BUCHI K-360 User Manual

Operation Manual

KjelFlex K 360

093176 en |

Table of contents

Table of contents

1 |

About this manual . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . . . . . . . |

. . |

|

. 6 |

|

|

1.1 |

Abbreviations . . . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

6 |

2 |

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . . . . . . . |

. . |

|

. 7 |

|

|

2.1 |

Safety warnings and safety signals used in this manual . . |

. . |

. . . . . . |

. |

|

7 |

|

2.2 |

User qualification . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

. |

9 |

|

2.3 |

Proper use . . . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

. |

9 |

|

2.4 |

Improper use . . . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

9 |

|

2.5 |

Product safety |

|

|

|

|

9 |

|

2.5.1 |

General hazards and safety measures |

|

|

|

|

10 |

|

2.5.4 |

Safety elements |

|

|

|

|

10 |

|

2.6 |

General safety rules . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

11 |

3 |

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . . . . . . . |

. . |

|

12 |

|

|

3.1 |

Scope of delivery . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

. 12 |

|

|

3.1.1 |

Standard instrument |

|

|

|

|

12 |

|

3.1.2 |

Standard accessories . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

13 |

|

3.1.3 |

Optional accessories K-360 |

|

|

|

|

14 |

|

3.2 |

Technical data K-360 . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

16 |

|

3.3 |

Titration solution |

|

|

|

|

17 |

|

3.4 |

Reference substances |

|

|

|

|

17 |

|

3.5 |

Materials used |

|

|

|

|

18 |

4 |

Description of function . . . . . . . . . . . . . . . . . . . . . |

. . . |

. . . . . . . . . |

. . |

|

19 |

|

|

4.1 |

Instrument overview |

|

|

|

|

19 |

|

4.2 |

Function principle . . . . . . . . . . . . . . |

. . |

. . . . . . |

. |

. 20 |

|

|

4.3 |

Kjeldahl applications |

|

|

|

|

20 |

|

4.4 |

Non-Kjeldahl applications . . . . . . . . . . . . |

. . |

. . . . . . |

. |

|

20 |

|

4.5 |

Operational elements of the instrument . . . . . . . |

. . |

. . . . . . |

. |

|

22 |

Read this manual carefully before installing and running your system and note the safety precautions in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of Buchi. Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of this manual without prior written agreement is also prohibited.

If you need another language version of this manual, you can download it at www..buchi..com..

3 |

KjelFlex K-360 Operation Manual, Version C |

Table of contents

5 |

Putting into operation . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. |

23 |

|

|

5.1 |

Installation site |

|

|

23 |

|

5.2 |

Electrical connections |

|

|

23 |

|

5.3 |

Reagent and water connections |

|

|

24 |

|

5.3.1 |

Cooling water connection . . . . . . . . . . |

. . . . . . . . . . |

. |

24 |

|

5.3.2 |

Drainage of cooling water . . . . . . . . . . |

. . . . . . . . . . |

. |

24 |

|

5.3.3 |

Waste/aspiration hoses . . . . . . . . . . |

. . . . . . . . . . . |

|

. 25 |

|

5.3.4 |

Storage tank connection . . . . . . . . . . |

. . . . . . . . . . |

. |

25 |

|

5.4 |

Level sensors (optional) . . . . . . . . . . |

. . . . . . . . . . . |

|

. 26 |

|

5.5 |

Connections to peripheral devices |

|

|

26 |

|

5.5.1 |

Connecting a printer |

|

|

27 |

|

5.5.2 |

External keyboard |

|

|

27 |

|

5.6 |

Boric acid titration and back titration . . . . . . |

. . . . . . . . . . |

. |

28 |

6 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . |

. |

29 |

|

|

6.1 |

Overview over the software structure . . . . . . |

. . . . . . . . . . |

. |

30 |

|

6.2 |

General information on buttons . . . . . . . . |

. . . . . . . . . . |

. |

33 |

6.3Overview on how to prepare the instrument for routine operation . . . . . . . . 34

