ANRITSU MU195020A, MU195040A, MU195050A Operation Manual

MU195020A

Operation Manual

●

For safety and warning information, please read this

●

Additional safety and warning information is provided

before using

●

21G/32G bit/s SI PPG

MU195040A

21G/32G bit/s SI ED

MU195050A

Noise Generator

manual before attempting to use the equipment.

within the MP1900A Signal Quality Analyzer-R

Operation Manual. Please also refer to it

the equipment.

Keep this manual with the equipment.

11th Edition

ANRITSU CORPORATION

Document No.: M-W3915AE-11 .0

Safety Symbols

DANGER

WARNING

CAUTION

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the following

safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the symbols

BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu equipment. In addition,

there may be other labels attached to products that are not shown in the diagrams in this manual.

Symbols used in manual

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

MU195020A 21G/32G bit/s SI PPG

MU195040A 21G/32G bit/s SI ED

MU195050A Noise Generator Operation Manual

19 June 2017 (First Edition)

5 March 2021 (11th Edition)

Copyright © 2017-2021, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The operational instructions of this manual may be changed without prior notice.

Printed in Japan

ii

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before shipment

using calibrated measuring instruments with direct traceability to public

testing organizations recognized by national research laboratories, including

the National Institute of Advanced Industrial Science and Technology, and

the National Institute of Information and Communications Technology, and

was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction

occurs within one year after shipment due to a manufacturing fault, and

software bug fixes will be performed in accordance with the separate Software

End-User License Agreement, provide, however, that Anritsu Corporation will

deem this warranty void when:

The fault is outside the scope of the warranty conditions separately

●

described in the operation manual.

The fault is due to mishandling, misuse, or unauthorized modification or

●

repair of the equipment by the customer.

The fault is due to severe usage clearly exceeding normal usage.

●

The fault is due to improper or insufficient maintenance by the customer.

●

The fault is due to natural disaster, including fire, wind or flood,

●

earthquake, lightning strike, or volcanic ash, etc.

The fault is due to damage caused by acts of destruction, including civil

●

disturbance, riot, or war, etc.

The fault is due to explosion, accident, or breakdown of any other

●

machinery, facility, or plant, etc.

The fault is due to use of non-specified peripheral or applied equipment

●

or parts, or consumables, etc.

The fault is due to use of a non-specified power supply or in a non-

●

specified installation location.

The fault is due to use in unusual environments

●

The fault is due to activities or ingress of living organisms, such as

●

insects, spiders, fungus, pollen, or seeds.

In addition, this warranty is valid only for the original equipment purchaser. It

is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for damage or financial loss of

the customer due to the use of or a failure to use this equipment, unless the

damage or loss is caused due to Anritsu Corporation’s intentional or gross

negligence.

(Note)

.

iii

Note:

For the purpose of this Warranty, "unusual environments" means use:

In places of direct sunlight

●

In dusty places

●

Outdoors

●

In liquids, such as water, oil, or organic solvents, and medical fluids, or

●

places where these liquids may adhere

In salty air or in place chemically active gases (sulfur dioxide, hydrogen

●

sulfide, chlorine, ammonia, nitrogen dioxide, or hydrogen chloride etc.)

are present

In places where high-intensity static electric charges or electromagnetic

●

fields are present

In places where abnormal power voltages (high or low) or instantaneous

●

power failures occur

In places where condensation occurs

●

In the presence of lubricating oil mists

●

In places at an altitude of more than 2,000 m

●

In the presence of frequent vibration or mechanical shock, such as in

●

cars, ships, or airplanes

Anritsu Corporation Contact

In the event of this equipment malfunctions, please contact an Anritsu

Service and Sales office. Contact information can be found on the last page

of the printed version of this manual, and is available in a separate file on the

PDF version.

iv

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from your

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export

When

controlled items, the products/manuals need to

be broken/shredded so as not to be unlawfully used for military purpose.

you dispose of export-

Notes On Export Management

-controlled items or not.

v

Crossed-out Wheeled Bin Symbol

Equipment marked with the Crossed-out Wheeled Bin Symbol complies with

council directive 2012/19/EU (the “WEEE Directive”) in European Union.

For Products placed on the EU market after August 13, 2005, please contact

your local Anritsu representative at the end of the product's useful life to

arrange disposal in accordance with your initial contract and the local law.

vi

Software End-User License Agreement (EULA)

Please carefully read and accept this Software End-User License Agreement (hereafter this EULA)

before using (includes executing, copying, installing, registering, etc.) this Software (includes programs,

databases, scenarios, etc., used to operate, set, etc., Anritsu electronic equipment, etc.). By using this

Software, you shall be deemed to have agreed to be bound by the terms of this EULA, and Anritsu

Corporation (hereafter Anritsu) hereby grants you the right to use this Software with the Anritsu

specified equipment (hereafter Equipment) for the purposes set out in this EULA.

Article 1. Grant of License and Limitations

1. You may not to sell, transfer, rent, lease,

lend, disclose, sublicense, or otherwise

distribute this Software to third parties,

whether or not paid therefor.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer,

disassemble, decompile, modify or create

derivative works of this Software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

Article 2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for direct, or

any incidental, special, indirect or

consequential damages whatsoever,

including, without limitation, damages for

loss of profits, loss of data, business

interruption or any other commercial

damages or losses, and damages claimed by

third parties, arising out of or related to your

use or inability to use this Software, unless

the damages are caused due to Anritsu’s

intentional or gross negligence.

Article 3. Limitation of Liability

1. If a fault (bug) is discovered in this Software,

failing this Software to operate as described

in the operation manual or specifications

even though you have used this Software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or replace the

software, or suggest a workaround, free-ofcharge, provided, however, that the faults

caused by the following items and any of

your lost or damaged data whatsoever shall

be excluded from repair and the warranty.

i) If this Software is deemed to be used

for purposes not described in the

operation manual or specifications.

ii) If this Software has been used in

conjunction with other non-Anritsuapproved software.

iii) If this Software or the Equipment has

been modified, repaired, or otherwise

altered without Anritsu's prior

approval.

iv) For any other reasons out of Anritsu's

direct control and responsibility, such

as but not limited to, natural disasters,

software virus infections, or any

devices other than this Equipment, etc.

2. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs or

replacement by Anritsu engineers

necessitated by the above faults shall be

borne by you.

3. The warranty period for faults listed in

Section 1 of this Article shall be either 6

months from the date of purchase of this

Software or 30 days after the date of repair

or replacement, whichever is longer.

vii

Article 4. Export Restrictions

You shall not use or otherwise export or re-

export directly or indirectly this Software

except as authorized by the laws and

regulations of Japan and the United States,

etc. In particular, this Software shall not be

exported or re-exported (a) into any Japan or

US embargoed countries or (b) to anyone

restricted by the Japanese export control

regulations, or the US Treasury

Department's list of Specially Designated

Nationals or the US Department of

Commerce Denied Persons List or Entity

List. In using this Software, you warrant

that you are not located in any such

embargoed countries or on any such lists.

You also agree that you will not use or

otherwise export or re-export this Software

for any purposes prohibited by the Japanese

and US laws and regulations, including,

without limitation, the development, design

and manufacture or production of missiles or

nuclear, chemical or biological weapons of

mass destruction, and conventional

weapons.

Article 5. Change of Terms

Anritsu may change without your approval

the terms of this EULA if the changes are for

the benefit of general customers, or are

reasonable in light of the purpose of this

EULA and circumstances of the changes. At

the time of change, Anritsu will inform you

of those changes and its effective date, as a

general rule 45

website, or in writing or by e-mail.

days, in advance on its

Article 6. Termination

1. Anritsu may terminate this EULA

immediately if you violate any conditions

described herein. This EULA shall also be

terminated immediately by Anritsu if there

is any good reason that it is deemed difficult

to continue this EULA, such as your

violation of Anritsu copyrights, patents, etc.

or any laws and ordinances, or if it turns out

that you belong to an antisocial organization

or has a socially inappropriate relationship

with members of such organization.

2. You and Anritsu may terminate this EULA

by a written notice to the other party 30

days in advance.

Article 7. Damages

If Anritsu suffers any damages or loss,

financial or otherwise, due to your violation

of the terms of this EULA, Anritsu shall

have the right to seek proportional damages

from you.

Article 8. Responsibility after Termination

Upon termination of this EULA in

accordance with Article 6, you shall cease all

uses of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

Article 9. Negotiation for Dispute

Resolution

If matters of interpretational dispute or

items not covered under this EULA arise,

they shall be resolved by negotiations in

good faith between you and Anritsu.

Article 10. Governing Law and Court of

Jurisdiction

This EULA shall be governed by and

interpreted in accordance with the laws of

Japan without regard to the principles of the

conflict of laws thereof, and any disputes

arising from or in relation to this EULA that

cannot be resolved by negotiation described

in Article 9 shall be subject to and be settled

by the exclusive agreed jurisdiction of the

Tokyo District Court of Japan.

Revision History:

February 29th, 2020

viii

CE Conformity Marking

Anritsu affixes the CE conformity marking on the following product(s) in

accordance with the Decision 768/2008/EC to indicate that they conform to

the EMC, LVD and RoHS directive of the European Union (EU).

