DFG-100 AND DFG -200 SERIES

CONVECTION OVEN

INSTALLATION -- OPERATION -- MAINTENANCE

LA SÉRIE DFG-100 ET DFG-200

FOURS À CONVECTION

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN 90055 Rev U (1/03)

E 2003 --- G.S. Blodgett Corporation

IMPORTANT

WARNIN G:IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENAN C E CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH .READ THE

INSTALLA TION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTI SSEMEN T: UNE INST A L LATION, UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGESÀ LA PROPRIÉTE,DES BLESSURES OU LA MORT. LISEZ ATTENTIVEMENT LES DIRECTIVES D’INST A L LATION, D’OPÉRATI ON ET D’ENTRETIENAV A N T

DE FAIRE L’INST A L LATION OU L’ENTRETIEN DE CET ÉQUIPEMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future refere nce.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entretenir correctement ce four. Le respect de ces instructio n s et procédures permettra d’obtenir de bons résultats de cuisson et une longue durée de service sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

THE REPUTATION YOU CAN COUNT ON

UNE RÉPUTATION SUR LAQUELLE VOUS POUVEZ COMPTER

For over a century and a half, The Blodgett Oven Company has been building

ovens and nothing but ovens. We’ve set the industry’s quality standard for all

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, no one offers more models, sizes, and oven applications

than Blodgett; gas and electric, full-size, half-size, countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the full line of Blodgett ovens contact your

Blodgett representative.

Cela fait maintenant dessus un siècle et demi que Blodgett se spécialisedans

la fabrication de fours. Nous avons établi les normes de qualité qui s’appliquent dans l’industrie à tous les types de fours utilisés dans les services alimentaires, quel qu’en soit la taille, l’exploitation ou le budget. En fait, ni n’offre

plus de modèles, de tailles et d’applications de fours que Blodgett. À gaz et

électriques. De tailles différentes, sur plan de travail et superposables. Qu’il

s’agisse de fours à convection, des modèles Cook’n Hold et Combi-Oven, ou

de la gamme de fours à pizzas de la plus haute qualité offerte sur le marché.

Pour de plus amples informations sur la gamme complète de fours Blodgett,

veuillez contacter votre représentant Blodgett.

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your oven was installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Table of Contents/Table des Matières

Introduction

Oven Description and Specifications 2....

Oven Components 3....................

Installation

Delivery and Location 4.................

Oven Assembly 5......................

NSF Bolts 5..........................

Leg Attachment 6.....................

Caster Assembly 6....................

Double Section Assembly 7............

Oven Leveling 7......................

Ventilation 8...........................

Canopy Type Exhaust Hood 8..........

Direct Flue Arrangement 9.............

Utility Connections ---

Standards and Codes 10.................

Gas Connection 11......................

Electrical Connection 14.................

Initial Startup 15.........................

Operation

Safety Information 16....................

CH-Pro3 (Solid State Programmable

Digital Control) 17.......................

Solid State Digital Control 20..............

Solid State Manual Control 22.............

Blodgett IQ2T Control 23................

Cook and Hold Control 32................

Pulse Plus 34...........................

Humidaire 35...........................

Intelliplus with Chain Event Control 36.....

Intellitouch II Control 39..................

How Cook and Hold Works 42............

General Guidelines for Operating

Personnel 43............................

Suggested Times and Temperatures 44....

Maintenance

Cleaning and Preventative Maintenance 45.

Troubleshooting Guide 46................

Introduction

Description et Spécifications du Four 48....

Éléments du Four 49.....................

Installation

Livraison et Implantation 50...............

Montage du Four 51.....................

Boulons NSF 51.......................

Assemblage des Pieds 52...............

Montage des Roulettes 52..............

Montage de la Section Double 53........

MiseàNiveauduFour 53...............

Ventilation 54...........................

Hotte D’évacuation Type Voûte 54.......

En Prise Directe 55.....................

Branchements de Service --- Normes et

Codes 56...............................

Branchement de Gaz 57.................

Raccordement Électrique 60..............

Mise en Marche Initiale 61................

Utilisation

Informations de Sécurité 62...............

CH-Pro3 (Commande Numérique Program-

mable pour Semi-Conducteurs) 63........

Commandes Numériques à

Semi-Conducteurs 67....................

Commandes à Semi -Conducteurs 70......

Contrôle du Blodgett IQ2T 71............

Commande Cuisson et Maintien 81........

Pulse Plus 83...........................

Humidaire 84...........................

Intelliplus avec Commandes à

Enchaînement 85........................

Intellitouch II 88.........................

Principe de la Fonction de Cuisson et

Maintien 91.............................

Consignes Générales à l’Intention des

Utilasateurs 92..........................

Durées et Températures Suggérées 93.....

Entretien

Nettoyage et Entretien Préventif 94........

GuidedeDétectiondesPannes 95........

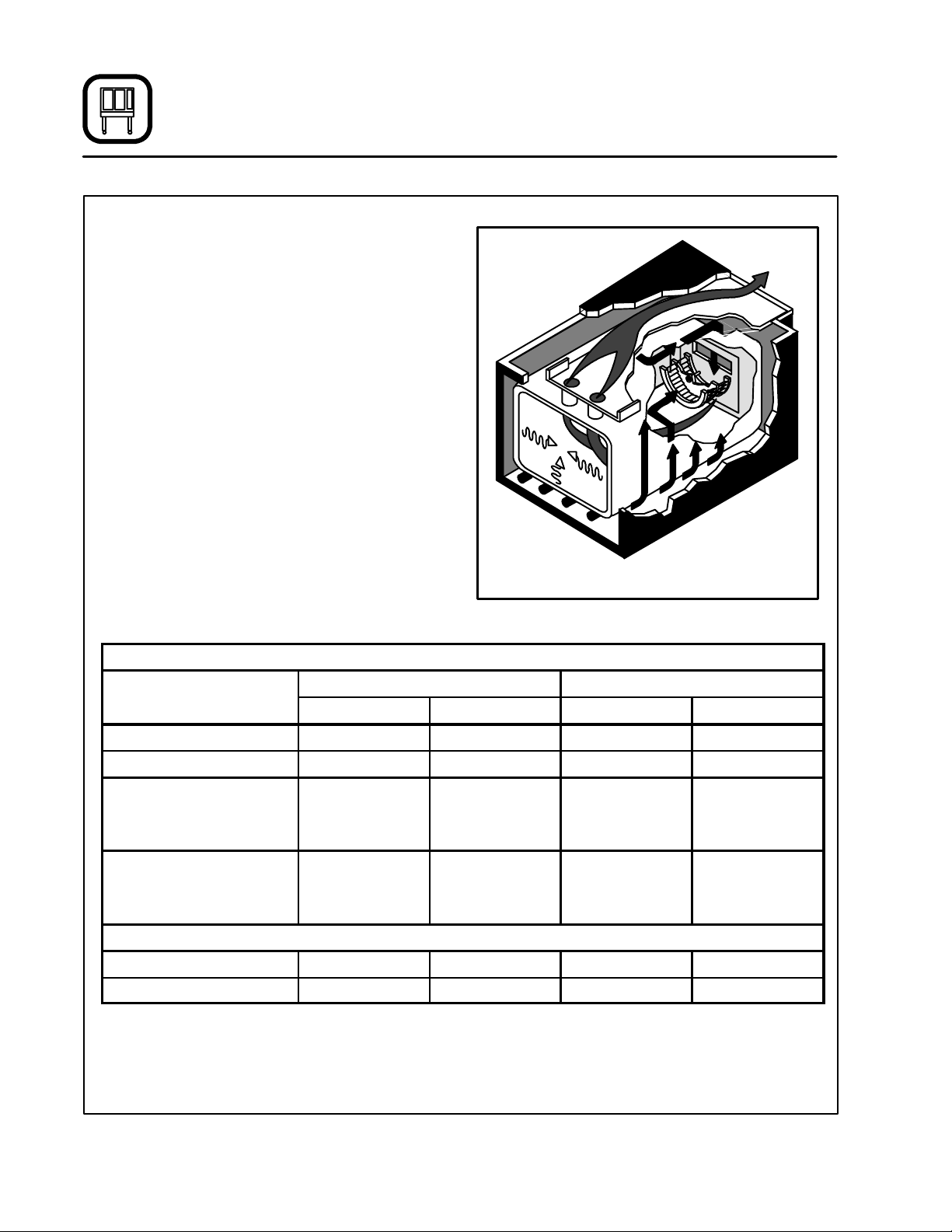

Introduction

Oven Description and Specifications

Cooking in a convection oven differs from cooking

in a conventionaldeck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The moving air continually strips away the layer of cool air surrounding the product, quickly allowing the heat to penetrate. The result is a high quality product, cooked

at a lower temperature in a shorter amount of time.

Blodgettconvection ovens represent the latest advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recircu lated within the cooking chamber before being

vented from the oven: resulting in substantial reductions in energy consumption and enhanced

oven performance.

Air Flow Pattern for Blodgett DFG Convection Ovens

Figure 1

GAS SPECIFICATIONS -- U.S., Cana da and General Export

Natural Gas Propane Gas

US Units SI Units US Units SI Units

Heating Value 1000 BTU/cu.ft. 37.3 MJ/m

Specific Gravity (air=1.0) 0.63 0.63 1.53 1.53

Oven Input

DFG-100-3

DFG-200-L

Main Burner Orifice Size

DFG-100-3

DFG-200-L

GAS SPECIFICATIONS -- DFG-100-3 for Australia

Oven Input --- 58 MJ/h --- 58 MJ/h

Main Burner Orifice Size 38 MTD* 2.58 mm 1/16” dia. 1.6 mm

NOTE: * --- Multiple Twist Drill

55,000 BTU/hr

60,000 BTU/hr

38 MTD*

36 MTD*

16.2 kW

17.6 kW

2.6 mm

2.7 mm

3

2550 BTU/cu. ft. 95.0 MJ/m

55,000 BTU/hr

60,000 BTU/hr

1/16” dia.

52 MTD*

16.2 kW

17.6 kW

1.6 mm

1.6 mm

3

2

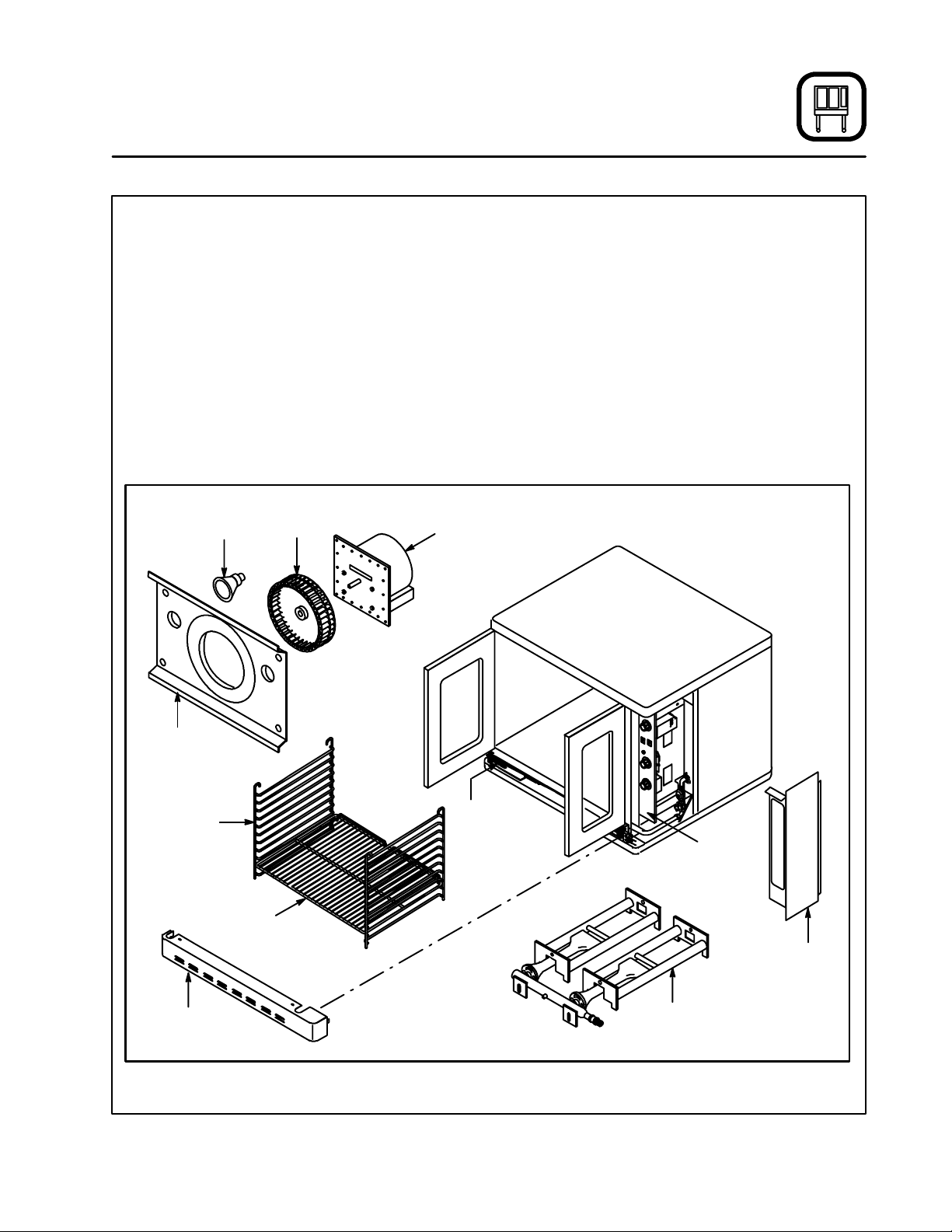

Introduction

Oven Components

Combustion Cover --- provides access to the

combustion compartment on gas ovens.

Combustion Compartment --- contains combus-

tion burners on gas ovens.

Combustion Burners --- provide heat to the bak-

ing chamber on gas ovens.

Chain & Turnbuckle --- controls operation of the

oven doors.

Control Panel --- contains wiring and components

to control the oven operation.

Oven Racks --- five racks are provided standard.

Additional racks are available.

Oven

Lights

Blower

Wheel

Convection

Motor

Rack Supports --- h o l d ov e n r a c k s .

Blower Wheel Cover --- locatedon the back interi-

or wall of the oven. Protects the blower wheel.

