Aprilia Quasar 125-180 2003 Owner's manual

1122 3

00/2003-09

www.serviceaprilia.com

QUASAR 125 - 180

workshopmanual

UK

8140724

QUASAR 125-180

FOREWORD

FOREWORD

0

0

GENERAL INFORMATION

1

PERIODIC MAINTENANCE

2

ENGINE

3

FUEL SYSTEM

4

ELECTRIC SYSTEM

CYCLE PARTS

5

6

Release 00/2003 - 06

- 1 - 00

0

FOREWORD

FOREWORD

CONTENTS

0.1 RELEASE 00/2003-09 UPDATE................................................................................................ 0-3-00

0.1.1 MANUAL UPDATES ....................................................................................................................................... 0-3-00

0

1

0.1.2 LIST OF MANUAL PAGES AND UPDATE NUMBERS ................................................................................. 0-3-00

0.2 FOREWORD.............................................................................................................................. 0-5-00

0.3 REFERENCE MANUALS........................................................................................................... 0-5-00

0.3.1 OWNER'S MANUALS..................................................................................................................................... 0-5-00

0.3.2 SPARE PARTS CATALOGUE........................................................................................................................ 0-5-00

0.4 ABBREVIATIONS/SYMBOLS/CONVENTIONS.......................................................................... 0-6-00

QUASAR 125-180

2

3

4

5

6

7

i

9

- 2 - 00

0

Release 00/2003 - 06

QUASAR 125-180

FOREWORD

0.1 RELEASE 00/2003-09 UPDATE

Issue date of original release (Release 00) and subsequent releases:

First edition (Release 00)...............................September 2003

0.1.1 MA NUAL UPDATES

Always keep manual updated to the latest release you have received.

Add the latest release pages to the manual and destroy all superseded pages (even if they belong to the release before

last).

Failure to keep the manual up-to-date or to eliminate su perseded p ages will make the man ual more d ifficult to consult

and creates a risk of improper servicing.

0.1.2 LIST OF MANUAL PAGES AND UPDATE NUMBERS

0-1 -00 ........................09

0-2 -00 ........................09

0-3 -00 ........................09

0-4 -00 ........................09

0-5 -00 ........................09

0-6 -00 ........................09

0-7 -00 ........................09

0-8 -00 ........................09

0-8 -00 ........................09

0-9 -00 ........................09

1-10 -00 ......................09

1-2 -00 ........................09

1-3 -00 ........................09

1-4 -00 ........................09

1-5 -00 ........................09

1-6 -00 ........................09

pag.# Release

2-1 -00 ........................09

2-2 -00 ........................09

2-3 -00 ........................09

2-4 -00 ........................09

2-5 -00 ........................09

2-6 -00 ........................09

2-7 -00 ........................09

2-8 -00 ........................09

2-9 -00 ........................09

2-10 -00 ...................... 09

2-11 -00 ...................... 09

2-12 -00 ...................... 09

2-13 -00 ...................... 09

2-14 -00 ...................... 09

2-15 -00 ...................... 09

2-16 -00 ...................... 09

pag.# Release

2-29 -00 ......................09

2-30 -00 ......................09

3-1 -00 ........................09

3-2 -00 ........................09

3-3 -00 ........................09

3-4 -00 ........................09

3-5 -00 ........................09

3-6 -00 ........................09

3-7 -00 ........................09

3-8 -00 ........................09

3-9 -00 ........................09

3-10 -00 ......................09

3-11 -00 ......................09

3-12 -00 ......................09

3-13 -00 ......................09

3-14 -00 ......................09

pag.# Releasepag.# Release

3-27 -00 ......................09

3-28 -00 ......................09

3-29 -00 ......................09

3-30 -00 ......................09

3-31 -00 ......................09

3-32 -00 ......................09

3-33 -00 ......................09

3-34 -00 ......................09

3-35 -00 ......................09

3-36 -00 ......................09

3-37 -00 ......................09

3-38 -00 ......................09

3-39 -00 ......................09

3-40 -00 ......................09

3-41 -00 ......................09

3-42 -00 ......................09

1-7 -00 ........................09

1-8 -00 ........................09

1-9 -00 ........................09

1-10 -00 ......................09

1-11 -00 ......................09

1-12 -00 ......................09

1-13 -00 ......................09

1-14 -00 ......................09

1-15 -00 ......................09

1-16 -00 ......................09

1-17 -00 ......................09

1-18 -00 ......................09

Release 00/2003 - 06

2-17 -00 ...................... 09

2-18 -00 ...................... 09

2-19 -00 ...................... 09

2-20 -00 ...................... 09

2-21 -00 ...................... 09

2-22 -00 ...................... 09

2-23 -00 ...................... 09

2-24 -00 ...................... 09

2-25 -00 ...................... 09

2-26 -00 ...................... 09

2-27 -00 ...................... 09

2-28 -00 ...................... 09

3-15 -00 ......................09

3-16 -00 ......................09

3-17 -00 ......................09

3-18 -00 ......................09

3-19 -00 ......................09

3-20 -00 ......................09

3-21 -00 ......................09

3-22 -00 ......................09

3-23 -00 ......................09

3-24 -00 ......................09

3-25 -00 ......................09

3-26 -00 ......................09

3-43 -00 ......................09

3-44 -00 ......................09

3-45 -00 ......................09

3-46 -00 ......................09

3-47 -00 ......................09

3-48 -00 ......................09

3-49 -00 ......................09

3-50 -00 ......................09

4-1 -00 ........................09

4-2 -00 ........................09

4-3 -00 ........................09

4-4 -00 ........................09

- 3 - 00

0

FOREWORD

QUASAR 125-180

pag.# Release

4-5 -00 ........................09

4-6 -00 ........................09

5-1 -00 ........................09

5-2 -00 ........................09

5-3 -00 ........................09

5-4 -00 ........................09

5-5 -00 ........................09

5-6 -00 ........................09

5-7 -00 ........................09

5-8 -00 ........................09

5-9 -00 ........................09

5-10 -00 ......................09

5-11 -00 ......................09

5-12 -00 ......................09

5-13 -00 ......................09

5-14 -00 ......................09

pag.# Release

6-14 -00 .......................09

6-15 -00 .......................09

6-16 -00 .......................09

6-17 -00 .......................09

6-18 -00 .......................09

6-19 -00 .......................09

6-20 -00 .......................09

6-21 -00 .......................09

6-22 -00 .......................09

6-23 -00 .......................09

6-24 -00 .......................09

6-25 -00 .......................09

6-26 -00 .......................09

6-27 -00 .......................09

6-28 -00 .......................09

6-29 -00 .......................09

5-15 -00 ......................09

5-16 -00 ......................09

5-17 -00 ......................09

5-18 -00 ......................09

5-19 -00 ......................09

5-20 -00 ......................09

5-21 -00 ......................09

5-22 -00 ......................09

5-23 -00 ......................09

5-24 -00 ......................09

5-25 -00 ......................09

5-26 -00 ......................09

5-27 -00 ......................09

5-28 -00 ......................09

6-1 -00 ........................09

6-2 -00 ........................09

6-3 -00 ........................09

6-4 -00 ........................09

6-30 -00 .......................09

7-1 -00 .........................09

7-2 -00 .........................09

7-3 -00 .........................09

7-4 -00 .........................09

7-5 -00 .........................09

7-6 -00 .........................09

7-7 -00 .........................09

7-8 -00 .........................09

7-9 -00 .........................09

7-10 -00 .......................09

6-5 -00 ........................09

6-6 -00 ........................09

6-7 -00 ........................09

6-8 -00 ........................09

6-9 -00 ........................09

6-10 -00 ......................09

6-11 -00 ......................09

6-12 -00 ......................09

6-13 -00 ......................09

- 4 - 00

0

Release 00/2003 - 06

QUASAR 125-180

FOREWORD

0.2 FOREWORD

- This manual provides the information required for normal servicing.

- The information and illustrations contained in this manual will be updated through subsequent releases, see see 0.1 (RELEASE

00/2003-09 UPDATE).

- This manual is intended for use by Aprilia Dealers and their qualified mechanics. Certain information has been omitted

intentionally, as this manual does not purport to provide a comprehensive treatise on mechanics. The persons who will use this

manual must be fully conversant with the basics of mechanics and with the basic procedures of motorcycle repair. Repairing or

inspecting a motorcycle when one does not possess such basic knowledge or trai ning could result in improper servicing and

make the motorcycle unsafe to ride. For the same reason, certain basic precautions have been omitted in the descriptions of

repair and inspection procedures. Take special care to avoid damage to motorcycle components or injury to persons. Aprilia's

mission is to constantly enhance the riding pleasure of final users through the on-going improvement of its products as well as

of the relevant technical literature. All Aprilia Points of Sale and Subsidiaries worldwide are kept updated on major engineering

changes and modifications to repair procedures. Such changes and modifications are then reflected in the next release of the

relevant manual. When in doubt about an inspection or repair procedure, please contact the Aprilia Consumer Service (A.C.S.)