6.3.1 |

Standard instrument configuration |

|

34 |

6.3.2 |

Distillation methods . . . . . . . . . . . . . . . . . . . . . . |

. |

34 |

6.3.3 |

System preparation . . . . . . . . . . . . . . . . . . . . . . |

. |

34 |

6.3.4 |

Individual working method |

|

35 |

6.4 |

Configuring the instrument . . . . . . . . . . . . . . . . . . . . |

|

35 |

6.4.1 |

Pump calibration . . . . . . . . . . . . . . . . . . . . . . . |

|

. 36 |

6.4.2 |

Setting date and time . . . . . . . . . . . . . . . . . . . . . . |

|

36 |

6.4.3 |

Defining general instrument settings |

|

37 |

6.4.4 |

Defining the titrator settings . . . . . . . . . . . . . . . . . . . . |

|

37 |

6.4.5 |

Boric acid / end point titration |

|

38 |

6.4.6 |

Back titration with dispenser . . . . . . . . . . . . . . . . . . . |

|

. 39 |

6.4.7 |

Defining user and password settings . . . . . . . . . . . . . . . . |

. |

39 |

6.4.8 |

Defining the keypad settings . . . . . . . . . . . . . . . . . . . |

|

. 40 |

6.5 |

Defining a distillation method . . . . . . . . . . . . . . . . . . . |

|

. 41 |

6.6 |

Instrument modes |

|

42 |

6.7 |

System preparation . . . . . . . . . . . . . . . . . . . . . . |

. |

42 |

6.7.1 |

Preheating |

|

42 |

6.7.2 |

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

42 |

6.7.3 |

Cleaning |

|

42 |

6.7.4 |

Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

42 |

6.8 |

Carrying out a distillation . . . . . . . . . . . . . . . . . . . . |

. |

43 |

6.8.1 |

Single sample analysis . . . . . . . . . . . . . . . . . . . . . |

|

. 43 |

6.8.2 |

Rack oriented analysis . . . . . . . . . . . . . . . . . . . . . |

|

. 44 |

6.8.3 |

Analysis screen . . . . . . . . . . . . . . . . . . . . . . . . |

|

44 |

6.8.4 |

Result screen . . . . . . . . . . . . . . . . . . . . . . . . |

. |

45 |

6.8.5 |

Result list . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

45 |

6.8.6 |

After distillation . . . . . . . . . . . . . . . . . . . . . . . . |

|

46 |

6.9 |

Switching ON/OFF checklist |

|

46 |

4 |

KjelFlex K-360 Operation Manual, Version C |

Table of contents

7 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

47 |

|

|

7.1 |

Daily maintenance |

|

48 |

|

7.1.1 |

Cleaning the housing . . . . . . . . . . . . . . . . . . . . . . |

|

48 |

|

7.1.2 |

Cleaning the glass parts |

|

48 |

|

7.1.3 |

Cleaning the rubber bung seal |

|

49 |

|

7.2 |

Monthly maintenance . . . . . . . . . . . . . . . . . . . . . . |

|

49 |

|

7.2.1 |

Calibrating the pumps |

|

49 |

|

7.2.2 |

Checking the distillate amount |

|

49 |

|

7.3 |

Maintenance as required . . . . . . . . . . . . . . . . . . . . |

. |

49 |

|

7.3.1 |

Cleaning the splash protector . . . . . . . . . . . . . . . . . . . |

|

. 49 |

|

7.3.2 |

Replacing the splash protector . . . . . . . . . . . . . . . . . . |

. |

50 |

7.3.3Replacing the rubber bung seals and the splash protector . . . . . . . . . . 50

|

7.3.4 |

Glass parts . . . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 52 |

|

7.3.5 |

Replacing the hoses |

|

|

|

|

52 |

|

7.4 |

Yearly maintenance . . . . . . . . . . |

. . . . . . |

. . . . |

. . |

. |

53 |

|

7.4.1 |

Customer service . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 53 |

|

7.4.2 |

Decalcification of the steam generator |

|

|

|

|

53 |

8 |

Troubleshooting . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . |

. . . . |

54 |

||

|

8.1 |

Malfunctions and their remedy |

|

|

|

|

54 |

|

8.2 |

Diagnostics . . . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 56 |

|

8.2.1 |

Operational Tests . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 56 |

|

8.2.2 |

Test sensors |

|

|

|

|

57 |

|

8.2.3 |

Test Printer . . . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 57 |

|

8.2.4 |

Operating Hours |

|

|

|

|

57 |

|

8.2.5 |

Hardware Info |

|

|

|

|

57 |

|

8.2.6 |

Service Test . . . . . . . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 57 |

