Anritsu MW82119B User Manual

User Guide

PIM Master™

Passive Intermodulation Analyzer

with Site Master™ Cable &

Antenna Analyzer (331) and

2-Port Options (703)

MW82119B

Anritsu Company

490 Jarvis Drive

Morgan Hill, CA 95037-2809

USA

http://www.anritsu.com

Part Number: 10580-00400

Published: February 2021

Copyright 2014, 2021 Anritsu Company

Revision: N

Table of Contents

Chapter 1—General Information

1-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Contacting Anritsu for Sales and Service . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Instrument Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

PIM Master Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Instrument Care and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . 1-4

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Connecting Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Test Cable from PIM Master to DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Disconnecting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Connector Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Battery Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

PIM Master Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4 Calibration Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-5 Wireless Remote Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2—PIM Master Overview

2-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2 Turning On the PIM Master for the First Time . . . . . . . . . . . . . . . . . . . . . . 2-1

Calibration Due Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Calibration Reminder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Front Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

MW82119B PIM Master Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-4 Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5 Top Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-6 Top Connector Panel -- Option 703 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-7 Side Panel Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-8 Measurement Display Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Front Panel Display Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Main Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Submenu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2-9 Secondary Function Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2-10 Mode Selector Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2-11 Menu Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

MW82119B UG PN: 10580-00400 Rev. N Contents-1

Table of Contents (Continued)

2-12 Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Graphical User Interface (GUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-13 Touch Screen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Calibrate Touch Screen Shortcut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Arrow Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2-14 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2-15 Symbols and Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-16 Soft Carrying Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2-17 Tilt Bail Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Chapter 3—Quick Start Guide

3-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 Measurement Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 Cable & Antenna Analyzer Measurements (Option 331) . . . . . . . . . . . . . . 3-3

Select the Measurement Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Set the Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Set the Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Turn on Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Single Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

DTF Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Calibrate with OSL Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-4 Passive Intermodulation (PIM) Measurements . . . . . . . . . . . . . . . . . . . . . . 3-8

Preparing for PIM Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Calibrating the PIM Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Verifying Residual PIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Verifying the PIM Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Verifying the PIM Test Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Checking for External Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Making PIM Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Measurement Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Adding a Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3-5 Setting Up Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3-6 Saving Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Chapter 4—File Management

4-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 Managing Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Contents-2 PN: 10580-00400 Rev. N MW82119B UG

Table of Contents (Continued)

4-3 File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Saving Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Save Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Quick Name Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Recalling Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Recall Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Copying Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Deleting Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Delete Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4-4 File Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-5 File Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4-6 Save Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-7 Save Location Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Select Save Location Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Create Directory Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4-8 Recall Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Recall Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4-9 Copy Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Copy Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

4-10 Delete Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Chapter 5—System Operation

5-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 System Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

System Menu Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

System Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Display Settings Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Brightness Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Reset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5-4 Preset Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5-5 Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Chapter 6—GPS (Option 31)

6-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2 Setting Up GPS (Option 31) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Activating the GPS Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

MW82119B UG PN: 10580-00400 Rev. N Contents-3

Table of Contents (Continued)

6-3 GPS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

GPS Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7—Anritsu Tool Box with LST

7-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-2 Anritsu Tool Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-3 Install the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-4 Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Why use Line Sweep Tools? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Line Sweep Tools Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Using Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Markers and Limit Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Marker Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Naming Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Report Generator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Appendix A—Other Documents

A-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

PIM Master Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B—PIM Carrier Bands

B-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B-2 PIM Master Carrier Bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Appendix C—Wireless Remote Control

C-1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C-2 Portable Router for Wireless Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C-3 Configuring the PIM Master for Wireless Browser Control . . . . . . . . . . . . .C-2

Contents-4 PN: 10580-00400 Rev. N MW82119B UG

Table of Contents (Continued)

C-4 Using a ZyXEL MWR102 Travel Router. . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Connecting the Router to the PIM Master . . . . . . . . . . . . . . . . . . . . . . . C-3

Configuring PIM Master for use with Router . . . . . . . . . . . . . . . . . . . . . C-4

C-5 Remote Control via a Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Screen Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

List of Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Using Anritsu Line Sweep Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Saving Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

Instrument Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Appendix D—Instrument Messages and Errors

D-1 Error Messages: Stop Current Measurements . . . . . . . . . . . . . . . . . . . . . .D-1

D-2 PIM Analyzer Warning Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

D-3 Operation Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Appendix E—Instrument Care

E-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Appendix Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-2 Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

E-3 Battery Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

E-4 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

E-5 PIM Master Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Determining the Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Downloading the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Updating with a USB Memory Device . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

E-6 Adding Options with a License File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

Appendix F—LAN and DHCP

F-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

MW82119B UG PN: 10580-00400 Rev. N Contents-5

Table of Contents (Continued)

F-2 Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

LAN Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Ethernet Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-3

Ethernet Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-4

F-3 DHCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

F-4 ipconfig Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

F-5 Ping Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-7

Appendix G—Glossary

G-1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

G-2 Glossary Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Index

Contents-6 PN: 10580-00400 Rev. N MW82119B UG

Chapter 1 — General Information

1-1 Introduction

The PIM Master MW82119B User Guide is one of the set of manuals that cover all of the

instrument’s functions and uses. The PIM Master with Site Master and 2-port LTE 700 MHz

(option 703) options is capable of performing a wide variety of Passive Intermodulation (PIM)

and Line Sweep measurements. This guide provides a quick-start section with a brief

overview of the available PIM, Line Sweep, and 2-port measurements. Please refer to the

measurement guides listed in Table 1-1, “Related Documentation” for more detailed

measurement instructions. This guide also provides a summary of the hardware and software

features of the PIM Master that are common to all measurement modes.

Throughout this user guide, screen images are provided as examples. The image

Note

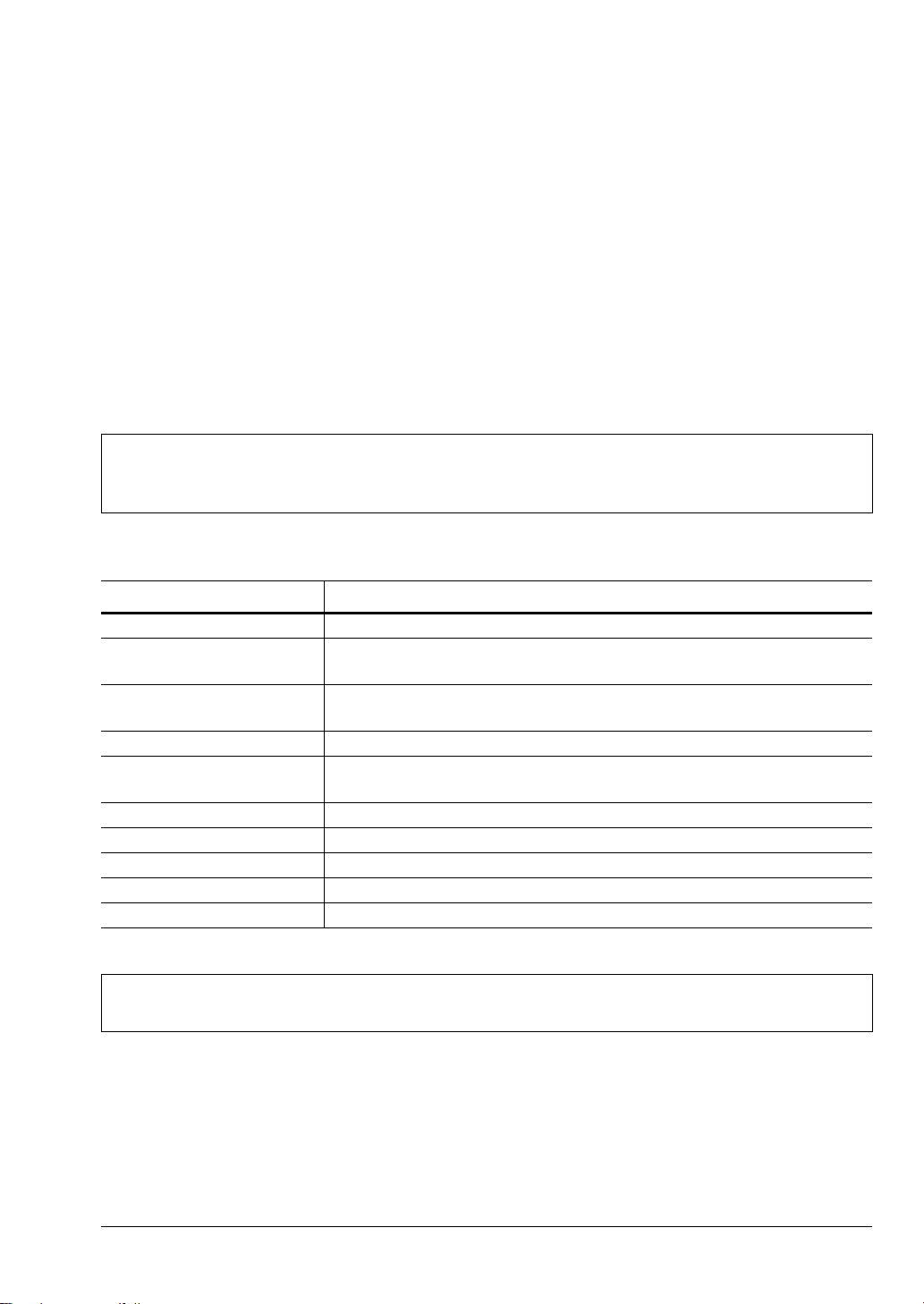

Related Documentation

Document Part Number Description (Required Option)

