MAINTENANCE MANUAL

Site Master™ Model S251C

Antenna and Cable Analyzer

Figure 1. Site Master Model S251C

1. INTRODUCTION

This manual provides maintenance instructions for

the Site Master S251C Antenna and Cable Analyzer.

It describes the product and provides performance

verification procedures, parts replacement proce

-

dures, and a replaceable parts list.

2. DESCRIPTION

The Site Master (Figure 1) is a hand held S

mission gain or loss), SWR/RL (standing wave ra

21

(trans

tio/return loss), and Distance-To-Fault measurement

instrument. It combines a synthesized source, VSWR

Bridge, and receiver on a single printed circuit board

(PCB). An optional power monitor is also available. A

block diagram is shown in Figure 2.

3. PERFORMANCE VERIFICATION

Paragraphs 4 through 10 contain tests that can be

used to verify the performance of the Site Master

model S251C having any version of firmware.

3.1. Initial Setup for Testing

1. Press and hold the

press the

-

ter. (This sets the instrument to the factory

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

preset state.)

2. If necessary, use the Up/Down arrow key to

adjust the contrast to give a readable display.

Press

ENTER to accept.

-

490 JARVIS DRIVE ¨ MORGAN HILL, CA 95037-2809

P/N: 10580-00067

REVISION B

PRINTED: FEBRUARY 2003

COPYRIGHT 2001-2003 ANRITSU CO.

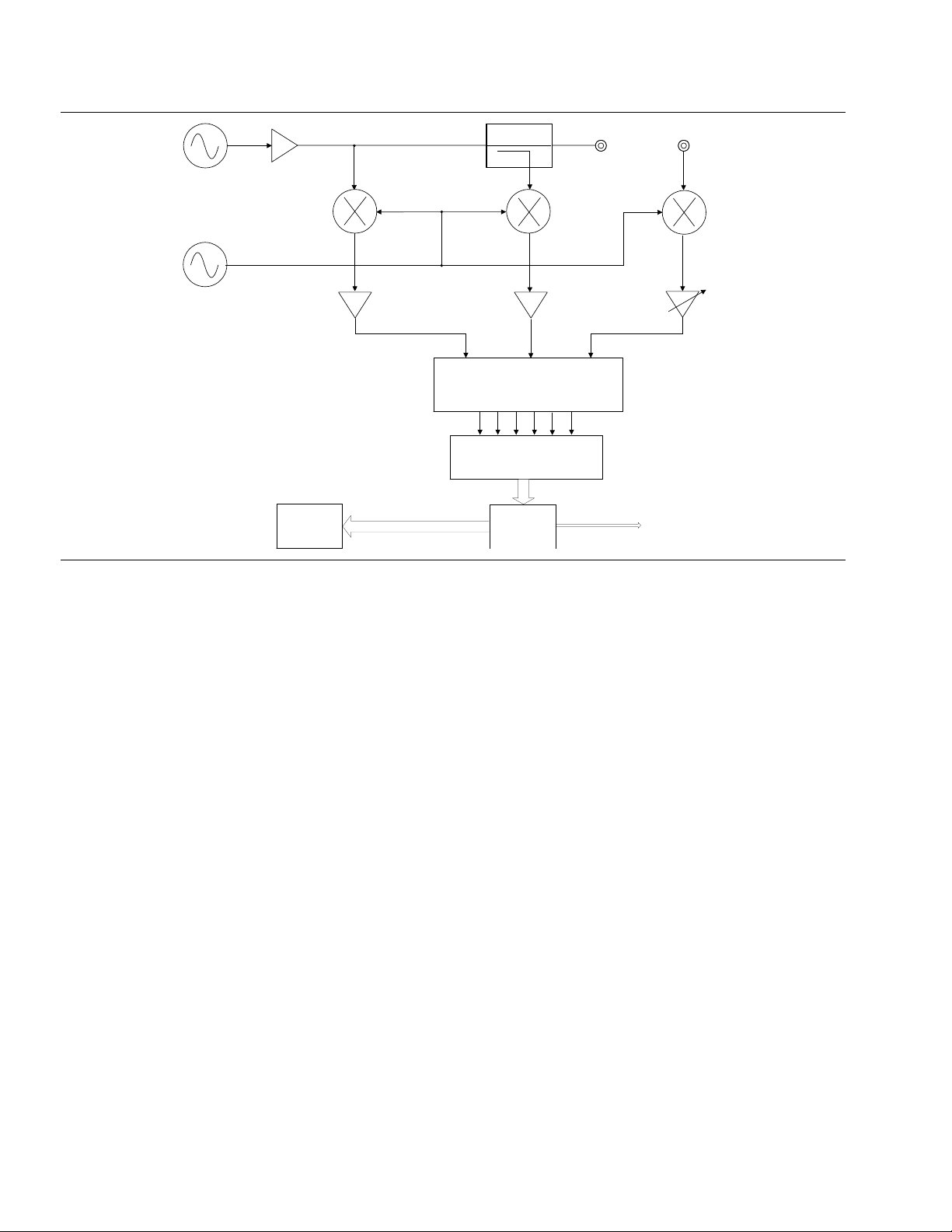

R F

S o u r c e

C o u p l e r

R F O u t

P o r t

R F I n

P o r t

I n c i d e n t

L o c a l

O s c i l l a t o r

D i s p l a y

Figure 2. Site Master Block Diagram

4. FREQUENCY ACCURACY

The following test can be used to verify the CW frequency accuracy of the Site Master. Measurement

calibration of the Site Master is not required for this

test.

a. Equipment Required:

·

Spectrum Analyzer

Anritsu Model MS2668C or equivalent

b. Procedure:

1. Press and hold the

press the

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

ter. (This sets the instrument to the factory

preset state.)

NOTE

Before continuing, allow a five minute

warm up for the internal circuitry to

stabilize.

2. Press the

3. Use the Up/Down Arrow key to highlight

SOURCE

4. Press the

MODE key.

RF

, then press ENTER.

FREQ soft key.

R e f l e c t e d

S y n c h r o n o u s

D e t e c t o r

A / D C o n v e r t e r

C P U

T r a n s m i t t e d

S e r i a l

P o r t

5. Using the keypad or Up/Down Arrow key enter 1000.0 MHz then press the

ENTER key.

