Teledyne 703E User Manual

OPERATOR’S MANUAL

MODEL 703E

PHOTOMETRIC O3 CALIBRATOR

© TELEDYNE INSTRUMENTS

ADVANCED POLLUTION INSTRUMENTATION DIVISION (TAPI)

9480 CARROLL PARK DRIVE

SAN DIEGO, CALIFORNIA 92121-5201

USA

Toll-free Phone: |

800-324-5190 |

Phone: |

858-657-9800 |

Fax: |

858-657-9816 |

Email: |

api-sales@teledyne.com |

Website: |

http://www.teledyne-api.com/ |

|

05743 Rev. C |

Copyright 2007 |

DCN 5521 |

Teledyne Advanced Pollution Instrumentation |

29 July 2009 |

THIS PAGE IS INTENTIONALLY LEFT BLANK

PRINTED DOCUMENTS ARE UNCONTROLLED.

We recommend that this document be read in its entirety before any attempt is made to operate the instrument.

DOCUMENTS

Document P/N |

Revision |

DCN |

Nomenclature |

Dated |

|

|

|

|

|

05743 |

B |

5359 |

M703, Manual, Instruction - Title |

03/20/09 |

|

|

|

|

|

05744 |

B |

5359 |

M703, Manual, Instruction - Text |

03/20/09 |

|

|

|

|

|

05745 |

C |

5359 |

M703, Appendix A, Menu Tree |

03/20/09 |

|

|

|

|

|

05746 |

B |

5359 |

M703, Appendix B, Spare Parts |

03/20/09 |

|

|

|

|

|

05747 |

B |

5359 |

M703, Appendix C, Repair Form |

03/20/09 |

|

|

|

|

|

05748 |

B |

5359 |

M703, Appendix D, Schematics |

03/20/09 |

|

|

|

|

|

05834 |

F |

5359 |

List, Spare Parts, M703 |

03/20/09 |

|

|

|

|

|

05863 |

B |

5359 |

List, Recommended Spares Stocking Levels, |

03/20/09 |

|

|

|

M703 |

|

|

|

|

|

|

05834 |

J |

5480 |

List, Spare Parts, M703 |

07/15/09 |

|

|

|

|

|

05863 |

D |

5480 |

List, Recommended Spares Stocking Levels, |

07/15/09 |

|

|

|

M703 |

|

|

|

|

|

|

THIS PAGE IS INTENTIONALLY LEFT BLANK

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Safety Messages |

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided many important safety messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is associated with a safety alert symbol. These symbols are found in the manual and inside the M703E Photometric O3 Calibrator. The definition of these symbols is described below:

GENERAL SAFETY HAZARD: Refer to the instructions for details on the specific hazard.

CAUTION: Hot Surface Warning.

CAUTION: Electrical Shock Hazard.

TECHNICIAN SYMBOL: All operations marked with this symbol are to be performed by qualified maintenance personnel only.

CAUTION

The M703E Photometric O3 Calibrator should only be used for the purpose and in the manner described in this manual. If you use the M703E in a manner other than that for which it was intended, unpredictable behavior could ensue with possible hazardous consequences.

NOTE

Technical Assistance regarding the use and maintenance of the M703E or any other Teledyne Instruments product

can be obtained by:

Contacting Teledyne Instruments’ Customer Service Department at 800-324-5190 or

Via the internet at http://www.teledyne-api.com/forms

05744 Rev B |

i |

TELEDYNE API |

|

Safety Messages |

M703E Dynamic Operator’s Manual |

USER NOTES:

ii |

05744 Rev B |

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Table of Contents |

TABLE OF CONTENTS |

|

GENERAL INFORMATION....................................................................................................... |

1 |

1. INTRODUCTION .................................................................................................................. |

3 |

1.1. M703E calibrator Overview............................................................................................................................ |

3 |

1.2. Using This Manual ......................................................................................................................................... |

3 |

2. SPECIFICATIONS, APPROVALS AND WARRANTY ......................................................... |

5 |

2.1. Specifications ................................................................................................................................................. |

5 |

2.2. CE Mark Compliance ..................................................................................................................................... |

6 |

2.3. Warranty......................................................................................................................................................... |

7 |

3. GETTING STARTED ............................................................................................................ |

9 |

3.1. Unpacking and Initial Setup ........................................................................................................................... |

9 |

3.1.1. Model 703E calibrator............................................................................................................................ |

10 |

3.2. Electrical Connections ................................................................................................................................. |

13 |

3.2.1. Power Connection.................................................................................................................................. |

13 |

3.2.2. Analog output TEST CHANNEL Connections ....................................................................................... |

13 |

3.2.3. Connecting the Status Outputs.............................................................................................................. |

14 |

3.2.4. Connecting the Control Inputs ............................................................................................................... |

15 |

3.2.5. Connecting the Control Outputs ............................................................................................................ |

17 |

3.2.6. Connecting the Serial Ports ................................................................................................................... |

18 |

3.2.7. Connecting to a LAN or the Internet ...................................................................................................... |

18 |

3.2.8. Connecting to a Multidrop Network........................................................................................................ |

18 |

3.3. Pnenumatic Connections ............................................................................................................................. |

19 |

3.3.1. Dry Air In ................................................................................................................................................ |

19 |

3.3.2. Zero Air In .............................................................................................................................................. |

19 |

3.3.3. Output Manifold...................................................................................................................................... |

20 |

3.3.4. Exhaust .................................................................................................................................................. |

20 |

3.3.5. Measuring An External Ozone Source .................................................................................................. |

20 |

3.4. Initial Operation............................................................................................................................................ |

21 |

3.4.1. START-UP ............................................................................................................................................. |

21 |

3.4.2. Warm Up................................................................................................................................................ |

22 |

3.4.3. Warning Messages ................................................................................................................................ |

22 |

3.4.4. Functional Check ................................................................................................................................... |

24 |

3.4.5. Operating Modes for the O3 Generator.................................................................................................. |

25 |

3.4.5.1. CNST (CONSTANT)....................................................................................................................... |

25 |

3.4.5.2. REF (REFERENCE)....................................................................................................................... |

25 |

3.4.5.3. BNCH (BENCH) ............................................................................................................................. |

25 |

3.4.6. Setting the O3 Generator Mode............................................................................................................. |

25 |

3.4.7. Setting the M703E’s output Flow Rate .................................................................................................. |