Department, who will be glad to provide full informatio n on the pr oced ure in q uestion as well as on any upd ates o r enginee ring

changes affecting the motorcycle under consideration.

Aprilia reserves the right to make changes to its products at any time, barring any such changes as may alter the essential

features of a product as specified in the relevant manual.

All rights of storage using electronic means, reproduction and total or partial adaptation, whatever the means adopted, are

reserved in all countries.

The mention of third parties' products is only ma de for information purposes, and is not binding.

Aprilia is not liable in any way for the performance or use of any such products.

For further information, see 0.3 (REFERENCE MANUALS).

First edition: September 2003

Produced and printed by:

DECA s.r.l.

via Risorgimento, 23/1 - 48022 Lugo (RA) - Italy

Tel. +39 - 0545 35235

Fax +39 - 0545 32844

E-mail: deca@decagroup.it

www.decaweb.it

On behalf of:

aprilia Consumer Service s.p.a.

via Noalese, 156 - 30036 Santa Maria di Sala (VE) - Italy

Tel. +39 - 041 57 86 101

Fax +39 - 041 57 86 100

www.aprilia.com

0.3 REFERENCE MANUALS

0.3.1 O WNER'S MANUALS

Aprilia part# (description)

Model year 2003

8104713

UK E D F

0.3.2 SPARE PARTS CATALOGU E

Aprilia part# (description)

Model year 2003

A 60200

UK E D F

Release 00/2003 - 06

- 5 - 00

0

FOREWORD

0.4 ABBREVIATIONS/SYMBOLS/CONVENTIONS

# = number

< = is less than

> = is more than

<

> = is more than or equal to

~ = approximately

= is less than or equal to

∞ = infinite

°C = degrees Celsius (centigrade)

°F = degrees Fahrenheit

± = plus or minus

AC = Alternated Current

A = Ampere

Ah = Ampere per hour

API = American Petroleum Institute

HT = high tension

AV/DC = Anti-Vibration Double Countershaft

bar = pressure measurement (1 bar =100 kPa)

DC = Direct Current

cm³ = cubic centimeters

CO = carbon oxide

CPU = Central Processing Unit

DIN = German industrial standards

(Deutsche Industrie Norm)

DOHC = Double Overhead Camshaft

ECU = Electronic Control Unit

rpm = revolutions per minute

HC = unburnt hydrocarbons

ISC = Idle Speed Control

ISO = International Standardization Organization

Kg = kilograms

Kgm = kilogram per metre (1 kgm =10 Nm)

km = kilometres

kph = kilometres per hour

Ω = kiloohm

k

kPa = kiloPascal (1 kPa =0.01 bar)

KS = clutch side

(from the German "Kupplung Seite")

kW = kiloWatt

= litres

LAP = racetrack lap

LED = Light Emitting Diode

LEFT

SIDE = left side

m/s = metres per second

max = maximum

mbar = millibar (1 mbar =0.1 kPa)

mi = miles

MIN = minimum

MPH = miles per hour

MS = flywheel side

Ω = megaohm

M

N.A. = Not Available

N.O.M.M. = Motor Octane Number

N.O.R.M. = Research Octane Number

Nm = Newton per metre (1 Nm =0.1 kgm)

Ω = ohm

PICK-UP = pick-up

BDC = Bottom Dead Centre

TDC = Top Dead Centre

PPC = Pneumatic Power Clutch

RIGHT

SIDE = right side

SAE = Society of Automotive Engineers

TEST = diagnostic check

T.B.E.I. = crowned-head Allen screw

T.C.E.I. = cheese-headed Allen screw

QUASAR 125-180

- 6 - 00

0

Release 00/2003 - 06

QUASAR 125-180

T.E. = hexagonal head

T.P. = flat head screw

TSI = Twin Spark Ignition

UPSIDEDOWN = inverted fork

V = Volt

W = Watt

Ø = Diameter

FOREWORD

Release 00/2003 - 06

- 7 - 00

0

FOREWORD

NOTE

QUASAR 125-180

- 8 - 00

0

Release 00/2003 - 06

QUASAR 125-180

GENERAL INFORMATION

GENERAL INFORMATION

1

Release 00/2003 - 09

- 1 - 00

1

GENERAL INFORMATION

GENERAL INFORMATION

CONTENTS

1.1 CONVENTIONS USED IN THE MANUAL.................................................................................. 1-3-00

1.2 SAFETY WARNINGS................................................................................................................ 1-3-00

1.3 GENERAL SAFETY RULES ...................................................................................................... 1-4-00

0

1.3.1 CARBON OXIDE............................................................................................................................................. 1-4-00

1.3.2 FUEL................................................................................................................................................................ 1-4-00

1.3.3 HOT COMPONENT PARTS......................................... ..................................... .............................................. 1-4-00

1.3.4 TRANSMISSION OIL....................................................................................................................................... 1-4-00

1

2

3

4

5

1.3.5 ENGINE OIL ............................. ....................................................................................................................... 1-5-00

1.3.6 HYDROGEN GAS AND BATTERY ELECTROLYTE ..................................................................................... 1-5-00

1.3.7 GENERAL PRECAUTIONS AND INFORMATION...... ... ... ............................................................................. 1-6-00

1.3.8 BEFORE DISASSEMBLING ANY COMPONENTS........................................................................................ 1-6-00

1.3.9 DISASSEMBLING THE COMPONENTS ........................................................................................................ 1-6-00

1.3.10 REASSEMBLING THE COMPONENTS ......................................................................................................... 1-7-00

1.3.11 ELECTRICAL CONNECTORS........................................................................................................................ 1-7-00

1.3.12 TORQUE FIGURES......................................................................................................................................... 1-7-00

1.4 WARNINGS REGARDING FUEL, LUBRICANTS AND OTHER COMPONENTS .......................... 1-8-00

1.4.1 FUEL................................................................................................................................................................ 1-8-00

1.4.2 LUBRICANTS.................................................................................................................................................. 1-9-00

1.5 LOCATION OF SERIAL NUMBERS......................................................................................... 1-10-00

1.5.1 FRAME NUMBER.......................................................................................................................................... 1-10-00

1.5.2 ENGINE NUMBER......................................................................................................................................... 1-10-00

1.6 SPARE PARTS ....................................................................................................................... 1-10-00

1.7 TECHNICAL DATA................................................................................................................. 1-11-00

1.8 LUBRICANT CHART .............................................................................................................. 1-13-00

1.9 SPECIAL TOOLS.................................................................................................................... 1-14-00

1.10 TORQUE FIGURES................................................................................................................. 1-15-00

QUASAR 125-180

6

7

1i

9

- 2 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

1.1 CONVENTIONS USED IN THE MANUAL

- This manual is divided in sections and subsections, each covering a set of the most significant components.

- For quick reference, see the summary of sections on page 0-1.

- Unless expressly specified otherwise, assemblies are reassembled by reversing the dismantling procedure.

- The terms "right" and "left" are referred to the rider seated on the vehicle in the normal riding position.

- Motorcycle operation and basic maintenance are covered in the "OWNER'S MANUAL".

! Any opera tions preceded by the star symbol must be repeated on the opposite side of the motorcycle.

In this manual any variants are identified with these symbols:

Frame Quasar 125 HP:ZD4KY10003TXXXXXX (STARTING FROM MODEL YEAR 2003);

Frame Quasar 125 Grip:ZD4KY11003TXXXXXX (STARTING FROM MODEL YEAR 2003);

Frame Quasar 180 HP:ZD4KY00003TXXXXXX (STARTING FROM MODEL YEAR 2003);

Frame Quasar 180 Grip:ZD4KY01003TXXXXXX (STARTING FROM MODEL YEAR 2003).

ASD

automatic light switching version (Automatic Switch-on Device)

OPT

optional

VERSION:

I

Italy Greece Malaysia

UK

United

Kingdom

A

Austria Switzerland Croatia

P

Portugal Denmark Australia

SF

Finland Japan

B

Belgium Singapore Brazil

D

Germany Slovenia

GR

NL

Holland Chile

CH

DK

J

SGP

SLO

MAL

RCH

HR

AUS

United States

USA

of America

BR

Republic of

South Africa

RSA

New Zeland

F

France Israele

E

Spain

IL

ROK

South Korea

NZ

CDN

Canada

1.2 SAFETY WARNINGS

The following precautionary warnings are used throughout this manual in order to convey the following messages:

Safety warning. When you find this symbol on the vehicle or in the manual , be ca reful to th e potenti al risk of persona l injury.

Disregarding the instructions identified by this symbol may compromise the safety of the user, the motorcycle and third par-

ties.

Indicates a potential hazard which may result in serious injury or even death.

Indicates a potential hazard which may result in minor personal injury or damage to the vehicle.

NOTE The word "NOTE" in this manual precedes important information or instructions.

