Bosch Worcester Greenstar HIU E, Worcester Greenstar HIU, Worcester Greenstar HIU E Plus, Worcester Greenstar HIU KE Plus Installation And Maintenance Instructions Manual

Installation and maintenance instructions

Heat Interface Unit

Greenstar HIU, HIU E, HIU E Plus & HIU KE Plus

6720808928-00.1Wo

For connection to a district heating system supplying heating and domestic hot water

6 720 808 928 (2017/06) UK & IE

Contents

Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 4

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Appliance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7 Appliance dimensions and hydraulic connections . . . . . 8

2.8 Internal layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.9 Electrical schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.10 Designation of components . . . . . . . . . . . . . . . . . . . . . 12

2.11 Appliance information . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12 Function Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Standards and Guidelines . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Inspection and maintenance . . . . . . . . . . . . . . . . . . . . 17

4 Pre-installation requirements . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 System preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Domestic water supply . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Pressure relief pipe work . . . . . . . . . . . . . . . . . . . . . . . 18

4.5 Cleaning primary system . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Appliance locations and clearances . . . . . . . . . . . . . . . 19

4.6.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6.2 Rooms containing a bath or a shower . . . . . . . . . . . . . 19

4.6.3 Installation and maintenance Clearances . . . . . . . . . . 19

4.6.4 Compartment clearances . . . . . . . . . . . . . . . . . . . . . . . 20

4.7 Example layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.7.1 Unmixed central heating with radiators . . . . . . . . . . . . 20

4.7.2 Unmixed central heating with under-floor . . . . . . . . . . 21

4.8 Mounting frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Support bracket and mounting frame fitting . . . . . . . . 22

5.1.1 Wall mounting template . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.2 Fitting support bracket and mounting rail . . . . . . . . . . 23

5.1.3 Example pipe-work installation. . . . . . . . . . . . . . . . . . . 23

5.1.4 Fitting the filling link assembly . . . . . . . . . . . . . . . . . . . 23

5.1.5 Fitting an external filling link (not supplied with appliance)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.6 Flushing valve accessory installation . . . . . . . . . . . . . . 24

5.1.7 Flow regulating valve (not supplied with appliance) . . 25

5.1.8 Hydraulic connections on mounting frame . . . . . . . . . 25

5.2 Hanging the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.1 Pre wired mains cable . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.3.2 Installer connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3.3 Access to electrical connections: . . . . . . . . . . . . . . . . . 27

5.3.4 Cable retainer clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.4 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 By-pass function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.6 Limit return temperature . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Cleaning the primary circuit . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Flushing kit accessory . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Filling and venting the unit . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.1 Integral keyless filling link . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.2 External filling link (not supplied with appliance) . . . . . 31

6.4 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.1 Control unit LED Indicators . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2 Domestic hot water rotary switch . . . . . . . . . . . . . . . . . 32

6.4.3 Central heating rotary switch . . . . . . . . . . . . . . . . . . . . . 32

6.5 Control valve status indication . . . . . . . . . . . . . . . . . . . . 33

6.6 Central heating circulation pump . . . . . . . . . . . . . . . . . . 33

6.6.1 Pump key lock function . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6.2 Pump operational status and view pump curve setting 33

6.6.3 Available hydraulic pressure . . . . . . . . . . . . . . . . . . . . . 34

6.6.4 Central heating circulation pump Characteristics . . . . 34

6.6.5 Pump curve adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7 Sense II (EMS controller) configuration . . . . . . . . . . . . 35

6.7.1 Operating the service menu . . . . . . . . . . . . . . . . . . . . . . 35

6.7.2 Central heating settings - Outdoor temperature or Room

temperature compensated control . . . . . . . . . . . . . . . . 36

6.7.3 Heat Interface Unit settings . . . . . . . . . . . . . . . . . . . . . . 36

6.7.4 Electronic by-pass function setup . . . . . . . . . . . . . . . . . 36

6.7.5 Floor drying function . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8 Integral heat meter (if fitted) . . . . . . . . . . . . . . . . . . . . . 38

6.9 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.9.1 Typical for District heating water . . . . . . . . . . . . . . . . . . 40

6.9.2 Domestic hot water for copper brazed plate heat

exchangers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.10 Domestic hot water performance chart . . . . . . . . . . . . . 42

6.11 Central heating performance charts . . . . . . . . . . . . . . . 44

6.11.1 15kW & 7.5kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.11.2 5kW & 3.5kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.12 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.13 Commissioning checklist . . . . . . . . . . . . . . . . . . . . . . . . 48

6.14 Fitting the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.15 Hand over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.16 Appliance guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.16.1 Guarantee registration . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7 Inspection and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1 Cleaning the district filter . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.1 Removing the cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.2 Draining the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.1.3 Filter removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.2 Inspection record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8 Replacement of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1 Draining the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.2 Plate heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.3 Control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 720 808 928 (2017/06)2

8.4 Differential pressure control valve . . . . . . . . . . . . . . . . 55

8.5 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.6 Heat meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.7 Expansion vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.8 Domestic hot water NTC sensor and safety valve . . . . 56

8.9 Flow turbine, flow regulator assembly and filter . . . . . 57

8.10 Summer by-pass (if fitted) . . . . . . . . . . . . . . . . . . . . . . 57

8.11 District and central heating NTC sensors . . . . . . . . . . . 57

8.12 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9 Fault finding and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1 Central heating trouble shooting guide . . . . . . . . . . . . 59

9.2 Domestic hot water trouble shooting guide . . . . . . . . . 60

9.3 HIU Control unit LED indications . . . . . . . . . . . . . . . . . 61

9.4 Control valve fault indication . . . . . . . . . . . . . . . . . . . . 62

9.4.1 Action of control valve during an error . . . . . . . . . . . . . 62

9.4.2 Control valve calibration . . . . . . . . . . . . . . . . . . . . . . . . 62

9.5 Circulating pump fault indication . . . . . . . . . . . . . . . . . 62

9.6 Sense II (EMS controller) Diagnosis menu . . . . . . . . . . 63

9.6.1 Operating the service menu . . . . . . . . . . . . . . . . . . . . . 63

9.6.2 Heat Interface Unit diagnosis menu . . . . . . . . . . . . . . . 63

9.6.3 Heat Interface Unit diagnosis functions . . . . . . . . . . . . 63

9.6.4 Heat Interface Unit function test menu . . . . . . . . . . . . . 64

9.7 Central heating pump test . . . . . . . . . . . . . . . . . . . . . . . 64

9.8 Heat meter (if fitted) . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.9 Component resistance characteristics . . . . . . . . . . . . . 64

9.9.1 Flow/return temperature NTC sensors . . . . . . . . . . . . . 64

9.9.2 DHW NTC wet sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.9.3 Outdoor weather compensation sensor . . . . . . . . . . . . 64

Contents

6 720 808 928 (2017/06) 3

Key to symbols and safety instructions

1

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

List entries, first and second levels

• A single component/item

• A component/list, made up of multiple parts/items.

– Sub component or sublist of main component/list.

–etc.

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Important information

This symbol indicates important information where

there is no risk to people or property.

Additional symbols

Symbol Meaning

a numbered step in an action sequence

a step in an action sequence

a reference to a related part in the document or to other

related documents

a reference number to identify or refer to a part or item

a list entry

a list entry (second level)

Table 1 Symbols

Examples of additional symbols used

A numbered step in an action sequence

A sequence of numbered steps or actions carried out in a specific order

to complete a task.

1. First action

2. Second action

3. Third action

etc.

A step in an action sequence

A sequence of defined actions or steps carried out in order to complete

a task.

▶Action

▶Next action

▶etc

A reference to a related part in the document or to other related

documents.

To refer the reader to a specific figure/table/section within the manual.

e.g. figure 1.

A reference number to identify or refer to a part or item.

In a related figure, items or parts identified by a sequential number.

1.2 General safety instructions

Follow these guidelines

▶ Country-specific regulations and standards must be observed when

installing the appliance.

▶ The local regulations and requirements for the electrical connection

of the power supply.

▶ The regulations and standards relating to the safety equipment of the

heating system.

▶ Read any installation instructions (Heat interface unit, heating

controls, etc.) carefully before starting the installation.

▶ Observe the safety instructions and warnings.

▶ Observe national and regional regulations, technical rules and

guidelines.

▶ Record all work carried out.

Risk of electrical shock

▶ Any electrical work or maintenance must only be carried out by

qualified/registered person.

▶ Before carrying out any work on electrical components, isolate them

from the power supply (230 V AC) (fuse, circuit breaker) and secure

against unintentional reconnection.

Appliance operation

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge, if

they have been given supervision or instruction concerning

the use of the appliance, in a safe way, and understand the

hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

Important handling instructions

Care should be taken when transporting, lifting and carrying the

appliance.

▶ Use a means of transport suitable for handling appliances (e.g. sack

truck with strap, stair climbing or step trolley).

▶ When handling appliances, secure them against a fall.

▶ Let only trained personnel undertake the handling.

▶ The correct method for handling heavy objects should be strictly

observed, at all times.

General handling guidelines

▶ Only remove packaging at the time of the final installation.

▶ Never lift or carry the appliance on your own.

▶ Never lift or carry packages by the shipping straps.

▶ During handling and unpacking, wear safety gloves to prevent

injuries to your hands through sharp-edged appliance components.

▶ Dispose of packaging materials appropriately.

6 720 808 928 (2017/06)4

Key to symbols and safety instructions

Packaging

The following points should be observed during unpacking:

• Check the delivery immediately upon receipt for completeness and

transport damage

• In the event of transport damage, the delivery should only be

accepted conditionally

• Do not use damaged components for assembly

• The first fix rail can be removed from the side of the carton via a

perforated flap so that it can be fitted without having to remove the

rest of the appliance and cover from the packaging. This will reduce

the risk of damage to the rest of the appliance whilst the system is

being commissioned. The remainder of the appliance will remain in

the packaging and can be stored safely until needed.

• Carefully unpack the unit

• Ensure that all packaging material is removed and the unit is free from

all materials that may prevent the unit from operating correctly

Siting and installation

Correct siting, assembly and installation of the individual components

are the fundamental requirements for safe and economical operation of

the appliance.

▶ Only trained contractors are to site and install the appliance and its

components.

▶ The appliance must only be installed in rooms and locations that

meet the manufactures requirements.

Commissioning

▶ The appliance and the components must only be commissioned by a

competent person.

▶ Check all connections for leakages prior to starting up the heating

system.

▶ All fixings and fittings must be checked and tightened if required after

the unit has been installed.

Risk of damage due to operator error

Operator errors can result in injury and damage to property.

▶ Ensure that only personnel who can operate this appliance correctly

have access to it.

Inspection, maintenance and repairs

▶ Inspection, maintenance and repairs must only be carried out by

competent persons.

▶ Use only original spare parts from the manufacturer. The

manufacturer can assume no liability for damage caused by spare

parts not supplied by the manufacturer.

Electrical work

Electrical work must only be carried out by a qualified electrician:

▶ Before starting electrical work;

– Ensure that the electricity supply is safely isolated and secure to

prevent inadvertent re-connection.

– Information on safe isolation can be found in the Health and

Safety Executive Guidance HSG85.

– Using test equipment approved to GS38 confirm that the

electricity supply is disconnected.

▶ Refer to the manufacturer’s information when installing other

components with Worcester equipment within the system.

Heat Exchanger

The unit contains copper-brazed stainless steel heat exchangers.

Please ensure the system complies with the requirements in

BS EN 12502 Part 1 and 2 to avoid any damage caused by corrosion.