26 |

4. FREQUENTLY ASKED QUESTIONS AND GLOSSARY .................................................. |

27 |

4.1. FAQ’s ........................................................................................................................................................... |

27 |

4.2. Glossary ....................................................................................................................................................... |

27 |

5. OPTIONAL HARDWARE AND SOFTWARE..................................................................... |

29 |

5.1. Carrying Strap Handle (OPT 29).................................................................................................................. |

29 |

5.2. Communication Options............................................................................................................................... |

30 |

5.2.1. RS232 Modem Cables (OPTs 60 and 60A) .......................................................................................... |

30 |

5.2.2. ETHERNET Cable (OPT 60B)............................................................................................................... |

30 |

5.2.3. RS-232 Multidrop (OPT 62) ................................................................................................................... |

30 |

5.2.4. Ethernet (OPT 63).................................................................................................................................. |

31 |

5.2.5. Ethernet + Multidrop (OPT 64)............................................................................................................... |

32 |

5.3. Additional Manual (OPT 70)......................................................................................................................... |

32 |

5.4. Extended Warranty (OPT 92) ...................................................................................................................... |

32 |

5.5. NIST Traceable, Primary Standard CERTIFICATION ................................................................................. |

32 |

OPERATING INSTRUCTIONS................................................................................................ |

33 |

6. OPERATING THE M703E CALIBRATOR ......................................................................... |

35 |

6.1. Test Functions.............................................................................................................................................. |

36 |

05744 Rev B |

iii |

TELEDYNE API |

|

|

Table of Contents |

M703E Calibrator Operator’s Manual |

|

6.2. Overview of Operating modes ..................................................................................................................... |

|

37 |

6.3. STANDBY Mode .......................................................................................................................................... |

|

38 |

6.4. General Information about the GENERATE mode ...................................................................................... |

|

39 |

6.4.1. GENERATE AUTO: Basic Generation of Calibration Gas................................................................ |

|

39 |

6.5. AUTOMATIC CALIBRATION SEQUENCES ............................................................................................... |

|

40 |

6.5.1. SETUP SEQ: Programming Calibration Sequences......................................................................... |

|

40 |

6.5.1.1. Activating a Sequence from the M703E Front Panel ..................................................................... |

|

41 |

6.5.1.2. Naming a Sequence....................................................................................................................... |

|

42 |

6.5.1.3. Setting the Repeat Count for a Sequence ..................................................................................... |

|

43 |

6.5.1.4. Using the M703E’s Internal Clock to Trigger Sequences............................................................... |

|

44 |

6.5.1.5. Setting Up Control Inputs for a Sequence...................................................................................... |

|

47 |

6.5.1.6. Setting Up Control Outputs for a Sequence................................................................................... |

|

48 |

6.5.1.7. Setting the PROGRESS Reporting Mode for the Sequences........................................................ |

49 |

|

6.5.2. Adding Sequence Steps ........................................................................................................................ |

|

50 |

6.5.2.1. The Generate Step ......................................................................................................................... |

|

51 |

6.5.2.2. The STANDBY Step....................................................................................................................... |

|

52 |

6.5.2.3. The DURATION Step ..................................................................................................................... |

|

52 |

6.5.2.4. The EXECSEQ Step....................................................................................................................... |

|

53 |

6.5.2.5. The CC OUTPUT Step................................................................................................................... |

|

54 |

6.5.2.6. Deleting or Editing an Individual Step in a Sequence .................................................................... |

|

55 |

6.5.3. Deleting a Sequence ............................................................................................................................. |

|

56 |

6.6. SETUP CFG ............................................................................................................................................ |

|

57 |

6.7. SETUP CLK............................................................................................................................................. |

|

58 |

6.7.1. Setting the internal Clock’s Time and Day............................................................................................. |

|

58 |

6.7.2. Adjusting the internal Clock’s speed...................................................................................................... |

|

59 |

6.8. SETUP PASS .......................................................................................................................................... |

|

60 |

6.9. SETUP DIAG TEST CHAN OUTPUT: Using the TEST Channel Analog Output............................... |

62 |

|

6.9.1. Configuring the TEST CHANNEL Analog Output.................................................................................. |

|

62 |

6.9.1.1. The Analog I/O Configuration Submenu. ....................................................................................... |

|

62 |

6.9.1.2. Selecting a Test Channel Function to Output ................................................................................ |

|

64 |

6.9.1.3. TEST CHANNEL VOLTAGE RANGE Configuration...................................................................... |

|

66 |

6.9.1.4. Turning the TEST CHANNEL Over-Range Feature ON/OFF........................................................ |

67 |

|

6.9.1.5. Adding a Recorder Offset to the TEST CHANNEL ........................................................................ |

|

68 |

6.9.2. TEST CHANNEL CALIBRATION .......................................................................................................... |

|

69 |

6.9.2.1. Enabling or disabling the TEST CHANNEL Auto-Cal Feature....................................................... |

69 |

|

6.9.2.2. Automatic TEST CHANNEL Calibration......................................................................................... |

|

70 |

6.9.2.3. Manual Calibration of the TEST CHANNEL configured for Voltage Ranges ................................. |

72 |

|

6.9.3. AIN Calibration....................................................................................................................................... |

|

74 |

6.10. SETUP MORE VARS: Internal Variables (VARS)............................................................................ |

|

75 |

6.11. Operating the M703E Calibrator as an O3 Photometer ............................................................................. |

|

77 |

6.11.1. Set up for Operating the M703E as an O3 Photometer ....................................................................... |

|

77 |

6.12. SETUP LVL: Setting up and using LEADS (Dasibi) Operating Levels ................................................. |

79 |

|

6.12.1. General Information about LEADS LEVELS ....................................................................................... |

|

79 |

6.12.2. Dot commands..................................................................................................................................... |

|

79 |

6.12.3. Levels................................................................................................................................................... |

|

80 |

6.12.4. Activating an existing LEVEL............................................................................................................... |

|

80 |

6.12.5. Programming New LEVELS ................................................................................................................ |

|

81 |

6.12.5.1. Creating a GENERATE LEVEL.................................................................................................... |

|

82 |

6.12.5.2. Creating a MANUAL LEVEL......................................................................................................... |

|

83 |

6.12.5.3. Editing or Deleting a LEVEL......................................................................................................... |

|

84 |

6.12.6. Configuring LEVEL Status Blocks ....................................................................................................... |

|

86 |

7. OPERATING THE M703E OVER THE SERIAL I/O PORTS.............................................. |

87 |

|

7.1. Using the Analyser’s Communication Ports................................................................................................. |

|

87 |

7.1.1. RS-232 DTE and DCE Communication................................................................................................. |

|

87 |

7.1.2. COMM Port Default Settings and Connector Pin Assignments............................................................. |