10100-00065 Important Product Information, Compliance, and Safety Notices

10580-00240

10580-00241

11410-00824 PIM Master Product Brochure

11410-00821

10580-00402 Passive Intermodulation Analyzer Measurement Guide

10580-00403 PIM Master MW82119B Programming Manual

10580-00401 PIM Master MW82119B Maintenance Manual

11410-00784 Configuring the Anritsu PIM Master for Wireless Browser Control

10580-00252 Site Master User Guide

Table 1-1. Related Documentation

and measurement details on your instrument may differ from the examples in this

user guide.

Power Meter Measurement Guide

High-Accuracy Power Meter (Option 19)

Cable and Antenna Analyzer Measurement Guide

Cable and Antenna Analyzer (Option 331)

PIM Master Technical Data Sheet

Performance Specifications

Note

Read the Handheld Instruments Product Information, Compliance, and Safety Guide

(PN: 10100-00065) for important safety, legal, and regulatory notices before operating the

equipment. For additional information and literature covering your product, visit the product

page of your instrument and select the Library tab:

http://www.anritsu.com/en-US/test-measurement/products/mw82119B

MW82119B UG PN: 10580-00400 Rev. N 1-1

PIM is a measure of system linearity as compared to line sweeping, which is a

measure of system impedance. Both tests are critical to validate a cellular system.

1-1 Introduction Chapter 1 — General Information

Document Conventions

Main menus and keypad buttons are shown in the user guide using a Serif Bold typeface.

Main menus are the buttons displayed at the bottom of the touchscreen. Submenus and

submenu buttons are displayed on the right side of the touchscreen display and shown in the

user guide using Serif Regular typeface.

Menu and button locations may be described in this document by their path:

Measurement > VSWR

The line above reads as “Press the Measurement main menu, then press the VSWR button."

Contacting Anritsu for Sales and Service

To contact Anritsu, please visit:

http://www.anritsu.com/contact-us

Here, you can find sales, customer service, and support contact information for your country

or region, provide online feedback, complete a “Talk to Anritsu” form to have your questions

answered, or obtain other services offered by Anritsu.

Updated product information can be found on the Anritsu web site:

http://www.anritsu.com/

Search for the product model number. The latest documentation is on the product page under

the Library tab.

Example URL for MW82119B:

http://www.anritsu.com/en-US/test-measurement/products/mw82119b

1-2 PN: 10580-00400 Rev. N MW82119B UG

Chapter 1 — General Information 1-2 Instrument Description

1-2 Instrument Description

Anritsu developed the PIM Master, with Site Master and 2-Port LTE options, to fully

characterize the RF performance of transmission systems with a single test instrument.

Previously, two separate analyzers were required to measure Passive Intermodulation (PIM)

and impedance mismatches in RF transmission lines. With Site Master Option 331 installed,

the PIM Master can now perform both tests to ensure minimum signal degradation,

minimum noise generation, and maximum signal throughput. Capabilities with Option 331

installed include:

• PIM vs. TIME • Swept PIM

• Noise Floor • Distance-to-PIM

• Return Loss • VSWR

• Cable Loss • Distance-to-Fault (DTF)

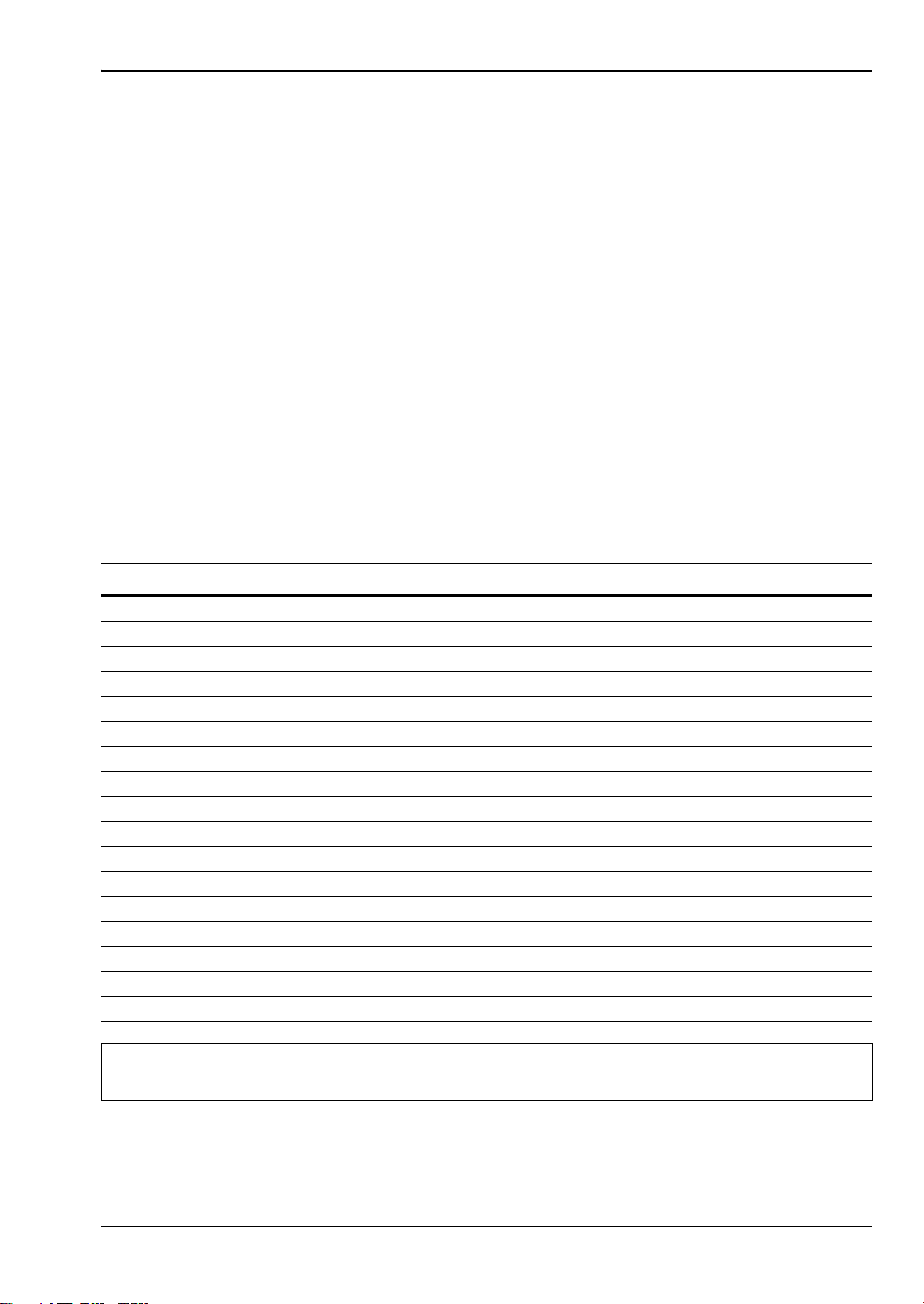

PIM Master Options

Table 1-2 lists the current available options. Refer to the Anritsu web site for the latest

information on available PIM Master options and frequency ranges.

