Aprilia RST Mille Futura Service Manual

RST mille

INTRODUCTION

INTRODUCTION |

0 |

|

|

|

|

|

|

GENERAL INFORMATION |

1 |

|

|

|

|

PERIODIC MAINTENANCE AND |

2 |

ADJUSTMENTS |

|

|

|

|

|

ENGINE |

3 |

|

|

|

|

|

|

FUEL SYSTEM |

4 |

|

|

|

|

|

|

COOLING SYSTEM |

5 |

|

|

|

|

|

|

ELECTRICAL SYSTEM |

6 |

|

|

|

|

|

|

CHASSIS |

7 |

|

|

|

|

|

|

REPAIR INFORMATION |

8 |

|

|

|

|

|

|

INDEX |

i |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 1 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

INTRODUCTION

CONTENTS

|

0.1 |

RELEASE 00/2001-11 UPDATE ....... |

0-3-00 |

||

0 |

0.1.1 |

..............................MANUAL UPDATES |

0-3-00 |

||

0.1.2 LIST OF MANUAL PAGES AND UPDATE |

|||||

|

|

NUMBERS ............................................. |

0-3-00 |

||

|

0.2 |

REFERENCE GUIDE ........................ |

0-6-00 |

||

1 |

0.3 |

FOREWORD ..................................... |

0-7-00 |

||

0.4 |

REFERENCE MANUALS .................. |

0-7-00 |

|||

|

0.4.1 |

ENGINE WORKSHOP MANUALS |

0-7-00 |

||

|

|||||

|

0.4.2 |

PARTS CATALOGUES......................... |

0-7-00 |

||

2 |

|||||

0.4.3 |

SPECIAL TOOLS CATALOGUES ........ |

0-7-00 |

|||

0.4.4 |

OWNER'S MANUALS ........................... |

0-7-00 |

|||

|

0.5 |

SAFETY INFORMATION .................. |

0-8-00 |

||

|

|||||

|

0.5.1 |

GENERAL PRECAUTIONS AND |

|

||

3 |

|

||||

|

|

INFORMATION...................................... |

0-8-00 |

||

0.5.2 |

BEFORE DISASSEMBLING ANY |

|

|||

|

|

COMPONENTS...................................... |

0-8-00 |

||

|

0.5.3 |

DISASSEMBLING THE COMPONENTS 0-8- |

|||

|

|||||

|

|

|

00 |

|

|

4 |

|

|

|

||

0.5.4 |

REASSEMBLING THE COMPONENTS 0-8-00 |

||||

0.6 |

SAFETY INFORMATION .................. |

0-9-00 |

|||

|

0.6.1 |

CONVENTIONS USED IN THE MANUAL 0-9-00 |

|||

|

|||||

|

0.7 |

ABBREVIATIONS/SYMBOLS/ |

|

||

5 |

0-10-00 |

||||

|

CONVENTIONS |

||||

|

|

||||

|

|

|

|

|

|

6

7

8

9

0 - 2 - 00

RST mille

Release 00/2001 - 11

RST mille

INTRODUCTION

0.1 RELEASE 00/2001-11 UPDATE

Issue date of original release (Release 00) and subsequent releases:

Original release (Release 00)..................November 2001

0.1.1 MANUAL UPDATES

Always keep manual updated to the latest release you have received.

Add the latest release pages to the manual and destroy all superseded pages (even if they belong to the release before last).

CAUTION

Failure to keep the manual up-to-date or to eliminate superseded pages will make the manual more difficult to consult and creates a risk of improper servicing.

This manual is made up of 10 sections for a total of 376 pages (listed below).

NOTE Please see 0.2 (REFERENCE GUIDE) for details of standard page nomenclature and page numbering.

