BOSCH 3915 User guide

IMPORTANT: |

IMPORTANT : |

IMPORTANTE: |

Read Before Using |

Lire avant usage |

Leer antes de usar |

Operating/Safety Instructions Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

3915

Consumer Information

Renseignement des consommateurs

Información para el consumidor

Toll Free Number: |

Appel gratuit : |

Número de teléfono gratuito: |

|

1-877-BOSCH99 (1-877-267-2499) |

http://www.boschtools.com. |

||

|

|

|

|

For English |

Parlez-vous français? |

¿Habla español? |

|

See page 2 |

Voir page 36 |

Ver página 70 |

|

Safety

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

General Safety Rules

For Bench Top Tools

Work Area

●Keep work area clean and well lit. Cluttered benches and dark areas invite accidents.

●Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

●Keep bystanders, children and visitors away while operating a power tool. Distractions can cause you to lose control.

●Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

●Do not leave tool running unattended, turn power off. Do not leave tool until it comes to a complete stop.

●MAKE WORKSHOP CHILDPROOF with pad lock, master switches, or by removing starter keys.

Electrical Safety

●Before plugging in the tool, be certain the outlet voltage supplied is compatible with the voltage marked on the nameplate within 10%. An outlet voltage incompatible with that specified on the nameplate can result in serious hazards and damage to the tool.

●Double insulated tools are equipped with a polarized plug (one blade is wider than the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double insulation eliminates the need for the three wire grounded power cord and grounded power supply.

●Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

●Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

●Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

●When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

●Stay alert, watch what you are doing and use common sense when operating a power tool. A moment of inattention or use of drugs, alcohol or medication while operating power tools can be dangerous.

●Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts. Roll long sleeves above elbows. Rubber gloves and non-skid footwear are recommended when working outdoors.

●Avoid accidental starting. Be sure switch is “OFF” before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch “ON” invites accidents.

●Remove adjusting keys or wrenches before turning the tool “ON”. A wrench or a key that is left attached to a rotating part of the tool will be thrown.

●Do not overreach, keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

●Do not stand on tool or its stand. Serious injury may occur if the tool is tipped or if the cutting tool is accidentally contacted. Do not store materials on or near the tool such that it is necessary to stand on the tool or its stand to reach them.

“SAVE THESE INSTRUCTIONS” 2.

Safety

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

●Use safety equipment. Always wear safety goggles. Dust mask, safety shoes, hard hat or hearing protection must be used for appropriate conditions. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

Tool Use and Care

●Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable. It allows for work to shift, causes binding of the tool and loss of control.

●Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed. Do not use the tool for purpose not intended - for example; do not use the miter saw for slicing meats.

●Do not use tool if switch does not turn it “ON” or “OFF”. Any tool that cannot be controlled with the switch is dangerous.

●Disconnect the plug from the power source before making any adjustments or changing accessories. Such preventive safety measures reduce the risk of starting the tool accidentally.

●Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges, are less likely to bind and easier to control. When mounting saw blades be certain that the arrow on the blade matches the direction of the arrow marked on the tool and that the teeth are also pointing in the same direction.

●Inspect guards before using a tool. Keep guards in place. Check moving parts for binding or any other condition that may affect the normal operation or safety features of the tool. If damaged, have tool serviced before using the tool. Many accidents are caused by poorly maintained tools.

●Do not alter or misuse tool. Any alteration or modification is a misuse and may result in serious personal injury.

●The use of any other accessories not specified in this manual may create a hazard.

Accessories that may be suitable for one type of tool, may become hazardous when used on an inappropriate tool.

Service

●Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel may result in misplacing internal wires and components which could cause serious hazard.

●When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a hazard.

Safety Rules

For Miter Saws

●Use clamps to support workpiece whenever possible. If supporting the workpiece by hand, you must always keep hand outside of “No Hand” area as marked with a symbol on the base. Do not use this saw to cut pieces that are too small to be securely clamped.

Your hand if placed inside the “No Hands” region can easily slip or be pulled into the blade.

●Do not reach in back of the saw blade behind the fence with either hand to hold down or support the workpiece, remove wood scraps, or for any other reason. The proximity of the spinning saw blade to your hand may not be obvious and you may be seriously injured.

●Never cross your hand over intended line of cutting. Supporting the workpiece “cross handed” i.e. holding the left side of the workpiece with your right hand is very dangerous.

●Always disconnect the power cord from the power source before making any adjustments or attaching any accessories. You may unintentionally start the saw, leading to serious personal injury.

●Miter saws are intended to cut wood or woodlike products, they cannot be used with abrasive cutoff wheels for cutting ferrous material such as bars, rods, studs, etc. However, if cutting materials like aluminum or other non-ferrous metals, use only saw blades specifically recommended for nonferrous metal cutting. Cutting ferrous materials causes excessive sparking and will damage the lower guard and will overload the motor. (NOTE: S-B Power Tool Company does not offer 10” metal cutting blades.)

“SAVE THESE INSTRUCTIONS” 3.

Safety

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

●Inspect your workpiece before cutting. If workpiece is bowed or warped, clamp it with the outside bowed face toward the fence. Always make certain that there is no gap between the workpiece, fence and table along the line of the cut. Bent or warped workpieces can twist or rock and may cause binding on the spinning saw blade while cutting. Also, make sure there are no nails or foreign objects in the workpiece.

