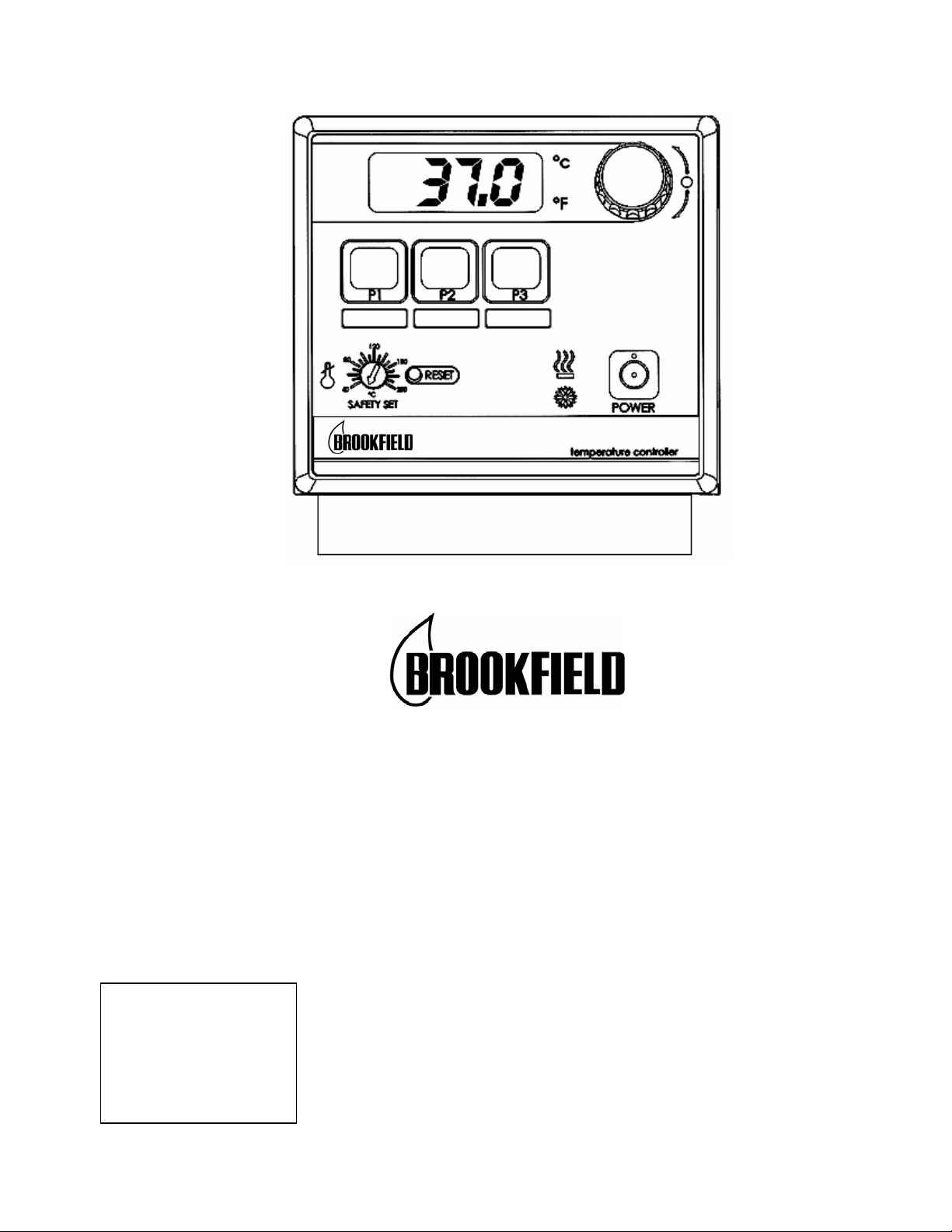

Brookfield TC-602 User Manual

Operators Manual

Circulating Bath with Digital Controller

110-241 Rev. D

ECN 1970

7/04

Table of Contents

Section 1 - General Information

1.1 Unpacking

1.2 Contents

1.3 General Description

1.4 Circulator Pump

1.5 Pump Inlet and Outlet Connections

1.6 Closed Loop Circulation

1.7 Reservoir Purge

1.8 Ambient and Cooling Coil

Section 2 - Standard Controller Information

2.1 Front and Rear Panels

2.2 Heater/Pump Assembly

Section 3 - Operation

3.1 Circulator Location

3.2 Filling the Reservoir

3.3 Power

3.4 Setting the Safety Set Point

3.5 Selecting Temperature Units

3.6 Setting the High Limit

3.7 Setting the Set Point Temperature

3.8 User-Defined Preset Temperatures

3.9 Local Lockout Feature

3.10 Stick-on Strips for Preset Buttons

3.11 Auto-Refrigeration Operation

3.12 Controller Display Messages

Section 4 - Calibration and Maintenance

4.1 Calibration

4.2 Heater

4.3 Pump Motor

4.4 Cleaning

4.5 Maintaining Clear Bath Water

4.6 Condenser, Air Vents, and Reusable Filter

(Refrigerating/Heating Circulators Only)

