Maintenance Manual

Site Master™

Model S810D and S820D

Broadband Microwave Transmission Line and

Antenna Analyzer

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

P/N: 10680-00003

Copyright 2006 - 2014 Anritsu Company

Printed: January 2014

Revision: H

CE Conformity Marking

Anritsu affixes the CE Conformity marking onto its conforming products in accordance with Council Directives

of The Council Of The European Communities in order to indicate that these products conform to the EMC and

LVD directive of the European Union (EU).

C-tick Conformity Marking

Anritsu affixes the C-tick marking onto its conforming products in accordance with the electromagnetic

compliance regulations of Australia and New Zealand in order to indicate that these products conform to the

EMC regulations of Australia and New Zealand.

Notes On Export Management

This product and its manuals may require an Export License or approval by the government of the product

country of origin for re-export from your country.

Before you export this product or any of its manuals, please contact Anritsu Company to confirm whether or

not these items are export-controlled.

When disposing of export-controlled items, the products and manuals need to be broken or shredded to such a

degree that they cannot be unlawfully used for military purposes.

Mercury Notification

This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated due to

environmental considerations. Please contact your local authorities or, within the United States, the

Electronics Industries Alliance (www.eiae.org) for disposal or recycling information.

EPC WEEE Directive 2002/96/EC

Chinese RoHS Statement

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Company uses the

following symbols to indicate safety-related information. For your own safety, please read the information

carefully before operating the equipment.

Symbols Used in Manuals

Danger

This indicates a risk from a very dangerous condition or procedure that could result in

serious injury or death and possible loss related to equipment malfunction. Follow all

precautions and procedures to minimize this risk.

Warning

Caution

This indicates a risk from a hazardous condition or procedure that could result in

light-to-severe injury or loss related to equipment malfunction. Follow all precautions

and procedures to minimize this risk.

This indicates a risk from a hazardous procedure that could result in loss related to

equipment malfunction. Follow all precautions and procedures to minimize this risk.

Safety Symbols Used on Equipment and in Manuals

The following safety symbols are used inside or on the equipment near operation locations to provide

information about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions before operating the equipment. Some or all of the following

five symbols may or may not be used on all Anritsu equipment. In addition, there may be other labels attached

to products that are not shown in the diagrams in this manual.

This indicates a prohibited operation. The prohibited operation is indicated symbolically

in or near the barred circle.

This indicates a compulsory safety precaution. The required operation is indicated

symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or near

the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

S810D/S820D MM 10680-00003 Rev. H Safety-1

For Safety

Warning

Warning

Warning

Always refer to the operation manual when working near locations at which

the alert mark, shown on the left, is attached. If the operation, etc., is

performed without heeding the advice in the operation manual, there is a

risk of personal injury. In addition, the equipment performance may be

reduced.

Moreover, this alert mark is sometimes used with other marks and

descriptions indicating other dangers.

When supplying power to this equipment, connect the accessory 3-pin

power cord to a 3-pin grounded power outlet. If a grounded 3-pin outlet is

not available, use a conversion adapter and ground the green wire, or

connect the frame ground on the rear panel of the equipment to ground. If

power is supplied without grounding the equipment, there is a risk of

receiving a severe or fatal electric shock.

This equipment can not be repaired by the operator. Do not attempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire and

shock hazards should service this equipment. There are high-voltage parts

in this equipment presenting a risk of severe injury or fatal electric shock to

untrained personnel. In addition, there is a risk of damage to precision

components.

Electrostatic Discharge (ESD) can damage the highly sensitive circuits in

the instrument. ESD is most likely to occur as test devices are being

Caution

Warning

Safety-2 S810D/S820D MM 10680-00003 Rev. H

connected to, or disconnected from, the instrument’s front and rear panel

ports and connectors. You can protect the instrument and test devices by

wearing a static-discharge wristband. Alternatively, you can ground

yourself to discharge any static charge by touching the outer chassis of the

grounded instrument before touching the instrument’s front and rear panel

ports and connectors. Avoid touching the test port center conductors

unless you are properly grounded and have eliminated the possibility of

static discharge.

Repair of damage that is found to be caused by electrostatic discharge is

not covered under warranty.

This equipment is supplied with a rechargeable battery that could

potentially leak hazardous compounds into the environment. These

hazardous compounds present a risk of injury or loss due to exposure.

Anritsu Company recommends removing the battery for long-term storage

of the instrument and storing the battery in a leak-proof, plastic container.

Follow the environmental storage requirements specified in the product

data sheet.

Table of Contents

Chapter 1 — General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4 Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-5 Top Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

S810D/S820D with RF Detector Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-6 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-7 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2 — Performance Verification

2-1 Introduction to Performance Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Frequency Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Frequency Accuracy Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-3 Return Loss Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-4 Power Monitor (Option 5) Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5 Two-Port Cable Loss Measurement Verification (Option 22) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

CW Power Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

CW Frequency Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Two-Port Cable Loss Measurement Accuracy Procedure. . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Chapter 3 — Removal and Replacement

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Accessories, Parts, and Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Case Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3 Battery Pack Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-4 Battery General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-5 Battery Testing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-6 Front Panel Assembly Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-7 LCD Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

S810D/S820D MM 10680-00003 Rev. H Contents-1

Table of Contents (Continued)

3-8 Keypad PCB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-9 Keypad Membrane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-10 Power Monitor PCB Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-11 Real Time Clock Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3-12 Main/RF PCB Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3-13 Source Control PCB Assembly Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Appendix A — Test Data Master for CW Source Modules

Index

Contents-2 S810D/S820D MM 10680-00003 Rev. H

Chapter 1 — General Information

1-1 Introduction

This manual provides maintenance instructions for the Site Master Model S810D/S820D Broadband

Microwave Transmission Line and Antenna Analyzer. It describes the product and provides performance

verification procedures, parts replacement procedures, and a replaceable parts list.

1-2 Description

The Site Master S810D, covering 25 MHz to 10.5, and the S820D, covering 25 MHz to 20.0 GHz, are the most

accurate, reliable and convenient one port microwave transmission line and antenna analyzers available for

installation, verification, troubleshooting, and repair of microwave communication systems.

Measurement capabilities includes return loss, SWR, cable loss, and distance-to-fault (DTF) analysis. Patented

RF interference rejection enables accurate measurements in the presence of high RF activity. Data Analysis

software enables assessment of system trends, problems, and performance in addition to professional report

generation. An optional power monitor is available to make power measurements quickly and easily. A built-in

GPS receiver (optional) provides location information for each trace and saved with archived data.

The Site Master Models S810D and S820D use vector error correction, solving the most common and the most

difficult accuracy problems of field test equipment operation, while improving system quality and reducing

maintenance expenses. Difficult test specifications are easy to verify with the Site Master Models S810D and

S820D. Vector error correction and a simple, friendly user interface within the unit further improve the quality

and convenience of measurements compared to traditional scalar techniques. Vector error correction also

improves the quality of Distance-To-Fault data. Not only is the reflection magnitude more accurate, the

waveguide dispersion correction for fault distance (different frequencies travel at different speeds) is also more

accurate and repeatable.

1-3 Related Documents

Other documents are available for the S810D and S820D at the Anritsu web site at www.anristu.com.

• Site Master S810D and S820D User Guide (10680-00001)

• Site Master S8x0D Programming Manual (10680-00002)

S810D/S820D MM 10680-00003 Rev. H 1-1

Front Panel Keys General Information

1-4 Front Panel Keys

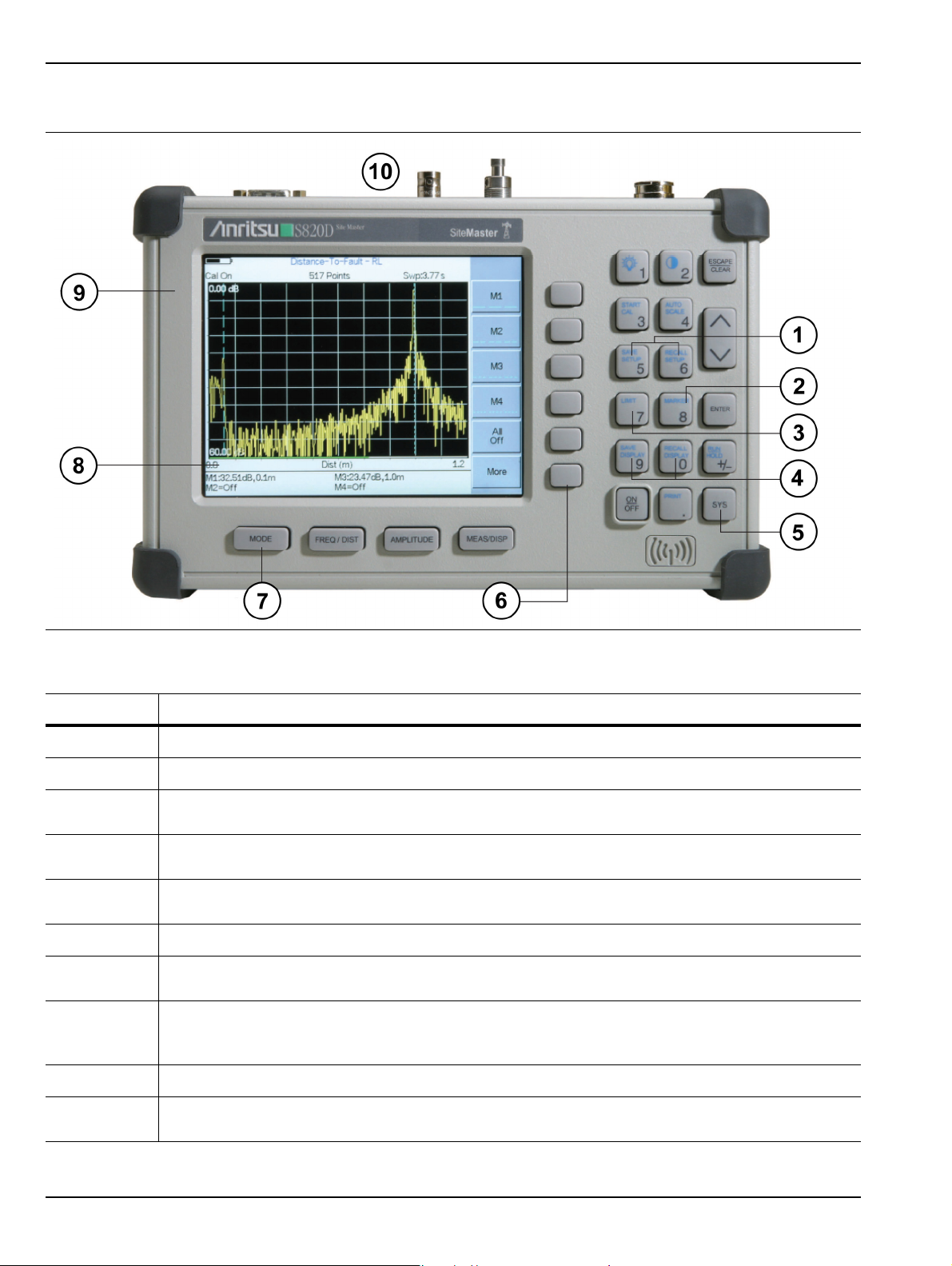

Figure 1-1. S810D/S820D Site Master Front Panel Hard and Soft Keys

Tab le 1-1. Callout Index for Figure 1-1, “S810D/S820D Site Master Front Panel Hard and Soft Keys”

Index Description

1

2

3

4

5

6

7

8

9

Save and Recall Setup buttons. 21 setups available.