0.1.2LIST OF MANUAL PAGES AND UPDATE NUMBERS

page# |

Release |

page# |

Release |

0-1 -00 ........................ |

00 |

1-8 -00 ......................... |

00 |

0-2 -00 ........................ |

00 |

1-9 -00 ......................... |

00 |

0-3 -00 ........................ |

00 |

1-10 -00 ....................... |

00 |

0-4 -00 ........................ |

00 |

1-11 -00 ....................... |

00 |

0-5 -00 ........................ |

00 |

1-12 -00 ....................... |

00 |

0-6 -00 ........................ |

00 |

1-13 -00 ....................... |

00 |

0-7 -00 ........................ |

00 |

1-14 -00 ....................... |

00 |

0-8 -00 ........................ |

00 |

1-15 -00 ....................... |

00 |

0-9 -00 ........................ |

00 |

1-16 -00 ....................... |

00 |

0-10 -00 ...................... |

00 |

1-17 -00 ....................... |

00 |

0-11 -00 ...................... |

00 |

1-18 -00 ....................... |

00 |

0-12 -00 ...................... |

00 |

1-19 -00 ....................... |

00 |

1-1 -00 ........................ |

00 |

1-20 -00 ....................... |

00 |

1-2 -00 ........................ |

00 |

1-21 -00 ....................... |

00 |

1-3 -00 ........................ |

00 |

1-22 -00 ....................... |

00 |

1-4 -00 ........................ |

00 |

2-1 -00 ......................... |

00 |

1-5 -00 ........................ |

00 |

2-2 -00 ......................... |

00 |

1-6 -00 ........................ |

00 |

2-3 -00 ......................... |

00 |

1-7 -00 ........................ |

00 |

2-4 -00 ......................... |

00 |

page# |

Release |

page# |

Release |

2-5 -00 ........................ |

00 |

2-49 -00 |

...................... 00 |

2-6 -00 ........................ |

00 |

2-50 -00 ...................... |

00 |

2-7 -00 ........................ |

00 |

2-51 -00 ...................... |

00 |

2-8 -00 ........................ |

00 |

2-52 -00 ...................... |

00 |

2-9 -00 ........................ |

00 |

2-53 -00 ...................... |

00 |

2-10 -00 ...................... |

00 |

2-54 -00 ...................... |

00 |

2-11 -00 ...................... |

00 |

2-55 -00 ...................... |

00 |

2-12 -00 ...................... |

00 |

2-56 -00 ...................... |

00 |

2-13 -00 ...................... |

00 |

2-57 -00 ...................... |

00 |

2-14 -00 ...................... |

00 |

2-58 -00 ...................... |

00 |

2-15 -00 ...................... |

00 |

2-59 -00 ...................... |

00 |

2-16 -00 ...................... |

00 |

2-60 -00 ...................... |

00 |

2-17 -00 ...................... |

00 |

2-61 -00 ...................... |

00 |

2-18 -00 ...................... |

00 |

2-62 -00 ...................... |

00 |

2-19 -00 ...................... |

00 |

2-63 -00 ...................... |

00 |

2-20 -00 ...................... |

00 |

2-64 -00 ...................... |

00 |

2-21 -00 ...................... |

00 |

2-65 -00 ...................... |

00 |

2-22 -00 ...................... |

00 |

2-66 -00 ...................... |

00 |

2-23 -00 ...................... |

00 |

2-67 -00 ...................... |

00 |

2-24 -00 ...................... |

00 |

2-68 -00 ...................... |

00 |

2-25 -00 ...................... |

00 |

3-1 -00 ........................ |

00 |

2-26 -00 ...................... |

00 |

3-2 -00 ........................ |

00 |

2-27 -00 ...................... |

00 |

3-3 -00 ........................ |

00 |

2-28 -00 ...................... |

00 |

3-4 -00 ........................ |

00 |

2-29 -00 ...................... |

00 |

3-5 -00 ........................ |

00 |

2-30 -00 ...................... |

00 |

3-6 -00 ........................ |

00 |

2-31 -00 ...................... |

00 |

3-7 -00 ........................ |

00 |

2-32 -00 ...................... |

00 |

3-8 -00 ........................ |

00 |

2-33 -00 ...................... |

00 |

3-9 -00 ........................ |

00 |

2-34 -00 ...................... |

00 |

3-10 -00 ...................... |

00 |

2-38 -00 ...................... |

00 |

3-11 -00 ...................... |

00 |

2-39 -00 ...................... |

00 |

3-12 -00 ...................... |

00 |

2-40 -00 ...................... |

00 |

3-13 -00 ...................... |

00 |

2-41 -00 ...................... |

00 |

3-14 -00 ...................... |

00 |

2-42 -00 ...................... |

00 |

3-15 -00 ...................... |

00 |

2-43 -00 ...................... |

00 |

3-16 -00 ...................... |

00 |

2-44 -00 ...................... |

00 |

3-17 -00 ...................... |

00 |

2-46 -00 ...................... |

00 |

3-18 -00 ...................... |

00 |

2-47 -00 ...................... |

00 |

4-1 -00 ........................ |

00 |

2-48 -00 ...................... |

00 |

4-2 -00 ........................ |

00 |

|

|

|

|

|

|

|

|

CONTINUED |

||

|

|

|

|

|

|

|

|

|

|

- 3 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

RST mille

CONTINUED |

|

|

|

|

|

|

|

|

|

|

|

|

|

page# |

Release |

page# |

Release |

|

page# |

Release |

page# |

Release |

|||||

4-3 -00 ........................ |

00 |

6-11 -00 |

...................... 00 |

6-52 -00 |

...................... 00 |

7-40 -00 |

...................... 00 |

||||||

4-4 -00 ........................ |

00 |

6-12 -00 ...................... |

00 |

7-1 -00 ........................ |

00 |

7-41 -00 ...................... |

00 |

||||||

4-5 -00 ........................ |

00 |

6-13 -00 ...................... |

00 |

7-2 -00 ........................ |

00 |

7-42 -00 ...................... |

00 |

||||||

4-6 -00 ........................ |

00 |

6-14 -00 ...................... |

00 |

7-3 -00 ........................ |

00 |

7-43 -00 ...................... |

00 |

||||||

4-7 -00 ........................ |

00 |

6-15 -00 ...................... |

00 |

7-4 -00 ........................ |

00 |

7-44 -00 ...................... |

00 |

||||||

4-8 -00 ........................ |

00 |

6-16 -00 ...................... |

00 |

7-5 -00 ........................ |

00 |

7-45 -00 ...................... |

00 |

||||||

4-9 -00 ........................ |

00 |

6-17 -00 ...................... |

00 |

7-6 -00 ........................ |

00 |

7-46 -00 ...................... |

00 |

||||||

4-10 -00 ...................... |

00 |

6-18 -00 ...................... |

00 |

7-7 -00 ........................ |

00 |

7-47 -00 ...................... |

00 |

||||||

4-11 -00 ...................... |

00 |

6-19 -00 ...................... |

00 |

7-8 -00 ........................ |

00 |

7-48 -00 ...................... |

00 |

||||||

4-12 -00 ...................... |

00 |

6-20 -00 ...................... |

00 |

7-9 -00 ........................ |

00 |

7-49 -00 ...................... |

00 |

||||||

4-13 -00 ...................... |

00 |

6-21 -00 ...................... |

00 |

7-10 -00 ...................... |

00 |

7-50 -00 ...................... |

00 |

||||||

4-14 -00 ...................... |

00 |

6-22 -00 ...................... |

00 |

7-11 -00 ...................... |

00 |

7-51 -00 ...................... |

00 |

||||||

4-15 -00 ...................... |

00 |

6-23 -00 ...................... |

00 |

7-12 -00 ...................... |

00 |

7-52 -00 ...................... |

00 |

||||||

4-16 -00 ...................... |

00 |

6-24 -00 ...................... |

00 |

7-13 -00 ...................... |

00 |

7-53 -00 ...................... |

00 |

||||||

4-17 -00 ...................... |

00 |

6-25 -00 ...................... |

00 |

7-14 -00 ...................... |

00 |

7-54 -00 ...................... |

00 |

||||||

4-18 -00 ...................... |

00 |

6-26 -00 ...................... |

00 |

7-15 -00 ...................... |

00 |

7-55 -00 ...................... |

00 |

||||||

4-19 -00 ...................... |

00 |

6-27 -00 ...................... |

00 |

7-16 -00 ...................... |

00 |

7-56 -00 ...................... |

00 |

||||||

4-20 -00 ...................... |

00 |

6-28 -00 ...................... |

00 |

7-17 -00 ...................... |

00 |

7-57 -00 ...................... |

00 |

||||||

4-21 -00 ...................... |

00 |

6-29 -00 ...................... |

00 |

7-18 -00 ...................... |

00 |

7-58 -00 ...................... |

00 |

||||||

4-22 -00 ...................... |

00 |

6-30 -00 ...................... |

00 |

7-19 -00 ...................... |

00 |

7-59 -00 ...................... |

00 |

||||||

5-1 -00 ........................ |

00 |

6-31 -00 ...................... |

00 |

7-20 -00 ...................... |

00 |

7-60 -00 ...................... |

00 |

||||||

5-2 -00 ........................ |

00 |

6-32 -00 ...................... |

00 |

7-21 -00 ...................... |

00 |

7-61 -00 ...................... |

00 |

||||||

5-3 -00 ........................ |

00 |

6-33 -00 ...................... |

00 |

7-22 -00 ...................... |

00 |

7-62 -00 ...................... |

00 |

||||||

5-4 -00 ........................ |

00 |

6-34 -00 ...................... |

00 |

7-23 -00 ...................... |

00 |

7-63 -00 ...................... |

00 |

||||||

5-5 -00 ........................ |

00 |

6-35 -00 ...................... |

00 |

7-24 -00 ...................... |

00 |

7-64 -00 ...................... |

00 |

||||||

5-6 -00 ........................ |

00 |

6-36 -00 ...................... |

00 |

7-25 -00 ...................... |

00 |

7-65 -00 ...................... |

00 |

||||||

5-7 -00 ........................ |

00 |

6-37 -00 ...................... |

00 |

7-26 -00 ...................... |

00 |

7-66 -00 ...................... |

00 |

||||||

5-8 -00 ........................ |

00 |

6-38 -00 ...................... |

00 |

7-27 -00 ...................... |

00 |

7-67 -00 ...................... |

00 |

||||||

5-9 -00 ........................ |

00 |

6-39 -00 ...................... |

00 |

7-28 -00 ...................... |

00 |

7-68 -00 ...................... |

00 |

||||||

5-10 -00 ...................... |

00 |

6-40 -00 ...................... |

00 |

7-29 -00 ...................... |

00 |

7-69 -00 ...................... |

00 |

||||||

6-1 -00 ........................ |

00 |

6-41 -00 ...................... |

00 |

7-30 -00 ...................... |

00 |

7-70 -00 ...................... |

00 |

||||||

6-2 -00 ........................ |

00 |

6-42 -00 ...................... |

00 |

7-31 -00 ...................... |

00 |

7-71 -00 ...................... |

00 |

||||||

6-3 -00 ........................ |

00 |

6-43 -00 ...................... |

00 |

7-32 -00 ...................... |

00 |

7-72 -00 ...................... |

00 |

||||||

6-4 -00 ........................ |

00 |

6-44 -00 ...................... |

00 |

7-33 -00 ...................... |

00 |

7-73 -00 ...................... |

00 |

||||||

6-5 -00 ........................ |

00 |

6-45 -00 ...................... |

00 |

7-34 -00 ...................... |

00 |

7-74 -00 ...................... |

00 |

||||||

6-6 -00 ........................ |

00 |

6-46 -00 ...................... |

00 |

7-35 -00 ...................... |

00 |

7-75 -00 ...................... |

00 |

||||||

6-7 -00 ........................ |

00 |

6-47 -00 ...................... |

00 |

7-36 -00 ...................... |

00 |

7-76 -00 ...................... |

00 |

||||||

6-8 -00 ........................ |

00 |

6-48 -00 ...................... |

00 |

7-37 -00 ...................... |

00 |

7-77 -00 ...................... |

00 |

||||||

6-9 -00 ........................ |

00 |

6-49 -00 ...................... |

00 |

7-38 -00 ...................... |

00 |

7-78 -00 ...................... |

00 |

||||||

6-10 -00 ...................... |

00 |

6-51 -00 ...................... |

00 |

7-39 -00 ...................... |

00 |

7-79 -00 ...................... |

00 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTINUED |

|

- 4 - 00 |

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

Release 00/2001 - 11 |

||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RST mille

INTRODUCTION

CONTINUED |

|

|

|

|

|

|

|

|

|

|

|

|

|

page# |

Release |

page# |

Release |

||||||||||

7-80 -00 ...................... |

|

00 |

8-16 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-81 -00 ...................... |

|

00 |

8-17 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-82 -00 ...................... |

|

00 |

8-18 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-83 -00 ...................... |

|

00 |

8-19 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-84 -00 ...................... |

|

00 |

8-20 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-85 -00 ...................... |

|

00 |

8-21 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-86 -00 ...................... |

|

00 |

8-22 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-87 -00 ...................... |

|

00 |

8-23 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-88 -00 ...................... |

|

00 |

8-24 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-89 -00 ...................... |

|

00 |

8-25 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-90 -00 ...................... |

|

00 |

8-26 -00 ....................... |

00 |

|

|

|

|

|

|

|

||

7-91 -00 ...................... |

|

00 |

i -1 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-92 -00 ...................... |

|

00 |

i -2 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-93 -00 ...................... |

|

00 |

i -3 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-94 -00 ...................... |

|

00 |

i -3 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-95 -00 ...................... |

|

00 |

i -5 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-96 -00 ...................... |

|

00 |

i -6 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-97 -00 ...................... |

|

00 |

i -7 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-98 -00 ...................... |

|

00 |

i -8 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-99 -00 ...................... |

|

00 |

i -9 -00 ...................... |

00 |

|

|

|

|

|

|

|

||

7-100 -00 .................... |

|

00 |

i -10 -00 .................... |

00 |

|

|

|

|

|

|

|

||

7-101 -00 .................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

7-102 -00 .................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

7-103 -00 .................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

7-104 -00 .................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-1 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-2 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-3 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-4 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-5 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-6 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-7 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-8 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-9 -00 ........................ |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-10 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-11 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-12 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-13 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-14 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