Table 1-2. PIM Master Options

Note

Instrument Option Description

MW82119B-0600 LTE 600 MHz with 1900 MHz

MW82119B-0700 LTE 700 MHz

MW82119B-0701 APT 700 MHz

MW82119B-0703 2-Port LTE 700MHz

MW82119B-0800 LTE 800 MHz

MW82119B-0850 Cellular 850 MHz

MW82119B-0900 E-GSM 900 MHz

MW82119B-0902 E-GSM 900 MHz with IM2

MW82119B-0180 DCS 1800 MHz

MW82119B-0194 PCS/AWS 1900/2100 MHz

MW82119B-0210 UMTS 2100 MHz

MW82119B-0260 LTE 2600 MHz

MW82119B-0331 Site Master Cable and Antenna Analyzer

MW82119B-0031 GPS Receiver (requires antenna)

MW82119B-0019 High Accuracy Power Meter (requires sensor)

MW82119B-0098 Standard Calibration Certification

MW82119B-0099 Premium Calibration Certification

For ordering information and for option and accessory part numbers, refer to the

technical data sheet (listed in Appendix A).

MW82119B UG PN: 10580-00400 Rev. N 1-3

1-3 Instrument Care and Preventive Maintenance Chapter 1 — General Information

1-3 Instrument Care and Preventive Maintenance

Site Master care and preventive maintenance consists of cleaning the unit and inspecting and

cleaning the RF connectors on the instrument and all accessories. Clean the Site Master with

a soft, lint-free cloth dampened with water or water and a mild cleaning solution.

Caution To avoid damaging the display or case, do not use solvents or abrasive cleaners.

Connector Care

Clean the RF connectors and center pins with a cotton swab dampened with denatured

alcohol. Visually inspect the connectors. The fingers of the N(f) connectors and the pins of the

N(m) connectors should be unbroken and uniform in appearance. If you are unsure whether

the connectors are undamaged, gauge the connectors to confirm that the dimensions are

correct. Visually inspect the test port cable(s). The test port cable should be uniform in

appearance, and not stretched, kinked, dented, or broken.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

Type-N connectors. The recommended torque is 12 lbf ·in to 15 lbf· in (1.36 N·m to 1.70 N·m).

Inadequate torque settings can affect measurement accuracy. Over-tightening connectors can

damage the cable, the connector, the instrument, or all of these items.

Visually inspect connectors for general wear, cleanliness, and for damage such as bent pins or

connector rings. Repair or replace damaged connectors immediately. Dirty connectors can

limit the accuracy of your measurements. Damaged connectors can harm the instrument.

Connection of cables carrying an electrostatic potential, excess power, or excess voltage can

damage the connector, the instrument, or both.

Connecting Procedure

1. Carefully align the connectors.

The male connector center pin must slip concentrically into the contact fingers of the

female connector.

2. Push connectors straight together. Do not twist or screw them together.

3. To tighten, turn the connector nut, not the connector body. Major damage can occur to

the center conductor and to the outer conductor if the connector body is twisted.

4. When you use a torque wrench, initially tighten by hand so that approximately 1/8 turn

or 45 degrees of rotation remains for the final tightening with the torque wrench.

Relieve any side pressure on the connection (such as from long or heavy cables) in order

to assure consistent torque. Use an open-end wrench to keep the connector body from

turning while tightening with the torque wrench.

Do not over-torque the connector.

1-4 PN: 10580-00400 Rev. N MW82119B UG

Chapter 1 — General Information 1-3 Instrument Care and Preventive Maintenance

Test Cable from PIM Master to DUT

Remove O-rings from the test cable and be sure that the connectors are clean. If the DUT

connector has an O-ring, then use a torque wrench to tighten the connector.

When testing, cables are connected and disconnected many times. In order to

save wear on these test cables and RF adapters, Anritsu recommends removing

the O-rings. This allows getting a sufficiently tight connection without unnecessary

Note

stress on the connectors. In the field, O-rings are important to maintain connection

integrity over long time periods. Connections must be torqued to specifications in

order to ensure that they prevent water intrusion.

During your test, if the DUT connector has an o-ring, leave it in place and tighten

to the correct torque.

Disconnecting Procedure

1. If a wrench is needed, use an open-end wrench to keep the connector body from turning

while loosening with a second wrench.

2. Complete the disconnection by hand, turning only the connector nut.

3. Pull the connectors straight apart without twisting or bending.

Connector Saver

Anritsu recommends using an adapter on the intrument's 7/16 DIN female RF Out connector

to act as a connector saver. Typically, the instrument's connector has a useful life of 500

matings. A 7/16 DIN(f) to 7/16 DIN(m) and 50 Ω connector saver reduces wear on the

connector, and may stay on the instrument while it is in the soft case or transit case. One

connector saver is provided with your test instrument.

The recommended torque for attaching the connector saver to the instrument is 25 N · m

(~18 lbf · ft). Use a torque wrench to make the connection.

Replacement connector savers can be purchased from Anritsu. The part number is in your

Technical Data Sheet.

MW82119B UG PN: 10580-00400 Rev. N 1-5

1-3 Instrument Care and Preventive Maintenance Chapter 1 — General Information

ESD Caution

The PIM Master, like other high-performance instruments, is susceptible to electrostatic

discharge (ESD) damage. Coaxial cables and antennas often build up a static charge, which

(if allowed to discharge by connecting directly to the PIM Master without first discharging the

static charge) may damage the PIM Master input circuitry.

Caution

Operators should exercise practices outlined within industry standards such as JEDEC-625

(EIA-625), MIL-HDBK-263, and MIL-STD-1686, which pertain to ESD and ESDS devices,

equipment, and practices. Because these apply to the PIM Master, Anritsu recommends that

any static charges that may be present be dissipated before connecting coaxial cables or

antennas to the PIM Master. This may be as simple as temporarily attaching a short or load

device to the cable or antenna prior to attaching to the PIM Master. It is important to

remember that the operator may also carry a static charge. Following the practices outlined

in the referenced standards will ensure a safe environment for both personnel and

equipment.

Operators must be aware of the potential for ESD damage and take all necessary

precautions.

Battery Information

The batteries that are supplied with the PIM Master may need charging before use. They can

be charged using either the AC-DC Adapter or the DC adapter. The batteries can also be

charged by using an external charger (refer to your Technical Data Sheet). Refer to

Section E-3 “Battery Care” on page E-2.

Use only Anritsu Company approved batteries, adapters, and chargers with this

instrument.

The batteries charge at a faster rate when the instrument is turned off. Charging

the batteries while the instrument is running requires a longer time to reach a full

charge.

Note

To prolong the useful battery life, the internal charging circuit monitors the battery

temperature. Normal charging occurs when the battery temperature is between

0 °C and 45 °C. Charging is paused if the internal battery temperature is beyond

this range.

Anritsu Company recommends removing the battery for long-term storage of the

instrument.

When using the Automotive Cigarette Lighter Adapter, always verify that the

Caution

The PIM Master batteries can be replaced without the use of tools. The battery compartment

access is on the bottom of the PIM Master. Refer to Section E-4 “Battery Replacement”

on page E-3.

1-6 PN: 10580-00400 Rev. N MW82119B UG

supply is rated for a minimum of 40 Watts at 12 VDC, and that the socket is clear

of any dirt or debris. If the adapter plug becomes hot to the touch during operation,

then discontinue use immediately.

Chapter 1 — General Information 1-4 Calibration Requirements

PIM Master Firmware Update

Refer to Section E-5 “PIM Master Firmware Update” on page E-6 for firmware upgrade

procedures.

1-4 Calibration Requirements

Field-calibrate your PIM Master as required to achieve acceptable residual PIM. The

instrument provides calibration prompts to help you determine calibration status. Anritsu

recommends annual factory calibration and performance verification by local Anritsu

service centers. The Cable and Antenna Analyzer mode requires calibration standards for

OPEN, SHORT, and LOAD (OSL), which are sold separately.

Note

Anritsu recommends allowing the instrument to warm up to typical operation

temperature (approximately 15 minutes) before calibrating.

1-5 Wireless Remote Control

Browser-based control allows you to remotely control the PIM Master from any Wi-Fi enabled

device with web browser software (Chrome or Firefox preferred). This includes a wide range

of tablets and phones running Android or iOS operating systems as well as the traditional

Linux and Windows laptop and desktop computers.

Wi-Fi links are useful in the field, particularly when the PIM Master is on a tower, and you

are on the ground.

For wireless remote control, a Wi-Fi router must be connected to the PIM Master.

Refer to Appendix C, “Wireless Remote Control” for more details on using this capability to

enable wireless control.

