Page 1

Operation Manual

KjelFlex K�360

093176

en

Page 2

Page 3

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Safety warnings and safety signals used in this manual . . . . . . . . . . . . . . . . . 7

2.2 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5.1 General hazards and safety measures. . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.4 Safety elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Standard instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Optional accessories K-360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Technical data K-360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Titration solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Reference substances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1 Instrument overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Function principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Kjeldahl applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.4 Non-Kjeldahl applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Operational elements of the instrument . . . . . . . . . . . . . . . . . . . . . . . . 22

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

Buchi. Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

If you need another language version of this manual, you can download it at

www.buchi.com.

3 KjelFlex K-360 Operation Manual, Version C

Page 4

Table of contents

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Reagent and water connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.1 Cooling water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.2 Drainage of cooling water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3.3 Waste/aspiration hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3.4 Storage tank connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Level sensors (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 Connections to peripheral devices. . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5.1 Connecting a printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5.2 External keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.6 Boric acid titration and back titration . . . . . . . . . . . . . . . . . . . . . . . . . 28

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 Overview over the software structure . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 General information on buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 Overview on how to prepare the instrument for routine operation . . . . . . . . . . . 34

6.3.1 Standard instrument configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.2 Distillation methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.3 System preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.3.4 Individual working method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4 Configuring the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.1 Pump calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.2 Setting date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4.3 Defining general instrument settings. . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.4 Defining the titrator settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.5 Boric acid / end point titration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.6 Back titration with dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.7 Defining user and password settings . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.8 Defining the keypad settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.5 Defining a distillation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.6 Instrument modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7 System preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.1 Preheating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.2 Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.3 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.7.4 Aspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.8 Carrying out a distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.8.1 Single sample analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.8.2 Rack oriented analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.8.3 Analysis screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

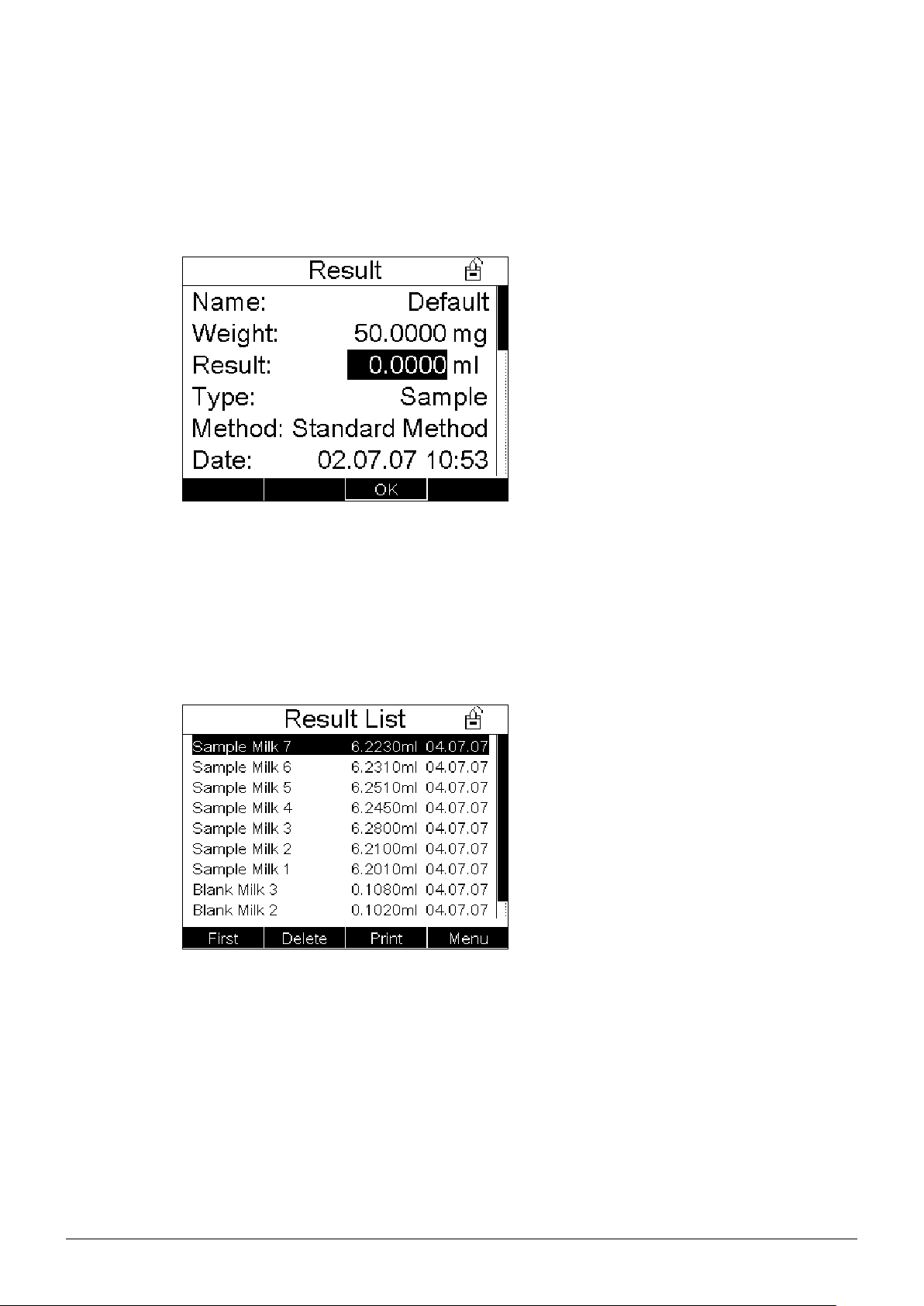

6.8.4 Result screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.8.5 Result list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.8.6 After distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.9 Switching ON/OFF checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4

KjelFlex K-360 Operation Manual, Version C

Page 5

Table of contents

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.1 Daily maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1.1 Cleaning the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1.2 Cleaning the glass parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.1.3 Cleaning the rubber bung seal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2 Monthly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2.1 Calibrating the pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.2.2 Checking the distillate amount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Maintenance as required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.1 Cleaning the splash protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3.2 Replacing the splash protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.3.3 Replacing the rubber bung seals and the splash protector . . . . . . . . . . . . . . 50

7.3.4 Glass parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.5 Replacing the hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4 Yearly maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4.2 Decalcification of the steam generator. . . . . . . . . . . . . . . . . . . . . . . . . 53

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2.1 Operational Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2.2 Test sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.3 Test Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.4 Operating Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.5 Hardware Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2.6 Service Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1 Preparing the instrument for transport. . . . . . . . . . . . . . . . . . . . . . . . . 58

9.2 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.1 Spare parts K-360 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.2 Hosing connection schemes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 67

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

12 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5 KjelFlex K-360 Operation Manual, Version C

Page 6

1 About this manual

This manual describes the KjelFlex K-360 and provides all information required for its safe operation

and to maintain it in good working order.

It is addressed to laboratory personnel in particular.

NOTE

The symbols pertaining to safety messages are explained in chapter 2.

1.1 Abbreviations

EPDM: Ethylene Propylene Dimonomer

FCC: Federal Communications Commission

FEP: Fluorethylene Propylene

NBR: Nitrile Butadiene Rubber

PE: Polyethylene

PMMA: Polymethyl methacrylate

PP: Polypropylene

PTFE: Ethylenetetrafluoroethylene (Teflon)

PUR: Polyurethane

RSD: Relative Standard Deviation

1 About this manual

6 KjelFlex K-360 Operation Manual, Version C

Page 7

2 Safety

!

