Brother KE-430D, BE-438D Service Manual

KE-4300 BE-4380

SERVICE MANUAL

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

ELECTRONIC DIRECT DRIVE LOCKSTITCH BAR TACKER

ELECTRONIC DIRECT DRIVE LOCKSTITCH BUTTON SEWER

From the library of: Superior Sewing Machine & Supply LLC

This service manual is intended for KE-4300, BE-4380; be sure to read the KE-4300, BE-4380 instruction manual before

this manual.

Carefully read the "SAFETY INSTRUCTIONS" below and the whole of this manual to understand this product before you

start maintenance.

As a result of research and improvements regarding this product, some details of this manual may not be the same as those

for the product you purchased.

If you have any questions regarding this product, please contact a Brother dealer.

SAFETY INSTRUCTIONS

1. Safety indications and their meanings

This service manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

~-· Indications

A DANGER The instructions which follow this term indicate situations where failure to follow the instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the A cAUTION instructions could cause injury when using the machine or physical damage to equipment

and surroundings.

Symbols

.&. ..... .

This symbol (b.) indicates something that you should be careful of. The picture inside the triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means "beware of injury".)

This symbol ((9) indicates something that you must not do.

This symbol ( e )indicates something that you must do. The picture inside the circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

KE-4300, BE-4380

From the library of: Superior Sewing Machine & Supply LLC

2. Notes on safety

A DANGER

lA Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

~before opening the face plate of the control box. Touching areas where high voltages are present can result in severe injury.

A CAUTION

Environmental requirements

ft |

Use the sewing machine in an area which is free from |

A The ambient temperature should be within the range |

||||

V |

sources of |

strong |

electrical |

noise such as |

V |

of 5°C to 35°C during use. |

|

high-frequency welders. |

|

|

|

Temperatures which are lower or higher than this |

|

|

Sources of strong electrical noise may cause |

|

may cause problems with correct operation. |

|||

|

problems with correct operation. |

|

A The relative humidity should be within the range of |

|||

ft Any fluctuations in the power supply voltage should |

V |

45% to 85% during use, and no dew formation should |

||||

V |

be within ±10% of the rated voltage for the machine. |

|

occur in any devices. |

|||

|

Voltage fluctuations which are greater than this may |

|

Excessively dry or humid environments and dew |

|||

|

cause problems with correct operation. |

A |

formation may cause problems with correct operation. |

|||

ft The power supply capacity should be greater than the |

Avoid exposure to direct sunlight during use. |

|||||

V |

requirements |

for the |

sewing |

machine's electrical |

V |

Exposure to direct sunlight may cause problems with |

|

consumption. |

|

|

|

A |

correct operation. |

|

Insufficient power supply capacity may cause |

In the event of an electrical storm, tum off the power |

||||

|

problems with correct operation. |

|

V |

and disconnect the power cord from the wall outlet. |

||

Lightning may cause problems with correct operation.

Installation

I(:\ Machine installation should only be carried out by a \..Y qualified technician.

0 |

Contact your Brother dealer or a qualified electrician |

for any electrical work that may need to be done. |

|

A |

The sewing machine weighs approximately 56 kg. |

V |

The installation should be carried out by two or more |

|

people. |

f(;'\Do not connect the power cord until installation is \..Y complete, otherwise the machine may operate if the foot switch is depressed by mistake, which could

result in injury.

A Hold the machine head with both hands when tilting it

~back or returning it to its original position. Furthermore, after tilting back the machine head, do not push the face plate side or the pulley side from above, as this could cause the machine head to topple over, which may result in personal injury or damage to the machine.

Be sure to connect the ground. If the ground

•connection is not secure, you run a high risk of receiving a serious electric shock, and problems with correct operation may also occur.

0 All cords should be secured at least 25 mm away

from any moving parts. Furthermore, do not t<::"\ excessively bend the cords or secure them too firmly

\..Y with staples, otherwise there is the danger that fire or electric shocks could occur.

A Install the safety covers to the machine head and V motor.

A If using a work table which has casters, the casters V should be secured in such a way so that they cannot

move.

t<::"\ Be sure to wear protective goggles and gloves when \..Y handling the lubricating oil and grease, so that they do not get into your eyes or onto your skin, otherwise

inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

ii |

KE-4300, BE-4380 |

|

From the library of: Superior Sewing Machine & Supply LLC |

A CAUTION

Sewing

tC'\ This sewing machine should only be used by \Y operators who have received the necessary training

in safe use beforehand.

tC'\ The sewing machine should not be used for any \Y applications other than sewing.

0 Be sure to wear protective goggles when using the machine.

If goggles are not worn, there is the danger that if a needle breaks, parts of the broken needle may enter your eyes and injury may result.

A Tuin off the power switch at the following times,

~otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

•When threading the needle

•When replacing the needle and bobbin

•When not using the machine and when leaving the machine unattended

0 |

If using a work table which has casters, the casters |

should be secured in such a way so that they cannot |

move.

A Attach all safety devices before using the sewing L.:!:::l. machine. If the machine is used without these

'devices attached, injury may result.

A Do not touch any of the moving parts or press any L.:!:::l. objects against the machine while sewing, as this

may result in personal injury or damage to the machine.

If an error occurs in machine operation, or if abnormal 0 noises or smells are noticed, immediately tum off the power switch. Then contact your nearest Brother

|

dealer or a qualified technician. |

0 |

If the machine develops a problem, contact your |

nearest Brother dealer or a qualified technician. |

Cleaning

A Tum off the power switch before carrying out |

tC'\ Be sure to wear protective goggles and gloves when |

~ cleaning, otherwise the machine may operate if the |

\Y handling the lubricating oil and grease, so that they |

foot switch is depressed by mistake, which could |

do not get into your eyes or onto your skin, otherwise |

result in injury. |

inflammation can result. |

|

Furthermore, do not drink the oil or eat the grease |

|

under any circumstances, as they can cause vomiting |

|

and diarrhoea. |

|

Keep the oil out of the reach of children. |

Maintenance and inspection

tC'\ Maintenance and inspection of the sewing machine \Y should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to 0 carry out any maintenance and inspection of the

electrical system.

A Tum off the power switch and disconnect the power

~cord from the wall outlet at the following times, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

•When carrying out inspection, adjustment and maintenance

•When replacing consumable parts such as the rotary hook

A If the power switch needs to be left on when carrying L.:!:::l. out some adjustment, be extremely careful to observe

all safety precautions.