Danger of burns and scalds

▶ Surfaces of individual components, connections and leaking water

can be very hot and cause severe burns and scalds.

▶ Do not touch hot surfaces.

▶ Caution should be taken not to touch any leaking water or drained

system water unless the temperature is known and safe.

Leakage

If leaks are observed:

▶ Immediately close all isolation valves.

▶ Ensure all leaks are repaired by a suitably qualified professional.

CAUTION: The district heating side of the appliance can

be operated with high pressure and high temperature

systems.

▶ Please apply extreme caution and wear the

appropriate safety equipment (PPE) when working

on suspected leaks.

NOTICE: The pressure differential across the primary

circuit of the heat interface unit must not exceed 80kPa

(800mbar) on units without a DPCV (differential

pressure control valve) as standard.

For units with internal DPCV (differential pressure

control valve) fitted, the maximum differential pressure

is 400kPa (4000mbar).

▶ A suitable means of control should be installed to

limit the differential pressure if the system design is

expected to exceed the limits above (depending on

the HIU model).

Instructing the customer

When handing over, instruct the user how to operate the heating system

and inform them about its operating conditions.

▶ Explain how to operate the heating system and draw the user's

attention to any safety-relevant action.

▶ Explain that modifications and repairs must only be carried out by an

authorised contractor.

▶ Hand customers the appliance documentation for safekeeping.

6 720 808 928 (2017/06) 5

Appliance information

2 Appliance information

2.1 General information

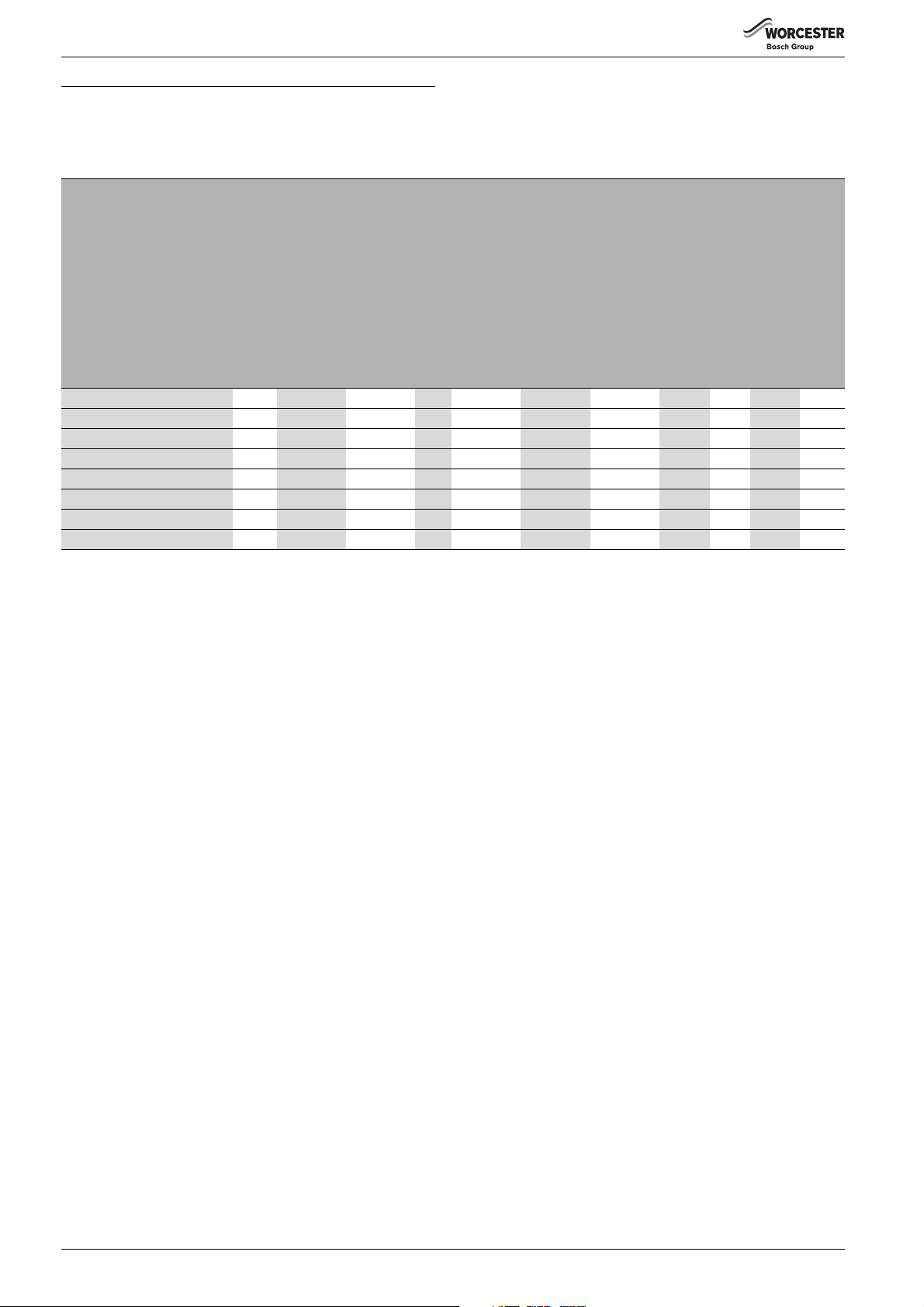

Model matrix

2)

1)

Model

Heat meter

Differential pressure control valve

Summer by-pass

Keyless filling link assembly

Flushing valve

Vertical pipe kit

Heat meter adaptor kit

Domestic hot water output (KW)

Domestic hot water flow rate (l/m)

Flow regulator colour

HIU KE Plus with heat meter Yes Yes Yes Yes Accessory Accessory No 58.6 21 Red 15

HIU KE Plus No Yes Yes Yes Accessory Accessory Accessory 58.6 21 Red 15

HIU E Plus with heat meter Yes Yes Yes Yes Accessory Accessory No 39.1 14 Pink 15

HIU E Plus No Yes Yes Yes Accessory Accessory Accessory 39.1 14 Pink 15

HIU E with heat meter Yes Yes Accessory Yes Accessory Accessory No 39.1 14 Pink 15

HIU E No Yes Accessory Yes Accessory Accessory Accessory 39.1 14 Pink 15

HIU with heat meter Yes Accessory Accessory Yes Accessory Accessory No 39.1 14 Pink 15

HIU No Accessory Accessory Yes Accessory Accessory Accessory 39.1 14 Pink 15

Table 2 Model matrix

1) Domestic hot water output values are for a temperature rise of 40K.

2) Domestic how water flow rate values are for a temperature rise of 40K.

Main Features

• Easy to install with minimal installation space required.

• Internally insulated to minimise heat loss.

• Provides domestic hot water and central heating to properties.

• Hydraulic system separation with two heat exchangers.

• Domestic hot water demands take priority over central heating demands.

• The domestic hot water plate heat exchanger temperature is optimised to reduce the risk of lime scale formation.

• The electronic control unit provides fully modulated central heating and domestic hot water temperature control.

• Temperature controlled primary heating flow, via a by-pass valve, ensures heat is immediately available when domestic hot water is required.

• Low return temperature in the primary circuit maximises efficiency of the system.

• The appliance can be supplied with or without a heat meter fitted.

• Installation pipe work can be routed down behind the back of the HIU.

– Pre-plumbing kit available

Central heating output (kW)

6 720 808 928 (2017/06)6

Appliance information

6720808928-46.1Wo

2

0086

1

6720810422-03.1Wo

1

2.2 Intended use

The appliance provides domestic hot water and central heating to

properties that are serviced from district heating or central boiler plants.

The appliance consists of two heat exchangers, one for the domestic hot

water providing instant hot water at a safe regulated temperature and

the second for central heating. The appliance is indirect so the primary

heating circuit is hydraulically separated from the property central

heating by the second plate heat exchanger. Domestic hot water takes

priority over the central heating demand.

This appliance must only be used as a source of heating and hot water in

a sealed system.

Refer to the details on the type plate and the specifications to ensure

correct use of this appliance.

2.3 Misuse

Appliance must be used as per the intended use statement. Operation

outside the parameters of the intended use is considered misuse and

could cause harm to people and damage to property.

Using the appliance outside of its intended use may also invalidate the

manufacturer's guarantee.

2.4 Declaration of conformity

This product, in design and operation, conforms to the European

Directives and supplementary national requirements.

Compliance is demonstrated by the CE marking.

You can request the declaration of conformity for the product. To do so,

send your request to the address on the back of the manual.

The appliance is tested to the relevant clauses of the following

standards: EN60335,EN62233,EN55014 and EN61000.

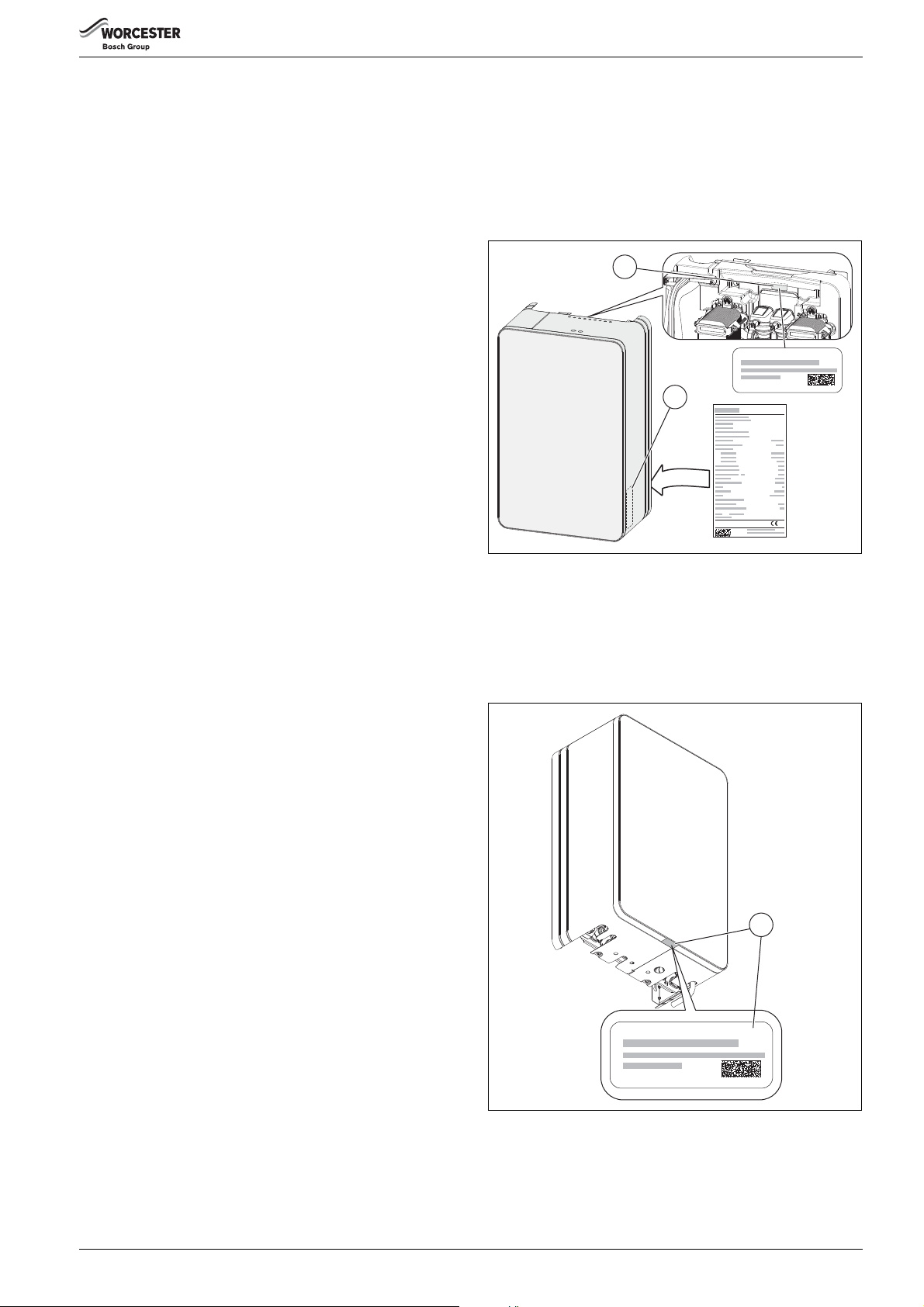

2.5 Type plate

Refer to figure 1

The type plate contains information on device performance, the

registration data and the serial number. This is located inside the

appliance cover [2].