MW82119B UG PN: 10580-00400 Rev. N 1-7

1-5 Wireless Remote Control Chapter 1 — General Information

1-8 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview

2-1 Introduction

This chapter describes the MW82119B PIM Master. It also includes a brief description of

preventive maintenance, calibration requirements, and additional PIM Master documents.

The Anritsu PIM Master is capable of producing 80 Watts of RF power in the

cellular communications bands. Users must take precautions to minimize

exposure to these RF fields:

Always terminate the PIM output port of the test equipment into a load, a

loaded line, or a line that will radiate or absorb the energy before beginning

a PIM test.

Warning

Confirm that the PIM Master RF power is off after a PIM test.

Always confirm that the PIM RF power is off before disconnecting a coaxial

connection, otherwise RF burns may result. Immediate burns to fingers or

eyes can result from exposure to live connectors.

Ensure that all antennas under test are placed so that no personnel are

exposed to RF levels that exceed the maximum allowable exposure.

2-2 Turning On the PIM Master for the First Time

The Anritsu MW82119B PIM Master is capable of more than 3.0 hours of continuous

operation from a fully charged, field-replaceable battery (refer to Section E-4 “Battery

Replacement” on page E-3). The PIM Master can also be operated from a 12 VDC source

(which will also simultaneously charge the battery). This can be achieved with either the

Anritsu AC Adapter or Automotive 12 Volt Adapter. Both items are included as standard

accessories (refer to the list of accessories in the Technical Data Sheet for your specific

instrument, as listed in Appendix A).

When using the Automotive Adapter, always verify that the supply is rated for a

Caution

To turn on the MW82119B PIM Master, press the On/Off button on the front panel

(Figure 2-3 on page 2-4). The PIM Master takes approximately 40 seconds to complete

power-up and to load the application software. At the completion of this process, the

instrument is ready to be used.

Note

minimum of 60 Watts at 12 VDC and that the socket is clear of any dirt or debris. If

the adapter plug becomes hot to the touch during operation, then discontinue use

immediately.

Anritsu recommends that you turn on your PIM Master and let it warm up for

10 minutes before performing your first calibration.

MW82119B UG PN: 10580-00400 Rev. N 2-1

2-2 Turning On the PIM Master for the First Time Chapter 2 — PIM Master Overview

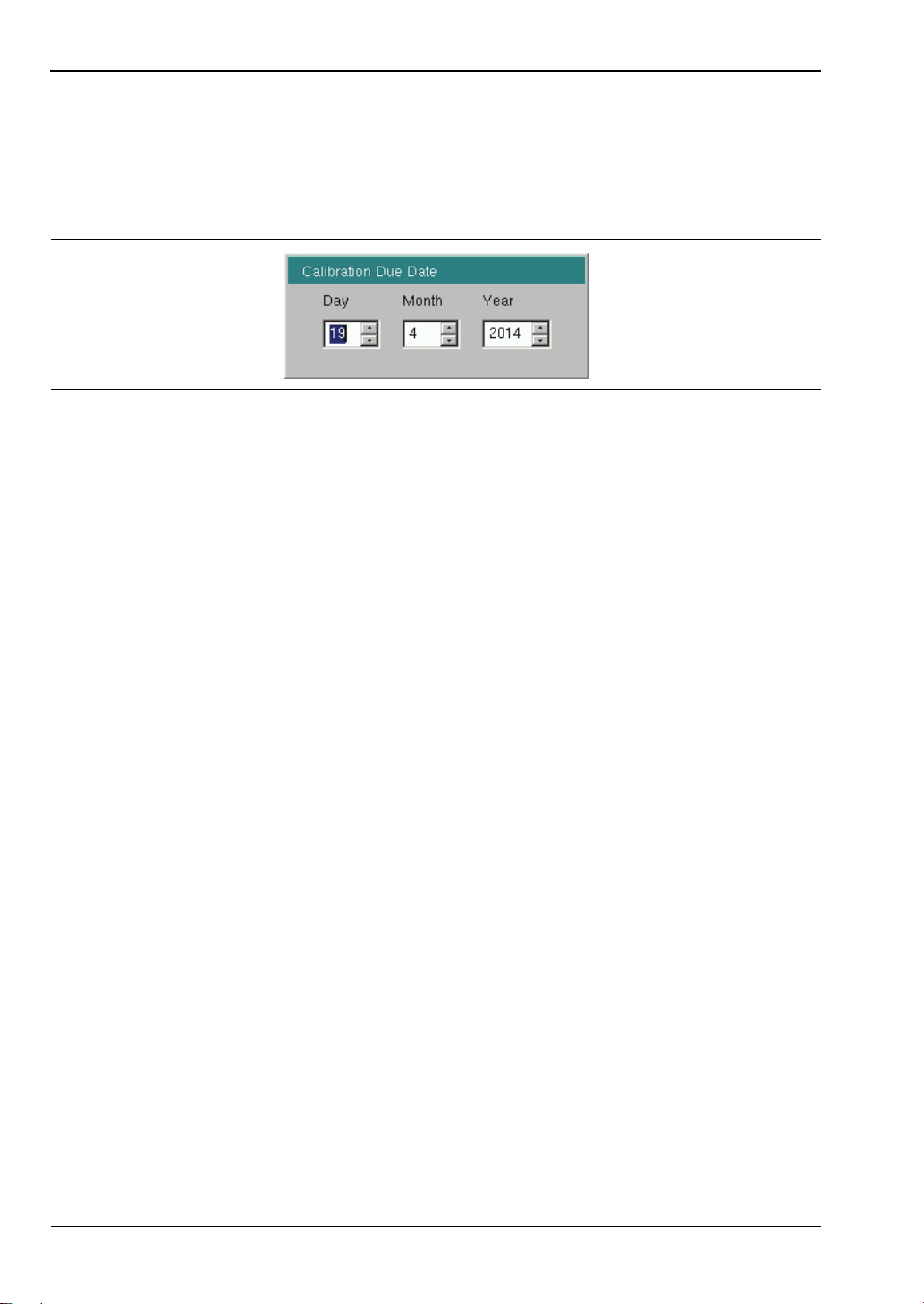

Calibration Due Date

On first use, or if the Calibration Reminder setting is greater than the due date, a menu is

displayed requesting that you enter the Calibration Due Date for this instrument. This date is

available on the calibration sticker that is provided with the instrument. Enter the correct

day, month, and year and then press Enter.

Figure 2-1. Calibration Due Date Dialog Box

The initial calibration due date is set to one year from the Factory Calibration Date, unless

you enter a different date.