Blower Wheel --- spins to circulate hot air in the

baking chamber.

Convection Motor --- provides power to turn the

blower w h eel.

Oven Lights --- provide lighting inside the baking

compartment.

Blower

Wheel Cover

Rack Support

Combustion

Cover

Chain &

Turn b u c kle

Control

Panel

Oven Rack

Control

Panel Cover

Combustion

Burners

Figure 2

3

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external damage. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Carriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

DFG100

D

Oven body right side --- 2” (5cm)

D

Oven body left side --- 2” (5cm)

D

Oven body back --- 0” (0cm)

D

Oven body bottom --- 6” (15cm)

DFG200

D

Oven body right side --- 6” (15cm)

D

Oven body left side --- 6” 6” (15cm)

D

Oven body back --- 6” (15cm)

D

Oven body bottom --- 6” (15cm)

The following clearances must be available for servicing.

D

Oven body sides --- 12” (30cm)

D

Oven body back --- 12” (30cm)

NOTE: On gas models, routine servicingcan usu-

ally be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the wall, the gas must first be

turned off and disconnected from the oven

before removing the restraint. Reconnect

the restraint after the oven has been returned to its normal position.

It is essential that an adequate air supply to the

oven be maintained to provide a sufficient flow of

combustion and ventilation air.

D

Place the oven in an area that is free of drafts.

D

Keepthe oven area free and clear of all combustiblessuch as paper, cardboard, and flammable

liquids and solvents.

D

NSF requires 6” of clearance on the bottom a nd

sides of the unit for cleaning. Do not place the

oven on a curb base or seal to a wall.

D

The location must provide adequate clearance

for the air opening into the combustion chamber.

Before making any utility connections to this oven,

check the rating plate to be sure the oven specifications are compatible with the gas and electrical

services supplied for the oven.

1. Remove the combustion compartment cover.

The rating plate is attached to the frame on the

left side of the combustion compartment.

4

Installation

Oven Assembly

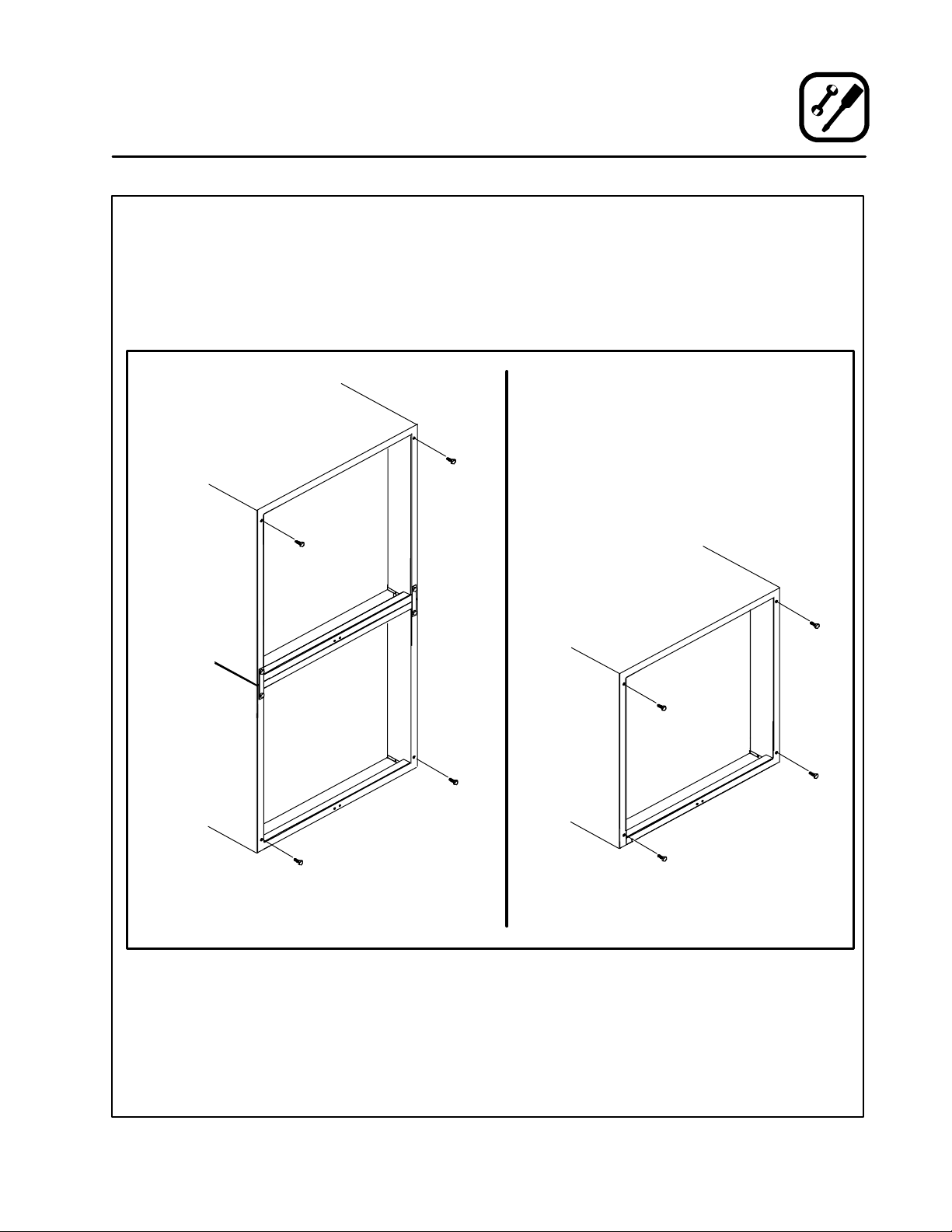

NSF BOLTS

These bolts are required by NSF to block any exposed hole on the back of an oven. This includes:

D

any unit, single or stacked, without a back panel.

D

any holes in stacked units not used for mounting stacking brackets.

1. Locate the 5/16” bolts that were shipped with

the oven.

2. InstalltheboltsasshowninFigure3.

Double Stacked Units Units without Back Panels

Figure 3

5

Installation

Oven Assembly

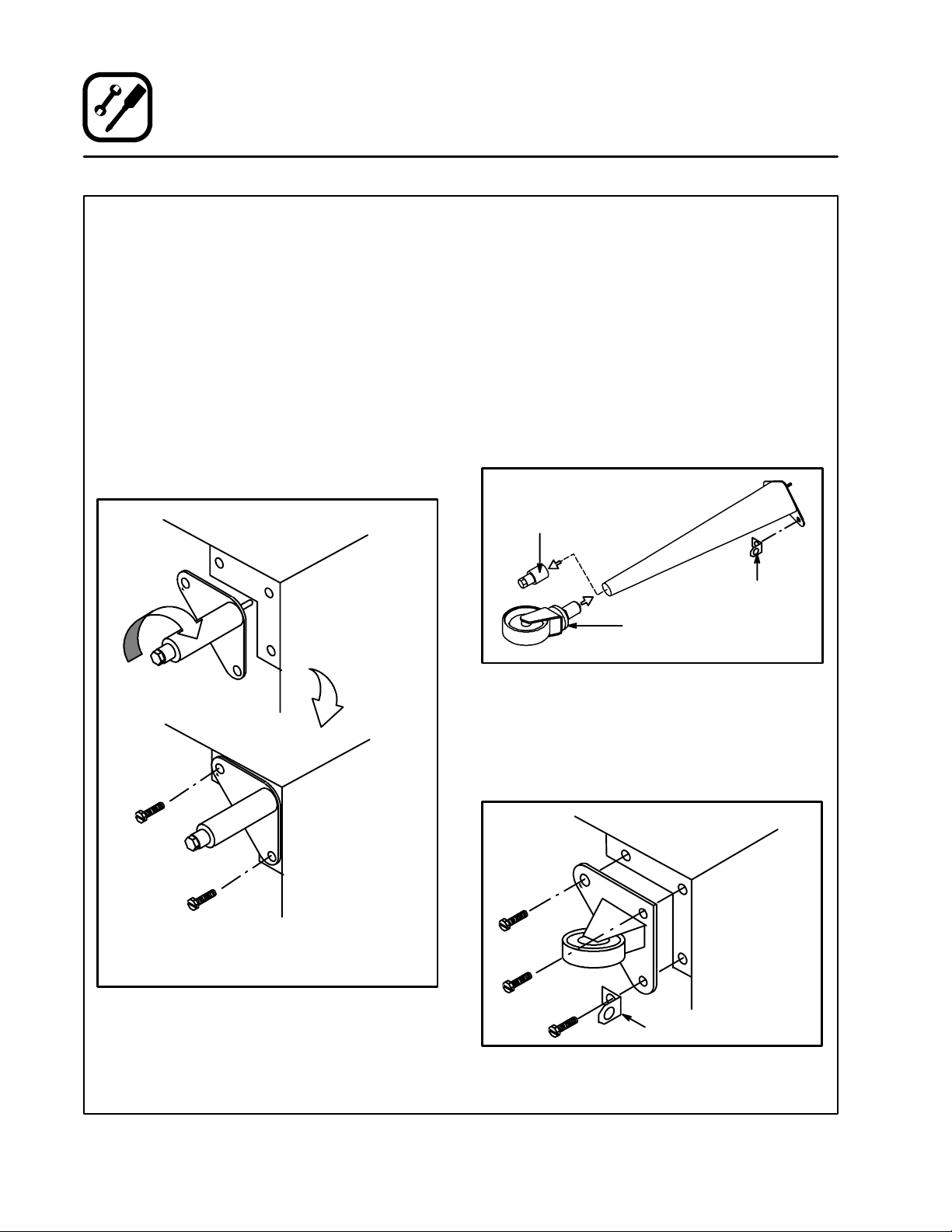

LEG ATTACHMENT

1. Push the oven onto a lift with the bottom of the

oven down.

2. Align the threaded stud in each leg with the

nut located inside each bottom corner of the

oven frame. Turn the legs clockwise and tighten to the nearest full turn.

3. Align the two leg plate holes in each leg with

those in the oven bottom. Secure each leg using two 1/2” bolts.

NOTE: If using casters see CASTER AS-

SEMBLY before proceeding.

4. Level the oven by screwing the adjustable leg

feet in or out as necessary.

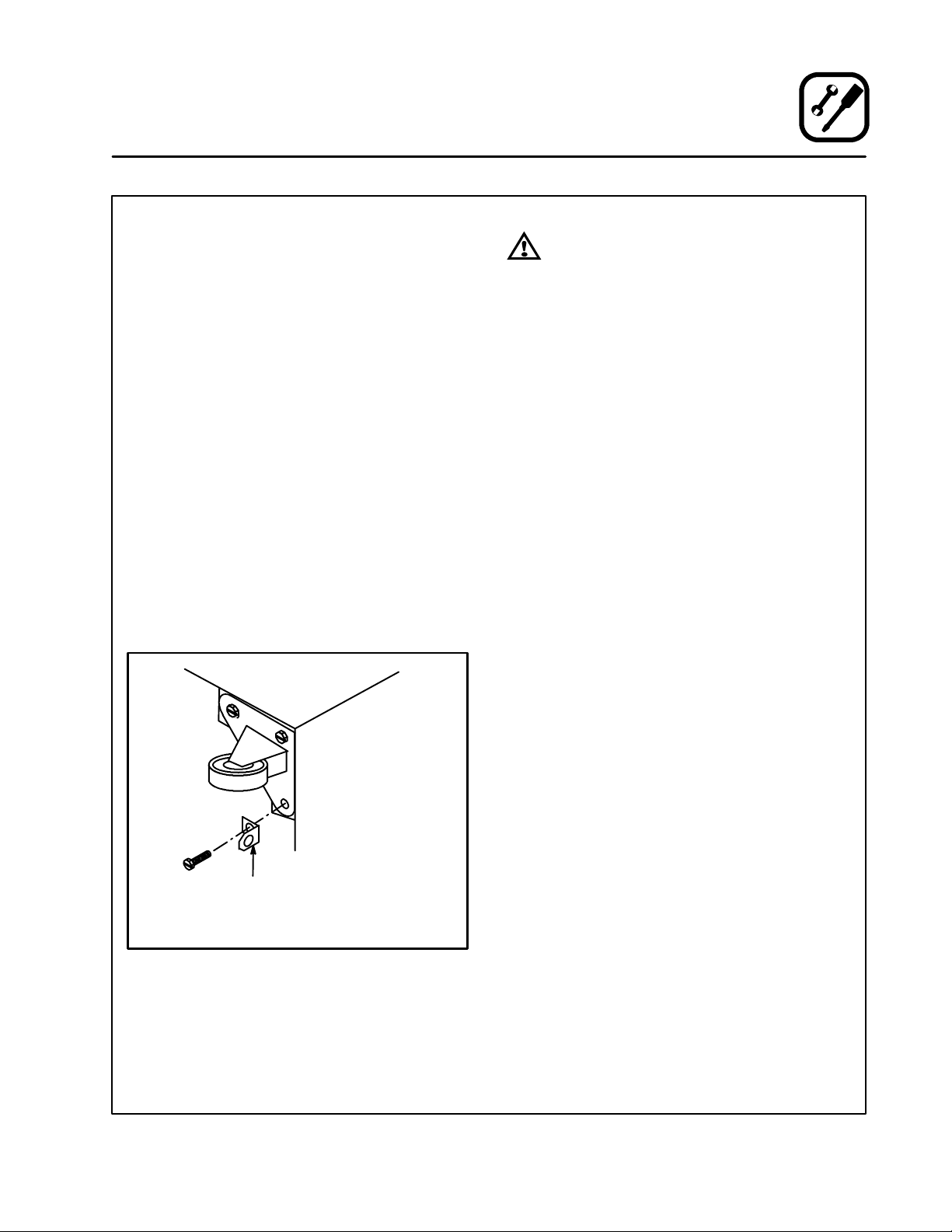

CASTER ASSEMBLY

NOTE: Install the locking casters on the front of

the oven. Install the non-locking casters on

the back of the oven.

NOTE: Use a gas hose restraint on all units with

casters. See page 13.

Casters for Singl e and Double Stacked Ovens:

1. Attach the legs as described.

2. Pry the adjustable feet out of the legs.

3. Insert one caster into each leg as shown.

Tighten the lock nuts to secure the casters.