There is an addition data label [1] which also has the registration data

and the serial number. This is located on the back plate behind the

control unit.

Fig. 1 Type plate location

Customer identification of the appliance

Refer to figure 2

The customer can easily identify the appliance as there is also a

additional data label [1.] This contains information of the appliance

model and serial number and is located on the bottom centre of the

cover panel.

Fig. 2 Customer data label

6 720 808 928 (2017/06) 7

Appliance information

6720808928-03.1Wo

263

1 2 3 4 5 6

7

440

270

390

18

19

18

65 65 65 65 65

40

127 50

79

700

582

37

81

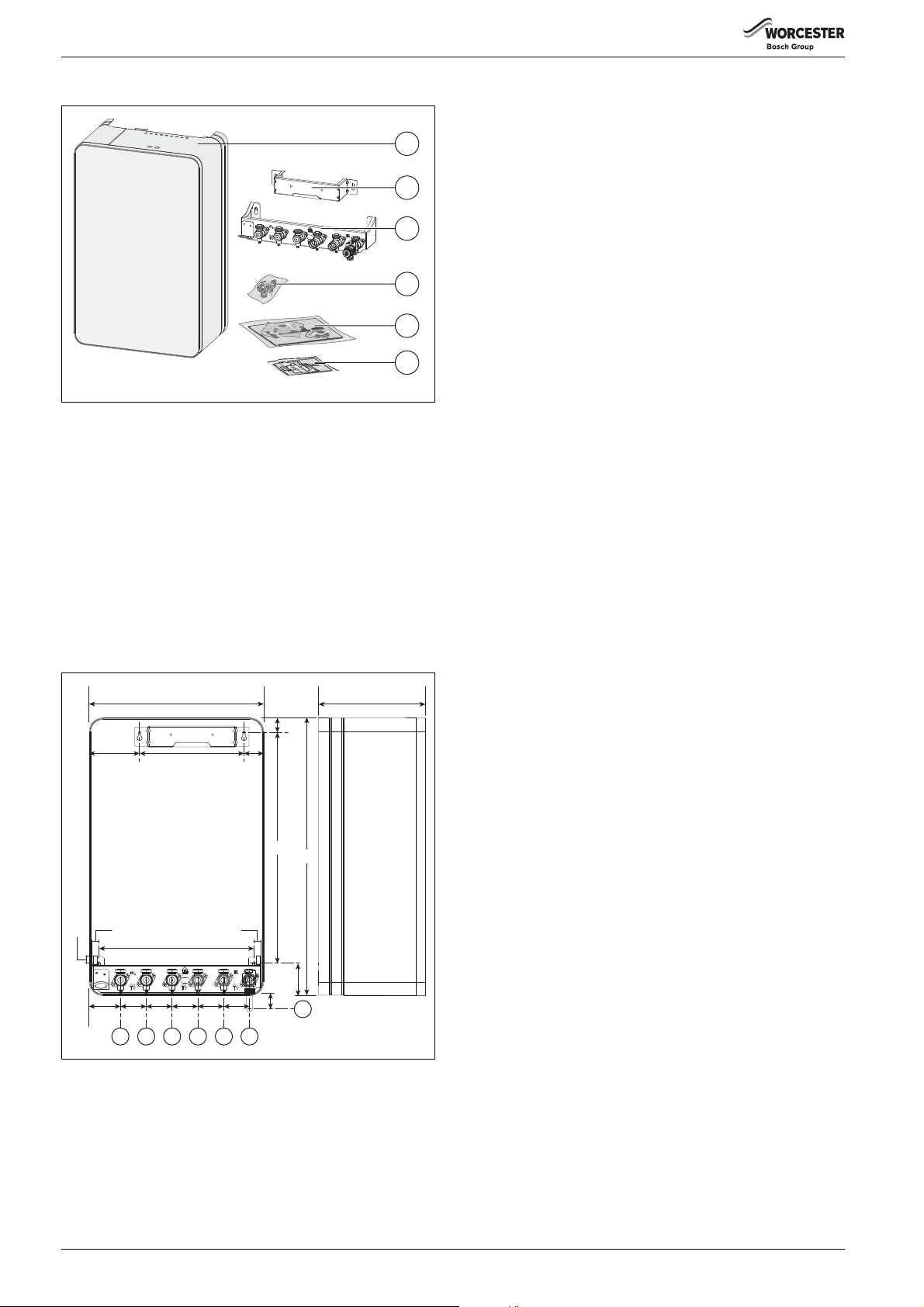

2.6 Standard delivery

Fig. 3 Standard package contents

[1] Heat Interface Unit

[2] Support bracket

[3] Mounting frame

[4] Filling link assembly

[5] Fittings and literature pack:

- Installation and Maintenance Instructions

- User Instructions

- Wall mounting template

- Sealing pack

- Compression fittings

- Pressure Relief Valve installer connection elbow

[6] Pre-payment scheme kit

1

2

3

4

5

6

6720808928-07.1Wo

2.7 Appliance dimensions and hydraulic connections

Fig. 4 Casing dimensions and hydraulic connections

[1] Cold mains inlet (22mm)

[2] Domestic Hot Water outlet (22mm)

[3] District heating supply (22mm)

[4] District heating return (22mm)

[5] Central heating flow (22mm)

[6] Central heating return (22mm)

[7] Pressure relief valve (15mm)

6 720 808 928 (2017/06)8

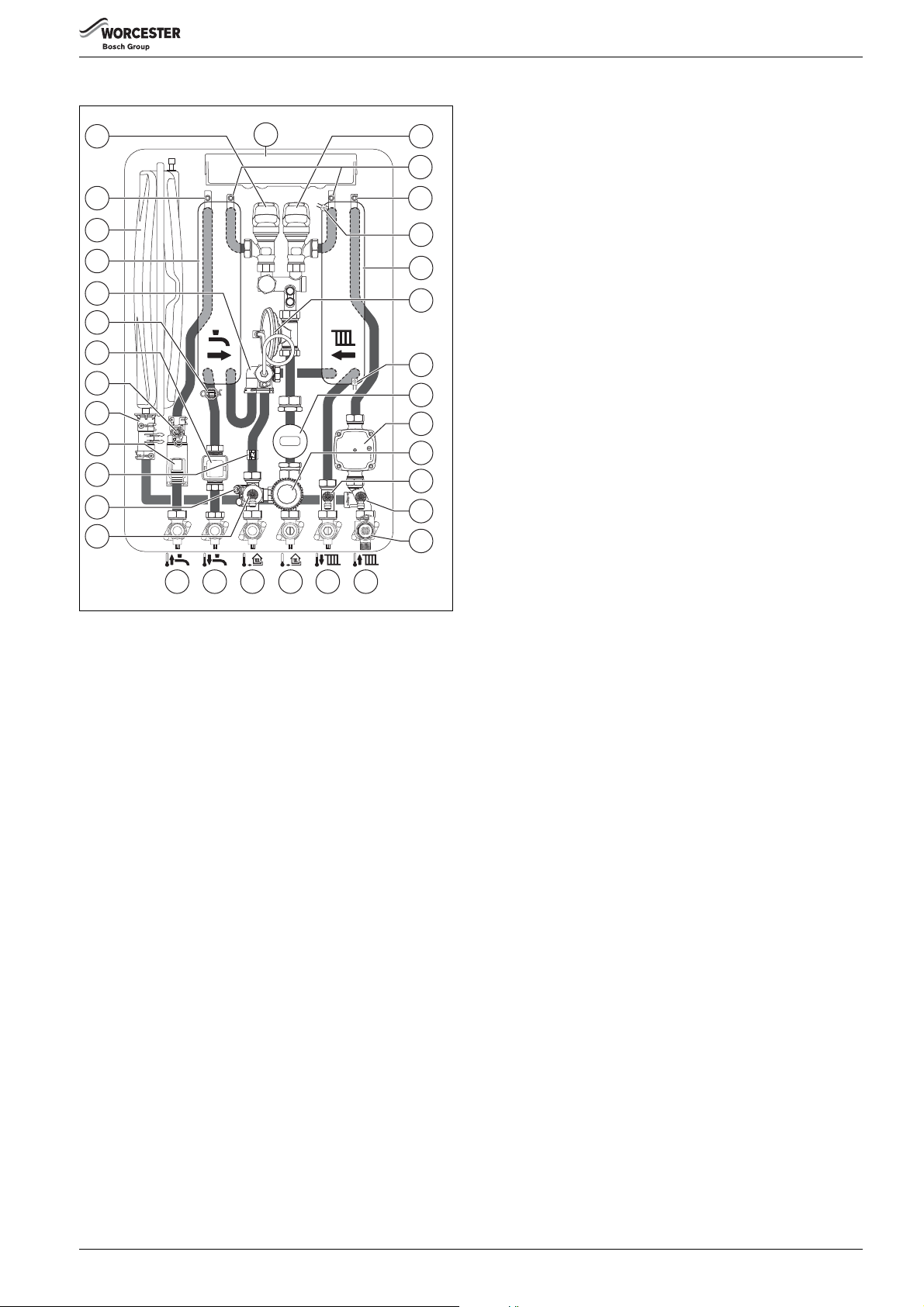

2.8 Internal layout

1

2

33

32

31

30

29

28

27

26

25

24

23

22

21

20 19 18

Fig. 5 Example HIU KE Plus with heat meter

17 16

3

4

5

6

7

8

9

10

11

12

13

14

15

Appliance information

[1] Domestic Hot Water control valve

[2] Control unit

[3] Central heating control valve

[4] Manual air vent (district heating)

[5] Manual air vent (central heating)

[6] Return sensor NTC (district heating)

[7] Plate heat exchanger (central heating)

[8] Differential pressure control valve (if fitted, Table 2, Model

matrix for standard component or accessory)

[9] Flow sensor NTC (central heating)

[10] Heat meter (if fitted, Table 2, Model matrix for standard

component or accessory)

[11] Central heating circulating pump

[12] By-pass valve (if fitted, Table 2, Model matrix for standard

component or accessory)

[13] Drain point (central heating flow)

[14] Drain point (central heating return)

[15] Pressure relief valve (central heating)

[16] Central heating return connection

[17] Central heating flow connection

[18] District heating return connection

[19] District heating supply connection

[20] Domestic Hot Water outlet connection

[21] Cold mains inlet connection

[22] Filter and drain point (district heating)

[23] Heat meter flow sensor connection point

[24] Supply sensor NTC (district heating)

[25] Flow turbine and flow regulator

[26] Expansion vessel connection point

6720808928-01.2Wo

[27] Domestic Hot Water pressure relief valve

[28] Domestic Hot Water safety valve

[29] Domestic Hot Water outlet sensor NTC

[30] Manifold (district heating)

[31] Plate heat exchanger (Domestic Hot Water)