CE marking

1. Product Model

Plug-in Units: MU195020A 21G/32G bit/s SI PPG

MU195040A 21G/32G bit/s SI ED

MU195050A Noise Generator PG

2. Applied Directive and Standards

When the MU195020A 21G/32G bit/s SI PPG, MU195040A 21G/32G

bit/s SI ED, and MU195050A Noise Generator PG are installed in the

MP1900A, the applied directive and standards of this unit conform to

those of the MP1900A main frame.

PS: About main frame

Please contact Anritsu for the latest information on the main frame

types that MU195020A, MU195040A, and MU195050A can be used

with.

ix

RCM Conformity Marking

Anritsu affixes the RCM mark on the following product(s) in accordance with

the regulation to indicate that they conform to the EMC framework of

Australia/New Zealand.

RCM marking

1. Product Model

Plug-in Units: MU195020A 21G/32G bit/s SI PPG

MU195040A 21G/32G bit/s SI ED

MU195050A Noise Generator PG

2. Applied Directive and Standards

When the MU195020A 21G/32G bit/s SI PPG, MU195040A 21G/32G

bit/s SI ED, and MU195050A Noise Generator PG are installed in the

MP1900A, the applied directive and standards of this unit conform to

those of the MP1900A main frame.

PS: About main frame

Please contact Anritsu for the latest information on the main frame

types that MU195020A, MU195040A, and MU195050A can be

used with.

x

About This Manual

Configuration of Signal Quality Analyzer-R Series Operation

Describes the basic operations, panel details, and maintenance of the MP1900A, as

well as the steps from module installation to the start of u

indicates this document.

Describes the panel details, how to operate, performance test, maintenance, and

troubleshooting of the

Module Operation Manual

Operation Manual

Describes the panel details, how to operate, performance test, maintenance, and

troubleshooting of the MU181000A

Describes the panel details, how to operate, performance test and maintenance of the

MU181500B.

MU195050A Noise Generator Operation Manual

Describes the panel details, how to operate, performance test, maintenance, and

Operation Manual

Describes the panel details, performance test, maintenance, and troubleshooting of

Describes the panel details, performance test, maintenance, and troubleshooting of

the

A testing system combining an MP1900A Signal Quality Analyzer-R,

module(s), and control software is called a Signal Quality Analyzer-R

Series. The operation manuals of the Signal Quality Analyzer-R Series

consist of separate documents for the MP1900A, module(s), and control

software, as shown below.

MP1900A Signal Quality Analyzer-R Operation Manual

se.

MU195020A 21G/32G bit/s SI PPG MU195040A 21G/32G bit/s SI ED

module to be installed on the MP1900A.

MU196020A PAM4 PPG MU196040A PAM4 ED MU196040B PAM4 ED

Operation Manual

MU196020A, MU196040A, and MU196040B.

MU181000A 12.5GHz Synthesizer MU181000B 12.5GHz 4 port Synthesizer

and MU181000B.

MU181500B Jitter Modulation Source Operation Manual

MU183020A 28G/32G bit/s PPG MU183021A 28G/32G bit/s 4ch PPG

the MU183020A and MU183021A.

MU183040A 28G/32G bit/s ED MU183041A 28G/32G bit/s 4ch ED

MU183040B 28G/32G bit/s High Sensitivity ED

MU183041B 28G/32G bit/s 4ch High Sensitivity ED Operation Manual

troubleshooting of the MU183040A, MU183041A, MU183040B, and MU183041B.

I

MX183000A High-Speed Serial Data Test Software Operation Manual

Describes the setup and operating procedure of MX183000A.

Describes the operation of the extended application for the Signal Quality Analyzer-R

Series.

Configuration of Signal Quality Analyzer-R Series Operation (Cont’d)

indicates this document.

MX190000A Signal Quality Analyzer-R Control Software Operation Manual

Describes the operation of the software that controls the Signal Quality Analyzer-R

Series.

Extended Application Operation Manual

II

1 2 3 4

7

Table of Contents

About This Manual ................................................. I

Chapter 1 Overview ............................................ 1-1

1.1 Product Overview........................................................ 1-2

1.2 Product Configuration ................................................. 1-4

1.3 Specifications............................................................ 1-10

Chapter 2 Before Use ......................................... 2-1

2.1 Installation to MP1900A .............................................. 2-2

2.2 How to Operate Application ......................................... 2-2

2.3 Preventing Damage .................................................... 2-2

Chapter 3 Panel Layout and Connectors......... 3-1

3.1 Panel Layout ............................................................... 3-2

3.2 Inter-Module Connection ............................................. 3-5

Chapter 4 Configuration of Setup Dialog Box 4-1

4.1 Configuration of Entire Setup Dialog Box ..................... 4-2

4.2 Equipment Composition .............................................. 4-3

5

6

8

Chapter 5 Operation Method ............................. 5-1

5.1 Setting Output Interface .............................................. 5-3

5.2 Setting Emphasis and ISI .......................................... 5-13

5.3 Setting Test Patterns (MU195020A) .......................... 5-22

5.4 Adding Errors ............................................................ 5-59

5.5 Setting Pre-Code Function ........................................ 5-62

5.6 Misc1 Function (MU195020A) ................................... 5-64

5.7 Misc2 Function .......................................................... 5-73

5.8 Multi-channel Function .............................................. 5-83

5.9 Inter-module Synchronization Function...................... 5-87

5.10 Multi Channel Calibration Function ............................ 5-87

5.11 Displaying Measurement Results .............................. 5-88

5.12 Setting Measurement Conditions ............................. 5-112

5.13 Setting Test Patterns (MU195040A) ........................ 5-117

9

10

Appendix

III

5.14 Setting Input Interface ............................................. 5-125

5.15 Capturing Test Patterns .......................................... 5-136

5.16 Misc1 Function (MU195040A) ................................. 5-144

5.17 Auto Search Function.............................................. 5-151

5.18 Auto Adjust Function ............................................... 5-154

5.19 Auto Measurement .................................................. 5-156

5.20 Noise Generation Function ...................................... 5-157

Chapter 6 Usage Examples ............................... 6-1

6.1 Measuring Optical Transceiver Module........................ 6-2

6.2 Generating 56 Gbit/s DQPSK Signals ......................... 6-4

Chapter 7 Remote Command ............................ 7-1

Chapter 8 Performance Test ............................. 8-1

8.1 Performance Test Items .............................................. 8-2

8.2 Devices Required for Performance Tests .................... 8-2

8.3 Performance Test Items .............................................. 8-3

IV

Chapter 9 Maintenance ...................................... 9-1

9.1 Daily Maintenance ...................................................... 9-2

9.2 Cautions on Storage ................................................... 9-2

9.3 Transportation............................................................. 9-3

9.4 Calibration .................................................................. 9-3

9.5 Disposal ...................................................................... 9-4

Chapter 10 Troubleshooting ........................... 10-1

10.1 Problems Discovered during Module Replacement .... 10-2

10.2 Problems Discovered during Output Waveform

Observation .............................................................. 10-3

10.3 Problems Discovered during Error Rate

Measurement ............................................................ 10-4

10.4 Synchronization Failure ............................................. 10-5

1 2 3 4

7

Appendix A

Appendix B List of Initial Settings ................... B-1

Pseudo-Random Pattern

................. A-1

5

6

8

9

10

Appendix

V

VI.

Overview

Chapter 1 Overview

This chapter describes the overview of the following modules.

● MU195020A 21G/32G bit/s SI PPG (hereafter, MU195020A)

● MU195040A 21G/32G bit/s SI ED (hereafter, MU195040A)

● MU195050A Noise Generator (hereafter, MU195050A)

1.1

Product Overview........................................................ 1-2

1.2 Product Configuration ................................................. 1-4

1.2.1 Standard configuration .................................... 1-4

1.2.2 Options ........................................................... 1-7

1.2.3 Optional Accessories....................................... 1-9

1.3 Specifications............................................................ 1-10

1.3.1 Specifications for MU195020A ...................... 1-10

1.3.2 Specifications for MU195040A ...................... 1-44

1.3.3 Specifications for MU195050A ...................... 1-68

1

1-1

Chapter 1 Overview

1.1 Product Overview

The MU195020A, MU195040A, and MU195050A (hereinafter “MP1900A

modules”) are plug-in modules that can be built into the MP1900A Signal

Quality Analyzer-R. The MP1900A modules support the error

measurements of PRBS, DATA, Zero-Substitution, and Mixed patterns

within the operating frequency range. The combination of MU195020A

and MU195050A can generate data to which common mode noise,

differential mode noise, and white noise are added. The data is optimal

for signal integrity evaluation.

Various option configurations are available for the MP1900A modules.

This module is therefore useful for research, development, and

production of various types of digital communication equipment,

modules, and devices.

The features of the MP1900A modules are as follows:

MU195020A features

● Capable of generating PRBS, DATA, Zero-Substitution, Mixed, PAM4,

and Sequence patterns.

● MU195020A-x20 allows channel combination between two channels

inside the module (Channel Combination).

This function enables the generation of multiplexing signal by using

Multiplexer (MUX) .

● Multiple MU195020As installed in MP1900A allow channel

combination between channels.

This function allows generating synchronous data corresponding to

the applications that require Multi Channel.

● Capable of signal integrity evaluation using 10TAP Emphasis

(MU195020A-x11/x21).