This chapter points out the safety concept of the instrument and contains general rules of behavior

and warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed. Therefore, the manual

must always be available to all persons performing the tasks described herein.

2.1 Safety warnings and safety signals used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness for risks, related to personal injury and property damage. All signal words which

are related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the below table with the different signal

words and their definitions!

2 Safety

Sign Signal word Definition Risk level

DANGER

WARNING

CAUTION

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

Supplementary text, describing the kind and level of hazard / risk seriousness.

•

•

•

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

SIGNAL WORD

List of measures to avoid the herein described, hazard or hazardous situation.•

״

״

״

★★★★

★★★☆

★★☆☆

★☆☆☆

(property damage only)

״

״

״

7 KjelFlex K-360 Operation Manual, Version C

Page 8

2 Safety

Table of supplementary safety information symbols

The below reference list incorporates all safety information symbols used in this manual and their

meaning.

Warning symbols Meaning

Electrical hazard

Hot machine parts, hot surface

Corrosive substances

General warning sign

General system damage

Mandatory action symbols Meaning

Wear safety gloves

Wear protective goggles

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device / software or

its supplementaries. NOTEs are not related to any kind of hazard or damage (see below example).

NOTE

Useful tips for the easy operation of the instrument / software.

8 KjelFlex K-360 Operation Manual, Version C

Page 9

2.2 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of

training or professional experience have an overview of the dangers which can develop when

operating the instrument.

Personnel without this training or persons who are currently being trained require careful instruction.

The present Operation Manual serves as the basis for this.

2.3 Proper use

The instrument has been designed and built for laboratories. It serves for the distillation of steam-volatile substances.

2.4 Improper use

Applications not mentioned above are improper. Also, applications which do not comply with the technical data are considered improper.

The operator bears the sole risk for any damages caused by such improper use.

The following uses are expressly forbidden:

Use of the instrument in rooms which require ex-protected instruments.•

Use on samples, which can explode or inflame (e.g. explosives, etc.) due to shock, friction, heat or •

spark formation.

2 Safety

2.5 Product safety

The instrument is designed and built in accordance with state-of-the-art technology. Nevertheless,

risks to users, property and the environment can arise when the instrument is used carelessly or

improperly.

The manufacturer has determined residual dangers emanating from the instrument

if the instrument is operated by insufficiently trained personnel.•

if the instrument is not operated according to its proper use.•

Safety warnings in this manual (as discribed in section 2.1 ff) serve to make the user alert and to avoid

hazardous situations emanating from residual dangers by giving appropriate counter meassured.

9 KjelFlex K-360 Operation Manual, Version C

Page 10

2.5.1 General hazards and safety measures

!

!

WARNING

Death or serious injuries by explosive solvent atmosphere.

Operate the system in well ventilated environments only.•

Do not use open flames in explosive environments.•

Avoid eletrostatic and electric spark formation in explosive environments.•

WARNING

Death or serious injuries by strong corrosives.

Observe supplementary data sheets of all used chemicals.•

Handle corrosives in well ventilated environments only.•

Always wear protective goggles.•

Always wear protective gloves.•

2 Safety

2.5.4 Safety elements

The instrument is provided with the following safety elements:

Protective door: Safety appliance to protect users from burns at the splash protector (distillation •

area), which is hot during distillation.

Protective door sensor: Prevents the start of a distillation with the protective door open and stops •

a running distillation and the dosing of reagents immediately when the protective door is opened

during the process.

Sample tube sensor: Prevents the start of a distillation without a sample tube inserted.•

Protective shield (cover) at condenser: Protects the glass parts.•

Service door sensor/switch: Electrical power is disconnected immediately when the service door is •

opened, thus preventing electrical shock during maintenance.

Cooling water flow sensor: Stops a running distillation.•

Optional level sensors for reagent and waste tank: A running distillation is interrupted when the •

tanks are too full or too empty respectively.

Drip tray: Collects overflowing liquids.•

Automatic chemical dosage: Ensures the use of homogeneous liquid amounts.•

10 KjelFlex K-360 Operation Manual, Version C

Page 11

2.6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument. Legal regulations, such as local, state and federal laws

applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is operated in proper condition only, and

that maintenance, service, and repair jobs are performed with care and on schedule, and by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system

performance and reliability. Any modifications to the spare parts used are only allowed with the prior

written permission of the manufacturer.

2 Safety

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written

approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized

Buchi technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

11 KjelFlex K-360 Operation Manual, Version C

Page 12

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery,

technical data, requirements and performance data.

3.1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products see www.buchi.com or contact your local dealer.

3.1.1 Standard instrument

3 Technical data

Table 3-1: Standard instrument

Product Order number

KjelFlex K-360 Standard with glass

splash protector, 230 V, 50/60 Hz

KjelFlex K-360 Standard with splash

protector made of fiber glass reinforced

polypropylene, 230 V, 50/60 Hz

KjelFlex K-360 with glass splash

protector and acid resistant pump, 230 V,

50/60 Hz

KjelFlex K-360 with splash protector

made of fiber glass reinforced polypropylene and acid resistant pump, 230 V,

50/60 Hz

KjelFlex K-360 Standard with glass

splash protector and titration set, 230 V,

50/60 Hz

KjelFlex K-360 with splash protector

made of fiber glass reinforced polypropylene and titration set, 230 V, 50/60 Hz

KjelFlex K-360 with glass splash

protector, acid resistant pump and titration set, 230 V, 50/60 Hz

KjelFlex K-360 with splash protector

made of fiber glass reinforced polypropylene, acid resistant pump and titration

set, 230 V, 50/60 Hz

43600

43601

43605

43604

43607

43606

43609

43608

12 KjelFlex K-360 Operation Manual, Version C

Page 13

3.1.2 Standard accessories

1

8

2

3 Technical data

Table 3-2: Standard accessories

Product Order number

Mains cable of the following types

Type CH 10010

Type Schuko 10016

Type GB 17835

Type AUS 17836

Type USA 33763

Type Japan 10016

a Pair of glass tongs 02004

7

6

b Cooling water hose complete: G ¾",

½", L = 1.5 m

c Hose cooling water drain, silicone,

3

4

5

L = 1.8 m, Ø 14/10 mm

d Weighing boats 40444

e Hose chemical supply, Solaflex,

37780

43439

43185

L = 6 m, Ø 10/5 mm

f 3 suction hoses to tanks, FEP,

43407

L = 580 mm

g Hose waste drain, EPDM,

43457

L = 1.8 m, Ø 18/11 mm

for acid resistant pump

h Hose Viton (acid resistant),

43693

L = 1.2 m, Ø 6/3 mm

(only supplied for instruments with

acid resistant pump)

4 clamps Ø 11.9 43841

i 3 tanks 10 l, without caps 43410

j 1 cap for 10 l tanks, large 25869

9

k 12 tank labels 43434

11

10

12

l 1 cap for 10 l and 20 l tanks, small 43477

Operation Manual:

English 93176

German 93177

French 93178

Italian 93179

Spanish 93180

13 KjelFlex K-360 Operation Manual, Version C

Page 14

3.1.3 Optional accessories K-360

1

7

2

5

3

6 8

3 Technical data

Table 3-3: Optional accessories K-360

Product Order number

a Sample tube (set of 4), 500 ml 43982

b Set of sample tubes (set of 4), 300 ml 37377

c Receiving vessel 420 ml 43390

4

d Receiving vessel 340 ml 43333

Tanks without level sensors, including caps

e 10 l chemicals 43468

e 10 l waste 43470

h 20 l chemicals 43469

h 20 l waste 43471

Tanks with level sensors, including caps

g 10 l chemicals 43472

g 10 l waste 43374

f 20 l chemicals 43473

f 20 l waste 43475

Indicator according to Sher, 100 ml 03512

External PC keyboard (US) 31456

External PC keyboard (D) 31457

External dosage device for back titration,

43367

115 V

External dosage device for back titration,

43596

230 V

Cable for external dosage device for back

43621

titration (Schott Titronic)

