BUCHI E-816 HE User Manual

Operation Manual

Extraction Unit

E 812/816 HE

093164 en

093164 en

Table of contents

Table of contents

1 |

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . |

. . |

|

. 5 |

|

|

1.1 |

Reference documents |

|

|

|

5 |

|

1.2 |

Abbreviations . . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

5 |

2 |

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . |

. . |

|

. 6 |

|

|

2.1 |

User qualification . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. |

6 |

|

2.2 |

Proper use . . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. |

6 |

|

2.3 |

Improper use . . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

6 |

|

2.4 |

Safety warnings and safety signs used in this manual . . . . |

. . . . . . |

. |

. |

7 |

|

2.5 |

Product safety |

|

|

|

9 |

|

2.5.1 |

General hazards |

|

|

|

9 |

|

2.5.2 |

Warning labels on housing and assemblies . . . . . . . . |

. . . . . . |

. |

|

10 |

|

2.5.3 |

Personal protective equipment . . . . . . . . . . . . |

. . . . . . |

. |

|

10 |

|

2.5.4 |

Safety elements |

|

|

|

11 |

|

2.6 |

General safety rules . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

11 |

3 |

Technical data . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . |

. |

|

.12. . . . |

|

|

3.1 |

Scope of delivery . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. 12 |

|

|

3.1.1 |

Standard instrument |

|

|

|

12 |

|

3.1.2 |

Standard accessories . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

13 |

|

3.1.3 |

Optional accessories . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

16 |

|

3.2 |

Technical data overview |

|

|

|

17 |

|

3.3 |

Materials used |

|

|

|

17 |

4 |

Description of function . . . . . . . . . . . . . . . . . . |

. . . . . . . |

. |

|

. 18. . . . . |

|

|

4.1 |

Overview over the instrument . . . . . . . . . . . . |

. . . . . . |

. |

. 18 |

|

|

4.2 |

Functional principle of a hot extraction . . . . . . . . . |

. . . . . . |

. |

|

19 |

|

4.2.1 |

Step 1 - extraction . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

19 |

|

4.2.2 |

Step 2 - rinsing . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

19 |

|

4.2.3 |

Step 3 - drying . . . . . . . . . . . . . . . . . |

. . . . . . |

. |

|

20 |

|

4.2.4 |

Solvent collection . . . . . . . . . . . . . . . . |

. . . . . . |

. |

. 20 |

|

|

4.3 |

Controls of the Extraction Unit |

|

|

|

20 |

5 |

Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . |

. . |

|

21 |

|

|

5.1 |

Installation site |

|

|

|

21 |

|

5.2 |

Electrical connections |

|

|

|

22 |

|

5.3 |

Condensers |

|

|

|

22 |

|

5.4 |

Water supply connections |

|

|

|

23 |

|

5.5 |

Cooling water connection . . . . . . . . . . . . . . |

. . . . . . |

. |

|

23 |

|

5.6 |

Cooling medium connection with a chiller . . . . . . . . |

. . . . . . |

. |

. 24 |

|

|

5.6.1 |

Recirculating Chiller B-740/41 or equivalent model . . . . . |

. . . . . . |

. |

|

24 |

|

5.6.2 |

Recirculating Chiller F-1xx |

|

|

|

24 |

|

5.7 |

Solvent hose connection . . . . . . . . . . . . . . |

. . . . . . |

. |

|

25 |

3 |

E-812/816 Hot Extraction Operation Manual, Version B |

Table of contents

6 |

Operation . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

. |

. |

27. . . . . |

|

|

6.1 |

Main screen |

|

|

|

27 |

|

6.2 |

General information on buttons . . . . . . . . |

. . . . . . . . . . |

. |

|

28 |

|

6.3 |

Description of the menu functions |

|

|

|

29 |

|

6.3.1 |

Starting up the instrument |

|

|

|

29 |

|

6.3.2 |

Instrument settings . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

29 |

|

6.3.3 |

Occupying the positions |

|

|

|

30 |

|

6.3.4 |

Defining a method |

|

|

|

31 |

|

6.3.5 |

Saving a method . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 33 |

|

|

6.3.6 |

Opening a method . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

34 |

|

6.3.7 |

Deleting a method |

|

|

|

35 |

|

6.3.8 |

Abort function |

|

|

|

35 |

|

6.3.9 |

Skip function . . . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

36 |

|

6.3.10 |

Service functions . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 36 |

|

|

6.4 |

Example of an extraction process . . . . . . . |