● Capable of adding variable ISI using 10TAP Emphasis (MU195020Ax40/x41).

MU195040A features

● Capable of measuring PRBS, Data, Zero-Substitution, Mixed, PAM4,

and HSSB Data patterns.

● Provides a large amount of user-programmable patterns (256 Mbits)

● Installing MU195040A-x20 allows 32 Gbit/s data input up to 2ch and

enables evaluation of 64 Gbit/s serial communication.

● With input sensitivity of Typ. 25 mVp-p, the MU195040A is the best

for signal evaluation.

● Installing MU195040A-x22 enables clock recovery or clock and data

recovery.

● Installing MU195040A-x11/x21 enables loss signal evaluation using

CTLE (Continues Time Linear Equalizer).

1-2

1.1 Product Overview

Overview

MU195050A features

Capability of adding common mode noise and/or differential mode

•

noise to input data and outputting it

Installing MU195050A-x01 enables adding white noise with a band of

•

10 MHz to 10 GHz.

1

1-3

Mainframe

MU195020A

21G/32G bit/s SI PPG

1

Accessories

J1632A

Terminator

5

Clock Output,

Gating Output × 2

J1341A

Open

2

Ext Clock Input,

AUX Input

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

1

Clock Output

J1717A

Coaxial Adaptor (SMA-P, SMA-J)

6

Ext Clock Input,

AUX Input

When the MU195020A-x10 is installed:

J1632A

Terminator

2

Data Output × 2

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

2

Data Output × 2

When the MU195020A-x20 is installed:

J1632A

Terminator

4

Data Output × 4

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

4

Data Output × 4

Chapter 1 Overview

1.2 Product Configuration

1.2.1 Standard configuration

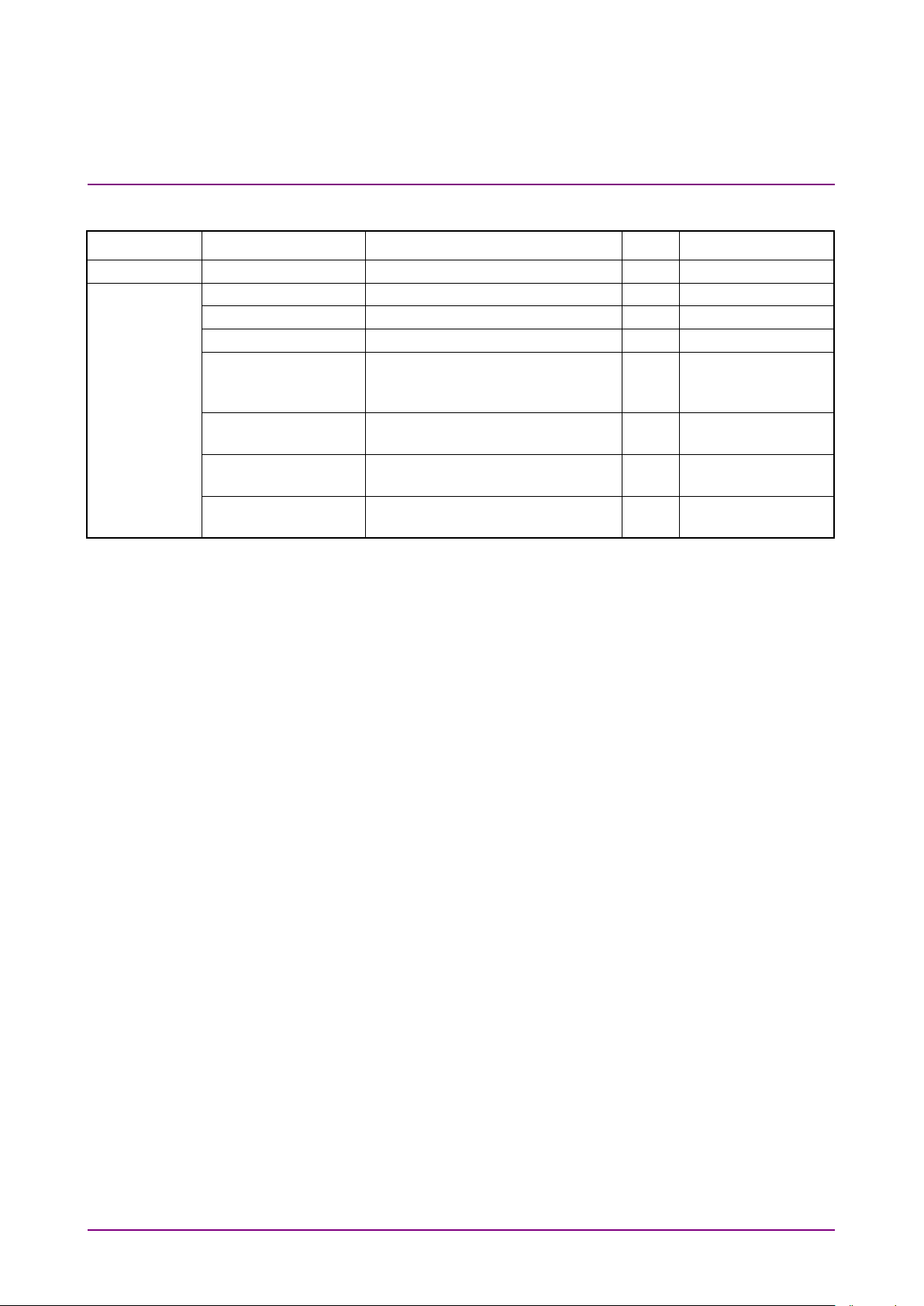

Table 1.2.1-1, Table 1.2.1-2, and Table 1.2.1-3 below show the standard

configurations of the three MP1900A modules respectively.

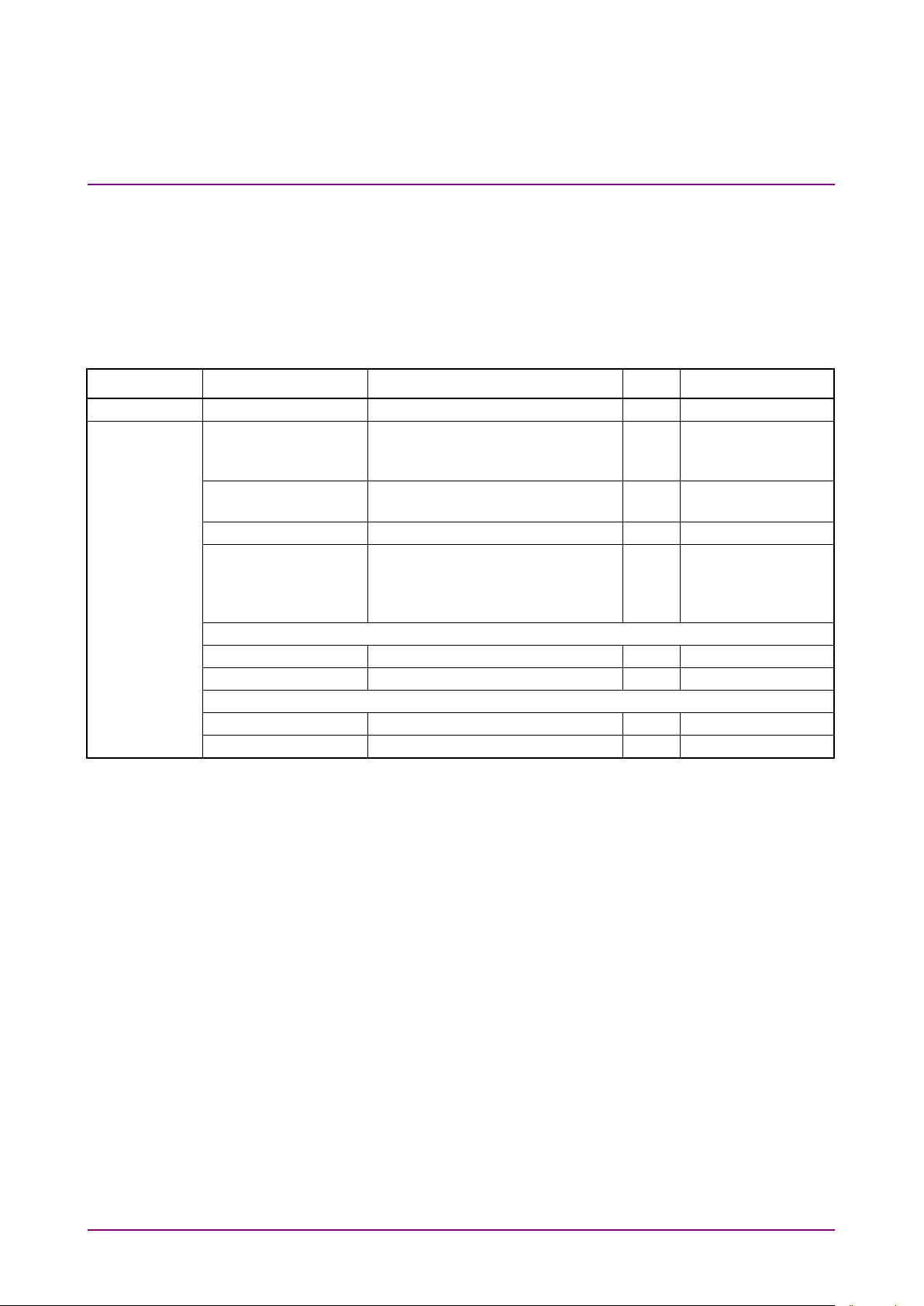

Table 1.2.1-1 Standard Configuration of MU195020A

Item Model name/symbol Product name Q'ty Remarks

Aux Output × 2,

Aux Output × 2,

Gating Output × 2,

1-4

1.2 Product Configuration

Overview

Mainframe

MU195040A

21G/32G bit/s SI ED

1 Accessories

J1632A

Terminator

2

Aux Output × 2,

J1341A

Open

2

Ext Clock Input

J1717A

Coaxial Adaptor (SMA-P, SMA-J)