Section 5 - Troubleshooting

5.1 Unit Will Not Operate (no heat, cooling, or pumping)

5.2 No Pumping

5.3 Slow or Insufficient Pumping

5.4 No Heating

5.5 Insufficient Heating

5.6 No Cooling or Insufficient Cooling

5.7 Triac Failure

Section 6 - Reservoir Fluids

Section 7 - Service and Technical Support

7.1 Replacement Parts

Section 8 - After-sale Support

Section 9 – Warranty

Section 10 – EC Declaration of Conformity

1

This symbol marks chapters and sections of this instruction manual which are particularly relevant to safety. When

attached to the unit, this symbol draws attention to the relevant section of the instruction manual.

This symbol indicates that hazardous voltages may be present.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation is the users’ responsibility.

Section 1 - General Information

1.1 Unpacking

Your circulator is shipped in a special carton.

unit is completely assembled and working properly. Set up and run the unit immediately to confirm

proper operation. Beyond one week, your unit may be warranty repaired, but not replaced. If the

unit is damaged or does not operate properly, contact the transportation company, file a damage

claim and immediately contact the company where your unit was purchased.

Remove any loose packing material that may have fallen into the reservoir during shipping. Before

powering up, check that nothing remains around the heater or circulator pump.

The instructions in this manual pertain to circulating baths, both refrigerated and cooling coil types.

Read the section pertaining to the special instructions for your model.

Retain the carton and all packing materials until the

1.2 Contents

Circulator Bath TC-102D TC-202D TC-502D TC-602D

Operators Manual, warranty card

3/16 in., 1/4 in., and 3/8 in. Nylon

Barbed Tubing Adapters

6 ft. of 1/4 in. ID Latex Tubing HT-Tubing

Adapter Fittings* 1/4 in. NPT – M16, Male (qty 2)

Beaker Platform(s) for Bath

Reservoir

Deck Lid(s)

Blue Hole Plugs

Note: Do NOT Use Above 120°C

Stick-on Strips for Preset Buttons (qty 2)

IEC Power Cord (qty 1)

Note: Work area "opening" is designed to measure samples directly in the bath. If additional viscometer height

is required (spindle/guard clearance), either a 4 inch rod extension (part number BLM-4E) used with type A lab

stand or an 18 inch rod replacement (part number VS-38) used with type S lab stand are available from

Brookfield or an authorized dealer.

*Included with 50Hz Models only.

— 600 ml

— 1000ml

— Solid

— w/Beaker Holes

— 3-1/2 inch

— 4-1/4 inch

701-402

510-209

510-211

TBPS300-295

110-241

510-011

701-402 (qty 2)

701-403

510-210

TBPS300-295

(qty 2)

TBPS300-296

701-402

510-290

510-293

TBPS300-295

701-402

510-246

2

1.3 General Description

Refrigerating/Heating and Heat Only Circulating Baths with the Digital Controller are designed for

use as stand-alone baths or to provide precise temperature control of fluids for closed loop

circulation to external equipment.

All Circulating Bath models feature a reservoir which may be used for immersing samples while the

unit is connected to an external device. Circulating bath models are equipped with either 6 or 10 liter

reservoirs. All wetted parts are corrosion resistant 300 series stainless steel.

Refrigeration is normally required for operation at temperatures below 40°C. However, refrigeration

should not be used when the fluid temperature is above 55°C. Refrigeration should not be turned on

when the ambient air temperature is above 32°C.