Markers button. Six markers available.

Limits button. Create pass/fail measurements with single limit line, upper mask limit, and/or lower

mask limit.

Save and Recall Display buttons. Up to 200 memory locations with alphanumeric data labeling

and automatic time/date stamps.

Sys button. Allows language selection for user interface on-screen menus and messages in

Chinese, English, French, German, Japanese, and Spanish.

Soft Keys (six) on right with corresponding soft menu labels on left.

Function Hard Keys (four). From left to right, the keys are Mode, Freq/Dist, Amplitude, and

Meas/Disp.

TFT Color Display. Standard TFT color display (640 x 480) with variable brightness control and

viewable in direct sunlight. Displays signal traces and graphs, as well as Soft Key Menu on right

side.

System case. Overall size is 24.4 cm x 17.8 cm x 6.1 cm (9.52” x 7.0” x 2.4”)

10

1-2 S810D/S820D MM 10680-00003 Rev. H

System top connectors. From left to right, RS-232 Serial Interface (DB-9 m), External DC Power

Port (Coaxial Connector), GPS Antenna (BNC), RF Out/Reflection 50Ω.

General Information Top Connectors

1-5 Top Connectors

S810D/S820D with RF Detector Option

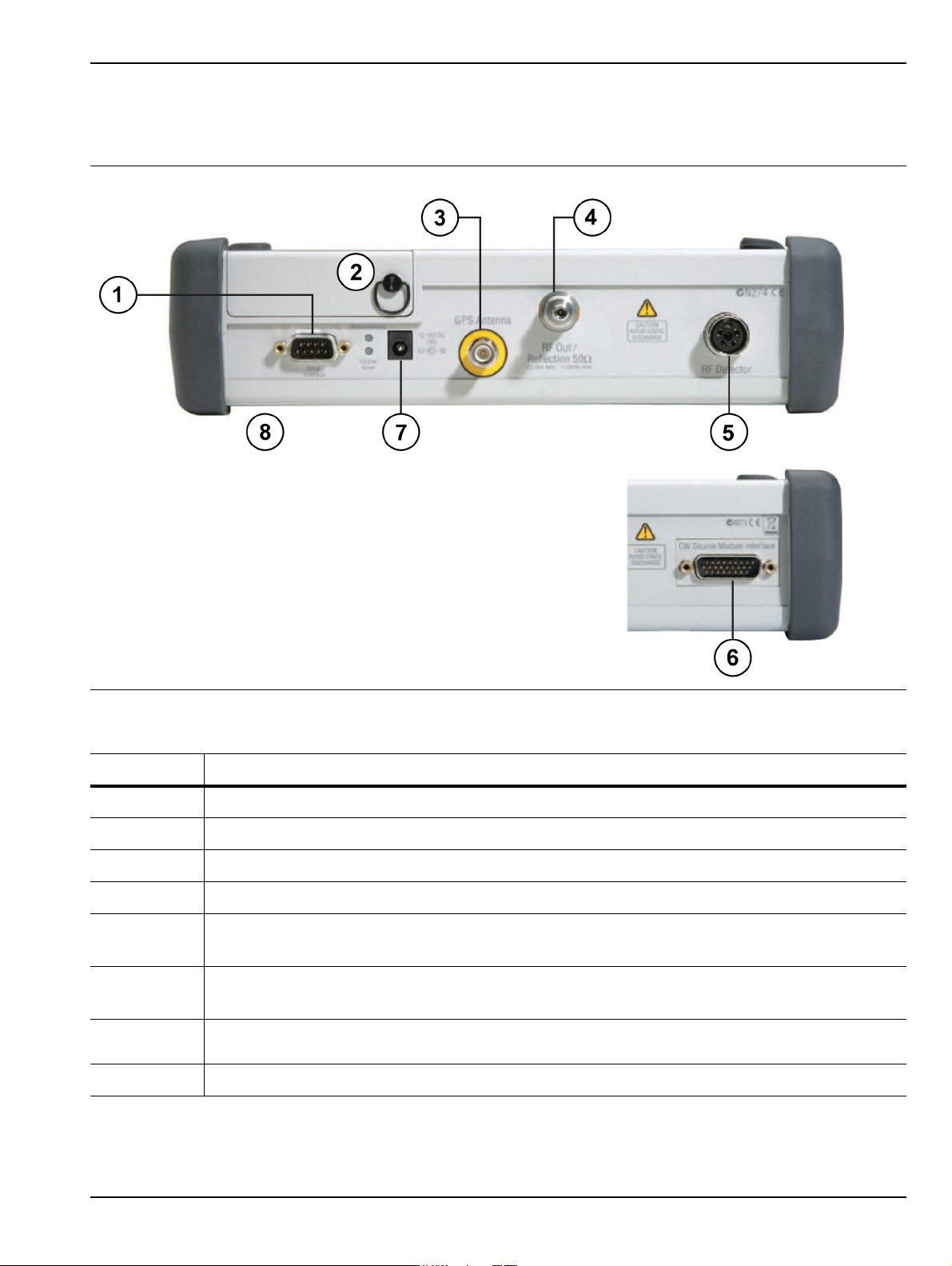

Figure 1-2. S810D/S820D Top Connectors with RF Detector Option on Right

Table 1-2. Callout Index for Figure 1-2, “S810D/S820D Top Connectors with RF Detector Option on Right”

Index Description

1

2

3

4

5

6

7

8

RS-232C Serial Interface. DB-9(m).

Battery Compartment with opening ring.

GPS Antenna connector. Reverse BNC (m).

RF Out/Reflection 50Ω. –23 dBm Maximum. ±50 VDC Maximum.

RF Detector connector.

(Instrument will be equipped with this connector, or #6 below, or fitted with a hole plug.)

CW Source Module Interface connector. DB-26(m).

(Instrument will be equipped with this connector, or #5 above, or fitted with a hole plug.)

External DC Power connector for 12-15 VDC at 3A. Coaxial power connector (m). To the left are

the Batter Charging Green LED (top) and External Power Green LED (bottom).

TFT Color Display.

S810D/S820D MM 10680-00003 Rev. H 1-3

Options General Information

1-6 Options

• Option 2, 2 MHz Frequency Extension (S8X0D/2)

• Option 5, Power Monitor (S8X0D/5 sensor not included)

• Option 11NF, Replaces Standard K (f) Test Port Connector with N(f) (S8X0D/11NF)

• Option 22NF, N(f) 2-Port Cable Loss Measurements (S8X0D/22NF)

• Option 22SF, SMA (f) 2-Port Cable Loss Measurements (S8X0D/22SF)

• Option 31, GPS Receiver (S8X0D/31)

1-7 Recommended Test Equipment

The following test equipment is recommended for use in testing and maintaining the Site Master S810D and

S820D.

Tab le 1-3. Recommended Text Equipment

Instrument Critical Specification Recommended Manufacturer/Model

Frequency Counter Frequency: < 3 GHz Anritsu Model MF2412B/C with

Option 01. Without Option 01

requires a 10 MHz external

reference

Calibration/Verification Kit Special, designed by Anritsu Anritsu Model SC6815, includes

components with N and K type

connectors.

Calibration/Verification Kit Special, designed by Anritsu Anritsu Model SC7668, includes

components with N connectors. Use

with instruments with Option 11NF.

RF Reference Source Frequency: 50 MHz

Anritsu Model MA2418A

Power Output: 0 dBm

DC Power Supply For Anritsu Model MA2418A Anritsu Part Number 2000-933

RF Detector Frequency: 10 MHz to 20 GHz Anritsu Model 560-7N50B

Adapter Connector: N(m) to K (f) Anritsu Model 34NKF50

Attenuator Attenuation: 10 dB

Connector: N(m) to N(f)

Attenuator Attenuation: 30 dB

Connector: N(m) to N(f)

RF Coaxial Cable Frequency: 10 MHz to 20 GHz

Connector: K (m) to K (m)

RF Coaxial Cable Connector: BNC (m) to BNC (m) Any

Personal Computer Serial Port Any Windows XP PC

Serial Cable Null Modem Anritsu Part Number 800-441

Attenuator Attenuation: 10 dB

Connector: K (m) to K (f)

Attenuator Attenuation: 20 dB

Connector: K (m) to K (f)

Adapter Connector: N(f) to K (m) Anritsu Model 34NFK50

Aeroflex/Weinschel Model 1-10

Aeroflex/Weinschel Model 1-30

Any

Anritsu Model 43KC-10

Anritsu Model 43KC-20

1-4 S810D/S820D MM 10680-00003 Rev. H

Chapter 2 — Performance Verification

2-1 Introduction to Performance Verification

This chapter contains tests that can be used to verify the performance of the Site Master Models S810D and

S820D.

• Section “2-2 Frequency Accuracy” on page 2-1

• Section “2-3 Return Loss Verification” on page 2-2

• Section “2-4 Power Monitor (Option 5) Verification” on page 2-5

• Section “2-5 Two-Port Cable Loss Measurement Verification (Option 22)” on page 2-7

• “CW Power Verification Procedure” on page 2-8

• “CW Frequency Verification Procedure” on page 2-10

2-2 Frequency Accuracy

The following test can be used to verify the CW frequency accuracy of the Site Master. Measurement

calibration of the Site Master is not required for this test.

Equipment Required

• Anritsu Model MF2412B/C Frequency Counter or equivalent

• RF Cable with appropriate connectors to connect the instrument and the frequency counter

Frequency Accuracy Procedure

1. Connect the external power supply (Anritsu part number 40-187-R) to the Site Master.

2. Press and hold the ESCAPE/CLEAR

• This sets the instrument to the factory preset state.

Note Before continuing, allow a five minute warm up for the internal circuitry to stabilize.

3. Press the FREQ/DIST

4. Press the

5. Press the

6. Press the MEAS/DISP

7. Connect the RF cable from the Site Master Test Port to the RF Input on the Frequency Counter.

8. Verify that the frequency readout on the Frequency Counter is 2 GHz ±6 kHz.

9. Press the

F1 soft key, set to 2 GHz, then press the ENTER key.

F2 soft key, set to 2 GHz, then press the ENTER key.

Fixed CW soft key to turn Fixed CW off.

key.

key and then the Fixed CW soft key to turn Fixed CW on.

key, then press the ON/OFF key to turn on the Site Master.

S810D/S820D MM 10680-00003 Rev. H 2-1

Return Loss Verification Performance Verification

2-3 Return Loss Verification

The following test can be used to verify the accuracy of return loss measurements. Measurement calibration of

the Site Master is required for this test. The Verification Software (P/N 2300-488) included with the Anritsu

SC6815 Calibration/Verification Kit or the Anritsu SC7668 Calibration Kit must be installed into the PC prior

to performing this test.