8-15 -00 ...................... |

|

00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 5 - 00 |

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|

|

0 |

||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

RST mille

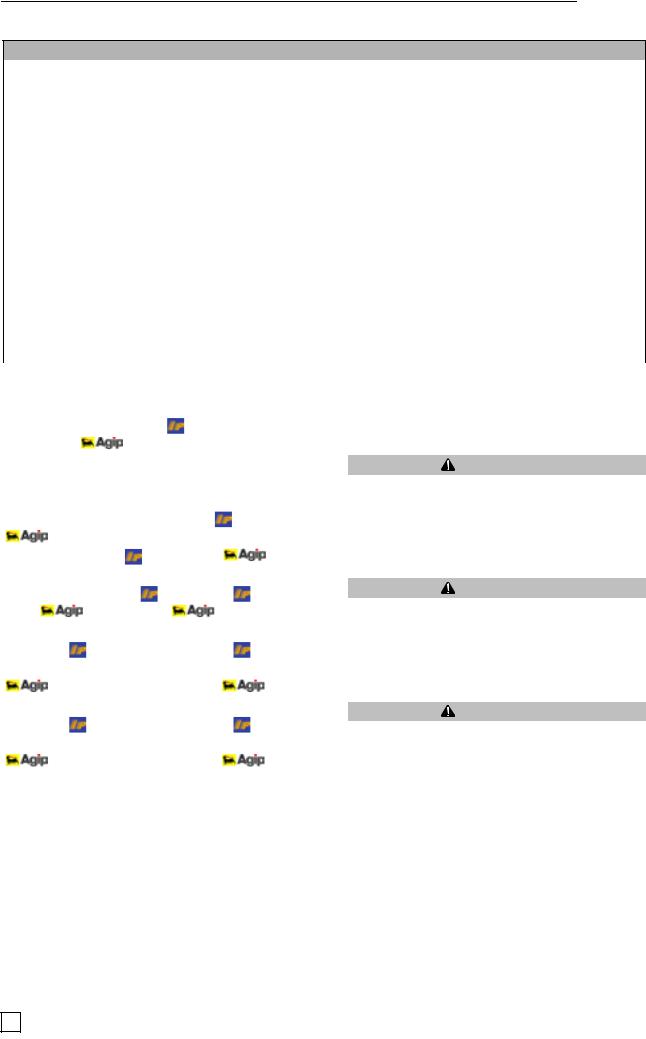

0.2 REFERENCE GUIDE

INFORMAZIONI GENERALI

RST mille

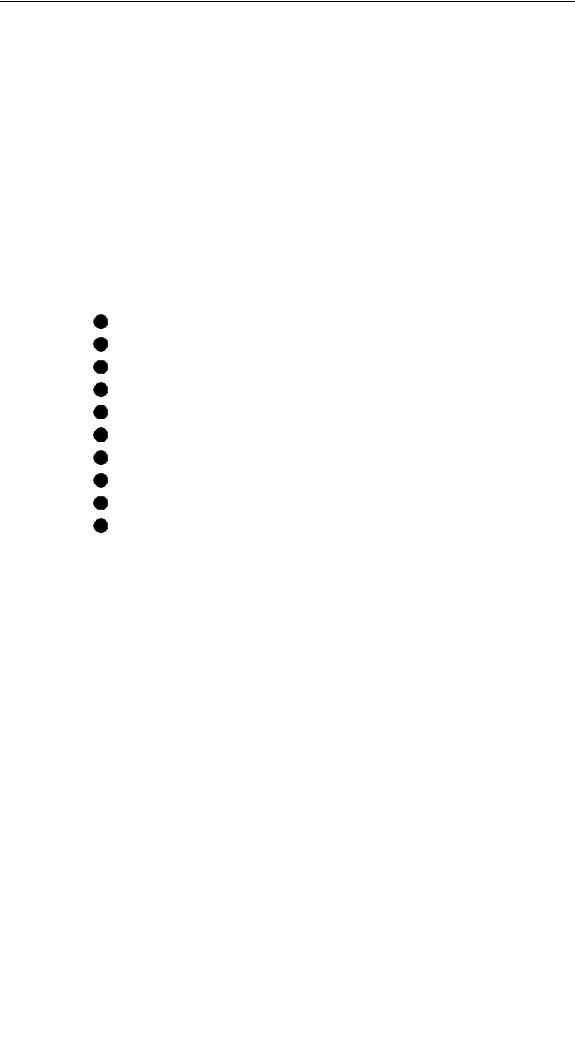

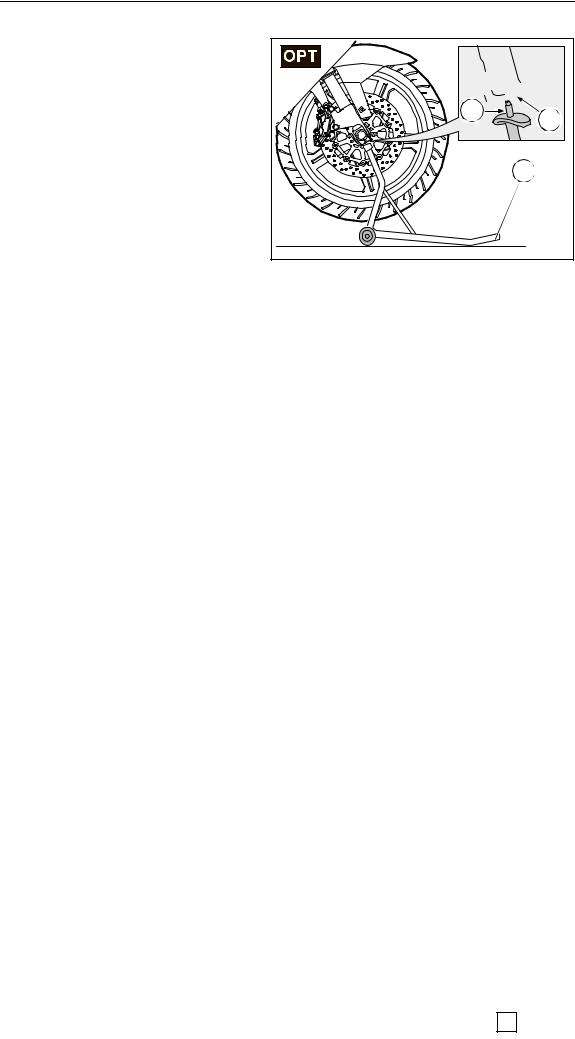

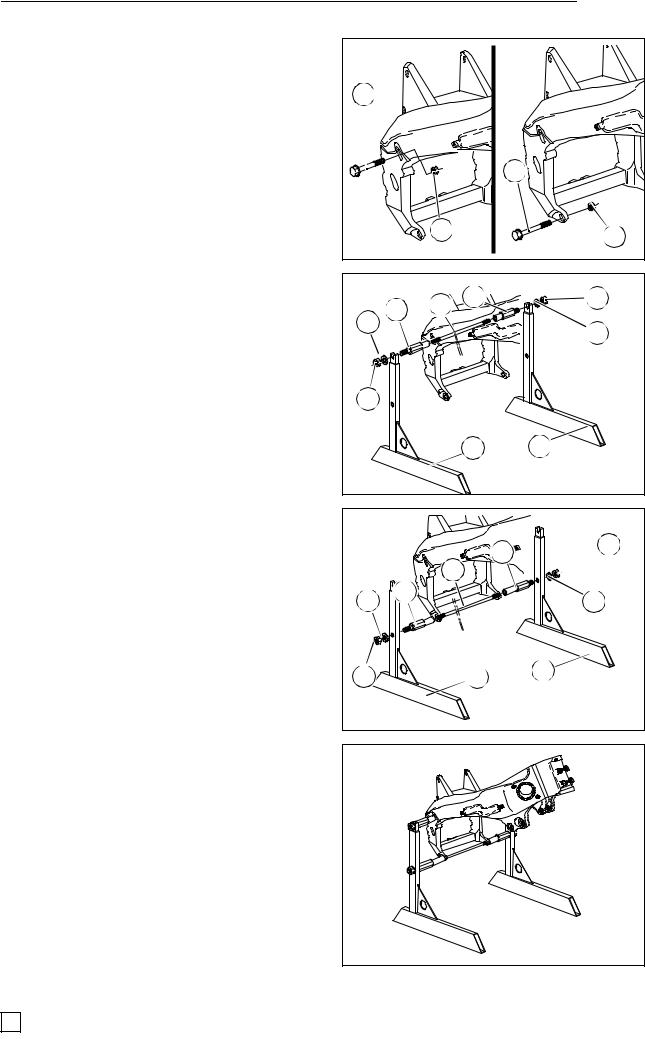

1.9PLACING THE MOTORCYCLE ON THE SERVICE STAND

1.9.1PLACING THE MOTORCYCLE ON THE FRONT WHEEL STAND

Place the motorcycle on the centre stand.

Place the motorcycle on the centre stand.

Slide both pins (1) of the front wheel stand into the holes (2) at front fork bottom end of the same time.

Slide both pins (1) of the front wheel stand into the holes (2) at front fork bottom end of the same time.

Put one foot on the front end of the stand (3).

Put one foot on the front end of the stand (3).  Press down on stand (3) until it rests fully on the ground.

Press down on stand (3) until it rests fully on the ground.

1.9.2PLACING THE MOTORCYCLE ON THE CENTRE STAND

Read paragraph 0.2.1 (GENERAL PRECAUTIONS AND INFORMATION) carefully.

Part no. 8140176 (complete stand).

Remove the lower fairing, see 7.1.33 (REMOVING THE LOWER FAIRING).

Remove the lower fairing, see 7.1.33 (REMOVING THE LOWER FAIRING).

Place the motorcycle on the front wheel stand

Place the motorcycle on the front wheel stand

, see 1.9.1 (PLACING THE MOTORCYCLE ON THE FRONT WHEEL STAND).

, see 1.9.1 (PLACING THE MOTORCYCLE ON THE FRONT WHEEL STAND).

Hold the nut (1) steady on the inside.

Hold the nut (1) steady on the inside.

Release and remove the rear upper right-hand engine mounting bolt (2).

Torque wrench setting for nut (1) / bolt (2):50 Nm (5,0 kgm).

Torque wrench setting for nut (1) / bolt (2):50 Nm (5,0 kgm).

NOTE The bolt (2) on the left-hand side is longer

Collect the nut (1).

Slide the upper right-hand mounting boss (3) into the upper hole on the right-hand side.

Slide the upper right-hand mounting boss (3) into the upper hole on the right-hand side.

Fit the stud bolt (4) into the upper hole on the left-hand side and screw it fully into the mounting boss (3).

Fit the stud bolt (4) into the upper hole on the left-hand side and screw it fully into the mounting boss (3).

Screw the upper left-hand mounting boss (5) fully onto stud bolt (4) and tighten.

Screw the upper left-hand mounting boss (5) fully onto stud bolt (4) and tighten.

Hold the nut (6) on the inside steady.

Release and remove the rear lower engine mounting bolt (7).

|

|

1 |

|

|

2 |

|

|

3 |

2 |

|

|

|

|

7 |

|

1 |

6 |

|

|

|

3 |

4 |

5 |

|

||

|

|

Release 00/2001 - 07

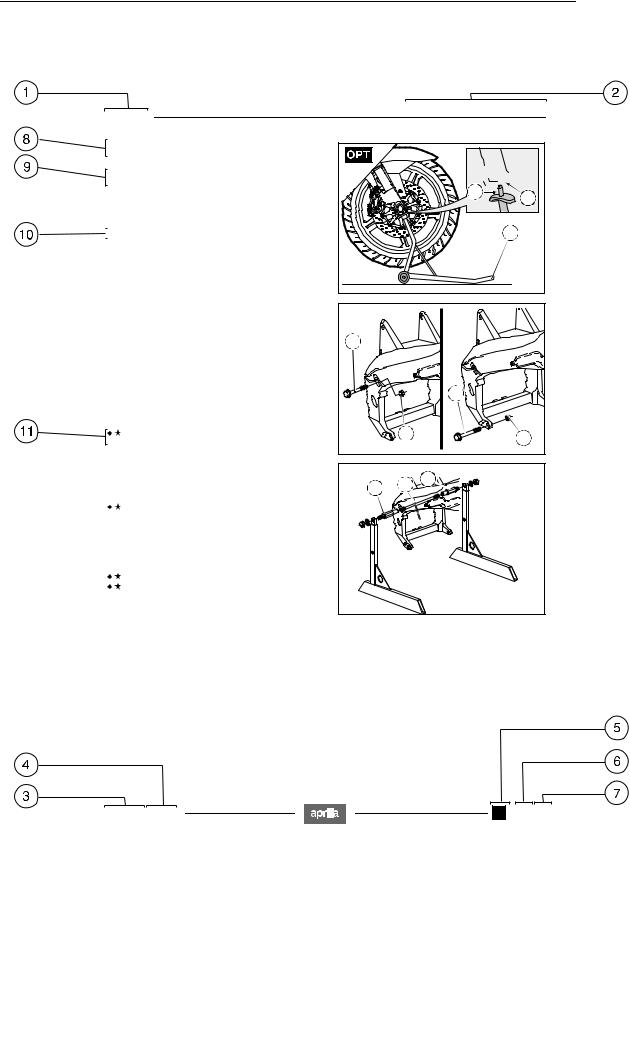

1)Motorcycle model (or engine type)

2)Section title

3)Release progressive number (“00” identifies the original release)

4)Year and month of issue of relevant release

5)Section number

6)Page number (pages are numbered sequentially, numbering begins anew in each section)

1 - 17 - 00

7)Page update number (progressive number)

8)Subsection number (progressive number)

9)Paragraph number (progressive number)

10)Description of operation (always preceded by the lozenge symbol)

11)Description of operation: the star means that the operation must be repeated on the opposite side of the motorcycle

|

- 6 - 00 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille

INTRODUCTION

0.3 FOREWORD

-This manual provides the information required for normal servicing.

-The information and illustrations contained in this manual are updated through subsequent releases, see

0.1(RELEASE 00/2001-11 UPDATE).

-This manual is intended for use by aprilia Dealers and their qualified mechanics. Certain information has been omitted intentionally, as this manual does not purport to provide a comprehensive treatise on mechanics. The persons who will use this manual must be fully conversant with the basics of mechanics and with the basic procedures of motorcycle repair. Repairing or inspecting a motorcycle when one does not possess such basic knowledge or training could result in improper servicing and make the motorcycle unsafe to ride. For the same reason, certain basic precautions have been omitted in the descriptions of repair and inspection procedures. Take special care to avoid damage to motorcycle components or injury to persons. aprilia s.p.a.'s mission is to constantly enhance the riding pleasure of final users through the on-going improvement of its products as well as of the relevant technical literature.

All aprilia Points of Sale and Subsidiaries worldwide are kept updated on major engineering changes and modifications to repair procedures. Such changes and modifications are then reflected in the next release of the relevant manual. When in doubt about an inspection or repair procedure, please contact the aprilia Consumer Service (A.C.S.) Department, who will be glad to provide full information on the procedure in question as well as on any updates or engineering changes affecting the motorcycle under consideration.

aprilia s.p.a. reserves the right to make changes to its products at any time, barring any such changes as may alter the essential features of a product as specified in the relevant manual.

All rights of storage using electronic means, reproduction and total or partial adaptation, whatever the means adopted, are reserved in all countries.

Any reference to products or services provided by outside suppliers is for information only and by no means binding, and implies no warranties or responsibilities as to the performance or use of any such products and/or services.

Please read 0.4 (REFERENCE MANUALS) for more detailed information.

Original release: November 2001

Produced and printed by:

DECA s.n.c.

via Risorgimento, 23/1 - 48022 Lugo (RA) - Italia Tel. +39 - 0545 35235

Fax +39 - 0545 32844 E-mail: deca@decagroup.it www.decaweb.it

for:

aprilia Consumer Service s.p.a.

via Noalese, 156 - 30036 Santa Maria di Sala (VE) - Italia Tel. +39 - 041 57 86 101

Fax +39 - 041 57 86 100 www.aprilia.com

0.4 REFERENCE MANUALS

0.4.1 ENGINE WORKSHOP MANUALS

aprilia part# (description)

8140582 (1051-1) |

I |

|

|

8140584 (1053-1) |

F |

|

|

8140585 (1054-1) |

D |

|

|

8140583 (1052-1) |

E |

|

|

8140586 (1055-1) |

UK |

|

|

8140587 (1056-1) |

USA |

0.4.2 PARTS CATALOGUES

aprilia part# (description)

390W ............... |

I |

UK |

|

|

|

390Y ................ |

I |

UK |

|

|

|

3901................. |

I |

UK |

RSV01

0.4.3 SPECIAL TOOLS CATALOGUES

aprilia part# (description)

8202278 I |

F |

D |

E UK |

0.4.4 OWNER'S MANUALS

aprilia part# (description)

Model years 1998 -1999

8102623 |

I |

F |

D |

|

|

|

|

8102857 |

P |

E |

UK |

|

|

|

|

8102858 |

NL |

DK |

SF |

|

|

|

|

8102859 |

GR |

J |

UK |

|

|

|

|

8104128 |

AUS |

|

|

|

|

|

|

8104099 |

USA |

|

|

Model years 2000

8104089 |

I |

F |

D |

||

|

|

|

|

|

|

8104142 |

P |

E |

UK |

||

|

|

|

|

|

|

8104143 |

NL |

DK |

SF |

||

|

|

|

|

|

|

8104141 |

GR |

J |

UK |

||

|

|

|

|

|

|

8104164 |

AUS |

|

|

|

|

|

|

|

|

|

|

8104171 |

USA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RSV01 |

|

|

|

|

|

|

|

8104152 |

I |

F |

D |

||

|

|

|

|

|

|

8104269 |

P |

E |

UK |

||

|

|

|

|

|

|

8104267 |

NL |

DK |

SF |

||

|

|

|

|

|

|

8104268 |

GR |

J |

UK |

||

|

|

|

|

|

|

8104270 |

AUS |

|

|

|

|

|

|

|

|

|

|

8104264 |

USA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 7 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

RST mille

0.5 SAFETY INFORMATION

The following conventions are used to identify safety information throughout the manual.

This symbol identifies safety-related information. Whenever you see this symbol in the manual or attached to the motorcycle, use utmost care to avoid the risk of injury. Disregarding the instructions identified by this symbol may put your safety, as well as that of other

persons or of the motorcycle at risk!

CAUTION

Disregarding these indications may lead to severe injury or death.

WARNING

WARNING

Disregarding these indications may lead to minor injury or motorcycle damage.

NOTE The term "NOTE" in this manual precedes important information or instructions.

0.5.1 GENERAL PRECAUTIONS AND INFORMATION

Follow these instructions closely when repairing, disassembling or reassembling the motorcycle or its components.

CAUTION

Using bare flames is strictly forbidden when working on the motorcycle. Before servicing or inspecting the motorcycle: stop the engine and remove the key from the ignition switch; allow for the engine and exhaust system to cool down; where possible, lift the motorcycle using adequate equipment placed on firm and level ground. Be careful of any parts of the engine or exhaust system which may still be hot to the touch to avoid scalds or burns.

CAUTION

Never put any mechanical parts or other vehicle components in your mouth when you have both hands busy. None of the motorcycle components is edible. Some components are harmful to the human body or toxic.

Unless expressly specified otherwise, motorcycle assemblies are refitted or re-assembled by reversing the removal or dismantling procedure. Where a procedure is cross-referred to relevant sections in the manual, proceed sensibly to avoid disturbing any parts unless strictly necessary. Never attempt to polish matte-finished surfaces with lapping compounds.

Never use fuel instead of solvent to clean the motorcycle.

