Bernina 830LE, 830 Manual

Dear BERNINA 830 customer,

Congratulations! With the purchase of the BERNINA

830, you have acquired the ultimate sewing and

embroidery system available in today’s market. By

purchasing this system, you have established that you

are a creative person who is looking for the opportunity

to explore and expand the unlimited world of creativity.

The use of modern, future-oriented technologies in the

computerized sewing and embroidery field coupled with

the tradition of BERNINA quality and reliability offer you

the best of the future and the best of the past. With the

BERNINA 830 system you will be able to sew faster,

smarter, longer, and more creatively- and with more

enjoyment. We have put all the dreams that our

customers have shared with us into this product.

BERNINA wants you to fully enjoy the enormous

possibilities that the BERNINA 830 sewing system

offers you. To do so, you must learn all the wonderful

features of the product. Therefore, don’t hesitate to

frequent your local BERNINA dealer and tap into the

knowledge of the BERNINA educators.

I wish you much happiness and great satisfaction while

enjoying your creative pastime.

H.P. Ueltschi

President

BERNINA International AG

CH-8266 Steckborn

www.bernina.com

2

Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

WARNING!

To reduce the risk of burns, fire, electric shock or injury to

persons:

Use this sewing-/embroidery computer only for its 1

intended use as outlined in this manual. Use only

attachments, accessories and parts recommended

by the manufacturer.

Do not use the sewing-/embroidery computer as a 2

toy. Caution is advised when the sewing-/embroidery

computer is used by children, or near children. The

sewing-/embroidery computer is not intended for use

by persons (including children) with reduced

physical, sensory or mental capabilities or lack of

experience and knowledge, unless they have been

given supervision or instruction concerning use of

the sewing -/embroidery computer by a person

responsible for their safety. To ensure children do

not play with the sewing-/embroidery computer they

must be supervised.

Never operate this sewing-/embroidery computer if:3

the cord or plug are damaged ►

it is not working properly ►

it has been dropped or damaged ►

it has fallen into water ►

Return the sewing-/embroidery computer to your

local authorized BERNINA dealer for examination or

repair.

Never operate the sewing-/embroidery computer 4

with any air openings blocked. Keep ventilation

openings of the sewing-/embroidery computer and

foot controller free from the accumulation of lint, dust

and loose cloth.

Keep fingers away from all moving parts. Special 5

care is required around the sewing needle.

Never drop or insert any objects into any openings

6

on the sewing-/embroidery computer.

Do not use the sewing-/embroidery computer

7

outdoors.

Do not operate the sewing-/embroidery computer

8

where aerosol products (sprays) or oxygen are being

used or where oxygen is being administered.

Do not pull or push fabric while stitching - this may

9

cause the needle to break.

Do not use bent needles.10

Always use a proper BERNINA stitch plate. The 11

wrong plate can cause needle breakage.

To disconnect, turn all controls to the OFF («0»)

12

position, then remove the plug from the outlet. To

unplug, pull the plug not the cord.

Turn all controls OFF (to the «0» position) when 13

making any adjustments in the needle area - such as

changing or threading the needle, presser foot etc.

Always unplug the sewing-/embroidery computer

14

from the electrical outlet when removing covers,

lubricating, or when making other user servicing

adjustments mentioned in this instruction manual.

This sewing-/embroidery computer is provided with 15

double insulation (except USA and Canada). Use

only identical replacement parts. See instructions for

servicing of double-insulated products.

SERVICING DOUBLE

INSULATED PRODUCTS

In a double-insulated product two systems of insulation are

provided instead of grounding. No grounding means is

provided on a doubleinsulated product, nor should a

means for grounding be added to the product. Servicing a

doubleinsulated product requires extreme care and

knowledge of the system and should be done only by qualified service personnel. Replacement parts for a doubleinsulated product must be identical to those parts in the

product. A double-insulated product is marked with the

words «DOUBLE INSULATION» or «DOUBLE INSULATED».

The symbol

may also be marked on the product.

DISCLAIMER

No liability will be assumed for any possible damage which

arises from misuse of this sewing-/embroidery computer.

This sewing-/embroidery computer is intended for

household use only.

SAVE THESE

INSTRUCTIONS!

When using an electrical appliance, basic safety precautions should always be followed, including the following:

Read all instructions before using this sewing-/embroidery

computer.

When the sewing-/embroidery computer is not in use,

it should be disconnected from the electricity supply

by removing the plug from the outlet.

DANGER!

To reduce the risk of electrical shock:

An appliance should never be left unattended 1

when plugged in.

Always unplug this sewing-/embroidery computer

2

from the electrical outlet immediately after using

and before cleaning.

LED Radiation – Do not view directly with optical

3

instruments. Class 1M LED product.

Accessory & Preparation

Functions & Settings

Main Stitch Categories

BERNINA World

Maintenance / Troubleshooting

Sewing

Stitch & Motif Overview

Index

Text

Gayle Hillert, Herbert Stolz, Joanna Wild

Sewing & Embroidering Projects

Colette Cogley, Jeanne Delpit, Susan Fears, Claudia Giesser,

Gayle Hillert, Nina McVeigh, Pia Welsch, Joanna Wild

Screen Design & Drawings

sculpt.ch, CH-Steckborn

Photographs

Sterling Rice Group, USA

Patrice Heilmann, CH-Winterthur

Manual Design & Concept

Erika Vollenweider-Czibulya

Typesetting, Layout, DTP

Susanne Ribi, Erika Vollenweider-Czibulya

Copyright

2008 BERNINA International AG, CH-Steckborn

All rights reserved

In order to improve the product, and for our customers‘ benefit, all of the sewing-/embroidery computer‘s features, parts, and

accessories are subject to unannounced changes and alterations at any time.

Very important!

Risk of damage!

Ver

Ris

Helpful tips!

Accessory & Preparation

Accessory 6

Your Delivery 6

Sewing computer cover 6

Included in the package 6

In plastic bag 6

Presser Feet 7

BERNINA Specialty presser feet 7

Accessory Box 8

Free Standing 8

Lay-out 9

Sewing Computer 10

Details 10

Preparation 12

Power Switch / Power Cable 12

Free-Hand-System (FHS)

Presser Foot Lifter 12

Foot Control 13

LED Sewing Light 13

Pivotable Triple Spool Holder 14

Bobbin 14

Winding the Bobbin 15

Interrupting the winding process 15

Removing / Inserting the Bobbin 16

Threading Lower Thread 16

Slide-on Table 17

Thread Cutter 17

Threading the Upper Thread 18

Double/Triple Needle 19

Changing the Needle 20

Changing the Presser Foot 20

Stitch plates 21

Feed-Dog and Fabric Feed 21

Sewing with the Height Compensation Tool 22

Sewing Corners 22

Thread Tension 23

Upper Thread Tension 23

Lower Thread Tension 23

Altering the Tension 23

Needles 24

Important facts about

Thread and Needles 24

Thread 24

Needle, Thread and Fabric 24

Needle/Thread 24

Guidelines 25

Overview 26

oy

ivery y

comput

comput

ERNINA Specialty presser feet

ccessory Box

ree Standin

g ay-

out

w t 1

tails

1

r

e

p

arat

i

o

n

1

1

wer Sw

ch

/ Power

C

ab

1

1

1

ree-Han

d-

Sy

st

em (FHS)