14 KjelFlex K-360 Operation Manual, Version C

Page 15

3 Technical data

Table 3-3: Optional accessories K-360

Product Order number

Sample tube holder for 4 sample tubes,

16951

500 ml each

Holder for 6 sample tubes, 300 ml 43039

Holder for 12 sample tubes, 300 ml 43041

Titration set 43698

Splash protector for Devarda method 43335

Connection cable to:

Mettler (DL15 / 22) titrator

Metrohm (785 / 719 / 702)

Mettler (Txx) titrator

43616

43617

Metrohm (848) titrator 11055333

Schott titrator 43618

Radiometer titrator 43619

Adapter for Metrohm 719 / 702 47803

15 KjelFlex K-360 Operation Manual, Version C

Page 16

3 Technical data

Table 3-3: Optional accessories K-360 (cont.)

Product Order number

SO2 accessory 48680

IQ/OQ set for K–360, English 93189

IQ/OQ set for K–360, German 45541

Repeating OQ, English 11055493

Repeating OQ, German 11055494

3.2 Technical data K-360

Table 3-4: Technical data K-360

Power consumption max. 2.2 kW

Connection voltage 220 - 240 VAC ± 10%

Frequency 50/60 Hz

Mains connection 3-pole (P, N, E) via power cord

Recovery rate ≥ 99.5%

Reproducibility (RSD) ≤ ± 1%

Detection limit ≥ 0.1 mg Nitrogen

Vapor output control 30 - 100%

Environmental conditions

Temperature

Altitude

Humidity

Installation category II

Pollution degree 2

Dimensions (W x H x D) 405 x 660 x 400 mm

Weight 22 kg

Printer interface USB 2.0, PCL 6

KjelFlex K-360

for indoor use only

5 - 35 °C

up to 2000 m

maximum relative humidity 80% for temperatures up to

31 °C decreasing linearly to 67% relative humidity at

35 °C

16 KjelFlex K-360 Operation Manual, Version C

Page 17

3.3 Titration solution

The amount of sample and the concentration of the titrant should be optimized, so that the titrant

volume is between 2 and 18 ml (burette volume: 20 ml).

Table 3-5: Titration solution 1

N-amount N-content Sample size Titrant Titrant concentration Titrant volume

5 mg N 0.5 % N 1 g

10 mg N 1.0 % N 1 g

50 mg N 5 % N 0.1 g

100 mg N 10 % N 1 g

100 mg N 10 % N 1 g

200 mg N 20 % N 1 g

200 mg N 20 % N 1 g

Table 3-6: Titration solution 2

P-content P-factor N-content Sample size Titrant Titrant concentration Titrant volume

1 % P 6.25 0.16 % N 2 g

2 % P 6.25 0.32 % N 1 g

5 % P 6.25 0.80 % N 2 g

10 % P 6.25 1.6 % N 2 g

10 % P 6.25 1.6 % N 2 g

20 % P 6.25 3.2 % N 2 g

50 % P 6.25 8.0 % N 2 g

H2SO

H2SO

H2SO

H2SO

H2SO

H2SO

H2SO

4

4

4

4

4

4

4

H2SO

H2SO

H2SO

H2SO

H2SO

H2SO

H2SO

3 Technical data

0.01 mol/l

0.05 mol/l

0.01 mol/l

0.25 mol/l

0.5 mol/l

0.5 mol/l

1 mol/l

4

4

4

4

4

4

4

0.01 mol/l

0.01 mol/l

0.1 mol/l

0.1 mol/l

0.25 mol/l

0.25 mol/l

0.5 mol/l

17.8 ml

7.1 ml

17.8 ml

14.3 ml

7.1 ml

14.3 ml

7.1 ml

11.42 ml

11.42 ml

5.71 ml

11.42 ml

4.57 ml

9.14 ml

11.42 ml

General recommendation

Hydrochloric acid has the disadvantage of degassing. Therefore Buchi recommends to use sulfuric

acid as titrant.

The correction factor for self prepared solutions is called a titer.

The use of standardized titration solutions make a titer determination unnecessary.

Exact titrant concentration = concentration x titer

The titer of the titrant must be known. In case, it is unknown, it must be determined.

Example: Exact titrant concentration = 0.100 mol/l x 0.998

3.4 Reference substances

Table 3-7: Reference substances

Name Purity % N theoretical

Ammonium

dihydrogen

phosphate

Glycine 99.7 18.66 0.5 g c(H2SO4) = 0.25

Phenylalanine 99.0 8.47 0.9 g c(H2SO4) = 0.25

Ammonium

sulfate

99.5 12.18 0.8 g c(H2SO4) = 0.25

99.5 21.21 0.4 g c(H2SO4) = 0.25

(100 % purity)

Recommended

sample size

Recommended titrant

concentration

mol/l

mol/l

mol/l

mol/l

Digestion necessary

No

Yes

Yes

No

17 KjelFlex K-360 Operation Manual, Version C

Page 18

3.5 Materials used

Table 3-8: Materials used for the K-360

Component Material designation Material code

Housing Polyurethane PUR / UL V0

Glass parts Borosilicate glass 3.3 DIN/ISO 3585

Steam generator isolation Ceramic fiber Multitherm 550

Steam generator housing Stainless steel 1.4301

Protective door Polymethyl methacrylate PMMA

Condenser cover Polymethyl methacrylate PMMA

Connecting stopper Hypalon CSM

Plastic splash protector Glass fiber reinforced polypropylene PP

Stop-cock Polypropylene/polyethylene PP/PE

3 Technical data

18 KjelFlex K-360 Operation Manual, Version C

Page 19

4 Description of function

This chapter explains the basic principle of the instrument, shows how it is structured and gives a

functional description of the assemblies.

4.1 Instrument overview

4

4 Description of function

1

2

3

a Splash protector

b Sample tube

c Protective door

Fig. 4.1: Instrument overview

5

6

d Condenser

e Operating panel

f Service door

19 KjelFlex K-360 Operation Manual, Version C

Page 20

4.2 Function principle

The KjelFlex K-360 is suitable for determining nitrogen using the Kjeldahl (TKN; Total Kjeldahl Nitrogen)

and Devarda methods as well as for other distillations of steam-volatile substances (e.g. of alcohol,

SO2, volatile acids).

2

4 Description of function

a Sample tube

3

4

5

b Splash protector

c Steam generator

d Condenser

e Distillate outlet tube

f Receiving vessel with receiver solution

1

Fig. 4.2: Function principle

Steam is introduced into the sample solution (in sample tube a) to drive out volatile components

(such as ammonia, alcohol, etc.). After condensation (in condenser d) the distillate is collected in a

receiver solution (in receiving vessel f).

4.3 Kjeldahl applications

Determination of nitrogen/protein.

For system configuration with reagent-pump:

Warnmeldung

4.4 Non-Kjeldahl applications

Typical examples for non-Kjeldahl methods.

6

Determination of:

SO•

2

Phenol•

Formaldehyde•

TVBN•

Alcohol•

Volatile acids•

20 KjelFlex K-360 Operation Manual, Version C

Page 21

4 Description of function

!

Fig. 4.3: Stop-cock

The stop-cock is located at the inside of the service door.

To carry out a Kjeldahl application the stop-cock must be in downwards position.