Adjustable

Leg Foot

Gas Hose

Restraint Bracket

Caster Assembly

Figure 5

6” (15 cm) Legs Shown

Figure 4

Low Profile Castersfor Double StackedOvens:

1. Align the three holes in each caster assembly

plate with those in the oven bottom. Secure

each caster using three 1/2” bolts.

Gas Hose Restraint Bracket

Figure 6

6

Installation

Oven Assembly

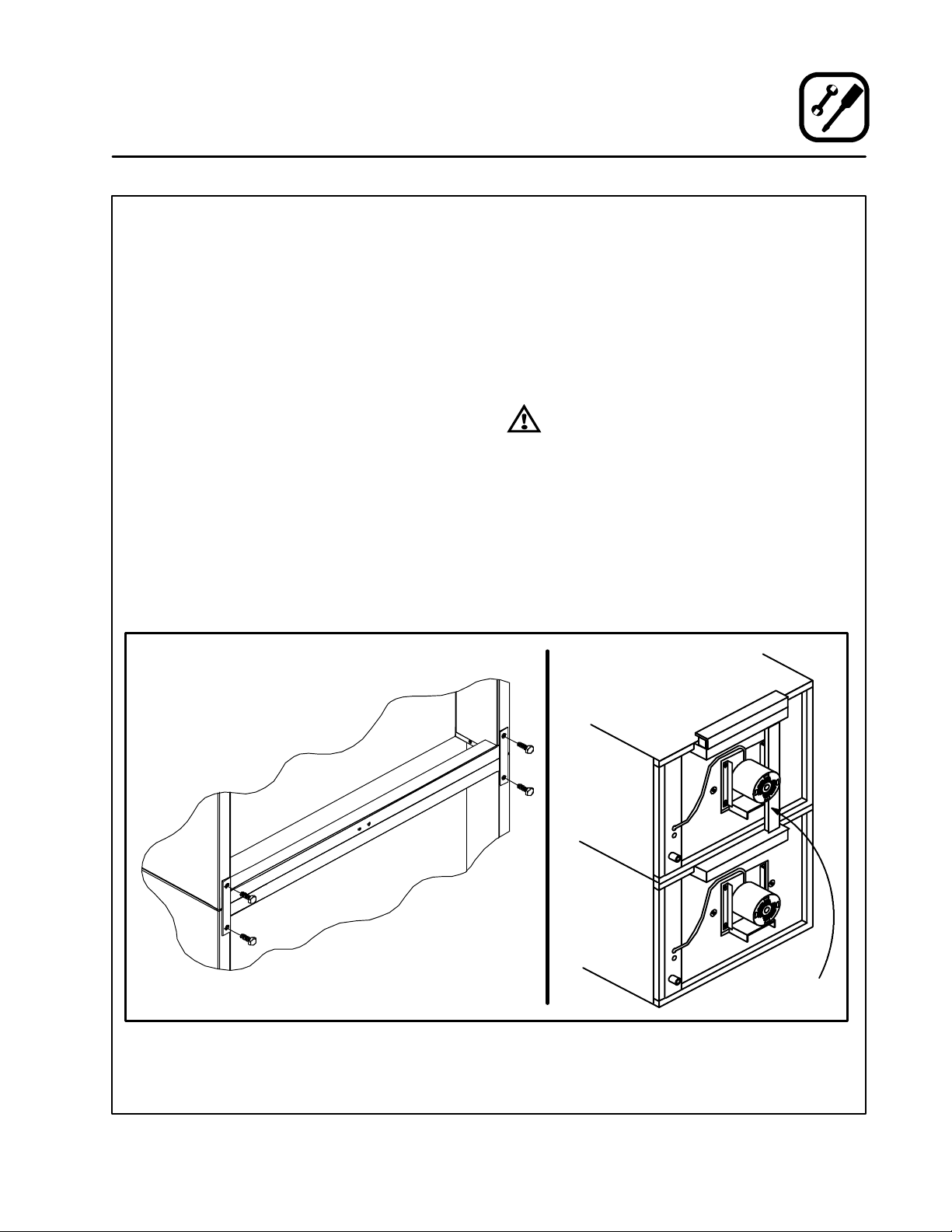

DOUBLE SECTION ASSEMBLY

NOTE: Old style ovens refer to units with painted ex-

posed rear angle. New style ovens refer to

units with rear angle iron enclosed in steel.

The following instructions apply to stacking two

new style ovens.

1. Secure the short legs to the bottom sections

as described.

2. Place the upper section in position on top of

the lower oven.

3. Attach the stacking brackets using the remaining 5/16” bolts shipped with the ovens.

4. Attach the flue connector.

The following instructions apply to stacking a new

styleovenonanoldstyleoven.

1. Secure the short legs to the bottom sections

as described.

2. Place the upper section in position on top of

the lower oven.

3. Attach the stacking brackets using the remaining 5/16” bolts shipped with the ovens.

4. Drill a clearance hole for a 5/16” bolt in the

angle iron of the old style oven. Use the holes

in the stacking brackets as a pilot.

5. Attach the stacking brackets to the old style

oven with the 5/16” bolts and nuts provided in

the kit.

6. Attach the flue connector.

WARNING!!

Whenstackingovensbesuretoremove

thesingleovenflueboxespriortoattaching three-piece connector.

OVEN LEVELING

After assembly, the oven should be leveled and

moved to the operating location.

1. The oven can be leveled by adjusting the feet

or casters located on the bottom of each leg.

Figure 7

7

Flue

Connector

Installation

Ventilation

On gas models the installation of a proper ventilation system cannot be over emphasized. This system removes unwanted vapors and products of

combustion from the operating area.

This oven may be vented using either:

D

A mechanically driven, canopy type, exhaust

hood, or

D

A direct flue arrangement.

U.S. and Canadian installations

Refer to your local ventilation codes. In the absence of local codes, refer to the National ventilation code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96-Latest Edition.

Australia and general export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local distributor, please callthe Blodgett Oven Companyat

0011-802-860-3700.

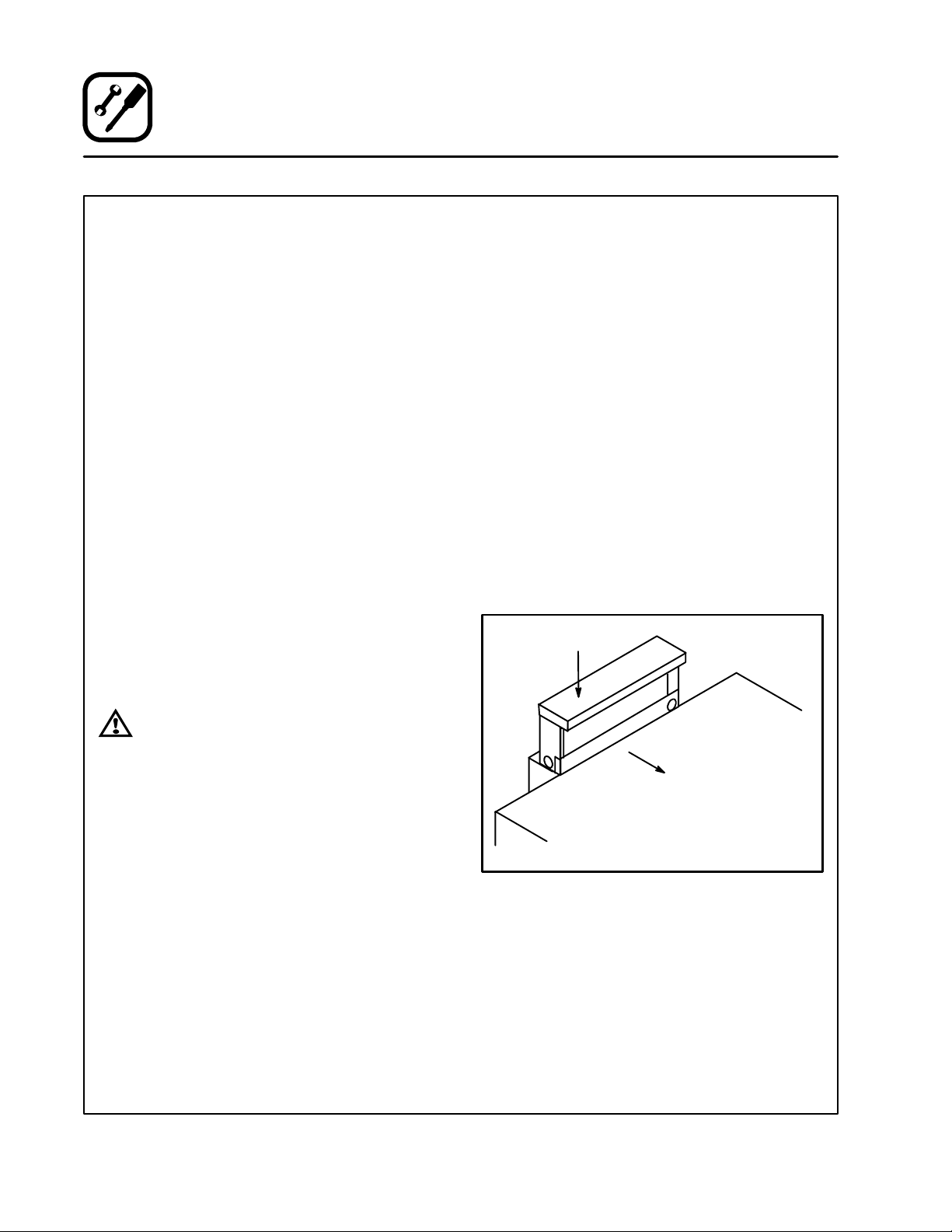

CANOPY TYPE EXHAUST HOOD

A mechanically driven, canopy type exhaust hood

is the preferred method of ventilation.

The hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall. The distance

from the floor to the lower edge of the hood should

not exceed 7’ (2.1m).

The total makeup and exhaust air requirements for

hood capacity should be approximately 30 CFM

3

(.85 m

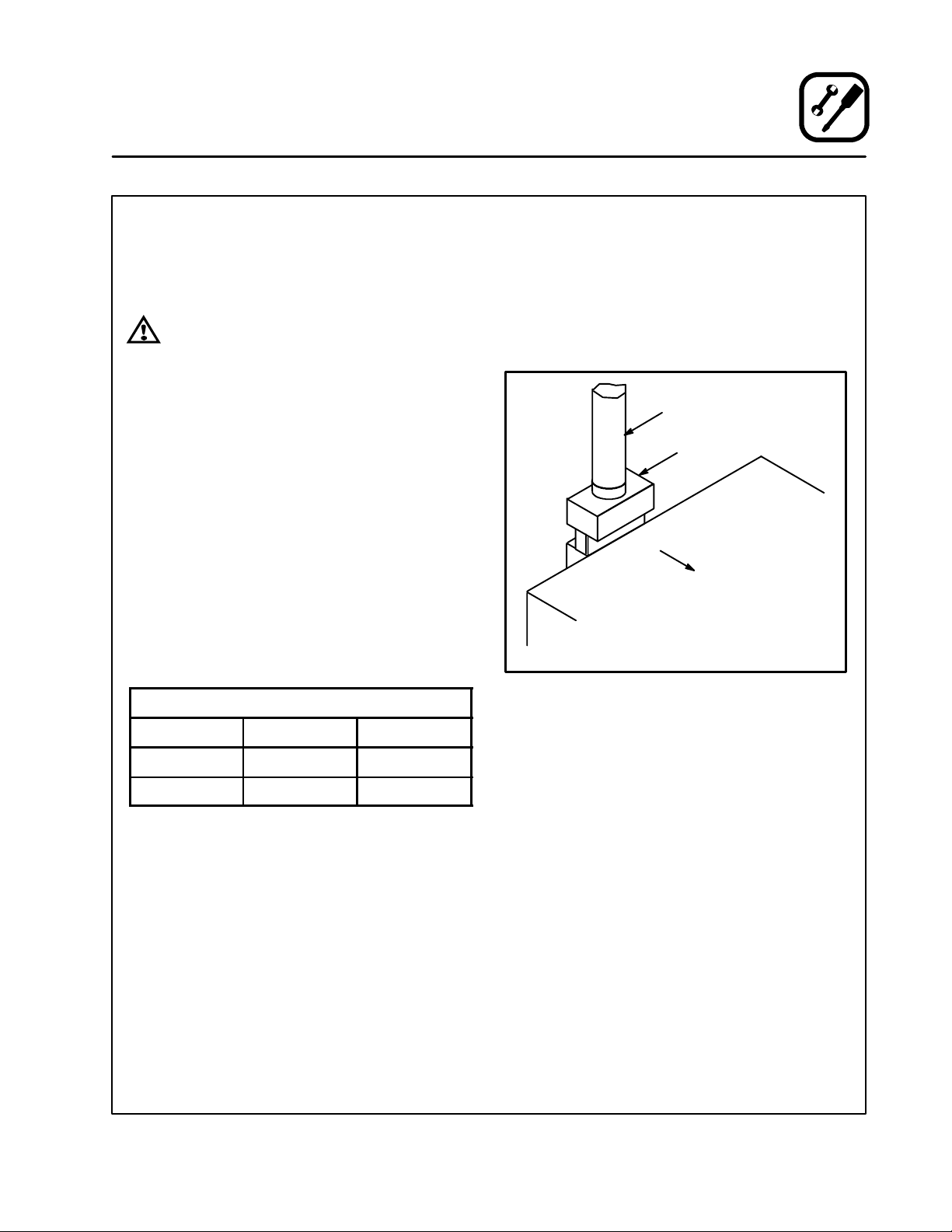

Installing the canopy hood draft diverter

Ovens ordered for hood venting are supplied with

a draft diverter. Install the draft diverter as follows:

1. Place the diverter over the flue connector with

2. Secure both ends with the sheet metal screw s

) for each oven section.

the open area facing the front of the oven. See

Figure 8.

provided.

Draft Diverter

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by

the manufacturer’s warranty.

Front of

Oven

Figure 8

8

Installation

Ventilation

DIRECT FLUE ARRANGEMENT

When the installation of a mechanically driven exhaust hood is impractical the oven may be vented

by a direct flue arrangement.

WARNING!!

It is essential that the direct flue be

installed as follows. Incorrect installation

will result in unsatisfactory baking and

oven damage.

