Page 1

K

Service Source

Apple Two-Page Mono

Monitor

Page 2

K

Service Source

Basics

Two-Page Monochrome Monitor

Page 3

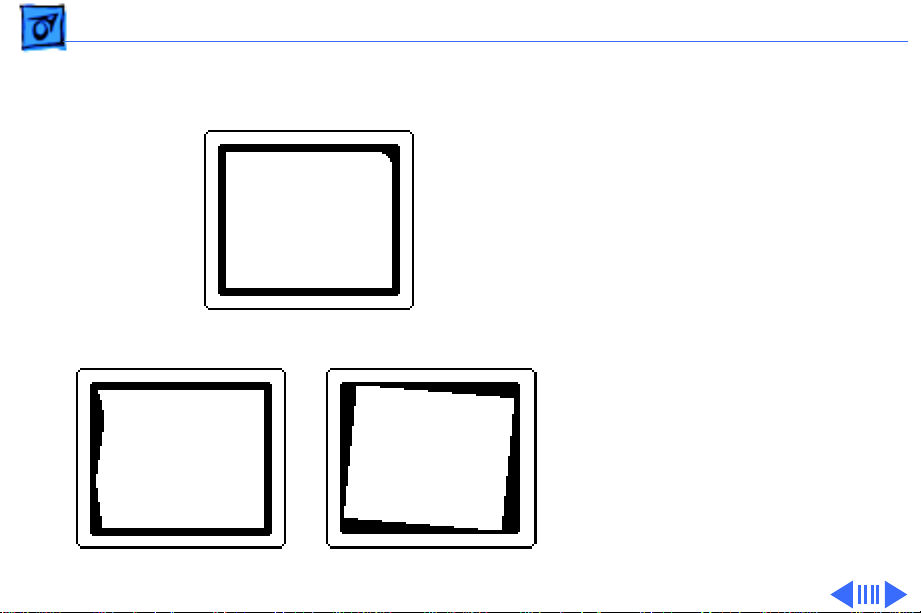

Basics Monitor Distortion - 1

Monitor Distortion

Overview

All large-screen monitors

are susceptible to

distortions caused by

environmental conditions.

Ideal Raster

These distortions are

usually not visible on

monitors with smaller

screens.

Raster Shifted Up

and Left

Raster Shifted Right

Page 4

Basics Monitor Distortion - 2

Important:

set to factory specifications

may appear distorted when

set up in a new environment.

Common environmentallycaused distortions are shown

on this and the following

cards. Always check first for

environmental causes before

attempting to repair or

adjust a monitor with a

distorted raster.

Even monitors

Page 5

Basics Monitor Distortion - 3

Environmental

Influences

The following environmental

conditions may distort the

raster of a Two-Page

Monochrome Monitor:

• Proximity to metal

objects, such as metal

Right Edge Not Straight

Left Side Bowed Out Right Side Bowed In

desks, file cabinets, and

bookshelves. Metal

objects affect the earth’s

magnetic field. Earth

magnetism usually

distorts only the edges of

the screen.

Page 6

Basics Monitor Distortion - 4

• Fluorescent lights, other

monitors, or electronic

appliances such as coffee

makers and copy

machines. These objects

cause dynamic raster

distortion, that is,

movement or jitter of the

image.

Page 7

Basics Monitor Distortion - 5

Troubleshooting

Upper-Right Corner Rounded

Left Edge S-Shaped Raster Tilted Right

Important:

swapping cannot fix a

monitor with

environmental distortion

problems, and adjusting a

monitor with such

problems alters the factory

settings.

Note:

shifted up/down or right/

left only, adjust it using the

centering controls. If you

then move the monitor, you

may need to readjust the

centering controls.

Module

If the monitor has

Page 8

Basics Monitor Distortion - 6

Before adjusting a monitor

with a distorted raster, try

the following:

• Swivel or move the

monitor, or

• Remove the monitor from

the building and recheck

it in another location.

If the display changes (for

better or worse) when you

move it to another location,

the environment is the

source of the problem.

Relocate the monitor or

remove the distortioncausing object.

Page 9

Basics Monitor Distortion - 7

If the display does not change

when you move the monitor

to another location,

continue troubleshooting

the problem (refer to

Troubleshooting/Symptom

Charts).

Page 10

K

Service Source

Specifications

Apple Two-Page Monochrome

Monitor

Page 11

Specifications Characteristics - 2

Characteristics

Picture Tube

Screen Resolution

Scan Rates

21-in. diagonal screen (20-in. viewable image)

Phosphor EIA Type P4 (white)

Flat, square, high-contrast, antiglare surface

1,152 x 870 lines; 77 dpi

Displays up to 16 grays with 512K of video RAM

Vertical refresh rate: 75 Hz

Horizontal scan rate: 68.7 kHz

Dot clock: 100 MHz

Page 12

Specifications Characteristics - 3

Active V ideo Display Area

Input Signal

15 in. by 11.3 in.