88 |

|

7.1.3. COMM Port Baud Rate.......................................................................................................................... |

|

90 |

7.1.4. COMM Port Communication Modes ...................................................................................................... |

|

91 |

7.1.5. COMM Port Testing ............................................................................................................................... |

|

93 |

iv |

|

05744 Rev B |

|

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Table of Contents |

|

7.1.6. Machine ID |

............................................................................................................................................. |

94 |

7.1.7. Terminal Operating Modes .................................................................................................................... |

95 |

|

7.1.7.1. Help Commands in Terminal Mode................................................................................................ |

95 |

|

7.1.7.2. Command Syntax ........................................................................................................................... |

96 |

|

7.1.7.3. Data Types ..................................................................................................................................... |

96 |

|

7.1.7.4. Status Reporting............................................................................................................................. |

97 |

|

7.1.7.5. COM Port Password Security......................................................................................................... |

98 |

|

7.2. Remote Access by Modem .......................................................................................................................... |

99 |

|

7.3. Multidrop RS-232 Set Up .......................................................................................................................... |

101 |

|

7.4. RS-485 Configuration of COM2 ................................................................................................................ |

103 |

|

7.5. Remote Access via the Ethernet............................................................................................................... |

105 |

|

7.5.1. Ethernet Card COM2 Communication Modes and Baud Rate........................................................... |

105 |

|

7.5.2. Configuring the Ethernet Interface Option using DHCP ..................................................................... |

105 |

|

7.5.2.1. Manually Configuring the Network IP Addresses........................................................................ |

108 |

|

7.5.3. Changing the Calibrator’s HOSTNAME.............................................................................................. |

110 |

|

7.6. APICOM Remote Control Program........................................................................................................... |

111 |

|

8. M703E CALIBRATION AND VERIFICATION.................................................................. |

113 |

|

8.1. Verifying and Calibrating the M703E’s O3 Photometer............................................................................. |

113 |

|

8.1.1. Setup for VERIFYING AND calibrating the O3 Photometer................................................................ |

113 |

|

8.1.1.1. Calibration Manifold Exhaust/Vent Line ...................................................................................... |

114 |

|

8.1.2. Verifying O3 Photometer Performance ............................................................................................... |

115 |

|

8.1.3. Calibrating the O3 Photometer............................................................................................................ |

116 |

|

8.1.3.1. Photometer Zero Calibration ....................................................................................................... |

116 |

|

8.1.3.2. Photometer Span Calibration ...................................................................................................... |

117 |

|

8.1.4. O3 Photometer Dark Calibration ......................................................................................................... |

118 |

|

8.2. Calibrating the O3 Generator .................................................................................................................... |

119 |

|

8.2.1. O3 Generator Calibration table........................................................................................................... |

119 |

|

8.2.2. Viewing O3 Generator Calibration Points............................................................................................ |

120 |

|

8.2.3. Adding or Editing O3 Generator Calibration Points............................................................................. |

121 |

|

8.2.4. Deleting O3 |

Generator Calibration Points ........................................................................................... |

122 |

8.2.5. Turning O3 |

Generator Calibration Points ON / OFF ........................................................................... |

123 |

8.2.6. Performing an Automatic Calibration of the O3 Generator ................................................................. |

124 |

|

8.3. M703E Gas Pressure Sensor Calibration................................................................................................. |

125 |

|

8.3.1.1. Gas Pressure Sensor Calibration Set Up.................................................................................... |

125 |

|

8.3.2. Calibrating the Regulator and Photometer Pressure Sensors ........................................................... |

127 |

|

8.4. M703E Gas Flow Calibration .................................................................................................................... |

128 |

|

8.4.1. Calibrating the Photometer’s Sample Gas Flow................................................................................. |

129 |

|

8.4.2. Calibrating the OuTput Gas Flow ....................................................................................................... |

130 |

|

8.4.2.1. Output Gas Flow Set Up ............................................................................................................. |

130 |

|

8.4.2.2. Performing an Output Gas Flow Calibration ............................................................................... |

131 |

|

TECHNICAL INFORMATION................................................................................................ |

133 |

|

9. THEORY OF OPERATION............................................................................................... |

135 |

|

9.1. Pneumatic Operation ................................................................................................................................ |

135 |

|

9.1.1. Gas Flow Control ................................................................................................................................ |

135 |

|

9.1.1.1. Flow Control Assemblies............................................................................................................. |

135 |

|

9.1.1.2. Photometer Critical Flow Orifice.................................................................................................. |

135 |

|

9.1.2. Internal Gas Pressure Sensors........................................................................................................... |

136 |

|

9.2. Electronic Operation ................................................................................................................................. |

137 |

|

9.2.1. Overview ............................................................................................................................................. |

|

137 |

9.2.2. CPU .................................................................................................................................................... |

|

138 |

9.2.2.1. Disk On Chip ............................................................................................................................... |

139 |

|

9.2.2.2. Flash Chip ................................................................................................................................... |

139 |

|

9.2.3. Relay PCA |

.......................................................................................................................................... |

140 |

9.2.3.1. Valve Control ............................................................................................................................... |

141 |

|

9.2.3.2. Heater Control ............................................................................................................................. |

141 |

|

9.2.3.3. Relay PCA Status LEDs & Watch Dog Circuitry ......................................................................... |

141 |

|

9.2.3.4. Relay PCA Watchdog Indicator (D1)........................................................................................... |