es

ser Lifter C C

tro

l

1

S

ewing Light

1

1

1

votabl

e Trle S Holl

de

1

n

1

11111

1

nding t

h

Bobbi

n

1

1

Interr

ti

the windi process

1

1

emoving / Inserti

ng

t t

B

B

n

re

ad

in

in

g

wer Thre

1

6

6

e-

o

n T

ab

1

1

1

1

r

ead Cut

te

re

ad

g

g e Up

Thad 1

1

1

1

ole

/Trie edle 1

1

1

an

ngng

ng

t Neeeeee 2

2

an

an

ng

ng

t Pssere Foot 2

p

p

latete

22

ed

ed-D a

a

F

F

ab

c ced

ed

2

2

2

2

wi

ng

ng

witth h tht C Comatation ToTo 2

2

wi

ng

nngn

Coror

2

2

222

2

2

222

adad T T

ensio

n

2

222

2

ppe

r

Th

Tre T

en

ension

on

2

2

ower

Thre Tenen

sisisono 2

2

2

ter

i

ng

t

t

Tens

i

on 2

eedles

rtant facts abou

t

r

ead and Needles 2

4

rea

d

2

eedle, Thread and Fabric

2

edle/T

h

r

d

2

idelin

es

2

verview

2

6

Accessory

Your Delivery

Sewing computer cover

protects from dust and dirt ►

Included in the package

foot control ►

instruction manual ►

power cable ►

warranty card ►

FHS presser foot lifter (Free Hand System) ►

slide-on table ►

seam guide for slide-on table ►

Instructional DVD ►

sewing computer cover ►

accessory box ►

accessory catalog ►

CD of BUILT-IN Embroidery Motifs ►

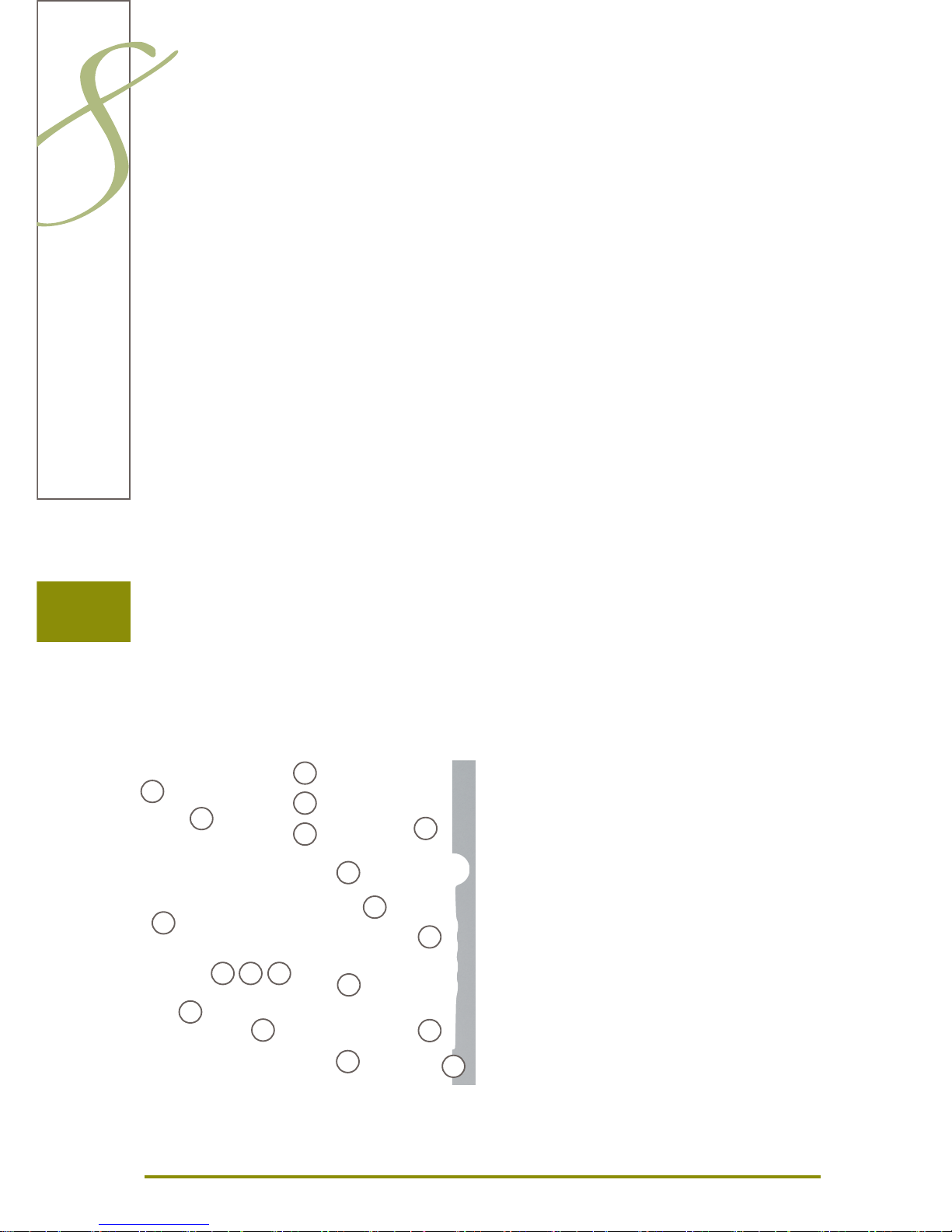

In plastic bag

4 bobbins1

adjustable guides 2

wire threader for threading cording for bobbin play3

tweezers4

2 nets5

cording attachment6

magnifying glass adapter7

small screwdriver, gray8

touch pen9

seam ripper10

lint brush11

multifunction tool12

manual threader13

spool disc small14

holder for king-size spools, cone holder15

height compensating tool16

needle pack 130/705H17

lubricator18

monitoring mirror19

1

2

345

7

8

9

10

6

11

12

13

14

15

16

17

18

19

7

Accessory

Presser Feet

1C Reverse pattern foot

1D Reverse pattern foot

2A Overlock foot

3C Buttonhole foot

3A Automatic buttonhole

foot with slide

4D Zipper foot

5 Blindstitch foot

18 Button sew-on foot

20C Open embroidery foot

40C Sideways motion foot

42 BSR foot

BERNINA Specialty presser feet

8 Jeans foot

50 Walking foot

It is recommended that BERNINA specialty

presser feet be used for specific sewing tasks

such as quilting, heirloom sewing, home

decorating, tailoring etc.

All the presser feet are shown in the

enclosed accessory catalog.

They are available at your BERNINA dealer.

8

Accessory Box

on the back of the box, pull both ►

extensions out until they click into

place

Accessory

Free Standing

9

Accessory

The box is equipped as standard with

one small A and one large B drawer

as well as a compartment for bobbin

holders C and presser feet D.

to remove a bobbin, press the

►

compartment holder E lightly

buttonhole foot with slide no. 3A ►

can be stored in the left compartment F

store the needle range supplied in ►

the special compartment G

Lay-out

A

B

C

D

E

F

G

10

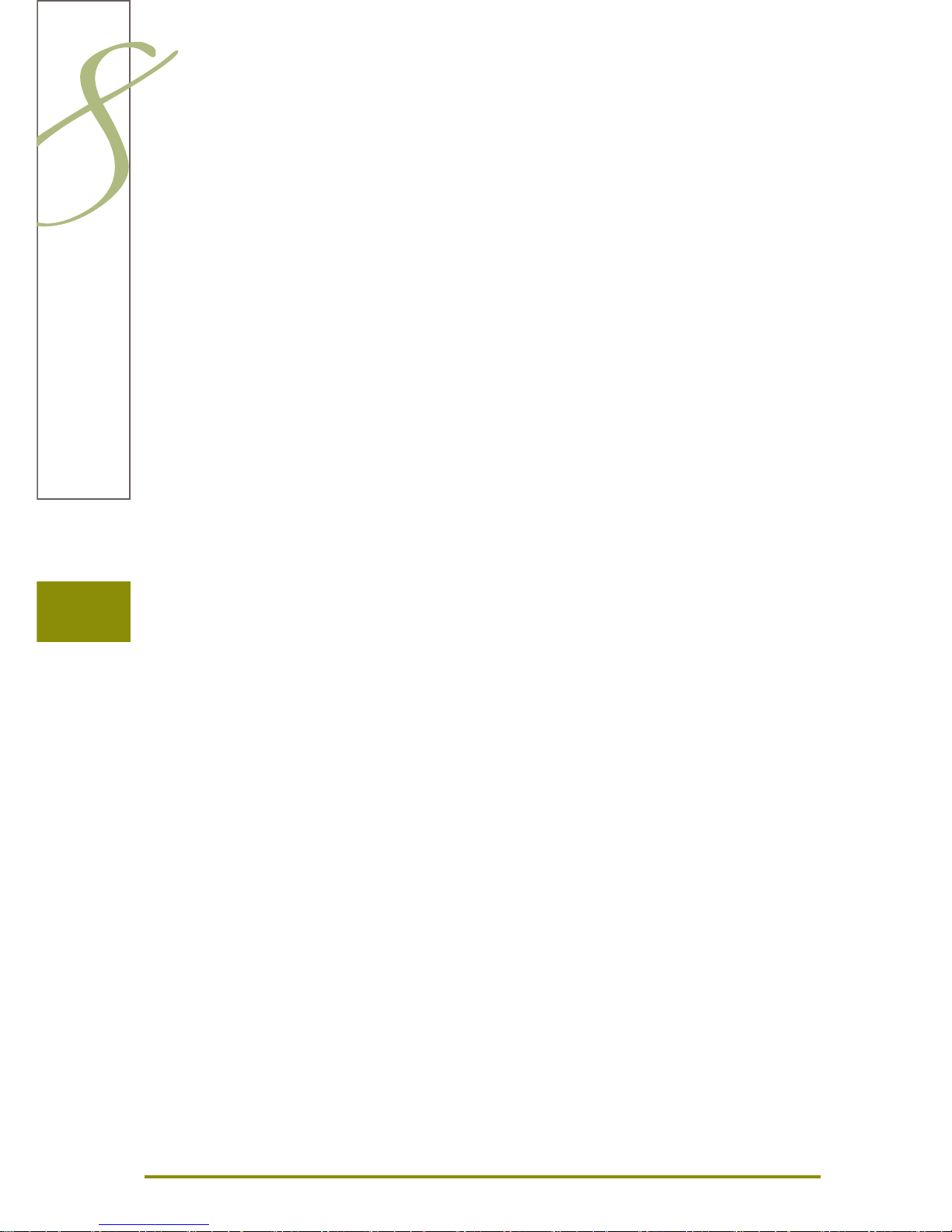

Sewing Computer

Details

1

12

15

11

10

14

13

2

5

8

7

4

6

9

3

16

17

18

19

20

21

23

24

25

26

27

28

22

29

30

31

32

33

34

35

36

37

38 39

17

16

11

Sewing Computer

Bobbin cover1

Stitch plate2

Attachment base for special accessories3

Presser foot4

Needle clamp5

Thread guide6

Screen7

Carrying handle8

System Settings9

Setup button ‣

Tutorial button ‣

Creative Consultant button ‣

Help button ‣

Eco button ‣

Sewing-/Embroidery mode button ‣

«clr» clear button ‣

Stitch width knob10

Stitch length knob11

Needle position buttons12

Bobbin winder13

Thread cutter for bobbin winder14

Threading slit15

Triple spool pin16

Telescope17

Bobbin pre-tension18

Slide-on table socket19

Darning hoop connection20

FHS (Free Hand System) connection21

Slide speed control22

Automatic needle threader23

Needle stop up/down button24

Presser foot up/down button25

Securing button26

Pattern end button27

Automatic thread cutter28

Start/stop button29

Quick reverse button30

Special-accessories port31

BSR connection32

BERNINA Dual Feed33

Handwheel34

USB connection35

PC connection36

Foot control socket37

Power switch on/off («I», «0»)38

Power plug socket39

Connection for Magnifying glass40

(optional accessory)

Thread cutter on head frame41

Embroidery module connection42

33

42

41

40

12

Preparation

Power Switch / Power Cable

Power SwitchA

The sewing computer is switched on («I») and off («0»)

with the power switch.

I the sewing computer is switched on

0 the sewing computer is switched off

Power connectionB

Foot control connectionC

PC connectionD

USB stick connectionE

Free-Hand-System (FHS) Presser Foot Lifter

The FHS is used to raise and lower the Presser Foot.

Attaching the Free Hand System

insert into the opening; you should be able to operate ►

the FHS with your knee in your normal sitting position

Raising and Lowering the Presser Foot

with knee push FHS to the right ►

the presser foot is raised and the feed-dog is lowered ►

simultaneously. Tension is released

the feed-dog is raised as soon as the first stitch is sewn ►

A B

C

D

E

If the sewing computer is kept in a cold room,

place it in a warm room for 1 hour before use.

(USA/Canada only):

The sewing computer has a polarized

plug (one blade wider than the other). To

reduce the risk of electrical shock, this

plug is intended to fit in a polarized outlet

only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician

to install the proper outlet. Do not modify

the plug in any way!

U

S

e

u

e

d

Your dealer can adjust the FHS if necessary.

13

Preparation

Foot Control

Sewing Speed

sewing speed is controlled by pressure on the foot ►

control

Raise or Lower the Needle

entire foot rests comfortably on Foot Pedal ►

tap the Foot Control with your heel to raise or lower the ►

needle

Cable tidy

wind the cable around the reel ►

insert the cable end (plug) into ► A

When sewing

unwind the cable to the desired length and slip into ► B

or C

LED Sewing Light

The LED sewing light illuminates the sewing area with no

shadows and has a very long service life.