Release 00/2003 - 09

- 3 - 00

1

GENERAL INFORMATION

QUASAR 125-180

1.3 GENERAL SAFETY RULES

1.3.1 CARBON OXIDE

When an operation must be performed with the engine running, position the motorcycle out of doors or in a well-ventilated area.

Never operate the engine indoor.

Use an exhaust emission extraction plant when working indoor.

Exhaust emissions contain carbon oxide, which is a poisonous gas and may lead to loss of conscience or even death.

Operate the engine out of doors or, if working indoors, use an exhaust emission extraction plant.

1.3.2 FUEL

The fuel used to operate engines is highly flammable and becomes explosive under particular conditions.

Refuelling and engine service should take place in a well-ventilated area with the engine stopped.

Do not smoke when refuelling or in the proximity of sources of fuel vapours. Avoi d contact with bare flames, sources of

sparks or any other source which may ignite the fuel or lead to explosion.

DO NOT RELEASE FUEL INTO THE ENVIRONMENT.

KEEP AWAY FROM CHILDREN.

1.3.3 HOT COMPONENT PARTS

The engine and exhaust component parts become hot when the engine is running and will stay hot for some time after the engine

has been stopped.

Wear heat gloves before handling these components or allow for the engine and exhaust system to cool down before proceeding.

1.3.4 T RANSMISSION OIL

Use PONTIAX HDI SAE 85W - 140 or POTRAIMP 85W-140. As an alternative to recommended fluids it is possible to

use high-quality fluids having equal or higher ratings with respect to A.P.I. GL-4 specifications.

Insufficient lubrication or the use of unsuitable lubricants may result in irreparable damage due to increased wear and

tear of the moving parts.

Do not overtighten the drain plug as this could damage the crankcase.

Used oil contains substances that are harmful to the environment, even small quantities must be disposed of in compliance with the regulations in force.

To avoid serious skin damage due to p rolonged contact with oil, accurately wash your hands after handling the lubricant.

KEEP AWAY FROM CHILDREN.

- 4 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

1.3.5 ENGINE OIL

Use SUPERMOTOROIL SAE 15W - 40 or F1 SUPERMOTOROIL 15W-40.

As an alternative to recommended fluids it is possible to use high-q uality fluids having equal or higher ratings with respect to

A.P.I. SJ/eF specifications.

Insufficient lubrication or the use of unsuitable lubricants may result in irrepara ble damage due to increase d wear and

tear of the moving parts.

Do not overtighten the drain plug as this could damage the crankcase.

Used oil contains substances that are harmful to the environment, even small quantities must be disposed of in compliance with the regulations in force.

To avoid serious skin damage due to prolonged contact with oil, accurately wash your hands after handling the lubricant.

KEEP AWAY FROM CHILDREN.

1.3.6 HYDROGEN GAS AND BATTERY ELECTROLYTE

Battery electrolyte fluid is toxic and caustic. It contains sulphuric acid and can cause burns if spilled on the skin.

Wear close-fitting gloves and protective clothing when handling the battery electrolyte.

If any battery fluid gets on your skin, rinse the affected area with abundant fresh water.

Take special care to protect your eyes - even a small amount of battery acid can cause blindness. If battery fluid is

spilled into your eyes, flush with abundant water for fifteen minutes and contact an eye specialist immediately.

If battery fluid is swallowed accid entally, dr ink abunda nt water or milk. Seek medical advice immediately and keep drinking magnesia milk or vegetable oil in the meantime. The battery gives off explos ive gases. Keep the battery well away

from any sources of ignition, such as flames, sparks, or any heat sources. Do not smoke nea r the battery.

Make sure the area is well-ventilated when servicing or charging the battery.

KEEP AWAY FROM CHILDREN.

Battery fluid is corrosive.

Avoid spillage. Take special care not to spill battery fluid on plastic parts.

Ensure that the electrolyte fluid you are using is suitable for your battery.

Release 00/2003 - 09

- 5 - 00

1

GENERAL INFORMATION

QUASAR 125-180

1.3.7 G ENERA L PRECAUTIONS AND INFORMATION

Follow these instructions closely when repairing, disassembling or reassembling the motorcycle or its components.

Using bare flames is strictly forb idden when w orking on the mo torcycle. Befo re ser vicing or inspectin g the motor cycle :

stop the engine and remove the key from the ignition switch; allow for the engine and exh aust system to cool down;

where possible, lift the motorcycle using adequate equipment placed on firm and level ground. Be careful of any parts of

the engine or exhaust system which may still be hot to the touch to avoid scalds or burns .

Never put any mechanical parts or other vehicle components in your mout h when you have both hands busy. None of

the motorcycle components is edible. Some components are harmful to the human body or toxic.

If not expressly indicated otherwise, for the reassembly of the units repeat the dis assembly operations in reverse order.

Where a procedure is cross-referred to rele vant sections in th e manual, procee d sensibly to a void disturbing any parts

unless strictly necessary. Do not use polishing paste on matt paint.

Never use fuel instead of solvent to clean the motorcycle.

Do not use alcohol, petrol or solvents to clean the rubber and plastic parts and the seat: use only water and mild soap.

Always disconnect the battery negative (-) lead before soldering any electrical components.

When two or more persons service the same motorcycle together, special care must be taken to avoid personal injury.

Read carefully 1.4 (WARNINGS REGARDING FUEL, LUBRICANTS AND OTHER COMPONENTS).

1.3.8 BEFORE DISASSEMBLING ANY COMPONENTS

- Clean off all dirt, mud, and dust and clear any foreign objects from the vehicle before disassembling any components.

- Use the model-specific special tools where specified.

1.3.9 DISASSEMBLING THE COMPONENTS

- Never use pliers or similar tools to slacken and/or tighten nuts and bolts. Always use a suitable spanner.

- Mark all connections (hoses, wiring, etc.) with their positions before disconnecting them. Identif y each connection using a distinctive symbol or convention.

- Mark each part clearly to avoid confusion when refitting.

- Thoroughly clean and wash any components you have removed using a detergent with low flash point.

- Mated parts should always be refitted together. These parts will have seated themselves against one anoth er in service as a

result of normal wear and should never be mixed up with other similar parts on refitting.

- Certain components are matched-pair parts and should always be replaced as a set.

- Keep the motorcycle and its components well away from heat sources.

- 6 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

1.3.10 REASSEMBLING THE COMPONENTS

Never reuse a circlip or snap ring. These parts must always be renewed once they have been disturbed.

When fitting a new circlip or snap ring, take care to move the open ends apart just enough to allow fitment to the shaft.

Make it a rule to check that a newly-fitted circlip or snap ring has located fully into its groove.

Never clean a bearing with compressed air.

NOTE All bearings must rotate freely with no hardness or noise. Replace any bearings that do not meet these requirements.

- Use ORIGINAL Aprilia SPARE PARTS only.

- Use the specified lubricants and consumables.

- Where possible, lubricate a part before assembly.

- When tightening nuts and bolts, start with the largest or innermost nut/bolt and observe a cross pattern. Tighten evenly in subsequent steps until achieving the specified torque.

- Replace any self-locking nuts, gaskets, seals, circlips or snap rings, O-rings, split pins, bolts and screws which have a damaged

thread.

- Abundantly lubricate parts subject to wear before fitting the bearings.

- Make it a rule to check that all components you have fitted are correctly in place.

- After repairing the motorcycle and after each service inspection, perform the preliminary checks, and then operate the motorcycle in a private estate area or in a safe area away from traffic.

- Clean all joint surfaces, oil seal edges and gaskets before assembly.

- Apply a light coat of lithium grease along the edges of oil seals. Fit oil seals and bearings with the brand or serial number facing

outwards (in view).

1.3.11 ELECTRICAL CONNECTORS

Disconnect electrical connectors as follows; failure to follow the instructions can seriously damage the connectors and the wiring:

" Press down on the locking tab, where fitted.

Never separate two connectors by pulling on the wiring.

" Grasp both connectors and pull them in opposite directions until they become separated.

" Remove any dirt, rust, moisture, etc. from inside the connector blowing with compressed air.

" Ensure that the wires are securely crimped to the terminals inside each connector.

NOTE A connector will only locate properly into the matching connector when it is inserted in the correct mounting position.

" Reconnect the two connectors and ensure that they are fully engaged (where fitted, the locking tab should cli ck audibly into

place).

1.3.12 TORQUE FIGURES

Do not forget that the tightening torques of all fasteners on wheels, brakes, wheel spindles and other suspens ion components are essential to ensure safe operation of the motorcycle and must be set to the indicated values.

Regularly check the tightening torques on all fasteners, and always use a torque wrench when fitting them.

Failure to observe these instructions can result in pa rts coming loose or off, thus jamming a wheel or creating other

problems which could affect the handling of the motorcycle, potentially resulting in serious inju ry or death.

Release 00/2003 - 09

- 7 - 00

1

GENERAL INFORMATION

QUASAR 125-180

1.4 WARNINGS REGARDING FUEL, LUBRICANTS AND OTHER COMPONENTS

1.4.1 FUEL

The fuel used to operate engines is highly flammable and becomes explosive under particular conditions.

Refuelling and engine service should take place in a well-ventilated area with the engine stopped.

Do not smoke when refuelling or in the proximity of sources of fuel vapours. Avoi d contact with bare flames, sources of

sparks or any other source which may ignite the fuel or lead to explosion.

Take care not to spill fuel out of the filler, or it may ignite when in contact with hot engine parts.

In the event of accidental fuel spillage, make sure the affected area is fully dry before starting the engine. Fuel exp ands

from heat and when left under direct sunlight. Never fill the fuel tank up to the rim. Tighten the filler cap securely after

each refuelling.

Avoid contact with skin. Do not inhale vapours. Do not swallow fuel. Do not transfer fuel between different containers

using a hose.

In case of contact with the eyes, rinse abundantly with clean water and immediately seek medical attention.

If accidentally swallowed, do not induce vomiting.

Drink abundant milk or cool water and seek medical attention immedi ately.

DO NOT RELEASE FUEL INTO THE ENVIRONMENT.

KEEP AWAY FROM CHILDREN.

Use only premium-grade unleaded fuel with a minimum octane rating of 95 (N.O.R.M.) and 85 (N.O.M.M.).

ENGINE OIL

Engine oil may cause serious damage to the skin if handled daily and for long periods.

Wash your hands carefully after use.

Do not release oil into the environment.

Put it in a sealed container and take it to the filling station where you usually buy it or to an oil salvage centre.

In case any maintenance operation should be requir ed, it is advisable to use latex gloves.

Change engine oil after running-in, namely after two weeks of usage, and then every six months, see 2.3 (PERIODIC MAINTENANCE CHART), see 1.8 (LUBRICANT CHART).

Change oil every three months if the vehicle is used in rainy or dusty areas, on uneven surfaces or on racetracks.

- 8 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

1.4.2 LU BRICANTS

Correct lubrication is essential to the safety of the motorcycle.

Failure to maintain the lubricant level or the use of incorrect, old or dirty lubricant can cause the engine or transmission

to seize, resulting in accidents, serious injury or death.

Prolonged or repeated contact with lubricant may cause severe skin damage.

Wash your hands thoroughly after handling engine oil.

Do not release into the environment.

Dispose of engine oil through the nearest waste oil reclamation firm or through the supplier.

When filling the vehicle with lubricant, make sure not to spill it. Immediately clean up spilled oil, as it can damage the

motorcycle paint.

Oil on the tyres can make them very slippery and dangerous to use.

In case of oil leaks, do not use the motorcycle. Identify the cause of the leak and repair it.

Release 00/2003 - 09

- 9 - 00

1

GENERAL INFORMATION

QUASAR 125-180

1.5 LOCATION OF SERIAL NUMBERS

These numbers are necessary for vehicle registration.

NOTE Altering the identification numbers of vehicle or engine is a legal

offence punishable by heavy fines and penalties. In addition, altering the

frame number (VIN) results in immediate warranty invalidation.

1.5.1 FRAME NUMBER

The motorcycle's frame number is stamped on the front part of the frame

under front mudguard support.

1.5.2 E NGINE NUMBER

The engine number is stamped on the crankcase, on the left side of the motorcycle.

1.6 SPARE PART S

Use Original Aprilia Spare Parts only for repairs.

Original Aprilia spare parts are high-quality comp onents designed and built

expressly for Aprilia motorcycles.

Using any parts OTHER THAN original Aprilia parts may lead to loss of

performance and damage.

- 10 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

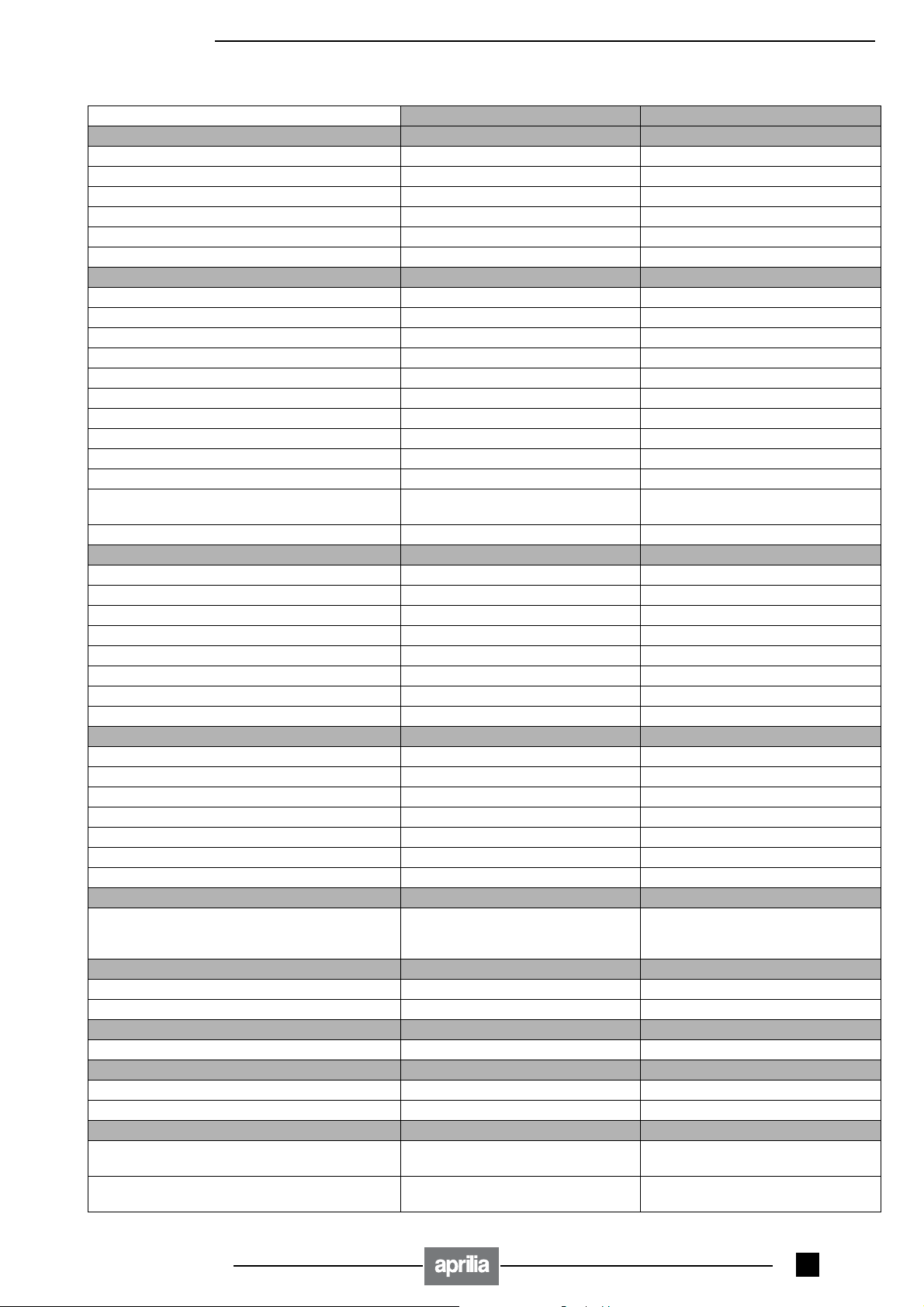

1.7 TECHNICAL DATA

QUASAR 125 QUASAR 180

DIMENSIONS

Length 1790 mm GRIP 1675 mm (HP) 1790 mm GRIP 1675 mm (HP)

Width 970 mm (GRIP/HP) 970 mm (GRIP/HP)

Max. height (to handlebars) 1060 mm (GRIP/HP) 1060 mm (GRIP/HP)

Wheel base 1065 mm (GRIP/HP) 1065 mm (GRIP/HP)

Min. ground clearance 160 mm (GRIP/HP) 160 mm (GRIP/HP)

Weight ready for starting 174 Kg (GRIP) - 171 kg (HP) 174 Kg (GRIP) - 171 kg (HP)

ENGINE

Type 4-stroke 4-stroke

Number of valves 2 2

Number of cylinders horizontal single cylinder horizontal single cylinder

Total displacement 125 cm³ 169 cm³

Bore/stroke 52,4 mm x 57,8 mm 61 mm x 57,8 mm

Compression ratio 9,1±1:1 9,1±1:1

Starting electric + kick starter electric + kick starter

Engine idling rpm 1800 ± 100 giri/min 1800 ± 100 giri/min

Clutch automatic, dry centrifugal automatic, dry centrifugal

Gearbox automatic converter transmission automatic converter transmission

Lubrication circuit

Cooling air air

CAPACITY

Fuel (reserve included) 8 l 8 l

Fuel reserve 1,5 l 1,5 l

Transmission oil 200 cm³ 200 cm³

Engine oil

1) engine oil change only 0,9 l 0,9 l

2) change for engine overhaul 1,2 l 1,2 l

Seats 2 2

Vehicle max. load (driver + possible luggage) 98 Kg (GRIP) - 98 kg (HP) 98 Kg (GRIP) - 98 kg (HP)

TRANSMISSION

Converter automatic continuous automatic continuous

Primary with trapezoidal belt with trapezoidal belt

Ratios

1) minimum for continuous variable transmission 3 3

2) maximum for continuous variable transmission 0,789 0,789

Secondary gear-type gear-type

Final chain-type chain-type

FUEL SUPPLY

Fuel

CARBURETTOR

Type WALBRO WALBRO

Choke Ø 22 mm Ø 22 mm

FRAME

Type tube tube

SUSPENSIONS

Front with independent arms with independent arms

Rear hydraulic monoshock absorber hydraulic monoshock absorber

BRAKES

Front

Rear

wet casing, forced circulation via

mechanical pump

premium grade unleaded petrol, number

DIN 51607, min. O.N. 95 (N.O.R.M.) and

85 (N.O.M.M.).

Ø 110 mm mechanically driven drum

brake

Ø 130 mm mechanically driven drum

brake

wet casing, forced circulation via

mechanical pump

premium grade unleaded petrol, number

DIN 51607, min. O.N. 95 (N.O.R.M.) and

85 (N.O.M.M.).

Ø 110 mm mechanically driven drum

brake

Ø 130 mm mechanically driven drum

brake

Release 00/2003 - 09

- 1 1 - 00

1

GENERAL INFORMATION

QUASAR 125 QUASAR 180

WHEEL RIMS

Type steel steel

Front 10X5.5 10X5.5

Rear 8X8.0 8X8.0

TYRES

Type tubeles tubeles

Front HP 21x7-10 21x7-10

Rear HP 22x11-8 22x11-8

Front GRIP AT 21x7-10 AT 21x7-10

Rear GRIP AT 21x10-8 AT 21x10-8

Inflating pressure 20 - 25 kPa (0,20 - 0,25 bar) 30 kPa (0,30 bar)

IGNITION

Type C.D.I. C.D.I.

Ignition advance 13° ± 2° 13° ± 2°

SPARK PLUG

Standard NGK CR8HSA NGK CR8HSA

Spark plug gap 0,6 - 0,7 mm 0,6 - 0,7 mm

ELECTRIC SYSTEM

Battery 12 V - 9 Ah 12 V - 9 Ah

Fuse 15 A 15 A

Generator (with permanent magnet) 12 V - 110 W 12 V - 110 W

BULBS

Parking light 12 V - 5 W 12 V - 5 W

Low/high beam 12 V - 35/35 W 12 V - 35/35 W

Direction indicators 12 V- 10 W 12 V- 10 W

Rear parking lights/Stoplight 12 V - 5/21 W 12 V - 5/21 W

Number plate light 12 V - 5 W 12 V - 5 W

QUASAR 125-180

- 12 - 00

1

Release 00/2003 - 09

QUASAR 125-180

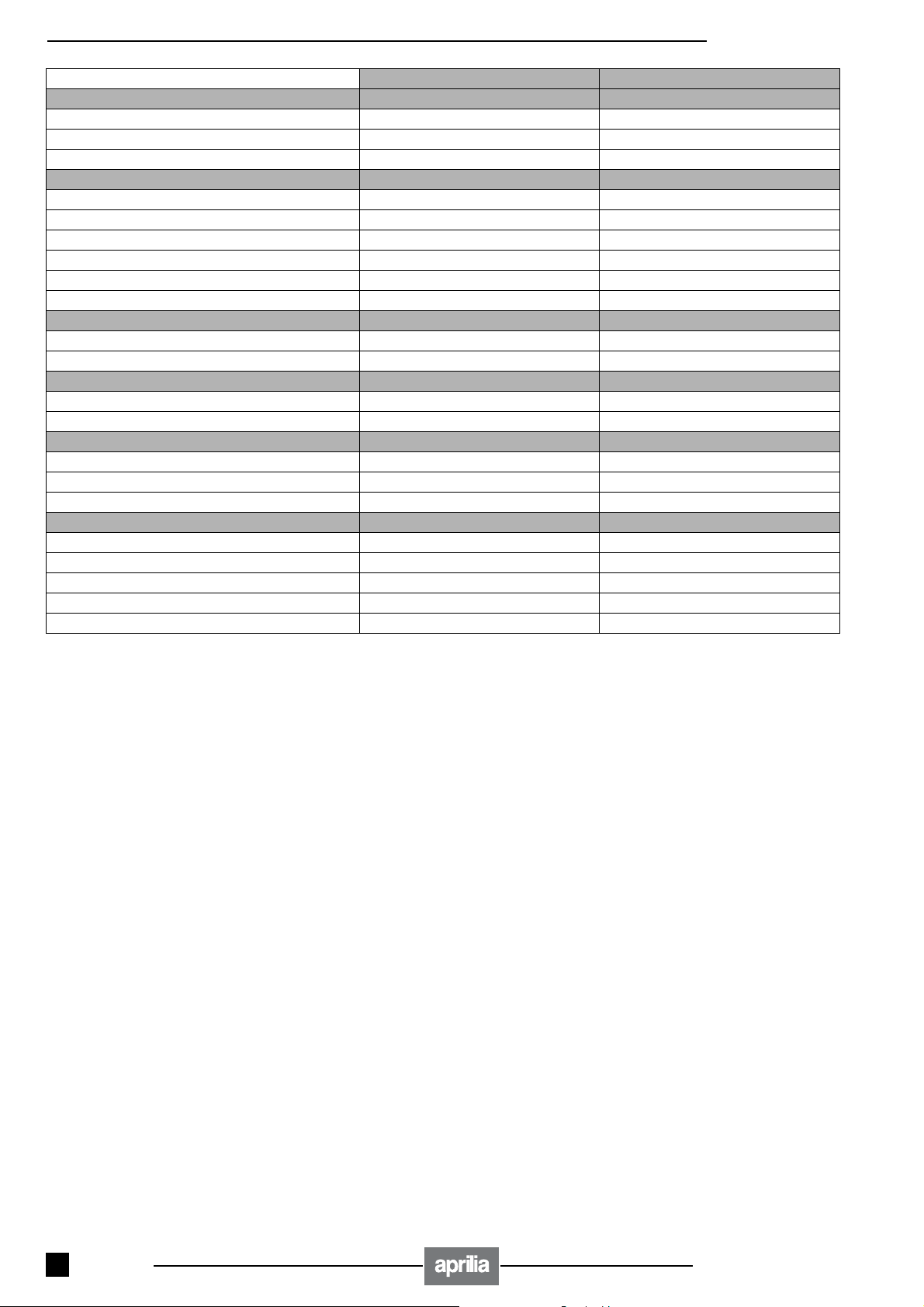

1.8 LUBRICANT CHART

LUBRICANT PRODUCT

GENERAL INFORMATION

Transmission oil

Engine oil

Bearings and other lubrication points

Battery lead protection Use neutral grease or vaseline.

Aerosol chain lubricant RECOMMENDED: CHAIN SPRAY or CHAIN LUBE.

RECOMMENDED: PONTIAX HDI SAE 85W - 140 or ROTRA MP 85W-140.

As an alternative to recommended fluids it is possible to use high-quality fluids having equal

or higher ratings with respect to A.P.I. GL-5 specifications.

RECOMMENDED: SUPERMOTOROIL SAE 15W - 40 or F1 SUPERMO-

TOROIL 15W-40.

As an alternative to recommended oil it is possible to use high-quality oil having equal or

higher ratings with respect to A.P.I. SJ/eF specifications.

RECOMMENDED: AUTOGREASE MP or GREASE 30.

As an alternative to recommended fluids it is possible to use high-quality grease for bearings, temperature range -30°C...+140°C, dripping point 150°C...230°C, highly corrosion

protectant, good waterproof and oxidization-proof ability.