142 |

|

05744 Rev B |

v |

TELEDYNE API |

|

|

Table of Contents |

M703E Calibrator Operator’s Manual |

|

9.2.4. Motherboard........................................................................................................................................ |

|

143 |

9.2.4.1. A to D Conversion ....................................................................................................................... |

|

143 |

9.2.4.2. Sensor Inputs .............................................................................................................................. |

|

143 |

9.2.4.3. Thermistor Interface .................................................................................................................... |

|

143 |

9.2.4.4. Analog Outputs............................................................................................................................ |

|

143 |

9.2.4.5. External Digital I/O....................................................................................................................... |

|

144 |

9.2.4.6. I2C Data Bus................................................................................................................................ |

|

144 |

9.2.4.7. Power-up Circuit .......................................................................................................................... |

|

144 |

9.2.5. Power Supply and Circuit Breaker...................................................................................................... |

|

145 |

9.2.6. AC Power Configuration ..................................................................................................................... |

|

146 |

9.2.6.1. AC configuration – Internal Pump (JP7)...................................................................................... |

|

146 |

9.3. Front Panel Interface ................................................................................................................................ |

|

147 |

9.3.1.1. Calibrator Status LEDs................................................................................................................ |

|

148 |

9.3.1.2. Keyboard ..................................................................................................................................... |

|

148 |

9.3.1.3. Display......................................................................................................................................... |

|

148 |

9.3.1.4. Keyboard/Display Interface Electronics....................................................................................... |

|

149 |

9.4. Software Operation ................................................................................................................................... |

|

150 |

9.5. O3 generator operation............................................................................................................................. |

|

151 |

9.5.1. Principle of Photolytic O3 Generation ................................................................................................. |

|

151 |

9.5.2. Generator Pneumatic Operation......................................................................................................... |

|

152 |

9.5.3. O3 Generator Electronic Operation ..................................................................................................... |

|

152 |

9.5.3.1. O3 Generator Temperature Control............................................................................................. |

|

154 |

9.6. Photometer Operation............................................................................................................................... |

|

155 |

9.6.1. Measurement Method......................................................................................................................... |

|

155 |

9.6.1.1. Calculating O3 Concentration ...................................................................................................... |

|

155 |

9.6.1.2. The Measurement / Reference Cycle.......................................................................................... |

|

156 |

9.6.1.3. The Absorption Path.................................................................................................................... |

|

158 |

9.6.1.4. Interferent Rejection .................................................................................................................... |

|

158 |

9.6.2. Photometer Layout.............................................................................................................................. |

|

159 |

9.6.3. Photometer Pneumatic Operation ...................................................................................................... |

|

159 |

9.6.4. Photometer Electronic Operation........................................................................................................ |

|

160 |

9.6.4.1. O3 Photometer Temperature Control .......................................................................................... |

|

160 |

9.6.4.2. Pneumatic Sensors for the O3 Photometer ................................................................................. |

|

161 |

10. MAINTENANCE SCHEDULE & PROCEDURES .......................................................... |

|

163 |

10.1. Maintenance Schedule ........................................................................................................................... |

|

163 |

10.2. Performing Leak Checks ........................................................................................................................ |

|

167 |

10.2.1. Pressure Leak Check ....................................................................................................................... |

|

167 |

10.3. Cleaning or replacing the Absorption Tube ............................................................................................ |

|

171 |

10.4. Rebuilding the Dry Air Pump .................................................................................................................. |

|

171 |

10.5. Photometer UV Source Lamp Adjustment.............................................................................................. |

|

172 |

10.6. Photometer UV Source Lamp Replacement .......................................................................................... |

|

173 |

10.7. Adjustment or Replacement of Ozone Generator UV Lamp .................................................................. |

|

174 |

11. GENERAL TROUBLESHOOTING & REPAIR OF THE M703E CALIBRATOR ........... |

177 |

|

11.1. General Troubleshooting ........................................................................................................................ |

|

177 |

11.1.1. Fault Diagnosis with WARNING Messages...................................................................................... |

|

178 |

11.1.2. Fault Diagnosis With Test Functions ................................................................................................ |

|

180 |

11.1.3. Using the Diagnostic Signal I/O Function ......................................................................................... |

|

182 |

11.2. Using the Analog Output Test Channel .................................................................................................. |

|

183 |

11.3. Using the Internal Electronic Status LEDs.............................................................................................. |

|

184 |

11.3.1. CPU Status Indicator ........................................................................................................................ |

|

184 |

11.3.2. Relay PCA Status LEDs ................................................................................................................... |

|

184 |

11.3.2.1. I2C Bus Watchdog Status LEDs ................................................................................................ |

|

184 |

11.3.2.2. O3 Status LEDs ......................................................................................................................... |

|

185 |

11.4. Subsystem Checkout.............................................................................................................................. |

|

186 |

11.4.1. Verify Subsystem Calibration............................................................................................................ |

|

186 |

11.4.2. AC Main Power ................................................................................................................................. |

|

186 |

11.4.3. DC Power Supply.............................................................................................................................. |

|

187 |

vi |

05744 Rev B |

|

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Table of Contents |

|

11.4.4. I2C Bus .............................................................................................................................................. |

|

188 |

11.4.5. Keyboard/Display Interface............................................................................................................... |

|

188 |

11.4.6. Relay PCA ........................................................................................................................................ |

|

189 |

11.4.7. PHOTOMETER O3 Generator Pressure /FLOW SENSOR Assembly ............................................ |

|

189 |

11.4.8. Motherboard...................................................................................................................................... |

|

191 |

11.4.8.1. A/D Functions ............................................................................................................................ |

|

191 |

11.4.8.2. Test Channel / Analog Outputs Voltage.................................................................................... |

|

191 |

11.4.8.3. Status Outputs........................................................................................................................... |

|

192 |

11.4.8.4. Control Inputs ............................................................................................................................ |

|

193 |

11.4.8.5. Control Outputs ......................................................................................................................... |

|

194 |

11.4.9. CPU .................................................................................................................................................. |

|

194 |

11.4.10. RS-232 Communications................................................................................................................ |

|

195 |

11.4.10.1. General RS-232 Troubleshooting............................................................................................ |

|

195 |

11.4.10.2. Troubleshooting Calibrator/Modem or Terminal Operation..................................................... |

|

195 |

11.4.11. Temperature Problems ................................................................................................................... |

|

196 |

11.4.11.1. Box / Chassis Temperature..................................................................................................... |

|

196 |

11.4.11.2. Photometer Sample Chamber Temperature ........................................................................... |

|

196 |

11.4.11.3. UV Lamp Temperature............................................................................................................ |

|

196 |

11.4.11.4. Ozone Generator Temperature ............................................................................................... |

|

197 |

11.5. Troubleshooting the O3 photometer........................................................................................................ |

|

197 |

11.5.1. Dynamic Problems with the O3 photometer...................................................................................... |

|

197 |

11.5.1.1. Noisy or Unstable O3 Readings at Zero .................................................................................... |

|

197 |

11.5.1.2. Noisy, Unstable, or Non-Linear Span O3 Readings .................................................................. |

