Page 1

BÜCHI Distillation Unit K-314

Contents

Contents

1 Scope of Delivery 2

2 Safety 3

2.1 Symbols 3

2.2 Requirements for the operator 3

2.3 Regulation use 3

2.4 Non-regulation use 3

2.5 General hazards 4

2.6 Safety measures 4

3 Function 6

3.1 Principle of operation 6

4 Putting into operation 7

4.1 Setup location 7

4.2. Unpacking 7

4.3 Water supply 7

4.4 Drain hose 8

4.5 Connection of the supply tanks 8

Read these instructions thoroughly before you use the BÜCHI

Distillation Unit K-314. Store these instructions in the immediate vicinity of the apparatus so that they may be consulted at

any time. The unit must only be connected to the mains and

switched on after having completed all necessary preparations.

Chapter 2 contains important safety information. Knowledge

of this is imperative for the safe operation of the Distillation

unit.

Subject to technical change without notice. No part of these

instructions may be reproduced in any form whatsoever or

processed, reproduced or disseminated by means of

electronic or optical systems without the express written

permission of Büchi Labortechnik AG. All rights reserved.

Copyright © Büchi Labortechnik AG 1998

5 Operation 9

5.1 Control elements 9

5.2 Control elements and their function 9

5.3 Start-up Checklist 10

5.4 Supply tanks 10

5.5 Rubber bung and PTFE hose 10

5.6 Sample tube holder 11

5.7 Distillation outlet tube 12

5.8 Connection to the mains 12

5.9 Adjusting the cooling water flow 12

5.10 K-314 switching ON/OFF checklist 12

5.11 Carrying out the Kjeldahl distillation 13

5.12 Cleaning the unit 13

5.13 Malfunctions 14

6 Maintenance 15

6.1 General information and preparations 15

6.2 Maintenance: daily, weekly 15

6.3 Rubber bung and PTFE hose 15

6.4 Cleaning the feeding pump 16

6.5 Changing glass parts 16

6.6 Customer service 16

6.7 Main fuses 17

6.8 Checking the unit 17

7 Taking out of operation 18

7.1 Storage/Transport 18

7.2 Disposal 18

8 Replacement parts 19

9 Appendix 20

en, Version C (22 pages) Order No.