9 |

Shutdown, storage, transport and disposal . . . . |

. . . . . . . . . . |

. . . . . . |

. . . . |

58 |

||

|

9.1 |

Preparing the instrument for transport |

|

|

|

|

58 |

|

9.2 |

Storage and transport |

|

|

|

|

59 |

|

9.3 |

Disposal |

|

|

|

|

59 |

10 |

Spare parts . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . |

. . . . 60 |

|||

|

10.1 |

Spare parts K-360 . . . . . . . . . . |

. . . . . . |

. . . . |

. . |

. |

60 |

|

10.2 |

Hosing connection schemes . . . . . . |

. . . . . . . |

. . . . |

. . |

|

. 62 |

11 |

Declarations and requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 |

||||||

|

11.1 |

FCC requirements (for USA and Canada) . . |

. . . . . . . |

. . . . |

. . |

|

. 67 |

|

11.2 |

Declaration of conformity . . . . . . . . |

. . . . . . |

. . . . |

. . |

. |

68 |

12 |

Index . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . |

. . . |

. |

69 |

|

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . |

. . . . . . |

. . . |

. |

69 |

||

5 |

KjelFlex K-360 Operation Manual, Version C |

1 About this manual

1 About this manual

This manual describes the KjelFlex K-360 and provides all information required for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel in particular.

NOTE

The symbols pertaining to safety messages are explained in chapter 2.

1..1 Abbreviations

EPDM: Ethylene Propylene Dimonomer

FCC: Federal Communications Commission

FEP: Fluorethylene Propylene

NBR: Nitrile Butadiene Rubber

PE: Polyethylene

PMMA: Polymethyl methacrylate

PP: Polypropylene

PTFE: Ethylenetetrafluoroethylene (Teflon)

PUR: Polyurethane

RSD: Relative Standard Deviation

6 |

KjelFlex K-360 Operation Manual, Version C |

2 Safety

2 Safety

This chapter points out the safety concept of the instrument and contains general rules of behavior and warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed. Therefore, the manual must always be available to all persons performing the tasks described herein.

2..1 Safety warnings and safety signals used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of hazard seriousness for risks, related to personal injury and property damage. All signal words which are related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the below table with the different signal words and their definitions!

Sign |

Signal word |

Definition |

Risk level |

|

|

|

|

|

|

|

DANGER |

Indicates a hazardous situation which, if not avoided, will result in |

|

|

|

death or serious injury. |

|||

|

|

|

||

|

|

|

|

|

|

WARNING |

Indicates a hazardous situation which, if not avoided, could result |

|

|

|

in death or serious injury. |

|||

|

|

|

||

|

|

|

|

|

|

CAUTION |

Indicates a hazardous situation which, if not avoided, may result |

|

|

|

in minor or moderate injury. |

|||

|

|

|

||

|

|

|

|

|

no |

NOTICE |

Indicates possible property damage, but no |

|

|

practices related to personal injury. |

(property damage only) |

|||

|

|

|||

|

|

|

||

|

|

|

|

Supplementary safety information symbols may be placed in a rectangular panel on the left to the signal word and the supplementary text (see below example).

Space for supplementary safety information symbols.

!SIGNAL WORD

Supplementary text, describing the kind and level of hazard / risk seriousness.

•List of measures to avoid the herein described, hazard or hazardous situation.

• |

״ |

״ |

• |

״ |

״ |

• |

״ |

״ |

7 |

KjelFlex K-360 Operation Manual, Version C |

2 Safety

Table of supplementary safety information symbols

The below reference list incorporates all safety information symbols used in this manual and their meaning.

Warning symbols |

Meaning |

|

Electrical hazard |

|

Hot machine parts, hot surface |

|

Corrosive substances |

|

General warning sign |

|

General system damage |

Mandatory action symbols Meaning

Wear safety gloves

Wear protective goggles

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device / software or its supplementaries. NOTEs are not related to any kind of hazard or damage (see below example).

NOTE

Useful tips for the easy operation of the instrument / software.

8 |

KjelFlex K-360 Operation Manual, Version C |

2 Safety

2..2 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of training or professional experience have an overview of the dangers which can develop when operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction. The present Operation Manual serves as the basis for this.

2..3 Proper use

The instrument has been designed and built for laboratories. It serves for the distillation of steam-vola- tile substances.

2..4 Improper use

Applications not mentioned above are improper. Also, applications which do not comply with the technical data are considered improper.

