AEG Thyro-S H1 User Manual

Operating Instructions

Ethernet Bus Module ProfiNet

•Thyro-S ...H1, ..HRL1

•Thyro-A ...H1, ..HRL1, ..HRLP1

•Thyro-A …C01, ..C02, ..C03, ..C05, ..C07

•Thyro-Power Manager

•Thyro-Step Controller

•Thyro-Measurement Unit

PERFECT IN FORM AND FUNCTION

Contents

1. |

Introduction |

5 |

1.1 |

General |

5 |

1.2 |

Special features |

5 |

1.3 |

Type designation |

5 |

1.4 |

Abbreviations |

5 |

1.5 |

Warranty |

5 |

2. |

Safety |

6 |

2.1 |

Identification in the operating instructions |

6 |

2.2 |

General danger information |

6 |

2.3 |

Operator requirements |

7 |

2.4 |

Personnel requirements |

7 |

2.5 |

Intended use |

7 |

2.6 |

Use of the device |

7 |

2.6.1 |

Operation |

7 |

2.6.2 |

Prior to installation / commissioning |

8 |

2.6.3 |

Maintenance, service, faults |

8 |

2.6.4 |

Transport |

8 |

3. |

Functions |

9 |

3.1 |

Processing the setpoint Thyro-S |

9 |

3.2 |

Processing the setpoint Thyro-A |

9 |

3.3 |

Processing the setpoint Thyro-Step Controller |

10 |

3.4 |

Freely addressable digital outputs |

10 |

4. |

Installation |

11 |

4.1 |

Connection terminals (overview) |

11 |

4.2 |

Connecting a 24 V power supply |

11 |

4.3 |

Connecting the power controller to X1-X8 |

11 |

4.4 |

Connecting the Ethernet bus module to the master |

11 |

5. |

Settings |

12 |

5.1 |

Setting the protocol |

12 |

5.2 |

Setting the number of slots |

12 |

5.3 |

Setting the device name |

12 |

5.4 |

Operating display of the bus module |

13 |

6. |

Operation |

14 |

6.1 |

Start configuration (parameterization) |

14 |

6.2 |

Cyclical data transmission (configuration) |

14 |

6.3 |

Input and output data Thyro-S |

14 |

6.4 |

Input and output data Thyro-A |

16 |

6.5 |

Input and output data Thyro-Power Manager |

23 |

6.6 |

Input and output data Thyro-Step Controller |

24 |

6.7 |

Input and output data Thyro Input / Output Unit |

24 |

6.8 |

Input and output data ThyroMeasurerment Unit |

25 |

6.9 |

Acyclic data transmission (parameterization) |

26 |

7. |

External connections |

27 |

7.1 |

Power supply |

27 |

7.2 |

Operating elements and terminal blocks |

28 |

8. |

Interfaces |

29 |

8.1 |

System interface |

29 |

8.2 |

Ethernet interface |

29 |

2

9. |

Connection diagrams Thyro-A |

30 |

10. |

Connection diagrams Thyro-S |

31 |

11. |

Connection diagrams Thyro-Step Controller |

32 |

12. |

Specific notes |

33 |

12.1 |

Installation |

33 |

12.2 |

Service |

33 |

13. |

Technical Data |

33 |

14. |

Dimension drawings |

34 |

15. |

Accessories and options |

34 |

16. |

Approvals and conformity |

34 |

17. |

Appendix A Acyclic parameter tables |

36 |

List of figures and tables

Fig. 1 |

|

Configuration & LED displays |

12 |

Fig. 2 |

|

Connection diagram Thyro-A |

30 |

Fig. 3 |

|

Connection diagram Thyro-S |

31 |

Fig. 4 |

|

Connection diagram TSC |

32 |

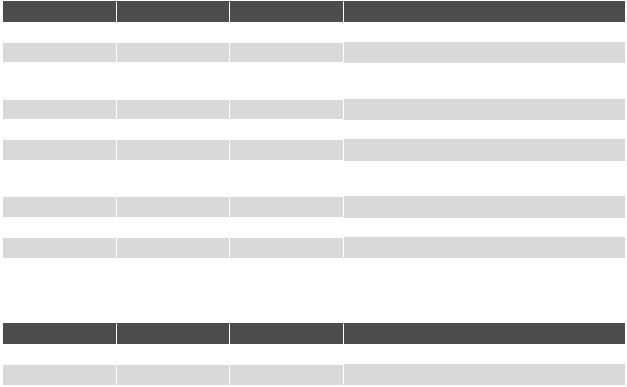

Tab. |

1 |

Connecting terminals (overview) |

11 |

Tab. |

2 |

Operating display of the bus module |

13 |

Tab. |

3 |

Interpretation of the master setpoint for Thyro-S |

15 |

Tab. |

4 |

Cyclic input and output data for Thyro-S…H1 |

15 |

Tab. |

5 |