A

B

C

(USA/Canada only):

Use only foot controller type LV1 or WFC1

with sewing computer model 830.

S

Us

e

t

A defective sewing light must only be

replaced by a technician.

Take the sewing-/embroidery computer

to your BERNINA dealer.

d

re

p

Ta

ko y

14

Preparation

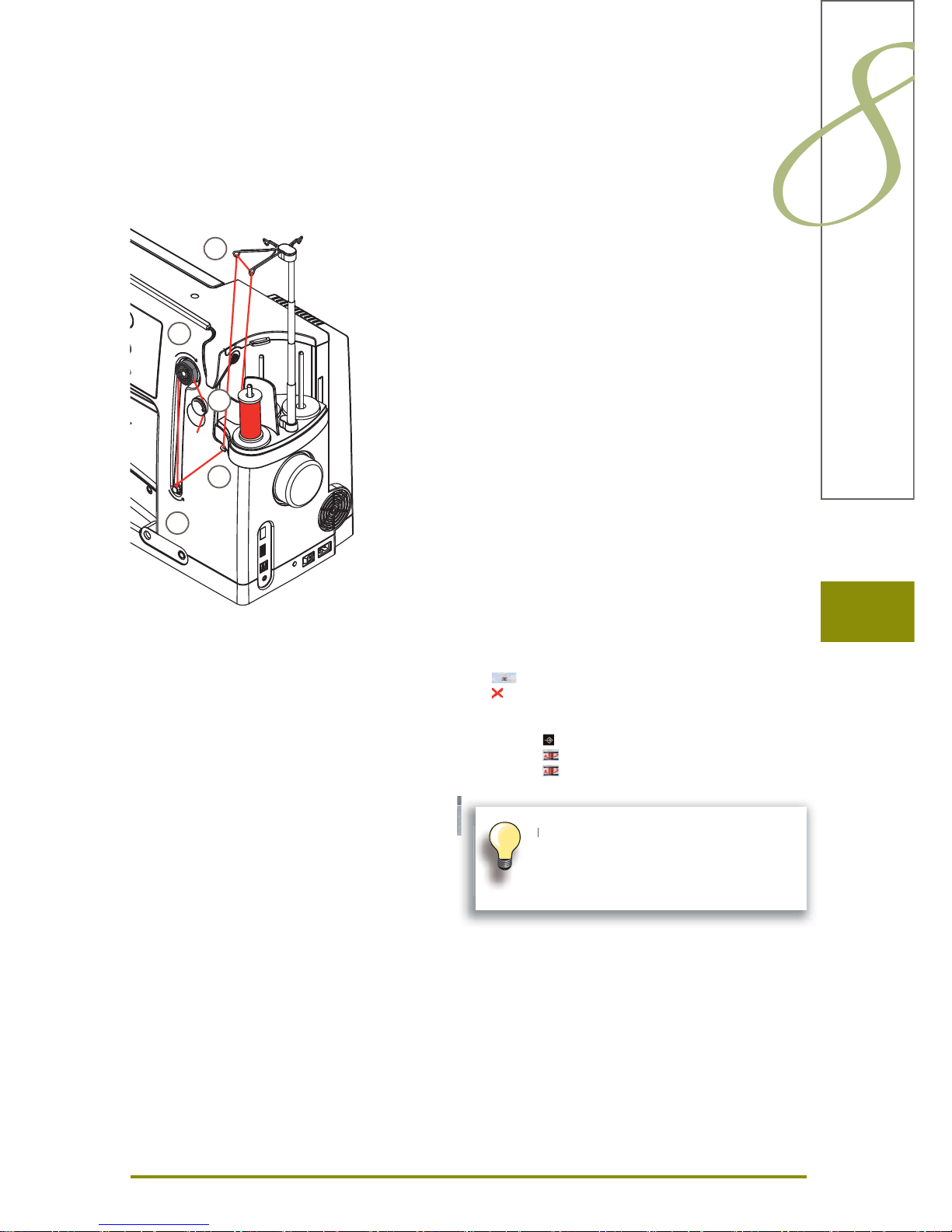

Bobbin

The 830 bobbin, exclusive to BERNINA, supplies till 40%

more lower thread. If the bobbin is not inserted correctly,

an error message is displayed.

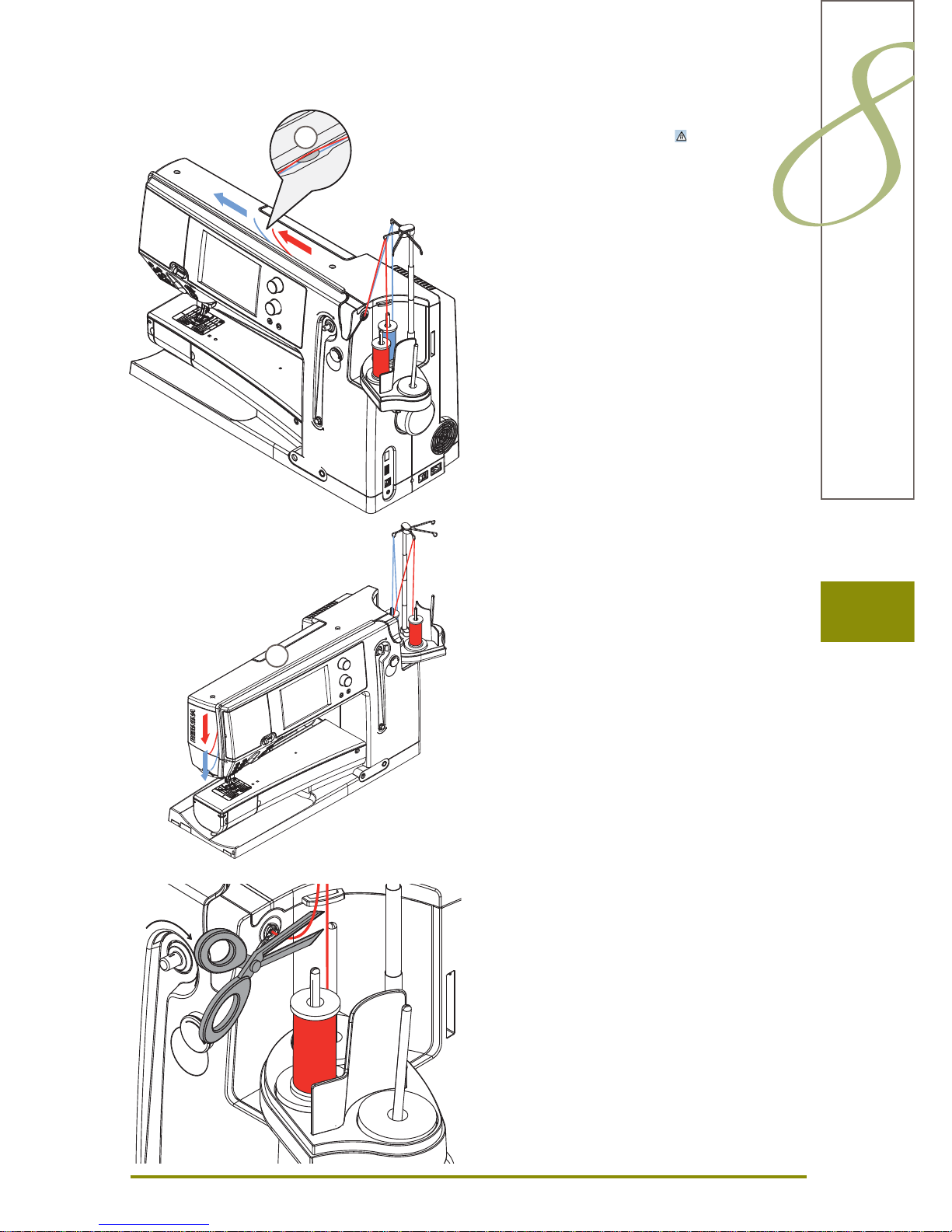

Pivotable Triple Spool Holder

remove spool-pin cover vertically upwards ►

pull out the telescopic rod and ensure that all the parts ►

snap into place

swing spool pin to the right until it is engaged. This

►

ensures a good overall view and access to the spool

pins

eyelet ► A is used when winding a bobbin

A

You can preselect a bobbin fill of 25%, 50%

or 100%.

Treat the bobbins with care. Keep the

white sensor surfaces free of scratches or

stains to ensure correct functioning of the

lower thread indicator. Store the bobbins

in the respective compartment of the

accessories box.