(381 mm by 287 mm)

Video: analog; RS–343 standard

Page 13

Specifications Controls - 4

Controls

User Controls

Rear panel: power switch

Right side: brightness and contrast controls

Page 14

Specifications Physical and Electrical - 5

Physical and Electrical

Power Supply

Size and Weight

Monitor Stand

Universal power supply

Voltage: 90–270 VAC, self-configuring

Frequency: 47–63 Hz

Power: 95 W maximum

Height: 15.7 in. (399 mm)—add 3.2 in. (81 mm) for integrated

stand

Width: 19.5 in. (495 mm)

Depth: 17.4 in. (442 mm)

Weight: 55 lb. (25 kg)

Integrated, tilt-and-swivel stand

Page 15

Specifications Operating Environment - 6

Operating Environment

Temperature

Humidity

Altitude

50°F–95°F (10°C–35°C)

90% maximum, noncondensing

10,000 ft. (3,048 m) maximum

Page 16

K

Service Source

Troubleshooting

Apple Two-Page Monochrome

Monitor

Page 17

Troubleshooting General/ - 1

General

The Symptom Charts included in this chapter will help you

diagnose specific symptoms related to your product. Because cures

are listed on the charts in the order of most likely solution, try

the first cure first. Verify whether or not the product continues to

exhibit the symptom. If the symptom persists, try the next cure.

(Note: If you have replaced a module, reinstall the original module

before you proceed to the next cure.)

If you are not sure what the problem is, or if the Symptom Charts

do not resolve the problem, refer to the Flowchart for the product

family.

For additional assistance, contact Apple Technical Support.

Page 18

Troubleshooting Symptom Charts/No Raster - 2

Symptom Charts

No Raster

No raster, LED off 1 Check AC power cord connections.

2 Check internal power connectors.

3 Replace blown fuse.

4 Replace power supply.

5 Replace on/off switch filter assembly.

6 Replace deflection board.

No raster, LED on 1 Adjust brightness and contrast knobs.

2 Verify that video card in computer is working properly.

3 Check power supply and deflection board connections.

4 Check CRT socket connectors.

5 Replace video board.

6 Replace deflection board.

7 Replace CRT and yoke assembly.

Page 19

Troubleshooting Symptom Charts/Geometry - 3

Geometry

Raster size too short,

tall, narrow, or wide

Raster not centered 1 Verify that distortion is not due to environmental conditions.

Bad vertical linearity 1 Adjust vertical linearity control.

Bad horizontal

linearity

1 Adjust horizontal-size and vertical-size controls.

2 Replace deflection board.

3 Replace CRT and yoke assembly.

Move monitor to another location.

2 Adjust horizontal-shift and vertical-shift controls.

3 Replace video board.

2 Replace deflection board.

1 Adjust horizontal linearity control.

2 Replace deflection board.

Page 20

Troubleshooting Symptom Charts/Synchronization - 4

Synchronization

Single horizontal or

vertical line appears

on screen

Picture breaks into

diagonal lines

Picture rolls

vertically

1 Check yoke connectors.

2 Check CRT socket connectors.

3 Replace deflection board.

4 Replace CRT and yoke assembly.

1 Connect another monitor to computer. Switch on monitor to

verify that computer produces video signal.

2 Check connections between video board and deflection board.

3 Replace deflection board.

4 Replace video board.

1 Verify that video card in computer is working properly.

2 Check connections between video board and deflection board.

3 Replace deflection board.

4 Replace video board.

Page 21

Troubleshooting Symptom Charts/Video - 5

Video

Picture is too dark or

too bright

Contrast/brightness

unadjustable

1 Adjust contrast and brightness knobs.

2 Verify that video card in computer is working properly.

3 Check connection between contrast/brightness assembly and

video board.

4 Perform video adjustments.

5 Replace video board.

6 Replace contrast/brightness assembly.

7 Replace CRT and yoke assembly.

1 Check connection between contrast/brightness assembly and

video board.

2 Replace contrast/brightness assembly.

3 Replace video board.

4 Replace deflection board.

5 Replace CRT and yoke assembly.

Page 22

Troubleshooting Symptom Charts/

(Continued)

Out of focus 1 Check CRT socket connectors.

2 Check connections between video board and deflection board.

3 Perform focus adjustment.

4 Check screen brightness with a light meter. If reading is

“10” or higher, perform the cutoff and screen luminance

adjustments.

5 Replace video board.

6 Replace deflection board.

7 Replace CRT and yoke assembly.

(Continued)

- 6

Page 23

Troubleshooting Symptom Charts/Miscellaneous - 7

Miscellaneous

Picture jitters or

flashes

At a resolution of

1152x870, jitter or

a wavy image appears

on right side, left

side, or entire screen

Black spots on screen

(burnt phosphors)

1 Check all grounding cable connections.

2 Confirm that adjacent computer equipment is properly

grounded. Move electrical devices away from the monitor and

temporarily shut off all fluorescent lights.