K-314 Operating instructions 96706

1

Page 2

1 Scope of delivery

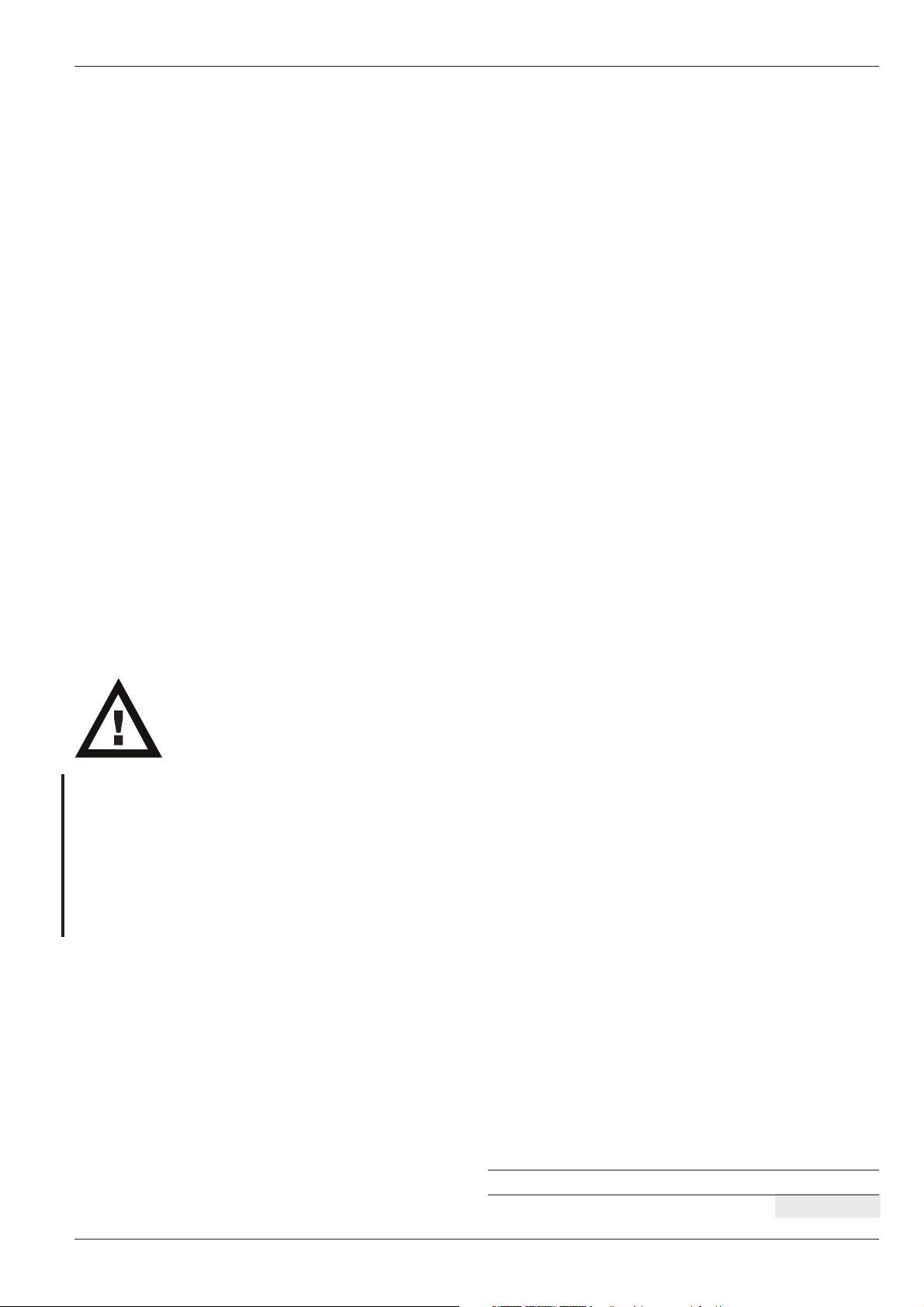

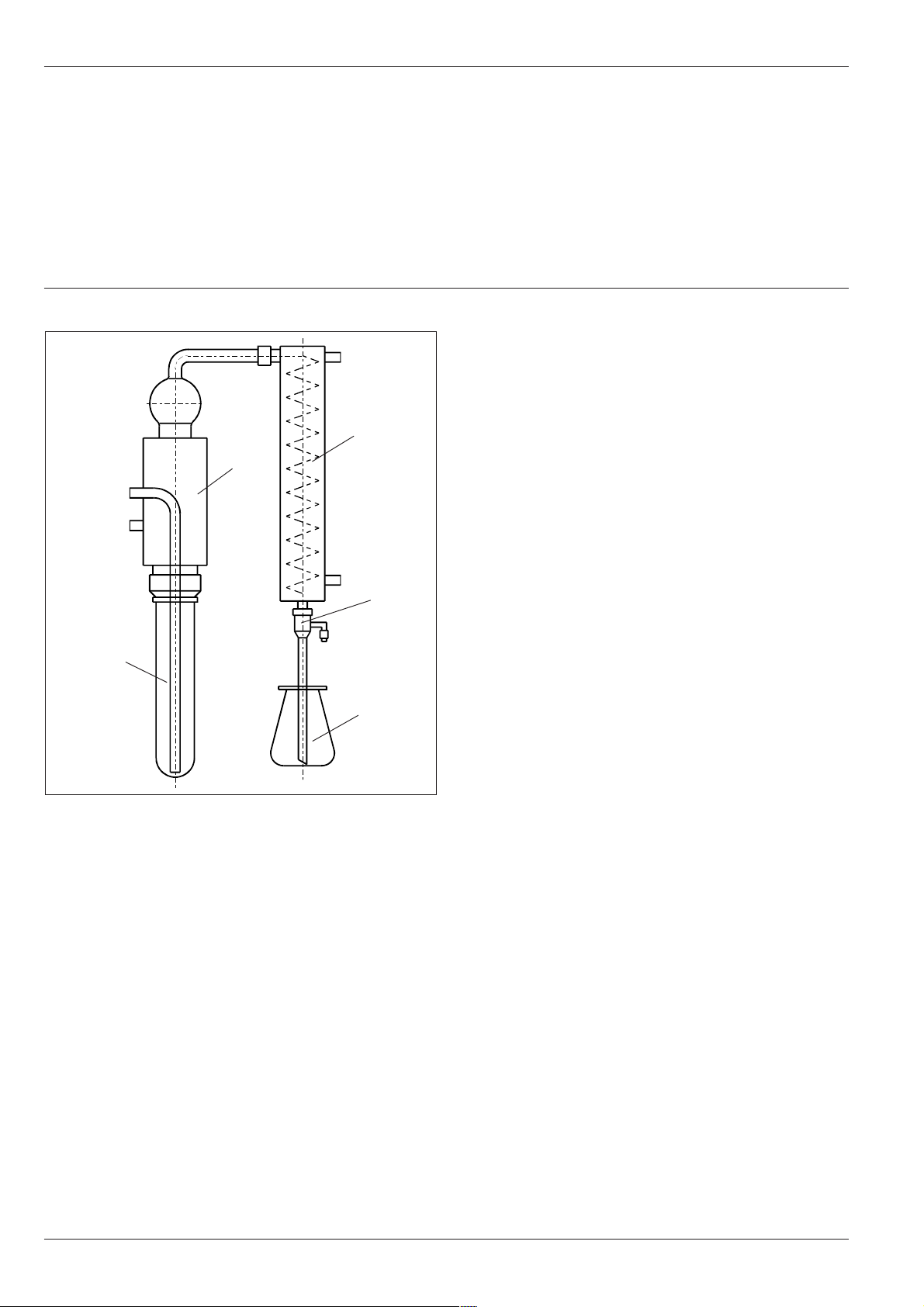

Fig. 1: General view

BÜCHI Distillation Unit K-314

1 Scope of Delivery

Description Order No.