A Hold the machine head with both hands when tilting it

~back or returning it to its original position. Furthermore, after tilting back the machine head, do not push the face plate side or the pulley side from above, as this could cause the machine head to topple over, which may result in personal injury or damage to the machine.

0 |

Use only the proper replacement parts as specified |

||

|

|||

|

by Brother. |

|

|

|

If any safety |

devices have been |

removed, be |

0 absolutely sure |

to re-install them to |

their original |

|

positions and check that they operate correctly before using the machine.

tC'\ Any problems in machine operation which result from \Y unauthorized modifications to the machine will not be

covered by the warranty.

KE-4300, BE-4380 |

iii |

From the library of: Superior Sewing Machine & Supply LLC |

|

3. Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are difficult to read, please contact your nearest Brother dealer.

1

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric shock, and problems with correct operation may also occur.

Direction of operation

2 A

A~B

lb<U~"t!ltil<f1"tl.

i.'i:!l&i&l!f?lt-c6Ulfllll.

f"tt~::c!::. Uf~-:~"Cil'i:;,•

.tti!L.. ~1!:..-~ttOl~!i. tiDII*:~KIUilfTt~::c!::.

A CAUTION

Moving parts may cause injury. Operate with safety devices. Tum off main switch before threading, changing bobbin and needle, cleaning etc.

Safety devices

Eye guard Finger guard

Tension release solenoid cover Thread take-up cover

Frame side cover Back cover, etc.

Thread take-up cover

4

Finger guard |

Tension release |

|

solenoid cover |

4399Q |

4467Q |

iv |

KE-430D, BE-438D |

|

From the library of: Superior Sewing Machine & Supply LLC |

CONTENTS

|

1. SPECIFICATIONS .................................... |

1 |

|

2. FUNCTION SETTINGS ............................ |

2 |

|

2-1. List of special functions INhen power is turned on....... |

2 |

|

2-2. Ust of advanced functions ..................................... |

3 |

|

2-3. Setting memory switches {Advanced) ................. |

4 |

|

2-4. Ust of memory switches ........................................ |

5 · |

|

2-5. Setting the work clamp mode.............................. |

1o |

|

2-6. X-V parallel movement for sewing patterns....... |

11 |

,-..,_/ |

2-7. Clearing saved data (Initialization)...................... |

12 |

|

2-8. Checking the error history ................................... |

13 |

|

2-9. Input checking method......................................... |

14 |

|

2-10. Output checking method ................................... |

16 |

|

2-11. Confirming software version ............................. |

17 |

|

3. USING CF CARDS .................................. |

18 |

|

3-1. Notes on handling CF cards |

|

|

(purchase at local retailers) ................................. |

18 |

|

3-2. Structure of a CF card folder............................... |

18 |

|

3-3. Preparation for reading and writing data............ |

19 |

|

3-4. Reading additional sewing data |

|

|

Selecting the "r 1" CF data read/write mode ..... |

20 |

|

3-5. Writing additional sewing data to the CF card ... |

20 |

|

3-6. Reading memory switch data ............................. |

21 |

|

3-7. Writing memory switch data to the CF card ...... |

21 |

|

3-8. Reading user program data ................................ |

22 |

|

3-9. Writing user program data to the CF card ......... |

22 |

|

3-10. Updating the control programs ......................... |

23 |

|

3-11. Writing error log data to the CF card ................ |

24 |

|

4. MECHANICAL DESCRIPTIONS............ |

25 |

|

4-1. Needle bar and thread take-up mechanisms.... |

25 |

|

4-2. Lower shaft and shuttle race mechanisms ........ |

25 |

|

4-3. Work clamp lifter mechanism.............................. |

26 |

|

4-4. Thread wiper mechanism.................................... |

27 |

|

4-5. Feed mechanism.................................................. |

28 |

|

4-6. Thread trimmer mechanism ................................ |

29 |

|

4-7. Tension release mechanism ............................... |

30 |

|

4-8. Thread nipper mechanism .................................. |

30 |

5. DISASSEMBLY....................................... |

31 |

5-1. Covers ................................................................... |