3 Check connections between video board and deflection board.

4 Replace deflection board.

Note:

This symptom occurs with Power Macintosh 9600

computers using an Apple/IMS video card with any display set at

1152x870 screen resolution. The computer and the display are

working properly. However, video cards with serial numbers

lower than Fx705xxx should be replaced. Apple’s service stock

has been inspected and upgraded, so replacement video boards

should not exhibit this symptom.

Check the serial number on the video card. If it is lower than

Fx705xxx, replace the video card with a new one (Apple service

part number 661-1409).

Replace CRT.

Page 24

Troubleshooting Symptom Charts/Monitor Stand - 8

Monitor Stand

Monitor stand does not

swivel

Monitor stand does not

tilt

1 Verify that “Front” indicator on tilt/swivel mechanism

aligns with “Front” indicator on base of monitor stand.

2 Verify that snap lock assembly on bottom of monitor stand is

in place.

1 Verify that plastic plug is in snap lock assembly.

2 Verify that snap lock assembly on bottom of monitor stand is

in place.

Page 25

K

Service Source

T ak e Apart

Apple Two-Page Monochrome

Monitor

Page 26

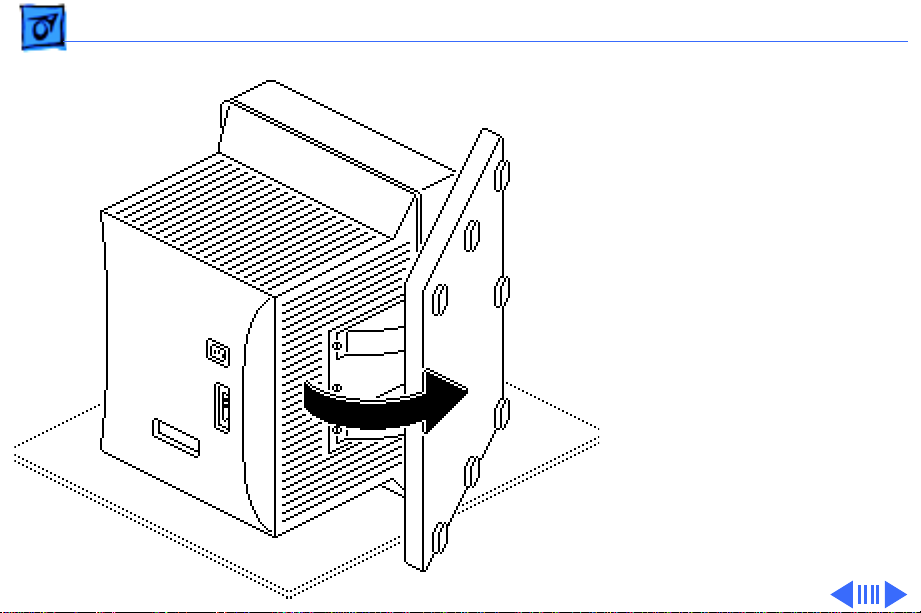

Take Apart Swivel Stand - 1

Swivel Stand

No preliminary steps are

required before you begin

this procedure.

Note:

Remove the tiltswivel stand before you

remove the CRT.

1 Tilt the monitor onto its

left side.

2 Slide the monitor stand

forward toward the

bezel.

Swivel Stand

Page 27

Take Apart Swivel Stand - 2

3 With one hand, slightly

lift up the monitor and

rotate the base of the

stand until you can reach

the three screws that

secure the stand to the

chassis.

Page 28

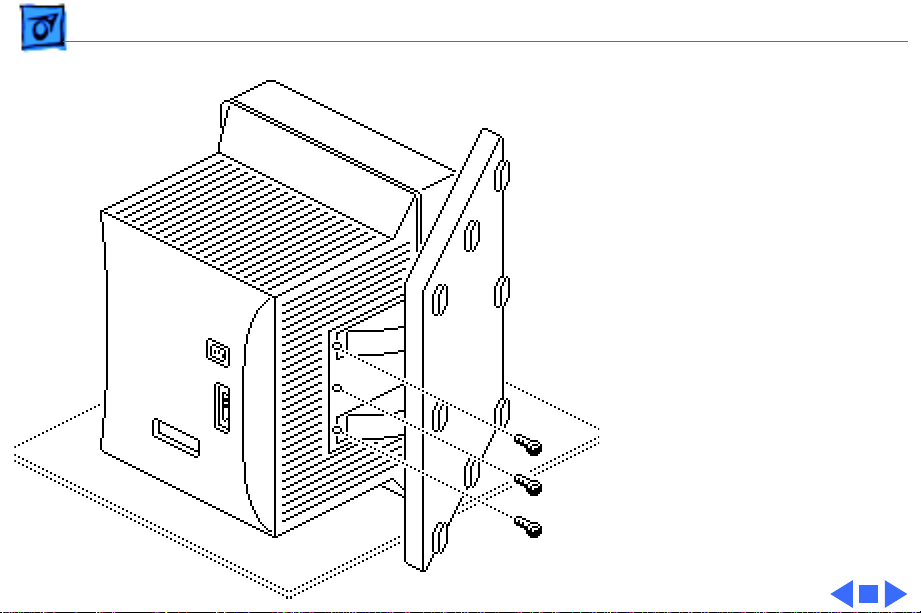

Take Apart Swivel Stand - 3

4 Remove the three

mounting screws.

