Blodgett MARK V 111-H Service Manual

MARK V SERIES

CONVECTION OVEN

SERVICE AND REPAIR MANUAL

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (802) 658Ć6600 Fax: (802)864Ć0183

PN 33144 Rev F (7/02)

E 2002 - G.S. Blodgett Corporation All rights reserved.

Duplication of the information in this manual is prohibited without the consent of the Blodgett Service Department.

TABLE OF CONTENTS

i

1. INTRODUCTION

Oven Specifications 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. OPERATION

Sequence of Operations 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cook Only - 18459 Rev D 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Approved Cook Only - 33339 Rev C 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cook and Hold - 18791 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital - 30070 Rev B 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Approved Solid State Digital - 33345 Rev C 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Delay with Pulse Plus - 18466 Rev D 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidaire - 1846 Rev M 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus - 22027 Rev A 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch - 19361 Rev A 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control - 33078 Rev A 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CALIBRATION AND ADJUSTMENT

Doors 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Blower Switch 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Manual 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solid State Digital Control 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus Controls 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch Control 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch II Control 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ2T Control Factory Level Programming 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IQ VVCĆ208 Control 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Resistance vs Heating Elements 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Resistance vs Temperature 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. TROUBLESHOOTING

Heat System 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Error Codes 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellitouch 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intellihold and Intelliplus 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blodgett IQ Control 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

ii

5. PARTS REPLACEMENT

Door Assembly 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Arm Support Assembly 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Window Assembly 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compartment Liner Bottom 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor and Blower Assembly 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Wheel 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bulb and Capillary Thermostat 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Components Located in the Control Module 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Switch 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION

CHAPTER 1

MARK V

1-1

OVEN SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

Installations within the U.S. and Canada

Single phase models require a 60 Hz,

208/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 60 Hz,

208/240/440/480, 4 wire service consisting of L1,

L2, L3 and ground. Wiring from the power source

to any of the single phase units must be a minimum

of #6 AWG copper stranded wire. Wiring from the

power source to the 208/240 three phase units

must be a minimum of #8 AWG copper stranded

wire. Wiring from the power source to the 440/480

three phase units must be a minimum of #12 AWG

copper stranded wire.

General Export Installations

Single phase models require a 50 Hz,

220/240VAC, 3 wire service consisting of L1, L2

and ground. Three phase models require a 50 Hz,

415/240 or 380/220 VAC, 5 wire service consisting

of L1, L2, L3, neutral and ground. Use 90_C wire

and size according to local codes.

CE approved installations

Single phase models require a 50 Hz, 230VAC 3

wire service consisting of L1, neutral and ground.

Three phase models require a 50 Hz, 400/230VAC,

5 wire service consisting of L1, L2, L3, neutral and

ground. Use 90_C wire and size according to local

codes.