Equipment Required

• Anritsu SC6815 Calibration/Verification Kit.

• Anritsu SC7668 Calibration/Verification Kit.

Note

• Personal Computer running Windows 95 or later, one available COM port, a CDROM drive and/or a

The SC6815 kit can be used with all S8x0D units.

The SC7668 kit can only be used with S8x0D units with Option 11NF.

USB port.

Return Loss Software Installation

1. Insert the Verification Software CD into the CDROM drive.

2. Click the Start button and select Run.

3. In the Run box, type x:\setup (where x is the drive letter of the CDROM drive) and select OK.

4. Follow the on screen setup instructions to install the Verification Software.

5. After the software has been installed, re-boot the PC.

Return Loss Verification Procedure

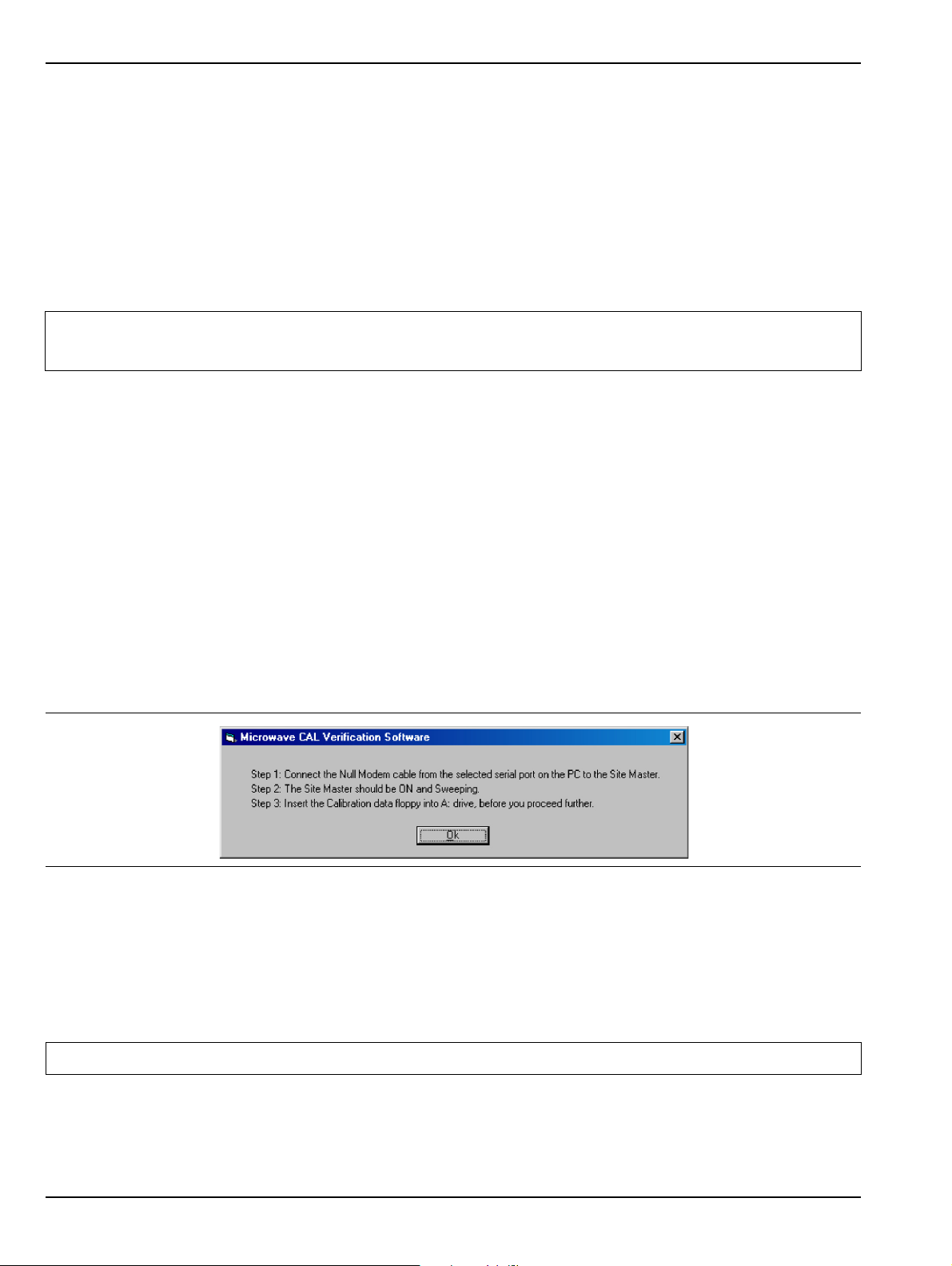

1. On the PC, start the Microwave CAL Verification Software from the Start menu and follow the steps

below as presented in the opening dialog box.

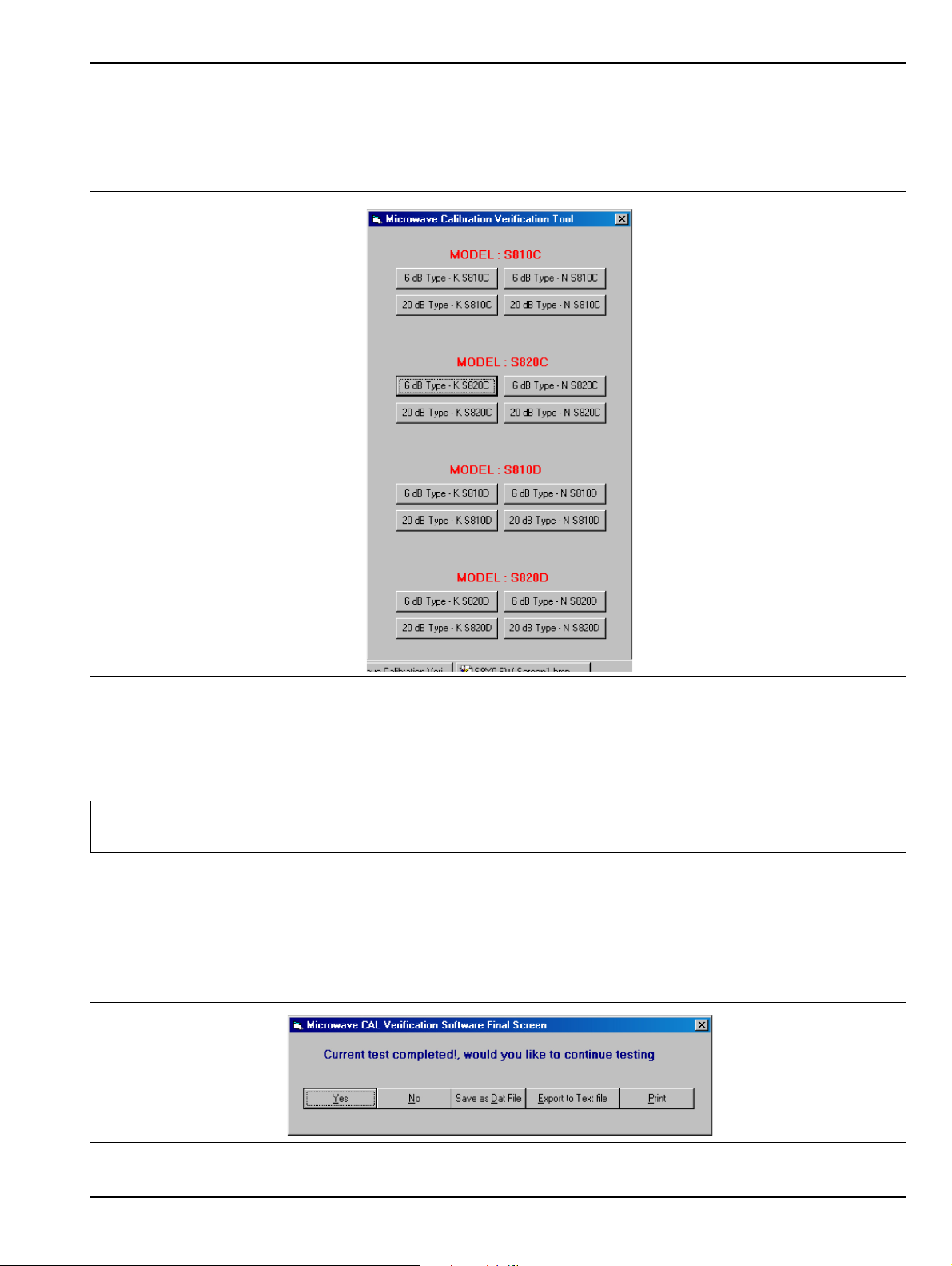

Figure 2-1. CAL Verification Software Opening Dialog Box

2. Install the Serial Interface cable (Anritsu P/N 800-441) to the PC COM port and the Serial Interface

connector on the Site Master Test Connector Panel.

3. Connect the external power supply (Anritsu P/N 40-187-R) to the Site Master.

4. Press and hold the ESCAPE/CLEAR

• This sets the instrument to the factory preset state.

Note Before continuing, allow a five minute warm up for the internal circuitry to stabilize.

5. Press the MEAS/DISP

6. Press the

2-2 S810D/S820D MM 10680-00003 Rev. H

Resolution soft key, and select 517.

key.

key, then press the ON/OFF key to turn on the Site Master.

Performance Verification Return Loss Verification

7. Insert the Calibration USB memory device or disc that came with the SC6815 kit or the SC7668 kit

into the PC disk drive.

8. On the PC, select OK to close the opening window. The test selection dialog box appears as shown

below.

Figure 2-2. Test Selection Dialog Box

9. Click on the appropriate db Type button for the Site Master being tested:

• If instrument is a Site Master S810D, click on the

• If instrument is a Site Master S820D, click on the

Note

If the instrument has Option 11NF installed, skip Step #10 through Step #22 on page 2-4 and go to

Step #23 on page 2-4,

6 dB Type - K S810D button.

6 dB Type - K S820D button.

10. Follow the on-screen instructions and connect the Open, Short, Load, and SC6729 6 dB Offset

Termination from the SC6815 Calibration Kit to the S8X0D test port when instructed.

11. After the final test, the test results will be displayed on the screen. Verify that the displayed trace is

within the limit lines.

12. The final selection screen provides options to save, print or continue testing.

Figure 2-3. CAL Verification Software Final Screen Dialog Box

S810D/S820D MM 10680-00003 Rev. H 2-3

Return Loss Verification Performance Verification

13. To save the data as a text file, select Export to Text File. The software will prompt for a name and

location to save the file. The data will be saved in a tabular format that can be read by most text

editor programs.

14. To save the data as a dat file, select Save as Dat File. The software will prompt for a name and

location to save the file. A dat file saves the data in a graphical format that can be recalled and

viewed using the Verification Software program.

15. To print the data, select Print. The software first prompts to save the data as a text file (see Step #13)

and then prints the data to the default printer connected to the PC.

