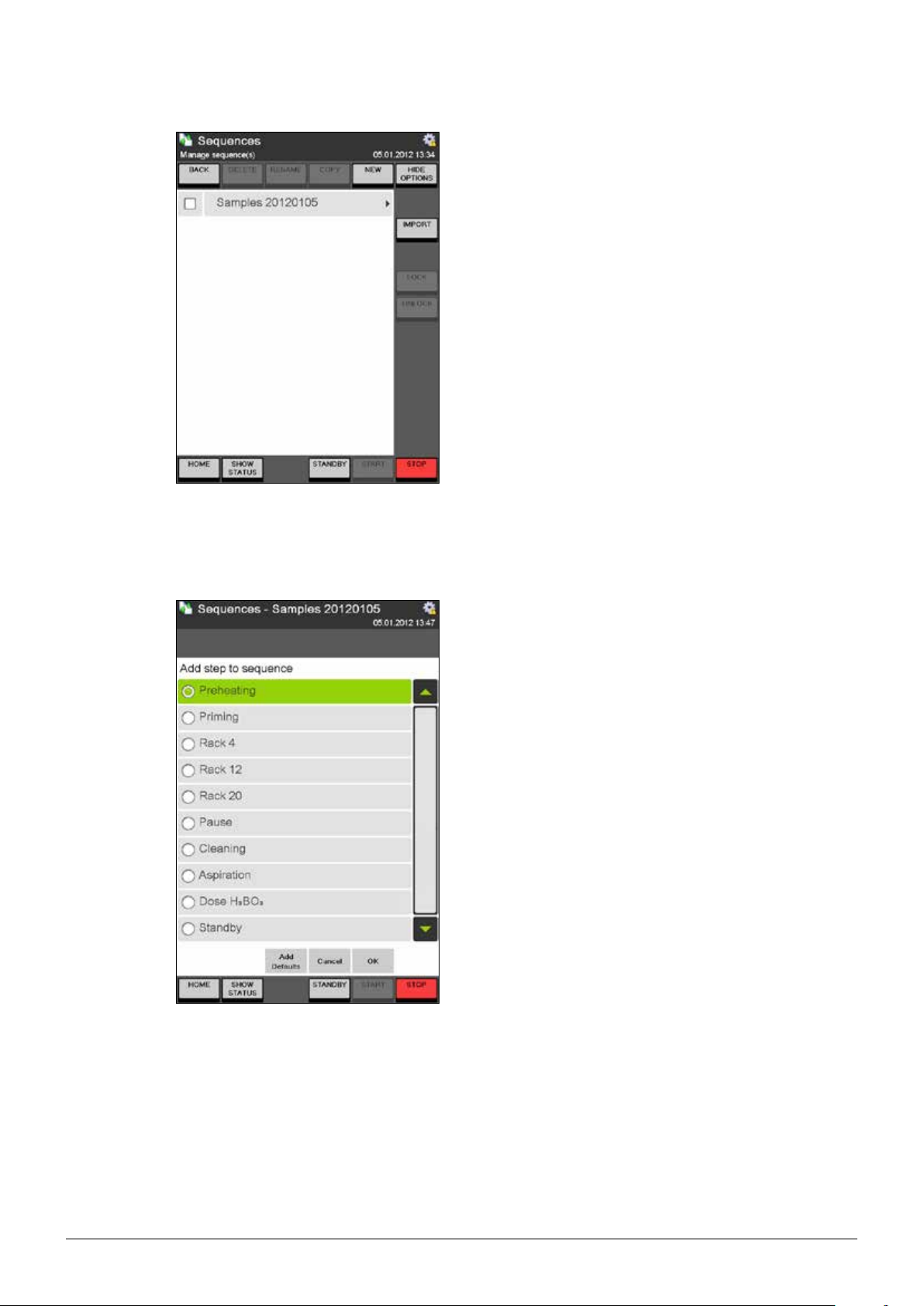

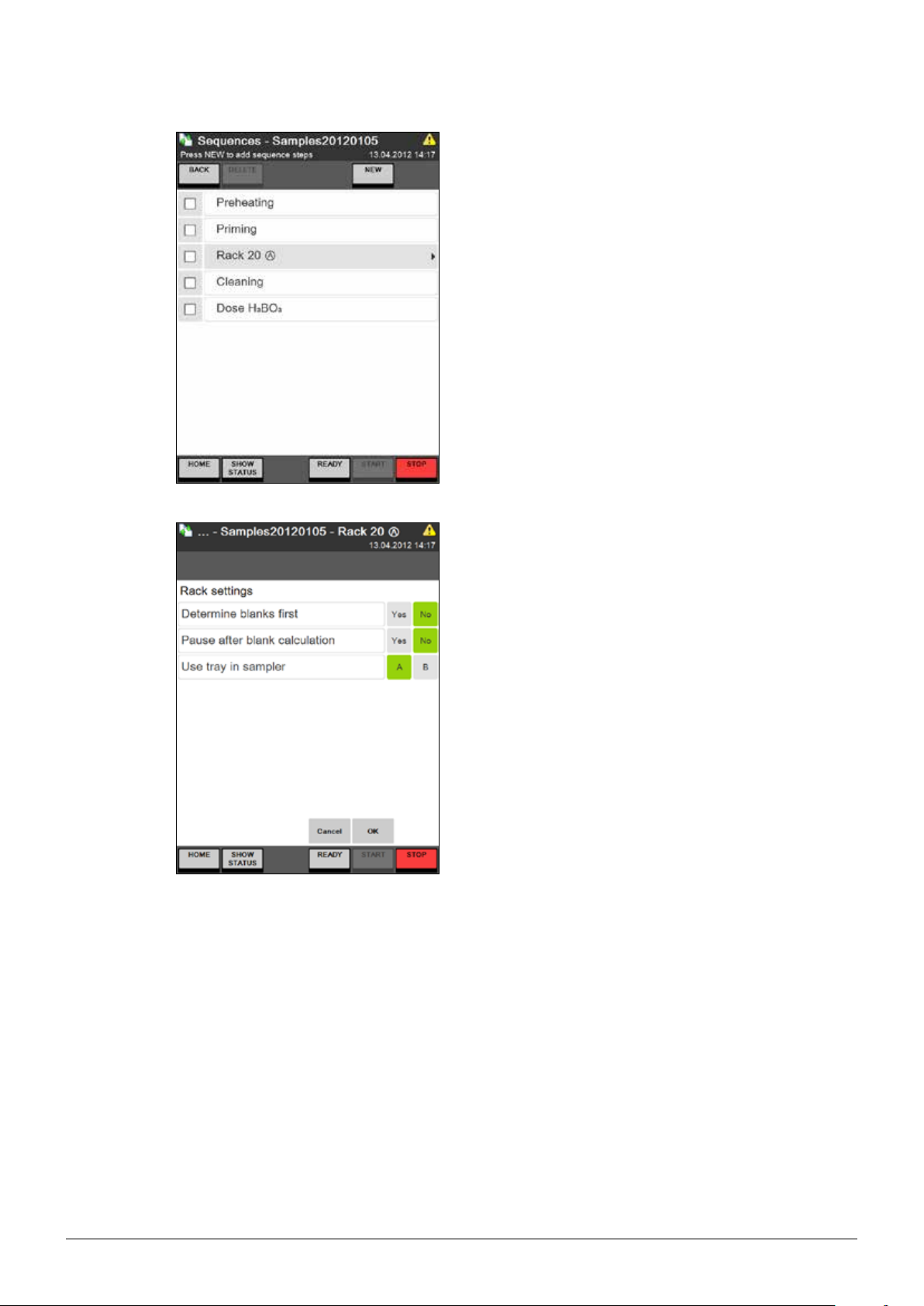

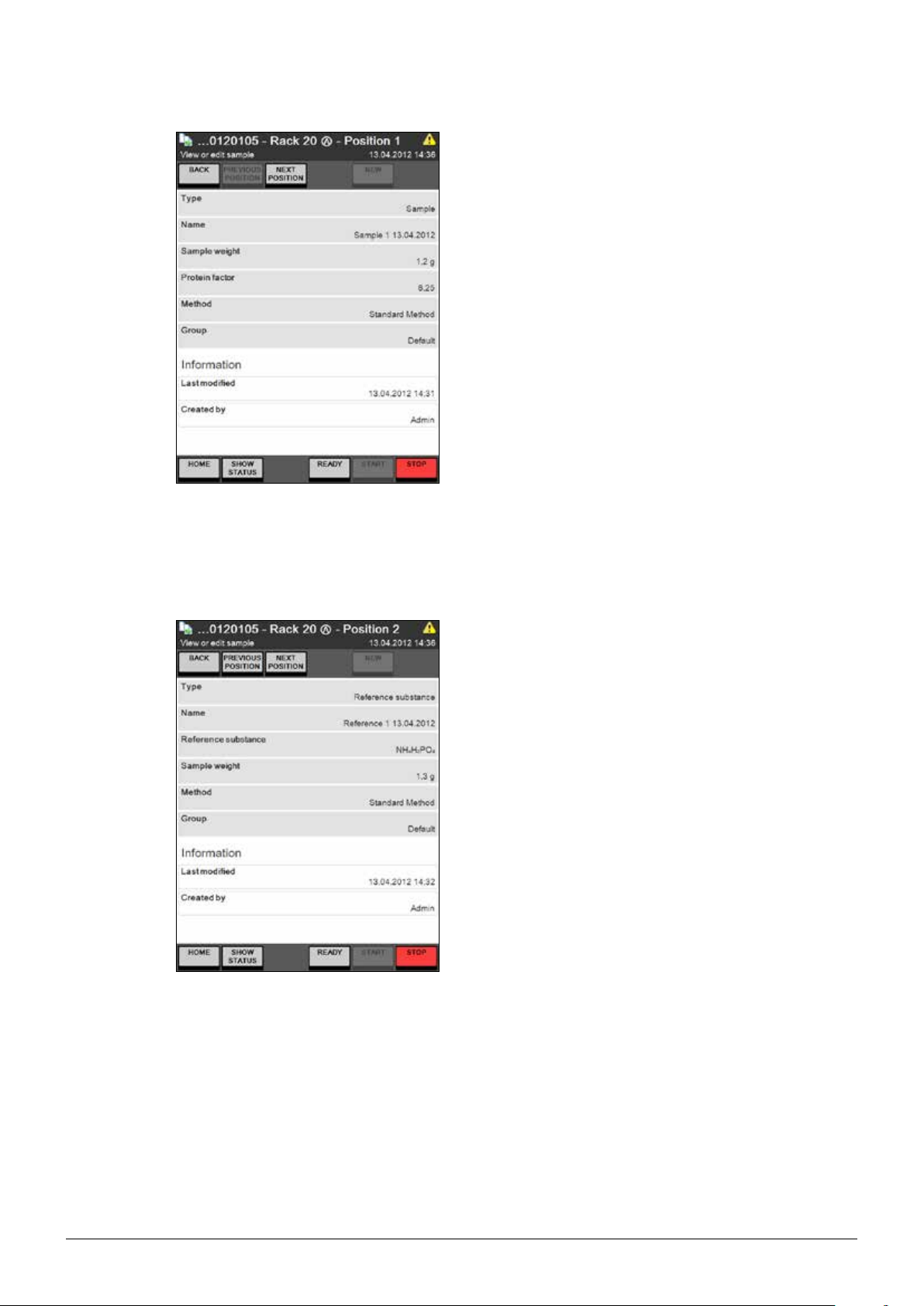

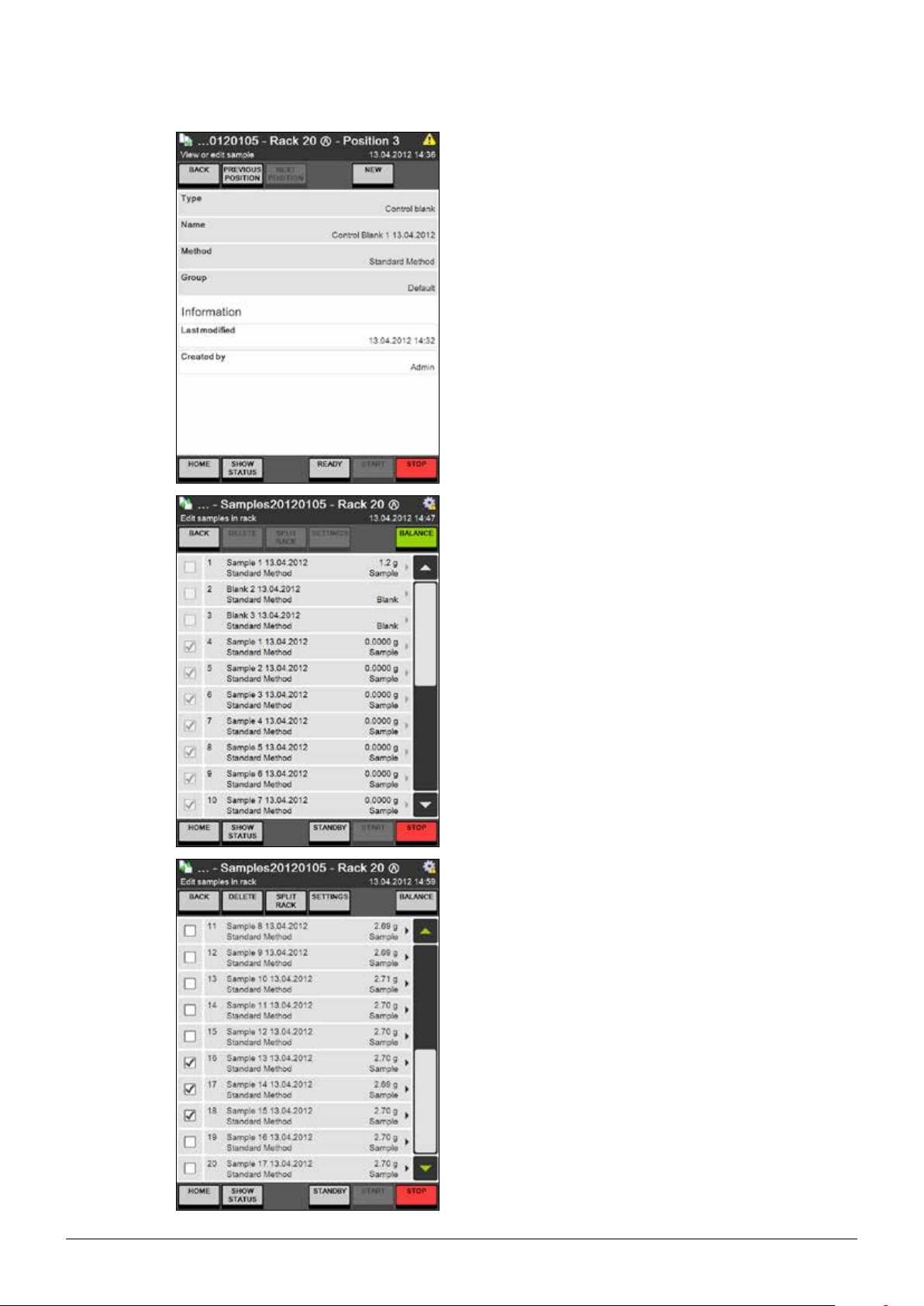

6.6.4 Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

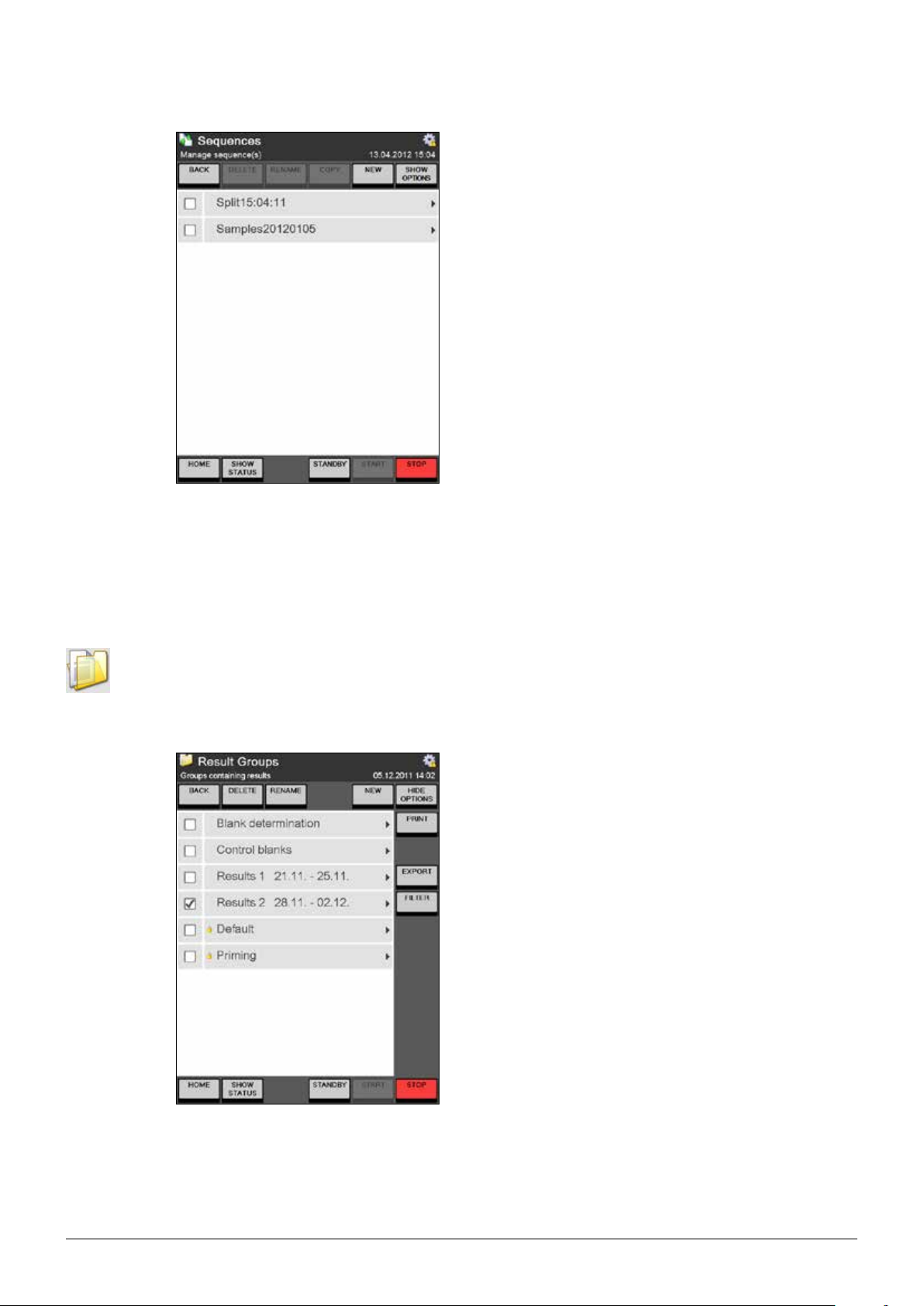

6.7 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.7.1 Result groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.7.2 Last Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