31 |

5-2. Work clamp arm mechanism .............................. |

32 |

5-3. Needle bar mechanism ....................................... |

33 |

5-4. Upper shaft mechanism ...................................... |

34 |

5-5. Lower shaft mechanism ...................................... |

35 |

5-6. Feed mechanism.................................................. |

36 |

5-7. Work clamp lifter mechanism.............................. |

37 |

5-8. Thread wiper mechanism .................................... |

39 |

5-9. Tension release mechanism ............................... |

39 |

5-10. Thread nipper mechanism ................................ |

40 |

5-11. Thread trimmer mechanism.............................. |

41 |

5-12. Shuttle hook mechanism ................................... |

42 |

6. ASSEMBLY ............................................. |

43 |

6-1. Thread trimmer mechanism (1) .......................... |

43 |

6-2. Tension release mechanism ............................... |

45 |

6-3. Thread wiper mechanism.................................... |

45 |

6-4. Thread nipper mechanism .................................. |

46 |

6-5. Work clamp lifter mechanism.............................. |

47 |

6-6. Feed mechanism.................................................. |

50 |

6-7. Upper shaft mechanism ...................................... |

54 |

6-8. Needle bar mechanism ....................................... |

55 |

6-9. Lower shaft mechanism ...................................... |

57 |

6-10. Shuttle hook mechanism ................................... |

59 |

6-11. Thread trimmer mechanism {2) ........................ |

60 |

6-12. Work clamp arm mechanism {KE-4300) ........ |

61 |

6-13. Work clamp arm mechanism {BE-4380) ........ |

62 |

6-14. Covers ................................................................. |

53 |

7. ADJUSTMENT ........................................ |

64 |

7-1. Standard thread tension ...................................... |

64 |

7-1-1. Upper and lower thread tension............... |

64 |

7-1-2. Thread take-up spring ............................... |

65 |

7-2. Adjusting the needle bar height .......................... |

66 |

7-3. Adjusting the needle bar lift amount ................... |

66 |

7-4. Adjusting the driver needle guard ....................... |

66 |

7-5. Adjusting the needle clearance........................... |

67 |

7-6. Adjusting the shuttle race thread guide.............. |

67 |

KE-430D, BE-438D

From the library of: Superior Sewing Machine & Supply LLC

7-7. Adjusting the position of the movable knife ....... |

68 |

7-8. Replacing the movable knife and fixed knife ..... |

69 |

7-9. Adjusting the work clamp lift amount |

|

(KE-4300} ............................................................. |

70 |

7-10. Adjusting the button clamp lift amount |

|

(BE-4380)........................................................... |

70 |

7-11. Adjusting the holding pressure (BE-4380) ...... |

71 |

7-12. Adjusting the position of the button clamp |

|

(BE-4380)........................................................... |

71 |

7-13. Adjusting the thread trimmer cam position ...... |

71 |

7-14. Adjusting the thread wiper................................. |

72 |

7-15. Adjusting the tension release amount.............. |

73 |

7-16. Adjusting the backlash of the |

|

lower shaft gear.................................................. |

73 |

7-17. Adjusting the home position .............................. |

74 |

7-17-1. X-V feed home position ........................ |

74 |

7-17-2. Work clamp lift home position .............. |

75 |

7-18. Adjusting the position of the thread nipper ...... |

76 |

7-19. Adjusting the needle up stop home position ... |

78 |

7-20. Adjusting the needle up stop position .............. |

79 |

7-21. Checking the machine head switch ................. |

80 |

8. Applying grease |

|

(When "GREASEUP" appears) ............ |

81 |

9. ELECTRIC MECHANISM ....................... |

84 |

9-1. Precautions at the time of adjustment................ |

84 |

9-2. Components inside the control box and |

|

the operation panel............................................... 85 |

|

9-3. Fuse explanation .................................................. |

86 |

9-4. Connectors............................................................ |

87 |

9-4-1. Connector positions .................................. |

87 |

9-4-2. Contact failure............................................ |

89 |

10. TABLE OF ERROR CODES ................ |

92 |

11. SEGMENT DISPLAY UST ................... |

95 |

KE-4300, BE-4380

From the library of: Superior Sewing Machine & Supply LLC

1. SPECIFICATIONS

1. SPECIFICATIONS

|

|

KE-4300 |

BE-438D · |

|

||

|

|

Electronic direct drive lockstiteh bar tacker |

Electronic direct drive lockstitch button sewer |

|||

|

|

|

|

|

|

|

Stitch formation |

|

Single needle lock stitch |

|

|||

|

||||||

|

|

|

|

|

|

|

Maximum sewing speed |

3,200 rpm |

2,700 rpm |

|

|||

|

|

|

|

|

|

|

Pattern size (X x Y) |

40 x 30 mm max. |

6.4 x 6.4 mm max. |

|

|||

|

|

|

|

|

|

|

Feed mechanism |

---------Y 6 intermittent feed mechanism |

(pulse-motor driven mechanism) |

||||

Dimensions of |

|

|

Outer diameter of button 8 - 30 mm |

|||

buttons that can be |

|

|

(Use the optional button clamp B for |

|||

sewn |

|

|

diameters of 20 mm or greater.) |

|||

|

|

|

|

|

|

|

Stitch length |

|

0.1 -12.7 mm |

|

|||

|

|

|

|

|

|

|

Number of stitches |

Variable (Refer to "Program List" for details on the number of stitches |

|||||

|

for sewing patterns that are already preset.) |

|

||||

|

|

|

|

|||

Maximum stitch number |

210,000 stitches (including 200,000 stitches which can be added) |

|||||

|

|

|

|

|

|

|

Work clamp lifter |

|

Pulse-motor driven mechanism |

|

|||

|

|

|

|

|

|

|

Work clamp height |

17 mm max. |

13 mm max. |

|

|||

Button clamp height |

|

|||||

|

|

|

|

|

||

|

|

|

|

|

|

|

Rotary hook |

Shuttle hook (shuttle hook 2, optional) |

Shuttle hook |

|

|||

|

|

|

|

|

|

|

Wiper device |

|

Standard equipment |

|

|||

|

|

|

|

|

|

|

Thread trimmer device |

|

Standard equipment |

|

|||

|

|

|

|

|

|

|

Thread nipper device |

|

Standard equipment |

|

|||

|

|

|

|

|

|

|

Data storage method |

Flash memory (Any sewing pattern can be added using CF card) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of user programs |