2-2 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-3 Front Panel Overview

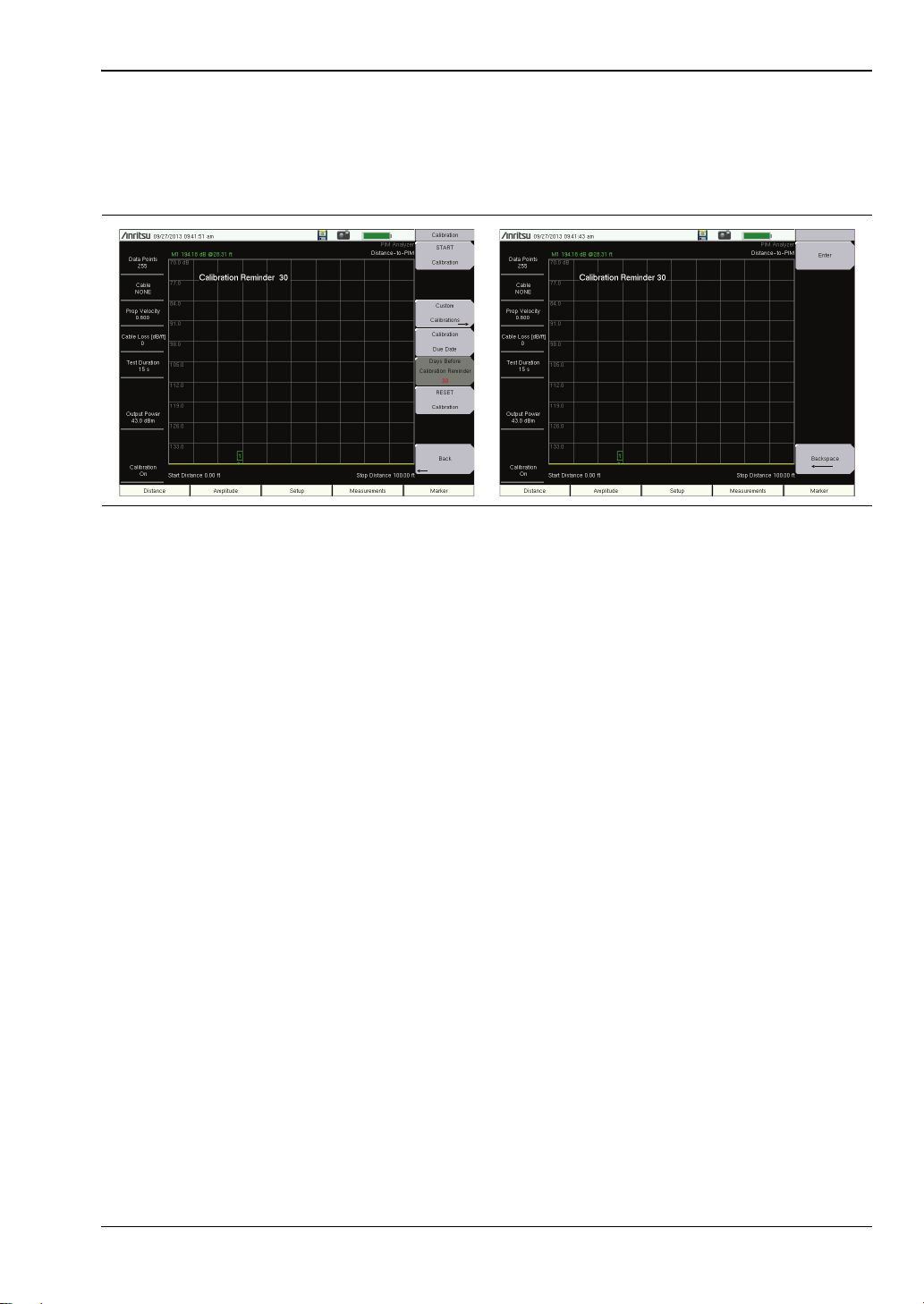

Calibration Reminder

You can set a reminder of the due date by pressing the Days Before Calibration Reminder

submenu key and entering a number with the number keypad. Complete the entry by

pressing the Enter submenu key or the instrument Enter key.

Figure 2-2. Days Before Calibration Reminder

2-3 Front Panel Overview

The PIM Master menu-driven interface is easy to use and requires little training. The

PIM Master uses a touch screen and keypad for data input. The five bottom menu keys and

eight submenu keys on the right side are touch screen keys. The menu and submenu keys will

vary depending upon the selected mode of operation, refer to “Mode Selector Menu”

on page 2-20.

Number keys 1 through 9 are dual purpose, depending upon the current mode of operation.

The dual-purpose keys are labeled with a number on the key itself with the alternate function

printed in blue above each of the keys. Use the blue Shift key to access the functions printed

on the panel. The Escape key, used for aborting data entry, is the button located above

number key 8. The four Arrow keys and the keypad can be used to change the value of an

active parameter.

MW82119B UG PN: 10580-00400 Rev. N 2-3

2-3 Front Panel Overview Chapter 2 — PIM Master Overview

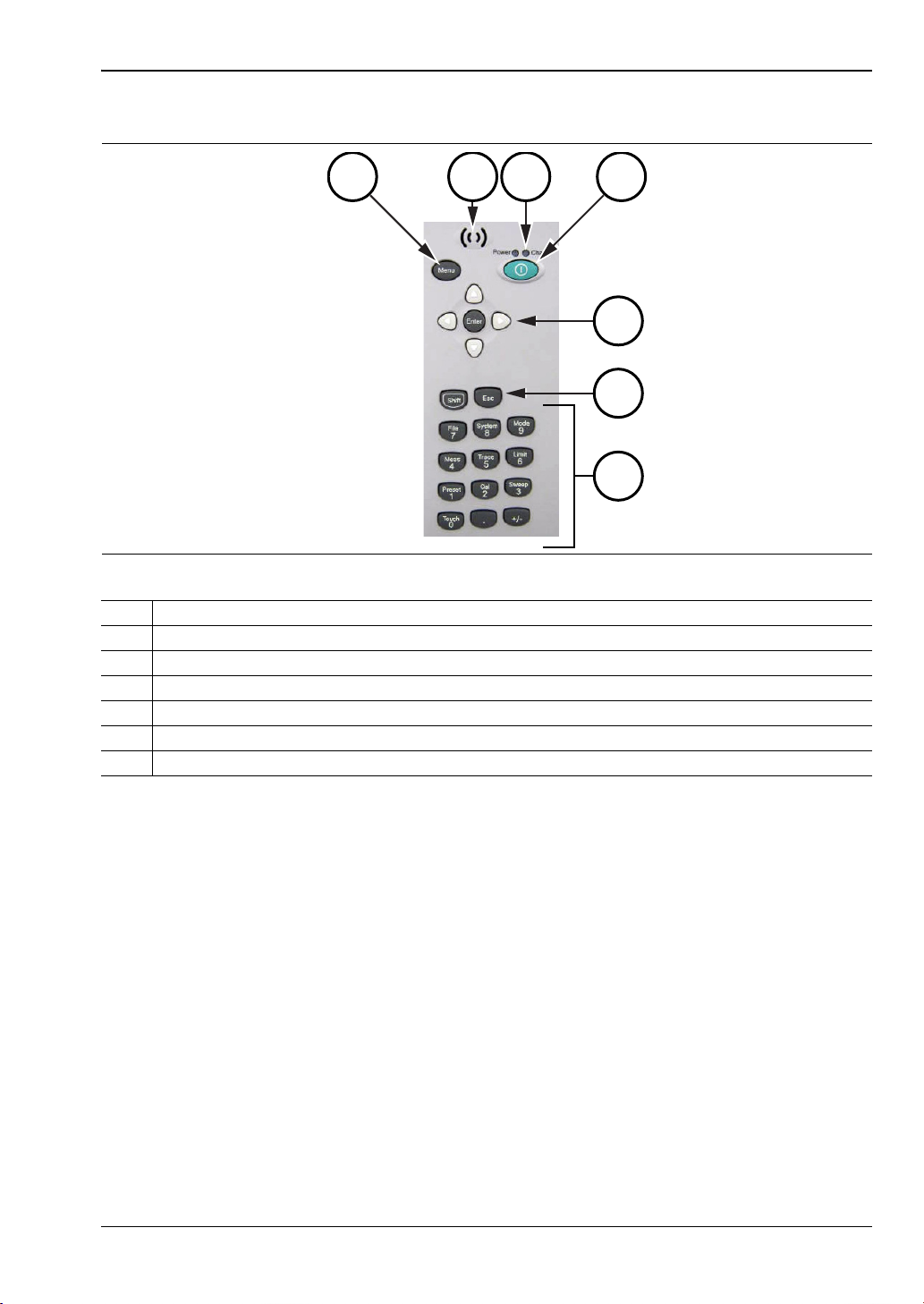

2

1

3

MW82119B PIM Master Front Panel

Figure 2-3. MW82119B PIM Master Front Panel

1. On/Off Button (and Battery and Power LEDs)

2. Number Keypad

3. Measurement Display (a Touch Screen)

2-4 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-4 Front Panel Keys

1

4

2

5

7

6

3

2-4 Front Panel Keys

Figure 2-4. Front Panel Layout

1. Menu Key

2. Speaker Grill

3. LED Indicators for Battery Charge and Power

4. On/Off Button

5. Arrow Keys and Enter Key in center

6. Shift Key and Escape Key

7. Number Keypad

The terms button and hard key refer to all of the buttons on the instrument face. These keys

perform as follows:

Menu Key

(item 1 in Figure 2-4)

Press the Menu key to display the Menu Key Screen, a grid of shortcut icons for installed

measurement modes and user-selected menus and setup files.

MW82119B UG PN: 10580-00400 Rev. N 2-5

2-4 Front Panel Keys Chapter 2 — PIM Master Overview

On/Off Button

(item 4 in Figure 2-4)

Press this button to turn on power to the PIM Master. Press and hold this button to turn off

power.

Arrow Keys

(item 5 in Figure 2-4)

The four Arrow keys are used to scroll up, down, left, or right. The Arrow keys can often be

used (depending upon measurement selection) to change a value or to change a selection from

a list. In some measurements, the Left/Right arrow keys change values by different

increments than the Up/Down arrow keys. The Arrow keys are also used to move markers.

Enter Key

(item 5 in Figure 2-4)

Press this key to finalize data input.