4

Ext Clock Input,

AUX Input

When the MU195040A-x10 is installed:

J1341A

Open

2

Data Input × 2,

AUX Input

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

2

Data Input × 2

mainframe)

41KC-6

Precision Fixed Attenuator 6 dB

2

Data Input × 2

factory)

When the MU195040A-x20 is installed:

J1341A

Open

4

Data Input × 4,

AUX Input

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

4

Data Input × 4

mainframe)

41KC-6

Precision Fixed Attenuator 6 dB

4

Data Input × 4

Table 1.2.1-2 Standard Configuration of MU195040A

Item Model name/symbol Product name Q'ty Remarks

Aux Output × 2,

(Supplied

separately from the

(Installed on the

mainframe at

1

(Supplied

separately from the

(Installed on the

mainframe at

factory)

1-5

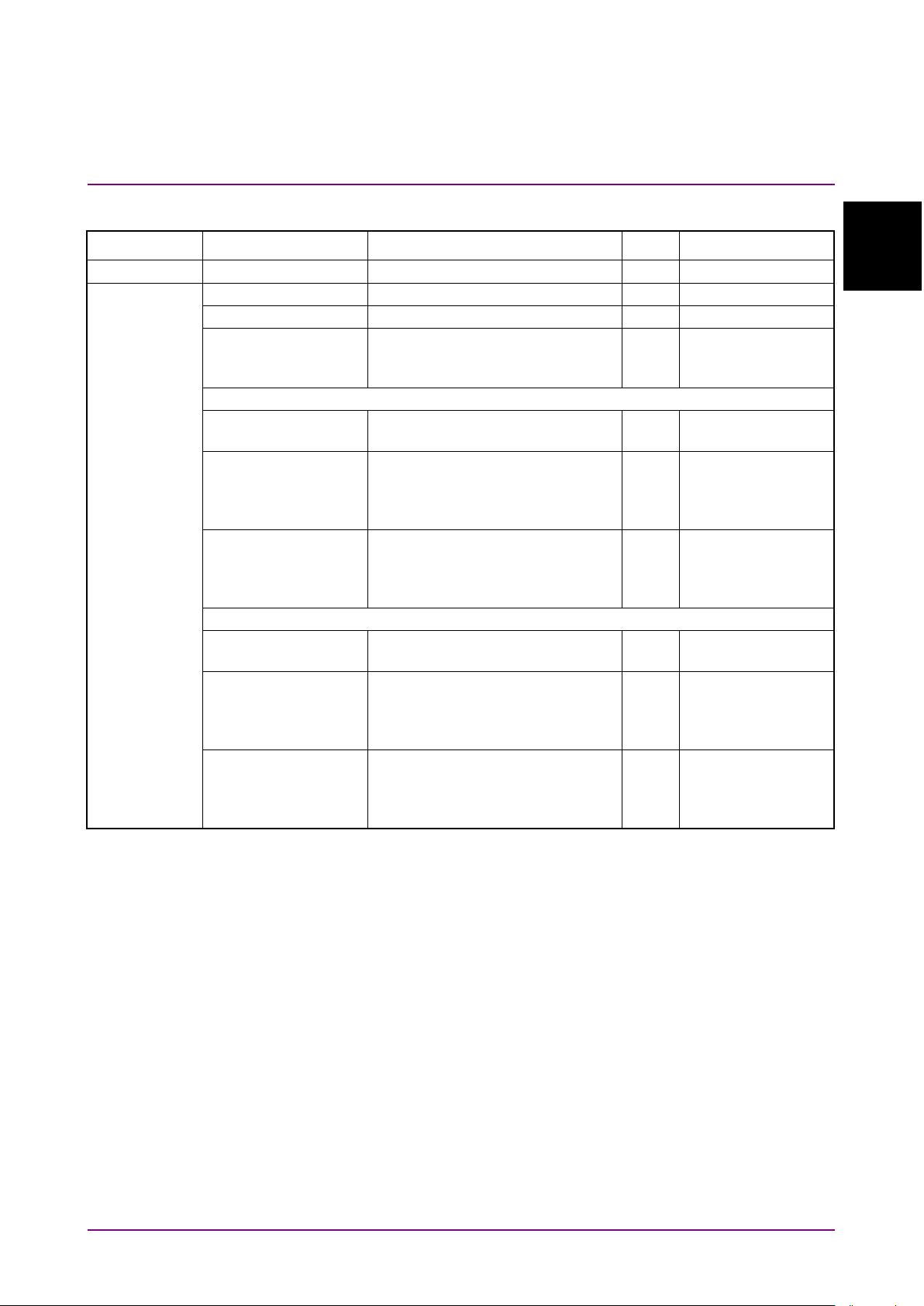

Mainframe

MU195050A

Noise Generator

1

Accessories

J1632A

Terminator

4

Data Output × 4*1

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

4

Data Output × 4*2

J1717A

Coaxial Adaptor (SMA-P, SMA-J)

2

External Input*2

J1341A

Open

6

Data Input × 4*1

2*1

J1746A

Skew match pair semirigid cable

(K connector, Data Input1)

1 set

Data Input1 × 2*3

J1747A

Skew match pair semirigid cable

(K connector, Data Input2)

1 set

Data Input2 × 2*4

J1792A

Skew match pair semirigid cable

(V-K connector, Data Input1)

1 set

Data Input1 × 2*5

Chapter 1 Overview

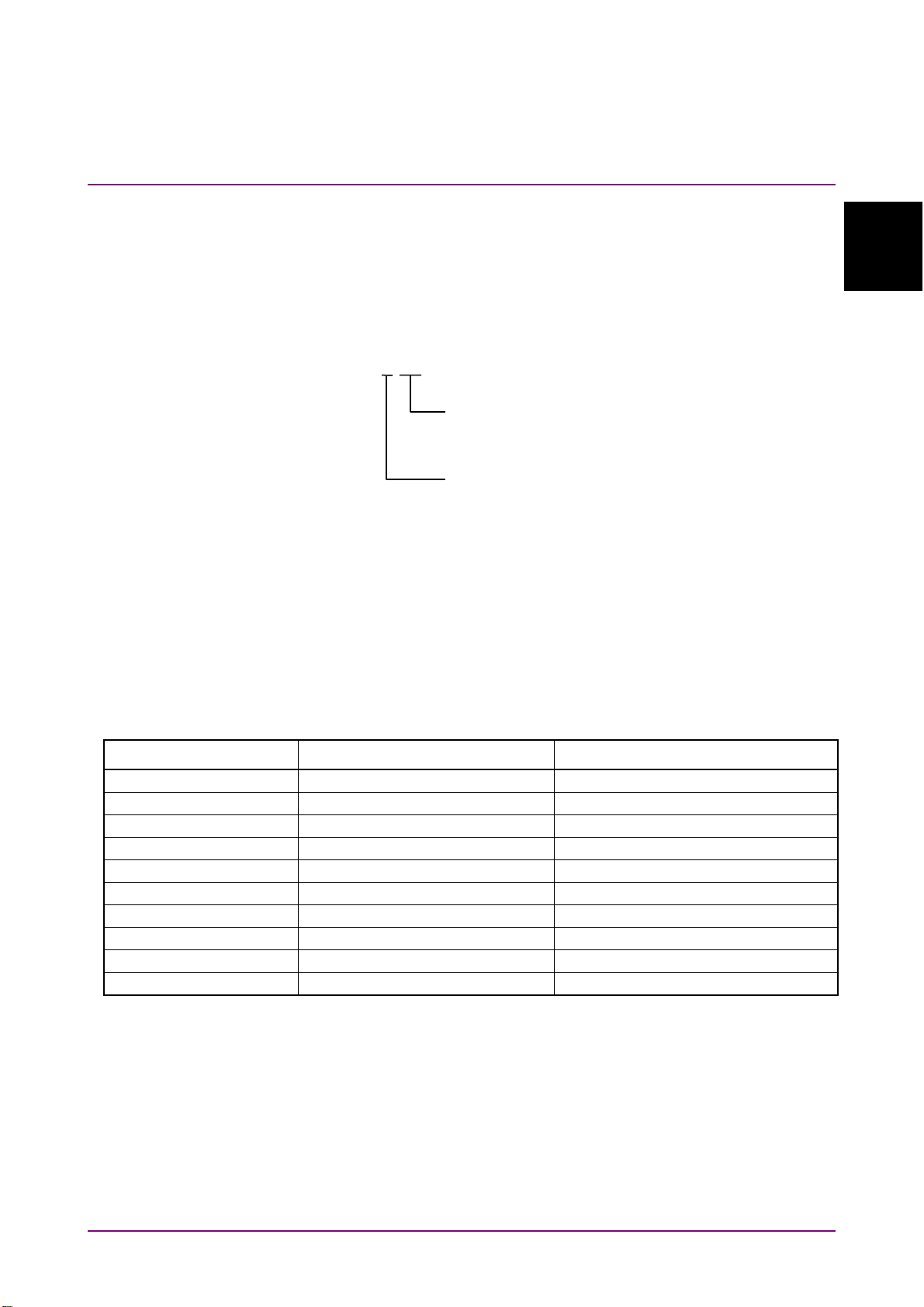

Table 1.2.1-3 Standard Configuration of MU195050A

Item Model name/symbol Product name Q'ty Remarks

External Input ×

*1: Installed on MU195050A at factory.