The operator bears the sole risk for any damages caused by such improper use. The following uses are expressly forbidden:

•Use of the instrument in rooms which require ex-protected instruments.

•Use on samples, which can explode or inflame (e.g. explosives, etc.) due to shock, friction, heat or spark formation.

2..5 Product safety

The instrument is designed and built in accordance with state-of-the-art technology. Nevertheless, risks to users, property and the environment can arise when the instrument is used carelessly or improperly.

The manufacturer has determined residual dangers emanating from the instrument

•if the instrument is operated by insufficiently trained personnel.

•if the instrument is not operated according to its proper use.

Safety warnings in this manual (as discribed in section 2.1 ff) serve to make the user alert and to avoid hazardous situations emanating from residual dangers by giving appropriate counter meassured.

9 |

KjelFlex K-360 Operation Manual, Version C |

2 Safety

2..5..1 General hazards and safety measures

!WARNING

Death or serious injuries by explosive solvent atmosphere.

•Operate the system in well ventilated environments only.

• Do not use open flames in explosive environments.

•Avoid eletrostatic and electric spark formation in explosive environments.

!WARNING

Death or serious injuries by strong corrosives.

•Observe supplementary data sheets of all used chemicals.

•Handle corrosives in well ventilated environments only.

•Always wear protective goggles.

•Always wear protective gloves.

2..5..4 Safety elements

The instrument is provided with the following safety elements:

•Protective door: Safety appliance to protect users from burns at the splash protector (distillation area), which is hot during distillation.

•Protective door sensor: Prevents the start of a distillation with the protective door open and stops a running distillation and the dosing of reagents immediately when the protective door is opened during the process.

•Sample tube sensor: Prevents the start of a distillation without a sample tube inserted.

•Protective shield (cover) at condenser: Protects the glass parts.

•Service door sensor/switch: Electrical power is disconnected immediately when the service door is opened, thus preventing electrical shock during maintenance.

•Cooling water flow sensor: Stops a running distillation.

•Optional level sensors for reagent and waste tank: A running distillation is interrupted when the tanks are too full or too empty respectively.

•Drip tray: Collects overflowing liquids.

•Automatic chemical dosage: Ensures the use of homogeneous liquid amounts.

10 |

KjelFlex K-360 Operation Manual, Version C |

2 Safety

2..6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might occur during operation of the instrument. Legal regulations, such as local, state and federal laws applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is operated in proper condition only, and that maintenance, service, and repair jobs are performed with care and on schedule, and by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system performance and reliability. Any modifications to the spare parts used are only allowed with the prior written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized Buchi technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

11 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery, technical data, requirements and performance data.

3..1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products see www.buchi.com or contact your local dealer.

3..1..1 Standard instrument

Table 3-1: Standard instrument

Product |

Order number |

|

|

KjelFlex K-360 Standard with glass |

43600 |

splash protector, 230 V, 50/60 Hz |

|

|

|

KjelFlex K-360 Standard with splash |

43601 |

protector made of fiber glass reinforced |

|

polypropylene, 230 V, 50/60 Hz |

|

|

|

KjelFlex K-360 with glass splash |

43605 |

protector and acid resistant pump, 230 V, |

|

50/60 Hz |

|

|

|

KjelFlex K-360 with splash protector |

43604 |

made of fiber glass reinforced polypro- |

|

pylene and acid resistant pump, 230 V, |

|

50/60 Hz |

|

|

|

KjelFlex K-360 Standard with glass |

43607 |

splash protector and titration set, 230 V, |

|

50/60 Hz |

|

|

|

KjelFlex K-360 with splash protector |

43606 |

made of fiber glass reinforced polypro- |

|

pylene and titration set, 230 V, 50/60 Hz |

|

|

|

KjelFlex K-360 with glass splash |

43609 |

protector, acid resistant pump and titra- |

|

tion set, 230 V, 50/60 Hz |

|

|

|

KjelFlex K-360 with splash protector |

43608 |

made of fiber glass reinforced polypro- |

|

pylene, acid resistant pump and titration |

|

set, 230 V, 50/60 Hz |

|

|

|

12 |

KjelFlex K-360 Operation Manual, Version C |

3..1..2 Standard accessories

1 |

8 |

7 |

6 |

|

|

3 |

4 |

2 |

|

|

|

5 |

|

|

|

9

11

10 |

12 |

3 Technical data

Table 3-2: Standard accessories

Product |

Order number |

|

|

Mains cable of the following types |

|

|

|

Type CH |

10010 |

|

|

Type Schuko |

10016 |

|

|

Type GB |

17835 |

|

|

Type AUS |

17836 |

|

|

Type USA |

33763 |

|

|

Type Japan |

10016 |

|

|

a Pair of glass tongs |

02004 |

|

|

b Cooling water hose complete: G ¾", |

37780 |

½", L = 1.5 m |

|

|

|

c Hose cooling water drain, silicone, |

43439 |

L = 1.8 m, Ø 14/10 mm |

|

|

|

d Weighing boats |

40444 |

|

|

e Hose chemical supply, Solaflex, |

43185 |

L = 6 m, Ø 10/5 mm |

|

|

|

f 3 suction hoses to tanks, FEP, |

43407 |

L = 580 mm |

|

|

|

g Hose waste drain, EPDM, |

43457 |

L = 1.8 m, Ø 18/11 mm |

|

for acid resistant pump |

|

|

|

h Hose Viton (acid resistant), |

43693 |

L = 1.2 m, Ø 6/3 mm |

|

(only supplied for instruments with |

|

acid resistant pump) |

|

|

|

4 clamps Ø 11.9 |

43841 |

|

|

i 3 tanks 10 l, without caps |

43410 |

|

|

j 1 cap for 10 l tanks, large |

25869 |

|

|

k 12 tank labels |

43434 |

|

|

l 1 cap for 10 l and 20 l tanks, small |

43477 |

|

|

Operation Manual: |

|

|

|

English |

93176 |

|

|

German |

93177 |

|

|

French |

93178 |

|

|

Italian |

93179 |

|

|

Spanish |

93180 |

|

|

13 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

3..1..3 Optional accessories K-360

Table 3-3: Optional accessories K-360

|

|

|

|

Product |

Order number |

|

|

|

|

|

|

|

|

|

|

a Sample tube (set of 4), 500 ml |

43982 |

|

|

|

|

|

|

|

|

|

|

b Set of sample tubes (set of 4), 300 ml |

37377 |

|

|

|

|

|

|

|

|

|

|

c Receiving vessel 420 ml |

43390 |

1 |

2 |

3 |

4 |

|

|

d Receiving vessel 340 ml |

43333 |

||||

|

|

|

|

|

|

|

|

|

|

Tanks without level sensors, including caps |

|

|

|

|

|

|

|

|

|

|

|

e 10 l chemicals |

43468 |

|

|

|

|

|

|

|

|

|

|

e 10 l waste |

43470 |

|

|

|

|

|

|

|

|

|

|

h 20 l chemicals |

43469 |

|

|

|

|

|

|

|

|

|

|

h 20 l waste |

43471 |

|

|

|

|

|

|

7 |

5 |

6 |

8 |

Tanks with level sensors, including caps |

|

|

|

|

|

g 10 l chemicals |

43472 |

|

|

|

|

|

|

|

|

|

|

g 10 l waste |

43374 |

|

|

|

|

|

|

|

|

|

|

f 20 l chemicals |

43473 |

|

|

|

|

|

|

|

|

|

|

f 20 l waste |

43475 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicator according to Sher, 100 ml |

03512 |

|

|

|

|

|

|

External PC keyboard (US) |

31456 |

|

|

External PC keyboard (D) |

31457 |

|

|

|

|

External dosage device for back titration, |

43367 |

115 V |

|

|

|

External dosage device for back titration, |

43596 |

230 V |

|

|

|

Cable for external dosage device for back |

43621 |

titration (Schott Titronic) |

|

|

|

14 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

Table 3-3: Optional accessories K-360

Product |

Order number |

|

|

Sample tube holder for 4 sample tubes, |

16951 |

500 ml each |

|

|

|

Holder for 6 sample tubes, 300 ml |

43039 |

|

|

Holder for 12 sample tubes, 300 ml |

43041 |

|

|

Titration set |

43698 |

|

|

Splash protector for Devarda method |

43335 |

|

|

Connection cable to: |

|

|

Mettler (DL15 / 22) titrator |

43616 |

|

|

|

|

Metrohm (785 / 719 / 702) |

43617 |

|

Mettler (Txx) titrator |

||

|

||

|

|

|

Metrohm (848) titrator |

11055333 |

|

|

|

|

Schott titrator |

43618 |

|

|

|

|

Radiometer titrator |

43619 |

|

|

|

|

Adapter for Metrohm 719 / 702 |

47803 |

15 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

Table 3-3: Optional accessories K-360 (cont.)