|

198 |

11.5.1.3. Slow Response to Changes in Concentration........................................................................... |

|

198 |

11.5.1.4. The Analog Output Signal Level Does Not Agree With Front Panel Readings......................... |

198 |

|

11.5.1.5. Cannot Zero............................................................................................................................... |

|

198 |

11.5.1.6. Cannot Span.............................................................................................................................. |

|

198 |

11.5.2. Checking Measure / REFERENCE VALVE...................................................................................... |

|

199 |

11.6. Troubleshooting the O3 Generator.......................................................................................................... |

|

200 |

11.6.1. Checking The UV Lamp Power Supply ............................................................................................ |

|

200 |

11.7. Trouble Shooting the Optional O3 generator .......................................................................................... |

|

201 |

11.7.1. Checking The UV Source Lamp Power Supply................................................................................ |

|

201 |

11.8. Repair Procedures.................................................................................................................................. |

|

202 |

11.8.1. Repairing Sample Flow Control Assembly ....................................................................................... |

|

202 |

11.8.2. Disk-On-Chip Replacement Procedure ............................................................................................ |

|

203 |

11.9. Technical Assistance .............................................................................................................................. |

|

203 |

12. A PRIMER ON ELECTRO-STATIC DISCHARGE......................................................... |

|

205 |

12.1. How Static Charges are Created............................................................................................................ |

|

205 |

12.2. How Electro-Static Charges Cause Damage ......................................................................................... |

|

206 |

12.3. Common Myths About ESD Damage ..................................................................................................... |

|

207 |

12.4. Basic Principles of Static Control............................................................................................................ |

|

207 |

12.4.1. General Rules ................................................................................................................................... |

|

207 |

12.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance ................................................. |

|

209 |

12.4.2.1. Working at the Instrument Rack ................................................................................................ |

|

209 |

12.4.2.2. Working at an Anti-ESD Work Bench........................................................................................ |

|

209 |

12.4.2.3. Transferring Components from Rack to Bench and Back......................................................... |

|

210 |

12.4.2.4. Opening Shipments from Teledyne Instruments Customer Service. ........................................ |

|

210 |

12.4.2.5. Packing Components for Return to Teledyne Instruments Customer Service.......................... |

|

211 |

05744 Rev B |

vii |

TELEDYNE API |

|

|

|

|

Table of Contents |

M703E Calibrator Operator’s Manual |

|||

LIST OF FIGURES |

|

|

||

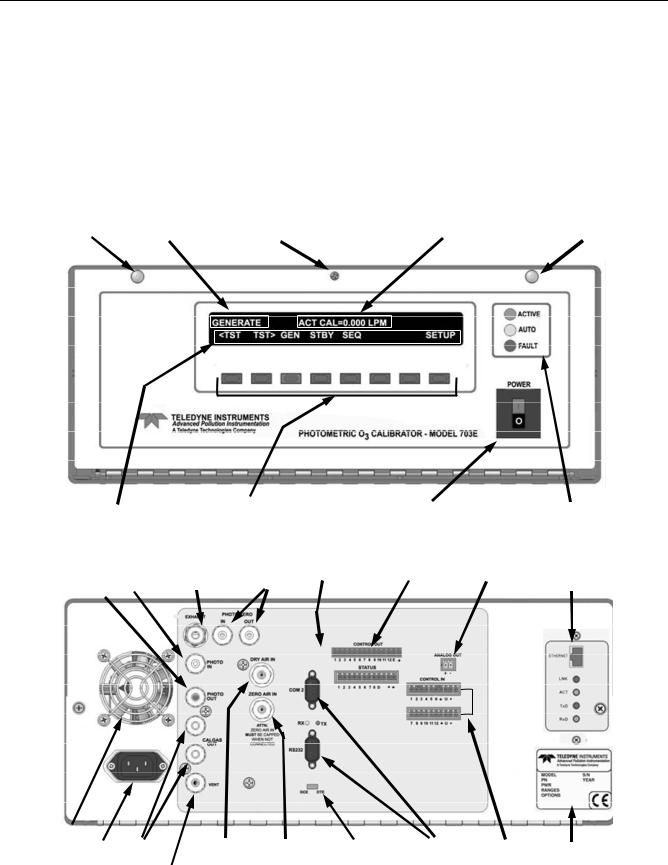

Figure 3-1: |

M703E Front Panel Layout ................................................................................................................ |

|

10 |

|

Figure 3-2: |

M703E Rear Panel Layout................................................................................................................. |

|

10 |

|

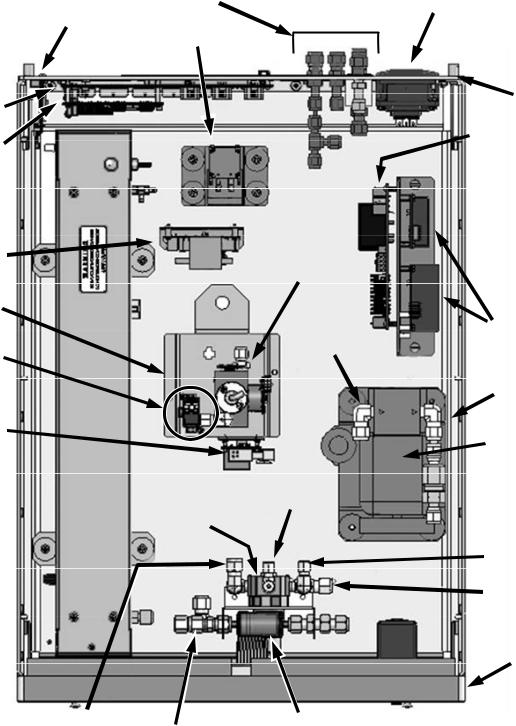

Figure 3-3: |

M703E Internal Layout – Top View ................................................................................................... |

11 |

||

Figure 3-4: |

M703E Pneumatic Diagram............................................................................................................... |

|

12 |

|

Figure 3-5: |

M703E the TEST CHANNEL Connector ........................................................................................... |

13 |

||

Figure 3-6: |

Status Output Connector ................................................................................................................... |

|

14 |

|

Figure 3-7: |

M703E Digital Control Input Connectors ........................................................................................... |

16 |

||

Figure 3-8: |

M703E Digital Control Output Connector .......................................................................................... |

17 |

||

Figure 3-9: |

Basic Pneumatic Setup of M703E ..................................................................................................... |

19 |

||

Figure 3-10: |

Location of Pressure Regulator Adjustment Knob............................................................................. |