5 Slide the monitor stand

back and remove it from

the chassis.

Page 29

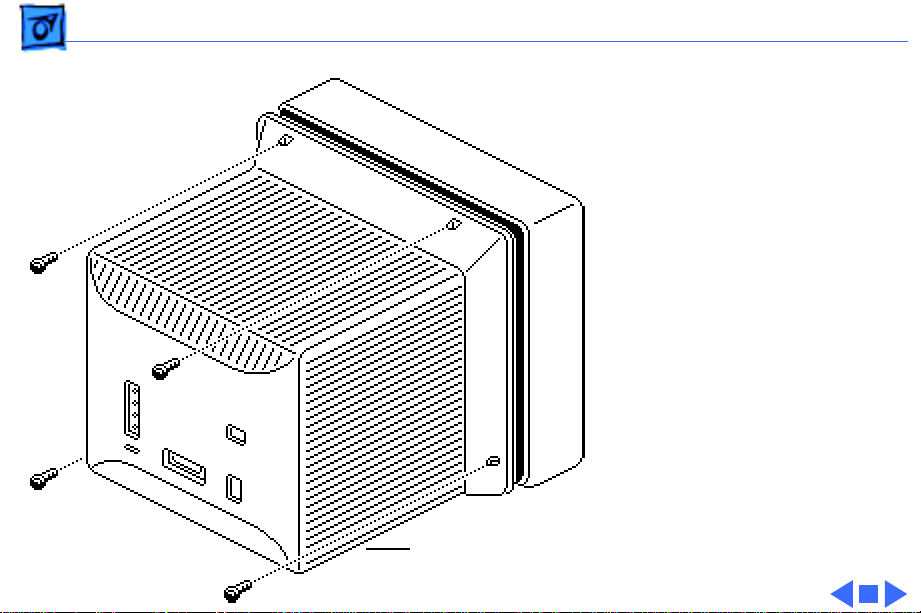

Take Apart Rear Cover - 4

Rear Cover

No preliminary steps are

required before you begin

this procedure.

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

1 Remove the four cover

mounting screws.

2 Pull the rear cover off

the bezel.

Rear Cover

This product

Page 30

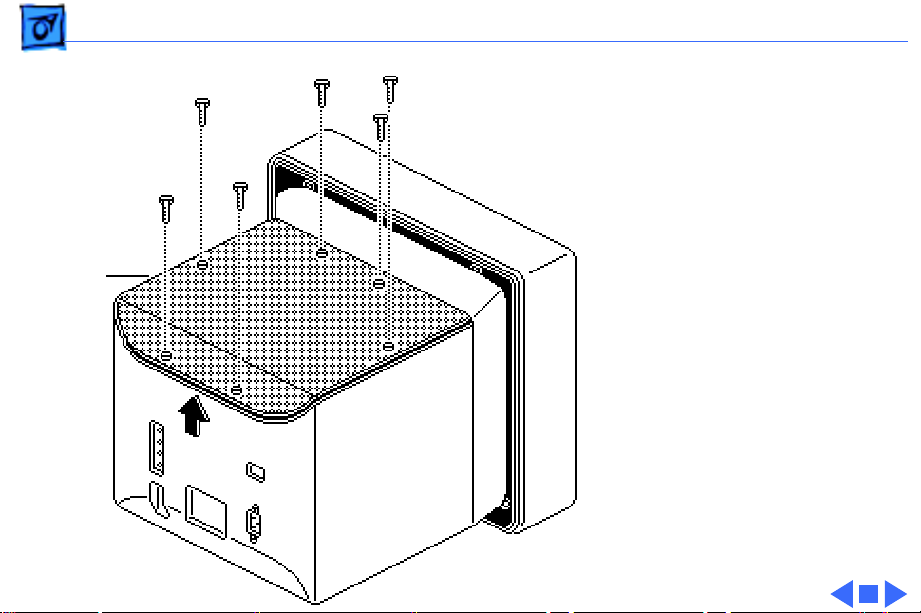

Take Apart Access Cover - 5

Access Cover

Before you begin, remove

the rear cover.

±

Access

Cover

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

1 Remove the six mounting

screws and lockwashers

that hold the access

cover in place.

2 Lift the access cover off

the chassis.

This product

Page 31

Take Apart Video Board - 6

Video Board

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Video Board

Warning:

grounding wriststrap until

after discharging the CRT.

Never use a

Page 32

Take Apart Video Board - 7

Disconnect the following

cable connectors from the

video board:

• 13-wire (white)

J604

J601

cable from J601

• 11-wire (white)

cable from J602

• 6-wire (white) cable

from J603

• 2-wire (red/orange)

cable from J604

J602

J603

Page 33

Take Apart Video Board - 8

Caution:

the connectors by

pulling on the connector

cables. If the connectors

are difficult to

disconnect, slip a

jeweler’s screwdriver

between the two halves

of the connector and

carefully pry the halves

apart.

Do not remove

Page 34

Take Apart Video Board - 9

1 Remove the hex nut,

washer, and green

grounding wire from the

metal post on the floor of

the monitor.

2 Pull the CRT socket off

the neck of the CRT.

Page 35

Take Apart Video Board - 10

3 Remove the four screws

that secure the video

board to the chassis.

4 Carefully lift the video

board up and out of the

chassis.

Page 36

Take Apart Deflection Board - 11

Deflection Board

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

• Remove the anode cap

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 37

Take Apart Deflection Board - 12

1 Remove the four screws

that secure the deflection

board to the chassis.

Deflection Board

Page 38

Take Apart Deflection Board - 13

2 Disconnect the following

cable connectors from

the deflection board:

J402

• 11-wire (white)

from J402

J301

• 3-wire (red/blue)

from J202

• 2-wire (red/orange)

from J501

J202

• 5-wire (rd/blk/or/

yel) from J201

• 13-wire (white)

from J401

J501

J401

J403

J201

• 2-wire (gray) from

J403

• 2-wire (yellow/

black) from J301

Page 39

Take Apart Deflection Board - 14

Caution:

the connectors by

pulling on the connector

cables. If the connectors

are difficult to

disconnect, slip a

jeweler’s screwdriver

between the two halves

of the connector and

carefully pry the halves

apart.

Do not remove

Page 40

Take Apart Deflection Board - 15

3 Locate the bleeder

resistor on the floor of

the monitor.

4 If the resistor is cigar-

shaped, slide the

resistor sideways, pull

up slightly on the plastic

clip, and remove the

resistor.

Cigar-shaped Resistor

5 If the resistor is box-

shaped, remove the

screw that holds the

resistor. Slide the

resistor forward and

release it from the metal

bracket.

Box-shaped Resistor

Page 41

Take Apart Deflection Board - 16

6 Remove the anode wire

from the plastic cable

clamp.

7 Lift the deflection board

up and out of the chassis.

Page 42

Take Apart Power Supply - 17

Power Supply

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 43

Take Apart Power Supply - 18

1 Remove the two screws

that fasten the power

supply to the chassis.

Power SupplyPower Supply

Page 44

Take Apart Power Supply - 19

Power Supply

2 Disconnect the three-

wire connector from the

top of the power supply

and the five-wire

connector from the

front of the power

supply.

3 Carefully lift the power

supply from the chassis.

Page 45

Take Apart Fuse - 20

Fuse

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

Fuse

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 46

Take Apart Fuse - 21

Note

: Some units with serial

numbers between

43661GXW and 44718HQX

have 1.6 A for the fuse on

the power supply board.

This amperage is incorrect.

The correct value is 2.5 A.

Using your fingers or a flatblade screwdriver, gently

pry up one end of the fuse

and remove the fuse from

the holder.

Page 47

Take Apart On/Off Switch - 22

On/Off Switch

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

On/Off

Switch

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 48

Take Apart On/Off Switch - 23

1 Remove the three hex

nuts, the washers, and

the three grounding

wires from the metal

post on the floor of the

monitor.

2 Disconnect the 3-wire

connector from the top of

the power supply.

Page 49

Take Apart On/Off Switch - 24

3 Pull the plastic knob off

the on/off switch.

4 Remove the two screws

that secure the on/off

switch to the chassis.

5 Remove the two screws

that secure the A/C

power socket to the

chassis.

6 Lift out the on/off switch

assembly.

Page 50

Take Apart Contrast/Brightness Assembly - 25

Contrast/ Brightness Assembly

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

Contrast/Brightness

Assembly

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 51

Take Apart Contrast/Brightness Assembly - 26

1 Pull off the contrast and

brightness control

knobs.

2 Remove the four screws

that secure the deflection

board to the chassis. Pull

the logic board slightly

away from the side of the

chassis.

Page 52

Take Apart Contrast/Brightness Assembly - 27

3 Disconnect the six-wire

cable from connector

J603 on the video board.

J603

Page 53

Take Apart Contrast/Brightness Assembly - 28

4 Remove the two hex nuts

and pull the contrastbrightness assembly off

the chassis.

Page 54

Take Apart Bezel - 29

Bezel

Bezel

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 55

Take Apart Bezel - 30

1 Remove the four hex

nuts that secure the

bezel to the chassis.

2 Pull the bezel off the

chassis.

Page 56

Take Apart Bezel - 31

3 Remove the hex nut that

secures the LED and the

black paper baffle to the

bezel.