Product |

Order number |

|

|

SO2 accessory |

48680 |

IQ/OQ set for K–360, English |

93189 |

|

|

IQ/OQ set for K–360, German |

45541 |

|

|

Repeating OQ, English |

11055493 |

|

|

Repeating OQ, German |

11055494 |

|

|

3..2 |

Technical data K-360 |

|

|

|

|

|

|

|

|

Table 3-4: Technical data K-360 |

|

|

|

|

KjelFlex K-360 |

|

|

|

|

|

|

Power consumption |

max. 2.2 kW |

|

|

|

|

|

|

Connection voltage |

220 - 240 VAC ± 10% |

|

|

|

|

|

|

Frequency |

50/60 Hz |

|

|

|

|

|

|

Mains connection |

3-pole (P, N, E) via power cord |

|

|

|

|

|

|

Recovery rate |

≥ 99.5% |

|

|

Reproducibility (RSD) |

≤ ± 1% |

|

|

Detection limit |

≥ 0.1 mg Nitrogen |

|

|

Vapor output control |

30 - 100% |

|

|

|

|

|

|

Environmental conditions |

for indoor use only |

|

|

Temperature |

5 - 35 °C |

|

|

Altitude |

up to 2000 m |

|

|

Humidity |

maximum relative humidity 80% for temperatures up to |

|

|

|

31 °C decreasing linearly to 67% relative humidity at |

|

|

|

35 °C |

|

|

|

|

|

|

Installation category |

II |

|

|

|

|

|

|

Pollution degree |

2 |

|

|

|

|

|

|

Dimensions (W x H x D) |

405 x 660 x 400 mm |

|

|

|

|

|

|

Weight |

22 kg |

|

|

|

|

|

|

Printer interface |

USB 2.0, PCL 6 |

|

|

|

|

16 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

3..3 Titration solution

The amount of sample and the concentration of the titrant should be optimized, so that the titrant volume is between 2 and 18 ml (burette volume: 20 ml).

Table 3-5: Titration solution 1

N-amount |

N-content |

Sample size |

Titrant |

|

Titrant concentration |

Titrant volume |

|

|

|

|

|

|

|

5 mg N |

0.5 % N |

1 g |

|

H2SO4 |

0.01 mol/l |

17.8 ml |

10 mg N |

1.0 % N |

1 g |

|

H2SO4 |

0.05 mol/l |

7.1 ml |

50 mg N |

5 % N |

0.1 g |

|

H2SO4 |

0.01 mol/l |

17.8 ml |

100 mg N |

10 % N |

1 g |

|

H2SO4 |

0.25 mol/l |

14.3 ml |

100 mg N |

10 % N |

1 g |

|

H2SO4 |

0.5 mol/l |

7.1 ml |

200 mg N |

20 % N |

1 g |

|

H2SO4 |

0.5 mol/l |

14.3 ml |

200 mg N |

20 % N |

1 g |

|

H2SO4 |

1 mol/l |

7.1 ml |

Table 3-6: Titration solution 2

P-content |

P-factor |

N-content |

Sample size |

Titrant |

Titrant concentration |

Titrant volume |

|

|

|

|

|

|

|

1 % P |

6.25 |

0.16 % N |

2 g |

H2SO4 |

0.01 mol/l |

11.42 ml |

2 % P |

6.25 |

0.32 % N |

1 g |

H2SO4 |

0.01 mol/l |

11.42 ml |

5 % P |

6.25 |

0.80 % N |

2 g |

H2SO4 |

0.1 mol/l |

5.71 ml |

10 % P |

6.25 |

1.6 % N |

2 g |

H2SO4 |

0.1 mol/l |

11.42 ml |

10 % P |

6.25 |

1.6 % N |

2 g |

H2SO4 |

0.25 mol/l |

4.57 ml |

20 % P |

6.25 |

3.2 % N |

2 g |

H2SO4 |

0.25 mol/l |

9.14 ml |

50 % P |

6.25 |

8.0 % N |

2 g |

H2SO4 |

0.5 mol/l |

11.42 ml |

General recommendation

Hydrochloric acid has the disadvantage of degassing. Therefore Buchi recommends to use sulfuric acid as titrant.

The correction factor for self prepared solutions is called a titer.

The use of standardized titration solutions make a titer determination unnecessary. Exact titrant concentration = concentration x titer

The titer of the titrant must be known. In case, it is unknown, it must be determined. Example: Exact titrant concentration = 0.100 mol/l x 0.998

3..4 |

Reference substances |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Table 3-7: Reference substances |

|

|

|

|

|

|

|

Name |

Purity |

% N theoretical |

Recommended |

Recommended titrant |

Digestion necessary |

|

|

|

|

(100 % purity) |

sample size |

concentration |

|

|

|

|

|

|

|

|

|

|

|

Ammonium |

99.5 |

12.18 |

0.8 g |

c(H2SO4) = 0.25 |

No |

|

|

dihydrogen |

|

|

|

mol/l |

|

|

|

phosphate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Glycine |

99.7 |

18.66 |

0.5 g |

c(H2SO4) = 0.25 |

Yes |

|

|

|

|

|

|

mol/l |

|

|

|

|

|

|

|

|

|

|

|

Phenylalanine |

99.0 |

8.47 |

0.9 g |

c(H2SO4) = 0.25 |

Yes |

|

|

|

|

|

|

mol/l |

|

|

|

|

|

|

|

|

|

|

|

Ammonium |

99.5 |

21.21 |

0.4 g |

c(H2SO4) = 0.25 |

No |

|

|

sulfate |

|

|

|

mol/l |

|

17 |

KjelFlex K-360 Operation Manual, Version C |

3 Technical data

3..5 Materials used

Table 3-8: Materials used for the K-360

Component |

Material designation |

Material code |

|

|

|

Housing |

Polyurethane |

PUR / UL V0 |

|

|

|

Glass parts |

Borosilicate glass 3.3 |

DIN/ISO 3585 |

|

|

|

Steam generator isolation |

Ceramic fiber |

Multitherm 550 |

|

|

|

Steam generator housing |

Stainless steel |

1.4301 |

|

|

|

Protective door |

Polymethyl methacrylate |

PMMA |

|

|

|

Condenser cover |

Polymethyl methacrylate |

PMMA |

|

|

|

Connecting stopper |

Hypalon |

CSM |

|

|

|

Plastic splash protector |

Glass fiber reinforced polypropylene |

PP |

|

|

|

Stop-cock |

Polypropylene/polyethylene |

PP/PE |

|

|

|

18 |

KjelFlex K-360 Operation Manual, Version C |

4 Description of function

4 Description of function

This chapter explains the basic principle of the instrument, shows how it is structured and gives a functional description of the assemblies.

4..1 Instrument overview

4

1 |

5 |

|

6

2

3

a Splash protector |

d Condenser |

b Sample tube |

e Operating panel |

c Protective door |

f Service door |

Fig. 4.1: Instrument overview |

|

19 |

KjelFlex K-360 Operation Manual, Version C |

4 Description of function

4..2 Function principle

The KjelFlex K-360 is suitable for determining nitrogen using the Kjeldahl (TKN; Total Kjeldahl Nitrogen) and Devarda methods as well as for other distillations of steam-volatile substances (e.g. of alcohol, SO2, volatile acids).

a Sample tube

|

3 |

b Splash protector |

|

|

|

|

|

c Steam generator |

|

|

d Condenser |

2 |

|

e Distillate outlet tube |

|

f Receiving vessel with receiver solution |

|

|

|

4 |

5

1

6

Fig. 4.2: Function principle

Steam is introduced into the sample solution (in sample tube a) to drive out volatile components (such as ammonia, alcohol, etc.). After condensation (in condenser d) the distillate is collected in a receiver solution (in receiving vessel f).

4..3 Kjeldahl applications

Determination of nitrogen/protein.

For system configuration with reagent-pump:

Warnmeldung

4..4 Non-Kjeldahl applications

Typical examples for non-Kjeldahl methods.

Determination of:

•SO2

•Phenol

•Formaldehyde

•TVBN

•Alcohol

•Volatile acids

20 |

KjelFlex K-360 Operation Manual, Version C |

4 Description of function

Fig. 4.3: Stop-cock

The stop-cock is located at the inside of the service door.