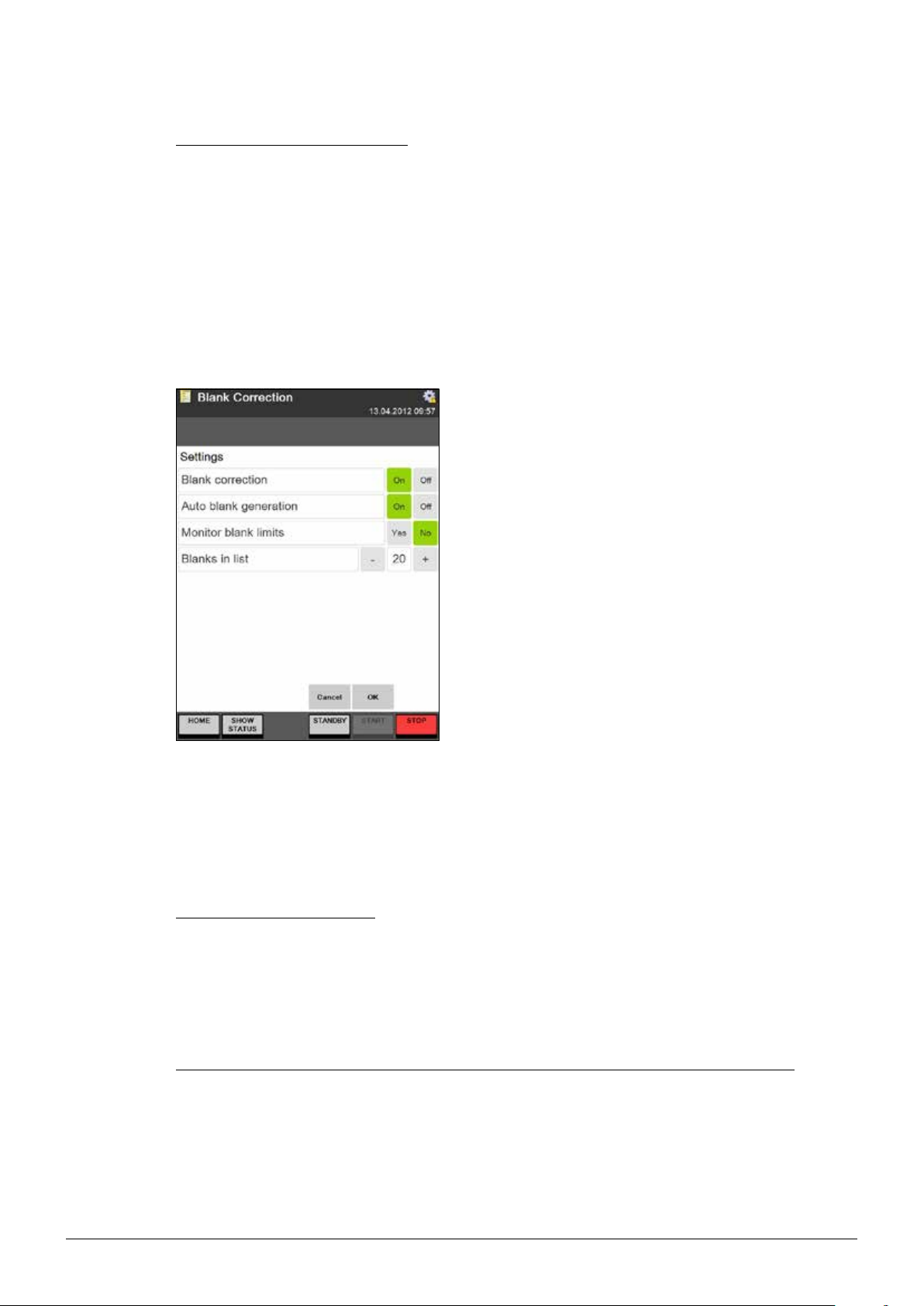

6.7.3 Blank Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.8 Determination Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

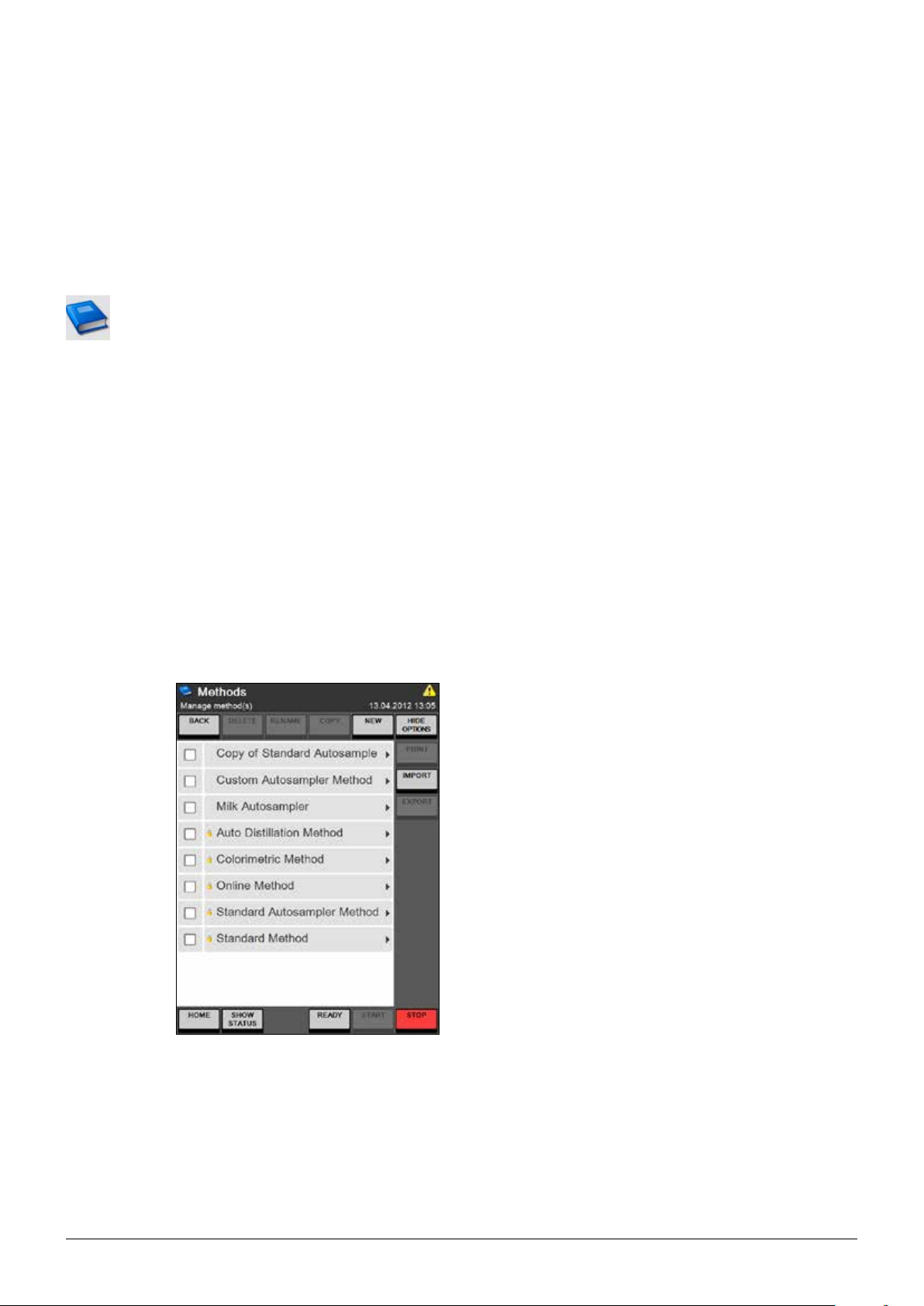

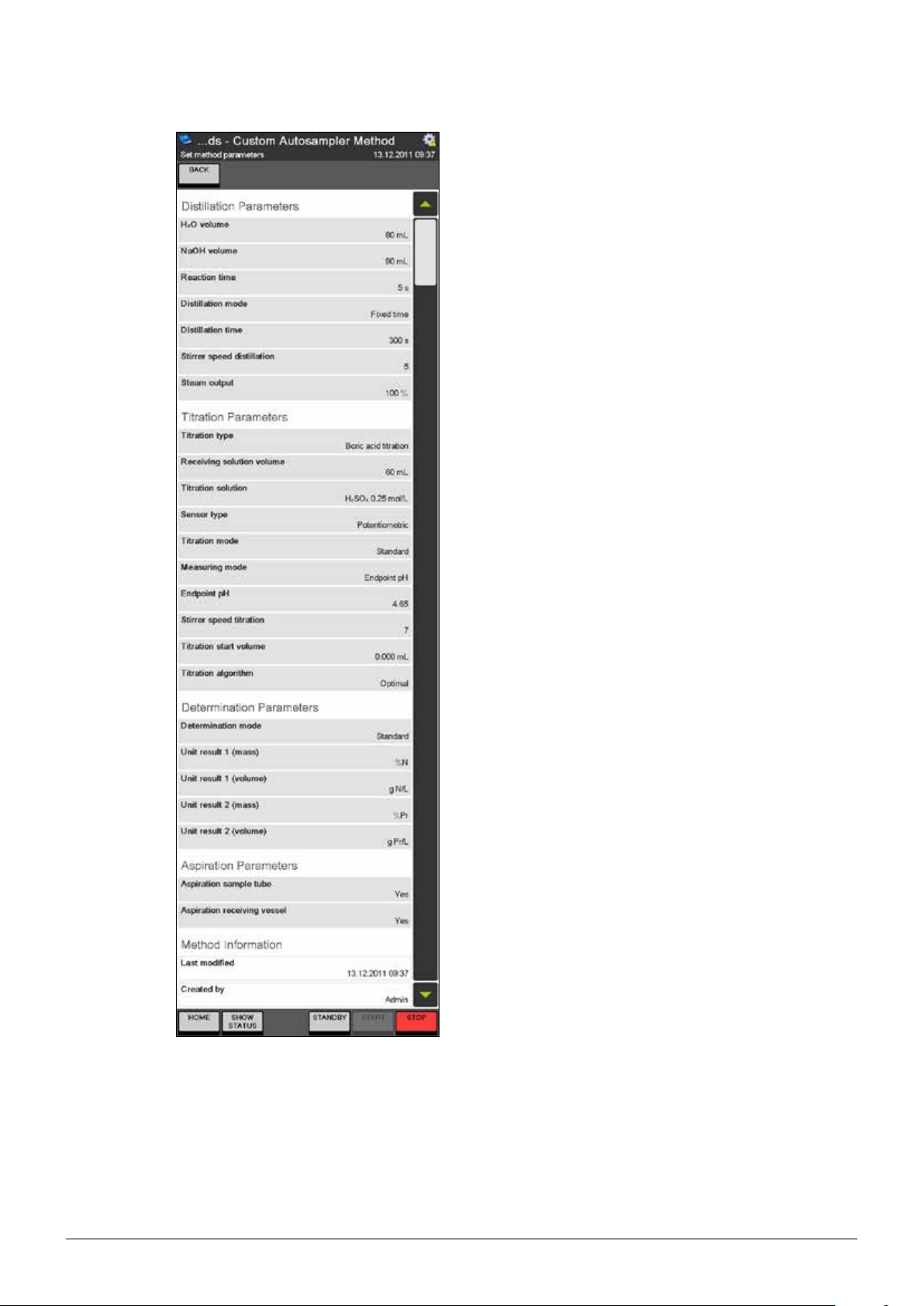

6.8.1 Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.8.2 Volumetric Solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

6.8.3 Reference Substances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

6.9 Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

6.9.1 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

6.9.2 Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

6.9.3 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

6.9.4 Logout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

7.1 Daily maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

7.1.1 Before sample determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

7.1.2 After sample determination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

7.1.3 pH electrode/pH calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

7.1.4 Filling boric acid into receiving vessel after last sample of rack was determined . . . .122

7.2 Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

7.2.1 Cleaning the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

7.2.2 Cleaning the titrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

7.2.3 Cleaning the glass parts of the dosing unit . . . . . . . . . . . . . . . . . . . . . .123

7.2.4 Cleaning the dip tube of the sampler . . . . . . . . . . . . . . . . . . . . . . . . .123

7.2.5 Device monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

7.3 Monthly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

7.3.1 Calibrating the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

7.3.2 Checking the distillate amount . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

7.3.3 Inspecting the buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

7.3.4 Inspecting the titrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

7.3.5 Inspecting the sample tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

7.4 Half-yearly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

7.4.1 K-375 Sealing between sample tube and splash protector . . . . . . . . . . . . . .128

7

K-375/376/377 Operation Manual, Version B

Page 8

Table of contents

7.4.2 K-376/K-377 dip tube and sealing cap . . . . . . . . . . . . . . . . . . . . . . . .129

7.4.3 Replacing the splash protector . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

7.5 Yearly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

7.5.1 Replacement of wear parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

7.5.2 Decalcification of the steam generator . . . . . . . . . . . . . . . . . . . . . . . . .134

7.5.3 Replacement of the sodium hydroxide pump . . . . . . . . . . . . . . . . . . . . .134

7.5.4 Replacement of the wave spring. . . . . . . . . . . . . . . . . . . . . . . . . . . .136

7.6 Replace every two years . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

7.6.1 Replacement of the transfer connection . . . . . . . . . . . . . . . . . . . . . . . .137

7.7 Maintenance work if required . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

7.7.1 Changing the buret tip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

7.7.2 Cleaning the pH electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

7.7.3 Replacing the buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

7.7.4 Cleaning the splash protector and the rubber seal . . . . . . . . . . . . . . . . . . .139

7.7.5 Glass parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

7.7.6 Troubleshooting the dosing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

7.7.7 Adjusting the sample tube holder . . . . . . . . . . . . . . . . . . . . . . . . . . .140

7.8 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

8.1 Problems that may occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

8.2 Error messages on the display of the K-375. . . . . . . . . . . . . . . . . . . . . .146

8.3 Eliminating errors of the KjelSampler K-376/K-377 . . . . . . . . . . . . . . . . . .150

8.4 Eliminating errors of the titrator . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

9 Taking out of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

9.1 Emptying the steam generator . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

9.2 Emptying the buret of the titrator . . . . . . . . . . . . . . . . . . . . . . . . . . .154

9.3 Storage/shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

9.4 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

10.1 Spare parts K-375 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

10.2 Spare parts K-376/K-377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

10.3 Hosing connection scheme Kjeldahl Sampler System K-375/K-376. . . . . . . . . .156

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . .157

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .158

8

K-375/376/377 Operation Manual, Version B

Page 9

1 About this manual

This manual describes the KjelMaster Sampler System K-375/K-376/K-377 and provides all information required for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel in particular.

NOTE

The symbols pertaining to safety (DANGER, CAUTION and WARNING) are explained in chapter 2.

1.1 Trademarks

DURAN® is a registered trademark of the SCHOTT AG.

1.2 Abbreviations

CSM: Chopped Strand Mat

ETFE: Polytetrafluorethylene

FEP: Fluorinated Ethylene Propylene

KCI: Potassium chloride

PCTFE: Polychlorotrifluoroethylene

PMMA: Polymethyl methacrylate

POM: Polyoxymethylene

PP: Polypropylene

PTFE: Ethylenetetrafluoroethylene

PUR: Polyurethane

UV: Ultraviolet

EPDM: Ethylene propylene diene monomer

PVDF: polyvinylidene difluoride

PA: Polyamide

1 About this manual

9

K-375/376/377 Operation Manual, Version B

Page 10

1 About this manual

10

K-375/376/377 Operation Manual, Version B

Page 11

2 Safety

This chapter points out the safety concept of the device and contains general rules of behavior and

warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safety

related warnings in the individual chapters are strictly observed and followed. Therefore, the manual

must always be available to all persons performing the tasks described herein.

2.1 User qualification

The device may only be used by laboratory personnel and other persons who on account of training

or professional experience have an overview of the dangers which can develop when

operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction.

The present Operation Manual serves as the basis for this.

2 Safety

2.2 Proper use

The device has been designed and built for laboratories. It serves for nitrogen determination

according to Kjeldahl. The KjelMaster K-375 as stand-alone device may also be used for distillations

of steam-volatile substances.

2.3 Improper use

Applications not mentioned above are improper. Also applications which do not comply with the

technical data are considered improper.

The operator bears the sole risk for any damages caused by such improper use.

The following uses are expressly forbidden:

• Use of the device in rooms which require ex-protected devices.

• Use on samples which can explode or inflame (e.g.: explosives, etc.) due to shock, friction, heat or

spark formation.

!

Danger

During any improper use, the effectiveness of the protection systems of the devices

can be affected.

• Avoid any improper use of the devices!

