Actron CP7605 User Manual [en, es]

requerimiento para el buen funcionamiento y facilidad de manejo del motor.

2.Ajustes de la inyección de combustible - Algunos sistemas de inyección de combustible tienen un ajuste de autoridad mínimo y máximo que se debe comprobar durante la puesta a punto periódica o cuandoquiera que se encuentre algún problema con la velocidad en vacío.

3.Pruebas misceláneas del motor - Muchos de

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 9999 Walford Avenue, Cleveland, Ohio 44102, warrants to the user that this unit will be free from defects in materials and workmanship for a period of one (1) year from thedateoforiginalpurchase.Anyunitthatfailswithin this period will be repaired without charge when returned to the Factory. Actron requests that a copy of the original, dated sales receipt be returned with the unit to determine if the warranty period is still in effect. This warranty does not apply to damages caused by accident, alterations, or improper or unreasonable use. Expendable items, such as batteries, fuses, lamp bulbs, flash tubes also are excluded from thescopeofthiswarranty.ACTRONMANUFACTURING COMPANYDISCLAIMSANYLIABILITYFORINCIDENTAL ORCONSEQUENTIALDAMAGESFORBREACHOFANY WRITTEN WARRANTY ON THE UNIT. Some states do not allow the disclaimer of liability for incidental or consequential damages, so the above disclaimer may not apply to you. This warranty gives specific legal rights, and you may also have rights which vary from state to state.

©1996, Actron Manufacturing Company

Sunpro is a registered trademark of Sun Electric Corporation and is used under exclusive license.

2-219301

los procedimientos de prueba indicados en el manual de servicio del motor requieren que el motor funcione a una velocidad específica durante la prueba. Este instrumento proporciona excelentes capacidades de monitoreo para este propósito.

GARANTIA COMPLETA DE UN AÑO

Actron Manufacturing Company, 9999 Walford Avenue,

Cleveland,Ohio44102,EE.UU.,garantizaalusuarioqueesta unidad estará libre de defectos de materiales y mano de obra por un (1) año a partir de la fecha de compra del comprador original. Cualquier unidad que falle dentro de este período será reparada opción de Actron sin cargo cuando seregresealafábrica.Actronrequierequeuncomprobante de compra (recibo de venta) fechado acompañe la unidad para determinar si está en garantía. Esta garantía no es aplicable a daños causados por accidente, alteraciones, usos impropios o no razonables. Artículos consumibles, tales como baterías, fusibles, lámparas y tubos de destello quedan excluidos de esta garantía. Actron Manufacturing

Company rechaza cualquier responsabilidad de daños incidentales o indirectos por incumplimiento de cualquier garantía escrita de la unidad. Algunos estados de los

EE.UU. y ciertos países no permiten el rechazo de cualquier responsabilidad de daños incidentales o indirectos, por lo que el rechazo anterior puede no ser aplicable en su caso. Esta garantía concede derechos legales específicos y es posible que Ud. tenga otros derechos que varían de estado a estado de los EE.UU. y de país a país.

Actron Manufacturing Co.

9999 Walford Avenue

Cleveland, Ohio 44102-4696

CP7605

OPERATING INSTRUCTIONS

Dwell/Tach/Voltmeter

FOR 12 VOLT ELECTRONIC OR

CONVENTIONAL IGNITION SYSTEMS

•OPERATING INSTRUCTIONS

•SAFETY RULES

•TUNE-UP PROCEDURES

•REPAIR PARTS

Angulo de cierre/Tacómetro/Voltímetro

PARA SISTEMAS DE ENCENDIDO ELECTRONICO O CONVENCIONAL DE 12 VOLTIOS

•INSTRUCCIONES DE OPERACION

•REGLAS DE SEGURIDAD

•PROCEDIMIENTOS PARA LA PUESTA A PUNTO

•PIEZAS DE REPUESTO

Instrucciones en español — página 11

20

SAFETY GUIDELINES

TO PREVENT ACCIDENTS THAT COULD RESULT IN SERIOUS INJURY AND/OR DAMAGE TO YOUR VEHICLE OR TEST EQUIPMENT, CAREFULLY FOLLOW THESE SAFETY RULES AND TEST PROCEDURES

SAFETY EQUIPMENT

Fire Extinguisher

Never work on your car without having a suitable fire extinguisher handy. A 5-lb or larger CO2 or dry chemical unit specified for gasoline/chemical/electrical fires is recommended.