|

|

50 |

|

|

|

|

|

|

|

|

|

|

Number of cycle programs |

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

89 sewing patterns |

49 sewing patterns |

|

||

Number of stored data |

|

are set already |

are set already |

|

||

|

|

|

|

|

|

|

|

|

(Up to 200 patterns can be added. Total number of stitches of stored data |

||||

|

|

|||||

|

|

|

which can be added is within 200,000.) |

|

||

Motor |

|

AC servo motor 550 W |

|

|||

|

|

|

|

|||

Weights |

Machine head: approx. 56 kg, Operation panel: approx. 0.6 kg |

|

||||

Control box: 14.2-16.2 kg (depending on destination) |

|

|||||

|

|

|

||||

|

|

|

||||

Power source |

Single-phase 1OOV I 220V, 3-phase 200V I 220V I 380V I 400V |

400VA |

||||

|

|

|

|

|

|

|

KE-430D, BE-438D |

1 |

From the library of: Superior Sewing Machine & Supply LLC |

|

2.FUNCTION SETTINGS

2.FUNCTION SETTINGS

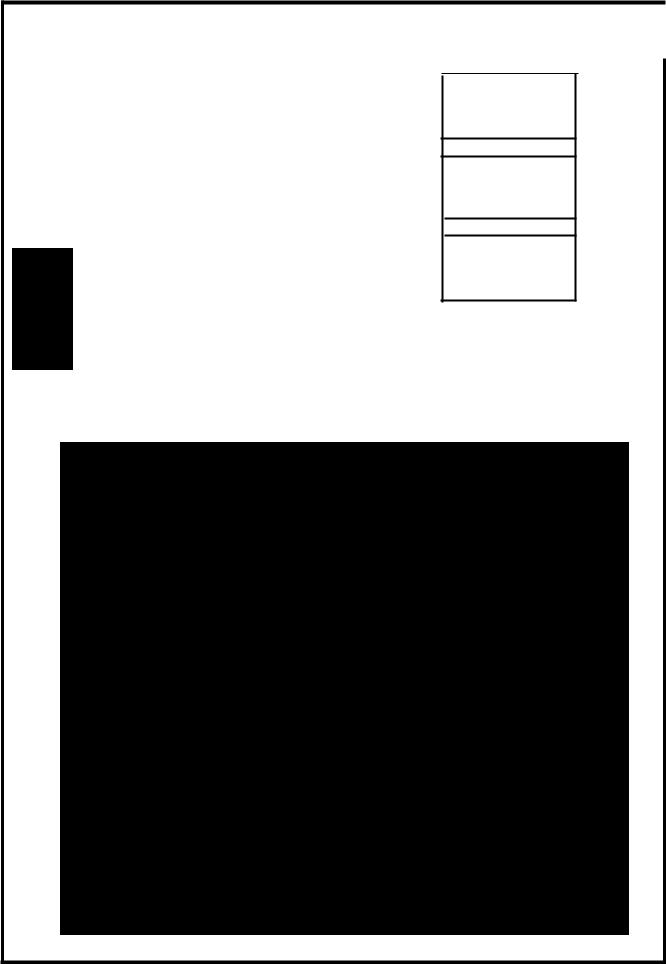

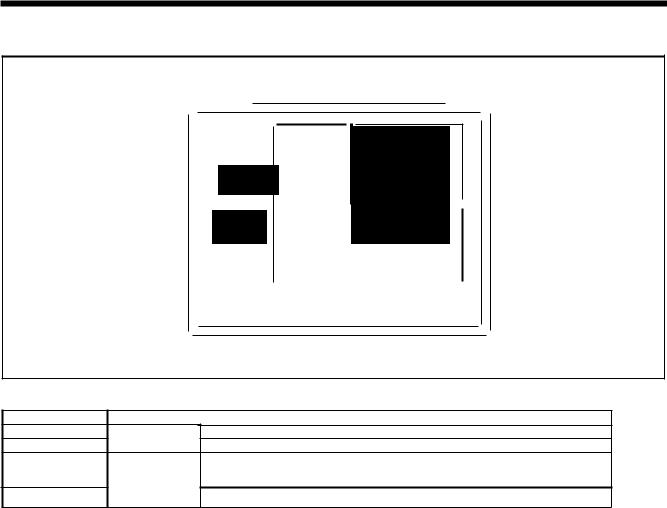

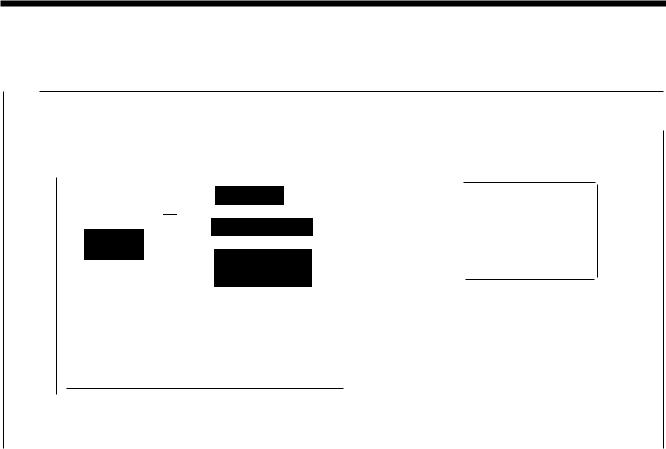

2..1. List of special functions when power is turned on

|

|

|

|

|

|

|

|

brother |

0 |

X X·SCALE |

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

O!CAUTION |

|

+-+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

0 |

tYY·SCALE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

||||||||

|

|

3 |

|

|

|

|

|

|

|

|

|

|

oE)SPEED |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

||||||||

2 |

|

|

|

|

|

|

|

|

|

|

OIDEIEIICOUNTER |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

0 |

_, SPRIT No. |

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-~ |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

§) 888 |

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

1 |

|

8 |

|

|

|

|

|

|

|

|

|

|

4540Q |

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Memory switch setting mode (Standard) |

|

6 |

Output check function |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

+ |

EJ 4541Q |

|

|

|

|

|

|

® |

+ |

D |

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

0 |

|

|

|

|

|

4546Q |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

Refer to the Instruction Manual. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

method". |

||||||||||||||

2 Memory switch setting mode (Advanced) |

|

7 |

|

|

|

|

|

|

|

EJ 4547Q |

|||||||||||||||||||||||

|

|

|

|

|

|

+Q |

|

|

® |

|

li!ll!l |

+ |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

~ |

|||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

04542Q |

|

|

|

STEP |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

Refer to "2-11. Confirmin |

software version". |

|||||||||||||

3 |

+ EJ <5<3Q |

|

Home position adjusting mode |

|

|

|

|

|

|

|

|||||||||||||||||||||||

|

|

|

~ty\ |

~IB!J |

|

D |

|||||||||||||||||||||||||||

|

|

|

STEP\.!_) |

~s':P |

+ u 4548Q |

||||||||||||||||||||||||||||

Refer to "2-7. Clearing saved data (Initialization)".

4 |

Error log display function |

9 |

lmt!J3(!) |

|

EJ |

|

@ |

|

D |

|

. T |

+ |

4544Q |

® |

+ |

0 |

4549Q |

|

STEP |

|

|

|

|

|

|

|

Refer to "2-8. Checkin the error histo |

|

|

|

|

|||

5 Input check function |

|

|

|

|

|

|

|

@ + D |

|

|

|

|

|

||

|

|

0 |

4545Q |

|

|

|

|

2 |

KE-4300, BE-438D |

|

From the library of: Superior Sewing Machine & Supply LLC |

2. FUNCTION SETTINGS

2-2. List of advanced functions

While holding down the TEST key, press the corresponding combination key.

|

|

|

brother |

0 |

X X-SCALE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

O!CAUTION |

|

..... |

|

|

|

|

|

|

|

7 |

||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

tY Y-SCALE |

|

|

|

|

|

|

|

|

|

||

4 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

||

|

|

|

oE}SPEED |

|

|

|

|

|

|

6 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O[Df.JI!1[COUNTER |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

0 |

_I SPRIT No. |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

~--- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

EJ§J§J§J |

|

|

2 |

||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4550Q |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||