r

e

w

h

st

a

lo

w

15

Preparation

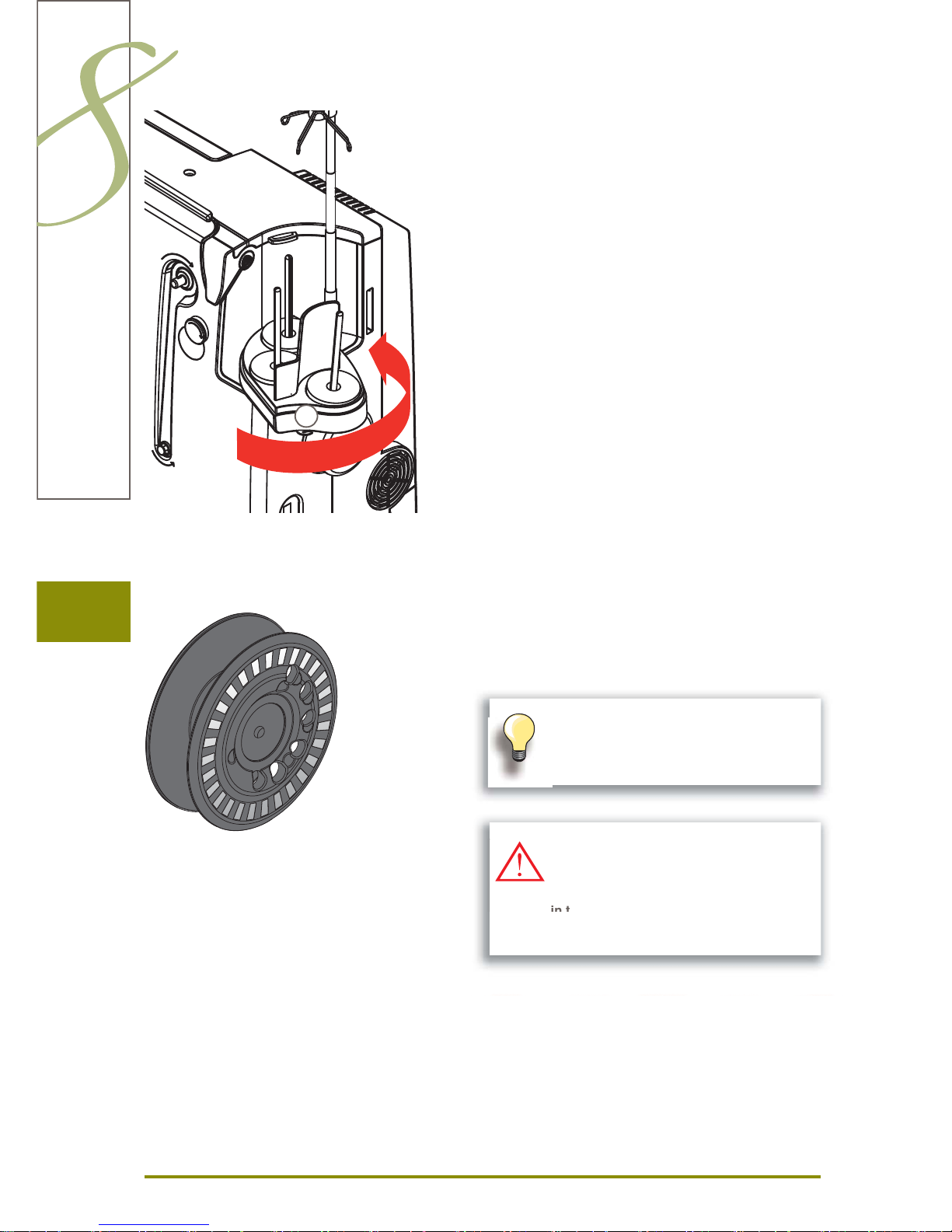

Winding the Bobbin

Preparation

turn power switch on (to «I») ►

place empty bobbin on Pin, white mark in front ►

the bobbin winding screen appears ►

the amount of bobbin fill is recognized by the system ►

and displayed by bar below the selectable bobbin fill

place thread spool on the front spool pin and thread the

►

respective guides 1 on the telescope

Winding the Bobbin

hold thread with both hands, guide the thread in the ►

thread guide on the swivel plate 2 in the direction of the

arrows and around the bobbin pre-tension 3

wind the thread one to two times around the empty ►

bobbin 4 following the direction of the arrows and pull

any excess thread in the direction of the arrows, cut off

on the thread cutter 5

select the bobbin filling, standard = 100% ►

«Start» field = touch bobbin symbol ►

adjust the winding speed with the «+» or «-» icon or with ►

the stitch width knob

winding process stops as soon as the selected fill

►

percentage is reached

remove the bobbin and pull the thread over the thread

►

cutter

the screen is closed ►

Interrupting the winding process

the winding process can be interrupted by touching the ►

icon, and the screen can be closed by touching the

icon

Continuing the winding process ►

touch ‣

touch ‣ , the screen for winding appears

touch ‣

to start winding process

1

3

2

4

5

It is possible to wind the bobbin while

embroidering.

We recommend to reducing the winding

speed.

16

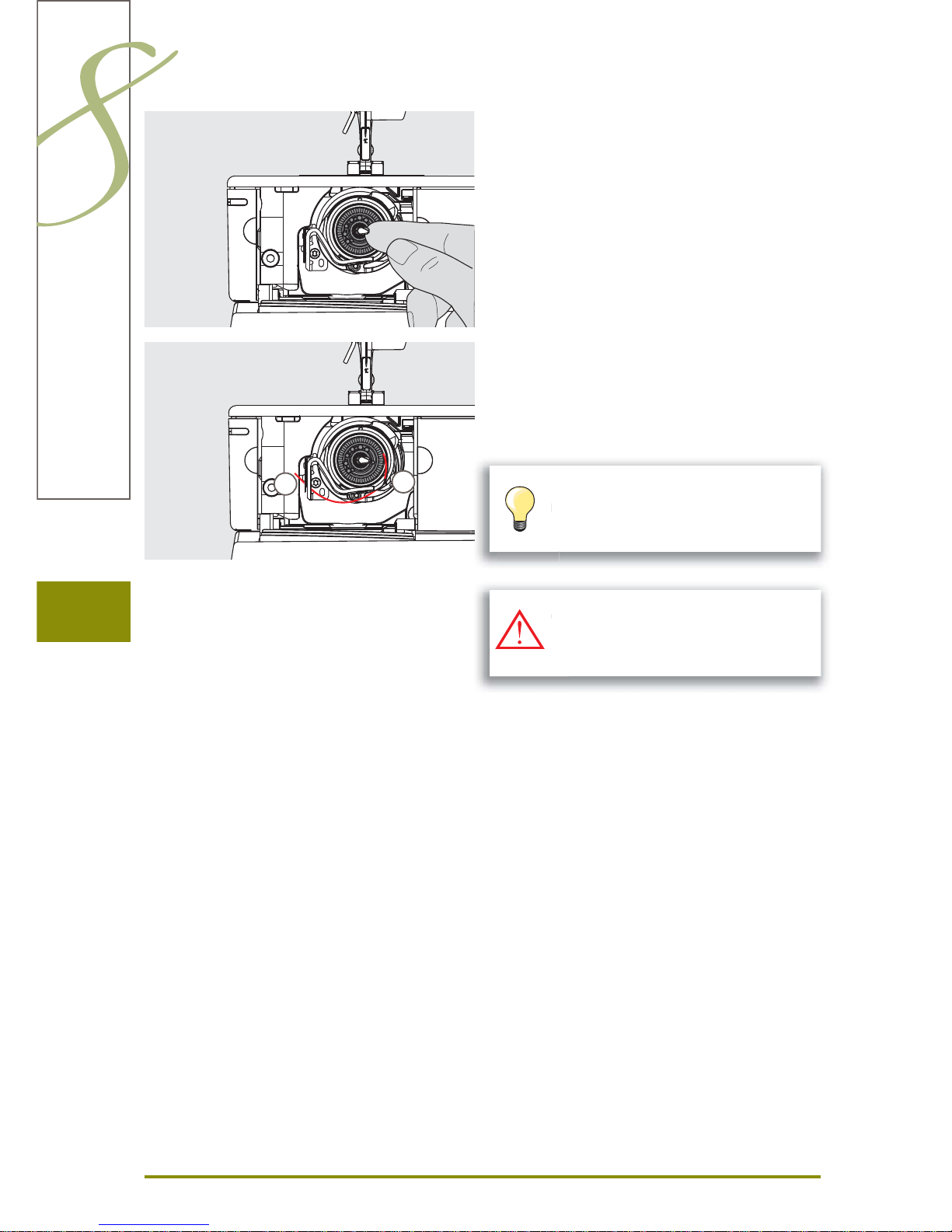

Preparation

Removing / Inserting the Bobbin

Removing the Bobbin

open bobbin cover, the hook system swings to the front ►

push the latch in the center of the bobbin to the left, the ►

bobbin pops out and can be removed

Inserting the Bobbin

with bobbin markings facing the front, place the bobbin ►

into the hook and push until it clicks into place

Threading Lower Thread

pull the thread to the right into slit ► A, then left under the

spring

pull thread over thread cutter ► B and cut

close the bobbin cover slowly, the hook swings back to

►

the rear

A

B

Only remove the bobbin if the hook is at

the end position.

n

e

The bobbin thread does not have to be

brought up as the loose end is just the right

length to start sewing.

Check the threading path

After threading the hook, hold the mirror under the

swung-out hook unit as shown in the pictures below.

Position of bobbin thread when threaded for sewing ►

17

Preparation

Slide-on Table

The slide-on table increases the sewing surface.

Attaching the Table

raise the needle and presser foot ►

from the left, push table to the right over the free-arm ►

and push firmly so that it engages over the fixing cam

Removing the Table

raise needle and presser foot ►

press the button down and remove to the left ►

Seam Guide

press the release button and insert into the groove ►

(underside of table) from left or right

can be moved over the entire table length ►

Scale

«0» corresponds to the center needle position ►

Thread Cutter

on Head Frame

pull both threads from back to front over the cutter ►

threads release automatically as soon as the first stitch ►

is sewn

at bobbin winder

after winding bobbin, pull thread in direction of arrow ►

over thread cutter

Remove the slide-on table only when

bobbin cover is closed.