Page 57

Take Apart CRT - 32

CRT

CRT

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

• Remove the anode cap

• Remove the bezel

• Remove the swivel stand

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 58

Take Apart CRT - 33

1 Disconnect the following

cable connectors from

the deflection board:

• 3-wire (CRT neck)

from J202

• 2-wire (CRT neck)

J301

J202

from J301

Page 59

Take Apart CRT - 34

2 Pull the CRT socket off

the neck of the CRT.

Page 60

Take Apart CRT - 35

3 While supporting the

CRT with one hand,

remove the four screws

and washers that secure

the CRT to the chassis

frame. Save the washers

to use on the

replacement CRT.

±

Warning:

handle the CRT by the

neck!

4 Carefully grasp the sides

of the CRT and lift the

CRT out of the chassis.

Do not

Page 61

Take Apart CRT - 36

5 Place the CRT face-down

on a soft, protective

surface.

6 Remove the grounding

strap and the spring.

Grounding Strap

Spring

Save them to use on the

replacement CRT.

±

Warning:

is cracked or broken,

refer to the CRT

disposal instructions in

Bulletins/Safety.

If the CRT

Page 62

Take Apart LED Assembly - 37

LED Assembly

Before you begin, do the

following:

• Remove the rear cover

• Remove the access cover

• Discharge the CRT

• Remove the anode cap

• Remove the bezel

• Remove the swivel stand

• Remove the CRT

±

LED Assembly

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 63

Take Apart LED Assembly - 38

1 Disconnect the LED

cable from the

Deflection Board

deflection board.

2 Remove the hex nut that

secures the green

grounding wire to the

inside of the chassis. Lift

out the LED assembly.

LED

Cable

Page 64

K

Service Source

Adjustments

Apple Two-Page Monochrome

Monitor

Page 65

Adjustments Geometry - 1

Geometry

Before you begin, remove

the following:

• Rear cover

• Access cover

±

Horizontal

Linearity

Control

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

Adjustment

Controls

This product

Page 66

Adjustments Geometry - 2

Warning:

make the adjustments from

the rear of the computer,

position a mirror to view

the computer screen. Do not

reach around the computer

to adjust the controls.

Note:

should always be performed

whenever you replace the

CRT, deflection board, or

video board.

Because you must

Geometry adjustments

Page 67

Adjustments Geometry - 3

Horizontal Linearity

1 Use Display Service

Utility to display the

Crosshatch II (white

background) test

pattern.

Horizontal

Linearity

Control

Caution:

adjustment tool is the

only tool that can be used

to adjust the Horizontal

Linearity control! Use

of any other tool may

damage the adjustment

control coil core or

cause a short in the

monitor’s circuitry.

The linearity

Page 68

Adjustments Geometry - 4

2 Using the linearity

adjustment tool, adjust

the horizontal linearity

control until the raster

is as wide as possible.

3 Using the linearity

adjustment tool, slowly

adjust the horizontal

linearity control until

the left and right halves

of the raster are the

same distance from the

center of the screen.

• To measure the left

half of the raster,

place a flexible ruler

Horizontal

Linearity

Control

against the screen

Page 69

Adjustments Geometry - 5

directly over the

black horizontal line.

Align the zero mark of

the ruler with the left

edge of the raster.

Note the measurement

at the point where the

two black lines

intersect.

• To measure the right

half of the raster,

align the zero mark of

the ruler where the

two black lines

intersect. Note the

measurement at the

right edge of the

raster.

Page 70

Adjustments Geometry - 6

4 Using the plastic

alignment tool, slowly

adjust the horizontal

size control until the

raster is 15 inches (±

1/8") or 381 mm (± 3

mm) wide.

5 Verify that the left and

right halves of the

raster are still the same

distance from the center

of the screen. If

necessary, adjust the

horizontal linearity

Horizontal Size

control.

Page 71

Adjustments Geometry - 7

6 Verify that the boxes on

both the left and right

sides of the screen are

the same size as the

boxes in the center of the

screen. If they are not

the same size, perform

the next step.

±

Warning:

monitor operates at

extremely high voltages.

To prevent electrical

shock, use a plastic

alignment tool to set the

3-position switch.

Avoid touching the

heatsink or any other

The

Page 72

Adjustments Geometry - 8

part of the monitor.

±

Warning:

not use a plastic

alignment tool, turn off

the power before

reaching inside the

chassis and adjusting

the switch. Then turn on

the power and view the

monitor screen.

If you do

Page 73

Adjustments Geometry - 9

7 Using the plastic

alignment tool, set the

3-position switch to the

lowest of the three

settings and recheck the

relative size of the

boxes. Repeat for all

three positions of the

switch and select the

best position.

3-Position Switch

Page 74

Adjustments Geometry - 10

8 Using the plastic

alignment tool, slowly

adjust the horizontal

size control until the

raster is 15 inches (±

1/8") or 381 mm (± 3

mm) wide.

9 Verify that the raster is

centered on the screen. If

necessary, adjust the

horizontal shift control.