*2: It is recommended to keep it connected to the MU195020A

connector.

*3: Semi rigid cable to connect Data Output1 of MU195020A and Data

Input1 of MU195050A at the shortest length.

*4: Semi rigid cable to connect Data Output2 of MU195020A and Data

Input2 of MU195050A at the shortest length.

*5: Semi rigid cable to connect Data Output of MU196020A PAM4 PPG

and Data Input1 of MU195050A at the shortest length.

1-6

1.2.2 Options

g

1.2 Product Configuration

Table 1.2.2-1, Table 1.2.2-2, and Table 1.2.2-3 show the options for the

MP1900A modules . All options are sold separately.

1

Note:

Option name format is as follows:

MU195020A-x x x

Indicates function.

This value is reco

Anritsu management number.

This value is not recognized by the mainframe.

0: Installed at time of shipping

1: Retro-fitted option.

Must be returned to Anritsu (Japan) when

installing.

2: Retro-fitted option.

Must be returned to an Anritsu Service and

Sales office when installing.

3: Retro-fitted option.

The user can install the option.

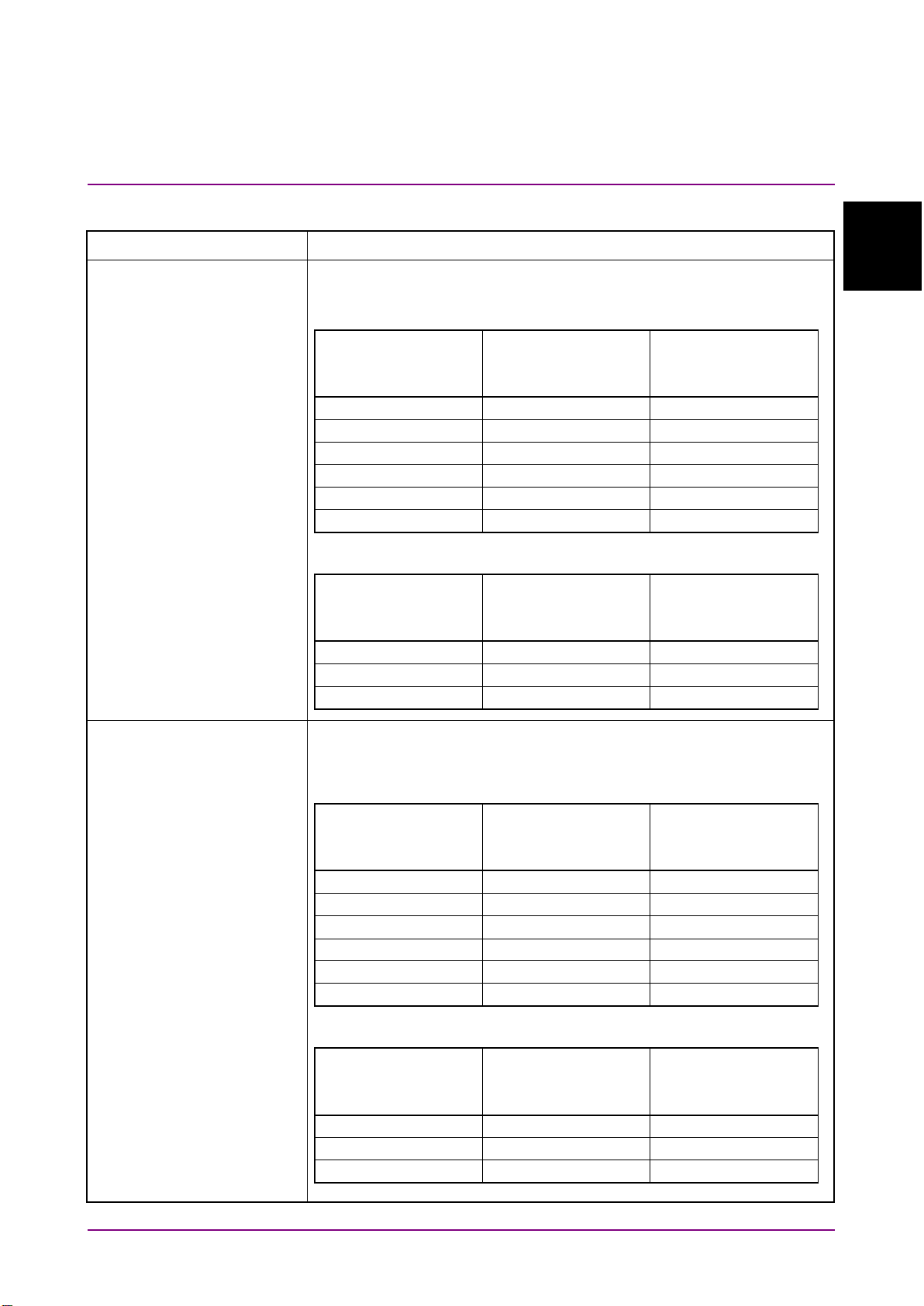

Table 1.2.2-1 Options of MU195020A

Overview

nized by the MP1900A.

Model name Product name Remarks

MU195020A-y01 32Gbit/s Extension *1

MU195020A-x10 1ch Data Output *

MU195020A-x20 2ch Data Output *

MU195020A-y11 1ch 10Tap Emphasis *

MU195020A-y21 2ch 10Tap Emphasis *

MU195020A-y30 1ch Data Delay *

MU195020A-y31 2ch Data Delay *

MU195020A-y40 1ch Variable ISI *

MU195020A-y41 2ch Variable ISI *

2, *3

2, *3

1, *4

1, *5

1, *4

1, *5

1, *4, *6

1, *5, *7

MU195020A-z50 Sequence Editor Function *8

*1: The y in the model name represents 0, 1, or 2.

*2: The x in the model name represents 0 or 1.

*3: Select either of them.

*4: The MU195020A-x10 is required.

*5: The MU195020A-x20 is required.

*6: The MU195020A-y11 is required.

*7: The MU195020A-y21 is required.

*8: The z in the model name represents 0 or 3.

1-7

Chapter 1 Overview

Table 1.2.2-2 Options of MU195040A

Model name Product name Remarks

MU195040A-y01 32Gbit/s Extension *1

MU195040A-x10 1ch ED *

MU195040A-x20 2ch ED *

MU195040A-y11 1ch CTLE *

MU195040A-y21 2ch CTLE *

MU195040A-y22 Clock Recovery *1

*1: The y in the model name represents 0, 1, or 2.

*2: The x in the model name represents 0 or 1.

*3: Select either of them.

*4: The MU195040A-x10 is required.

*5: The MU195040A-x20 is required.

2, *3

2, *3

1, *4

1, *5

Table 1.2.2-3 Option of MU195050A

Model name Product name Remarks

MU195050A-x01 White Noise *

*: The x in the model name represents 0 or 1.

