ABB ACS355 Technical Catalog

Low voltage AC drives

ABB machinery drives

ACS355

0.5 to 30 hp/0.37 to 22 kW

Catalog

Introduction to ACS355

ACS355 - 0XX - 0XAX - X + XXXX

ABB machinery drives

The ABB machinery drives are designed to be fast drives to

install, parameter-set and commission. Thus saving hours

of engineering work. They are highly compact and costeffective. Equipped with cutting-edge intelligence and safety

capability the drives are designed specifically to meet the

production and performance needs of system integrators,

original equipment manufacturers (OEMs) and panel builders,

as well as the requirements of end users in a broad range of

applications.

In the ABB machinery drives portfolio, ACS355 represents the

micro drive range; meeting requirements like compact size,

being optimized for a lower power range, cost-effectiveness,

and ease of use. By choosing an ABB machinery drive,

machine builders not only get all the clever things inside the

drive, but also everything outside it: the entire global ABB.

This means a full range of products and services designed to

support their business.

Contents

2 Introduction to ACS355

4 Little big drives without limiting your business

6 Typical applications

7 How to select a drive

8 Ratings and types

9 Technical data

10 Dimensions and weights

12 Cooling

13 Circuit protection

14 Control connections

15-16 Control program example

17-18 Control program variants for advanced performance

17 High speed application

18 Enhanced sequence programming

19-20 Product variants for application-specific operation

19 High protection class drive

20 Solar pump drive

21 Control program variants

22-36 Options

22 Selecting options

23 Interface

25 Software tools

28 External

36 Compact PLC and AC drive starter kit

37-38 ABB automation products

39 Life cycle services

Applications

ABB machinery drives are designed to meet the requirements

of an extensive range of machinery ap pli ca tions. The drives

are ideal for food and beverage, material handling, lifting,

textile, printing, rubber and plastics, and woodworking

applications.

Highlights

– Exceptionally compact drives and uniform design

– Quick commissioning with application macros and panel

assistants

– Safe torque off function (SIL3) as standard

– Sensorless vector control for induction motors and

permanent magnet motors up to 599 Hz

– Built-in braking chopper

– IP66 product variant for harsh environments and solar

pump drive variant available

2 ABB machinery drives ACS355 | Catalog

Catalog | ABB machinery drives ACS355 3

Little big drives without limiting your business

ACS355 drives are designed to maximize your machine’s availability with drives that are easy to install and setup.

The drive is highly modular and supports a variety of fieldbus protocols thus providing flexible connectivity. In addition

to a broad range of built-in options such as different I/O and communications, a wide selection of external accessories

is also available. Wherever your machine is located, the local ABB will be there to support you and your clients.

Flexible performance

Reduce the need for external PLC components

with built-in sequence programming providing

simple drive control logic. Improve production flow

and increase cost savings with built-in features,

such as speed compensated stop enabling

precision stopping, and patented smooth start for

permanent magnet motors.

Quick and easy commissioning

Predefined I/O configurations for application

macros and built-in assistants speed up

commissioning of the drive, allowing you to

concentrate on your business.

Compact and uniform design

Compact size, the broadest power range in

its class from 0.37 to 22 kW and side-by-side

mounting ensure optimized cabinet installation in

a wide range of machinery applications, resulting

in space and cost savings.

4 ABB machinery drives ACS355 | Catalog

Supported motor types

Same drive can be used for sensorless

induction and permanent magnet motor

control without a feedback device.

Application-specific product variants

Ensure long life time of equipment and reliable

energy supply with a drive for solar pumps including

embedded pump-specific features protecting

the pump. The high speed variant for spindle

applications provides speed controller tuning

without use of encoder.

Protection against harsh environments

Increase time and cost savings with NSF certified

product variant for IP66/67/69K, UL Type 4X

protection classes with no need to design special

enclosures for applications that require a high

ingress protection against dirt, dust and moisture.

Communication with

major automation networks

Optional fieldbus adapters enable

connectivity with major

industrial automation networks.

Remote monitoring

With a built-in web server and

stand-alone datalogger, available

remote monitoring options enables

worldwide and secure access to

drives.

Safety

Integrated safe torque off (STO) function up to

SIL 3 is a cost-effective and certified solution for

safe machine maintenance by fulfilling IEC 61508,

EN 62061 and EN ISO 13849-1 standards. The

safety function can also be used to implement

Emergency Stop without contactors.

Catalog | ABB machinery drives ACS355 5

Typical applications

Mixer

In mixing applications the drive provides a high starting

torque. The silent operation mode adjusts the switching

frequency of the drive to a higher level after the high-torque

start, resulting in lower audible noise. The FlashDrop tool

provides a quick and safe way to confi gure multiple drives for

identical mixer applications.

Conveyor

Production lines often have multiple stages, including

conveyors, which need to be efficiently linked with each other

to provide high production output. A drive provides smooth

start and stop of the conveyor, thereby reducing mechanical

stress and lowering maintenance costs.

Packaging machine

Packaging machines often require a drive to provide a high

degree of repeatability and accuracy during the packing

operation. As such, the ACS355 is well suited for packaging

duties and also provides good dynamic and static speed

control accuracy. Sequence programming enables the drive

to perform sequences of tasks, reducing the need for a PLC.

Software features include timer, counter, brake control and

jogging – all of which can be used in a packaging machine.

Bottling line

When filling the bottles with liquid, bottling lines require a drive

which offers high accuracy. The ACS355 is perfect for this

purpose, with its good dynamic and static speed control.

When dealing with liquids, the ACS355 with a high protection

class (IP66) would also be a good choice.

Winders

The ACS355 offers high static speed accuracy. When dealing

with thin strings like in string winders, it is essential to control

the winder speed accurately in order to prevent the strings

from snapping. Surface winders, on the other hand, require

high static speed accuracy to keep control of the material

thickness or tension.