11

K-375/376/377 Operation Manual, Version B

Page 12

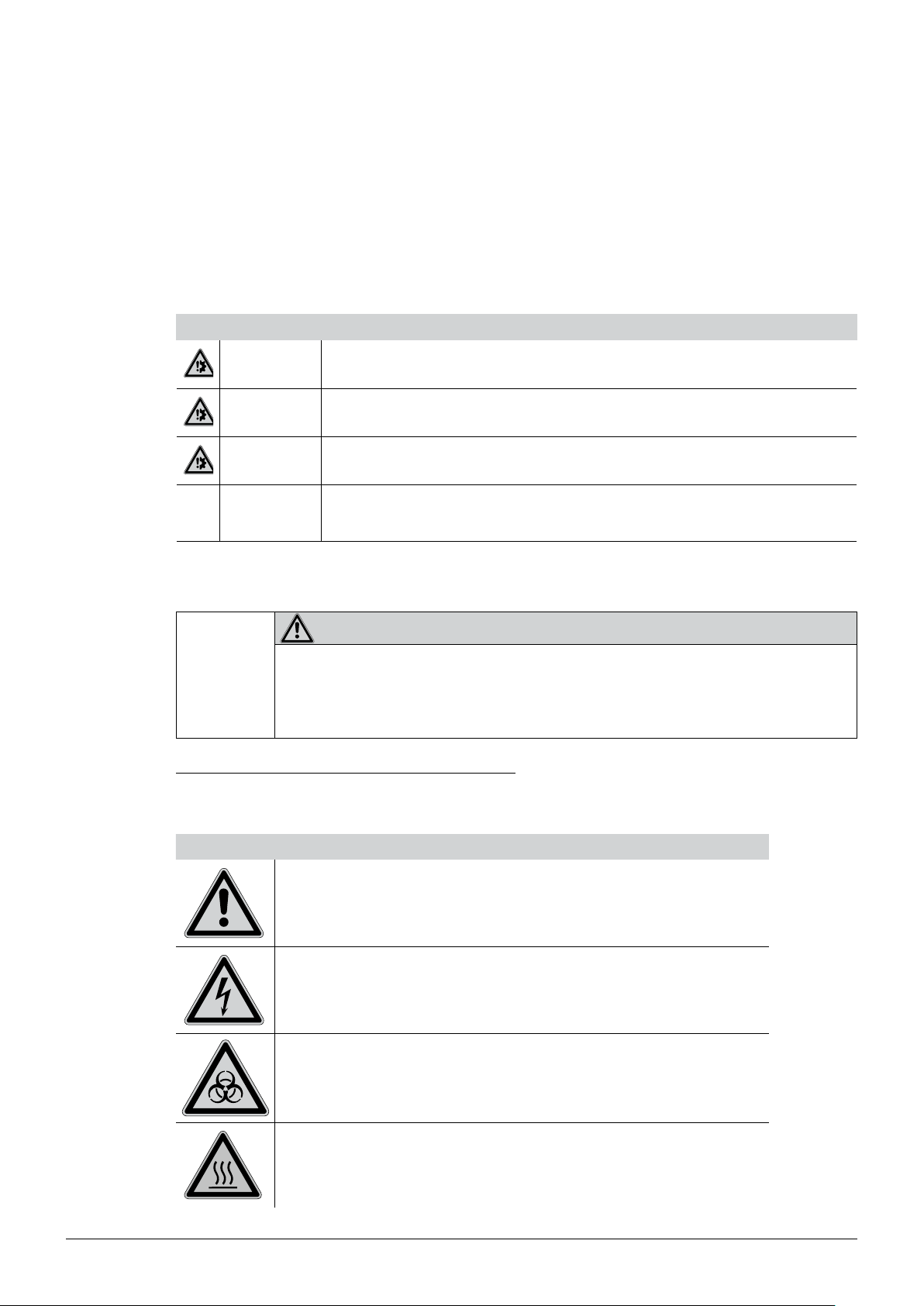

2.4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which

are related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal

words and their definitions!

Sign Signal word Definition Risk level

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

CAUTION

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see example below).

Space for

supplementary

safety

information

symbols.

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Symbol Meaning

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

SIGNAL WORD

Supplementary text, describing the kind and level of hazard / risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

(property damage only)

★★★☆

★★☆☆

★☆☆☆

12

General warning

Electrical hazard

Biohazard

Hot surface

K-375/376/377 Operation Manual, Version B

Page 13

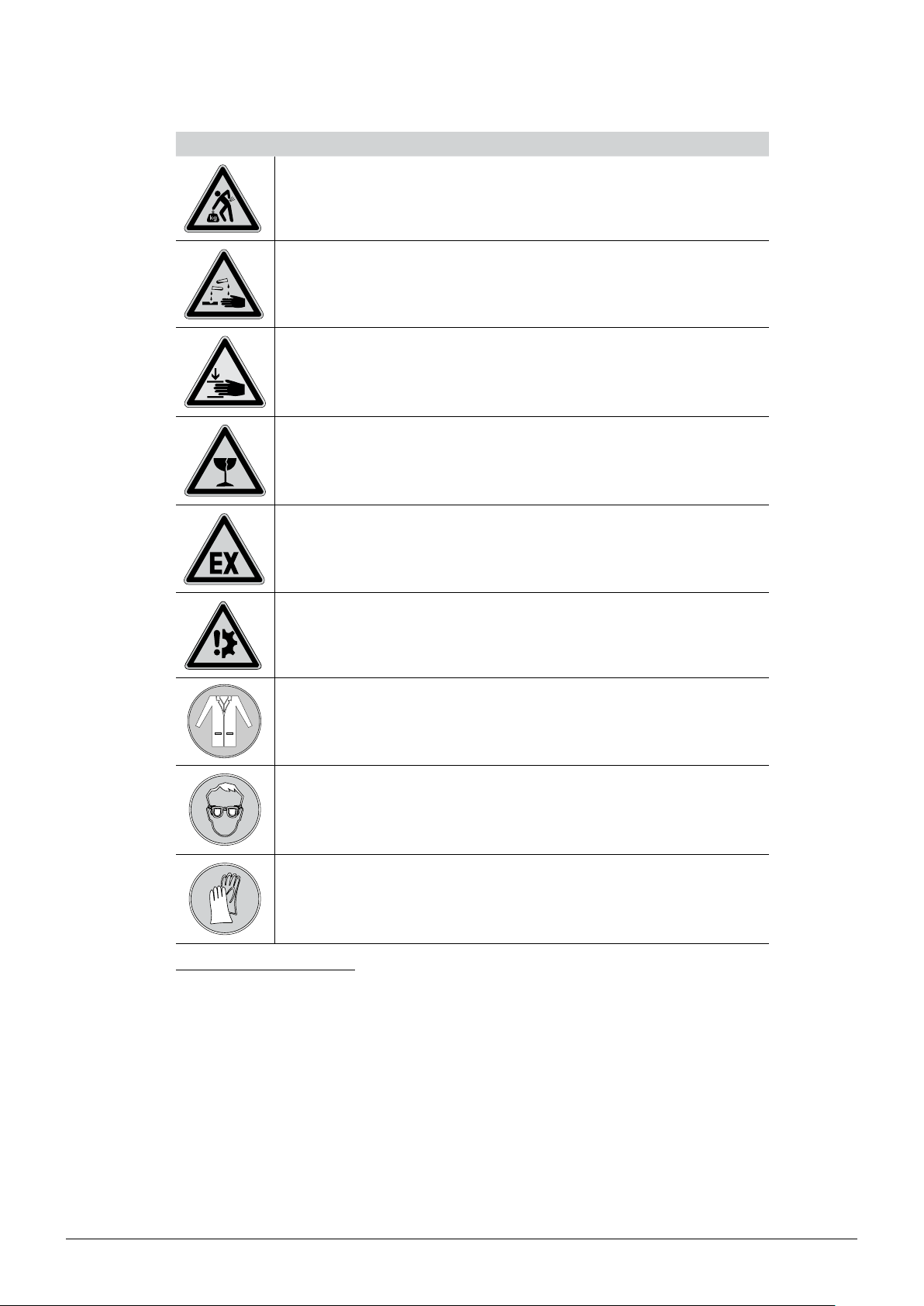

Symbol Meaning

Heavy weight, avoid overexertion

Chemical burns by corrosives

Pinch point. Mechanical hazard.

Fragile components

2 Safety

Explosive gases, explosive environment

Device damage

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device / software or

its supplementaries. NOTEs are not related to any kind of hazard or damage (see following example).

NOTE

Useful tips for the easy operation of the instrument / software.

13

K-375/376/377 Operation Manual, Version B

Page 14

2.5 Product safety

The device is designed and built in accordance with current state-of-the-art technology. Nevertheless, risks to users, property, and the environment can arise when the device is used carelessly or

improperly.

The manufacturer has determined residual dangers emanating from the instrument

• if the device is operated by insufficiently trained personnel.

• if the device is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

2 Safety

!

Death or serious injuries by use in explosive environments.

• Do not store or operate the device in explosive environments.

• Remove all sources of flammable vapors.

• Do not store chemicals in the vicinity of the device.

!

Risk of minor or moderate cuts by sharp edges.

• Do not touch defective or broken glassware with bare hands.

• Do not touch thin metal edges.

Risk of device damage by liquids or mechanical shocks.

• Do not spill liquids over the device or its components.

• Do not drop the device or its components.

• Keep external vibrations away from the instrument.

2.5.2 Instrument-related hazards

DANGER

CAUTION

NOTICE

14

!

CAUTION

Risk of injury.

• Never touch the surface of the touchscreen with pointed or sharp objects! Otherwise the

screen might get damaged and splinter.

K-375/376/377 Operation Manual, Version B

Page 15

2 Safety

!

CAUTION

Risk of burns by hot surface. Surface temperature exceeds 60 °C.

• Do not touch hot surfaces of the instrument.

!

CAUTION

Risk of pinch point injuries.

• In order to avoid injuries to the hands and fingers the K-376 and K-377 KjelSamplers may not

be manipulated during the moving action of the sampler arm.

!

CAUTION

Risk of burns by hot steam.

• The system works with hot steam. Avoid any contact with hot steam.

!

DANGER

Risk of chemical burns by corrosives.

• Wear laboratory coat, protective gloves and protective goggles at all times.

!

DANGER

Risk of chemical burns by corrosives.

• During operation the sample tube contains either strong acid or strong base. In case the

sample tube brakes, the content of the sample tube is collected in the drip tray on the bottom

of the housing. Wear laboratory coat protective gloves and protective goggles when emptying

the drip tray.

15

K-375/376/377 Operation Manual, Version B

Page 16

2.5.3 Other hazards

Fundamental dangers arise from.

• acids and lye

• flammable gases or solvent fumes in the direct vicinity of the instrument

• damaged glass parts

• insufficient distance between the device and the wall (see chapter 5.1, Installation site)

• burns caused by contact with hot glass parts

• burns caused by contact with steam at the waste-outlet

• defective transfer tube: escape of steam and/or sulfuric acid

2.5.4 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing

and gloves. The personal protective equipment must meet all requirements of all data sheets for

the chemicals used. These instructions are an important part of the K-375, K-376 and K-377 and

must be made available at all times to the operating personnel at the place where the equipment is

deployed. This also applies to additional language versions of these instructions, which can be reordered separately.

2 Safety

!

WARNING

Serious chemical burns by corrosives.

• Observe all data sheets of the used chemicals.

• Handle corrosives in well ventilated environments only.

• Always wear protective goggles.

• Always wear protective gloves.

• Always wear protective clothes.

• Do not use damaged glassware.

16

K-375/376/377 Operation Manual, Version B

Page 17

2.5.5 Built-in safety elements and measures

The KjelMaster K-375 has monitored protective doors which prevent a distillation to start while a

door is open. A running distillation is immediately interrupted when a door is opened. The dosing of

reagents is also immediately stopped.

The sample changers K-376/K-377 have monitored protective shields. Running a sample changer

with opened shield is impossible. For the K-377 only the shield of the tray, that is currently not in use

can be opened.

K-375:

• Protective door: Safety appliance to protect users from burns at the splash protector (distillation

area) which is hot during distillation.

• Protective door sensors: Prevents to start a distillation with the protective doors open and stops

the distillation as soon as a protective door is opened during the process.

• Sample tube sensor: Prevents to start a distillation without a sample tube inserted.

• Service door sensor/switch: Electrical power is disconnected immediately when the service door

is opened, thus preventing electrical shock during maintenance.

K-376:

• Protective shield with sensor/switch: As soon as the shield is opened an alarm sound is triggered

and any movement of the arm is stopped.

2 Safety

K-377:

• Protective shield with sensor/switch: As soon as the shield of the tray in use is opened an alarms

sound is triggered and any movement of the arm is stopped. (The shield of the respective tray

that is not operated can still be opened without any restrictions.)

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the device or its accessories. Legal regulations, such as local, state and

federal laws applying to the device or its accessories must be strictly followed.

Duty of maintenance and care

The operator is responsible for the proper condition of instrument. This includes maintenance, service

and repair jobs that are performed on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and spare parts for maintenance to assure good system performance, reliability and safety. Any modifications of spare parts or assemblies are only allowed with the

prior written permission of the manufacturer.

Modifications

Modifications to the device are only permitted after prior consultation and with the written approval

of the manufacturer. Modifications and upgrades shall only be carried out by an authorized BUCHI

technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

17

K-375/376/377 Operation Manual, Version B

Page 18

2 Safety

18

K-375/376/377 Operation Manual, Version B

Page 19

3 Technical data

This chapter introduces the reader to the device specifications. It contains the scope of delivery,

technical data, requirements and performance data.

3.1 Scope of delivery

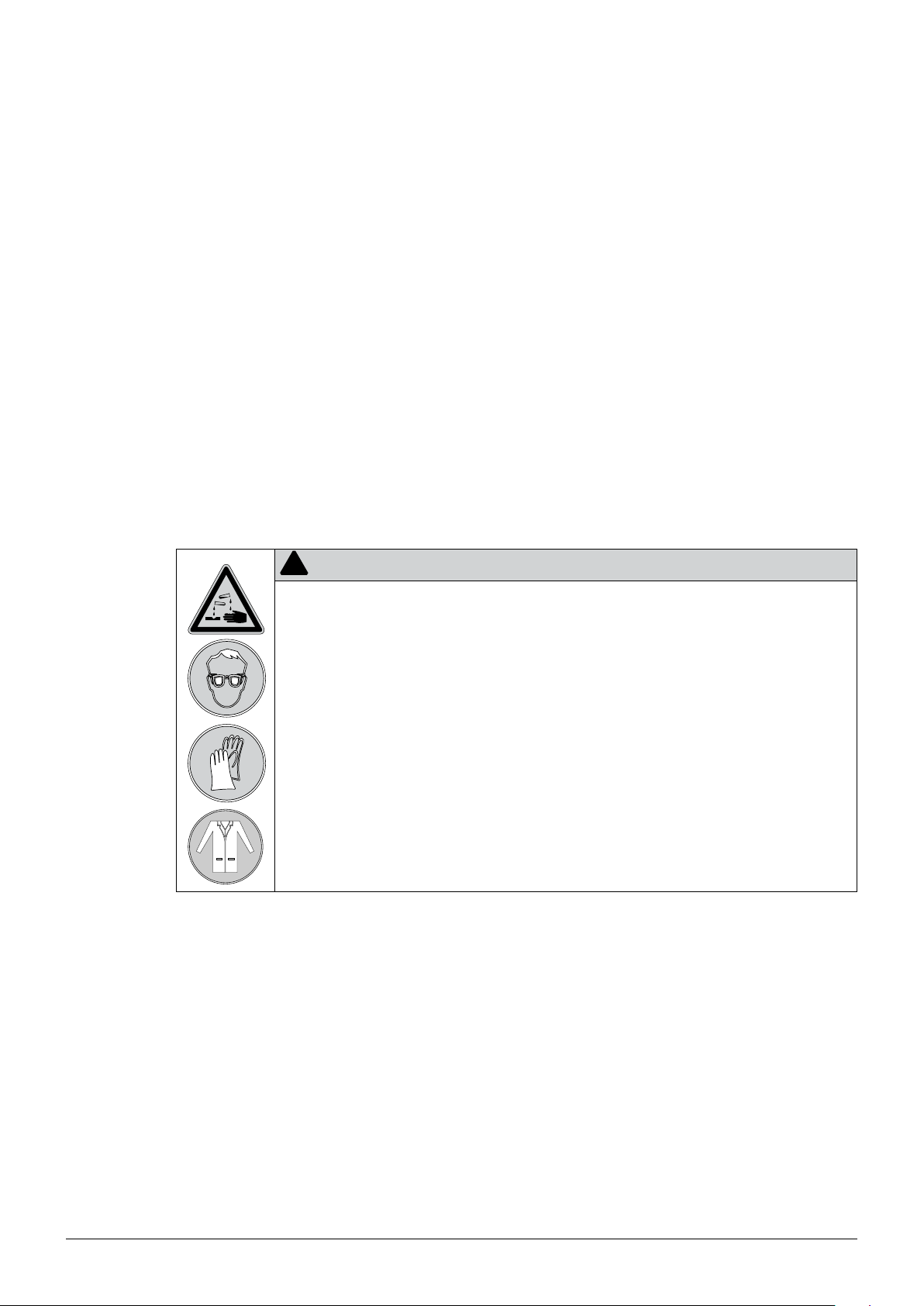

3.1.1 Basic devices

3 Technical data

Table 3-1: KjelMaster K-375

Product Order number

KjelMaster K-375

with glass splash protector and

potentiometric sensor

(220 – 240 V, 50/60 Hz)

KjelMaster K-375

with glass splash protector and

colorimetric sensor

(220 – 240 V, 50/60 Hz)

KjelMaster K-375

with plastic splash protector and

potentiometric sensor

(220 – 240 V, 50/60 Hz)

KjelMaster K-375

with plastic splash protector and

colorimetric sensor

(220 – 240 V, 50/60 Hz)