Shift Key

(item 6 in Figure 2-4)

Press the Shift key and then press a number key to open the menu that is indicated in text

above the key number. When the Shift key is active, its icon is displayed at the top-right of the

measurement display area between the battery charge indicator and the submenu key labels.

Figure 2-5. Shift Key Icon

Esc Key

(item 6 in Figure 2-4)

Press this key to cancel any setting that is currently being made.

LED Indicators (above the On/Off Button)

(item 3 in Figure 2-4)

Battery Charge LED (Green)

The Battery Charge LED flashes if the battery is charging, and remains on steady when the

battery is fully charged.

Power LED (Green)

The Power LED remains on when the PIM Master is on.

2-6 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-4 Front Panel Keys

Number Keypad

(item 7 in Figure 2-4)

Press these keys to directly input numbers. Number keys are also used to open menus when

used with the “Shift Key”. For example, press Shift and Touch (0) to initiate Touch Screen

Calibration.

+/– Key

(item 7 in Figure 2-4)

Press this key to change the sign of numbers that are entered with the number keys.

MW82119B UG PN: 10580-00400 Rev. N 2-7

2-5 Top Connector Panel Chapter 2 — PIM Master Overview

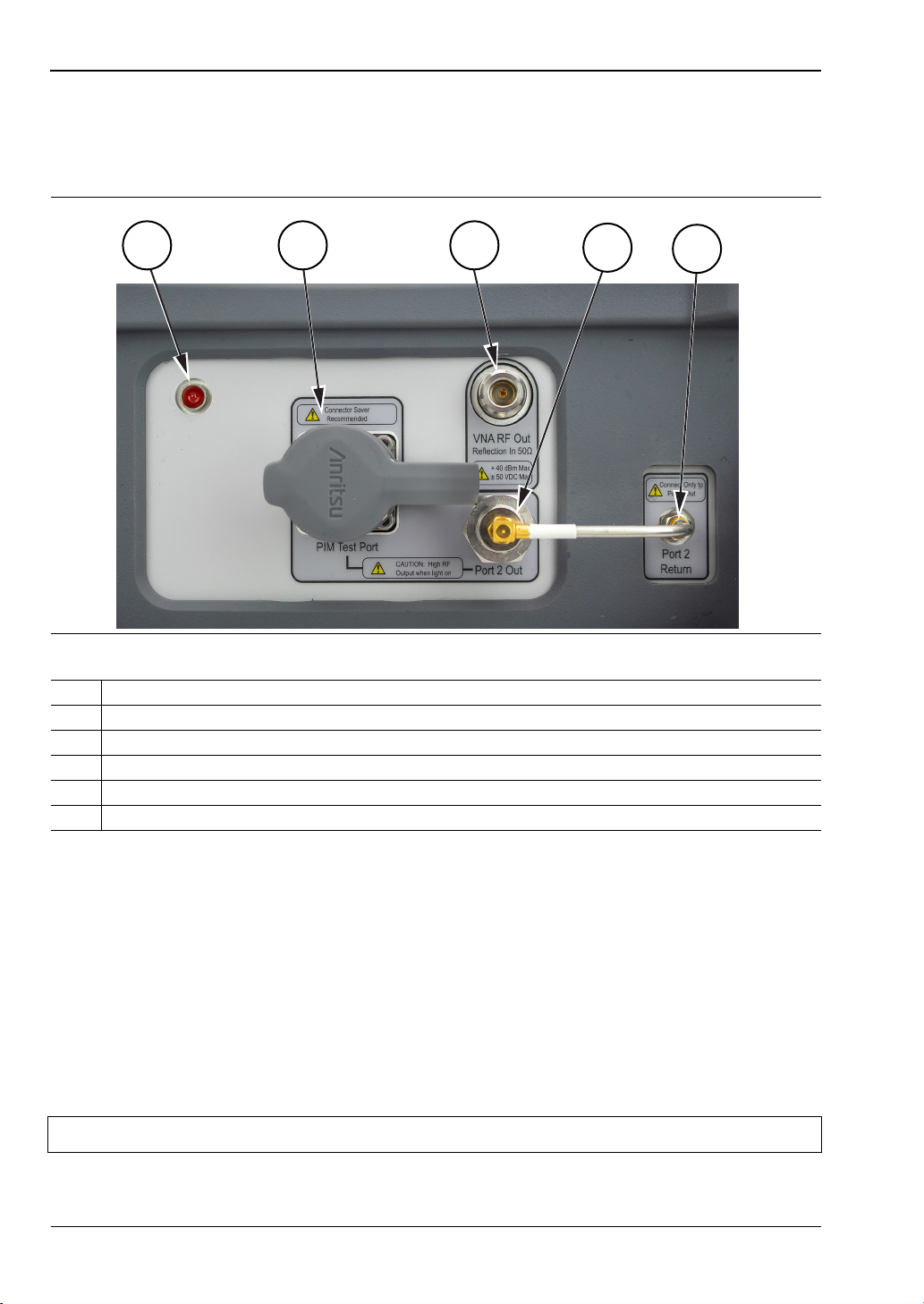

1

3

2

54

2-5 Top Connector Panel

The top connector panel includes the test port connectors and the Radio Frequency On light.

Figure 2-6. PIM Master Top Panel Layout

1. Indicator Light for RF On (Red)

2. PIM Test Connector, 7/16 DIN, female, 50 Ω

3. VNA RF Out Connector, Type-N, female, 50 ohms (Option 331)

4. IM2 In Connector, Type-N, female, 50 ohms (Option 902)

5. Strap Bracket (shown without strap), 2x

PIM Radio Frequency ON Light (item 1 in Figure 2-6)

This red indicator is illuminated when PIM RF output power is On.

PIM Test Connector (item 2 in Figure 2-6)

Type 7/16 DIN(f), 50 test port connector that is used to perform PIM versus Time, Swept

PIM, Noise Floor, and Distance-to-PIM (DTP) measurements.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the DIN

connector. Do not over-tighten the connector. The recommended torque is 25 N ·m (~18 lbf·ft).

To prevent rotation, secure the PIM test connector or the recommended connector saver with

a wrench when attaching a test lead.

Refer to “Connector Saver” on page 1-5.

2-8 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-5 Top Connector Panel

VNA RF Out Connector (item 3 in Figure 2-6)

VNA RF Out Connector, Type-N, female, 50 ohms (Option 331). This test port is available

only on instruments with Site Master Option 331. It is used to perform Return Loss, VSWR,

Cable Loss, and Distance-to-Fault (DTF) measurements. Hand tighten this connection. Do

not use a wrench.

IM2 In Connector (item 4 in Figure 2-6)

IM2 In Connector, Type-N, female, 50 ohms (Option 902). This test port is available only with

frequency Option 902. It is used to receive second order intermodulation products. Hand

tighten this connection. Do not use a wrench.

Strap Bracket (item 5 in Figure 2-6)

The Strap Brackets hold the Handle Strap and can accommodate a Carabiner. Note that each

bracket is secured to the PIM Master with 2 screws. The handle is sewn to the brackets, but is

not shown in the figure in order to reveal the bracket design. See Figure 2-23 on page 2-30 for

the complete bracket, mounted and in use.

MW82119B UG PN: 10580-00400 Rev. N 2-9

2-6 Top Connector Panel -- Option 703 Chapter 2 — PIM Master Overview

5

3

2

1

4

2-6 Top Connector Panel -- Option 703

The 2-port top connector panel includes the base features from Figure 2-6 plus those for the

2-port.

Figure 2-7. PIM Master Top Panel Layout: 2-Port

1. Indicator Light for RF On (Red)

2. PIM Test Connector, 7/16 DIN, female, 50 Ω

3. VNA RF Out Connector, Type-N, female, 50 Ω (Option 331)

4. Port 2 Out Connector, 4.3-10, female, 50 Ω (Option 703)

5. Port 2 Return Connector, Type SMA, female, 50 Ω (Option 703)

6. Strap Bracket (not shown), 2x

Port 2 Out Connector (item 4 in Figure 2-7)

VNA RF Out Connector, 4.3-10, female, 50 ohms (Option 703). This test port is available only

on instruments with 2-Port LTE Option 703. It is used to perform Return Loss, VSWR, Cable

Loss, and Distance-to-Fault (DTF) measurements. Hand tighten this connection. Do not use a

wrench.