Fireproof Container

Rags and flammable liquids should be stored only in fireproof, closed metal containers. A gasolinesoaked rag should be allowed to dry thoroughly outdoors before being discarded.

Safety Goggles

We recommend wearing safety goggles when working on your car, to protect your eyes from battery acid, gasoline, and dust and dirt flying off moving engine parts.

NOTE:Neverlookdirectlyintothecarburetorthroat while the engine is cranking or running, as sudden backfire can cause burns.

LOOSE CLOTHING AND LONG HAIR (MOVING PARTS)

Beverycarefulnottogetyourhands,hairorclothes near any moving parts such as fan blades, belts and pulleys or throttle and transmission linkages. Never wear neckties or loose clothing when working on your car.

JEWELRY

Never wear wrist watches, rings or other jewelry when working on your car. You’ll avoid the possibility of catching on moving parts or causing an electrical short circuit which could shock or burn you.

VENTILATION

Thecarbonmonoxideinexhaustgasishighlytoxic. To avoid asphyxiation, always operate vehicle in a well-ventilatedarea.Ifvehicleisinanenclosedarea, exhaust should be routed directly to the outside via leakproof exhaust hose.

SETTING THE BRAKE

Make sure that your car is in Park or Neutral, and that the parking brake is firmly set.

NOTE: Some vehicles have an automatic release on the parking brake when the gear shift lever is removed from the PARK position. This feature must be disabled when it is necessary (for testing) to have the parking brake engaged when in the

DRIVEposition.Refertoyourvehicleservicemanual for more information.

HOT SURFACES

Avoid contact with hot surfaces such as exhaust manifoldsandpipes,mufflers(catalyticconverters), radiator and hoses. Never remove the radiator cap while the engine is hot, as escaping coolant under pressure may seriously burn you.

SMOKING AND OPEN FLAMES

Never smoke while working on your car. Gasoline vapor is highly flammable, and the gas formed in a charging battery is explosive.

BATTERY

Do not lay tools or equipment on the battery. Accidentallygroundingthe“HOT”batteryterminalcan shock or burn you and damage wiring, the battery or your tools and testers. Be careful of contact with battery acid. It can burn holes in your clothing and burn your skin or eyes.

When operating any test instrument from an auxiliary battery, connect a jumper wire between the negative terminal of the auxiliary battery and ground on the vehicle under test. When working in a garage or other enclosed area, auxiliary battery should be located at least 18 inches above the floor to minimize the possibility of igniting gasoline vapors

HIGH VOLTAGE

High voltage — 30,000 to 50,000 volts — is present in the ignition coil, distributor cap, ignition wires and spark plugs. When handling ignition wires while the engine is running, use insulated pliers to avoid a shock. While not lethal, a shock may cause you to jerk involuntarily and hurt yourself.

JACK

The jack supplied with the vehicle should be used only for changing wheels. Never crawl under car or run engine while vehicle is on a jack.

2

VEHICLE MANUAL, SOURCES FOR SERVICE INFORMATION

The following is a list of publishers who have service manuals for your specific vehicle at nominal cost.

Write to them for availability and prices, specifying the make, style, and model year of your vehicle.