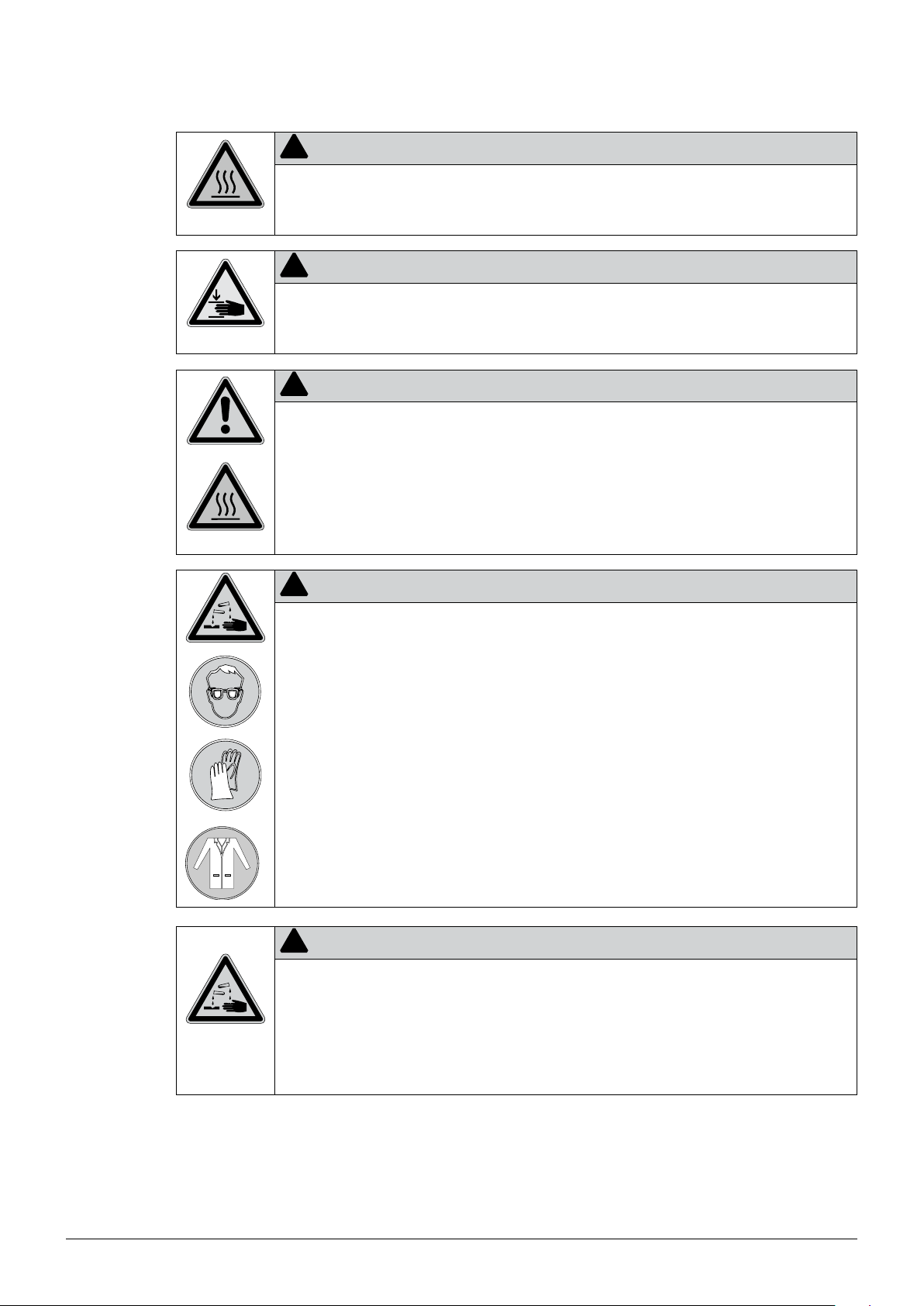

Table 3-2: KjelSampler K-376

Product Order number

KjelSampler K-376

with one tray

(100 – 240 V, 50/60 Hz)

113751700

113752700

113753700

113754700

113750710

19

Table 3-3: KjelSampler K-377

Product Order number

KjelSampler K-377

with two trays

(100 – 240 V, 50/60 Hz)

K-375/376/377 Operation Manual, Version B

113750720

Page 20

3 Technical data

Table 3-4: KjelMaster/Sampler Systems

K-375/K-376

Product Order number

KjelMaster Sampler System K-375/K-376

113751710

K-375 with glass splash protector and

potentiometric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-376

113752710

K-375 with glass splash protector and

colorimetric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-376

113753710

K-375 with plastic splash protector and

potentiometric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-376

113754710

K-375 with plastic splash protector and

colorimetric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

Table 3-5: KjelMaster/Sampler Systems

K-375/K-377

Product Order number

KjelMaster Sampler System K-375/K-377

K-375 with glass splash protector and

potentiometric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-377

K-375 with glass splash protector and

colorimetric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-377

K-375 with plastic splash protector and

potentiometric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

KjelMaster Sampler System K-375/K-377

K-375 with plastic splash protector and

colorimetric sensor

K-375: 220 – 240 V, 50/60 Hz

K-376/K-377: 100 – 240 V, 50/60 Hz

113751720

113752720

113753720

113754720

20

K-375/376/377 Operation Manual, Version B

Page 21

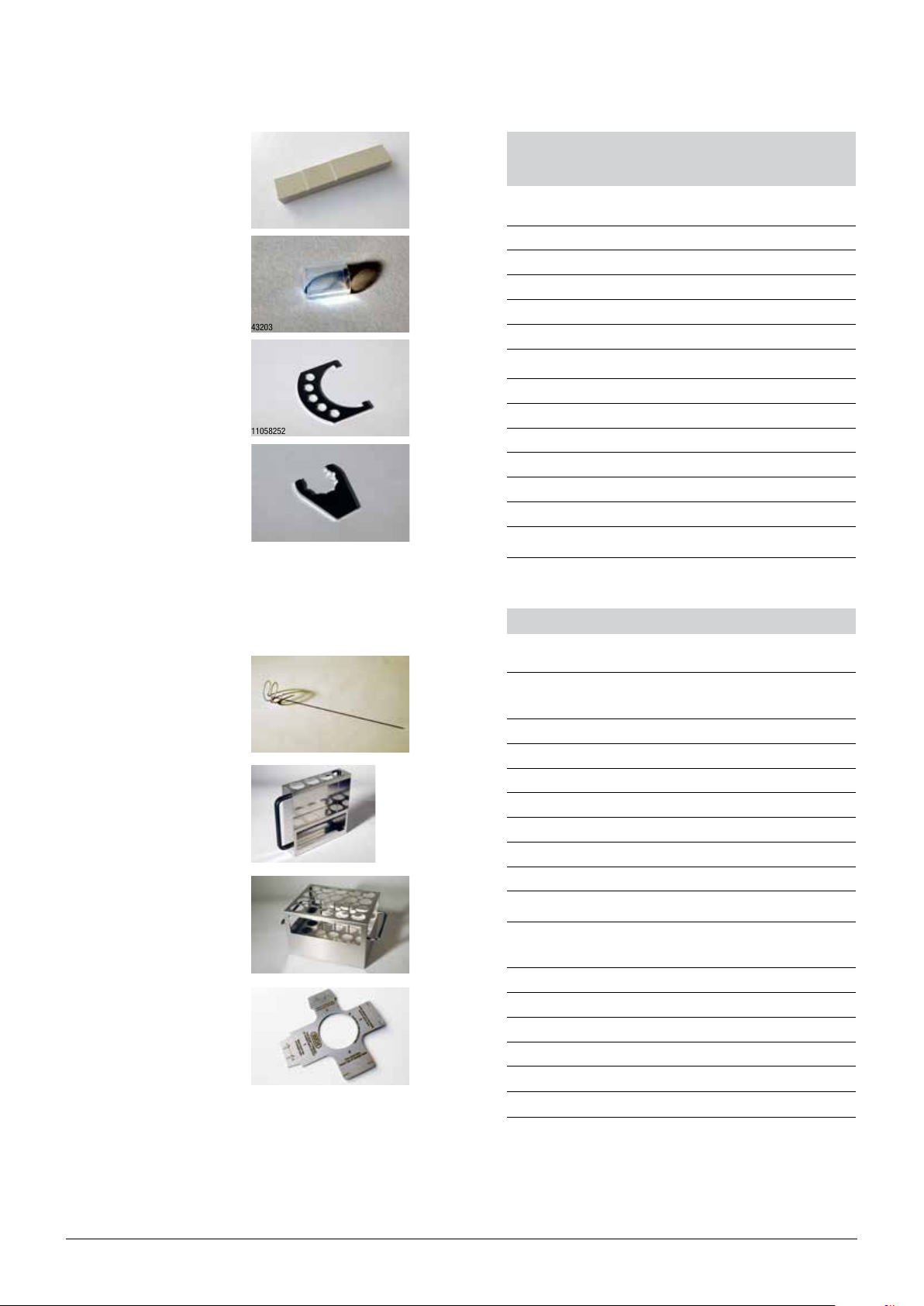

3.1.2 Standard accessories for K-375

11057410

43178

43185

43407

49151

3 Technical data

Table 3-6: Standard accessories for K-375

Number

of pieces

Product Order number

1 Pair of glass tongs 02004

1 Connection cable RJ45 length

44989

2 m

1 Mains cable of the following

types

Type CH 10010

Type Schuko/Japan 10016

Type GB 17835

Type AUS 17836

Type USA 33763

1 pH electrode

or (according to purchase order)

colorimetric sensor

1 Indicator according to Sher,

11056842

11057410*

003512

100 mL

(if device version with colorimetric sensor is shipped)

1 Buffer set pH 4 and pH 7

43188

(3 x 20 mL each)

1 KCI electrolyte, sat. , 250 mL 11059759

43457

11058157

11055914

11056835

11056836

1 Hose connector in line 11–13 43178*

1 Hose chemical supply, Nyflex,

43185*

length 6 m, Ø 5/10 mm

3 Suction tube to tanks, FEP,

43407*

length 580 mm

1 Connection grommet 49151*

2 Hose waste drain, EPDM,

43457*

L = 1.8 m, ø 11/18 mm

5 Clamp D15.6 49167

1 Silicone hose ø 8 mm/12x1.8m 11058157*

1 Clamp D12.8 43297

1 Y-piece ø12 mm 11058358

1 Cooling water hose complete:

37780

G 3/4”, G 1/2”, L = 1.5 m

3 Clamp D11.9 43841

2 O-ring 190.1 x 3.53 EPDM 75 49676

2 O-ring 247.2 x 3.53 EPDM 11058241

4 Level sensor 11055914*

1 Laboratory vessel 53203

1 Dosino 800 11056835*

1 Dosing unit 11056836*

21

K-375/376/377 Operation Manual, Version B

Page 22

3 Technical data

43203

11058252

Table 3-6: Standard accessories for K-375

(continued)

11059802

11057779

3.1.3 Standard accessories for K-376

43482

11057711

Number

of pieces

Product Order number

1 Gauge sample tube holder 11059802

2 Tank 10 L, without caps 43410

2 Cap for 10 L tank, large 25869

4 Cap for 10 L and 20 L tank, small 43477

4 Tank labels 43434

2 Tank 20 l, without caps 43408

2 Cap for 20 L tank, large 43478

1 Distance holder buret tip 43203*

1 Mini gender changer 43108

1 Weighing boat 40444

4 EPDM sealing for tanks 43048

1 Open end spanner 11058252*

1 Tool SVL 22 11057779*

Table 3-7: Standard accessories for K-376

Number of

pieces

1 K-376/K-377 cable RS232

Product Order number

43920

(crossed)

1 Sample tube 300 mL 3904

1 Sample tube 500 mL 26128

1 Clamp ring 43238

1 Hose clamp 22352

1 Fastener for transfer tube 43482*

6 Sample tubes (set of 4), 300 mL 37377

1 Express rack, 4 places 11057711*

1 Rack complete, 20 places 11059831*

22

11059831

11058240

1 Mains cable of the following

types

Type CH 10010

Type Schuko/Japan 10016

Type GB 17835

Type AUS 17836

Type USA 33763

1 Test gauge for sample tubes 11058240

K-375/376/377 Operation Manual, Version B

Page 23

3.1.4 Standard accessories for K-377

11058240

3 Technical data

Table 3-8: Standard accessories for K-377

Number of

pieces

1 K-376/K-377 cable RS232

Product Order

number

43920

(crossed)

2 Sample tube 300 mL 3904

1 Sample tube 500 mL 26128

1 Clamp ring 43238

1 Hose clamp 22352

1 Fastener for transfer tube 43482

12 Sample tubes (set of 4), 300 mL 37377

2 Rack complete, 20 places 38621

1 Mains cable of the following types

Type CH 10010

Type Schuko/Japan 10016

Type GB 17835

Type AUS 17836

Type USA 33763

1 Test gauge for sample tubes 11058240

Table 3-9: Operation Manuals and Quick Guides

Product Order number

Operation Manual:

English 11593514

German 11593515

French 11593516

Italian 11593517

Spanish 11593518

Chinese 11593519

Japanese 11593520

23

K-375/376/377 Operation Manual, Version B

Page 24

3.1.5 Optional accessories K-375

43333

43390

3 Technical data

Table 3-12: Optional accessories K-375

Product Order number

Sample tubes (set of 4), 300 mL 37377

Sample tube 500 mL 26128

Sample tubes (set of 4), 500 mL 43982

Pair of glass tongs 02004

Receiving vessel 340 mL 43333*

Receiving vessel 420 mL 43390*

Devarda splash protector 43335

Tanks without level sensors, including caps

10 L chemicals 43468

10 L waste 43470

20 L chemicals 43469

20 L waste 43471

11056851

Level sensor 11055914

O-ring level sensor (10 L tank) 49676

O-ring level sensor (20 L tank) 11058241

Spectrosense 610 nm with cable 11057410

Buffer solution pH 4, 1000 mL 26321

Buffer solution pH 7, 1000 mL 26322

Indicator according to Sher, 100 mL 03512

Temperature sensor for titrator 11056851*

Dosing unit (for back titration) 11056836

Motor for dosing unit 11056835

Sample tube holder for 4 sample tubes,

16951

500 mL each

IQ/OQ Package K-375 (English) 11058677

IQ/OQ Package K-375/K-376/K-377

11058678

(English)

Repeating OQ Package K-375 (English) 11058679

Repeating OQ Package K-375/K-

11058680

376/K-377 (English)

24

K-375/376/377 Operation Manual, Version B

Page 25

3.1.6 Optional accessories K-376/K-377

3 Technical data

Table 3-14: Optional accessories for K-376/K-377

Product Order number

Stand for rack 11058659

Sample tubes (set of 4), 500 mL 43982

Rack for 12 sample tubes, 500 mL 43970*

Retainer plate (holds tubes firmly in rack

43970

for machine washing)

Set of 10 boiling rods for digestion of

samples with tendency of boiling retardation (alternative for boiling chips)

Sample tubes (set of 4), 300 mL 37377

Dip tube with cross-slot for soil/stone

containing samples

Glassfinger for sample tubes

for soil samples

38559

43087

47845

48638

25

K-375/376/377 Operation Manual, Version B

Page 26

3.2 Technical data overview

3.2.1 Technical data KjelMaster K-375 and KjelSampler K-376/K-377

Table 3-15: Technical data

KjelMaster K-375 KjelSampler K-376 KjelSampler K-377

Connection voltage 220 – 240 VAC ±10% 100 – 240 VAC ± 10 % 100 – 240 VAC ± 10 %

Frequency 50/60 Hz 50/60 Hz 50/60 Hz

Power consumption max. 2.2 kW max. 150 W max. 150 W

Current consumption (230 V) 9.5 A 650 mA 650 mA

Weight 32 kg 40 kg

3 Technical data

64 kg

(without rack and sample

tubes)

Dimensions (W x H x D) 458 x 670 x 431 mm 505 x 750* x 655

* 1000 mm height

required to allow free

movement of the sampler

arm

(without rack and sample

tubes)

1015 x 750** x 655

**1250 mm height

required to allow free

movement of the sampler

arm

Interfaces RS232 RS232 RS232

Recovery rate > 99.5 % (1 – 200 mg N)

Reproducibility (RSD) < 1 %

Measuring range 0.1 – 200 mg N

Environmental conditions

Temperature

Altitude

Humidity

for indoor use only

+ 5 °C to + 40 °C

up to 2000 m above sea level

maximum relative humidity 80 % for temperatures up to 31 °C, decreasing linearly to

50 % relative humidity at 40 °C

Mains connection Device plug C14 Device plug C14 Device plug C14

Overvoltage category II II II

Pollution degree 2 2 2

Approval CE/CSA CE/CSA CE/CSA

3.2.2 Technical data titrator

The following sensors can be connected to the titrator:

• combined pH glass electrode

• optical sensor with measuring range between 50 and 1000 mV (max. 1200 mV)

• temperature measuring sensor for Resistance Thermometer Pt 1000, connection: 2 x 4 mm

sockets and 1 x 2 mm socket

Dosing accuracy:

According to DIN EN ISO 8655, Part 3, or better

Typical accuracy: Systematic error max. ± 30 µL

26

K-375/376/377 Operation Manual, Version B

Page 27

3 Technical data

Measuring input: pH/mV input with 12 bit transducer for accurate resolution during the titration

Connection:

Measuring range Display resolution Accuracy* without sensor Input resistance (Ω)

pH 0…14 0.01 0.05 ±1 digit > 5·10

mV –1400 ... +1400 0.1 2 ±1 digit > 5·10

Measuring range Display resolution Accuracy* without sensor

T [°C] –30…115 0,1 0,5 K ±1 digit

*Accuracy:

Indicated in terms of measuring incertainty with a confidence of 95%. In addition the measuring uncertainty of the sensor has to be taken into account as well. For pH electrodes e.g.: ∆ pH= 0.012...0.03

according to DIN 19 266, Part 3.

3.3 Titration solution

The amount of sample and the concentration of the titrant should be optimized, so that the titrant

volume is between 3 and 17 mL (buret volume: 20 mL).

Table 3-16: Nitrogen expected

N-amount N-content Sample size Titrant Titrant concentration Titrant volume

5 mg N 0.5 % N 1 g

50 mg N 5 % N 1 g

100 mg N 10 % N 1 g

100 mg N 10 % N 1 g

200 mg N 20 % N 1 g

200 mg N 20 % N 1 g

electrode socket according to DIN 19 262 or BNC socket and reference electrode 1 x 4 mm socket

12

12

H2SO4 0.01 mol/L

H2SO4 0.1 mol/L

H2SO4 0.25 mol/L

H2SO4 0.5 mol/L

H2SO4 0.5 mol/L

H2SO4 1 mol/L

17.8 mL

17.8 mL

14.3 mL

7.1 mL

14.3 mL

7.1 mL

Table 3-17: Protein expected

P-content P-factor N-content Sample size Titrant Titrant concentration Titrant volume

1 % P 6.25 0.16 % N 2 g

2 % P 6.25 0.32 % N 1 g

5 % P 6.25 0.80 % N 2 g

10 % P 6.25 1.6 % N 2 g

10 % P 6.25 1.6 % N 2 g

20 % P 6.25 3.2 % N 2 g

50 % P 6.25 8.0 % N 2 g

H2SO4 0.01 mol/L

H2SO4 0.01 mol/L

H2SO4 0.1 mol/L

H2SO4 0.1 mol/L

H2SO4 0.25 mol/L

H2SO4 0.25 mol/L

H2SO4 0.5 mol/L

11.4 mL

11.4 mL

5.7 mL

11.4 mL

4.6 mL

9.1 mL

11.4 mL

General recommendation

The correction factor for self prepared solutions is called titer.