6. Connect the RF cable from the Site Master

RF Out Test Port to the RF Input on the Spectrum Analyzer.

7. Set up the Spectrum Analyzer as follows:

(a) Press

Preset

(b) Press the PRESET ALL soft key

(c) Press

(d) Press

-

(e) Press

Frequency and enter 1 GHz

Span and enter 200 kHz

Amplitude

(f) Press the REFERENCE LEVEL soft key and

enter 10 dB

8. If the Site Master has gone into the hold

mode, press the

RUN/HOLD key to make the

measurement.

9. On the Spectrum Analyzer:

(a) Press

Marker

(b) Press PEAK SEARCH. The frequency

should be 1000 MHz ±75 kHz.

2 Site Master S251C MM

5. TRANSMISSION/ISOLATION

VERIFICATION

The following test can be used to verify transmission

test port isolation and the accuracy of transmission

measurements. Measurement calibration of the Site

Master is required for this test.

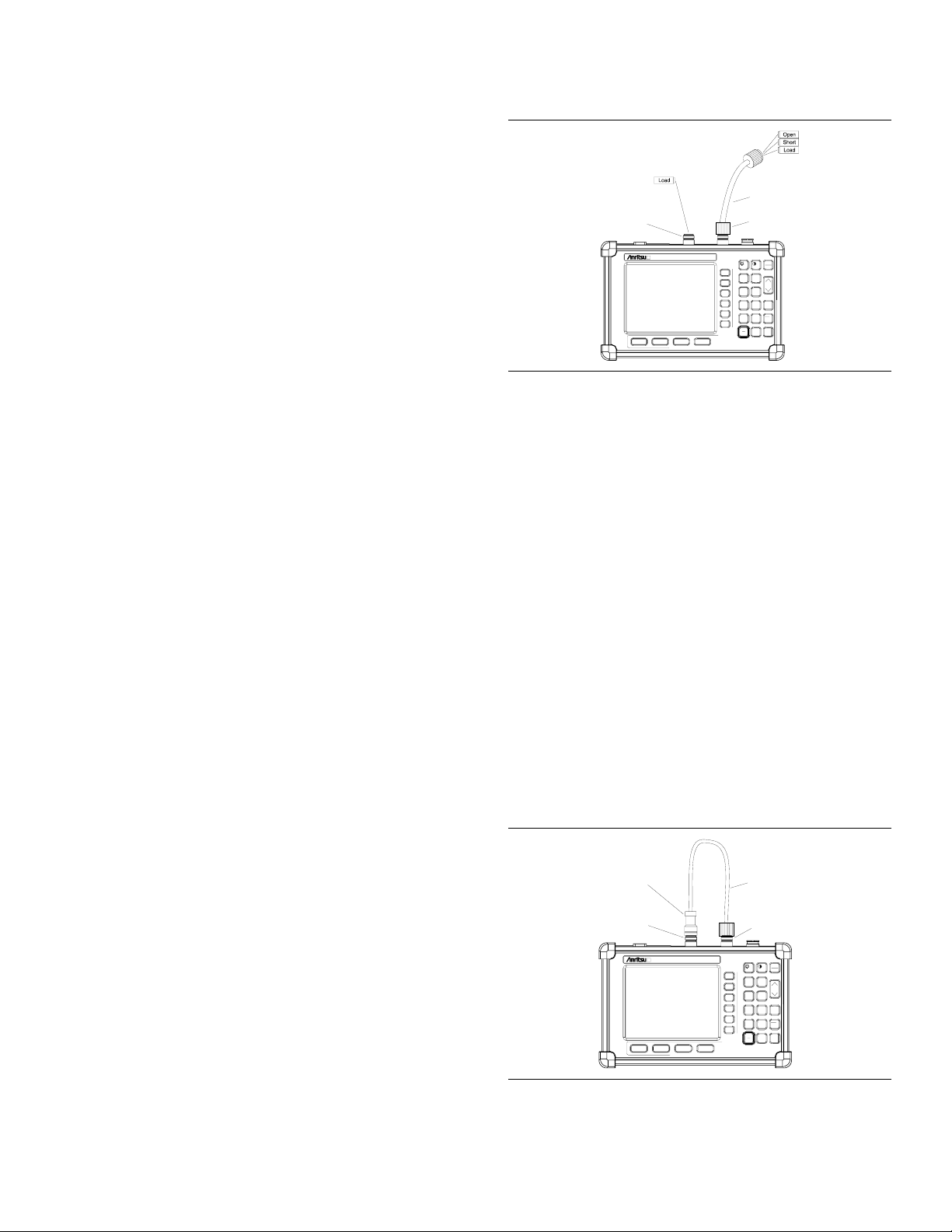

TransTest Port

TestPort

Extension Cable

Refl Test Port

a. Equipment Required:

10 dB Attenuator, Weinshel 1-10

·

30 dB Attenuator, Weinshel 1-30

·

Open/Short, Anritsu 22NF50

·

50 Ohm Terminations,

·

Anritsu SM/PL or 28N50-2

Anritsu SM/PLNF or 28NF50-2

Armored Test Port Extension Cable,

·

1.5 Meter, N(m) to N(m),

Anritsu 15NN50-1.5A

b. Procedure:

1. Press and hold the

press the

ON/OFF key to turn on the Site Mas-

ESCAPE/CLEAR key, then

ter. (This sets the instrument to the factory

preset state.)

NOTE

Before continuing, allow a five minute

warm up for the internal circuitry to

stabilize.

2. Press the

MODE key.

3. Use the Up/Down Arrow key to highlight

SERTION LOSS

4. Press the

5. Press the

, then press ENTER.

AMPLITUDE key.

TOP soft key.

6. On the keypad, press “0”, then press

(Verify the bottom limit is set to –120 dB.)

7. Press the

LIMIT key.

IN

ENTER.

Site Master S251C

MODE

FREQ/DIST

SWEEP

AMPLITUDE

Figure 3. OSL-THRU-ISOL Calibration Setup

12. Connect a Load (28N50-2 or SM/PL) to the

RF In Test Port and verify that the noise floor

(isolation) is below –80 dB.

13. Press the

14. Press the

MARKER key.

M1 soft key, then the EDIT soft key.