6 ABB machinery drives ACS355 | Catalog

How to select a drive

It is very easy to select the right drive.

This is how you build up your own ordering code using the type designation key.

Start with identifying your supply voltage.

1

This tells you what rating table to use. See page 8.

Choose your motor’s power and current rating

2

from the ratings table on page 8.

Ratings and types

ACS355 - 03E - 02A4 - 2 + N830

Type designation

This is the unique reference number (shown above and in

column 4, right) that clearly identifies your drive by current

rating and frame size. Once the drive’s type designation has

been selected, the frame size (column 5) can be used to

determine the drive dimensions, shown on page 10.

Voltages

ACS355 is available in two voltage ranges:

2 = 200 to 240 V

4 = 380 to 480 V

Insert either “2” or “4”, depending on your chosen

construction, current rating, voltage, and option and variant

codes into the type designation shown above.

Ratings IP20/UL Open type/

[hp]

1-phase AC supply, 200 to 240 V +B063

3-phase AC supply, 200 to 240 V +B063

0.75 0.55 3.5 ACS355-03X-03A5-2 R0 R1

10.0 7.5 31.0 ACS355-03X-31A0-2 R4 -

15.0 11.0 46.2 ACS355-03X-46A2-2 R4 -

3-phase AC supply, 380 to 480 V +B063

0.75 0.55 1.9 ACS355-03X-01A9-4 R0 R1

10.0 7.5 15.6 ACS355-03X-15A6-4 R3 R3

15.0 11.0 23.1 ACS355-03X-23A1-4 R3 -

20.0 15.0 31.0 ACS355-03X-31A0-4 R4 -

25.0 18.5 38.0 ACS355-03X-38A0-4 R4 -

30.0 22.0 44.0 ACS355-03X-44A0-4 R4 -

8 ABB machinery drives ACS355 | Catalog

Type designation Frame

NEMA 1 option

P

P

I

N

N

2N

[kW]

[A]

0.5 0.37 2.4 ACS355-01X-02A4-2 R0 -

1.0 0.75 4.7 ACS355-01X-04A7-2 R1 -

1.5 1.1 6.7 ACS355-01X-06A7-2 R1 -

2.0 1.5 7.5 ACS355-01X-07A5-2 R2 -

3.0 2.2 9.8 ACS355-01X-09A8-2 R2 -

0.5 0.37 2.4 ACS355-03X-02A4-2 R0 R1

1.0 0.75 4.7 ACS355-03X-04A7-2 R1 R1

1.5 1.1 6.7 ACS355-03X-06A7-2 R1 R1

2.0 1.5 7.5 ACS355-03X-07A5-2 R1 R1

3.0 2.2 9.8 ACS355-03X-09A8-2 R2 R3

5.0 4.0 17.6 ACS355-03X-17A6-2 R2 R3

7.5 5.5 24.4 ACS355-03X-24A4-2 R3 -

0.5 0.37 1.2 ACS355-03X-01A2-4 R0 R1

1.0 0.75 2.4 ACS355-03X-02A4-4 R1 R1

1.5 1.1 3.3 ACS355-03X-03A3-4 R1 R1

2.0 1.5 4.1 ACS355-03X-04A1-4 R1 R1

3.0 2.2 5.6 ACS355-03X-05A6-4 R1 R1

5.0 4.0 8.8 ACS355-03X-08A8-4 R1 R1

7.5 5.5 12.5 ACS355-03X-12A5-4 R3 R3

size

IP20

Page 8

Select your drive’s ordering code from the rating

3

table based on your motor’s nominal power rating.

Current rating

Current rating represents the rated continuous drive output

current inside the drive specification. Motor power stated in

the table below states the typical motor power.

Variant code

This code states the factory installed SW variants to the drive.

See pages 16 - 19 for details.

Construction

“01E” within the type designation (shown above) varies

depending on the drive phase and EMC filtering. Choose

below the one you need.

01 = 1-phase

03 = 3-phase

E = EMC filter connected, 50 Hz frequency

U = EMC filter disconnected, 60 Hz frequency

,QFDVHWKHƄOWHULVUHTXLUHGLWFDQHDVLO\EHFRQQHFWHG

X within the type designation stands for E or U.

Frame

for kW = Typical motor power in 400 V at normal use

P

N

size

for hp = Typical motor power in 460 V at normal use

P

N

IP66

for A = Continuous rms current. 50% overload is allowed

I

2N

for one minute in ten minutes.

P

P

[kW]

I

N

2N

[A]

N

[hp]

1-phase AC supply, 200 to 240 V

0.5 0.37 2.4

1.0 0.75 4.7

1.5 1.1 6.7

2.0 1.5 7.5

3.0 2.2 9.8

3-phase AC supply, 200 to 240 V

0.5 0.37 2.4

0.75 0.55 3.5

1.0 0.75 4.7

1.5 1.1 6.7

2.0 1.5 7.5

3.0 2.2 9.8

5.0 4.0 17.6

7.5 5.5 24.4

10.0 7.5 31.0

15.0 11.0 46.2

3-phase AC supply, 380 to 480 V

0.5 0.37 1.2

0.75 0.55 1.9

1.0 0.75 2.4

1.5 1.1 3.3

2.0 1.5 4.1

3.0 2.2 5.6

5.0 4.0 8.8

7.5 5.5 12.5

10.0 7.5 15.6

15.0 11.0 23.1

20.0 15.0 31.0

25.0 18.5 38.0

30.0 22.0 44.0

Choose your options (on pages 20 to 29) and

4

add the option codes to drive’s ordering code.

Remember to use a “+” mark before each option code.