The use of standardized titration solutions make a titer determination unnecessary.

Exact titrant concentration = concentration x titer

The titer of the titrant must be known. In case, it is unknown, it must be determined.

Example: Exact titrant concentration = 0.100 mol/L x 0.998

27

K-375/376/377 Operation Manual, Version B

Page 28

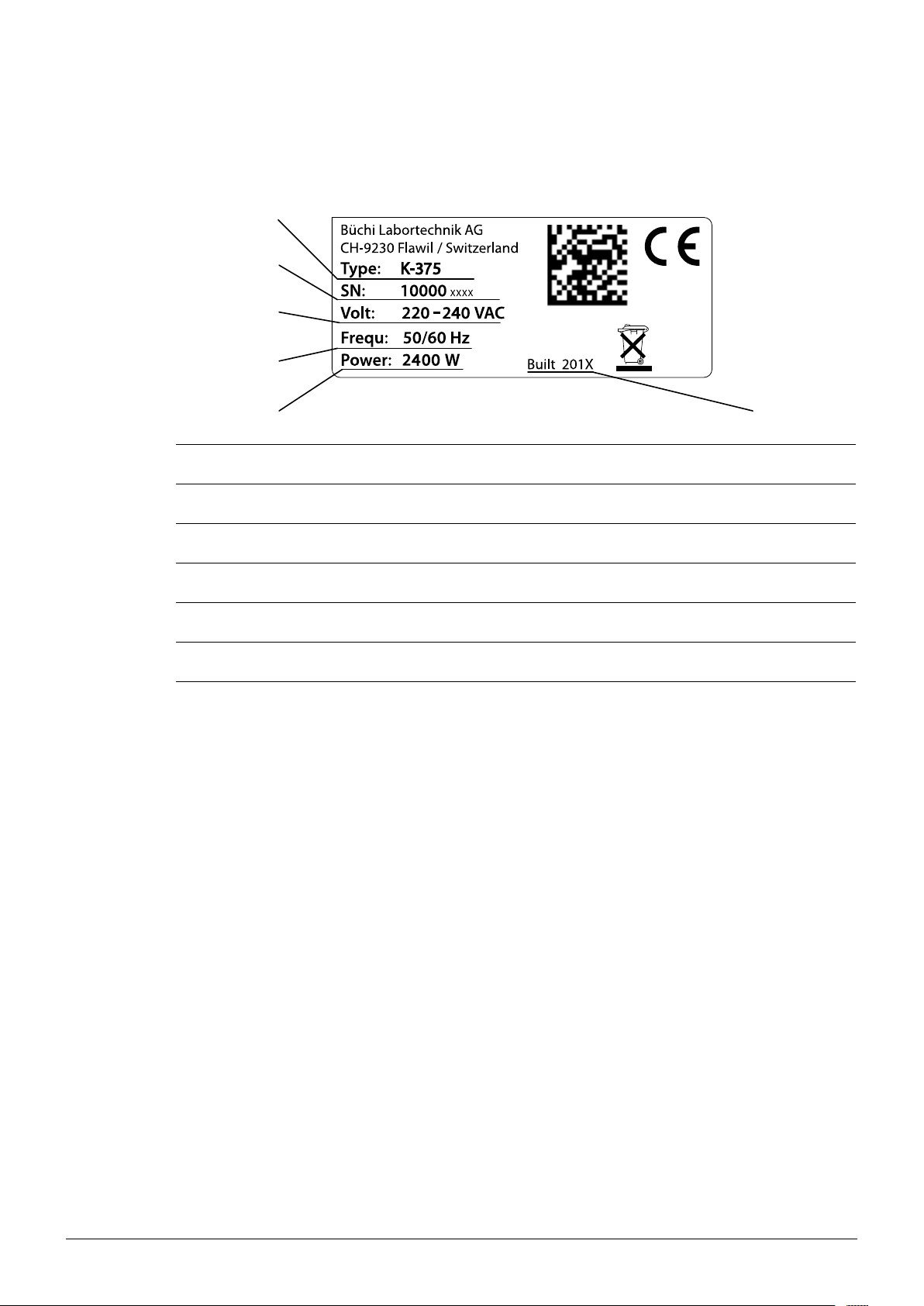

3.4 Information on type plate

a Device type code

b Serial number

3 Technical data

c Supply voltage range/type

d Frequency of supply voltage

e Nominal power rating

f Year of manufacture

28

K-375/376/377 Operation Manual, Version B

Page 29

3.5 Reference substances

Table 3-18: Reference substances

Name Purity % N theoretical

Ammonium

99.5 12.18 0.2 g c(H2SO4) = 0.1 mol/L No

dihydrogen

phosphate

Glycine 99.7 18.66 0.2 g c(H

Phenylalanine 99.0 8.47 0.3 g c(H2SO4) = 0.1 mol/L Yes

Ammonium

99.5 21.21 0.2 g c(H2SO4) = 0.1 mol/L No

sulfate

Tryptophan 99.0 13.72 0.2 g c(H

Acetanilide 99.0 10.36 0.2 g c(H2SO4) = 0.1 mol/L Yes

3.6 Materials used

(100 % purity)

Recommended

sample size

3 Technical data

Recommended titrant concentration Digestion necessary

2SO4) = 0.1 mol/L Yes

2SO4) = 0.1 mol/L Ye s

3.6.1 Titrator module and dosing unit

Table 3-19: Materials on the titrator

part Material designation

Housing sheet steel

NOTE

For the materials of the Dosing Unit, please refer to its manual which is delivered together with

dosing unit.

3.6.2 K-375

Table 3-20: Material on the K-375

Part Material Material code

Housing Polyurethane PUR/UL VO

Glass parts Borosilicate glass 3.3 DIN/ISO 3585

Insulation steam generator Ceramic fiber Multitherm 550

Steam generator housing Stainless steel 1.4301

Protective door Polymethyl methacrylate PMMA

Seal ring Chlorosulfonyl polyethylene elastomer CSM

29

K-375/376/377 Operation Manual, Version B

Page 30

3.6.3 K-376/K-377

Table 3-21: Material on the K-376/K-377

Part Material Material code

Housing (mounting plate) Steel sheet St 12 ZE 1.0330

Housing (casing-below) Stainless steel 1.4301 (L 314)

Housing (top cover) Alu-sheet AlMgSi1

Guide express rack PP PP

Coating Polyester/Epoxy PEP 31

Protective shield Polymethyl methacrylate/Alu PMMA/Alu

Drip tray Polypropylene PP

Housing y-axle Alu-sheet AlMgSi1

End cap y-axle POM POM

Dip tube PVDF PVDF

Sealing cap EPDM EPDM

Transfer hose linear PTFE PTFE

Steam tube Silicone/polyester MQ-PU

Protective hose PP PP

Hose chain PA PA

3 Technical data

30

K-375/376/377 Operation Manual, Version B

Page 31

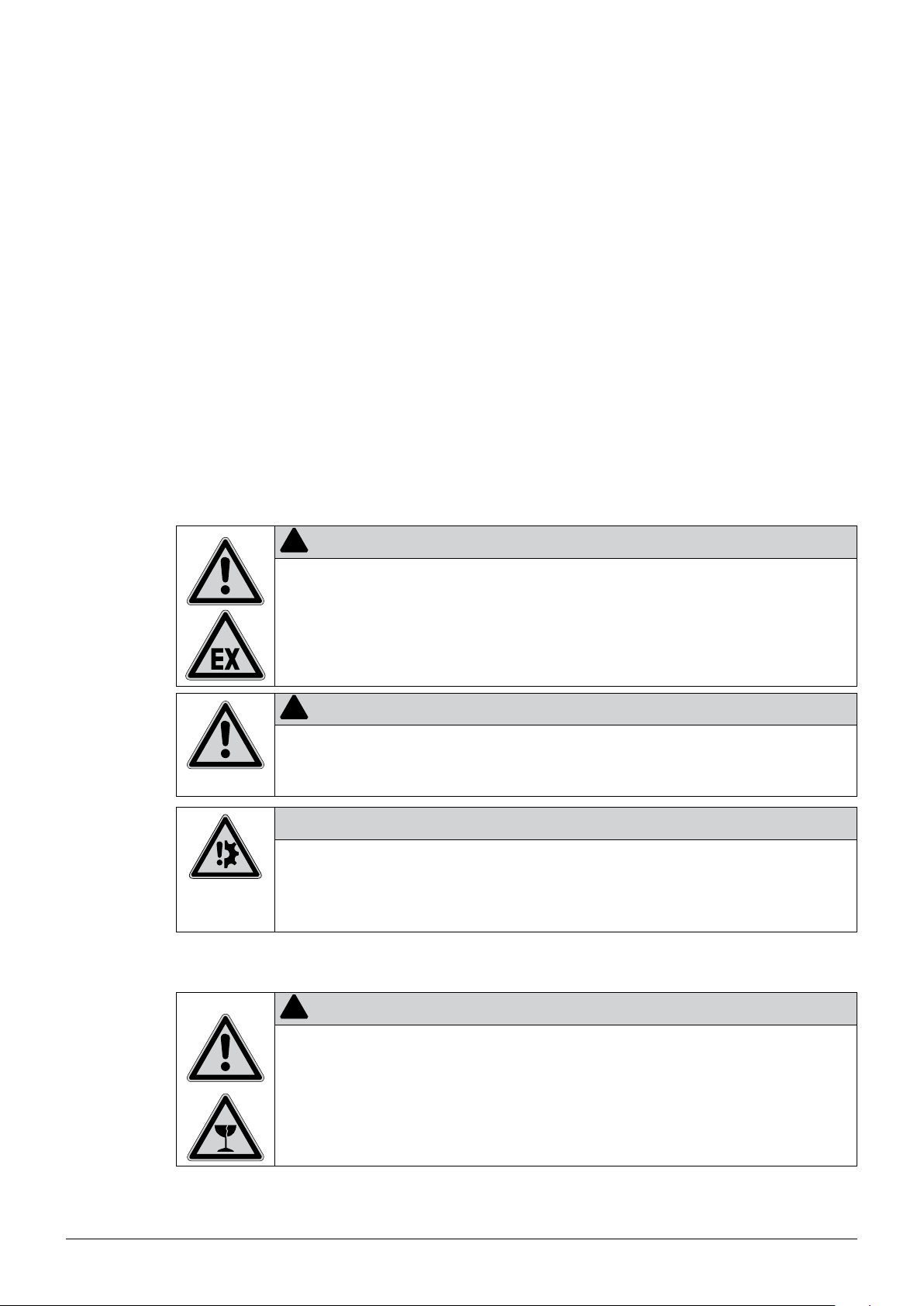

4 Description of function

This chapter explains the basic principle of the instrument, shows how it is structured and gives a

functional description of the assemblies.

The KjelMaster K-375 is dedicated to Kjeldahl and Devarda nitrogen deter mination including potentiometric or colorimetric titration.

Automation of Kjeldahl determination is possible with the KjelSampler K-376/K-377.

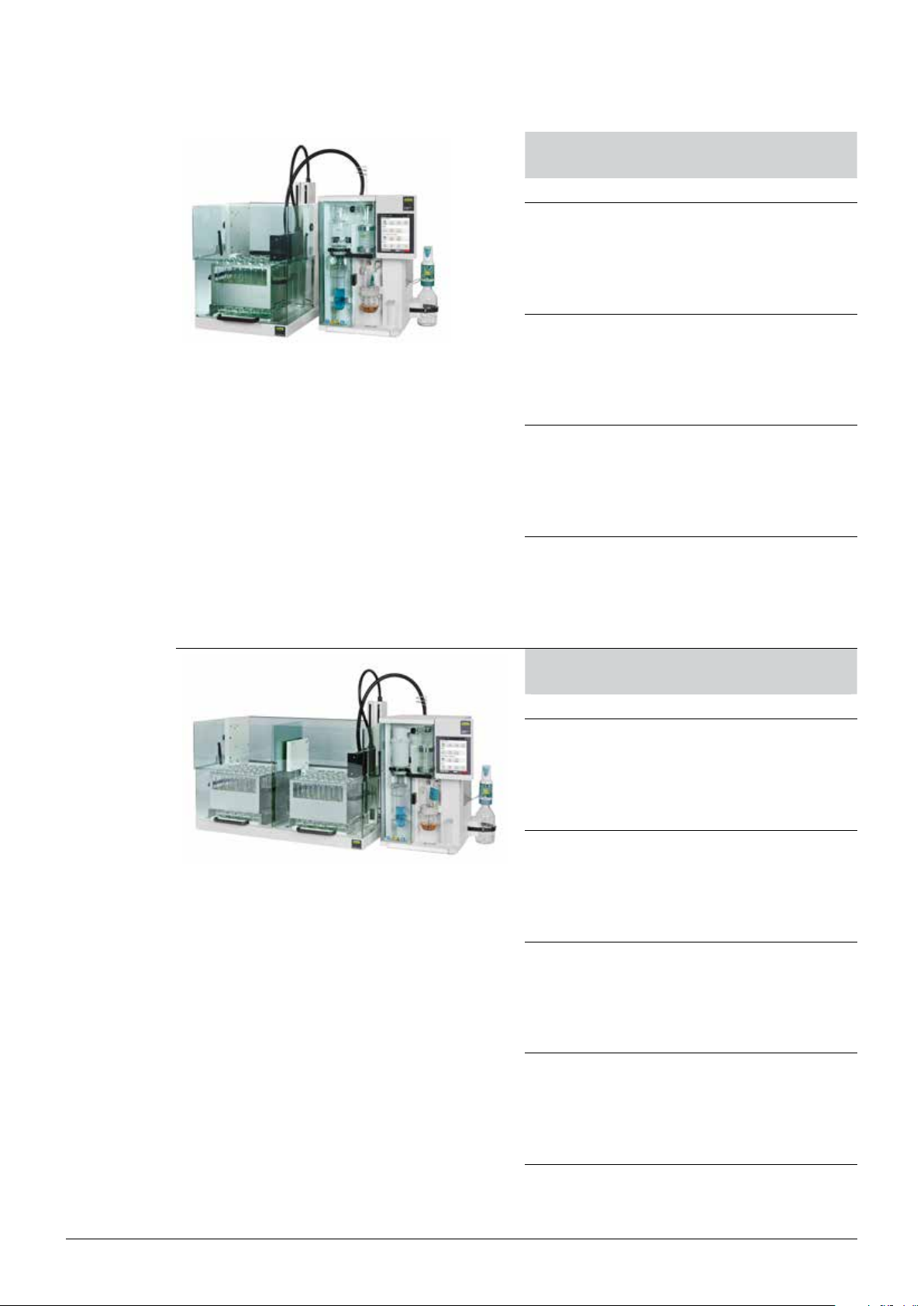

4.1 Device overview

4 Description of function

a KjelMaster K-375

b KjelSampler K-376

c Protective shield

d Rack with sample tubes

e Handle for protective shield

f Transfer hose

g Splash protector

h Sample tube bracket

Fig. 4.1: Device overview

i Sample tube

j Protective door

k Condenser

l Receiving vessel

m Touch screen with display

n pH electrode or optical sensor

o Service door

p External buret

NOTE

The main switch of each device can be found on the rear right side of the housing.

31

K-375/376/377 Operation Manual, Version B

Page 32

4.1.1 Opening the service door

The service door is secured with a sensor/switch: Electrical power is disconnected immediately when

the service door is opened, thus preventing electrical shock during maintenance.