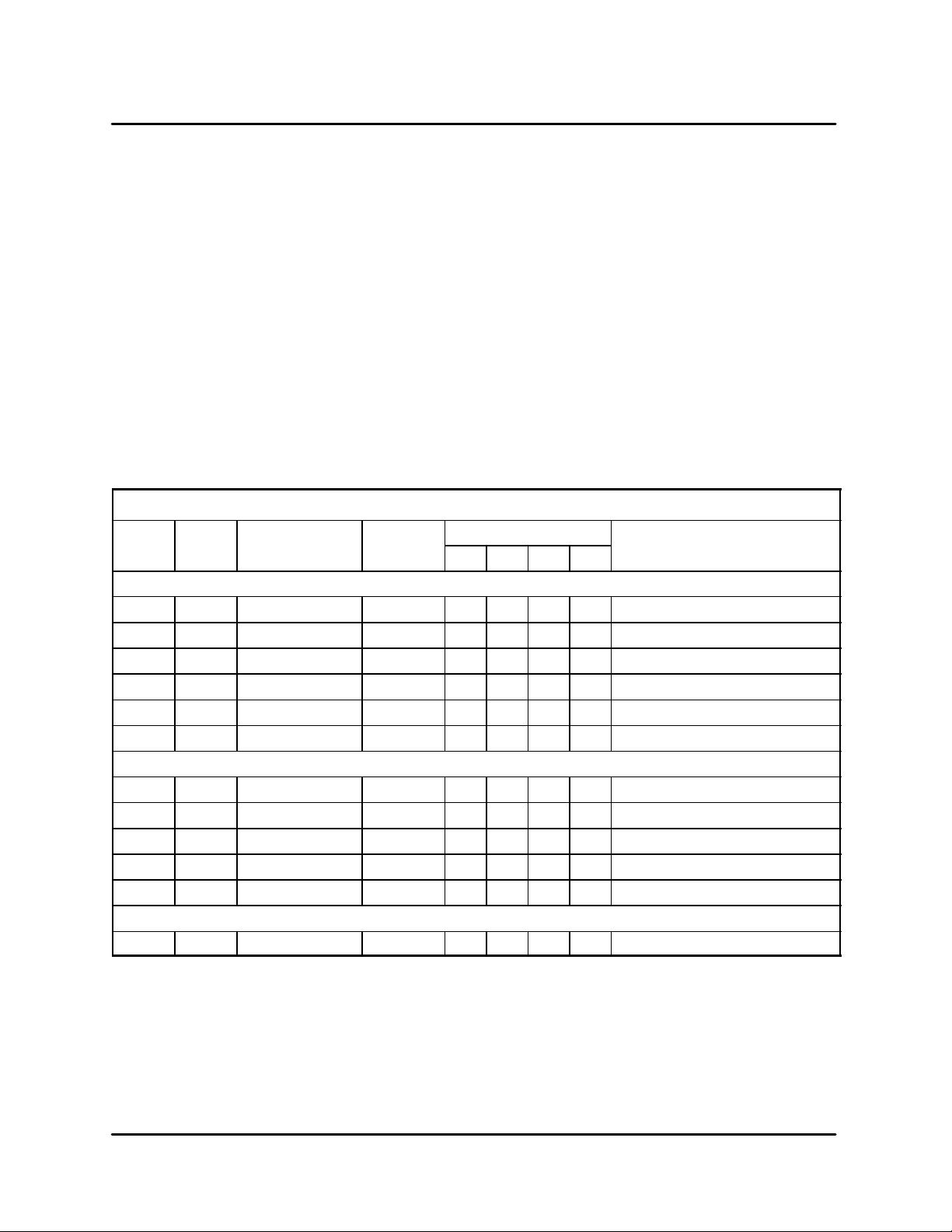

ELECTRICAL SPECIFICATIONS (per section)

KW Hz Volts Phase

Amps

Electrical Connection

L1 L2 L3 N

(minimum size)

U.S. and Canadian installations

11.0 60 208 1 51 - 51 - 6 AWG

11.0 60 208 3 31 29 29 - 8 AWG

11.0 60 220Ć240 1 44 - 44 - 6 AWG

11.0 60 220Ć240 3 26 24 24 - 8 AWG

11.0 60 440 3 15 14 14 - 12 AWG

11.0 60 480 3 14 13 13 - 12 AWG

General Export installations

11.0 50 208 3 18 18 18 4 Size per local code

11.0 50 220Ć240 1 48 - - 48 Size per local code

11.0 50 220/380 3 18 16 16 2 Size per local code

11.0 50 240/415 3 18 14 14 4 Size per local code

11.0 50 230/400 3 18 15 15 3 Size per local code

CE installations

11.0 50 400 3N 18 15 15 3 Size per local code

OPERATION

CHAPTER 2

MARK V

2-1

SEQUENCE OF OPERATIONS

NOTE: The following instructions represent the most common controllers. For questions regarding other

options call the Blodgett Service Department at (800)331Ć5842.

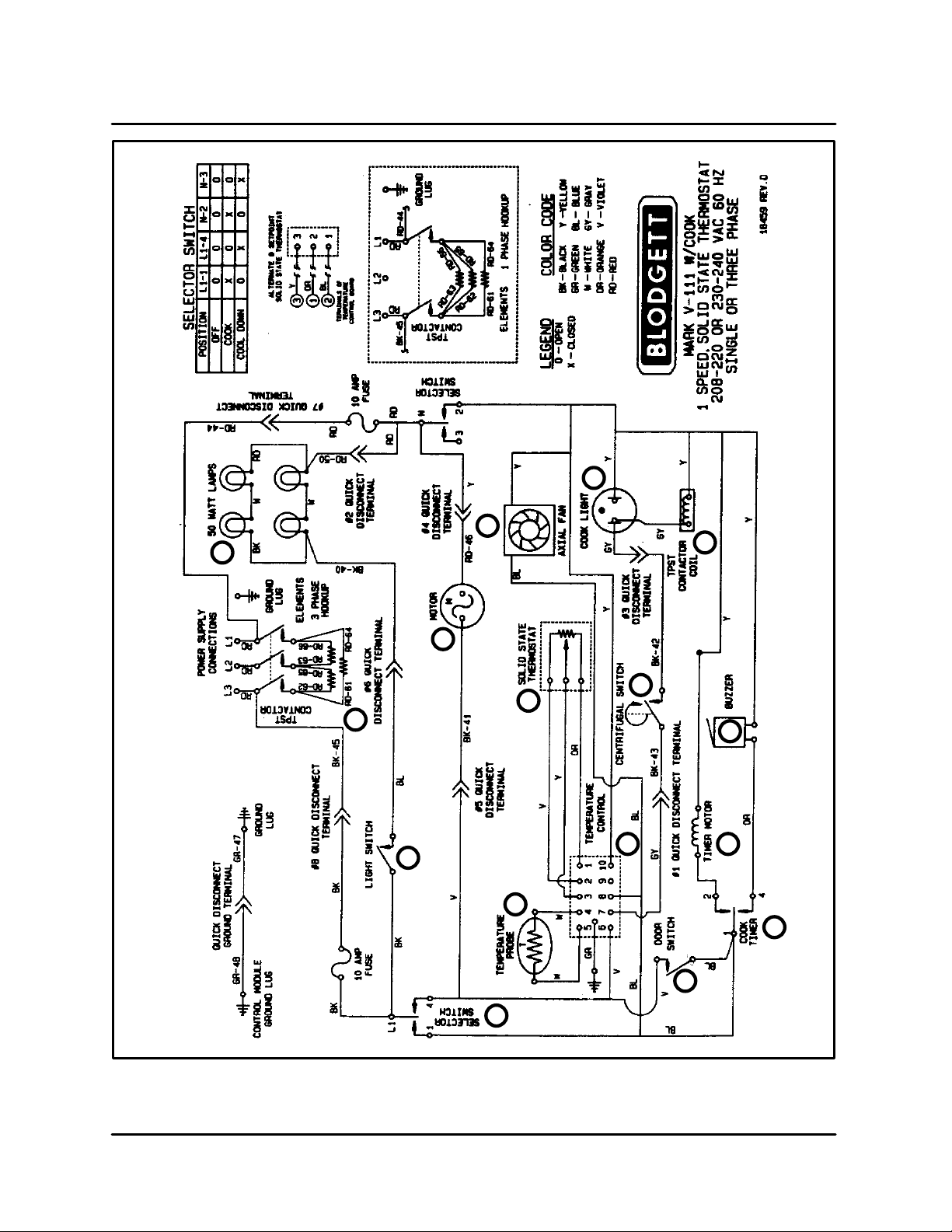

COOK ONLY - 18459 REV D

Component Reference

NOTE: Refer to FIGURE 1 page 2-2 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. DOOR SWITCH

4. TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. CONV ECTION FAN MOTOR

7. TEMPERATURE PROBE

8. SOLID STATE POTENTIOMETER

9. CENTRIFUGAL SWITCH

10. COOK LIGHT

11. ELEMENT CONTACTOR

12. HEATING ELEMENTS

13. 50 WATT LAMPS

14. LIGHT SWITCH

15. TIMER MOTOR

16. BUZZER

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), one side of the door switch (3),

terminal #8 of the temperature control board

(4) and the axial fan (5).

2. If the doors are closed the door switch (3)

should also be closed sending power to termiĆ

nal #6 of the temperature control board (4)

and to the convection fan motor (6).

NOTE: This motor has a built in centrifugal

switch (9) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

3. On a call for heat from the temperature control

circuit, a circuit is completed between termiĆ

nals #6 and #7 of the temperature control

board (4).

NOTE: The temperature control circuit conĆ

sists of the temperature probe (7), the

temperature control board (4) and the

solid state potentiometer (8).

Power is sent out of terminal #7 to one side of

the centrifugal switch (9). If the convection fan

motor (6) is at full speed the centrifugal switch

(9) closes sending power to the cook light (10)

and one side of the element contactor (11).

When the contactor closes the heating eleĆ

ments (12) power up.

4. The 50 watt lamps (13) only receive power when

the light switch (14) is activated. These lamps

are 115 volt and are wired in series parallel.

5. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (2) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 1.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the resistive values of the

heating elements. The reading should be

taken in a cold state.

OPERATION

2-2

1

2

3

4

15

16

9

8

7

14

6

12

13

5

10

11

FIGURE 1

MARK V

2-3

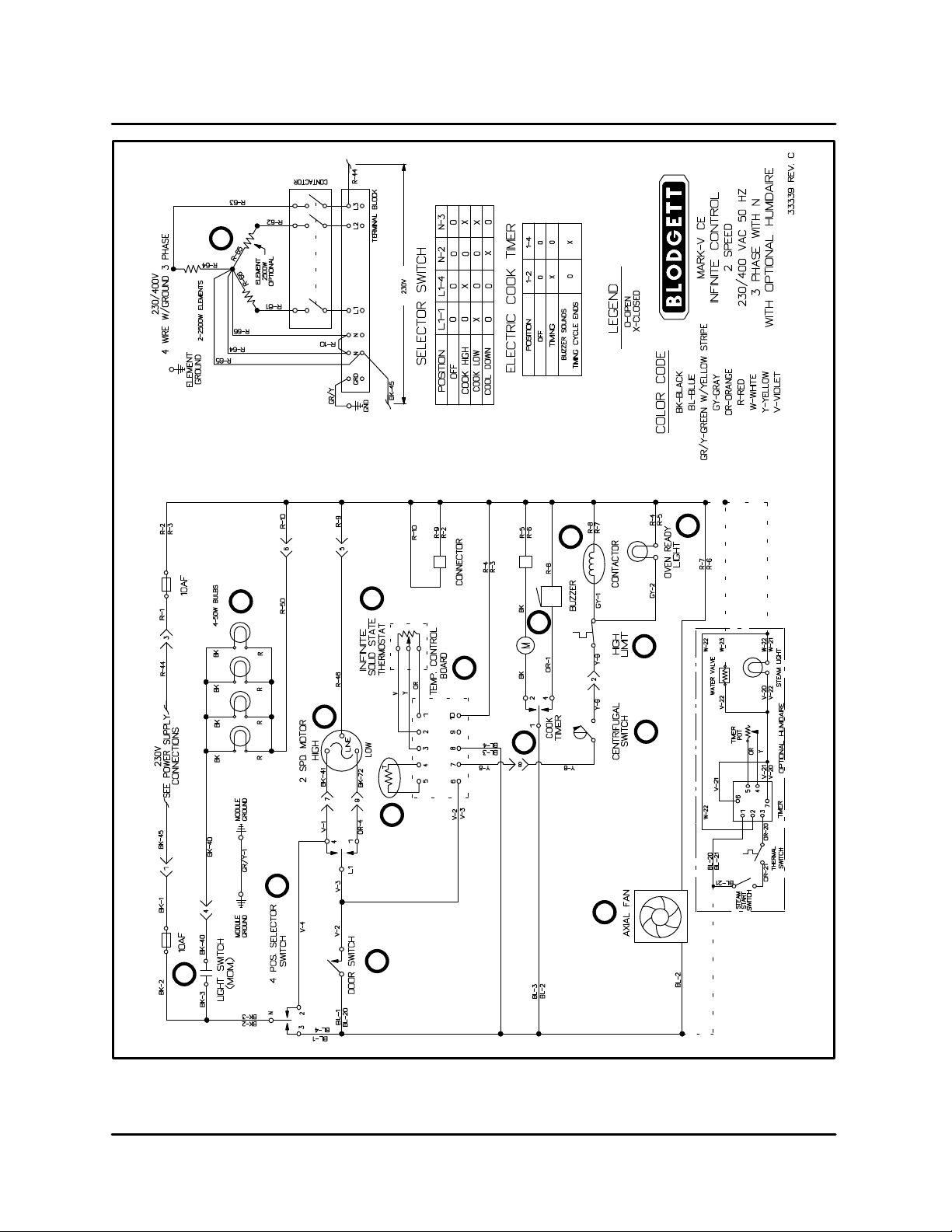

CE APPROVED COOK ONLY - 33339 REV C

Component Reference

NOTE: Refer to FIGURE 2 page 2-4 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. DOOR SWITCH

4. TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. CONVECTION FAN MOTOR

7. TEMPERATURE PROBE

8. SOLID STATE POTENTIOMETER

9. CENTRIFUGAL SWITCH

10. HIGH LIMIT SWITCH

11. ELEMENT CONTACTOR

12. COOK LIGHT

13. HEATING ELEMENTS

14. 50 WATT LAMPS

15. LIGHT SWITCH

16. TIMER MOTOR

17. BUZZER

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), one side of the door switch (3),

terminal #8 of the temperature control board

(4) and the axial fan (5).

