BUCHI K-355 User Manual

Operation Manual

Distillation Unit

K 355

93036 en

Table of contents

Table of contents

1 |

About this manual . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . . |

. . . |

. . |

|

. 5 |

|

|

1.1 |

Abbreviations . . . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

5 |

2 |

Safety . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . . |

. . . |

. . |

|

. 6 |

|

|

2.1 |

User qualification . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. . |

6 |

|

|

2.2 |

Proper use . . . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. . |

6 |

|

|

2.3 |

Improper use . . . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

6 |

|

2.4 |

Warning notices used in this manual . . |

. . . . . . . . . . |

. . |

. . |

. |

|

7 |

|

2.5 |

Product safety |

|

|

|

|

|

7 |

|

2.5.1 |

Instrument-related hazards . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

. 7 |

|

2.5.2 |

Other hazards |

|

|

|

|

|

8 |

|

2.5.3 |

Safety measures . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. . |

8 |

|

|

2.5.4 |

Safety elements |

|

|

|

|

|

8 |

|

2.6 |

General safety rules . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

9 |

3 |

Technical data . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . . |

. . . |

. . |

|

10 |

|

|

3.1 |

Scope of delivery . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

. 10 |

|

|

3.1.1 |

Standard instrument |

|

|

|

|

|

10 |

|

3.1.2 |

Standard accessories . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

11 |

|

3.1.3 |

Optional accessories . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

12 |

|

3.2 |

Technical data |

|

|

|

|

|

15 |

|

3.3 |

Materials used |

|

|

|

|

|

15 |

4 |

Description of function . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . . . . . |

. . |

|

16 |

||

|

4.1 |

Instrument overview |

|

|

|

|

|

16 |

|

4.2 |

Function principle . . . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

. 17 |

|

|

4.3 |

Controls of the instrument |

|

|

|

|

|

18 |

5 |

Putting into operation . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . . . . . |

. . |

|

19 |

||

|

5.1 |

Installation site |

|

|

|

|

|

19 |

|

5.2 |

Electrical connections |

|

|

|

|

|

19 |

|

5.3 |

Reagent and water connections |

|

|

|

|

|

20 |

|

5.3.1 |

Cooling water connection . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

20 |

|

5.3.2 |

Drainage of cooling water . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

20 |

|

5.3.3 |

Storage tank connection . . . . . . |

. . . . . . . . . . |

. . |

. . |

. |

|

21 |

Read this manual carefully before installing and running your system and note the safety precautions in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of Buchi. Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without prior written agreement is also prohibited.

If you need another language version of this manual, you can download it at www..buchi..com..

3 |

K-355 Operation Manual, Version G |

Table of contents

6 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

22 |

|

|

6.1 |

Addition of chemicals . . . . . . . . . . . . . . . . . . . . . . |

|

22 |

|

6.1.1 |

Manual dosage . . . . . . . . . . . . . . . . . . . . . . . . |

|

22 |

|

6.1.2 |

Automatic dosage |

|

22 |

|

6.1.3 |

General information . . . . . . . . . . . . . . . . . . . . . . |

. |

22 |

|

6.2 |

Setting the distillation time |

|

23 |

|

6.3 |

Setting the steam power . . . . . . . . . . . . . . . . . . . . |

. |

23 |

|

6.4 |

Program storage . . . . . . . . . . . . . . . . . . . . . . . |

. 23 |

|

|

6.4.1 |

Storing a program |

|

23 |

|

6.4.2 |

Selecting a stored program . . . . . . . . . . . . . . . . . . . . |

|

23 |

|

6.5 |

Steam generator status . . . . . . . . . . . . . . . . . . . . . |

. 24 |

|

|

6.5.1 |

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

24 |

|

6.5.2 |

Standby mode (after 30 minutes) . . . . . . . . . . . . . . . . . . |

|

24 |

|

6.6 |

Switching ON/OFF checklist |

|

24 |

|

6.7 |

Carrying out a distillation . . . . . . . . . . . . . . . . . . . . |

. |

24 |

7 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

26 |

|

|

7.1 |

Daily maintenance |

|

26 |

|

7.1.1 |

Cleaning the instrument from inside . . . . . . . . . . . . . . . . . |

. 26 |

|

|

7.1.2 |

Cleaning the housing . . . . . . . . . . . . . . . . . . . . . . |

|

26 |

|

7.1.3 Cleaning the glass parts |

|

26 |

|

|

7.1.4 Preparing the instrument for a standstill overnight |

|

27 |

|

|

7.2 |

Weekly maintenance . . . . . . . . . . . . . . . . . . . . . . |

|

27 |

|

7.2.1 Cleaning the splash protector and the rubber bung seal |

|

27 |

|

|

7.3 |

Monthly maintenance . . . . . . . . . . . . . . . . . . . . . . |

|

27 |

|

7.3.1 Checking the distillate amount |

|

27 |

|

|

7.4 |

Half-yearly maintenance |

|

28 |

|

7.4.1 Replacing the NaOH tube |

|

28 |

|

|

7.5 |

Yearly maintenance . . . . . . . . . . . . . . . . . . . . . . |

. |

28 |

|

7.5.1 |

Replacing the rubber bung seal . . . . . . . . . . . . . . . . . . |

. |

28 |

|

7.5.2 |

Replacing the NaOH pump . . . . . . . . . . . . . . . . . . . . |

|

28 |

|

7.6 |

Customer service . . . . . . . . . . . . . . . . . . . . . . . |

|

. 28 |

8 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

29 |

|

|

8.1 |

Malfunctions and their remedy |

|

29 |

9 |

Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . |

. |

30 |

|

|

9.1 |

Preparing the instrument for transport |

|

30 |

|

9.2 |

Storage and transport |

|

30 |

|

9.3 |

Disposal |

|

30 |

10 |

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

31 |

|

|

10.1 |

Spare parts K-355 . . . . . . . . . . . . . . . . . . . . . . |

. |

31 |

|

10.2 |

Hosing connection scheme . . . . . . . . . . . . . . . . . . . . |

|

32 |

11 Declarations and requirements . . . . . . . . . . . . |

. . . . . . . . |

. . . . . . |

. . . |

. . |

34 |

||

11.1 |

FCC requirements (for USA and Canada) . . |

. |

. . . . . |

. . . . |

. . |

. |

. 34 |

11.2 |

Declaration of conformity . . . . . . . . |

|

. . . . . . |

. . . . |

. . |

. |

35 |

4 |

K-355 Operation Manual, Version G |

1 About this manual

1 About this manual

This manual describes the Distillation Unit K-355 and provides all information required for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel in particular.

NOTE

The symbols pertaining to safety (WARNINGS and ATTENTIONS) are explained in chapter 2.

1..1 Abbreviations

EPDM: Ethylene Propylene Dimonomer

FEP: Fluorinated Ethylene Propylene

FPM: Fluoroelastomer

PP: Polypropylene

PTFE: Polytetrafluoroethylene

RSD: Relative Standard Deviation

5 |

K-355 Operation Manual, Version G |

2 Safety

2 Safety

This chapter points out the safety concept of the instrument and contains general rules of behavior and warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed. Therefore, the manual must always be available to all persons performing the tasks described herein.

2..1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of training or professional experience have an overview of the dangers which can develop when operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction. The present Operation Manual serves as the basis for this.

2..2 Proper use

The instrument has been designed and built for laboratories. It serves for the distillation of steam-vola- tile substances.

2..3 Improper use

Applications not mentioned above are improper. Also, applications which do not comply with the technical data are considered improper.

The operator bears the sole risk for any damages caused by such improper use. The following uses are expressly forbidden:

•Use of the instrument in rooms which require ex-protected instruments.

•Use on samples, which can explode or inflame (e.g. explosives, etc.) due to shock, friction, heat or spark formation.

6 |

K-355 Operation Manual, Version G |

2 Safety

2..4 Warning notices used in this manual

WARNING

Generally, the triangular warning symbol indicates the possibility of personal injury or even loss of life if the instructions are not followed.

WARNING

Hot surface.

WARNING

Electrical hazard.

WARNING

Caustic substances.

ATTENTION

With the general „Read this” symbol, ATTENTIONs indicate the possibility of equipment damage, malfunctions or incorrect process results, if instructions are not followed.

NOTE

Useful tips for the easy operation of the instrument.

2..5 Product safety

The instrument is designed and built in accordance with state-of-the-art technology. Nevertheless, risks to users, property, and the environment can arise when the instrument is used carelessly or improperly.

The manufacturer has determined residual dangers emanating from the instrument

•if the instrument is operated by insufficiently trained personnel.

•if the instrument is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2..5..1 Instrument-related hazards

Pay attention to the following safety notices:

WARNING

Potential implosion risk if used with damaged glassware.

• Beware of damaged or cracked glass parts.

WARNING

Potentially hot surfaces during operation (surfare temperatures at times exceed 60 °C) and hot steam passing off the waste outlet.

• Always be aware of the risk of being burned.

WARNING

Potentially lethal voltage inside the instrument.

•Do not remove covers and other parts protecting from electricity.

•Always keep the areas of electric parts, such as power supply plug, mains switch, etc. dry.

7 |

K-355 Operation Manual, Version G |

2 Safety

2..5..2 Other hazards

WARNING

Certain solvents in or in the vicinity of the instrument can form peroxides and/or are highly inflammable.

•Always be aware of the explosion risk when working with hazardous substances or with substances of unknown composition.

•Always provide a good ventilation within or in the vicinity of the system.

2..5..3 Safety measures

WARNING

Sodium hydroxide, acids and lye are used for applications according to Kjeldahl. For this reason, protective goggles must be worn at all times when using the instrument or working in its immediate proximity.

2..5..4 Safety elements

The instrument is provided with the following safety elements:

•Protective door: Safety appliance to protect users from burns at the splash protector (distillation area), which is hot during distillation.

•Protective door sensor: Prevents the start of a distillation with the protective door open and stops a running distillation and the dosing of reagents immediately when the protective door is opened during the process.

•Sample tube sensor: Prevents the start of a distillation without a sample tube inserted.

•Protective shield (cover) at condenser: Protection of glass parts.

•Service door sensor/switch: Electrical power is disconnected immediately when the service door is opened, thus preventing electrical shock during maintenance.

8 |

K-355 Operation Manual, Version G |

2 Safety

2..6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might occur during operation of the instrument. Legal regulations, such as local, state and federal laws applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is operated in proper condition only, and that maintenance, service, and repair jobs are performed with care and on schedule, and by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system performance and reliability. Any modifications to the spare parts used are only allowed with the prior written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized Buchi technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

9 |

K-355 Operation Manual, Version G |

3 Technical data

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery, technical data, requirements and performance data.

3..1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products see www.buchi.com or contact your local dealer.

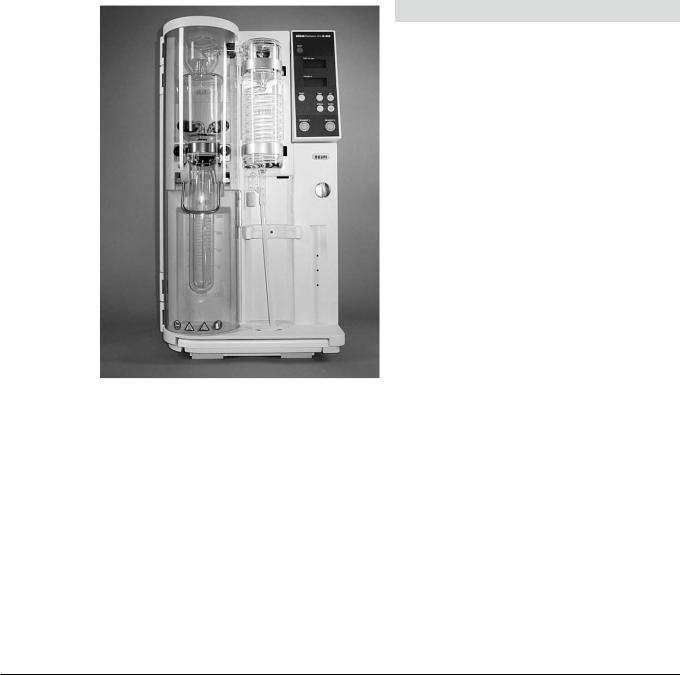

3..1..1 Standard instrument

Table 3-1: Standard instrument

Product |

Order number |

|

|

Distillation Unit K-355 Standard with |

43505 |

glass splash protector, 230 V, 50/60 Hz |

|

|

|

Distillation Unit K-355 with splash |

43419 |

protector made of fiber glass reinforced |

|

polypropylene, 230 V, 50/60 Hz |

|

|

|

Distillation Unit K-355 Standard with |

43070 |

glass splash protector and SO2 determi- |

|

nation kit |

|

|

|

10 |

K-355 Operation Manual, Version G |

3 Technical data

3..1..2 |

Standard accessories |

|

|

|

|

|

|

|

|

|

|

|

|

Table 3-2: Standard accessories |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Product |

Order number |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a 1 mains cable of the following types |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

2 |

|

Type CH |

10010 |

|

|

|

|

|

|

||

|

|

|

|

|

|

Type Schuko |

10016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type GB |

17835 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type AUS |

17836 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type USA |

33763 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type Japan |

10016 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b 1 pair of glass tongs |

02004 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c 1 hose cooling water drain, silicone, |

43439 |

|

|

|

|

|

6 |

L = 1.8 m, Ø 10/14 mm |

|

|

|

4 |

5 |

|

|

|

|

|

3 |

|

d 1 hose chemical supply, solaflex, |

43555 |

|||

|

|

|

|||||

|

|

|

|

||||

|

|

|

7 |

|

|

L = 3.5, Ø 10/5 mm |

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

e 1 hose tygon, L = 530 mm |

43029 |

|

|

11 |

10 |

9 |

|

|

||

|

|

|

|

f 3 suction tubes to tanks, FEP, |

43407 |

||

|

|

|

|

|

|

||

|

|

|

|

|

|

L = 580 mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

g 1 hose connector PP |

43565 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

h 1 Y hose coupling |

11043 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i 2 clamps Ø 7.6 |

43571 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

i 6 clamps Ø 11.9 |

43841 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

j 1 hose viton (acid resistant) L = 2 m |

20344 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

k 1 cooling water hose complete: G ¾", |

37780 |

|

|

|

|

|

|

½", L = 1.5 m |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

l 3 tanks 10 l, without caps |

43410 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

m 1 cap for 10 l tanks, large |

25869 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

n 3 tank labels |

43434 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o 1 cap for 10 l and 20 l tanks, small |

43477 |

|

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

14 |

|

|

|

|

|

|

|

|

15 |

|

|

|

|

11 |

K-355 Operation Manual, Version G |

3..1..3 Optional accessories

1 |

2 |

3 |

4

5

7

6

3 Technical data

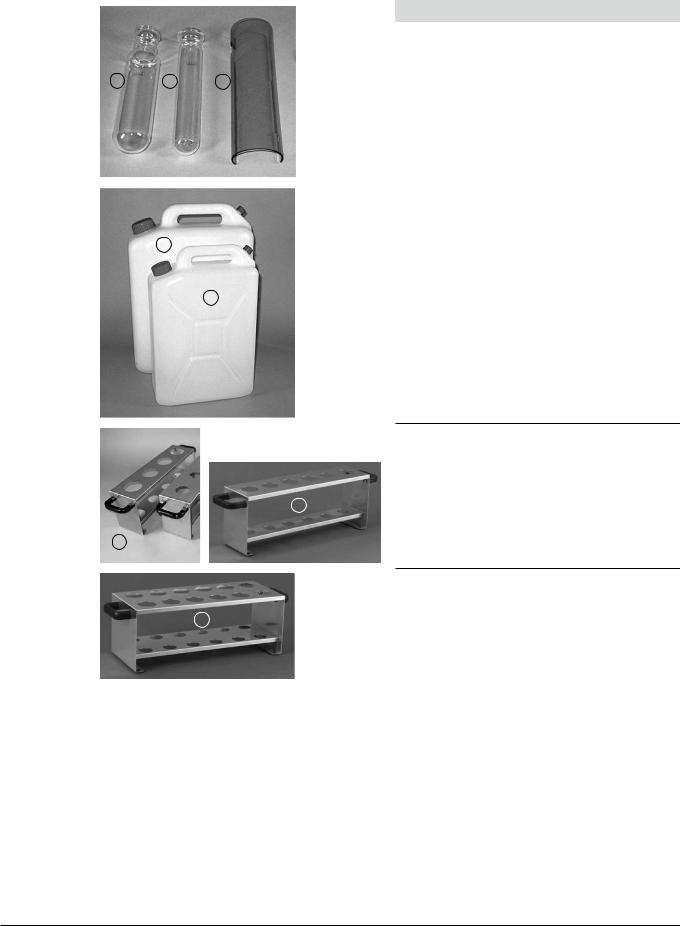

Table 3-3: Optional accessories K-355

Product |

Order number |

|

|

a 1 sample tube 500 ml |

26128 |

4 sample tubes 500 ml |

43982 |

|

|

b 4 sample tubes 300 ml |

37377 |

|

|

c Condenser cover, complete |

43484 |

|

|

|

|

d 20 l tank for chemicals |

43469 |

|

|

e 10 l tank for chemicals |

43468 |

|

|

f Holder for 4 sample tubes, 500 ml |

16951 |

|

|

g Holder for 6 sample tubes, 300 ml |

43039 |

|

|

h Holder for 12 sample tubes, 300 ml |

43041 |

|

|

8

12 |

K-355 Operation Manual, Version G |

Loading...

Loading...