To open the the service door for maintenance proceed as follows:

4 Description of function

To open the service door,

• pull the door lock ① upwards

• open the door ②

Fig. 4.2: Opening the service door

32

K-375/376/377 Operation Manual, Version B

Page 33

4 Description of function

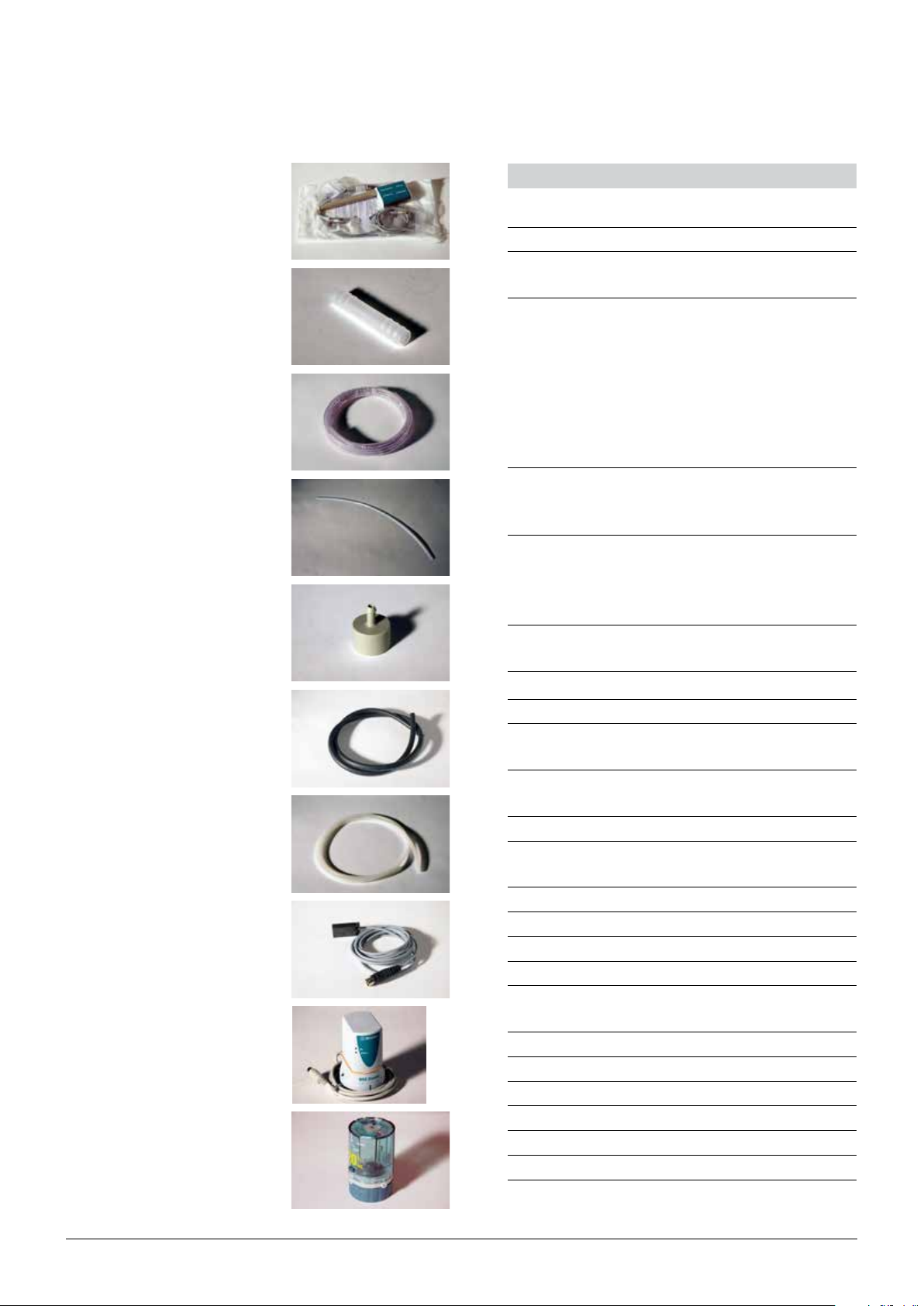

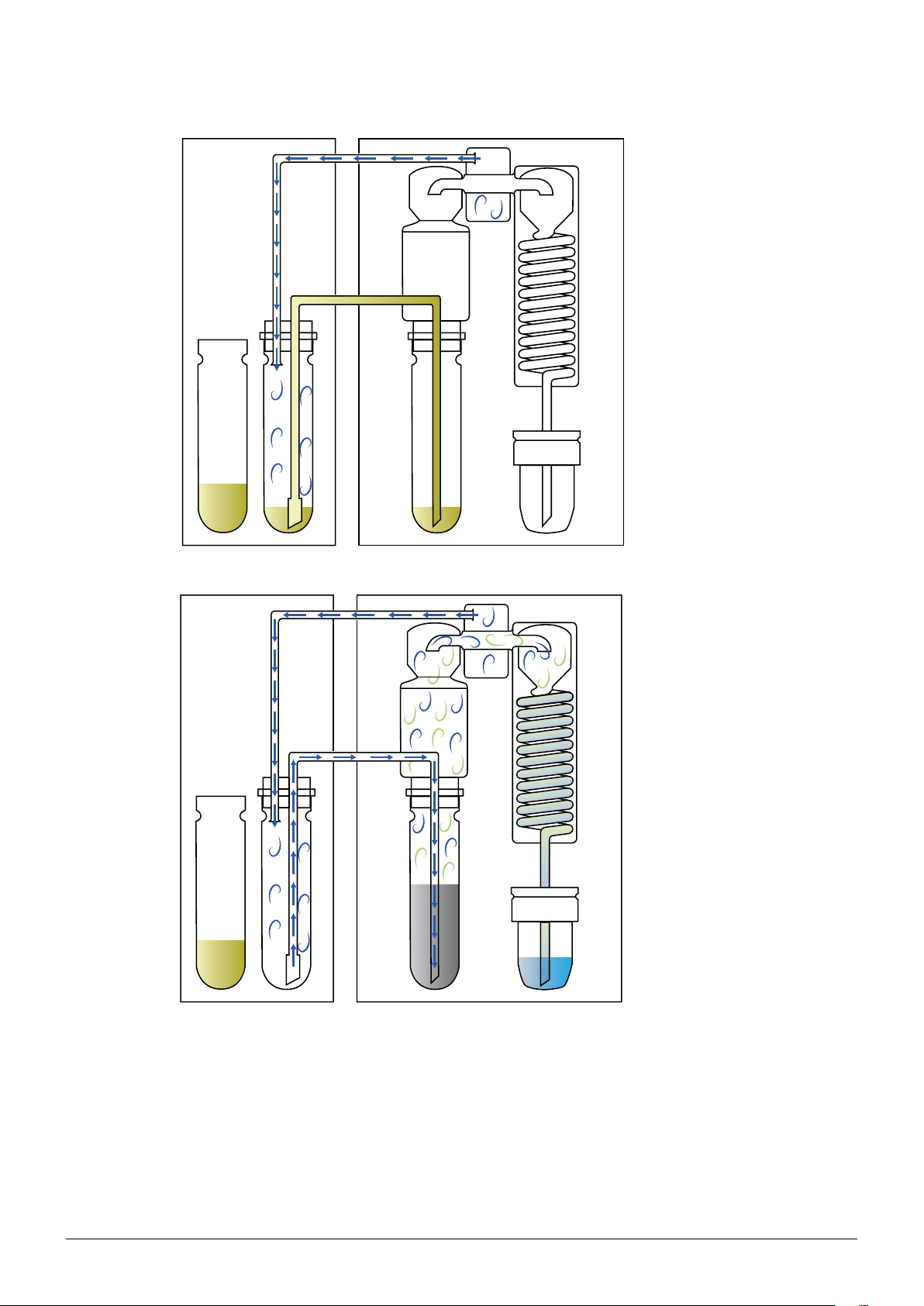

4.2 Functional principle of Sampler System K-375 with K-376 or K-377

a K-376/K-377

b K-375

c Sample tube

d Dip tube

e Splash protector

f Steam generator

g Condenser

h Distillate outlet tube

i Receiving vessel

Fig. 4.3: Functional principle of the K-375 with K-376 or K-377

The sampler arm with dip tube is positioned in a sample tube in the K-376/K-377. The steam

generator of the K-375 generates steam which is lead into the sample tube in the K-376/K-377 via

the steam hose.

The steam presses the sample into the dip tube, so that the sample is transferred into the sample

tube in the K-375 via the transfer hose.

Water and sodium hydroxide is dosed into the sample tube in the K-375. Then steam is introduced

to drive out ammonia. The ammonia evaporates into the splash protector and condensates in the

condenser.

Boric acid is dosed into the receiving vessel, where the condensated ammonia is collected and finally

titrated.

During the entire distillation process, steam is transferred via the sample tube of the K-376/K-377 to

the sample tube of the K-375, thus ensuring a thorough cleaning of the sample tube and the transfer

hose.

33

K-375/376/377 Operation Manual, Version B

Page 34

4 Description of function

Fig. 4.4: Sample transfer principle

Fig. 4.5: Steam transfer during distillation

34

K-375/376/377 Operation Manual, Version B

Page 35

4.3 Standby function

4 Description of function

Press the key READY to start heating the steam

generator.

Press the key STANDBY to stop heating the

steam generator.

Fig. 4.6: Status view

After 30 minutes without operation, the heating of the steam generator is automatically turned off.

In this case „Standby“ is displayed on the Status view.

To activate the device press the READY key. The steam generator will need 120 seconds for heating

up to the operating temperature.

4.4 System preparation

4.4.1 Preheating

The glass parts of the distillation system have to be preheated prior to analysis. This is done by

means of a clean and empty sample tube. It is recommended to perform a preheating, when the

glass (splash protector) has cooled down. The preheating time is predefined and can not be adapted.

4.4.2 Priming

Priming is used to prepare the entire system. This preparation procedure includes distillation and

titration with a clean and empty sample tube. It is recommended to perform a priming at least once a

day, before starting analysis. The priming method can be modified.

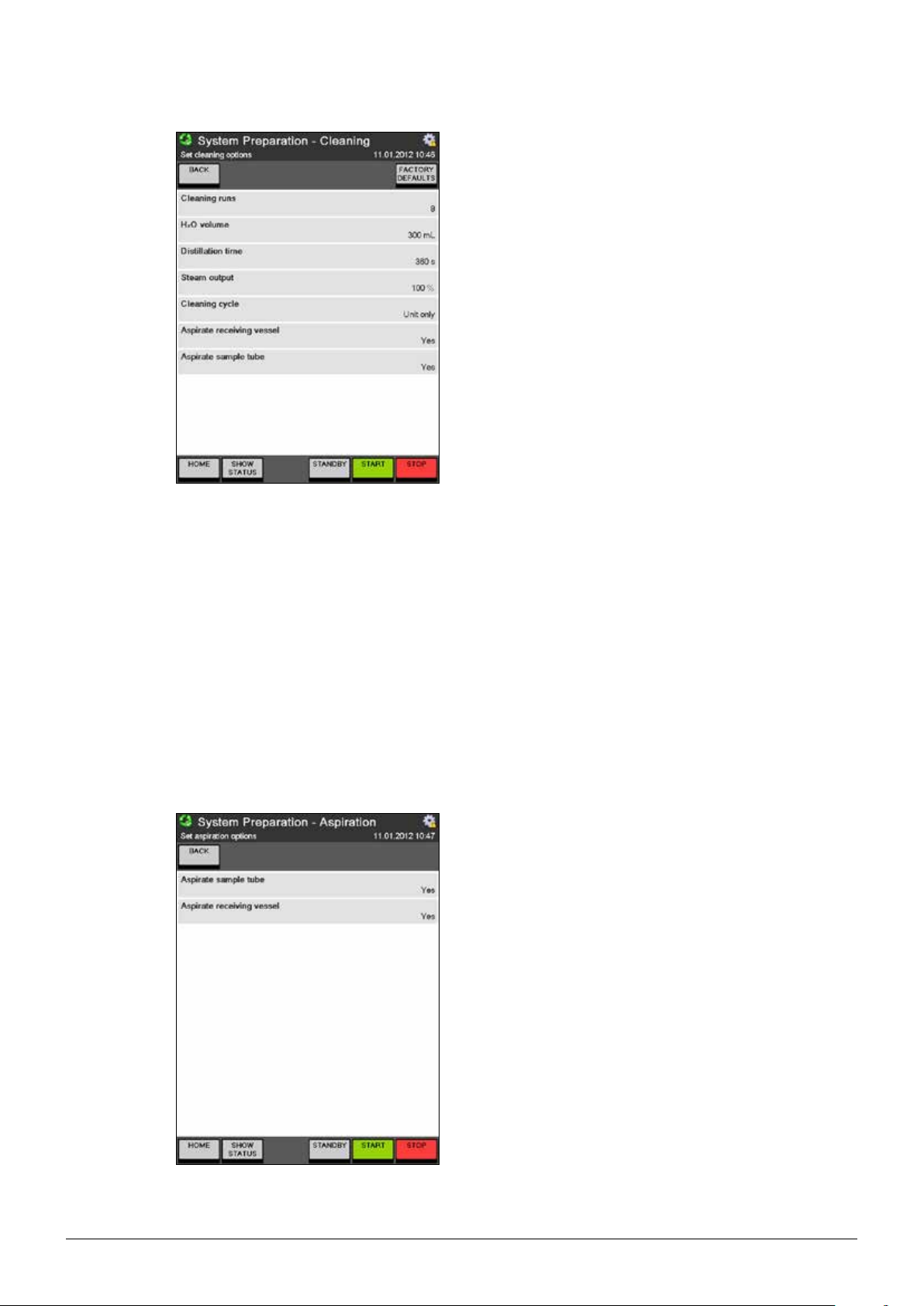

4.4.3 Cleaning

At the end of a day, the system should be rinsed thoroughly by performing a cleaning procedure. The

splash protector and the condenser are rinsed with water to remove sodium hydroxide residues. With

regular cleaning, the lifetime of the glass parts can be extended. The cleaning method is predefined,

but can be modified and adapted to the size of the sample tube.

4.4.4 Aspiration

With this procedure residues in the sample tube and in the receiving vessel can be aspirated.

For more details see also chapter “6.6.1 System preparation”.

35

K-375/376/377 Operation Manual, Version B

Page 36

4.5 Distillation and titration

4.5.1 Distillation Mode

Automatic – IntelliDist

This mode eliminates errors caused by a cooled instrument. The countdown of the set distillation

time only starts after operating temperature is attained. With single samples or sample list measurements this mode guarantees result accuracy from the very first run.

Fixed Time

The countdown of the set distillation time starts immediately with the start of the distillation process.

This setting is recommended when a sample changer is used for the analysis of samples in a rack (or

sequence).

4.5.2 Titration Type

The built-in titrator is fully controlled via the K-375 software. It is not possible to use the titrator

without the KjelMaster K-375. It can be used for boric acid or back titration. The measuring mode

can be determined as endpoint or startpoint titration by defining the method in the K-375. The software of the K-375 allows to choose between standard and online titration. The endpoint detection

can be performed either with a potentiometric sensor or a colorimetric sensor in combination with a

color-indicator.

4 Description of function

Boric Acid Titration

Boric acid is used as receiving solution to capture the nitrogen carried over as ammonia during the

steam distillation. The subsequent endpoint titration is performed with an acid titration solution. This

titration type is easy to carry out and does not require an accurate dosage of the boric acid.

Back Titration

The receiving solution is a standardized acid of which an accurate volume is dispensed into the

receiving vessel. After collecting the ammonia the excess acid is titrated with a basic titration solution. If the use of boric acid has to be avoided the back titration is the procedure of choice.

4.5.3 Sensor Type

Potentiometric

Potentiometric electrodes for the pH measurement are commonly used and allow both boric acid

and back titrations. They need regular calibration with buffers and are the most cost-effective solution

for end point titrations.

Colorimetric

Optical sensors used for colorimetric titrations detect the color change of an indicator at the equivalence point of the titration curve. The indicator has to be added to the receiving solution. These

sensors do not require calibration, have an extended life time but are more expensive.

4.5.4 Titration Mode

Standard

In the standard mode the distillation and titration are performed sequentially. First the distillation is

completed before the titration starts.

Online

With this mode activated the titration will start while the distillation is still in progress. The start time of

the titration depends on the pH value and is determined automatically. The online mode can only be

used with potentiometric titrations. It helps optimize the speed of measurements as it saves time.

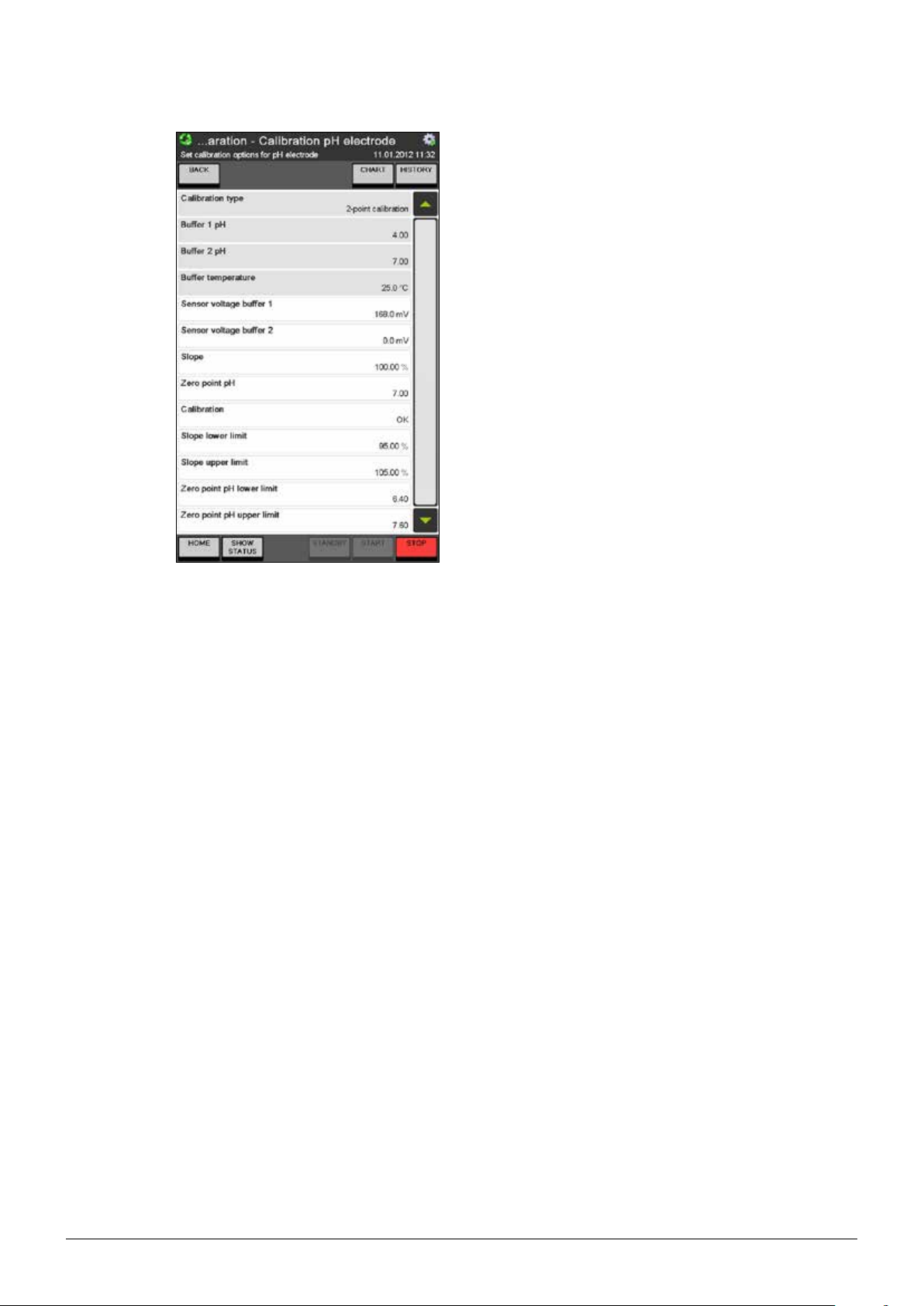

36

K-375/376/377 Operation Manual, Version B

Page 37

4.5.5 Measuring Mode

Startpoint pH

The device measures the pH of the boric acid before the distillation is started and uses it later on as

enpoint for the titration. If the boric acid used as receiving solution is not adjusted to pH 4.65 the

startpoint mode is recommended.