ThefluemustbeclassBorbetter.Theheightof

theflueshouldrise6-8ft(2-2.5m)abovetheroof

of the building or any proximate structure. Never

direct vent the oven into a hood. The flue should

be capped with a UL Listedtype vent cap to isolate

the unit from external environmental conditions.

Thedirectventcannotreplaceairconsumedand

vented by the oven. Provisions must be made to

supply the room with sufficient make-up air. Total

make-up a ir requirements for each oven section

should be approximately 30 CFM (.85 m

tion. To increase t he supply air entering the room,

a ventilation expert should be consulted.

3

)persec-

Installing the draft hood

Ovens ordered for direct venting are supplied with

a draft hood. Install the draft hood as follows:

1. Place the draft hood over the flue connector .

SeeFigure9.

2. Secure both ends with the sheet metal screw s

provided.

Flue

Draft Hood

Front of

Oven

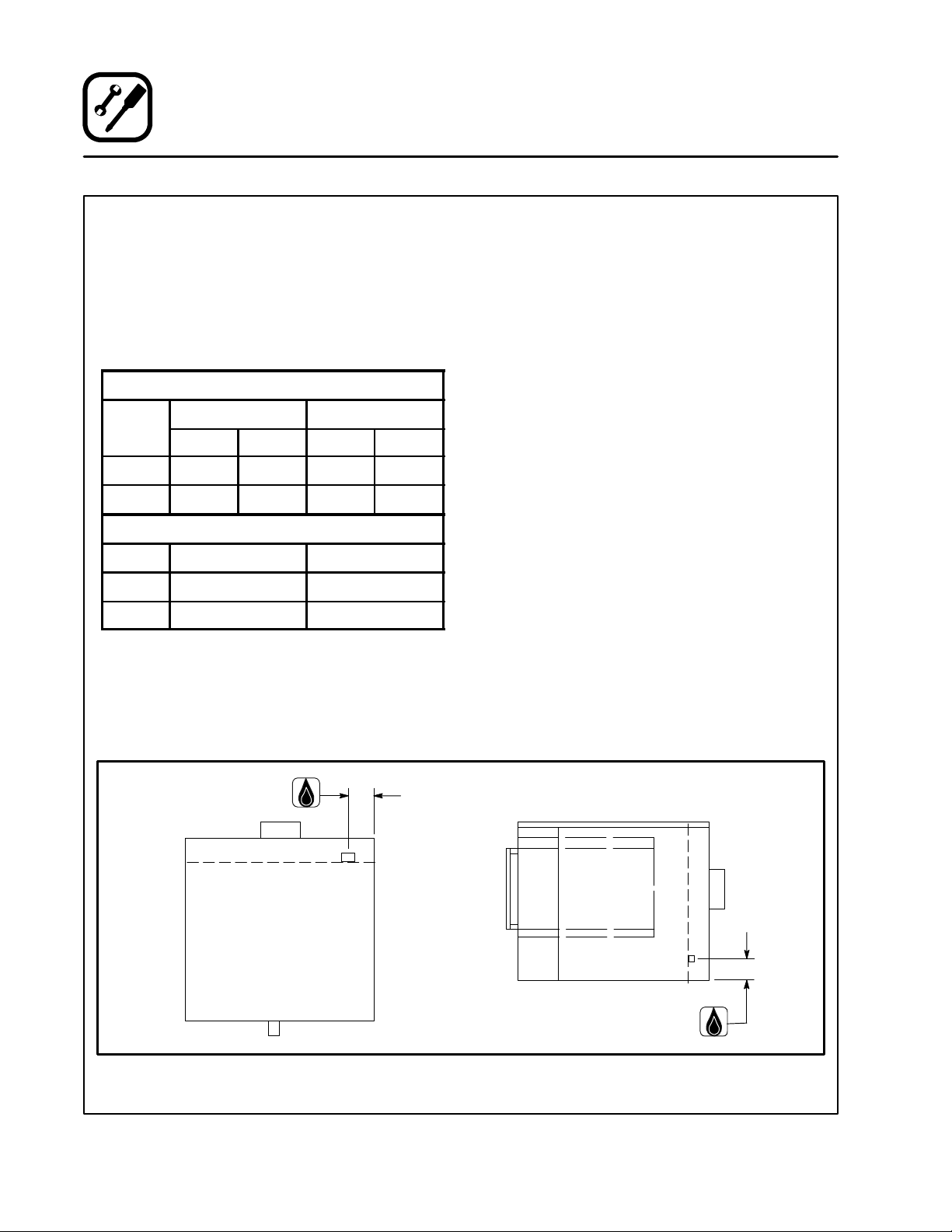

FLUE DIAMETER

Oven Single Double

DFG-100 6” (15cm) 6” (15cm)

DFG-200 6” (15cm) 8” (20cm)

Figure 9

9

Installation

Utility Connections --- Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATIONAND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR I NJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installation or replacement of gas piping

and the connection, installation, repair or s ervicing of equipment.

D

the installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such work, familiar with all precautions

required, and have complied with all requirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

Installation must conform with local codes, or in

the absence of local codes, with the National Elec-

trical Code, ANSI/NFPA 70---Latest Edition and/or

CanadianNationalElectric Code C22.2 as applica-

ble.

Australia and general export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your Blodgett oven, please contact

your local distributor. If you do not have a local distributor, please callthe Blodgett Oven Companyat

0011-802-860-3700.

10

Installation

p

p

g

Gas Connection

GAS PIPING

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a DFG-100 convection oven to add

to your existing cook line.

1. Add the BTU rating of yourcurrentappliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

DFG-100 55,000 BTU

New Total 285,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let’s say

the pipe length is 40’ (12.2 m) and the pipe

size is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 320,000

BTU. Since the total required gas pressure,

285,000 BTU is less than 320,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capacities. Contact your local gas supplier if you

have any questions.

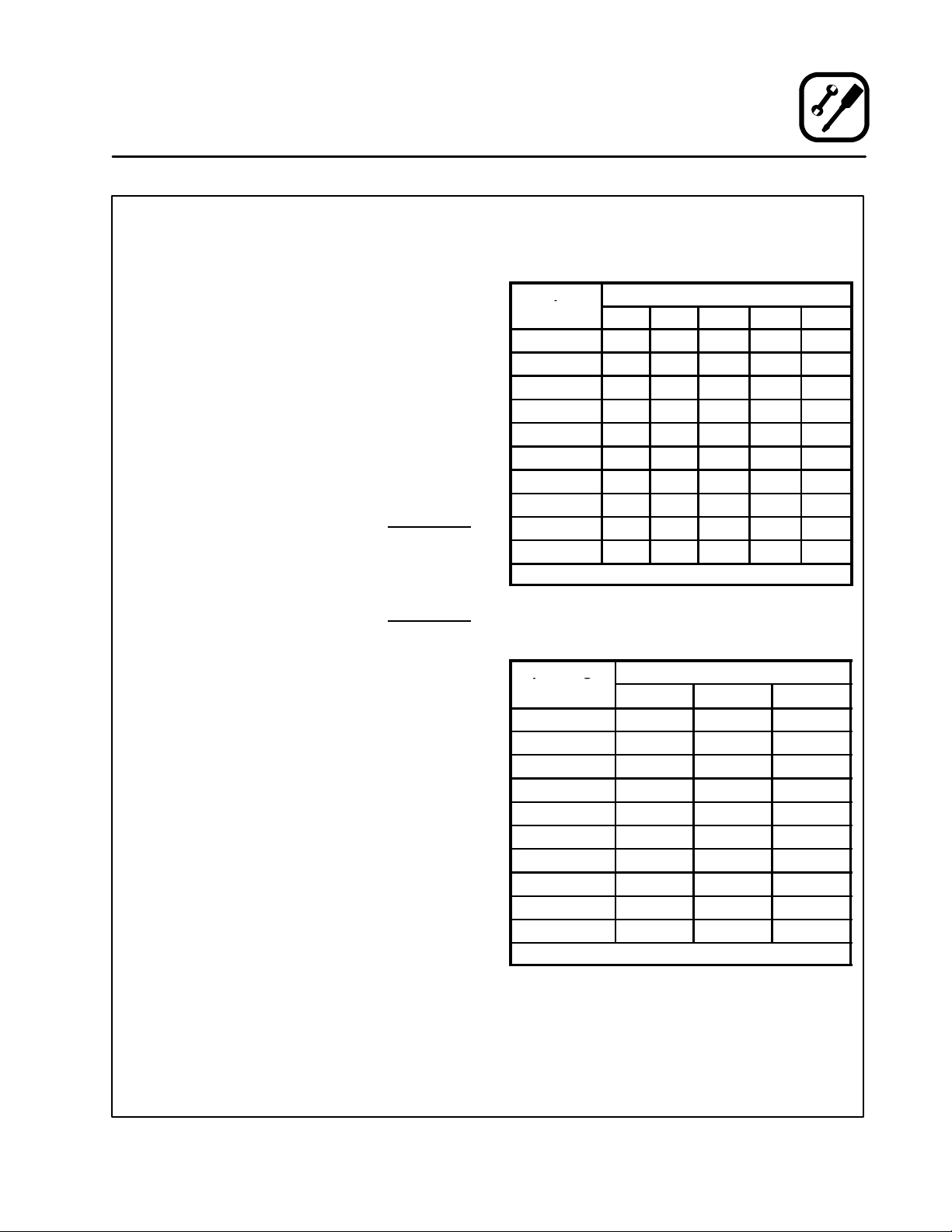

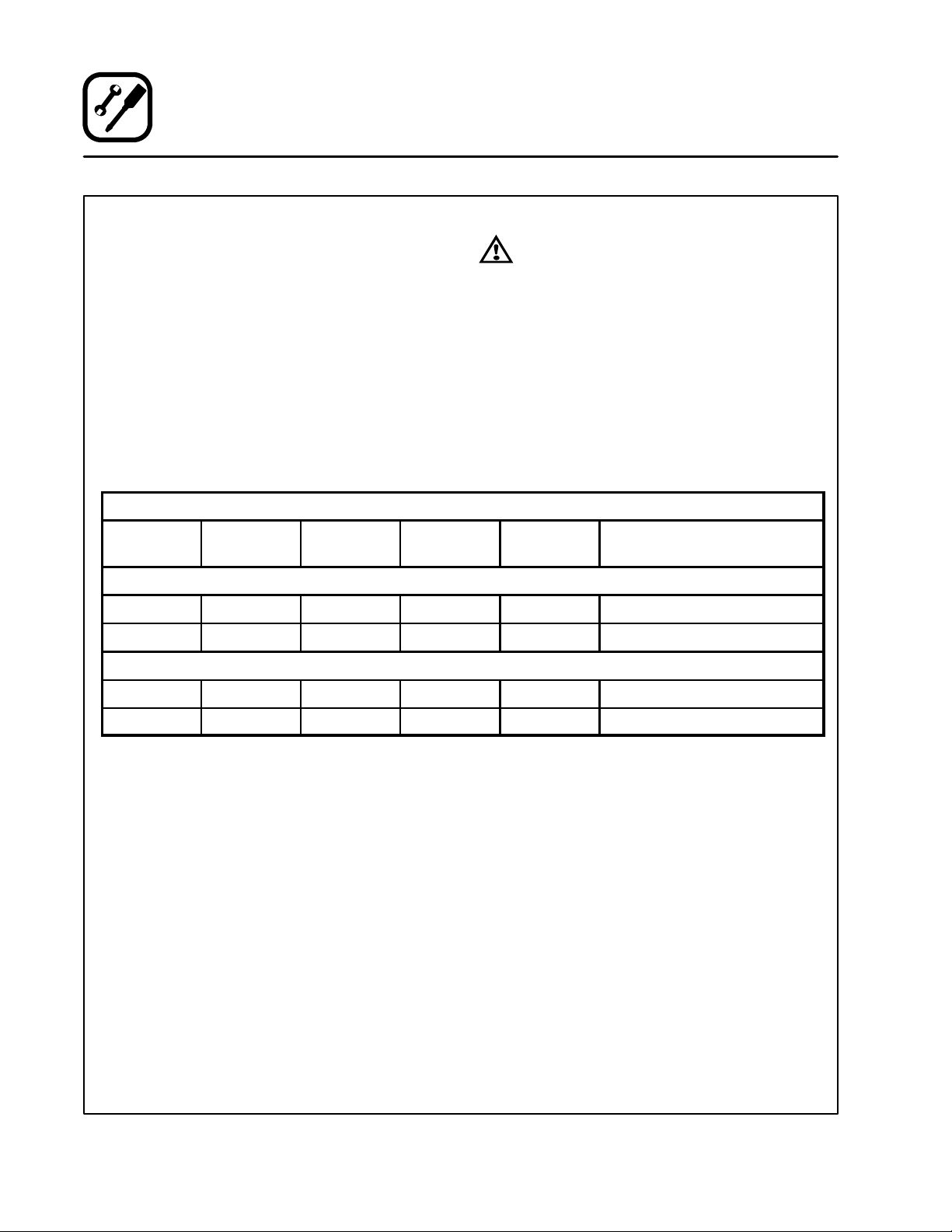

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

Length (ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted L.P. Gas at 11” W.C.

(Pressure drop of 0.5 Inch W.C.)

Pipe Length

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

From the National Fuel Gas Code Part 10 Ta ble 10-15

Nominal Size, Inches

3/4” 1” 1-1/4” 1-1/2” 2”

Outside Diameter, Inches

3/4” 1” 1-1/2”

11

Installation

Gas Connection

PRESSURE REGULATION AND TESTING

DFG-100-3 ovens are rated at 55,000 BTU/Hr.

(16.2 kW) (58 MJ) per section. DFG-200-L ovens

are rated at 60,000 BTU/Hr. (17.6 kW) (63 MJ) per

section. Each oven has been adjusted at the factory to operate with the type of gas specified on the

rating plate.

Inlet Pressure

Natural Propane

Min Max Min Max

W.C. 7.0 10.5 11.0 13.0

kPa 1.742 2.61 2.74 3.23

Manifold Pressure

Natural Propane

W.C. 3.5 10.0

kPa .87 2.49

D

Inlet Pressure --- the pressure of the gas before

it reaches the oven.

D

Manifold Pressure --- the pressure of the gas

as it enters the main burner(s).

D

Min --- the minimum pressure recommended to

operate the oven.