e

m

o

b

18

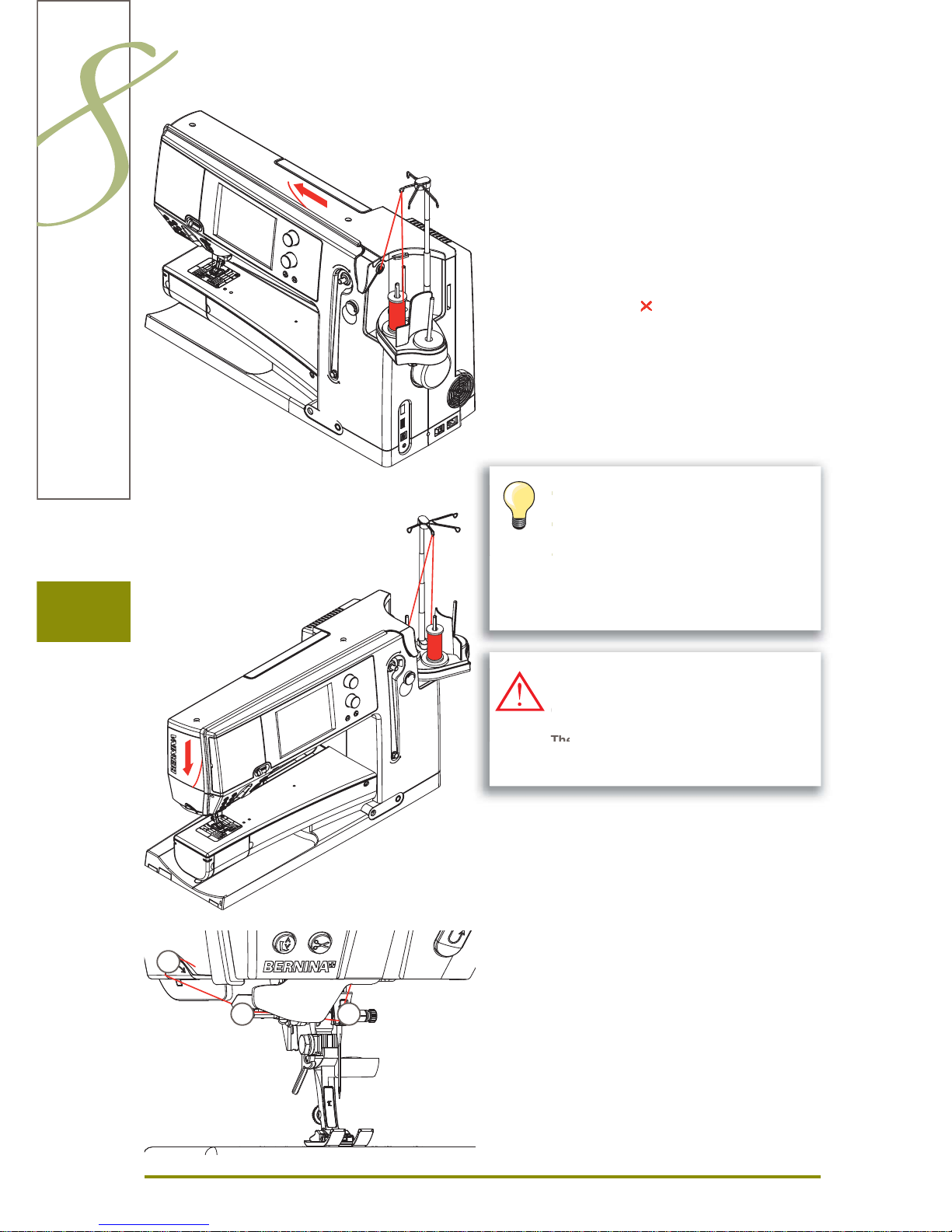

Preparation

Threading the Upper Thread

Automatic threading

place thread spool on the rear or center spool pin ►

thread the corresponding guide on the telescopic rod, ►

hold with both hands and guide into the threading

opening of the sewing computer, taking it up to the

thread guide in the needle clamp A and B and pull from

back to front over the thread cutter C

touch the automatic threader button, a message and an ►

animation appear

during threading the start-stop button is illuminated red ►

if the thread has not been threaded correctly, an error ►

message appears

close the message with ► and start again

if the thread has been threaded correctly the start-stop ►

button is illuminated green

Manual threading

follow the two first steps as described above ►

touch «Manual threading» icon on screen ►

press «Automatic threading» button, then thread the ►

needle by hand

when using unruly threads, slip the net over ►

the upper thread spool

large net for large spools, small net for ►

small spools

this prevents the upper thread from slipping ►

and gives an even thread feed

place the thread(s) under the presser foot ►

and to the back before starting to sew

Do not start the threaded sewing-/

embroidery computer if there is no fabric

on the stitch plate.

The sewing-/embroidery computer must

be switched ON for threading.

o

m

n

AB

C

19

Preparation

Double Needle

touch the Security Program icon ►

touch the appropriate needle icon (double needle) in the ►

Security Program screen

place a thread spool on the center spool pin and one on

►

the rear spool pin and thread the corresponding guides

on the telescopic rod

guide the thread from the rear spool pin into the ►

threading slit and the rear of the tension disc A. Insert

thread into the thread guide of the needle clamp

guide the thread from the center spool pin into the ►

threading slit and in front of the tension disc A. Insert

thread into the thread guide of the needle clamp

join both threads in one hand and guide them both in

►

the defined groove of the thread holder and pull them

back to front over the thread cutter, cutting both threads

touch the icon «Manual Threading» on the threading

►

animation screen. Next touch the illuminated automatic

threading button

using the manual threader in your accessory kit, ►

manually thread the left needle and then the right

needle

Triple Needle

in the Security Program select triple needle ►

place a thread spool on each spool pin and thread the ►

respective guides on the telescopic rod

thread as usual, guiding the thread from the rear and

►

center spool pin in the threading slit to the rear of

thread tension disc A and the thread from the front

spool pin in front of the tension disc A

Double/Triple Needle

Changing the thread

cut the spool thread before the pre-tension and pull out ►

of the sewing computer to front near the needle

A

A

20

Preparation

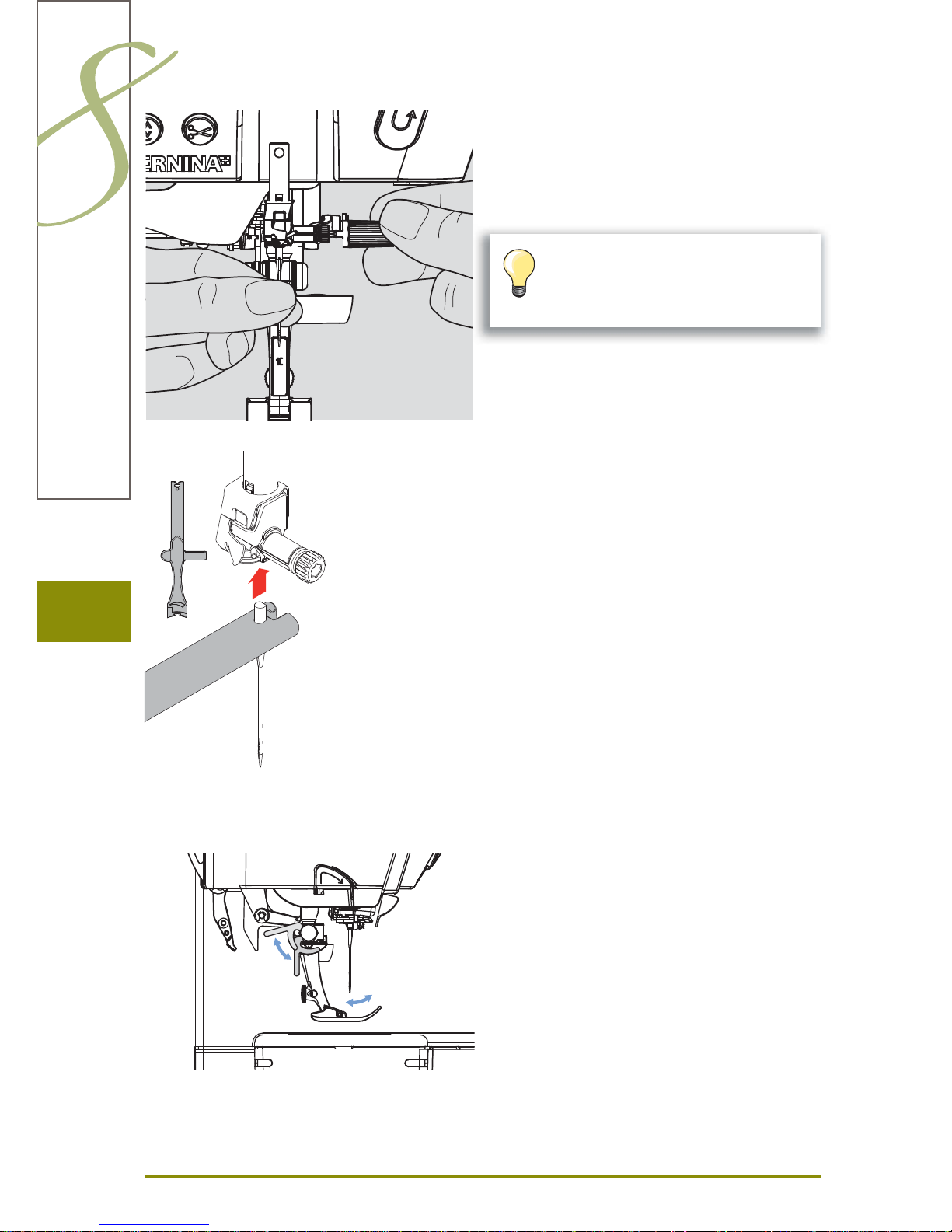

Changing the Needle

raise the needle ►

lower the presser foot and turn the power switch to «0» ►

Removing the Needle

loosen the clamp screw with the gray screwdriver and ►

pull needle down

Inserting the Needle

flat side of needle to the back ►

insert the needle with the mulitfunction tool as far as it ►

will go

tighten needle clamp screw ►

Changing the Presser Foot

raise the needle and presser foot ►

turn power switch to «0» (off) ►

Releasing the Presser Foot

raise the clamping lever ►

remove presser foot ►

Attaching the Presser Foot

guide the presser foot upwards over the cone ►

touch the clamping lever down ►

Turn the handwheel to lower the needle in

order to get better access to the fastening

screw.