Endpoint pH

The set value, normally 4.65, is used as endpoint for the titration. The boric acid has to be adjusted

to pH 4.65 before starting sample measurements. This mode is more accurate and yields the highest

accuracy.

4.5.6 Titration Algorithm

Normal

This algorithm is the most accurate one and is recommended for samples with low nitrogen content

(below 1 mg) and for the use of highly-concentrated titration solutions (e.g. 0.5 N acids).

Optimal

The best ratio between accuracy and process speed is achieved with this algorithm.

4 Description of function

4.5.7 Determination Mode

Standard

In the majority of cases it is necessary to digest samples to make the nitrogen accessible to steam

distillation. Whenever digested samples are analyzed the standard determination mode is used.

Direct Distillation

A small number of applications allow freeing the nitrogen via direct steam distillation without requiring

a digestion. In such a case the direct distillation mode needs to be activated.

37

K-375/376/377 Operation Manual, Version B

Page 38

4.6 Different methods

BUCHI standard methods are stored in the instrument. All BUCHI methods are “read only“, but it is

possible to copy and save them under a different name as an editable customer method.

All methods are listed in alphabetical order, customer methods are first, followed by the “read only”

BUCHI methods (marked with a small yellow lock).

4 Description of function

Fig. 4.7: Methods screen

38

K-375/376/377 Operation Manual, Version B

Page 39

4.7 Blank values

The K-375 differentiates between blanks and control blanks. Blanks are performed to correct minimal

contamination of chemicals on sample determination (sample and reference substance).

Control blanks are performed to check the determination process for cross contaminations and are

not used for calculation.

The determination and the definition of blank values is described in chapter 6 Operation.

4.7.1 Blanks

It is recommended to run blank values with exactly the same method as the subsequent samples.

The blank values may vary, depending on the receiver solution (e.g. concentration of the boric acid,

amount of indicator added, pH value set), the concentration of the titration solution, and the purity of

chemicals.

It is recommended to perform blank values, if:

• Fresh chemicals are used or

• Before starting determination in order to check the system.

If a blank value is activated for calculation, it remains active, until another blank value is activated.

4 Description of function

4.7.2 Control blanks

A control blank enables to check for crosscontamination, e.g. in the middle of a rack, without

affecting the calculation of the following samples.

Example:

Determination of

3 blanks, 6 samples, 1 control blank, 10 samples in a 20-position rack.

All samples are calculated with the mean value of blank 1-3. The control blank allows to check the

system without interruption.

4.8 Reference substances

Reference substances are substances with known nitrogen content and serve to check the performance of the system and the application.

It is recommended to analyze reference substances regularly. For information on reference

substances, see chapter 3, Technical data.

A check of the K-375 without digestion is done with a standardized ammonium salt (e.g. ammonium

di-hydrogen phosphate).

In order to check the entire Kjeldahl process (including digestion), standardized amino acids are used

(e. g. Glycine).

The determination of reference substances is done like a normal sample determination (Sample type:

“Reference substance”) as single sample, sample list or a sequence. See Chapter “6.6 Determina-

tion” for details.

4.9 Result Groups

Each result of a sample determination can be assigned to a group, e.g. the results of samples taken

from the same batch/lot, place, at the same day, etc. can be assigned to the same result group.

All results in the same group are treated the same way regarding sample printout and export of data.

39

K-375/376/377 Operation Manual, Version B

Page 40

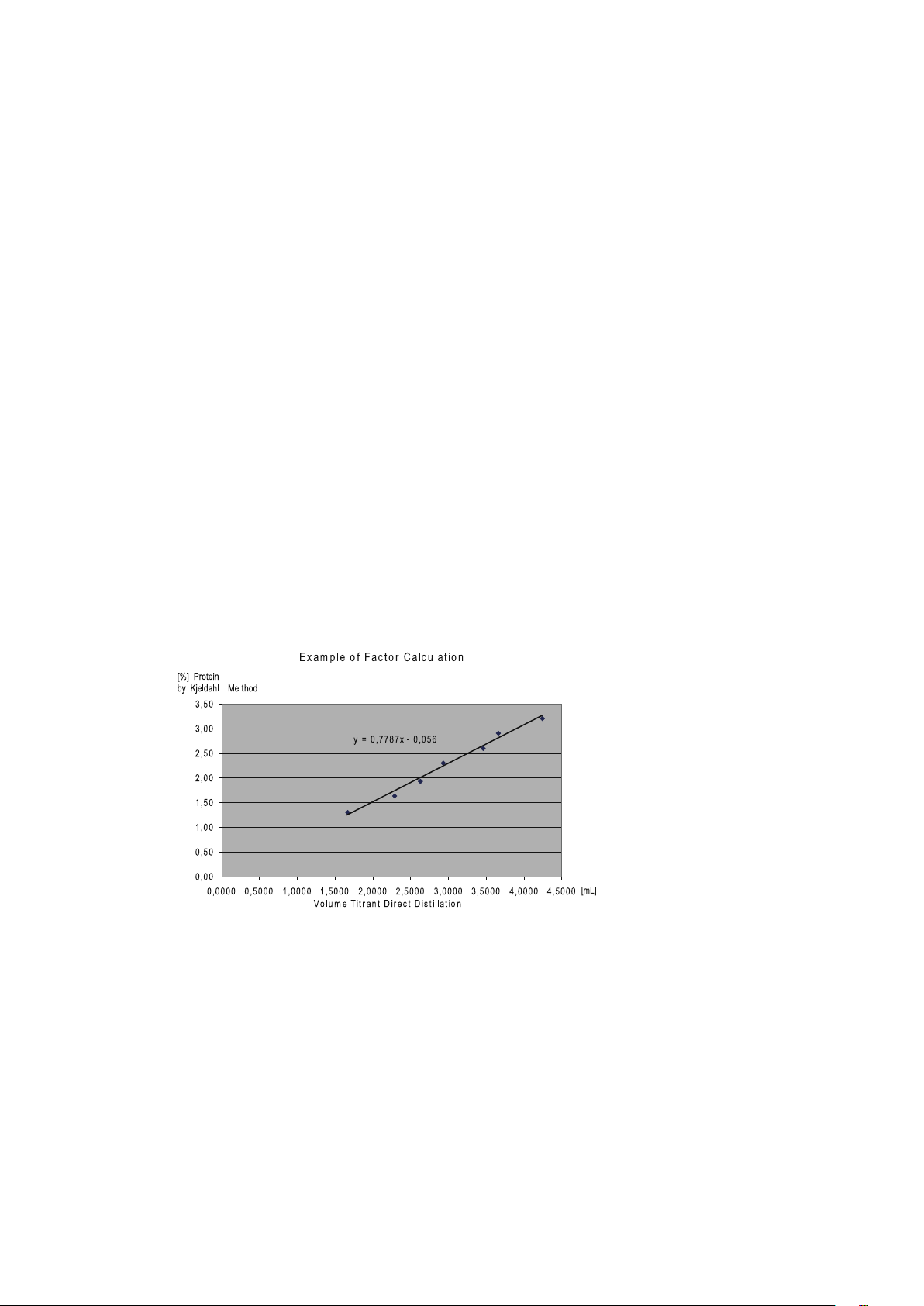

4.10 Explanation of alkaline direct distillation

As an example, the protein content in milk samples can be determined by direct distillation. This

quick method is based on the fact that milk releases ammonia when boiled in an alkaline solution.

Most of this ammonia is produced by the rapid hydrolysis of proteins containing glutamine and asparagine. This decomposition is completed within a few minutes. An additional quantity of ammonia,

although small, is released through the complete transformation of other amino-acids. This second

reaction occurs very slowly however, and does not interfere with the quick method. This fact permits

an experimental determination of the ratio of total nitrogen or protein to ammonia nitrogen which is

released by boiling in an alkaline solution. Once the resulting conversion factor is determined, a series

of analysis can be carried out for control purposes without the time-consuming digestion step. The

overall analysis is reduced to the following steps:

• Sample addition

• Dilution

• Alkalisation

• Distillation

• Titration

• Calculation

A determination can be completed in approx. 10 minutes according to this procedure. All working

conditions chosen for the experimental determination of the conversion factor must be strictly

adhered to during sample measurements.

For details on the application procedure, please contact your local BUCHI representative.

Determination of the conversion factor and the regression factor:

4 Description of function

Fig. 4.8: Example of factor calculation

40

K-375/376/377 Operation Manual, Version B

Page 41

4 Description of function

Factors of above Example

Conversion Factor = 0.7787; Regression Factor = -0.055.

NOTE

Milk samples with a reduced protein content are obtained by dilution with distilled water.

Calculation:

Calculation of the protein content after factor determination.

g protein/100 mL = (V

sample-Vblank )xConv. Fact.+Reg. Fact.

Vsample = Volume Titrant for sample determination in mL

Vblank = Volume Titrant for blank determination in mL

Conv. Fact. = Conversion factor for direct distillation

Reg. Fact. = Regression factor for direct distillation

41

K-375/376/377 Operation Manual, Version B

Page 42

4 Description of function

42

K-375/376/377 Operation Manual, Version B

Page 43

5 Putting into operation

This chapter describes how the device is installed and gives instructions on initial startup.

NOTE

Inspect the device for damages during unpacking. If necessary, prepare a status report immediately

to inform the postal company, railway company or transportation company.

Keep the original packaging for future transportation.

!

CAUTION

Heavy weight, avoid overexertion.

• Due to the heavy weight of the devices at least two people are required for taking the KjelMaster K-375 or the KjelSamplers K-376 out of their corresponding packaging. Watch your

fingers when putting the device down.

• For the K-377 at least three people are required for taking the device out of the corresponding packaging. Watch your fingers when putting the device down.

5 Putting into operation

5.1 Installation site

The device must be set-up on a stable, clean and level surface.

For safety reasons the distance between the back of the device and the wall or to another object

must be at least 30 cm. No containers, chemicals or other objects must be located behind the instrument.

The KjelSampler K-376 or K-377 is set-up on the left side of the KjelMaster K-375 with a space of

approximate 10 cm. Make sure that the back of the KjelSampler is not in contact with anything, e.g.

hoses, etc.

All devices must be set up in such a way that the main switches and the mains plugs are easily

accessible at all times.

Risk of device damage.

• The sampler arm of the Autosampler K-376/K-377 must have enough space in height for

Heavy weight, avoid overexertion.

• At least two people are required for carrying the KjelSampler K-376 or the KjelMaster K-375

• At least three people are required for carrying the KjelSampler K-377 due to the heavy

NOTICE

movement.

!

CAUTION

due to the heavy weight of the devices. Watch your fingers when putting the devices down.

weight of the device. Watch your fingers when putting the device down.

43

K-375/376/377 Operation Manual, Version B

Page 44

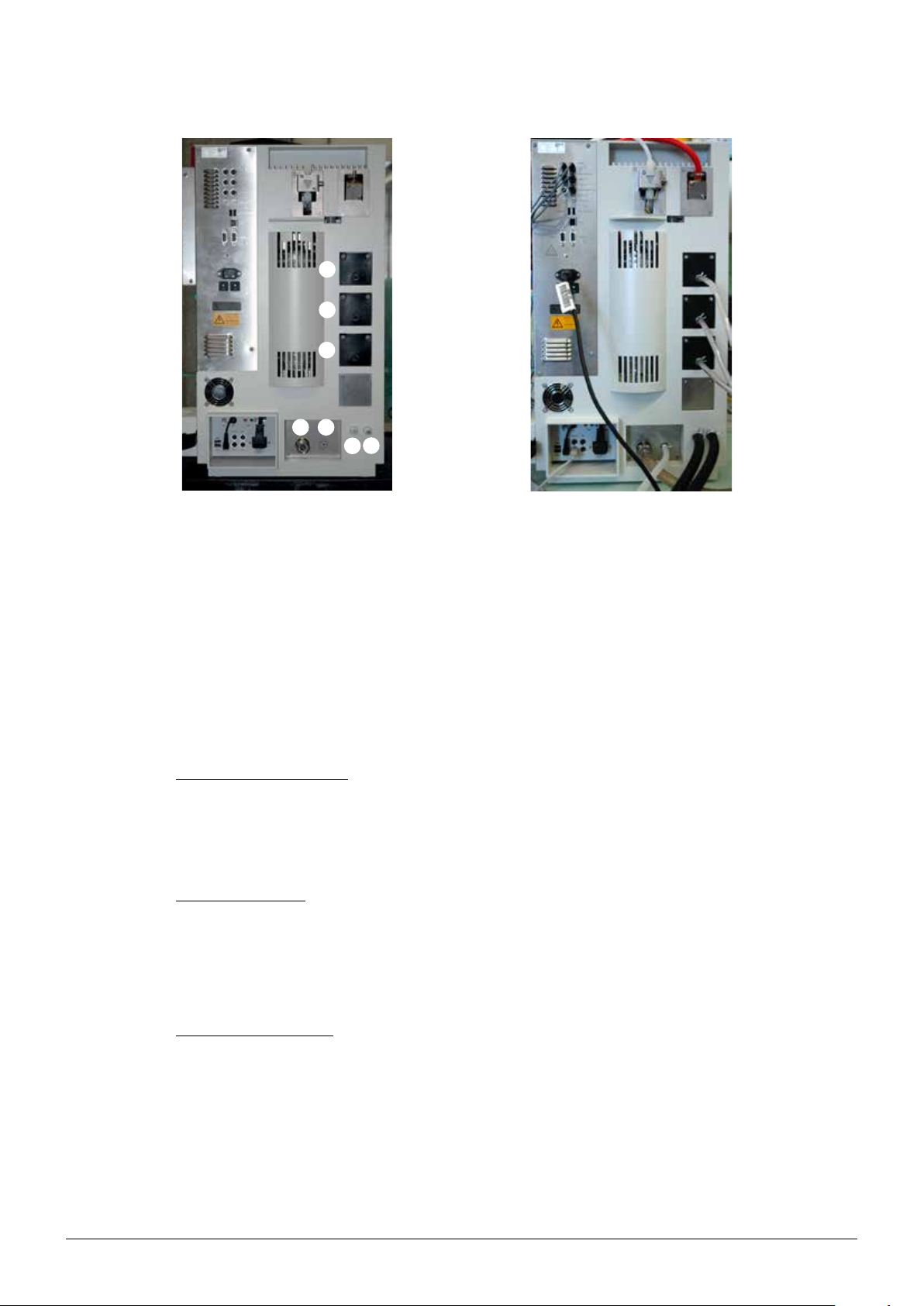

5.2 Electrical connections

5.2.1 Connections of the K-375

5 Putting into operation

a Power connection K-375

b RS232 connection to K-376/K-377

c RS232 connection to external bal-

ance

d LAN connection

e USB connection for external printer

f USB connection for bar code reader

g Connectors for level sensors

Fig. 5.1: Electrical connections of the K-375

NOTICE

Risk of device damage by wrong voltage.

• Make sure that the voltage on the socket corresponds to the voltage given on the type plate

of the instrument.

• Always connect the device to an earthed socket. External connections and extension cables

must be provided with an earthed conductor lead (3-pole couplings, cable or plug equipment)

as the mains lead has a molded plug, thus avoiding risks due to inadvertent defective wiring.

• Make sure that no electric sparks form in the device or its surroundings as they might

damage the instrument.

h Fuses (2 x 10A)

i Connector for dosing unit (Acid)

j Connector for additional dosing unit (Base)

k Additional USB-ports

l Connectors for colorimetric sensor (Ind. and Pwr. Col.) or pH electrode

(Ind. only)

m Connectors for temperature sensor

On the K-375 instrument

• Connect the power cable to the power connection

a.

• Connect the level sensors to the corresponding connectors g.

NOTE

Unlike the level sensors for the storage tanks of H

20, NaOH and H3BO3, the presence of the level

sensors for the waste containers has to be indicated within the software! (See section “Peripherals”

in chapter 6.9.1)

44

K-375/376/377 Operation Manual, Version B

Page 45

• Connect the dosing unit for the acid to connector i.

• Connect the RS232 cable to the sampler (if present) to the corresponding connector b.

• Connect any additional perihperals according to the description in figure 5.1.

5.2.2 Connections of the K-376/K-377

5 Putting into operation

(left rear side of the housing)

(right rear side of the housing)

a Power switch K-376/K-377

b Power connection K-376/K-377

c Fuses (2 x 3A)

Fig. 5.2: Electrical connections of the K-376/K-377

d RS232 connection to K-375

e Toggle switch (see chapter 8.3)

NOTICE

Risk of device damage by wrong voltage.

• Make sure that the voltage on the socket corresponds to the voltage given on the type plate

of the instrument.

• Always connect the device to an earthed socket. External connections and extension cables

must be provided with an earthed conductor lead (3-pole couplings, cable or plug equipment)

as the mains lead has a molded plug, thus avoiding risks due to inadvertent defective wiring.

• Make sure that no electric sparks form in the device or its surroundings as they might

damage the instrument.

On the K-376/K-377 sampler

• Connect the power cable to the power connection b

• Connect the cable to the K-375 device to the RS232 connector d

45

K-375/376/377 Operation Manual, Version B

Page 46

5.3 Transfer connection K-376 (K-377) – K-375

The transfer connection between the K-375 and the K-376 or K-377 sampler consists of two hoses,

the white transfer hose and the red steam hose.

Both hoses have to be connected to the K-375 as well as to the sampler (K-376 or K-377) and

secured with hose clamps. The K-376 is delivered with both hoses premounted to the device.

!

WARNING

Serious chemical burns by corrosives. Risk of burns by hot steam.

• Never operate the K-375 together with a sampler while the sample transfer and steam hoses

are missing, defective, or incorrectly mounted.

• Make sure there is always enough room for a free movement of the sampler arm – if the

sampler arm collides with any object during movement, the transfer hose and/or the steam

hose may break!