D

Max --- the maximum pressure at which the

manufacturer warrants the oven’s operation.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is essen-

tial to the proper operation of the oven and

shouldnot be removed. It is preset to provide the

oven with 3.5” W.C. (0.87 kPa) for natural gas and

10.0” W.C. (2.50 kPa) for Propane at the manifold.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE OVEN CONNECTS TO THE GAS

SUPPLY UNLESS THE INLET PRESSURE IS

ABOVE MAXIMUM.

Prior to connecting the oven, gas lines should be

thoroughly purged of all metal filings, shavings,

pipe dope, and other debris. After connection, the

oven should be checked for correct gas pressure.

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (13.85” W.C., 3.45

kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (13.85” W.C., 3.45 kPa).

Gas Connection 2.5” (64 mm)

Gas Connection 3.75” (85.7 mm)

Figure 10

12

GAS HOSE RESTRAINT

If the oven is mounted on casters, a commercial

flexible connector with a minimum of 3/4” (1.9 cm)

inside diameter must be used along with a quick

connect device.

The restraint, supplied with the oven, must be

used to limit the movement of the unit so that no

strain is placed upon the flexible connector . With

the restraint fully stretched the connector should

be easy to install a nd quick connect.

The restraint (ie: heavy gauge cable) should be

1,000 lb. (453 kg) test load andshould be attached

without damaging the building. DO NOT use the

gas piping or electrical conduit for the attachment

of the permanent end of the restraint! Use anchor

bolts in concrete or cement block. On wooden

walls, drive hi test wood lag screws into the studs

of the wall.

1. Mount the supplied bracket to the leg bolt just

below the gas inlet. See Figure 11.

2. Attach the clip on restraining cable to the

mounting bracket.

Installation

Gas Connection

WARNING!!

If the restraint is disconnected for any

reason it must be reconnected when the

oven is returned to its original position.

U.S. and Canadian installations

The connector must comply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas Appliances CAN/CGA-6.16 and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending on the connection and the quick disconnect device or its associated piping.

Australie and general export installations

The restraint and quick connect must conform

with Local and National installation standards. Local installation codes and/or requirements may

vary. If you have any questions regarding the proper installation and/or operation of your Blodgett

oven, please contact your local distributor . If you

do not have a local distributor, please call the

Blodgett Oven Company at 0011-802-860-3700.

Back of Oven

Restraint Cable

Bracket

Double stacked unit shown. Use the same procedure for

single units.

Figure 11

13

Installation

Electrical Connection

Wiring diagrams are located in the control

compartment and on the back of the oven.

This oven is supplied for connection to 115 volt

grounded circuits. The electric motor, indicator

lights and related switches are connected through

the 6’ electric supply cord found at the rear of the

oven.

ELECTRICAL SPECIFICATIONS

Model Hz Volts Phase Amps Electrical Connection

U.S. and Canadian Installations

WARNING!!

This appliance is equipped with three

pronggroundingtypeplugforyour

protection against shock hazard and

shouldbe plugged directlyintoa properly

grounded three prong receptacle. DO

NOT cut or remove the grounding prong

from this plug.

THE BLODGETT OVEN COMPANY CANNOT ASSUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTALLATION.

(minimum size)

DFG-100-3 60 115 1 6 Cord set provided

DFG-200-L 60 115 1 6 Cord set provided

Australia and General Export Installations

DFG-100-3 50 220-240 1 3 Size per local code

DFG-200-L 50 220-240 1 3 Size per local code

14

Installation

Initial S tartup

The following is a check-list to be completed by

qualified personnel prior to turning on the

applianceforthefirsttime.

j

Open the manual shut-off valve at the rear of

the oven.

j

Remove the control panel and combustion

covers.

j

Turn the combination valve’s manual shut-off

to the on position.

j

Turn the selector switch to Cook, and the thermostat to 500_F (260_C).

The oven main burner lights, and the Oven Ready

Light comes on. With the main burner on, check

the following.

j

Verify there are no gas leaks, by checking all

gas connections w ith a soapy water solution.

j

Verify that the inlet pressure is correct. The inlet pressure can be checked at the pressure

tap located on the combination valve’s inlet

side.

j

Verify that the manifold pressure is correct.

The manifold pressure can be checked at the

pressure tap located on the manifold.

j

If the above pressure readings are set to the

recommended pressure requirements, allow

the oven to burn-off for 2 hours. If the pressure

readings are not set correctly, turn off the oven

and readjust accordingly.

ADJUSTMENTS ASSOCIATED WITH INITIAL

INSTALLATION

Each oven, and its component parts, have been

thoroughly tested and inspected prior to shipment. However, it is often necessary to further

test or adjust the oven as part of a normal and

proper installation. These adjustments are the

responsibility of the installer, or dealer. Since

these adjustments are not considered defects

in material or workmanship, they are not covered by the Original Equipment Warranty. They

include, but are not limited to:

DDDD

calibration of the thermostat

DDDD

adjustment of the doors

DDDD

burner adjustments

DDDD

leveling

DDDD

testing of gas pressure

DDDD

tightening of fasteners.

No installation should be considered complete

without proper inspection, and if necessary,

adjustment by qualified installation or service

personnel.

WARNING

The break in procedure burns off excess

oils present in the metals during fabrication. Smoke may be produced. Proper

ventilation is required.

15

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light any appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to call your gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

Turn a ll sw itch es t o off.

D

DO NOT attempt to operate the oven until the

power is restored.

NOTE: In the event of a shut-down of any kind, al-

low a five (5) minute shut off period before

attempting to restart the oven.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for a ny reason,

the gas must be turned off and disconnected

from the unit before removing the restraint

cable. Reconnect the restraint after the oven

has been returned to its original location.

D

DO NOT remove the control panel cover unless

the oven is unplugged.

16

11

13

14

Operation

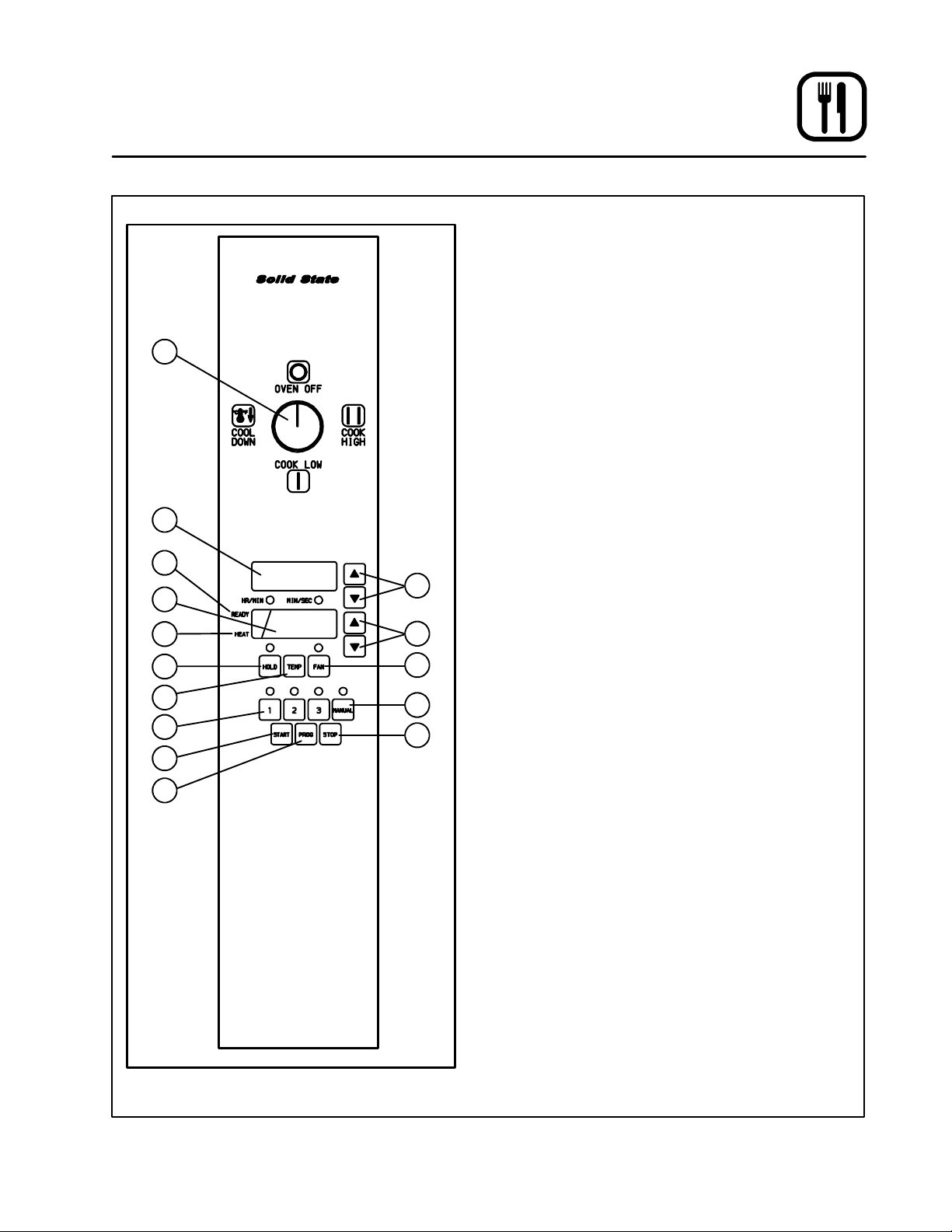

CH-Pro3 (Solid State Programmable Digital Control)

COMPONENT DESCRIPTION

1. SELECTOR SWITCH --- turns power to the

oven on or off. Allows selection of cook or cool

down modes and fan speed (if applicable).

2. TI M E DI SPL A Y --- g i v e s c o ok t i m e .

3. TIME ARROW KEYS -- - press to enter cook and/

1

2

4

5

6

8

9

3

7

10

12

15

or pulse times.

4. READY INDICATOR --- when lit indicates the

oven has reached the setpoint temperature

and product may be loaded.

5. TEMPERATURE DISPLAY --- gives cook and

hold temperatures.

6. HEAT INDICATOR --- when lit indicates the

oven is heating.

7. TEMPERATURE ARROW KEYS --- press to enter cook and hold temperatures.

8. HOLD KEY --- turns hold mode on or off.

9. TEMP KEY --- press to display actual oven

temperature.

10. F AN KEY --- turns pulse mode on or off. The

LED above the fan key is always on.

11. PRODUCT KEYS --- three programmable keys.

12. MANUAL PRODUCT KEY - -- default product key

used for manual operation.

13. START KEY --- press to begin a cook cycle.

14.PROGRAMKEY---presstoenterprogramming mode and save programmed settings.

15. STOP KEY --- press to silence audible alarms

and cancel cook cycles.

Figure 12

17

Operation

CH-Pro3 (Solid State Programmable Digital Control)

MANUAL OPERATION

NOTE: Press the arrow keys to change the cook

time and temperature at any point duringmanual operation.

Cook Only:

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the TIME ARROW KEYS (3) to enter the

cook time.

3. PresstheTEMPERATUREARROWKEYS(7)

to enter the cook temperature.

4. The READY INDICATOR (4) lights when the

oven is at the set temperature. Load product

into the oven.

5. Press the START KEY (13). The TIME DISPLAY

(2) counts down. The manual key LED flashes.

6. When the cook time expires the LEDs and

both displays flash and an audible alarm

sounds. Press t he STOP KEY (15) to silence

the alarm.

7. Remove the product.

Cook with Hold:

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the TIME ARROW KEYS (3) to enter the

cook time.

3. PresstheTEMPERATUREARROWKEYS(7)

to enter the cook temperature.

4. Press and hold the HOLD KEY (8) then release. Use the TEMPERATURE ARROW KEYS

(7) to enter the hold temperature. The hold key

LED lights. Press the hold key again to exit the

hold mode.

5. The READY INDICATOR (4) lights when the

oven is at the set temperature. Load product

into the oven.

6. Press the START KEY (13). The TIME DISPLAY

(2) counts down. The manual key LED flashes.

7. When the cook time expires both displays

flash and an audible alarm sounds for several

seconds then self cancels. The hold key LED

flashes. The time display begins to count up

while the oven cools to the hold temperature.

When the oven reaches the hold temperature

the time display resets to 00:00 then begins to

count up the hold time. The fan cycles with

heat demand in the hold mode.

8. Press the STOP KEY (15) to stop the timer.

9. Remove the product.

10. Push the HOLD KEY (8) to turn off hold mode.

Cook with Pulse:

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the TIME ARROW KEYS (3) to enter the

cook time.

3. PresstheTEMPERATUREARROWKEYS(7)

to enter the cook temperature.

4. Press the FAN KEY (10) for five seconds. The

TEMPERATURE DISPLAY (5) goes blank. The

fan key LED flashes. Use the TIME ARROW

KEYS (3) to enter the pulse time.

NOTE: Pulse time is a portion of the cook time

and does not increase the previously

entered cook time.

5. Pressthe FANKEY (10) again. The TEMPERATURE DISPLAY (5) lights.

6. The READY INDICATO R (4) in the temperature

display lights when the oven is at the set temperature. Load product into the oven.

7. Press the START KEY (13). The manual key

LED flashes. The TIME DISPLAY (2) counts

down the cook time. The fan cycles on for 30

seconds then off for 30 seconds until the set

pulse time has expired.

8. When the pulse time expires both displays

flash and an audible a larm sounds. Press the

STOP KEY (15) to silence the alarm.

9. Remove the product.

Oven Shut Down:

1. T urn the SELECTOR SWITCH (1) to OVEN OFF.

18

Operation

CH-Pro3 (Solid State Programmable Digital Control)

PROGRAMMING THE MANUAL KEY DEFA U LT

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the MANUAL KEY (12). The manual and

fan key LEDs light.

3. Press the TIME ARROW KEYS (3) to enter the

cook time.

4. PresstheTEMPERATUREARROWKEYS(7)

to enter the cook temperature.

5. For Cook and Hold --- Press and hold the

HOLD KEY (8). Use the TEMPERATURE ARROW KEYS (7) to enter t he hold temperature.

The hold key LED lights. Press the hold key

again to exit the hold mode.

For Cook with Pulse --- P r e s s t h e FA N KE Y

(10). Use the TIME ARROW KEYS (3) to enter

the pulse time. If no pulse is required, leave

pulsetimeat0:00.ThefankeyLEDflashes.