15. Using the keypad or the Up/Down Arrow key,

enter 1000.0 MHz, and press

NOTE

For the following steps in the procedure,

use only attenuators that have Type N

connectors. The use of attenuators with

other type connectors and adapters will

cause measurement errors.

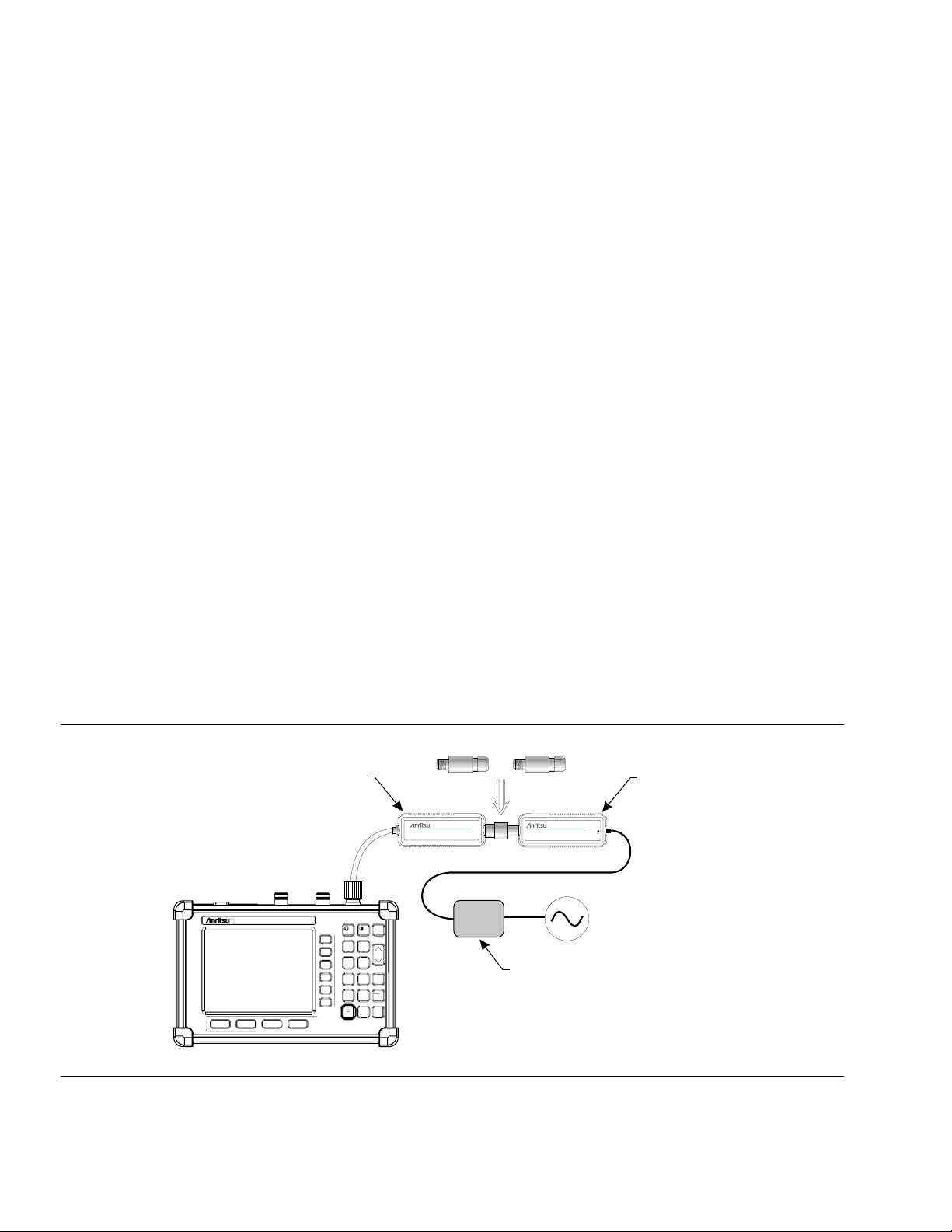

16. Connect the 10 dB attenuator to the RF In

-

Test Port (refer to Figure 4) and verify that

the reading is –10 dB ±2.25 dB @ 1000 MHz.

17. Connect the 10 dB and 30 dB attenuators in

series to the RF In Test Port and verify that

the reading is –40 dB ±3.25 dB @ 1000 MHz.

Attenuator

ESCAPE

CLEAR

2

1

START

AUTO

CAL

SCALE

3

4

SAVE

RECALL

SETUP

SETUP

6

5

LIMIT

MARKER

ENTER

8

7

RECALL

RUN

SAVE

DISPLAY

DISPLAY

HOLD

+

9

0

-

/

PRINT

ON

SYS

OFF

.

ENTER.

TestPort

Extension Cable

8. Press the

9. Press the

the

10. Press the

11. Follow the instructions on the display to per

form a OSL-THRU-ISOL calibration using a

22NF50 Open/Short, 28NF50-2 or SM/PLNF

Terminations, and 15NN50-1.5ATest Port Ex

tension Cable (refer to Figure 3).

SINGLE LIMIT soft key.

EDIT soft key, enter –80, and press

ENTER key.

START CAL key.

-

-

Figure 4. Test Setup

TransTest Port

Refl Test Port

Site Master S251C

MODE

FREQ/DIST

AMPLITUDE

SWEEP

ESCAPE

CLEAR

2

1

START

AUTO

CAL

SCALE

3

4

SAVE

RECALL

SETUP

SETUP

6

5

LIMIT

MARKER

ENTER

8

7

RECALL

RUN

SAVE

DISPLAY

DISPLAY

HOLD

+

9

0

-

/

PRINT

ON

SYS

OFF

.

Site Master S251C MM 3

6. RETURN LOSS VERIFICATION

The following test can be used to verify the accuracy

of return loss measurements. Measurement calibra

tion of the Site Master is required for this test.

a. Equipment Required:

5. Follow the instructions on the screen to per

-

form a calibration using a 22N50 Open/Short

-

and 28N50-2 or SM/PL Termination.

6. Connect the 20 dB offset to the RF Out Test

Port and verify that the reading is 20 dB

±1.7 dB

20 dB offset, Anritsu SC5270

·

6 dB offset, Anritsu SC5237

·

Open/Short, Anritsu 22N50

·

50 Ohm Termination,

·

Anritsu 28N50-2 or SM/PL

b. Procedure:

1. Press and hold the

press the

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

ter. (This sets the instrument to the factory

preset state.)