[32] Expansion vessel

[33] Manual air vent (Domestic Hot Water)

6 720 808 928 (2017/06) 9

Appliance information

6720808928-14.1Wo

2

18

17

16

11

12

15 14

13

10

6

7

4

3

5

1

9

8

1

5

3

2

4

M

LR

L

120/230 VAC

PW2PW1

N

14 N

14 N

2.9 Electrical schematic

Fig. 6 Electrical schematic

[1] Control unit

[2] Low voltage connections (rear in service position)

[3] 230V connections (rear in service position)

[4] Low voltage connections (front in service position)

[5] 230V connections (front in service position)

[6] Sense II connection

[7] Outdoor weather sensor

[8] 230V external control system

[9] Limiter connection (pre-wired link) remove link to connect limit

thermostat (for under-floor heating circuit protection)

[10] Mains 230V supply

[11] Circulating pump

[12] Flow sensor NTC (central heating)

[13] Return sensor NTC (district heating)

[14] Central heating control valve

[15] Domestic Hot Water control valve

[16] Supply sensor NTC (district heating)

[17] Domestic Hot Water outlet sensor NTC

[18] Flow turbine

[M] Provision for heat meter M-Bus connection

6 720 808 928 (2017/06)10

Control unit connections

63 N

4321

21

4321

4321

21

21

21

21

BUS

EMS

21

21

PW1

14 N

21

Component connections Installer connections

Connections/

Symbol

Function

Circulation pump

• Live output [Brown]

• Neutral output [Blue]

• Earth output [Green/Yellow]

Flow turbine connection

• Red [4]

•-

• Yellow [2]

• Black [1]

Flow sensor NTC (district heating)

• White [2]

• White [1]

Connections/

Symbol

LR L

230V

OUT

LN

230V

IN

LN

Function

Limiter thermostat (under-floor safety cut-off)

•Potential free

230 V feed to external controls modules

• Live output [L]

• Neutral output [N]

• Earth output [ ]

230 V supply to the appliance

• Live input [L]

• Neutral input [N]

• Earth input [ ]

Not used

Domestic Hot Water sensor NTC

• Blue [2]

21

• Blue [1]

Central heating control valve

Sense II connection

• Not polarity sensitive

• Brown [4]

• Black [3]

• White [2]

• Yellow [1]

Outdoor temperature sensor

• Not polarity sensitive

Domestic Hot Water control valve

• Blue [4]

• Green [3]

• Grey [2]

• Red [1]

Flow sensor NTC (central heating)

• Yellow [2]

• Yellow [1]

Return sensor NTC (district heating)

• Green [2]

• Green [1]

LR

14 N

120/230 VAC

L

PW2

N

Not used

230 V feed to external time and temperature

control

• Switch live demand input [LR]

• Live output [L]

• Neutral output [N]

• Earth output [ ]

Not used

Not used

Appliance information

Not used

Control panel fuse

Table 4

Table 3

6 720 808 928 (2017/06) 11

Appliance information

6720808928-02.2Wo

1

2

7

3

6

5

4

3

8

9

39

38

10

11

13

14

32

31

27

28

15

12

16

17

19

18

20

22

23

30

29

25

24

26

21

36

37

35

33

34

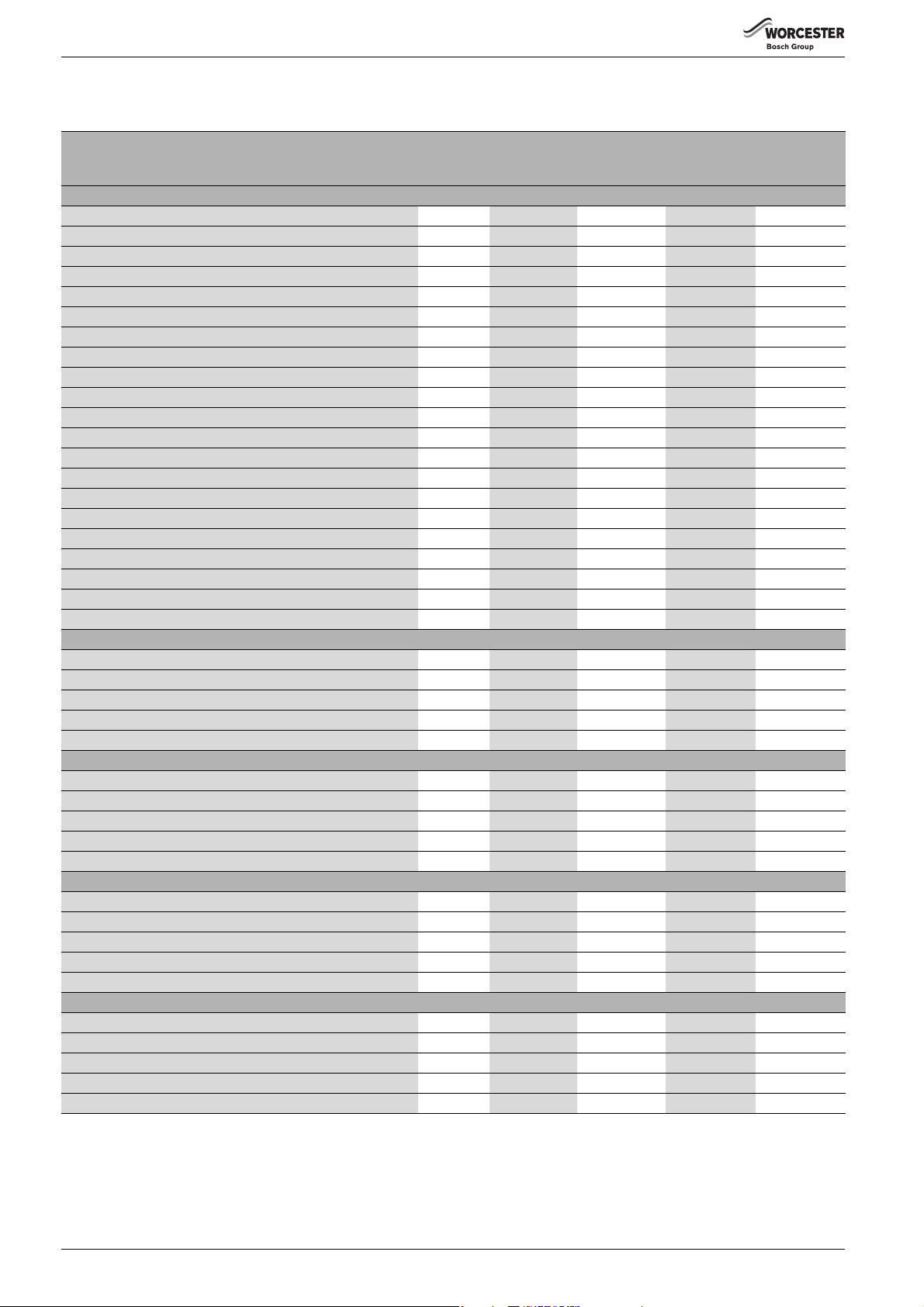

2.10 Designation of components

Fig. 7 Designation of components

6 720 808 928 (2017/06)12

Legend to Figure 7, Designation of components:

[1] Control unit

[2] Manual air vent (Domestic Hot Water)

[3] Manual air vent (district heating)

[4] Domestic Hot Water control valve

[5] Central heating control valve

[6] Return sensor NTC (district heating)

[7] Manual air vent (central heating)

[8] Plate heat exchanger (central heating)

[9] Flow sensor NTC (central heating)

[10] Circulating pump

[11] Drain point (central heating return)

[12] Central heating return connection

[13] Pressure relief valve (central heating)

[14] Pressure relief valve installer connection elbow

[15] Central heating flow connection

[16] Keyless filling link assembly

[17] District heating return connection

[18] Summer by-pass valve ( Table 2, Model matrix for standard component or accessory)

[19] District heating supply

[20] Filter and drain point (district heating)

[21] Heat meter flow sensor point

[22] Domestic Hot Water outlet

[23] Supply sensor NTC (district heating)

[24] Cold mains inlet

[25] Optional position for pressure gauge (pressure gauge can be moved from position [28] here)

[26] Domestic Hot Water safety valve

[27] Domestic flow turbine and flow regulator

[28] Pressure gauge

[29] Domestic Hot Water outlet sensor NTC

[30] Expansion vessel connector

[31] Domestic pressure relief valve

[32] Differential pressure control valve capillary connection onto manifold

[33] Manifold (district heating)

[34] Differential pressure control valve ( Table 2, Model matrix for standard component or accessory)

[35] Plate heat exchanger (Domestic Hot Water)

[36] Expansion vessel (Schrader valve located top, right hand side towards the back)

[37] Schrader valve access point

[38] Heat meter display (part of heat meter accessory), ( Table 2, Model matrix for standard component or accessory)

[39] Heat meter sensor (part of heat meter accessory), ( Table 2, Model matrix for standard component or accessory)

Appliance information

6 720 808 928 (2017/06) 13

Appliance information

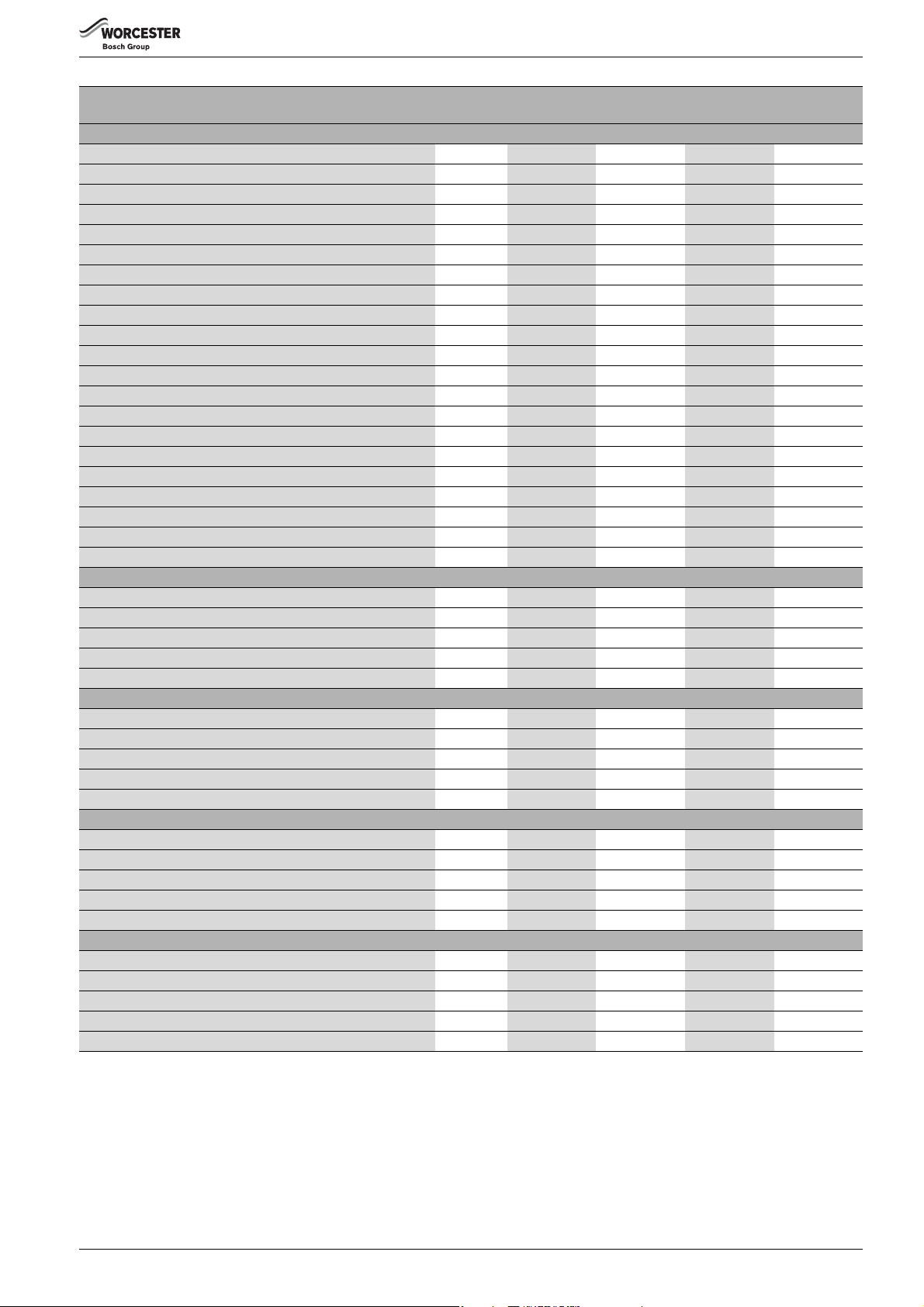

2.11 Appliance information

Technical data

HIU KE plus

with heat

Description Units HIU KE plus

meter

HIU E Plus

General

Height mm 700 700 700 700

Width mm 440 440 440 440

Depth mm 270 270 270 270

Total unit weight (lift weight) kg 33 33 31 31

Packaged unit weight kg 36 36 34 34

Minimum inlet pressure to achieve nominal DHW flow rate bar 2.0 2.0 1.5 1.5

Nominal output to domestic hot water

1)

kW 58.6 58.6 39.1 39.1

Output range to central heating kW 1.5 - 15 1.5 - 15 1.5 - 15 1.5 - 15

Maximum flow temperature secondary heating °C 80 80 80 80

Maximum flow temperature DHW °C 60 60 60 60

District heating flow and return connections (compression) mm 22 22 22 22

Secondary heating flow and return connections (compression) mm 22 22 22 22

Cold feed and DHW connections (compression) mm 15 15 15 15

Pressure relief valve connection mm 15 15 15 15

Maximum district limited flow rate with integrated DPCV l/s 0.38 0.38 0.355 0.355

Maximum working pressure district heating side bar 10 10 10 10

Pressure relief valve setting secondary heating side bar 3333

Maximum working pressure domestic hot water side bar 10 10 10 10

pH value (district water supply), approximate 7-9 7-9 7-9 7-9

Expansion vessel l 55 55

Expansion vessel charge bar 0.75 0.75 0.75 0.75

District Temperature (80°C)

Primary flow rate l/s 0.24 0.24 0.16 0.16

Primary return temperature °C 21.1 21.1 22.2 22.2

Primary pressure drop kPa 41.3 56.4 19.9 26.8

DHW output (50°C @ 40K rise) kW 58.6 58.6 39.1 39.1

DHW flow rate (50°C @ 40K rise) l/min 21 21 14 14

District Temperature (70°C)

Primary flow rate l/s 0.25 0.25 0.17 0.17

Primary return temperature °C 20.8 20.8 21.8 21.8

Primary pressure drop at 65/21 kPa 45.1 61.5 21.8 29.4

DHW output (45°C @ 35K rise) kW 51.3 51.3 34.2 34.2

DHW flow rate (45°C @ 35K rise) l/min 21 21 14 14

District Temperature (65°C)

Primary flow rate l/s 0.23 0.23 0.16 0.16

Primary return temperature °C 18.6 18.6 19.5 19.5

Primary pressure drop kPa 37.4 51.0 17.9 24.2

DHW output (40°C @ 30K rise) kW 44.0 44.0 29.3 29.3

DHW flow rate (40°C @ 30K rise) l/min 21 21 14 14

Electrical

Electrical power supply voltage AC...V 230 230 230 230

Frequency Hz 50 50 50 50

Maximum power consumption W 41.3 41.3 41.3 41.3

Standby power consumption W 3.1 3.1 3.1 3.1

Appliance protection rating IP X4D 40 X4D 40

Table 5

1) Nominal output to domestic hot water values are for a temperature rise of 40K.

HIU E Plus with

heat meter

6 720 808 928 (2017/06)14

Appliance information

Description Units HIU E

HIU E with

heat meter

HIU

HIU with heat

meter

General

Height mm 700 700 700 700

Width mm 440 440 440 440

Depth mm 270 270 270 270

Total unit weight (lift weight) kg 31 31 31 31

Packaged unit weight kg 34 34 34 34

Minimum inlet pressure to achieve nominal DHW flow rate bar 1.5 1.5 1.5 1.5

Nominal output to domestic hot water

1)

kW 39.1 39.1 39.1 39.1

Output range to central heating kW 1.5 - 15 1.5 - 15 1.5 - 15 1.5 - 15

Maximum flow temperature secondary heating °C 80 80 80 80

Maximum flow temperature DHW °C 60 60 60 60

District heating flow and return connections (compression) mm 22 22 22 22

Secondary heating flow and return connections (compression) mm 22 22 22 22

Cold feed and DHW connections (compression) mm 15 15 15 15

Pressure relief valve connection mm 15 15 15 15

Maximum district limited flow rate with integrated DPCV l/s 0.355 0.355 N/A N/A

Maximum working pressure district heating side bar 10 10 10 10

Pressure relief valve setting secondary heating side bar 3333

Maximum working pressure domestic hot water side bar 10 10 10 10

pH value (district water supply), approximate 7-9 7-9 7-9 7-9

Expansion vessel l 5555

Expansion vessel charge bar 0.75 0.75 0.75 0.75

District Temperature (80°C)

Primary flow rate l/s 0.16 0.16 0.16 0.16

Primary return temperature °C 22.2 22.2 22.2 22.2

Primary pressure drop kPa 19.9 26.8 12.1 19.1

DHW output (50°C @ 40K rise) kW 39.1 39.1 39.1 39.1

DHW flow rate (50°C @ 40K rise) l/min 14 14 14 14

District Temperature (70°C)

Primary flow rate l/s 0.17 0.17 0.17 0.17

Primary return temperature °C 21.8 21.8 21.8 21.8

Primary pressure drop kPa 21.8 29.4 13.3 20.9

DHW output (45°C @ 35K rise) kW 34.2 34.2 34.2 34.2

DHW flow rate (45°C @ 35K rise) l/min 14 14 14 14

District Temperature (65°C)

Primary flow rate l/s 0.16 0.16 0.16 0.16

Primary return temperature °C 19.5 19.5 19.5 19.5

Primary pressure drop kPa 17.9 24.2 11.0 17.3

DHW output (40°C @ 30K rise) kW 29.3 29.3 29.3 29.3

DHW flow rate (40°C @ 30K rise) l/min 14 14 14 14

Electrical

Electrical power supply voltage AC...V 230 230 230 230

Frequency Hz 50 50 50 50

Max. power consumption W 41.3 41.3 41.3 41.3

Standby power consumption W 3.1 3.1 3.1 3.1

Appliance protection rating IP X4D 40 X4D 40

Table 6

1) Nominal output to domestic hot water values are for a temperature rise of 40K.

6 720 808 928 (2017/06) 15

Appliance information

6720808928-18.1Wo

11

10

5

416

317

2

6

7

12

1

9

13

14

15

8

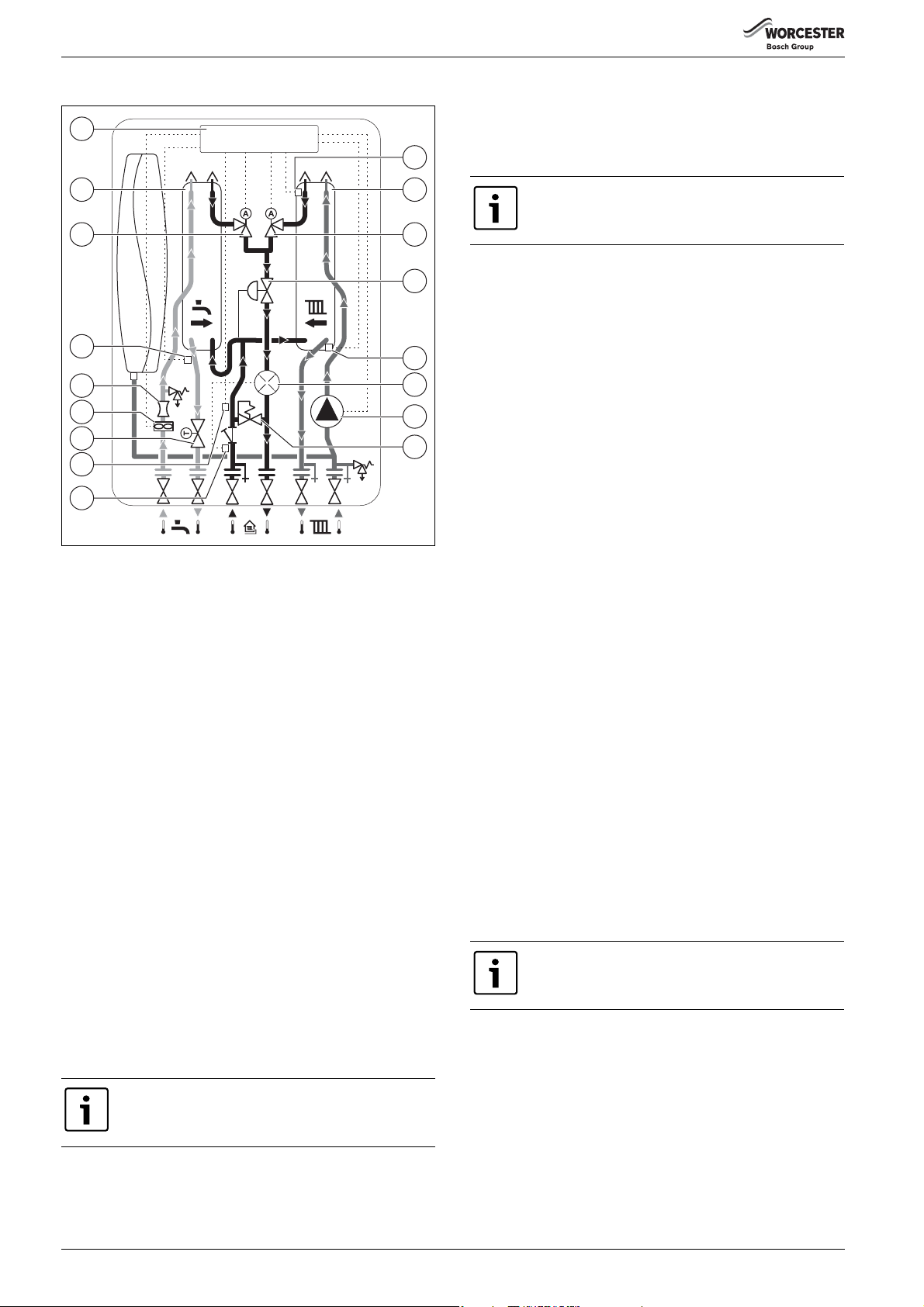

2.12 Function Schematic

Fig. 8 Function schematic

[1] Control unit

[2] Return sensor NTC (district heating)

[3] Central heating plate heat exchanger

[4] Central heating control valve

[5] Differential pressure control valve (if fitted)

[6] Flow sensor NTC (central heating)

[7] Heat meter (if fitted)

[8] Circulating pump

[9] Summer by-pass valve (if fitted)

[10] Heat meter flow sensor connection point

[11] Supply sensor NTC (district heating)

[12] Domestic Hot Water safety valve

[13] Flow turbine

[14] Flow regulator

[15] Domestic Hot Water outlet sensor NTC

[16] Domestic Hot Water control valve

[17] Domestic Hot Water plate heat exchanger

System description

If a summer by-pass valve [9] is fitted; in stand-by mode, the district

supply water flows from the district heating main, via the thermostatic

by-pass valve, therefore ensuring that hot water at 45 °C - 50 °C is

immediately available at the heat interface unit. This ensures a fast

warm-up of hot water at the tap, often referred to as keep hot function.

The above function is also available on a Sense II without the need for a

by-pass valve [9]. In this case, the domestic hot water control valve [16]

modulates to maintain 0 °C -60 °C at the primary water side of the heat

interface unit, depending on the temperature set for the by-pass

function in the controller settings menu.

The electronic control unit [1] provides fully modulated heating and hot

water control between maximum and minimum heat output. There are

two LEDs located on the top of the control unit [1] (visible through two

viewing holes in the top of the case). These indicate operating modes

and fault conditions.

Control unit LED indicators

▶ When an obstruction e.g. a shelf is positioned above

the unit it may be difficult to see the LED indicators.

If a hot water tap is opened, the flow turbine [13] is activated, the

central heating control valve [4] remains closed and the domestic hot

water control valve [16] modulates, allowing district supply water to

flow through the domestic hot water heat exchanger [18] to maintain

the pre-set hot water outlet temperature, which is measured using a NTC

sensor[15].

A domestic hot water safety shut-off valve [12] is provided in order to

interrupt the hot water flow to the tap in the event of excessive hot water

temperatures due to a failure condition. The domestic hot water outlet

temperature is adjustable between 30 °C - 60 °C on the heat interface

unit control unit [1].

During a central heating demand, the domestic hot water control valve

[16] remains closed and the central heating control valve [4]

modulates, allowing district water to flow through the central heating

heat exchanger [3] to maintain the pre-set central heating flow

temperature which is measured using a NTC sensor [6]. A low energy

self regulating pump [8] is used to provide water circulation through the

central heating circuit. The central heating flow temperature is

adjustable between 30 °C - 80 °C on the heat interface unit control [1].

The district heating return temperature is measured using a NTC sensor

[2].The control unit [1] will automatically modulate the central heating

delivery to ensure low return temperatures back to the district network.

The district return temperature will be kept below the central heating

flow temperature. This function prevents the HIU working in case the

district flow and return connections are reversed.

The default district heating return temperature limit is 50 °C, this can

only be adjusted with a Sense II.

If a Sense II is not used as a permanent device within the customers

property for controlling the system, it is possible to connect a Sense II to

the HIU control unit during commissioning only, in order to a set the

maximum allowable return temperature.

The heat interface unit can operate up to a supply differential pressure of

80kPa (800mbar). For supply differential pressures above 80kPa

(800mbar), a differential pressure control valve [5] should be fitted.

This provides a controlled differential pressure of 30kPa (300 mbar)

across the heat interface unit as the supply differential pressure varies

up to a maximum of 400kPa (4000mbar), the Worcester KE Plus, E Plus

and E HIU’s incorporate a DPCV as standard.

Worcester KE Plus with by-pass valve

▶ The maximum supply differential pressure is 400kPa

(4000mbar)

Electronic keep hot function

▶ This function will allow a small amount of district

water to flow through the heat meter.

6 720 808 928 (2017/06)16

Regulations

3Regulations

3.1 General

The special rules must be followed for buildings where the appliance is

installed.

The installation and maintenance of the unit must be performed by a

qualified person in accordance with regulations and rules of the local

area where installation is to take place.

3.2 Standards and Guidelines

Observe all rules, regulation, standard and guidelines

applicable to the installation and operation of the

appliance in your country.

When installing and operating, please refer to country-specific

regulations and standards, note in particular:

▶ The local standards and regulations on the installation conditions.

▶ The provision for the electrical connection to the power supply.

▶ The standards and regulations relating to the safety equipment of the

water heating system.

▶ The standards and regulations relating to the connection of drinking

water.

3.3 Inspection and maintenance

The heating system should be inspected regularly for the following

reasons:

• To achieve and maintain a high efficiency.

• To ensure operational safety.

The recommendation from BSRIA BG62/2015 is a maintenance check

every 3 years should be sufficient.

4.2 System preparation

Water system and pipe-work

• Any plastic pipe-work used on the central heating system must have

a polymeric oxygen barrier coating and at least 1000mm length of

copper or steel pipe connected to the appliance.

• Plastic pipe-work used for under-floor heating must be correctly

controlled and must not exceed the under-floor manufacturers’

specifications.

– With a single under-floor heating zone this may be able to be

controlled by the HIU provided the under-floor heating design

does not exceed the hydraulic capacity of the HIU internal

circulating pump, refer to section 6.6, Central heating circulation

pump.

• The district circuit is completely separated from the central heating

circuit by the use of a plate heat exchanger. However, in order to

protect the under-floor circuit in the event of a failure condition, a

limiter thermostat must be fitted onto the flow pipe to the under-floor

circuit and wired into the control unit ( figure 6). This switches off

the central heating pump in the event of an over temperature

condition.

• A single under-floor heating circuit can be controlled without the

need for an external mixing valve.

The switching point of the limiter thermostat, and if

fitted a thermostatic blending valve must be set at the

temperature set point + 10K for the under-floor heating

circuit.

The minimum flow temperature of the appliance is 30 °C.

NOTICE: Risk of system damage!

Damage to the system caused by a lack of, or insufficient

cleaning and servicing.

▶ Ensure that the heating system is inspected regularly

by an authorised heating engineer.

▶ Carry out any repairs immediately to avoid any

damage to the system.

4 Pre-installation requirements

4.1 General

NOTICE: Differential pressures above 80kPa

(800mbar) when no internal DPCV is fitted.

High differential pressure could affect the performance

of some components in the unit.

▶ Fit a differential pressure control valve to protect the

unit.

▶ The maximum allowable supply differential pressure

when the internal differential pressure control valve

is fitted is 400kPa (4000mbar).

It is recommended to insulate all service pipe work to the

heat interface unit in order to reduce heat losses and

improve system efficiency.

NOTICE: Under-floor heating circuits.

Damage caused by excessive flow temperature.

▶ Ensure the flow temperature does not exceed the

requirements of the under-floor heating circuit

manufacturer.

Secondary circuit/connections/valves

• All system connections, taps and mixing valves must be capable of

sustaining a pressure of 3 bar.

• Radiator valves should conform to local regulations.

• A thermostatic radiator valve (TRV) must be fitted to radiators in all

rooms except the room with the room thermostat. This must be fitted

with lock-shield valves and left open.

• Drain cocks are required at all the lowest points on the system.

• Air vents are required at all high points on the system.

6 720 808 928 (2017/06) 17

Pre-installation requirements

1

2

3

4

2

3

4

1

2

6720646608-123.1Wo

4.3 Domestic water supply

Use in hard water areas

Normally there is no need for water treatment to prevent scale formation

as the maximum temperature of the DHW heat exchanger is limited by

the electronic control.

In areas where temporary water hardness exceeds 200 ppm,

consideration may need to be given to the fitting of a scale prevention

device. In such circumstances, the advice of the local water authority

should be sought.

Showers/bidets:

• Ensure that the shower is suitable for use with mains water pressure.

• If a shower head can be immersed in water or comes closer than

25mm from the top edge of a bath or shower tray spill over level then

an anti-siphon device must be fitted to the shower hose.

• Bidets with direct hot and cold mains water can be used (with the

approval of the local water authority) and must be the over rim

flushing type with shrouded outlets to prevent the fitting of hand held

sprays.

Water mains pressure

• Minimum inlet pressure to achieve nominal DHW flow rate

– 58.6kW units - 2.0 bar

– 39.1kW units - 1.5 bar

• Maximum mains fed water pressure 10 bar.

– If necessary fit a pressure reducing valve.

• Where the mains water supply has a non-return, back flow

prevention valve fitted, a mini expansion vessel should be connected

to the mains water inlet pipe between the non-return valve and the

appliance.

NOTICE: Risk of damage to household appliances!

Non-return, back flow prevention devices (including

those associated with water meters) fitted to the mains

water supply can cause a pressure build up which could

damage the appliance and other household appliances.

▶ Fit a mini expansion between the non-return valve,

back flow prevention device.

4.4 Pressure relief pipe work

WARNING: Risk of scalding!

Injury if discharge pipe is not routed correctly.

▶ The pressure relief valve is a safety device for the

appliance and if activated may discharge boiling

water or steam through the relief valve drain pipe.

▶ Care should be taken when siting the outlet pipe so

that it does not cause an obstruction or discharge

above a window, entrance or other public access

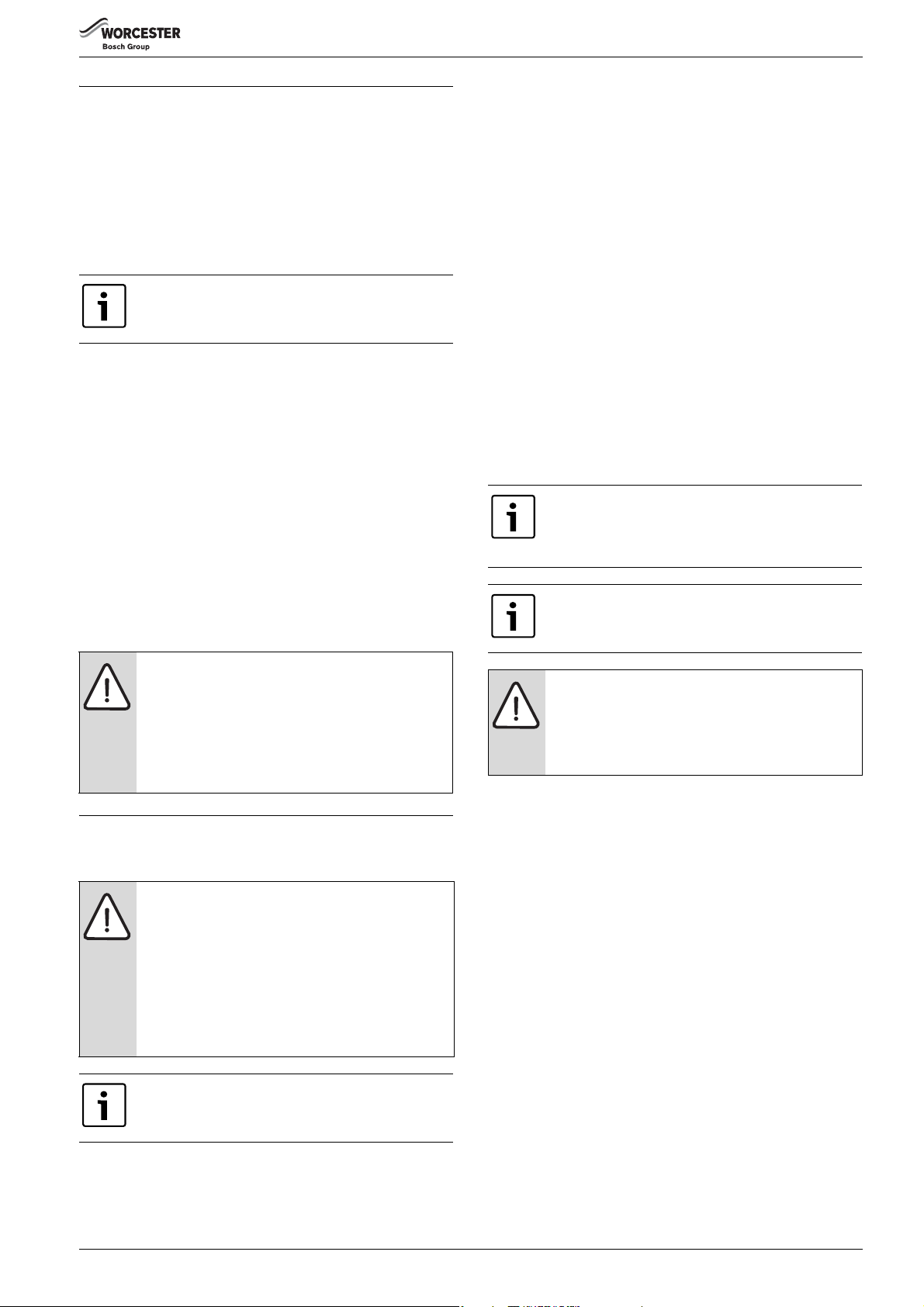

Refer to figure 9

• The pressure relief drain pipe [1] and [3] from the appliance should

be at least 15mm diameter copper pipe and run downwards to a safe

point of discharge, away from any electrical equipment or other

hazard, preferably to an external drain or soak away.

• Pipe [1] should be finished with a partial bend, near the outlet to face

the external wall (as shown) to help prevent freezing.

where it could cause a hazard.

Fig. 9 Pressure relief pipe-work external routing

[1] Outlet facing external wall

[2] External wall

[3] Outlet to external drain

[4] External drain

Internal PRV discharge

The PRV discharge pipe may terminate internally to a safe position such

as a waste pipe or soil pipe, provided that the following conditions are

met:

• The material used must be capable of taking the maximum

temperature provided by the District Heating primary flow.

• The discharge must be directly or indirectly visible and will not

discharge onto the occupants of the premises or onto any electrical

wiring or components. An example of "directly" is a tundish and

"indirectly" an audible indication of pressure loss.

• There is a continual fall towards the discharge point from the HIU.

• Where a tundish is used, a suitable trap is installed to protect against

foul smells entering into the living areas, whilst ensuring no undue

resistance to the discharge. An example would be a washing m achine

trap with upstand.

• For the higher district flow temperatures above 85 °C, It is

recommended to use the Hotun Hiflo tundish manufactured by RA

Tech UK. Guidance on this product can be found at http://

hutun.co.uk.

– We would also recommend that the Hotun Shield is used in

conjunction with the Hotun Hiflo on HIU installations. The Hotun

Hiflo tundish can also be used for providing a visual indicator

which will allow connection of a PRV directly into internal waste

pipes or soil stacks.

6 720 808 928 (2017/06)18

4.5 Cleaning primary system

6720646608-124.5Wo

2*

1

2

1

2

2

1

600mm

600mm

600mm

2250mm

2250mm

2*

†

†

†

6720808928-26.1Wo

NOTICE: Risk of damage to system or appliance!

Debris from the system can damage the appliance and

reduce efficiency. Failure to comply with the guidelines

for the use of water treatment with the appliance will

invalidate the appliance guarantee.

▶ Before installation, ensure that the central heating

system is cleaned and thoroughly flushed in

accordance to the standards and guidelines of the

country of installation.

4.6 Appliance locations and clearances

4.6.1 Location

• Follow local regulations for the location within the property that the

appliance is to be installed.

• This appliance is only suitable for installing internally within a

property at a suitable location onto a fixed rigid surface at least the

same size as the appliance and capable of supporting the appliance

weight.

• The appliance is not suitable for external installation.

No surface protection is required against heat transfer

from the appliance.

Pre-installation requirements

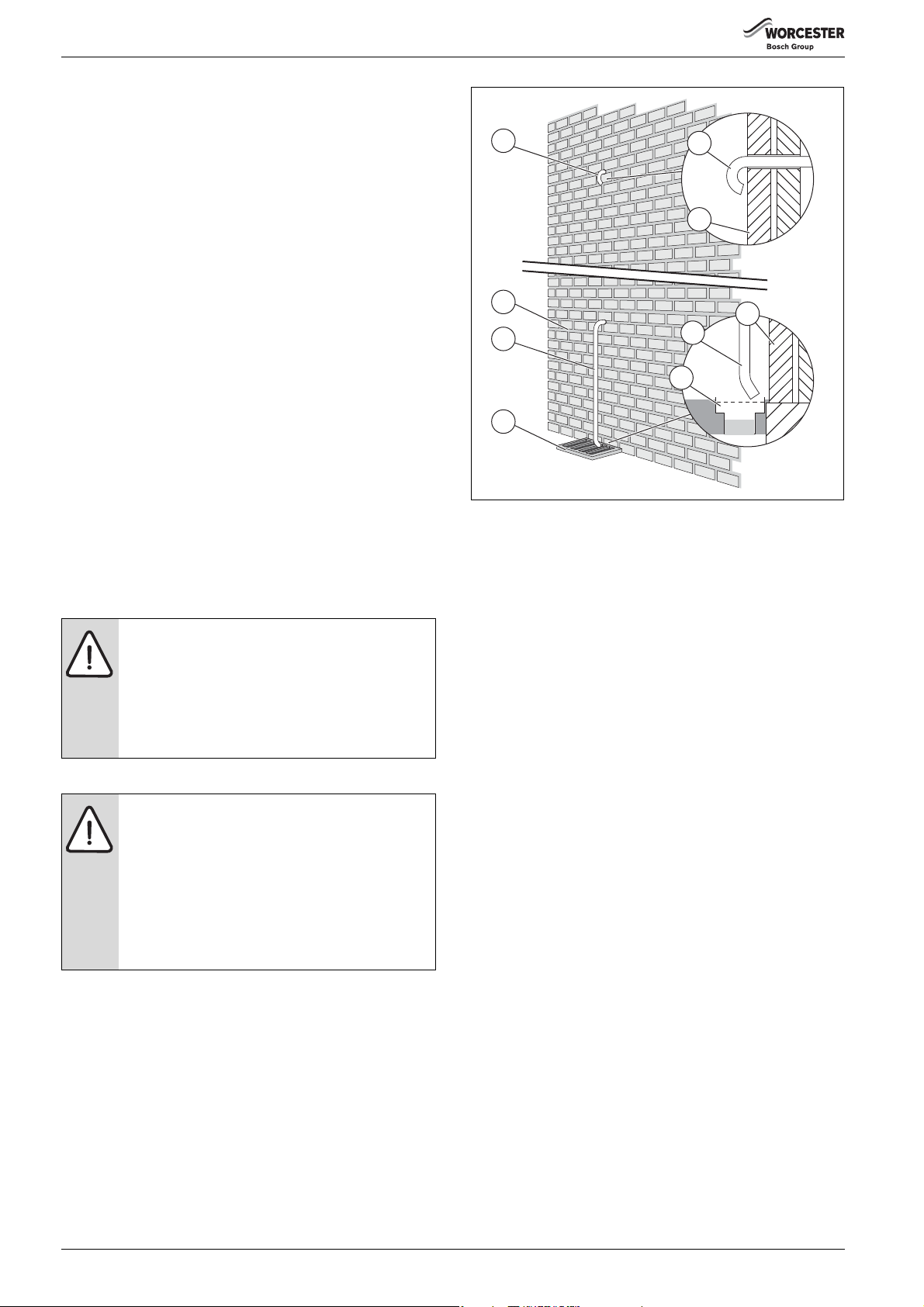

Fig. 10 Installations in rooms containing a bath or a shower

[2*] Without the end wall, zone 2 must extend 600mm from the bath.

[†] Radius 600mm.

4.6.3 Installation and maintenance Clearances

NOTICE: Appliance damage.

Damage caused by extreme temperatures.

▶ Ensure the ambient temperature is above 2 °C and

below 30 °C.

NOTICE: System damage.

Very cold t empera tures c an cause the heating system to

freeze, if there is a power failure or a fault in the system

the units frost protection function ( section 5.4

be compromised.

▶ Do not fit the appliance in areas with no heat

emitters, e.g. garage.

▶ Drain the central heating system if it is to be shut

down for an extended period.

4.6.2 Rooms containing a bath or a shower

NOTICE: Risk of electric shock

▶ Any switch or appliance control using mains

electricity must not be within reach of a person using

the bath or shower.

• In all cases the installation must be in accordance with the latest

amendments to the latest edition of the IET Wiring Regulations

(BS7671).

• The IP rating of the appliance.

– Units without internal heat meter, IPX4D.

The IP rating of the appliance allows it to be installed in, and

outside of, zone 2.

– Unit with internal heat meter, IP40.

The IP rating of the appliance dictates that it must be installed

outside of zone 2.

• Circuit breaking devices should be used in accordance with the

regulations.

• The diagram is for guidance only.

) will

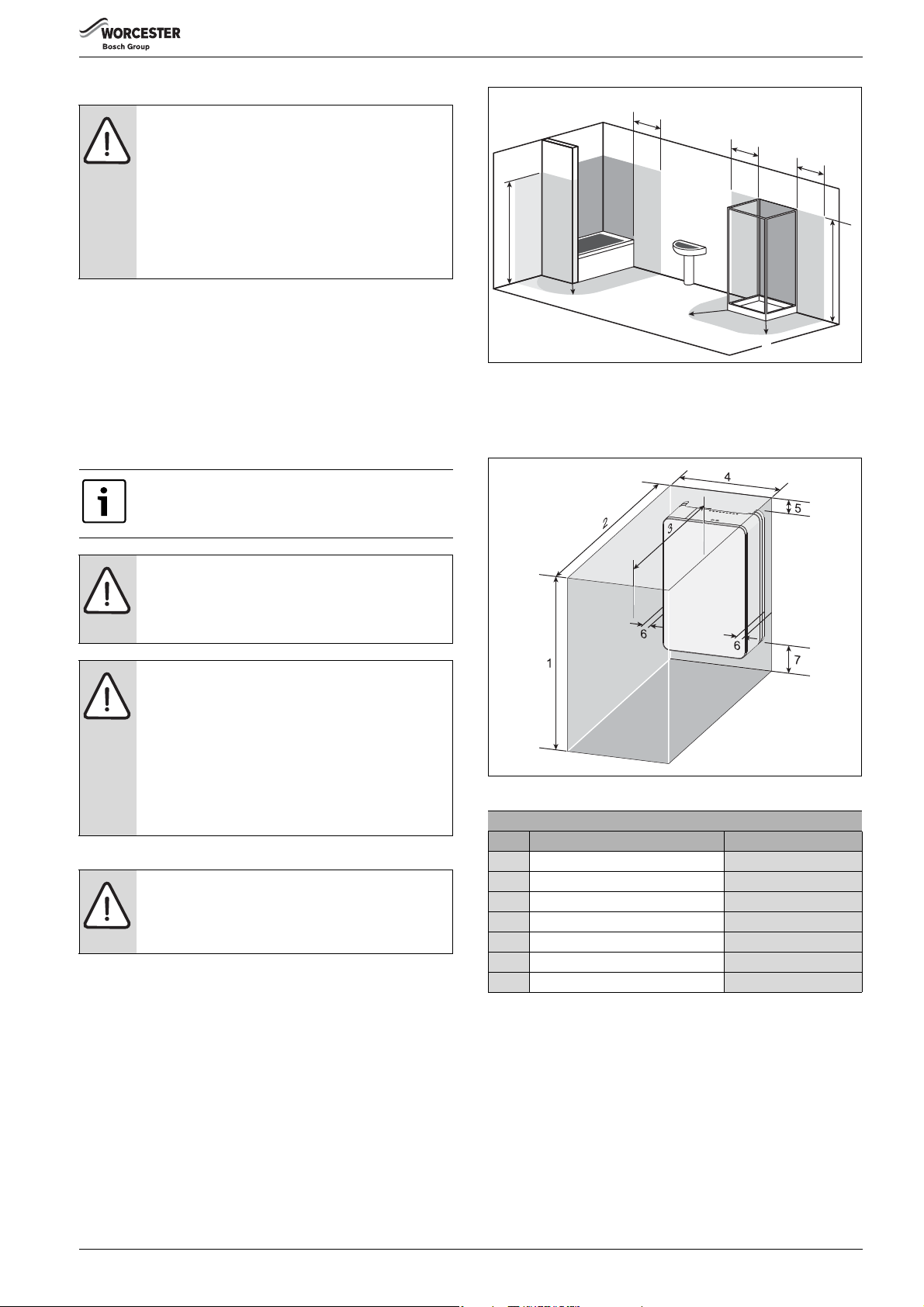

Fig. 11 Minimum installation and maintenance clearances

Minimum Installation and Maintenance clearances

Description Dimensions (mm)

1 Overall clearance height 930

2 Overall clearance depth 870

3 In front of appliance 600

4 Overall clearance width 450

5 Above the appliance 30

6 Either side of appliance 5

7Below the appliance 200

6 720 808 928 (2017/06) 19

Pre-installation requirements

6720808928-39.1Wo

6720808928-47.1Wo

EMS

21

21

6720808928-49.1Wo

LR

L

120/230 VAC

N

4.6.4 Compartment clearances

If the appliance is to be fitted in a compartment, the following minimum

clearances for the compartment dimensions apply. This is in addition to

the normal installation and servicing clearances.