Cyclic input and output data for Thyro-S…HRL1 |

15 |

Tab. |

5b |

Thyro-S Status / Faults |

15 |

Tab. |

6 |

Cyclic input and output data for Thyro-A 1A…H1 |

16 |

Tab. |

7 |

Cyclic input and output data for Thyro-A 1A…HRL1 |

16 |

Tab. |

8 |

Cyclic input and output data for Thyro-A 1A…HRLP1 |

17 |

Tab. |

9 |

Cyclic input and output data for Thyro-A 2A…H1 |

17 |

Tab. 10 |

Cyclic input and output data for Thyro-A 2A…HRL1 |

17 |

|

Tab. 11 |

Cyclic input and output data for Thyro-A 2A…HRLP1 |

18 |

|

Tab. 12 |

Cyclic input and output data for Thyro-A 3A…H1 |

18 |

|

Tab. 13 |

Cyclic input and output data for Thyro-A 3A…HRL1 |

19 |

|

Tab. 14 |

Cyclic input and output data for Thyro-A 3A…HRLP1 |

19 |

|

Tab. 14b |

Thyro-A Status / Fault |

20 |

|

Tab. 15 |

Cyclic input and output data for Thyro-A 1A…C01 |

21 |

|

Tab. 16 |

Cyclic input and output data for Thyro-A 1A…C02 |

21 |

|

Tab. 17 |

Cyclic input and output data for Thyro-A 1A…C03 |

21 |

|

Tab. 18 |

Cyclic input and output data for Thyro-A 1A…C05 |

22 |

|

Tab. 19 |

Cyclic input and output data for Thyro-A 1A…C07 |

22 |

|

Tab. 20 |

Supported operating modes |

22 |

|

Tab. 21 |

Cyclic input and output data TPM automatic mode |

23 |

|

Tab. 22 |

Cyclic input and output data TPM manual mode |

23 |

|

Tab. 23 |

Cyclic input and output data TSC mode |

24 |

|

Tab. 24 |

Cyclic input and output data TIO mode |

24 |

|

Tab. 25 |

Cyclic input and output data TMU mode |

25 |

|

Tab. 25b |

TPM, TSC, TIO,TMU Status / Faults |

25 |

|

3

Contact

Technical queries

Do you have any technical queries regarding the subjects dealt with in these operating instructions? If so, please get in touch with our team for power controllers:

Tel. +49(0)2902 763-520 or +49(0)2902 763-290

Commercial queries

Do you have any commercial queries on power controllers? If so, please get in touch with our team for power controllers.

Tel. +49 (0)2902 763-591 or +49 (0)2902 763-558

Service-Hotline

Our team is at your service on the following hotline:

AEG Power Solutions GmbH

Emil-Siepmann-Strase 32

D-59581 Warstein

Tel. +49 (0)2902 763-100

http://www.aegps.de

Copyright

No part of these operating instructions may be transmitted, reproduced and/or copied by any electronic or mechanical means without the express prior written permission of AEG Power Solutions.

© Copyright AEG Power Solutions GmbH 2010. All rights reserved.

Further information on copyright

Thyrois an international registered trademark of AEG Power Solutions GmbH. Windows and Windows NT are registered trademarks of the Microsoft Corporation.

All other company and product names are (registered) trademarks of the respective owners.

4

1. Introduction

The operating instructions below serve only as an addition to be used in conjunction with the operating instructions of the AEG Power Solutions Thyro-A power controller, Thyro-S power switch, and ThyroPower Manager in the versions of the types indicated on the covering page. The safety instructions contained therein are to be observed in particular.

1.1 General

The Ethernet bus module can connect up to 8 power controllers of type Thyro-A and type Thyro-S with a master in any desired order.