Press the fan key again to exit fan mode.

6. Press the PROGRAM KEY (14) to save the program settings.

MANUAL KEY DEFAULT OPERATION

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the MANUAL KEY (12). The applicable

LEDs light.

3. Press the START KEY (13). The TIME DISPLAY

(2) counts down. The manual key LED flashes.

NOTE: InCookwithPulsethefanLEDflashes.

NOTE: Press the arrow keys to change the

cook time and temperature at any

point during manual key operation.

4. When the cook time expires the applicable

LEDs and both displays flash and an audible

alarm sounds.

5. Press the STOP KEY (15) to silence the alarm.

NOTE: In Cook & Hold the alarm self cancels.

The oven cools to the hold temperature and the time display counts up.

6. Remove the product.

7. Turn the SELECTOR SWITCH (1) to OFF to

shut down the oven.

PROGRAMMING THE PRODUCT KEYS

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the des ired PRODUCT KEY (11). The

product and fan key LEDs light.

3. Press and hold the PROGRAM KEY (14) until

the corresponding LED flashes, approximately five seconds.

4. Press the TIME ARROW KEYS (3) to enter the

cook time.

5. PresstheTEMPERATUREARROWKEYS(7)

to enter the cook temperature.

6. For Cook and Hold --- Press and hold the

HOLD KEY (8). Use the TEMPERATURE ARROW KEYS (7) to enter t he hold temperature.

The hold key LED lights. Press the hold key

again to exit the hold mode.

For Cook with Pulse --- P r e s s t h e FA N KE Y

(10). Use the TIME ARROW KEYS (3) to enter

the pulse time. If no pulse is required, leave

pulsetimeat0:00.ThefankeyLEDflashes.

Pressthefankeyagaintoexitthefanmode.

7. Press the PROGRAM KEY (14) to save the program settings.

PRODUCT KEY OPERATION

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Press the des ired PRODUCT KEY (11). The

applicable LEDs light.

3. Press the START KEY (13). The TIME DISPLAY

(2) counts down. The product key LED flashes.

NOTE: InCookwithPulsethefanLEDflashes.

4. When the cook or pulse time expires the applicable LEDs and both displays flash and an audible alarm sounds.

5. Press the STOP KEY (15) to silence the alarm.

NOTE: In Cook and Hold the alarm self can-

cels. The oven cools to the hold temperature and the time display counts

up.

6. Remove the product.

7. Turn the SELECTOR SWITCH (1) to OFF to

shut down the oven.

19

Operation

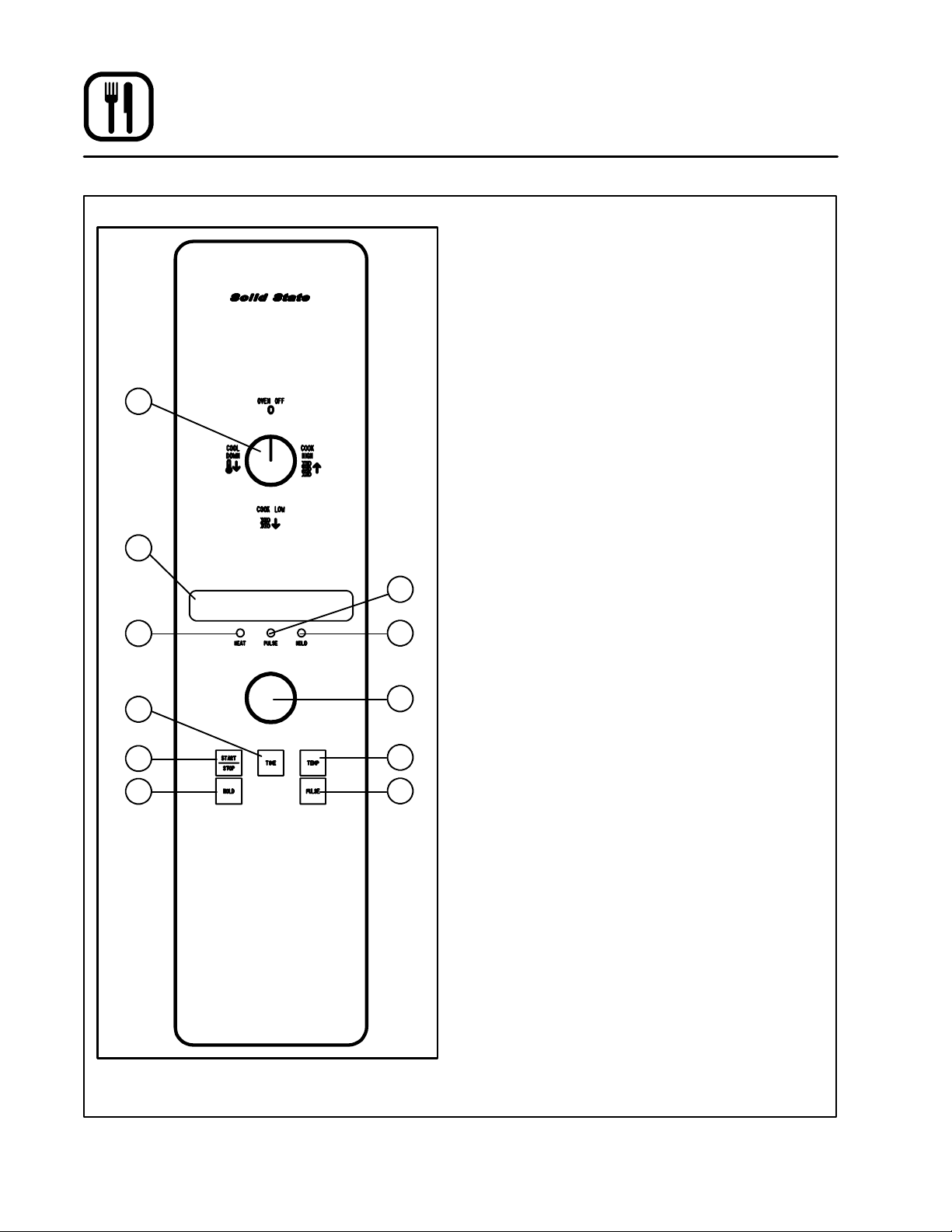

Solid State Digital Control

1

2

3

CONTROL DESCRIPTION

1. SELECTOR SWITCH --- turns power to the

oven on or off. Allows selection of Cook or

Cool Down Modes and fan speed (if applicable).

2. DISPLAY --- displays time or temperature and

other information related to oven function.

3. HEAT LAMP --- lights when heater is on.

4. PULSE LAMP -- - lights when Pulsed Fan Mode

is turned on.

5. HOLD LAMP --- lights when Hold Mode is

turned on.

6. DIAL --- used to enter set points in display

7. START/STOP KEY --- s tarts or stops the timer.

8. TIME KEY --- used to show time in the display.

9. TEMP KEY --- used to show set temperature in

the display.

NOTE: Actual temperature is shown while the

4

10. HOLD KEY --- turns Hold Mode on or off.

5

11. PULSE KEY --- turns Pulse Mode on or off.

TEMP key is held down.

10

PROGRAMMING

8

7

Figure 13

6

9

11

To set the cook temperature:

1. Press TEMP (9) key.

2. Rotate dial (6) to enter temperature.

To set the cook time:

1. Press TIME (8) key.

2. Rotate the dial (6) to enter time.

NOTE: Time is entered in hours : minutes or

minutes : seconds.

To set the hold time:

1. Press HOLD key (10) to turn hold mode on.

NOTE: HOLD light is on.

2. Rotate dial (6) to enter the hold temperature.

3. Press START/STOP key (7)

To s et the pul s e tim e:

1. Press PULSE KEY (11) to turn pulse mode on.

NOTE: Pulse light is on.

2. Rotate DIAL (6) to enter the pulse time. Pulse

time is a portion of the pre-set cook time.

20

Operation

Solid State Digital Control

OPERATION

Cook Only:

1. Turn the SELECTOR switch (1) to the desired

position.

2. Enter the cook time and temperature.

3. Load product into t he oven.

NOTE: The display reads LOAD when the

oven is near the set temperature.

4. Press the START/STOP key (7). The t imer begins to count down.

5. When the cook timer reaches 00:00 the buzzer sounds and the display reads DONE.

6. Press the START/STOP key (7) to silence the

buzzer.

7. Remove the product.

Cook with Hold:

NOTE: HOLD light is on when hold mode is on

and off when hold mode is off.

1. Turn the SELECTOR switch (1) to the desired

position.

2. Enter the cook time and temperature.

3. Press the HOLD key (10). Enter the hold temperature.

4. Load product into t he oven.

NOTE: The display reads LOAD when the

oven is near the set temperature.

5. Push the START/STOP (7) key. Timer begins

to count down.

6. When the cook timer reaches 00:00 the buzzer sounds and the display reads DONE. The

buzzer turns off after a few seconds. The display reads HOLD until the oven reaches the

hold temperature. Then the timer begins to

count up.

7. Push the START/STOP key (7) to stop timer.

8. Remove the product.

9. Push HOLD (10) key to turn off hold mode.

Cook with Pulse:

NOTE: PULSE light is on when pulse mode is on

andoffwhenpulsemodeisoff.

1. Turn the SELECTOR SWITCH (1) to the desired position.

2. Enter cook time and cook temperature.

3. Press PULSE KEY (11). Enter the pulse time.

NOTE: Pulse time is a portion of the cook time

and does not increase the previously

entered cook time.

4. Load product into t he oven.

NOTE: The display reads LOAD when the

oven is near the set temperature.

5. Push START/STOP K EY (7). The timer begins

to count down the cook time. The oven will be

inpulsemodeforthesetpulsetime.Oncethe

set time has expired, the unit will automatically

switch to cook mode and continue counting

down.

6. When the cook timer reaches 00:00 the buzzer sounds and the display reads DONE.

7. Push the START/STOP KEY (7) to turn the

buzzer off.

8. Remove the product.

WARNING!!

Acompletefiveminuteshutdownmustbe

observed before the oven is relighted.

21

Operation

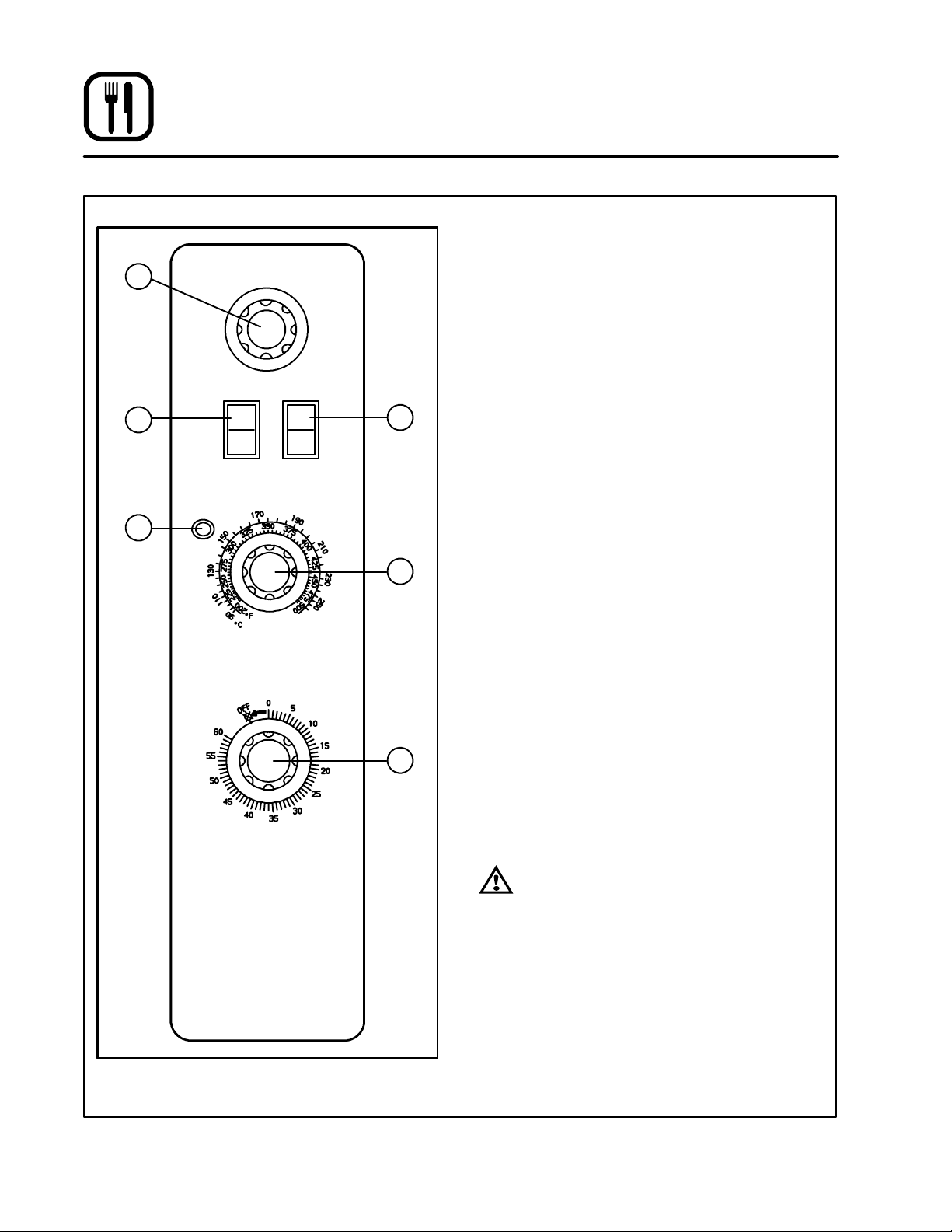

Solid State Manual Control

1

3

4

COOL

DOWN

LIGHT OFF

OVEN READY

OVEN OFF

ON

OFF

LIGHTS

SOLID STATE

THERMOSTAT

TIMER

COOK

HI

LO

BLOWER

2

60 Hz

Only

5

6

CONTROL DESCRIPTION

1. SELECTOR SWITCH --- controls power to the

oven for cook or cool down.

2. BLOWER SWITCH --- controls blower speed, either hi or lo. T wo speed not available in 50 Hz.

3. LIGHTS SWITCH --- controls interior lights.

4. OVEN READY LIGHT --- when lit indicates

burner operation. When the light goes out the

oven has reached operating temperature.