●Do not use the saw until the table is clear of all tools, wood scraps, etc., except the workpiece. Small debris or loose pieces of wood or other objects that contact the revolving blade can be thrown with high speed at the operator.

●Do not feed workpiece into the blade or cut “freehand” in any way. Workpiece must be stationary and clamped or braced by your hand. Saw must be fed through the workpiece smoothly and at a rate which will not overload the saw’s motor.

●Cut only one workpiece at a time. Multiple workpieces cannot be adequately clamped or braced and may bind on the blade or shift during cutting.

●Be certain the miter saw is mounted or placed on a level, firm work surface before using. A level and firm work surface reduces the risk of the miter saw becoming unstable.

●Plan your work. Provide adequate support accessories such as tables, saw horses, table extension, etc. for workpieces wider or longer than the table top (see page 20). Workpieces longer or wider than the miter saw table can tip if not securely supported. If the cutoff piece or workpiece tips it can lift the lower guard or be thrown by the spinning blade.

●Do not use another person as a substitute for a table extension or as additional support. Unstable support for the workpiece can cause the blade to bind or the workpiece to shift during the cutting operation pulling you and the helper into the spinning blade.

●The cutoff piece must not be jammed against or pressured by any other means against the spinning saw blade. If confined, i.e. using length stops, it could get wedged against the blade and thrown violently.

●Always use a clamp or a fixture designed to properly support round material such as dowel rods, or tubing. Rods have a tendency to roll while being cut, causing the blade to “bite” and pull the work with your hand into the blade.

●When cutting irregularly shaped work-

pieces, plan your work so it will not slip and pinch the blade and be torn from your hand.

A piece of molding, for example, must lie flat or be held by a fixture or jig that will not let it twist, rock or slip while being cut.

●Let the blade reach full speed before contacting the workpiece. This will help avoid thrown workpieces.

●If the workpiece or blade becomes jammed or bogged down, turn miter saw “OFF” by releasing switch. Wait for all moving parts to stop and unplug the miter saw, then work to free the jammed material. Continued sawing with jammed workpiece could cause loss of control or damage to compound miter saw.

●Braking action of the saw causes the saw head to jerk downward. Be ready for this reaction when making an incomplete cut or when releasing the switch before the head is completely in the down position.

●After finishing the cut, release the switch, hold the saw arm down and wait for blade to stop before removing work or cutoff piece. If blade does not stop within five (5) seconds, unplug the saw and follow the instructions in the Troubleshooting section.

REACHING WITH YOUR HAND UNDER A COASTING BLADE IS DANGEROUS!

●There are additional safety instructions for particular operations of the saw in the operating section. Read the rest of the manual for safe operation.

●For slide action cutting, first PULL saw head assembly away from the fence, until blade clears the workpiece or to its maximum extension if blade cannot clear the workpiece. Make certain the clamp does not interfere with the guard and head assembly. Second, turn saw “ON” and lower the saw to the table. Then PUSH saw through the workpiece. Release the switch and wait for the blade to completely stop before raising the head assembly and removing the workpiece.

Never “pullcut” since blade may climb the workpiece causing KICKBACK.

●For chop action cutting, slide the head assembly to the rear as far as it will go and tighten slide lock knob. Then turn the saw “ON” and lower the head assembly to make the cut. Release the switch and wait for the blade to completely stop before raising the head assembly and removing the workpiece.

Failure to tighten the slide lock knob can cause the blade to suddenly climb up on the top of the workpiece and force itself toward you.

“SAVE THESE INSTRUCTIONS” 4.

Safety

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

●Do not allow familiarity gained from frequent use of your miter saw to become commonplace. Always remember that a careless fraction of a second is sufficient to inflict severe injury.

●THINK SAFETY! SAFETY IS A COMBINATION OF OPERATOR’S COMMON SENSE, KNOWLEDGE OF THE SAFETY AND OPERATING INSTRUCTIONS AND ALERTNESS AT ALL TIMES WHEN THE MITER SAW IS BEING USED.

WARNING THE WARNINGS SHOWN BELOW CAN BE FOUND ON YOUR TOOL. THESE WARNINGS ARE ONLY A CONDENSED FORM OF THE MORE DETAILED SAFETY RULES AND PRECAUTIONS THAT APPEAR IN YOUR OWNER'S MANUAL. THEY SERVE AS A REMINDER OF ALL SAFETY RULES NEEDED FOR SAFE OPERATION OF THIS MITER SAW.

WARNING THE WARNINGS SHOWN BELOW CAN BE FOUND ON YOUR TOOL. THESE WARNINGS ARE ONLY A CONDENSED FORM OF THE MORE DETAILED SAFETY RULES AND PRECAUTIONS THAT APPEAR IN YOUR OWNER'S MANUAL. THEY SERVE AS A REMINDER OF ALL SAFETY RULES NEEDED FOR SAFE OPERATION OF THIS MITER SAW.

WARNING Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from lead-based paints,

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

DESIGNATED DANGER ZONE. AVOID POSITIONING HANDS, FINGERS OR ARMS IN THE AREA DESIGNATED BY THIS SYMBOL.