American Motors Corporation |

Buick |

OTHER SOURCESNonfactory |

|

Tuar Company |

|

||

Myriad |

Domestic and Import Cars |

||

Post Office Box 354 |

|||

8835 General Drive |

Flint, MI 48501 |

Chilton Book Company |

|

Plymouth Township, MI 48170 |

|

Chilton Way |

|

Chrysler Corporation |

Oldsmobile |

Radnor, PA 19089 |

|

Lansing Lithographers |

|

||

Dyment Distribution Service |

Cordura Publications |

||

Post Office Box 23188 |

|||

Service Publication |

Lansing, MI 48909 |

Mitchell Manuals, Inc. |

|

20770 Westwood Drive |

|

Post Office Box 26260 |

|

Strongsville, OH 44136 |

Cadillac, Chevrolet, Pontiac |

San Diego, CA. 92126 |

|

Ford Publications Department |

Helm Incorporated |

Motor’s Auto Repair Manual |

|

Post Office Box 07130 |

|||

Helm Incorporated |

Detroit, MI 48207 |

Hearst Company |

|

Post Office Box 07150 |

|

250 W. 55th Street |

|

Detroit, MI 48207 |

|

New York, NY 10019 |

IMPORTANT

THIS MANUAL PRESENTS COMPLETE HOOKUP INSTRUCTIONS FOR THE DWELL/TACH/VOLTMETER, IT ALSO DESCRIBES MANY OF THE TESTS THAT THIS INSTRUMENT IS CAPABLE OF PERFORMING AS WELL AS WHEN THEY SHOULD BE USED BASED ON VEHICLE PERFORMANCE, TUNE-UP OR TROUBLE ENCOUNTERED. CONSULT YOUR VEHICLE SERVICE MANUAL FOR SPECIFIC TUNE-UP INFORMATION AND TEST PROCEDURES. ALWAYS FOLLOW THE MANUFACTURER’S SPECIFICATIONS AND TEST PROCEDURES FOR ADJUSTING DWELL ANGLE AND IDLE SPEED, ESPECIALLY ON VEHICLES WITH MODERN ELECTRONIC IGNITION AND EMISSION CONTROLS. DO NOT ATTEMPT TO SERVICE A VEHICLE WITHOUT THE MANUFACTURER’S INSTRUCTIONS AND SPECIFICATIONS.

3

FUNCTIONS, CONNECTIONS AND ACCESSORIES

DESCRIPTION

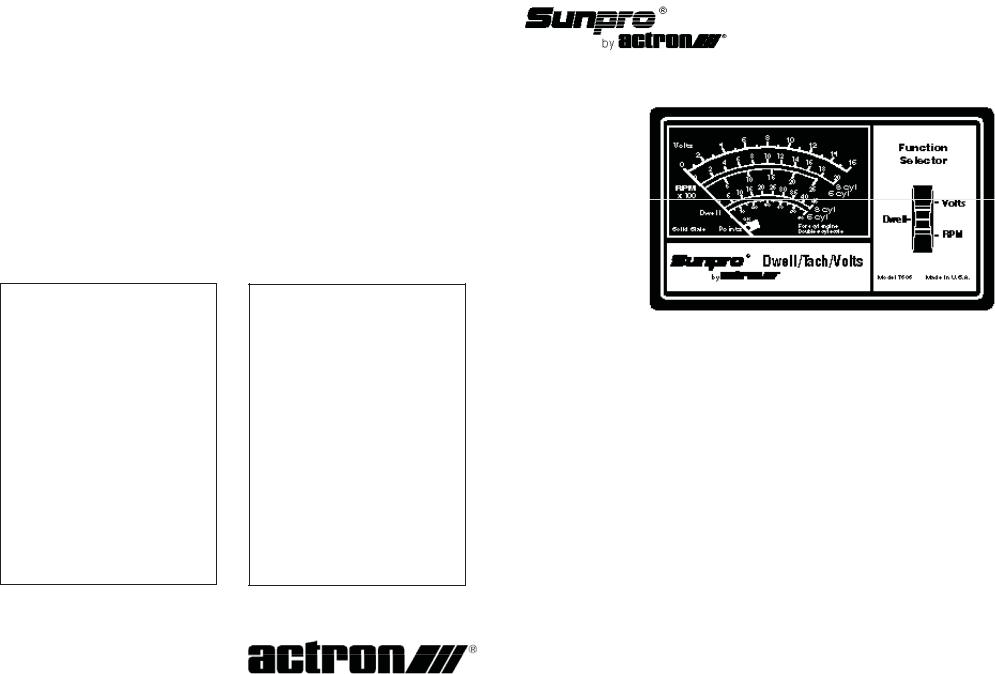

The Model CP7605 Dwell/Tach/Voltmeter has a clearlylabeledfunctionswitchandmeterasshown in the Master Hookup diagram, Figure 1 below.