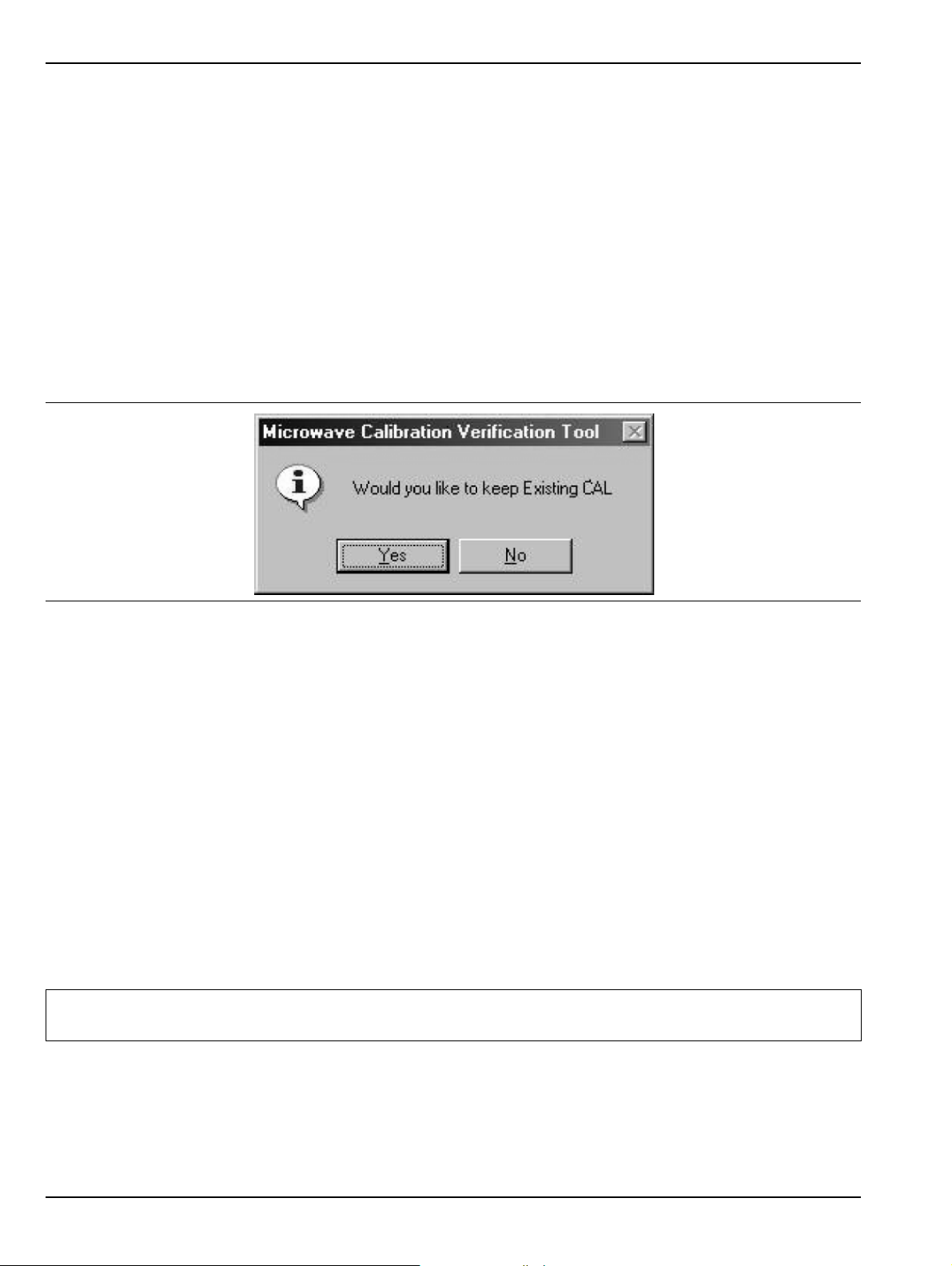

16. When the final selection screen reappears, click the Yes

button to continue.

17. When the test selection screen reappears:

• If the instrument is a Site Master S810D, click on the 20 dB Type - K S810D

• If the instrument is a Site Master S820D, click on the 20 dB Type - K S820D

18. Click the Yes

button to keep the existing calibration.

button.

button.

Figure 2-4. Keep Existing Calibration Screen

19. Follow the instructions on the screen to test the 20 dB offset termination. Verify that the measured

results are within the limit lines.

20. Save or print the test data if desired.

21. When the final selection screen reappears, click the Yes

button to continue.

22. Install the 34RKNF50 to the S8X0D K female test port.

23. On the test selection screen, click on the appropriate db Type button for the Site Master being tested:

• If instrument is a Site Master S810D, click on the

• If instrument is a Site Master S820D, click on the

6 dB Type - N S810D button.

6 dB Type - N S820D button.

24. Follow the instructions on screen to perform the calibration and measurement.

25. Save or print the test data if desired.

26. Repeat the measurement process for the 20 dB offset termination.

27. Verify that the measured result is within the limit lines.

28. Save or print the test data if desired.

Note

For the S820D, N-Type verification will be performed up to 18 GHz only due to the frequency limit of

the N-Type connector. Any data displayed above 18 GHz is for reference only.

2-4 S810D/S820D MM 10680-00003 Rev. H

Performance Verification Power Monitor (Option 5) Verification

2-4 Power Monitor (Option 5) Verification

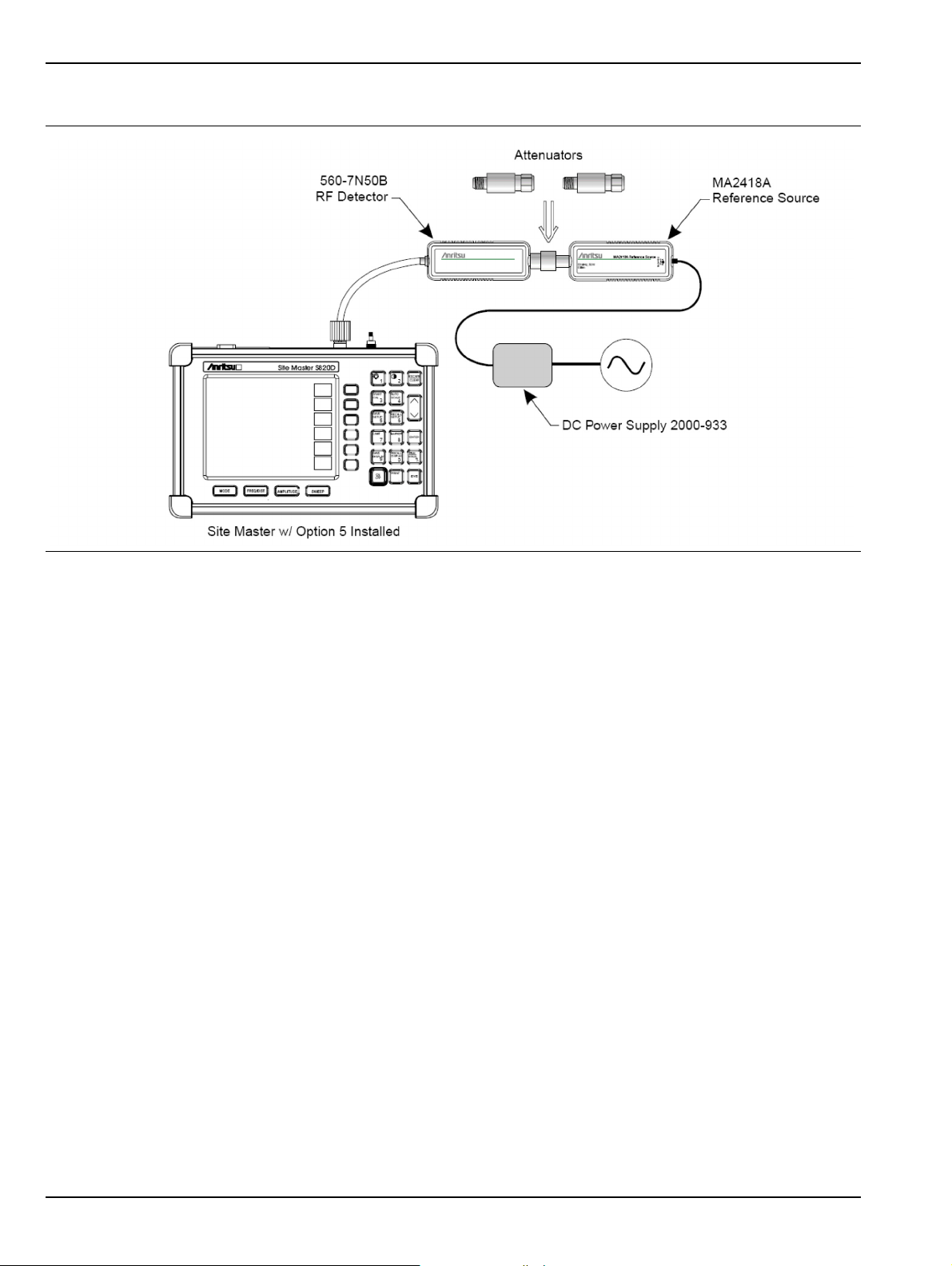

If the Power Monitor (Option 5) is installed in the Site Master, the following test can be used to verify the

accuracy of the power measurements. Measurement calibration of the Site Master is not required for this test.

Equipment Required

• RF Detector, 10 MHz to 20 GHz, Anritsu 560-7N50B

• 10 dB Attenuator, Aeroflex/Weinschel 1-10

• 30 dB Attenuator, Aeroflex/Weinschel 1-30

• 0 dBm 50 MHz RF Reference Source, Anritsu MA2418A

• The 50 MHz Calibrator Output on a power meter can be used as a substitute for the RF

Reference Source.

• DC Power Supply for the MA2418A, Anritsu 2000-933

Procedure

1. Connect the DC power supply to the MA2418A Reference Source.

• For Power Monitor Setup, see Figure 2-5, “Power Monitor Verification Setup” on page 2-6.

2. Connect the external power supply (Anritsu part number 40-187-R) to the Site Master.

3. Press and hold the ESCAPE/CLEAR

• This sets the instrument to the factory preset state.

key, then press the ON/OFF key to turn on the Site Master.

4. Press the MODE (9)

5. Use the Up/Down arrow key to highlight

6. Connect the RF Detector output to the

7. With no power applied to the detector, press the

complete,

8. Connect the MA2418A Reference Source to the input of the 560-7N50B RF detector. Verify that the

power monitor reading is 0.0 dBm ±1 dB.

9. Connect the output of the MA2418A Reference Source to the two attenuators so as to add 40 dB of

attenuation (see Figure 2-5, “Power Monitor Verification Setup” on page 2-6).

10. Connect the MA2418A Reference Source and the attenuators to the input of the 560-7N50B RF

detector.

Zero Adj:On is displayed in the message area.

key.

Power Monitor, then press ENTER.

RF Detector input of the Site Master.