21

Preparation

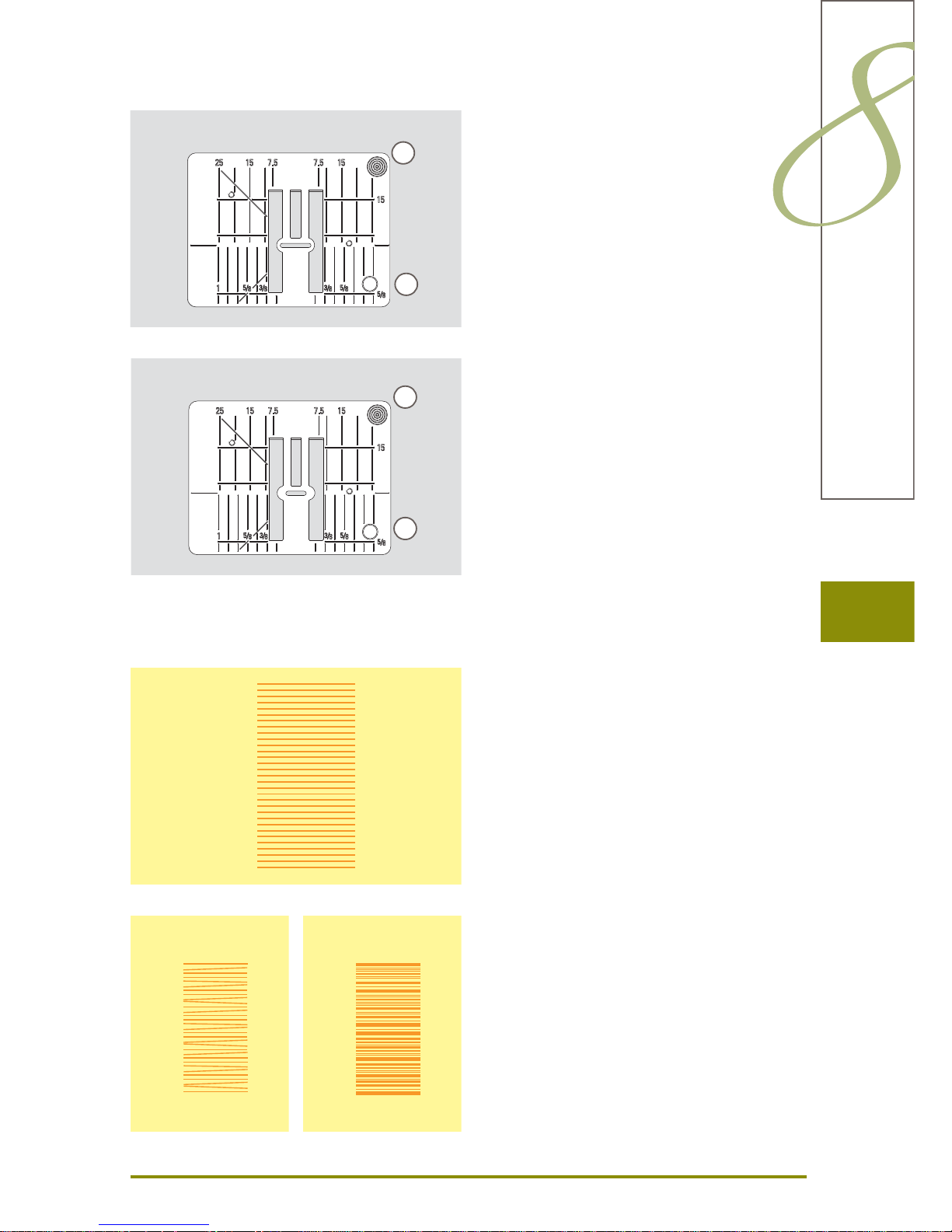

Stitch plates

Stitch Plate Markings

the stitch plates are marked horizontally, vertically and ►

diagonaly in mm and inches

markings help with sewing e.g. precise seaming and top

►

stitching

horizontal markings are helpful for sewing corners and ►

buttonholes etc.

diagonal markings are helpful for Quilt piecing ►

the vertical markings refer to the distance from the ►

needle to the marking

needle insertion point is position «0» (= center needle ►

position)

measurements are marked to the right and to the left of ►

center needle position

Removing the Stitch Plate

raise the presser foot and needle ►

turn power switch to «0» (off) ►

press the stitch plate down at the right back corner ► B

until it flips up

remove stitch plate ►

Replacing the Stitch Plate

place the stitch plate over the opening ► A and press

down until it clicks into place

5.5mm (Optional accessory)

9mm

With each stitch the feed-dog moves forward one step. The

length of this step is determined by the stitch length

selected.

With a very short stitch length the steps are very short. The

fabric moves relatively slowly under the presser foot, even

at full sewing speed, e.g. buttonholes and satin stitch and

decorative stitches are sewn with a very short stitch length.

Let the fabric feed fabric evenly.

Pulling, pushing or holding back the fabric will result in uneven stitches.

Feed-Dog and Fabric Feed

A

A

B

B

2222

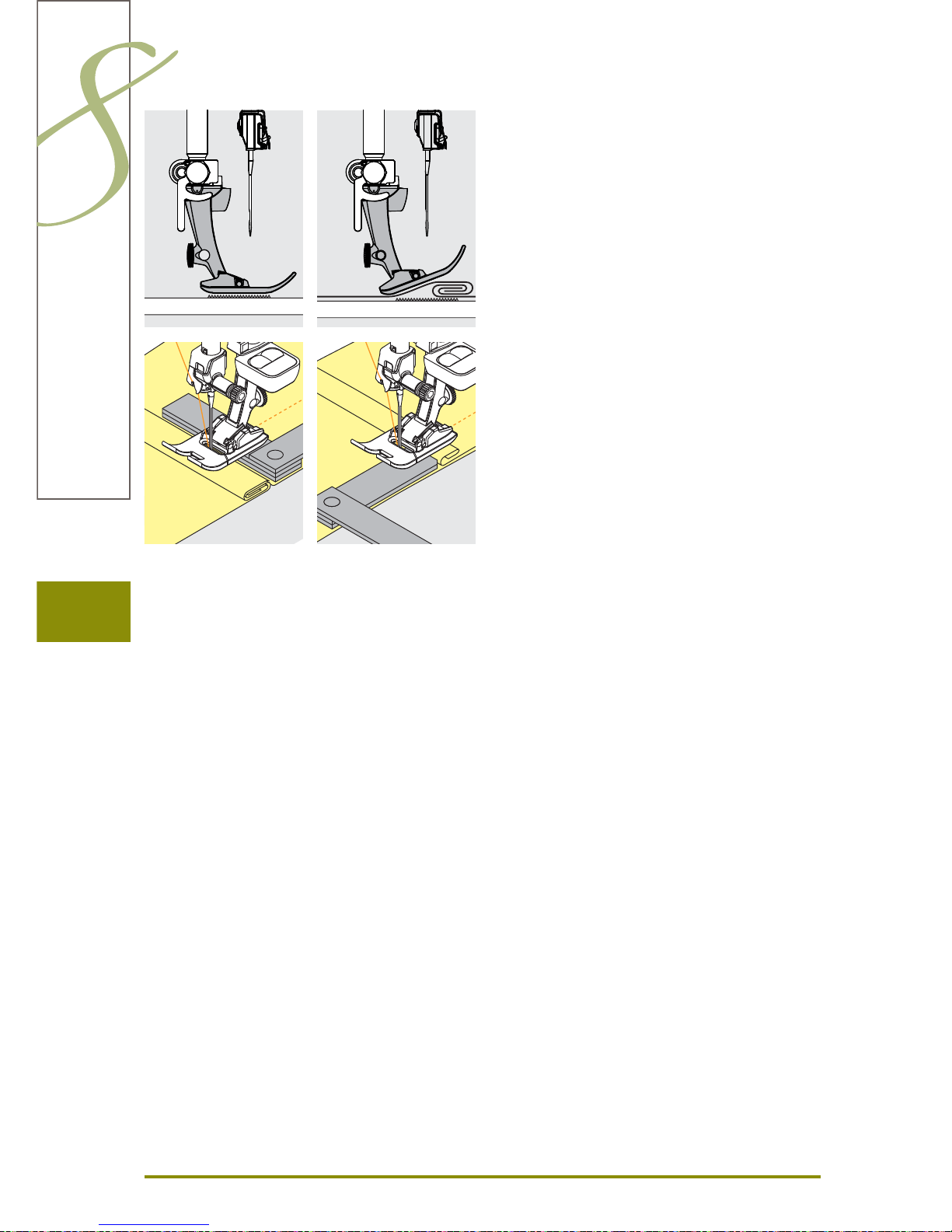

Due to the width of the stitch plate hole the outer feed-dog

rows are relatively far apart.

When sewing corners the fabric does not feed well, since

only a part of the fabric is on the feed-dog.

Correct this by placing one or more plates close to the

edge of the fabric.

Sewing Corners

Sewing with the Height Compensation Tool

Preparation

The feed-dog works accurately if the presser foot is level.

If the presser foot is at an angle when sewing over a thick

seam, the feed-dog cannot grip. The fabric may jam.

To level the presser foot as required, place one, two or

three height-compensating plates behind the needle under

the presser foot.

To level the front of the foot, place one or more plates

under the right of the presser foot close to the needle.

Sew until the presser foot has passed the thick area and

remove the plates.

23

Preparation

Thread Tension

Upper Thread Tension

Basic settings are applied automatically when a stitch

pattern or program is selected.

Optimal upper thread tension is set in the factory. For this,

Metrosene threads 100/2 weight (Mettler, Switzerland) are

used in the bobbin and also in the upper thread.

When using decorative thread, tension adjustments may

be neccessary to receive optimal stitching results.