. . . . . . . . . . |

. |

|

41 |

|

6.4.1 |

Material and equipment . . . . . . . . . . |

. . . . . . . . . . |

. |

. 41 |

|

|

6.4.2 |

Preparing an extraction . . . . . . . . . . |

. . . . . . . . . . |

. |

. 41 |

|

|

6.4.3 |

After the extraction process |

|

|

|

42 |

|

6.4.4 |

Emptying the solvent tank |

|

|

|

42 |

|

6.4.5 |

Reusing the solvent . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

42 |

7 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . |

|

43 |

|

|

7.1 |

Daily maintenance |

|

|

|

43 |

|

7.1.1 |

Housing |

|

|

|

43 |

|

7.1.2 |

Hoses and hose connections . . . . . . . . |

. . . . . . . . . . |

. |

. 43 |

|

|

7.1.3 |

Glass parts . . . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 43 |

|

|

7.1.4 |

Solvent tank |

|

|

|

44 |

|

7.2 |

Weekly maintenance . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

45 |

|

7.2.1 |

Heating elements . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 45 |

|

|

7.3 |

Monthly maintenance . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

45 |

|

7.3.1 |

Cleaning the seals |

|

|

|

45 |

|

7.3.2 |

Replacing the seals . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

46 |

|

7.3.3 |

Condenser . . . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 46 |

|

|

7.3.4 |

Flushing the tank valve . . . . . . . . . . |

. . . . . . . . . . |

. |

. 46 |

|

|

7.4 |

Customer service . . . . . . . . . . . . |

. . . . . . . . . . |

. |

. 46 |

|

8 |

Troubleshooting . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . |

. |

. 47. . . . . |

||

|

8.1 |

Malfunctions and their remedy |

|

|

|

47 |

|

8.2 |

Error messages . . . . . . . . . . . . . |

. . . . . . . . . . |

. |

|

48 |

|

8.3 |

Too high/too low results |

|

|

|

49 |

9 |

Shutdown, storage, transport and disposal . . . . . . . |

. . . . . . . . . . . . . . . |

. . |

|

50 |

|

|

9.1 |

Preparing the instrument for storage and transport . |

. . . . . . . . . . |

. |

|

50 |

|

9.1.1 |

Dismantling the condenser . . . . . . . . . |

. . . . . . . . . . |

. |

|

50 |

|

9.1.2 |

Emptying the solvent tank |

|

|

|

50 |

|

9.2 |

Storage and transport |

|

|

|

50 |

|

9.3 |

Disposal |

|

|

|

51 |

10 |

Spare |

parts . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . |

. . |

|

52 |

11 |

Declarations and requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 |

|||||

|

11.1 |

FCC requirements (for USA and Canada) . . . . |

. . . . . . . . . . |

. |

. 53 |

|

|

11.2 |

Declaration of conformity . . . . . . . . . . |

. . . . . . . . . . |

. |

|

54 |

4 |

E-812/816 Hot Extraction Operation Manual, Version B |

1 About this manual

1 About this manual

This manual describes the Extraction Unit E-812/816 HE and provides all information required for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel and operators in particular.

Read this manual carefully before installing and running your system and note the safety precautions in section 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of BUCHI. Unauthorized modifications may affect the system safety or result in accidents. Technical data are subject to change without notice.

NOTE

The symbols pertaining to safety are explained in section 2.

This manual is copyright. Information from it may not be reproduced, distributed or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations into other languages. If you need another language version of this manual, you can download available versions at www.buchi.com.

1..1 Reference documents

For information on the Extraction Unit E-812/816 Soxhlet, please refer to the corresponding manuals as PDF on CD available in English, German, French, Italian and Spanish

• Extraction Unit E-812/816 Soxhlet, Operation Manual number 93169 - 93173

1. .2 Abbreviations

FEP: Fluorinated Ethylene Propylene

FPM: Fluorpolymer rubber

PMMA: Polymethyl methacrylate

PTFE: Ethylenetetrafluoroethylene

PVDF: Polyvinylidene difluoride

5 |

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

2 Safety

This chapter points out the safety concept of the instrument and contains general rules of behavior and warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed. Therefore, the manual must always be available to all persons performing the tasks described herein.

2..1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of training or professional experience have an overview of the dangers which can develop when operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction. The present Operation Manual serves as the basis for this.

2..2 Proper use

The instrument has been designed and built for laboratories. It serves for activities associated with fat extraction.

It is used for:

• Hot extraction with diethyl ether, hexane, petroleum ether and chloroform.

2..3 Improper use

Applications not mentioned above are improper. Also, applications, which do not comply with the technical data, are considered improper. The operator bears the sole risk for any damages caused by such improper use.

The following uses are expressly forbidden:

•Use of the instrument in rooms which require ex-protected instruments.

•Determination of samples, which can explode or inflame (example: explosives, etc.) due to shock, friction, heat or spark formation.

•Use in overpressure situations.

•Use with other glassware than the original from BUCHI.

•Use with other solvents than diethyl ether, hexane, petroleum ether or chloroform.

•Use with more than the allowed maximum solvent amount (max. 150 ml).

•Use with samples that react with solvent.

6 |

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

2..4 Safety warnings and safety signs used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of hazard seriousness of risks related to personal injury and property damage. All signal words, which are related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal words and their definitions!

Sign |

Signal word |

Definition |

Risk level |

|

|

|

|

|

|

! |

DANGER |

Indicates a hazardous situation which, if not avoided, will result in |

|

|

death or serious injury. |

||||

|

|

|

||

|

|

|

|

|

! |

WARNING |

Indicates a hazardous situation which, if not avoided, could result |

|

|

in death or serious injury. |

||||

|

|

|

||

|

|

|

|

|

! |

CAUTION |

Indicates a hazardous situation which, if not avoided, may result |

|

|

in minor or moderate injury. |

||||

|

|

|

||

|

|

|

|

|

no |

NOTICE |

Indicates possible property damage, but no |

|

|

practices related to personal injury. |

(property damage only) |

|||

|

|

|||

|

|

|

||

|

|

|

|

Supplementary safety information symbols may be placed in a rectangular panel on the left to the signal word and the supplementary text (see below example).

Space for |

! |

SIGNAL WORD |

|

|

|

||

Supplementary text, describing the kind and level of hazard / risk seriousness. |

|||

supplementary |

|||

safety |

• List of measures to avoid the herein described, hazard or hazardous situation. |

||

information |

• ... |

|

|

symbols. |

• ... |

|

|

|

|

|

|

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their meaning.

Symbol Meaning

General warning

Electrical hazard

Heavy weight, avoid overexertion

7 |

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

Symbol Meaning

Harmful to life-forms

Pinch point, mechanical hazards

Fire hazard

Hot item, hot surface

Device damage

Inhalation of substances

Chemical burns by corrosives

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Heavy weight, lifting requires more than one person

Additional user information

Paragraphs starting with Note transport helpful information for working with the device / software or its supplementaries. Notes are not related to any kind of hazard or damage (see following example).

8 |

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

NOTE

Useful tips for the easy operation of the instrument / software.

2..5 Product safety

The Extraction Unit is designed and built in accordance with state-of-the-art technology. Nevertheless, risks to users, property, and the environment can arise when the instrument is used carelessly or improperly.

The manufacturer has determined residual dangers emanating from the instrument

•if the instrument is operated by insufficiently trained personnel.

•if the instrument is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2..5..1 General hazards

Pay attention to the following safety notices:

!WARNING

Death or serious injuries by formation of explosive atmospheres inside the instrument.

•Before operation, check all tube connections for correct installation

•Check for proper system tightness

!DANGER

Death or serious injuries by use in explosive environments.

•Do not store or operate the instrument in explosive environments

•Provide sufficient ventilation and make sure to directly withdraw fumes

!WARNING

Death or serious burns by flammable vapors.

•Remove all sources of flammable vapors

•Do not store flammable chemicals in the vicinity of the device

!CAUTION

Risk of burns by hot heating glass plate (up to 250°C).

•Do not touch hot parts or surfaces

•Let the system and inserted extraction cells cool down safely

•Do not move the instrument or parts of it when hot

NOTICE

Risk of instrument damage by liquids or mechanical shocks.

•Do not spill liquids over the instrument or its components

•Do not move the instrument when it is loaded with sample liquid

•Do not drop the instrument or its components

•Keep external vibrations away from the instrument

•Safely attach the instrument to the bench in earthquake prone regions

•Do not operate the instrument without the safety shield installed

9 |

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

NOTICE

Risk of instrument damage by wrong mains supply.

•External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

2..5..2 Warning labels on housing and assemblies

The following warning sticker(s) can be found on the housing or assemblies of the instrument:

Symbol |

Meaning |

Location |

|

Hot item, hot surface |

Sticker / label, located at the heating block |

2..5..3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and gloves. The personal protective equipment must meet all requirements of the supplementary data sheets for the chemicals used.

!WARNING

Serious chemical burns by corrosives.

•Observe supplementary data sheets of all used chemicals.

•Handle corrosives in well ventilated environments only.

•Always wear protective goggles.

•Always wear protective gloves.

•Always wear protective clothes.

•Do not use damaged glassware.

|

|

|

|

|

10 |

|

|

|

E-812/816 Hot Extraction Operation Manual, Version B |

2 Safety

2..5..4 Safety elements

Electronics

•The heating element is equipped with an electronic over-temperature protection.

•If no cooling water is detected at the cooling water output (for example, due to a leak in the condenser), the electronic over-protection will stop all processes.

•To start a program at least one extraction position must be activated in the software.

•Safety shield: The protective shield protects operators from broken glass, solvent splashes and prevents burns from the hot plates.

•Safety shield sensor: To start an extraction the protective shield must be closed.

Optional

•The protective shield (optional accessory) for the condenser protects operators from broken glass in case of an accident or explosion.

2..6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might occur during operation of the instrument. Legal regulations, such as local, state and federal laws applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is operated in proper condition only, and that maintenance, service, and repair jobs are performed with care and on schedule, and by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system performance and reliability. Any modifications to the spare parts used are only allowed with the prior written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized BUCHI technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

11 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery, technical data, requirements and performance data.

3..1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products, see www.buchi.com or contact your local dealer.

3..1..1 Standard instrument

Table 3-1: Standard instrument

Product |

Order number |

|

|

Extraction Unit E-816 Hot Extraction |

47580 |

(6 place; 100 - 120 VAC / 220 - 240 VAC; |

|

50/60 Hz; 1950/1200 W) |

|

|

|

Extraction Unit E-812 Hot Extraction |

49100 |

(2 place; 100 - 120 VAC / 220 - 240 VAC; 50/60 Hz; 700/1200 W)

12 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

3..1..2 Standard accessories

Table 3-2: Standard accessories

1 |

|

E-812 |

E-816 |

Product |

Order |

|

|

|

|

|

|

number |

|

|

|

|

|

|

|

|

2 |

|

1 |

1 |

Beaker pliers, 50 mm a |

02004 |

|

|

4 |

1 |

1 |

Pliers for glass sample tubes with frit b |

47609 |

|

3 |

|

|

|

|

||

1 |

1 |

Turix wrench c |

44349 |

|||

|

||||||

|

|

|

|

|

|

|

|

|

5 |

5 |

Hose clamp, Ø 10.1 mm d |

28737 |

|

|

|

|

|

|

|

|

|

|

- |

1 |

Holder for 6 beakers (for E-816) |

47643 |

|

|

|

|

|

|

|

1 |

3 |

Set of glass sample tubes, 2 pieces |

49430 |

|

|

|

|

1 |

1 |

Set of holders for glass sample tubes |

49432 |

|

|

with frits, set of 6 pieces |

|

|

|

|

|

1 |

3 |

Set of beakers Hot Extraction, 2 pieces |

49426 |

|

|

|

|

2 |

2 |

Paper thimbles 25 x 100 mm, |

41882 |

|

|

set of 6 pieces |

|

|

|

|

|

2 |

2 |

Paper thimbles 33 x 94 mm, |

41883 |

|

|

set of 6 pieces |

|

|

|

|

|

1 |

1 |

Set of holders for paper thimbles |

49428 |

|

|

25 x 100 mm, 6 pieces |

|

|

|

|

|

1 |

1 |

Set of holders for paper thimbles |

49429 |

|

|

33 x 94 mm, 6 pieces |

|

|

|

|

|

1 |

1 |

Boiling stones, 10 g |

42864 |

|

|

|

|

13 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

Table 3-2: Standard accessories (cont.)

E-812 |

E-816 |

Product |

Order |

|

|

|

number |

|

|

|

|

1 |

1 |

Plastic funnel |

51167 |

|

|

|

|

|

|

|

|

1 |

1 |

Hose adapter for cooling media input |

49151 |

|

|

|

|

1 |

1 |

Cooling water hose complete, |

37780 |

|

|

G3/4”, G1/2”, L = 1.5 m |

|

|

|

|

|

1 |

1 |

Solvent hose, Tygon SE 200, 1 m a |

49450 |

|

|

|

|

1 |

1 |

PTFE hose, 500 mm b |

25315 |

|

|

|

|

2 |

1 |

|

|

2 |

2 |

Knurled screw (for solvent hose) a |

43237 |

|

|

|

|

|

|

|

3 |

2 |

2 |

Clamping ring (for solvent hose) a |

43238 |

|

1 |

|

|

|

|

|

5 |

5 |

Hose clamp, Ø 9.6 mm b |

27738 |

|

|

5 |

||||

|

|

|

|

|

|

|

2 |

2 |

Hose, silicone, Ø 6/9 |

43940 |

|

|

|

||||

4 |

2 |

|

|

L = 1.5 m c |

|

|

|

2 |

2 |

Condenser connection hose, silicone, |

49161 |

|

|

|

|

L = 0.35 m, mounted |

|

|

|

|

|

|

|

|

|

1 |

5 |

Condenser hose, silicone, L = 0.20 m d |

49163 |

|

|

|

|

|

|

|

|

2 |

2 |

Hose coupling (wide and small) e |

43565 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

3 |

Set of seals, Viton, 2 pieces |

49431 |

|

|

|

|

|

|

|

|

2 |

6 |

Seal PVDF holder |

47610 |

|

|

|

|

|

|

|

|

1 |

1 |

Set of seals PTFE |

49433 |

|

|

|

|

|

|

14 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

Table 3-2: Standard accessories (cont.)

E-812 |

E-816 |

Product |

Order |

|

|

|

number |

|

|

|

|

1 |

1 |

Sound absorber |

15641 |

|

|

|

|

|

|

|

|

1 |

1 |

Power cable |

|

|

|

|

|

|

|

Type CH |

10010 |

|

|

|

|

|

|

Type Schuko |

10016 |

|

|

|

|

|

|

Type GB |

17835 |

|

|

|

|

|

|

Type USA |

10020 |

|

|

|

|

|

|

Type AUS |

17836 |

|

|

|

|

1 |

1 |

Operation Manual E-812/816 HE |

|

|

|

|

|

|

|

English |

93164 |

|

|

|

|

|

|

German |

93165 |

|

|

|

|

|

|

French |

93166 |

|

|

|

|

|

|

Italian |

93167 |

|

|

|

|

|

|

Spanish |

93168 |

|

|

|

|

15 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

3..1..3 Optional accessories

Table 3-3: Optional accessories

Product |

Order number |

|

|

Holder for glass sample tubes, micro- |

49424 |

wavable (6 positions), PTFE |

|

|

|

Holder for glass sample tubes, |

37462 |

(4 positions), PP |

|

|

|

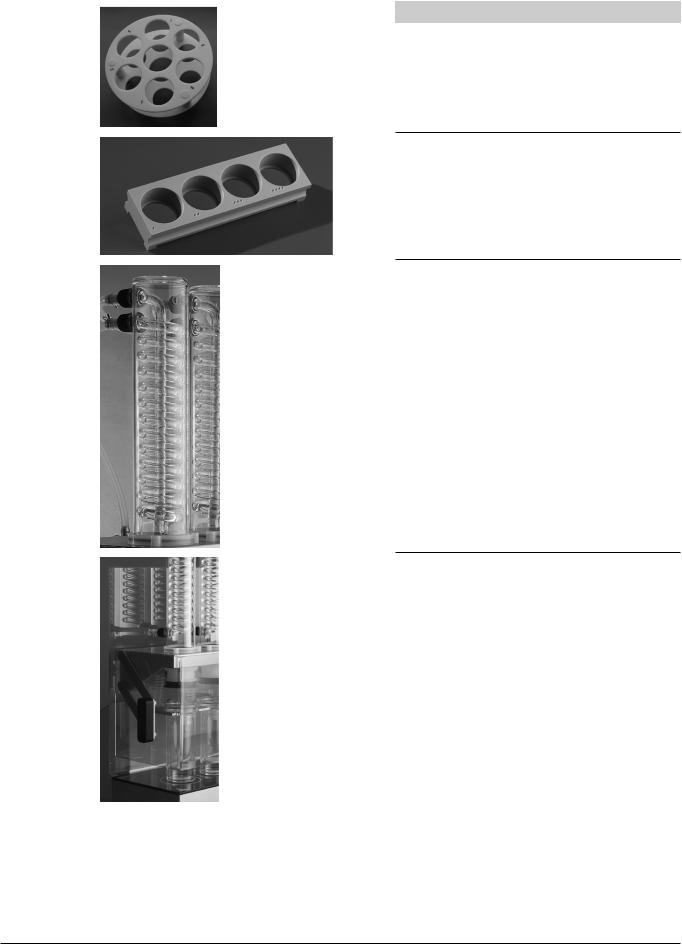

Condenser complete, including connector, |

47604 |

straight |

|

|

|

Protective shield |

E-816 HE |

45521 |

|

|

|

Protective shield |

E-812 HE |

45522 |

|

|

|

16 |

E-812/816 Hot Extraction Operation Manual, Version B |

3 Technical data

3..2 |

Technical data overview |

|

|

||

|

|

|

|

|

|

|

|

|

Table 3-4: Technical data |

|

|

|

|

|

|

Extraction Unit E-812 HE |

Extraction Unit E-816 HE |

|

|

|

|

|

|

|

|

|

Dimensions (L x H x D) |

275 x 596 x 456 mm |

635 x 596 x 456 mm |

|

|

|

|

|

|

|

|

|

Connection voltage |

100 - 120 VAC / 220 - 240 VAC |

100 - 120 VAC / 220 - 240 VAC |

|

|

|

|

± 10%, 50/60 Hz |

± 10%, 50/60 Hz |

|

|

|

|

|

|

|

|

|

Power consumption |

max. 700/1200 W |

max. 1950/1200 W |

|

|

|

|

|

|

|

|

|

Weight |

18 kg |

30 kg |

|

|

|

|

|

|

|

|

|

Overvoltage category |

II |

II |

|

|

|

|

|

|

|

|

|

Pollution degree |

2 |

2 |

|

|

|

|

|

|

|

|

|

Environmental conditions |

for indoor use only |

for indoor use only |

|

|

|

Temperature |

5 – 40 °C |

5 – 40 °C |

|

|

|

Altitude |

up to 2000 m above sea level |

up to 2000 m above sea level |

|

|

|

Humidity |

maximum relative humidity 80% for |

maximum relative humidity 80% for |

|

|

|

|

temperatures up to 31 °C, and then |

temperatures up to 31 °C, and then |

|

|

|

|

linearly decreasing to 50% at 40 °C |

linearly decreasing to 50% at 40 °C |

|

|

|

|

|

|

3..3 |

Materials used |

|

|

|

|

|

Table 3-5: Materials used |

|

|

|

|

Component |

Material designation |

Material code |

|

|

|

|

|

|

|

Housing |

Stainless steel |

|

|

|

|

|

|

|

|

Glass parts |

Borosilicate glass 3.3 |

|

|

|

|

|

|

|

|

Axial seal |

FPM 80-Shore A |

170-A |

|

|

|

|

|

|

|

Solvent hose inside instrument |

FEP DN 3.18/2.18; FEP DN 8/6 |

|

|

|

|

|

|

|

|

Solvent hose |

Tygon with FEP veneer |

|

|

|

|

|

|

|

|

Solvent tank |

Borosilicate glass 3.3 |

|

|

|

|

|

|

|

|

Solvent valve and valve piston |

Body: Al Mg Si Sn Bi (Stanal-32) |

|

|

|

|

Surface: Ematal, plane, high corro- |

|

|

|

|

sive-compressed |

|

|

|

|

|

|

|

|

Cooling media hoses |

Silicone |

|

|

|

|

|

|

|

|

Condenser holder |

PVDF |

|

|

|

|

|

|

|

|

Heating plate |

Ceran-Hightrans |

|

|

|

|

|

|

|

|

Protective shield |

PMMA transparent green 777 |

|

|

|

|

|

|

|

|

Membrane glass valve |

Fluorez® |

|

17 |

E-812/816 Hot Extraction Operation Manual, Version B |

Loading...

Loading...