1.METER

This meter displays the following scales:

• Volts |

0-16 |

• RPM |

0-2000 (8 cylinder) |

0-4000(4cylinder

– multiply

by 2) |

8 cylinder scale |

|

|

• RPM |

0-2500 (6 cylinder) |

• Dwell |

0-45 degrees (8 cylinder) |

0-90 degrees (4

cylinder–

multiply 8 cylinder by 2)

• Dwell 0-60 degrees (6 cylinder)

• Points OK/Defective

2.FUNCTION SELECTOR

This selects the RPM, Dwell, or Volts functions

of the instrument.

3.TEST LEAD

Hook this lead to the proper test point in the vehicle to perform tests as required and as described below:

VOLTAGE MEASUREMENTS

GREEN CLIP – Connect to the Positive (+) voltagesourcetobemeasured.(+Batteryterminal, alternator output terminal, lamp socket, etc.).

BLACK CLIP – Vehicle ground.

CAUTION!

Avoid connecting the BLACK CLIP to the negative(-) battery terminal or any fuel system components in the event that glasses are present which could explode from sparking connections.

DWELL/TACH/BREAKER POINT RESISTANCE MEASUREMENT

GREEN CLIP – Connect to the Tach or negative (-) ignition coil terminal. See Figures 3 through 10 for specific applications

BLACK CLIP – Vehicle Ground. See CAUTION under voltage measurements.

Fig. 1

Master Hookup Diagram

BLACK

ENGINE

GROUND

DIST. OR

TACH

GREEN

BAT.

DISTRIBUTOR

COIL

ACCESSORIES

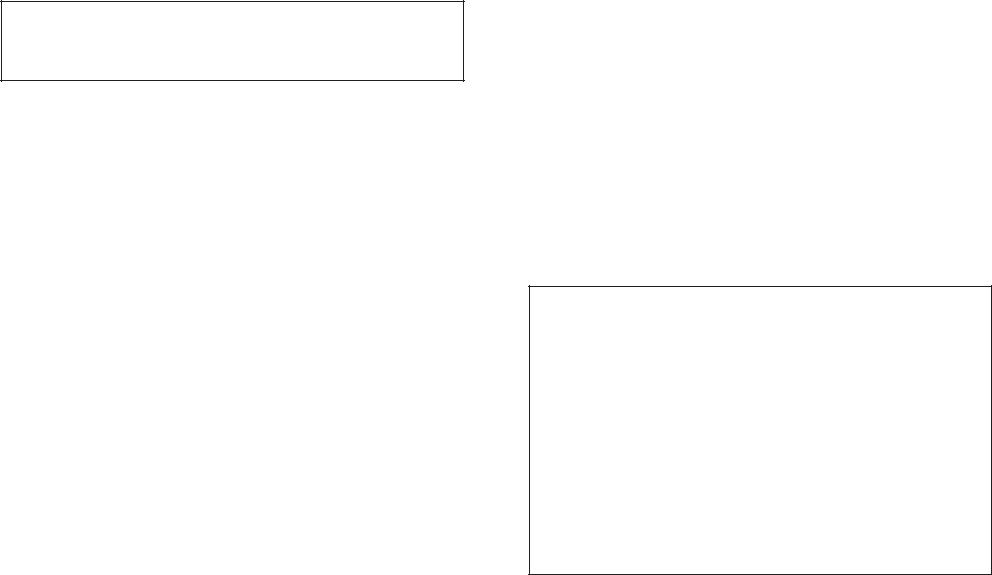

See Figure 2.