1 |

Memory switch setting mode (Standard) |

|

5 |

User program setting mode |

|

|

|

|||||

|

|

+ |

|

|

|

4489Q |

|

• |

+ |

|

|

4493Q |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Refer to the Instruction Manual. |

|

Refer to the Instruction Manual. |

||||||||

|

|

|

||||||||||

|

|

|

||||||||||

|

|

|

|

|

Parallel movement mode |

|

|

|

||||

2 |

Lower thread counter setting mode |

|

6 |

|

|

|

||||||

|

• |

+ |

|

~(!) |

4490Q |

|

Refer-to "2-6. X-Y |

+ |

® |

|

4551Q |

|

|

|

|

STEP |

|

|

|

|

|||||

|

Refer to the Instruction Manual. |

|

rallel movement for sewi |

ttems". |

||||||||

3 |

Production counter setting mode |

|

|

7 |

Grease up counter setting mode |

|

||||||

|

|

+ |

~STEP |

|

|

|

+@ |

|

|

|||

|

|

|

|

ri\ ·:·4491Q |

|

|

|

|

|

4552Q |

||

|

|

Refer to the Instruction Manual. |

|

|

Refer to "8. A |

rease". |

||||||

4 |

Production counter temporary display function |

8 |

CF data read/write mode |

|

|

|

||||||

|

When the SPEED indicator lights |

|

|

|

|

|

|

|

||||

|

Iii+ |

|

|

4492Q |

|

|

+ |

|

|

4553Q |

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Refer to the Instruction Manual. |

|

Refer to "3-3. Pre |

aration for readin |

|

||||||

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

KE-430D, BE-438D |

3 |

From the library of: Superior Sewing Machine & Supply LLC

2. FUNCTION SETTINGS

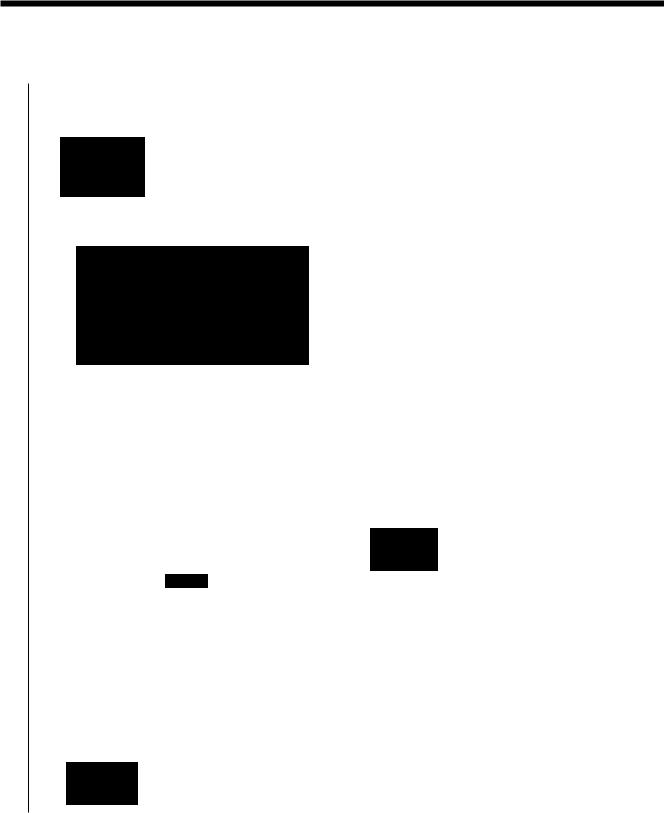

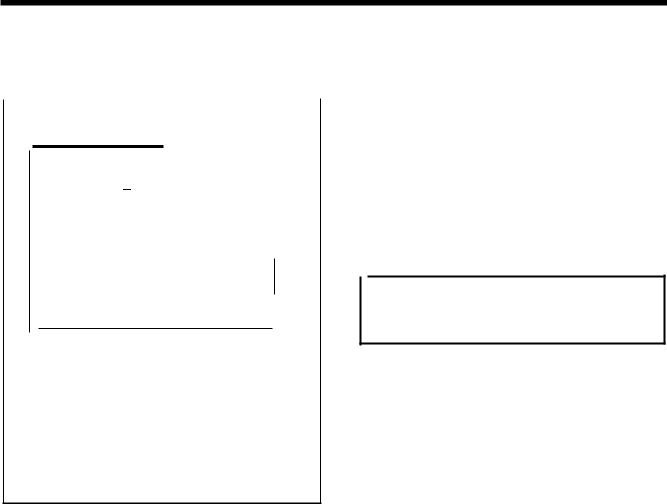

2-3. Setting memory switches (Advanced)

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

While pressing the TEST key and SELECT key, turn on |

|

|

All indicators switch off |

|

|

|

|

|

|

the power switch. |

|||||||||||

|

|

|

|

|

|

|

|

I |

|

|

|

|

|

|

|

* Keep pressing the TEST key and SELECT key until the |

||||

|

|

|

|

|

|

|

|

ol |

YY•SCAlE |

.... |

] ---- , |

|

model name is displayed and the buzzer beeps once. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

brother |

|

....I... |

~ |

|

@ |

|

|

|

|

|||||||||

|

|

|

0 ( X·SCALE |

|

|

|

|

|

||||||||||||

|

|

O!CAIITION |

|

... |

|

|

|

|

PlllGIWINo |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

- |

|

|

|

|

|

ol |

~SPEED |

|

0001:) |

® |

|

|

|

• |

|||||

|

|

|

|

|

|

Ot; |

IIJCOUifi'ER |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

0 I SPRITNo. |

|

|

|

|

|

|

|

|||||||

|

|

• |

|

|

|

|

.....:- |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

1111!(!) ®! |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|||||||||||||

|

|

-• |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

8§)8811 |

|

|

|

PROGRAM No. display, and its setting value will |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• The memory switch number will appear in the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

appear in the menu display. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Menu indicators switch off |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TEST indicator li hts |

4449Q 4421Q |

|||||

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Press the ll or V key to select the memory switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

number. |

Press the A or T key to change the setting value.

~fT\ ® mm...

STEP\!._) STEP

4554Q

-11- you·-.,ioui(l-lii<e -i,,--ilisplay·oniy·tile·iiumilerii·a;·- wtiil~-j,;~~;i~-9thesi=-CEcr·it~y.-j,;~~;iiie-K. -~~-v-i<~y.-- memory switches that have been changed from • The numbers of memory switches that have been default settings changed from default settings will appear in order.

• If no memory switches have been changed from their default settings, the display will not change and the buzzer will beep twice.

|

4555Q |

|

|

3 Ending setting mode |

Press the TEST key. |

|

• The changes will be memorized and the sewing |

|

machine will switch to home position detection standby. |

|

TEST indicator switches off |

•If you would like to return the setting for a single memory switch to the default setting, press the RESET key while the number for that memory switch is displayed.

•To return the settings for all memory switches to the default settings, keep pressing the RESET key for two or more seconds until the buzzer makes a long beep.