Versions:

220 - 240V 50/60 Hz

K-314 complete 37961

Table 1: Versions

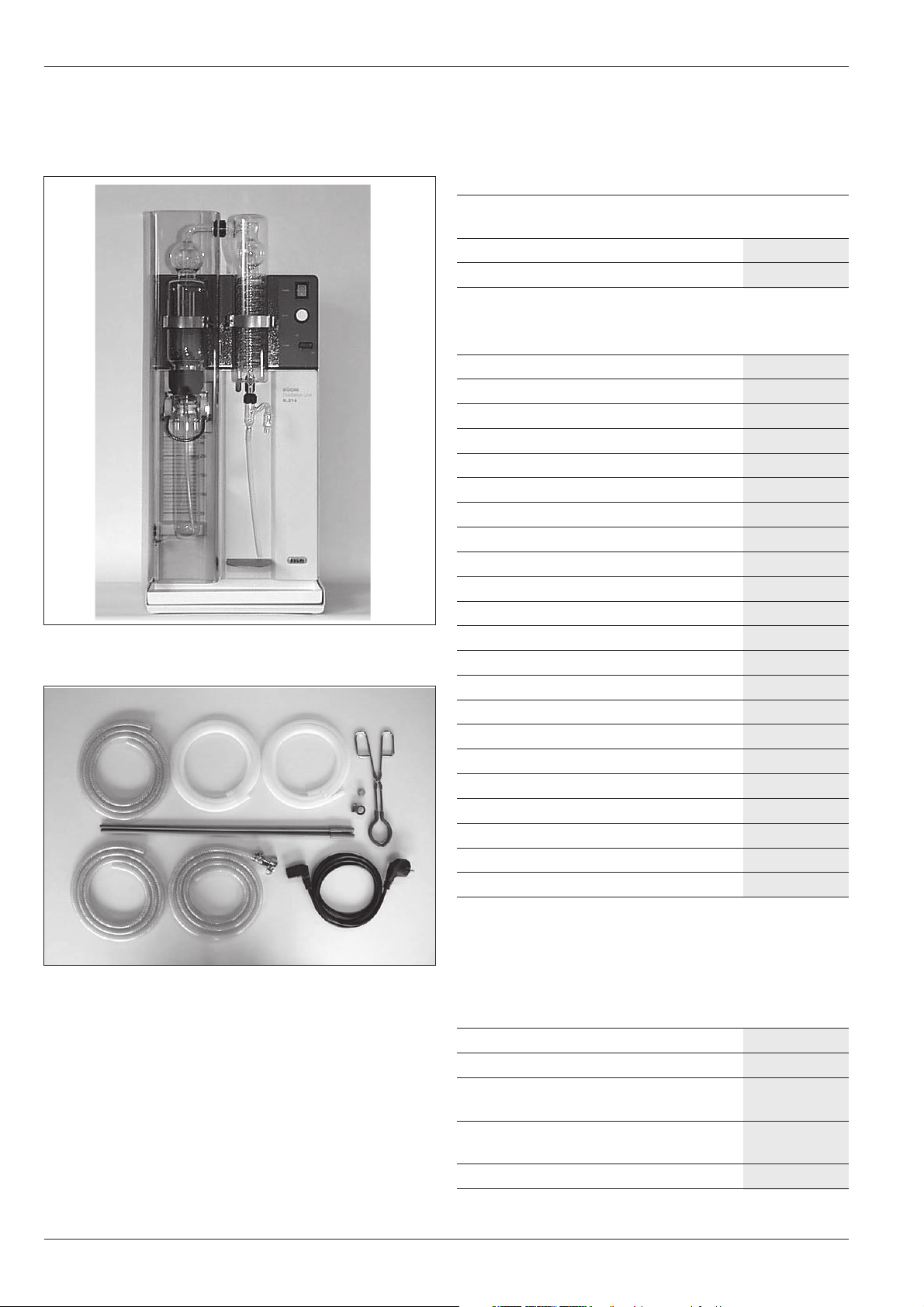

Enclosed parts:

1 Digestion tube 03904

1 Distillate outlet tube complete 26301

1 Pair of glass tongs 02004

1 Drip tray 26290

1 Water supply complete 10992

3 Nyflex hose ø 14/8 mm to 1,5 m 04113

2 Silicone hose ø 9/6 mm to 1,5 m 04133

2 Flow-through tube ø 8/6 mm 26058

1 Hose clamp 22352

1 NaOH tank 10 L, complete 26112

1 Water tank 10 L, complete 26113

1 Mains cable Type CH 10010

Typ Schuko 10016

Type GB 17835

Type AUS 17836

Type USA 33756

1 Operating instructions

German 96705

English 96706

French 96707

Italian 96708

Spanish 96709

Table 2: Enclosed parts

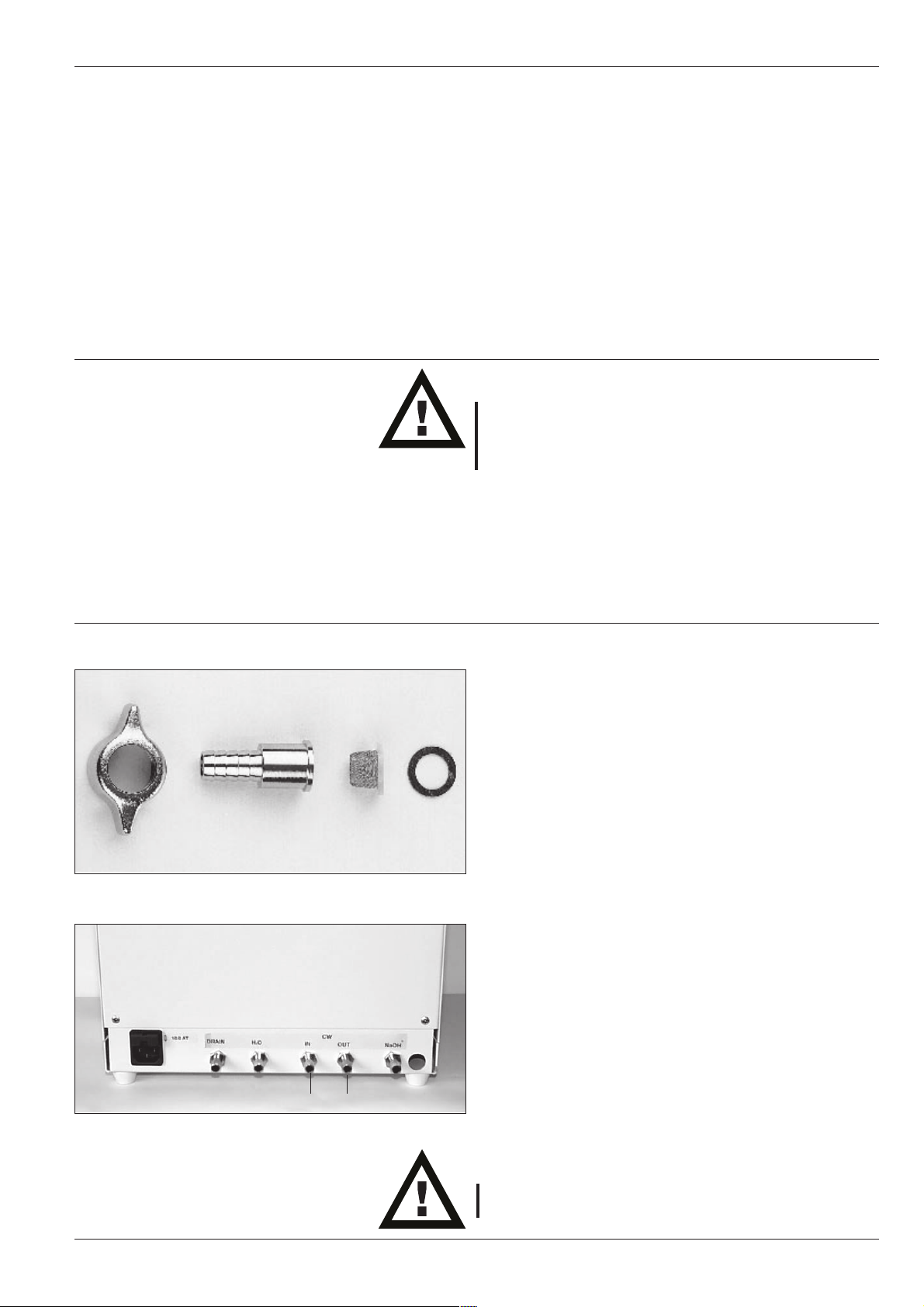

Fig. 2: Enclosed parts

2

Accessories:

1 Sample tube 500 mL 26128

1 Rack for 4 sample tubes 500 mL 16951

1 Special rubber bung for 16890

Tecator/Gerhardt glasses

1 Handle with cam for 26109

Tecator/Gerhardt glasses

1 Indicator acc.Sher, 100 ml 03512

Table 3: Accessories

Page 3

BÜCHI Distillation Unit K-314

2 Safety

2 Safety

The apparatus has been built in accordance with state-ofthe art technology and recognized safety regulations.

Nonetheless risks and dangers can arise from the

apparatus:

• If the apparatus is operated by insufficiently trained

personnel.

• If the apparatus is not used as directed.

2.1 Symbols

Stop

Information on dangers which can lead to serious damage

to property, to severe or life-threatening injuries.

Warning

Information on dangers which can lead to damage to health

or property.

Please note

Information on technical requirements. Noncompliance can

lead to faults, inefficiency and production losses.

2.2 Requirements for the operator

The unit is only to be used by laboratory and specialist

personnel and other persons, who, because of their training

or professional experience, are able to assess the dangers

which can result while operating the equipment.

Personnel without this training or persons who are in training

require thorough instruction. These operating instructions

are the basis.

2.3 Regulation use

The unit is conceived and built as a piece of laboratory

equipment. Its regulation use is the distillation of steam

volatile substances.

2.4 Non-regulation use

Any use other than those listed as well as any use which

does not correspond to the technical data is a misuse. The

operator bears sole risk for eventual damage related to

such use.

In particular the following uses are not allowed:

• operation in explosion-prone areas

• operation with samples that can explode or ignite due to

impact, friction, heat or sparking.

3

Page 4

2 Safety5BÜCHI Distillation Unit K-314

BÜCHI Distillation Unit K-314

2.5 General hazards

General hazards arise from:

• Hot acids and bases

• Combustible gases or vapors in the immediate vicinity

of the apparatus

• Damaged glassware

• Location of the apparatus to close to the wall (see

section 4.1 Set up location)

• Hot surfaces

Except for authorized repair personnel it is forbidden to remove

covers using commercially available tools.

The device must not be put into operation with damaged

glass parts.

Contact with electrically live parts presents a danger to life

and limb!

2.6 Safety measures

The distillation unit K-314 is equipped with a protective

door, which must be closed during operation.

The wearing of personal safety equipment such as safety

glasses, gloves and

As a necessary part of the distillation unit K-314, this

instruction manual must at all times be available to the

operating personnel at the location where the apparatus is

being used. This also applies to the further editions in other

languages which may be ordered seperately.

The fusion processing glass must only be removed with

pliers because of danger beeing burnt.

Modifications

Any modifications on the apparatus itself or on replacement

or accessory parts, and any use of replacement or

accessory parts other than those listed in these operating

instructions is permissible only with the express written

approval of Büchi Labortechnik AG.

Responsibilities of the operator

The operator is responsible for providing proper instruction

for his staff. For that purpose, these operating instructions

may also be ordered in other languages.

The operator must inform the manufacturer immediately of

any and all events relevant to product safety that arise

during his operation of the apparatus.

If assuming that a safe operation is not possible any more

the unit must be put out of operation and secured against

unintended further operation.

ll

laboratory coats is necessary.

ll

4

Page 5

2 Safety

It is to be assumed that a safe operation is not possible

any more

• if the unit is visibly damaged,

• If the unit is not functioning any more

• after long storage under anfavourable conditions,

• after being transported under difficult conditions.

The unit must not be operated with combustible substances.

If you need the assistance of Büchi Service, it is required

to indicate and declare eventually remaining dangerous

substances (e.g., as defined in EC guidelines L 360, 1976/

79 or VBG 16) in or on the apparatus for reason of on-thejob safety or pollution control.

Page 6

3 Function

햳

햴

BÜCHI Distillation Unit K-314

3 Function

The distillation unit K-314 is suitable for determining nitrogen

using the Kjeldahl and Devarda methods

distillations (e.g., of alcohol) can also be carried out easily.

3.1 Principle of operation

햲 Sample tube

햳 Splash protection

햴 Cooler

햵 Distillate outlet tube

햶 Receiving vessel

. .

. Other steam

. .

햲

Fig. 3: Principle of operation K-314

햵

햶

6

Page 7

BÜCHI Distillation Unit K-314

4 Putting into operation

4 Putting into operation

4.1 Setup location

The distillation unit must be installed on a stable, clean and

flat base.

For reasons of safety, a gap of at least 30 cm must be left

open between the back of the machine and the wall or

other objects. Never place any containers, chemical

products or other equipment behind the distillation unit.

4.2 Unpacking

The original package must be kept for possible later

transport.

If the package has been damaged, check the machine

carefully for broken glass or damage to the housing.

Make certain that the socket voltage is the same as that

shown on the machine nameplate. Always connect the

machine to an earthed (grounded) socket. This avoids risks

due to an internal defect.

Fig. 4: Standard sleeve nut (premounted)

Fig. 5: K-314 rear

햲

햳

4.3 Water supply

The distillation unit K-314 is delivered with 3 Nyflex highpressure hoses intended for the following connections:

• cooling water inlet

•H

O supply tank

2

• NaOH supply tank

Connect the cooling water connector to the mains water tap.

The standard sleeve nut has an R 1/2” thread (Fig. 4).

Accessories:

Reducer 1/2" 3/8" Art.No. 11289

Reducer 1/2" 3/4" Art.No. 11290

Cooling water inlet (1):

Shorten the Nyflex hose to the optimum length, connect it

to the water connector, and secure it with a hose clamp.

Connect the other end of the hose to the cooling water

inlet nipple.

Cooling water outlet (2):

Shorten the silicone hose [9/6 mm] to the optimum length

and connect it to the cooling water oulet nipple (OUT

nipple). Direct the open end into the drain.

Check

The cooling water must flow through the cooling unit from

the bottom to the top.

Make sure that the hose drains freely. No kinks! No airtraps

in the hose!

7

Page 8

4 Putting into operation

BÜCHI Distillation Unit K-314

4.4 Drain hose (3)

Make sure that the hose drains freely. No kinks! No airtraps

in the hose!

Fig. 6: Drain hose arrangement

004113

026058

026660

026411

ca. 456

Fig. 7: Connection supply tanks

4.5 Connection of the supply tanks

• Connect the Nyflex hose to the flow-through tube

• Unscrew the small tank cap and stick it on the flowthrough tube

• Insert the flow-through tube with the tank cap on into

the tank until it reaches the stop

• Tighten the tank cap

• Connect the hose from the water tank to the K-314

(H

O nipple)

2

• Connect the hose from the sodium hydroxide tank to

the K-314 (NaOH nipple

• Fix the hose nozzle in place on the large tank cap.

The supply tanks must not be any higher than the unit

itself, nor any lower than 1 meter below it.

8

Page 9

BÜCHI Distillation Unit K-314

5 Operation

5 Operation

5.1 Control elements

햶

햷

햵

햻

Fig. 8: Arrangement and designation of the control and display elements

햽

헂 헁

Fig. 9: Arrangement and designation of the connection nipples

헀

햾

햿

햲

햳

햴

햸

햹

햺

햲 Main switch

햳 Pressure switch for adding the sodium hydroxide

solution

햴 Steam tap

햵 Digestion tube

햶 Rubber bung with PTFE hose

햷 Sample tube holder

햸 Distillate outlet tube with PTFE hose

햹 Receiver plate

햺 Drip tray

햻 Protective door

햽 Connection nipple for cooling water inlet hose (IN)

햾 Connection nipple for cooling water outlet hose (OUT)

햿 Connection nipple for sodium hydroxide solution

(NaOH)

헀 Connection nipple for water (H

O)

2

헁 Connection nipple for drain

헂 Mains connector with 2 fuses 20x5,10 AT

Fig. 10: Control elements and their function

I/O

NaOH

Steam

5.2 Control elements and their function

I / O After switching on the distillation unit, it takes

about 90 seconds before the unit is ready for

operation.

Before switching on, check that the supply tanks

and/or the hoses are filled with reagents.

NaOH Sodium hydroxide adding switch.

The alkali is dosed in as long as the switch is

pressed.

Steam Steam on / off.

Switching the distillation on and off manually.

9

Page 10

5 Operation

BÜCHI Distillation Unit K-314

5.3 Start-up checklist

The first time that the distillation unit is started up, there is

a penetrating odor. This smell, however, is of no importance.

It occurs when the heater pipe and the isolation become

warm. No overheating of the steam generator is possible.

5.4 Supply tanks

Fill the supply tanks. This can be done, for example, using

a bent funnel (Item No. 16662) or a footpump. The reagents

are forwarded within the K-314 unit by suction.

To ensure optimum long-time operation, the steam generator

must only be operated on distillated or deionized water!

Advantages:

1. No cleaning of the steam generator is necessary

2. The blank values can be kept under control.

Never supply the steam generator from a building distilled

water distribution pipe!

5.5 Rubber bung and PTFE hose

Check that the rubber bung and the PTFE hose are still properly

fitted, especially after they have been subjected to stresses

during transport or otherwise.

Mounting instruction:

If the PTFE hose has become loose, hold it with a piece of

sandpaper and refit it without kinking.

10

Page 11

BÜCHI Distillation Unit K-314

햲

5 Operation

5.6 Sample tube holder

The sample tube holder has been correctly adjusted in the

factory.

Check whether the holder is still correctly positioned;

• Push the quick-locking clamp all the way up (1)

• Insert the test tube as shown on the figure (2)

• Now push the quick-locking clamp all the way down (3)

• The sample tube is now positioned.

The tube should not be too loose (possible

leakage) or too tight (deformation of the

rubber bung).

햳

Loosen the holders Phillips-head screws (4)

and adjust the holder according to the

position of the sample tube.(4).

햴

Fig. 11: Inserting the sample tube

햵

11

Page 12

5 Operation

BÜCHI Distillation Unit K-314

5.7 Distillation outlet tube

Fit the distillate outlet tube onto the cooler outlet using the

coupling ring and inserted gasket. Slide the PTFE hose,

top down, as far to the bottom of the receiving vessel as

possible.

The distillate outlet tube has an aeration valve (patented

by Büchi) that keeps the receiving solution from being

sucked back.

5.8 Connection to the mains

Before switching the distillation machine K-314 on for the

first time, make certain that the power system voltage is

the same as that indicated on the unit's nameplate.

Then connect the distillation unit cable to the mains.

5.9 Adjusting the cooling water flow

• Open the cooling water tap until the flow of water at the

outlet hose is 1 l/min.

The distillate must leave the cooler cooled!.

5.10 Switching the K-314 ON/OFF checklist

Switching on and preheating the distillation unit K-314

• Check the filling of the supply tanks,

• Open the main water tap, regulate the water flow,

• Switch on the distillation unit K-314 and wait until the

steam generator is ready,

• Insert an empty sample tube and an empty receiving

vessel,

• Close the protective door,

• Turn steam tap to ON (2 minutes),

• The unit is now ready for the distillation.

12

Page 13

BÜCHI Distillation Unit K-314 6 Bedienung

5.11 Carrying out the Kjeldahl distillation

• Switch the unit on and preheat,

• Wear goggles!

• Insert the digestion tube containing the specimen diluted

in water

Dilution with water prevents too violent a reaction when

subsequently adding the hydroxide solution.

The specimen must be diluted in a ratio of approximatly

1 part of acid to 2 parts of water.

• Prepare a conical flask or a similar receptacle (250 ml)

as the receiving vessel, dilute with 60 ml boric acid

(2%) and 2-3 drops of Sher indicator (Item No. 03512).

Alternative: Choose a suitable indicator for the back

titration.

Fig. 13: K-314 in operation

• Add sodium hydroxide solution:

Recommeded alkali concentration: 32%

Add alkali to the specimen in a ratio of about 1 part

acid to 3 parts sodium hydroxide solution. The volume

of the added sodium hydroxide solution is measured

on the scale (behind the distillation glass).

The added volume selected must produce a clear shift

in color to brown or blue.

• Distillation

Steam tap to ON

A distillation time of approximately 3 minutes is required

to get a volume of 100 ml.

• After the completion of the distillation turn the steam

tap back to OFF.

5.12 Cleaning the unit

Clean the unit by distilling 100 ml distilled water for a period

of 2 minutes.

13

Page 14

BÜCHI Distillation Unit K-3145 Operation

5.13 Malfunctions

Malfunction Possible cause Remedy

No steam production, 1. Water tank is empty 1. Fill water tank

other functions OK 2. Water pump does not suck any 2. Fill water tank

water, hoses remain empty

3. Steam generator or steam 3. Replace the defective part

valve defective

Distillate receiving solution is sucked Drain tube with ventilation Clean the ventilation valve

into the cooler valve obstructed thoroughly

Resultats too low 1. Screwed fitting between the cooler 1. Tighten the screwed fitting

and splash protection is

2. Distillation time too short 2. Extend distillation time

3. Unit not preheated 3. Preheat the unit

4. Fusion processing time too short 4. Extend fusion processing time

Sodium hydroxide not fed in 1. Tank empty 1. Fill the tank

2. The pump is not sucking 2. Check electrical connections

3. The pump is blocked 3. Clean the pump

4. The pump is faulty 4. Exchange the pump

Steam escapin from the housing 1. Hose connection leaking 1. Check hose connection

2. Steam generator leaking 2. Check steam generator

Distillate too warm 1. Main water tap closed 1. Open main water tap

2. Too little cooling water 2. Increase cooling water flow

Unit does not work 1. Mains fuse(s) defective 1. Replace the fuse(s)

Green check lamp not lit.

14

Page 15

BÜCHI Distillation Unit K-314

6 Maintenance

6 Maintenance

6.1 General information and Preparations

The distillation unit K-314 casing has a plastic coating. The

wet domain also has a plastic jacketing.

In order to avoid damage to these plastic coverings, wipe

off any acid or alkaline splashes immediately with a wet

cloth.

6.2 Maintenance: daily, weekly

Daily:

• Check for damage on glass parts

After stand still overnight, or after long periods of non-use:

• Insert a sample tube containing approximatively 30 ml

destillated water,

• Fill the receiving vessel with destillated water so that

the PTFE hose is just barely immersed.

Weekly:

• Remove the rubber bung and clean it with water.

• Also clean the exposed glass nozzle on the splash

protection.

The glass parts are cleaned.

6.3 Rubber bung and PTFE hose

During the life duration of the rubber bung it is advantageous

to remove it periodically, approximately after 100 distillations,

and to clean it with water without any cleaning product or

solvent.

• Remove the rubber bung by turning it downwards and

clean it carefully with water,

• Clean also the liberated glass nozzle of the splash

protection with a wet cloth.

15

Page 16

6 Maintenance

BÜCHI Distillation Unit K-314

6.4 Cleaning the feeding pump

Proceed as follows when the sodium hydroxide feed pump

no longer functions correctly:

• Prepare approximately 1 liter water,

• Open the small cover of the supply tank,

• Carefully take out the flow-through tube and place it in

the water vessel,

• Press the NaOH switch until the sample tube is filled,

• Remove the sample tube and empty it,

• If necessary, repeat the process.

6.5 Changing glass parts

The glass parts are held in place with a quick-locking

fastening device.

• Close the water tap,

• Switch off the unit

• Pull the mains plug

• Loosen the screw cap connecting the splash protection

and the cooler and carefully take the splash protection

out of the cooler. Release the holding springs by simply

pressing them down by hand.

• Slowly pull the splash protection out forward and pull

the distributor off the glass part (if necessary, replace

the distributor as well).

Proceed in the reverse order for reassembly.

After the first distilllation, check that the screw cap is

correctly positioned. If necessary, tighten it.

6.6 Customer service

Any intervention on or in the apparatus may only be carried

out by authorized service technicians. These are persons

with a sound technical training and knowledge of the

dangers which result from not observing safety regulations.

Authorized Büchi serve centers have available to them a

special service manual for this apparatus. That manual can

only be obtained by authorized personnel.

16

The addresses of the official Büchi service centers are

shown on the last cover page of these operating

instructions. Please contact these service centers whenever

you have a malfunction, technical questions, or problems

in using the equipment.

Page 17

BÜCHI Distillation Unit K-314

햲

6 Maintenance

Büchi’s customer service offers the following services:

• Replacement part service

• Repair service

• Maintenance service

• Technical consultation.

6.7 Main fuses

Please change the main fuses as follows::

• Pull out mains cables

• Pull out fuse holders 햲

• Replace the defective mains fuse by a new one with same

performance 햳:

- 230V: T 10A L 250V

Fig. 14: Device plug, inserted

• Insert again fuse holders

햳

6.8 Checking the unit

In order to check that the unit is functioning properly, do a

nitrogen analysis using ammonia salt. For a standard

application, we recommend the following parameters:

Standard substance: Ammonium dihydrogen phosphate

p.A.

Molecular weight: 115.03

Nitrogen content: 12.17%

Originally weighed in: 400 to 500 mg

H2O: 20 ml

NaOH: 20 ml

Distillation time: 4 min

Titration: Sulphuric acid 0.5 N

Consumption: approx. 7-10 mL

Table 7: Checking th unit parameters

17

Page 18

7 Taking out of service

BÜCHI Distillation Unit K-314

7 Taking out of service

Remove all dangerous substances and clean the unit

thoroughly.

This avoids any risk that individuals could come into contact

with dangerous substances.

7.1 Storage/Transport

The unit has to be cleaned and repacked in its original

packaging when it is being stored or transported.

7.2 Disposal

To ensure as ecologically sound a disposal of the apparatus

as possible, the Appendix in Chap. 9 contains a list of the

materials used in its most important parts.

This makes it possible for you to separate the parts and to

send them on for recycling. For disposal of electronic

parts, we refer you to official regulations governing such

action. In addition, all pertinent regional and local laws

must be observed.

18

Page 19

BÜCHI Distillation Unit K-314

8 Replacement parts

8 Replacement parts

Only original Büchi accessories and replacement parts

guarantee safe operation and a proper functioning of the

unit. The use of replacement parts and accessories other

than those recommended by Büchi is permissible only with

prior approval from the manufacturer. The replacements

parts cited herein may be used only for purposes of

disassembly and reassembly as described in Chap. 6 of

this Instruction Manual. It is strictly forbidden to disclose

this manual or its contents to third parties. No production

of parts based on the information contained herein is

permissible.

8.1 Replacement parts

1 Fuses 10*10 AT 16952

1 Splash protection 36900

1 Cooler 26004

1 Distillate outlet tube, complete 26302

1 Set of sample tubes 300 mL (4 pieces) 37377

1 PTFE hose to digestion tube 19010

1 PTFE hose to distillate outlet tube 26300

1 Rubber bung 03907

1 Connector (Hypalon) 19002

1 Seal ø 22 mm 02073

1 Seal ø 15 mm 03574

1 Screw cap nut ø 22 mm 03577

1 Screw cap nut ø 15 mm 03549

1 Sample tube 500 mL 26128

1 Drip tray 26290

1 Silicone hose D 9/6 04133

1 Silicone hose D 14/10 04134

1 Nyflex hose D 14/8 04113

1 Water connection 10992

1 Tank 10 L NaOH, complete 26112

1 Tank 10 L H2O, complete 26113

1 Gasket for tank 26411

1 Flow-through tube D 8/6 mm 26058

1 Screw cap 26660

1 Tank plug 25869

Table 5: Replacement parts

19

Page 20

BÜCHI Distillation Unit K-3149 Appendix

9 Appendix

9.1 Technical data

Dimensions (Width x Height x Depth) 245 x 420 x 220 mm

Nominal voltage 230 V, 50/60 Hz

Mains voltage tolerance +10 % / -15 %

Power rating 1800 Watt

Power consumption approx. 8 Ampère

Volume supply tank 10 L

Volume sample tubes 300 ml (Standard)

500 ml (Special)

Weight (netto) approx. 16 kg

Dimensions 320 x 695 x 320 mm

Ambient temperature Operation: +10 to +40° C

Storage: - 40 bis +70° C *

Steam or distillate flow capacity approx. 30ml/min

Overvoltage Category II

Pollution degree 2

*Note: If being stored at temperatures below +5° C, remove all liquid from the unit.

Due to the danger of frost, the steam generator, cooler, hoses etc. must all be emptied !

Caution: The steam generator may only be emptied by authorized service personnel.

Table 6: Technical data

9.2 Materials used

Part Material Material code

Housing Zinkor ST 1203 ELVZ

Glass parts Borosilicate glass 3.3 DIN/ISO 3585

Front protection Polystyrene PS

Protective door Polymethylmethacrylate PMMA

Contact guard AIMgSi1

Isolation steam generator Alkaline earth silicate fibers X-607

Housing steam generator Polysulphones with 20% fiberglass PSU/20% GF

Rubber bung Hypalon CSM

Distributor Ethylene-propylene rubber EPDM

Metals X5CrNi1810 1.4301

X10CrNiS189 1.4305

Hoses Polytetrafluorethyleen PTFE

Silicone

Table 7: Materials used

20

Page 21

BÜCHI Distillation Unit K-314

9.3 FCC requirements (for USA and Canada)

English:

This equipment has been tested and found to comply with the limits for a Class A digital device, pusuant to both Part

15 of the FCC Rules and the radio interference regulations of the Canadian Department of Communications. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in

a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is like to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Français:

Cet appareil a été testé et s'est avéré conforme aux limites prévues pour les appareils numériques de classe A et à

la partie 15 des règlementation FCC à la règlementation des radio-interférences du Canadian Department of

communications. Ces limites sont destinées à fournir une protection odéquate contre les interférences nétastes

lorsque l'appareil est utilisé dans un environnement commercial.

9 Appendix

Cet appareil génère, utilise et peut radier une énergie à fréquence radioélectrique, il est en outre susceprible d'engendrer

des interferences avec les communications radio, s'il n'est pas installé et utilisé conformément aux instructions du

mode d'emploi. L'utilisation de cet appareil dans les zones résidentielles peut causer des interférences nèfastes,

auquel cas l'exploitant sera amené à prendre les dispositions utiles pour polier aux interférences à ses propres frais.

21

Page 22

9 Appendix

We

declare under our sole responsibility that the product:

to which this declaration relates is in conformity with the following standards:

BÜCHI Distillation Unit K-314

9.4 Declaration of conformity

BÜCHI Labortechnik AG

Postfach, CH-9230 Flawil

Switzerland

BÜCHI Distillation Unit K-314

EN 61010-1:1993 (~ IEC 1010-1, VDE 0411-1)

Safety requirements for electrical equipment for measurement, control an laboratory use: General requirements

EN 55011:1991/B (~ VDE 0875/B, VDE 0871/B)

Maximum permissible values and measurement technique for radio interference by industrial, scientific and medical

high-frequency devices

EN 61000-3-2: 1995/1996

Limits for harmonic current emissions

EN 61000-3-3: 1995

Limitation of voltage fluctuations and flicker

In accordance with the regulations of the EU guidelines:

73/23/EWG (Electrical special tools/low voltage guidelines)

89/336/EWG (electromagnetic compatibility)

Flawil, 19th December 2000

BÜCHI Labortechnik AG

Meierseggstrasse 40

9230 Flawil

Schweiz

Tel +41 (0)71 394 63 63 Guido Worch

Fax +41 (0)71 394 65 65 Qualitymanager

buchi@buchi.com

www.buchi.com

22

Loading...

Loading...