WARNING

WARNING

EXTEND SLIDING

BASE WHEN

MAKING BEVEL CUTS OR TABLE IS TURNED TO LEFT SIDE.

WARNING

WARNING

FOR SLIDE ACTION CUTTING, ALWAYS FOLLOW THESE INSTRUCTIONS:

1 |

BOSCH |

2

3

WARNING

WARNING

KEEP HANDS AT A SAFE DISTANCE FROM THE SAW BLADE.

NEVER CROSS YOUR HANDS WITH THE PATH OF SAW BLADE. DO NOT REACH BEHIND, BENEATH OR IN FRONT OF THE BLADE.

CLAMP WORKPIECE AGAINST BASE AND FENCE. NEVER PERFOAM ANY OPERATION FREEHAND.

ALL ELECTRIC BRAKE SAWS MAY, ON OCCASIONS, FAIL TO STOP THE BLADE. AFTER TURNING SAW “OFF”, ALWAYS MAINTAIN SAW HEAD IN DOWN POSITION AND WAIT FOR BLADE TO STOP BEFORE REMOVING CUTOFF PIECES OR

CLEANING THE TABLE. |

* |

|

BOSCHR 3915

1.PULL saw carriage away from the fence, until blade clears the workpiece or to its maximum extension if blade can not clear the workpiece.

2.Turn saw “ON” and lower the saw to the table.

3.PUSH saw thru the workpiece. Never “pull-cut” since blade may climb the workpiece causing KICKBACK.

10" (254mm) SLIDE COMPOUND MITER SAW |

|||||

120 VOLTS AC ONLY TO 60 Hz |

R |

||||

13 AMPS 4700 RPM |

511 |

|

|||

DOUBLE INSULATED |

|

LR61595 LISTED 407J |

|||

SN. |

|

|

|

|

0 601 475 035 |

|

|

|

|

||

READ AND UNDERSTAND WARNING THE OWNER'S MANUAL

BEFORE USING THIS TOOL.

ALWAYS WEAR SAFETY GOGGLES.

ALWAYS WEAR SAFETY GOGGLES.

TO AVOID ELECTRICAL SHOCK DO NOT EXPOSE SAW TO RAIN OR USE IN DAMP LOCATIONS.

TO AVOID ELECTRICAL SHOCK DO NOT EXPOSE SAW TO RAIN OR USE IN DAMP LOCATIONS.

USE SAW BLADE RATED 6000 RPM OR GREATER.

USE SAW BLADE RATED 6000 RPM OR GREATER.

DISCONNECT SAW FROM POWER SOURCE BEFORE SERVICING OR CHANGING BLADE.

DISCONNECT SAW FROM POWER SOURCE BEFORE SERVICING OR CHANGING BLADE.  WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. * S–B Power Tool Co. Chicago, IL Made in Taiwan

WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS. * S–B Power Tool Co. Chicago, IL Made in Taiwan

WARNING

WARNING

KEEP GUARDS IN PLACE.

KEEP GUARDS IN PLACE.

RETURN GUARD TO OPERATING POSITION AFTER CHANGING THE BLADE.

RETURN GUARD TO OPERATING POSITION AFTER CHANGING THE BLADE.

IF GUARD FAILS TO WORK SMOOTHLY, STOP SAWING AND SERVICE IT BEFORE PROCEEDING.

IF GUARD FAILS TO WORK SMOOTHLY, STOP SAWING AND SERVICE IT BEFORE PROCEEDING.

10-41

“SAVE THESE INSTRUCTIONS”

5.

Safety

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

WARNING “READ ALL INSTRUCTIONS” — Failure to follow the SAFETY RULES identified by

BULLET (●) symbol listed BELOW and other safety precautions, may result in serious personal injury.

Double Insulated Tools Extension Cords

Double insulation

is a design concept used in electric power tools which eliminates the need for the three wire grounded power cord and grounded power supply system. It is a recognized and approved system by Underwriter’s Laboratories, CSA and Federal OSHA authorities.

is a design concept used in electric power tools which eliminates the need for the three wire grounded power cord and grounded power supply system. It is a recognized and approved system by Underwriter’s Laboratories, CSA and Federal OSHA authorities.

●Servicing of a tool with double insulation requires care and knowledge of the system and should be performed only by a qualified service technician.

●Replace damaged cords immediately. Use of damaged cords can shock, burn or electrocute.

●If an extension cord is necessary, a cord with adequate size conductors should be used to prevent excessive voltage drop, loss of power or overheating. The table shows the correct size to use, depending on cord length and nameplate amperage rating of tool. If in doubt, use the next heavier gauge. Always use U.L. and CSA listed extension cords.

●WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

●POLARIZED PLUGS. Your tool is equipped with a polarized plug (one blade is wider than the other), this plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. To reduce the risk of electrical shock, do not change the plug in any way.