Do not clean any rubber or plastic parts or the seat with alcohol, petrol or solvents. Clean with water and neutral detergent.

Always disconnect the battery negative (–) lead before soldering any electrical components.

When two or more persons service the same motorcycle together, special care must be taken to avoid personal injury.

Read 1.2 (WARNINGS CONCERNING FUEL, LUBRICANTS, COOLANT AND OTHER COMPONENT PARTS) carefully.

0.5.2BEFORE DISASSEMBLING ANY COMPONENTS

-Clean off all dirt, mud, and dust and clear any foreign objects from the vehicle before disassembling any components.

-Use the model-specific special tools where specified.

0.5.3 DISASSEMBLING THE COMPONENTS

-Never use pliers or similar tools to slacken and/or tighten nuts and bolts. Always use a suitable spanner.

-Mark all connections (hoses, wiring, etc.) with their positions before disconnecting them. Identify each connection using a distinctive symbol or convention.

-Mark each part clearly to avoid confusion when refitting.

-Thoroughly clean and wash any components you have removed using a detergent with low flash point.

-Mated parts should always be refitted together. These parts will have seated themselves against one another in service as a result of normal wear and tear and should never be mixed up with other similar parts on refitting.

-Certain components are matched-pair parts and should always be replaced as a set.

-Keep the motorcycle and its components well away from heat sources.

0.5.4 REASSEMBLING THE COMPONENTS

WARNING

WARNING

Never reuse a circlip or snap ring. These parts must always be renewed once they have been disturbed.

When fitting a new circlip or snap ring, take care to move the open ends apart just enough to allow fitment to the shaft.

Make a rule to check that a newly –fitted circlip or snap ring has located fully into its groove.

Never clean a bearing with compressed air.

NOTE All bearings must rotate freely with no hardness or noise. Replace any bearings that do not meet these requirements.

-Use ORIGINAL aprilia SPARE PARTS only.

-Use the specified lubricants and consumables.

-Where possible, lubricate a part before assembly.

-When tightening nuts and bolts, start with the largest or innermost nut/bolt and observe a cross pattern. Tighten evenly in subsequent steps until achieving the specified torque.

-Replace any self-locking nuts, gaskets, seals, circlips or snap rings, O-rings, split pins, bolts and screws which have a damaged thread.

-Clean all joint surfaces, oil seal edges and gaskets before assembly.

-Apply a light coat of lithium grease along the edges of oil seals. Fit oil seals and bearings with the brand or serial number facing outwards (in view).

-Lubricate the bearings abundantly before assembly.

-Make a rule to check that all components you have fitted are correctly in place.

|

- 8 - 00 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille

INTRODUCTION

-After repairing the motorcycle and after each service inspection, perform the preliminary checks, and then operate the motorcycle in a private estate area or in a safe area away from traffic

0.6 SAFETY INFORMATION

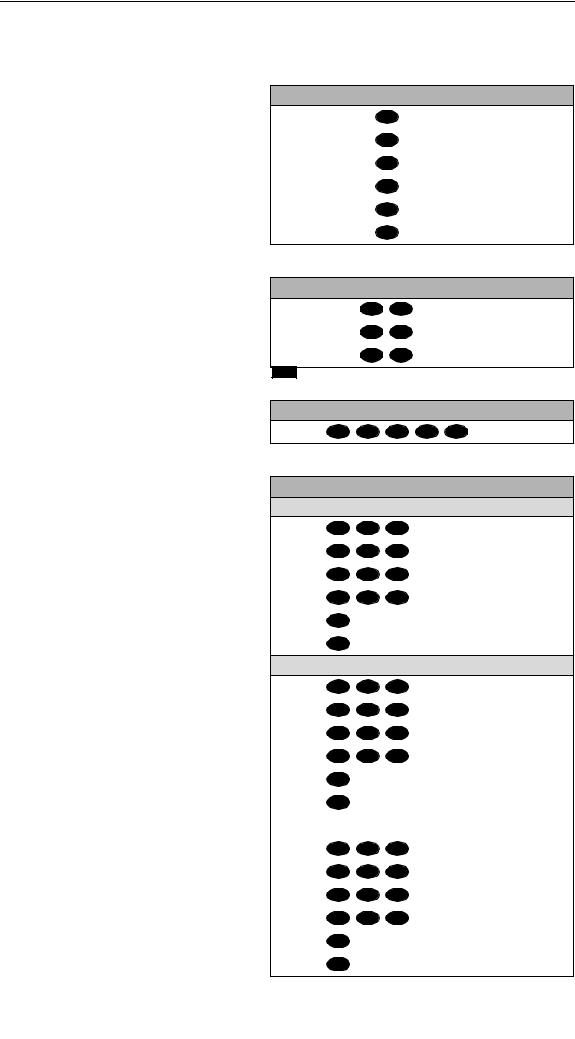

0.6.1 CONVENTIONS USED IN THE MANUAL

-This manual is divided in sections and subsections, each covering a set of the most significant components.

For quick reference, see the summary of sections on page 0-1.

-Unless expressly specified otherwise, assemblies are reassembled by reversing the dismantling procedure.

-The terms “left” and “right” are referred to the motorcycle when viewed from the riding position.

-Motorcycle operation and basic maintenance are covered in the “OWNER'S MANUAL”.

Any operations preceded by the star symbol must

be repeated on the opposite side of the motorcycle.

In this manual any variants are identified with these symbols:

|

Frame # ZD4DW......(STARTING FROM MODEL YEAR |

||||

|

2001). |

|

|

|

|

|

AUTOMATIC SWITCH-ON DEVICE |

|

|

||

ASD |

|

|

|||

|

Option |

|

|

|

|

OPT |

|

|

|

|

|

|

Catalysed version |

|

|

|

|

VERSION: |

|

|

|

|

|

I |

Italy |

GR |

Greece |

Mal |

Malaysia |

UK |

United |

NL |

Netherlands |

RCH |

Chile |

|

Kingdom |

||||

|

|

|

|

|

|

A |

Austria |

CH |

Switzerland |

HR |

Croatia |

P |

Portugal |

DK |

Denmark |

AUS |

Australia |

|

|

|

|

USA |

United |

SF |

Finland |

J |

Japan |

|

States of |

|

|

|

|

|

America |

B |

Belgium |

SGP Singapore |

BR |

Brazil |

|

|

|

|

|

RSA |

Republic of |

D |

Germany |

SLO |

Slovenia |

|

South |

|

|

|

|

|

Africa |

F |

France |

IL |

Israel |

NZ |

New |

|

Zealand |

||||

|

|

|

|

|

|

E |

Spain |

ROK |

South |

CDN |

Canada |

|

Korea |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 9 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

RST mille

0.7ABBREVIATIONS/SYMBOLS/ CONVENTIONS

#= Number

<= is less than

>= is more than

<= is less than or equal to

>= is more than or equal to

~ |

= approximately |

∞ |

= infinite |

°C |

= degrees Celsius (centigrade) |

°F |

= degrees Fahrenheit |

±= plus or minus

A |

= Ampere |

AC |

=Alternated Current |

Ah |

=Ampere per hour |

API |

= American Petroleum Institute |

AV/DC |

= Anti-Vibration Double Countershaft |

bar |

= pressure measurement (1 bar =100 kPa) |

BDC |

= Bottom Dead Centre |

CO |

= carbon oxide |

CPU |

= Central Processing Unit |

cu cm |

= cubic centimetres |

DC |

= Direct Current |

DIN |

= German industrial standards |

DOHC |

(Deutsche Industrie Norm) |

= Double Overhead Camshaft |

|

ECU |

= Electronic Control Unit |

HC |

= unburnt hydrocarbons |

HT |

= High Tension |

ID |

= inner diameter |

ISC |

= Idle Speed Control |

ISO |

= International Standardization Organization |

kg |

= kilograms |

kgm |

= kilograms per metre (1 kgm =10 Nm) |

km |

= kilometres |

km/h |

= kilometres per hour |

kPa |

= kiloPascal (1 kPa =0.01 bar) |

KS |

= clutch side (from the German "Kupplung |

kW |

seite") |

= kiloWatt |

|

kΩ |

= kiloOhm |

l |

= litres |

LAP |

= racetrack lap |

LED |

= Light Emitting Diode |

m/s |

= metres per second |

max |

= maximum |

mbar |

= millibar (1 mbar =0.1 kPa) |

mi |

= miles |

MIN |

= minimum |

MPH |

= miles per hour |

MS |

= flywheel side (from the German |

MΩ |

"Magnetoseite") |

= megaOhm |

|

N.A. |

= Not Available |

N.O.M.M. |

= Motor Octane Number |

N.O.R.M. |

= Research Octane Number |

Nm |

= Newton per metre (1 Nm =0.1 kgm) |

Ø= Diameter

OD |

= outer diameter |

Ω |

= ohm |

PPC |

= Pneumatic Power Clutch |

rpm |

= revolutions per minute |

SAE |

= Society of Automotive Engineers |

T.B.E.I. |

= crowned-head Allen screw |

T.C.E.I. |

= cheese-headed Allen screw |

T.E. |

=hexagonal head |

T.P. |

=flat head screw |

TDC |

= Top Dead Centre |

TEST |

= diagnostic check |

TSI |

= Twin Spark Ignition |

UPSIDE- |

|

DOWN |

= inverted fork |

V= Volt

W= Watt

|

- 10 - 00 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille

NOTES

INTRODUCTION

|

|

|

|

|

|

|

|

|

|

- 11 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

0 |

||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

INTRODUCTION

RST mille

NOTES

|

- 12 - 00 |

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille

GENERAL INFORMATION

GENERAL INFORMATION |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 1 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