To carry out a non-Kjeldahl application the stop-cock must be in horizontal position.

CAUTION

Risk of burnings by hot machine parts and water steam.

Let the system cool down before performing any service.•

Do not operate the instrument when enclosure is open or removed.•

Notice

Wrong stop-cock setting will result in system overpressure. Tubing may come off.

Set stop-cock to correct working-position.•

21 KjelFlex K-360 Operation Manual, Version C

Page 22

4 Description of function

NOTE

A warning message will be displayed, when the method is changed from a Kjeldahl to a non-Kjeldahl

method or vice versa:

Fig. 4.4: Warning message on the display Fig. 4.5: Warning message on the display

4.5 Operational elements of the instrument

1

3

3 3

2

3

4

5

a Stop button to stop a process

b Display

c Functional buttons to operate the software

d Navigation buttons to navigate within the

software

e Start button to start a process like preheating,

priming, cleaning, etc.

f Enter button to move forward within the sub-

menu structure

g Escape button

h Delete button to delete a digit entered via the

keypad

i Keypad

6

9

7

8

Fig. 4.6: Controls of the instrument

22 KjelFlex K-360 Operation Manual, Version C

Page 23

5 Putting into operation

L

N

IEC-60320, Type: C13

!

This chapter describes how the instrument is installed and gives instructions on initial startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company.

Keep the original packaging for future transportation.

5.1 Installation site

Install the instrument on a clean, flat and stable base and place the tanks for chemicals beside the

instrument (not higher and not more than 1 m lower).

Notice

Reduced instrument safety and lifetime due to improper handling and installation location.

Do not place any object on top of the instrument.•

Keep a free safety space of 30 cm around the instrument.•

Do not place items behind the instrument.•

Do not operate the instrument within an fume cabinet.•

5 Putting into operation

5.2 Electrical connections

Fig. 5.1: Electrical connections

Death or serious burnings by electric shock.

Mains voltage must match the voltage reading on the type plate.•

Instrument must be earthed by the mains socket.•

Only use a molded 3-pole device plug (IEC-60320, type C13 or C15).•

Do not use damaged cables.•

WARNING

23

KjelFlex K-360 Operation Manual, Version C

Page 24

5.3 Reagent and water connections

5 Putting into operation

a H3BO3 inlet from tank

b H2O inlet from tank

1

2

3

4

c NaOH inlet from tank

d Reagent inlet for acid resistant pump

e Cooling water inlet

f Cooling water outlet

g Drain to waste

Fig. 5.2: Reagent and water connections

All pumps are self-priming, no overpressure is necessary at the tanks.

5.3.1 Cooling water connection

The water pressure should be at a maximum of 4 bar. The built in valve reduces the water flow to 1.2

liters per minute.

The flanged screw coupling for the water connection has a standard screw thread of G ¾”.

5.3.2 Drainage of cooling water

Place the drain hose for the cooling water directly into the drain. For this purpose, shorten the silicone

hose to the optimal length. The drain hose should not show any kinks, sharp bends and/or siphoning

effect. Prevent flooding inside and outside the instrument by securing the drain hose.

5

6

7

24 KjelFlex K-360 Operation Manual, Version C

Page 25

5.3.3 Waste/aspiration hoses

The distillation and sample residue can be aspirated and collected separately from the cooling water.

For this purpose a separate collection tank is necessary. The collection tank must be located lower

than the instrument to guarantee proper drainage.

Connect the waste/aspiration hose to the waste outlet and place it directly into the drain (sink). For this

purpose, shorten the EPDM hose to the optimal length. In order to prevent any back-flow, the hose

may be placed maximum 10 cm into the tank.

5.3.4 Storage tank connection

To connect the storage tanks, proceed as follows:

Cut the solaflex hose into pieces of the appropriate length (use a Viton hose for the acid resistant •

pump).

Insert a FEP suction hose into the solaflex hose.•

Push an EPDM sealing ring over the solaflex hose.•

Now fasten the hoses to the tank with the red screw cover.•

Connect the hoses at the appropriate connections at the instrument side and secure them with the •

clamps.

5 Putting into operation

Fig. 5.3: Tank connection

Notice

Possible instrument damage by calcification or corrosion.

Use only distilled water in the H•

Do not mix up liquids at the instrument inlets, observe the inlet labelling.•

O storage tank to operate the system.

2

25

KjelFlex K-360 Operation Manual, Version C

Page 26

5.4 Level sensors (optional)

Level sensors are optionally available for all Buchi tanks. The individual sensors are connected to the

corresponding socket.

H2O: Connection to the tank with distilled water for the steam generator and sample tube.

NaOH: Connection to the tank with sodium hydroxide.

H3BO3: Connection to the tank with boric acid.

Waste: Connection to the waste tank.

The length of the level sensor for chemicals can be adapted by means of the the rubber cap, see Fig.

5.4.

NOTE

The level sensor for the waste tank must be set active at: Configuration, Settings, Level Sensor

Waste. This is not necessary for the other sensors.

5 Putting into operation

Fig. 5.4: Adapting the length of the level sensor

Adapt the length of the level sensor for chemical by moving up and down the rubber cap according to

the size of the tank.

5.5 Connections to peripheral devices

6

1

7

2

3

4

8

5

9

The following instruments and accessories can

be connected to the K-360:

a Level sensors

b TTL interface to a titrator

c TTL interface to a dispenser (external

dosage device for back titration)

d USB interface to a printer

e USB interface (for service purposes)

f COM1 (reserve)

g RS interface to a dispenser

h RS interface to a titrator

i External keyboard

Fig. 5.5: Connections to peripheral devices

26 KjelFlex K-360 Operation Manual, Version C

Page 27

5.5.1 Connecting a printer

The K-360 supports printers with USB port and language PCL 3 or higher (e.g. PCL 5, PCL 5e, PCL

6, PCL 7 etc.) which are available e.g. from Hewlett Packard or Lexmark.

The printer is connected to the USB port.

To print out the results directly after each determination, go to Configuration > Titrator and set Print

Data to Yes. You also have to configure the titrator for data printout. For this purpose, please consult

the corresponding manual.

The following printers have been tested together with the K-360:

HP Color LaserJet 3700DN•

HP Deskjet 1280c•

Brother mfc 8820d•

Lexmark E120•

Lexmark E240•

HP OfficeJet Pro K550•

Brother HL-5240•

OKI B4250•

The following printer causes problems:

HP LaserJet 1022•

5 Putting into operation

5.5.2 External keyboard

As an option, an external keyboard can be connected to the instrument to make data entry more

comfortable. The internal keyboard is still active, even if an external keyboard is connected.

Special functions on the external keyboard are:

Table 5-1: External keyboard

K-360 keyboard External keyboard

START F3

STOP F2

Function key below display F5...F8

Other functions (e. g. up/down) are the same as on the internal keyboard.

27 KjelFlex K-360 Operation Manual, Version C

Page 28

5.6 Boric acid titration and back titration

5 Putting into operation

The K-360 offers the possibility to work with boric

acid titration or back titration. It is recommended

to choose a permanent configuration as different

hardware is needed to convert between the two

titration methods.

Buchi recommends to work with boric acid titration.

Boric acid titration

Receiving vessel: Boric acid solution 2 % or 4 %,

adjusted to pH 4.65.

Titrant: Standardized sulfuric acid solution or hydrochloric acid solution

It is recommended to use boric acid solution 4 %,

adjusted to pH 4.65 and standardized sulfuric acid

solution.

Fig. 5.6: K-360 for boric acid titration (with titrator)

The K-360 includes all necessary hardware to

work with boric acid titration. Boric acid is dosed

via the integrated pump.