NOTE

Before continuing, allow a five minute

warm up for the internal circuitry to

stabilize

2. Press the

MODE key.

3. Use the Up/Down Arrow key to highlight

TURN LOSS

4. Press the

, then press ENTER.

START CAL key.

RE-

7. Connect the 6 dB offset to the RF Out Test

Port and verify that the reading is 6 dB

±1.2 dB

7. POWER MONITOR VERIFICATION

If the Power Monitor (Option 5) is installed in the

Site Master, the following test can be used to verify

the accuracy of the power measurements. Measure

ment calibration of the Site Master is not required

for this test.

-

a. Equipment Required:

RF Detector, 10 MHz to 20 GHz,

·

Anritsu 560-7N50B

· 10 dB Attenuator, Weinschel 1-10

· 30 dB Attenuator, Weinschel 1-30

· RF Reference Source, 0.050 GHz,

Anritsu MA2418A

· DC Power Supply, Anritsu 2000-933

-

Attenuators

560-7N50B

RF Detector

MA2418AReference Source

W

50MHz, 50

0dBm

Site Master S251C

MODE

FREQ/DIST

AMPLITUDE

SWEEP

ESCAPE

CLEAR

2

1

START

AUTO

CAL

SCALE

3

4

SAVE

RECALL

SETUP

SETUP

6

5

LIMIT

MARKER

ENTER

8

7

RECALL

RUN

SAVE

DISPLAY

DISPLAY

HOLD

+

9

0

-

/

PRINT

ON

SYS

OFF

.

DC Power Supply 2000-933

20mA

15-24VDC

MA2418A

Reference Source

Site Master w/ Option 5 Installed

Figure 5. Power Monitor Verification

4 Site Master S251C MM

b. Procedure

1. Connect the DC power supply to the

MA2418A Reference Source. (Refer to Figure

5.)

2. Connect the MA2418A Reference Source to

the input of the 560-7N50B RF detector.

3. Connect the RF Detector output to the RF De

tector input of the Site Master.

(Option 10A only works with the AC-DC

Adapter).

2. Apply AC power to the power supply.

3. Press and hold the

press the

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

-

ter. (This sets the instrument to the factory

-

preset state.)

4. Press the

SYS key.

4. Connect the DC power supply to the appropri

ate line voltage to supply power to the

MA2418A Reference Source.

5. Press and hold the

press the

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

ter. (This sets the instrument to the factory

preset state.)

6. Press the

MODE key.

7. Use the Up/Down Arrow key to highlight

POWER MONITOR, then press ENTER.

8. Press the

ZERO soft key to zero the power

monitor.

When complete,

ZERO ADJ:ON is displayed in

the message area.

9. Verify that the power monitor reading is

0.0 dBm ±1 dB.

10. Connect the output of the MA2418A Reference Source to the two attenuators so as to

add 40 dB of attenuation (Figure 5).

11. Connect the MA2418A Reference Source and

the attenuators to the input of the 560-7N50B

RF detector.

-

5. Press the

6. Press the

OPTIONS soft key.

BIAS-T soft key to activate the Bias

Tee option.

-

7. Verify that the display shows

15.0V, 0 mA.

8. Connect the 22NF50 short to the RF In test

port.

9. Verify the test port voltage relay clicks on and

off, and

FAULT is shown in the upper left cor

ner of the display.

10. Remove the short and install the 100 Ohm

load.

CAUTION

The 100 Ohm resistor will get hot. Verify the readings and remove the 100

Ohm load immediately.

11. Verify that the display shows

BIAS, with a

reading of 14.8 to 15.3 Volts, and 120 to 160

milliamps.

9. BIAS T (OPTION 10B) VERIFICATION

a. Equipment Required:

-

·

12. Verify that the power monitor reading is now

–40.0 dBm ±2 dB.

8. BIAS T (OPTION 10A) VERIFICATION

a. Equipment Required:

·

AC-DC Adapter Power Supply 40-115

·

Open/Short, Anritsu 22N50

·

100 Ohm, 1 Watt load (100 Ohm, 1 Watt re

sistor soldered from the center pin to ground

of an N-type connector.)

b. Procedure:

1. Connect the AC-DC Adapter Power Supply to

the battery charging port on the Site Master

-

Open/Short, Anritsu 22N50

·

100 Ohm, 1 Watt load (100 Ohm, 1 watt resis

tor soldered from the center pin to ground of

a N-type connector)

·

Anritsu T2904

b. Procedure:

1. Ensure the battery is fully charged. (Option

10B only works with the battery).

2. Press and hold the

press the

ON/OFF key to turn on the Site Mas

ESCAPE/CLEAR key, then

ter. (This sets the instrument to the factory

preset state.)

3. Press the

4. Press the

SYS key.

OPTIONS soft key.

Site Master S251C MM 5

-

-

5. Press the BIAS-T soft key to activate the Bias

Tee option.

NOTE

When the Bias Tee option is selected,

the unit is automatically forced into sin

-

gle sweep mode.

6. Press the

ON/OFF soft key.

7. Verify that 15.1V, 0 mA is shown in the upper

left corner of the display.

10. TERMINATION VERIFICATION

This test verifies the accuracy of the Site Master

SM/PL termination using the precision return loss

mode of the 541XXA Scalar Measurement System.

Measurements of terminations using this mode pro

vide results that are traceable to the NIST (National

Institute of Standards and Technology) standards for

the precision airline.

a. Equipment Required:

8. Connect the 22N50 SHORT to the RF In test

port.

9. Press the

RUN/HOLD key.

NOTE

The message “

displayed whenever the

Powering up TMA…” will be

RUN/HOLD key

is pressed.

10. Verify the test port voltage relay clicks on and

off, and

FAULT is shown in the upper left cor

-

ner of the display.

11. Remove the 22N50.

12. Select LOW VOLTAGE (12V) and LOW CURRENT (460 mA(), 244 mA(–)) by pressing

LOW/HIGH VOLTAGE soft key.

the

13. Connect the 100 Ohm load to the

RF In test

port.

14. Press the

RUN/HOLD key and verify the read-

ing displayed in upper left corner is

approximately 11.9V to 12.9V, 120 mA to 160

mA.