Options

ACS355 - 0XX - 0XAX - X + XXXX

Selecting options

The options shown in the table are available within the ACS355

range. The ordering code, which is shown in the second

Options Ordering

Protection class

Control panel

(choose one option only)

Panel mounting kit

Potentiometer

Fieldbus

(choose one option only)

Extension modules

(choose one option only)

Remote monitoring

High protection class

options

Pressure compensation

Tools

External options

= standard

= product variant

22 ABB machinery drives ACS355 | Catalog

code

*)

*)

*)

B063 IP66/IP67/UL type 4X enclosure -

J400 Assistant control panel ACS-CP-A

J404 Basic control panel ACS-CP-C -

*)

*)

J402 Potentiometer MPOT-01

K451 DeviceNet

K452 LonWorks

K454 PROFIBUS DP FPBA-01

K457 CANopen

K458 Modbus RTU FMBA-01

K462 ControlNet

K466

K469 EtherCAT

*)

K470 Etherner PowerLink FEPL-02

K473

K475

*)

*)

L502 Speed encoder module MTAC-01

L511 Relay output module MREL-01

G406 Auxiliary power extension module MPOW-01

*)

3AUA0000094517 Remote monitoring adapter NETA-21

H376 Cable gland kit (IP66/IP67/UL Type 4X) -

F278 Input switch kit (factory installed variant) -

C169 Pressure compensation valve -

*)

*)

**)

P924

*)

*)

*)

*)

N826 High speed application

N827 Solar pump drive -

N828 Low ambient start

N830 Enhanced sequence programming

= option, external

- = not available

column, replaces the XXXX in the type designation above. You

can order as many options as required, simply by extending

the code as necessary.

Description Model Availability

NEMA 1/UL type 1 (R0, R1, R2) MUL1-R1 -

NEMA 1/UL type 1 (R3) MUL1-R3 -

NEMA 1/UL type 1 (R4) MUL1-R4 -

Panel mounting kit ACS/H-CP-EXT -

Panel holder mounting kit OPMP-01 -

TM

®

®

TM

TM

1 port EtherNet/IP

, Modbus TCP,

PROFINET IO

®

RS-485/Modbus FRSA-00

TM

1 port EtherNet/IP

, Modbus TCP,

PROFINET IO

TM

2 port EtherNet/IP

, Modbus TCP,

PROFINET IO

20 pack PROFIBUS DP for machinery drives FPBA-01-M

20 pack CANopen for machinery drives FCAN-01-M

Remote monitoring adapter SREA-01

FlashDrop tool MFDT-01

DriveWindow Light DriveWindow Light

PLC and AC drive starter kit

Input chokes

EMC filters

Braking resistors

Output chokes

*)

= To be ordered as a separate item.

**)

= Available in selected countries.

Type designation:

Product series

Types and construction

Rating

Voltage

Options

FDNA-01

FLON-01

FCAN-01

FCNA-01

FENA-01

FECA-01

FENA-11

FENA-21

1)

External options not available in IP66/IP67/UL Type 4X

protection class.

ACS355

IP20

IP66/67

drive

drive

Fieldbus

K451 DeviceNet

K452 LonWorks

K454 PROFIBUS DP FPBA-01

K457 CANopen

-

Pages 22 to 36

-

-

-

1)

1)

1)

1)

3 4

0XAX XXXX

TM

FDNA-01

®

FLON-01

®

FCAN-01

X

+ 0XX

–––

Ratings and types

ACS355 - 03E - 02A4 - 2 + N830

Type designation

This is the unique reference number (shown above and in

column 4, right) that clearly identifies your drive by current

rating and frame size. Once the drive’s type designation has

been selected, the frame size (column 5) can be used to

determine the drive dimensions, shown on page 10.

Voltages

ACS355 is available in two voltage ranges:

2 = 200 to 240 V

4 = 380 to 480 V

Insert either “2” or “4”, depending on your chosen

construction, current rating, voltage, and option and variant

codes into the type designation shown above.

Ratings IP20/UL Open type/

[hp]

1-phase AC supply, 200 to 240 V +B063

0.5 0.37 2.4 ACS355-01X-02A4-2 R0 -

1.0 0.75 4.7 ACS355-01X-04A7-2 R1 -

1.5 1.1 6.7 ACS355-01X-06A7-2 R1 -

2.0 1.5 7.5 ACS355-01X-07A5-2 R2 -

3.0 2.2 9.8 ACS355-01X-09A8-2 R2 -

3-phase AC supply, 200 to 240 V +B063

0.5 0.37 2.4 ACS355-03X-02A4-2 R0 R1

0.75 0.55 3.5 ACS355-03X-03A5-2 R0 R1

1.0 0.75 4.7 ACS355-03X-04A7-2 R1 R1

1.5 1.1 6.7 ACS355-03X-06A7-2 R1 R1

2.0 1.5 7.5 ACS355-03X-07A5-2 R1 R1

3.0 2.2 9.8 ACS355-03X-09A8-2 R2 R3

5.0 4.0 17.6 ACS355-03X-17A6-2 R2 R3

7.5 5.5 24.4 ACS355-03X-24A4-2 R3 -

10.0 7.5 31.0 ACS355-03X-31A0-2 R4 -

15.0 11.0 46.2 ACS355-03X-46A2-2 R4 -

3-phase AC supply, 380 to 480 V +B063

0.5 0.37 1.2 ACS355-03X-01A2-4 R0 R1

0.75 0.55 1.9 ACS355-03X-01A9-4 R0 R1

1.0 0.75 2.4 ACS355-03X-02A4-4 R1 R1

1.5 1.1 3.3 ACS355-03X-03A3-4 R1 R1

2.0 1.5 4.1 ACS355-03X-04A1-4 R1 R1

3.0 2.2 5.6 ACS355-03X-05A6-4 R1 R1

5.0 4.0 8.8 ACS355-03X-08A8-4 R1 R1

7.5 5.5 12.5 ACS355-03X-12A5-4 R3 R3

10.0 7.5 15.6 ACS355-03X-15A6-4 R3 R3

15.0 11.0 23.1 ACS355-03X-23A1-4 R3 -

20.0 15.0 31.0 ACS355-03X-31A0-4 R4 -

25.0 18.5 38.0 ACS355-03X-38A0-4 R4 -

30.0 22.0 44.0 ACS355-03X-44A0-4 R4 -

8 ABB machinery drives ACS355 | Catalog

P

N

NEMA 1 option

[kW]

Type designation Frame

P

I

N

2N

[A]

size

IP20

Page 8

Current rating

Current rating represents the rated continuous drive output

current inside the drive specification. Motor power stated in

the table below states the typical motor power.