Several bus modules can be used on one system.

The power supply of the bus module comes from an external 24V DC voltage source (150mA), which is to be fed in (reverse polarity protected) at X11.1 (+) and X11.2 (ground). Several modules can be operated from one power supply.

As short a ground connection as possible is needed at terminal X11.3 for EMC reasons.

1.2Special features

•The Ethernet bus module connects the devices with several Ethernet bus systems. By setting the “Protocol” switch to 0, the Ethernet bus module becomes a ProfiNet IO-device.

•function control via LED

•8 free application outputs X1 to X8 in each case terminal 5

•C-rail assembly

1.3Type designation

Ethernet bus module ProfiNet order-no. 2000 000 846

1.4 Abbreviations

AEG PS |

AEG Power Solutions GmbH |

TPM |

Thyro – Power Manager |

TSC |

Thyro – Step Controller |

TMU |

Thyro – Measurement Unit |

TIO |

Thyro Input / Output Unit |

1.5 Warranty

In the event of any claims in connection with the Ethernet bus module, please contact us quoting:

•type designation

•fabrication number / serial number

•reason for the complaint

•environmental conditions of the device

•operating mode

•period of use

Goods and services are subject to the general conditions of supply for products of the electrical industry, and our general sales conditions. Claims in connection with supplied goods must be submitted within one week of receipt, along with the delivery note. AEG PS will rescind all obligations such as warranty agreements, service contracts, etc. entered into by AEG PS or its representatives without prior notice if maintenance and repair work is carried out using anything other than original AEG PS spare parts or spare parts purchased from AEG PS.

5

2. Safety

2.1 Identification in the operating instructions

In these operating instructions, there are warnings before dangerous actions. These warnings are divided into the following danger categories:

DANGER

Dangers that can lead to serious injuries or fatal injuries.

WARNING

Dangers that can lead to serious injuries or considerable damage to property.

CAUTION

Dangers that can lead to injuries and damage to property.

CAUTION

Dangers that can lead to minor damage to property.

The warnings can also be supplemented with a special danger symbol (e.g. „Electric current“ or „Hot parts“) , e.g.

risk of electric current or

risk of electric current or  risk of burns

risk of burns

In addition to the warnings, there is also a general note for useful information.

NOTE

Content of note

2.2 General danger information

DANGER

Not adhering to the safety stipulations in the operating instructions of the power controllers used can lead to danger of injury / danger of damaging the device or system.

> Adhere to all safety stipulations in the chapter “Safety” of the operating instructions of the power controllers being used.

DANGER

Electric current

Risk of injury from current carrying parts / danger of damaging the bus module.

>Never operate the device without the covering.

>Undertake settings and wiring without current being supplied

CAUTION

Danger of damaging the bus module

The current at terminals X1.5 to X8.5 must not exceed 120 mA. > Check the connection information of the preceding relay.

6

NOTE

Communication errors

To avoid communication errors please note the following points:

>Use shielded cables.

>Undertake grounding of the bus module (X1.7 to X8.7). Do not ground additionally at the power controller.

2.3Operator requirements

The operator must ensure the following:

-The safety regulations of the operating instructions are observed.

-The accident prevention regulations valid in the respective country of use and the general safety regulations are observed.

-All safety devices (covers, warning signs etc.) are present, in perfect condition and are used correctly.

-The national and regional safety regulations are observed.

-The personnel has access to the operating instructions and safety regulations at all times.

-The operating conditions and restrictions resulting from the technical data are observed.

-Should abnormal voltages, noises, increased temperatures, vibration or similar occur, the device is immediately put out of operation and the maintenance personnel is informed

2.4Personnel requirements

Only qualified electro-technical personnel who are familiar with the pertinent safety and installation regulations may perform the following:

-transport

-installation

-connection

-commissioning

-maintenance

-testing

-operation

These operating instructions must be read carefully by all persons working with or on the equipment prior to installation and initial start-up

2.5 Intended use

The device may only be used for the purpose for which it was intended, as persons may otherwise be exposed to dangers (e.g. electric shock, burns) and plants also (e. g. overload). The user must therefore observe the following points:

-It is not permitted to make any unauthorized modifications to the unit or to use any spare parts or replacement parts not approved by AEG PS, or to use the unit for any other purpose.

-The warranty obligations of the manufacturer are only applicable if these operating instructions are observed and complied with.

-The device is a component that cannot function alone.

-Project planning must account for the proper use of the device.

2.6Use of the device

2.6.1Operation

-Only switch on the mains voltage at the device when there is no danger to persons, system or load.

-Protect the device against dust and damp.

-Ensure that the ventilation openings are not blocked.

7

2.6.2Prior to installation / commissioning

-If stored in a cold environment: ensure that the device is absolutely dry. (Allow the device a period of at least two hours to acclimatize before commissioning)

-Ensure sufficient ventilation of the cabinet if mounted in a cabinet.

-Observe minimum spacing.

-Ensure that the device cannot be heated up by heat sources below it. (see page 33, Technical data).

-Ground the device in accordance with local regulations.

-Connect the device in accordance with the connection diagrams.

2.6.3Maintenance, service, faults

In order to avoid personal and material damages, the user must observe the following:

-Before all work:

>Disconnect the device from all external voltage sources.

>Secure the device against accidentally being switched back on.

>Use suitable measuring instruments and check that there is no voltage present.

>Ground and short circuit the device.

>Provide protection by covers or barriers for any neighboring live parts.

-The device may only be serviced and repaired by trained electro-technical personnel.

2.6.4Transport

-Only transport the device in the original packaging.

-Protect the device against damage, caused by jolts, knocks and contamination, for instance.

8

3. Functions

3.1 Processing the setpoint Thyro-S

Only local setpoints, no bus setpoint

Switching signal (24DC) at the control terminal X22.1 of the Thyro-S > No wiring of the terminal point X22.4 at the power controller

-The bus module is fully functional. The analog signal from the control terminal X22.1 is used as setpoint (on/off).

Setpoint from the bus module (X22.3), no local setpoint

> Connect the ground to terminal X22.4 of the power controller.

-The master setpoint of the bus module is used. For this purpose the setpoint is interpreted as the operating mode.

Bus setpoint, switching over to „local“ in case of bus fault

Only use the setpoint of the bus module if there is an IO connection.

> Connect terminal X22.4 of the power controller to one of the terminals X1.1 to X8.1 of the bus module. - If there is an IO connection the master set point is used.

If not then the analog signal from the control terminal X22.1 is used as setpoint (on/off).

Switching over to bus / local setpoint switchable for each controller in operation

Individual setpoint from the bus module for each power controller.

>Connect terminal X22.4 of the power controller to one of the terminals X1.5 to X 8.5 of the bus module.

-The power controllers can be switched over individually (targeted) via the bus between master setpoint and terminal X22.1

3.2Processing the setpoint Thyro-A

Only local setpoints, no bus setpoint

Analog input at control terminal X2.4 of Thyro-A

> Do not connect anything to terminal X22.1 of the power controller.

-The bus module is fully functional. The analog signal from the control terminal X2.4 is used as setpoint (on/off).

Setpoint from the bus module (X22.3), no local setpoint

> Connect the ground to terminal X22.1 of the power controller. - The master setpoint of the bus module is used.

Bus setpoint, switching over to “local” in case of bus fault

Only use the setpoint of the bus module if there is an IO connection.

> Connect terminal X22.1 of the power controller to one of the terminals X1.1 to X8.1 of the bus module.

-If there is an IO connection the master setpoint is used. If there is no IO connection then the analog signal from the control terminal X2.4 is used as setpoint.

Switching over to bus / local setpoint switchable for each controller in operation Individual setpoint from the bus module for each power controller.

> Connect terminal X22.1 of the power controller to one of the terminals X1.5 to X8.5 of the bus module.

-The power controllers can be switched over individually (targeted) via the bus between master setpoint and terminal X2.4.

9

3.3 Processing the setpoint Thyro-Step Controller

Only local setpoints, no bus setpoint

Analog input at control terminal X6.1 or X6.4 (depending on X6.7) of the TSC > Do not connect anything to terminal X2.1 of the power controller.

-The bus module is fully functional. The analog signal from the control terminal X6.1 or X6.4 is used as setpoint.

Setpoint from the bus module (X22.3), no local setpoint > Connect the ground to terminal X2.1 of the TSC.

- The master setpoint of the Ethernet bus module is used.