15. Remove the 100 Ohm load.

16. Select HIGH VOLTAGE (15V) and HIGH

CURRENT (1A(), 650 mA(–)) by pressing the

LOW/HIGH VOLTAGE and LOW/HIGH CURRENT

soft keys.

17. Connect the T2904 to the

18. Press the

RUN/HOLD key and verify the read

ing displayed in upper left corner is approxi

RF In test port.

-

-

mately 14.8V to 15.3V, 343 mA to 379 mA.

Scalar Measurement System,

·

Anritsu 541XXA

Offset SWR Autotester,

·

Anritsu 560-97A50-20

Precision Airline, Anritsu 18N50

·

Open/Short, Anritsu 22N50

·

50 Ohm Termination, Anritsu 26N50

·

Source Adapter, Anritsu 34NN50A

·

b. Procedure

1. Connect the test equipment as shown in Figure 6.

2. Press the

3. Press the

Power key on the 541XXA to On.

System Menu key.

4. Using the Menu up-down keys: Highlight

SET

, then press the Select key.

5. At the

up-down keys to highlight

DEFAULTS

RESET MENU display, use the Menu

RESET TO FACTORY

, then press the Select key.

6. Set the signal source for the frequency range

as follows:

(a) Press the

Frequency key.

(b) Using the Data Entry Keypad or Data

Entry Knob, set the Start frequency to

0.01 GHz. Press the

Enter key.

(c) Using the Data Entry Keypad or Data

Entry Knob, set the Stop frequency to

4.0 GHz. Press the

Enter key.

RE-

7. Press the Channel 2 Display On/Off key to

Off.

8. Press the Channel 1 Menu key.

9. Using the Menu up-down keys: Highlight

PRECISION RL, then press the Select key.

6 Site Master S251C MM

10. At the PRECISION RETURN LOSS menu

display, use the Menu up-down keys to high

light

FINAL, then press the Select key.

11. Press the

12. At the CALIBRATION menu display, use the

Menu up-down keys to highlight

then press the

13. At the PRECISION RETURN LOSS CALI

BRATION menu display prompt, connect the

Offset SWR Autotester to Input A, if you have

not done so yet.

14. Connect the precision air line to the Offset

SWR Autotester test port. Position the air

line pointing vertically upward. Downward or

horizontal positions make connector pin

alignment difficult.

Calibration key.

START CAL,

Select key.

-

16. At the PRECISION RETURN LOSS CALI

-

BRATION menu prompt, connect the Open to

the beadless end of the airline. Press the

lect

key to start the calibration.

17. Verify that the display resembles that shown

in Figure 8.

CAUTION

During both calibration and measure

ment, be sure to properly align the

beadless connector of the airline. When

the connectors are mis-aligned, a spike

will usually be visible on the display.

18. At the next menu prompt, remove the Open

and connect the Short to the beadless end of

the airline. Press the

calibration process.

Select key to start the

-

Se

-

-

NOTE

Ensure that the beadless end of the pre

cision airline is at the measurement con

nection point.

15. Press the

Select key when ready.

50 Ohm

Termination

541XXA Scalar Measurement System

-

-

Open/Short

Precision

Air Line

19. At the next menu prompt, remove the Short

and connect the 50 Ohm Termination to the

beadless end of the air line. Press the

key to start the calibration process.

20. When the calibration is complete, remove the

50 Ohm Termination.

Select

Termination

under Test

Beadless

End

Connect Dashed Line Connections

When Directed By Procedure

B

A

Source

Adapter

Figure 6. 541XXA Precision Return Loss Setup

Offset SWR

Autotester

Site Master S251C MM 7

2: OFF

10.0 dB/DIV OFFSET1: PRECSN RL (A)

2: OFF

+0.0dB

2 GHz/DIV

START: 0.0100 GHz

401 pts

STOP: 20.0000 GHz

LEVEL +7.0 dBm

54147A

CURSOR

1: -46.02 dB

PRESS SELECT

FOR

CURSOR MENU

10.0050 GHz

1

10.0 dB/DIV OFFSET1: PRECSN RL (A)

+0.0dB

54147A

PRECISION

RETURN LOSS

CALIBRATION

bles that shown in Figure 7.

22. Observe that the waveform displayed resem

-

1

START: 0.0100 GHz

401 pts

2 GHz/DIV

Figure 7. Example of a Good Connection

21. Connect the SM/PL termination to the

beadless end of the air line and press the Select key to begin the measurement.

STOP: 20.0000 GHz

LEVEL +7.0 dBm

CONNECT OPEN

TO AIRLINE

PRESS SELECT

WHEN READY

Figure 8. Direct Readout of the Precision Return Loss

23. Press the

Cursor On/Off key to On.

24. Observe the Cursor menu readout. The minimum return loss reading for the SM/PL termination should be 42 dB.

8 Site Master S251C MM

11. BATTERY PACK REMOVAL AND

REPLACEMENT

This procedure provides instructions for removing

and replacing the Site Master battery pack.

1. With the Site Master standing upright on a

stable surface, locate the battery access door

(Figure 9).

BATTERYACCESS DOOR

Figure 9. Battery Access Door Location

Figure 11. Removing the Battery Access Door

2. Lift up the access door handle and rotate it

90 degrees counterclockwise, as illustrated in

Figure 10.

Figure 10. Rotate the Battery Access Door Handle

3. Lift the door and remove, as illustrated in

Figure 11.

4. Grasp the battery lanyard and pull the bat

tery straight up and out of the unit, as illus

trated in Figure 12.

Figure 12. Removing the Battery

5. Replacement is the opposite of removal. Note

the orientation of the battery contacts, and

be sure to insert the new battery with the

contacts facing the rear of the unit (Figure

13).

BATTERYCONTACTS

-

-

Figure 13. Battery Orientation

Site Master S251C MM 9

12. BATTERY INFORMATION

The following information relates to the care and

handling of the Site Master battery, and NiMH bat

teries in general.

Figure 14. Site Master Battery

The Nickel Metal Hydride (NiMH) battery sup

·

plied with the Site Master is shipped in a dis

charged state. Before using the Site Master, the

internal battery must first be charged for three

hours, either in the Site Master or in the optional battery charger (Anritsu part number:

2000-1029).

The battery may need to be replaced when the

·

operating time between charging becomes no

-

-

-

ticeably shorter than normal.