2. If the doors are closed the door switch (3)

should also be closed sending power to termiĆ

nal #6 of the temperature control board (4)

and to the convection fan motor (6).

NOTE: This motor has a built in centrifugal

switch (9) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

3. On a call for heat from the temperature control

circuit, a circuit is completed between termiĆ

nals #6 and #7 of the temperature control

board (4).

NOTE: The temperature control circuit conĆ

sists of the temperature probe (7), the

temperature control board (4) and the

solid state potentiometer (8).

Power is sent out of terminal #7 to one side of

the centrifugal switch (9). If the convection fan

motor (6) is at full speed the centrifugal switch

(9) closes sending power to one side of a high

limit switch (10), if the high limit is closed then

power will be sent to one side of the contactor

(11) and an indicator light (12). When the conĆ

tactor closes the heating elements (12) power

up.

4. The 50 watt lamps (13) only receive power when

the light switch (14) is activated.

5. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (2) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 2.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the resistive values of the

heating elements. The reading should be

taken in a cold state.

OPERATION

2-4

1

15

3

6

14

4

2

17

11

12

10

9

5

13

7

8

FIGURE 2

MARK V

2-5

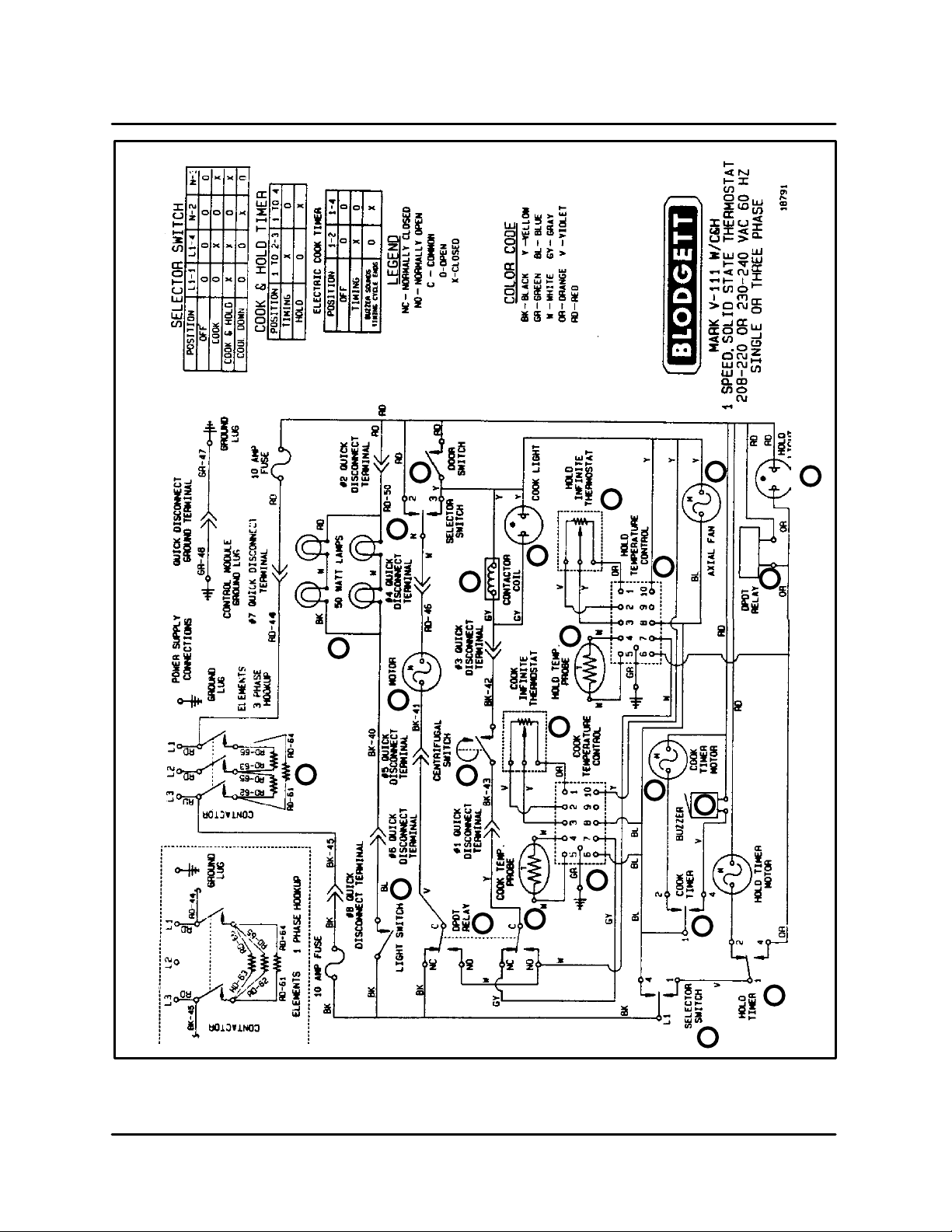

COOK AND HOLD - 18791

Component Reference

NOTE: Refer to FIGURE 3 page 2-7 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOK TIMER