Back titration

Receiving vessel: Standardized sulfuric acid

Titrant: Standardized sodium hydroxide solution

An external dosage device must be connected for

the exact addition of the receiving solution. See

chapter 6.4.6 for information on the installation

and set-up of the external dosage device.

Fig. 5.7: K-360 for back titration (with external dosage device)

28 KjelFlex K-360 Operation Manual, Version C

Page 29

6 Operation

!

!

This chapter gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely.

CAUTION

Risk of cuts by defective glassparts.

Handle glassparts with care.•

Exchange defective glassparts directly.•

Do not operate the instrument when glassparts are damaged.•

WARNING

Serious chemical burnings by corrosives.

Observe supplementary data sheets of all used chemicals.•

Wear protective goggles.•

Wear protective gloves.•

Wear protective clothing.•

6 Operation

NOTE

Close unused connections with plug caps.

29 KjelFlex K-360 Operation Manual, Version C

Page 30

6.1 Overview over the software structure

Main menu 2nd stage 3rd stage 4th stage

1 Determination Sample List

2 Preheating

6 Operation

H2O, NaOH, H3BO3,

(Reagent) volumes

Reaction Time

Steam Power

3 Priming Priming Method

4 Cleaning Cleaning Method

5 Aspiration Aspiration Method Aspirate Sample

6 Results Result List

7 Methods Method List

Distillation Time

Titration Start

Titr. Type

Stirrer Speed

Aspiration Sample / Receiver

H2O

Steam Power

Distillation Time

Aspirate Receiver

30 KjelFlex K-360 Operation Manual, Version C

Page 31

6 Operation

Main menu 2nd stage 3rd stage 4th stage

8 Configuration

1 Pump Calibration

2 Set Date and Time Date / Time Details

3 Settings

4 Titrator

Calibration of: H2O, NaOH,

H3BO3, (Reagent) Pump

Language

Display Contrast

Demo Mode

Endless Mode

Level Sensor Waste

Rec. Vessel Present

Reagent Pump

Print Data

Titrator Present

Titrator Signals

Signal “ready”

5 Dispenser Signal “active”

6 User / Password User / Password List

7 Keypad Keypad Time

Dispenser Signals

Signal “end”

31 KjelFlex K-360 Operation Manual, Version C

Page 32

6 Operation

Main menu 2nd stage 3rd stage 4th stage

Valves

Pumps

Stirrer

Alarm

1 Operational Tests

Steam Unit

Titrator

Dispenser

Battery

Cooling Water Flow

Tube Shield Switch

9 Diagnostics

2 Test Sensor

3 Test Printer

4 Operating Hours

Tube Present Check Switch

Service Door Switch

Steam Unit

Level Sensors

Titrator

Dispenser

Voltage

Temperature

Print Page

Formfeed

Reset

Steam Generator

Number of Distillations

32

Production Date

Serial Number

5 Hardware Info

CPU

PCB

6 Service Test

KjelFlex K-360 Operation Manual, Version C

Page 33

6.2 General information on buttons

The following control buttons are available in the software for navigation and input confirmation:

Go to the main menu

Confirm a message and get back to the previous screen

Save

Close a screen (without saving) and get back to the previous one

Delete

Edit

Mark the currently highlighted result/method in the list as first result/method on a report

Mark the currently highlighted result/method in the list as last result/method on a report

6 Operation

Add 10 ml of H2O

Add 10 ml of H3BO

Add 10 ml of NaOH

Add 10 ml of reagent

Go to the method screen to view, define or edit a method

Go to the Method List screen

Print

Switch from Standby to Ready mode

Go to the sample screen to define a sample

Switch from Ready to Standby mode

Go to the status screen to view the status, the time and the user logged in

Reset the operating hours / numbers of distillation

3

Switch to the screen with Operational Tests

Switch to the screen with Test Sensors

Switch to offline operation in the Operational Tests screen

Switch to online operation in the Operational Tests screen

Run the pump in the Pump Calibration screen

Calibrate the pump in the Pump Calibration screen

33 KjelFlex K-360 Operation Manual, Version C

Page 34

Change password

Define a new user

Switch to previous screen e.g. in Service Test

Switch to next screen e.g. in Service Test

Confirm a message or affirm a question

Negate a question

Backward button to move to the previous digit

Forward button to move to the next digit

6 Operation

Move up within the entries of a screen

Move down within the entries of a screen

6.3 Overview on how to prepare the instrument for routine operation

Configure the software according to the following steps to prepare it for routine operation:

Standard instrument configuration1.

Distillation methods2.

System preparation3.

Individual working methods4.

6.3.1 Standard instrument configuration

This configuration consists of typical settings, which have to be defined before the instrument is used

for the first time. As long as the instrument is not updated or extended by any additional optional

accessory these settings do not have to be changed again.

The settings are carried out in the menu Configuration.

6.3.2 Distillation methods

The distillation methods you like to use can be defined in the menu Method. For this purpose you use

an existing Buchi standard method and modify it to your needs. Thus you can define up to 50 individual methods according to e.g. distillation time, aspiration yes/no, volume of boric acid/NaOH/water,

etc.

6.3.3 System preparation

The system preparation is carried out every day before the instrument is taken into operation and an

analysis is started. It consists of e.g. filling the hoses and priming the system.

34 KjelFlex K-360 Operation Manual, Version C

Page 35

6.3.4 Individual working method

The software offers two working methods for sample determination, the single sample analysis and

the rack oriented analysis.

Single sample analysis

This working method is straight forward and is used especially when you are not interested in sample

name input and storing the volume consumption of the titrant solution in the system memory, see also

chapter 6.8.1.

Rack oriented analysis

Here all sample names and the corresponding weight is entered prior to determination. The volume

consumption of the titrant solution is stored together with the sample name, see also chapter 6.8.2.

You can switch between these two working methods at any time.

6.4 Configuring the instrument

6 Operation

To configure the instrument in the Main Menu go to Configuration and press Enter. The following

screen appears:

Fig. 6.2: Configuration

NOTE

To access the individual menus you can either use the arrow keys to move up and down in the list

and press Enter or the Forward button or you can type in the number of the corresponding menu

directly (e.g. 3 for Settings).

35 KjelFlex K-360 Operation Manual, Version C

Page 36

6.4.1 Pump calibration

Go to Pump Calibration and press Enter. The following screen appears:

Fig. 6.3: Pump calibration

It is recommended to calibrate the pumps with the same volume as used for the methods. To perform

the calibration a graduated cylinder is needed.

To carry out the pump calibration, proceed as follows:

Choose the required pump by pressing left / right arrow repeatedly, when e.g. “H•

Enter the quantity to be dosed (Dose Volume), e.g. 50 ml.•

Press Run to start dosing.•

Measure the dosed volume and enter the measured volume.•

Press Cal to calibrate the pump. When the calibration is finished a corresponding calibration factor •

appears.

6 Operation

0” is highlighted.

2

NOTE

Repeat this procedure until the entered and the dosed volume correspond. An acceptable difference

at 50 ml is ±2 ml. NaOH/H2O/Reagent can be dosed into the sample tube and then poured into a

graduated cylinder. H3BO3 is dosed directly into the receiving vessel and then poured into a graduated cylinder.

It is recommended to repeat the pump calibration regularly (once a month or every 100 distillations).

6.4.2 Setting date and time

Go to Set Date and Time and press Enter. The following screen appears:

Fig. 6.4: Date/Time

Enter the corresponding settings via keypad and press Save to store them.

36 KjelFlex K-360 Operation Manual, Version C

Page 37

NOTE

The day, month and year settings can be entered with one or two digits.

