Brookfield KU-2 Viscometer User Manual

BROOKFIELD

BROOKFIELD KU-2

KU-2

Viscometer

Operating Instructions

Manual No. M04-242-D0612

SPECIALISTS IN THE

MEASUREMENT AND

CONTROLOFVISCOSITY

with o ces in : Boston • Chicago • London • Stuttgart • Guangzhou

BROOKFIELD ENGINEERING LABORATORIES, INC.

11 Commerce Boulevard, |

M iddleboro, M A 02346 |

USA |

|

TEL 508-946-6200 |

or 800-628-8139 (USA e xcluding |

MA) |

|

FAX 508-946-6262 |

INTERNET |

http://www.brookŒeldengineering.com |

|

Brookfield Engineering Labs., Inc. |

Page 2 |

Manual No. M04-242-D0612 |

|

|

|

|

TABLE OF CONTENTS |

|

I. INTRODUCTION...................................................................................... |

4 |

|

I.1 |

Components................................................................................................................. |

4 |

I.2 |

Options........................................................................................................................ |

5 |

I.2.1 Air Purge................................................................................................................. |

5 |

|

I.2.2 Optional Paste Spindle............................................................................................ |

5 |

|

I.3 |

Specifications............................................................................................................... |

6 |

I.4 |

Sample Container Specifications................................................................................. |

6 |

I.5 |

Utilities........................................................................................................................ |

6 |

I.6 |

Safety Symbols and Precautions................................................................................. |

7 |

I.7 |

Printer Connection....................................................................................................... |

7 |

I.8 |

Viscosity Units............................................................................................................. |

8 |

I.9 |

Cleaning....................................................................................................................... |

8 |

II. OPERATION............................................................................................ |

9 |

|

II.1 |

Set-Up......................................................................................................................... |

9 |

II.2 |

Taking Measurements................................................................................................. |

9 |

II.3 |

Troubleshooting........................................................................................................ |

10 |

Appendix A - KU-2 Calibration Information................................................................ |

11 |

|

Appendix B - References........................................................................................... |

16 |

|

Appendix C - Online Help and Addtional Resources................................................. |

17 |

|

Appendix D - Warranty Repair and Service............................................................... |

18 |

|

Brookfield Engineering Labs., Inc. |

Page 3 |

Manual No. M04-242-D0612 |

|

|

|

I.INTRODUCTION

The Brookfield KU-2 Viscometer measures fluid viscosity in Krebs units. A paddle type spindle is driven at 200 rpm by a constant speed motor. The reaction torque of the spindle rotating at 200 rpm is converted to viscosity in Krebs Units. The digital display of the Viscometer shows viscosity in Krebs Units (KU), the associated grams value (gm), and viscosity in centipoise (cP). The value for centipoise is a conversion from the Krebs value as described in theASTM standard D562. The Viscometer will measure viscosity from 40 KU to 141 KU, at weights of 32 to 1,099 grams (the equivalent centipoise range is 27 - 5,274 cP). Application reference information can be found in ASTM D562.

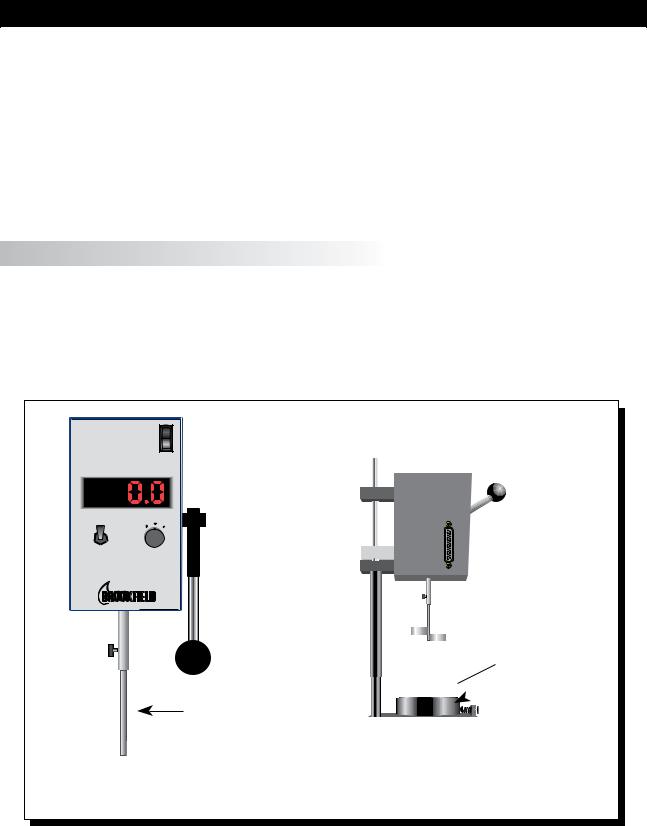

I.1 Components

The KU-2 Viscometer package (Figure 1 and Figure 1.1) includes:

(1) |

KU-2 Viscometer, upright rod and base |

(1) |

U.S. pint can (KU1-34) - not shown |

|

(1) |

Paddle spindle (KU1-10) |

(1) |

Power Cord, 115 VAC (DVP-65) |

or |

(1) |

US 1/2 pint can adapter (KU1-73) |

(1) |

220 VAC (DVP-66) |

|

(1) |

US pint can adapter (KU1-74) |

Operating instructions (M/04-242) |

|

|

POWER |

KU-2

VISCOMETER

gm

KREBS UNITS |

cP |

HOLD

KU1-10

KU1-73

KU1-74

KU1-74

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 1 (front view) |

Figure 1.1 (side view) |

||||

Please check to be sure that you have received all components, and that there is no damage. If you are missing any parts, please notify Brookfield or your local Brookfield agent immediately.