Zero soft key to zero the power monitor. When

S810D/S820D MM 10680-00003 Rev. H 2-5

Power Monitor (Option 5) Verification Performance Verification

11. Verify that the power monitor reading is now –40.0 dBm ±2 dB.

Figure 2-5. Power Monitor Verification Setup

2-6 S810D/S820D MM 10680-00003 Rev. H

Performance Verification Two-Port Cable Loss Measurement Verification (Option 22)

2-5 Two-Port Cable Loss Measurement Verification (Option 22)

Overview

The two-port cable loss measurement verification consists of three procedures:

• CW Power Verification Procedure with the CW Frequency Verification

• Two-Port Cable-Loss Measurement Accuracy Verification Procedure

Equipment Required

• CW Source Module, Anritsu CWM220NF (shown below in Figure 2-6) or Anritsu CWM220SF.

• RF Detector, Anritsu 560-7N50B RF Detector (shown below in Figure 2-6) or Anritsu 560-7S50B.

• Anritsu MF2412B/C Frequency Counter

• BNC cable

• BNC to N adapter (or BNC to K adapter)

• Anritsu 43KC-10 10 dB Attenuator

• Anritsu 43KC-20 20 dB Attenuator

• Anritsu 34NKF50 N (m) to K (f) Adapter

• Anritsu 34NFK50 N (f) to K (m) Adapter

Figure 2-6. CW Source Module (CWM220NF) and RF Detector (560-7N50B)

S810D/S820D MM 10680-00003 Rev. H 2-7

Two-Port Cable Loss Measurement Verification (Option 22) Performance Verification

Note

Always turn off the S8X0D before connecting or disconnecting the CWM220xF CW Source Module

to the CW Source Module Interface port of the S8X0D.

CW Power Verification Procedure

1. Turn off the Site Master.

2. Connect the input port of the detector to the RF OUT X (f) of the CW Source Module.

3. Connect the cable of the detector to the DETECTOR INPUT of the CW Source Module.

4. Connect the TO S8X0D RF PORT X-TYPE of the CW Source Module to RF OUT of S8X0D.

5. Connect the cable of the CW Source Module to the CW Source Module Interface port of the S8X0D as

shown in Figure 2-7 below.

Figure 2-7. Two-Port Cable Loss General Connections

Tab le 2-1. Callout Index for Figure 2-7, “Two-Port Cable Loss General Connections”

Index Callout Description (1 of 2)

1

2

3

4

5

6

2-8 S810D/S820D MM 10680-00003 Rev. H

S810D/S820D SiteMaster

CW Source Module To S8X0D RF Port connected to the S8xD RF Out/Reflection 50Ω connector

Anritsu CW Source Module

CW Source Module RF OUT port connected the RF Detector Input Port

RF Detector

RF Detector Cable Input Plug connected to the CW Source Module Detector Input port

Performance Verification Two-Port Cable Loss Measurement Verification (Option 22)

Table 2-1. Callout Index for Figure 2-7, “Two-Port Cable Loss General Connections”

Index Callout Description (2 of 2)

7

6. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the S8x0D.

7. Press MODE hard key.

8. Use the Up/Down arrow key to highlight Cable Loss – Two Port, then press ENTER.

9. Press the F1 soft key and set F1 = 10 MHz.

10. Press the F2 soft key and:

11. Observe that the waveform displayed resembles the display shown in Figure 2-8 below.

CW Source Module CW Source Module Interface port connected to the S8x0D CW Source

Module Interface

• If the instrument is a Site Master S810D unit, set F2 = 10.5 GHz.

• If the instrument is a Site Master S820D unit:

with CWM220NF and CWM220B-NF, set F2 = 18 GHz

with CWM220SF and CWM220B-SF, set F2 = 20 GHz.

Figure 2-8. Cable Loss Two-Port Typical Waveform

12. Press the MARKER soft key and:

• Select M1, select Marker to Peak.

•Select M2, select Marker to Valley.

13. Verify that:

• M1 is less than +15 dBm.

• M2 is greater than –15 dBm.

S810D/S820D MM 10680-00003 Rev. H 2-9

Two-Port Cable Loss Measurement Verification (Option 22) Performance Verification

CW Frequency Verification Procedure

1. Turn off the Site Master

2. Connect the TO S8X0D RF PORT X-TYPE of the CW Source Module to RF OUT of S8X0D.

3. Connect the cable of the CW Source Module to the CW Source Module Interface port of the S8X0D.

4. Connect the RF-OUT X (f) to the Anritsu MF2412B/C with appropriate adapter and BNC cable as

shown in Figure 2-9 below.

Figure 2-9. Two-Port CW Frequency Verification Connections

Tab le 2-2. Callout Index for Figure 2-9, “Two-Port CW Frequency Verification Connections”

Index Callout Description

1

2

3

4

5

6

7

Note

5. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the S8X0D.

S810D/S820D SiteMaster

CW Source Module To S8X0D RF Port connected to the S8xD RF Out/Reflection 50Ω connector

Anritsu CW Source Module

CW Source Module CW Source Module Interface port connected to the S8x0D CW Source

Module Interface

BNC to N connector or BNC to K connector adapters as required.

BNC Cable as required

Anritsu MF2412B/C Frequency Counter with Opt 01

A 10 MHz external reference is required if the Anritsu MF2412B/C does not have Option 01

installed.

2-10 S810D/S820D MM 10680-00003 Rev. H

Performance Verification Two-Port Cable Loss Measurement Verification (Option 22)

6. Press MODE hard key.

7. Use the Up/Down arrow key to highlight Cable Loss – Two Port, then press ENTER.

8. Press the F1 soft key and set F1 to 2.75 GHz.

9. Press the F2 soft key and set F2 to 2.75 GHz.

10. Power on the Anritsu MF2412B/C Frequency Counter.

11. Verify that the frequency displayed on the frequency counter is 2,750,000 kHz ±8.25 kHz.

S810D/S820D MM 10680-00003 Rev. H 2-11

Two-Port Cable Loss Measurement Verification (Option 22) Performance Verification

Two-Port Cable Loss Measurement Accuracy Procedure

1. Turn off the Site Master

2. Connect the input port of the detector to the RF OUT X (f) of the CW Source Module.

• When using the Anritsu CWM220NF CW Source Module and the Anritsu 560-7N50B

RF Detector, insert Anritsu 34NKF50 and 34NFK50 adapters between the CWM220NF and the

560-7N50B, as shown below in Figure 2-11 below

• When using the Anritsu CWM220SF CW Source Module and the Anritsu 560-7S50B

RF Detector, adapters are not required.

Figure 2-10. Two-Port Cable Loss Measurement Accuracy Connections

Tab le 2-3. Callout Index for Figure 2-10, “Two-Port Cable Loss Measurement Accuracy Connections”

Index Callout Description (1 of 2)

1

2

3

2-12 S810D/S820D MM 10680-00003 Rev. H

S810D/S820D SiteMaster

CW Source Module To S8X0D RF Port connected to the S8xD RF Out/Reflection 50Ω connector

Anritsu CW Source Module

If using the Anritsu CWM220NF CW Source Module and the Anritsu 560-7N50B RF Detector,

insert an Anritsu 34NKF50* adapter (see index #6) and an Anritsu 34NFK50 adapter (see index #7

below) between the CW Source Module and the RF Detector.

* The 34NKF50 adapter is not required if the instrument is equipped with Option 11NF (Nconnector)

Performance Verification Two-Port Cable Loss Measurement Verification (Option 22)

Table 2-3. Callout Index for Figure 2-10, “Two-Port Cable Loss Measurement Accuracy Connections”

Index Callout Description (2 of 2)

4

5

6

7

8

3. Connect the cable of the detector to the DETECTOR INPUT of the CW Source Module.

4. Connect the TO S8X0D RF PORT X-TYPE of the CW Source Module to RF OUT of S8x0D.

5. Connect the cable of the CW Source Module to the CW Source Module Interface port of the S8x0D.

6. Press and hold the ESCAPE/CLEAR key, then press the ON/OFF key to turn on the S8x0D.

7. Let the S8x0D warm up for 15 minutes.

8. Press MODE hard key.

9. Use the Up/Down arrow key to highlight Cable Loss – Two Port, then press ENTER.

10. Press START CAL, then press ENTER.

CW Source Module CW Source Module Interface port connected to the S8x0D CW Source

Module Interface

CW Source Module RF Out port.

Adapter, Anritsu 34NKF50 adapter, N(m) to K (f). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

Adapter, Anritsu 34NFK50 adapter, N(f) to K (m). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

RF Detector, Anritsu 560-7N50B or Anritsu 560-7S50B.

S810D/S820D MM 10680-00003 Rev. H 2-13

Two-Port Cable Loss Measurement Verification (Option 22) Performance Verification

11. Wait until the Cal On display appears in the top left corner of the screen.

Figure 2-11. Two-Port Cable Loss Measurement Verification with 10 db Attenuator

Tab le 2-4. Callout Index for Figure 2-11, “Two-Port Cable Loss Measurement Verification with 10 db Attenuator”

Index Callout Description (1 of 2)

1

2

3

4

5

6

7

S810D/S820D SiteMaster

CW Source Module To S8X0D RF Port connected to the S8xD RF Out/Reflection 50Ω connector

Anritsu CW Source Module

If using the Anritsu CWM220NF CW Source Module and the Anritsu 560-7N50B RF Detector,

insert an Anritsu 34NKF50* adapter (see index #6) and an Anritsu 34NFK50 adapter (see index #7

below) between the CW Source Module and the RF Detector.

* The 34NKF50 adapter is not required if the instrument is equipped with Option 11NF (Nconnector)

CW Source Module CW Source Module Interface port connected to the S8x0D CW Source

Module Interface.

CW Source Module RF Out port.

Adapter, Anritsu 34NKF50 adapter, N(m) to K (f). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

Adapter, Anritsu 34NFK50 adapter, N(f) to K (m). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

2-14 S810D/S820D MM 10680-00003 Rev. H

Performance Verification Two-Port Cable Loss Measurement Verification (Option 22)

Table 2-4. Callout Index for Figure 2-11, “Two-Port Cable Loss Measurement Verification with 10 db Attenuator”

Index Callout Description (2 of 2)

8

9

12. Connect the Anritsu 43KC-10 10 dB Attenuator between the detector and the CW Source Module (or

Note

13. Press MARKER, then select M1, and then select Marker To Peak.

14. Press MARKER, then select M2, and then select Marker To Valley.

15. Verify that both M1 and M2 are –10 dB ±0.85 dB.

16. If they are marginally out of specification, repeat from Step #9 on page 2-13.

RF Detector, Anritsu 560-7N509B or Anritsu 560-7S50B.

Attenuator, Anritsu 43KC-10, 10dB Attenuator.

between the 34NKF50 and 34NFK50, as shown in Figure 2-12 above).

The frequency range is from 10 MHz to 18 GHz for CWM220NF and CWM220B-NF.

The frequency range is from 10 MHz to 20 GHz for CWM220SF and CWM220B-SF.