Variant code

This code states the factory installed SW variants to the drive.

See pages 16 - 19 for details.

Construction

“01E” within the type designation (shown above) varies

depending on the drive phase and EMC filtering. Choose

below the one you need.

01 = 1-phase

03 = 3-phase

E = EMC filter connected, 50 Hz frequency

U = EMC filter disconnected, 60 Hz frequency

,QFDVHWKHƄOWHULVUHTXLUHGLWFDQHDVLO\EHFRQQHFWHG

X within the type designation stands for E or U.

Frame

for kW = Typical motor power in 400 V at normal use

P

N

size

for hp = Typical motor power in 460 V at normal use

P

N

IP66

for A = Continuous rms current. 50% overload is allowed

I

2N

for one minute in ten minutes.

ACS355-01X-02A4-2

ACS355-01X-04A7-2

ACS355-01X-06A7-2

ACS355-01X-07A5-2

ACS355-01X-09A8-2

ACS355-03X-02A4-2

ACS355-03X-03A5-2

ACS355-03X-04A7-2

ACS355-03X-06A7-2

ACS355-03X-07A5-2

ACS355-03X-09A8-2

ACS355-03X-17A6-2

ACS355-03X-24A4-2

ACS355-03X-31A0-2

ACS355-03X-46A2-2

ACS355-03X-01A2-4

ACS355-03X-01A9-4

ACS355-03X-02A4-4

ACS355-03X-03A3-4

ACS355-03X-04A1-4

ACS355-03X-05A6-4

ACS355-03X-08A8-4

ACS355-03X-12A5-4

ACS355-03X-15A6-4

ACS355-03X-23A1-4

ACS355-03X-31A0-4

ACS355-03X-38A0-4

ACS355-03X-44A0-4

Catalog | ABB machinery drives ACS355 7

Ratings and types

ACS355 - 03E - 02A4 - 2 + N830

Type designation

This is the unique reference number (shown above and in

column 4, right) that clearly identifies your drive by current

rating and frame size. Once the drive’s type designation has

been selected, the frame size (column 5) can be used to

determine the drive dimensions, shown on page 10.

Voltages

ACS355 is available in two voltage ranges:

2 = 200 to 240 V

4 = 380 to 480 V

Insert either “2” or “4”, depending on your chosen

construction, current rating, voltage, and option and variant

codes into the type designation shown above.

Ratings IP20/UL Open type/

NEMA 1 option

P

N

[hp]

1-phase AC supply, 200 to 240 V +B063

0.5 0.37 2.4 ACS355-01X-02A4-2 R0 -

1.0 0.75 4.7 ACS355-01X-04A7-2 R1 -

1.5 1.1 6.7 ACS355-01X-06A7-2 R1 -

2.0 1.5 7.5 ACS355-01X-07A5-2 R2 -

3.0 2.2 9.8 ACS355-01X-09A8-2 R2 -

3-phase AC supply, 200 to 240 V +B063

0.5 0.37 2.4 ACS355-03X-02A4-2 R0 R1

0.75 0.55 3.5 ACS355-03X-03A5-2 R0 R1

1.0 0.75 4.7 ACS355-03X-04A7-2 R1 R1

1.5 1.1 6.7 ACS355-03X-06A7-2 R1 R1

2.0 1.5 7.5 ACS355-03X-07A5-2 R1 R1

3.0 2.2 9.8 ACS355-03X-09A8-2 R2 R3

5.0 4.0 17.6 ACS355-03X-17A6-2 R2 R3

7.5 5.5 24.4 ACS355-03X-24A4-2 R3 -

10.0 7.5 31.0 ACS355-03X-31A0-2 R4 -

15.0 11.0 46.2 ACS355-03X-46A2-2 R4 -

3-phase AC supply, 380 to 480 V +B063

0.5 0.37 1.2 ACS355-03X-01A2-4 R0 R1

0.75 0.55 1.9 ACS355-03X-01A9-4 R0 R1

1.0 0.75 2.4 ACS355-03X-02A4-4 R1 R1

1.5 1.1 3.3 ACS355-03X-03A3-4 R1 R1

2.0 1.5 4.1 ACS355-03X-04A1-4 R1 R1

3.0 2.2 5.6 ACS355-03X-05A6-4 R1 R1

5.0 4.0 8.8 ACS355-03X-08A8-4 R1 R1

7.5 5.5 12.5 ACS355-03X-12A5-4 R3 R3

10.0 7.5 15.6 ACS355-03X-15A6-4 R3 R3

15.0 11.0 23.1 ACS355-03X-23A1-4 R3 -

20.0 15.0 31.0 ACS355-03X-31A0-4 R4 -

25.0 18.5 38.0 ACS355-03X-38A0-4 R4 -

30.0 22.0 44.0 ACS355-03X-44A0-4 R4 -

P

[kW]

N

I

[A]

2N

Type designation Frame

size

IP20

Frame

size

IP66

Current rating

Current rating represents the rated continuous drive output

current inside the drive specification. Motor power stated in

the table below states the typical motor power.

Variant code

This code states the factory installed SW variants to the drive.