26 |

||

Figure 5-1: |

M703E with Carrying Strap Handle and Rack Mount Brackets......................................................... |

29 |

||

Figure 5-1: |

M703E Multidrop Card....................................................................................................................... |

|

30 |

|

Figure 5-2: |

M703E Ethernet Card ........................................................................................................................ |

|

31 |

|

Figure 5-3: |

M703E Rear Panel with Ethernet Installed........................................................................................ |

31 |

||

Figure 6-1: |

Front Panel Display ........................................................................................................................... |

|

37 |

|

Figure 6-2: |

M703E the TEST CHANNEL Connector ........................................................................................... |

62 |

||

Figure 6-3: |

Setup for Calibrating the TEST CHANNEL ....................................................................................... |

72 |

||

Figure 6-4: |

Set up for Using the M703E to Measure an External O3 Source ...................................................... |

77 |

||

Figure 6-5: |

LEADS Level Display Format ............................................................................................................ |

|

85 |

|

Figure 7-1: |

Default Pin Assignments for Back Panel COMM Port connectors (RS-232 DCE & DTE) ................ |

88 |

||

Figure 7-2: |

Default Pin Assignments for CPU COM Port connector (RS-232).................................................... |

88 |

||

Figure 7-3: |

Location of JP2 on RS232-Multidrop PCA (option 62) ................................................................... |

101 |

||

Figure 7-4: |

RS232-Multidrop PCA Host/Calibrator Interconnect Diagram........................................................ |

102 |

||

Figure 7-5: |

CPU card Locations of RS-232/485 Switches, Connectors and Jumpers...................................... |

103 |

||

Figure 7-6: |

Back Panel connector Pin-Outs for COM2 in RS-485 mode.......................................................... |

104 |

||

Figure 7-7: |

CPU connector Pin-Outs for COM2 in RS-485 mode..................................................................... |

104 |

||

Figure 7-8: |

APICOM Remote Control Program Interface ................................................................................. |

111 |

||

Figure 8-1: |

Set up for Verifying Optional O3 Photometer Using Internal O3 Generator .................................... |

114 |

||

Figure 8-2: |

Set up for Verifying Optional O3 |

Photometer Using an External O3 Generator.............................. |

114 |

|

Figure 8-3: |

Pressure Calibration Monitor Points ............................................................................................... |

125 |

||

Figure 8-4: |

O3 Generator Pressure Monitor Point Physical Location– M703E ................................................. |

126 |

||

Figure 8-5: |

Output Flow Calibration Monitor Point............................................................................................ |

130 |

||

Figure 9-1: |

Location of Gas Flow Control Assemblies...................................................................................... |

135 |

||

Figure 9-2: |

M703E Electronic Block Diagram ................................................................................................... |

137 |

||

Figure 9-3: |

M703E CPU Board Annotated........................................................................................................ |

|

138 |

|

Figure 9-4: |

Relay Board PCA with AC Relay Retainer Removed..................................................................... |

140 |

||

Figure 9-5: |

Heater Control Loop Block Diagram............................................................................................... |

141 |

||

Figure 9-6: |

Status LED Locations – Relay PCA ............................................................................................... |

141 |

||

Figure 9-7: |

M703E Power Distribution Block diagram ...................................................................................... |

145 |

||

Figure 9-8: Location of the AC Configuration Jumper for the Dry Air Pump.................................................... |

146 |

|||

Figure 9-9: Pump AC Power Jumpers (JP7).................................................................................................... |

147 |

|||

Figure 9-10: |

M703E Front Panel Layout ............................................................................................................. |

|

147 |

|

Figure 9-11: |

Keyboard and Display Interface Block Diagram ............................................................................. |

149 |

||

Figure 9-12: |

Schematic of Basic Software Operation ......................................................................................... |

150 |

||

Figure 9-13: |

O3 |

Generator Internal Pneumatics.................................................................................................. |

151 |

|

Figure 9-14: |

O3 |

Generator Valve and Gas Fixture Locations ............................................................................. |

152 |

|

Figure 9-15: |

O3 |

Generator Electronic Block Diagram ......................................................................................... |

153 |

|

Figure 9-16: |

O3 |

Generator Electronic Components Location ............................................................................. |

153 |

|

Figure 9-17: |

O3 |

Generator Temperature Thermistor and DC Heater Locations................................................. |

154 |

|

Figure 9-18: |

O3 |

Photometer Gas Flow – Measure Cycle.................................................................................... |

157 |

|

Figure 9-19: |

O3 |

Photometer Gas Flow – Reference Cycle ................................................................................. |

157 |

|

Figure 9-20: |

O3 |

Photometer Absorption Path |

..................................................................................................... |

158 |

Figure 9-21: |

O3 |

Photometer Layout – Top Cover Removed............................................................................... |

159 |

|

Figure 9-22: |

O3 |

Photometer Electronic Block Diagram....................................................................................... |

160 |

|

Figure 10-2: |

Pneumatic setup for performing Pressure Leak Checks ................................................................ |

170 |

||

Figure 10-3: Photometer – Location of UV Detector Gain Adjustment & UV Lamp Set Screw ........................... |

173 |

|||

viii |

05744 Rev B |

|

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Table of Contents |

|

Figure 10-4: O3 Generator Temperature Thermistor and DC Heater Locations |

................................................. 174 |

|

Figure 10-5: Location of O3 Generator Reference Detector Adjustment Pot...................................................... |

174 |

|

Figure 11-1: Example of Signal I/O Function ...................................................................................................... |

182 |

|

Figure 11-2: CPU Status Indicator ...................................................................................................................... |

184 |

|

Figure 11-3: Relay PCA Status LEDS Used for Troubleshooting....................................................................... |

185 |

|

Figure 11-4: Location of DC Power Test Points on Relay PCA .......................................................................... |

187 |

|

Figure 11-5: Critical Flow Restrictor Assembly Disassembly.............................................................................. |

202 |

|

Figure 12-1: |

Triboelectric Charging..................................................................................................................... |

205 |

Figure 12-2: |

Basic anti-ESD Work Station .......................................................................................................... |

207 |

LIST OF TABLES |

|

|

Table 2-1: |

M703E Analytical Specifications.......................................................................................................... |

5 |

Table 2-2: |

M703E Electrical and Physical Specifications ..................................................................................... |

5 |

Table 2-3: |

M703E Specifications for Ozone Generator ........................................................................................ |