Release 00/2003 - 09

- 13 - 00

1

GENERAL INFORMATION

QUASAR 125-180

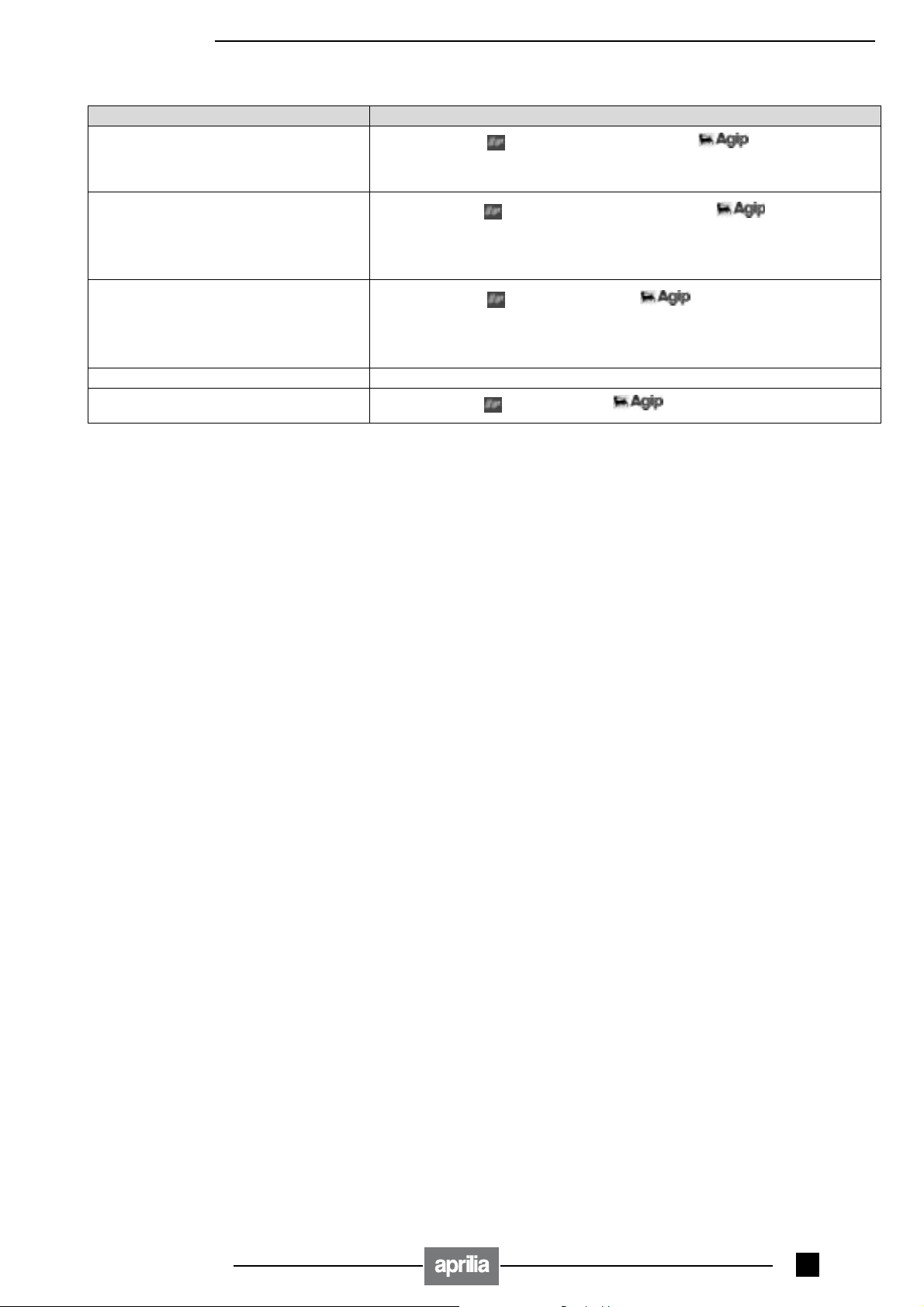

1.9 SPECIAL TOOLS

Special tools have been developed to ensure proper disassembly, re-assembly and adjustment withou t the risk of damaging any

components.

Using inadequate tools and/or improvised procedures may lead to irreparable damage. Model-speci fic special tools for this vehicle are listed below.

If needed, order the brand-specific special tools (see Special Tools Catalogue).

Always read the instructions supplied with the special tools before use.