Figure 2-12. Two-Port Cable Loss Measurement Verification with 10 dB and 20 dB Attenuators

S810D/S820D MM 10680-00003 Rev. H 2-15

Two-Port Cable Loss Measurement Verification (Option 22) Performance Verification

Tab le 2-5. Callout Index for Figure 2-12, “Two-Port Cable Loss Measurement Verification with 10 dB and 20 dB

Attenuators”

Index Callout Description

1

2

3

4

5

6

7

8

9

10

S810D/S820D SiteMaster

CW Source Module To S8X0D RF Port connected to the S8xD RF Out/Reflection 50Ω connector

Anritsu CW Source Module

If using the Anritsu CWM220NF CW Source Module and the Anritsu 560-7N50B RF Detector,

insert an Anritsu 34NKF50* adapter (see #6 below) and an Anritsu 34NFK50 adapter (see #7

below) between the CW Source Module and the RF Detector.

* The 34NKF50 adapter is not required if the instrument is equipped with Option 11NF (Nconnector)

CW Source Module CW Source Module Interface port connected to the S8x0D CW Source

Module Interface

CW Source Module RF Out port.

Adapter, Anritsu 34NKF50 adapter, N(m) to K (f). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

Adapter, Anritsu 34NFK50 adapter, N(f) to K (m). Only required if using a CWM220NF CW Source

Module and a 560-7N50B RF Detector.

RF Detector, Anritsu 560-7N50B or Anritsu 560-7S50B.

Attenuator, Anritsu 43KC-10, 10dB Attenuator.

Attenuator, Anritsu 43KC-20, 20 dB Attenuator.

17. Add the 43KC-20 attenuator to the 43KC-10 attenuator to make 30 dB attenuation.

18. Press MARKER, select M1, select Marker To Peak.

19. Press MARKER, select M2, select Marker To Valley.

20. Verify that both M1 and M2 are –30 dB ±1.35 dB.

21. If M1 and M2 are marginally out of specification, repeat from Step #9 on page 2-13, but skip Step #12,

Step #13, and Step #14, and then continuing with the rest of this procedure.

2-16 S810D/S820D MM 10680-00003 Rev. H

Chapter 3 — Removal and Replacement

3-1 Introduction

The removal and replacement chapter provides the following sections, information, and procedures:

• Section 3-2, “Accessories, Parts, and Hardware” on page 3-2

• “Accessories” on page 3-2

• “Replaceable Parts” on page 3-3

• “Hardware” on page 3-3

• “Case Parts” on page 3-4

• Section 3-3, “Battery Pack Removal and Replacement” on page 3-5

• Section 3-4, “Battery General Information” on page 3-7

• Section 3-5, “Battery Testing Procedure” on page 3-8

• Section 3-6, “Front Panel Assembly Removal and Replacement” on page 3-9

• Section 3-7, “LCD Assembly Replacement” on page 3-11

• Section 3-8, “Keypad PCB Replacement” on page 3-12

• Section 3-9, “Keypad Membrane Replacement” on page 3-13

• Section 3-10, “Power Monitor PCB Replacement” on page 3-14

• Section 3-11, “Real Time Clock Battery Replacement” on page 3-15

• Section 3-12, “Main/RF PCB Assembly Replacement” on page 3-16

• Section 3-13, “Source Control PCB Assembly Replacement” on page 3-18

S810D/S820D MM 10680-00003 Rev. H 3-1

Accessories, Parts, and Hardware Removal and Replacement

3-2 Accessories, Parts, and Hardware

Accessories

Tab le 3-1. S810D/S820D Site Master Accessories

Part Number Description Qty

10680-00001 User’s Guide, Site Master S810D and S820D

10680-00002 Programming Manual, Site Master S810D and S820D (disk only)

2300-347 Handheld Software Tools

40-187-R AC/DC Adapter

2000-1029 Battery Charger

806-141 Automotive Power Adapter

65717 Soft Carrying Case

800-441 Serial Interface Cable Assembly

551-1961-R USB to RS232 Adapter Cable

22N50 Open/Short, N(m)

28N50-2 Precision Termination, N(m)

22K50 Open/Short, K (m)

28K50 Precision Termination, K (m)

34NFK50 Adapter, N(m) to K (f)

SC6815 Calibration/Verification Kit

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3-2 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Accessories, Parts, and Hardware

Replaceable Parts

Table 3-2. S810D/S820D Site Master Replaceable Parts

Part Number Description Qty

15-123 Color Liquid Crystal Display Assembly

551-1694 Adapter, 2-Row 32-Pin Inter-Connect Adapter (m-m) for Option PCB

633-26 Lithium Coin Real-Time Clock Battery

633-27 Rechargeable Battery, NiMH

46649-4 Membrane Keypad, Main

3-71657-3 Keypad PCB Assembly

ND64376 Power Monitor PCB Assembly

ND66448 Main/RF PCB Exchange Assembly, S810D

ND66449 Main/RF PCB Exchange Assembly, S810D with Option 11NF

ND66450 Main/RF PCB Exchange Assembly, S820D

ND66451 Main/RF PCB Exchange Assembly, S820D with Option 11NF

ND67171 Exchange Module, CWM220NF

ND67172 Exchange Module, CWM220SF

ND68537 Source Control PCB Exchange Assembly, S8x0D, part of Option 22,

Two-Port Cable Loss Measurement, provides control for external CW

Source Module, CWM220xF

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Hardware

Table 3-3. S810D/S820D Site Master Hardware

Part Number Description Qty

900-861 Pan Head Screw, 4-20, 0.365

900-791 Screw, 2-56, 0.375

900-720 Screw, 4-40, 0.187

900-326 Kep Nut, 4-40, 0.187

790-18 M-F Standoff, 4-40, 0.375, Hex

785-405 Plain Standoff, 4-40, 0.187, Hex

785-927 M-F Standoff, 4-40, 0.625

761-79 Cap Vinyl, Black, Round

19

77

6

3

4

4

3

2

S810D/S820D MM 10680-00003 Rev. H 3-3

Accessories, Parts, and Hardware Removal and Replacement

Case Parts

Tab le 3-4. S810D/S820D Site Master Case Parts

Part Number Description Qty

61440-1 Top Case

46653-3 Bottom Case

48231-3 Battery Door

790-509, 790-510, and 48241 Battery Door Latch (3 pieces)

790-515 Spring, Battery Compartment

790-551 Door Lock Receptacle

46655 Case Corner Bumpers

62934 ID Label, Model S820D

62935 ID Label, Model S810D

1

1

1

1

1

1

4

1

1

3-4 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Battery Pack Removal and Replacement

3-3 Battery Pack Removal and Replacement

This procedure provides instructions for removing and replacing the Site Master battery pack.

Note

1. With the Site Master standing upright on a stable surface, locate the battery access door (see

2. Lift up the access door handle and rotate it 90 degrees counterclockwise.

Many of the procedures in this section are generic, and apply to many similar instruments. Photos

and illustrations used are representative and may show instruments other than the Site Master.

Figure 3-1).

Figure 3-1. Removing the Battery Access Door

3. Lift the door and remove the door.

4. Grasp the battery lanyard and pull the battery straight up and out of the unit, as illustrated in

Figure 3-1 above.

S810D/S820D MM 10680-00003 Rev. H 3-5

Battery Pack Removal and Replacement Removal and Replacement

5. Replacement is the opposite of removal. Note the orientation of the battery contacts, and be sure to

insert the new battery with the contacts facing the rear of the unit (Figure 3-2).

Figure 3-2. Battery Orientation

3-6 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Battery General Information

3-4 Battery General Information

The following information relates to the care and handling of the Site Master battery, and NiMH batteries in

general.

Anritsu Batteries and Chargers

• Use only Anritsu approved battery packs.

• Recharge the battery only in the Site Master or in an Anritsu-approved charger.

Battery General Care and Use

• Always use the battery for its intended purpose only.

• Never use a damaged or worn out charger or battery.

• Never short-circuit the battery terminals.

• Do not drop, mutilate or attempt to disassemble the battery.

Charging

• The Nickel Metal Hydride (NiMH) battery supplied with the Site Master is shipped in a

discharged state.

• Before using the Site Master, the internal battery must first be charged for three hours, either in

the Site Master or in the optional battery charger (Anritsu part number: 2000-1029).

• When the Site Master or battery charger is not in use, disconnect it from the power source.

• Do not charge batteries for longer than 24 hours; overcharging may shorten battery life.

• If left unused a fully charged battery will discharge itself over time.

Storage Temperatures

• Temperature extremes will affect the ability of the battery to charge. Allow the battery to cool

down or warm up as necessary before use or charging.

• Storing the battery in extreme hot or cold places will reduce the capacity and lifetime of the

battery.

Battery Conditioning

• With a new NiMH battery, full performance is achieved after three to five complete charge and

discharge cycles.

• Discharge an NiMH battery from time to time to improve battery performance and battery life.

Battery Replacement and Disposal

• The battery can be charged and discharged hundreds of times, but it will eventually wear out.

• The battery may need to be replaced when the operating time between charging becomes

noticeably shorter than normal.

• Do not dispose of batteries in a fire!

• Batteries must be recycled or disposed of properly.

• Do not place batteries in household garbage.

S810D/S820D MM 10680-00003 Rev. H 3-7

Battery Testing Procedure Removal and Replacement

3-5 Battery Testing Procedure

The following procedure describes how to test the battery.

1. With the Site Master off and the battery installed, connect the Universal AC Adapter to the

15VDC (1350 mA)

connector. The External Power LED and the Battery Charging LED will light.

If the Battery Charging LED does not light, the battery may be too low to immediately start full

charging. Leaving the unit connected to AC power for several hours may bring the battery up to a

Note

level where full charging can begin. Turn the unit off and back on to see if the Battery Charging LED

lights indicating a full charge cycle has begun. Charging is inhibited below 0ºC (0 degrees C) and

above 45ºC (45 degrees C). If the unit is too hot, the battery will not start charging until the unit

temperature has reached 43ºC (43 degrees C).

2. Disconnect the AC-DC Adapter when the Battery Charging LED turns off, indicating the battery is

fully charged.

3. Press and hold the ESCAPE/CLEAR

key, then press the ON/OFF key to turn on the Site Master. This

sets the instrument to the factory preset state. Press ENTER when prompted to continue.

4. Press the SYS key, followed by the

Status soft key. Verify that the indicated battery charge is greater

than or equal to 80%.

• If the value is 80% or above, press the ESCAPE/CLEAR

key and continue with this procedure.

• If the value is lower than 80%, a discharge/charge cycle may be needed to improve the battery

capacity.

- Completely discharge the battery, as described in Step #5 and Step #6 below.

- Then recharge the battery as described in Step #1 and Step #2 above.

• If the battery capacity does not increase after a discharge/charge cycle, replace the battery.

5. Press the START CAL

key (to keep the Site Master from going into HOLD mode) and make note of

the test start time.

12.5-

6. When the Site Master display fades and the Site Master switches itself off, make note of the test stop

time.

7. The total test time from Step #5 to Step #6 should be greater than or equal to 1.5 hours.

8. If the battery charge started at 80% or more and the total battery test time is less than 70 minutes,

replace the battery.

3-8 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Front Panel Assembly Removal and Replacement

3-6 Front Panel Assembly Removal and Replacement

Overview

This procedure provides instructions for removing and replacing the Site Master front panel assembly. With

the front panel assembly removed, the LCD display, keypad PCB, keypad membrane, and main PCB

assemblies can be removed and replaced.