Horizontal Size

Horizontal Shift

Page 75

Adjustments Geometry - 11

Vertical Linearity

1 Use Display Service

Utility to display the

Crosshatch I or

Crosshatch II test

pattern.

2 Using the plastic

alignment tool, adjust

the orange capacitor at

C306 until the top two

rows of boxes are the

same height.

Vertical

Linearity

Page 76

Adjustments Geometry - 12

3 Using the plastic

alignment tool, adjust

the vertical linearity

control until the top and

bottom rows of boxes are

the same height.

4 Use Display Service

Utility to display the

Full White Screen test

pattern.

5 Using the plastic

alignment tool, adjust

the vertical shift control

until the white raster is

Vertical Shift

vertically centered.

Page 77

Adjustments Geometry - 13

6 Use Display Service

Utility to display the

All-White Screen test

pattern.

All-White Screen

7 Using a plastic alignment

tool, adjust the vertical

size control until the

white raster is 11 5/

16 inches (± 1/8”) or

287.3 mm (± 3 mm)

high.

Vertical Size

Page 78

Adjustments Geometry - 14

Focus

1 Use Display Service

Utility to display the

Focus test pattern.

2 Using a plastic

screwdriver, adjust the

static focus control for

the best focus in the box

at the center of the

screen.

Static

Focus

Page 79

Adjustments Geometry - 15

3 Using a plastic

screwdriver, adjust the

horizontal focus control

for the best focus in the

box at the left and right

sides of the screen.

4 Using a plastic

screwdriver, adjust the

vertical focus control

for the best focus in the

box at the top and bottom

center of the screen.

5 Repeat the adjustments

until you have attained

Horizontal

Focus

Vertical

Focus

the best focus possible.

Page 80

Adjustments Video - 16

Video

Brightness

Contrast

Cutoff

Brightness

Subcontrast

Range

Before you begin, remove

the following:

• Rear cover

• Access cover

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 81

Adjustments Video - 17

Warning:

make adjustments from the

rear of the computer,

position a mirror to view

the computer screen. Do not

reach around the computer

to adjust the controls.

Note:

should always be performed

whenever you replace the

CRT, deflection board, or

video board.

Because you must

Video adjustments

Page 82

Adjustments Video - 18

1 Switch off the power and

remove the video cable

from the back of the

monitor.

All-White Screen

2 Set the external (user)

contrast knob to

maximum (turn fully

clockwise) and the

brightness knob to the

center (detent) position.

Brightness

Contrast

Page 83

Adjustments Video - 19

3 Using the plastic

screwdriver, adjust the

cutoff control to

minimum (turn fully

All-White Screen

counterclockwise).

4 Switch on the power and

wait 20 minutes for the

monitor to warm up.

5 Use Display Service

Utility to display the

All-White Screen test

pattern.

Cutoff

Page 84

Adjustments Video - 20

Note:

The Cutoff

adjustment should be

performed in a dimly lit

room after the monitor

All-White Screen

has been on for at least

20 minutes.

6 Using the plastic

screwdriver, turn the

cutoff control clockwise

until a white raster just

appears, then turn

counterclockwise until

the raster just fades to

black.

7 Switch off the power and

reconnect the video

cable.

Cutoff

Page 85

Adjustments Video - 21

8 Switch on the power.

Note:

If the power is

turned off for more than

a few seconds, you must

wait for another 20

minutes for the monitor

to warm up.

Page 86

Adjustments Video - 22

9 Use Display Service

Utility to display the

Gray Bars test pattern.

10 Using a plastic alignment

tool, adjust the cutoff

control until the

leftmost bar (darkest)

is black and the next bar

is barely distinguishable

from the black bar.

Cutoff

Page 87

Adjustments Video - 23

All-White Screen

Sub-contrast

Important:

Readings

from light meters R77,

L–248, and 246 differ.

Please note which meter

you are using before

making adjustments.

(See “Light Meter

Setup.”)

11 Using Display Service

Utility, display the AllWhite Screen test

pattern.

Page 88

Adjustments Video - 24

12 Using the light meter and

a two-inch plastic

screwdriver, adjust the

sub-contrast control

until you get 31 foot

lamberts (± 3 foot

lamberts), which on the

light meter is

• Model R77: 23 on the

bottom scale

• Model L-248: middle

of the 10 scale

• Model 246: 23 on the

red scale

Page 89

Adjustments Video - 25

Brightness

Knob

Brightness

Range

All-White Screen

Important:

Over time,

light meter tolerances

can vary. If you doubt

your meter’s accuracy,

verify the readings with

a known-good light

meter or photometer.

13 Set the external (user)

brightness knob to

maximum (turn fully

clockwise).

Page 90

Adjustments Video - 26

14 Using the plastic

screwdriver, adjust the

brightness range

control until you get 31

foot lamberts (± 3 foot

lamberts), which on the

light meter is

• Model R77: 23 on the

bottom scale

• Model L-248: middle

of the 10 scale

• Model 246: 23 on the

red scale

15 Reset the brightness

knob to the center

(detent) position.