Port 2 Return Connector (item 5 in Figure 2-7)

Port 2 Return Connector, SMA, female, 50 ohms (Option 703). This test port is available only

on instruments with 2-Port LTE Option 703. Hand tighten this connection. Do not use a

wrench.

Note Use care to use all wrenches in such a way that the rigid cable is not impacted.

2-10 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-7 Side Panel Connectors

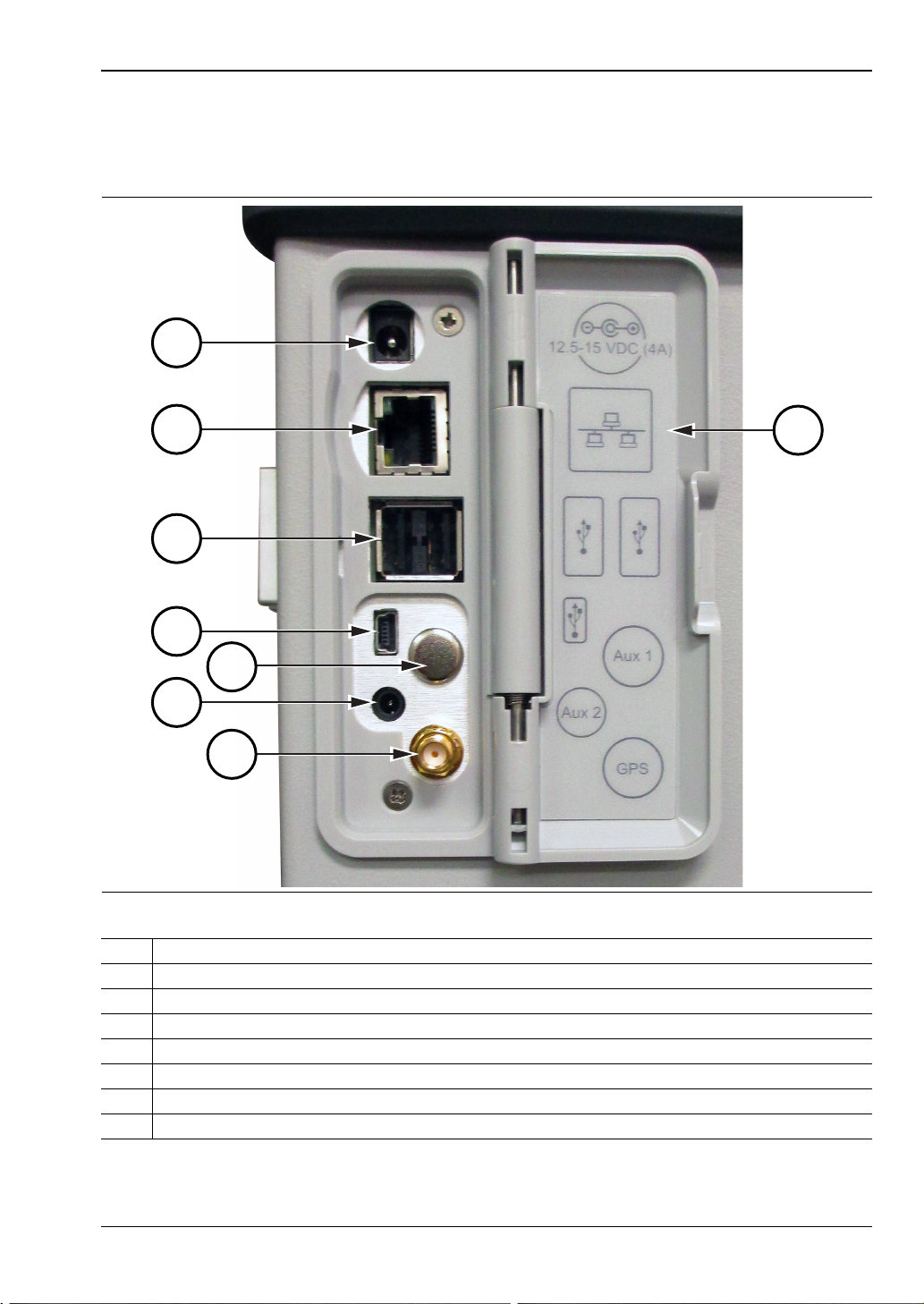

7

5

1

3

2

4

6

8

2-7 Side Panel Connectors

The side connector panel includes connectors for External Power, Ethernet/LAN, USB

interface, and GPS.

Figure 2-8. PIM Master Side Panel Overview

1. External Power

2. LAN Connection, RJ45

3. USB Interface, Type A

4. USB Interface, 5-pin mini-B

5. Auxiliary 1 (factory use only)

6. Auxiliary 2 (factory use only)

7. GPS Connector, SMA female (with Option 31)

8. Legend (icons identify connection types)

MW82119B UG PN: 10580-00400 Rev. N 2-11

2-7 Side Panel Connectors Chapter 2 — PIM Master Overview

External Power (item 1 in Figure 2-8)

This 2.1 mm by 5.5 mm barrel connector is used to power the unit and for battery charging.

Input is 12 VDC to 15 VDC at up to 5.0 A.

When using the AC-DC Adapter, always use a three-wire power cable that is

Warning

connected to a three-wire power line outlet. If power is supplied without grounding

the equipment in this manner, then the user is at risk of receiving a severe or fatal

electric shock.

LAN Connection (item 2 in Figure 2-8)

The RJ45 connector is used to connect the PIM Master to a local area network. Integrated

into this connector are two LEDs. The amber LED shows the presence of a 10 Mbit/s LAN

connection when on, and a 100 Mbit/s LAN connection when off. The green LED flashes to

show that LAN traffic is present. For additional information about the LAN connection,

Ethernet connection, and DHCP, refer to Appendix F, “LAN and DHCP”.

USB Interface – Type A (item 3 in Figure 2-8)

This interface has two connectors for flash drive and USB Power Sensor. The MW82119B

PIM Master can also be a USB Host and allow various USB Flash Memory devices to be

connected to the instrument for storing measurements, setups, files, and firmware upgrades.

Either USB connection can be used with a USB power sensor (but only one power sensor at a

time).

USB Interface – Type Mini-B (item 4 in Figure 2-8)

The USB 2.0 interface can be used to connect the MW82119B PIM Master directly to a PC for

data transfer. The first time the PIM Master is connected to a PC, the normal USB device

detection by the computer operating system will take place. Drivers are available for

Windows XP (or later).

Note

For proper detection, Line Sweep Tools should be installed on the PC prior to

connecting the PIM Master to the USB port.

GPS Antenna Connector (Option 31) (item 7 in Figure 2-8)

The GPS antenna connection on the PIM Master is type SMA(F). Selectable +3 VDC or

+5 VDC antenna power.

To prevent damage to your instrument, do not use pliers or a plain wrench to tighten the

SMA connector. Do not overtighten the connector. The recommended torque is 8 lbf·in

(0.9 N·m or 90 N·cm).

2-12 PN: 10580-00400 Rev. N MW82119B UG

Chapter 2 — PIM Master Overview 2-8 Measurement Display Overview

Date/Time GPS Battery Indicator

Measurement Title Area

Main Graph Area

Submenu

Keys

Main Menu Keys

Numerical Measurement Result Area

Instrument

Settings

Summary

2-8 Measurement Display Overview

Throughout this manual, typical measurement displays are shown for the basic measurement

modes of the PIM Master. Note that the images shown in this manual may be different from

any images that are displayed on your PIM Master.

Front Panel Display Areas

Figure 2-9. Front Panel Overview

MW82119B UG PN: 10580-00400 Rev. N 2-13

2-8 Measurement Display Overview Chapter 2 — PIM Master Overview

Main Menu Keys

The PIM Master menu-driven interface is easy to use and requires little training. The five

Main Menu keys are located below the measurement display. These five keys are used to

display the function-specific menus in the active menu (submenu labels). These Main Menu

keys vary in function based on the selected mode of operation (Shift, Mode (9)) or

measurement type within a mode. Refer to “Mode Selector Menu” on page 2-20 for more

information on changing the instrument mode. Table 2-1 lists from left to right the Main

Menu Key labels for each mode of instrument operation.