Any shipping damage must be reported to the carrier.

Brookfield Engineering Labs., Inc. |

Page 4 |

Manual No. M04-242-D0612 |

|

|

|

I.2 Options

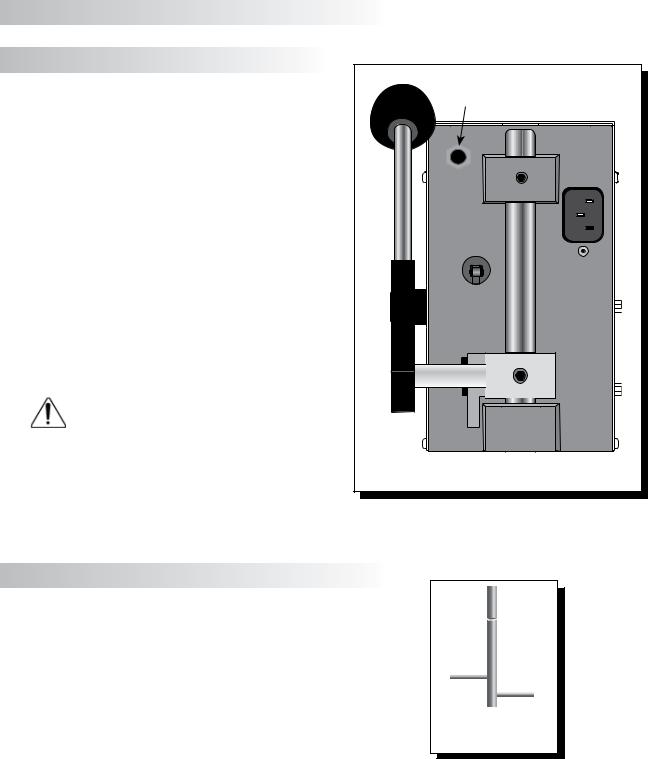

I.2.1 |

Air Purge |

Theairpurgeoption,PartNo.KU-2A(Figure2), allows the interior of the KU-2 to be pressurized with air (or an inert gas) when the instrument is to be used in a hazardous environment. A builtin pressure switch turns the instrument off when the pressure drops below 2.0 PSI (falling). The switch comes on at 10.0 PSI (rising).

Connect a regulated clean air (or inert gas) supply which is non-corrosive to brass to the fitting shown in Figure 2. Adjust the pressure to approximately 25 PSI.

Note: The pressure switch range is 0-40 PSI.

DO NOT CONNECT PRESSURE HIGHER THAN 40 PSI TO THE SWITCH!

Air Purge Fitting |

Figure 2 |

I.2.2 Optinal Paste Spindle

The paste spindle, Part No. KU1-75Y (Figure 3), is a special spindle; it is not included in a standard shipment/order. The designconsistsofoffsetrod-typevanes,approximately2mm diameter x 19 mm long. This spindle is suitable for use with high consistency materials such as roller mill pastes. Do not use this spindle to report normal Krebs Unit measurements or centipoise. Record the grams value shown in the digital display and note that the paste spindle was used to make the viscosity measurement.

Figure 3

Brookfield Engineering Labs., Inc. |

Page 5 |

Manual No. M04-242-D0612 |

|

|

|

I.3 Specifications |

|

Range: |

40–141 KU |

|

32–1,099 gm |

|

27 - 5,274 cP* |

Accuracy: |

± 1% of full scale range |

Repeatability: |

± 0.5% of full scale range |

Paddle speed: |

200 rpm ± 0.1 rpm |

Printer output: |

25D-Type Centronics Parallel Printer Output |

Net weight: |

22 lb. (10 kg) |

Gross weight: |

25 lb. (11 kg) |

Dimensions: |

15 x 11 x 20 |

Operating Environment: |

0°C (32°F) to 40°C (104°F) |

|

20% - 80% R.H.: non-condensing atmosphere |

Electrical Certifications: Conforms to CE Standards for: Electromagnetic Compatibility (EMC),LowVoltage(LVD)andSafetyRequirementsforelectricalequipmentformeasurement control and laboratory use.

*Centipoise scale is for reference only. Do not use for calibration.

I.4 Sample Container Specifications

Container Dimensions |

Can Height |

Bottom Flange Diameter |

|||

U.S. Pint |

|||||

3.850" |

(9.78 cm) |

3.385" |

(8.60 cm) |

||

U.S. Half Pint |

2.850" |

(7.24 cm) |

2.875" |

(7.30 cm) |

|

U.S. Quart |

4.845" (12.31 cm) |

4.230" (10.74 cm) |

|||

If you have a requirement for container dimensions other than those listed above, please contact Brookfield or an authorized Brookfield agent.

I.5 Utilities |

|

|

|

|

|

Input voltage: |

115 VAC or 230 VAC* |

||

|

Input frequency: |

50/60 Hz |

|

|

|

Power consumption: 16 VA (watts) |

|

||

|

Power cord color code: |

|

||

|

|

|

|

|

|

|

|

USA |

Outside USA |

|

Hot (live) |

|

Black |

Brown |

|

Neutral |

|

White |

Blue |

|

Ground (earth) |

|

Green |

Green/Yellow |

*Main supply voltage fluctuations are not to exceed ± 10% of the nominal supply voltage.

Brookfield Engineering Labs., Inc. |

Page 6 |

Manual No. M04-242-D0612 |

|

|

|

Loading...

Loading...