Altering the Tension

touch the icon and the optimal stitch formation (stitch ►

formation in the fabric) is displayed

the red bar on the scale shows the basic value ►

turn the stitch width or stitch length knob to the left or ►

the right = the thread tension is loosened or tightened

the tension alteration is indicated on the right side of the ►

thread tension scale

the tension alteration only affects the stitch selected ►

the alteration is shown on the scale (red) and in the ►

function icon

the basic setting remains visible (gray) when a change ►

is made

the settings are saved by touching ►

touch «Reset» to return to basic settings ►

touch ►

, settings do not change

delete: with «clr», «Reset», also when turning off the ►

sewing computer

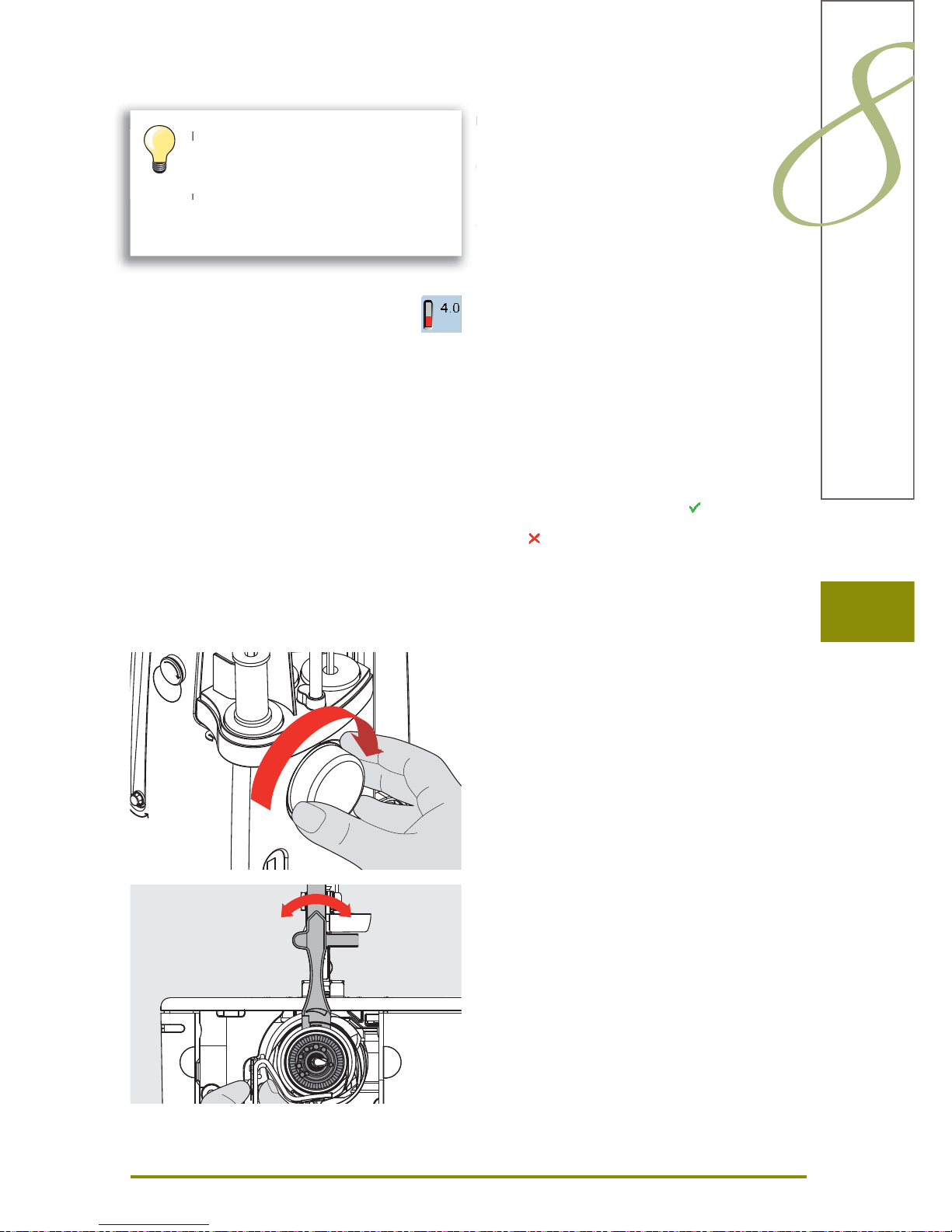

Lower Thread Tension

hold bobbin case firmly with your left hand; with your ►

right hand, turn the hand wheel clockwise until the

setting tool can be slid over the lug at the slider

basic value: ►

lug of the slider matches with the marking of the ‣

bobbin carrier, or

lug is shifted 1-2 points to the right, or ‣

lug is shifted 1-2 points to the left ‣

turn lug to the left with the setting tool = thread tension ►

becomes looser

turn lug to the right with the setting tool = thread tension ►

becomes tighter

change per point = 4 g ►

a

s

pa

tt

p

t

Me

s

e

n

Higher upper thread tension = the upper

thread is tightened, which pulls the lower

thread up to the topside of fabric.

Lower upper thread tension = the upper

thread is loosened, which enables it to be

pulled to the backside of the fabric.

24

Needles

Important facts about Thread and Needles

The thread is chosen according to its intended use. For a perfect sewing result,

thread and fabric quality play an important role. Use of quality brands is

recommended.

Cotton Thread

cotton thread has the advantage of being a natural fiber and is therefore ►

particularly suited for sewing cotton fabrics

mercerized cotton thread has a slight sheen and is preshrunk ►

Polyester Thread

polyester thread has a high tensile strength and is particularly colorfast ►

polyester thread is more resiliant than cotton thread and is recommended

►

where a strong and elastic seam is required

Thread

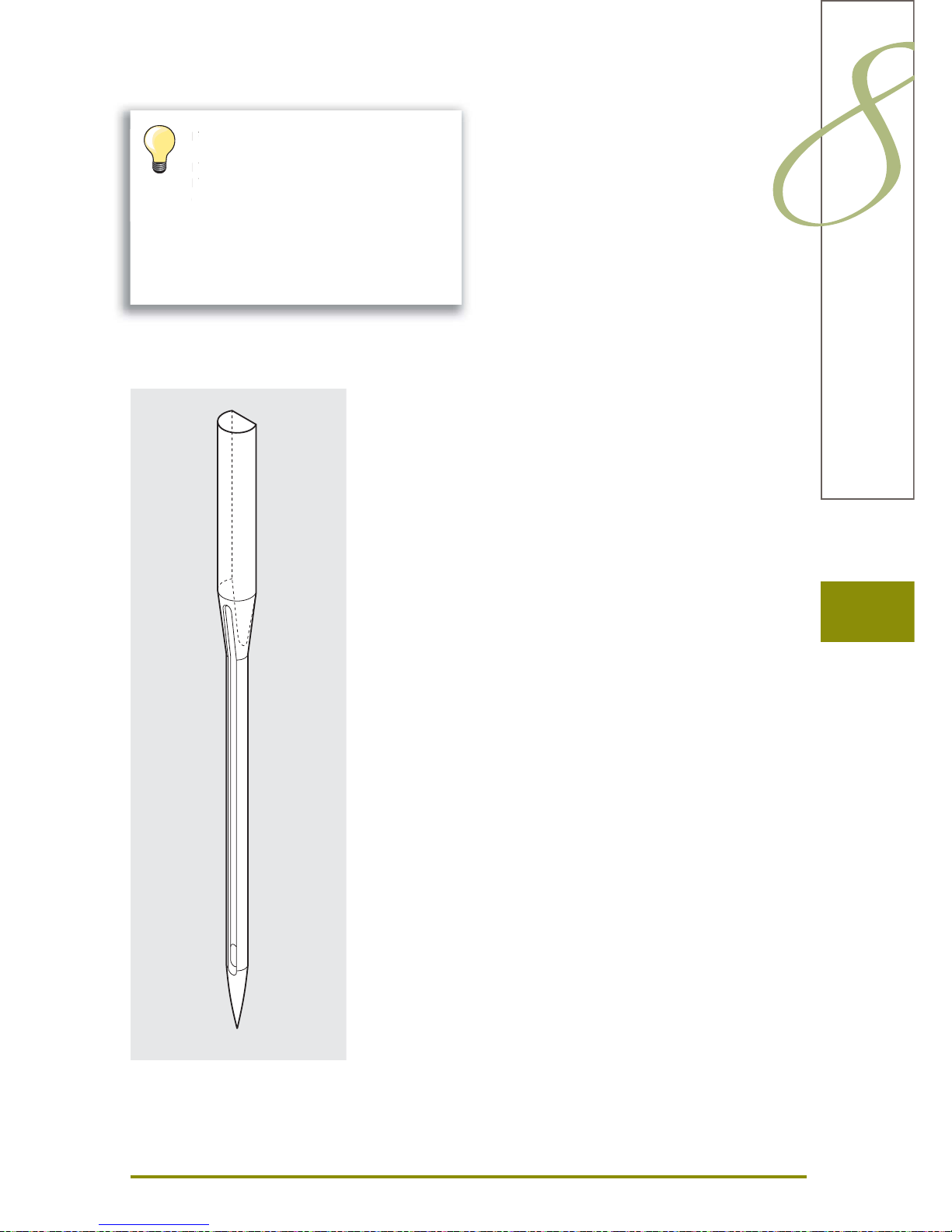

Correct Combination

To sew optimally, the thread should travel smoothly down the long groove on

the front of the needle.

Thread Too Thin or Needle Too Thick

The thread has too much clearance in the groove; there may be skipped

stitches or damage to the thread.

Thread Too Thick or Needle Too Thin

The thread rubs on the edges of the groove and can get jammed. This can

break the thread.

Needle/Thread

Needle, Thread and Fabric

Care should be taken when matching the needle and thread.

The correct needle size does not just depend on the thread selected but also

on the fabric to be used. The fabric weight and type determines which thread

weight, needle size and needle tip to use.

Checking Needle Condition

The condition of the sewing needle should be

checked and the needle replaced regularly.

A defective needle does not just damage the

fabric but also the sewing computer.

As a guide:

Replace the needle before starting a new

sewing project.

h

e

Th

e

e

d

25

Guidelines

130/705 H - S / 70

130 Shank length

705 Flat shank

H Needle scarf

S Needle point (here e.g. medium ball point)

70 Needle size (shank diameter)

Fabric / Thread Needle size

Fine fabrics:

Fine thread (darning thread,

embroidery thread) 70–75

Medium weight fabrics:

Normal thread 80–90

Heavy weight fabrics: 100, 110, 120

Needle

26

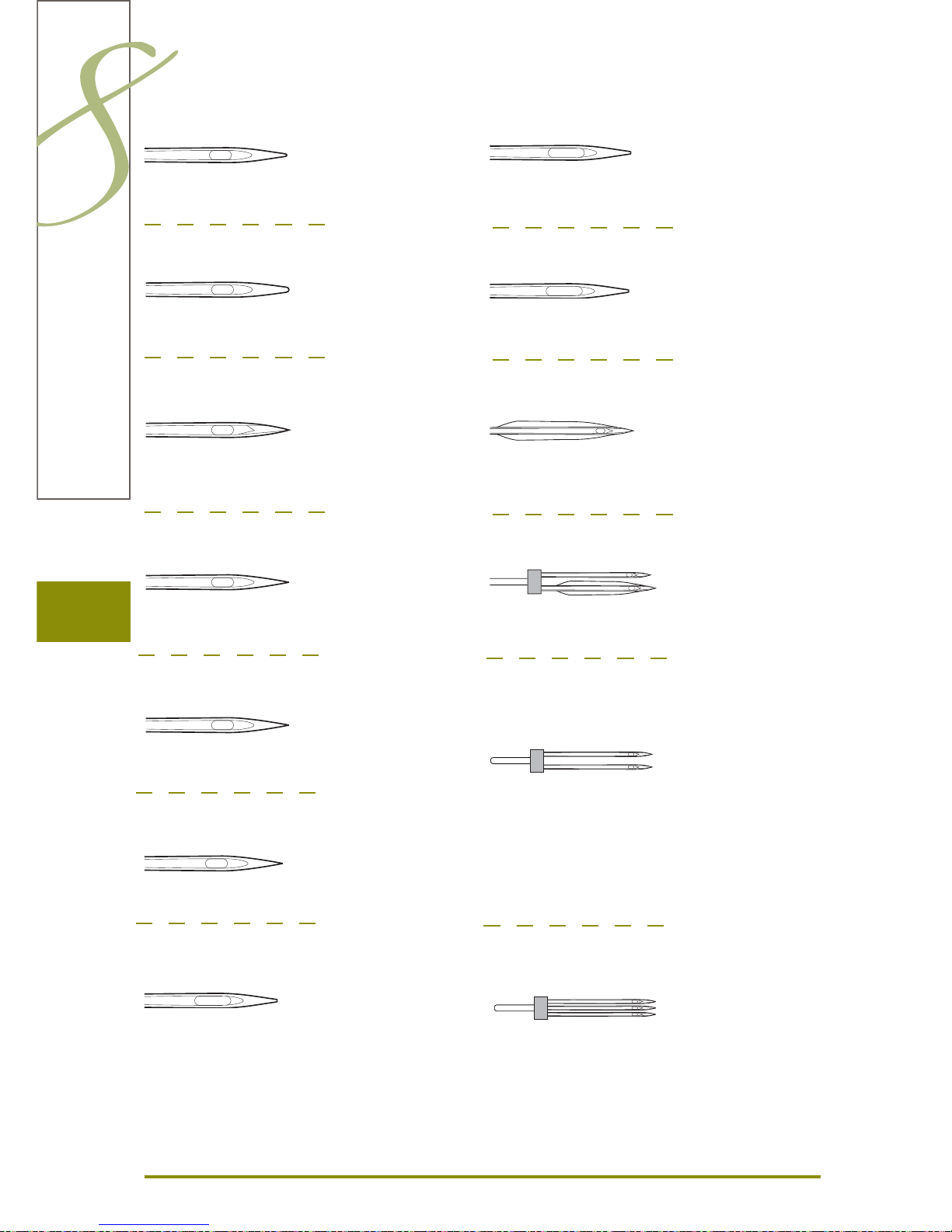

Needle

Overview

Universal

130/705 H / 60 –100

Normal point,

slightly rounded

For nearly all natural and synthetic

fabrics (woven and knitted)