4 |

KE-430D, BE-438D |

|

From the library of: Superior Sewing Machine & Supply LLC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. FUNCTION SETTINGS |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

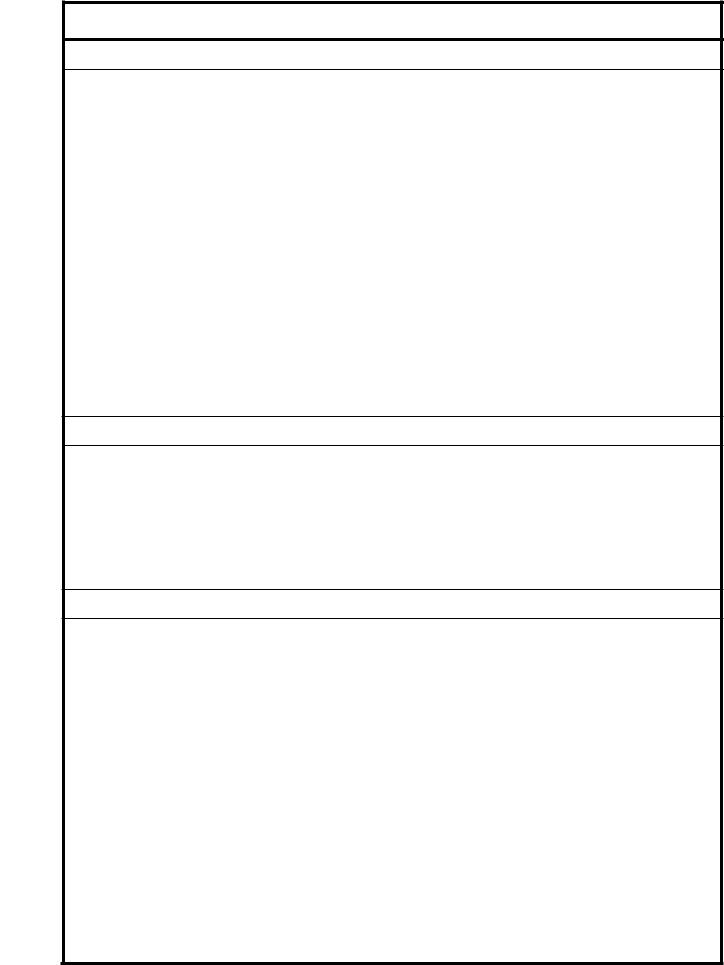

2-4. List of memory switches |

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

Setting |

|

|

|

|

|

|

Setting items |

|

|

Default |

|

||||||

|

range |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

001 |

|

|

Work clamp/button clamp lift timing when sewing is complete |

|

|

|

|

|||||||||||

|

|

|

OFF |

Lifts at the final stitch position. |

|

|

|

|

|

OFF |

|

||||||||

|

|

|

|

ON |

|

Lifts after moving to the home position. |

|

|

|

|

|

|

|

||||||

|

|

|

|

2-step work |

|

clamp |

|

|

|

|

|

|

|

|

|||||

|

003 |

|

|

OFF |

Disable |

|

|

|

|

|

|

|

|

||||||

|

|

|

ON |

Stops at intermediate work clamp height setting mode when foot switch |

is |

OFF |

|

||||||||||||

|

|

|

|

depressed to 1st step, and then drops fully and sewing starts when foot switch is |

|

|

|||||||||||||

|

|

|

|

|

|

|

depressed to 2nd step. |

|

|

|

|

|

|

|

|

||||

|

|

|

|

Slow start |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF |

The sewing speed for the first 1 - 5 stitches is set by memory switch nos. 151 |

- |

|

|

|

||||||||||

|

100 |

|

|

155. |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OFF |

|

||||

|

|

|

ON |

KE-430D: Slow start with 1st stitch sewn at 400 rpm and 2nd stitch sewn at 800 |

|

||||||||||||||

|

|

|

|

|

|

||||||||||||||

|

|

|

|

rpm. |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

BE-438D: Slow start with 1st and 2nd stitches sewn at 400 rpm. |

|

|

|

|

||||||||

|

|

|

|

Sinole-stitch |

test feed |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

OFF |

Test feed starts when the foot switch is depressed, and it continues automatically |

|

|

||||||||||||

|

200 |

|

|

until the final stitch. |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

*1 |

|

||||||

|

|

|

|

|

|

Test feeding is carried out stitch by stitch when the foot switch is depressed. |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

ON |

In addition, when the test indicator is illuminated, test feeding will move foiWard |

|

|

||||||||||||

|

|

|

|

|

|

|

one stitch at a time when the machine pulley is turned by hand. |

|

|

|

|

||||||||

|

|

|

|

Production counter display |

|

|

|

|

|

|

|

|

|||||||

|

300 |

|

|

OFF |

Lower thread counter display |

|

|

|

|

|

OFF |

|

|||||||

|

|

|

|

ON |

Production counter display |

|

|

|

|

|

|

|

|||||||

|

400 |

|

|

User programs |

|

|

|

|

|

|

|

|

|

|

|

OFF |

|

||

|

|

|

OFF |

Disable |

|

|

|

|

|

|

|

||||||||

|

|

|

|

ON |

User program mode is enabled. |

|

|

|

|

|

|

|

|||||||

|

|

|

|

Cycle programs |

|

|

|

|

|

|

|

|

|||||||

|

401 |

|

|

OFF |

Disable |

|

|

|

|

|

|

OFF |

|

||||||

|

|

|

|

ON |

When sewing user programs, the set programs are sewn in numeric order. |

|

|

|

|

||||||||||

|

402 . |

|

Units display for pattern zoom ratio (*2) |

|

|

|

|

|

OFF |

|

|||||||||

|

|

OFF |

Displayed as %. |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

ON |

Displayed as mm. |

|

|

|

|

|

|

|

|

||||||

|

500 |

|

|

Thread nipper |

device |

|

|

|

|

|

|

OFF |

|

||||||

|

|

|

OFF |

Disable |

|

|

|

|

|

|

|

||||||||

|

|

|

|

ON |

Thread nipper device can be used. {*3) |

|

|

|

|

|

|

|

|||||||

*1 Off for KE-430D and ON for BE-438D. |

|

|

|

|

|

|

|

|

|||||||||||

*2 |

The mm display may differ slightly from the actual sewing size. |

|

|

|

|

|

|

|

|||||||||||

*3 |

May not operate if the settings for the memory switches have been changed, or at some sewing speeds. |

|

|

|

|

||||||||||||||

|

*If memory switch No. 151 and No. 152 are set to a combination that does not appear in the following table, the thread |

||||||||||||||||||

|

nipper device will not work. |

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

No. |

|

|

Setting value [1] |

|

Setting value [2} |

Setting value [3] |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

151 |

|

|

|

15 |

|

|

8 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

152 |

|

|

|

20 |

|

|

12 |

6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*If the sewing speed is set to a lower speed than the setting for memory switch No. 152, the thread nipper device will not work.