6.4.3 Defining general instrument settings

Go to Settings and press Enter. The following screen appears:

6 Operation

Fig. 6.5: Settings

The following settings can be entered:

Language•

Display Contrast•

Demo Mode•

Endless Mode•

Level Sensor Waste•

Receiving Vessel present•

Reagent pump present•

Enter the desired settings via arrow buttons and press Save to store them. These settings have to be

defined before the instrument is used for the first time.

6.4.4 Defining the titrator settings

Go to Titrator and press Enter. The following screen appears:

Fig. 6.6: Titrator

Press Edit to edit the settings. By changing the number at “Titrator present” the settings for the titrators listed in the following table will be adjusted automatically.

37 KjelFlex K-360 Operation Manual, Version C

Page 38

6 Operation

Table 6-1: Titrator settings

Titrator present Configuration Signal ready Signal active Signal end Baud Data bit Parity Stop bit

1 e.g. Mettler Toledo DL 15/22 Low No RS232 9600 8 no 2

2 e.g. Mettler Toledo T50/Txx No No RS232 4800 8 even 1

3 e.g. Metrohm Food Titrino

No No RS232 9600 8 no 1

DMP785 / 719 / 702

4 e.g. Schott TitroLine Easy No RS232 RS232 4800 7 no 1

5 e.g. Radiometer TitraLab 840 Low High Low 9600 8 no 1

6 e.g. Metrohm 848 Plus Low High RS232 19200 8 no 1

Custom other titrators

When you have selected “Custom” you can enter the corresponding settings via the arrow buttons

and press Save to store them.

At the moment there are the following titrator types that enable a signal transfer and thus an automatic

result display in the K-360 software:

Mettler Toledo DL 15 / 22 / Txx•

Schott TitroLine Easy•

Metrohm Titrino DMP 785 / 719 / 702 / 848 Plus•

To assure a correct signal transfer, the respective titrator has to be configurated according to the

Büchi specifications.

6.4.5 Boric acid / end point titration

Receiving vessel: see chapter 5.6

Titrant: see chapter 5.6

It is recommended to use boric acid solution 4%, adjusted to pH 4.65 and standardized sulfuric acid

solution.

Titrate the distillate with sulfuric acid standard solution to the end point of pH 4.65.

Defining settings to work with a titrator

Configuration > Settings > Rec Vessel present: Yes

Configuration > Titrator: Titrator present: (1, 2, 3, 4, 5, 6, Custom)

Methods > Select the corresponding method from the method list and press Enter

> Aspiration Sample: Yes

> Aspiration Rec. Sol’n: Yes

Defining settings without a titrator

Configuration > Settings > Rec Vessel Present: No

Configuration > Titrator: Titrator present: No

Methods > Select the corresponding method from the method list and press Enter

> Aspiration Sample: Yes

38 KjelFlex K-360 Operation Manual, Version C

Page 39

6.4.6 Back titration with dispenser

External dosage device for back titration

The external dosage device is connected to the port for the manual key button. The volume of the

receiving solution must be entered at the external dosage device. For this purpose, refer to the Operation Manual of the dosage device.

The K-360 sends an impulse to the connected device to start the dosing procedure.

Receiving vessel: Standardized sulfuric acid

Titrant: Standardized sodium hydroxide solution

Defining the K-360 settings for back titration

The following setting at the K-360 is a prerequisite for working with a dispenser:

Method > Titr. Type > Back Titration

Go to Configuration > Dispenser and press Enter. The following screen appears:

6 Operation

Fig. 6.7: Dispenser

Enter the corresponding settings via the arrow buttons and press Save to store them.

Table 6-2: Dispenser settings

Configuration Signal ready Signal active Signal end

Schott Titronic universal No No 60 s

6.4.7 Defining user and password settings

Go to User/Password and press Enter. The following screen appears:

Fig. 6.8: User/Password

39 KjelFlex K-360 Operation Manual, Version C

Page 40

6 Operation

To define a new user, press New. The following screen opens:

Fig. 6.9: User

Enter a new name and a password. To change your password, enter a new one and confirm it. Press

Save to store your settings.

NOTE

A password is not mandatory.

When a password is used the corresponding user is indicated on the result printout list.•

When a password is forgotten, the determination can be started with the Buchi default login: •

User name: buchi, password: buchi01.

When the Buchi default login is used, all other passwords will be deleted.

6.4.8 Defining the keypad settings

Go to Configuration > Keypad and press Enter. The following screen appears:

Fig. 6.10: Keypad

Set the desired Edit Time, i.e. the waiting time until a new character can be typed in, and press Save

to store your setting.

40 KjelFlex K-360 Operation Manual, Version C

Page 41

6.5 Defining a distillation method

The Standard method that is stored in the instrument cannot be deleted. It can be used as basis to

define further methods. Up to 50 different methods can be saved.

To define a method in the main menu go to Methods and press Enter. The Standard Method is

displayed in the Method List by default. Press Enter again, the following screen appears:

6 Operation

Fig. 6.11: Method

A method consists of the following settings:

Name•

User•

Amount of chemicals to be dosed (H•

O / NaOH / H3BO3 / Reagent)

2

Reaction time•

Titration type•

Stirrer speed (Distillation / Titration)•

aspiration (Sample / Receiving vessel)•

To define a new method, press Edit and enter the corresponding settings. Then press Save to store

them.

NOTE

For Kjeldahl applications define a volume of H2O and NaOH, for non-Kjeldahl applications, define the

volume of your used reagent (acid).

A list of all defined methods is displayed on pressing the List button:

Fig. 6.12: Method list

To print out a method, highlight the method-name in the list and press Print.

41 KjelFlex K-360 Operation Manual, Version C

Page 42

6.6 Instrument modes

The instrument has two different modes, Standby and Ready. In Ready mode the steam generator

heats continuously, so that a distillation can be started immediately. When the instrument is not operated for thirty minutes, it switches to Standby mode and stops heating to save electric power. When

it is switched back to Ready mode, it has to heat up first. You can see the icon “Process in progress”

(see position 3 in Fig. 6.8.3) flashing during heating.

6 Operation

Fig. 6.13: Standby mode

To switch from Standby to Ready mode, press Menu and subsequently Ready.

6.7 System preparation

6.7.1 Preheating

The glass parts of the distillation system have to be preheated prior to analysis. Use a clean and

empty sample tube for this processing. It is recommended to perform a preheating, when the glass

(splash protector) has cooled down. The preheating time is predefined.

6.7.2 Priming

This preparation procedure includes distillation and titration with a clean and empty sample tube. It is

recommended to perform a priming at least once a day, before starting analysis. The priming method

can be modified.

6.7.3 Cleaning

At the end of a day, the system should be rinsed thoroughly by carrying out a cleaning. The splash

protector and the condenser are rinsed with water to remove sodium hydroxide residues. With regular

cleaning, the lifetime of the glass parts can be extended. The cleaning method is predefined, but can

be modified and adapted to the size of the sample tube.

6.7.4 Aspiration

With this procedure sample residue in the sample tube and titration residue in the receiving vessel can be

aspirated.

42 KjelFlex K-360 Operation Manual, Version C

Page 43

6.8 Carrying out a distillation

To carry out a distillation, proceed as follows:

Switch on the instrument and wait until the steam generator is ready.•

Insert the sample tube containing the sample.•

If you do not work with the titration set, prepare a conical flask or a similar receptacle with a volume •

of about 250 ml as receiving vessel.