1.GM DIAGNOSTIC ADAPTOR

The GM Diagnostic Adaptor is used to make connectiontovehicleequippedwiththeGMDi- agnosticConnector,(1976–1982).Itisalsoused to make connection to Toyota vehicles which use the IIA (Integrated Ignition Assembly). See Figures 9 and 10 for adaptor application.

2.GM HEI ADAPTOR

TheGMHEIAdaptorisusedtoprovideconnection to the“TACH”terminal on GM HEI systems. See Figure 7 for typical installation.

3.FORD COIL CLIP

The Ford Coil Clip is used for ignition systems which have booted ignition coil connections. See Figure 4 for clip application.

ELECTRICAL SYSTEM TESTS – "VOLTS" POSITION

Fig. 2

Accessories

1

2

3

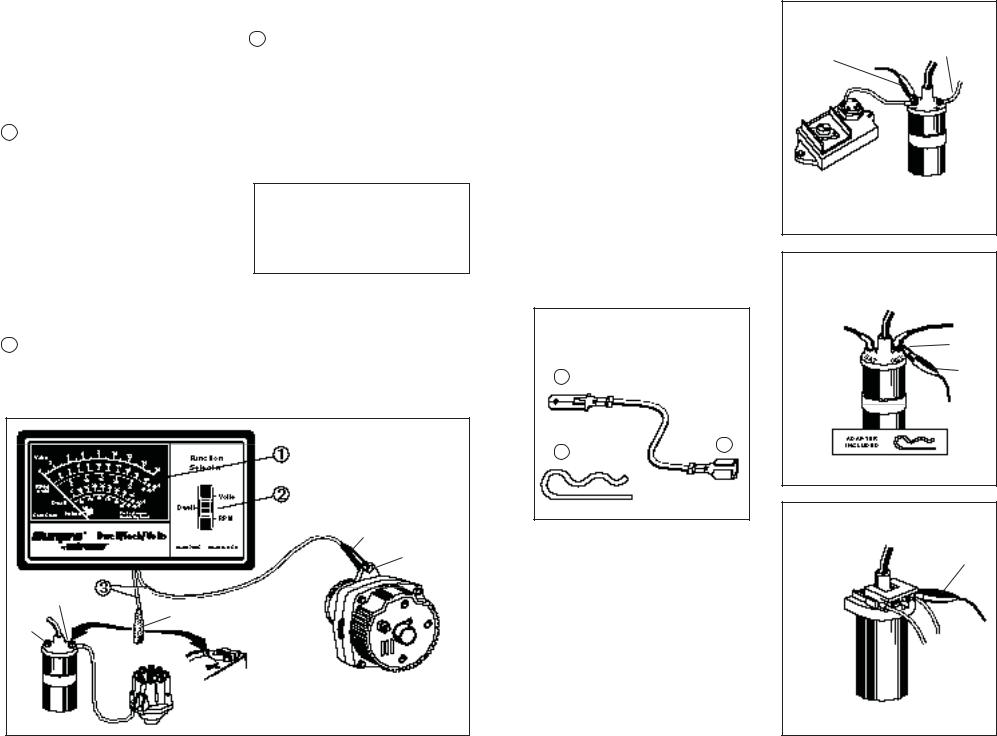

Fig. 3 Primary Tach Connection —

GREEN Clip

TO BALGREEN LAST CLIP

(BAT.)

CONTROL UNIT

TO CONTROL

UNIT

COIL

All Chrysler Corporation Electronic Ignitions, 6 & 8 cylinder shown

1972 - 1986

Fig. 4 Primary Tach/Dwell Connection –

GREEN Clip

TO IGNITION |

TO DIST. |

SWITCH |

|

|

FORD |

|

ADAPTER |

|

GREEN |

|

CLIP |

1974 Ford Electronic and All Breaker

Points Ignition Systems

Fig. 5 Primary Tach Connection —

GREEN Clip

GREEN

CLIP

Ford Solid State & Dura Spark systems 1975 - 1986

4 |

5 |

Loading...

Loading...