GENERAL INFORMATION

GENERAL INFORMATION

CONTENTS

1.1 LOCATION OF SERIAL NUMBERS .. 1-3-00

0 |

1.1.1 |

FRAME NUMBER.................................. |

1-3-00 |

1.1.2 |

ENGINE NUMBER................................. |

1-3-00 |

1.2WARNINGS CONCERNING FUEL, LUBRICANTS, COOLANT AND OTHER

1 |

|

|

......................COMPONENT PARTS |

1-3-00 |

|

|

1.2.1 |

FUEL...................................................... |

1-3-00 |

||

|

1.2.2 |

ENGINE OIL........................................... |

1-4-00 |

||

|

|

1.2.3 |

.......................................BRAKE FLUID |

1-4-00 |

|

|

|

||||

|

|

1.2.4 |

COOLANT |

1-5-00 |

|

2 |

|

||||

|

|||||

|

1.2.5 |

CLUTCH FLUID..................................... |

1-5-00 |

||

|

1.2.6 |

CARBON OXIDE ................................... |

1-6-00 |

||

|

1.2.7 |

HOT COMPONENT PARTS .................. |

1-6-00 |

||

|

1.3 |

RUNNING-IN RECOMMENDATIONS 1-6-00 |

|||

3 |

|

1.4 |

.................................SPARE PARTS |

1-7-00 |

|

|

1.5 |

SPECIFICATIONS ............................ |

1-7-00 |

||

|

|

1.6 |

LUBRICANT CHART |

1-10-00 |

|

|

|

||||

4 |

|

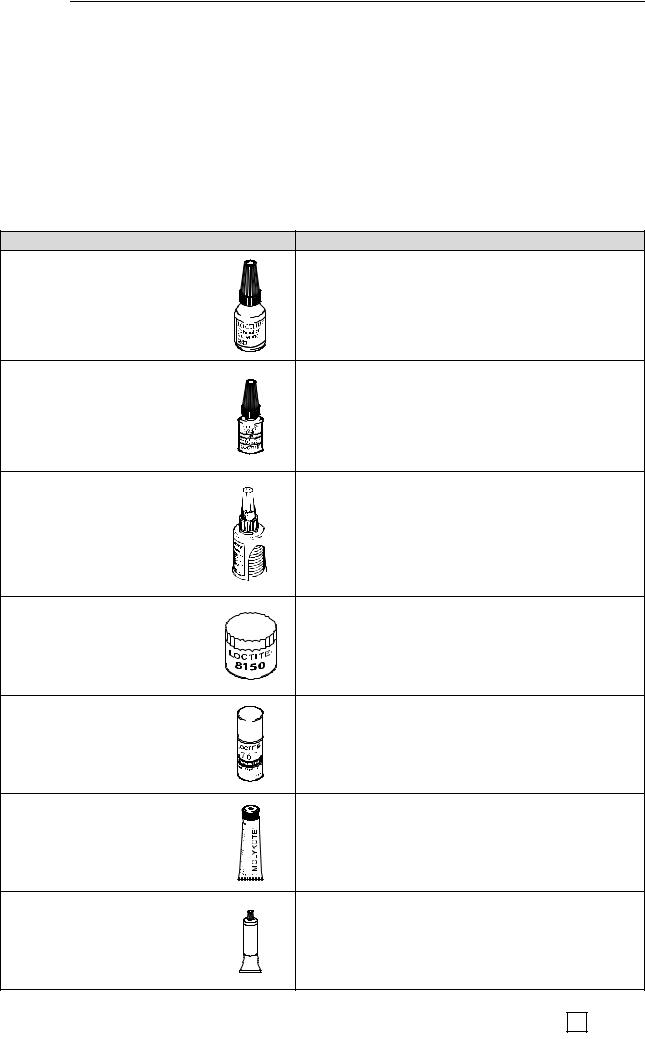

CONSUMABLES |

1-11-00 |

||

|

1.7 |

||||

|

1.7.1 |

PRODUCT FEATURES ....................... |

1-11-00 |

||

|

1.7.2 |

PRODUCT APPLICATIONS ............... |

1-12-00 |

||

|

1.8 |

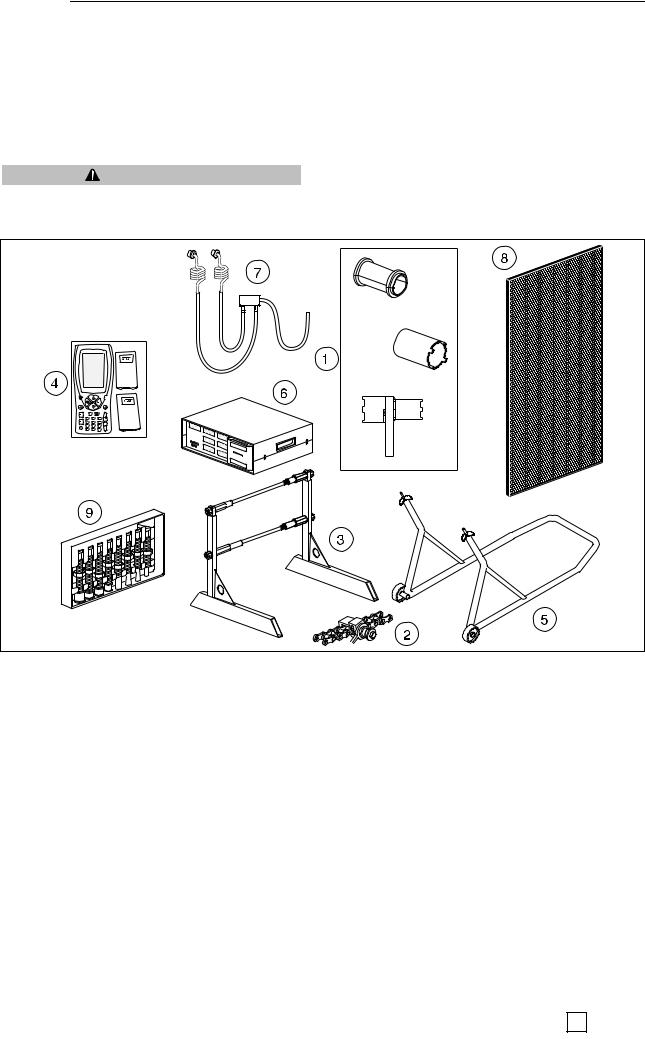

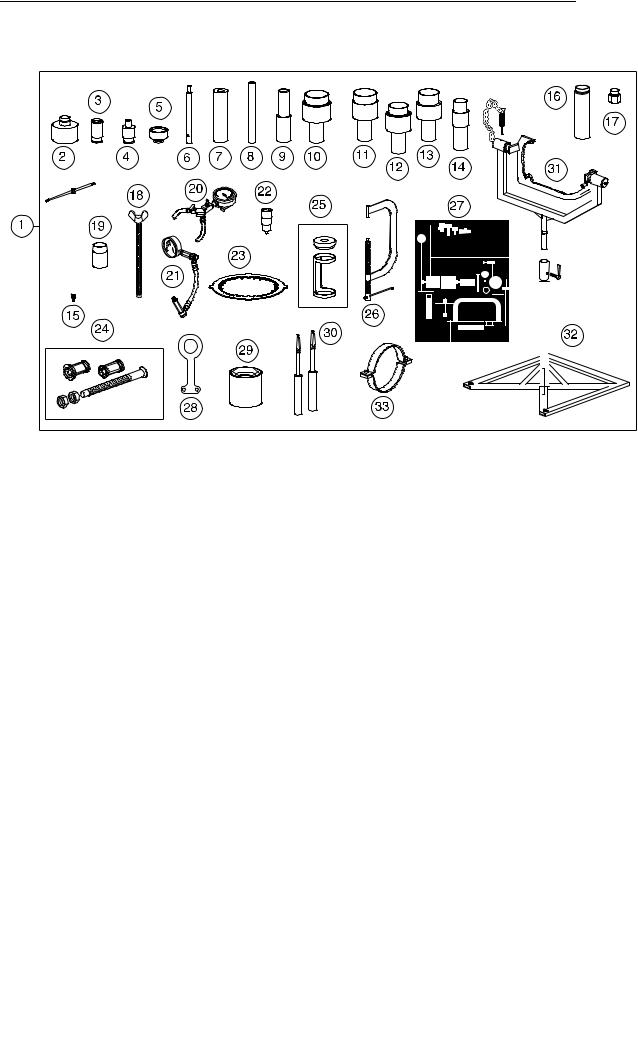

SPECIAL TOOLS............................ |

1-15-00 |

||

5 |

|

1.8.1 |

...............................SUNDRY TOOLS |

1-15-00 |

|

|

1.8.2 |

ENGINE TOOLS .................................. |

1-16-00 |

||

|

|

1.9 |

PLACING THE MOTORCYCLE ON THE |

||

|

|

|

.........................SERVICE STANDS |

1-17-00 |

|

6 |

|

1.9.1 PLACING THE MOTORCYCLE ON THE |

|||

|

|

|

FRONT WHEEL STAND ..................... |

1-17-00 |

|

|

1.9.2 |

PLACING THE MOTORCYCLE ON THE |

|||

|

|

|

|

CENTRE STAND ................................ |

1-18-00 |

|

|

|

|

||

7 |

|

1.10HOW TO APPLY THE DECALS |

1-19-00 |

||

|

|||||

|

1.11TORQUE FIGURES ........................ |

1-21-00 |

|||

8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 - 2 - 00

RST mille

Release 00/2001 - 11

RST mille

GENERAL INFORMATION

1.1 LOCATION OF SERIAL NUMBERS

These numbers are necessary for vehicle registration.