Bus setpoint, switching over to “local” in case of bus fault

Only use the setpoint of the bus module if there is an IO connection.

> Connect terminal X2.1 of the TSC to one of the terminals X1.1 to X8.1 of the bus module.

-If there is an IO connection the master setpoint is used. If there is no IO connection then the analog setpoint is used.

Switching over to bus / local setpoint value switchable for each controller in operation Individual setpoint from the bus module for each power controller.

> Connect terminal X2.1 of the power controller to one of the terminals X1.5 to X8.5 of the bus module.

-The power controllers can be switched over individually (targeted) via the bus between master setpoint and the analog setpoint.

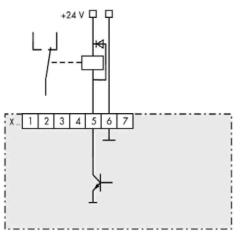

3.4Freely addressable digital outputs

>As long as the terminals X1.5 to X8.5 of the bus module are not being used for switching over the setpoint, these can be used as switch outputs.

>Connect the relay to a 24 V DC coil voltage for free use. The idle circuit is integrated. The actuating current is a maximum 120 mA per output. As a result it is possible to switch over, for example, the room ventilators, anti-condensation heating, circuit breakers or control lamps via the bus.

Relais Control

10

4. Installation

DANGER

Dangers during Installation

Risk of injury / Risk of damage to the device or plant

Observe all safety regulations in the chapter “Safety”.

4.1 Connection terminals (overview) |

||

Tab.1 Connecting terminals (overview) |

||

Terminal |

|

Description |

X11 |

.1 |

24V (+) |

|

.2 |

24V (ground) |

|

.3 |

grounding, carry out as short as possible |

X1 - X8 |

.1 |

jointly switchable ground potential |

|

.2 |

RxD |

|

.3 |

TxD |

|

.4 |

ground |

|

.5 |

separately switchable ground potential |

|

.6 |

ground |

|

.7 |

ground potential for shield connection |

Connection diagram see page 30.

4.2Connecting a 24 V power supply

>Switch off the main power supply including the external 24 V power source and make sure these cannot be accidentally switched back on again.

>Connect the external 24 V voltage supply (150 mA) to X11.1 (+) and X11.2 (-) (reverse polarity protection).

>Ground the X11.3 terminal by as short a route as possible (for EMC reasons).

REMARK

24 V DC power source

Several bus modules can be operated with one power supply.

>In cases of SELV (safety extra low voltages) do not ground the 24 V power source.

4.3Connecting the power controller to X1-X8

>Switch off the main power supply including the external 24 V power source and make sure these cannot be accidentally switched back on again.

>Connect the interfaces X1 to X8 of the bus module to the system interfaces of the power controller (shielded four-wire cable)

Attention: To control all parameters by ProfiNet we recommend closing the Thyro-A switches S1.3, S1.4, S1.5 (Thyro-Tool Mode).

4.4 Connecting the Ethernet bus module to the master

The Ethernet bus module has two Ethernet ports which are equipped with a switch functionality which allows a line topology to be constructed.

A standard patch cable is required for connecting with a switch. For a direct connection (line topology) a cross-over cable is required.

11

5. Settings

5.1 Setting the protocol

The Ethernet bus module supports various real time Ethernet bus systems. The desired system can be selected using the rotary switch “Protocol”. For ProfiNet this needs to be set to 0.

5.2 Setting the number of slots

The number of devices which are connected to the Ethernet bus module is set with the rotary switch “Slots”. After switching on, the Ethernet bus module reads all the parameters of the device. Following this it starts communicating.

Attention: To change the number of slots when switched on, the switch “Slots” must first be turned to 0. Communication with the master is then interrupted. Following this the desired number can be set. After leaving the position 0 you have about 2 seconds time for this.

5.3 Setting the device name

Every IO device is identified by its device name. The setting of the device name can be undertaken using, for example, the program “Step 7 – HW Config” in the menu “Target system / Ethernet / Edit Ethernet participant…”

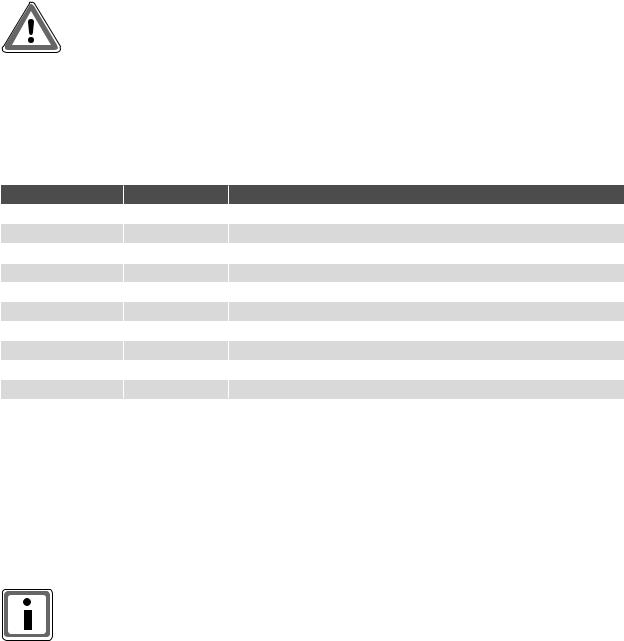

Fig. 1 Configuration & LED displays

1 |

Terminal X1 |

10 |

Terminal X11 |

2 |

Terminal X2 |

11 SYS LED |

|

3 |

Terminal X3 |

12 |

COM0 (BF) LED |

4 |

Terminal X4 |

13 |

COM1 (SF) LED |

5 |

Terminal X5 |

14 |

Fault LED |

6 |

Terminal X6 |

15 |

Switch Slots |

7 |

Terminal X7 |

16 |

Switch Protocol |

8Terminal X8

9Ethernet Port

12

5.4 Operating display of the bus module

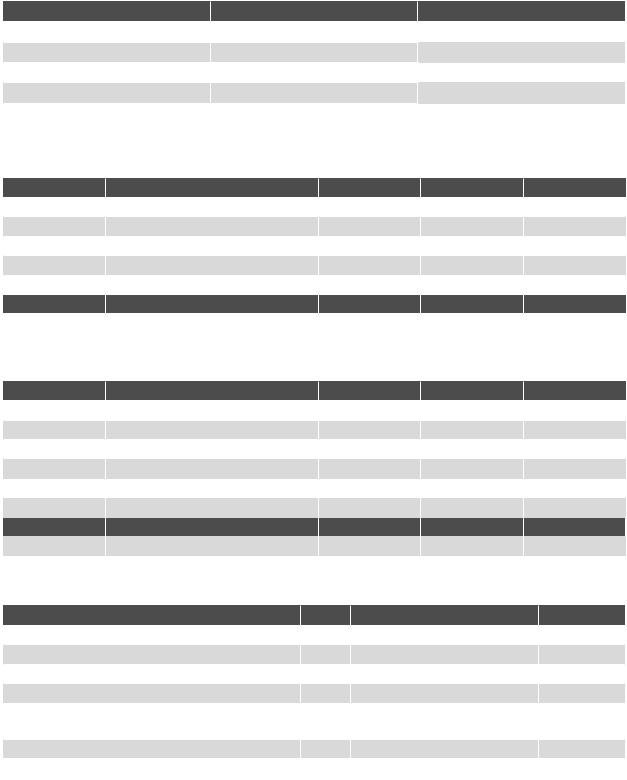

Table 2 Operating display of the bus module

LED |

Color |

Status |

Meaning |

SYS |

Green |

On |

Operating system running |

|

Red |

Flashing with 1Hz |

Error in boot process |

|

Red |

On |

Waiting for boot process (check position of |

|

|

|

“Protocol” switch) |

|

|

Off |

No supply voltage |

COM0 (BF) |

Red |

On |

No physical connection |

|

Red |

Flashing with 2Hz |

No data exchange |

|

|

Off |

The device is exchanging data with the ProfiNet IO |

|

|

|

Controller |

COM1 (SF) |

Red |

On |

Watchdog time out or system error |

|

|

Off |

No error |

Fault |

Red |

On |

Hardware error |

Operating status of the Ethernet bus module

LED |

Color |

Status |

Meaning |

Link |

Green |

On |

There is an Ethernet connection |

Activity |

Yellow |

On |

Data are being exchanged via Ethernet |

Status LED of the Ethernet Ports

13

6. Operation

6.1 Start configuration (parameterization)

Via the parameterization (in step 7 – HW Config, double-click on slot 0 of the bus module, parameter tab) the following settings can be undertaken.