Never use a damaged or worn out charger or

·

battery.

Storing the battery in extreme hot or cold

·

places will reduce the capacity and lifetime of

the battery.

Never short-circuit the battery terminals.

·

Do not drop, mutilate or attempt to disassemble

·

the battery.

Do not dispose of batteries in a fire!

·

Batteries must be recycled or disposed of prop

·

erly. Do not place batteries in household gar

bage.

Always use the battery for its intended purpose

·

only.

-

-

-

· Use only Anritsu approved battery packs.

· Recharge the battery only in the Site Master or

in an Anritsu approved charger.

· With a new NiMH battery, full performance is

achieved after three to five complete charge and

discharge cycles.

·

When the Site Master or the charger is not in

use, disconnect it from the power source.

·

Do not charge batteries for longer than 24

hours; overcharging may shorten battery life.

·

If left unused a fully charged battery will dis

charge itself over time.

·

Temperature extremes will affect the ability of

the battery to charge: allow the battery to cool

down or warm up as necessary before use or

charging.

·

Discharge an NiMH battery from time to time

to improve battery performance and battery

life.

·

The battery can be charged and discharged

hundreds of times, but it will eventually wear

out.

-

10 Site Master S251C MM

13. FRONT PANEL ASSEMBLY REMOVAL AND

REPLACEMENT

This procedure provides instructions for removing

and replacing the Site Master front panel assembly.

With the front panel assembly removed, the LCD

display, keypad PCB, keypad membrane, and main

PCB assemblies can be removed and replaced.

1. Place the Site Master face up on a work sur

-

face.

2. Remove the four rubber corner bumpers by

carefully sliding the bumpers off of the case

corners (Figure 15).

7. Carefully disconnect the LCD display

backlight cable from J15 on the main PCB.

J15

J1

J12

Figure 16. Site Master Front Panel Cable Connections

8. Remove the front panel assembly.

9. Reverse the above steps to replace the front

panel assembly.

Figure 15. Removing the Corner Bumpers

3. With the bumpers removed, the access holes

for the case screws are revealed. Use a Phillips screwdriver to remove the four screws

securing the two halves of the Site Master

case together.

4. Carefully lift up on the right side (as viewed

from the front) of the front half of the case

and begin to separate the two halves.

CAUTION

Do not force or pull the two halves of the

case apart as there are delicate cables

attached between the two halves that

must be disconnected first.

5. Carefully depress the latch tab and discon

nect the LCD display cable from J12 on the

main PCB.

The corner bumpers only mount one

way. That is, the raised area inside one

end of the bumper (Figure 17) is made

to conform to the contour of the front

cover only.

-

Figure 17. Corner Bumper Detail

NOTE

RAISED AREA

6. Carefully disconnect the keypad interface ca

-

ble from J1 on the main PCB.

Site Master S251C MM 11

14. LCD ASSEMBLY REPLACEMENT

15. KEY PAD PCB REPLACEMENT

This procedure provides instructions for removing

and replacing the Liquid Crystal Display (LCD) once

the front panel assembly has been separated from

the Site Master.

1. Remove the front panel assembly as directed

in section 13.

2. Place the front panel assembly face down on

a protected work surface.

3. Remove the 14 Phillips screws that attach

the LCD retainer plate to the front panel as

sembly.

4. Release the LCD display cable from the cable

clamp on the LCD retainer plate.