5. SOLID STA TE THERMOSTAT --- allows either 8

pre-set temperatures to be selected in accordance with customer requirements, or an infinite selection of temperatures from 200-500_F

(95-260_C). (infinite control shown)

6. TIMER --- activates an electric buzzer that

sounds when the cook time expires.

OPERATION

1. Turn the SELECTOR Switch (1) to COOK.The

blower and control compartment cooling fan

operate and are controlled automatically by

the action of the doors.

2. Set BLOWER Switch (2) to the desired speed.

3. Set the SOLID STATETHERMOSTAT(5) to the

desired setting or temperature.

4. Preheat until the OVEN READY LIGHT (4)

goes out.

5. Load product into the oven. Determine cook

time and set the TIMER (6).

6. When the buzzer sounds, remove the product

fromthe oven. Turnthe TIMER knob (6) to OFF

to silence the buzzer.

7. Turn the SELECTOR Switch (1) to OVEN OFF.

Figure 14

WARNING!!

Acompletefiveminuteshutdownmustbe

observed before the oven is relighted.

22

2

7

8

10

11

17

18

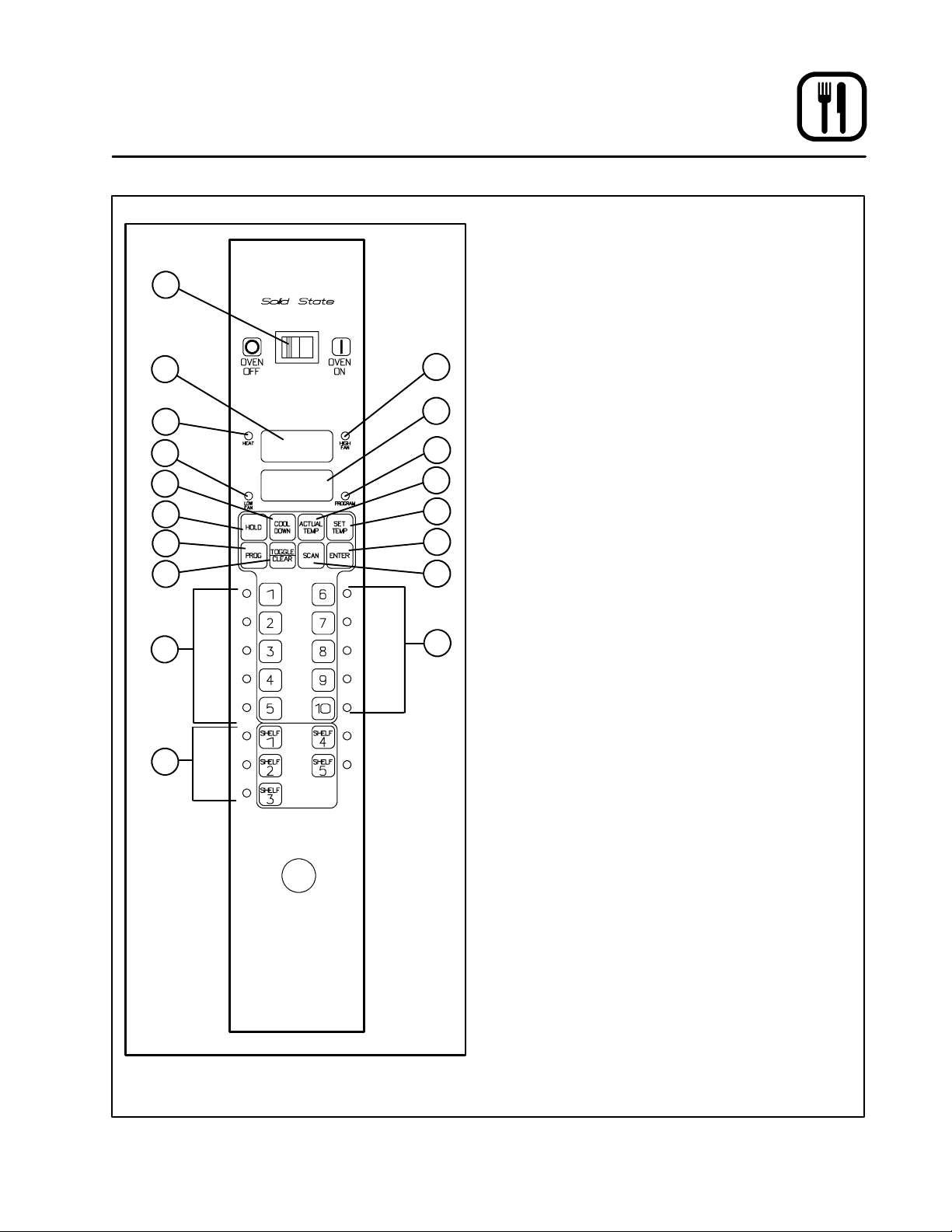

Operation

Blodgett IQ2T Control

COMPONENT DESCRIPTION

1. OVEN POWER SWITCH --- controls power to

1

3

6

9

4

5

12

13

14

15

16

the oven.

2. TOP DISPLAY --- displays temperature and

other controller related information.

3. FAN HI LED --- when lit indicates the fan is run-

ning at high speed.

4. B O T T O M DI SPL A Y --- d is p la ys co o k ti m e an d

other controller related information.

5. PROG LED --- when lit indicates the controller

is in the programming mode.

6. HEAT LED --- when lit indicates the control is

calling for heat.

7. FAN LOLED --- when litindicates the fan is run-

ning at low speed.

8. COOL DOWN KEY --- press to enter the cool

down mode.

9. HOLD KEY --- press to enter hold mode.

10. PROG KEY --- press to enter the programming

mode.

11. TOGGLE/CLEAR KEY --- press during pro-

gramming to toggle options.

12. ACT TEMP KEY --- press to display the actual

oven temperature.

13. SET TEMP KEY --- press to display the pro-

grammed cook temperature for the current

stage of the product key.

14. ENTER KEY --- press to enter new values into

product key programming. Also used to view

recovery time.

15. SCAN KEY --- completes the programming for

the current parameter and advances the con trollerto the next parameter.Press to view time

remaining on multiple cook cycles.

16. PRODUCT LEDS --- when lit indicate which

product keys are currently in use or programmed for the current oven temperature

and fan speed.

17. PRODUCT KEYS --- assigns a key to a pro-

grammed recipe and begins a programmed

cooking process.

18. SHELF KEYS --- assigns a shelf key.

Figure 15

23

Operation

Blodgett IQ2T Control

OVEN OPERATION

Oven Startup:

1. Toggle the POWER SWITCH (1) to ON.The

oven preheats to the lowest programmed first

stage temperature. The LEDS (16) for all products with the same first stage temperature light.

While the unit preheats the TOP DISPLAY (2)

gives the set temperature. The BOTTOM DISPLAY (4) reads Lo iftheovenismorethan10_

below setpoint. When the oven reaches ¦10_

of the preheat temperature an alarm sounds

and the bottom display reads Ready.

Single Product Cooking Procedure:

NOTE: If the led next to the desired product key i s

lit skip step 1.

1. Press the desired PRODUCT KEY (17). The

oven preheats to the first stage temperature for

the selected product. When the oven reaches

¦10_ of the preheat temperature an alarm

sounds and the bottom display reads Ready .

2. Load the product into the oven. Press the desired PRODUCT KEY (17).

If the shelf timing function is toggledon for that

product key, the top display reads SHLF and

the bottom display reads the programmed

product’s time. Press a SHELF K EY (18) to assign the product to that shelf and start the

cook cycle. The top display reads SHLF,the

bottom display gives the shelf #. Within five

seconds, the top display reads SH-1,thebottom display gives the remaining cook time.

If the shelf timing function is toggled off for that

product key, pressing the product key will

start the cook cycle. The TOP DISPLAY (2)

re a d s --- --- --- --- . T h e B O T T O M D I S P L AY (4 )

counts down the cook time in minutes: seconds.

NOTE: If the selected product has a cook time

of greater than 59:59 the top display

r e ad s H r --- --- f o r the to t a l nu m b e r of

hours. The bottom display counts down

the cook time in minutes:seconds.

NOTE: If the selected product is a single stage

recipe the LEDS for all single stage

products with the same cook tempera-

ture and fan speed will light. If the selected product is a multiple stage recipe no other product LEDS will light.

NOTE: Press and hold the selected product

key for three seconds to cancel the

cook cycle for normal operation. To

cancel the cook cycle when using

shelf timing, press and hold the

SHELF KEY (18) for 3 seconds or

press TOGGLE/CLEAR (11) and the

corresponding shelf key.

3. When the cook time expires an alarm sounds

and the top display reads donE.

4. Press the selected product key to silence the

alarm. Remove the product. If shelf timing is

used, press the flashing SHELF KEY (18) to silence the alarm.

Multiple Batch Cooking Procedure:

This procedure is for single stage recipes with the

same cook temperature and fan speed only.

NOTE: If the led next to the first desired product

key is lit skip step 1.

1. Press the first desired PRODUCT KEY (17).

The LEDS for all recipes with the same cook

temperature and fan speed will light.

The oven preheats to the cook temperature for

the selected product. When the oven reaches

¦10_ of the preheat temperature an alarm

sounds and the bottom display reads Ready.

2. Load the product into the oven. Press the desired PRODUCT KEY (17).

If the shelf timing function is toggledon for that

product key, the top display reads SHLF and

the bottom display reads the programmed

product’s time. Press a SHELF K EY (18) to assign the product to that shelf and start the

cook cycle. The top display reads SHLF,the

bottom display gives the shelf #. Within five

seconds, the top display reads SH-1,thebottom display gives the remaining cook time.

If the shelf timing function is toggled off for that

product key, pressing the product key will

start the cook cycle. The TOP DISPLAY (2)

re a d s --- --- --- --- . T h e B O T T O M D I S P L AY (2 )

counts down the cook time in minutes: seconds.

24

Operation

Blodgett IQ2T Control

3. Load the second product. Press the appropriate PRODUCT KEY (17). Press a SHELF KEY

(18) to activate shelf timing.

NOTE: Only products with lighted LEDS may

be selected.

4. The top display reads SHLF. The bottom dis-

play gives the numbers of the shelves that

have been assigned. Within five seconds the

shelf with the least amount of time remaining

is displayed. The led for the product with the

least time remaining flashes faster than the led

for the other products.

NOTE: To view the remaining cook time for

the other products press and hold the

SCAN KE Y (15). The bottom display

cycles through the remaining cook

times for each product. Only the led

for the product with the cook time displayed will be lit.

5. When a cook time expires an alarm sounds.

The top display reads donE.Theledforthefinished product lights. All other LEDS are dark.

6. Press the SHELF KEY (18) for the finished

product to silence the alarm. Remove the

product. Close the oven door. The TOP DISPLAY (2) reads SH-X for the shelf with the least

amount of cook time. The BOTTOM DISPLAY

(4) counts down the cook time for t he other

product.

7. When the cook time expires an alarm sounds

and the top display reads donE.

8. Press the SHELF KEY (18) to silence the

alarm. Remove the product.

Oven Cool Down:

1. Close the oven door . Press the COOL DOWN

KEY (8).

NOTE: Cool down cannot be activated with the

oven door open. Once the cool down cycle

has begun the doors may be opened to

speed the cooling process.

25

Operation

Blodgett IQ2T Control

PROGRAMMING SINGLE STAGE RECIPES

Entering the Programming Mode:

1. Press and hold the PROG KEY (10). The top

display reads CodE.

2. Use the product keys to enter the programming access code: 3 1 2 4. Press the ENTER

KEY (14). The top display reads Prod.

3. Press the desired product key followed by the

ENTER KEY (14).

NOTE: During the programming process you may:

Press the TOGGLE/CLEAR KEY (11) to

erase the current setting or toggle between specific settings. Press the SCAN

KEY (15) to move to the next programming

function keeping the current setting the

same. Press the PROG KEY (10) to exit the

programming mode.

Programming the Cook Time:

1. The top display reads P1:__. The bottom display gives the current programmed cook time

for stage 1 in minutes:seconds. Press the

TOGGLE/CLEAR KEY (11). Use the product

keys to enter the new cook time. Press the ENTER KEY (14) to save the new cook time.

2. The top display reads P2:__. The control is

asking for the cook time for stage 2 of this recipe. Press the TOGGLE/CLEAR KEY (11) to

enter a time of 0:00:00 for P2:.

NOTE: This tells the controller that there are

no more stages for this recipe. Once

a single stage recipe has been established the control will only allow entries for one stage on all further parameters for this product.

3. Press the ENTER KEY (14) again. The t op display reads P1:. The bottom display shows the

cook time.

4. Press t he SCAN KEY (15) to advance the pro gramming mode to cook temperature.

Programming the Cook Temperature:

1. The top display reads C t --- 1 . The bottom dis-

play gives the current cook temperature. Use

the product keys to enter the desired cook

temperature.

2. Press t he SCAN KEY (15) to advance the pro gramming mode to fan speed.

Programming the Fan Speed:

1. The top display reads SPd1. The bottom display gives the current fan speed. Press the

TOGGLE/CLEAR KEY (11). The bottom display toggles between HI and Lo.

2. Press t he SCAN KEY (15) to advance the pro gramming mode to the fan cycle time.

Programming the Fan Cycle Time:

There are 3 options for fan cycle time: Pulse, Heat

and Full. Pulse allows the fan to turn on and off as

programmed. Heat allows the fan to operate with

heat only. Full provides continuous fan operation.

1. The top display reads CYC1. The bottom display gives the current fan cycle. Press the

TOGGLE/CLEAR KEY (11). The bottom display toggles between PULS, HEAt and FULL.

2. If heat or full are selected press the SCAN KEY

(15) to save the new fan cycle and advance to

timing mode.

If pulse is selected press the SCAN KEY (15)

and continue with Steps 3---4 to program the

pulse cycle.

3. The top display reads o n --- 1 . The bottom display gives the current pulse on time. Use the

product keys to enter the desired pulse on

time from 10 to 60 seconds. Press the SCAN

KEY (15).

4. The top display reads o f --- 1 . The bottom display gives the current pulse off time. Use the

product keys to enter the desired pulse off

time from 10 to 60 seconds. Press the SCAN

KEY (15) to advance the programming mode

to shelf mode.