RECOMMENDED SIZES OF EXTENSION CORDS

Tools |

|

120 Volt A.C. Tools |

|

|

Ampere |

|

Cord Length in Feet |

|

|

Rating |

|

Cord Size in A.W.G. |

|

|

|

25 |

50 |

100 |

150 |

3-6 |

18 |

16 |

16 |

14 |

6-8 |

18 |

16 |

14 |

12 |

8-10 |

18 |

16 |

14 |

12 |

10-12 |

16 |

16 |

14 |

12 |

12-16 |

14 |

12 |

N/A |

N/A |

NOTE: The smaller the gauge number, the heavier the cord.

“SAVE THESE INSTRUCTIONS”

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2-6 |

Basic Saw Operations. . . . . . . . . . . . . . . . . |

19-22 |

|

General Safety Rules For Bench Top Tools . |

. . . 2 |

Body and Hand Position . . . . . . . . . . . . . . . |

. . 19 |

|

Safety Rules For Miter Saws . . . . . . . . . . . . |

. 3-6 |

Workpiece Support. . . . . . . . . . . . . . . . . . . |

. . 20 |

|

Table of Contents . . . . . . . . . . . . . . . . . . . . . |

. . . 6 |

Switch Activation . . . . . . . . . . . . . . . . . . . . |

. . 21 |

|

Electrical Requirements |

7 |

Detent Override . . . . . . . . . . . . . . . . . . . . . |

. . 22 |

|

Sliding Base/Fence Extension |

22 |

|||

Getting To Know Your Miter Saw |

8-9 |

|||

Saw Operations |

23-30 |

|||

Assembly |

10-12 |

|||

Chop Cut . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 23 |

|||

Tools Needed For Assembly And Alignment |

. . 10 |

Slide Cut . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 23 |

|

Unpacking and Checking Contents . . . . . . . |

. . 10 |

Miter Cut . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 24 |

|

Installation and Removal of the Blade . . . . |

11-12 |

Bevel Cut . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 24 |

|

Assembling Dust Elbow and Dust Bag . . . . |

. . 12 |

Compound Cuts . . . . . . . . . . . . . . . . . . . . . |

. . 25 |

|

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . |

13-16 |

Cutting Grooves (Dado Cut) . . . . . . . . . . . . |

. . 26 |

|

Blade Square To Table (90°) . . . . . . . . . . . . |

. . 13 |

Cutting Base Molding . . . . . . . . . . . . . . . . . |

. . 27 |

|

Blade 45° To The Table . . . . . . . . . . . . . . . . |

. . 14 |

Cutting Crown Molding . . . . . . . . . . . . . . . . |

. . 27 |

|

Blade Square To Fence . . . . . . . . . . . . . . . |

. . 15 |

Special Cuts. . . . . . . . . . . . . . . . . . . . . . . . |

. . 30 |

|

Miter Scale Indicator Adjustment . . . . . . . . |

. . 15 |

Maintenance and Lubrication . . . . . . . . . . . |

. . 31 |

|

Kerf Insert . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 16 |

Troubleshooting |

32-33 |

|

Depth Stop Adjustment |

16 |

|||

Accessories |

34 |

|||

Installation |

17-18 |

|||

|

|

|||

Mounting Applications . . . . . . . . . . . . . . . . |

. . 17 |

|

|

6.

Electrical Requirements

1.Connect this saw to a 120V, 15-amp branch circuit with a 15-amp time delay fuse or circuit breaker. Using the wrong size fuse can damage the motor.

2.Fuses may “blow” or circuit breakers may trip frequently if motor is overloaded. Overloading can occur if you feed the blade into the workpiece too rapidly or start and stop too often in a short time.

3.Most motor troubles may be traced to loose or incorrect connections, overload, low voltage (such as small size wire in the supply circuit or too overly long supply circuit wire). Always check the connections, the load and the supply circuit whenever motor does not work well.

Electric Brake

Your saw is equipped with an automatic electric brake which is designed to stop the blade from spinning in about five (5) seconds after you release the trigger switch. It is useful when making certain cuts in wood where a coasting blade would result in a wide, imprecise cut.

WARNING |

When electrical power is lost |

|

due to blown fuse or other causes, the motor will gradually slow down and the braking action is initiated ONLY by the release of the trigger switch.

The electric blade brake of your miter saw has been designed for highest degree of reliability, but unexpected circumstances such as contamination on the commutator and brushes or failure of motor’s components can cause the brake not to activate. If this condition occurs, turn the saw “ON” and “OFF” four to five times without contacting the workpiece. If the tool operates but the brake does not consistently stop the blade in about five (5) seconds, DO NOT use saw and have it serviced immediately.

WARNING |

The brake action of this saw |

|

is not intended as a safety feature. Remember to let the saw blade come to a complete stop before raising the blade from the workpiece. As always the guard system is your best protection against unintentional contact with a spinning saw blade. NEVER wedge

open or defeat the closing action of the lower guard. |

|

WARNING |

To avoid injury from acciden- |

|

|

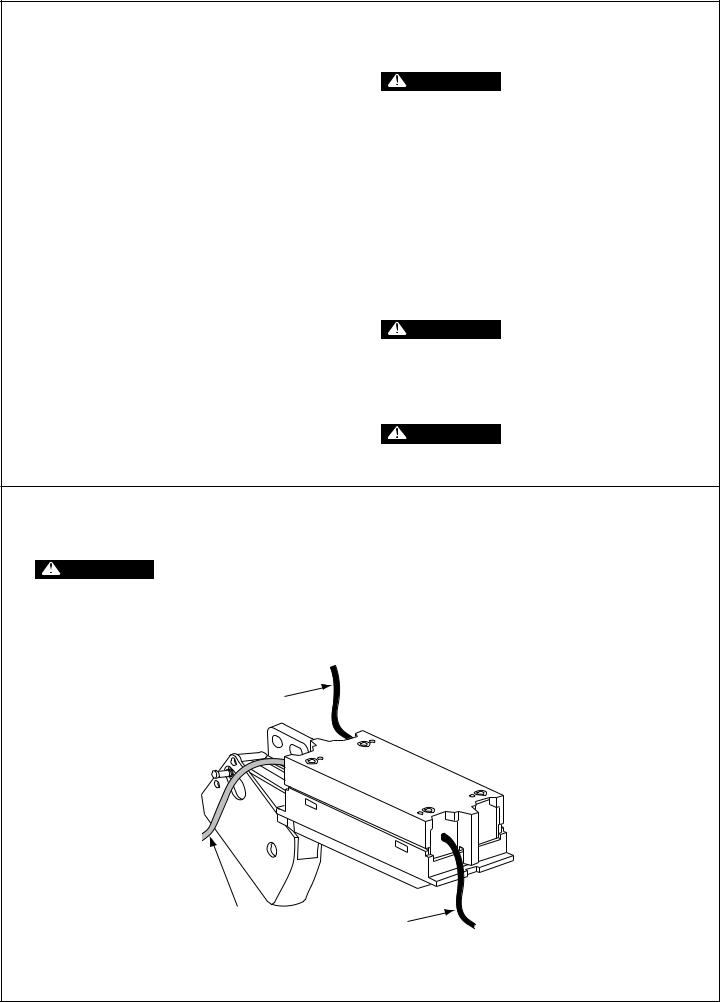

Wiring Diagram

WARNING |

This wiring diagram can be used only with switch (Part No. 2610911881) supplied with |

|

your miter saw. Other switches may look the same, but internal switch components can be different, thus creating electrical shock hazard if wired according to this diagram.

Black From

Power Cord

Grey From |

Black |

|

From Field |

|

|

Brake Lead |

10-45 |

|

|

|

7.

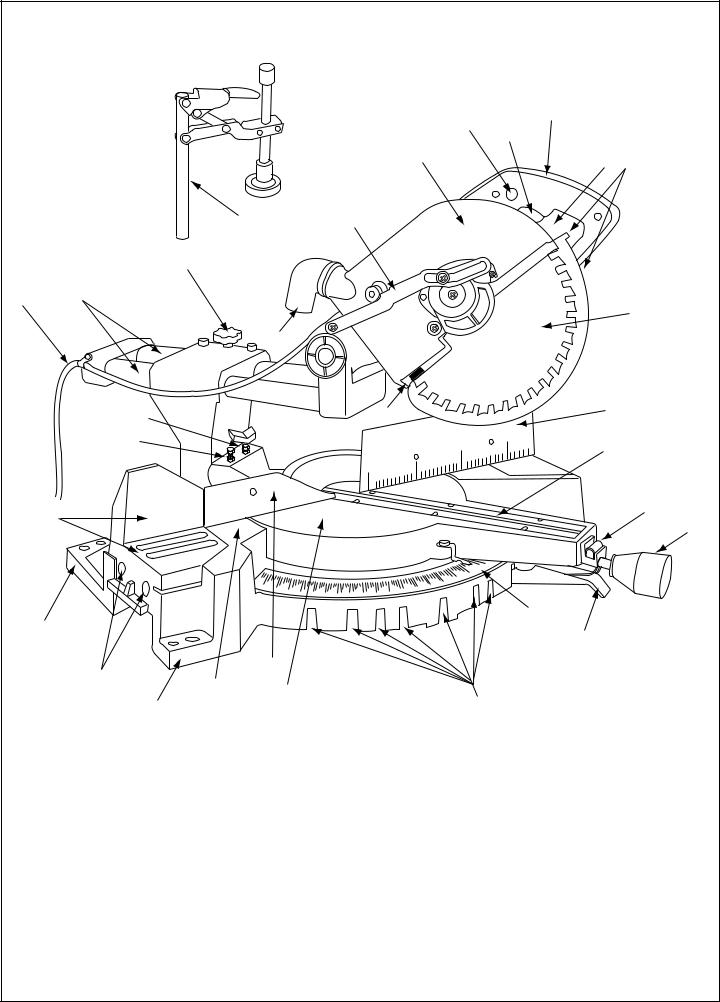

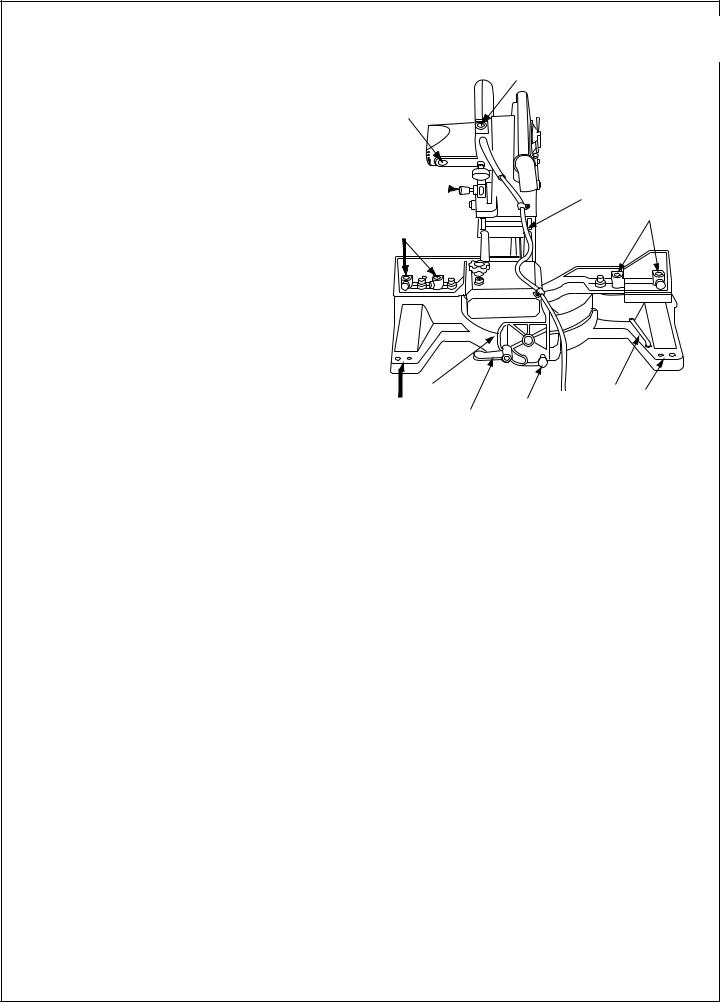

Getting To Know Your Miter Saw

23

29 24

|

3 |

|

|

1 |

|

|

2 |

|

27 |

4 |

5 |

|

25 |

26 |

BOSCH

6

20

21 |

19 |

7 |

|

22

8

18 |

9 |

|

10 |

||

|

50

45

40

16

7

17

15 14

16

35

30

25 |

20 |

15 |

10 |

5

0

5

10

35

30

25

20

15

12

11

10-00a

13

tal starting, remove plug from power source outlet before making any adjustments.

1. Switch “Lock-OFF” Button

This button must be pressed to activate the power switch.

2. Power Switch

The power switch used with the “Lock-OFF” button energizes the unit.

3. Switch Handle

This handle contains the switch. The blade is lowered into the workpiece by pushing/pulling down on the handle.

4. Arbor Lock

Allows the user to keep the blade from rotating while

tightening or loosening arbor screw during blade replacement or removal (Figure 34, page 28).

5. Lower Blade Guard/Lower Guard Lip

The lower blade guard helps protect your hands from the spinning blade. It retracts as the blade is lowered. Lip can be used to raise the lower guard when guard becomes jammed on a workpiece.

6. Blade

Use only 10" blades with 5/8" arbor hole.

7. Fence

Supports the workpiece. The fence has a cast in scale to make repetitive cuts easy. The fence also has holes which are used to secure an auxiliary fence if desired.

8.

Getting To Know Your Miter Saw

8. Kerf Inserts

Kerf inserts can be adjusted to different blade widths to minimize workpiece tear-out.

9. Miter Detent Override

Allows detent action to be locked out allowing for micro adjustments to any miter angle.

10. Miter Lock Knob

The miter lock knob locks the miter saw table at any desired miter angle.

11. Miter Detent Trigger

The trigger releases the table from the detent.

12. Miter Scale/Miter Angle Indicator

This scale is cast in on the base of the saw. Indicator is fastened to the table.

13. Miter Detents

There are ten (10) miter detents for fast and accurate miter cuts of common miter angles.

14. Table

Sits in base, provides workpiece support, rotates for desired miter cuts and rotates the head assembly. The front extended part of the table is called the miter arm.

15. Base

Provides working surface to support workpiece.

16 Tool Mounting Pads

The four corners of the saw provide areas to clamp, bolt or nail the saw to a flat work surface.

17.Accessory Extension and Stock Stop

Machined holes that accept the extension wing/stop accessory.

18.Sliding Base/Fence

This provides extra support and clamping area for compound miter cuts.

19. Chip Deflector

This protects against large chips from entering the upper guard.

20. Dust Chute Elbow

The dust chute elbow rotates 360° and can accommodate the dust bag or a 1-1/4" vacuum hose hookup.

21. 0° Bevel Stop

Adjustable stop for a quick and accurate 0° bevel index.

22. 45° Bevel Stop

Adjustable stop for a quick and accurate 45° bevel index.

23. Slide Rail Lock Knob

The slide rail lock knob locks the slide rails when you are not making slide cuts and when you are transporting the saw.

24. Slide Rails

Guide the head assembly when making slide cuts.

25. Quick Action Clamp

Provides fast clamping of workpiece.

26. Lower Guard Actuation Link

Allows for smooth movement of the lower guard.

27. Upper Blade Guard

Covers upper portion of the blade.

28

37

36

35

29

30

30

10-21b

34 |

32 |

31 |

16 |

16 |

|

||

|

|

||

|

33 |

|

|

28. Blade Wrench

Used for tightening/loosening blade and adjusting bevel stops. Blade wrench is stored in the switch handle.

29. Power Cord

Supplies power to motor. Has molded cord retainer for storage.

30. Quick Action Clamp Positions

There are four (4) positions behind the fence for the quick action clamp.

31. Hex Wrench

Used to adjust sliding base/fence, fence and blade bolt. Hex wrench is stored in the base.

32 Bevel Detent Pin (Crown Molding Setting)

Allows you to easily move the head assembly to the bevel angle of 33.9°.

33. Bevel Lock Handle

The bevel lock handle locks the head assembly at a desired bevel angle. Handle ratchets for use in tight spaces.

34. Bevel Scale

This scale is cast in on the saw. Allows you to read the bevel angles easily (Figure 7, page 13).

35. Head Assembly Lock Pin

The compound miter saw is equipped with a lock pin used to lock the head assembly in the lower position.

36. Depth Stop

Allows you to adjust the depth of the blade for cutting grooves in the workpiece (Figure 14, page 16).

37. Brush Caps

These caps keep the motor brushes in position and provide easy access for inspecting and replacing brushes.

9.

Assembly

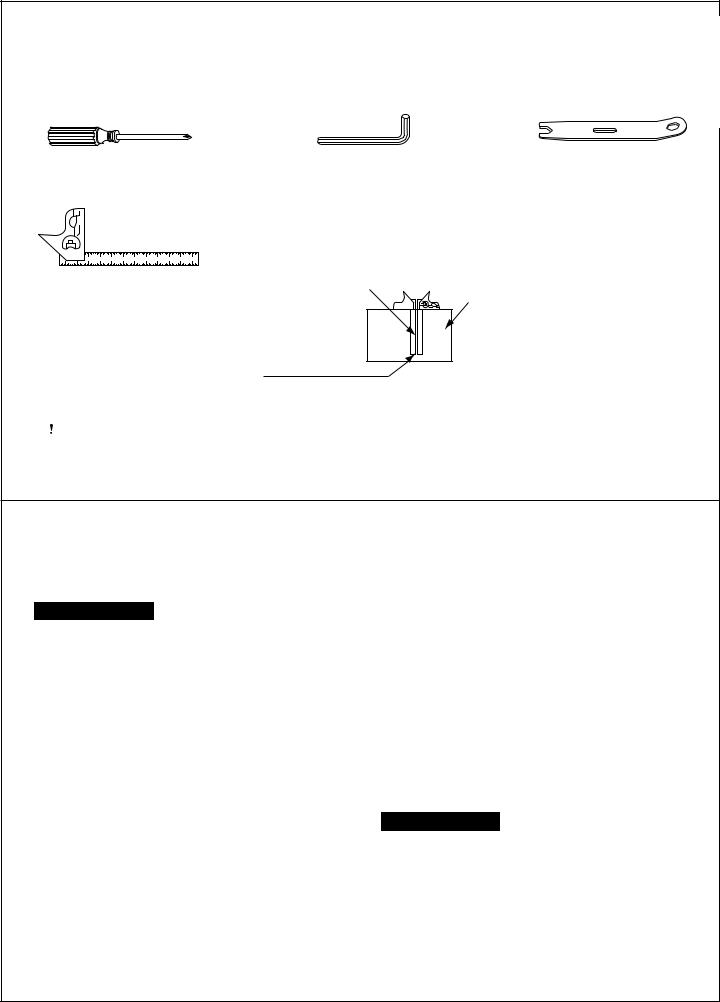

Tools Needed For Assembly And Alignment

Phillips Screwdriver |

|

Hex “L” Wrench |

Blade Wrench |

||||||||||||||

|

(supplied) 6mm |

(supplied) |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Combination Square Must be True |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Draw Light |

Straight Edge of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Line on Board |

Board 3/4" Thick |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Combination Square |

|

Along this Edge |

This Edge Must be |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Perfectly Straight |

Should be no Gap or Overlap

when Square is Flipped Over in

10-37

Dotted Position

|

|

WARNING |

|

Disconnect plug from power source before performing any assembly, adjustment or |

|

|

|

|

|

repair to avoid possible injury. |

||||

Unpacking And Checking Contents

CAUTION Before moving the saw:

CAUTION Before moving the saw:

Lock the miter lock knob in 45° position. Lock bevel lock handle. Pull the head assembly completely toward you and tighten the slide rail lock knob. Lock head assembly in the down position.

Never carry the tool by the slide rails, this may cause blade misalignment.

Never carry the tool by the cord or head assembly power switch handle. Damage to insulation could cause an electric shock. Damage to wire connections could cause a fire.

Model 3915 Slide Compound Miter Saw is shipped complete in one box.

1. Separate all parts from packing materials and check each one with the “Table of Loose Parts” to make sure all items are accounted for before discarding any packing material.

2.Table of Loose Parts:

Quick Action Clamp - Used to clamp workpieces.

Dust Elbow/Dust Bag - Used to collect saw dust.