Note

Many of the procedures in this section are generic, and apply to many similar instruments. Photos

and illustrations used are representative and may show instruments other than the Site Master.

Replacement Procedure

1. Place the Site Master face up on a stable work surface.

2. Remove the four rubber corner bumpers by carefully lifting and sliding the bumpers off of the case

corners (Figure 3-3).

Figure 3-3. Remove the Corner Bumpers

3. With the bumpers removed, the access holes for the case screws are revealed.

4. Use a Phillips screwdriver to remove the four screws securing the two halves of the Site Master case

together.

5. Carefully lift up on the right side (as viewed from the front) of the front half of the case and begin to

separate the two halves.

Caution

6. Carefully disconnect the LCD display cable from J14 on the main PCB.

7. Carefully disconnect the keypad interface cable from J4 on the main PCB.

8. Carefully disconnect the LCD display backlight cable from J1 on the main PCB.

9. Remove the front panel assembly.

S810D/S820D MM 10680-00003 Rev. H 3-9

Do not force or pull the two halves of the case apart completely, as there are delicate cables

attached between the two halves that must be disconnected first.

Front Panel Assembly Removal and Replacement Removal and Replacement

10. Reverse the above steps to replace the front panel assembly.

Note The corner bumpers only mount one way. That is, the raised area inside one end of the bumper

(Figure 12) is made to conform to the contour of the front cover only.

Figure 3-4. Corner Bumper Detail with Raised Area

3-10 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement LCD Assembly Replacement

3-7 LCD Assembly Replacement

Overview

This procedure provides instructions for removing and replacing the Liquid Crystal Display (LCD) once the

front panel assembly has been separated from the Site Master.

Replacement Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Place the front panel assembly face down on a protected work surface.

3. Remove the 14 Phillips screws that attach the backing plate to the front panel assembly.

4. Remove the front panel backing plate, carefully feeding the cables through the access holes to avoid

damage to the cables or connectors.

Note

5. Remove the rubber cushion pad from the LCD assembly and remove the assembly.

6. Reverse the above steps to install the replacement assembly.

Remove the speaker wire from the retaining clip to allow the removal of the front backing plate. The

speaker is not used in the S810D/S820D.

Figure 3-5. Front Panel Backing Plate

S810D/S820D MM 10680-00003 Rev. H 3-11

Keypad PCB Replacement Removal and Replacement

3-8 Keypad PCB Replacement

Overview

This procedure provides instructions for removing and replacing the keypad PCB.

Replacement Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Place the front panel assembly face down on a protected work surface.

3. Remove the 14 Phillips screws that attach the backing plate to the front panel assembly.

4. Remove the front panel backing plate, carefully feeding the cables through the access holes to avoid

damage to the cables or connectors.

5. Remove the rubber cushion pad from the key pad PCB and remove the PCB.

Figure 3-6. Front Panel Keypad PCB Location

6. Reverse the steps above steps to install the replacement assembly.

3-12 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Keypad Membrane Replacement

3-9 Keypad Membrane Replacement

Overview

This procedure provides instructions for replacing the key pad membrane.

Replacement Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Remove the key pad PCB as directed in section Section 3-8, “Keypad PCB Replacement” on page 3-12

3. Remove the keypad membrane by gently pulling the membrane up and out of the holes in the front

panel.

4. Reverse the above steps to install the replacement membrane.

Figure 3-7. Front Panel Keypad Membrane

S810D/S820D MM 10680-00003 Rev. H 3-13

Power Monitor PCB Replacement Removal and Replacement

3-10 Power Monitor PCB Replacement

Overview

This procedure provides instructions for replacing the Power Monitor PCB (P/N ND64376).

Replacement Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Disconnect the RF Detector connector ribbon cable from P1 on the Power Monitor PCB.

Figure 3-8. RF Detector PCB Replacement

3. Remove the three Phillips screws that secure the Power Monitor PCB to the Main PCB.

4. Gently lift the Power Monitor PCB and separate connector J1 of the Power Monitor PCB from J6 of

the Main PCB.

5. Reverse the above steps to install the replacement Power Monitor PCB, taking care to properly align

the pins of connector J1 of the Power Monitor PCB with connector J6 of the Main PCB.

3-14 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Real Time Clock Battery Replacement

3-11 Real Time Clock Battery Replacement

Overview

This procedure provides instructions for replacing the Lithium Coin Real Time Clock Battery (P/N 633-26).

Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Locate the RTC battery as shown in Figure 3-9 below.

Figure 3-9. Real Time Clock Battery

3. Using a non-metallic probe, gently pry the battery from its holder, taking care not to damage the

holder or surrounding components.

The RTC battery may be secured in the holder with a small quantity of clear RTV sealant on top of

Note

4. Install the new RTC battery, making sure that the positive (+) side of the battery faces up.

5. Replace the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

the battery. Replace this sealant when replacing the battery to insure that the battery remains

properly secured. Do not allow the sealant to come between the battery and the holder contacts.

Replacement” on page 3-9.

S810D/S820D MM 10680-00003 Rev. H 3-15

Main/RF PCB Assembly Replacement Removal and Replacement

3-12 Main/RF PCB Assembly Replacement

Overview

This procedure provides instructions for replacing the Main/RF PCB assembly.

Note

Some photos and steps in this procedure may vary depending on the options installed in the unit.

Disregard any steps that do not apply to the specific unit being serviced.

Replacement Procedure

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

Replacement” on page 3-9.

2. Disconnect the battery connector from J7 on the Main PCB.

3. Disconnect the semi-rigid coaxial cable from the RF PCB, as indicated in Figure 3-10 below.

Figure 3-10. Main/RF PCB Assembly

4. Disconnect the RF Detector connector ribbon cable from P1 on the Power Monitor PCB.

5. Remove the PCB mounting screws and the GPS and Serial Interface connector mounting fasteners.

6. Remove the GPS connector from the connector panel.

7. Carefully lift the top of the Main PCB up and clear of the connector panel.

8. Fold the Main PCB back to allow access to the RF PCB below and remove the three 0.25” standoffs

that secure the RF PCB to the case (Figure 3-11).

9. Remove the Main/RF PCB assembly with the connector panel.

10. Reverse the steps above to install the new Main/RF PCB assembly.

Note

3-16 S810D/S820D MM 10680-00003 Rev. H

The connector panel fits into grooves in the two halves of the case. Make sure the panel is correctly

aligned with the grooves before reassembling the two halves together.

Removal and Replacement Main/RF PCB Assembly Replacement

Figure 3-11. Main/RF PCB Removal

Table 3-5. Callout Index for Figure 3-11, “Main/RF PCB Removal”

Index Callout Description

1

Remove the three (3) 0.25” standoffs that secure the RF PCB to the case.

S810D/S820D MM 10680-00003 Rev. H 3-17

Source Control PCB Assembly Replacement Removal and Replacement

3-13 Source Control PCB Assembly Replacement

Overview

This procedure provides instructions for replacing the Option 22 CW Source Control PCB assembly.

Note

Some photos and steps in this procedure may vary depending on the options installed in the unit.

Disregard any steps that do not apply to the specific unit being serviced.

Replacement Procedure

Caution

1. Remove the front panel assembly as directed in Section 3-6, “Front Panel Assembly Removal and

2. Place the instrument with the display and front panel buttons facing down.

If the Option 22 CW Source Control PCB assembly removal procedure is done incorrectly, it can

bend or break the pins on the 551-1694 2-row 32-pit (m-m) adapter that connects the Option 22 PCB

assembly to the Main PCB assembly. It is highly recommended to only perform this procedure when

spare 551-1694 adapters are available.

Replacement” on page 3-9.

3-18 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Source Control PCB Assembly Replacement

Figure 3-12. Main PCB Assembly and Option 22 CW Source Control PCB Assembly

Table 3-6. Callout Index for Figure 3-12, “Main PCB Assembly and Option 22 CW Source Control PCB Assembly”

Index Callout Description (1 of 2)

1 Option 22 CW Source Control PCB assembly.

2 RS-232C DB-9 (m) connector. Remove two (2) hex mounting standoffs.

3 GPS Antenna connector. Remove to two (2) 6-32 kep nuts.

4 RF Coaxial cable and connector. Undo the SMA connector.

5 Internal mounting bracket for Option 22. Remove the 6-32 kep nut.

6 Option 22 CW Source DB-26 (m) connector. Remove two (2) hex mounting standoffs.

7 Option 22 CW Source Control PCB assembly. Remove five (5) 6-32 Phillips mounting screws.

S810D/S820D MM 10680-00003 Rev. H 3-19

Source Control PCB Assembly Replacement Removal and Replacement

Tab le 3-6. Callout Index for Figure 3-12, “Main PCB Assembly and Option 22 CW Source Control PCB Assembly”

Index Callout Description (2 of 2)

8 Main PCB assembly. Remove five (5) 6-32 Phillips mounting screws.

9 Main PCB assembly. Disconnect the battery connector from J7.

Out of view and mounted on the other side of the Option 22 PCB assembly is the 2-Row 32-

10

11 Connector panel and top of instrument.

12 Bottom of instrument

3. Outside the case, remove two (2) hex standoffs from the RS-232C DB-9 (m) connector

4. Inside the case, remove two (2) 6-32 kep nuts from the GPS connector (Figure 3-12 #3).

5. Disconnect the semi-rigid coaxial cable SMA connector from the RF PCB. Leave the cable in place

6. Remove the 6-32 kep nut holding the Connector Adapter Plate in place. The plate will be lose but not

Socket Interconnect Header Connector. Below that is the 551-1694 2-row 32-pin (m-m) adapter.

The adapter connects to a second 2-Row 32-Socket Interconnect Header Connector mounted on

the Main PCB.

(Figure 3-12 #2).

(Figure 3-12 #4).

removable at this point (Figure 3-12 #5).

7. Outside the case, remove two (2) hex standoffs from the Option 22 CW Source DB-26 (m) connector

(Figure 3-12 #6).

8. Inside the case, remove five (5) 6-32 Phillips mounting screws holding the Option 22 CW Source

Control PCB assembly in place (Figure 3-12 #7).

9. Remove five (5) 6-32 Phillips mounting screws holding the Main PCB assembly in place (Figure 3-12

#8).

10. Disconnect the battery connector from J7 on the Main PCB (Figure 3-12 #9).

11. The Connector Panel, Main PCB, and the Option 22 CW Source Module assemblies should be loose.

12. Gently lift the bottom edge of the Main PCB assembly closest to the ribbon cable (Figure 3-12 #11)

and gently pull towards the bottom of the case. The goal is to create clearance between the Connector

Panel and the Main PCB assembly.

13. Gently lift the Connector Panel assembly (Figure 3-12 #12) and pull it towards the top of the

instrument. The goal is to create more clearance between the Connector Panel and the DB-26

connector on the Option 22 CW Source Control PCB assembly.

14. Finally, gently lift the back edge of the Option 22 CW Source Control assembly.

15. When the Option 22 DB-26 connector is free from the Connector Panel, continue to lift the Option 22

CW Source Control PCB assembly.