26

Operation

Blodgett IQ2T Control

Programming the Shelf ID:

The Shelf ID option can be turned on or off for specific product keys.

NOTE: Shelf ID is not allowed with multiple stage

recipes.

1. The top display reads SHLF. The bottom dis-

play reads the current shelf ID mode. Press

the TOGGLE/CLEAR KEY (11) to toggle between yes a nd no. Press the SCAN KEY (15)

to advance the programming mode to timing.

Programming the Timing Mode:

There are 3 options for timing mode: Straight, Flex

and Sensitivity.

1. The top display reads t C --- 1 . The bottom dis-

play gives the current timing mode. Press the

TOGGLE/CLEAR KEY (11) to toggle between

St, FL and SEns.

NOTE: Sensitivity adjusts the cook time to

compensate for any difference between the setpoint and actual temperature. The lower the sensitivity value

the shorter the time adjustment. Sensitivity values are set in the manager level programming.

If Shelf ID is activated, all three timing modes

are available. If Shelf ID is not activated, only

straight or flex timing modes are available.

2. Press t he SCAN KEY (15) to advance the pro gramming mode to hold mode.

Programming Hold Mode:

The hold mode can be toggled on or off for specific

product k eys.

1. The top display reads HOLD. The bottom dis-

play reads the current hold mode. Press

TOGGLE/CLEAR KEY (11) to toggle between

on and off. Press the SCAN KEY (15).

2. If the hold mode is a ctivated, the bottom display give the current hold time. Press the

TOGGLE/CLEAR KEY (11). Use the product

keys to enter the new hold time. Press the

SCAN KEY (15).

3. The bottom display gives the current hold

temperature. Press the TOGGLE/CLEAR KEY

(11). Use the product keys to enter the new

hold temperature from 140-210_F(60-99_C).

Press the SCAN KEY (15).

4. The top display reads HFAN (hold fan speed).

The bottom display gives t he current hold fan

speed setting. Press the TOGGLE/CLEAR

KEY (11) to toggle between high and low.

Press the SCA N KEY (15) to exit the hold

mode programming.

Check all Settings (SEE Mode):

TheSEEmodeallowstheoperatortoscrollthrough

and view settings of a particular product key.

1. Press the PROG KE Y (10). The top display

reads Code.

2. Use the product keys to enter the SEE access

code: 2 4 4 4. Press the ENTER KEY (14). The

top display reads SEE.

3. Press the product key you wish to view. Press

the ENTER KEY (14).

4. The control will automatically scroll through

the programmable features showing the programmed values for each.

Exiting the programming mode:

1. The top display reads Prod. Press the PROG KEY

(10). The control returns to operating mode.

27

Operation

Blodgett IQ2T Control

PROGRAMMING MULTIPLE STAGE RECIPES

Entering the Programming Mode:

1. Press and hold the PROG KEY (10). The top

display reads CodE.

2. Use the product keys to enter the programming access code: 3 1 2 4. Press the ENTER

KEY (14). The top display reads Prod.

3. Press the desired product key followed by the

ENTER KEY (14).

Programming the Cook Time:

NOTE: When multiple stage cooking is being

used, the countdown time displayed during cooking is the sum of all stages.

1. The top display reads P1:__. The bottom display gives the current programmed cook time

for stage 1 in minutes:seconds. Press the

TOGGLE/CLEAR KEY (11). Use the product

keys to enter the new cook time. Press the ENTER KEY (14) to save the new cook time.

2. The top display reads P2:__. The control is

asking for the cook time for the second stage

of this recipe. Repeat Step 1 for each additional stage.

3. When the cook times for all stages are programmed, press the TOGGLE/CLEAR KEY

(11) to clear the bottom display.

NOTE: This tells the controller that there are

no more stages for this recipe. Once

the number of stages has been established the control will only allow entries for these stages on all further parameters for this product.

4. Press the ENTER KEY (14) again. The display

reads P1:. The bottom display shows the cook

time.

5. Press t he SCAN KEY (15) to advance the pro gramming mode to cook temperature.

Programming the Cook Temperature:

1. The top display reads C t --- 1 . The bottom dis-

play gives the current cook temperature for

stage 1 of this recipe. Use the product keys to

enter the desired cook temperature.

2. Press the ENTER KEY (14) to save the new

cook temperature for stage 1. The top display

re a d s Ct --- 2 .

NOTE: Repeat Steps 1---2 to program the

cook temperature for additional

stages. When the cook temperature

for the final stage has been entered

the top display reads Ct---1.

3. Press t he SCAN KEY (15) to advance the pro gramming mode to fan speed

Programming the Fan Speed:

1. The top display reads SPd1. The bottom display gives the current fan speed. Press the

TOGGLE/CLEAR KEY (11). The bottom display toggles between HI and Lo.

2. Press t he SCAN KEY (15) to advance the pro gramming mode to the fan cycle time.

28

Operation

Blodgett IQ2T Control

Programming the Fan Cycle Time:

There are 3 options for fan cycle time: Pulse, Heat

and Full. Pulse allows the fan to turn on and off as

programmed. Heat allows the fan to operate with

heat only. Full provides continuous fan operation.

1. The top display reads CYC1. The bottom dis-

play gives the current fan cycle for stage 1.

Press the TOGGLE/CLEAR KEY (11). The bottom display toggles between PULS, HEAt and

FULL.

2. Press the ENTER KEY (14) to save the new fan

cycle for stage 1. The top display reads CYC2.

NOTE: Repeat Steps 1 ---2 to program the fan

cycle for additional stages.

3. Whenthe fan cycle for the final stage has been

entered press the SCAN KEY (15).

If no pulse cycles are programmed the control

advances to timing mode.

If pulse is used, the control returns to the first

stage programmed for the pulse fan option.

Follow Steps 4---5 to program the pulse on

and off time.

4. The top display reads o n --- x . The bottom display gives the current pulse on time for this

stage. Use the product keys to enter the desired pulse on time from 10 to 60 seconds.

Press the SCAN KEY (15).

5. The top display reads o f --- x . The bottom display gives the current pulse off time. Use the

product keys to enter the desired pulse off

time from 10 to 60 seconds. Press the SCAN

KEY (15). The control advances to the next

stageprogrammedforthepulsefanoption.

NOTE: Repeat Steps 4 --- 5 to program cycle

times for all pulse fan stages. When the

final pulse off time has been entered the

control advances to timing mode.

Programming the Timing Mode:

NOTE: It may be necessary to press the ENTER

KEY (14) until the top display reads tC---1.

There are 2 options for timing mode: Straight and

Flex.

1. The top display reads t C --- 1 . The bottom dis-

play gives the current timing mode. Press the

TOGGLE/CLEAR KEY (11) to toggle between

St,andFL.

2. Press the ENTER KEY (14) to save the new

timingmode for stage 1. The top display reads

tC --- 2 .

NOTE: Repeat Steps 1 ---2 to program the tim-

ing mode for additional stages.

3. When the timing mode for the final stage has

been entered press the SCAN KEY (15).

Programming Hold Mode:

The hold mode can be toggled on or off for specific

product k eys.

1. The top display reads HOLD. The bottom display reads the current hold mode. Press

TOGGLE/CLEAR KEY (11) to toggle between

on and off. Press the SCAN KEY (15).

2. The bottom display give the current hold time.

Press the TOGGLE/CLEAR KEY (11). Use the

product keys to enter the new hold time. Press

the SCAN KEY (15).

3. The bottom display gives the current hold

temperature. Press the TOGGLE/CLEAR KEY

(11). Use the product keys to enter the new

hold temperature from 140-210_F(60-99_C).

Press the SCAN KEY (15).

4. The top display reads HFAN (hold fan speed).

The bottom display gives t he current hold fan

speed setting. Press the TOGGLE/CLEAR

KEY (11) to toggle between high and low.

Press the SCA N KEY (15) to exit the hold

mode programming.

Exiting the programming mode:

1. The top display reads Prod. Press the PROG

KEY (10). The control returns to operating

mode.

29

Operation

Blodgett IQ2T Control

MANAGER LEVEL PROGRAMMING

Entering the programming mo de

1. Press the PROG KE Y (10). The top display

reads CodE.

2. Use the product keys to enter the programming access code: 4 5 1 2. Press the ENTER

KEY (14). The top display reads SYS.

Programming hold

Hold allows product to be kept warm in the oven

at a programmed time and temperature by pressing the HOLD KEY (9).

1. Press the SCAN KEY (15). The top display

reads Hold. Press the TOGGLE/CLEAR KEY

(11) to toggle between YES and no.Pressthe

SCAN KEY (15).

If no is chosen:

a.) Press the SCAN KEY (15) to advance to

programming the setback mode.

Ifyesischosen:

a.) The top display reads HOLD. The bottom

display gives the current hold time. Press

the TOGGLE/CLEAR KEY (11). Use the

product keys to enter a hold time from 0

to 9 hours. Press the SCAN KEY (15) to

enter the new hold time (HR:MN)..

b.) The top display reads HOLD. The bottom

display gives the current hold temperature. Press the TOGGLE/CLEAR KEY (11).

Use the product k eys to enter a hold temperature from 140_F --- 210_F. P r e s s t h e

SCAN KEY (15) to enter the new hold temperature.

c.) The top display reads HFAn. The bottom

display gives the current fan mode. To

change the fan mode press the TOGGLE/

CLEAR KEY (11). The bottom display

toggles between Hi and Lo.Pressthe

SCAN KEY (15) to enter the new fan mode

and continue with programming the setback mode.

Programming the setback mode

The setback mode operates as a power saving

feature. After a period of non-use (the setback

time) the oven temperature automatically de creases to t he setback temperature. The oven will

maintain this temperature until a product key is

pressed. The minimum setback time is 20:00.

1. The top display reads SEtb. The bottom dis-

play gives the setback mode. To change the

setback press the TOGGLE/CLEAR KEY (11).

The bottom display toggles between YES and

no. Press the SCAN KEY (15).

If no is chosen:

a.) The controller advances to programming

the temperature mode.

Ifyesischosen:

a.) The bottom display gives the current set-

back time. Press the TOGGLE/CLEAR

KEY (11). Use the product keys to the enter the desired setback time. Press the

SCAN KEY (15) to enter the new setback

time.

b.) The bottom display gives the current set-

back temperature. Press the TOGGLE/

CLEAR KEY (11). Use the product keys to

the enter a setback temperature from

140_F --- 30 0 _F. P r e s s th e SC A N K E Y ( 1 5 ) t o

enter the new setback and continue with

programming the temperature mode.

Programming the temperature mode (_For_C)

1. The top display reads dEg. The bottom dis-

play gives the units. To change the units press

the TOGGLE/CLEAR KEY (11). The bottom

display toggles between F and C.

2. Press the SCAN KEY (15) to enter the new

temperature units and continue programming

the shelf sensitivity.

30

Operation

Blodgett IQ2T Control

Programming the shelf sensitivity

The controller allows the user to program a sensitivity value (0--- 9) for each shelf position. The sensitivity value will shorten or stretch cook time depending upon shelf position.

NOTE: SEN1 is the top shelf position, SEN5 is the

bottom shelf position.

1. The display reads SEN1.

2. Press the TOGGLE/CLEAR KEY (11) to clear

the current value to the desired value. Use the

product key numbers to input a new sensitivity

value.

3. Press the SCAN KEY (15) to advance to the

next shelf position, SEN2.

4. Repeat steps 2---3 for all five shelf positions.

Exiting the programming mode

1. The top display reads SYS.PressthePROG

KEY (10). The control returns to the operating

mode.

ERROR CODES AND A LARMS

NOTE: The error codes will appear in the top dis-

play. All error codes are accompanied by

an audible alarm.

Hi Oven temperature is more than

40_F above the highest setpoint.

Prob Probe failure.

HEAT ERR F rom a cool start (below 140_F), the

oven takes more than 10 minutes to

climb from 150-300_F. P r e s s t h e

TOGGLE/CLEAR KEY (11) to clear

the prompt. This code indicates a

problem with t he system. Contact a

service technician.

FAN ERR Indicates a fan failure during a call

for heat. Press the TOGGLE/CLEAR

KEY (11) to clear the alarm. The FAN

ERR display remains active. Press

the TOGGLE/CLEARKEY (11) again

to clear the message and return the

system to normal operation. If condition persists turn off the oven and

contact a service technician.

FANC ERR Indicates a contact failure has oc-

curred in the fan control circuit.

Press the TOGGLE/CLEARKEY(11)

to clear the alarm. The FANC ERR

display remains active. Press the

TOGGLE/CLEAR KEY (11) again to

clear the message and return the

system to normal operation. If condition persists turn off the oven and

contact a service technician.

DOOR OPEN The controller senses the door is

open. Close the door. If the door is

closed contact a service technician.

31

Operation

Cook and Hold Control

1

3

COOL

DOWN

LIGHT OFF

OVEN READY

OVEN OFF

COOK & HOLD

ON

OFF

LIGHTS

THERMOSTAT

COOK

COOK

CONTROL DESCRIPTION

1. SELECTOR SWITCH --- controls power to the

oven for cook, cook & hold, and cool down.

2. LIGHTS SWITCH --- controls interior lights.

3. OVEN READY LIGHT --- when lit indicates

burner operation. When the light goes out, the

oven has reached operating temperature.

4. COOK THERMOSTAT --- controls oven tem-

2

perature in the cook cycle.

5. COOK TIMER --- activates an electric buzzer

that sounds when the cook time expires.

6. HO L D TH E R M O S TA T --- co n t r o l s ov e n te m perature in the hold cycle.

7. HOLD LIGHT - indicates the oven is in hold.

8. COOK & HOLD TIMER --- controls the length

of cook time from 0 to 12 hours. When the

4

cook time ends, oven temperature control

switches from the cook to the hold thermostat.

COOK TIMER

5

HOLD

LIGHT

6

HOLD

THERMOSTAT

7

COOK & HOLD

TIMER

8

Figure 16

32

Operation

Cook and Hold Control

OPERATION

Cook Only:

1. Turn the SELECTOR SWITCH (1) to COOK.

The blower and control compartment cooling

fans operate and are controlled automatically

by the action of the doors.

2. Set the COOK THERMOSTAT (4) to the desired temperature.

3. Preheat until the OVEN READY LIGHT (3)

goes out.

4. Load product into the oven. Set the COOK

TIMER (5) to the desired cook time.