No connection (slot 1-8):

Here you can set what should happen with the output data of the devices if the connection to the master is interrupted.

Hold last values |

The output data are not changed. |

Outputs = 0 |

The output data are set to 0 |

No connection (slot 9):

Here you can set what should happen with the output data of the bus module if the connection to the master is interrupted.

Hold last value |

The digital outputs are not changed. |

Outputs = 0 |

The digital outputs are set to 0. |

Averaging of the measured values:

Here you can enter the number of actual values which flow into the averaging. A new value is calculated once a second. Values from 0-20 can be entered, whereby 0 or 1 deactivates this function.

Remove device when it is switched off:

Not all devices are equipped with a 24 V supply connection. When switching off the Thyro mains supply and the control voltage supply (24V) the Thyro no longer communicates with the bus modules. A switched off device will normally be displayed as pull. This display can be suppressed here.

Deactivate |

Devices which are no longer accessible (no communication) will continue to |

|

be displayed as plug. |

Activate |

Devices which are no longer accessible will be displayed as pull. |

Use output data:

The suppression of certain output data can be activated here.

Always |

New output data are transferred immediately. |

Only when Bit is set |

New output data are only transferred, if the Bit 0 is set in the output |

|

“Functions” |

6.2 Cyclical data transmission (configuration)

The configuration of the cyclical data traffic is undertaken by adding modules.

The input and output data depend on the device types. The following tables show the input and output data available for each of the devices.

6.3 Input and output data Thyro-S

With the Thyro-S the setpoint is interpreted as operating mode.

14

Tab. 3 Interpretation of the master setpoint with Thyro-S

Setpoint (Master) |

Status (return value) |

(Total setpoint) |

0 to 409 |

= OFF |

0 = |

410 to 1091 |

1/5 |

819 |

1092 to 1706 |

= 1/3 |

1365 = |

1707 to 3071 |

1/2 |

2047 |

3072 to 4096 |

= ON |

4096 |

Tab. 4 Cyclic input and output data with Thyro-S |

..H1 |

|

|

|

Offset |

Input data, actual values |

Data type |

Size |

Unit |

0 |

Load voltage L1 |

float |

4 |

[V] |

4 |

Mains voltage L1 |

integer |

2 |

[V] |

6 |

Total setpoint |

integer |

2 |

4096=100% |

8 |

Fault (see table 5b) |

integer |

2 |

- |

10 |

Status (see table 5b) |

integer |

2 |

- |

Offset |

Output data, setpoint |

Data type |

Size |

Unit |

0 |

Master Setpoint |

integer |

2 |

4096=100% |

Tab. 5 Cyclic input and output data with Thyro-S ..HRL1

Offset |

Input data, actual values |

Data type |

Size |

Unit |

0 |

Load voltage L1 |

float |

4 |

[V] |

4 |

Load current L1 |

float |

4 |

[A] |

8 |

Mains voltage L1 |

integer |

2 |

[V] |

10 |

Total setpoint |

integer |

2 |

4096=100% |

12 |

Fault (see table 5b) |

integer |

2 |

- |

14 |

Status (see table 5b) |

integer |

2 |

- |

Offset |

Output data, setpoint |

Data type |

Size |

Unit |

0 |

Master setpoint |

integer |

2 |

4096=100% |

Tab. 5b Thyro-S Faults

Description |

Bit |

LEDs |

Relay |

Frequency measurement outside of 47 Hz to 63 Hz |

Bit 0 |

Test LED flashing slowly |

open |

SYNC error, no zero-crossing within the gate |

Bit 1 |

Test LED flashing slowly |

open |

Temperature monitoring triggered |

Bit 2 |

Load Fault flashing slowly |

open |

Load fault |

Bit 3 |

Load Fault on |

open |

Flash values invalid |

Bit 4 |

Test LED and Load Fault LED |

open |

|

|

flashing simultaneously quickly |

|

Mains undervoltage (<AD_P_SPG_MIN) |

Bit 5 |

Load Fault LED and Test LED on |

open |

Mains overvoltage (>AD_P_SPG_MAX) |

Bit 6 |

None |

closed |

15

Loading...

Loading...