Connecting the 2-row 32-pin header connectors on the Option 22 and Main PCB assemblies is the

Note

551-1694 2-row 32-pin (m-m) adapter. The 32-pin adapter may remain in the Main PCB assembly or

stay with the Option 22 PCB assembly.

16. Inspect the pins on the 551-1694 2-row 32-pin (m-m) adapter. If they are bent, replace the adapter.

17. Installation of the replacement Option 22 CW Source Control PCB assembly is the reverse process.

18. Start with installing the 551-1694 2-row 32-pin (m-m) adapter on the Main PCB.

19. Make sure the Connector Adapter Plate is in place and that the slot on the Plate is correctly

positioned around the 6-32 mounting stud on the inside of the Back Panel.

3-20 S810D/S820D MM 10680-00003 Rev. H

Removal and Replacement Source Control PCB Assembly Replacement

20. Insert the DB-26 connector through the Connector Adapter Plate and Connector Panel openings.

21. When DB-26 connector is through the Connector Panel opening, gently lower the Option 22 CW

Source Control PCB assembly onto the Main PBC, making sure the header on the Option 22 header

connects successfully with the 551-1694 2-row 32-pin (m-m) adapter.

22. Once the headers and adapter have successfully connected, begin to add but not tighten the

remaining hardware.

23. Reconnect the J5 power connector.

24. Tighten the Phillips screws holding the Main PCB assembly.

25. Tighten the Phillips screws holding the Option 22 CW Source Control PSCB assembly.

26. Tighten the hex standoff nuts on the DB-26 connector.

27. Tighten the 6-32 kep nut holding the Connector Adapter panel in place.

28. Tighten the RF coax connector.

29. Tighten the 6-32 kep nuts holding the GPS connector.

30. Tighten the hex standoff nuts on the RS-232C DB-9 serial connector.

S810D/S820D MM 10680-00003 Rev. H 3-21

Source Control PCB Assembly Replacement Removal and Replacement

3-22 S810D/S820D MM 10680-00003 Rev. H

Appendix A — Test Data Master for CW Source Modules

S810D/S820D MM 10680-00003 Rev. H A-1

Customer

Model Serial No. Anritsu R.O. Customer P.O. Date Tested By

Reason Submitted: Calibration [ ] Evaluation [ ] Repair [ ] New Product Evaluation [ ]

Condition

Received:

Mechanical: Good [ ] Fair [ ] Poor [ ] Beyond Repair [ ]

Electrical: In Tolerance [ ] Out of Tolerance [ ]

Condition

Returned:

In Tolerance [ ] Un-repaired [ ] Performance exception, see attachment [ ]

PRECALIBRATION EVALUATION

POSTCALIBRATION EVALUATION

2-Port Cable Loss

Measurement

Accuracy

(10 MHz to 18 GHz)

Specification Measured Value In Tolerance?

+/- 0.85 dB @

10 dB attenuation

_________dB Yes [ ] No [ ]

+/- 1.35 dB @

30 dB attenuation

_________dB Yes [ ] No [ ]

CWM220NF, CWM220B-NF

Frequency Accuracy

Specification Measured Value In Tolerance?

+/- 8.25 kHz @ 2,750,000 kHz ________________kHz Yes [ ] No [ ]

CW Power

(10 MHz to 18 GHz)

Specification Measured Value In Tolerance?

M1= < +15 dBm

M2= > -15 dBm

_______dBm

_______dBm

Yes [ ] No [ ]

Yes [ ] No [ ]

2-Port Cable Loss

Measurement

Accuracy

(10 MHz to 18 GHz)

Specification Measured Value In Tolerance?

+/- 0.85 dB @

10 dB attenuation

_________dB Yes [ ] No [ ]

+/- 1.35 dB @

30 dB attenuation

_________dB Yes [ ] No [ ]

Frequency Accuracy

Specification Measured Value In Tolerance?

+/- 8.25 kHz @ 2,750,000 kHz ________________kHz Yes [ ] No [ ]

CW Power

(10 MHz to 18 GHz)

Specification Measured Value In Tolerance?

M1= < +15 dBm

M2= > -15 dBm

_______dBm

_______dBm

Yes [ ] No [ ]

Yes [ ] No [ ]

Test Data Master for CW Source Modules

A-2 S810D/S820D MM 10680-00003 Rev. H

Test Data Master for CW Source Modules

Customer

Model Serial No. Anritsu R.O. Customer P.O. Date Tested By

Reason Submitted: Calibration [ ] Evaluation [ ] Repair [ ] New Product Evaluation [ ]

Condition

Received:

Mechanical: Good [ ] Fair [ ] Poor [ ] Beyond Repair [ ]

Electrical: In Tolerance [ ] Out of Tolerance [ ]

Condition

Returned:

In Tolerance [ ] Un-repaired [ ] Performance exception, see attachment [ ]

PRECALIBRATION EVALUATION

POSTCALIBRATION EVALUATION

2-Port Cable Loss

Measurement

Accuracy

(10 MHz to 20 GHz)

Specification Measured Value In Tolerance?

+/- 0.85 dB @

10 dB attenuation

_________dB Yes [ ] No [ ]

+/- 1.35 dB @

30 dB attenuation

_________dB Yes [ ] No [ ]

CWM220SF, CWM220B-SF

Frequency Accuracy

Specification Measured Value In Tolerance?

+/- 8.25 kHz @ 2,750,000 kHz ________________kHz Yes [ ] No [ ]

CW Power

(10 MHz to 20 GHz)

Specification Measured Value In Tolerance?

M1= < +15 dBm

M2= > -15 dBm

_______dBm

_______dBm

Yes [ ] No [ ]

Yes [ ] No [ ]

2-Port Cable Loss

Measurement

Accuracy

(10 MHz to 20 GHz)

Specification Measured Value In Tolerance?

+/- 0.85 dB @

10 dB attenuation

_________dB Yes [ ] No [ ]

+/- 1.35 dB @

30 dB attenuation

_________dB Yes [ ] No [ ]

Frequency Accuracy

Specification Measured Value In Tolerance?

+/- 8.25 kHz @ 2,750,000 kHz ________________kHz Yes [ ] No [ ]

CW Power

(10 MHz to 20 GHz)

Specification Measured Value In Tolerance?

M1= < +15 dBm

M2= > -15 dBm

_______dBm

_______dBm

Yes [ ] No [ ]

Yes [ ] No [ ]

S810D/S820D MM 10680-00003 Rev. H A-3

Test Data Master for CW Source Modules

A-4 S810D/S820D MM 10680-00003 Rev. H

Index

Numerics to C

Numerics

2 MHz Frequency Extension, Option 2 . . . . . . . . 1-4

2-Port Cable Loss Measurements, Option 22NF 1-4

2-Port Cable Loss Measurements, Option 22SF . 1-4

2-Row 32-Pin (m-m) Adapter P/N 551-1694 3-18, 3-20

A

accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

AD/DC adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

adapters . . . 1-4, 2-7, 2-12, 2-14, 2-16, 3-2, 3-18, 3-20

Anritsu P/Ns

10680-00001 User Guide . . . . . . . . . . . . . 1-1, 3-2

10680-00002 Programming Manual . . . . 1-1, 3-2

10680-00002 User Guide . . . . . . . . . . . . . . . . . 1-1

15-123 Color Liquid Crystal Display Assembly 3-3

2000-1029 Battery Charger . . . . . . . . . . 3-2, 3-7

2000-933 DC Power Supply . . . . . . . . . . . . . . 1-4

22K50 Open/Short K(m) . . . . . . . . . . . . . . . . . 3-2

22N50 Open/Short N(m) . . . . . . . . . . . . . . . . . 3-2

2300-347 Handheld Software Tools . . . . . . . . 3-2

2300-488 Verification Software . . . . . . . . . . . 2-2

28K50 Precision Termination K(m) . . . . . . . . 3-2

28N50-2 Precision Termination N(m) . . . . . . 3-2

34NFK50 N(f) to K(m) Adapter . 2-7, 2-12, 2-14,

2-16, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

34NKF50 N(m) to K(f) Adapter 1-4, 2-7, 2-12, 2-14,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

40-187-R External Power Supply 2-1, 2-2, 2-5, 3-2

43KC-10 10 dB Attenuator . . . . . . . . . . 2-7, 2-16

43KC-20 20 dB Attenuator . . . . . . . . . . 2-7, 2-16

46649-4 Membrane Keypad Main . . . . . . . . . 3-3

46653-3 Bottom Case . . . . . . . . . . . . . . . . . . . . 3-4

46655 Case Corner Bumper . . . . . . . . . . . . . . 3-4

48231-3 Battery Door . . . . . . . . . . . . . . . . . . . 3-4

48241 Battery Door Latch . . . . . . . . . . . . . . . . 3-4

52737-3 Keypad PCB Assembly . . . . . . . . . . . 3-3

551-1694 2-Row 32-Pin (m-m) Adapter . . . . 3-18

551-1961-R USB to RS232 Adapter Cable . . . 3-2

560-7N50B RF Detector 1-4, 2-5, 2-7, 2-12, 2-13,

2-14

560-7S50B RF Detector . . . . . . . . . . . . . 2-7, 2-12

61440-1 Top Case . . . . . . . . . . . . . . . . . . . . . . 3-4

62934 ID Lablel S820D . . . . . . . . . . . . . . . . . . 3-4

62935 ID Label S810D . . . . . . . . . . . . . . . . . . 3-4

633-26 Lithium Clock Battery . . . . . . . 3-3, 3-15

633-27 Rechargeable Battery NiMH . . . . . . . 3-3

65717 Soft Carrying Case . . . . . . . . . . . . . . . . 3-2

785-405 Plain Standoff . . . . . . . . . . . . . . . . . . 3-3

785-927 M-F Standoff . . . . . . . . . . . . . . . . . . . 3-3

790-18 M-F Standoff . . . . . . . . . . . . . . . . . . . . 3-3

790-509 Battery Door Latch . . . . . . . . . . . . . . 3-4

790-510 Battery Door Latch . . . . . . . . . . . . . . 3-4

790-515 Sprint Battery Compartment . . . . . . 3-4

790-551 Door Lock Replacement . . . . . . . . . . 3-4

800-441 Serial Interface Cable . . . . . 1-4, 2-2, 3-2

806-141 Automotive Power Adapter . . . . . . . 3-2

900-326 Kep Nut . . . . . . . . . . . . . . . . . . . . . . . 3-3

900-720 Screw, Machine . . . . . . . . . . . . . . . . . 3-3

900-791 Screw, Machine . . . . . . . . . . . . . . . . . 3-3

900-861 Pan Head Screw . . . . . . . . . . . . . . . . 3-3

CWM220NF

CW Source Module 2-7, 2-8, 2-12, 2-13, 2-14,

2-16

CWM220SF

CW Source Module . . . . . . . . . 2-7, 2-8, 2-12

MA2418A RF Reference Source . . . . . . . .1-4, 2-5

MF2412B Frequency Counter . . . . . . . . .1-4, 2-1

ND64376 Power Monitor PCB Assembly . . . . 3-3

ND66448 Main/RF PCB Exchange Assembly