1-8

Overview

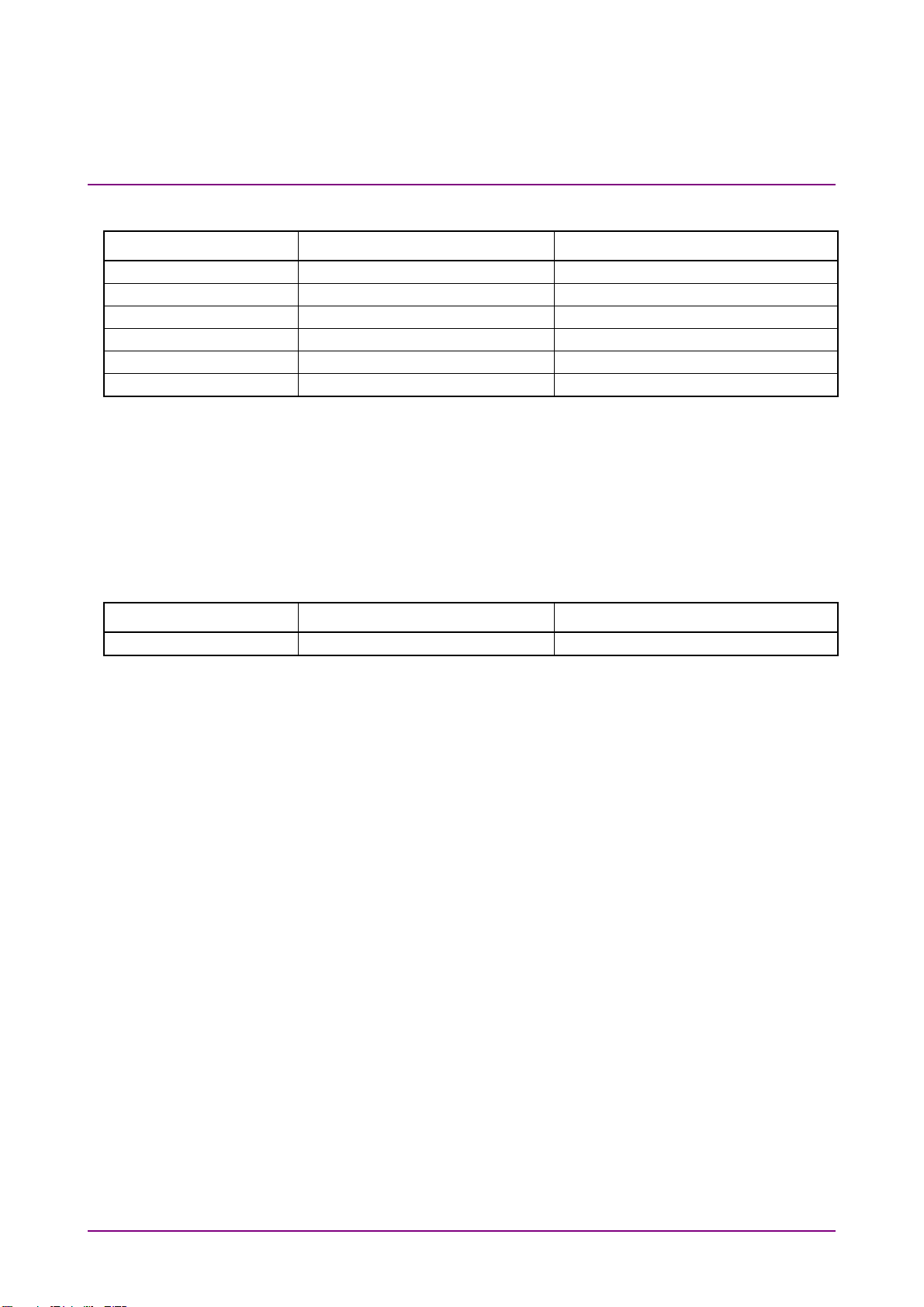

1.2.3 Optional Accessories

J1449A

Measurement kit (K connector)

Coaxial cable

Coaxial cable 1.0 m × 1

J1625A

Coaxial cable 1 m

SMA connector

J1342A

Coaxial cable 0.8 m

APC 3.5 mm connector

J1439A

Coaxial cable (0.8 m, K connector)

K connector

J1632A

Terminator

J1359A

Coaxial Adaptor (K-P.K-J, SMA)

41KC-3

Precision Fixed Attenuator 3 dB

41KC-6

Precision Fixed Attenuator 6 dB

41KC-10

Precision Fixed Attenuator 10 dB

41KC-20

Precision Fixed Attenuator 20 dB

K240C

Precision Power Divider

J1624A

Coaxial Cable 0.3 m (SMA connector)

SMA connector

J1550A

Coaxial skew match cable (0.8 m, APC 3.5 connector)

APC 3.5 mm connector,

Pair cable

J1551A

Coaxial skew match cable (0.8 m, K connector)

K connector, Pair cable

W3915AE

MU195020/40/50A Operation Manual

Printed version, English

Z0306A

Wrist strap

MZ1834A

4PAM Converter

MZ1838A

8PAM Converter

J1678A

ESD Protection Adapter-K

K connector

J1728A

Electrical Length Specified Coaxial Cable (0.4 m, K

J1741A

Electrical Length Specified Coaxial Cable (0.8 m, K

Connector)

J1742A

Electrical Length Specified Coaxial Cable (0.84 m, K

Connector)

J1735A

Combiner

J1758A

ISI Board

G0375A

32Gbaud Power PAM4 Converter

G0376A

32Gbaud PAM4 Decoder with CTLE

G0374A

64Gbaud PAM4 DAC

G0361A

64Gbaud 2-bit DAC with MUX

J1748A

Power Splitter (1.5G-18GHz)

Z1964A

Torque Wrench (Right Angle)

1.2 Product Configuration

Model name/

symbol

Table 1.2.3-1 shows the optional accessories for the MP1900A modules.

All optional accessories are sold separately.

Table 1.2.3-1 Optional Accessories

Product name Remarks

(K connector) 0.8 m × 2

Coaxial cable 0.8 m × 2

1

connector)

1-9

Operating Bit Rate

2.4 to 21.0 Gbit/s*1

2.4 to 32.1 Gbit/s*2

Setting Range

The range of the operating bit rate is determined by the interlocking

module*2 and Table 1.3.1-13 “Clock Output”.

MU181000A/B synchronized

operation ON

This item can be specified when MU181000A or MU181000B are

installed to the same unit.

Setting Range

2.400 000 to 21.000 000 Gbit/s, 0.000 002 Gbit/s step*1

Offset

–1000 to +1000 ppm, 1 ppm step*3

MU181500B synchronized

operation ON

This item can be specified when MU181000A, MU181000B and

MU181500B are installed to the same unit.

Setting Range

2.400 000 to 3.125 000 Gbit/s, 0.000 002 Gbit/s step

25.600 004 to 32.100 000 Gbit/s, 0.000 004 Gbit/s step*2

Offset

–1000 to +1000 ppm, 1 ppm step*4

Chapter 1 Overview

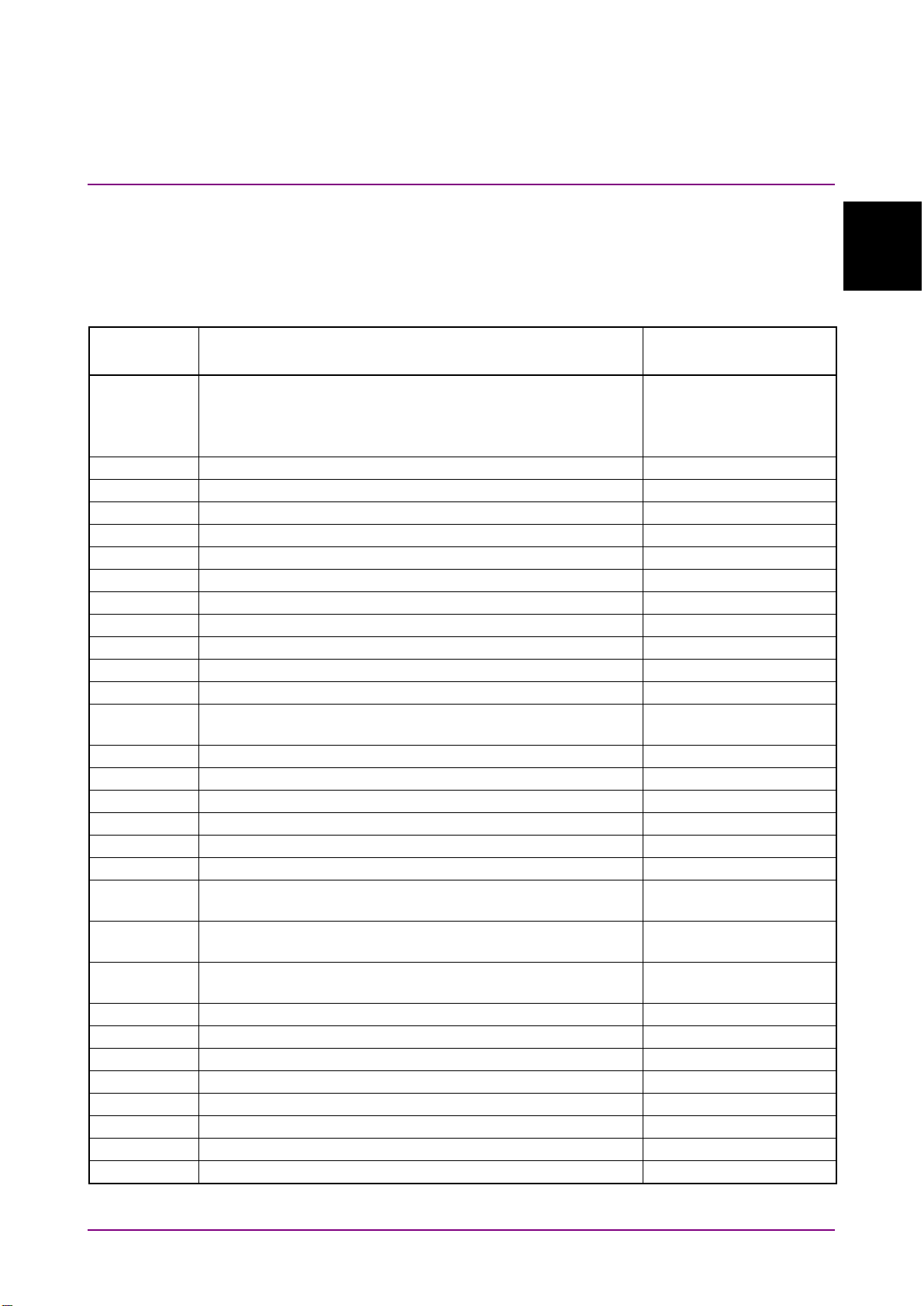

1.3 Specifications

1.3.1 Specifications for MU195020A

Table 1.3.1-1 Operating Bit Rate

Item Specifications

2.400 000 to 25.000 000 Gbit/s, 0.000 002 Gbit/s step*

25.000 004 to 32.100 000 Gbit/s, 0.000 004 Gbit/s step*2

3.200 002 to 6.250 000 Gbit/s, 0.000 002 Gbit/s step

6.400 002 to 12.500 000 Gbit/s, 0.000 002 Gbit/s step

12.800 002 to 21.000 000 Gbit/s, 0.000 002 Gbit/s step*

12.800 002 to 25.000 000 Gbit/s, 0.000 002 Gbit/s step*

*1: Not available Option x01

*2: Available Option x01

*3: Available when installed in the same mainframe as the MU195020A.