For sample analyses there are two different approaches, depending on how you prefer to work:

Single sample analyses•

Rack oriented analyses•

6.8.1 Single sample analysis

For single sample analyses, no predefined sample list is needed for identification. To start an analysis,

provide a sample and press the Sample button in the main menu. The following screen opens:

6 Operation

Fig. 6.14: Sample

Enter a sample name and sample weight via keypad. Choose the desired method and press Start to

start the distillation process.

NOTE

When you re-enter the screen, sample name, weight, unit, type and method are set to the latest •

entered settings.

You can start a determination at any time without a sample name or weight input.•

43 KjelFlex K-360 Operation Manual, Version C

Page 44

6.8.2 Rack oriented analysis

For the rack oriented analyses all sample data (name, weight, etc.) have to be entered.

The Sample List screen opens:

Fig. 6.15: Sample List

6 Operation

This screen allows to define a Sample List entry for every sample provided. To define a new entry,

press Edit. The Sample screen opens. Enter sample name and weight and press Save. The newly

created entry now appears in the list. Repeat this step for all provided samples.

To start distillation of a sample, enter Determination in the main menu, select an entry and press the

Start button. The distillation starts.

6.8.3 Analysis screen

1

Fig. 6.16: Analysis screen

a Status designation

b Titrator icon (titrator connected)

2

3

c Icon (turning when process is in progress,

4

flashing when instrument is heating, standing

still when instrument is ready)

d Current process step

5

e Name of currently processed sample

f Current date and time

6

g User currently logged in

7

44 KjelFlex K-360 Operation Manual, Version C

Page 45

6.8.4 Result screen

If a titrator has been connected to the K-360, which does not provide direct data transfer, the result

screen opens after a distillation. The corresponding ml-value indicated on the connected titrator can

be manually added under Result via keypad. Press OK to save the entry.

6 Operation

Fig. 6.17: Result screen

In case the connected titrator provides direct data transfer, the result is stored automatically.

If no titrator is connected, no Result screen is displayed.

6.8.5 Result list

To view the list of results measured, go to Results in the main menu and press Enter or just press 6.

The Result List opens:

Fig. 6.18: Result list

The result list can hold a maximum of 500 results. If this number is beeing exceeded, the “oldest”

results in the list will be overwritten successively by new results.

To print out a selection of results, highlight the first result and press the First button. Then highlight the

last result that should appear in the list and press the Last button to define your selection. Now press

Print.

For a detailed printout of a result, highlight a single result in the list and press Print.

45 KjelFlex K-360 Operation Manual, Version C

Page 46

6.8.6 After distillation

If you do not work with the titration set, empty the receiving vessel. The content of the receiving vessel

of the titration set is automatically aspirated at the end of the distillation, if this is configured within the

method.

It is recommended to clean the system using the cleaning method at the end of the day.

NOTE

The water volume can be adapted in the menu Cleaning under H2O.

6.9 Switching ON/OFF checklist

To switch on and preheat the instrument, proceed as follows:

Check the filling level of the supply tanks.•

Open the main water tap.•

Switch on the instrument and wait until the steam generator is ready.•

Insert an empty sample tube and an empty receiving vessel.•

Close the protective door.•

Start the preheating/priming by pressing the Start button in the corresponding menu.•

Start the distillation by pressing the Start button.•

6 Operation

To switch off the instrument, proceed as follows:

Start the cleaning process (see chapter 7.12).•

Rinse the acid resistant pump with distilled water (in case it was used for the dosage of strong •

acids, e.g. HCl).

Switch off the instrument.•

Close the main water tap.•

46 KjelFlex K-360 Operation Manual, Version C

Page 47

7 Maintenance

!

!

!

!

This chapter gives instructions on all maintenance work to be performed in order to keep the instrument in good working condition. All working steps described herein shall only be carried out by trained

personnel. After the maintenance has been finished, the person in charge with this maintenance must

bring the system into standard operating condition (e.g. close the service door) and check the proper

function of the instrument.

WARNING

Death or serious injuries by electric shock.

Switch off the instrument and remove the power cord.•

Do not bring any electrical component into contact with fluids.•

Do not operate the instrument when enclosure is open or removed.•

CAUTION

Risk of burnings by hot machine parts and water steam.

Let the system cool down for 30 minutes before performing any service.•

Do not operate the instrument when enclosure is open or removed.•

7 Maintenance

WARNING

Death or serious burnings by flammable vapors.

Remove all sources of flammable vapor.•

Avoid spark formation.•

Do not operate with open flames.•

WARNING

Serious chemical burnings by corrosives.

Observe supplementary data sheets of all used chemicals.•

Wear protective goggles.•

Wear protective gloves.•

Wear protective clothing.•

Note

The service door may only be opened for maintenance or service purposes and to switch the stopcock

47 KjelFlex K-360 Operation Manual, Version C

Page 48

7.1 Daily maintenance

Regular cleaning is vital to ensure proper instrument functioning. Thus the deposits of caustic

substances within the instrument (e.g. causing degradation of glassware) can be avoided.

7.1.1 Cleaning the housing

Check the housing for defects (switches, plugs) and clean it with a damp cloth.

NOTICE

Risk of housing damage by solvents and acids.

Open the service door and perform a visual check of all parts inside. Make sure that there is no leaking

at hoses and valves.

7 Maintenance

Do not clean the housing with solvents.•

Wipe off any acid drops immediately.•

7.1.2 Cleaning the glass parts

To extend the lifetime of the glass parts, we recommend to perform a cleaning at the end of the day.

For this purpose in the main menu select “Cleaning” and press the Start button. The system will start a

distillation with 300 ml water for a period of 5 minutes.

48 KjelFlex K-360 Operation Manual, Version C

Page 49

7.1.3 Cleaning the rubber bung seal

Clean the seal with a damp cloth.

7.2 Monthly maintenance

7.2.1 Calibrating the pumps

We recommend to calibrate the pumps once a month or every 100 distillations. Before calibrating the

pumps, make sure that the hoses are not bent inside the instrument. For a description on how to carry

out the calibration, see chapter 6.4.1.

7.2.2 Checking the distillate amount

To check the distillate amount, wait until the steam generator is ready, i.e. the preheating has been

performed. Then run a single sample with an empty tube and an empty receiving vessel with the

following parameters:

7 Maintenance

Table 7-1: Checking the distillate amount

Parameter Setting

Check distillate amount: Distillation

Sample tube: empty

Water: 0 ml

NaOH: 0 ml

Distillation time: 5:00

Measure the distillate amount by means of a measuring flask. With the above parameters it should be

minimum 130 ml.

7.3 Maintenance as required

We recommend to replace the parts listed in this chapter depending on the instrument use or at least

once a year.

7.3.1 Cleaning the splash protector

Glass splash protector:

It is recommended to unmount the splash protector if residues are visible in its upper part. It can be

cleaned with commercially cleaning agent or in an ultrasonic bath.

Plastic splash protector:

It is recommended to unmount the splash protector if you see the blank values continually increasing.

It can be cleaned with commercially cleaning agent or in an ultrasonic bath.

When unmounting the splash protector for cleaning, clean the seal as well to prolong its lifetime.

Rinse it with water, dry it with a soft cloth, remount it and put the splash protector back in place.

49 KjelFlex K-360 Operation Manual, Version C

Page 50

NOTICE

Risk of sealing damage by sharp edges or lubricants.

When installing, move sealing in perpendicular axis to the glass parts.•

Do not touch sealing with potentially sharp objects.•

Do not apply grease or any other lubricant to the sealing.•

For further information on how to unmount and remount the splash protector, see chapter 7.3.3.

7.3.2 Replacing the splash protector

Replace the Splash protector after approximately 5000 determinations.

7.3.3 Replacing the rubber bung seals and the splash protector

We recommend to replace the parts listed below depending on the instrument use, at least once a

year.

