Beko BP109C, BP113H, BP109AC, BP112H, BP112C User manual

...

Portable

Air-conditioner

User Manual

EN FR IT NL

BP109C BP112C BP112H

BP113H BP109AC BP109AH

Please read this user manual rst!

Dear Customer,

Thank you for preferring a Beko product. We hope that you get the best results

from your product which has been manufactured with high quality and state-of-

the-art technology. Therefore, please read this entire user manual and all other

accompanying documents carefully before using the product and keep it as a

reference for future use. If you handover the product to someone else, give the user

manual as well. Follow all warnings and information in the user manual.

Meanings of the symbols

Following symbols are used in the various section of this manual:

This product has been produced in environmentally friendly, modern facilities

Complies with the WEEE Regulation. Does not contain PCB.

C

Important information or

useful hints about usage.

A

Warning for hazardous

situations with regard to life

and property.

Warning to actions that must

never perform.

B

Warning for electric shock.

Warning for hot surfaces.

Do not cover it.

This symbol shows that the

operation manual should be

read carefully.

This symbol shows that a

service personnel should be

handling this equipment with

reference to the installation

manual.

This symbol

shows that this

appliance used

a flammable

refrigerant. If

the refrigerant

is leaked and

exposed to an

external ignition

source, there is

a risk of fire.

Portable Air-conditioner / User Manual

3 / 220 EN

Contents

1 Safety awareness 5

2 Name of parts 29

3 Accessores 30

4 Appearance and functon of control panel 31

4.1 Cooling only model (non-reversible). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Cooling & Heat pump model (reversible) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5 Appearance and functon of remote control 33

6 Operaton ntroducton 35

6.1 Before using . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2 Cooling operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.3 Dehumidifying operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 Fan operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5 Heating operation (this function is not available for acold-single unit) . . . . . . . . . . . . . . . . . . . . . 36

6.6 Timer operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7 Auto swing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8 Sleep mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.9 Water drainage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.10 Wireless function

10 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.11 Zone follow function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 Installaton explanatons 39

7.1 Installation explanations: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7.2 Introduction to exhaust hose installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3 Universal caulking kit accessory for mobile air conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.4 Use the Hepa 13 lter (only for BP113H model). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.5 Water full alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4 / 220 EN

Portable Air-conditioner / User Manual

Contents

8 Mantenance explanatons 47

8.1 Clean the air lter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2 Clean the air-conditioner surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9 Mantenance 49

10 Troubleshootng 50

11 Socable remark 51

12 Installaton nstructons 52

12.1 F-Gas instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

13 Specfcatons 53

Portable Air-conditioner / User Manual

5 / 220 EN

1 Safety awareness

Very mportant

Please do not install or use your portable air conditioner before you

have carefully read this manual. Please keep this instruction manual

for an eventual product warranty and for future reference.

Warnng

Do not use means to accelerate the defrosting process or to clean,

other than those recommended by the manufacturer.

The appliance shall be stored in a room without continuously

operating ignition sources (for example: open flames, an operating

gas appliance or an operating electric heater).

Do not pierce or burn.

Be aware the refrigerants may not contain an odour.

Appliance shall be installed, operated and stored in a room with a

floor area larger than X m

2

.

Model X (m

2

)

7000Btu/h 4

9000Btu/h, 10000Btu/h 12

12000Btu/h, 13000Btu/h 15

6 / 220 EN

Portable Air-conditioner / User Manual

Warnng (for R290)

Specific information regarding appliances with R290 refrigerant gas.

•

Thoroughly read all of the warnings.

•

When defrosting and cleaning the appliance, do not use any tools

other than those recommended by the manufacturing company.

•

The appliance must be placed in an area without any continuously

sources of ignition (for example: open flames, gas or electrical

appliances in operation).

•

Do not puncture and do not burn.

•

This appliance contains Y g (see rating label back of unit) of R290

refrigerant gas.

•

R290 is a refrigerant gas that complies with the European directives

on the environment. Do not puncture any part of the refrigerant

circuit.

•

If the appliance is installed, operated or stored in an unventilated

area, the room must be designed to prevent to the accumulation of

refrigerant leaks resulting in a risk of fire or explosion due to ignition

of the refrigerant caused by electric heaters, stoves, or other

sources of ignition.

•

The appliance must be stored in such a way as to prevent

mechanical failure.

•

Individuals who operate or work on the refrigerant circuit must have

the appropriate certification issued by an accredited organization

that ensures competence in handling refrigerants according to a

specific evaluation recognized by associations in the industry.

1 Safety awareness

Portable Air-conditioner / User Manual

7 / 220 EN

•

Repairs must be performed based on the recommendation from the

manufacturing company. Maintenance and repairs that require the

assistance of other qualified personnel must be performed under

the supervision of an individual specified in the use of flammable

refrigerants.

General safety nstructon

1. The appliance is for indoor use only.

2. Do not use the unit on a socket under repairs or not installed

properly.

3. Do not use the unit, follow these precautions:

A: Near to source of fire.

B: An area where oil is likely to splash.

C: An area exposed to direct sunlight.

D: An area where water is likely to splash.

E: Near a bath, a laundry, a shower or a swimming pool.

4. Never insert your fingers, rods into the air outlet. Take special care

to warn children of these dangers.

5. Keep the unit upward while transport and storage, for the

compressor locates properly.

6. Before cleaning the air-conditioner, always turn off or disconnect

the power supply.

7. When moving the air-conditioner, always turn off and disconnect

the power supply, and move it slowly.

1 Safety awareness

8 / 220 EN

Portable Air-conditioner / User Manual

1 Safety awareness

8. To avoid the possibility of fire disaster, the air-conditioner shall

not be covered.

9. All the air-conditioner sockets must comply with the local

electric safety requirements. If necessary, please check it for the

requirements.

10. Children should be supervised to ensure that they do not play with

the appliance.

11. If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent or similarly qualified persons in

order to avoid a hazard.

12. This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved. Children shall not

play with the appliance. Cleaning and user maintenance shall not

be made by children without supervision.

13. The appliance shall be installed in accordance with national wiring

regulations.

14. Details of type and rating of fuses: T, 250V AC, 2A or higher.

15. Contact authorized service technician for repair or maintenance of

this unit.

16. Do not pull, deform, or modify the power supply cord, or immerse

it in water. Pulling or misuse of the power supply cord can result in

damage to the unit and cause electrical shock.

17. Compliance with national gas regulations shall be observed.

Portable Air-conditioner / User Manual

9 / 220 EN

1 Safety awareness

18. Keep ventilation openings clear of obstruction.

19. Any person who is involved with working on or breaking into

arefrigerant circuit should hold a current valid certificate from

anindustry-accredited assessment authority, which authorizes

their competence to handle refrigerants safely in accordance with

an industry recognized assessment specification.

20. Servicing shall only be performed as recommended by the

equipment manufacturer. Maintenance and repair requiring the

assistance of other skilled personnel shall be carried out under

the supervision of the person competent in the use of flammable

refrigerants.

21. Do not operate or stop the unit by inserting or pulling out Die power

plug, it may cause electric shock or fire due to heat generation.

22. Unplug the unit if strange sounds, smell, or smoke comes from it.

23. This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by

aperson responsible for their safety.

24. If the supply cord is damaged, it must be replaced by the

manufacturer or its agent or similarly qualified person in order to

avoid hazard.

25. The appliance shall state the insulation of a residual current device

(RCD) having rated residual operating current not exceeding

30mA.

10 / 220 EN

Portable Air-conditioner / User Manual

1 Safety awareness

26. This appliance is intended to be used in household and similar

applications such as

–

Staff kitchen areas in shops, offices and other working

environments;

–

farm houses;

–

by clients in hotels, motels and other residential type

environments;

–

bed and breakfast type environments;

The appliance shall state the insulation of a residual current

device (RCD) having rated residual operating current not

exceeding 30mA.

Portable Air-conditioner / User Manual

11 / 220 EN

1 Safety awareness

C

Note:

•

If any parts damage, please contact the dealer or a

designated repair shop;

•

In case of any damage, please turn off the air switch,

disconnect the power supply, and contact the dealer or

adesignated repair shop;

•

In any case, the power cord shall be firmly grounded.

•

To avoid the possibility of danger, if power cord is

damaged, please turn off the air switch and disconnect

the power supply. It must be replaced from the dealer or

adesignated repair shop.

12 / 220 EN

Portable Air-conditioner / User Manual

Warnngs (for usng R290 refrgerant only)

1. General nstructons

1.1 Checks to the area

Prior to beginning work on systems containing flammable

refrigerants, safety checks are necessary to ensure that the risk

of ignition is minimized. For repair to the refrigerating system, the

following precautions shall be complied with prior to con-ducting

work on the system.

1.2 Work procedure

Work shall be undertaken under a controlled procedure so as to

minimize the risk of a flammable gas or vapour being present while

the work is being performed.

1.3 General work area

All maintenance staff and others working in the local area shall be

instructed on the nature of work being carried out. Work in confined

spaces shall be avoided. The area around the workspace shall be

sectioned off. Ensure that the conditions within the area have been

made safe by control of flammable material.

1.4 Checking for presence of refrigerant

The area shall be checked with an appropriate refrigerant

detector prior to and during work, to ensure the technician is

aware of potentially flammable atmospheres. Ensure that the leak

detection equipment being used is suitable for use with flammable

refrigerants, i.e. nonsparking, adequately sealed or intrinsically safe.

1 Safety awareness

Portable Air-conditioner / User Manual

13 / 220 EN

1.5 Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration equipment or

any associated parts, propriate fire extinguishing equipment shall

be available to hand. Have a dry powder or CO

2

fire extinguisher

adjacent to the charging area.

1.6 No ignition sources

No person carrying out work in relation to a refrigeration system

which involves exposing any pipe work that contains or has

contained flammable refrigerant shall use any sources of ignition

in such a manner that it may lead to the risk of fire or explosion.

Allpossible ignition sources, including cigarette smoking, should

be kept sufficiently far away from the site of installation, repairing,

removing and disposal, during which flammable refrigerant can

possibly be released to the surrounding space. Prior to work taking

place, the area around the equipment is to be surveyed to make sure

that there are no flammable hazards or ignition risks. “No Smoking”

signs shall be displayed.

1.7 Ventilated area

Ensure that the area is in the open or that it is adequately ventilated

before breaking into the system or conducting any hot work.

Adegree of ventilation shall continue during the period that the

work is carried out. The ventilation should safely disperse any

released refrigerant and preferably expel it externally into the

atmosphere.

1 Safety awareness

14 / 220 EN

Portable Air-conditioner / User Manual

1.8 Checks to the refrigeration equipment

Where electrical components are being changed, they shall be fit

for the purpose and to the correct specification. At all times the

manufacturer’s maintenance and service guidelines shall be followed.

If in doubt consult the manufacturer’s technical department for

assistance.The following checks shall be applied to installations using

flammable refrigerants: the charge size is in accordance with the

room size within which the refrigerant containing parts are installed;

the ventilation machinery and outlets are operating adequately and

are not obstructed; if an indirect refrigerating circuit is being used,

the secondary circuit shall be checked for the presence of refrigerant;

marking to the equipment continues to be visible and legible. Markings

and signs that are illegible shall be corrected; refrigeration pipe or

components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing

components, unless the components are constructed of materials

which are inherently resistant to being corroded or are suitably

protected against being so corroded.

1.9 Checks to electrical devices

Repair and maintenance to electrical components shall include

initial safety checks and component inspection procedures. If afault

exists that could compromise safety, then no electrical supply

shall be connected to the circuit until it is satisfactorily dealt with.

If the fault cannot be corrected immediately but it is necessary to

continue operation, an adequate temporary solution shall be used.

This shall be reported to the owner of the equipment so all parties

are advised.

1 Safety awareness

Portable Air-conditioner / User Manual

15 / 220 EN

Initial safety checks shall include: that capacitors are discharged: this

shall be done in a safe manner to avoid possibility of sparking; that

there no live electrical components and wiring are exposed while

charging, recovering or purging the system; that there is continuity

of earth bonding.

2. Repars to sealed components

2.1 During repairs to sealed components, all electrical supplies shall

be disconnected from the equipment being worked upon prior

to any removal of sealed covers, etc. If it is absolutely necessary

to have an electrical supply to equipment during servicing, then

a permanently operating form of leak detection shall be located

at the most critical point to warn of a potentially hazardous

situation.

2.2 Particular attention shall be paid to the following to ensure that

by working on electrical components, the casing is not altered

in such a way that the level of protection is affected. This shall

include damage to cables, excessive number of connections,

terminals not made to original specification, damage to seals,

incorrect fitting of glands, etc. Ensure that apparatus is

mounted securely. Ensure that seals or sealing materials have

not degraded such that they no longer serve the purpose of

preventing the ingress of flammable atmospheres. Replacement

parts shall be in accordance with the manufacturer’s

specifications.

1 Safety awareness

16 / 220 EN

Portable Air-conditioner / User Manual

C

Note:

The use of silicon sealant may inhibit the

effectiveness of some types of leak detection equipment.

Intrinsically safe components do not have to be isolated

prior to working on them.

3. Repar to ntrnscally safe components

Do not apply any permanent inductive or capacitance loads to the

circuit without ensuring that this will not exceed the permissible

voltage and current permitted for the equipment in use.

Intrinsically safe components are the only types that can be worked

on while live in the presence of a flammable atmosphere. The test

apparatus shall be at the correct rating. Replace components only

with parts specified by the manufacturer. Other parts may result in

the ignition of refrigerant in the atmosphere from a leak.

4. Cablng

Check that cabling will not be subject to wear, corrosion, excessive

pressure, vibration, sharp edges or any other adverse environmental

effects. The check shall also take into account the effects of aging

or continual vibration from sources such as compressors or fans.

5. Detecton of flammable refrgerants

Under no circumstances shall potential sources of ignition be used

in the searching for or detection of refrigerant leaks. A halide torch

(or any other detector using a naked flame) shall not be used.

1 Safety awareness

Portable Air-conditioner / User Manual

17 / 220 EN

6. Leak detecton methods

The following leak detection methods are deemed acceptable

for systems containing flammable refrigerants. Electronic leak

detectors shall be used to detect flammable refrigerants, but

the sensitivity may not be adequate, or may need recalibration.

(Detection equipment shall be calibrated in a refrigerant-free

area.) Ensure that the detector is not a potential source of ignition

and is suitable for the refrigerant used. Leak detection equipment

shall be set at a percentage of the LFL of the refrigerant and shall

be calibrated to the refrigerant employed and the appropriate

percentage of gas (25% maximum) is confirmed. Leak detection

fluids are suitable for use with most refrigerants but the use of

detergents containing chlorine shall be avoided as the chlorine may

react with the refrigerant and corrode the copper pipe-work. If a

leak is suspected, all naked flames shall be removed/extinguished.

If a leakage of refrigerant is found which requires brazing, all of

the refrigerant shall be recovered from the system, or isolated (by

means of shut off valves) in a part of the system remote from the

leak. Oxygen free nitrogen (OFN) shall then be purged through the

system both before and during the brazing process.

1 Safety awareness

18 / 220 EN

Portable Air-conditioner / User Manual

7. Removal and evacuaton

When breaking into the refrigerant circuit to make repairs – or for any

other purpose – con-ventional procedures shall be used.However,

it is important that best practice is followed since flammability is a

consideration. The following procedure shall be adhered to: remove

refrigerant; purge the circuit with inert gas; evacuate; purge again

with inert gas; open the circuit by cutting or brazing.The refrigerant

charge shall be recovered into the correct recovery cylinders. The

system shall be “flushed” with OFN to render the unit safe. This

process may need to be repeated several times.Compressed air or

oxygen shall not be used for this task. Flushing shall be achieved by

breaking the vacuum in the system with OFN and continuing to fill

until the working pressure is achieved, then venting to atmosphere,

and finally pulling down to a vacuum. This process shall be repeated

until no refrigerant is within the system. When the final OFN charge

is used, the system shall be vented down to atmospheric pressure to

enable work to take place.This operation is absolutely vital if brazing

operations on the pipework are to take place.

Ensure that the outlet for the vacuum pump is not close to any

ignition sources and there is ventilation available.

8. Chargng procedures

In addition to conventional charging procedures, the following

requirements shall be followed.

-

Ensure that contamination of different refrigerants does not occur

when using charging equipment. Hoses or lines shall be as short as

possible to minimise the amount of refrigerant contained in them.

1 Safety awareness

Portable Air-conditioner / User Manual

19 / 220 EN

-

Cylinders shall be kept upright.

-

Ensure that the refrigeration system is earthed prior to charging

the system with refrigerant.

-

Label the system when charging is complete (if not already).

-

Extreme care shall be taken not to overfill the refrigeration

system.

Prior to recharging the system it shall be pressure tested with OFN.

The system shall be leak tested on completion of charging but prior

to commissioning. A follow up leak test shall be carried out prior to

leaving the site.

9. Decommssonng

Before carrying out this procedure, it is essential that the technician

is completely familiar with the equipment and all its detail. It is

recommended good practice that all refrigerants are recovered

safely. Prior to the task being carried out, an oil and refrigerant

sample shall be taken in case analysis is required prior to re-use of

reclaimed refrigerant. It is essential that electrical power is available

before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically.

c) Before attempting the procedure ensure that: mechanical

handling equipment is available, if required, for handling

refrigerant cylinders; all personal protective equipment is

available and being used correctly; the recovery process

is supervised at all times by a competent person; recovery

equipment and cylinders conform to the appropriate standards.

1 Safety awareness

20 / 220 EN

Portable Air-conditioner / User Manual

d) Pump down refrigerant system,if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant

can be removed from various parts of the system.

f) Make sure that cylinder is situated on the scales before

recovery takes place.

g) Start the recovery machine and operate in accordance with

manufacturer’s instructions.

h) Do not overfill cylinders. (No more than 80 % volume liquid

charge).

i) Do not exceed the maximum working pressure of the

cylinder,even temporarily.

j) When the cylinders have been filled correctly and the process

completed, make sure that the cylinders and the equipment

are removed from site promptly and all isolation valves on the

equipment are closed off.

k) Recovered refrigerant shall not be charged into another

refrigeration system unless it has been cleaned and checked.

10. Labellng

Equipment shall be labelled stating that it has been de-

commissioned and emptied of refrigerant.The label shall be dated

and signed.

Ensure that there are labels on the equipment stating the

equipment contains flammable refrigerant.

1 Safety awareness

Portable Air-conditioner / User Manual

21 / 220 EN

11. Recovery

When removing refrigerant from a system, either for servicing

or decommissioning, it is recommended good practice that all

refrigerants are removed safely. When transferring refrigerant

into cylinders, ensure that only appropriate refrigerant recovery

cylinders are employed. Ensure that the correct number of cylinders

for holding the total system charge are available. All cylinders to be

used are designated for the recovered refrigerant and labelled for

that refrigerant (i.e. special cylinders for the recovery of refrigerant).

Cylinders shall be complete with pressure relief valve and associated

shut-off valves in good working order. Empty recovery cylinders are

evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of

instructions concerning the equipment that is at hand and shall be

suitable for the recovery of flammable refrigerants.In addition, a set

of calibrated weighing scales shall be available and in good working

order. Hoses shall be complete with leak-free disconnect couplings

and in good condition. Before using the recovery machine, check

that it is in satisfactory working order, has been properly maintained

and that any associated electrical components are sealed to prevent

ignition in the event of a refrigerant release. Consult manufacturer

if in doubt.

The recovered refrigerant shall be returned to the refrigerant

supplier in the correct recovery cylinder, and the relevant waste

transfer note arranged. Do not mix refrigerants in recovery units

and especially not in cylinders.

1 Safety awareness

22 / 220 EN

Portable Air-conditioner / User Manual

If compressors or compressor oils are to be removed, ensure that

they have been evacuated to an acceptable level to make certain

that flammable refrigerant does not remain within the lubricant.

The evacuation process shall be carried out prior to returning the

compressor to the suppliers. Only electric heating to the compressor

body shall be employed to accelerate this process.When oil is

drained from a system, it shall be carried out safely.

C

Note about fluornated gasses:

-

Fluorinated greenhouse gases are contained in

hermetically sealed equipment. For specific information

on the type, the amount and the CO

2

equivalent in tonnes

of the fluorinated greenhouse gas(on some models),

please refer to the relevant label on the unit itself.

-

Installation, service, maintenance and repair of this unit

must be performed by a certified technician.

-

Product uninstallation and recycling must be performed

by a certified technician.

Competence of servce personnel

General

Special training additional to usual refrigerating equipment repair

procedures is required when equipment with flammable refrigerants

is affected.

1 Safety awareness

Portable Air-conditioner / User Manual

23 / 220 EN

In many countries, this training is carried out by national training

organizations that are accredited to teach the relevant national

competency standards that may be set in legislation.

The achieved competence should be documented by a certificate.

Tranng

The training should include the substance of the following:

Information about the explosion potential of flammable refrigerants to

show that flammables may be dangerous when handled without care.

Information about potential ignition sources, especially those that

are not obvious, such as lighters, light switches, vacuum cleaners,

electric heaters.

Information about the different safety concepts:

Unventilated – (see Clause GG.2) Safety of the appliance does not

depend on ventilation of the housing. Switching off the appliance

or opening of the housing has no significant effect on the safety.

Nevertheless, it is possible that leaking refrigerant may accumulate

inside the enclosure and flammable atmosphere will be released

when the enclosure is opened.

Ventilated enclosure – (see Clause GG.4) Safety of the appliance

depends on ventilation of the housing. Switching off the appliance

or opening of the enclosure has a significant effect on the safety.

Care should be taken to ensure a sufficient ventilation before.

1 Safety awareness

24 / 220 EN

Portable Air-conditioner / User Manual

Ventilated room – (see Clause GG.5) Safety of the appliance depends

on the ventilation of the room. Switching off the appliance or opening

of the housing has no significant effect on the safety. The ventilation

of the room shall not be switched off during repair procedures.

Information about the concept of sealed components and sealed

enclosures according to IEC 60079-15:2010.

Information about the correct working procedures:

a) Commissioning

•

Ensure that the floor area is sufficient for the refrigerant charge

or that the ventilation duct is assembled in a correct manner.

•

Connect the pipes and carry out a leak test before charging with

refrigerant.

•

Check safety equipment before putting into service.

b) Maintenance

•

Portable equipment shall be repaired outside or in a workshop

specially equipped for servicing units with flammable refrigerants.

•

Ensure sufficient ventilation at the repair place.

•

Be aware that malfunction of the equipment may be caused by

refrigerant loss and a refrigerant leak is possible.

•

Discharge capacitors in a way that won’t cause any spark. The

standard procedure to short circuit the capacitor terminals usually

creates sparks.

•

Reassemble sealed enclosures accurately. If seals are worn,

replace them.

•

Check safety equipment before putting into service.

1 Safety awareness

Portable Air-conditioner / User Manual

25 / 220 EN

c) Repair

•

Portable equipment shall be repaired outside or in a workshop

specially equipped for servicing units with flammable refrigerants.

•

Ensure sufficient ventilation at the repair place.

•

Be aware that malfunction of the equipment may be caused by

refrigerant loss and a refrigerant leak is possible.

•

Discharge capacitors in a way that won’t cause any spark.

•

When brazing is required, the following procedures shall be

carried out in the right order:

-

Remove the refrigerant. If the recovery is not required by national

regulations, drain the refrigerant to the outside. Take care that

the drained refrigerant will not cause any danger. In doubt, one

person should guard the outlet. Take special care that drained

refrigerant will not float back into the building.

-

Evacuate the refrigerant circuit.

-

Purge the refrigerant circuit with nitrogen for 5 min.

-

Evacuate again.

-

Remove parts to be replaced by cutting, not by flame.

-

Purge the braze point with nitrogen during the brazing procedure.

-

Carry out a leak test before charging with refrigerant.

•

Reassemble sealed enclosures accurately. If seals are worn,

replace them.

•

Check safety equipment before putting into service.

1 Safety awareness

26 / 220 EN

Portable Air-conditioner / User Manual

d) Decommissioning

•

If the safety is affected when the equipment is putted out

of service, the refrigerant charge shall be removed before

decommissioning.

•

Ensure sufficient ventilation at the equipment location.

•

Be aware that malfunction of the equipment may be caused by

refrigerant loss and a refrigerant leak is possible.

•

Discharge capacitors in a way that won’t cause any spark.

•

Remove the refrigerant. If the recovery is not required by national

regulations, drain the refrigerant to the outside. Take care that

the drained refrigerant will not cause any danger. In doubt, one

person should guard the outlet. Take special care that drained

refrigerant will not float back into the building.

•

Evacuate the refrigerant circuit.

•

Purge the refrigerant circuit with nitrogen for 5 min.

•

Evacuate again.

•

Fill with nitrogen up to atmospheric pressure.

•

Put a label on the equipment that the refrigerant is removed.

e) Disposal

•

Ensure sufficient ventilation at the working place.

•

Remove the refrigerant. If the recovery is not required by national

regulations, drain the refrigerant to the outside. Take care that

the drained refrigerant will not cause any danger. In doubt, one

person should guard the outlet. Take special care that drained

refrigerant will not float back into the building.

1 Safety awareness

Portable Air-conditioner / User Manual

27 / 220 EN

1 Safety awareness

•

Evacuate the refrigerant circuit.

•

Purge the refrigerant circuit with nitrogen for 5 min.

•

Evacuate again.

•

Cut out the compressor and drain the oil.

Transportaton, markng and storage for unts that employ

flammable refrgerants

Transport of equpment contanng flammable refrgerants

Attention is drawn to the fact that additional transportation

regulations may exist with respect to equipment containing

flammable gas. The maximum number of pieces of equipment or

the configuration of the equipment, permitted to be transported

together will be determined by the applicable transport regulations.

Markng of equpment usng sgns

Signs for similar appliances used in a work area generally are

addressed by local regulations and give the minimum requirements

for the provision of safety and/or health signs for a work location.

All required signs are to be maintained and employers should ensure

that employees receive suitable and sufficient instruction and

training on the meaning of appropriate safety signs and the actions

that need to be taken in connection with these signs.

The effectiveness of signs should not be diminished by too many

signs being placed together.

Any pictograms used should be as simple as possible and contain

only essential details.

28 / 220 EN

Portable Air-conditioner / User Manual

Dsposal of equpment usng flammable refrgerants

See national regulations.

Storage of equpment/applances

The storage of equipment should be in accordance with the

manufacturer’s instructions.

Storage of packed (unsold) equipment

Storage package protection should be constructed such that

mechanical damage to the equipment inside the package will not

cause a leak of the refrigerant charge.

The maximum number of pieces of equipment permitted to be

stored together will be determined by local regulations.

1 Safety awareness

Portable Air-conditioner / User Manual

29 / 220 EN

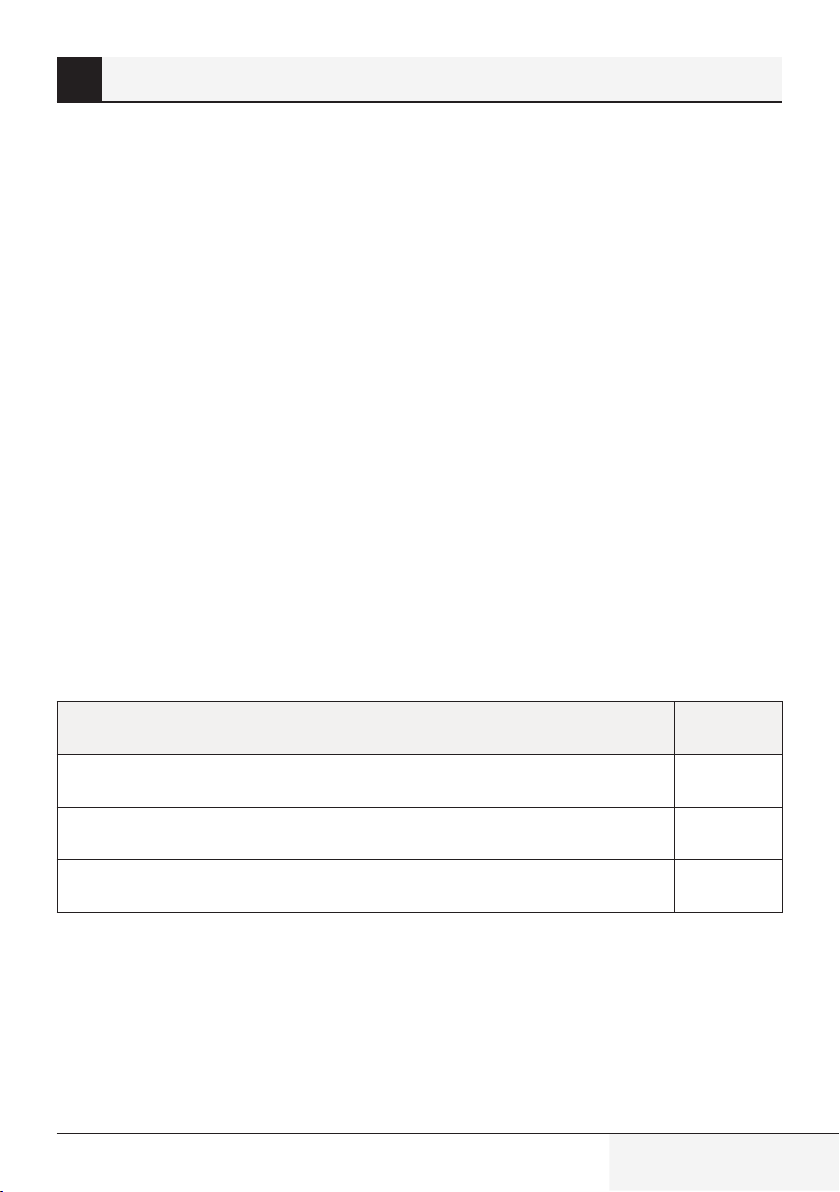

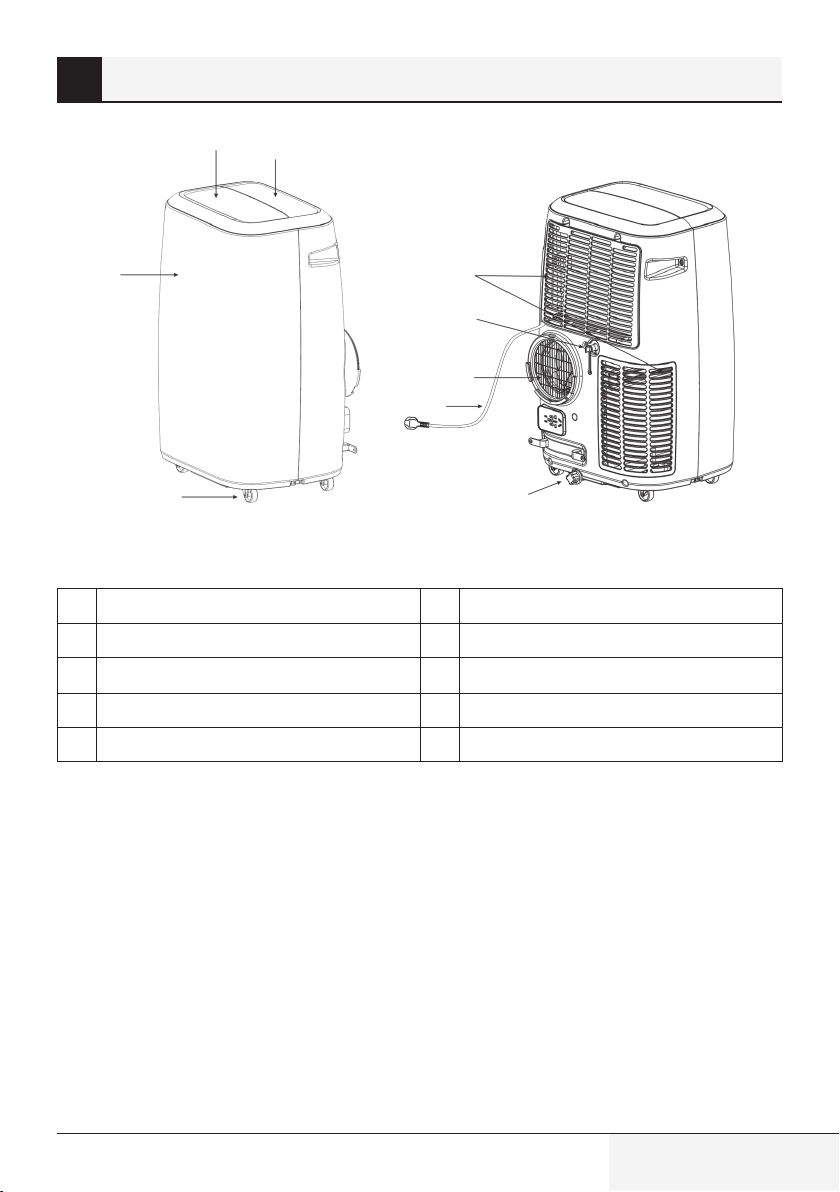

2 Name of parts

1

2

3 5

6

7

8

9

4

Fig. 1

1 Louver 5 Air inlet

2 Control panel 6 Drainage outlet

3 Front cover 7 Air outlet

4 Castor 8 Power cord

9 Drainage outlet

30 / 220 EN

Portable Air-conditioner / User Manual

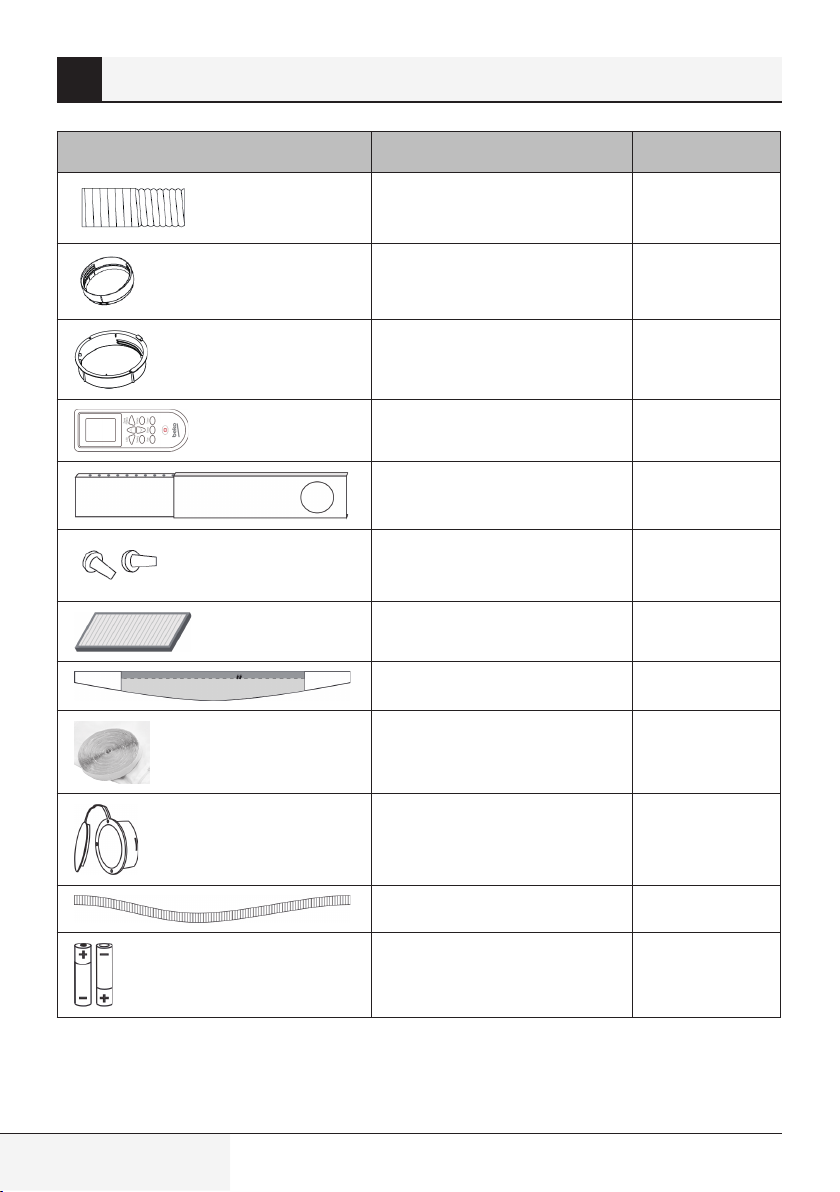

Part Descrpton Quantty

Exhaust hose 1

Window connector 1

Housing adaptor 1

Remote controller 1

Window kit 1

Dowel 1

Hepa 13 filter 1 (for BP113H only)

Fabric window kit 1 (optional)

Roll ribbon 1 (optional)

Air outlet 1

Water pipe 1

Batteries 2

After unpacking, please check whether the above-mentioned accessories are included, and check their

purposes in the installation introduction in this manual.

3 Accessores

Loading...

Loading...