• All service pipe work to the heat interface unit MUST be insulated

when installed within a ventilated compartment.

• If the ambient temperature within the compartment exceeds 30 °C

then it is recommended to make provision for ventilation.

– Ventilation openings must be provided at the front of the

compartment at the lower and upper positions. Each opening

must have a minimum size of 300mm by 80mm, 240cm

2

free

area.

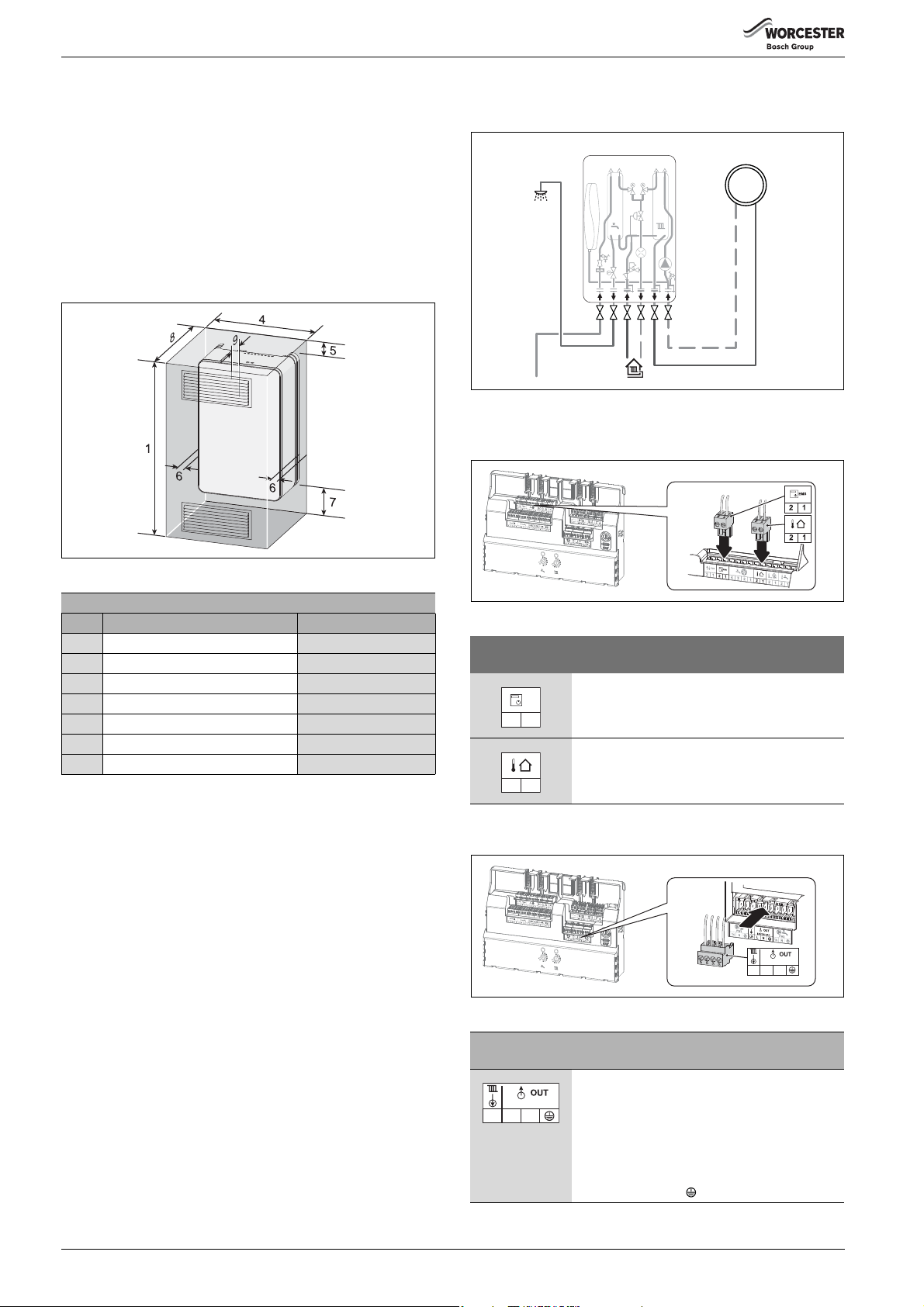

4.7 Example layouts

4.7.1 Unmixed central heating with radiators

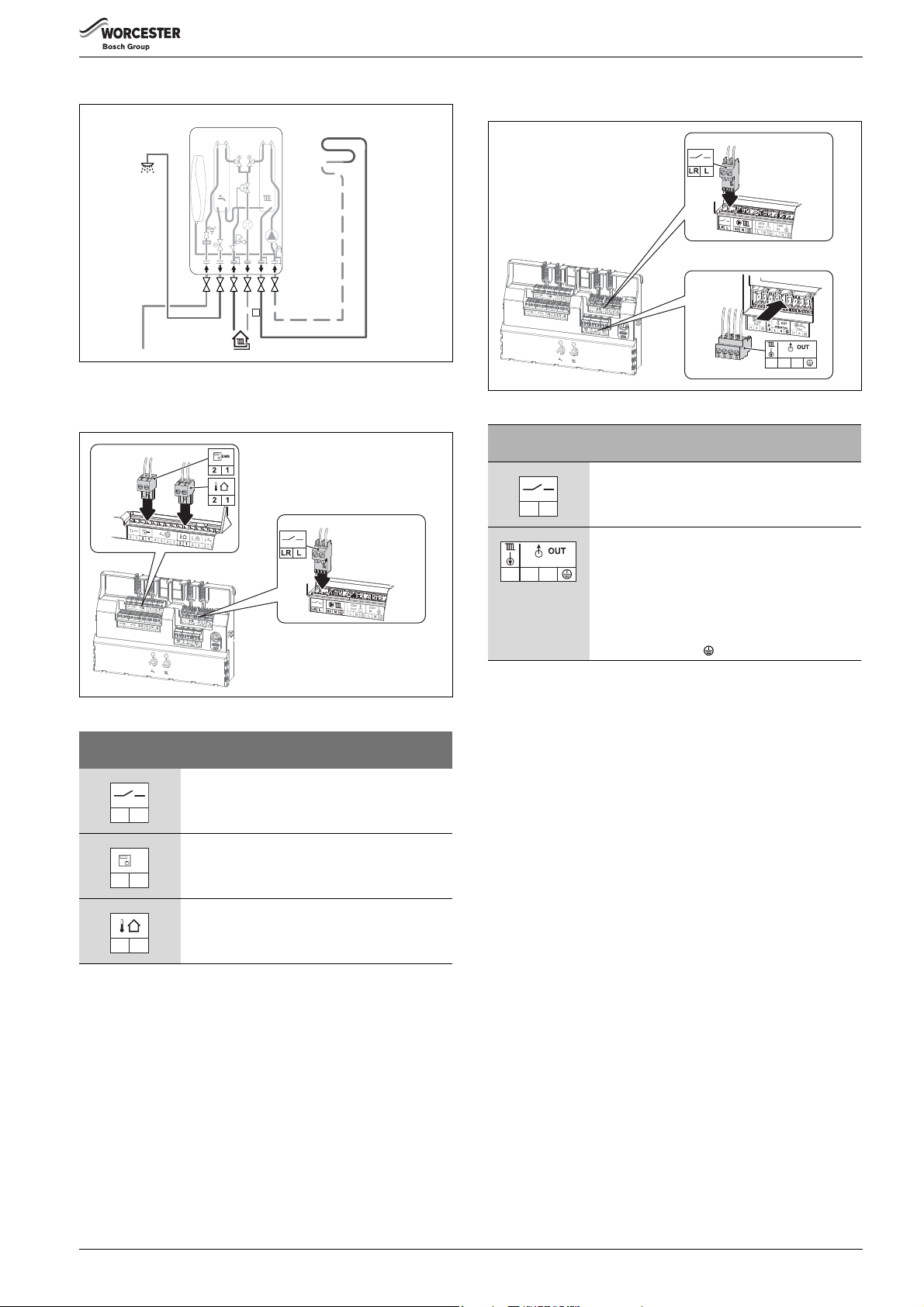

Fig. 13

Option 1: Control of radiator heating system with Sense II (EMS controller) example

Fig. 12 Minimum compartment clearances

Minimum Installation and Maintenance clearances

Description Dimensions (mm)

1 Compartment height 930

4 Compartment width 450

5 Above the appliance 30

6 Either side of appliance 5

7 Below the appliance 200

8 Compartment depth 290

9 Appliance to removable door 20

Fig. 14

Connections/

Symbol

Function

Sense II connection

• EMS2 Room control

– Not polarity sensitive

Outdoor temperature sensor

• Not polarity sensitive

Option 2: Control of radiator heating system with 230V programmable room thermostat example

Fig. 15

Connections/

Symbol

Function

230 V feed to external time and temperature

control

• 230V programmable room thermostat

LR

120/230 VAC

N

L

– Switch live demand input [LR]

– Live output [L]

– Neutral output [N]

– Earth output [ ]

6 720 808 928 (2017/06)20

Pre-installation requirements

6720808928-40.1Wo

T

LR L

21

6720808928-52.1Wo

LR

L

120/230 VAC

N

4.7.2 Unmixed central heating with under-floor

Fig. 16

Option 1: Control of under-floor with Sense II (EMS controller) example

Option 2: Control of under-floor with 230V programmable room thermostat example

Fig. 18

Connections/

Symbol

Function

Limiter thermostat (under-floor safety cut-off)

•Potential free

LR L

230 V feed to external time and temperature

control

• 230V programmable room thermostat

LR

120/230 VAC

N

L

– Switch live demand input [LR]

– Live output [L]

– Neutral output [N]

– Earth output [ ]

Fig. 17

Connections/

Symbol Function

Limiter thermostat (under-floor safety cut-off)

• Potential free

Sense II connection

EMS

21

• EMS2 Room control

– Not polarity sensitive

Outdoor temperature sensor

• Not polarity sensitive

6720808928-50.1Wo

6 720 808 928 (2017/06) 21

Loading...

Loading...