3. COOK TEMPERATURE CONTROL BOARD

4. HOLD TEMPERATURE CONTROL BOARD

5. AXIAL FAN

6. DPDT RELAY COIL

7. DOOR SWITCH

8. CONV ECTION FAN MOTOR

9. TEMPERATURE PROBE

10. SOLID STATE POTENTIOMETER

11. CENTRIFUGAL SWITCH

12. COOK LIGHT

13. ELEMENT CONTACTOR

14. HEATING ELEMENTS

15. TIMER MOTOR

16. BUZZER

17. COOK AND HOLD TIMER

18. COOK AND HOLD LIGHT

19. TEMPERATURE PROBE

20. SOLID STATE POTENTIOMETER

21. 50 WATT LAMPS

22. LIGHT SWITCH

Cook Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to terminal #1 of the

cook timer (2), terminals #6 and #8 of the cook

temperature control board (3), terminal #8 of

the hold temperature control board (4) and the

axial fan (5). Power is also applied to the N.C.

set of contacts in a DPDT relay (6).

NOTE: The coil of this relay will only be actiĆ

vated when the hold timer is set.

2. If the doors are closed the door switch (7)

should also be closed sending power to termiĆ

nal #3 of the mode selector switch (1). The

mode selector switch should already be made

between terminals #3 and N completing the

circuit to the convection fan motor (8).

NOTE: This motor has a built in centrifugal

switch (11) that closes when the motor

reaches full speed. If found faulty do

not bypass, the whole motor should be

replaced.

3. On a call for heat from the cook temperature

control system a circuit is completed between

terminals #6 and #7 of the temperature conĆ

trol board (3).

NOTE: The temperature control system conĆ

sists of the temperature probe (9), the

temperature control board (3) and the

solid state potentiometer (10)

Power is sent out of terminal #7 to the N.C. terĆ

minal of the DPDT relay (6). This relay should

be made between the N.C. terminal and the

common terminal sending power to one side

of the centrifugal switch (11). If the convection

fan motor (8) is at full speed the centrifugal

switch (11) closes sending power to the cook

light (12) and one side of the element contactor

(13). When the contactor closes the heating

elements (14) power up.

4. When the cook timer (2) is set for a time a cirĆ

cuit is made between terminals #1 and #2

powering up the timer motor (15). At the expiĆ

ration of the set time the switch in the cook timĆ

er (15) toggles from 1-2 to 1-4 powering up

the buzzer (16).

NOTE: Put the timer in the home position to siĆ

lence the buzzer.

5. The 50 watt lamps (21) only receive power when

the light switch (22) is activated. These lamps

are 115 volt and are wired in series parallel.

Cook and Hold Operation

1. Turn the mode selector switch (1) to the cook

and hold position. Power goes to terminal #1

of the cook and hold timer (17). When the cook

and hold timer is set power goes to terminal #6

of the hold temperature controller (4), the coil

of the DPDT relay (6) and the cook and hold

light (18). When the DPDT relay powers up the

switches in the relay toggle from the N.C. to the

N.O. position.

2. On a call for heat from the hold temperature

control system, a circuit is completed beween

terminals #6 and #7 of the hold temperature

control board (4).

OPERATION

2-6

NOTE: The hold temperature control system

consists of the temperature probe (19),

the hold temperature control board (4)

and the solid state potentiometer (20).

Power goes to the N.O. terminals of the DPDT

relay (6). Circuits should be made between the

N.O. and common terminals of the DPDT relay

(6) allowing power to run to the convection fan

motor (8) and one side of the centrifugal switch

(11). If the convection fan motor (8) is at full

speed the centrifugal switch (11) closes sending

power to the cook light (12) and one side of the

element contactor (13). When the contactor

closes the heating elements (14) power up.

NOTE: In cook and hold mode only, the conĆ

vection fan cycles on and off with the

hold thermostat system.

3. The 50 watt lamps (21) only receive power when

the light switch (22) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: The potentiometer and probes for cook

and cook & hold are identical. The cook

and cook & hold temperature boards are

NOT interchangeable.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 3.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

MARK V

2-7

1

17

2

16

15

3

9

6

10

19

4

5

6

18

20

12

13

11

8

1

7

21

14

22

FIGURE 3

OPERATION

2-8

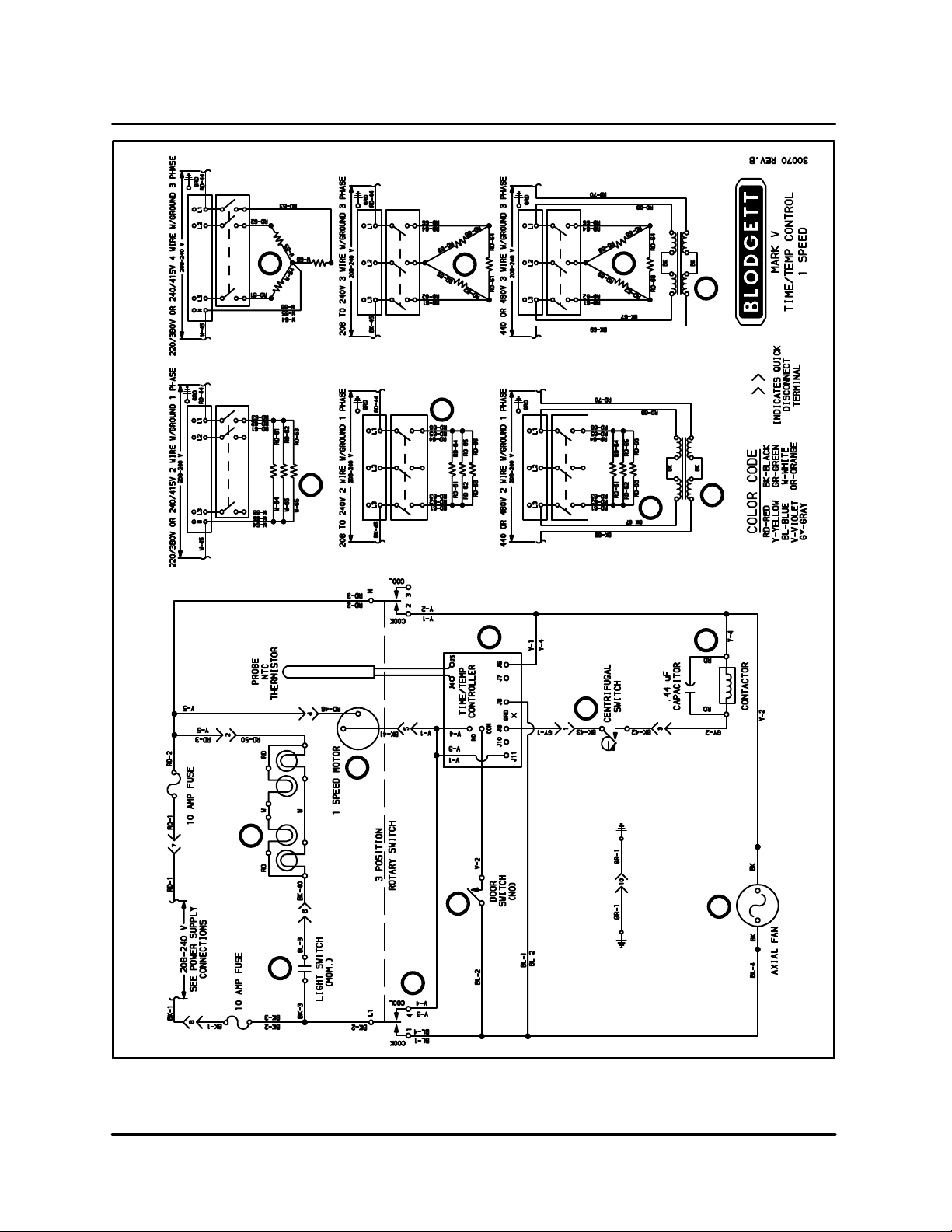

SOLID STATE DIGITAL - 30070 REV B

Component Reference

NOTE: Refer to FIGURE 4 page 2-9 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. TIME AND TEMPERATURE CONTROLLER

4. AXIAL FAN

5. CENTRIFUGAL SWITCH

6. CONVECTION FAN MOTOR

7. HOT AIR ELEMENT CONTACTOR

8. HEATING ELEMENTS

9. TRANSFORMER

10. 50 WATT LAMPS

11. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to one terminal of the

door switch (2), terminal J8 of the temperature

controller (3), and the axial fan (4). The main

blower fan starts. If a temperature is proĆ

grammed into the controller, the power goes

from J9 to the centrifugal switch (5) in the conĆ

vection fan motor (6).

2. If the doors are closed, the door switch (2)

should also be closed, sending power to the

common terminal of the time and temperature

controller (3). The relay on this controller

should be closed since a temperature has

been programmed into the controller. A circuit

is made between common and N.O. sending

power to, and starting the convection fan moĆ

tor (6).

NOTE: The relay in the time and temperature

controller is not field repairable. If

diagnosed as defective, the entire

board must be replaced.

3. When the convection fan motor (6) reaches full

speed the centrifugal switch (5) closes sendĆ

ing power to the coil of the hot air element conĆ

tactor (7). When the contactor closes power is

sent to the heating elements (8).

4. The 50 watt lamps (10) only receive power when

the light switch (11) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 4.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

NOTE: Reference page 4-2 of the TroubleshootĆ

ing section for the reistive values of the

heating elements. The reading should be

taken in a cold state.