6 |

Table 2-4: |

M703E Specifications for O3 Photometer ............................................................................................ |

6 |

Table 3-1: |

Status Output Pin Assignments......................................................................................................... |

14 |

Table 3-2: |

M703E Control Input Pin Assignments.............................................................................................. |

15 |

Table 3-3: |

M703E Control Input Pin Assignments.............................................................................................. |

17 |

Table 3-4: |

Front Panel Display during System Warm-Up................................................................................... |

22 |

Table 3-5: |

Possible Warning Messages at Start-Up........................................................................................... |

23 |

Table 6-1: |

Test Functions Defined...................................................................................................................... |

36 |

Table 6-2: |

Calibrator Operating Modes............................................................................................................... |

37 |

Table 6-3: |

Automatic Calibration SEQUENCE Set Up Attributes ....................................................................... |

40 |

Table 6-4: |

Calibration SEQUENCE Step Instruction .......................................................................................... |

40 |

Table 6-5: |

Sequence Progress Reporting Mode ................................................................................................ |

49 |

Table 6-6: |

Password Levels................................................................................................................................ |

60 |

Table 6-7: |

DIAG - Analog I/O Functions ............................................................................................................. |

62 |

Table 6-8: |

Test Channels Functions Available on the M703E’s Analog Output................................................. |

64 |

Table 6-9: |

Analog Output Voltage Range Min/Max ............................................................................................ |

66 |

Table 6-10: |

Voltage Tolerances for the TEST CHANNEL Calibration.................................................................. |

72 |

Table 6-11: |

Variable Names (VARS) .................................................................................................................... |

75 |

Table 7-1: |

COMM Port Communication Modes.................................................................................................. |

91 |

Table 7-2: |

Terminal Mode Software Commands ................................................................................................ |

95 |

Table 7-3: |

Teledyne Instruments Serial I/O Command Types............................................................................ |

96 |

Table 7-4: |

Ethernet Status Indicators .............................................................................................................. |

105 |

Table 7-5: |

LAN/Internet Configuration Properties............................................................................................ |

106 |

Table 8-1: |

M703E Pressure Sensors............................................................................................................... |

125 |

Table 8-2: |

M703E Gas Pressure to Output Flow conversion Table ................................................................ |

128 |

Table 9-1: |

Relay Board Status LEDs ............................................................................................................... |

142 |

Table 9-2: |

AC Power Configuration for Internal Pumps (JP7) ......................................................................... |

146 |

Table 9-3: |

Front Panel Status LEDs ................................................................................................................ |

148 |

Table 9-4: |

M703E Photometer Measurement / Reference Cycle.................................................................... |

156 |

Table 10-1: |

M703E Maintenance Schedule....................................................................................................... |

165 |

Table 11-1: |

Front Panel Warning Messages ..................................................................................................... |

179 |

Table 11-2: |

Test Functions - Indicated Failures ................................................................................................ |

180 |

Table 11-3: |

Test Channel Outputs as Diagnostic Tools .................................................................................... |

183 |

Table 11-4: |

Relay PCA Watchdog LED Failure Indications............................................................................... |

184 |

Table 11-5: |

Relay PCA Status LED Failure Indications..................................................................................... |

185 |

Table 11-6: |

DC Power Test Point and Wiring Color Codes............................................................................... |

187 |

Table 11-7: |

DC Power Supply Acceptable Levels ............................................................................................. |

188 |

Table 11-8: |

Relay PCA Control Devices............................................................................................................ |

189 |

Table 11-9: |

Analog Output Test Function - Nominal Values Voltage Outputs .................................................. |

192 |

Table 11-10: |

Status Outputs Check..................................................................................................................... |

192 |

Table 11-11: |

M703E Control Input Pin Assignments and Corresponding Signal I/O Functions ......................... |

193 |

05744 Rev B |

ix |

TELEDYNE API |

|

|

|

Table of Contents |

M703E Calibrator Operator’s Manual |

||

Table 11-12: Control Outputs Pin Assignments and Corresponding Signal I/O Functions Check ...................... |

194 |

||

Table 12-1: |

Static Generation Voltages for Typical Activities ............................................................................ |

|

205 |

Table 12-2: |

Sensitivity of Electronic Devices to Damage by ESD..................................................................... |

|

206 |

x |

05744 Rev B |

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Table of Contents |

LIST OF APPENDICES

APPENDIX A - VERSION SPECIFIC SOFTWARE DOCUMENTATION APPENDIX A-1: Model 703E Software Menu Trees, Revision C.0

APPENDIX A-2: Model 703E Setup Variables Available Via Serial I/O, Revision C.0 APPENDIX A-3: Model 703E Warnings and Test Measurements via Serial I/O, Revision C.0 APPENDIX A-4: Model 703E Signal I/O Definitions, Revision C.0

APPENDIX A-5: Model 703E Terminal Command Designators, Revision C.0 APPENDIX B - Model 703E SPARE PARTS LIST

APPENDIX C - Model 703E REPAIR QUESTIONNAIRE

APPENDIX D - Model 703E ELECTRONIC SCHEMATICS

USER NOTES:

05744 Rev B |

xi |

TELEDYNE API |

|

Table of Contents |

M703E Calibrator Operator’s Manual |

USER NOTES:

xii |

05744 Rev B |

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

GENERAL INFORMATION |

SECTION I

–

GENERAL INFORMATION

05744 Rev B |

1 |

TELEDYNE API |

|

GENERAL INFORMATION |

M703E Calibrator Operator’s Manual |

USER NOTES

2 |

05744 Rev B |

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Introduction |

1. INTRODUCTION

1.1. M703E CALIBRATOR OVERVIEW

The Model 703E is a microprocessor-based ozone calibrator for calibration of ambient ozone analyzers, such as the T-API M400E. The M703E features an internal ozone photometer that provides very accurate closed loop feedback control of the ozone concentration.

As many as 50 independent calibration sequences may be programmed into the M703E, covering time periods of up to one year. The setup of sequences is simple and intuitive. These sequences may be actuated manually, automatically, or by a remote signal. The sequences may be uploaded remotely, including remote editing. All programs are maintained in non-volatile memory.

The M703E design emphasizes fast response, repeatability, overall accuracy and ease of operation. It may be combined with the Model 701 Zero Air Generator to provide the ultimate in easy to use, precise calibration for your ozone analyzers.