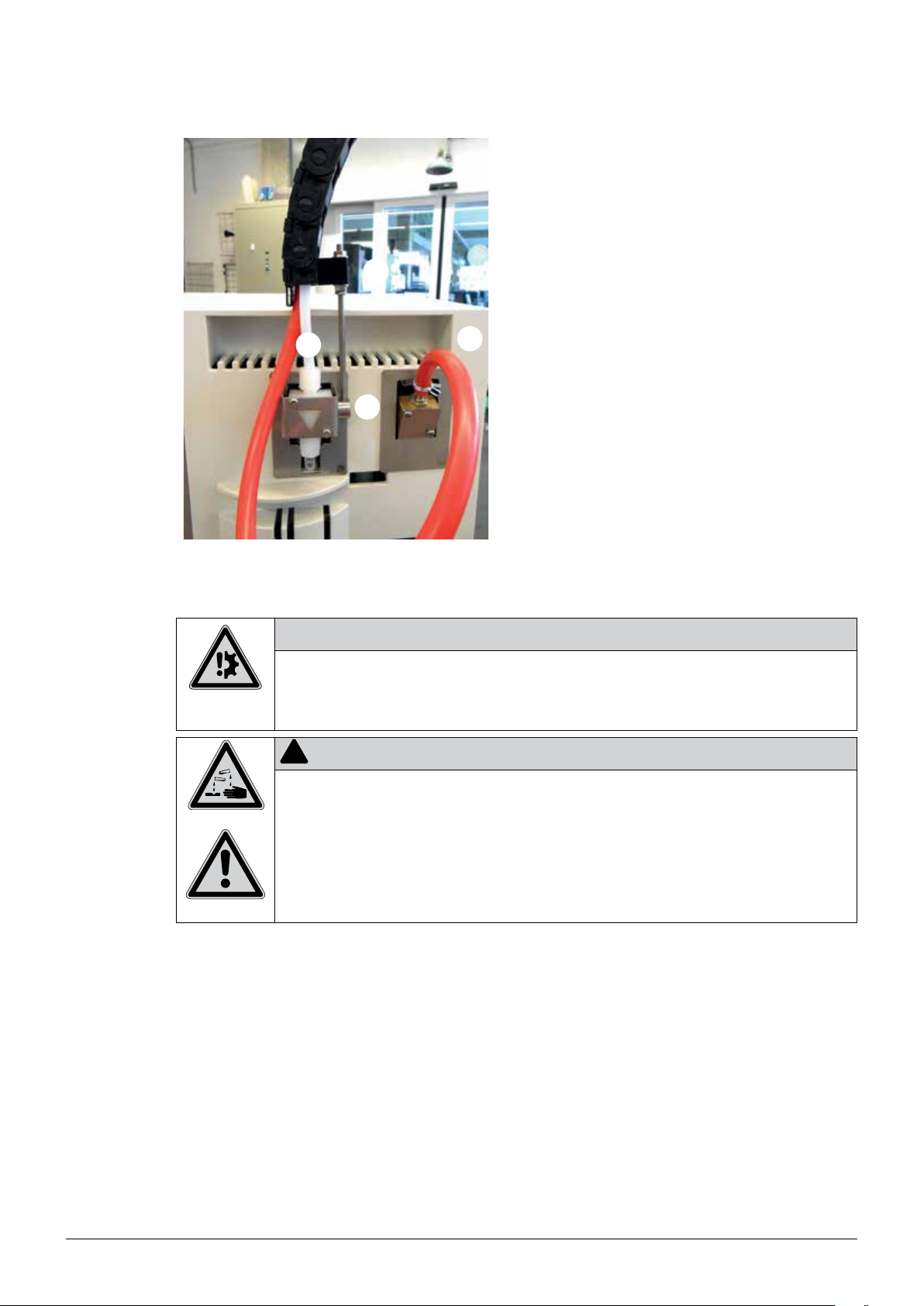

5 Putting into operation

5.3.1 Connecting the K-376 to the K-375

1. Fix the transfer hose support a with the

screw on the valve b on the rear side of

the K-375.

2. Guide both hoses c and d through the

transfer hose support.

46

K-375/376/377 Operation Manual, Version B

Page 47

5 Putting into operation

Fixing the transfer hose to the K-375

Mount the white transfer hose on the valve of the

K-375 (top right corner):

1. Unscrew the screw cap c from the

screw connection of the valve a (attention: 2 parts) and take out the cutting ring

b.

2. Slide the screw cap over the white hose

d.

3. Slide the cutting ring over the hose.

4. Plug the hose on the valve and fix it by

screwing the screw cap on the valve.

Fixing the steam hose to the K-375

Mount the red steam hose on the steam valve of

the K-375 (top right corner):

• Slide the red hose on the connector and

secure it with a hose clamp.

Fig. 5.4: Connection to the K-375

47

K-375/376/377 Operation Manual, Version B

Page 48

5 Putting into operation

Connect the K-375 and the K-376/K-377 with the corresponding/delivered RS232 cable (crossed)

• K-375: See b in picture 5.1

• K-376/K-377: see d in picture 5.2

!

WARNING

Risk of burns by hot steam.

• Make sure to place a sample tube in the washing position(s) of the sampler.

Place an empty sample tube into the washing position of the sampler:

The washing position is on the rear right side of the tray.

For the K-376 this is the fixed position to the right of the express rack.

The K-377 provides two washing positions – one on the rear right side of each tray.

5.3.2 Connecting the transfer hoses of the K-377

On the K-377

• Connect the transfer hose and the steam hose

to the two fittings on top of the sealing cap

on the sampler arm. Secure both connections

with hose clamps 1.

The red steam hose has to be fixed to the first

position (marked with a red ring) – pointing to

the front of the instrument!

• Fix the plastic cable channel with the two provided screws 2 on the sampler arm.

48

K-375/376/377 Operation Manual, Version B

Page 49

5 Putting into operation

On the K-375

• Remove the tightening screw from the holder

on the valve 1.

(The screw is not required for connection to

K-377)

• Slide the ring of the chain fastener onto the

holder on the valve 1 and fix it by tightening

the threaded bar.

• Slide the the plastic holder of the transfer

connection onto the threaded bar 2. Hold it in

place by screwing the second nut hand-tight

on top.

• Mount the white transfer hose on the valve

using the provided screw connection 3.

• Mount the red steam hose on the steam valve

and secure it with a hose clamp 4.

5.4 Reagent/water and waste connections

Risk of device damage by exceeding the maximum permissible pressure for the cooling water inlet.

• Make sure never to exceed the maximum permissible pressure of 6 bar for the cooling water

Serious chemical burns by corrosives.

• Make sure that the tanks are connected correctly. If the wrong tank (e. g. reagent tank

NOTICE

inlet.

!

WARNING

containing NaOH) is connected to the pump labelled as „H

H2O is expected.

2O”, NaOH might be dosed while

49

K-375/376/377 Operation Manual, Version B

Page 50

5 Putting into operation

a H2O pump (for steam generator and sample

tube)

b Boric acid (H3BO3) pump

c NaOH pump

Fig. 5.5: Reagent, water and waste connections

NOTE:

All pumps are self-priming, no overpressure is necessary at the tanks!

If the sample tube waste and the receiver waste shall be collected in the same tank, the Y-piece

(contained in the standard delivery) can be used to merge both tubes.

Cooling water connection

Screw the cooling water hose to the cooling water inlet on the device side and connect it to the

water supply. The water pressure should not exceed 4 bar and the cooling water temperature should

not exceed 25 °C. The flanged screw coupling for the water connection has a standard screw thread

3

of G

/4“.

Drain cooling water

Place the drain hose for the cooling water directly into the drain (sink). For this purpose, shorten the

silicone hose to the optimal length.

Make sure that the drain hose has no kinks and sharp bends.

Secure the drain hose to avoid any flooding inside or in the vicinity of the instrument.

d Waste outlet (receiver waste)

e Waste outlet (sample tube waste)

f Cooling water outlet

g Cooling water inlet

Waste/aspiration hoses

The sample residue can be aspirated and collected separately from the receiver waste. For this

purpose a separate collection tank is necessary. The collection tank must be located lower than the

device to guarantee proper drainage.

Connect the waste hose to the waste outlet and place it directly into the collection tank. For this

purpose, shorten the EPDM hose to the optimal length. In order to prevent any back-flow, the hose

may be placed maximum 10 cm into the tank.

50

K-375/376/377 Operation Manual, Version B

Page 51

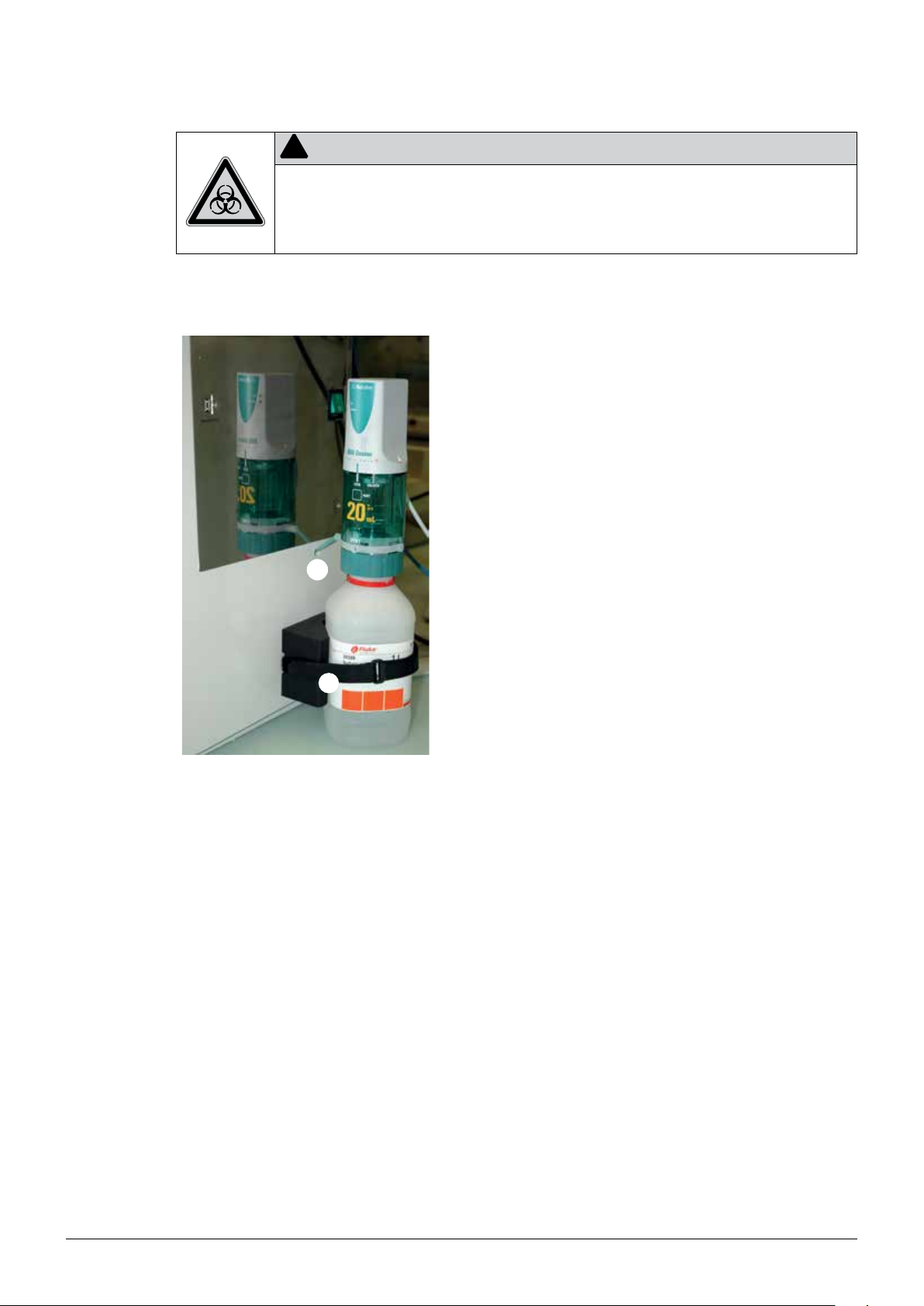

!

Risks and hazards for humans, animals and the environment.

• Make sure to carefully collect any residues that may be hazardous to humans, animals or the

5.5 Buret unit for titrant

5 Putting into operation

WARNING

environment and to dispose them according to your local laws and regulations.

Fig. 5.6: Buret mounted on the titration solution

bottle

The bottle containing the titration solution can be fixed on the right side of the device using the

provided hook-and-loop fastener a. The buret (consisting of the dosing unit and the corresponding

drive unit) is mounted on the bottle. The preinstalled tube for the titrant b is guided through a cut-out

in the housing and can be connected to the dosing unit.

The tube of an additional buret for back titration can also be guided through the provided cut-out in

the housing.

NOTE

In case the buret gets blocked, refer to chapter 7.7.6 “Troubleshooting the dosing unit”. The

assembly of the dosing unit is explained in detail in the separate operating instructions delivered

together with the dosing unit.

51

K-375/376/377 Operation Manual, Version B

Page 52

5.6 Storage tank connection

To connect the storage tanks, proceed as follows:

• Cut the solaflex tube into pieces to the appropriate length.

• Insert a PTFE suction tube into the solaflex tube.

• Push a EPDM sealing ring over the solaflex tube.

• Now fasten the tubes to the tank with the red screw cover.

The storage tanks should not be positioned higher than the device itself and not lower than

1 meter below the instrument.

5 Putting into operation

Fig. 5.7: Tank connection

All pumps are self-priming, no overpressure is necessary at the tanks.

Risk of device damage by calciferous water or wrong rong connected tanks.

• Use only distilled water for the H2O storage tank to keep the steam generator maintenance-

• Make sure that the tanks are connected correctly. If the wrong tank (e. g. reagent tank

NOTICE

free.

containing NaOH) is connected to the pump labelled as „H2O“, the steam generator will get

damaged.

52

K-375/376/377 Operation Manual, Version B

Page 53

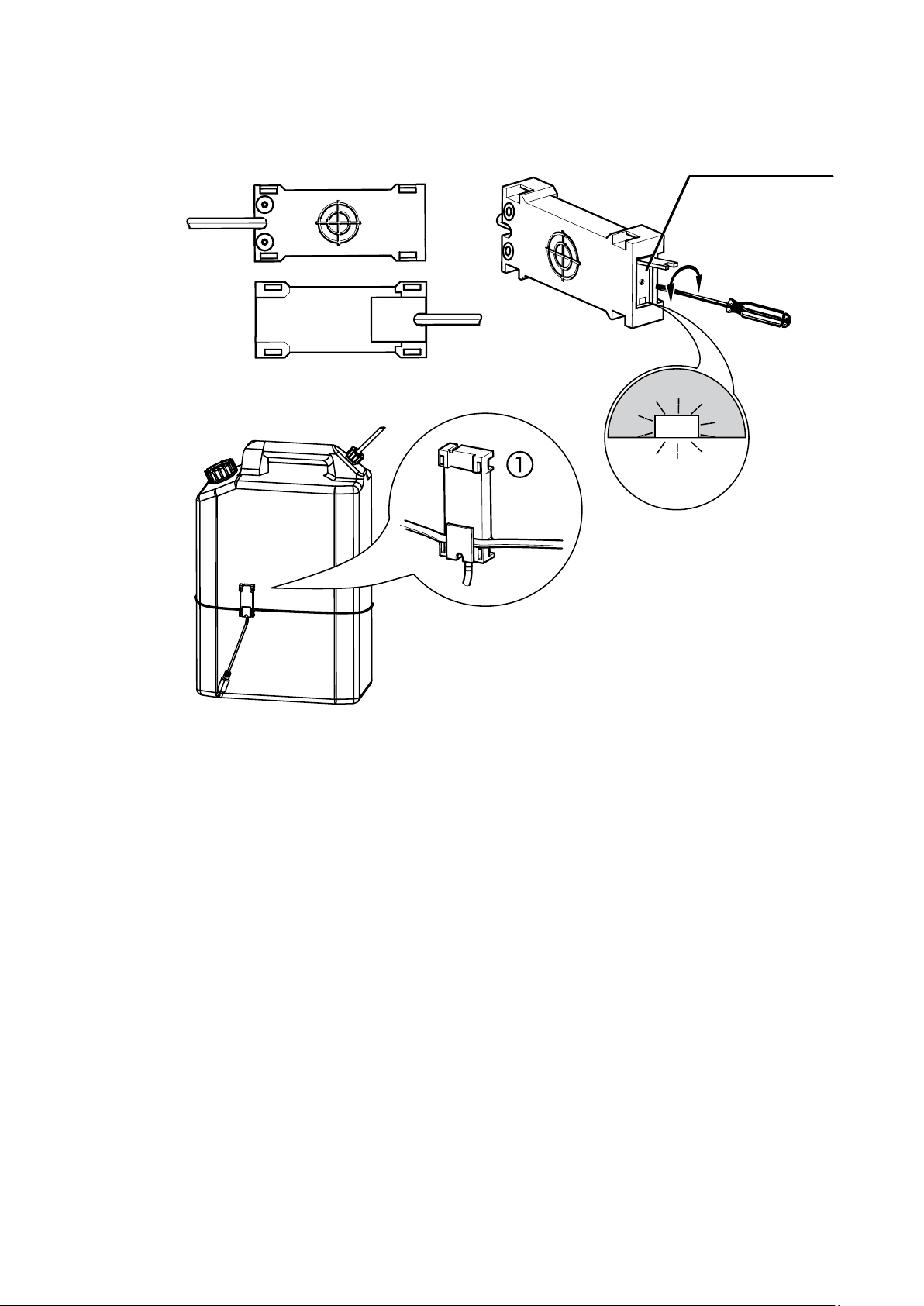

5.7 Level sensors

Four level sensors are contained in the standard delivery of the instrument. Three are intended for

the storage tanks (NaOH, H3BO3 and water) and one for the waste collection tank (either the sample

tube or receiver waste). Additional level sensors are available as optional equipment. Each individual

sensor is connected to the corresponding socket on the rear side of the device (see section 5.2.1).

The sensitivity of the capacitive level sensors can be adjusted to safely detect the liquid level, if

necessary.

Assemble the level sensors according to the following picture:

5 Putting into operation

Fig. 5.8: Assembly of the level sensors

• Mount the sensor at the tank using the provided O-ring (see a in figure 5.9) and connect it at

the rear-side of the device to the corresponding port (NaOH, H2O, H3BO3, Waste Sample Tube,

Waste Receiver, or Titrant). The sensitive side of the sensor (marked with the crosshair)

has to face the tank!

• Make sure the tank is filled with the corresponding liquid.