Jersey/Stretch

130/705 H-S, H-SES, H-SUK / 70–90

Ball point

Jersey, stretch fabrics

Leather

130/705 H-LL, H-LR / 90–100

With cutting point

All types of leather, synthetic leather,

plastic, sheeting

Jeans

130/705 H-J / 80–110

Very fine sharp point

Heavy weight fabrics such as jeans,

canvas, overalls

Microtex

130/705 H-M / 60–90

Especially fine sharp point

Micro fiber fabrics and silk

Quilting

130/705 H-Q / 75–90

Fine sharp point

Straight and topstitching

Embroidery

130/705 H-E / 75–90

Large eye, slight ball point

Embroidery on all natural and synthetic

fabrics

Metafil

130/705 H-MET / 75-90

Large eye

Sewing with metallic threads

Cordonnet (Topstitching)

130/705 H-N / 80–100

Small ball point, long eye

Topstitching with thick thread

Wing needle (hemstitch needle)

130/705 HO / 100–120

Wide needle (wing)

Hemstitching

Double wing needle

130/705 H-ZWI-HO / 100

For special effects with hemstitch

embroidery

Double needle

130/705 H-ZWI / 70–100

Needle distance: 1.0 / 1.6 / 2.0 /

2.5 / 3.0 / 4.0 / 6.0 / 8.0

Visible hems in stretch fabrics, pin tucks,

decorative sewing

Triple needle

130/705 H-DRI / 80

Needle distance: 3.0

For decorative sewing

Functions & Settings

Overview 28

Function Buttons 28

Display 30

Functions 32

Sewing 32

Setup Program 34

Entry Screen 34

Display 35

Wallpaper 35

Sewing 36

Securing stitches after thread is cut 36

Embroidery 38

Adjusting Embroidery Settings 38

Fabric Thickness 38

Screen Calibration 39

Monitoring 40

Information 41

Update 42

Version 42

Service Data 42

Cleaning the sewing/embroidery computer 43

Cleaning 43

Packing position 43

Calibrating buttonhole foot no. 3A 43

Reset / Delete User Data 44

Tutorial 45

Overview of Topics 45

Creative Consultant 46

General 46

Help Program 47

General 47

Stitch Pattern 47

Functions 47

Balance 48

Balance Description 48

Practical and Decorative Stitches 48

Corrections 48

Sideways Motion Stitches 48

BERNINA Dual Feed 49

ECO 50

ECO Description 50

28

Overview

Function Buttons

Start/Stop Button

starts and stops the sewing computer when ►

operating it without foot control

slightly raise the presser foot when turning or

►

moving the project while sewing - hover

position

Quick Reverse Button/Backstepping

secures the seam beginning and end: sews in ►

reverse as long as the button is pressed

used to program the buttonhole length ►

used to program the darning length ►

used to determine end of stitching in straight ►

stitch Securing stitch no. 5

used for securing in Quilters Securing

►

Program no. 1324

switching for accurate stitch-by-stitch reverse ►

sewing - Backstepping

Pattern End

a stop symbol which appears during sewing ►

indicates that the function is activated

sewing computer stops at the end of the active

►

single pattern or the active pattern of a

combination

Automatic Thread Cutter

upper and lower threads are cut automatically ►

2-6 securing stitches can be programmed in ►

the setup program - these are sewn before the

thread is cut

Automatic Needle Threader

touch button = completes the threading ►

process and threads the needle

Needle Stop Up/Down

In the default setting the needle symbol is

displayed above the presser foot indicator.

touch the button briefly: ►

the needle is raised or lowered (as when ‣

tapping the foot control with your heel)

touch the button longer: ►

the needle is lowered, the needle symbol is ‣

displayed below

the sewing computer stops with the needle

‣

down

this becomes your default setting ‣

touch the button longer again: ►

the needle is raised, the needle symbol is ‣

displayed above

the sewing computer stops with the needle ‣

up

Double, triple and wing needles require

manual threading after the button has been

pressed.

Use the automatic needle threader for needle

sizes 70 - 120. Metallic threads, thick threads

like cordonnet and difficult to work with

threads should be threaded by hand.

When using metallic or cordonnet thread,

use the thread cutter on the head frame

only.

W

h

e

n

l

The automatic threader mustn‘t be

activated with one of these presser feet

attached:

nos. 50, 55, 80, 85 and 86.

e

c

t

t

ta

o

s

29

Overview

Slide Speed Control

the motor speed is infinitely ►

variable with the slide

Altering Needle Positions

touch left button – the needle ►

moves to the left

touch right button – the needle ►

moves to the right

quick change – hold the button ►

down

total of 11 needle positions ►

(5 left, 5 right, 1 center)

Stitch Width/Length (Multifunction) Knobs

to adjust stitch width or length ►

to alter thread tension ►

to alter presser foot pressure ►

to adjust the sewing direction when ►

in «directional sewing»

to adjust button size or the slit size

►

of the buttonhole

to adjust the balance ►

Presser Foot Position

touch the button = the presser foot is lowered ►

and raised slightly again so the fabric can be

easily positioned. When sewing starts the foot

is lowered on to the material

touch the button again = the presser foot is ►

raised and the Feed-dog is simultaneously

lowered

Automatic Securing Program

touch the button before the sewing starts or ►

during sewing = single patterns are secured at

the end, with the selected number of stitches

programmed

touch the button before starting a combination ►

= the first pattern is secured at the end, with

the number of stitches programmed

touch the button while stitching a combination

►

= the active pattern is secured at the end, with

the number of stitches programmed

the sewing computer stops automatically after

►

all securing variations

the number and type of the securing stitches

►

can be programmed in the setup program

30

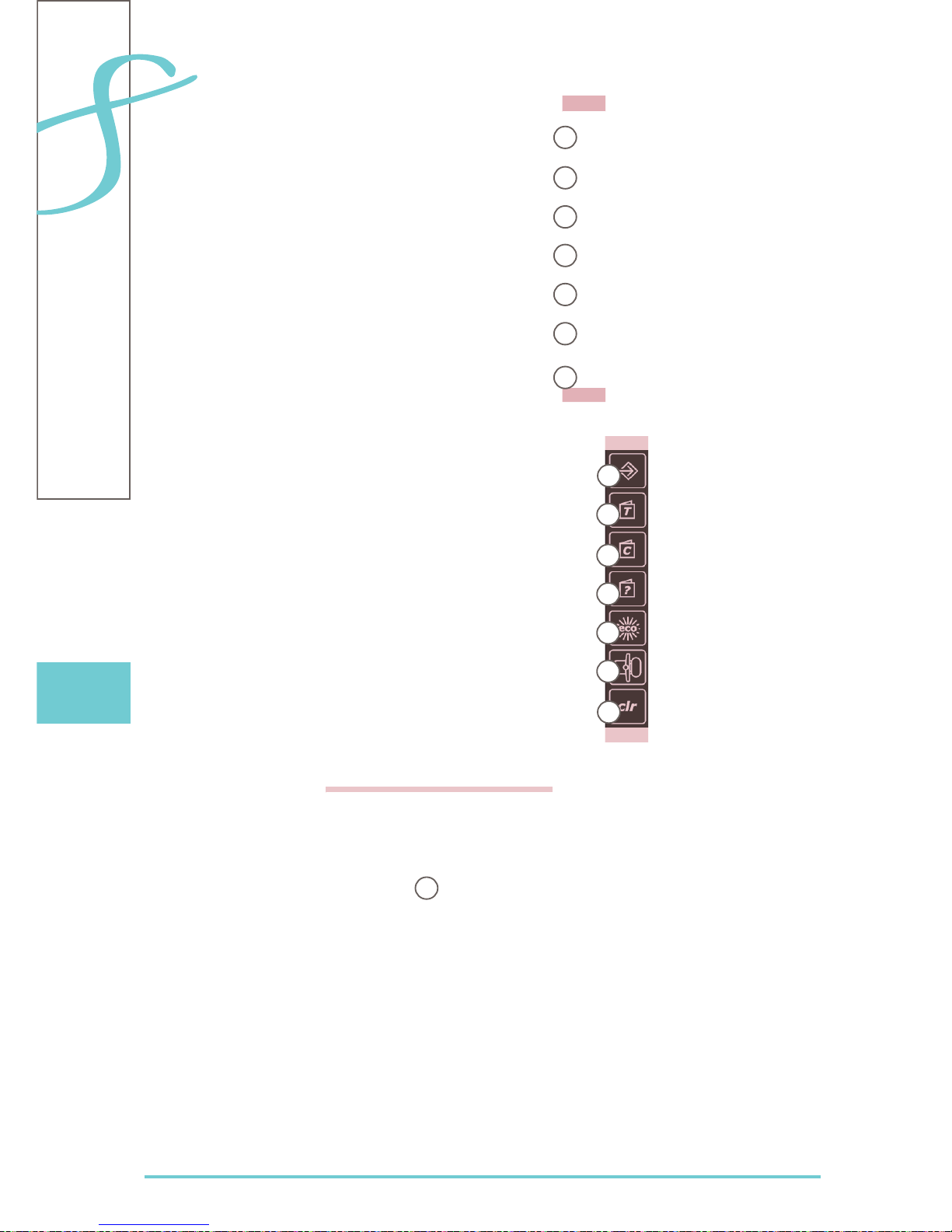

Overview

Display

Menu Selection

Practical stitchesA

Decorative stitchesB

AlphabetsC

ButtonholesD

Quilt stitchesE

Personal ProgramF

HistoryG

System Settings

Setup ProgramH

TutorialI

Creative ConsultantJ

HelpK

ECOL

Embroidery/Sewing M

mode

clr - Delete N

Stitch Display

Stitch Pattern O

selections

O

A

B

C

D

E

F

G

I

J

K

L

M

N

H

Loading...

Loading...