To carry out a Kjeldahl application the stop-cock must be in downwards position. To carry out a non-Kjeldahl application the stop-cock must be in horizontal position.

!CAUTION

Risk of burnings by hot machine parts and water steam.

•Let the system cool down before performing any service.

•Do not operate the instrument when enclosure is open or removed.

Notice

Wrong stop-cock setting will result in system overpressure. Tubing may come off.

•Set stop-cock to correct working-position.

21 |

KjelFlex K-360 Operation Manual, Version C |

4 Description of function

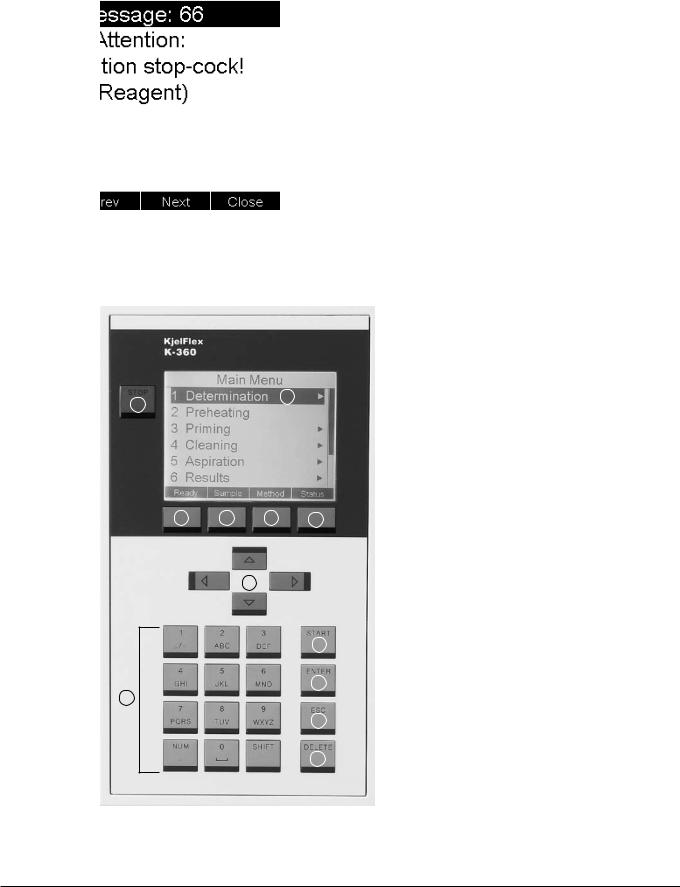

NOTE

A warning message will be displayed, when the method is changed from a Kjeldahl to a non-Kjeldahl method or vice versa:

Fig. 4.4: Warning message on the display |

Fig. 4.5: Warning message on the display |

4..5 Operational elements of the instrument

1 |

2 |

|

3 |

3 |

3 |

3 |

4

5

6

9

7

8

a Stop button to stop a process b Display

c Functional buttons to operate the software

dNavigation buttons to navigate within the software

eStart button to start a process like preheating, priming, cleaning, etc.

fEnter button to move forward within the submenu structure

g Escape button

hDelete button to delete a digit entered via the keypad

i Keypad

Fig. 4.6: Controls of the instrument

22 |

KjelFlex K-360 Operation Manual, Version C |

5 Putting into operation

5 Putting into operation

This chapter describes how the instrument is installed and gives instructions on initial startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company.

Keep the original packaging for future transportation.

5..1 Installation site

Install the instrument on a clean, flat and stable base and place the tanks for chemicals beside the instrument (not higher and not more than 1 m lower).

Notice

Reduced instrument safety and lifetime due to improper handling and installation location.

•Do not place any object on top of the instrument.

•Keep a free safety space of 30 cm around the instrument.

•Do not place items behind the instrument.

•Do not operate the instrument within an fume cabinet.

5..2 Electrical connections

L

N

N

IEC-60320, Type: C13

Fig. 5.1: Electrical connections

!WARNING

Death or serious burnings by electric shock.

•Mains voltage must match the voltage reading on the type plate.

•Instrument must be earthed by the mains socket.

•Only use a molded 3-pole device plug (IEC-60320, type C13 or C15).

•Do not use damaged cables.

23 |

KjelFlex K-360 Operation Manual, Version C |

Loading...

Loading...