Beko BX 109 C, BX 109 H, BX 112 C, BX 112 H, BX 109 AC Installation Manual

...

Mobile room air conditioner

Installation Manual

BX 109 C |

|

BX 109 H |

|

BX 112 C |

|

|

|||

BX 112 H |

|

BX 109 AC |

|

BX 109 AH |

|

|

EN FR

Please read this user manual first!

Dear Customer,

Thank you for preferring a Beko product. We hope that you get the best results from your product which has been manufactured with high quality and state-of- the-art technology. Therefore, please read this entire user manual and all other accompanying documents carefully before using the product and keep it as a reference for future use. If you handover the product to someone else, give the user

manual as well. Follow all warnings and information in the user manual.

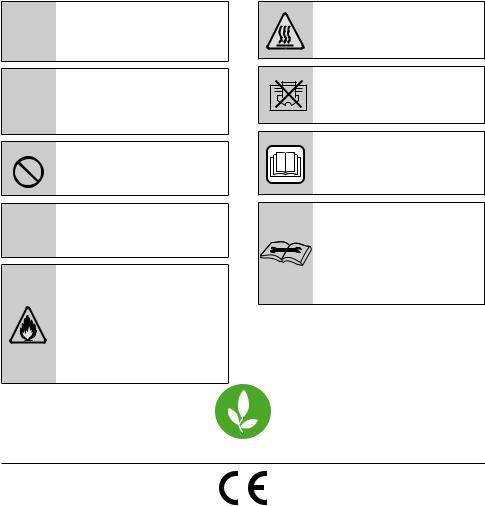

Meanings of the symbols

Following symbols are used in the various section of this manual:

C Important information or useful hints about usage.

Warning for hazardous A situations with regard to

life and property.

Warning to actions that must never perform.

B Warning for electric shock.

This symbol shows that this appliance uses a flammable refrigerant. If the refrigerant is leaked and exposed to

an external ignition source, there is a risk of fire.

Warning for hot surfaces.

Do not cover it.

This symbol shows that the operation manual should be read carefully.

This symbol shows that a service personnel should be handling this equipment with reference to the installation manual.

This product has been produced in environmentally friendly, modern facilities

Complies with the WEEE Regulation. |

Does not contain PCB. |

Contents |

|

|

1 |

Safety precautions |

5 |

2 |

Parts description |

21 |

2.1 |

Front view . . . . . . . |

. 21 |

2.2 |

Rear view |

21 |

3 |

Control panel |

23 |

3.1 |

TEMP. indicator |

23 |

3.2 |

Function buttons |

23 |

4 |

Operation |

25 |

5 |

Accessories |

27 |

6 |

Notice of installation |

28 |

6.1 Unpacking inspection 28

6.2 Safety principles for installing air conditioner 28

6.3 Requirements for installation position 28

6.4 Installation environment inspection 29

7 Installation |

30 |

7.1 Guide of customer 30

7.2 Select a best location 30

7.3 Duct mount instruction 30

7.4 Install the window slider kit 31 7.5 Install the exhaust duct into the window 33 7.6 Without installation 34 7.7 Water drainage 34

Mobile room air conditioner / Installation Manual |

3 / 88 EN |

Contents |

|

|

8 |

Maintenance |

36 |

8.1 |

Clean the unit |

36 |

8.2 Clean the air filter |

36 |

|

9 |

Troubleshooting |

38 |

10Installation instructions |

39 |

|

10.1 F-Gas instruction |

. 39 |

|

11 Specification |

40 |

|

4 / 88 EN |

Mobile room air conditioner / Installation Manual |

1 Safety precautions

Warning

This air conditioner uses R290 flammable refrigerant.

Note:

C Air conditioner with R290 refrigerant, if roughly treated, may cause serious harm to the human body or surrounding things.

••The room space for the installation, use, repair, and storage of this air conditioner should be greater than 12m2.

••Air conditioner refrigerant can not charge more than 250g.

••Do not use any methods to speed up defrost or to clean frosty parts except for particular recommended by manufacturer.

••The appliance shall be stored in a well-ventilated area where the room size corresponds to the room area as specified for operation.

••Not pierce or burn air conditioner, and check the refrigerant pipeline whether be damaged.

••The air conditioner should be stored in a room without lasting fire source, for example, open flame, burning gas appliance, working electric heater and so on.

••Be aware that refrigerants may not contain an odour.

••The storage of air conditioner should be able to prevent mechanical damage caused by accident.

••The appliance must be kept free from obstruction to ensure proper function and mitigate safety hazards.

Mobile room air conditioner / Installation Manual |

5 / 88 EN |

1 Safety precautions

••Maintenance or repair of air conditioners using R290 refrigerant must be carried out after security check to minimize risk of incidents.

••Please read the instruction carefully before installing, using and maintaining.

Warning

Incorrect installation or operation by not following these instructions may cause harm or damage to people, properties, etc.

The seriousness is classified by the following indications:

••This appliance can be used by children aged from 8 years and above if they have been given supervision or instruction concerning use of the appliance in a safe way and understand the hazards involved. Cleaning and user maintenance shall not be made by children unless they are aged from 8 years and above and supervised. Keep the appliance and its cord out of reach of children aged less than

8 years.

••This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.

(Except for the AC with CE-Marking )

••This unit is designed for indoor use only.

6 / 88 EN |

Mobile room air conditioner / Installation Manual |

1 Safety precautions

••The appliance shall be installed in accordance with national wiring regulations.

••The air conditioner must be grounded. Incomplete grounding may result in electric shocks.

Do not connect the earth wire to the gas pipeline, water pipeline, lightning rod, or telephone earth wire.

••After installment, earth leakage examination must be carried on through electrifying.

••An earth leakage breaker with rated capacity must be installed to avoid possible electric shocks.

••Don’ t install air conditioner in a place where there is flammable gas or liquid. It may cause fire or explosion.

••If the power supply cord is damaged, it must be replaced by the manufacture or its service agent or a similar qualified person.

••The specification of the fuse are printed on the circuit bord, such as: AC 250V/5A.

••Don’t put hands or any objects into the air inlets or outlets. This may cause personal injury or damage to the unit.

••Don’ t touch the swinging wind vanes.

It may damp your finger and damage the driving parts of the wind vanes.

••Don’t attempt to repair the air conditioner by yourself. You may be hurt or cause further malfunctions.

••In lighting storm weather, please cut off the primary power supply switch in order to prevent the machine from damage.

Mobile room air conditioner / Installation Manual |

7 / 88 EN |

1 Safety precautions

••Don’ t use liquid or corrosive detergent to clean the appliance and don’ t splash water or other liquid onto it , otherwise, it may damage the plastic components, even cause electric shock.

••Don’t operate the unit in a wet room such as the bath room or laundry rooms.

••Don’t touch the unit with wet or damp hands or when barefoot.

••Don’t pull the unit by the cord.

••Don’t remove any part of the unit unless instructed by an authorized technician.

••Don’t move the unit, unless the power has been cut off and the power cord is tied to the bending and winding column.

••Don’t operate the unit with a damaged plug or a loose socket.

••Ducts connected to an appliance shall not contain an ignition source.

••Unplug before cleaning or maintenance operations.

••Do not use manuals to accelerate the defrosting process or to clean, other than those recommended by the manufacturer. The appliance shall be stored in a room without Continuously operation ignition sources (for example: open flames, an operation gas appliance or an operating electric heater.) Do not pierce or burn. Be aware that refrigerants may not contain an odour.

••The appliance shall state the insulation of a residual current device (RCD) having rated residual operating current not exceeding 30mA.

••This appliance is intended to be used in household and similar applications such as

8 / 88 EN |

Mobile room air conditioner / Installation Manual |

1Safety precautions

-Staff kitchen areas in shops, offices and other working environments;

-farm houses;

-by clients in hotels, motels and other residential type environments;

-bed and breakfast type environments;

Warning:

Any person who is involved with working on or breaking into a refrigerant circuit should hold a current valid certificate from an industry-accredited assessment authority, which authorises their competence to handle

A refrigerants safely in accordance with an industry recognised assessment specification.

Servicing shall only be performed as recommended by the equipment manufacturer. Maintenance and repair requiring the assistance of other skilled personnel shall be carried out under the supervision of the person competent in the use of flammable refrigerants.

Qualification requirements of maintenance personnel

1.Special training additional to usual refrigerating equipment repair procedures is required when equipment with flammable refrigerants is affected. In many countries, this training is carried out by national training organisations that are accredited to teach the relevant national competency standards that may be set in legislation. The achieved competence should be documented by a certificate.

Mobile room air conditioner / Installation Manual |

9 / 88 EN |

1Safety precautions

2.The maintenance and repair of the air conditioner must be conducted according to the method recommended by the manufacturer. If other professionals are needed to help maintain and repair the equipment, it should be conducted under the supervision of individuals who have the qualification to repair AC equipped with flammable refrigerant.

Inspection of the site

Safety inspection must be taken before maintaining equipment with R290 refrigerant to make sure the risk of fire is minimized. Check whether the place is well ventilated, whether anti-static and fire prevention equipment is perfect.

While maintaining the refrigeration system, observe the following precautions before operating the system.

Operating procedures

1.General work area:

All maintenance staff and others working in the local area shall be instructed on the nature of work being carried out. Work in confined spaces shall be avoided. The area around the workspace shall be sectioned off. Ensure that the conditions within the area have been made safe by control of flammable material.

2.Checking for presence of refrigerant:

The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is aware of potentially toxic or flammable atmospheres. Ensure that the leak detection equipment being used is suitable for use with

10 / 88 EN |

Mobile room air conditioner / Installation Manual |

1 Safety precautions

all applicable refrigerants, i.e. non-sparking, adequately sealed or intrinsically safe.

3.Presence of fire extinguisher:

If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate fire extinguishing equipment shall be available to hand. Have a dry powder or CO2 fire extinguisher adjacent to the charging area.

4.No ignition sources:

No person carrying out work in relation to a refrigeration system which involves exposing any pipe work shall use any sources

of ignition in such a manner that it may lead to the risk of fire or explosion. All possible ignition sources, including cigarette smoking, should be kept sufficiently far away from the site of installation, repairing, removing and disposal, during which refrigerant can possibly be released to the surrounding space.

Prior to work taking place, the area around the equipment is to be surveyed to make sure that there are no flammable hazards or ignition risks.

‘No Smoking’ signs shall be displayed.

5.Ventilated area (open the door and window):

Ensure that the area is in the open or that it is adequately ventilated before breaking into the system or conducting any hot work. A degree of ventilation shall continue during the period that the work is carried out. The ventilation should safely disperse any released refrigerant and preferably expel it externally into the atmosphere.

Mobile room air conditioner / Installation Manual |

11 / 88 EN |

1Safety precautions

6.Checks to the refrigeration equipment:

Where electrical components are being changed, they shall be fit for the purpose and to the correct specification. At all times the manufacturer’s maintenance and service guidelines shall be followed. If in doubt, consult the manufacturer’s technical department for assistance. The following checks shall be applied to installations using flammable refrigerants:

•The charge size is in accordance with the room size within which the refrigerant containing parts are installed.

•The ventilation machinery and outlets are operating adequately and are not obstructed.

•If an indirect refrigerating circuit is being used, the secondary circuit shall be checked for the presence of refrigerant.

•Refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance which may corrode refrigerant containing components, unless the components are constructed of materials which are inherently resistant to being corroded or are suitably protected against being so corroded.

7. Checks to electrical devices:

Repair and maintenance to electrical components shall include initial safety checks and component inspection procedures. If a fault exists that could compromise safety, then no electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If the fault cannot be corrected immediately but it

12 / 88 EN |

Mobile room air conditioner / Installation Manual |

1 Safety precautions

is necessary to continue operation, an adequate temporary solution shall be used. This shall be reported to the owner of the equipment so all parties are advised.

Initial safety checks shall include:

•That capacitors are discharged: this shall be done in a safe manner to avoid possibility of sparking.

•That no live electrical components and wiring are exposed while charging, recovering or purging the system.

•Keep continuity of earthing.

Inspection of cable

Check the cable for wear, corrosion, overvoltage, vibration and check if there are sharp edges and other adverse effects in the surrounding environment. During the inspection, the impact of aging or the continuous vibration of the compressor and the fan on it should be taken into consideration.

Leakage check of R290 refrigeral

Note: Check the leakage of the refrigerant in an

C environment where there is no potential ignition source. No halogen probe (or any other detector that uses an open flame) should be used.

Leak detection method:

For systems with refrigerant R290, electronic leak detection instrument is available to detect and leak detection should not be conducted in environment with refrigerant. Make sure the leak

Mobile room air conditioner / Installation Manual |

13 / 88 EN |

1 Safety precautions

detector will not become a potential source of ignition, and is applicable to the measured refrigerant. Leak detector shall be set for the minimum ignitable fuel concentration (percentage) of the refrigerant. Calibrate and adjust to proper gas concentration (no more than 25%) with the used refrigerant.

The fluid used in leak detection is applicable to most refrigerants. But do not use chloride solvents to prevent the reaction between chlorine and refrigerants and the corrosion of copper pipeline.

If you suspect a leak, then remove all the fire from the scene or put out the fire.

If the location of the leak needs to be welded, then all refrigerants need to be recovered, or, isolate all refrigerants away from the leak site (using cut-off valve). Before and during the welding, use OFN to purify the entire system.

Removal and vacuum pumping

1.Make sure there is no ignited fire source near the outlet of the vacuum pump and the ventilation is well.

2.Allow the maintenance and other operations of the refrigeration circuit should be carried out according to the general procedure, but the following best operations that the flammability is already taken into consideration are the key. You should follow the following procedures:

•Remove the refrigerant.

•Decontaminate the pipeline by inert gases.

•Evacuation.

14 / 88 EN |

Mobile room air conditioner / Installation Manual |

1Safety precautions

•Decontaminate the pipeline by inert gases again.

•Cut or weld the pipeline.

3.The refrigerant should be returned to the appropriate storage tank. The system should be blown with oxygen free nitrogen to ensure safety. This process may need to be repeated for several times. This operation shall not be carried out using compressed air or oxygen.

4.Through blowing process, the system is charged into the anaerobic nitrogen to reach the working pressure under the vacuum state, then the oxygen free nitrogen is emitted to the atmosphere, and in the end, vacuumize the system. Repeat this process until all refrigerants in the system is cleared. After the final charging of the anaerobic nitrogen, discharge the gas into the atmosphere pressure, and then the system can be welded. This operation is necessary for welding the pipeline.

Procedures of charging refrigerants

As a supplement to the general procedure, the following requirements need to be added:

-Make sure that there is no contamination among different refrigerants when using a refrigerant charging device. The pipeline for charging refrigerants should be as short as possible to reduce the residual of refrigerants in it.

-Storage tanks should remain vertically up.

-Make sure the grounding solutions are already taken before the refrigeration system is charged with refrigerants.

Mobile room air conditioner / Installation Manual |

15 / 88 EN |

1Safety precautions

-After finishing the charging (or when it is not yet finished), label the mark on the system.

-Be careful not to overcharge refrigerants.

Scrap and recovery Scrap:

Before this procedure, the technical personnel shall be thoroughly familiar with the equipment and all its features, and make a recommended practice for refrigerant safe recovery. For recycling the refrigerant, shall analyze the refrigerant and oil samples before operation. Ensure the required power before the test.

1.Be familiar with the equipment and operation.

2.Discornect power supply.

3.Before carrying out this process, you have to make sure:

•lf necessary. mechanical equipment operation should facilitate the operation of the refrigerant tank.

•All personal protective equipment is effective and can be used correctly.

•The whole recovery process should be carried out under the guidance of qualified personnel.

•The recovering of equipment and storage tank should comply with the relevant national standards.

4.If possible. the refrigerating system should be vacuumized.

5.If the vacuum state can’t be reached, you should extract the refrigerant in each part of the system from many places.

16 / 88 EN |

Mobile room air conditioner / Installation Manual |

1Safety precautions

6.Before the start of the recovery, you should ensure that the capacity of the storage tank is sufficient.

7.Start and operate the recovery equipment according to the manufacturer’s instructions.

8.Don’t fill the tank to its full capacity (the liquid injection volume does not exceed 80% of the tank volume).

9.Even the duration is short, it must not exceed the maximum working pressure of the tank.

10.After the completion of the tank filling and the end of the operation process, you should make sure that the tanks and equipment should be removed quickly and all closing valves in the equipment are closed.

11.The recovered refrigerants are not allowed to be injected into another system before being purified and tested.

Note: The identification should be made after the appliance is scrapped and refrigerants are evacuated. The

C identification should contain the date and endorsement. Make sure the identification on the appliance can reflect the flammable refrigerants contained in this appliance.

Recovery:

1.The clearance of refrigerants in the system is required when repairing or scrapping the appliance. It is recommended to completely remove the refrigerant.

2.Only a special refrigerant tank can be used when loading the refrigerant into the storage tank. Make sure the capacity of the

Mobile room air conditioner / Installation Manual |

17 / 88 EN |

1 Safety precautions

tank is appropriate to the refrigerant injection quantity in the entire system. All tanks intended to be used for the recovery of refrigerants should have a refrigerant identification (i.e.

refrigerant recovery tank). Storage tanks should be equipped with pressure relief valves and globe valves and they should be in a good condition. If possible, empty tanks should be evacuated and maintained at room temperature before use.

3.The recovery equipment should be kept in a good working condition and equipped with equipment operating instructions for easy access. The equipment should be suitable for the recovery of R290 refrigerants. Besides, there should be a qualified weighting apparatus which can be normally used. The hose should be linked with detachable connection joint of zero leakage rate and be kept in a good condition.

Before using the recovery equipment, check if it is in a good condition and if it gets perfect maintenance. Check if all electrical components are sealed to prevent the leakage of the refrigerant and the fire caused by it. If you have any question, please consult the manufacturer.

4.The recovered refrigerant shall be loaded in the appropriate storage tanks, attached with a transporting instruction, and returned to the refrigerant manufacturer. Don’t mix refrigerant in recovery equipment, especially a storage tank.

5.The space loading R290 refrigeration can’t be enclosed in the process of transportation. Take anti electrostatic measures if necessary in transportation. In the process of transport, loading

18 / 88 EN |

Mobile room air conditioner / Installation Manual |

1 Safety precautions

and unloading, necessary protective measures must be taken to protect the air conditioner to ensure that the air conditioner is not damaged.

6.When removing the compressor or clearing the compressor oil, make sure the compressor is pumped to an appropriate level to ensure that there is no residual R290 refrigerants in the

lubricating oil. The vacuum pumping should be carried out before the compressor is returned to the supplier. Ensure the safety when discharging oil from the system.

Warning

Failure to follow the below precaution could result in electrical shock, fire or personal injury.

•The plug must be plugged into an outlet that is properly installed and grounded.

•Do not use an extension cord or plug adaptor with this unit.

•Don’t apply the cold air to the body for a long time. It will deteriorate your physical conditions and cause health problems.

•Don’t block air inlet or air outlet, otherwise, the cooling/heating capacity will be weakened, even cause system stop operating.

•Close the windows and doors, otherwise, the cooling/heating capacity will be weakened.

•If the air filter is very dirty, the cooling/heating capacity will be weakened. Please clean the air filter regularly.

Mobile room air conditioner / Installation Manual |

19 / 88 EN |

1 Safety precautions

WEEE Warning

Meaning of crossed out wheeled dustbin: Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact you local government for information regarding the collection systems available. If electrical appliances are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food chain, damaging your health and well-being.When replacing old appliances with new ones, the retailer is legally obligated to take back your old appliance for disposals at least free of charge.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 / 88 EN |

|

Mobile room air conditioner / Installation Manual |

|||||||

2 Parts description

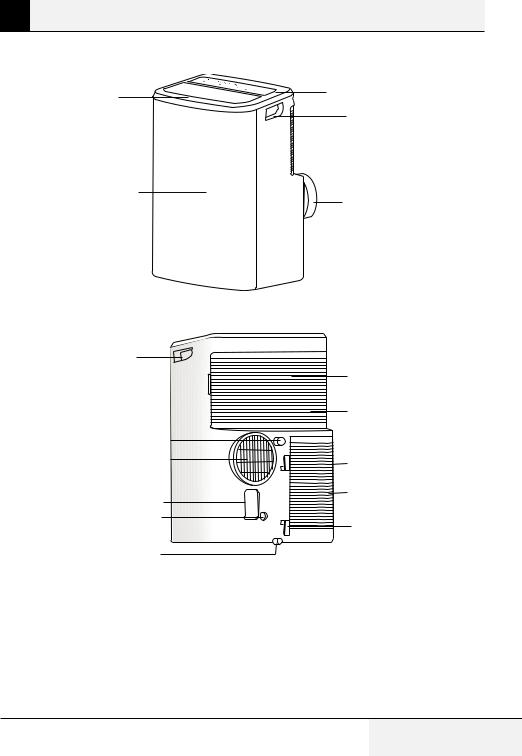

2.1 Front view

Air outlet |

Control panel |

|

Carrying handle (both sides)

Front panel |

Air outlet |

|

2.2 Rear view

11

|

1 |

|

2 |

10 |

|

9 |

3 |

8 |

4 |

|

|

7 |

5 |

|

|

6 |

|

1. Upper air filter (Behind the grille) |

7. Pump drain outlet |

2. Upper air intake |

8. Power plug socket |

3. Lower air filter (Behind the grille) |

9. Air outlet |

4. Lower air intake |

10. Drain outlet |

5. Power cord buckle |

11. Carrying handle (both sides) |

6. Bottom tray drain outlet |

|

Mobile room air conditioner / Installation Manual |

21 / 88 EN |

2 |

Parts description |

|

|

|

|

|

|

Note: |

C |

• The descriptions in this user manual are text and figures may have slightly |

|

difference to the promotion information and actual appliance. Please refer to the |

||

real appliance purchased, Thank you. |

||

|

|

• The woking temperature range of the air conditioner is 16-35°C (60-95°F) under |

cooling mode; 5-27°C (41-80°F) under heating mode.

22 / 88 EN |

Mobile room air conditioner / Installation Manual |

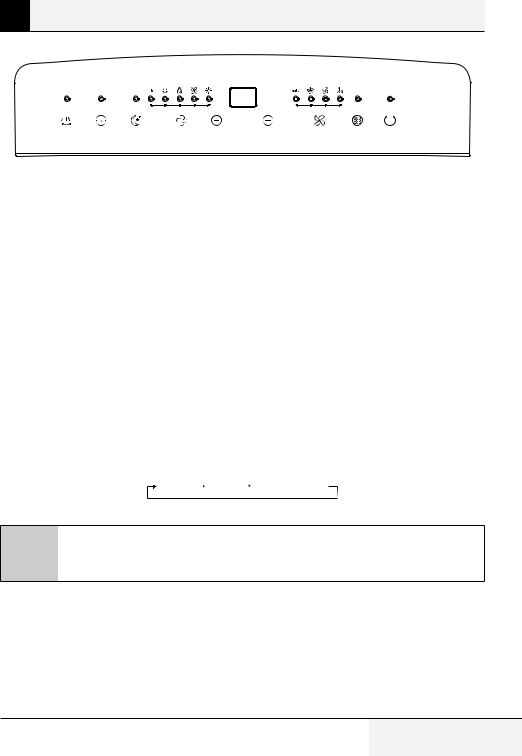

3 Control panel

SWING |

TIMER |

SLEEP |

MODE |

FAN |

FILTER |

|

|

|

|

SPEED |

RESET |

3.1 TEMP. indicator

In cooling or heating mode, when  or

or  button is pressed, the setting temperature is displayed and be adjusted.

button is pressed, the setting temperature is displayed and be adjusted.

1.In auto, cool and heat mode, TEMP.indicator display is setting temperature.

2.In dry and fan mode, TEMP.indicator display is room temperature.

3.2 Function buttons

1.

button — Press this button to make the unit run or stop.

button — Press this button to make the unit run or stop.

2. button

button

a.The running time of the unit has reached 250 hours, the filter reset indicator light will illuminates, and it means the air filter should be cleaned.

After cleaning, you can press the “ “ button, the filter reset indicator light will turns off and the running time will be cleared.

“ button, the filter reset indicator light will turns off and the running time will be cleared.

b.If you do not press the “ “ button when the filter reset indicator light illuminates, the indicator light will always illuminates except the unit is power off.

“ button when the filter reset indicator light illuminates, the indicator light will always illuminates except the unit is power off.

3. button — Press this button, you can select the fan speed as follows:

button — Press this button, you can select the fan speed as follows:

auto |

|

hi |

|

med |

|

low |

|

|

|

The fan speed indicator light illuminates under the different fan speed.

C Note: In fan mode,do not have auto fan speed.

4. or

or  button

button

a.Each time the  or

or  button is pressed, the setting temperature will increase or decrease by 1°C (1°F). The setting temperature ranges from 16°C (60°F)-32°C(90°F).

button is pressed, the setting temperature will increase or decrease by 1°C (1°F). The setting temperature ranges from 16°C (60°F)-32°C(90°F).

b.By pressing both the  and

and  button at the same time (≥3s), the display will toggle between Celsius and Fahrenheit.

button at the same time (≥3s), the display will toggle between Celsius and Fahrenheit.

Mobile room air conditioner / Installation Manual |

23 / 88 EN |

3Control panel

5. button — Press this button, you can select the running mode as follows:

button — Press this button, you can select the running mode as follows:

auto |

|

cool |

|

dry |

|

fan |

|

heat |

The mode indicator light illuminates under the different mode.

C Note: Heat mode is not available for cool only units.

6. button — Press this button to enter sleep mode, which the unit will exit after 8 hours of continuous operation and restore to the previous status.

button — Press this button to enter sleep mode, which the unit will exit after 8 hours of continuous operation and restore to the previous status.

C Note: The Sleep function can not be activated in fan and dry mode.

7. button

button

a.Press the “ “ button, the timer indicator light illuminates.

“ button, the timer indicator light illuminates.

b.Press  or

or  button to select the desired time.

button to select the desired time.

c.After setting time 5 seconds without other operation, the timing function will be initiated automatically. If you press the TIMER button, there are no operation within 5 seconds or setting time is 0, the timing function will be cancelled automatically.

d.When the timing function is initiated, the unit displays the remaining time by press the “TIMER” button once and cancel the timing function by press it again.

Note:

C With the unit on, press this button to set off timer.

With the unit off, press this button to set on timer.

8.

button— Press this button, the swing indicator light will illuminate.

button— Press this button, the swing indicator light will illuminate.

24 / 88 EN |

Mobile room air conditioner / Installation Manual |

4 |

Operation |

||

|

|

|

|

|

|

Warning: |

|

A |

Failure to follow the below precaution could result in electrical shock, fire , explosion or |

||

personal injury. |

|||

1. |

The plug must be plugged into an individual socket that is properly installed and |

||

|

|

|

grounded. |

|

|

2. |

Do not use an extension cord or plug adaptor with this unit. |

|

|

|

|

Before starting the unit

1.Select a suitable location, make sure the unit is near to an electrical outlet.

2.Install the flexible exhaust hose and the adjustable window slider kit.

3.Plug the unit into a right outlet.

Heating operation mode (Cool only unit has no heating function)

1.Press the MODE button in a sequence until the heat indicator is lighted.

2.Press the “ ”and “

”and “ ” button to setting your desired setting temperature.

” button to setting your desired setting temperature.