*4: Offset setting range depends on the bit rate. The range is –1000 to 0

ppm at the following bit rate.

Full Rate: 12.500000 Gbit/s, 25.000000 Gbit/s

Half Rate: 25.000000 Gbit/s

2

1

2

1-10

Overview

Table 1.3.1-1 Operating Bit Rate (Cont'd)

External Clock

When the Output Clock

2.4 to 16.0 Gbit/s

2.4 to 16.0 Gbit/s

Operate at 1/1 clock

16.0 to 20.0 Gbit/s*1

8.0 to 10.0 Gbit/s

Operate at 1/2 clock

20.0 to 21.0 Gbit/s*1

10.0 to 10.5 GHz

Operate at 1/2 clock

16.0 to 20.0 Gbit/s*2

8.0 to 10.0 GHz

Operate at 1/2 clock

20.0 to 32.1 Gbit/s*2

10.0 to 16.05 Gbit/s

Operate at 1/2 clock

25.0 to 32.1 Gbit/s*2

6.25 to 8.025 Gbit/s

Operate at 1/4 clock

When the Output Clock

Rate is set to Half Rate

2.4 to 28.1 Gbit/s*1

1.2 to 10.05 Gbit/s

Operate at 1/2 clock

2.4 to 32.1 Gbit/s*

1.2 to 16.05 Gbit/s

Operate at 1/2 clock

25.0 to 32.1 Gbit/s*

6.25 to 8.025 Gbit/s

Operate at 1/4 clock

Tracking with external clock

MU181500B

When the Output Clock

2.4 to 15.0 Gbit/s

2.4 to 15.0 Gbit/s

Operate at 1/1 clock

15.0 to 20.0 Gbit/s*1

7.5 to 10.0 Gbit/s

Operate at 1/2 clock

20.0 to 21.0 Gbit/s*1

10.0 to 10.5 GHz

Operate at 1/2 clock

15.0 to 20.0 Gbit/s*2

7.5 to 10.0 GHz

Operate at 1/2 clock

20.0 to 30.0 Gbit/s*

10.0 to 15.0 Gbit/s

Operate at 1/2 clock

25.0 to 32.1 Gbit/s*2

6.25 to 8.025 Gbit/s

Operate at 1/4 clock

When the Output Clock

Rate is set to Half Rate

2.4 to 21.0 Gbit/s*1

1.2 to 10.5 Gbit/s

Operate at 1/2 clock

2.4 to 30.0 Gbit/s*

1.2 to 15.0 Gbit/s

Operate at 1/2 clock

25.0 to 32.1 Gbit/s*

6.25 to 8.025 Gbit/s

Operate at 1/4 clock

1.3 Specifications

Item Specifications

Rate is set to Full Rate

Operating bit rate

range

Operating bit rate

range

1

Input Clock

Frequency

Input Clock

Frequency

2

2

Relationship

Between Bitrate and

Clock Frequency

Relationship

Between Bitrate and

Clock Frequency

Rate is set to Full Rate

Operating bit rate

range

Operating bit rate

range

Input Clock

Frequency

2

Input Clock

Frequency

2

2

Relationship

Between Bitrate and

Clock Frequency

Relationship

Between Bitrate and

Clock Frequency

1-11

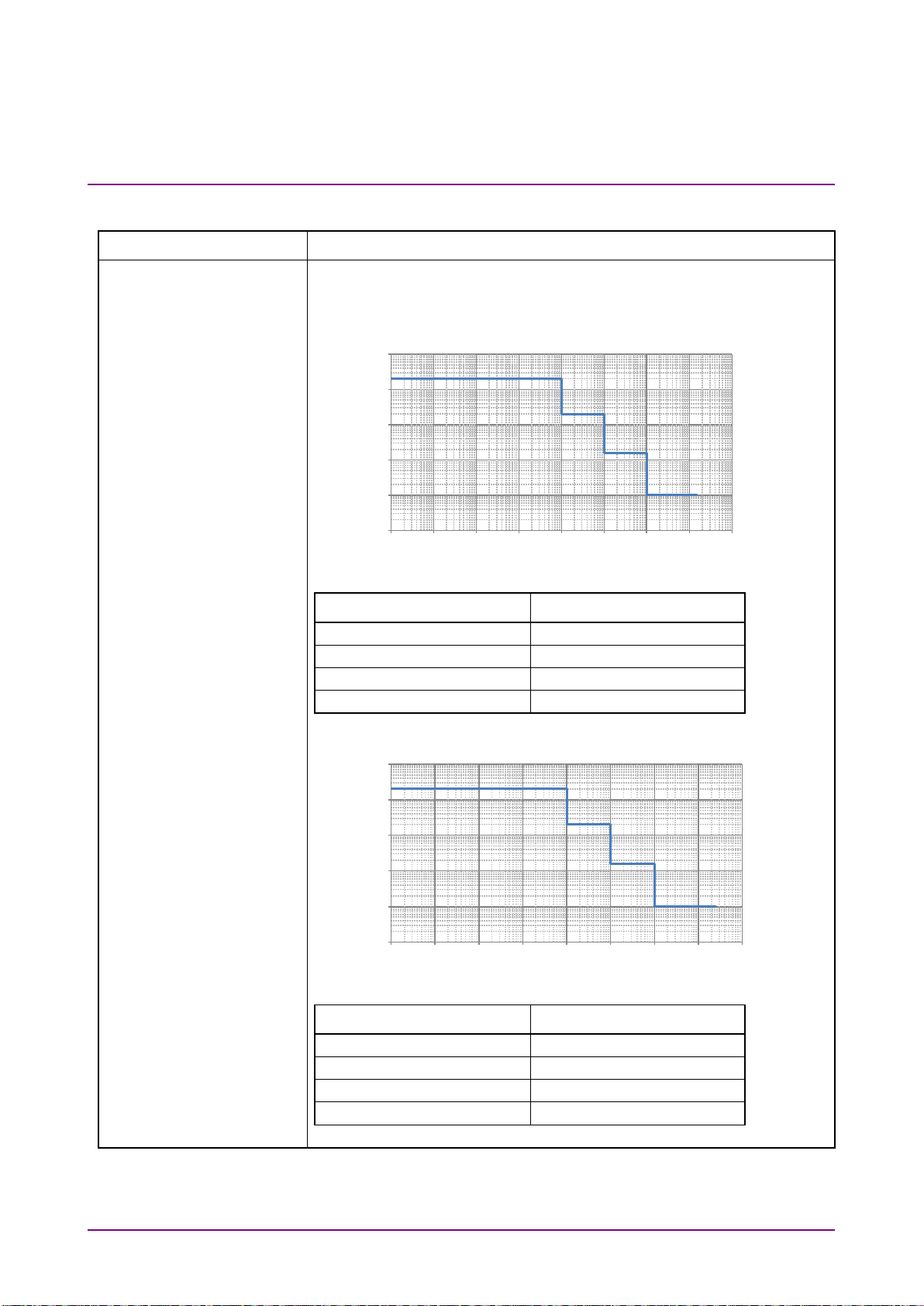

SJ1 Clock Output Rate

At MU181000A/B and MU181500B synchronized operation

range is narrowed by half.