NOTE Altering the identification numbers of vehicle or engine is a legal offence punishable by heavy fines and penalties. In addition, altering the frame number (VIN) results in immediate warranty invalidation.

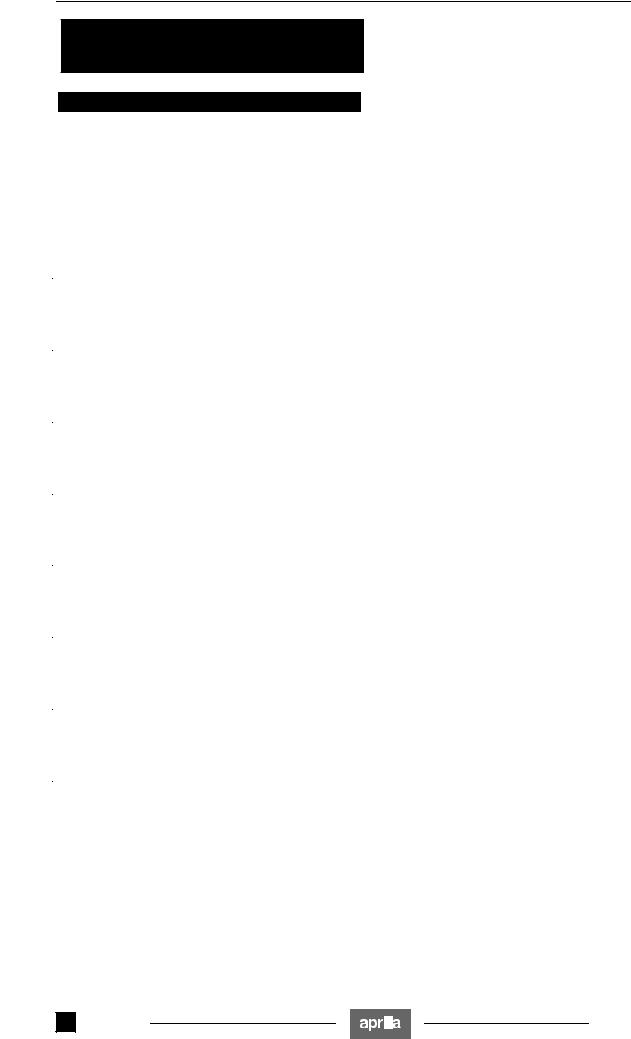

1.1.1 FRAME NUMBER

The frame number (Vehicle Identification Number) is etched on the right-hand side of the headstock.

1.1.2 ENGINE NUMBER

The engine number is etched at the rear end of engine, in the area near the sprocket.

1.2 WARNINGS CONCERNING FUEL, LUBRICANTS, COOLANT AND OTHER COMPONENT PARTS

1.2.1 FUEL

CAUTION

The fuel used to operate engines is highly flammable and becomes explosive under particular conditions. Refuelling and engine service should take place in a well-ventilated area with the engine stopped.

Do not smoke when refuelling or in the proximity of sources of fuel vapours.

Avoid contact with bare flames, sources of sparks or any other source which may ignite the fuel or lead to explosion.

Take care not to spill fuel out of the filler, or it may ignite when in contact with hot engine parts.

In the event of accidental fuel spillage, make sure the affected area is fully dry before starting the engine. Fuel expands from heat and when left under direct sunlight. Never fill the fuel tank up to the rim.

Tighten the filler cap securely after each refuelling. Avoid contact with skin. Do not inhale vapours. Do not swallow fuel. Do not transfer fuel between different containers using a hose.

DO NOT RELEASE FUEL INTO THE ENVIRONMENT. KEEP AWAY FROM CHILDREN.

Use only premium-grade unleaded fuel with a minimum octane rating of 95 (N.O.R.M.) and 85 (N.O.M.M.).

|

|

|

|

|

|

|

|

|

|

- 3 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

GENERAL INFORMATION

RST mille

1.2.2 ENGINE OIL

CAUTION

Prolonged or repeated contact with engine oil may cause severe skin damage. Wash your hands thoroughly after handling engine oil.

Do not release into the environment.

Dispose of engine oil through the nearest waste oil reclamation firm or through the supplier.

Wear latex gloves during servicing.

Change engine oil after the first 1000 km (625 mi) and every 7500 km (4687mi) (*), see 2.13 (ENGINE OIL AND FILTER CHANGE) afterwards.

(*) = On motorcycles used in competition trials, oil should be changed every 3750 km (2343 mi).

(Recommended) engine oil, see 1.6 (LUBRICANT CHART)Front fork fluid

CAUTION

Prolonged or repeated contact with front fork fluid may cause severe skin damage. Wash your hands thoroughly after handling front fork fluid. Dispose of front fork fluid through the nearest waste oil reclamation firm or through the supplier.

Wear latex gloves during servicing.

Front suspension response can be modified to a certain extent by changing damping settings and/or selecting a particular grade of oil. Standard oil grade is SAE 20 W. Different oil grades can be selected to obtain a particular suspension response. (Choose SAE 5W for a softer suspension, 20W for a stiffer suspension). The two grades can also be mixed in varying solutions to obtain the desired response.

F.A. or

F.A. or  Fork have special properties, which enable them to retain virtually the same viscosity regardless of temperature to give constant damping response.

Fork have special properties, which enable them to retain virtually the same viscosity regardless of temperature to give constant damping response.

(Recommended) front fork oil, see 1.6 (LUBRICANT CHART).

1.2.3 BRAKE FLUID

NOTEThis vehicle is fitted with front and rear disc brakes. Each braking system is operated by an independent hydraulic circuit. The information provided below applies to both braking systems.

CAUTION

Brake fluid is an irritant. Avoid contact with eyes or skin.

In the event of accidental contact, wash affected body parts thoroughly. In the event of accidental contact with eyes, contact an eye specialist or seek medical advice.

DO NOT RELEASE BRAKE FLUID INTO THE ENVIRONMENT.

KEEP AWAY FROM CHILDREN.

When handling brake fluid, take care not to spill it onto plastic or paint-finished parts or they will damage.

Check brake fluid level every 7,500 km (4687 mi), see 2.16 (CHECKING AND TOPPING UP FRONT BRAKE FLUID LEVEL). See also 2.17 (CHECKING AND TOPPING UP REAR BRAKE FLUID LEVEL). Change brake fluid every two years, see 2.21 (CHANGING THE FRONT BRAKE FLUID) and 2.22 (CHANGING THE REAR BRAKE FLUID).

(Recommended) brake fluid, see 1.6 (LUBRICANT CHART).

CAUTION

Do not use any brake fluids other than the specified type. Never mix different types of fluids to top up level, as this will damage the braking system.

Do not use brake fluid from containers which have been kept open or in storage for long periods.

Any sudden changes in play or hardness in the brake levers are warning signs of problems with the hydraulic circuits.

Ensure that the brake discs and brake linings have not become contaminated with oil or grease. This is particularly important after servicing or inspections. Make sure the brake lines are not twisted or worn.

Prevent accidental ingress of water or dust into the circuit. Wear latex gloves when servicing the hydraulic circuit.

|

- 4 - 00 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille

GENERAL INFORMATION

1.2.4 COOLANT

CAUTION

Coolant is toxic when ingested and is an irritant, contact with eyes or skin may cause irritation.

In the event of contact with eyes, rinse repeatedly with abundant water and seek medical advice. In the event of ingestion, induce vomiting, rinse mouth and throat with abundant water and seek medical advice immediately.

DO NOT RELEASE INTO THE ENVIRONMENT. KEEP AWAY FROM CHILDREN.

1.2.5 CLUTCH FLUID

NOTE This vehicle is fitted with a hydraulically operated clutch.

CAUTION

Clutch fluid is an irritant. Avoid contact with eyes or skin.

In the event of accidental contact, wash affected body parts thoroughly. In the event of accidental contact with eyes, contact an eye specialist or seek medical advice.

DO NOT RELEASE CLUTCH FLUID INTO THE ENVIRONMENT.

CAUTION

Take care not to spill coolant onto hot engine parts. It may ignite and produce invisible flames. Wear latex gloves when servicing.

Do not ride when coolant is below the minimum level.

Check coolant level before each ride and every 15000 km (9375 mi), see 2.14 (CHECKING AND TOPPING UP COOLANT LEVEL) as part of routine maintenance. Change coolant every two years, see 2.15 (COOLANT CHANGE).

Coolant mixture is a 50% solution of water and antifreeze. This is the ideal solution for most operating temperatures and provides good corrosion protection.

This solution is also suited to the warm season, as it is less prone to evaporative loss and will reduce the need for top-ups. In addition, less water evaporation means fewer minerals salts depositing in the radiator, which helps preserve the efficiency of the cooling system.

When temperature drops below zero degrees centigrade, check the cooling system frequently and add more antifreeze (up to 60% maximum) to the solution.

Use distilled water in the coolant mixture. Tap water will damage the engine.

(Recommended) engine anti-freeze, see 1.6 (LUBRICANT CHART).

Refer to the chart given below and add water with the quantity of anti-freeze to obtain a solution with the desired freezing point:

Freezing point °C |

Coolant |

|

% of volume |

|

|

-20° |

35 |

|

|

-30° |

45 |

|

|

-40° |

55 |

|

|

NOTE The different brands of anti-freeze available on the market have varying specifications. Always read product label to determine the degree of protection afforded.