Model Specifications TC-102D TC-202D TC-502D TC-602D

Temperature Range Ambient +5° to 150°C Ambient +5° to 150°C -20° to 150°C -20° to 150°C

Temperature Stability

Readout Accuracy

Heater 1100 Watts for 115V models, 1600 Watts for 240V models

Reservoir Volumes 6 liters 10 liters 6 liters 6 liters

Pump Speeds 2-speed - 9 liters per minute or 15 liters per minute

Over-Temp Protection Yes, user-adjustable

Dimensions

l x w x h

Unit Weights 22 lbs (10.0 kg) 28 lbs (12.7 kg) 63 lbs (28.6 kg) 62 lbs (28 kg)

Power Requirement 60Hz 9A @ 115V / 1 / 60Hz

Power Requirement 50Hz 4.5A @ 240V / 1 / 50Hz

14¾ x 8¼ x 14 in.

37.5 x 13.3 x 35.6 cm

(105V - 125V)

(200V - 260V)

13¼ x 14¼x 13¼ in.

33.7 x 36.2 x 33.7 cm

9A @ 115V / 1 / 60Hz

(105V - 125V)

4.5A @ 240V / 1 / 50Hz

(200V - 260V)

± 0.05°C

± 0.5°C

15¾ x 18¾ x 17 in.

40 x 47.6 x 43.2 cm

10A @ 115V / 1 / 60Hz

(105V - 125V)

5A @ 240V / 1 / 50Hz

(200V - 260V)

15¾ x 8¼ x 22½ in.

40 x 21 x 57.1

10A @ 115V / 1 / 60Hz

(105V - 125V)

5A @ 240V / 1 / 50Hz

(200V - 260V)

Environmental Conditions:

● Indoor Use Only ● Over Voltage: Category ll

● Maximum Altitude: 2000 meters ● Operating Ambient: 5° to 30°C

● Relative Humidity: 80% for temperatures to 30°C ● Pollution Degree: 2

● Class 1: Residential, Commercial, Light Industrial ● Class 2: Heavy Industrial

1.4 Circulator Pump

The two-speed simplex (pressure) pump may be used for tempering of samples in the reservoir or

for circulation in closed loops. It is not designed for pumping from the circulator's reservoir into and

out of a second open reservoir.

The HIGH or LOW Speed Selection Switch on the rear of the Controller is used to select pump

speed. LOW is adequate for most applications and provides quieter pumping. HIGH is

recommended where temperature varies frequently and there is a need for fast recovery or when

pumping to multiple external units.

Speed Maximum Pump Outlet Ratings

Selection Line Frequency = 50/60Hz

HIGH 15 LPM / 2.6 PSI

LOW 9 LPM / 1.5 PSI

The data in the table above are based on the following criteria:

1. Maximum pump outlet flow rate is measured in liters per minute (LPM) with no restriction on the

pump outlet.

2. Maximum pump outlet pressure is measured in pounds per square inch (PSI) at no flow.

3. Water was used as the circulation fluid. Water has a viscosity of one centistoke. High viscosity

or low-density fluids will change these figures.