MARK V

2-9

1

11

2

3

4

5

6

7

10

8

8

8

8

8

8

9

9

FIGURE 4

OPERATION

2-10

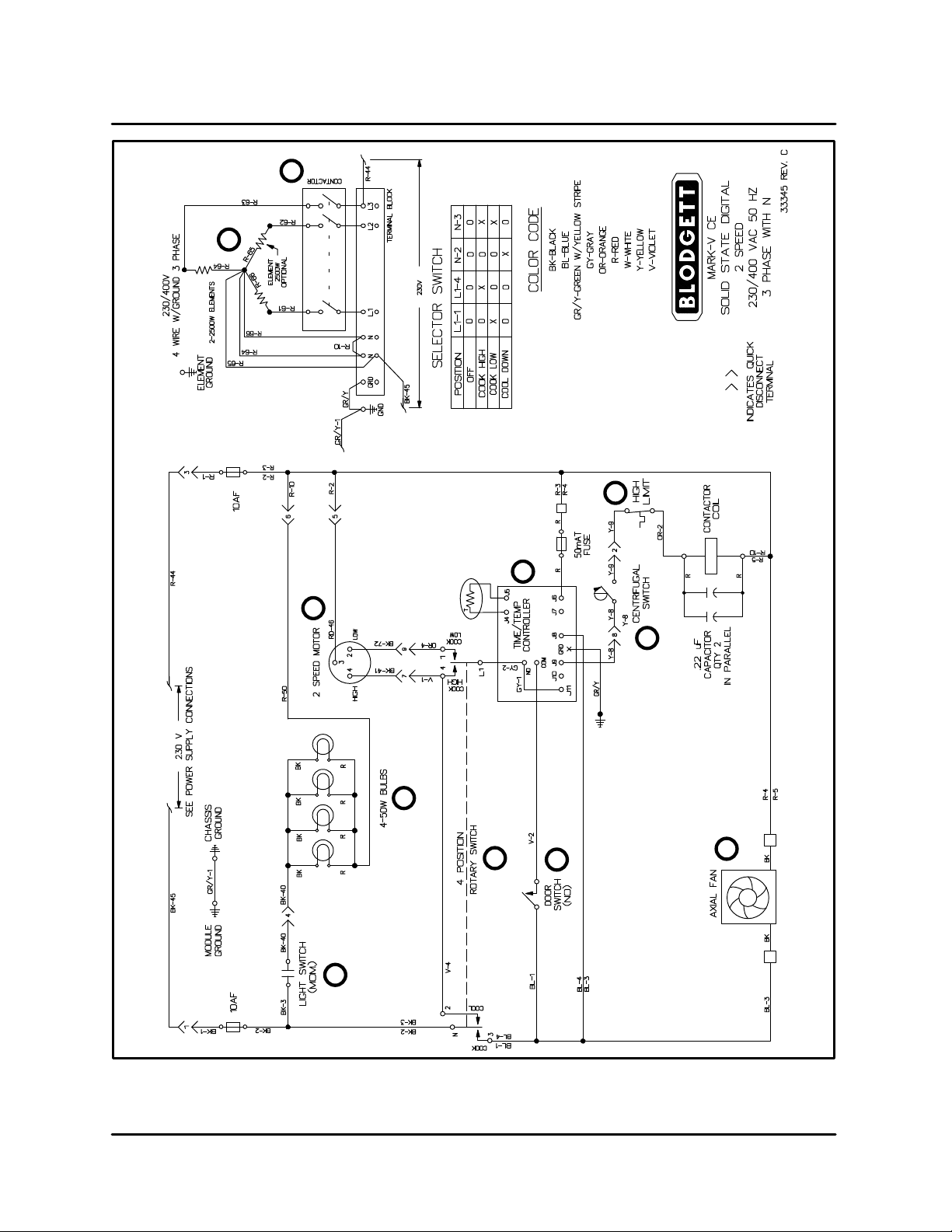

CE APPROVED SOLID STATE DIGITAL - 33345 REV C

Component Reference

NOTE: Refer to FIGURE 5 page 2-11 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. DOOR SWITCH

3. TIME AND TEMPERATURE CONTROLLER

4. AXIAL FAN

5. CENTRIFUGAL SWITCH

6. CONVECTION FAN MOTOR

7. HIGH LIMIT SWITCH

8. HOT AIR ELEMENT CONTACTOR

9. HEATING ELEMENTS

10. 50 WATT LAMPS

11. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to one terminal of the

door switch (2), terminal J8 of the temperature

controller (3), and the axial fan (4). The main

blower fan starts. If a temperature is proĆ

grammed into the controller, the power goes

from J9 to the centrifugal switch (5) in the conĆ

vection fan motor (6).

2. If the doors are closed, the door switch (2)

should also be closed, sending power to the

common terminal of the time and temperature

controller (3). The relay on this controller should

be closed since a temperature has been proĆ

grammed into the controller. A circuit is made

between common and N.O. sending power to,

and starting the convection fan motor (6).

NOTE: The relay in the time and temperature

controller is not field repairable. If

diagnosed as defective, the entire

board must be replaced.

3. When the convection fan motor (6) reaches full

speed the centrifugal switch (5) closes sending

power to the high limit (7). If the high limit is

closed, power goes to the coil of the hot air eleĆ

ment contactor (8). When the contactor closes

power is sent to the heating elements (9).

4. The 50 watt lamps (10) only receive power when

the light switch (11) is activated.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