SJ1 Clock Output Rate

30 < Bit rate ≤ 32.1 Gbit/s, 15 < Bit rate ≤ 17 Gbit/s

10 to 100k

0 to 2000

100.1k to 1M

0 to 200

1.001M to 10M

0 to 16

10.01M to 150M

0 to 1

17 < Bit rate ≤ 30 Gbit/s

10 to 100k

0 to 2000

100.1k to 1M

0 to 200

1.001M to 10M

0 to 16

10.01M to 250M

0 to 1

Jitter Amplitude [UIp

Jitter Amplitude [UIp

Chapter 1 Overview

Item Specifications

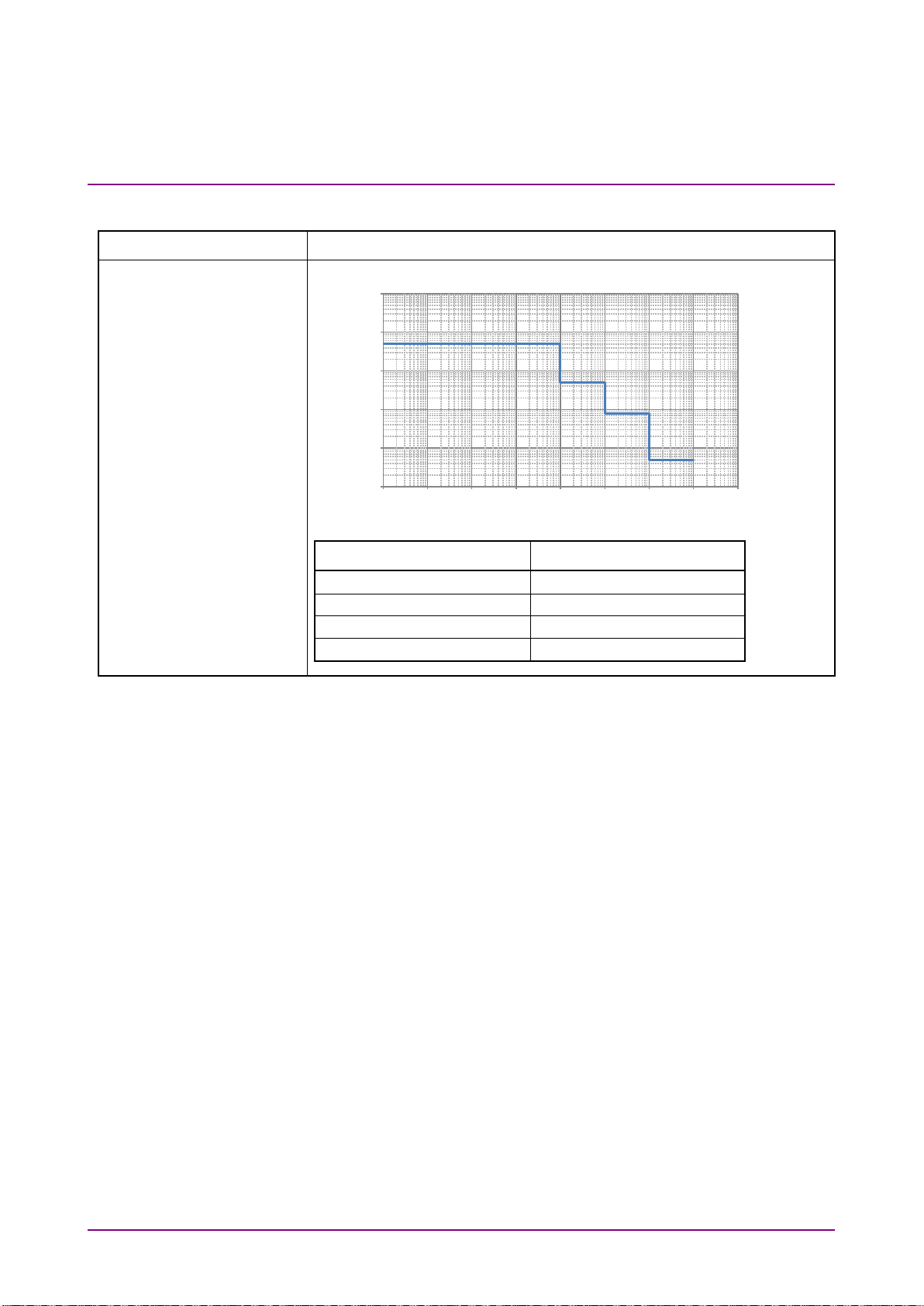

Table 1.3.1-2 Jitter Setting Range

When Built-in SJ2 is selected as SJ2, the Jitter Amplitude setting

At Full Rate

10000

-p]

1000

100

10

1

0.1

10 100 1k 10k 100k 1M 10M 100M 1000M

Modulation Frequency [Hz]

Modulation Frequency (Hz) Jitter Amplitude (UIp-p)

10000

-p]

1000

100

10

1

0.1

10 100 1k 10k 100k 1M 10M 100M 1 000M

Modulation Frequency (Hz) Jitter Amplitude (UIp-p)

1-12

Modulation Frequency [Hz]

Overview

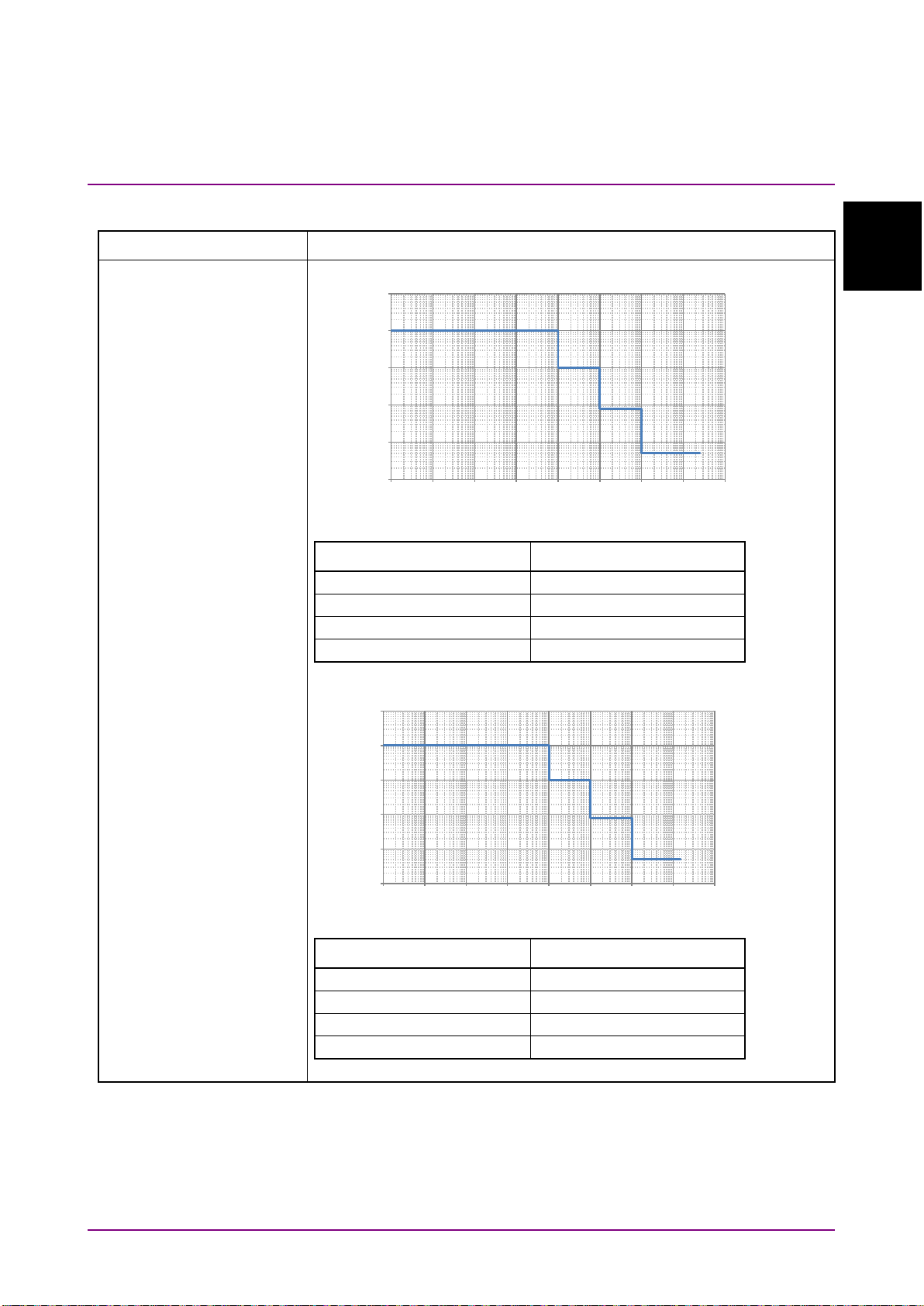

Table 1.3.1-2 Jitter Setting Range (Cont'd)

SJ1 Clock Output Rate

8.5 < Bit rate ≤ 15 Gbit/s

10 to 100k

0 to 1000

100.1k to 1M

0 to 100

1.001M to 10M

0 to 8

10.01M to 250M

0 to 0.5

4 < Bit rate ≤ 8.5 Gbit/s

10 to 100k

0 to 1000

100.1k to 1M

0 to 100

1.001M to 10M

0 to 8

10.01M to 150M

0 to 0.5

Jitter Amplitude [UIp

Jitter Amplitude [UIp

1.3 Specifications

Item Specifications

At Full Rate (Cont'd)

10000

-p]

1000

100

10

1

0.1

10 100 1k 10k 100k 1M 1 0M 100M 1000M

Modulation Frequency [Hz]

Modulation Frequency (Hz) Jitter Amplitude (UIp-p)

1

10000

-p]

1000

100

10

1

0.1

10 100 1k 1 0k 100k 1M 10M 100M 100 0M

Modulation Frequency [Hz]

Modulation Frequency (Hz) Jitter Amplitude (UIp-p)

1-13

SJ1 Clock Output Rate

2.4 < Bit rate ≤ 4 Gbit/s

10 to 100k

0 to 500

100.1k to 1M

0 to 50

1.001M to 10M

0 to 8

10.01M to 100M

0 to 0.5

Jitter Amplitude [UIp

Chapter 1 Overview

Item Specifications

Table 1.3.1-2 Jitter Setting Range (Cont'd)

At Full Rate (Cont'd)

10000

-p]

1000

100

10

1

0.1

10 100 1k 10 k 100k 1M 10M 10 0M 1000 M

Modulation Frequency [Hz]

Modulation Frequency (Hz) Jitter Amplitude (UIp-p)

1-14

Loading...

Loading...