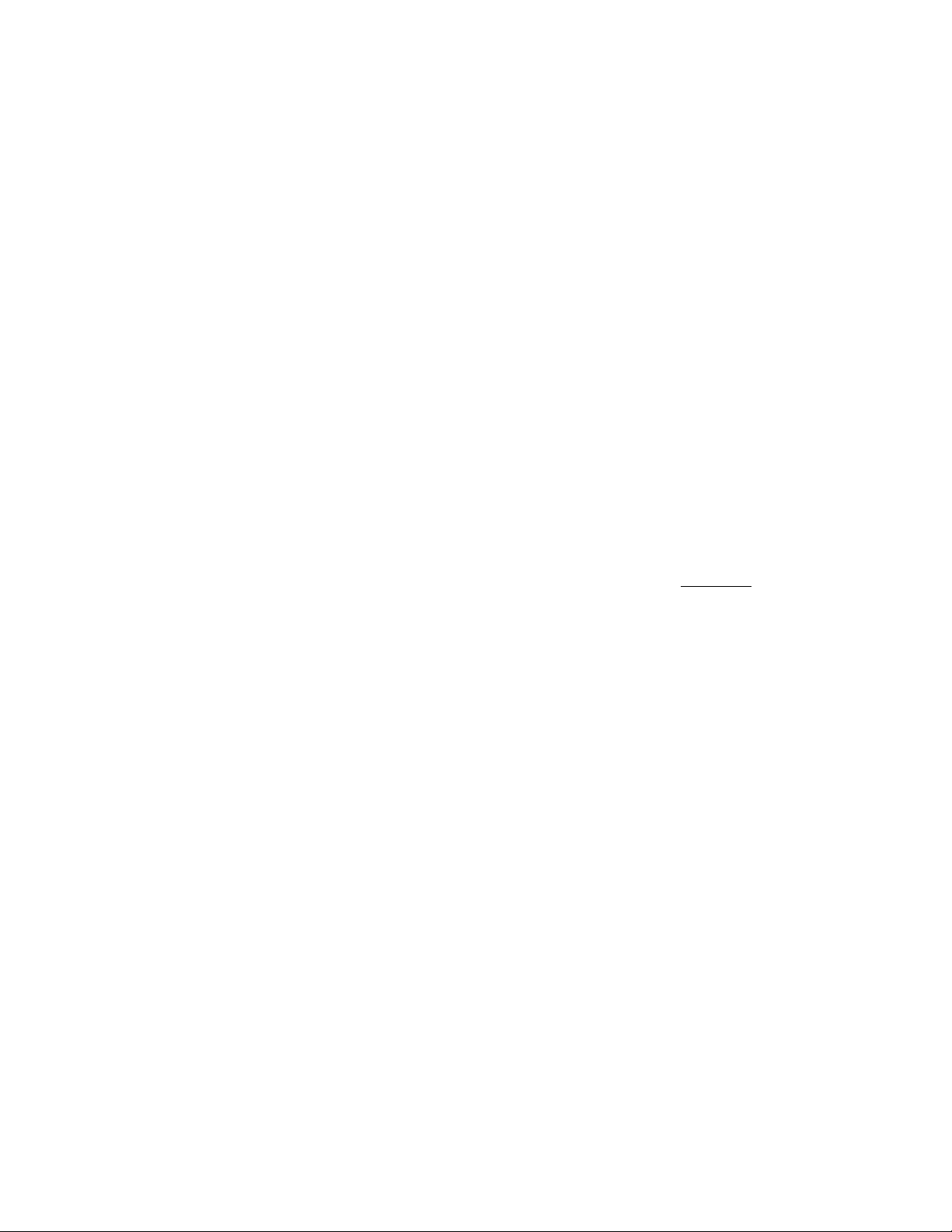

LCD RETAINER PLATE LCD CABLE CLAMP

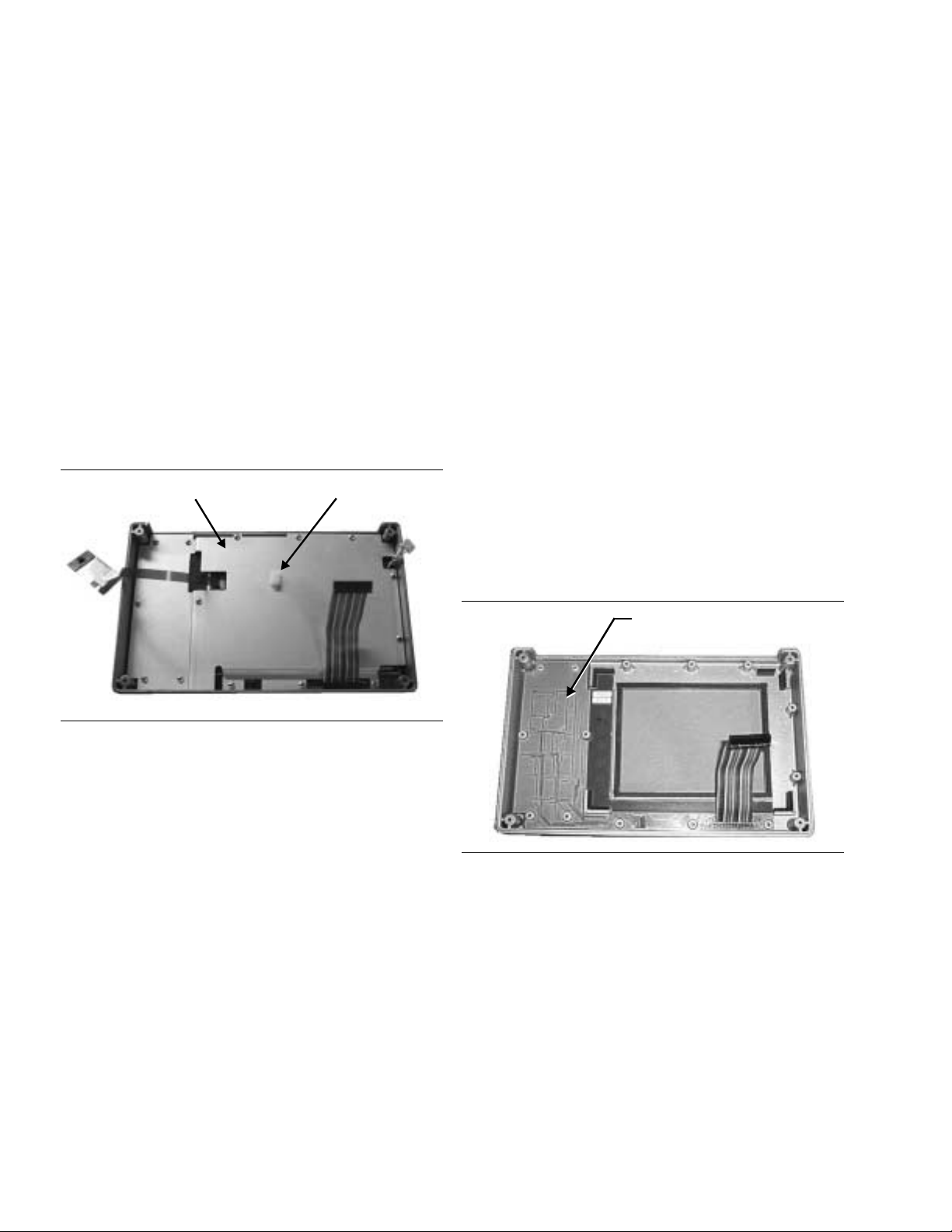

This procedure provides instructions for removing

and replacing the key pad PCB.

1. Remove the front panel assembly as directed

in section 13.

2. Place the front panel assembly face down on

a protected work surface.

3. Remove the 14 Phillips screws that attach

the backing plate to the front panel assem

bly.

-

4. Release the LCD display cable from the re

taining clip on the front panel backing plate

(Figure 19).

5. Remove the front panel backing plate, care

fully feeding the LCD cable through the ac

cess hole to avoid damage to the cable or con

nector.

6. Remove the rubber cushion pad from the key

pad PCB and remove the PCB.

-

-

-

-

-

Figure 18. Front Panel Backing Plate

5. Remove the LCD retainer plate, carefully

feeding the LCD cable through the access

hole to avoid damage to the cable or

connector.

6. Remove the rubber cushion pad from the

LCD assembly and remove the assembly.

7. Reverse the above steps to install the re

placement assembly.

KEYPAD PCB

Figure 19. Front Panel Keypad PCB Location

7. Reverse the above steps to install the re

-

placement assembly.

-

12 Site Master S251C MM

16. KEY PAD MEMBRANE REPLACEMENT

C

17. MAIN PCB ASSEMBLY REPLACEMENT

This procedure provides instructions for replacing

the key pad membrane.

1. Remove the front panel assembly as directed

in section 13.

2. Remove the key pad PCB as directed in sec

tion 15.

3. Remove the keypad membrane by gently

pulling the membrane up and out of the

holes in the front panel.

KEYPAD MEMBRANE

This procedure provides instructions for replacing

the main PCB assembly with the connector panel at

tached.

1. Remove the front panel assembly as directed

in section 13.

-

2. Disconnect the battery connector from J13

on the main PCB.