3

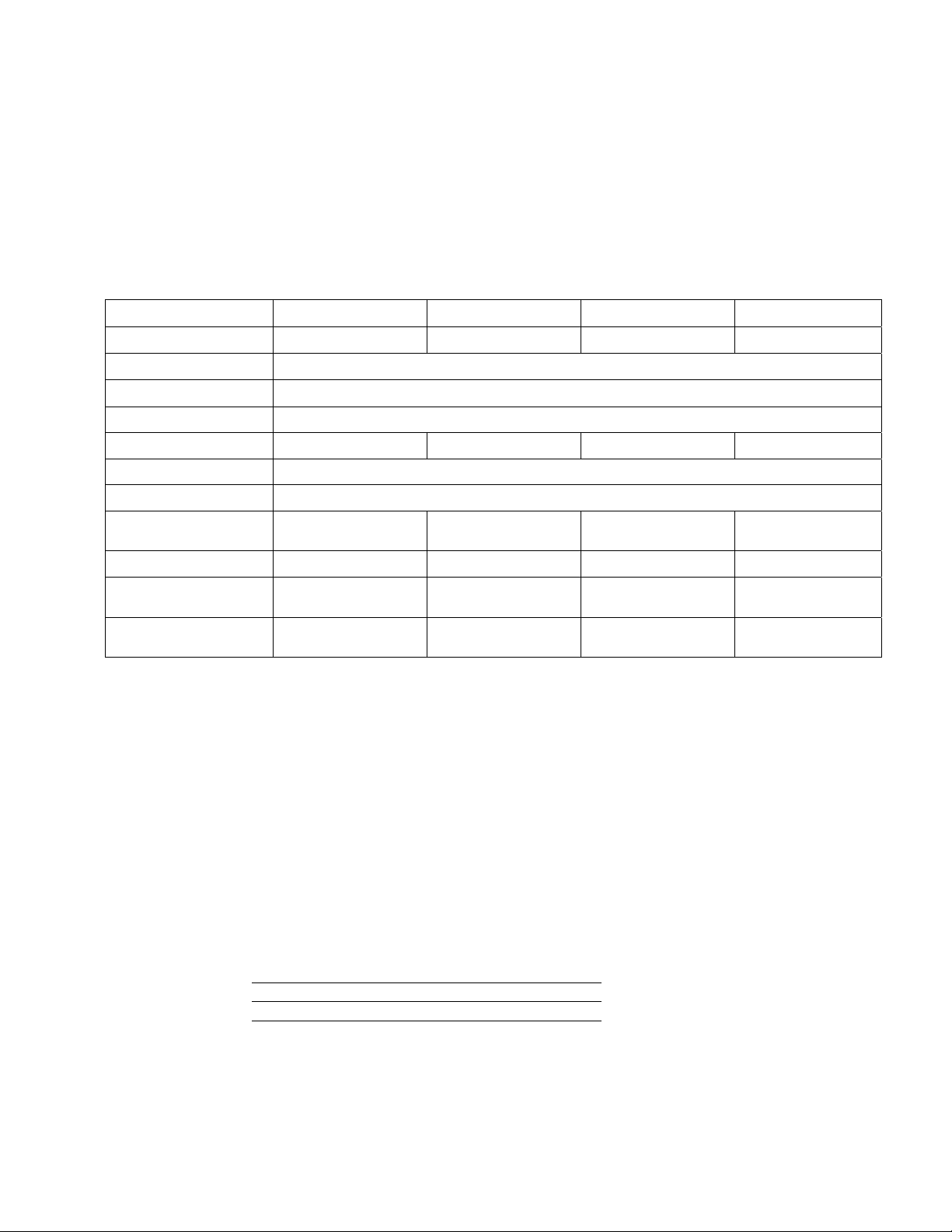

1.5 Pump Inlet and Outlet Connections

A

The pump inlet and outlet ports are female ¼ inch NPT connections that permit use of barbed tubing

adapters or hard plumbing fittings. ½ inch (13mm) ID tubing may also be slid over these connections

and held in place with a hose clamp. If the pump inlet and outlet are not used for external circulation,

they should be connected using the tubing provided with the unit in order to optimize fluid mixing

within the reservoir.

Picture 1: Inlet to Outlet Connection. When bath is not circulating with an external

device, the tubing provided with the unit should be used as shown above.

The nylon barbed tubing adapter fittings supplied with the unit are intended for temperature control from

-40°C to 93°C. For controlling temperature above 93°C, brass, stainless steel, or Teflon

recommended. ¼ inch NPT to M16 stainless steel male adapter fittings are provided with all 50Hz

models.

IT IS THE USER’S RESPONSIBILITY TO ENSURE THAT THE TUBING AND FITTINGS

CONNECTED TO THE CIRCULATOR ARE COMPATIBLE WITH THE BATH FLUID AND

TEMPERATURE RANGE BEING USED.

NOTE: The use of quick-connect fittings will restrict flow rate. Therefore a high or maximum pump

speed should be used.

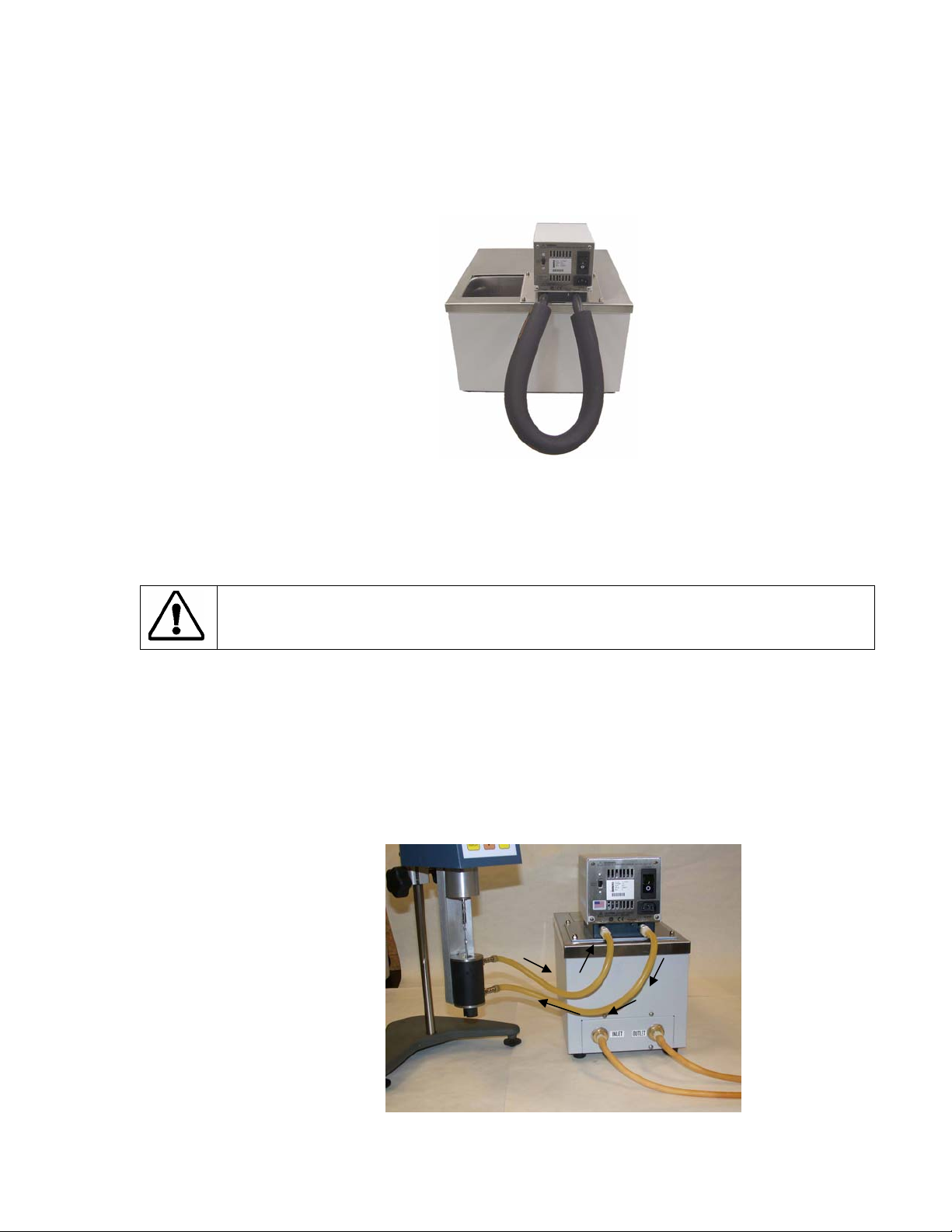

1.6 Closed Loop Circulation

Connect the pump inlet and outlet to the external apparatus (See Picture 2 below). To maintain

adequate flow, avoid restrictions in the tubing. When connecting the Circulator to more than two

closed loops, the use of a manifold made of "Y" adapters to divide the fluid into multiple banks is

recommended. After setting up multiple closed loops, check for adequate flow at the return manifold

of each loop and check that the bath fluid is at an adequate level. A booster pump may be added to

closed loops without damaging the Circulator’s bath pump.

®

fittings are

BATH INLET

B

TH OUTLET

Picture 2: Flow connections. Small Sample Adapter (shown),

DIN and UL Adapters, or Cone and Plate Viscometers.

4

The temperature control stability of a closed loop system is better at the external apparatus than in

the Circulator reservoir (provided the control point of the apparatus represents a constant load and is

well insulated). For example, if you circulate fluid through a viscometer at 50°C, the temperature

variation observed in the Circulator reservoir may be ±0.2°C while the temperature variation in the

viscometer may be only ±0.1°C.

Although temperature stability is generally better at the external apparatus control point, depending on

the length of tubing used and the efficiency of the insulation, the actual temperature reading at the

external apparatus may be slightly different than the temperature reading at the Circulator reservoir.

1.7 Reservoir Purge

When operating at low temperatures, atmospheric moisture tends to migrate into the reservoir and

condense. The 1/8 inch OD Reservoir Purge tube allows you to inject inert gas into the Circulating

bath to prevent the build-up of condensation.

1.8 Ambient and Cooling Coil (Non-refrigerated Models)

Used when auxiliary cooling of circulator coil is needed. Use of cooling coil is recommended when

the bath is operated at 24

o

– 35o C temperatures. When connected to a water source, the stainless

steel coil permits more rapid cooling from high temperatures and will ensure more precise

temperature control and faster response when operating close to ambient temperatures. The cooling

coil inlet and outlet ports are located on the rear of the bath, near the bottom of the reservoir.

5

Loading...

Loading...