KE-430D, BE-438D |

5 |

From the library of: Superior Sewing Machine & Supply LLC

2. FUNCTION SETTINGS

work c amp sett1ngs |

|

|

|

|

|

|

|

|

|

|

|||||

No. |

|

Setting |

|

|

|

|

Setting items |

|

|

|

|

Default |

|||

|

|

ranQe |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Work clamp |

motions |

|

|

|

|

|

|

|

||||||

. |

|

1 |

|

|

Single pedal |

Work clamp is raised automatically. |

|

|

|

|

|

||||

|

2 |

|

|

Work clamp is raised by depressing the foot switch. |

|

|

|

1 |

|||||||

|

|

|

|

|

|

|

|

|

|||||||

050 |

|

3 |

|

|

|

|

|

Work clamp is raised automatically, then it is lowered by depressing |

|||||||

|

|

|

|

|

|

|

the work clamp switch. |

|

|

|

|

|

|||

|

|

|

|

|

|

Two pedals |

|

|

|

|

|

|

|||

|

|

4 |

|

|

|

Work clamp is kept lifted while the work clamp pedal is depressing |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

the work clamp switch. |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Work clamp ooeration and thread winder operation before home position detection |

|

|

|

|

|

|||||||||

|

|

|

OFF |

Work clamp vertical movement and thread winder operation are |

not possible |

|

OFF |

||||||||

051 |

|

|

before home position detection. |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

ON |

Work clamp vertical movement and thread winder operation are possible before |

|

|

|||||||||

|

|

|

home position detection. |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

sewmg mach"me motor settings |

|

|

|

|

|

|

|

||||||||

No. |

|

Setting |

|

|

|

|

Setting items |

|

|

|

|

Default |

|||

|

|

range |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Highest needle position stop |

|

|

|

|

|

|

|

|||||||

|

|

|

OFF |

Disable |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

The motor operates in reverse when the upper shaft stops, to return the needle |

|

|

|||||||

150 |

|

|

|

|

|

bar to close to its highest position. |

|

|

|

|

OFF |

||||

|

|

|

|

|

(When the motor operates in reverse to raise the needle, the thread take-up will |

|

|||||||||

|

|

|

ON |

|

|

||||||||||

|

|

|

stop at a position which is lower than its normal stopping position. As a result, the |

|

|

||||||||||

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

thread take-up will rise slightly at the sewing start, and this may result in the thread |

|

|

|||||||

|

|

|

|

|

|

pulling out under certain conditions.) |

|

|

|

|

|

||||

151 |

Speed for the |

first stitch at the sewing start [Units x 100 rpm] |

|

|

|

|

|

||||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

|

|

||||

|

····.r.:-27···· |

-FCirEIE~:38ti~-------------------------------------------------------------- |

|

|

······--· |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

152 |

S_Qeed for the second stitch at the sewing start [Units x 100 rpm] |

|

|

|

|

|

|||||||||

· |

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

|

|

||||

|

----·.r.:-21 |

-FCirEIE~:3ati·-·--------------------------------------------------------------------- |

|

|

|

*4 |

|||||||||

153 |

Speed for the third stitch at the sewing start [Units x 100 rpm] |

|

|

|

|||||||||||

|

|

|

|

|

|||||||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

|

|

||||

|

-------.r.:-27· |

-FCirEIE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

|

|

||||||

154 |

Speed for the |

|

fourth stitch at the sewing start [Units x 100_!I>_m] |

|

|

|

|

|

|||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

|

|

||||

|

----4-.:-27 ____ |

|

-FCirEIE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

|

|

|||||

155 |

Speed for the |

fifth stitch at the sewing start [Units x 100 rpm] |

|

|

|

|

|

||||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

32 |

|||||

|

----4-~27 ____ |

|

-FCirEIE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

27______------ |

||||||

156 |

Speed for the |

fifth stitch before the sewing end [Units x 100 rpmJ |

|

|

|

|

|

||||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

32 |

|||||

|

----4-~27 ____ |

|

|

-FCirEiE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

27·------ ----- |

|||||

157 |

Speed for the |

|

fourth stitch before the sewing end [Units x 100 rpm] |

|

|

|

|

|

|||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

32 |

|||||

|

----4-~27 ____ |

|

|

·FCirEiE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

------27·----- |

|||||

158 |

Speed for the |

|

third stitch before the sewing end [Units x 100 rpmJ |

|

|

|

|

|

|||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

32 |

|||||

|

----4-~27·--- |

|

|

.FCirEIE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

------27·----- |

|||||

159 |

Speed for the |

|

second |

stitch before the sewing end [Units x 100 rpml |

|

|

|

|

|

||||||

|

4-32 |

|

|

ForKE-430D |

|

|

|

|

|

27 |

|||||

|

--·-.r~27 ____ |

-FCirEIE~:3ati·----------------------------------------------------------------------- |

|

|

|

|

|

|

|

||||||

*4 Defa uIt va ues or each modeI setf |

|

mg |

|

|||||||||||

|

|

|||||||||||||

|

No. |

|

KE-430D-01, -07 |

|

|

|

|

|

|

KE-430D-02 |

BE-438D |

|||

151 |

|

|

8 |

|

|

|

|

15 |

|

4 |

||||

152 |

|

|

|

12 |

|

|

|

20 |

|

6 |

||||

153 |

|

|

|

|

32 |

|

|

|

9 |

|||||

154 |

|

|

|

|

32 |

|

|

|

20 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

KE-4300, BE-4380 |

|

From the library of: Superior Sewing Machine & Supply LLC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. FUNCTION SEmNGS |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