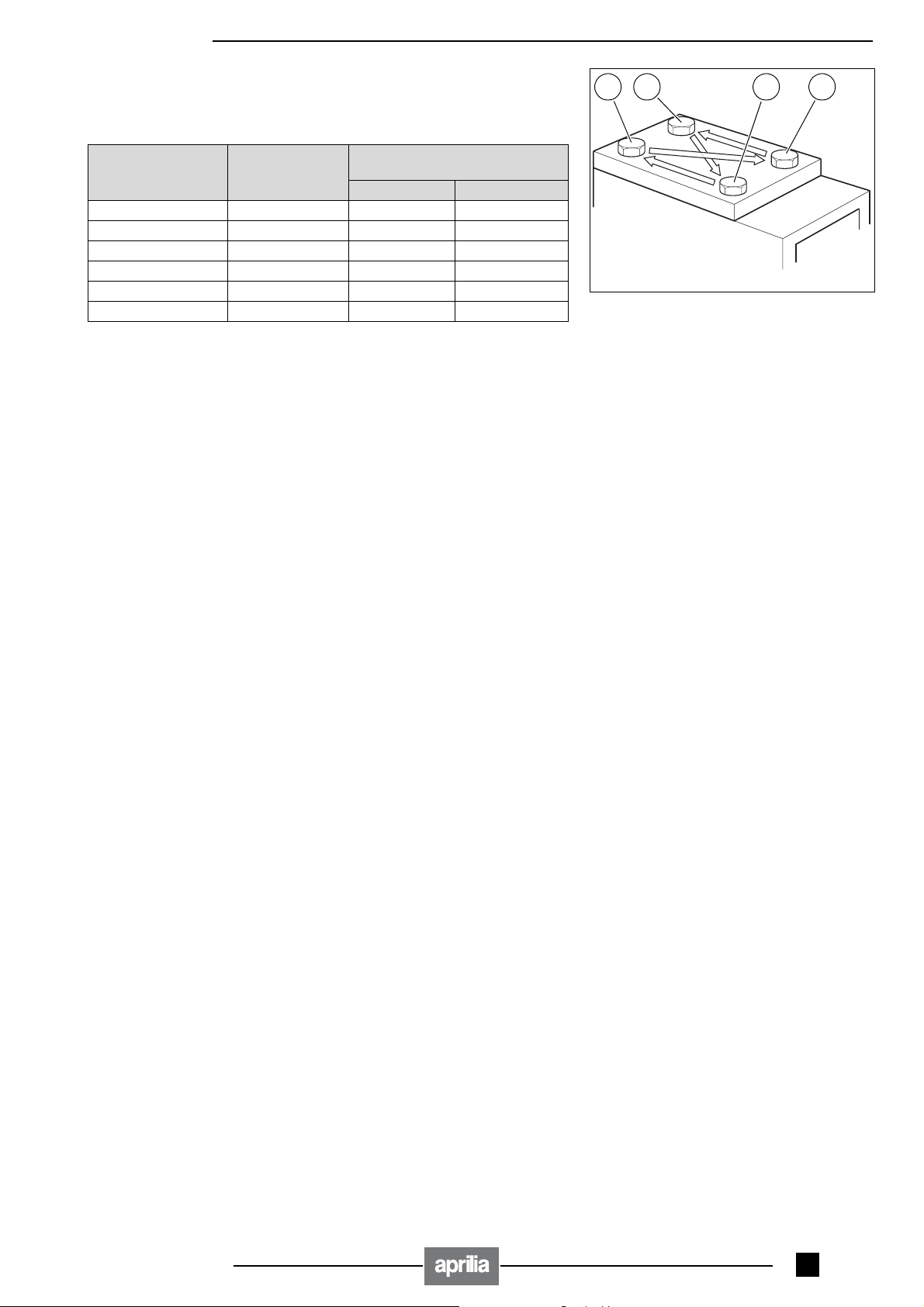

2

1

6

4

5

3

TOOLS

Ref. Tool designation and application Part number

1 Flywheel and clutch housing locking tool 8900675

2 Universal clutch assembly/disassembly tool 8900674

3 Converter locking tool 8900673

4 Ring nut spanner 8910599

5 Flywheel puller 8910600

6 Starting gear puller 8910601

- 14 - 00

1

Release 00/2003 - 09

QUASAR 125-180

GENERAL INFORMATION

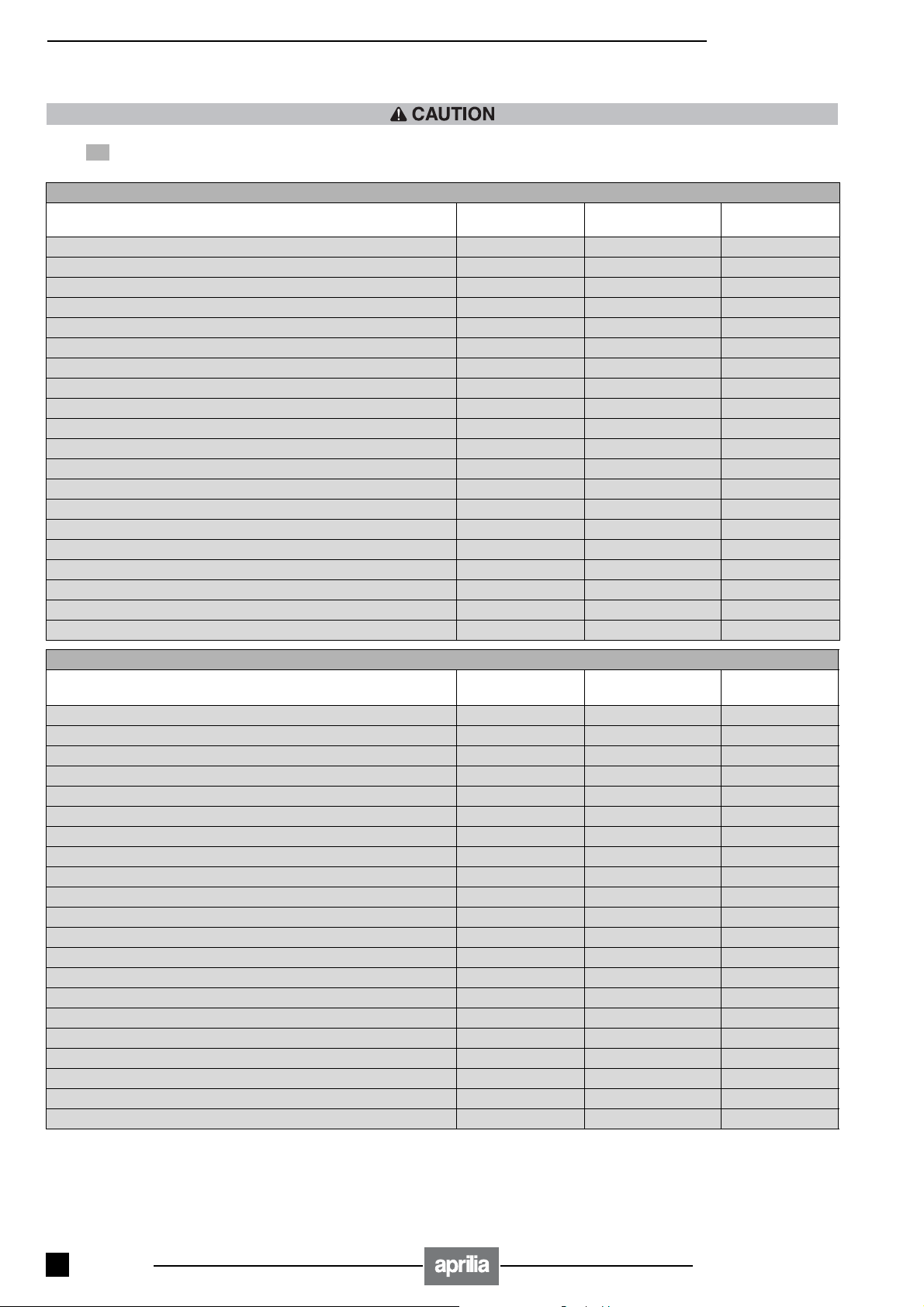

1.10 TORQUE FIGURES

The table below reports the standard torque figures for metric size screws and

bolts in accordance with ISO standards.

Screw or

bolt

M 6 10 6 0.6

M 8 12 15 1.5

M 10 14 30 3.0

M 12 17 55 5.5

M 14 19 85 8.5

M 16 22 130 13.0

For vehicle-specific fastenings see 2.2 (FAST ENERS).

Unless otherwise specified, torque figures are intended for application to

clean, dry threads at

room temperature.

Spanner

Tightening

torque

Nm kgm

NOTE Follow the instructions below to avoid distortion and/or improper fit:

" Screw all fasteners finger-tight.

" Tighten the opposing parts to half the prescribed torque: (A) and (B); (C)

and (D).

" Repeat sequence tightening to specified torque.

NOTE This way, the load generated by the fasteners is applied evenly across

joint surface.

BDCA

Release 00/2003 - 09

- 15 - 00

1

GENERAL INFORMATION

NOTE

QUASAR 125-180

- 16 - 00

1

Release 00/2003 - 09

QUASAR 125-180

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

2

Release 00/2003 - 09

- 1 - 00

2

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

CONTENTS

2.1 PERIODIC MAINTENANCE CHART.......................................................................................... 2-3-00

2.2 FASTENERS............................................................................................................................. 2-4-00

2.3 PERIODIC MAINTENANCE CHART.......................................................................................... 2-5-00

0

2.4 LUBRICATION ......................................................................................................................... 2-6-00

2.4.1 SWITCH........................................................................................................................................................... 2-6-00

2.4.2 MAIN SWITCH................................................................................................................................................. 2-7-00

2.5 BATTERY................................................................................................................................. 2-8-00

1

2.6 CHECKING THE ELECTROLYTE BATTERY LEVEL................................................................. 2-9-00

2.6.1 RECHARGING THE BATTERY ...................................................................................................................... 2-9-00

2.7 SPARK PLUG......................................................................................................................... 2-10-00

2.8 IDLING ADJUSTMENT........................................................................................................... 2-11-00

2

2.9 ADJUSTING THE THROTTLE CONTROL............................................................................... 2-11-00

2.10 AIR CLEANER........................................................................................................................ 2-12-00

2.11 FUEL VAPOURS FILTER........................................................................................................ 2-12-00

3

4

5

2.11.1 ENGINE OIL ............................................................ .. .................................................................................... 2-13-00

2.11.2 CHANGING THE ENGINE OIL AND THE ENGINE OIL FILTER................................................................. 2-14-00

2.12 CHECKING THE TRANSMISSION OIL LEVEL ....................................................................... 2-15-00

2.13 CHECKING AND ADJUSTING THE BRAKES......................................................................... 2-16-00

2.14 CHECKING THE STEERING................................................................................................... 2-17-00

2.15 INSPECTING THE FRONT SUSPENSIONS ............................................................................ 2-17-00

2.16 INSPECTING THE REAR SUSPENSION................................................................................. 2-18-00

2.17 WHEELS................................................................................................................................. 2-18-00

2.17.1 TYRES ........................................................................................................................................................... 2-18-00

2.18 DRIVE CHAIN......................................................................................................................... 2-19-00

2.19 MULTIFUNCTION COMPUTER .............................................................................................. 2-20-00

2.20 TOE IN ................................................................................................................................... 2-23-00

QUASAR 125-180

6

7

i

9

- 2 - 00

2

Release 00/2003 - 09

QUASAR 125-180

Outlined in this section are the recommended procedures for the periodic maintenance of the key components of the motorcycle.

Before proceeding to maintain or inspect the motorcycle, stop the engin e and remove the ignition switch key. Ensure

that the engine and exhaust system have cooled down. Wherever possible, place the motorcycle on firm and level

ground and lift it using suitable equipment. Be careful of any parts of the engine or exhaust system which may still be

hot to the touch to avoid scalds or burns.

All component parts of the vehicle are inedible. Do not bite, suck, chew or swallow any vehicle parts. If not expr essly

indicated otherwise, for the reassembly of the units repeat the disassembly operations in reverse order.

PERIODIC MAINTENANCE

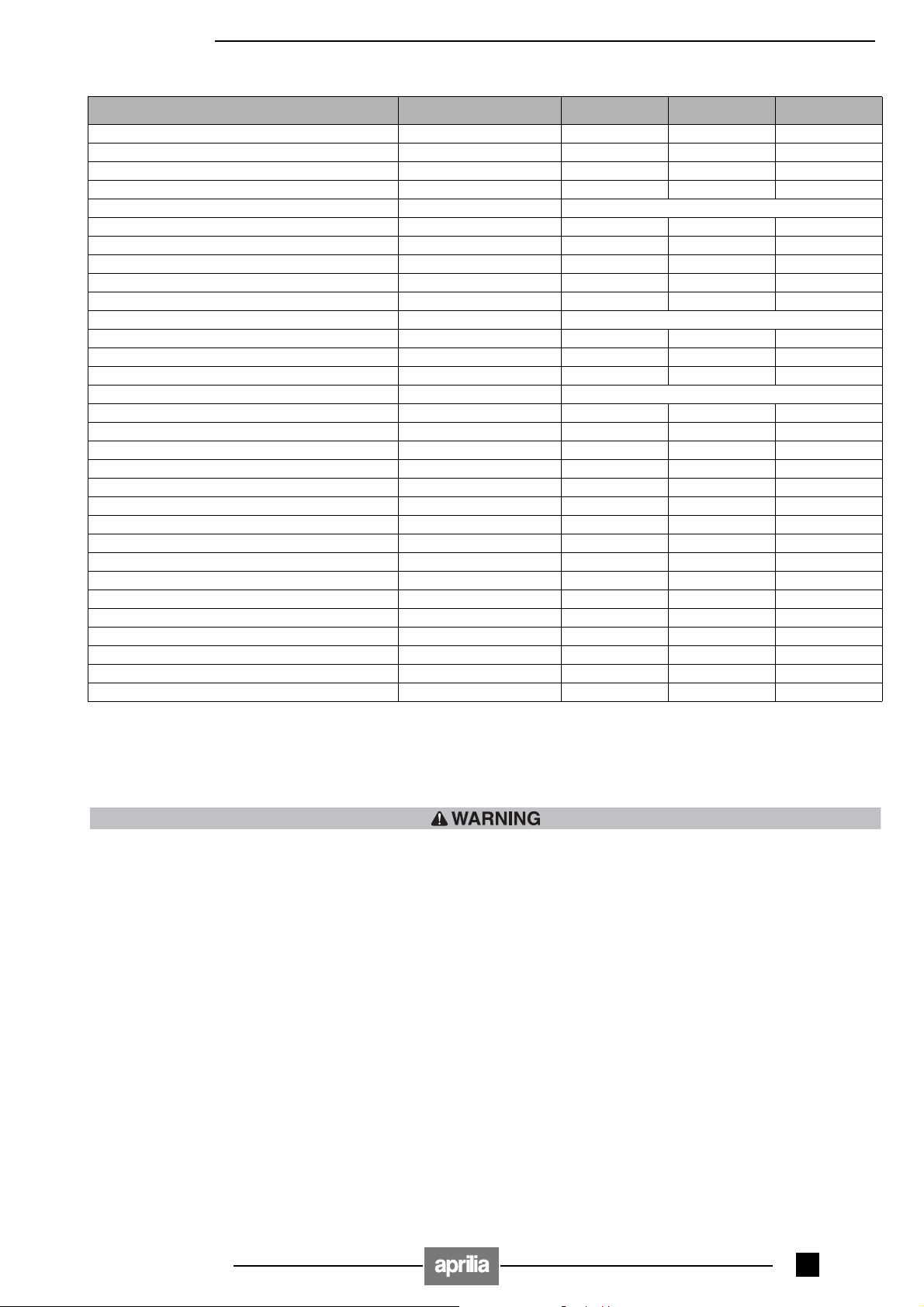

2.1 PERIODIC MAINTENANCE CHART

In order to preserve the motorcycle in sleek running order, Aprilia recommends that you strictly observe the periodic maintenance

intervals recommended for the different component parts.

Release 00/2003 - 09

- 3 - 00

2

PERIODIC MAINTENANCE

QUASAR 125-180

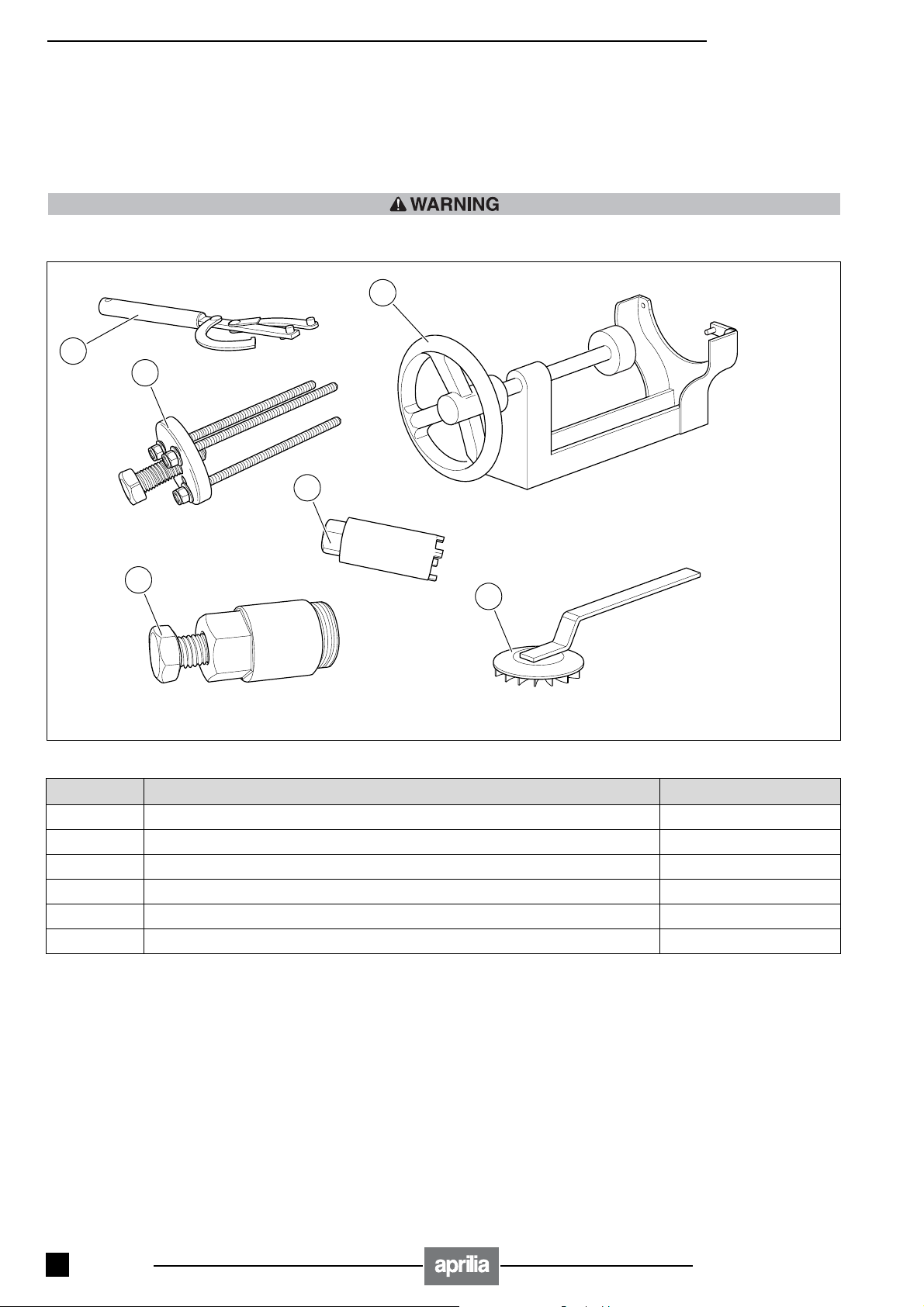

2.2 FASTENERS

The fasteners reported in the chart must be tightened to the specified torque using a torque wrench. Items highlighted

with ( ) are especially important for safety.

ENGINE

Component

Spark plug 20 2,0

Throttle control covers 13 1,3

Oil filter cover 15 1,5

Flywheel retaining nut 38 3,8

Camshaft flange nut 27 2,7

Mobile belt roller nut 38 3,8

Valve adjusting nut 5 0,5

Cylinder head nut 27 2,7

Primary drive gear nut 38 3,8

Head stud bolt 13 1,3

Oil bleeder 25 2,5

Right casing screw 10 1,0

Left casing screw 10 1,0

Valve cover screw 14 1,4

Converter cover screw 10 1,0

Oil cooler retaining screw 9 0,9

Starter motor screw 14 1,4

Oil pump screw 14 1,4

Stator screw 14 1,4

Engine mount screw 28 28

Nm kgm Note

FRAME

Component

Upper handlebars braces 4 0,4

Steering stem nut 10 1,0

Rear shock absorber retaining nut 40 4,0

Front hub retaining nut 60 6,0

Rear hub retaining nut 95 9,5

Front wheel retaining nut 38 3,8

Rear wheel retaining nut 38 3,8

Steering stem flange nut 25 2,5

Swinging arm spindle nut 90 9,0

Chain adjusting nut 22 2,2

Handlebars lower fastener 10 1,0

Front brake lever 10 1,0

Rear brake lever 10 1,0

Rear axle (inner) retaining screw 9 0,9

Rear axle (outer) retaining screw 15 1,5

Front shield retaining screw 4 0,4

Steering arm retaining screw 30 3,0

Headlight retaining screw 16 1,6

Muffler retaining screw 25 2,5

Footpeg retaining screw 4 0,4

Front suspension screw 40 4,0

Nm kgm Note

- 4 - 00

2

Release 00/2003 - 09

QUASAR 125-180

2.3 PERIODIC MAINTENANCE CHART

PERIODIC MAINTENANCE

Components

Throttle and brake cables

Battery

Spark plug

Carburettor/idle speed

Drive chain

Air cleaner

Engine oil filter

Light system

Stop light switch

Engine oil

Tyres pressure

Fuel indicator

Ignition advance

Transmission cables

Brake drums/blocks Always check before use

Drive belt

Steering tube bearing and steering clearance

Ties

Fuel filter

Clutch

Vehicle general operation

Valve clearance

Greasing

Exhaust pipe / exhaust silencer

Transmission oil

Rear belt roller pins

Fixed mobile front belt roller

Converter rollers

Bolt/screw/nut tightening

Suspensions

Fuel line

'

'

Post running-in checks

(after 2 weeks)

##

##

#$

#

##

##

%%

#

##

##

##

##

&&

%%#

##

##

Monthly Six-monthly Yearly

#

Every 10 hours of operation: #

$%

$

Always check before use

%

#

&

#

#

#

#

%

%

%

KEY

# Check, clean and lubricate, adjust, top up or change if necessary.

$ Cleaning.

% Replace.

& Adjustment.

' Run monthly in case of use on muddy, wet or rough surfaces (off-road).

Service the motorcycle more frequently when you ride in the rain, on dusty or bumpy roads, or in competition trials.

Release 00/2003 - 09

- 5 - 00

2

Loading...

Loading...