See pages 16 - 19 for details.

Construction

“01E” within the type designation (shown above) varies

depending on the drive phase and EMC filtering. Choose

below the one you need.

01 = 1-phase

03 = 3-phase

E = EMC filter connected, 50 Hz frequency

U = EMC filter disconnected, 60 Hz frequency

(In case the fi lter is required it can easily be connected)

X within the type designation stands for E or U.

for kW = Typical motor power in 400 V at normal use

P

N

for hp = Typical motor power in 460 V at normal use

P

N

for A = Continuous rms current. 50% overload is allowed

I

2N

for one minute in ten minutes.

8 ABB machinery drives ACS355 | Catalog

Technical data

ACS355 - 0XX - 0XAX - X + XXXX

Mains connection

Voltage and

power range

1-phase, 200 to 240 V ± 10%

0.37 to 2.2 kW (0.5 to 3 hp)

3-phase, 200 to 240 V ± 10%

0.37 to 11 kW (0.5 to 15 hp)

3-phase, 380 to 480 V ± 10%

0.37 to 22 kW (0.5 to 30 hp)

Frequency 48 to 63 Hz

Common DC connection

Voltage and

power range

230 V drives, 325 V ±15%

400/480 V drives, 540 ± 15% (common DC

manual)

P

= Pn of the drive

max

Motor connection

Voltage 3-phase, from 0 to U

SUPPLY

Frequency 0 to 599 Hz

Continuous loading

capability

(constant torque at a max.

am bi ent temperature of 40 °C)

Overload capacity

(at a max. ambient temperature

of 40 °C)

Switching frequency

Selectable

Rated output current I

1.5 x I

for 1 minute every 10 minutes

2N

At start 1.8 x I

for 2 s

2N

2N

Default 4 kHz

4 to 16 kHz with 4 kHz steps

Acceleration time 0.1 to 1800 s

Deceleration time 0.1 to 1800 s

Braking Built-in brake chopper as standard

Speed control

Static accuracy

Dynamic accuracy

20% of motor nominal slip

< 1% s with 100% torque step

Torque control

Torque step rise time

Non-linearity

< 10 ms with nominal torque

± 5% with nominal torque

Environmental limits

Ambient temperature -10 to 40 °C (14 to 104 °F), no frost allowed

50 °C (122 °F) with 10% derating

Altitude Rated current available at 0 to 1000 m.

In altitudes from 1000 to 2000 m (3300 to

13,200 ft) above sea level, the derating is

1% for every 100 m (330 ft). If the installation

site is higher than 2000 m (6600 ft) above

sea level, please contact your local ABB

distributor or offi ce for further information.

Relative humidity Lower than 95% (without condensation)

Degree of protection IP20/optional NEMA 1/UL type 1 enclosure

IP66/IP67/UL Type 4X as an option up to

7.5 kW, IP69K available for IP66/IP67 variant

with compatible cable glands

Enclosure colour NCS 1502-Y, RAL 9002, PMS 420 C

Contamination levels

IEC721-3-3

No conductive dust allowed

Transportation

Class 1C2 (chemical gas es)

Class 1S2 (solid particles)

Storage

Class 2C2 (chemical gases)

Class 2S2 (solid particles)

Operation

Class 3C2 (chemical gases)

Class 3S2 (solid particles)

Product compliance

Low Voltage Directive 2006/95/EC

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

Quality assurance system ISO 9001

En vi ron men tal sys tem ISO 14001

UL, cUL, CE, C-Tick and GOST R approvals

RoHS compliant

Programmable control connections

Two analog inputs

Voltage signal

Unipolar

Bipolar

Current signal

Unipolar

Bipolar

Potentiometer reference

value

Resolution

Accuracy

0 (2) to 10 V, R

-10 to 10 V, R

0 (4) to 20 mA, R

-20 to 20 mA, R

> 312 kΩ

in

> 312 kΩ

in

= 100 Ω

in

= 100 Ω

in

10 V ± 1% max. 10 mA, R < 10 kΩ

0.1%

± 2%

One analog output 0 (4) to 20 mA, load < 500 Ω

Auxiliary voltage 24 V DC ± 10%, max. 200 mA

Five digital inputs

12 to 24 V, PNP and NPN, programmable

DI5 0 to 16 kHz pulse train

Input impedance

2.4 kΩ

One relay output

Type

Maximum switching voltage

Maximum switching current

Maximum continuous current

NO + NC

250 V AC/30 V DC

0.5 A/30 V DC; 5 A/230 V AC

2 A rms

One digital output

Type

Maximum switching voltage

Maximum switching current

Frequency

Resolution

Accuracy

Transistor output

30 V DC

100 mA/30 V DC, short circuit protected

10 Hz to 16 kHz

1 Hz

0.2%

Serial and Ethernet communication

Fieldbuses

Refresh rate

DeviceNet

TM

Plug-in type

< 10 ms (between drive and fi eldbus module)

5-pin screw type connector, up to 500 kbit/s

baud rate

PROFIBUS DP 9-pin D-connector, up to 12 Mbit/s baud rate

PowerLink 2 pcs RJ-45 connector, 100 Mbit/s baud rate

ControlNet

CANopen

TM

®

2 pcs 8P8C modular jacks

9-pin D-connector, up to 1 Mbit/s

Modbus RTU 4-pin screw type connector, up to 115 kbit/s

baud rate

EtherNet/IPTM, Modbus

TCP, PROFINET IO

1 RJ45 connector (FENA-01 and -11) or 2

RJ45 connectors (FENA-21). 10/100Mbit/s

baud rate

LonWorks

®

3-pin screw type connector, up to 78 kbit/s

baud rate

EtherCAT

®

2 pcs RJ-45 connectors, 100 Mbit/s baud rate

Chokes

AC input chokes External option. For re duc ing THD in partial

loads and to comply with EN/IEC 61000-3-12.

AC output chokes External option. To achieve 2x longer motor

cables

Catalog | ABB machinery drives ACS355 9

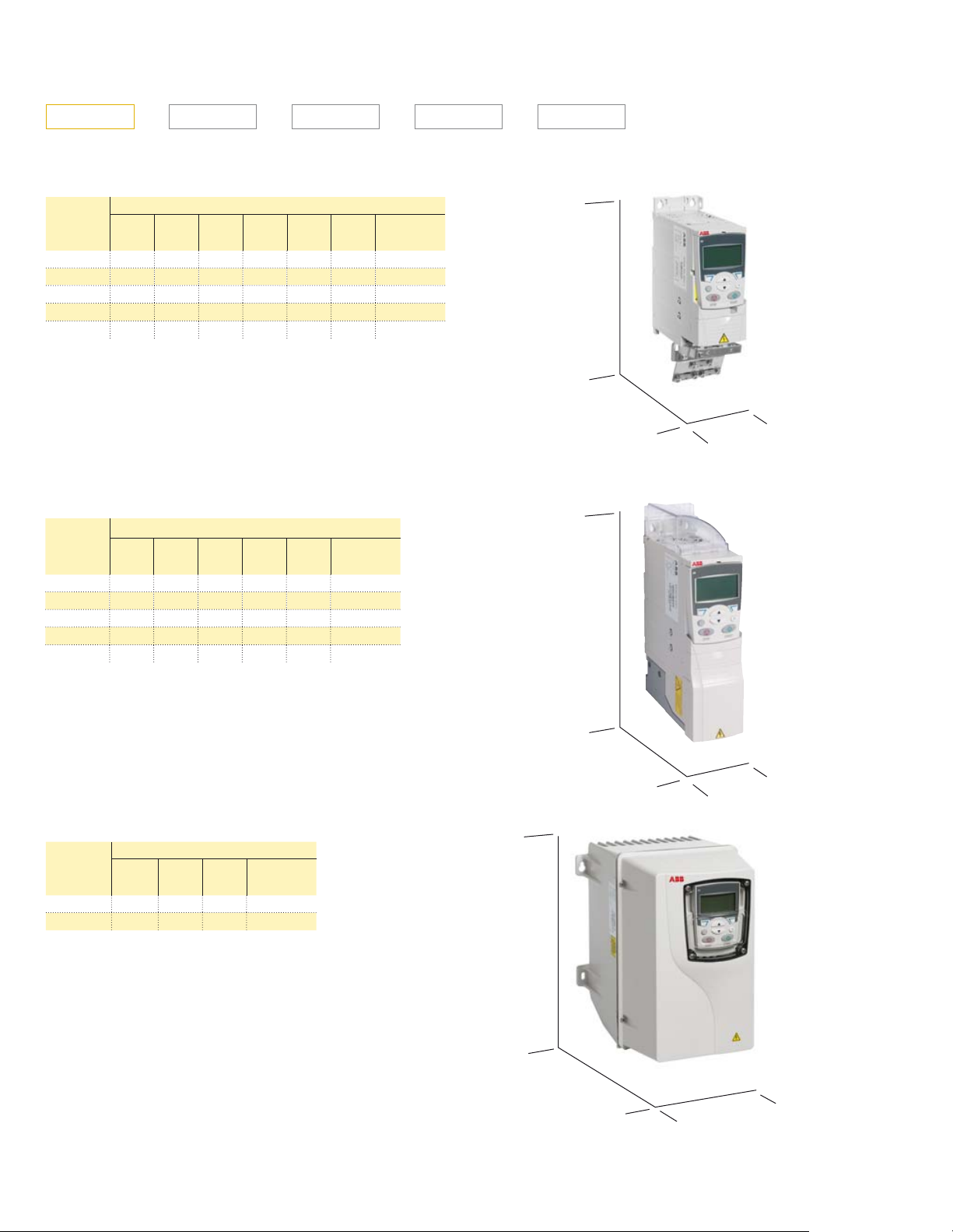

Dimensions and weights

ACS355 - 0XX - 0XAX - X + XXXX

Cabinet-mounted drives (IP20/UL Open)

Frame

size

R0 6.7 8.0 9.4 2.8 6.3 7.4 2.6

R1 6.7 8.0 9.4 2.8 6.3 7.4 2.6

R2 6.7 8.0 9.4 4.1 6.5 7.5 3.3

R3 6.7 8.0 9.3 6.7 6.7 7.7 5.5

R4 7.1 8.0 9.6 10.2 6.7 7.7 9.7

H1 = Height without fastenings and clamping plate

H2 = Height with fastenings but without clamping plate

H3 = Height with fastenings and clamping plate

W = Width

D1 = Standard depth

D2 = Depth with MREL, MPOW or MTAC option

H1inH2inH3inWinD1inD2inWeight

Wall-mounted drives (NEMA 1/UL Type 1)

Frame

size

R0 10.1 11.0 2.8 6.7 7.4 3.5

R1 10.1 11.0 2.8 6.7 7.4 3.5

R2 10.1 11.1 4.1 6.7 7.5 4.2

R3 10.2 11.8 6.7 7.0 7.7 6.8

R4 10.6 12.6 10.2 7.0 7.7 11.0

H4inH5

in

IP20/UL Open

lb

NEMA 1/UL Type 1

WinD1inD2inWeight

lb

H1

H2

H3

D1

D2

W

H4

H5

H4 = Height with fastenings and NEMA 1 connection box

H5 = Height with fastenings, NEMA 1 connection box and hood

W = Width

D1 = Standard depth

D2 = Depth with MREL, MPOW or MTAC option

Wall-mounted drives (IP66/UL Type 4X)

Frame

size

R1 12.0 7.7 11.1 16.9

R3 17.2 9.7 10.9 28.6

H = Height

W = Width

D1 = Standard depth

IP66/IP67/UL Type 4X

H

W

in

in

D

Weight

in

lb

D1

D2

H

D1

W

W

10 ABB machinery drives ACS355 | Catalog

Catalog | ABB machinery drives ACS355 11

Cooling

Cooling

ACS355 is fi tted with cooling fans as standard. The cooling

air must be free from corrosive substances and must not be

above the maximum ambient temperature of 40 °C (50 °C with

derating). Heat dissipation from IP66/IP67/UL Type 4X drive

equals to the IP20 UL Open values. For more specifi c limits see

the Technical specifi cation - Environmental limits in this catalog.

Cooling air flow

Type designation Frame

1-phase AC supply, 200 to 240 V

ACS355-01X-02A4-2 R0 48 163

ACS355-01X-04A7-2 R1 72 247 24 14

ACS355-01X-06A7-2 R1 97 333 24 14

ACS355-01X-07A5-2 R2 101 343 21 12

ACS355-01X-09A8-2 R2 124 422 21 12

3-phase AC supply, 200 to 240 V

ACS355-03X-02A4-2 R0 42 142 ACS355-03X-03A5-2 R0 54 183 ACS355-03X-04A7-2 R1 64 220 24 14

ACS355-03X-06A7-2 R1 86 295 24 14

ACS355-03X-07A5-2 R1 88 302 21 12

ACS355-03X-09A8-2 R2 111 377 21 12

ACS355-03X-17A6-2 R2 180 613 52 31

ACS355-03X-24A4-2 R3 285 975 71 42

ACS355-03X-31A0-2 R4 328 1119 96 57

ACS355-03X-46A2-2 R4 488 1666 96 57

3-phase AC supply, 380 to 480 V

ACS355-03X-01A2-4 R0 35 121 ACS355-03X-01A9-4 R0 40 138 ACS355-03X-02A4-4 R1 50 170 13 8

ACS355-03X-03A3-4 R1 60 204 13 8

ACS355-03X-04A1-4 R1 69 235 13 8

ACS355-03X-05A6-4 R1 90 306 19 11

ACS355-03X-08A8-4 R1 127 433 24 14

ACS355-03X-12A5-4 R3 161 551 52 31

ACS355-03X-15A6-4 R3 204 697 52 31

ACS355-03X-23A1-4 R3 301 1029 71 42

ACS355-03X-31A0-4 R4 408 1393 96 57

ACS355-03X-38A0-4 R4 498 1700 96 57

ACS355-03X-44A0-4 R4 588 2007 96 57

Heat dissipation Air flow

size

[W] BTU/hr

1)

m3/h ft3/min

2)

-

2)

2)

2)

2)

Free space requirements

Enclosure type Space aboveinSpace belowinSpace on left/right

in

All frame sizes 3.0 3.0 0.0

2)

-

2)

-

2)

-

2)

-

2)

-

IP66 enclosure 3.0 3.0 0.8

X within the type designation stands for E or U.

1)

BTU/hr = British Thermal Unit per hour. BTU/hr is approximately 0.293 Watts.

2)

Frame size R0 with free convection cooling.

12 ABB machinery drives ACS355 | Catalog

Circuit protection

Circuit protection

Standard fuses and manual motor protectors can be used

with ACS355 drive. See table below for selecting the correct

fuse for correct drive type.

Selection table

Type designation Frame

size

1-phase AC supply, 200 to 240 V

ACS355-01X-02A4-2 R0 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-01X-04A7-2 R1 16 gG 20 UL class T MS451-16E 11.0

ACS355-01X-06A7-2 R1 16/20

ACS355-01X-07A5-2 R2 20/25

ACS355-01X-09A8-2 R2 25/35

3-phase AC supply, 200 to 240 V

ACS355-03X-02A4-2 R0 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-03A5-2 R0 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-04A7-2 R1 10 gG 15 UL class T MS132-10 & S1-M3-25

ACS355-03X-06A7-2 R1 16 gG 15 UL class T MS451-16E 12.0

ACS355-03X-07A5-2 R1 16 gG 15 UL class T MS451-16E 12.0

ACS355-03X-09A8-2 R2 16 gG 20 UL class T MS451-16E 14.0

ACS355-03X-13A3-2 R2 25 gG 30 UL class T MS451-25E 22.0

ACS355-03X-17A6-2 R2 25 gG 35 UL class T MS451-32E 25.0

ACS355-03X-24A4-2 R3 63 gG 60 UL class T MS451-45E 41.0

ACS355-03X-31A0-2 R4 80 gG 80 UL class T MS495-63E 50.0

ACS355-03X-46A2-2 R4 100 gG 100 UL class T MS495-75E 69.0

3-phase AC supply, 380 to 415 V

ACS355-03X-01A2-4 R0 10 gG 10 UL class T MS132-2.5 & S1-M3-25

ACS355-03X-01A9-4 R0 10 gG 10 UL class T MS132-4.0 & S1-M3-25

ACS355-03X-02A4-4 R1 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-03A3-4 R1 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-04A1-4 R1 16 gG 15 UL class T MS132-10 & S1-M3-25