Hex Wrench - Should be stored on the left rear base.

Blade Wrench - Should be stored in the handle.

WARNING If any parts are missing, do not plug in power cord or turn the switch on until the missing parts are obtained and are installed correctly.

WARNING If any parts are missing, do not plug in power cord or turn the switch on until the missing parts are obtained and are installed correctly.

10.

Assembly

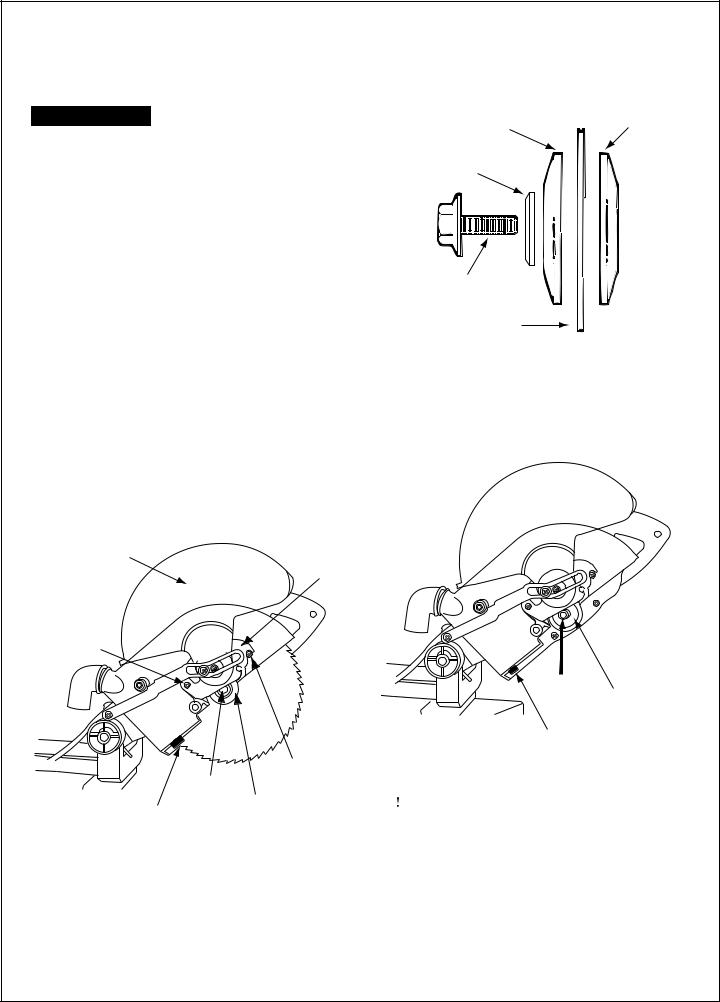

Installation And Removal Of The Blade

WARNING Disconnect plug from power

WARNING Disconnect plug from power

source before performing any assembly, adjustment or repair to avoid possible injury.

1.The slide compound miter saw is equipped with a lock pin used to lock the miter saw in the lower position. To release, push the handle down slightly and pull the lock pin to its full out position and rotate 90°.

NOTE: If the lock pin is stuck and will not pull out when the handle is pushed down slightly, you may have to adjust the depth stop screw (see Depth Stop Adjustment, page 16) slightly so the handle can be pushed down and the lock pin can be pulled out.

2.Loosen the rear cover plate screw using a Phillips screwdriver (Figure 1).

3.Rotate the lower guard by hand. Remove the front cover plate screw using a Phillips screwdriver (Figure 1).

4.Rotate the cover plate counterclockwise so the blade bolt is exposed (Figure 1).

5.Press and hold the arbor lock. Use the blade wrench to remove the blade bolt by turning wrench clockwise. NOTE: The blade bolt has a left hand thread.

Lower Guard |

Cover |

|

|

Plate |

|

Rear Cover |

BOSCH |

|

Plate Screw |

||

|

|

|

Front Cover |

|

Blade Bolt |

Plate Screw |

||

Outer |

|

||

Chip Deflector |

|

|

|

Washer |

10-20a |

||

|

|

|

|

Figure 1. Blade Removal

6. Remove the blade bolt, arbor washer, outer washer and the blade. Inner washer does not need to be removed (Figure 2).

Outer Washer |

Inner Washer |

Arbor Washer

Blade Bolt

(Left Hand Thread)

Sawblade |

10-33 |

Figure 2. Blade Hardware

7.To install the 10" blade, fit blade between the chip deflectors and onto arbor shaft (Figure 3). NOTE: Make sure the rotation arrow on the blade matches the clockwise rotation arrow on the lower guard.

Arbor |

Inner |

|

Shaft |

||

Washer |

||

|

|

|

|

Chip Deflector |

10-19a |

|

|

Figure 3. Blade Installation |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

To avoid injury, do not use a |

|||

blade larger or smaller than 10" diameter and 5/8" arbor.

8.Replace the outer washer in the proper orientation, insert the arbor washer, and tighten blade bolt finger tight. Press the arbor lock and tighten blade bolt securely using blade wrench, but do not overtighten.

9.Rotate cover plate clockwise to original position. Install the cover plate screw and tighten.

11.

Loading...

Loading...