3. Remove the three PCB mounting screws and

remove the PCB assembly with the connector

panel attached.

BATTERY

ONNECTOR

-

Figure 20. Front Panel Keypad Membrane

4. Reverse the above steps to install the replacement membrane.

PCB MOUNTING

SCREWS (3)

Figure 21. Main PCB

OPTION 10A

4. If Option 10A is installed (Figure 21) remove

the option PCB by gently squeezing the

standoff mounts to release the option PCB

and disconnect it from the main board. Re

move the standoffs and install them on the

new main PCB, then install the Option 10A

PCB on the new main PCB.

5. Reverse the above steps to install the new

main PCB.

NOTE

The main PCB connector panel fits into

grooves in the two halves of the Site

Master case. Make sure the panel is cor

rectly aligned with the grooves before

reassembling the two halves together.

-

-

Site Master S251C MM 13

18. REPLACEABLE PARTS

Replaceable parts for the Site Master Model S251C

are listed below.

Table 1. Replaceable Parts List

Part Number Description Qty

Accessories

10580-00065

10580-00066

2300-347 Software Tools, Site Master 1

40-115 Power Supply 1

2000-1029 Battery Charger

22N50 Precision Short/Open, N Male 1

SM/PL Connector, RF Termination 1

806-62 Cable Assy, Cig Plug, Female 1

800-441 Serial Interface Cable Assembly 1

48258 Soft Carrying Case 1

510-87 N-Connector 2

ND57371 Opt. 05 Input Connector w/cable 1

15-102 Liquid Crystal Display Assy 1

633-27 Rechargeable Battery, NiMH 1

ND57372 Main PCB Assembly,S251C 1

ND57373

ND57374

ND57375

ND60688

ND60690

52737-3 Keypad PCB Assembly 1

46649-1 Membrane Keypad, Main 1

User's Guide, Site Master

S251C

Programming Manual, Site Mas

ter S251C

(available on disk only)

Replaceable Parts

Main PCB Assembly,S251C with

Option 05

Main PCB Assembly,S251C with

Option 10A

Main PCB Assembly,S251C with

Option 05 and Option 10A

Main PCB Assembly,S251C with

Option 10B

Main PCB Assembly,S251C with

Option 05 and Option 10B

-

Part Number Description Qty

Hardware

1

1

1

1

900-160 Pan Head Screw, 4-40, 0.875 4

900-861 Pan Head Screw, 4-20, 0.365 15

900-869 Screw, 4-40, 0.875 4

900-720 Screw, 4-40, 0.187 3

900-754 Pan Head Screw, 4-40, 0.750 4

900-697 Screw, 4-40, 0.312 3

785-929 M-F Stand off, 4-40, 11/16 3

900-326 Kep Nut, 4-40, 0.187 8

790-516 Hole Plug, 0.6875L 1

790-42 Hole Plug, 0.625 1

761-79 Cap Vinyl, Black, round 1

Case Parts

46652-1 Top Case only 1

46653-1 Bottom Case only 1

48231-1 Battery Door 1

790-509

790-510

790-511

46655 Case Corner Bumpers 4

46662 LCD Retainer Plate 1

48241 Foam, LCD Corners 8

48278 Foam, LCD Window 1

46659 Foam, LCD Backing 1

46661 Foam, Keypad Backing 1

48246 Foam, Battery Door 1

48271 Foam, Battery Compartment 1

720-19 Cable Clamp 1

790-515 Spring, Battery Compartment 1

55217 ID Label, Model S251C 1

Battery Door Latch (3 pieces)

1

14 Site Master S251C MM

Table 2. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

490 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300

FAX: 408-776-1744

ANRITSU COMPANY

10 NewMaple Ave., Suite 305

Pine Brook, NJ 07058

Telephone: 973-227-8999

FAX: 973-575-0092

ANRITSU COMPANY

1155E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

FAX: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICA LTDA.

Praia de Botafogo 440. Sala 2401

CEP22250-040,Rio de Janeiro,RJ, Brasil

Telephone: 021-527-6922

FAX: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

700 Silver Seven Road, Suite 120

Kanata, Ontario K2V 1C3

Telephone: (613) 591-2003

FAX: (613) 591-1006

CHINA (SHANGHAI)

ANRITSU ELECTRONICS CO LTD

2F,Rm.B, 52 Section Factory Bldg.

NO 516 Fu Te Road (N)

Waigaoqiao Free Trade Zone

Pudong, Shanghai 200131

PR CHINA

Telephone: 86-21-58680226

FAX: 86-21-58680588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-09-21-550

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf

Germany

Telephone: 0211-968550

FAX: 0211-9685555

INDIA

MEERA AGENCIES (P) LTD

23 Community Centre

Zamroodpur, Kailash Colony Extension

New Delhi, India 110 048

Telephone: 011-644-2700

FAX: 011-644-2500

ISRAEL

TECH-CENT, LTD

4 Raul ValenbergSt.

Tel-Aviv, Israel 69719

Telephone: 972-36-478563

FAX: 972-36-478334

ITALY

ANRITSU Sp.A

Rome Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-2299-711

FAX: 06-50-22-4252

JAPAN

ANRITSU CUSTOMER SERVICES LTD.

1800 Onna Atsugi—shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-96-6688

FAX: 0462-25-8379

KOREA

ANRITSU SERVICE CENTER

8F Hyunjuk-Bldg, 832-41

Yeoksam-Dong

Kangnam-Gu

Seoul, 135-080, Korea

Telephone: 82-2-553-6603

FAX: 82-2-553-6605

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD

10, Hoe Chiang Road

#07-01/02

Keppel Towers

Singapore 089315

Telephone:65-282-2400

FAX:65-282-2533

SOUTH AFRICA

ETESCSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone: 011-27-11-787-7200

Fax: 011-27-11-787-0446

SWEDEN

ANRITSU AB

Botvid Center

Fittja Backe 13A

145 84

Stockholm, Sweden

Telephone: (08) 534-707-00

FAX: (08)534-707-30

TAIWAN

ANRITSU COMPANY

7F, NO.316, Sec.1,

Nei Hu Road

Taipei, Taiwan, R.O.C.

Telephone: 886-2-8751-2126

FAX: 886-2-8751-1817

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-43-3200

FAX: 015-82-73-1303

Loading...

Loading...