ACS355-03X-05A6-4 R1 16 gG 15 UL class T MS132-10 & S1-M3-25

ACS355-03X-07A3-4 R1 16 gG 20 UL class T MS451-16E 12.0

ACS355-03X-08A8-4 R1 20 gG 25 UL class T MS451-16E 14.0

ACS355-03X-12A5-4 R3 25 gG 30 UL class T MS451-20E 19.0

ACS355-03X-15A6-4 R3 35 gG 35 UL class T MS451-25E 22.0

ACS355-03X-23A1-4 R3 50 gG 50 UL class T MS451-32E 31.0

ACS355-03X-31A0-4 R4 80 gG 80 UL class T MS495-63E 52.0

ACS355-03X-38A0-4 R4 100 gG 100 UL class T MS495-63E 61.0

ACS355-03X-44A0-4 R4 100 gG 100 UL class T MS495-75E 67.0

3-phase AC supply, 440 to 480 V

ACS355-03X-01A2-4 R0 10 gG 10 UL class T MS132-2.5 & S1-M3-25

ACS355-03X-01A9-4 R0 10 gG 10 UL class T MS132-4.0 & S1-M3-25

ACS355-03X-02A4-4 R1 10 gG 10 UL class T MS132-4.0 & S1-M3-25

ACS355-03X-03A3-4 R1 10 gG 10 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-04A1-4 R1 16 gG 15 UL class T MS132-6.3 & S1-M3-25

ACS355-03X-05A6-4 R1 16 gG 15 UL class T MS132-10 & S1-M3-25

ACS355-03X-07A3-4 R1 16 gG 20 UL class T MS132-10 & S1-M3-25

ACS355-03X-08A8-4 R1 20 gG 25 UL class T MS451-16E 11.0

ACS355-03X-12A5-4 R3 25 gG 30 UL class T MS451-20E 16.0

ACS355-03X-15A6-4 R3 35 gG 35 UL class T MS451-20E 18.0

ACS355-03X-23A1-4 R3 50 gG 50 UL class T MS451-32E 26.0

ACS355-03X-31A0-4 R4 80 gG 80 UL class T MS451-45E 43.0

ACS355-03X-38A0-4 R4 100 gG 100 UL class T MS495-63E 51.0

ACS355-03X-44A0-4 R4 100 gG 100 UL class T MS495-63E 56.0

IEC fuses UL fuses Manual motor protector

3) 4)

Trip current setting

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

5)

[A]

6)

6)

Fuse

1)

type

2)

gG 25 UL class T MS451-20E 16.0

2)

gG 30 UL class T MS451-20E 17.0

2)

gG 35 UL class T MS451-25E 21.0

[A]

Fuse

type

MMP type code

1)

[A]

6.1

4.3

6.1

7.6

2.2

3.6

4.1

6.0

6.9

9.6

1.8

3.0

3.4

5.0

5.8

8.0

9.7

X within the type designation stands

for E or U.

1)

According to IEC-60269 standard.

2)

If 50% overload capacity is needed,

use the bigger fuse alternative.

3)

All manual motor protectors listed

are Type E self-protected up to 65 kA.

4)

Manual motor protectors may

require adjusting the trip limit from

the factory setting at or above the

drive input Amps to avoid nuisance

tripping. If the manual motor protector is set to the maximum current

trip level and nuisance tripping is

occurring, then select the next size

MMP. (MS132-10 is the highest size

in MS132 frame size to meet Type

E at 65 kA; the next size up is the

MS451-16E).

5)

S1-M3-25 line side feeder terminal

is needed with manual motor protector to meet Type E self protection

class according to UL and cUL

requirements.

6)

480Y/277V only.

Catalog | ABB machinery drives ACS355 13

Control connections

ACS355 - 0XX - 0XAX - X + XXXX

Application macros

Application macros are preprogrammed parameter sets. While

starting up the drive, the user typically selects one of the

macros that is best suited for the application. The diagram

below gives an overview of ACS355 control connections and

shows the default I/O connections for the ABB standard macro.

ABB machinery drives have eight application macros:

– ABB standard macro

– Torque control macro

Screen

Output frequency/speed

reference, 0 - 10 V

Analog input circuit common

Reference voltage

+10 V DC, max 10 mA

Not in use by default

Analog input circuit common

Aux. voltage output

+24 V DC, max. 200 mA

Aux. voltage output common

Digital input common

Stop/Start

Forward/Reverse

Constant speed selection

Constant speed selection

Acceler. and

PROGRAMMABLE

deceler. selection 1)

DIGITAL

INPUTS (ABB Standard

macro defaults shown)

1) DI5 can also be used

as a frequency input.

1 - 10 kohm

SCR

AI1

GND

+10 V

AI2

GND

+24 V

GND

DCOM

DI1

DI2

DI3

DI4

DI5

AI1

AI2

mA

V

AO

GND

ROCOM

RONC

RONO

DOSRC

DOOUT

DOGND

X1C:STO

OUT1

OUT2

IN1

IN2

EMC

VAR

– 3-wire macro

– Alternate macro

– AC500 Modbus macro

– Motor potentiometer macro

– Hand/auto macro

– PID control macro

In addition to the standard macros the user can create three

user macros. The user macro allows the user to save the

parameter settings for later use.

Control panel (RJ-45)

Modbus RTU (RS-232)

max 500 ohm

Output frequency 0 - 20 mA

Analog output circuit common

PROGRAMMABLE RELAY

AND DIGITAL OUTPUTS

Relay output

250 V AC / 30 V DC /2 Arms

Digital output, PNP transistor type

30 V DC, max. 100 mA

Safety Switch

EMC filter grounding screw

Varistor grounding screw

3-phase power supply

Ramp

Const

pair sel

Speed 1

Fwd /

Rev

Start /

Stop

Sinking DI configuration (NPN connected).

14 ABB machinery drives ACS355 | Catalog

ACS355: X1

+24 V

GND

DCOM

DI1

DI2

DI3

DI4

DI5

L1

L2

L3

U1

V1

Brake chopper

BRK+ BRK-

W1

U2

V2

W2

Optional brake resistor or DC power connection

AC motor

+24 V

Const

Speed 1

Fwd /

Rev

Start /

Stop

ACS355: X1

+24 V

GND

DCOM

DI1

DI2

DI3

0 V

DI4

DI5

Sourcing DI configuration (PNP connected) with external power supply.

Loading...

Loading...