MARK V

2-11

1

2

4

5

7

3

10

6

11

9

8

FIGURE 5

OPERATION

2-12

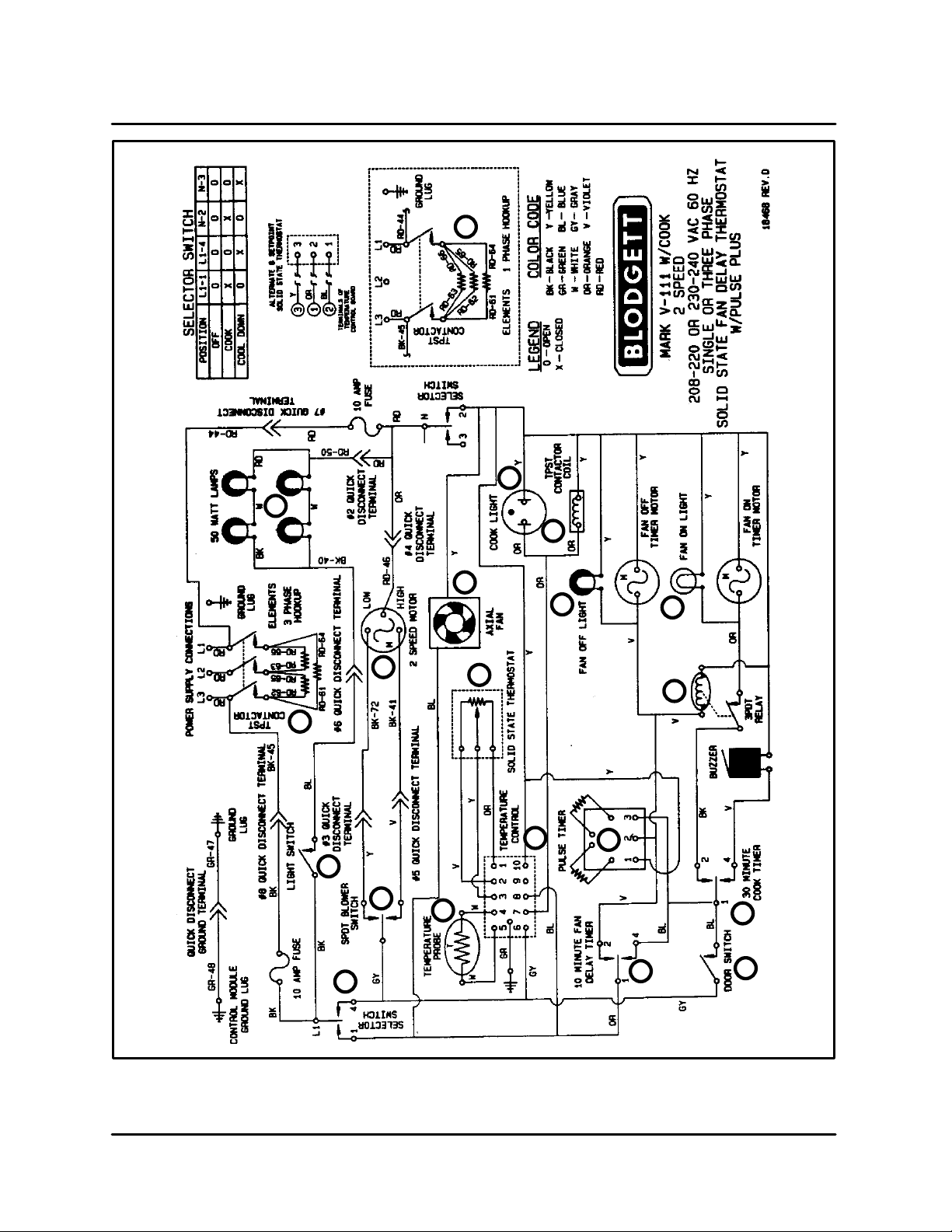

FAN DELAY WITH PULSE PLUS - 18466 REV D

Component Reference

NOTE: Refer to FIGURE 6 page 2-13 for compoĆ

nent locations.

1. MODE SELECTOR SWITCH

2. COOLING FAN

3. TEMPERATURE CONTROLLER

4. 10 MINUTE FAN DELAY TIMER

5. 30 MINUTE COOK TIMER

6. DOOR SWITCH

7. SPDT BLOWER SWITCH

8. CONVECTION FAN MOTOR

9. TEMPERATURE PROBE

10. POTENTIOMETER

11. HOT AIR ELEMENT CONTACTOR

12. COOK LIGHT

13. HOT AIR ELEMENTS

14. REPEAT SHOT PULSE TIMER

15. TPDT RELAY

16. FAN ON LIGHT

17. FAN OFF LIGHT

18. 50 WATT LAMPS

19. LIGHT SWITCH

Operation

1. Turn the mode selector switch (1) to the cook

position. Power goes to the cooling fan (2), terĆ

minal #8 of the temperature controller (3), and

terminal #1 of the ten minute fan delay timer (4).

2. If the ten minute fan delay timer is in the timed

out position a switch is made between terminals

#1 and #4 sending power to terminal #1 of the

thirty minute cook timer (5). Power is also sent

to one side of the door switch (6). If the doors are

closed the door switch should also be closed

sending power to terminal #6 of the temperature

control board (3) and the common terminal of a

SPDT blower switch (7). The speed of the conĆ

vection fan motor (8) is dependant on the posiĆ

tion of the SPDT blower switch.

3. On a call for heat from the cook temperature

control system a circuit is completed between

terminals #6 and #7 of the temperature conĆ

trol board (3).

NOTE: The temperature control system conĆ

sists of the temperature probe (9), the

temperature control board (3) and the

solid state potentiometer (10)

Power is sent out of terminal #7 to one coil of

the hot air element contactor (11) and the cook

light (12). When the contactor is energized the

hot air element (13) powers up.

4. To enable the pulse plus feature, the ten minĆ

ute fan delay timer (4) must be set to a time. A

switch is then made between terminals #1 and

#2 sending power to terminal #2 of a repeat

shot pulse timer (14).

NOTE: By setting the ten minute fan delay timer

(4) power is interrupted to the thirty minĆ

ute cook timer (5) making it inoperative.

The repeat shot pulse timer cycles a TPDT relay

(15) interrupting the circuit to the convection fan

motor (8). The convection fan motor cycles on

and off for approximately thirty second intervals

for the duration of the time set on the ten minute

fan delay timer (4). The fan on light (16) illumiĆ

nates whenever the TPDT relay closes. The fan

off light (17) illuminates whenever the ten minute

fan delay timer is set for a time.

5. The 50 watt lamps (18) only receive power when

the light switch (19) is activated. These lamps

are 115 volt and are wired in series parallel.

NOTE: Turn the mode selector switch to cool

down to bypass the door microswitch. This

allows the convection fan motor to operate

even when the doors are open.

NOTE: This oven may be converted from single to

three phase, however, contactors must be

changed due to the difference in amp

draw. Reference detail inset in FIGURE 6.

NOTE: The resistive values for the probes used in

this oven have descending temperature

coefficients. As the temperature increases

the resistive values decrease.

MARK V

2-13

1

19

7

9

3

14

4

6

5

15

16

17

11

12

10

2

8

13

18

13

FIGURE 6

Loading...

Loading...