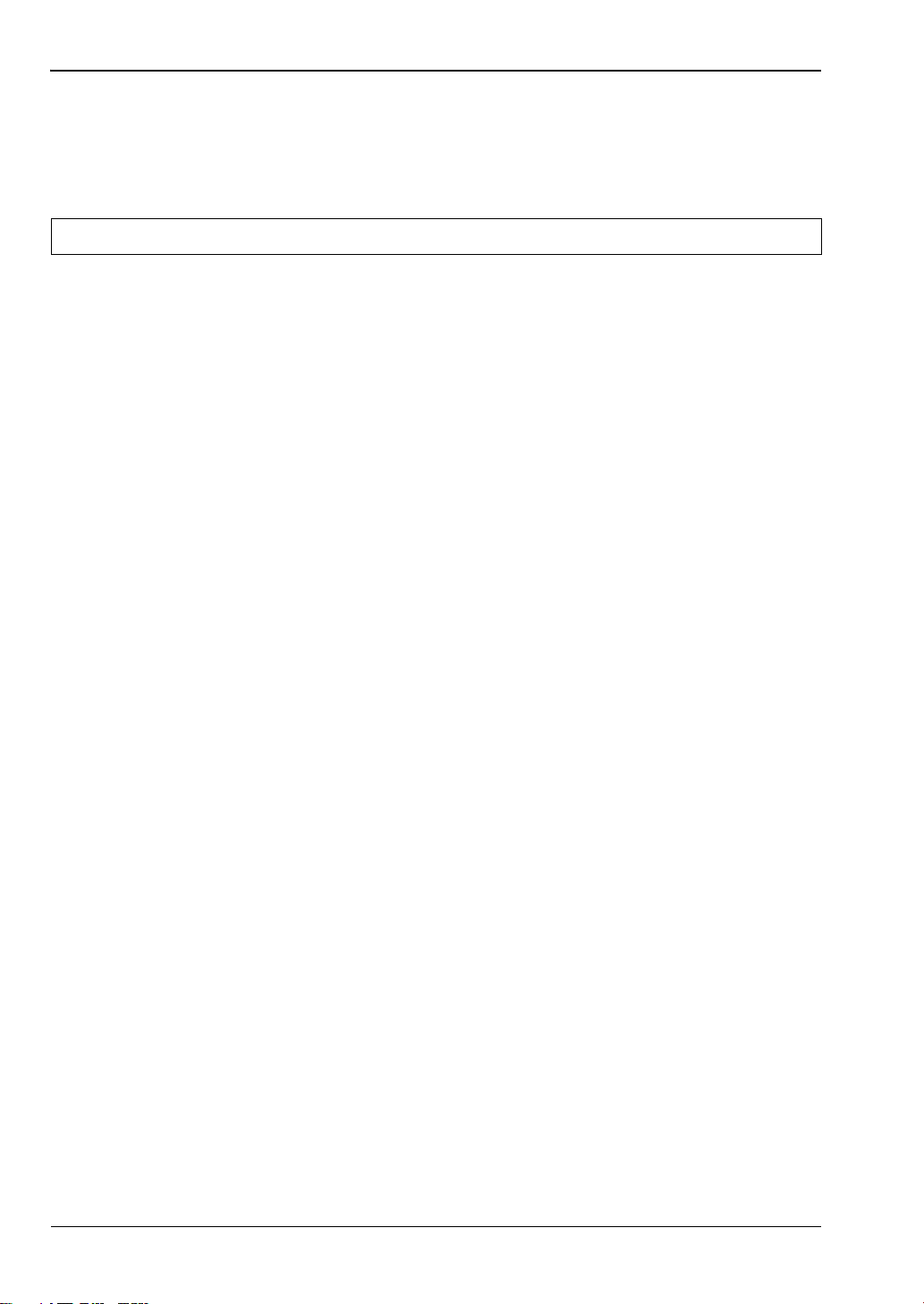

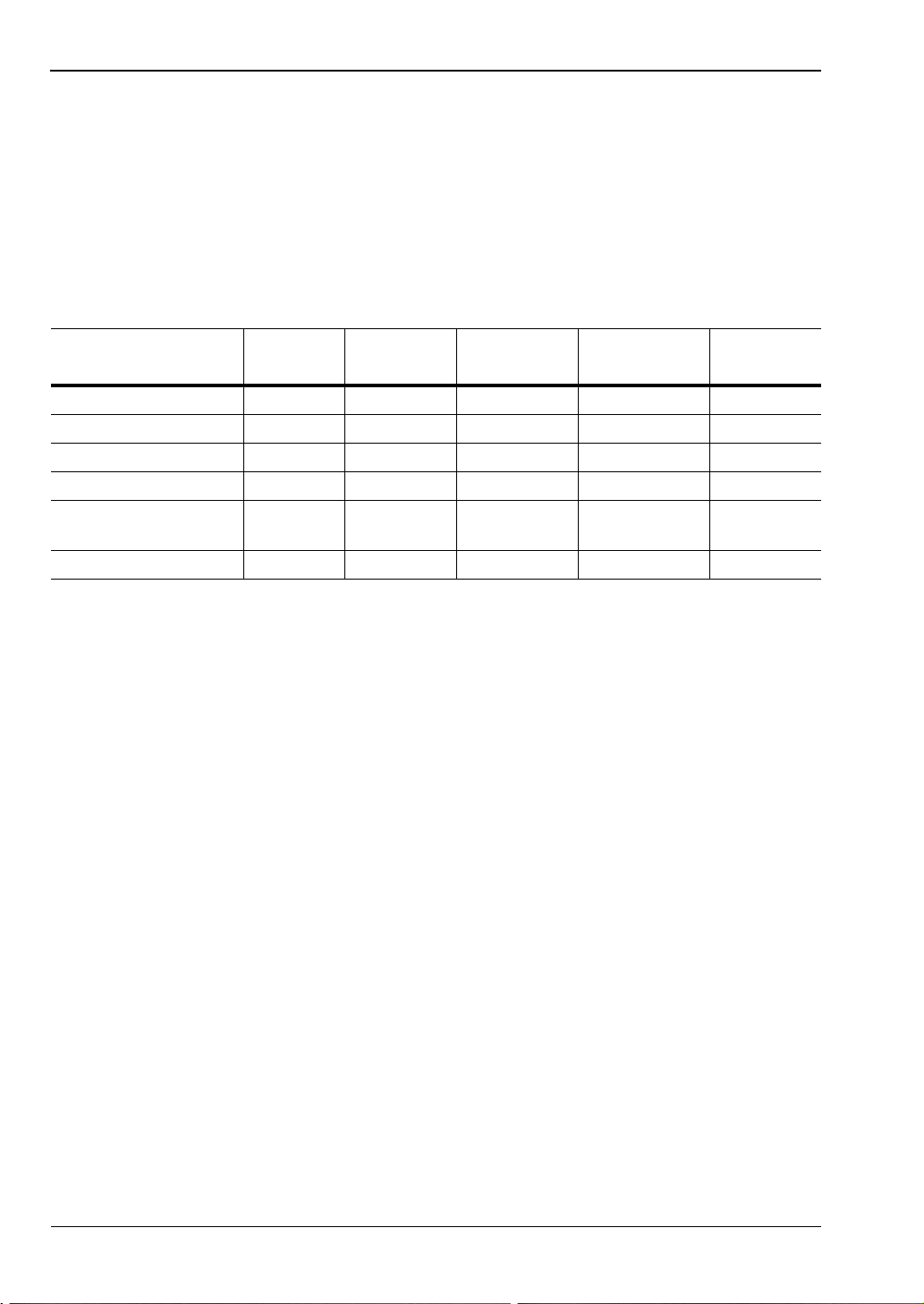

Tab le 2-1. Mode-Dependent Main Menu Keys Located at Bottom of Measurement Display

Mode/Measurement

Type Key 1 Key 2 Key 3 Key 4 Key 5

PIM vs. Time Freq Amplitude Setup Measurements Marker

Noise Floor Freq Amplitude Setup Measurements Marker

DTP Distance Amplitude Setup Measurements Marker

Swept PIM Freq Amplitude Setup Measurements Marker

High Accuracy

Power Meter

Cable & Antenna Freq/Dist Amplitude Sweep/Setup Measurements Marker

a

Amplitude Average Zero/Cal Limit

a.If High Accuracy Power Meter (option 19) is installed.

Submenu Keys

The eight submenu keys are located to the right of the measurement display. They change

function depending upon the current mode and current menu selection. The current submenu

title is shown at the top of the active function block (submenu key labels). For an example,

refer to item 6 in Figure 2-10 on page 2-15.

2-14 PN: 10580-00400 Rev. N MW82119B UG

Loading...

Loading...