7 Maintenance

The seals are subject to wear and tear, thus you should check them regularly. We recommend to

replace them once a year. The following parts need to be replaced (see also the spare parts list):

a Accessories splash protector

2

b Gasket for splash protector, complete

c SVL 22 sealing

3

1

Make sure that the instrument is cooled down.

Open the service door and loosen the two tubings

shown on the picture.

50 KjelFlex K-360 Operation Manual, Version C

Page 51

7 Maintenance

Open the screw-type cap of the hose.

Now loosen the two screws with black head to

remove the metal holder at the front side.

Carefully remove the bracket.

Now unscrew the black plastic screw with a

polygrip. Make sure to do this gently as you might

break the glass parts. This part of the procedure is

the most critical one.

Carefully remove the splash protector.

Unscrew the gasket.

51 KjelFlex K-360 Operation Manual, Version C

Page 52

Pull out the steam tubing.

7 Maintenance

Fig. 7.1: Installing the glass assembly

Exchange all the rubber and plastic parts shown on the first picture of chapter 7.3.3.

Put back the replaced parts in the reverse order and make sure to tighten the screw on top of the

splash protector very carefully with the Polygrip.

7.3.4 Glass parts

Replace the sample tubes and the condenser if broken.

To replace the rubber parts pull off the connecting

screw. The smaller sealing is located inside.

7.3.5 Replacing the hoses

Depending on the applications and the used chemicals, it might be necessary to replace some of the

hoses inside of the instrument to avoid leakages or aspiration problems.

52 KjelFlex K-360 Operation Manual, Version C

Page 53

7.4 Yearly maintenance

7.4.1 Customer service

In order to avoid down times of a KjelFlex, we recommend to have the following parts replaced at least

once a year by an authorized service person:

Membranes of the aspiration module valves•

NaOH pump, the other pumps if required•

Only authorised service personnel are allowed to perform repair work on the instrument. These

persons have a comprehensive technical training and knowledge of possible dangers which might

arise from the instrument.

Addresses of official Buchi customer service offices are given on the Buchi website under:

www.buchi.com. If malfunctions occur on your instrument or you have technical questions or application problems, contact one of these offices.

The customer service offers the following:

Spare part delivery•

Repairs•

Technical advice•

7 Maintenance

7.4.2 Decalcification of the steam generator

To decalcify the steam generator proceed as follows:

Make sure that the steam generator is cooled down (switch off the unit and let it cool down for at 1.

least 30 minutes)

Remove the water of the steam generator (see 9.1 Emptying the steam generator)2.

Mix about 0.8 L of solution for decalcification (use e.g. approx. 160 g citric acid or approx. 80 g 3.

amidosulfonic acid dissolved in 0.8 L water)

Remove the hose from the H4.

Connect a new hose to the H5.

O-inlet on the back of the instrument.

2

O-inlet and put its free end into decalcification solution

2

Switch on the K-3606.

After initialization the pump starts running7.

Switch off the unit after the steam generator is filled up with the solution (pump stops running)8.

Let the solution dissolve the lime for 0.5 – 1 hour9.

Remove the solution of the steam generator (see step 1 and 2)10.

Perform a second decalcification (see step 6 – 10)11.

Connect the hose from the water tank with the inlet of H12.

Flush the steam generator 2 – 3 times with distilled water (see step 6 – 8 and 10)13.

Perform 2 – 3 times a CLEANING (cleaning method) of the instrument14.

O

2

53 KjelFlex K-360 Operation Manual, Version C

Page 54

8 Troubleshooting

This chapter helps to resume operation after a minor problem has occurred with the instrument. It lists

possible occurrences, their probable cause and suggests how to remedy the problem.

The troubleshooting table below lists possible malfunctions and errors of the instrument. The operator

is enabled to correct some of those problems or errors by him/herself. For this, appropriate corrective

measures are listed in the column “Corrective measure”.

The elimination of more complicated malfunctions or errors is usually performed by a Buchi technical

engineer who has access to the official service manuals. In this case, please refer to your local Buchi

customer service agent.

8.1 Malfunctions and their remedy

Table 8-1: General malfunctions and their remedy

Error number / Error indication Possible cause Corrective measure

0 The current process was stopped. Press OK, aspirate manually and start

1 Steam Valve (Y1 on) malfunction. Contact the Buchi customer service

2 Aspiration Out Valve (Y2 on) malfunction. Contact the Buchi customer service

3 Aspiration In Valve (Y3 on) malfunction. Contact the Buchi customer service

4 Receiver Valve (Y4 on) malfunction. Contact the Buchi customer service

5 Cooling Water Valve (Y5 on) malfunction. Contact the Buchi customer service

8 Injection Valve (Y8 on) malfunction. Contact the Buchi customer service

9 Water Valve (Y9 on) malfunction. Contact the Buchi customer service

11 Steam Valve (Y1 off) malfunction. Contact the Buchi customer service

12 Aspiration Out Valve (Y2 off) malfunction. Contact the Buchi customer service

13 Aspiration In Valve (Y3 off) malfunction. Contact the Buchi customer service

14 Receiver Valve (Y4 off) malfunction. Contact the Buchi customer service

15 Cooling Water Valve (Y5 off) malfunction. Contact the Buchi customer service

18 Injection Valve (Y8 off) malfunction. Contact the Buchi customer service

19 Water Valve (Y9 off) malfunction. Contact the Buchi customer service

20 H2O Pump (M1 on) malfunction. Contact the Buchi customer service

21 NaOH Pump (M2 on) malfunction. Contact the Buchi customer service

22 Reagent Pump (M3 on) malfunction. Contact the Buchi customer service

23 H3BO3 Pump (M4 on) malfunction. Contact the Buchi customer service

25 H2O Pump (M1 off) malfunction. Contact the Buchi customer service

26 NaOH Pump (M2 off) malfunction. Contact the Buchi customer service

27 Reagent Pump (M3 off) malfunction. Contact the Buchi customer service

28 H3BO3 Pump (M4 off) malfunction. Contact the Buchi customer service

30 Calibration out of range, check pump. Check connection K-360/tank, check pump

33 The service door is open. If a process was

in progress, it may have been stopped.

34 The splash protector door is open. If a

process was in progress, it may have been

stopped.

8 Troubleshooting

again

Close the service door, start again

Close the splash protector door, start again

54 KjelFlex K-360 Operation Manual, Version C

Page 55

8 Troubleshooting

Table 8-1: General malfunctions and their remedy (cont.)

Error number / Error indication Possible cause Corrective measure

35 There is no sample tube. Sample tube present? Sample tube defec-

tive? Remove the sample tube and put it

back again. Restart the process

37 Boric acid level is low. Do you want to

Refill the boric acid tank

continue determination?

38 Water level for steam generator is low. Do

you want to continue determination?

39 Sodium hydroxide level is low. Do you want

Refill the water tank for the system

generator

Refill the sodium hydroxide tank

to continue determination?

40 Waste tank is full. Do you want to continue

Empty the waste tank

determination?

41 Titrator not ready. Retry? Wait until the titrator is ready, try again

42 Not enough cooling water! Cooling water connected? Cooling water

flowing? Flow sensor may be defective

Contact the Buchi customer service

43 Steam generator not ready. Set status of steam generator to “Ready”

mode until the steam generator is ready

(up to 2 minutes)

44 Steam generator over temperature. Check water connection

45 Cannot reach water level for steam

Fill water tank, check H2O pump

generator.

46 Titrator not ready or not configured. Configure titrator in Configuration menu

47 Dispenser not ready or not configured. Configure dispenser in Configuration menu