WARNING

WARNING

KEEP AWAY FROM CHILDREN.

When handling clutch fluid, take care not to spill it onto plastic or paint-finished parts or they will damage.

Check clutch fluid level every 7,500 km (4687 mi), see 2.18 (CHECKING AND TOPPING UP CLUTCH FLUID LEVEL). Change clutch fluid every two years, see 2.23 (CHANGING THE CLUTCH FLUID).

(Recommended) clutch fluid, see 1.6 (LUBRICANT CHART).

WARNING

WARNING

Do not use any clutch fluids other than the specified type. Never mix different types of fluids to top up level, as this will damage the clutch system. Do not use clutch fluid from containers which have been open or kept in storage for long periods. Any sudden changes in play or hardness in the clutch lever are warning signs of problems with the hydraulic circuit. Make sure the clutch hose is not twisted or worn.

Avoid accidental ingress of water or dust into the circuit.

Wear latex gloves when servicing the hydraulic circuit.

Use only nitrite-free anti-freeze and corrosion inhibitors with a freezing point of –35°C as a minimum.

|

|

|

|

|

|

|

|

|

|

- 5 - 00 |

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

||||

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

GENERAL INFORMATION

RST mille

1.2.6 CARBON OXIDE

When an operation must be performed with the engine running, position the motorcycle out of doors or in a wellventilated area. Never operate the engine in an enclosed place.

Use an exhaust emission extraction plant when working indoors.

CAUTION

Exhaust emissions contain carbon oxide, which is a poisonous gas and may lead to loss of conscience or even death.

Operate the engine out of doors or, if working indoors, use an exhaust emission extraction plant.

1.2.7 HOT COMPONENT PARTS

CAUTION

The engine and exhaust component parts become hot when the engine is running and will stay hot for some time after the engine has been stopped.

Wear heat gloves before handling these components or allow for the engine and exhaust system to cool down before proceeding.

1.3 RUNNING-IN RECOMMENDATIONS

Proper engine running-in is essential to preserving engine life and performance over time.

Twisty roads and gradients are ideal to break in engine, suspension and brakes effectively.

Varying speed frequently is also recommended. This will vary the amount of stress placed on vehicle components continuously, allowing engine parts to cool down when less stressed. While it is important to put a certain amount of stress to engine components during the running-in period, it is equally important to spare the engine at this stage in vehicle's life.

WARNING

WARNING

Top acceleration performance is only obtained after covering the first 1500 km (937 mi).

Observe the following instructions:

Avoid harsh accelerations and do not flip the throttle open abruptly when the engine is running at low speed, both during and after the running-in period.

Apply the brakes gently and avoid hard, prolonged braking until covering the first 100 km (62 mi).

This will allow the brake pad lining to wear in properly rubbing on the brake discs.

Never exceed 6000 rpm (see chart) during the first 1000 km (625 mi).

WARNING

WARNING

After covering the first 1000 km (625 mi), perform the checks listed in the “post running-in” column of the PERIODIC MAINTENANCE CHART (see 2.1.1). Failure to perform these checks may lead to personal injury to yourself or third persons, or vehicle damage.

After the first 1000 km (625 mi) and until covering the first 1500 km (937 mi), a somewhat brisker riding style is acceptable. Vary your speed and use peak acceleration for just a few instants, to allow the different components to become properly seated against one another.

Never exceed 7500-rpm engine speed (see table).

After 1500 km (937 mi), the engine will be ready for a more demanding use. However, never exceed the maximum engine speed allowed (10500 rpm).

Recommended maximum engine speed

Distance covered in |

rpm |

|

Km(mi) |

||

|

||

|

|

|

0-1000 (0-625) |

6000 |

|

|

|

|

1000-1500 (625-937) |

7500 |

|

|

|

|

over 1500 (937) |

10500 |

|

|

|

|

- 6 - 00 |

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|||

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

RST mille |

|

|

|

|

|

|

|

|

GENERAL INFORMATION |

||||

1.4 SPARE PARTS |

|

|

|

|

|

|

|

||||||

Use original aprilia spare parts only to replace original |

|

|

|

|

|

|

|

||||||

components. Original aprilia spare parts are high-quality |

|

|

|

|

|

|

|

||||||

components designed and built expressly for aprilia |

|

|

|

|

|

|

|

||||||

motorcycles. |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

WARNING |

|

|

|

|

|

|

|

||||

Using any parts OTHER THAN original aprilia parts |

|

|

|

|

|

|

|

||||||

may lead to loss of performance and damage. |

|

|

|

|

|

|

|

||||||

1.5 SPECIFICATIONS |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||

|

DIMENSIONS |

|

|

|

|

|

|

|

|||||

|

Overall length |

|

2170 mm |

||||||||||

|

|

|

|

||||||||||

|

Overall width |

|

740 mm |

||||||||||

|

|

|

|

||||||||||

|

Overall height (front fairing) |

|

1240 mm |

||||||||||

|

|

|

|

||||||||||

|

Seat height |

|

820 mm |

||||||||||

|

|

|

|

||||||||||

|

Wheelbase |

|

1435 mm |

||||||||||

|

Minimum ground clearance |

|

135 mm |

||||||||||

|

Weight in running order (including fuel, coolants and |

|

235 kg |

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

ENGINE |

|

|

|

|

|

|

|

|||||

|

Type |

|

4-stroke longitudinal 60° V twin-cylinder engine fitted |

||||||||||

|

|

with 4 valves per cylinder and 2 overhead camshafts |

|||||||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|||||

|

Number of cylinders |

|

2 |

|

|

|

|

|

|||||

|

Total displacement |

|

997.6 2cm³ |

||||||||||

|

Max rated crankshaft power |

|

86,5 kW (118 HP) at 9250 rpm |

||||||||||

|

Max rated crankshaft power |

|

77 kW (104 HP) at 9250 rpm |

||||||||||

|

|

|

|

||||||||||

|

Max torque |

|

96.5 Nm (9.78 kgm) at 7250 rpm |

||||||||||

|

|

|

|

||||||||||

|

Max torque |

|

90 Nm (9.17 kgm) at 7000 rpm |

||||||||||

|

|

|

|

||||||||||

|

Bore/stroke |

|

97 mm / 67.5 mm |

||||||||||

|

|

|

|

|

|

|

|||||||

|

Compression ratio |

|

11.8 ± 0.5: 1 |

|

|

|

|||||||

|

|

|

|

||||||||||

|

Average piston speed |

|

22,5 m/s at 10000 rpm |

||||||||||

|

|

|

|

||||||||||

|

Camshaft during intake stroke |

|

262°, valve lift = 10.6 mm |

||||||||||

|

|

|

|

||||||||||

|

Camshaft during exhaust stroke |

|

259°, valve lift = 10.6 mm |

||||||||||

|

|

|

|

||||||||||

|

Timing advance (with 1-mm valve clearance) intake valve opens |

|

20° before TDC |

||||||||||

|

|

|

intake valve closes |

|

59°after BDC |

||||||||

|

|

|

exhaust valve opens |

|

64° before TDC |

||||||||

|

|

|

exhaust valve closes |

|

15° after BDC |

||||||||

|

|

|

|

||||||||||

|

Valve clearance, intake |

|

0.12-0.17 mm |

||||||||||

|

|

|

|

||||||||||

|

Valve clearance, exhaust |

|

0.23-0.28 mm |

||||||||||

|

|

|

|

||||||||||

|

# Idling rpm |

|

1250 ± 100 rpm |

||||||||||

|

|

|

|

||||||||||

|

# Top speed rpm |

|

10500 ± 100 rpm |

||||||||||

|

|

|

|

||||||||||

|

Ignition |

|

computer ignition management |

||||||||||

|

|

|

|

||||||||||

|

Starter |

|

electric starter |

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

Spark advance: |

|

5° before TDC upon starting, advance is further |

||||||||||

|

|

increased to suit specific consumption. |

|||||||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

||||||||||

|

Starter motor |

|

12 V / 0.9 kW |

||||||||||

|

|

|

|

||||||||||

|

Transmission ratio of starter motor |

|

i= 49/9 * 30/11 * 64/30 = 31.677 |

||||||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

hydraulically operated wet multi-plate clutch with control |

|||||

|

Clutch |

|

lever on left-hand handlebar and PPC device |

||||||||||

|

|

- # 9 friction plates, 3.5 mm thick |

|||||||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

- # 9 clutch plates, 1.5 mm thick |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

CONTINUED |

|||

|

|

|

|

|

|

|

|

|

|

|

|

- 7 - 00 |

|

Release 00/2001 - 11 |

|

|

|

|

|

|

|

|

|

1 |

|||

|

|

|

|

|

|

|

|

||||||

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL INFORMATION

RST mille

|

ENGINE |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Transmission |

|

|

|

|

Mechanical 6-speed transmission with foot control on |

|

||||||||

|

|

|

|

|

left-hand side of engine |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Lubrication system |

|

|

|

|

Dry-sump lubrication system with remote oil tank, # 2 |

|

||||||||

|

|

|

|

|

trochoidal pumps and cooler |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Lubrication pressure |

|

|

|

|

min 500 kPa (5 bar) |

|

|

|

|

|||||

|

|

|

|

|

80 °C (176 °F) max. and 6000 rpm |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

Air cleaner |

|

|

|

|

with dry filter cartridge |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Cooling system |

|

|

|

|

liquid cooling |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|