No. |

|

Setting |

|

|

|

|

|

Setting items |

|

Default |

|

|

||||||||

|

range |

|

|

|

|

|

|

|||||||||||||

161 |

|

|

Needle penetration force increase |

|

|

|

|

|||||||||||||

|

|

OFF |

Disable |

|

OFF |

|

|

|||||||||||||

|

|

|

ON |

Needle penetration force is increased when sewing machine motor is locked. |

|

|

|

|

||||||||||||

|

|

|

Limitations on sewing speed changes due to chan_g_es in sewing pitch |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

||||||||||||||

162 |

|

|

OFF |

Sewing speed fluctuates accordi1!9_to the sewing pitch in the sewing data. |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

ON |

Sewing speed is fixed at slowest speed for the maximum sewing pitch in the |

|

OFF |

|

|

||||||||||||||

|

|

|

sewing data. |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

(Set to ON ifchanQes in sewi_!l9_sPeed due to change§_in sewil]Q ~itch might be a problem_,}_ |

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

163 |

|

|

Limits maximum sewing speed runits X 100!Il |

_m_1 |

|

|

|

|

|

|

|

|

||||||||

|

12-32 |

|

|

ForKE-430D |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

32 |

|

|

||||||||||

|

|

|

---1-2~-i]r___ |

|

-F<>rEiE:4:iati·----------------------------------------------------------------------- |

------2.,------ |

|

|

||||||||||||

164 |

|

|

No thread trimming |

|

|

|

|

|

|

|

||||||||||

|

|

OFF |

Thread trimming is carried out in accordance with sewing data. |

|

OFF |

|

|

|||||||||||||

|

|

|

ON |

|

|

All thread trimming operations are disabled. |

|

|

|

|

||||||||||

|

|

|

|

|

|

|||||||||||||||

165 |

|

|

Highest needle position stop angle [units 2-degree steps] (*5) |

|

|

|

|

|

||||||||||||

|

-15-0 |

|

|

0 : Normal needle up position |

0 |

|

|

|||||||||||||

|

|

|

|

Needle bar height increases for values in the n~ative direction. |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*5 If the value is set to too large a negative value, error "E11 0" may be generated at the first sewing start after the power is turned on.

Feed setrlnQS

|

No. |

Setting |

|

|

Setting items |

|

Default |

|

||||||

|

range |

|

|

|

|

|||||||||

|

|

|

|

Mechanism |

|

home position return when sewing is complete |

|

|

|

|

|

|||

|

250 |

|

|

OFF |

At the end of sewing, the feed plate will be returned to the sewii'!Qstart point directly. |

|

OFF |

|

||||||

|

|

|

|

|

|

At the end of sewing, |

the feed plate will be returned to the sewing start point via |

|

|

|||||

|

|

|

|

ON |

|

|

|

|||||||

|

|

|

|

mechanical home position. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

Feed speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

100 mm/s Slow |

|

|

|

||||

|

251 |

|

|

2 |

|

|

200 mm/s |

1 |

|

|||||

|

|

|

3 |

|

|

300 mm/s |

|

|||||||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

4 |

|

|

400 mm/s |

|

|

|

||||

|

|

|

|

5 |

|

|

500 mm/s Fast |

|

|

|

||||

|

|

|

|

High speed test feed |

|

|

|

|||||||

|

252 |

|

|

OFF |

Normally slow, but becomes faster when the foot switch is depressed to the 1st st~ |

|

OFF |

|

||||||

|

|

|

|

ON |

Test feeding is carried out at the same speed as normal sewing. |

|

|

|

||||||

|

|

|

|

Home position |

|

detection method |

|

|

|

|||||

|

253 |

|

|

OFF |

Depress foot switch while the program number is flashing. |

|

OFF |

|

||||||

|

|

|

|

|

|

Press the special external input switch [EXIN3] while the program number is |

|

|

||||||

|

|

|

|

ON |

|

|

|

|||||||

|

|

|

|

flashing (foot switch is disabled). |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

260 |

|

|

Changes the |

whole feed timing. |

|

0 |

|

||||||

|

|

|

-10 -10 |

|

|

-10: Early ll 0: Standard ll 10: Late |

|

|||||||

|

|

|

|

|

|

|

|

|

||||||

|

261 |

|

|

Changes the feed timing for the first stitch at the sewing start. |

|

|

|

|||||||

|

|

|

-10 -10 |

|

|

---~~j~~g--+~-}~~~~~~~--g~-~~g~~i~-~-{~~-t~!~---------------------------------- |

-------~------- |

|

||||||

|

|

|

|

|

|

|

||||||||

|

|

|

|

Changes the feed timing for the second stitch at the sewing start. |

|

|

|

|||||||

262 |

|

|

-10-10 |

|

|

---~~j~~g--+~-~-~~~~~~~--g~-~~g-~~~-~-{~~-t~!~--------------------------------- |

-------~------- |

|

||||||

|

|

|

|

|

|

|

||||||||

Changes the feed timing for the third stitch at the sewing start.

|

|

|

263 |

-10- 10 |

---~tl~~-g---~-~~-~~~~~~~--g-~-~~g~~~-~-{~~-t~!~--------------------------------- -------~------- |

|

|

|

|

|

|

Changes the feed timing for the third stitch before the sewing end.

264 |

-10 -10 |

---~~j~~-g---~~-~-~~~~~~~--g~-~~g~~~-~-~~~-t~!~--------------------------------- |

-------~------- |

|

|

|

|

|

|

|

|

Changes the feed liming for the second stitch before the sewi1!9_ end.

|

|

|

|

|

|

|

|

|

|

|

265 |

-10 -10 |

|

- |

~~~-~~~i:~~ |

g~-~~g~~~-~-{~~-t~!~ |

----------------------------- |

------- |

~ |

------- |

|

|

--~tl~~--- |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

Changes the |

feed timing for the first stitch before the sewi1!9_ end. |

|

|

|

|

|

|||

266 |

-10 -10 |

|

---~~j~~g |

~-~~-~~~~~ |

g~-~~g~~~-~-~~{~!~ |

|

_______5_______ |

|||

|

|

|||||||||

|

|

|

|

0 |

||||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

If the overall |

|

feed timing (No. 260 setting) is changed from the default value, this specifies the |

|

|

|

|

|||

|

effective number of stitches. |

|

|

|

|

|

|

|

||

267 |

0 |

|

No limit |

|

|

|

|

|

0 |

|

|

1-99 |

|

Once the specified number of stitches from the sewing start has been reached, |

|

|

|

|

|||

|

|

timing returns to standard feed timiog. |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

KE-4300, BE-4380 |

7 |

From the library of: Superior Sewing Machine & Supply LLC

|

2. FUNCTION SETTINGS |

|

|