3.Press FAN button to select the fan speed.

Cooling operation mode

1.Press the MODE button in a sequence until the cool indicator is lighted.

2.Press the “ ”and “

”and “ ” button to set your desired setting temperature.

” button to set your desired setting temperature.

3.Press FAN button to select the fan speed.

Drying operation mode

1.Press the MODE button in a sequence until the dry indicator is lighted.

2.The fan will run at a fixed speed at this operation mode.

3.Close windows and doors for the best dehumidifying effect.

C Note: The setting temperature and fan speed can not be adjusted.The setting temperature is 25°C (77°F) and the fan speed is low.

Fan operation mode

1.Press MODE button in a sequence until the fan indicator is lighted.

2.Press the FAN button to select the fan speed.

C Note: The setting temperature can not be adjusted.

Mobile room air conditioner / Installation Manual |

25 / 88 EN |

4 Operation

Auto-restart function:

If power to the unit is interrupted, the unit will restart itself in its last used mode/settings once power is restored. The compressor will restart after 4 minutes.

1.Set: Press the SLEEP button 10 times within 5 seconds, buzzer sounds 4 times.

2.Cancel: Press the SLEEP button 10 times within 5 seconds, buzzer sounds 2 times.

26 / 88 EN |

Mobile room air conditioner / Installation Manual |

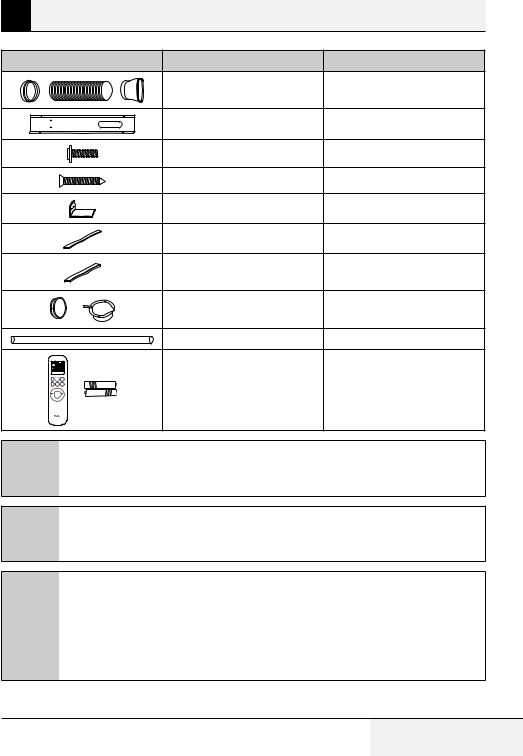

5 |

Accessories |

|

|

|

Parts |

Parts name |

Quantity |

|

|

Adaptor A, exhaust duct , |

1 set |

|

|

Adaptor B (flat mouth) |

|

|

|

|

|

|

|

Window Slider Kit (#) |

1 pc |

|

|

Type A Screws |

2 pc |

|

|

Type B Screws |

6 pc |

|

|

Security bracket |

1 pc |

|

|

Type A foam seal (adhesive) |

2 pc |

|

|

Type B foam seal (non- |

1 pc |

|

|

adhesive) |

|

|

|

|

|

|

|

Adaptor B (round mouth) (# ), |

1 set |

|

|

Wall exhaust Adaptor (# ) |

|

|

|

|

|

|

|

Drain hose |

1 pc |

|

|

Remote controller and Battery |

1 pc |

C Note: Some models without optional parts (#).

C Note: All the illustrations in this manual are for explanation purpose only. Your air conditioner may be slightly different. the actual shape shall prevail.

Mobile air-conditioner air louver notes:

1. |

With automatic wind sweep function models, the air louver can not be less than |

C 2. |

automatically wind smallest outlet angle when use it. |

No automatic wind sweep function models, air louver minimum opening angle: from |

|

|

air louver closed state breaking up 5 grid. air louver can not be less than the minimum |

open angle when use it.

Mobile room air conditioner / Installation Manual |

27 / 88 EN |

Loading...

Loading...