Page 91

Adjustments Light Meter Setup - 27

Light Meter Setup

This topic covers setup for

three light meter models:

R77, L-248, and 246.

Model R77 (Apple part

number 076-0310) is the

newest model available.

Model R77

The R77 light meter is

capable of reading luminance

from 10 to 1,000

footcandles (fc).

Before you begin, remove

the 10X multiplier plate

Page 92

Adjustments Light Meter Setup - 28

from the lens.

Three scales are shown on

the light meter:

• 200-1000 fc

• 50-250 fc

• 10-50 fc

Because display screen

luminance typically ranges

from 10 to 50 fc, take

readings from the bottom

scale only.

Page 93

Adjustments Light Meter Setup - 29

To measure a display

screen’s luminance,

1 Set the scale switch to

the bottom position (to

set up the 10-50 fc

scale).

2 Place the lens against the

middle of the screen and

read the bottom scale.

Note:

When the light meter

is not in use, slide the scale

switch to its top position,

and store the meter in its

protective case.

Important:

light meter is giving false

If you suspect the

Page 94

Adjustments Light Meter Setup - 30

readings, verify the

readings with a known-good

light meter or photometer.

Also check the age of the R77

light meter by its four-digit

manufacturing date stamp

(such as 0398 for March

1998).

Caution:

meter can permanently

damage its accuracy. A

shock-damaged meter might

read incorrectly or its

pointer may not drop to

zero.

Dropping the

Page 95

Adjustments Light Meter Setup - 31

Side Switch

Scale

Lens

Read Button

Red Area

Model L-248

1 Press the red button on

the back of the light

meter. If the reading is

out of the red area,

replace the battery.

2 Move the side switch to

its upper position so that

the scale reads 10

through 18.

3 Uncover the lens of the

meter.

4 Place the lens against the

middle of the screen and

press the read button to

read the scale.

Page 96

Adjustments Light Meter Setup - 32

Model 246

1 Remove the metal slide,

Lens

if installed, from the

top of the light meter.

Swivel Head

Scale

2 Install the white lens

with the red dot.

3 Rotate the swivel head

so the lens of the meter

faces the monitor.

4 Place the lens against the

middle of the screen and

read the scale.

Page 97

K

Service Source

Exploded V ie w

Apple Two-Page Monochrome

Monitor

Page 98

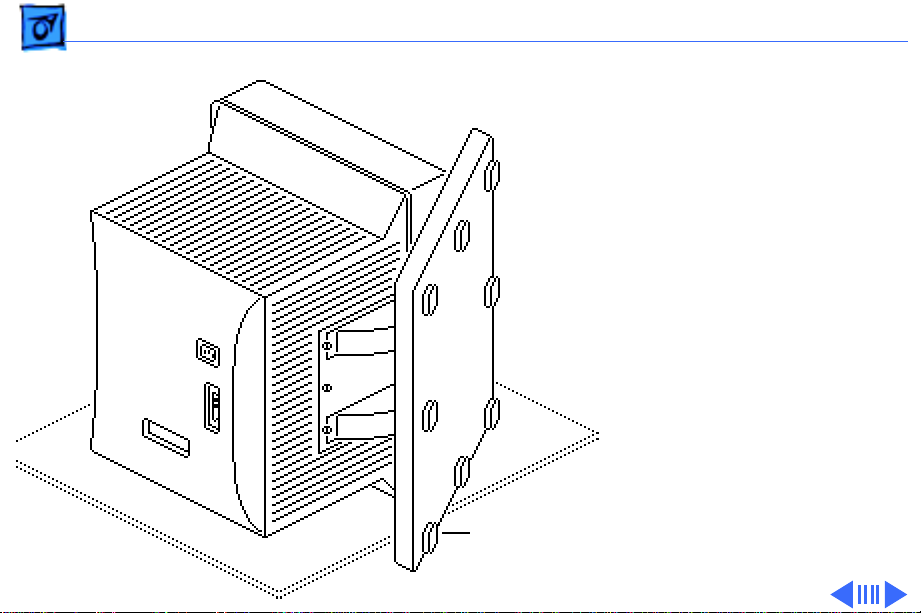

Exploded View 1

Access Cover

949-0223

Bezel

590-0393

Power Supply

Cable 6-Pin

590-0395

12-Pin Cable

590-0391

LED and Cable

Assembly

905-0007

Contrast/

Brightness

Assembly

661-0453

Power

Supply

941-0016

Fuse

949-0224

Rear Cover

076-0320

CRT

Assembly

590-0397

3-Pin Cable

590-0398

14-Pin Cable

661-0452

Video Board

661-0451

Deflection

Board

956-0012

Screw Knob Set

937-0040

On/Off Switch

Filter Assembly

815-0558

Tilt/Swivel

Monitor Stand

590-0371

Power

Cable

590-0615

Video

Cable

Loading...

Loading...