Some of the exceptional features of your M703E Photometric O3 Calibrator are:

Advanced E Series electronics

Lightweight for transportability

Optional Ethernet connectivity

12 independent timers for sequences

Nested sequences (up to 5 levels)

Internal ozone generator and photometer allows use as primary or transfer standard

1.2. USING THIS MANUAL

NOTE

Throughout this manual, words printed in capital, bold letters, such as SETUP or ENTR represent messages as they appear on the calibrator’s display.

This manual is organized in the following manner:

TABLE OF CONTENTS:

Outlines the contents of the manual in the order the information is presented. This is a good overview of the topics covered in the manual. There is also a list of appendices, figures and tables. In the electronic version of the manual, clicking on any of these table entries automatically views that section.

SECTION I – GENERAL INFORMATION

INTRODUCTION

A brief description of the M703E calibrator architecture as well as a description of the layout of the manual and what information is located in its various sections and chapters.

SPECIFICATIONS AND WARRANTY

Teledyne Instruments’ warranty statement.

05744 Rev B |

3 |

TELEDYNE API |

|

Introduction |

M703E Calibrator Operator’s Manual |

GETTING STARTED

Instructions for setting up, installing and running your calibrator for the first time.

GLOSSARY:

Answers to the most frequently asked questions about operating the calibrator and a glossary of acronyms and technical terms.

OPTIONAL HARDWARE & SOFTWARE

A description of optional equipment to add functionality to your calibrator.

SECTION II – OPERATING INSTRUCTIONS

USING THE M703E CALIBRATOR

Step-by-Step instructions for using the display/keyboard to set up and operate the M703E calibrator.

REMOTE OPERATION OF THE M703E CALIBRATOR

Information and instructions for interacting with the M703E calibrator via its several remote interface options (e.g. via RS-232, Ethernet, its built in digital control inputs/outputs, etc.)

M703E VALIDATION AND VERIFICATION

Methods and procedures for validating and verifying the correct operation of your M703E Photometric O3 Calibrator

SECTION III – TECHNICAL INFORMATION

THEORY OF OPERATION

An in-depth look at the various principals by which your calibrator operates as well as a description of how the various electronic, mechanical and pneumatic components of the calibrator work and interact with each other. A close reading of this section is invaluable for understanding the calibrator’s operation.

MAINTENANCE SCHEDULE AND PROCEDURES

Description of preventative maintenance procedures that should be regularly performed on you calibrator to assure good operating condition.

GENERAL TROUBLESHOOTING & REPAIR OF THE M703E CALIBRATOR

This section includes pointers and instructions for diagnosing problems with the calibrator in general as well as instructions on performing repairs.

A PRIMER ON ELECTRO-STATIC DISCHARGE

This section describes how static electricity occurs; why it is a significant concern and; how to avoid it and avoid allowing ESD to affect the reliable and accurate operation of your calibrator.

APPENDICES

For easier access and better updating, some information has been separated out of the manual and placed in a series of appendices at the end of this manual. These include version-specific software menu trees, warning messages, serial I/O variables as well as spare part listings, repair questionnaires, interconnect drawing, detailed pneumatic and electronic schematics.

USER NOTES:

4 |

05744 Rev B |

|

TELEDYNE API |

M703E Calibrator Operator’s Manual |

Specifications, Approvals and Warranty |

2.SPECIFICATIONS, APPROVALS AND WARRANTY

2.1. SPECIFICATIONS

Table 2-1: M703E Analytical Specifications

Linearity |

+/- 1.0% of full scale |

|

|

|

|

Precision |

1.0 ppb |

|

|

|

|

Stability |

+/- 2.0 ppb (photometer feedback mode) |

|

Response Time |

180 seconds to 95% |

|

Stability (7-days) |

1% photometer feedback; 3% without photometer feedback (CNST or REF) |

|

Table 2-2: M703E Electrical and Physical Specifications |

||

|

|

|

Temperature Range |

5-40ºC |

|

|

|

|

Humidity Range |

0 - 95% RH, non-condensing |

|

Dimensions (HxWxD) |

7” (178 mm) x 17” (432 mm) x 24” (609 mm) |

|

Operating Altitude |

10,000 ft Maximum |

|

Weight |

35.5 lbs (16.1 kg) including internal zero air pump |

|

|

||

|

|

|

AC Power |

115VAC, 60Hz |

|

230VAC,50HZ |

||

|

||

Analog Outputs |

1 user configurable output |

|

Analog Output Ranges |

0.1 V, 1 V, 5 V or 10 V |

|

Range with 5% under/over-range |

||

|

||

Analog Output Resolution |

1 part in 4096 of selected full-scale voltage (12 bit) |

|

|

|

|

Digital Control Outputs |

12 opto-isolated outputs |

|

Digital Control Inputs |

12 opto-isolated outputs |

|

Status Outputs |

12 opto-isolated outputs, 5 defined, 7 spare |

|

Serial I/O |

2 ports: 1x RS-232; 1x RS-485 or RS-232 (configurable) |

|

Communication speed: 300 - 115200 baud (user selectable) |

||

|

||

|

EN61326 (1997 w/A1: 98) Class A, FCC Part 15 Subpart B Section 15.107 Class |

|

Certifications |

A, ICES-003 Class A (ANSI C63.4 1992) & AS/NZS 3548 (w/A1 & A2; 97) |

|

Class A. |

||

|

||

|

IEC 61010-1:90 + A1:92 + A2:95, |

|

05744 Rev B |

5 |

TELEDYNE API

Specifications, Approvals and Warranty M703E Calibrator Operator’s Manual

Table 2-3: M703E Specifications for Ozone Generator

Maximum Output |

6 ppm LPM |

Minimum Output |

100 ppb LPM |

Response Time: |

180 Sec. (98%) |

Optical Feedback |

Standard |

|

|

Table 2-4: M703E Specifications for O3 Photometer |

|

|

|

Full Scale Range |

100 ppb to 10 ppm ; User Selectable |

|

|

Precision |

1.0 ppb |

Linearity |

1.0% of Full Scale |

Rise/Fall Time |

<20 sec (photometer response) |

Zero Drift |

<1.0 ppb / 7 days |

Span Drift |

<1% / 24 hours; <2% / 7 days |

Minimum Gas Flow Required |

800 cc3/min |

2.2. CE MARK COMPLIANCE

EMISSIONS COMPLIANCE

The Teledyne Instruments’ M703E Photometric O3 Calibrator is designed to be fully compliant with: